Page 1

Transfer Printer

BP-PR PLUS series

Configuration Instructions

Edition 12/09

Transfer Printer

BP-PR PLUS Series

User Manual

Edition 06/10

Page 2

BP-PR PLUS Series

Identification Solutions Division W.H. Brady

6555 W. Good Hope Road Lindestraat 21

PO Box 2131 Industriepark C3

Milwaukee, WI 53201 U.S.A. 9240 Zele Belgium

Phone: 1-800-537-8791 Fax: 1-800-292-2289 Tel.: +32 52 457 811

e-mail: support@brady.be

Information on the scope of delivery, appearance, performance, dimensions and weight reflect our

knowledge at the time of printing. We reserve the right to make modifications.

All rights, including those regarding the translat i on , ar e re se rved .

Trademarks

Centronics® is a registered trademark of the Centronics Data Computer Corporation.

®

Microsoft

Windows

Microsoft Corporation.

True Type

is a registered trademark of the Microsoft Corporation.

®

, Windows 2000®, Windows XP® and Windows Vista® are registered trademarks of the

TM

is a registered trademark of Apple Computer, Inc.

Edition 06/10

ii User Manual Edition 06/10

Page 3

BP-PR PLUS Series

Approvals

The transfer printers comply with the following regulatory guidelines:

EUROPE

Directive 2006/95/EC relating to electrical equipment designed for use within certain voltage limits:

EN 60950-1:2006

EN 61558-1:2005

Directive 2004/108/EC relating to electromagnetic compatibility:

EN 55022:2006

EN 55024:1998+A1:2001+A 2: 20 03

EN 61000-3-2:2006

EN 61000-3-3:1995+A1:2001+A2:2005

UNITED STATES

FCC Class A Notice (Printer with Optional Cutters, Type CU X, PCU X)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a comm ercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if it is not installed and used in accordance

with the instruction manual, it may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his/her own expense.

Modifications: Any modifications made to this device that are not approved by the Brady

Corporation may void the authority granted to the user by the FCC to operate this equipment.

CANADA

ICES-003 Class A Notice, Classe A (Printer with Optional Cutters, Type CU X, PCU X)

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numerique de la classe A respecte toutes les exigences du Reglement sur le Materiel

Brouilleur du Canada.

Edition 06/10 User Manual iii

Page 4

BP-PR PLUS Series

Batteries Directive 2006/66/EC

This product contains a lithium battery. The crossed-out wheeled bin is used to

indicate ‘separate collection’ for all batteries and accumulators in accordance

with European Directive 2006/66/EC. Users of batteries must not dispose of

batteries as unsorted municipal waste. This Directive determines the framework

for the return and recycling of used batteries and accumulators that are to be

collected separately and recycled at end of life. Please dispose of the battery

according to your local regulations.

Notice to Recyclers

To remove the lithium battery:

1. Disassemble printer and locate the lithium cell battery located on the main circuit board.

2. To remove, slide the battery from the coin cell retainer, remove the battery from the board, and

dispose of properly.

iv User Manual Edition 06/10

Page 5

BP-PR PLUS Series

Table of Contents

Product Description ............................................................................................ 1

Overview ........................................................................................................ 1

Device Types ..................................................................................................1

Standard Version ..................................................................................1-1

Peel-off Version ....................................................................................1-2

Overview of Types.................................................................................1-2

Technical Data . ... ... .... ... ... ... .... .......................................... ... ... .....................3

Parts of the Printer ...................................... ... ... .... ... ... ... ...............................5

Accessories.....................................................................................................6

External Unwinders and Rewinders .....................................................1-6

Cutter ..................................... .......................................... ..................... 1-6

Peel-off Modules ...................................................................................1-6

Memory Cards ... .... ... ... ... .... ... ... ... ... .... ... ... .......................................... ..1-6

External Keyboards ..............................................................................1-6

Print Media ................................................................ ..................................... 7

Printing Methods and Print Media ........................................................1-7

Label Formats ........................... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ...............1-7

Transfer Ribbons ..................................................................................1-8

Software ................................................ .........................................................9

Direct Programming ..............................................................................1-9

Windows Printer Driver .........................................................................1-9

Label Software .......................... ... ... .... ... ... ... .... ... ..................................1-9

Connecting Printer to Computer ..................................................................... 10

Connecting Printer via Serial RS-232 Interface ........................................... 11

Connecting Printer ................................. ... ... .... ... ... ... .... ... ... ... ... ..........1-11

Pin Assignment of Connection Jack of the RS-232 Interface ............. 1-11

Connecting Printer via Ethernet Interface .................................................... 12

Print Services Raw-IP and LPD in MS Windows ................................1-13

Adjusting Windows Printer Setting .....................................................1-14

Connecting Printer via USB Interface ..........................................................14

Offline Menu ...................................................................................................... 15

Structure of the Offline Menu .......................................................................15

Navigating the Offline Menu .........................................................................16

Configuration .................................................................................................... 17

Configuration via the Operating Panel .........................................................17

Local Settings .....................................................................................1-17

Device Settings ...................................................................................1-18

Printing Parameters ............................................................................1-19

Interfaces .................................. .......................................... ................ 1-21

Status Line ..........................................................................................1-23

Edition 06/10 User Manual v

Page 6

BP-PR PLUS Series

Security .............................................................................................. 1-24

Configuration via the Printer Website ...........................................................25

Calling up the Printer Website ............................................................ 1-25

Description of the Printer Website ...................................................... 1-25

Test Functions....................................................................................................34

Overview .................................... ......... .......... .......... ......... .......... .......... ......... 34

Short Status . .... ... ... ... .... ... ... ... .... ... ... .......................................... ... ... .... ... ... ...34

Status Print ...................................................................................................35

Font List ........................................ ... ... .......................................... ... .... .........37

Device List ....................................................................................................38

ASCII Dump Mode ........................................................................................40

Test Grid .......................................................................................................42

Label Profile ..................................................................................................43

Service Functions .............................................................................................45

Performing Firmware Update .......................................................................45

Copying New Firmware via Interface ................................................. 1-45

Copying New Firmware from Memory Card ....................................... 1-46

Error Messages during the Firmware Update .................................... 1-46

Save Settings ..............................................................................................47

Load Settings ...............................................................................................47

FTP Printer Management ..................................................................................48

FTP Logon ....................................................................................................48

Directory Structure of the FTP Server .......... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ...49

FTP Firmware Update ..................................................................................49

Memory Cards ...................................................................................................50

Insertion and Removal ..................................................................................50

Formatting ....................................................................................................51

Writing ..........................................................................................................51

Memory Card Functions in the Offline Menu ....................... .........................52

Loading Label ................................................................................... 1-52

Printing Card Index ............................................................................ 1-53

Copy Memory Card ............................................................................ 1-53

Format Card ....................................................................................... 1-55

Printing File Contents ......................................................................... 1-55

External Keyboard ............................................................................................56

Connecting External Keyboard .....................................................................56

Special Key Functions .. ... ... ... .... ... ... ... ... .......................................... .... ... ... ...56

Key Assignment and Special Characters .....................................................57

Country-Specific Special Characters: ................................................. 1-58

Other Special Characters.................................................................... 1-59

vi User Manual Edition 06/10

Page 7

BP-PR PLUS Series

1 Product Description

1-1 Overview

The BP-PR PLUS Series transfer printers can be operated in thermal direct or transfer

print mode. With thermal printing, heat from the printhead results in printing to a heatsensitive print medium. With thermal transfer printing, he at from th e p rinth ead cau s es the

color layer of a transfer ribbon to be transferred to the print medium.

The printers are equipped with every common in terface to ensure trouble- free con nection

to computers and networks. When using a memory card, the printers can also operate in

standalone mode. By connecting a keyboard, variable data can also be entered

conveniently in standalone mode.

The printers can be connected to AC mains networks from 100 V to 240 V without any

kind of adapter.

The large graphic LCD display and the context-controlled naviga tor pad allow the p rinters

to be monitored and operated efficiently. A variety of accessories allows the printers t o be

adapted to different product requ ire m en ts .

1-2 Device Types

The printers are available in a variety of models with different features.

1-2-1 Standard Version

The standard version is used for printing labels or endless media on rolls or fanfolds.

In Tear-off mode, labels are removed by hand. Because there is no internal rewinder,

automatic peeling off of the labels from the liner (peel-off mode) and intern al rewinding are

not possible.

The labels can be cut off automatically with the ‘cutter’ accessory. For details, see

documentation of the cutter.

The labels can be wound up with the ‘external rewinder’ accessory. For details, see

documentation of the external rewinder.

Edition 06/10 User Manual 1

Page 8

BP-PR PLUS Series

1-2-2 Peel-off V e rsion

The peel-off version is prepared for peel-off m ode and thus has an inter nal rewinder and a

pulling system comprised of a rewind assist roller and a locking system. Printing on labels

or endless media from rolls or fanfolds is possible.

Operation in Tear-off mode and with the ‘cutter’ or ‘external rewinder’ accessory is

possible by installing the tear-off plate (see “Operating Instructions“), as it is with the

standard version.

In peel-off mode, the label is peeled off the liner after printing. The label can be removed

by hand with the peel-off sensor (accessory). The liner is rolled up via the internal

rewinder.

For use in Internal Rewind mode, remove the locking system and replace the dispense

plate with a rewind guide plate. See “Operating Instructions“.

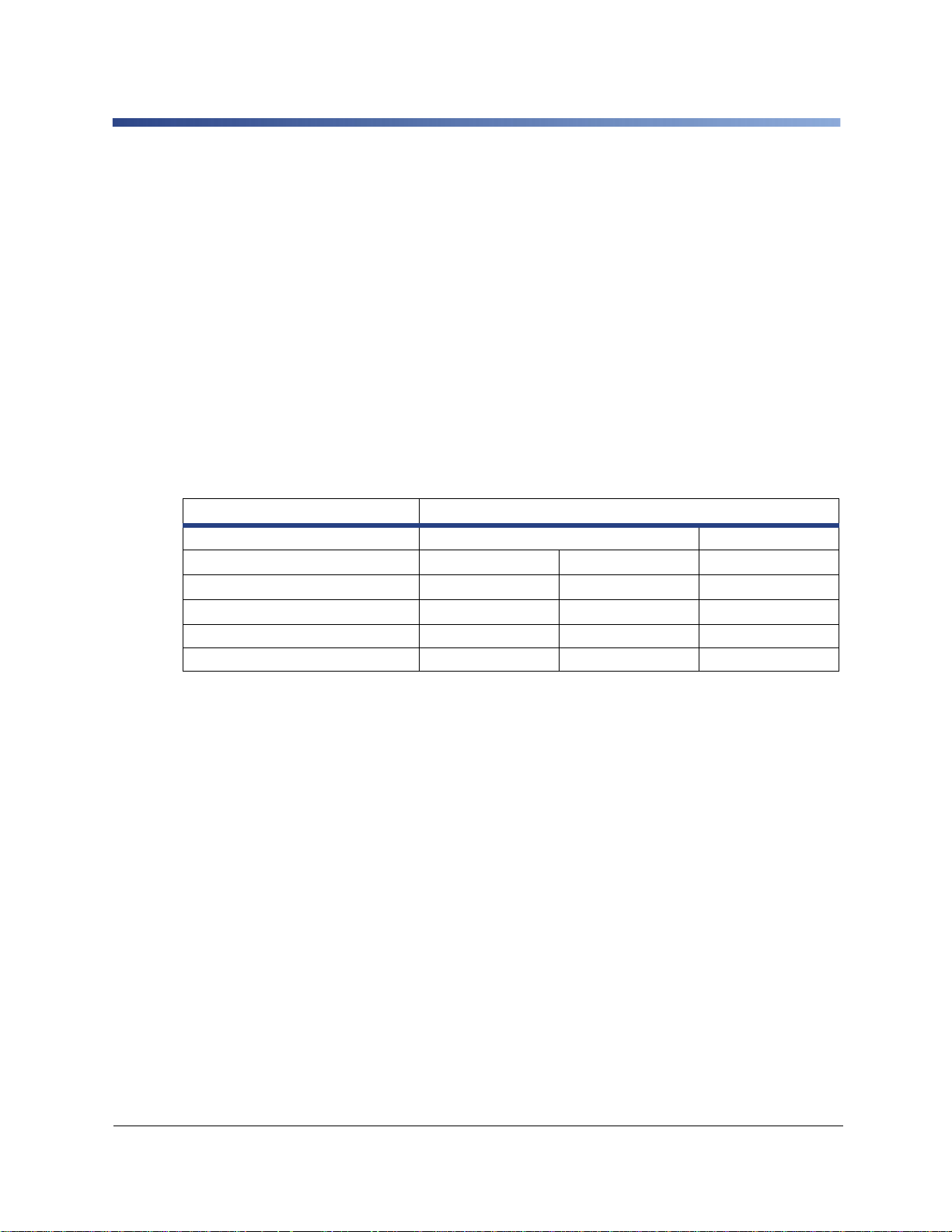

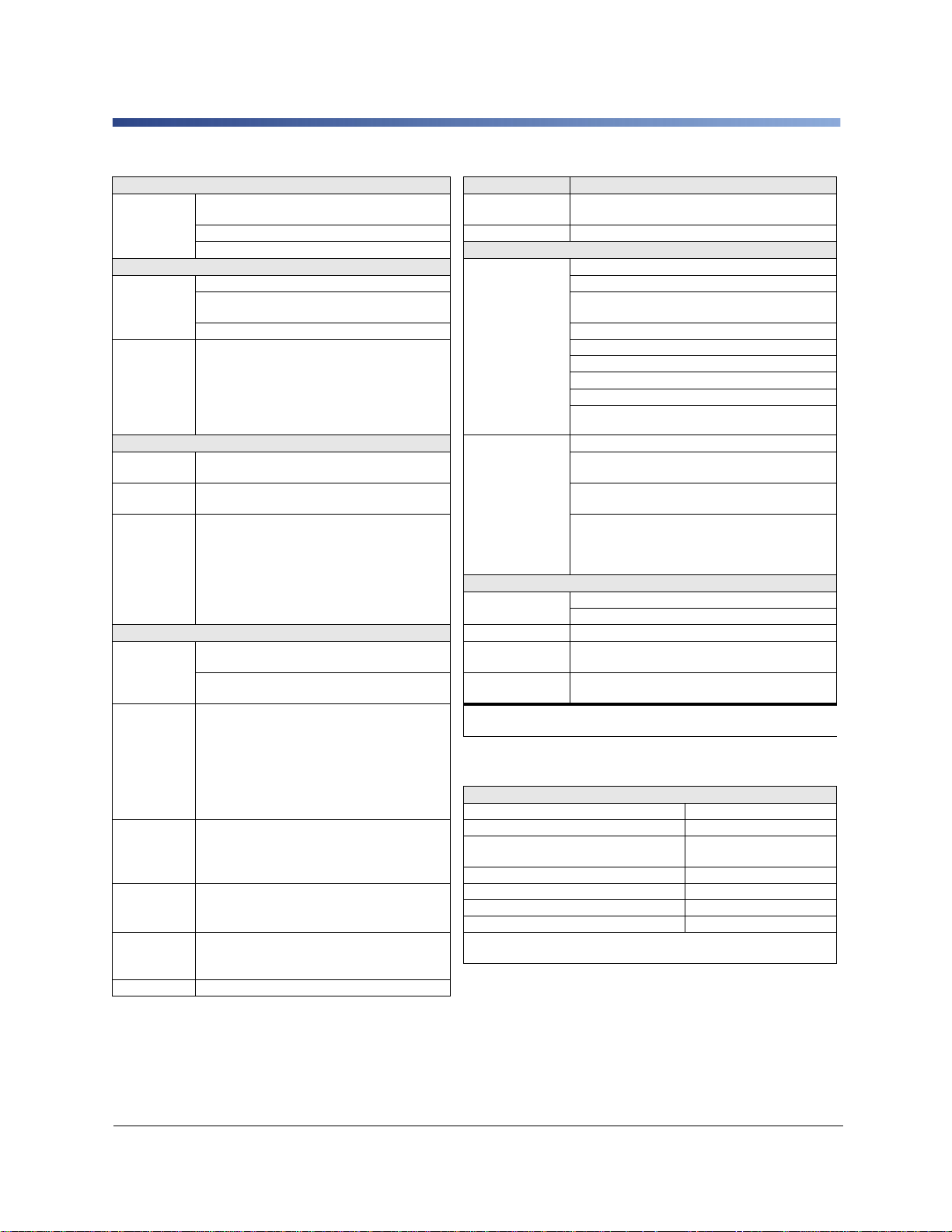

1-2-3 Overview of Types

Characteristics

Max. medium width in [mm]

Print resolution [dpi]

Printing width in [mm]

Max. print speed in [mm/s]

Standard version transfer printer

Peel-off version transfer printer

Table 1. Overview of BP-PR PLUS Series printer types

BP-PR PLUS Series

120 180

300 600 300

105.6 105.6 162.6

250 100 200

BP-PR 300 PLUS BP-PR 600 PLUS BP-PR 360 PLUS

BP-PR 300 PLUS-P BP-PR 600 PLUS-P BP-PR 360 PLUS-P

2 User Manual Edition 04/10

Page 9

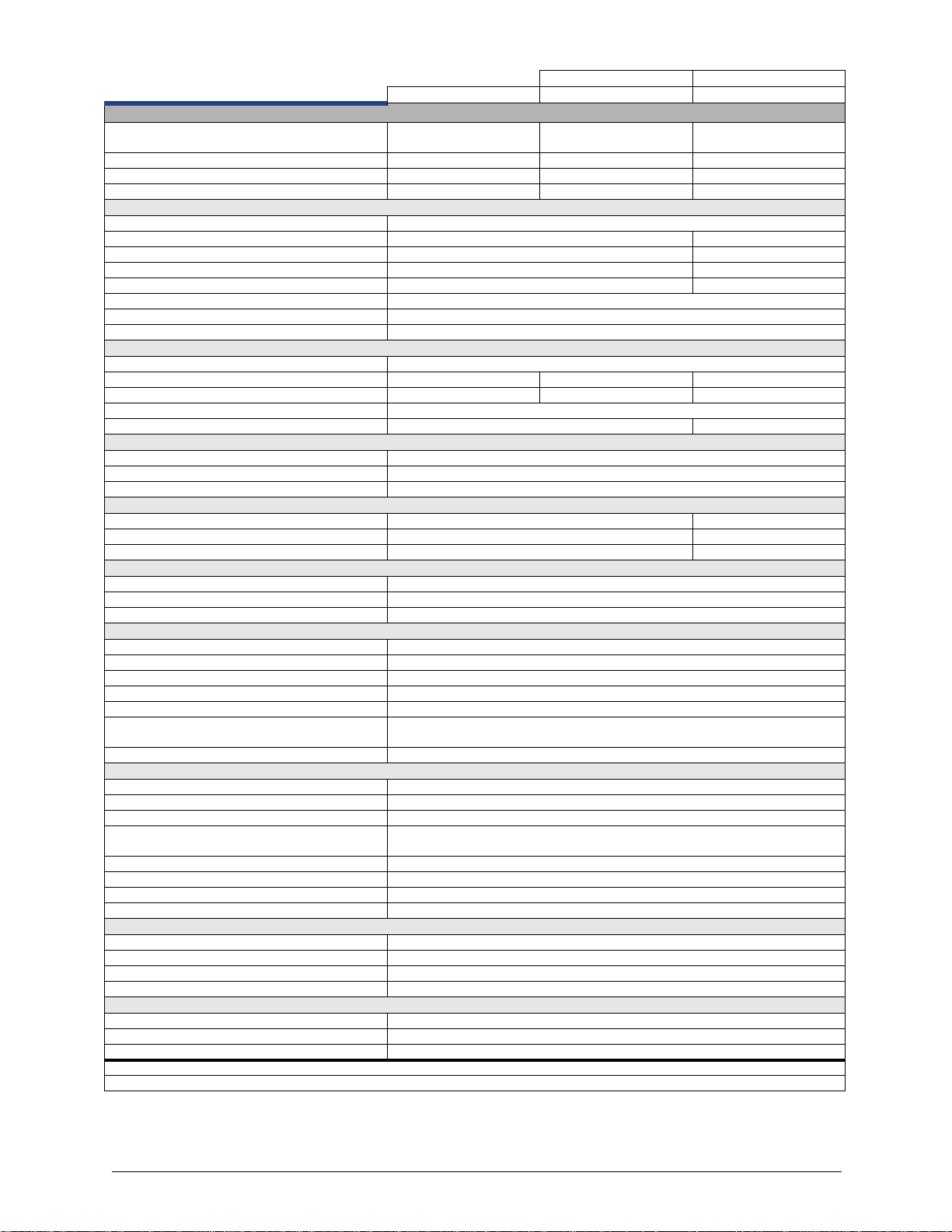

1-3 Technical Data

Standard Option

BP-PR 300 PLUS BP-PR 600 PLUS BP-PR 360 PLUS

1. Printhead

Printing Method Thermal

Direct

Print Resolution( dpi) 300 600 300

Print Speed (up to mm per s) 250 mm (9.8 in.) 100 mm (3.9 in.) 200 mm (7.9 in.)

Print Width 105.6 mm ( 4.2 in.) 105.6 mm ( 4.2 in.) 162.6 mm (6.4 in.)

2. Material

Material Thickness (mm/in. – weight g/m2) 0.055 - 1.2 mm (.002 - 0.5 in.) – 60-300 g/m

Label Width1 20- 116 mm (.8 - 4.5 in.) 50 - 176 (2 - 7 in.)

Width of Liner or of Continuous Material 25 - 120 mm (1 - 4.7 in.) 50 - 180 (2 - 7 in.)

Label Height 4 - 1000 mm (0.1 - 39 in.) 6 - 1000 (0.2 - 39 in.)

Label Height when dispensing1 12 - 200 mm (0.5 - 8 in.) 25 - 200 mm (1 - 8 in.)

Media Roll: Total Diameter (up to) 205 mm (8 in.)

Core Diameter 38 - 100 mm (1.5 - 3.9 in.)

Winding Direction Inside or Outside

3. Ribbon

Ink Inside or Outside

Roll Diameter (up to) 80 mm (3.1 in.) 80 mm (3.1 in.) 80 mm (3.1 in.)

Core Diameter (up to) 25 mm (1 in.) 25 mm (1 in.) 25 mm (1 in.)

Ribbon Length variable (up to) 500 m (196.9 in.)

Width (up to) 114 m (4.5 in.) 165 mm (6.5 in.)

4. Internal Rewinder (peel-off version only)

Total Diameter (up to) 142 mm (5.6 in.)

Core Diameter 38.1 mm (1.5 in.)

Winding Direction Outside only

5. Printer Dimensions

Height x Depth 274 x 446 mm (10.8 x 17.6 in.) 274 x 446 mm (10.8 x 17.6 in.)

Width 242 mm (9.5 in.) 302 mm (11.9 in.)

Weight 9 kg (20 lb) 13 kg (29 lb)

6. Label Sensor

See-through Sensor for leading edge of the label or punching marks and end of material

Reflective Sensor (from bottom / from top) for printing marks

Distance to Locating Edge 5 - 53 mm (0.2 x 2 in.)

7. Electronics

Processor High speed 32 Bit ColdFire 266 MHz Clock rate

RAM (MB) 64 MB

Memory IFF MB Flash 8 MB

Slot for Memory CompactFlash-Card Type 1

Slot for Wireless LAN Card

Battery Cache for Real-time clock, printout of time and date

Warning Signal Acoustic signal when error

8. Interfaces

Centronics bi-directional acc, IEEE 1284

RS232C 1,200 up to 230,400 Baud/8-Bit

USB 2.0 High Speed Slave for PC Connection

Ethernet 10/100 Base T, LPD, RAW-IP, ftp-Printing, DHCP,

HTTP, FTP, SMTP, SNMP, TIME, Zeroconf, mDNS, SOAP

RS422, RS485 1,200 up to 230,400 Baud/8-Bit

Peripheral Connection

WLAN Card 802.11b/g WEP/WPA PSK (TKIP)

2 x USB mater for external operation panel, keyboard, scanner, service key

9. Operational Data

Power Supply 100 - 240 V – 50/60 Hz, PFC

Power Consumption 300 W max.

Operating Temperature 10° - 35° C (50 - 95° F)

Humidity 30 - 85% non-condensing

10. Operation Panel

Buttons/LED Display Pause, Feed, Cancel, Menu, Enter, 4 x Cursor

LCD Graphic Display Text 4 lines, ca, 20 digits per line

Width x Height 60 x 40 mm (2.4 - 1.6 in.)

1) Depending on label size, material and adhesive limitations are possible. Critical material or applications have to be tested and cleared.

Note: The technical data specifications reflect the knowledge available at the time of printing. We reserve the right to make modifications.

Table 2. Technical Data

Storage of data with shut-down

2

3 User Manual Edition 06/10

Page 10

BP-PR PLUS Series

11. Settings 15. Graphics

Time, Date, Digital or Analog Clock Graphic Elements Line, arrow, box, circle, ellipse, filled and filled with

25 Language Settings Graphic Formats PCX, IMG, BMP, TIF, MAC, GIF, PNG

System Settings, Print Parameters, Interfaces, Security

12. Monitoring

Stop printing if: End of Ribbon Code 39 Full ASCII Interleaved 2/5

End of Labels Code 128 A, B, C Indent- and Leader Code of

Printhead Open Codabar MSI

On the display: Data Reception Remaining Ribbon Quantity EAN 8, 13 Plessey

WLAN Field Intensity Clock EAN/UCC 128 Postnat

Ethernet State Data Sheet EAN/UPC Appencix 2 RSS 14

Used Memory

Temperature Printhead

Access to Memory Card

abc Debug

Input Buffer

13. Test Routines

System

Diagnosis

Short Status,

Status Print

Status Reports Extensive status print with information about setting

When switched on with testing of printhead. UPS Maxicode, QR-Code, RSS 14 truncated, limited,

Font list, device list, WLAN state, profile of label, test

grid, monitor mode, PPP state.

(e.g., print length counter, runtime counter, etc.).

Request of machine state via software command.

Detailed status messages on the display (e.g., network

error-no-link, barcode error, etc.).

14. Fonts

Font Types 5 Bitmap fonts, incl. OCR-A, OCR-B and 3 Vector

Character Sets Windows 1250 up to 1257, DOS 437, 737, 775, 850, Note: The technical data specifications reflect the knowledge available at the

Bitmap Fonts Size of width and height 1-3 mm (0.04 - 0.1 in.) Perforation Cutter

Vector-/

TrueType Fonts

Font Formats Bold, italic, underlined, outline, negative, grey, 1) Depending on label size, material and adhesive limitations are possible.

Font Width Variable

fonts: Swiss 721, Swiss 721 Bold and Monospace.

821 available internally, loadable TrueT ype fonts.

Optional Chinese (simplified), Optional Thai

852, 857, 862, 864, 866, 869, EBCDIC 500.

ISO 8859-1 up to -10 and -13 up to -16, WinOEM

720, UTF-8, Macintosh Roman, DEC MCS, K018-R.

All West and East European Latin, Cyrillic, Greek,

Hebrew and Arabic characters are supported.

Optional Chinese (simplified) and Thai. Auto Cutter

zoom 2-10 Present Sensor PS6 (with internal rewinder) -

Orientation 0°, 90°, 180°, 270° External Unwinder

Size of width and height 0.9 - 128 mm (0.04 - 5 in.) External Rewinder

variable zoom, CompactFlash-Card Type I

Orientation 360° in steps of 1°. PC-Card Type II

vertical, depending on character fonts

16. Codes

Linear Barcodes Code 39, Code 93 HIBC

2D-Codes Aztec, Codablock F , Data Matrix, PDF-417, Micro PDF 417,

17. Software

Programming J-Script Direct Programming

Label Software Codesoft, LabelMark and BradySoft

Windows Driver XP 32/64 bit, 2003 32/64 bit, Vista 32/64 bit, 2008 32/64 bit,

Stand-alone

Operation

time of printing. We reserve the right to make modifications.

Accessories

Automatic Operation

Critical material or applications have to be tested and cleared.

fading

Deutsche Post AG JAN 8, 13

EAN/UPC Appendix 5 UPC A, E, E0

FIM

stacked and stacked omnidirectional, EAN-Datamatrix,

GS1 Data Bar

All codes variable in height, module width and ratio.

Orientation 0°, 90°, 180°, 270°. Optionally with check

digit, printed characters and Start/Stop code depending

on code type.

abc Basic Compiler

Windows 7 32/64 bit

Table 3. Technical data (continued)

4 User Manual Edition 04/10

Page 11

BP-PR PLUS Series

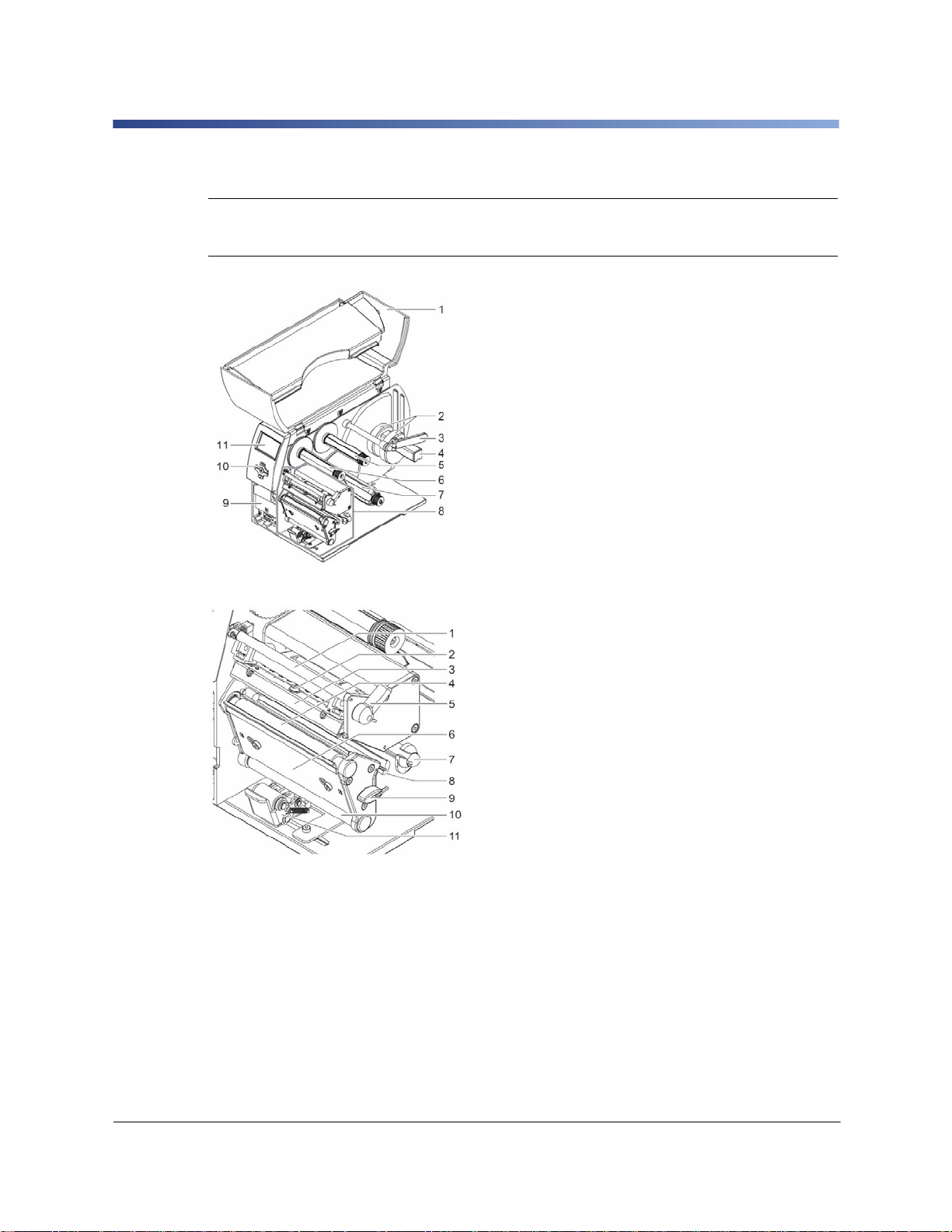

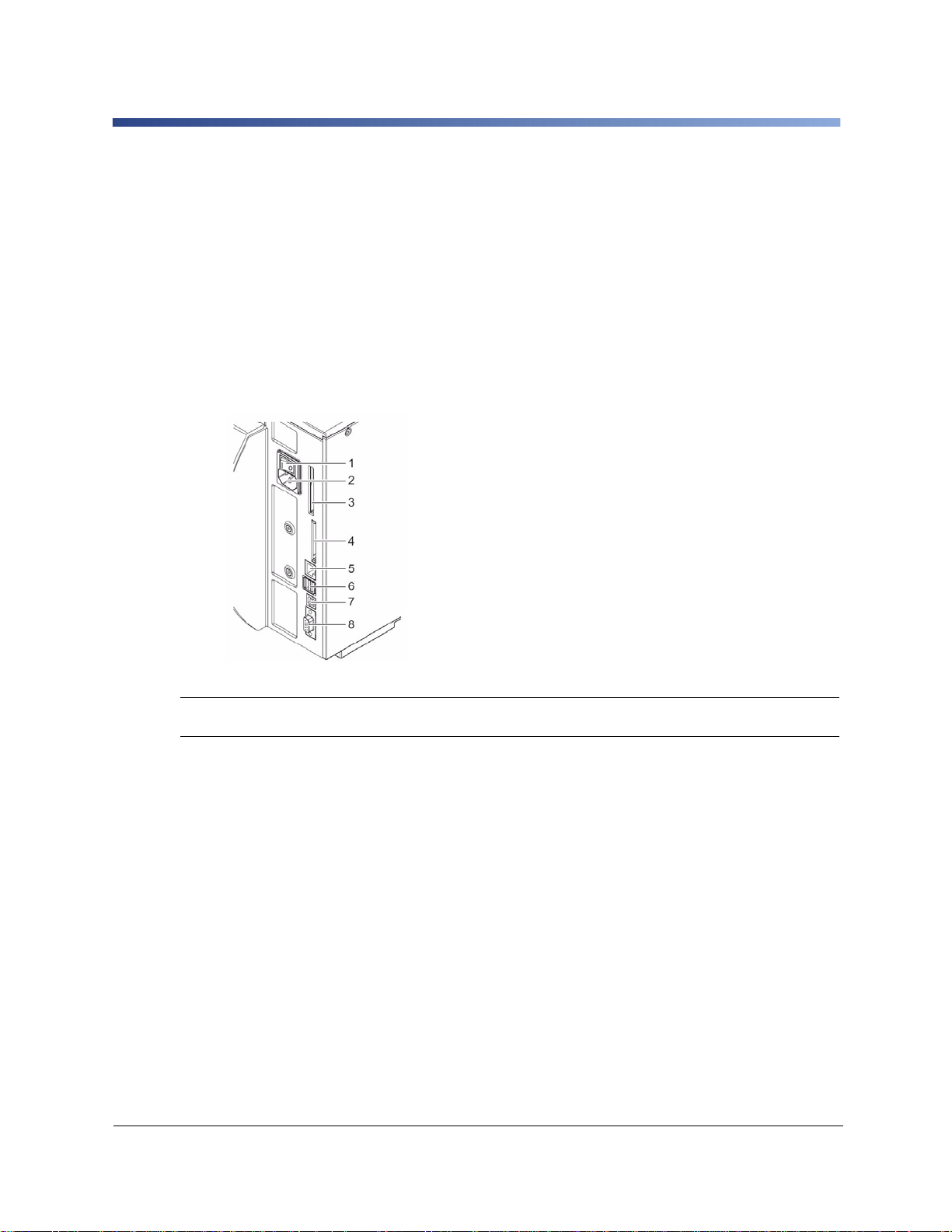

1-4 Parts of the Printer

i

Figure 1. General Overview

The following illustrations show the important parts for the example using the printer

with internal rewinder (peel-off version). The details of other printer versions may

vary. Major differences are indicated in the following.

1 Cover

2 Core Adapter

3 Media Retainer

4 Media hub

5 Transfer ribbon supply hub (transfer printers only)

6 Transfer ribbon t ake-u p hub (tra nsfer pr inters only)

7 Internal rewinder (peel-off version only)

8 Print unit

9 Mounting surface for accessories incl.

peripheral connection

10 Navigator pad

11 LCD display

1 Transfer ribbon deflector

2 Printhead securing screw

3 Printhead mounting bracket with printhead

4 Print roller

5 Lever for locking printhead

6 Dispense plate

7 Axis with ring

8 Label sensor

9 Allen key (hexagonal wrench)

10 Rewind assist roller (peel-off version only)

11 Locking system (peel-off version only)

Figure 2. Print unit for Tear-off mode

Edition 06/10 User Manual 5

Page 12

BP-PR PLUS Series

1-5 Accessories

1-5-1 External Unwinders and Rewinders

A variety of external unwinders and rewinders are available for large print jobs.

1-5-2 Cutter

The cutter accessory cuts labels or endless media right after printing, after a certain

number of labels or after the print job. The peripheral connection of the printer is used for

power supply and printer control.

1-5-3 Peel-off Modules

1-5-3-1 Peel-off Sensor PS 6 for Manual Removal and Automatic Mode

Two operating modes are possible:

• Manual mode: dispensing after removal of the label without connecting the

peripherals

• Semi-automatic mode: dispensing upon request from button, foot switch or

external control

1-5-4 Memory Cards

With the following memory cards, the printer can be operated in standalone mode without

being coupled with a computer:

• CompactFlash type 1 memory card (1 GB max.)

• Type II PC card

Label formats, fonts, texts and graphics on the computer or printer are loaded for this

purpose.

1-5-5 External Keyboards

A compact keyboard or numerical keypad for enter ing alphanumerical o r numerical data in

standalone mode can be connected to the printer via a USB master interface

(see 9-1 Connecting External Keyboard , on page 56).

6 User Manual Edition 04/10

Page 13

BP-PR PLUS Series

1-6 Print Media

1-6-1 Printing Methods and Print Media

The printers of the BP-PR PLUS Series can be operated both in thermal direct and in

transfer mode.

1-6-1-1 Thermal Direct Printing

The label medium is coated with a thermo-reactive material which responds by changing

color when heated (e.g. from white to black). The the rmal pr int he a d ge ne ra te s th e pr int

image via pointwise heating of the label medium.

1-6-1-2 Thermal Transfer Printing

Pointwise heating by the printhead causes color particles from the color coating of a

ribbon to be transferred to an uncoated label medium. The ribbon can only be used once

for printing. A great variety of media, e.g. normal paper, cardboard and polyester film, are

suitable for thermal transfer printing.

i

The print quality essentially depends on how well the coloring from the transfer

ribbon adheres to the label medium. Ask your dealer for advice when selecting

labels and transfer ribbons. Run tests if necessary.

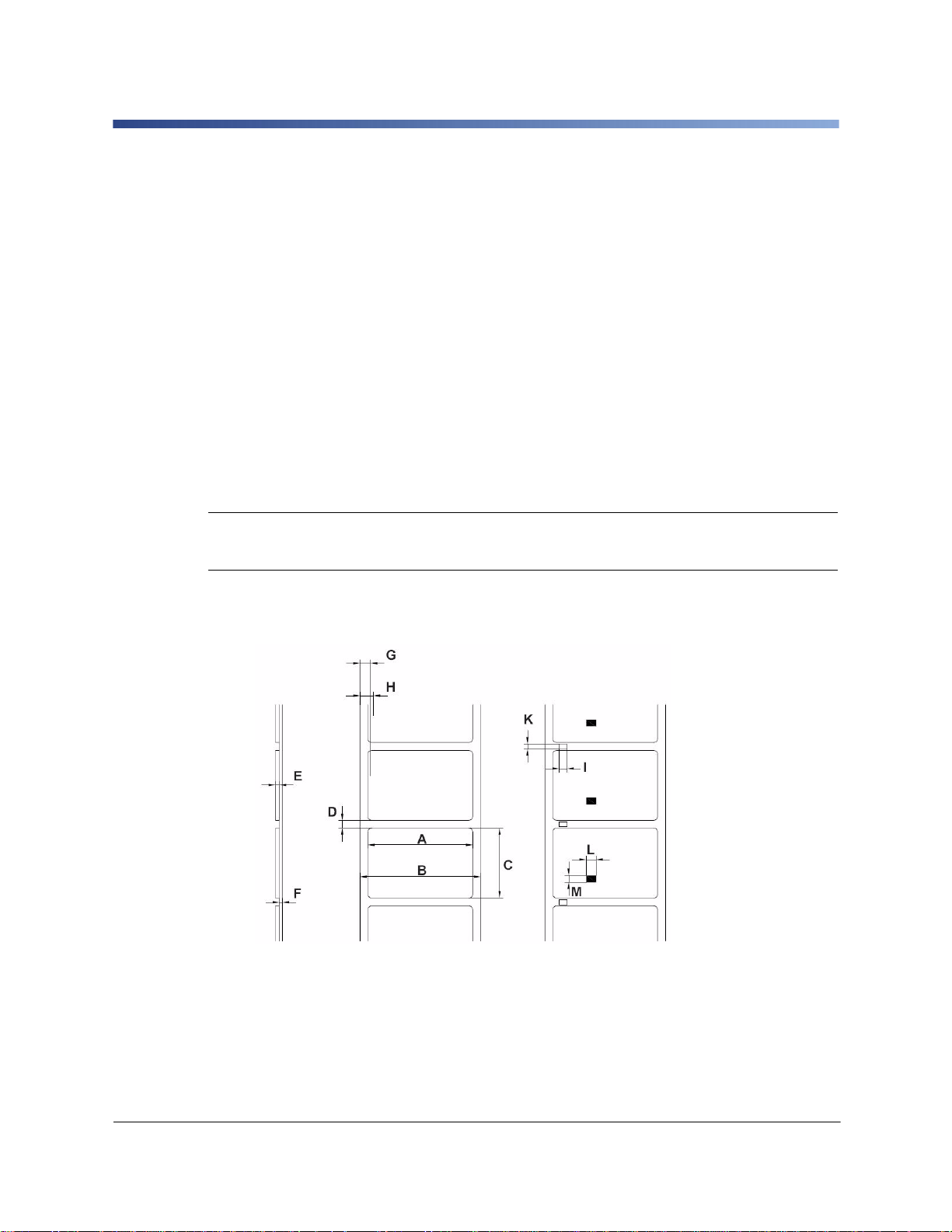

1-6-2 Label Formats

Before ordering label media, note the following permissible dimensions:

Figure 3. Label Dimensions

Edition 06/10 User Manual 7

Page 14

BP-PR PLUS Series

Dim. Designation Dimensions in [mm]

A Label width Label width in peel-off mode 4–116 25–116

Width of liner or endless medium With a medium thickness of

B

E = 0.07 – 0.25 With a medium thickness of E = 0.25 – 0.35

Label height Minimum label height Minimum label height in

peel-off mode Maximum label height with printhead 203 dpi

C

Maximum label height with printhead 300 dpi Maximum label

height with printhead 600 dpi

D Label gap 2–1000

E Label thickness 0.07–0.35

F Liner thickness 0.07–0.35

G Distance from 1st heating point to edge of liner 2

H Distance from label sensor to edge of liner 5–53

I Width of perforation mark >5

K Height of perforation mark 2–10

L Width of reflex mark >5

M Height of reflex mark 2–10

25–120 10–120

5 12 2000 2000 1000

Table 4. Permissible Label Dimensions

1-6-3 Transfer Ribbons

Select transfer ribbons which are only a little wider than the labels:

• If a ribbon is too narrow, the printhead comes into contact with the labels wear

• If a ribbon is too wide, there is a risk of wrinkling _ print image errors

Detection of the transfer ribbon occurs via checking the rotation of the transfer ribbon

supply hub. To print all labels up to the end of the transfer ribbon cleanly, the trailer tape

may not be longer than 60 mm. It must be possible to easily remove the end of the transfer

ribbon from the cardboard core.

8 User Manual Edition 04/10

Page 15

BP-PR PLUS Series

1-7 Software

You can use several methods to control the printer and create label layouts.

1-7-1 Direct Programming

The printer has an extensive command set for creating label layouts. With a text editor,

the printer commands can be combined in a file. This label programming can then be sent

to the printer via a data interface (e.g. via the DOS command COPY). Please contact

Brady technical support for direct programming.

1-7-2 Windows Printer Driver

You can obtain printer drives for various versions of Windows from your dealer or the

internet. Using the printer driver, you can control the printer from almost any Windows

application. Functionality depends on the selected application. Use of the printer driver is

explained in the online help.

1-7-3 Label Software

A variety of label programs which are adapted to the specific requirements of label

printing are offered for convenient label layout designs. Many programs use the printer

driver. Some programs already have their own driver for printers of the BP-PR PLUS

Series. These programs offer the greatest possible convenience when creating and

printing labels.

Edition 06/10 User Manual 9

Page 16

BP-PR PLUS Series

2 Connecting Printer to Computer

You can choose from the following options for connecting a computer to the printer:

• Direct connection to the serial RS-232 interface (8) (see 2-1 Connecting Printer via

Serial RS-232 Interface on page 11).

• Direct connection to the Ethernet interface (5) (see 2-2 Connecting Printer via

Ethernet Interface on page 12).

• Connection via a computer network to the Ethernet interface (5) (see 2-2

Connecting Printer via Ethernet Interface on page 12).

• Direct connection to a high-speed USB slave interface (7) (see 2-3 Connecting

Printer via USB Interface on page 14).

1 Power switch

2 Power connection jack

3 Slot for type II PC card

4 Slot for a CompactFlash memory card

5 Ethernet 10/100 Base-T

6 Two USB master interfaces for keyboard,

scanner or service key

7 High-speed USB slave interface

8 Serial RS-232 C interface

Figure 4. Power and computer connections

i

Insufficient or missing grounding can cause faults during operation.

Ensure that all computers and connection cables connected to the printer are grounded.

10 User Manual Edition 04/10

Page 17

BP-PR PLUS Series

2-1 Connecting Printer via Serial RS-232 Interface

2-1-1 Connecting Printer

The RS-232 interface is operated via an RS-232 cable.

If problems occur, contact the computer manufacturer for interface assignments and note

the pin assignment of the SUB-D jack described in 2-1-2 RS-232 Interface Connection

Jack Pin Assignment on page 11.

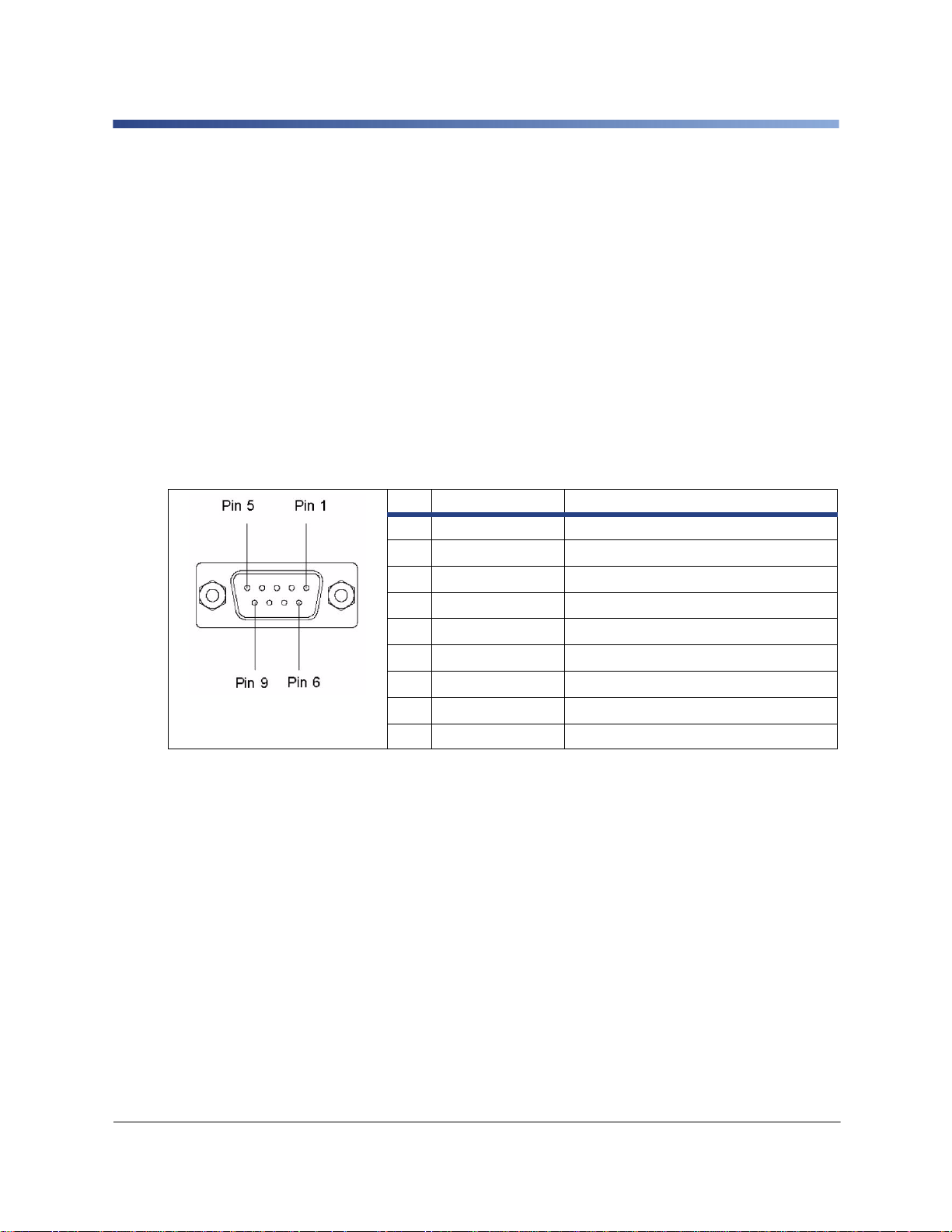

2-1-2 RS-232 Interface Connection Jack Pin Assignment

On the back of the printer there is a 9-pin SUB-D jack for the serial RS-232 interface.

1. Connect computer and printer with a suitable cable.

2. Secure cable connections with the screws found at the plugs.

3. Configure the RS-232 interface of the printer to match the settings of the

connected computer (see 4-1-4 Interfaces on page 21).

Pin Designation Function

1 CD Carrier Detect

2 TxD Transmit Data

3 RxD Receive Data

4 DTR Data Terminal Ready (not connected)

5 GND Ground

Figure 5. Pin assignment of the

9-pin SUB-D jack

6 DSR Data Set Ready (not connected)

7 RTS Request To Send

8 CTS Clear To Send

9 RI Ring Indication (not connected)

Edition 06/10 User Manual 11

Page 18

BP-PR PLUS Series

2-2 Connecting Printer via Ethernet Interface

To connect the printer to a network jack, you will require a patch cable with an RJ45 plug

for 10 Base T or 100 Base T. For direct connection of the printer to the Ethernet card of a

local computer, you will need an appropriate crossover cable.

i

i

A shielded cable must be used to connect the printer to the network.

1. Connect computer and printer with a suitable cable.

2. Make basic settings for operation of the Ethernet interface (see 4-1-4 Interfaces

on page 21).

3. Call up the printer website (see 4-2-1 Calling up the Printer Website on page 25).

4. Open the "Setup" tab on the printer website.

5. Set the parameters described in Table 13 on page 29 in the path

Setup > Interfaces > Ethernet.

6. Click Set on the "Setup" tab.

7. Enter PIN and click Confirm (see 4-1-6 Security on page 24).

8. Set up print service if necessary (see 2-2-1 Print Services Raw-IP and LPD in MS

Windows on page 13).

9. Adjust Windows printer setting (see 2-2-2 Adjusting Windows Printer Setting on

page 14).

Do not change the settings of the "IP" and "Gateway" on the printer website, as

otherwise the connection to the printer may be lost

12 User Manual Edition 04/10

Page 19

BP-PR PLUS Series

2-2-1 Print Services Raw-IP and LPD in MS Windows

The print services Raw-IP and LPD are not available in all operating systems. In general,

special tools are required to set up print services. Information on this can be obtained

from your dealer.

Print service Windows 2000 Windows XP Windows Vista Windows 7

Raw-IP Not available Available Available Available

LPD

Windows 2000 offers the port monitor SPM (Standard Port Monitor) which is installed

automatically when setting up the TCP/IP protocol. The SPM can be configured for RawIP or LPD.

Information on installation can be obtained from the Windows documentation.

During the installation of both print services, additional connections for print outp ut are set

up:

Available,

but not installed

Table 5. Availability of print services Raw-IP and LPD in Windows

Available Available Available

Raw-IP: Enter the same port address in the printer which you have selected

during installation.

LPD: "lp" (line printer) must be entered as the name of the printer on the

computer (queue name).

Edition 06/10 User Manual 13

Page 20

BP-PR PLUS Series

2-2-2 Adjusting Windows Printer Setting

If the printer driver valid for your Windows version is installed on your computer, you can

use the Windows standard applications to edit the label contents and to start the print jobs.

To use the Raw-IP or LPD print services, you must adjust the Windows printer settings:

2-3 Connecting Printer via USB Interface

The high-speed USB interface allows the printer to be operated via a USB interface of a

computer running the operating system Windows 2000, Windows XP, Windows Vista or

Windows 7.

1. Open the folder containing the printers via Start > Settings > Printers.

2. Right-click the icon of the printer. A pop-up menu appears.

3. In the pop-up menu, select Properties.

4. Open the Details or Connections tab.

This tab contains, among other things, the connections which were also set up

when the print services were installed. The names of these connections depend

on the installation tool used.

5. Select the Raw-IP or LPD connection.

6. Click OK.

A printer driver must be installed if a USB interface will be used for connection..

1. Switch printer off.

2. Connect computer and printer with an A-B cable.

3. Switch computer on.

4. Place the CD-ROM with the Windows driver in the CD-ROM drive.

5. Exit all programs currently running.

6. Switch printer on. The Windows Installation Wizard is started automatically.

7. Confirm the folder structure before continuing.

8. Follow the on-screen instructions. The source of the installation file is

"D:\WINDRV\9X2000XP", where D is the letter of the CD-ROM drive used.

9. If the "Has Not Passed Windows Logo Testing" error message appears during

installation, continue with the installation anyway.

After successful installation, an icon for the printer appears in the Windows

"Printer" system folder.

10. Click icon in "Printer" system folder and make printer settings if necessary.

14 User Manual Edition 04/10

Page 21

BP-PR PLUS Series

3 Offline Menu

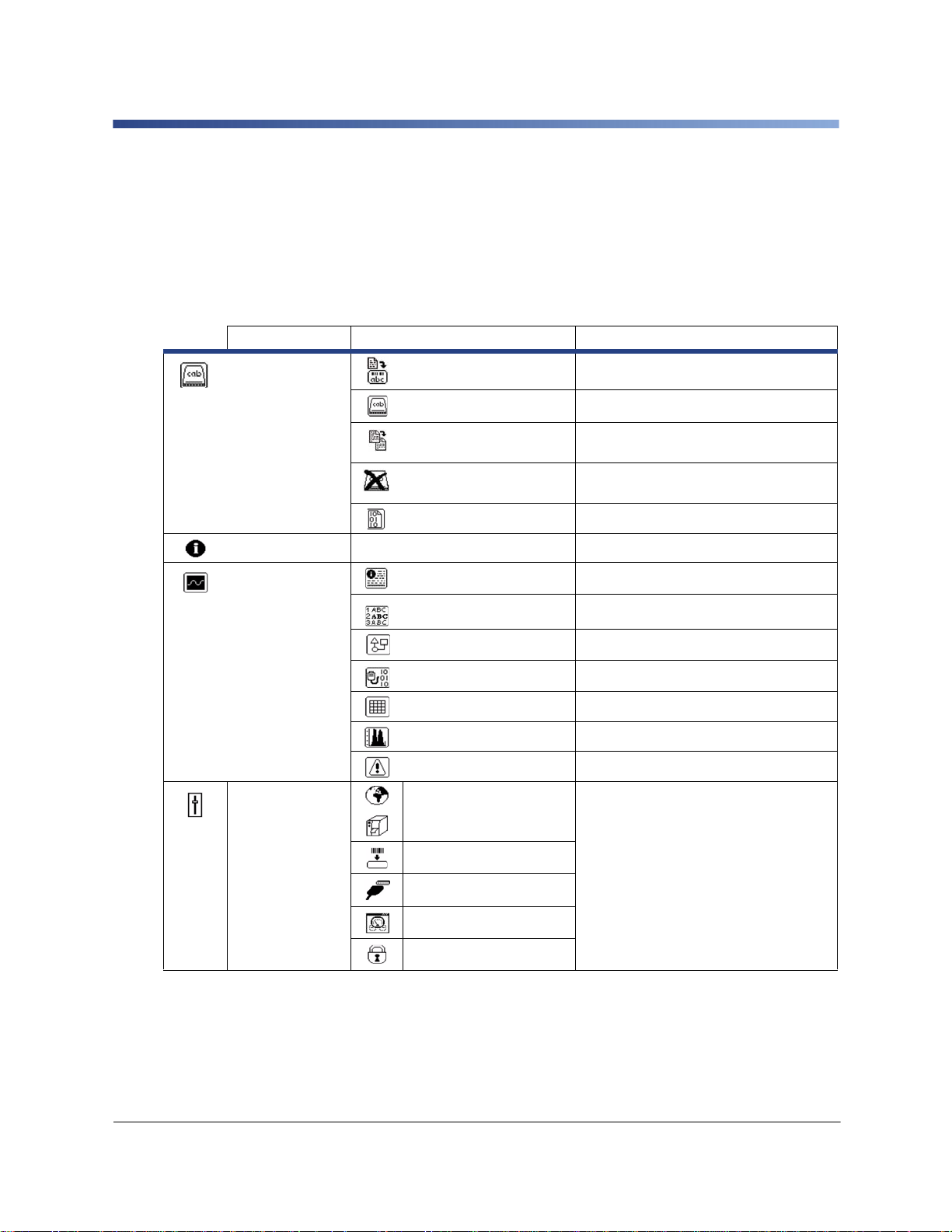

3-1 Structure of the Offline Menu

The offline menu contains setting options on several levels for configuring the printer to

meet your needs. In addition, the offline menu features test functions for supporting the

configuration or checking the function of the printer. Using status functions, the set

parameters can be displayed or printed.

1st Menu Level 2nd Menu Level Access

Memory Card Label from card

Only with memory card inserted

Print directory

Copy memory card

Format card

ASCII dump (Card) Only with memory card inserted

Short Status

Test Status print

Font list

Device list

ASCII Dump Mode

Test grid

Label profile

Event log

Setup Local settings

Machine param.

Only with memory card inserted

Only with memory card inserted, PIN

protection possible

Only with memory card inserted, PIN

protection possible

Only with service key inserted

PIN protection possible

Print param.

Interfaces

Status line

Security

Edition 06/10 User Manual 15

Page 22

BP-PR PLUS Series

1st menu level 2nd menu level Access

Service Firmware upd.

PIN protection possible

Firmw. fr. card

Clr. service ctr.

Adj. gap sensor

Save settings

Load settings

OEM Name

Cleaning interval

Table 6. Menu structure

3-2 Navigating the Offline Menu

You can control all settings and functions in the offline menu with the navigator pad.

Press the menu button to switch from Ready mode to the

offline menu.

Press the or button to select menu items on a menu

level or to select values on the parameter level.

Press the button on the top menu level several times, if

necessary, to switch from the offline menu to Ready

mode.

Press the or button to reach a higher or lower menu

level or to set values on the parameter level.

Press the button briefly to enable value selection on the

parameter level, accept a selected value or start a

function.

Figure 6. Navigator Pad

Press and hold (> 2 sec.) the button to exit the

parameter level without accepting the parameter setting.

PIN protection possible

Only with service key inserted

Only with service key inserted

Only with memory card inserted, PIN

protection possible

Only with memory card inserted, PIN

protection possible

Only with service key inserted

Only with service key inserted

i

16 User Manual Edition 04/10

You can also make all settings in the offline menu via the Ethernet interface (see 22 Connecting Printer via Ethernet Interface on page 12) or via direct control

commands (see “Programming Manual“).

Page 23

BP-PR PLUS Series

4 Configuration

4-1 Configuration via the Operating Panel

A host of parameters for configuring the printe r are foun d in the Setup menu of the offline

menu. Your printer is mainly configured via the operating panel during initial

commissioning and when making major changes to the operational conditions. Changes

required for processing different print jobs can be implemented via software settings.

You can protect the Setup menu from unauthorized access via a code number (PIN).

4-1-1 Local Settings

1. Press the menu button.

2. Select Setup > Local settings.

Parameter Meaning Default

Country

Timezone

Setting the display language and the country-specific date and time

formats. You can also overwrite the time formats via software. The

changes are not saved permanently, however.

Adaptation of the time display of the printer to the time zone in

relation to UTC (Universal Time Coordinated).

USA

UTC + 1

Daylight Saving

Set Date

Set Time

Selection of the daylight saving regulation applicable for the region.

The time is then changed automatically.

Setting of the system date in the format DD.MM.YYYY (DD: day,

MM: month, YYYY: year). The print output of the date occurs in the

format set via the "Country" parameter. You can also change the

date via software. The change is not saved permanently, however.

Setting the system time in the HH:MM:SS format. When changing

the time, ensure that the Timezone, Daylight saving and Set date

parameters are set correctly. The time can also be synchronized

automatically via the internet using the Ethernet interface. The print

output of the time occurs in the format set via the "Country"

parameter. You can also change the time via software. The change

is not saved permanently, however.

Table 7. Parameters of the menu Setup > Local settings

EU

–

–

Edition 06/10 User Manual 17

Page 24

BP-PR PLUS Series

4-1-2 Device Settings

Parameter Meaning Default

Printhead

Pos. X

Printhead

Pos. Y

Tear-off Pos.

1. Press the menu button.

2. Select Setup > Machine param.

Shifts entire print image perpendicular to direction of paper flow.

The absolute shifting of print image perpendicular to direction of paper flow is

limited to the difference between label width and printhead width set in the

software.

You can also set Printhead pos. X via software. The offset values from

Machine param. menu and the software are added together.

Shifts entire print image in direction of paper flow. With positive values,

printing begins later in the direction of paper flow.

Shifting the print image in the direction of paper flow also influences the peel

and cutting positions.

Correct the Peel position and Cut position parameters by the

same value in the opposite direction.

You can also set the Printhead pos. Y via software. The offset values from

Machine param. menu and the software are added together.

Shifts the tear-off position in the direction of paper flow. With positive values,

the label strip is transported farther out of the printer.

0.0 mm

0.0 mm

0.0 mm

Demand

Sensor

Cutter

Applicator

Brightn. LCD

Contrast LCD

Time

Powersave

Debug Mode

Configuration of optional peel-off module. See documentation of the peel-off module.

Configuration of the optional cutter. See documentation of the cutter.

Configuration of the optional applicator. See documentation of the applicator.

Brightness of the LCD display from 1 to 10

10

Contrast of the LCD display from 4 to 8. 6

Time between last operation and activation of Powersave mode. 5 min.

Operating mode which supports firmware programmer when localizing errors. Off

Table 8. Parameters of the menu Setup > Machine param.

18 User Manual Edition 04/10

Page 25

BP-PR PLUS Series

4-1-3 Printing Parameters

Parameter Meaning Default

Heat Level

1. Press the menu button.

2. Select Setup > Print param.

Heating value for compensating for differing thermal behavior of

print-heads. Changing this value is then necessary if printing

intensity has changed after replacing printhead. To adapt printing

intensity when using different media, print speeds or printing

contents, you should change the heat level in the software. The

settings from the Print param. menu and the software are added

together . The heat level setting also affects the test printouts.

0

Print Speed

Transfer Print

Warn Level

Ribbon

Label Sensor

Tear-off Mode

Basic print speed setting. You can re-specify the print speed for

each print job via software. The basic setting is not changed by

this. The print speed setting also affects the test printouts.

On for thermal transfer printing: Sensor for monitoring the transfer

ribbon is activated. Off for thermal direct printing: Sensor for

monitoring the transfer ribbon is not activated. You can overwrite

the setting for each print job via software.

Warning via the Ethernet interface by way of an SNMP message

or e-mail sent when the remaining diameter of the ribbon supply

roll undershoots the set value (32–74 mm).

Method for detecting the starting end of the label. Gap Sensor:

Detection using changes in the transparency between the label

and label gap. Bottom-Reflect: Detection using reflex marks on

the bottom of the medium. Continous media: Synchronization of

the paper flow when using endless media in cutting mode. More

detailed information is found in the documentation of the cutter.

Positioning the label medium for tearing off at the tear-off plate.

On: Additional advancement of the label medium which positions

the label gap after the last printed label at the dispense plate.

Off: Label advance stops once the last label has fully passed the

print line.

100 mm/s

On

Off

GapSensor

Off

Edition 06/10 User Manual 19

Page 26

BP-PR PLUS Series

Parameter Meaning Default

Backfeed

Method for backfeeding the label medium. Backfeeding is

necessary in the cutting and peel-off modes since a label is

pushed out passed the front edge of the next label above the print

line when peeling off/cutting. always: Backfeeding occurs

independently of label contents. smart: Backfeeding only occurs

when the next label is not yet fully prepared when peeling off/

cutting the current label. Otherwise, the second label is pushed on

and completed after removal of the first label without backfeeding.

smart

Error-Reprint

Pause reprint

Protocol error

Barcode error

Width ASCII

dump

On: With a correctable error and corresponding troubleshooting,

the label being printed when the error occurs is repeated . Off: Print

job is continued with the next label.

Printing of another label with the information of the previous print

job by pressing the pause button. This function can be executed

until the print buffer is cleared with the cancel button.

On: Printer switches to Error mode when unknown or faulty data is

received. Off: When working with older computer operating

systems, it is possible that the print spooler of the operating

system will reply to the printer with normal status messages of the

printer (e.g. end of paper) in the form of ASCII text. The printer

cannot interpret this data and outputs a large number of protocol

errors. In this case, it is advantageous if you set the Protocol

error parameter to Off. Caution: If the Protocol error parameter

is set to Off, protocol errors which can be traced back to faulty

programming are also ignored. There is a risk of data loss.

On: With faulty barcode contents or size specifications, printing is

interrupted. Off: Printing is not interrupted if an error occurs. If

barcode contents are faulty, the printer attempts to replace the

incorrect data with valid characters (e.g. zeros). If barcode size

specifications are faulty, a gray ar ea is printed instead of the

barcode.

Width of printing area in the "Monitor mode" test function (see 5-6

ASCII Dump Mode on page 40). With the Automatic setting, the

printout of the control sequences arriving at the printer occurs over

the maximum printing width. You can reduce the printing area

width down to 50 mm.

On

Off

On

On

Automatic

Table 9. Parameters of the menu Setup > Print param.

20 User Manual Edition 04/10

Page 27

BP-PR PLUS Series

4-1-4 Interfaces

Parameter Meaning Default

Default Card Slot

1. Press the menu button.

2. Select Setup > Interfaces.

Definition of the primary card slot. Select one of the card slots

on the back of the printer with CompactFlash or PC-Card or

the card slot in the external operating panel with Ext.

CompactFlash.

Compact-

Flash

Character Set

RS232

RS-422/485

IEEE 1284

Ethernet

> DHCP

> IP

Selection of the character set table for adaptation to the

computer system used. Switching the character set via software

Windows

1252

is not possible. You can access characters not available in the

selected character set, however, using the Unicode table.

Interface parameters Baud rate and Handshake for data

transfer via the serial RS-232 interface.

57600

RTS/CTS

Configuration of the optional serial RS-422 or RS-48 5 interface.

See documentation of the serial interface.

Configuration of the optional parallel interface. See the

documentation of the parallel interface.

Configuration parameters of the Ethernet interface card. You can access

additional configuration parameters for the Ethernet interface card via the

printer website (see 4-1-2 Device Settings on page 18).

Method of issuing IP address On: Dynamic issuing of IP

On

address by the DHCP server Off: Direct issuing of the IP

address by the operator

IP address of the printer. Only valid with DHCP = Off.

> Mask

Subnet mask (classification and address range) of the local

network. Only valid with DHCP = Off.

Edition 06/10 User Manual 21

Page 28

BP-PR PLUS Series

Parameter

> Gateway

> Network Error

Keyboard

> Layout

> NumLock

Meaning

Connection address between the local network and other

networks. The IP address of the computer (router) on the

network through which the connection can be established is

used for this. The address of the router can also be issued via

DHCP.

Printer switches to Error mode when problems with the network

connection occur.

Setting of the keyboard layout when using an external keyboard.

Country setting of the keyboard layout. With the Automatic

setting, the setting from the menu Local settings > Country is

used.

Activation or deactivation of the numerical keypad on the

keyboard.

Table 10. Parameters of the menu Setup > Interfaces

Default

Off

Off

Automatic

On

22 User Manual Edition 04/10

Page 29

BP-PR PLUS Series

4-1-5 Status Line

Select the parameters to be displayed in Ready mode.

Parameter Meaning Default

Clock

1. Press the menu button.

2. Select Setup > Status line menu.

Displays the current time. On

Date Sheet

Ribbon Supply

Ethernet Link Status

Temperature

Used Memory

Input Buffer

Card Access

Data Transfer

Displays the current calendar day. On

Displays current ribbon supply in the form of a horizontal bar. Off

Displays the Ethernet status. Off

Displays the current printhead temperature. Off

Displays the current memory used in the form of a vertical bar. Off

Displays the current input buffer used in the form of a vertical bar. Off

Icon displayed while an installed memory card is being accessed. On

Displays the current data transfer in the form of a falling drop. On

Table 11. Parameters of the menu Setup > Status line

Edition 06/10 User Manual 23

Page 30

BP-PR PLUS Series

4-1-6 Security

4-1-6-1 Activating a PIN

By activating a PIN, you can protect the Setup menu, certain memory card functions and

the firmware update from unauthorized access. Protected menu items are then marked

with the symbol and are only accessible after the PIN is entered.

4-1-6-2 Defining a PIN

1. Press the menu button.

2. Select Setup > Security > Security menu.

3. Select the value On with the and buttons

4. Accept the setting with the button.

1. Press the menu button.

2. Select Setup > Security > PIN menu.

3. Select the digit of the PIN to be changed with the and buttons.

4. Assign the selected digit a number with the and ⌃ buttons.

5. Repeat these two steps for the remaining digits of the PIN.

6. Accept the setting with the button.

24 User Manual Edition 04/10

Page 31

BP-PR PLUS Series

4-2 Configuration via the Printer Website

The parameters accessible via the operating panel can also be set via the website

accessed through the firmware of the printer. In addition, other parameters for the

Ethernet interface are accessible there. You can access the printer website with a Javacapable browser (e.g. Microsoft Internet Explorer, Netscape Navigator) via the Ethernet

interface. Use of the Java applets requires at least version 1.4.2 of Java.

4-2-1 Calling up the Printer Website

i

It is absolutely necessary to define a PIN to make settings via the printer website.

You are requested to enter this PIN whenever settings are changed via the

website. The initial setting of the PIN can be made via the operating panel of the

printer (see 4-1-6 Security on page 24) or via the printer website (see 4-2

Configuration via the Printer Website on page 25) .

1. Start the browser.

2. Call up printer website by entering the IP address via HTTP

(e.g., http://192.168.100.208). The "Status" tab is open on the home screen.

3. Check to see if the status "Ready" is displayed.

4-2-2 Description of the Printer Website

The printer website contains the following tabs:

• Status: general status description. see 4-2-2-2 Setup Tab on page 28.

• Setup: configuration parameter settings (see 4-2-2-2 Setup Tab on page 28).

• System messages: automatic sending of messages via e-mail (see 4-2-2-3

System Messages Tab on page 30).

• Printer status line: printer status line layout(see 4-2-2-4 Printe r S t atus Line Tab on

page 31).

• Fonts: overview of the available fonts (see 4-2-2-5 Fonts Tab on page 32).

• Devices: list of the hardware and optional components (.see 4-2-2-6 Devices Tab

on page 33).

• Help: online help (see 4-2-2-7 Help Tab on page 33).

Edition 06/10 User Manual 25

Page 32

BP-PR PLUS Series

4-2-2-1 Status Tab

The following information is contained in the top section of the "Status" tab:

Figure 7. "Status" Tab on the Printer Website

• Printer type

• Firmware version

• Bootloader version

• Printhead temperature and temperature of CPU

• Heat voltage for the printhead. The heat voltage is only active during printing.

Otherwise, 0.0 V is displayed.

• Operative time of the printer

• Number of labels printed since commissioning

• Previously printed paper length with thermal transfer printing

• Previously printed paper length with thermal direct printing

• Printer status: "Ready", "Printing label", "Settings" or "Error"

i

26 User Manual Edition 04/10

Information is not updated automatically while the "Status" tab is open. Updating

occurs when the tab is changed or by clicking the Update button.

Page 33

BP-PR PLUS Series

A list of the events which have occurred since the printer wa s switched on are found in the

bottom section of the tab. No more than the last eight events are displayed.

The "Ready" event provides information on when the printer was switched on.

The buttons on the bottom line of the "Status" tab have the following functions:

Button Function

Display

Opens a window which shows the current printer display. You can set

the update interval on the scale below the display. The display is not

updated automatically with the "0" setting.

Reset

Print

Update

Sends a soft reset signal to the printer.

Opens the window for the settings of a local printer or network printer

to be used to print the contents of the "Status" tab.

Updates the display on the "Status" tab.

Table 12. Buttons on the "Status" tab

Edition 06/10 User Manual 27

Page 34

BP-PR PLUS Series

4-2-2-2 Setup T ab

On the "Setup" tab, you can set all the configuratio n parameters which ar e also accessible

via the operating panel in the Setup menu. In addition, other parameters for the Ethernet

interface can be set (see below).

The menus and parameters are arra ng e d in a tre e str uc tu re in the to p se ctio n of the ta b.

The tree structure can be expanded in different ways:

Figure 8. "Setup" tab on the printer website.

Click circular symbol in front of the menu symbol once. The corresponding

menu is expanded.

Double-click menu symbol or menu name. The corresponding menu is

expanded

Click the Expand All button. The tree structure is fully expanded.

To change a parameter:

1. Locate parameter in the tree structure.

2. Click parameter name or the symbol next to it.

3. Enter value of the parameter in the input field in the bottom section of the tab.

4. Click Set.

5. Enter PIN and click OK.

The printer can be given a name on the top line of the tree structure. This name does not

have a functional meaning. Its sole purpose is to allow the operator to more easily

differentiate between the printer s on a netw or k.

i

28 User Manual Edition 04/10

Information is not updated automatically while the "Setup" tab is open. Updating

occurs when the tab is changed or by clicking the Update button.

Page 35

BP-PR PLUS Series

The following parameters for the Ethernet interface can only be accessed via the printer

website:

Parameter Meaning Default

SMTP

Server

E-mails can be sent to selected addresses when certain status and error

messages are generated. To activate:

Set parameter to "On".

Enter IP address of the SMTP server.

Enter a valid e-mail address for the printer in the "From address"

field.

More detailed information on sending e-mails is found in see 4-2-2-3

System Messages Tab on page 30.

Off

Raw-IP

Port

LPD

SNMP

Time

Server

Service for printing on the network (see 2-2-1 Print Services Raw-IP and

LPD in MS Windows on page 13).

Select a predefined port address.

Activation of the network printing service LPD (see 2-2-1 Print Services

Raw-IP and LPD in MS Windows on page 13):

Set parameter to "On". Enter "lp" as the queue name.

Data exchange between printer and management station via SNMP

(Simple Network Management Protocol). To activate:

Set parameter to "On".

Enter IP address of the management station(s) (receiver 1 or

receiver 2).

Assign the "Community" parameter the value "public".

Synchronization of the date and time of the printer. To activate:

Set parameter to "On".

Enter IP address of the time server.

Synchronization occurs hourly. The accepted time is not automatically

saved in the printer, however. To save the accepted time:

Call up the parameter time and select OK to save the displayed

setting.

Table 13. Additional parameters for Ethernet interface

9100

Off

Off

Off

Edition 06/10 User Manual 29

Page 36

BP-PR PLUS Series

4-2-2-3 System Messages Tab

Status and error messages can be sent automatically to the SNMP manager or via e-mail

to the selected addresses immediately after they occur via the Ethernet interface. Select

the messages to be sent and destination addresses on the "System messages" tab.

Figure 9. “System messages" tab on the printer website

Column Meaning

Description Status and error messages that can be sent.

To expand tree structure, click circular symbol once or double-click

description.

An entry for a higher-order description (e.g. note) is automatically accepted for

all subordinate descriptions (e.g. "Start", "Not ready", "Ribbon running out").

SNMP 1

SNMP 2

E-mail Valid e-mail address for the SMTP server to which the message is to be sent.

Sound Audible signal which indicates receipt of the message.

i

Management stations on local network which communicate with the printer via

SNMP. T o make use of SNMP functionality, the SNMP agent must be activated

(see 4-2-2-2 Setup Tab on page 28).

Select management station by clicking the corresponding cell.

The selection is indicated via a symbol. Undo the selection by clicking it again.

Click cell and enter e-mail address or select from pull-down menu.

Click cell and select signal type in pull-down menu.

Table 14. Parameters on "System messages" tab

The settings are not accepted until the Transfer button is clicked. If you switch to

another tab beforehand, the settings are lost.

30 User Manual Edition 04/10

Page 37

BP-PR PLUS Series

4-2-2-4 Printer Status Line Tab

On the "Printer status line" tab, you can select the status parameters which are to be

displayed on the printer status line.

Figure 10. ”Printer status line” tab on the printer website

Adding a status parameter:

1. Select widget in pull-down menu.

2. Click Set.

The symbol, the parameter designation and the width of the symbol in the display

(in pixels) are displayed in the top section of the tab. The entire width of all

symbols in the display (e.g., 92 pixels) and the maximum width of the display

(e.g., 128 pixels) are displayed in the "Display usage" field.

Removing a status parameter:

1. Select parameter in the list.

2. Click Remove.

Edition 06/10 User Manual 31

Page 38

BP-PR PLUS Series

4-2-2-5 Fonts Tab

The most important parameters of the fonts available in the printer are listed on the "Fonts"

tab. The table contains both the original fonts in the printer and other fonts lo aded in to the

printer.

Figure 11. ”Fonts” tab on the printer website

The parameters correspond to those in the Font list menu and are described in Table 17

on page 37.

32 User Manual Edition 04/10

Page 39

BP-PR PLUS Series

4-2-2-6 Devices Tab

The "Devices" tab provides an overview of the most important hardware components

installed in the printer and the optional devices connected.

Figure 12. ”Devices” tab on the printer website

The contents of the display correspond with those of the Device list and are d escrib ed in

Table 18 on page 39.

4-2-2-7 Help Tab

When the "Help" tab is selected, an internet connection to the support page website is

opened.

Edition 06/10 User Manual 33

Page 40

BP-PR PLUS Series

5 Test Functions

5-1 Overview

The printer is equipped with different te st fun ct ion s pr oviding information on:

• the most important configuration parameters

• the fonts available in the printer

• important hardware components and connected peripheral devices

• the print image quality and state of the thermal printhead

• the function of label detection in conjunction with the optical properties of the label

medium

• the label data sent from the computer or read out from the memory card.

The test functions are found in the Test menu:

1. Press the menu button.

2. Select Test menu.

3. Switch to the test function level with the ⌃ button.

4. Select the desired test function with the and buttons.

5. Start the selected test function with the button.

5-2 Short Status

The Short status menu provides an overview of important status information in the printer

display.

1. Press the menu button.

2. Select Short status menu.

3. Scroll through the individual lines with the and buttons.

You can exit the Short status menu with the button.

The following configuration parameters are displayed in the Short status menu:

Line Meaning Example

1 Printer type BP-PR 200 PLUS

2 Version number of the printer operating system (firmware) Firmware V3.04

3 Creation date of firmware (Jul 27 2006)

4 Version numbe r of the system loader (bootloader) Bootloader V1.14

5 Creation date of the bootloader (Jul 24 2006)

6 Revision of the CPU PCB PCB Rev. 04

7 Revision of the FPGA (Field Programmable Gate Array) FPGA Rev. 2

8 Resolution of the installed thermal printhead TPH 203dpi,832dots

9 Previously printed paper lengths with thermal transfer printing Transfer 181.44 m

10 Previously printed paper length with thermal direct printing Thermal 13.17 m

11 IP address of the printer when connected to a network 192.168.9.13

Table 15. Display in Short status menu

34 User Manual Edition 04/10

Page 41

BP-PR PLUS Series

5-3 Status Print

The Status print function prints a test image containing information on the conf iguration

and status of the printer. The printout occurs using the heat level and print speed

specified in the Setup > Print param. menu.

i

The printout occurs without taking the label gaps into consideration. This is why

endless media are most suitable for this purpos e.

1. Insert printable medium (labels, endless paper) which extends across the entire

printing width. If the printout is to occur using thermal transfer printing, insert

transfer ribbon with the maximum width.

2. Press the menu button.

3. Select Test > Status print menu.

4. Start printout with the button. You can cancel the printout with the cancel

button.

Figure 13. Status print

Edition 06/10 User Manual 35

Page 42

BP-PR PLUS Series

The Status print contains the following information:

A From address is displayed if the SMTP server is "On" or the service key is

inserted

E Recipients are displayed if SNMP is "On" or the service key is inserted

O Optional assemblies which are displayed with the service key inserted even if

they are not installed

S Service data only displayed when the service key is inserted

W Queue name is displayed when LPD is "On" or the service key is inserted

Symbol Information

• Device type

• Version and creation date of the firmware

• Version and creation date of the system loader (bootloader)

Current values of selected local settings (see 4-1-1 Local Settings on page

17).

Current values of selected device settings (see 4-1-2 Device Settings on

page 18).

Line

pattern

Current values of selected print parameters (see 4-1-3 Printing Parameters

on page 19).

Current values of selected interface parameters (see 4-1-4 Interfaces on

page 21).

Status of PIN activation (see 4-1-6 Security on page 24).

• Operative time

• Number of labels printed

• Printed length with thermal transfer printing and thermal direct printing

• Current measured values of the printhead temperature and heat voltage

• Information on the working points of the label sensor

The Status print presents lines differing in thickness at various distances at

the end. They are used to evaluate the print quality.

Table 16. Information in Status print

36 User Manual Edition 04/10

Page 43

BP-PR PLUS Series

5-4 Font List

The Font list function prints the most important parameters of the fonts available in the

printer in tabular form. The table contains both the original fonts in the printer and other

fonts loaded into the printer. The printout occurs using the heat level and print speed

specified in the Setup > Print param. menu.

i

The parameters have the following meaning:

The printout occurs without taking the label gaps into consideration. This is why

endless media are most suitable for this purpos e.

1. Insert printable medium (labels, endless paper) which extends across the entire

printing width.

2. If the printout is to occur using thermal transfer printing, insert transfer ribbon with

the maximum width.

3. Press the menu button.

4. Select Test > Font list menu.

5. Start printout with the button.

You can cancel the printout with the cancel button.

Figure 14. Font list

Column Meaning

No. ID number of the font required for programming (command T).

Name Name with which the font is saved internally.

Type

Description

Edition 06/10 User Manual 37

Type of font generation. It provides information on the variability of the font

and is important when programming (command T).

Explanations of the font: size, font family. The printout occurs in the

appropriate font.

Table 17. Parameters of the Font list

Page 44

BP-PR PLUS Series

Device list

Mach4/300 - 10/09/2007 -15:14:17

Firmware V3.11 (Aug 9 2007) - #111070553751

Name Description

CPU Thor, #111070553751

PCB-Rev. 7, CPU-Rev. 4

TPH 300 dpi, 1248 dots

I/F1 Ethernet 10/100 MBit/s

MAC: 00:02:E7:02:28:F4

I/F2 USB 2.0 Device

I/F3 RS-232

IFFS 8MB

USB [1] Generic/Generic Hub

[0] Full Rev. 3.00

Mfr: 03EB,Class: 09/00,Protocol: 00, Phase: 20/0

USB [3] Frontpanel

[1/3] Full Rev. 2.05

Mfr: 0985,Class: FF/1C,Protocol: 00, Phase: 20/1

abc licensed under Artistic license from Yabasic 2.715 (www.yabasic.de)

CMU-SNMP © 1988-89 Carnegie Mellon University,© 1995 Glenn Waters

jTreeTable © 1997-1999 Sun Microsystems, Inc. All Rights Reserved

Portions of this software are © 2005 The FreeType Project

(www.freetype.org). All rights reserved.

mDNSResponder © 2002-2006 Apple Computer Inc. All Rights Reserved

Licensed under the Apache License, Version 2.0

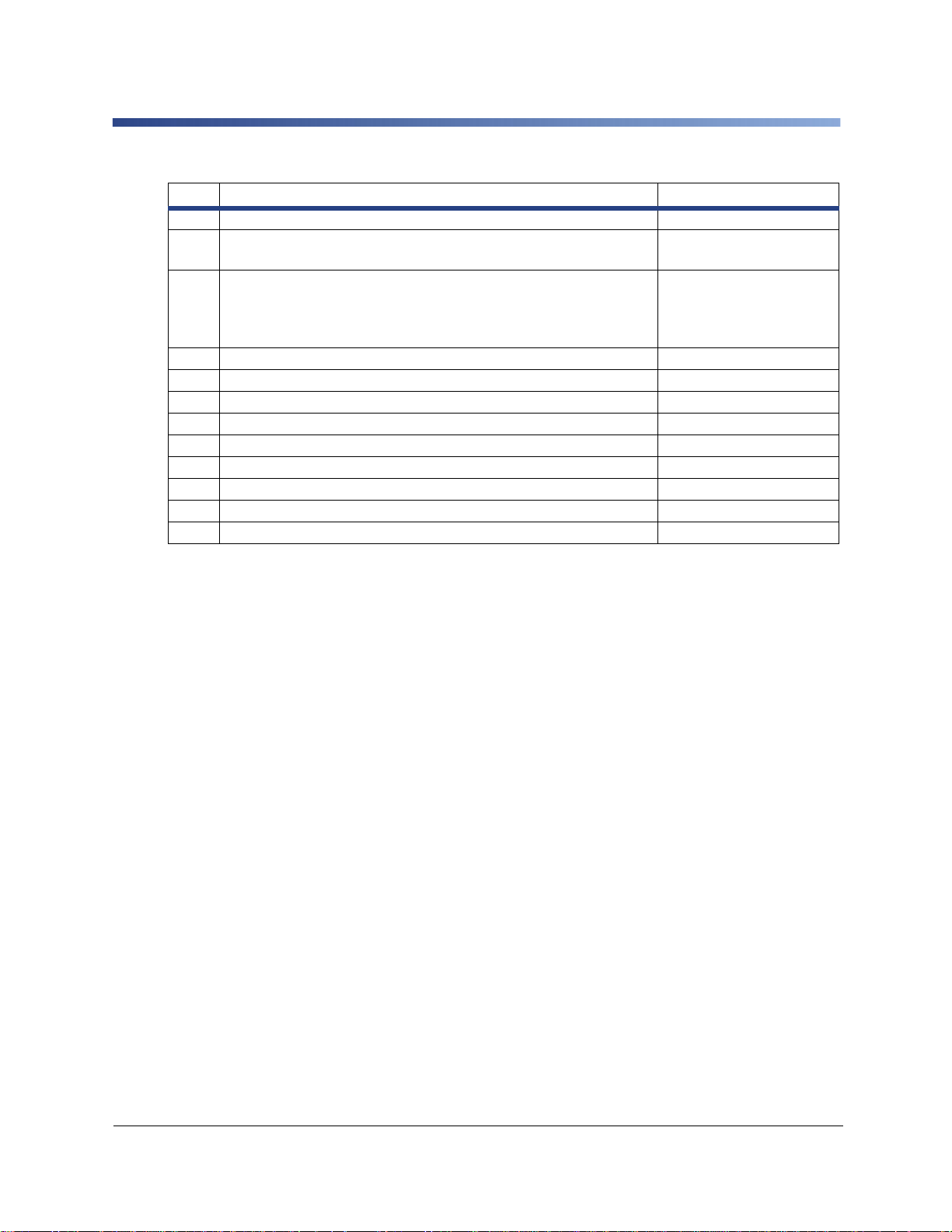

5-5 Device List

The Device list function prints out the most important information on hardware

components of the printer and connected devices. The printout occur s using the heat level

and print speed specified in the Setup > Print param. menu.

i

1. Insert printable medium (labels, endless paper) which extends across the entire

2. If the printout is to occur using thermal transfer printing , inser t tr an sfer r ibb on with

3. Press the menu button.

4. Select Test > Device list menu.

5. St art printout with the button.

You can cancel the printout with the cancel button.

The printout occurs without taking the label gaps into consideration. This is why

endless media are most suitable for this purpose.

printing width.

the maximum width.

Figure 15. Device list

38 User Manual Edition 04/10

Page 45

BP-PR PLUS Series

Name Information

CPU

• Type and serial number of the CPU PCB

• Revision of CPU PCB and FPGA

TPH Resolution and heating point number of the installed thermal printhead.

I/F [x] Type of interfaces installed x: Number of interface

Type and revision of installed USB devices

USB

[a] [b/c]

Speed

a: number of USB device

b: number of USB device to which device a is connected

c: number of interface of device b to which device a is connected

Speed: data transfer speed (low, full, high)

Table 18. Parameters of the Device list

Edition 06/10 User Manual 39

Page 46

BP-PR PLUS Series

5-6 ASCII Dump Mode

ASCII Dump Mode offers the option of checking incoming control sequences at the

interface when working with direct programming. The incoming commands at the printer

are printed out as text. In addition, a corresponding error message is printed out

immediately after an error occurs.

The printout occurs using the heat level and print speed specified in the Setup > Print

param. menu and is started after four lines are have been received.

i

i

Press the cancel button if you would like to cancel the printout or switch to the Ready

mode.

The control characters (ASCII code 00 to 31) ar e pr es en te d in the fo llo win g form:

• The printout occurs without taking the label gaps into consideration. This is

why endless media are most suitable for this purpose.

• If you only have media (labels, endless pa per) which do not cover the entire

printing width, you can reduce the width of the printout continuously down to

50 mm with the Width ASCII dump parameter (see 4-1-3 Printing

Parameters on page 193).

If you have questions about programming, keep a printout of your label file which

was created in ASCII Dump Mode handy . The p rintout can b e transmitted clearly

via fax.

1. Load printable medium (labels, endless paper).

2. If the printout is to occur using thermal transfer printing, insert transfer ribbon.

3. If the printable medium and/or the transfer ribbon does not co ver the entire

printing width, reduce the width of the printout accordingly with the Width ASCII

dump parameter see 4-1-3 Printing Parameters on page 19).

4. Press the menu button.

5. Select Test > ASCII Dump Mode menu.

6. Switch to Monitor mode with the button.

7. Send print jobs.

8. Call up the last few lines of a label description with the feed button.

Figure 16. Presentation of the control characters in ASCII dump mode

40 User Manual Edition 04/10

Page 47

BP-PR PLUS Series

Example:

In the following two figures, the printout in Monitor mode is contrasted with the "normal"

printout of a label.

Figure 17. Printout of example label in ASCII dump mode

Edition 06/10 User Manual 41

Page 48

BP-PR PLUS Series

5-7 Test Grid

The Test grid function prints out the geometric pattern on a background grid. This allows

you to assess the evenness of the print quality.

The printout occurs using the heat level and print speed specified in the Setup > Print

param. menu.

i

You can end the printout of the test grid wi th the cancel button.

The printout occurs without taking the label gaps into consideration. This is why

endless media are most suitable for this purpose.

1. Insert printable medium (labels, endless paper) which extends across the entire

printing width.

2. If the printout is to occur using thermal transfer printing , inser t tr an sfer r ibb on with

the maximum width.

3. Press the menu button.

4. Select Test > Test grid menu.

5. St art printout with the button. The geometric pattern is printed every 5 seconds

once the Test grid function is started. You can adjust the printer during the

pauses between the printouts.

Figure 18. Example test grid

42 User Manual Edition 04/10

Page 49

BP-PR PLUS Series

5-8 Label Profile

The Label profile function carries out a longer label advance. It saves the values

measured by the label sensor here and then prints them out in two diagrams. The printout

is used to check label detection in conjunction with the optical properties of the label

medium.

The printout occurs using the heat level and print speed specified in the Setup > Print

param. menu.

i

The printout of the diagram occurs without taking the label gap s into consideration.

This is why endless media are most suitable for the printout.

1. Select the label sensor to be tested in the menu Setup > Print param. (see 4-1-

3 Printing Parameters on page 19).

2. Load the label medium to be tested into the printer.

3. Press the menu button.

4. Select Test > Label profile menu.

5. Start the function with the button. The printer performs a longer label advance.

The label sensor measures the transparency/reflection capacity of the label

material here. The message Test print OK appears in the display once the

advance is complete.