Page 1

Brady WavePoint™ XE2000 User's Guide Notices

Copyright

This manual is copyrighted with all rights reserved. No portion of the manual

may be copied or reproduced by any means without the prior written consent of

Brady Worldwide, Inc.

While every precaution has been taken in the preparation of this document,

Brady assumes no liability to any party for any loss or damage caused by errors

or omissions or by statements resulting from negligence, accident, or any other

cause. Brady further assumes no liability arising out of the application or use of

any product or system described, herein; no any liability for incidental or

consequential damages arising from the use of this docume nt. Brady disclaims

all warranties of merchantability of fitness for a particular purpose.

Trademarks

WavePoint™ is a registered trademark of Brady Worldwide, Inc.

Pentium™ is a trademark of Intel Corporation.

Windows

Brady reserves the right to make changes without further notice to any product or

system described herein to improve reliability, function, or design.

©2000 Brady Worldwide, Inc. All Rights Reserved

U.S. & Canada Europe

®

and Windows NT® are registered trademarks of Microsoft Corporation.

Brady Worldwide, Inc.

6555 West Good Hope Road

P.O. Box 2131

Milwaukee, WI 53201

Brady Worldwide, Inc.

Lindestraat 20

9240—Zele

Belgium

Main Switchboard: (800) 541-1686

32-52-457.994

(414) 358-6600

FAX: (800) 292-2289

Sales/Customer

(800) 537-8791

Support:

Copyright © 2000, Brady Worldwide, Inc.

1

Page 2

Notices Brady WavePoint™ XE2000 User's Guide

Regulatory Statements

FCC Notice — U. S. Only

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including

interference that may cause undesired operation.

3. Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

Warning

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

RF Exposure

To comply with FCC RF exposure requirements for mobile transmitting devices, this

transmitter should only be used or installed at locations where there is at least 20cm

separation distance between the antenna and all persons.

FCC ID

NUC-BEPM13

2

Copyright © 2000, Brady Worldwide, Inc.

Page 3

Brady WavePoint™ XE2000 User's Guide Notices

Brady Warranty

Brady products are sold with the understanding that the buyer will test them in

actual use and determine for him or herself their adaptability to his/her intended

uses. Brady warrants to the buyer that its products are free from defects in

material and workmanship during the period of one year from the date of

purchase, but limits its obligation under this warranty to replacement of the Brady

WavePoint™ XE2000 RFID Smart Label Encoder shown to Brady's satisfaction

to have been defective. This warranty does not extend to any persons obtaining

the product from the buyer.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND OF

ANY OTHER OBLIGATIONS OR LIABILITY ON BRADY'S PART. UNDER NO

CIRCUMSTANCES WILL BRADY BE LIABLE FOR ANY LOSS, DAMAGE,

EXPENSE OR CONSEQUENTIAL DAMAGES OF ANY KIND ARISING IN

CONNECTION WITH THE USE, OR INABILITY TO USE, BRADY'S

PRODUCTS.

Copyright © 2000, Brady Worldwide, Inc.

3

Page 4

Notices Brady WavePoint™ XE2000 User's Guide

License Agreement

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS & CONDITIONS

OF THIS LICENSE AGREEMENT. IF YOU DO NOT AGREE WITH THESE

TERMS & CONDITIONS, PLEASE PROMPTLY RETURN THIS PACKAGE FOR

A FULL REFUND.

Brady Worldwide, Inc. (hereafter "BRADY") hereby grants you a non-exclusive,

non-transferable license to use the software and accompanying documentation

according to the following terms:

1. LICENSE GRANT: You may only use this software with the Brady

WavePoint™ XE2000 RFID Smart Label Encoder or other Brady

WavePoint™ products.

2. LICENSE RESTRICTIONS: You may not: 1) transmit the software over

a network without agreeing to an additional license; 2) modify, adapt,

translate, reverse engineer, decompile, disassemble, create derivative

works based on, or copy (except for one back-up copy) the software or

the accompanying documentation; 3) rent, transfer, or grant any rights

in the software or accompanying documentation without prior, express

written consent of BRADY; or 4) remove any proprietary notices, labels,

or marks on the software and accompanying documentation.

3. NATURE OF THIS AGREEMENT: This license is not a sale. Title and

copyrights to the software, and accompanying documentation remains

the property of BRADY. Unauthorized copying of the software or the

accompanying documentation, or failure to comply with the above

restrictions, shall automatically terminate this license without further

notice, and terminate your rights to use the software, and BRADY shall,

in addition to its other legal remedies, be entitled to its reasonable

attorney fees.

4. LIMITED WARRANTY: BRADY warrants that, for a period of one year

from the date of delivery to you as evidenced by a copy of your receipt,

the software, as furnished, under normal use, will perform without

significant errors that make it unusable. BRADY's entire liability and

your exclusive remedy under this warranty (which is subject to you

returning the software to BRADY) will be, at the option of BRADY, to

attempt to correct or help you around errors, or to replace the software

with functionally equivalent software or diskettes.

4

Copyright © 2000, Brady Worldwide, Inc.

Page 5

Brady WavePoint™ XE2000 User's Guide Notices

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, BRADY

MAKES AND YOU RECEIVE NO WARRANTIES, EXPRESS, IMPLIED,

STATUTORY OR IN ANY COMMUNICATION WITH YOU, AND

BRADY SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

BRADY DOES NOT WARRANT THAT THE OPERATION OF THE

PROGRAM WILL BE UNINTERRUPTED OR ERROR FREE.

Some states do not allow the exclusion of implied warranties so the

above exclusion may not apply to you. This warranty gives you specific

legal rights. You may also have other rights which vary from state to

state.

5. LIMITATION OF LIABILITY: IN NO EVENT WILL BRADY BE LIABLE

FOR ANY DAMAGES, INCLUDING LOSS OF DATA, LOST PROFITS,

COST OF COVER OR OTHER SPECIAL, INCIDENTAL,

CONSEQUENTIAL OR INDIRECT DAMAGES ARISING FROM THE

USE OF THE PROGRAM OR ACCOMPANYING DOCUMENTATION,

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY. THIS

LIMITATION WILL APPLY EVEN IF BRADY HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE. YOU ACKNOWLEDGE THAT

THE LICENSE FEE REFLECTS THIS ALLOCATION OF RISK.

Some states do not allow the limitation or exclusion of liability for

incidental, or consequential damages, so the above limitation may not

apply to you.

6. General: This Agreement shall be governed by, and interpreted under,

the laws of the State of Wisconsin. This Agreement is the entire

agreement between the parties and supersedes any other

communications or advertising with respect to the software and

accompanying documentation. If any provision of the Agreement is held

invalid, the remainder of this Agreement shall continue in full force and

effect.

Copyright © 2000, Brady Worldwide, Inc.

5

Page 6

Notices Brady WavePoint™ XE2000 User's Guide

Technical Support

Brady Worldwide, Inc. provides severa l Brady WavePo i nt™ XE2000 system

support options:

1. To speak with a Technical Support Representative, call (800) 643-8766;

Monday – Friday 7:00 a.m. – 7:00 p.m. (CST), or

2. FAX your inquiry to (414) 358-6767, or

3. Contact Brady's Technical Support Team on-line at:

tech_support@bradycorp.com

Technical Support / Canada (800) 643-8766

Technical Support / Europe 32-52-457.994

.

6

Copyright © 2000, Brady Worldwide, Inc.

Page 7

Brady WavePoint™ XE2000 User's Guide Notices

Copyright © 2000, Brady Worldwide, Inc.

7

Page 8

Brady WavePoint™ XE2000 User's Guide

Table of Contents

Chapter 1 - Getting Started..........................................................................10

Unpacking the XE2000................................................................................10

Equipment Checklist and Inspection...........................................................10

Components Included.............................................................................. 11

Reporting Damage...................................................................................12

Storage and Reshipping..........................................................................12

Chapter 2 - XE2000 Specifications.............................................................. 14

Power Adapter Specifications .....................................................................14

Chapter 3 - System Requirements..............................................................16

Chapter 4 - Product Description..................................................................18

Background Information...........................................................................18

XE2000 Components.................................................................................. 19

Chapter 5 - XE2000 Setup and Positioning ................................................22

XE2000 Setup.............................................................................................22

Software Installation................................................................................23

Power Connection ...................................................................................24

Serial Connection....................................................................................24

XE2000 Positioning.....................................................................................25

Encoder Module Height Adjustment........................................................26

Encoder Module Horizontal Adjustment...................................................26

LED Functions.............................................................................................27

XE2000 Status.........................................................................................27

Positioning the XE2000 for Use with RFID Smart Labels............................ 28

Using the XE2000 Utilities Program for Positioning Options.................... 31

Testing XE2000 Connectivity and Positioning.............................................33

Testing XE2000 Connectivity...................................................................33

Testing XE2000 Positioning.....................................................................35

Troubleshooting XE2000 Setup..................................................................37

Chapter 6 - Encoding Smart Labels with the XE2000................................ 38

Delay for Encoding......................................................................................39

Appendix A – Replacement Information..................................................... 40

Appendix B – Delay for Encoding............................................................... 42

Approximating the Delay for Encoding........................................................ 43

Appendix C – Working with Printers........................................................... 46

Printhead Pressure for Thermal Transfer Printers.......................................46

Temperature Settings for Thermal Transfer Printers................................... 47

Print Speed for Thermal Transfer Printers...................................................48

Backfeed.....................................................................................................48

Printhead Pressure Adjustment (for Zebra Printers) ...................................49

Appendix D – Using the Brady RFID Smart Label Demo........................... 50

8

Copyright © 2000, Brady Worldwide, Inc.

Page 9

Brady WavePoint™ XE2000 User's Guide

Index..............................................................................................................52

Copyright © 2000, Brady Worldwide, Inc.

9

Page 10

Getting Started Brady WavePoint™ XE2000 User's Guide

Chapter 1 - Getting Started

Brady WavePoint™ XE2000 is designed to be an integral part of

your asset management and tracking system. The XE2000 is easy

to use right out of the box, and works with a variety of RFID Smart

Labels and thermal transfer printers.

Unpacking the XE2000

Take a few moments to read over this documentation and inventory

the contents of your shipment.

When unpacking the Brady WavePoint™ XE2000, use a sharp knife

or razor to carefully cut along the taped seam on top of the carton,

and open it. Remove the material cushioning the XE2000 and lift it

from the carton.

Save all packing materials.

Equipment Checklist and Inspection

Upon receipt of your XE2000 shipment, check your packa ge

contents for the items listed below, then fill out and return the

enclosed product registration card.

If shortages exist, please contact your local distributor or Brady

Worldwide, Inc. immediately.

10

Copyright © 2000, Brady Worldwide, Inc.

Page 11

Brady WavePoint™ XE2000 User's Guide Getting Started

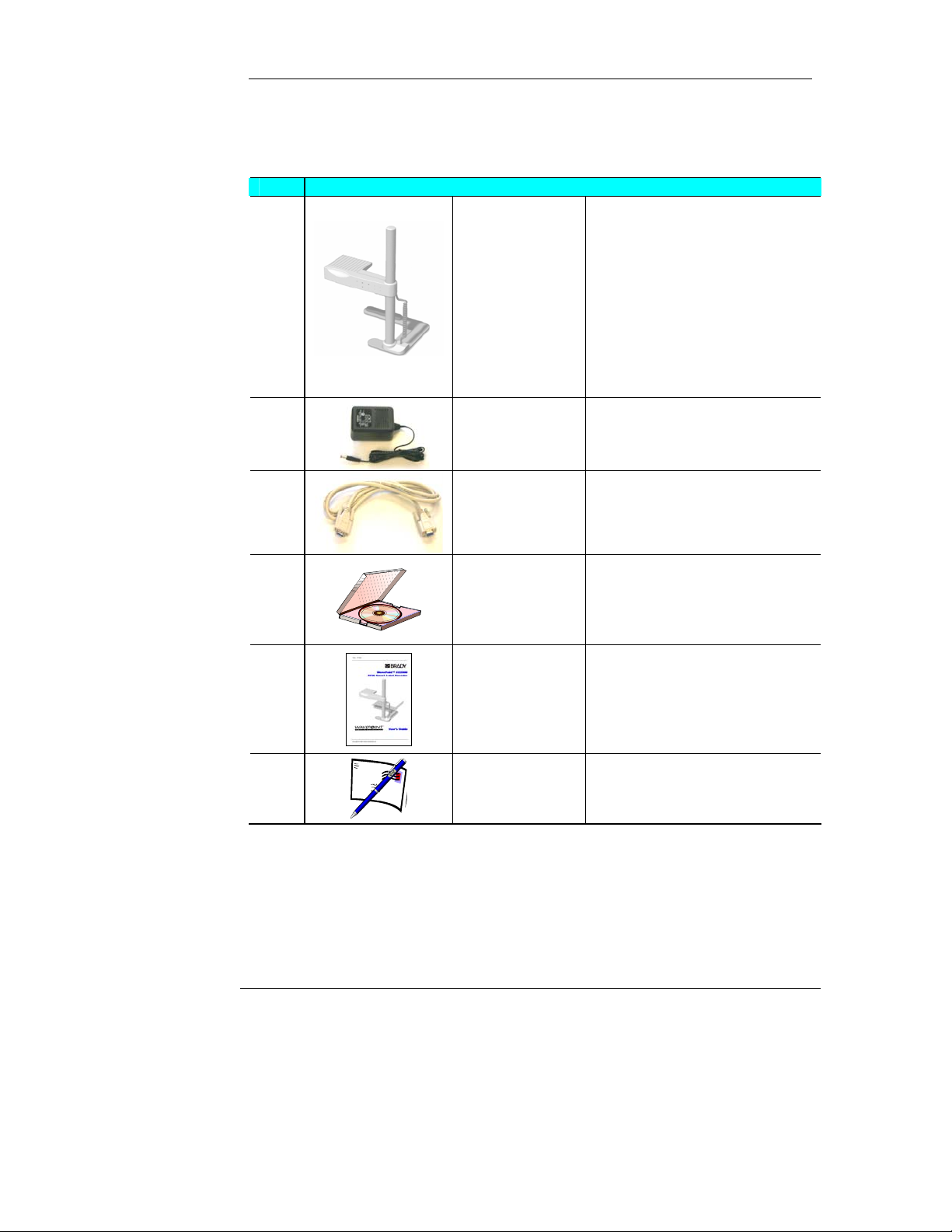

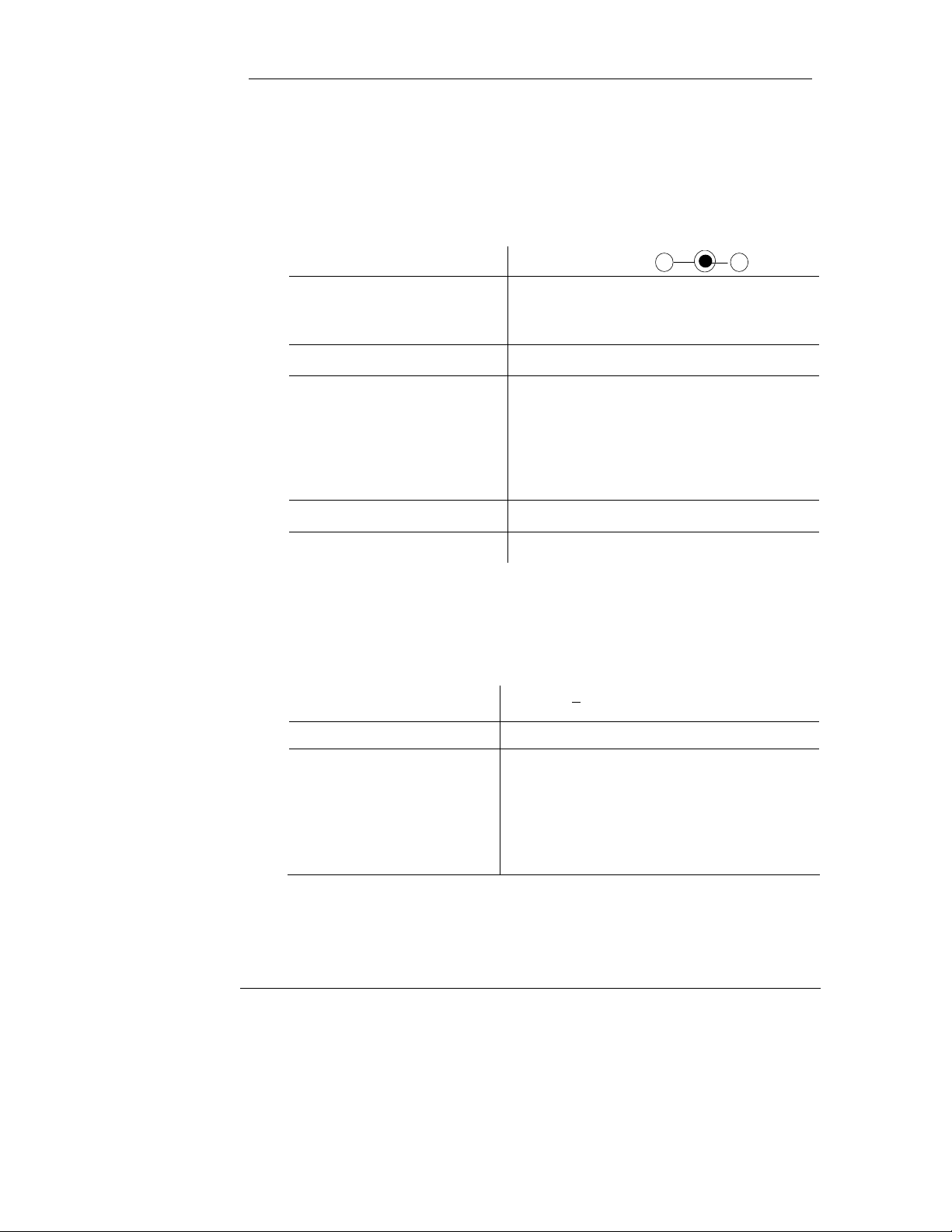

Components Included

Item Description

Encodes RFID Smart Labels

after the labels are imaged by

a thermal transfer printer.

The Mounting Base provides a

rigid structure for the XE2000.

The Post for the XE2000 is

mounted to the base, allowing

the XE2000 to be positioned

using the bolt, spring, and

adjustment knob.

1

Brady

WavePoint™

XE2000

(including

Mounting Base,

Foam Spacer,

Feet, Post, Bolt,

Adjustment

Knob, Spring,

and Retaining

Ring)

2

3

4

5

6

12V DC Power

Adapter

RS-232 Cable

XE2000

Software CD

(including

documentation)

XE2000 User's

Guide

(this manual)

Product

Registration

Card

Provides power to the Brady

WavePoint™ XE2000.

Connects the XE2000 to a host

computer.

Used to install XE2000 host

library functions on the host

PC. Documentation is also

included on the CD, in PDF

form.

Explains how the XE2000 is

assembled, along with setup

and positioning tips, and offers

suggestions for properly using

the XE2000 and RFID Smart

Labels.

Registers your product for

support, warranty, and product

updates.

Copyright © 2000, Brady Worldwide, Inc.

11

Page 12

Getting Started Brady WavePoint™ XE2000 User's Guide

Reporting Damage

Inspect the XE2000 for possible damage incurred during shipment.

If you discover shipping damage upon inspection, do the follo wing:

1. Immediately notify the shipping company of the damage.

2. Retain all packaging material for shippin g company

inspection.

3. File a Damage Report with the shipping company and notify

your local distributor and Brady Worldwide, Inc. of the

damage. Brady Worldwide, Inc. is not responsible for any

damage occurring during shipment of the equipment and

will not repair this damage under warranty. Immediate

notification of damage to the shipping company or its

insuring agency will generally result in ensuring any

damage claim validity and ultimate monetary compensation.

Storage and Reshipping

If not operating the XE2000 immediately, repackage it using the

original packing materials. The Brady WavePoint™ XE2000 may be

stored under the following conditions:

Temperature

-4° to 140° F (-20° to 60° C)

Relative Humidity 20% to 85% non-condensing

Should it become necessary to ship your Brady WavePoint™

XE2000, carefully pack it in a suitable container to avoid damage

during transit. Whenever possible, the original container from the

factory should be used. If you use a different container, follow a

similar procedure to that originally used to packa ge the XE2000.

12

Copyright © 2000, Brady Worldwide, Inc.

Page 13

Brady WavePoint™ XE2000 User's Guide Getting Started

Copyright © 2000, Brady Worldwide, Inc.

13

Page 14

XE2000 Specifications Brady RFID XE2000 User's Guide

Chapter 2 - XE2000 Specifications

Consider the following product specifications when setting up or

working with the Brady WavePoint™ XE2000:

Input Voltage

Input Current

While Activated

Standby

+12V DC Nominal

150 mA

20 mA

-

Frequency of Operation 13.56 MHz

Temperature

Operating

Storage

o

5

to 40o C (41o to 104o F)

20% to 85% RH, non-condensing

o

to 60o C (-4o to 140o F)

-20

20% to 85% RH, non-condensing

RS-232 Communications 19.2kb, 8 data, 1 stop, No parity

+

Host Software OS Windows 95, 98, or NT 4.0 (or later)

Power Adapter Specifications

Consider the following product specifications with regard to the

120V AC-DC/12V DC power adapter.

Input Voltage

120VAC +

(UL and CSA approvals)

Output 12V DC, 1 A

Temperature

Operating

Storage

o

0

to 40o C (continuous) (32o to 104o F)

10% to 90% RH, non-condensing

o

-20

10% to 90% RH, non-condensing

14

10%, 60Hz

to 80o C (-4o to 176o F)

Copyright © 2000, Brady Worldwide, Inc.

Page 15

Brady WavePoint™ XE2000 User's Guide Specifications

Copyright © 2000, Brady Worldwide, Inc.

15

Page 16

System Requirements Brady WavePoint™ XE2000 User's Guide

Chapter 3 - System Requirements

The Brady WavePoint™ XE2000 requires the following hardware

and softwar e co mponents:

• Pentium processor-based personal computer running

Windows 95, 98, or NT 4.0 (or later) as the operating

system.

• 16 MB of RAM

• CD-ROM drive

• Free Serial Port

• 50 MB of (free) hard drive space

16

Copyright © 2000, Brady Worldwide, Inc.

Page 17

Brady WavePoint™ XE2000 User's Guide System Requirements

Copyright © 2000, Brady Worldwide, Inc.

17

Page 18

Product Description Brady WavePoint™ XE2000 User's Guide

Chapter 4 - Product Description

The Brady WavePoint™ XE2000 is an encoding device for RFID

Smart Labels, generally used with label creation software. The

XE2000 provides a peripheral approach to programming RFI D

Smart Labels. This external approach allows various label

configurations to be used with existing thermal transfer printers.

The external approach also checks the RFID functionality of the

label to verify that it was not damaged during the printing process by

high printhead pressure or extreme angles.

Background Information

RFID Smart Labels are an alternative to traditional RFID cards and

tags. The labels operate at a higher frequency than traditional RFID

cards and tags, which allows the physical construct ion to be thinner,

more flexible, and lower in cost.

With the advent of RFID functionality embedded into standard

converted labels, there is a growing need for a seamless system

with which to image and encode labels. The combination of the

Brady WavePoint™ XE2000, label creation s oftware, RFID Smart

Labels, and a thermal transfer pri nter—along with Brady's traditional

application and integration support—brings the full RFID solution to

hand.

To learn more about Brady RFID Smart Labels and label creation

software, refer to the PDF included on the XE2000 software CDROM, or visit the Brady RFID website at

http://www.bradyrfid.com

.

18

Copyright © 2000, Brady Worldwide, Inc.

Page 19

Brady WavePoint™ XE2000 User's Guide Product Description

XE2000 Components

The following components make up the total Brady WavePoint™

XE2000 unit.

6

1

5

2

3

4

Figure 4-1 XE2000 Components

1. Encoder Module 4. Serial & Power Connection

2. Post 5. Mounting Base

3. Power & Serial Cable Coil 6. Foam Spacer

Copyright © 2000, Brady Worldwide, Inc.

19

Page 20

Product Description Brady WavePoint™ XE2000 User's Guide

h

b

s

Figure 4-2 Encoder Module

The Encoder Module is the portion of

the XE2000 that reads and writes to

RFID Smart Labels. The Encoder

Module is placed adjacent to the exit

bay of the printer so labels are

encoded as they rest over it after

being printed.

The Encoder Module contains three LEDs to indicate the operation

status of the XE2000 (see Chapter 5 for more information).

Figure 4-3 Mounting Base and Post

The mounting base and post provide the

XE2000 Encoder Module

foundation for use with a thermal transfer

printer. The base is positioned under the

printer and is held in place by a foam

spacer an d rubber feet.

The post supports the Encoder Module via

a bolt and adjustment knob located on the

back of the pos t . The height of t h e E nc o der

Module can be adjusted by loosening the

knob and sliding the module up or down.

The XE2000 can be set up and used to

encode a wide variety of labels simply by

adjusting the Encoder Module’s

the post. For example, the Encoder Module may be placed directly

adjacent to the exit bay of the printer for shorter labels, while longer

labels may require a gap between the module and the exit bay.

with a rigid

position on

Deleted: ¶

Deleted: ,

Deleted: w

capability of

Deleted: a

Deleted: it

20

Copyright © 2000, Brady Worldwide, Inc.

Page 21

Brady WavePoint™ XE2000 User's Guide Product Description

The post also allows the Encoder Module to swing out of the way s o

the user can gain access to the printer or the printed labels.

The physical construction of the base, post, and spring loaded

retaining ring precludes—for the most part—accidental movement of

the XE2000. This is extremely helpful in averting possible alignment

issues during encoding.

Figure 4-4 12V DC Adapter

The adapter provides the XE2000 with

12 volts direct current for proper

operation. The output of the adapter

plugs into the connector located on the

mounting base. The power is then

supplied to the Encoder Module via the

coiled cable.

Figure 4-5 Serial Cable

The serial cable provides a

communication channel between the

host and the XE2000. A connector

located on the mounting base routes

signals (along with power) to the

Encoder Module via the coiled cable.

Copyright © 2000, Brady Worldwide, Inc.

21

Page 22

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

Chapter 5 - XE2000 Setup and Positioning

Setting up the Brady WavePoint™ XE2000 is remarkably simple.

Right out of the box, all you need to do is connect the power and

serial cables, and install the software. Correctly positioning the

XE2000 with respect to your thermal transfer printer—although

equally simple—may require a bit of trial and error.

Following is a summary of the steps necessary to setup and position

the XE2000. Detailed instructions for each step follow later in this

chapter. After completing these steps, you are ready to begin

encoding labels.

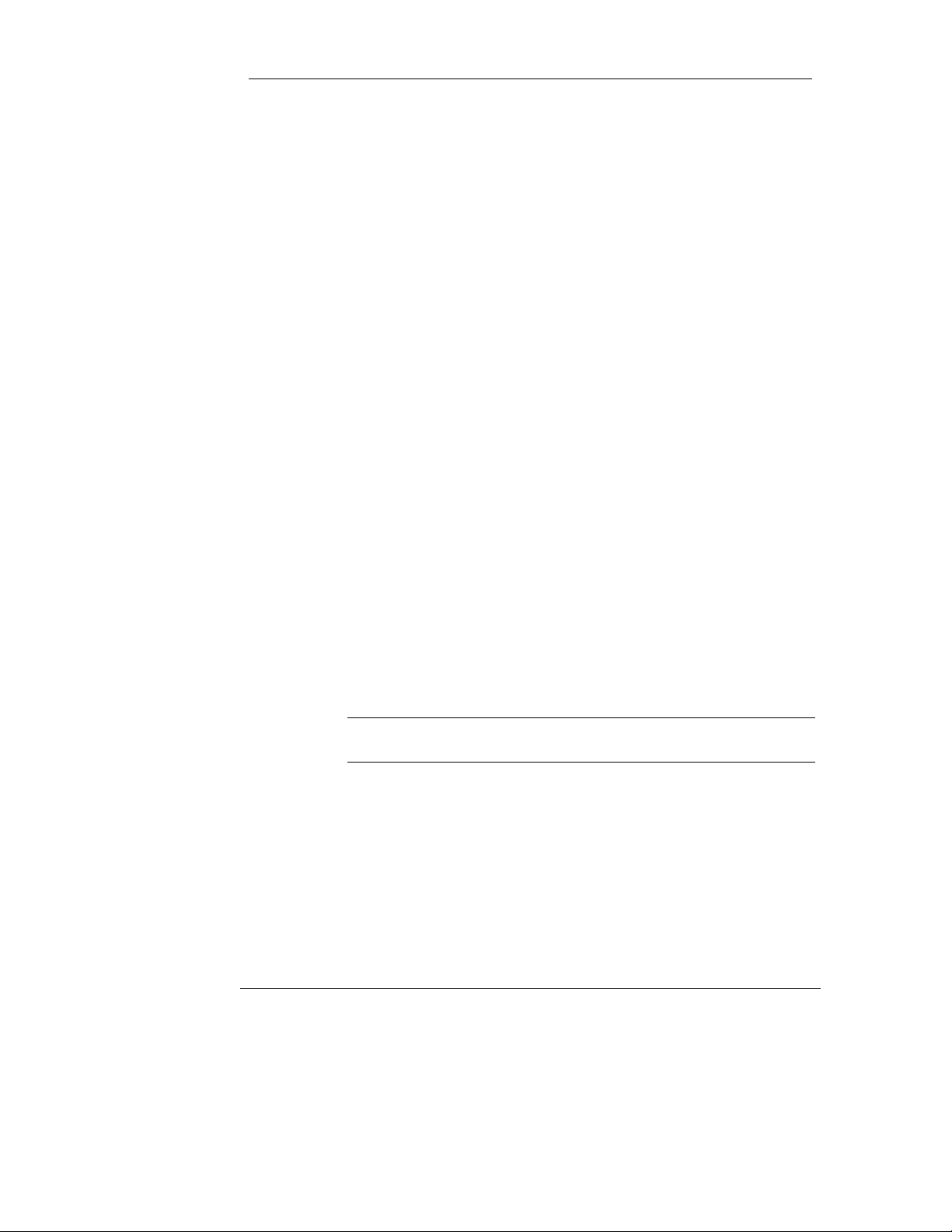

Step Brief Summary of Step Page

Setup XE2000

Position XE2000

Check LED Display

Position XE2000

For Use with RFID

Smart Labels

Test

Install software. Connect power and serial

cable.

Position mounting base arm under the

printer. Adjust encoder module vertically

and horizontally.

Determine XE2000 status and optimal

positioning.

Optimize label location. Use the XE2000

Utilities Program to view positioning

options.

Test for connectivity and positioning using

the XE2000 Utilities Program.

XE2000 Setup

The following sections describe how to set up the XE2000 to work

with your printer and host PC.

22

25

27

28

33

22

Copyright © 2000, Brady Worldwide, Inc.

Page 23

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

Software Installation

The CD that accompanies the XE2000 contains software necessary

for XE2000-enabled programs to interface with the module. The

software also contains a test program.

Use the auto-run CD to install the software on the PC that will serve

as the host.

The XE2000-enabling software should not be confused with your

label design and/or creation software application.

In addition to the host software installation program, the CD also

includes:

• XE2000 Utilities Program

• Brady RFID Smart Label Demo

• Documentation PDFs

Figure 5-1 XE2000 Software Setup Screen

To verify the hardware is working correctly, all software applications

and programs on the CD must be installed.

Copyright © 2000, Brady Worldwide, Inc.

23

Page 24

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

Power Connection

Plug one end of the 12V DC power connection into an outlet and the

other end into the power port on the back of the mounting base

(near the post). When properly connected, the amber LED on the

XE2000 is activated, indicating it is receiving power.

Serial Connection

Plug one end of the DB9 serial cable into the host PC, and the other

end into the DB9 connector next to the power connection on the

XE2000.

1

2

1. The Serial Connection is plugged in on the right side (when

viewed from back) of the coiled cable.

2. The 12V DC Power Connection is plugged in on the left side

(when viewed from back).

Formatted

Formatted

24

Copyright © 2000, Brady Worldwide, Inc.

Page 25

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

n

e

l

p

b

o

XE2000 Positioning

Positioning of the XE2000 is crucial to operational effectiveness in

reading and encoding RFID Smart Labels.

differ depending on the printer and labels being used.

padded portion of the mounting base (mounting base arm) is

The

designed to go under the printer.

Figure 5-2 Mounting Base Arm

Tilt the printer slightly to position the mountin g base arm about

halfway under the printer. This is a good starting position, but the

exact position depends on the printer and labels, and therefore may

require adjustment.

When the XE2000 mounting base is positioned correctly, the

Encoder Module itself should be located in such a manner that it

easily swings out of the way without catching on—or hitting—any

part of the printer. This allows for easy adjustments to the Encoder

Module, as well as providing access to the label exit area on the

printer.

Exact positioning will

Deleted: ,

Deleted: a

Deleted: d

Deleted: ¶

Deleted: Ti

so you can

Deleted: a

Deleted: p

adjustment.

Figure 5-3 XE2000 Mounting Base Positioned to Printer

Copyright © 2000, Brady Worldwide, Inc.

25

Page 26

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

Encoder Module Height Adjustment

The Encoder Module height can be adjusted by loosening the

adjustment knob on the back of the post and sliding the module up

or down.

The height of the Encoder Module should be such that the Encod er

Module sits just beneath the label exit area of the printer

(approximately 1/8 inch below the horizontal exit plane of the

labels). This ensures that labels will flow easily out of the printer and

over the Encoder Module.

Encoder Module Horizontal Adjustment

The encoder module can be adjusted horizontally by positioning the

mounting base arm either more or less under the printer. The exact

horizontal or vertical adjustment will depend on the printer and

labels.

The XE2000 Encoder Module was intentionally designed to have a

long but narrow "RF Active Area" for encoding RFID Smart Labels.

RF Active Areas

Antennas in both the Brady WavePoint™ XE2000 Encoder Module

and RFID Smart Labels are used to send and receive RF energy

and data. The areas where these antennas receive most of the

energy are referred to as RF Active Areas in this manual. Refer to

Figure 5-5 RFID Smart Label RF Active .

The length of the Encoder Module's RF Active Area allows for a

variety of label widths, while the narrowness allows you to encode

either long or short labels without encoding adjacent labels. The

current offering of Brady RFID Smart Label sizes can be found on

the CD-ROM provided, or by visiting the Brady RFID website at

http://www.bradyrfid.com

26

.

Copyright © 2000, Brady Worldwide, Inc.

Page 27

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

LED Functions

Once the XE2000 is positioned adjacent to the printer, and the

power and serial connections are made, refer to the LEDs (Light

Emitting Diodes) on the front of the XE2000 to check its status and

help determine its optimal positioning.

Figure 5-4 LED Display

XE2000 Status

The following list indicates the XE2000 state to which each LED

corresponds.

Amber

XE2000 is receiving power

Red

Green

Copyright © 2000, Brady Worldwide, Inc.

XE2000 is attempting to read/write a label

XE2000 has successfully read/written a

label

27

Page 28

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

Positioning the XE2000 for Use with RFID Smart Labels

There is no size standard for RFID Smart Labels, so the optimal

placement of various labels cannot be specified exactly. It is

suggested, however, that the most advantageous placement for an

effective read/write of an RFID Smart Label is one w here a majority

of the label's RF Active Area rests over the XE2000's RF Active

Area after the label exits the thermal transfer printer, as shown in

the following illustration:

3

1

2

Figure 5-5 RFID Smart Label RF Active Area—Not Drawn to Scale

1. RFID Smart Label RF Active Area

2. XE2000 RF Inactive Area

3. XE2000 RF Active Area (Inside the antenna coil)

Use the XE2000 Utilities Program to familiarize yourself with proper

label positioning. Refer to Using the XE2000 Utilities Program for

Positioning Options on page 31 of this document.

28

Copyright © 2000, Brady Worldwide, Inc.

Formatted

Page 29

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

The XE2000 was also intentionally designed to have a very large

"RF Inactive Area" next to the RF Active Area. When a label is

completely within this RF Inactive Area, there is no energy

transferred between the XE2000 and the label. This functionality

provides additional protection against encoding unnecessary or

undesired labels that may be adjacent to labels actually being

encoded.

To optimize label location, before printing on RFID Smart Labels, it

is suggested that you test non-RFID labels of the same size. This

allows for proper positioning of the labels (as well as a test of their

design and presentation), without wasting the more costly RFID

Smart Labels.

On exiting the printer, a large portion of the label's RF Active Area

should be positioned over the XE2000's RF Active Area. If this isn't

the case, adjusting the backfeed of the printer, or physically moving

the XE2000 with respect to the printer, can help you achieve the

correct positioning.

Refer to Appendix C – Working with Printers, for more information

on backfeed.

Copyright © 2000, Brady Worldwide, Inc.

29

Page 30

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

The following illustrations show examples of good and bad RFID

Smart Label positioning over the XE2000:

Figure 5-6 Good XE2000 & Label Positioning

Figure 5-7 Bad XE2000 & Label Positioning

30

Copyright © 2000, Brady Worldwide, Inc.

Page 31

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

Using the XE2000 Utilities Program for Positioning Options

Use the XE2000 Utilities Program to familiarize yourself with label

positioning that falls within the acceptable placement range.

1. Double-click the XE2000 Utilities Program icon

located on your desktop (installed from XE2000

CD).

2. When the XE2000 Utilities Program window is displayed,

click either the Square Label or Rectangle Label button to

indicate the type of label with which you are working.

3. Click and drag the label over the XE2000 to determine

where to position the label in order for it to be successfully

encoded by the XE2000.

The program's background color changes from green to red as you

move into an d ou t of accepta ble placem en t zones.

Figure 5-8 Good Placement Zone

Copyright © 2000, Brady Worldwide, Inc.

31

Page 32

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

Figure 5-9 Bad Placement Zone

4. Click the Close (X) button in the upper right corner of the

window to close the XE2000 Utilities Program.

32

Copyright © 2000, Brady Worldwide, Inc.

Page 33

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

Testing XE2000 Connectivity and Positioning

After the XE2000 is in position and the software is installed, you

should test both the connectivity and positioning using the XE2000

Utilities Program.

Testing XE2000 Connectivity

Prior to loading your thermal transfer printer with RFID Smart

Labels, run the following test using one label t o ensur e your XE 200 0

has power and is communicating with the host PC.

1. Double-click the XE2000 Utilities Program icon

located on your desktop (installed from XE2000

CD).

2. Click the Read Labels button located at the bottom right

corner of the XE2000 Utilities

Program window.

3. The COMM P o r t Number dialog is displayed:

Enter the COMM port to which you are connecting and click

the OK button.

4. The Reader Output window is displayed, and each label is

read as the user places a label over the XE2000’s RF

Active, its serial number is displayed:

Copyright © 2000, Brady Worldwide, Inc.

33

Page 34

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

At this point, the amber LED on the front of the XE2000

should be continually displayed (with no blinking),

indicating the XE2000 is receiving power

The red LED should be blinking, indicating it is

communicating with the host PC and is reading/writing (or

attempting to) labels.

When the XE2000 reads an RFID Smart Label (when the

XE2000 active area and the label active area overlap), the

green LED flashes quickly, indicating a successful read.

If a label is placed over the XE2000 and the green LED is not

activated, consider the possibility that the chip in the label is

damaged and can't be read. Try another l abel to verify that the

problem is not a damaged label.

5. When you are satisfied with the XE2000's connectivity, click

the Close (X) button on the Reader Output window to close

the XE2000 Utilities Program.

34

Copyright © 2000, Brady Worldwide, Inc.

Page 35

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

Testing XE2000 Positioning

Once you've confirmed the XE2000 is communicating with the host

PC, load RFID Smart Labels into your thermal transfer printer and

use the same XE2000 Utilities Program to check the positioning of

the XE2000. You will probably need to calibrate the printer (the

procedure for which depends on the specific printer being used).

1. Double-click the XE2000 Utilities Program

icon located on your desktop.

2. Click the Read Labels button located at the

bottom right corner of the XE2000

Utilities Program window.

3. The COMM P o r t Number dialog is displayed.

Enter the COMM port to which you are connecting and click

OK.

4. When the Reader Output window is displayed, press the

feed button on your printer to send a label through the

printer and over the XE2000.

Copyright © 2000, Brady Worldwide, Inc.

35

Page 36

XE2000 Setup and Positioning Brady WavePoint™ XE2000 User's Guide

5. As each label is read, its serial number should be displayed

on the Reader Output window. If a serial number is not

displayed, either the RF Active Areas are not aligned

properly or the RFID Smart Label could be damaged.

6. Advance (or feed) labels—one at a time—through the

printer and over the XE2000 to ensure its horiz ontal and

vertical position is correct. Feeding the labels one at a time

through without tearing them off, should further ensure your

positioning is good. Three to five labels should be sufficient

to test the XE2000's positioning.

It is suggested that you move the Encoder Module slightly in all

directions during testing to verify that it is not physically located in

an area that occasionally might not be encoded, due to RF Active

Areas not overlapping correctly.

7. Once you feel comfortable with the positioning of the

XE2000, print a few labels (using your label creation

software) to verify that your design is accurate, the delay for

encoding is sufficient (refer to Appendix B – Delay for

Encoding), and that the desired results are being achieved.

8. When you are done testing the positioning, click the Close

(X) button on the Reader Output window to close the

XE2000 Utilities Program.

Refer to your label creation software documentation for details on

enabling the RFID Smart Label functionality of the package.

36

Copyright © 2000, Brady Worldwide, Inc.

Page 37

Brady WavePoint™ XE2000 User's Guide XE2000 Setup and Positioning

Troubleshooting XE2000 Setup

.Use the following flowchart to troubleshoot problems encountered

when setting up your XE2000.

contact Brady Support. Refer to Technical Support on page 6 of this

document for contact numbers.

For further troubleshooting assistance,

1

1. XE2000 appears to be dead.

2. Is Amber LE D on?

3. Is the +12V DC power supply

connected?

4. Plug in supply and test XE2000

2

No

3

No

4

again.

5. Run XE2000 Utilities Program.

Yes

6. Are errors displayed?

7. XE2000 hardware and host software

5

are functioning; check label creation

software.

8. Is error software related?

6

Yes

8

No

No

7

9

9. Verify correct serial cable is properly

connected.

10. Is cabling OK?

11. Correct cabling problems and test

XE2000 again.

12. Uninstall XE2000 host software and

reinstall.

Yes

13. Is problem fixed?

14. Contact your supplier or Brady RFID

12

13

Yes

No

10

Yes

14

No

11

support.

15. Verify no problem exists with label

creation software.

15

Copyright © 2000, Brady Worldwide, Inc.

37

Page 38

Encoding Smart Labels with the EPM Brady WavePoint™ XE2000 User's Guide

Chapter 6 - Encoding Smart Labels with the

XE2000

Using the Brady WavePoint™ XE2000 to encode RFID Smart

Labels is typically done in conjunction with label creation software

and a thermal transfer printer.

Due to the variety of both software and printer products that may

suit your needs, specifics on using either are not covered in this

manual.

For details and instructions on formatting labels, refer to your label

creation software documentation. Likewise, for instructions on

loading and calibrating your printer, refer to the printer

documentation.

These steps provide a general procedure that may be followed

when printing RFID Smart Labels and encoding them with the

XE2000.

1. Open your label creation software program, which probably

requires you to indicate the label and library to be printed.

2. Click the "Print" button to send the labels to the printer.

3. Typically, a message is displayed, keeping you apprised of

the print status. The length of time this message is

displayed depends on the number of labels in the print job.

It is likely this message does not provide an encoding

status, merely a printing status.

4. Upon completion of the print/encoding job, the label creation

software can produce a log indicating the status of the

XE2000 label reads.

38

Copyright © 2000, Brady Worldwide, Inc.

Page 39

Brady WavePoint™ XE2000 User's Guide Encoding Smart Labels with the XE2000

Delay for Encoding

A delay is required during the printing process in order for the

XE2000 to encode the label.

The label creation software sends a print job to the printer and is

aware when the printer is finished accepting the job. However, the

label creation software is not aware of when the label is actually

printed and has come to a stop.

Therefor e, the delay for encoding is ba sed—primarily—on the time it

takes for the printer to physically print the label; and, possibly, for

the printer to backfeed the label into the printer (for printing).

A large variety of thermal transfer printers, RFID Smart Label sizes,

and label creation software packages exist. Therefore the delay

required is usually different for the variety of applications and must

be set accordingly to that application.

Refer to Appendix B – Delay for Encoding, for more information.

Copyright © 2000, Brady Worldwide, Inc.

39

Page 40

Appendix A – Replacement Information Brady WavePoint™ XE2000 User's Guide

Appendix A – Replacement Information

There is no maintenance required for the XE2000. If replacement

parts are needed, contact Brady, using the following part numbers.

Part # Description

Brady WavePoint™ XE2000 (including Encoder Unit and

63986

63987 XE2000 Software CD

63988 XE2000 User's Guide—English

63994 Power Supply

20887 European Power Supply

63073 Serial Cable

63989 Carriage Bolt/Spring Assembly

63990 Screws

63991 Rubber Feet

63992 Foam Spacers

63993

63995 XE2000 User's Guide—French

63996 XE2000 User's Guide—German

63997 XE2000 User's Guide—Spanish

63998 XE2000 User's Guide—Italian

63999 XE2000 User's Guide—Dutch

Electronics, XE2000 Software CD, XE2000 Users Guide,

Power Supply, and Serial Cable)

Serial Cable Adapter (to convert 9-pin female to 25-pin

female)

40

Copyright © 2000, Brady Worldwide, Inc.

Page 41

Brady WavePoint™ XE2000 User's Guide Appendix A – Replacement Information

Copyright © 2000, Brady Worldwide, Inc.

41

Page 42

Appendix B – Delay for Encoding Brady WavePoint™ XE2000 User's Guide

Appendix B – Delay for Encoding

A delay is required during the printing process in order for the

XE2000 to encode the label. This required minimum delay is an

estimate based on the overall printing and encoding process.

The label creation software sends a print job to the printer and is

aware when the printer is finished accepting the job. However, the

label creation software is not aware of when the label is actually

printed and has come to a stop.

Therefor e, the delay for encoding is ba sed—primarily—on the time it

takes for the printer to physically print the label; and, possibly, for

the printer to backfeed the label into the printer (for printing). The

overall delay should also include a margin of error for other minor,

unknown factors.

42

Copyright © 2000, Brady Worldwide, Inc.

Page 43

Brady WavePoint™ XE2000 User's Guide Appendix B – Delay for Encoding

i

i

Approximating the Delay for Encoding

Calculate the following to determine the encoding delay based on

the label and printer parameters. Examples are given below:

Setting Value Description

Backfeed Speed 2 in/sec Usually fixed

Backfeed Amou nt 0.5 in

Label Print Speed 4 in/sec

Label Length 2 in User-defined when formatting labels

Suggested Margin +150%

The following example demonstrates this calculation based on the

values in the preceding table:

Delay =

0.5in 2in

n

(

+ ) * 150% = (250ms + 500ms) * 1.50 = 1125ms

2

n

sec

4 sec

Typically user-defined, but can be

fixed

Typically user-defined, but can be

fixed

Equates to 50% more time than the

backfeed speed & amount, and the

label print speed and length. The

margin can be reduced as the user

becomes familiar with the system.

Copyright © 2000, Brady Worldwide, Inc.

43

Page 44

Appendix B – Delay for Encoding Brady WavePoint™ XE2000 User's Guide

The delay should not be reduced below the minimum required

value, as below this value there is a significant chance the label

might still be moving from the printing process.

Since alignment of the XE2000 and label RF active areas is critical,

lowering the delay could negatively affect the encoding process.

This negative effect could manifest itself as failing to read good

labels, not properly writing to good labels, not proper ly recognizing

bad labels, etc.

If an unknown—yet significant—delay factor exists outside the

parameters of the previous calculation, the system will attempt to

encode labels before they come to a stop. The same negative

effects (mentioned earlier) could also be seen in this circumstance.

Although it may seem the human ear and eye are not perceptive

enough to distinguish if the delay is appropriate; in fact, the ear and

eye combination should be able to recognize a delay of a few

hundred milliseconds, and determine if the delay is sufficient.

A good rule of thumb is to listen for the printing to stop and w atch for

the red LED to display.

Delay for encoding settings can be managed from the RFID Options

window in certain label creation software packages.

44

Copyright © 2000, Brady Worldwide, Inc.

Page 45

Brady WavePoint™ XE2000 User's Guide Appendix B – Delay for Encoding

Copyright © 2000, Brady Worldwide, Inc.

45

Page 46

Appendix C – Working with Printers Brady WavePoint™ XE2000 User's Guide

Appendix C – Working with Printers

Some printer settings can have an impact on the XE2000's ability to

encode RFID Smart Labels. For example, if the printhead pressure

is too high, the chip can be damaged.

This appendix is not meant to be an all-inclusive guide to working

with your thermal transfer printer, but is provided to point you in the

direction of the most obvious answers to the most common

questions you may have with regard to using the XE2000 and your

thermal transfer printer.

In all cases, refer to your printer documentation for specific

adjustments and recommendations from the printer manufacturer.

Printhead Pressure for Thermal Transfer Printers

The more pressure applied to the printhead, the greater the

possibility of chip damage. Therefore, it is generally advisable to try

increasing the printing temperature to achieve the desired print

quality, as opposed to increasing the printhead pressure.

Note: Using the lowest pressure that produces the desired print

quality maximizes printhead life.

46

Copyright © 2000, Brady Worldwide, Inc.

Page 47

Brady WavePoint™ XE2000 EPM User's Guide Appendix C – Working with Printers

Temperature Settings for Thermal Transfer Printers

The temperature setting for thermal transfer printers refers to the

temperature at which the resin is transferred to the label surface.

Increasing the temperature when printing labels causes the amount

of resin transferred to the label to increase. This may cause printed

images to appear blotchy, which can severely affect barcode quality.

Higher temperatures also reduce printhead life. Print quality is

determined by temperature, print speed, and printhead pressure.

Darkness (or temperature) settings are dependent upon a variety of

factors, including ribbon type, media, and the condition of the

printhead. You may find it necessary to adjust the temperature

parameter on your printer for consistent high-quality printing.

If print is too light or if there are voids in printed areas, you should

increase the temperature.

If print is too dark or if there is spreading or bleeding of printed

areas, you should decrease the temperature.

Caution: Set the temperature to the lowest setting possible while

maintaining the desired print quality. A temperature set too high for

a given ribbon may cause smearing and/or burning through the

ribbon.

Copyright © 2000, Brady Worldwide, Inc.

47

Page 48

Appendix C – Working with Printers Brady WavePoint™ XE2000 User's Guide

Print Speed for Thermal Transfer Printers

Print speed refers to the speed at which the label is printed.

Reducing print speed will usually increase print quality. Print quality

is usually determined by print head pressure, print speed, and

printing temperature.

Backfeed

Some printers have the ability to backfeed the label so that it is

easier to tear off the last label printed.

The backfeed offset is the amount of label that is advanced beyond

the end of a printing batch. When printing is resumed, the label is

drawn back into the printer to its starting position.

48

Copyright © 2000, Brady Worldwide, Inc.

Page 49

Brady WavePoint™ XE2000 EPM User's Guide Appendix C – Working with Printers

Printhead Pressure Adjustment (for Zebra Printers)

The following procedure is specific to Zebra printers, but can be

used to help determine how to adjust the printhead pressure on

other types of printers.

If printhead pressure must be adjusted (for example if the printer is

printing too light on one side of the label, or if a thick media is used),

follow these steps (or those specified by your thermal transfer

printer manufacturer).

1. Lower the Darkness setting and print PAUSE test label at

speed A.

2. Loosen the knurled (upper) locking nut.

3. Increase or decrease spring pressure (using the knurled

adjustment nut on the shaft of the toggle) until the left and

right edges of the printed area are equally dark.

4. Increase Darkness to optimum level for the media being

used.

5. Retighten locking nut.

Copyright © 2000, Brady Worldwide, Inc.

49

Page 50

Appendix D – Smart Label Demo Brady WavePoint™ XE2000 User's Guide

Appendix D – Using the Brady RFID Smart Label

Demo

From time to time you may have a need to verify encoding results,

and the Brady RFID Smart Label Demo provides you visual

verification, quickly and easily.

1. Double-click the Label Demo icon on your

desktop (installed from XE2000 CD).

2. When the Brady RFID Smart Label Demo opens, position a

label on the XE2000 and click the Repeatedly Read Labels

button:

3. The label read times out after 10 seconds, and you are

prompted to place another label on the XE2000:

Click the Stop Reading button to freeze the screen display

by disabling the timeouts.

50

Copyright © 2000, Brady Worldwide, Inc.

Page 51

Brady WavePoint™ XE2000 EPM User's Guide Appendix D – Smart Label Demo

The demo program recognizes unprogrammed labels, as

shown her e:

4. When you finish reading labels, click the Stop Reading

button on the Brady RFID Smart Label Demo dialog and

close all windows related to this program.

Copyright © 2000, Brady Worldwide, Inc.

51

Page 52

Index Brady WavePoint™ XE2000 User's Guide

Index

1

12V DC Power Adapter.........12, 22

B

Backfeed .....................................49

Getting Started............................ 11

Inspecting the XE2000................ 11

G

I

amount.....................................44

speed.......................................44

Brady RFID External Programming

Module.....................................19

description ...............................19

XE2000....................................19

Brady RFID Smart Labels............19

Label Creation Software

using........................................39

Labels

length ...................................... 44

L

print speed...............................44

C

License Agreement....................... 5

License Restrictions...................... 5

Components - XE2000..........12, 20

Limited Warranty........................... 5

Copyright.......................................1

Customer Support.........................7

D

Delay for Encoding......................40

calculating................................44

Demo...........................................51

Description of XE2000.................19

Ordering Information................... 41

Power Adapter............................22

Power Supply Specifications....... 15

O

P

input voltage............................15

E

operating temperature.............15

output......................................15

Encoding

Smart Labels............................39

Encoding Delay.....................40, 43

Equipment Checklist....................11

storage temperature................ 15

Printing

adjusting printhead pressure...50

backfeed.................................. 49

delay for encoding................... 43

F

FCC ID..........................................2

FCC Notice....................................2

52

label length..............................44

label print speed...................... 44

print speed...............................49

temperature settings.......... 47, 48

working with printers................47

Copyright © 2000, Brady Worldwide, Inc.

Page 53

Brady WavePoint™ XE2000 EPM User's Guide Appendix D – Smart Label Demo

R

Reordering Information................41

storage temperature................ 15

Technical Support......................... 7

Trademarks............................... 1, 2

Replacement Parts

ordering....................................41

W

Reporting Damage

from shipping...........................13

Warranty.......................................4

RFID Smart Label Demo.............51

RFID Smart Labels......................19

encoding..................................39

X

RS-232

serial cable...............................22

RS-232 Cable..............................12

RS-232 Communications.............15

XE2000

components included ........ 12, 20

demo.......................................51

description............................... 19

encoding Smart Labels............ 39

S

equipment checklist................. 11

External Programming Module 21

Serial Cable.................................22

Setup and Positioning .................23

Shipping ......................................13

Smart Label Demo ......................51

Smart Labels...............................19

encoding..................................39

Software CD................................12

software installation.................24

Software Installation....................24

Storage........................................13

humidity ...................................13

temperature .............................13

Support..........................................7

System Requirements.................17

power adapter .........................22

reporting damage....................13

serial cable..............................22

setup ....................................... 23

setup and positioning .............. 23

shipping...................................13

storage....................................13

storage humidity...................... 13

storage temperature................ 13

system requirements............... 17

technical specifications............ 15

XE2000

getting started with..................11

inspecting contents..................11

unpacking................................11

T

Technical Specifications..............15

host software OS.....................15

input current.............................15

input voltage ............................15

operating sys tem for host

software................................15

operating temperature..............15

operational frequency ..............15

RS-232 communications..........15

XE2000 Setup............................. 23

software installation.................24

XE2000 Specifications................ 15

input current ............................15

input voltage............................15

operating system..................... 15

operating temperature.............15

operational frequency.............. 15

power supply specifications..... 15

RS-232 Communications.........15

storage temperature................ 15

Copyright © 2000, Brady Worldwide, Inc.

53

Loading...

Loading...