Page 1

®

BBP

LABEL PRINTER

USER’S MANUAL

30

Page 2

Page 3

Copyright

Trademarks

This manual is copyrighted with all rights reserved. No portion of this manual may be copied

or reproduced by any means without the prior written consent of BRADY Worldwide, Inc.

While every precaution has been taken in the preparation of this document, BRADY assumes

no liability to any party for any loss or damage caused by errors or omissions or by statements

resulting from negligence, accident, or any other cause. BRADY further assumes no liability

arising out of the application or use of any product or system described, herein; nor any

liability for incidental or consequential damages arising from the use of this document.

BRADY disclaims all warranties or merchantability of fitness for a particular purpose.

BBP®30 Sign and Label Printer is a trademark of BRADY Worldwide, Inc.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

BRADY reserves the right to make changes without further notice to any product or system

described herein to improve reliability, function, or design.

© 2015 BRADY Worldwide, Inc. All Rights Reserved

Printed July 2015

Firmware Version 1

Brady Worldwide Inc.

6555 West Good Hope Road

Milwaukee, WI 53223 U.S.A.

Telephone: 414-358-6600 USA Domestic

Facsimile: 414-438-6958

iBBP

®

30 User’s Manual

Page 4

UNITED STATES

NoteNote

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates and may radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increaase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult BRADY Technical Support for help.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference and, (2) this device must

accept any interference received, including interference that may cause undesired operation.

INDUSTRY CANADA

Industry Canada ICES-003:

CAN ICES-3 (A)/NMB-3(A)

EUROPE

Waste Electrical and Electronic Equipment Directive

In accordance with the European WEEE Directive, this device needs to be

recycled in accordance with local regulations.

BBP®30 User’s Manual ii

Page 5

RoHS Directive 2011/65/EU

This product is CE marked and complies with the European Union's Directive 2011/65/EU OF

THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 8 June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronic equipment.

Turkey

Turkish Ministry of Environment and Forestry

(Directive on the Restriction of the use of certain hazardous substances in electrical and

electronic equipment).

Türkiye Cumhuriyeti: EEE Yönetmeliğine Uygundur

iii BBP®30 User’s Manual

Page 6

BRADY Warranty

Our products are sold with the understanding that the buyer will test them in actual use and

determine for him or herself their adaptability to his/her intended uses. BRADY warrants to

the buyer that its products are free from defects in material and workmanship, but limits its

obligation under this warranty to replacement of the product shown to BRADY’s satisfaction

to have been defective at the time BRADY sold it. This warranty does not extend to any

persons obtaining the product from the buyer.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EPXRESSED OR

IMPLIED INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY

OTHER OBLIGATIONS OR LIABILITY ON BRADY’S PART. UNDER NO

CIRCUMSTANCES WILL BRADY BE LIABLE FOR ANY LOSS, DAMAGE, EXPENSE

OR CONSEQUENTIAL DAMAGES OF ANY KIND ARISING IN CONNECTION WITH

THE USE, OR INABILITY TO USE, BRADY’S PRODUCTS.

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS & CONDITIONS OF

THIS LICENSE AGREEMENT. IF YOU DO NOT AGREE WITH THESE TERMS &

CONDITIONS, PLEASE PROMPTLY RETURN THIS PACKAGE FOR A FULL REFUND.

BBP®30 User’s Manual iv

Page 7

Technical Support

Technical Support Numbers/On-line Help

For repair or technical assistance, find your regional Brady Tech Support office in the

following list.

•United States: 1-800-643-8766

• Australia: 1-800 644 834 or via the web at www.bradyid.com.au/en-au/supportlanding

• Canada: 1-888-262-7576 or via the web at www.bradycanada.ca

• Mexico & Latin America: 01-800-212-8181 or via the web at

www.bradylatinamerica.com

• Europe: +44 333 333 1111 or via the web at www.bradyeurope.com/services

Repair and Replacement Parts

Brady Corporation offers repair and replacement services. Contact Brady Technical Support

for repair and replacement information.

or via the web at www.bradyid.com/techsupport

vBBP

®

30 User’s Manual

Page 8

Page 9

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Compatible Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Keypad and Menu Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ready Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Menu Selection Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

User Interface Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Printer Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpack and Set up Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What’s in the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Set up the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connect Printer Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install or Change Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Feeding and Cutting Label Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Starting Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Powering Off the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rebooting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Printer to a PC via USB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

User Interface Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cut Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Status Info. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Upgrade from USB Flash Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Enter Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Print Engine Base (PEB) Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sensor Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Analog Readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Copy Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Printer Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Script Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rev A vii BBP®35/37 User’s Manual

Page 10

Table of Contents

USB Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

USB Flash Drive Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

USB Type-B Cable Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Keyboard Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Advanced Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Removing Power and Media from Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remove Dust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Clean Printer and Keypad Residue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Clean LCD Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Clean Auto-Cutter Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Clean Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Clean Tape Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Clean the Cutter Blade Exit Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Clean Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Replacing the Media Wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Clearing Jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replacing/Adjust Media End Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Printing Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Hardware Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Media Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ribbon Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

BMP®30 User’s Manual viii Rev A

Page 11

Introduction

Thank you for purchasing the BBP®30 Label Printer mono-color peripheral printer. This

compact, easy-to-operate thermal transfer printer easily connects to your computer for printing

labels that you produce using Brady Workstation software. Media and ribbons from Brady

Corporation are programmed to work specifically with the printer.

Features and Functions

The following are just some of the features that make this system so easy to use and ready to

meet your label-printing requirements:

• Small, lightweight (approximately 11 lbs [4.9 kg]) unit, ready for your desktop.

• A variety of media colors, styles and materials and a wide range of single-color ribbons.

• Smart-cell technology that works intelligently with Brady consumables.

• Easy loading media and ribbon supplies.

• Continuous and die-cut media in a variety of high-performance materials.

• Maximum print speed of 4 ips.

Introduction

• 300 dpi (11.8 dot/mm) print resolution.

• USB device ports.

• Brady Workstation

• Built-in autocutter.

• LED display screen to view system status and set printer defaults and options.

Compatible Applications

The BBP®30 Sign and Label Printer is compatible with Brady Workstation software. When

used with this software package, the printer automatically recognizes all enabled and

compatible media.

Note: Only Brady BBP

®

30 supplies work with this printer.

Rev A 1 BBP®30 User’s Manual

Page 12

Introduction

System Specifications

• Wei ght: 11 lbs (4.9 kg)

• Dimensions (stored): 8.9 in. x 12.0 in. x 9.5 in. (22.6 cm x 30.5 cm x 24.1 cm)

• Operating Temperature: 50 to 104°F (10-40°C)

• Relative Humidity: 10% to 80% RH non-condensing

• Storage: -4 to 122°F (-20 to 50°C) at 15% to 90% RH non-condensing

• Vo lt age : 90 to 264 VAC, 47 to 63 Hz

• Print Resolution: 300 dpi, 11.8 dot/mm

• Output media size: up to 4 in. (101.6 mm) wide

BBP®30 User’s Manual 2 Rev A

Page 13

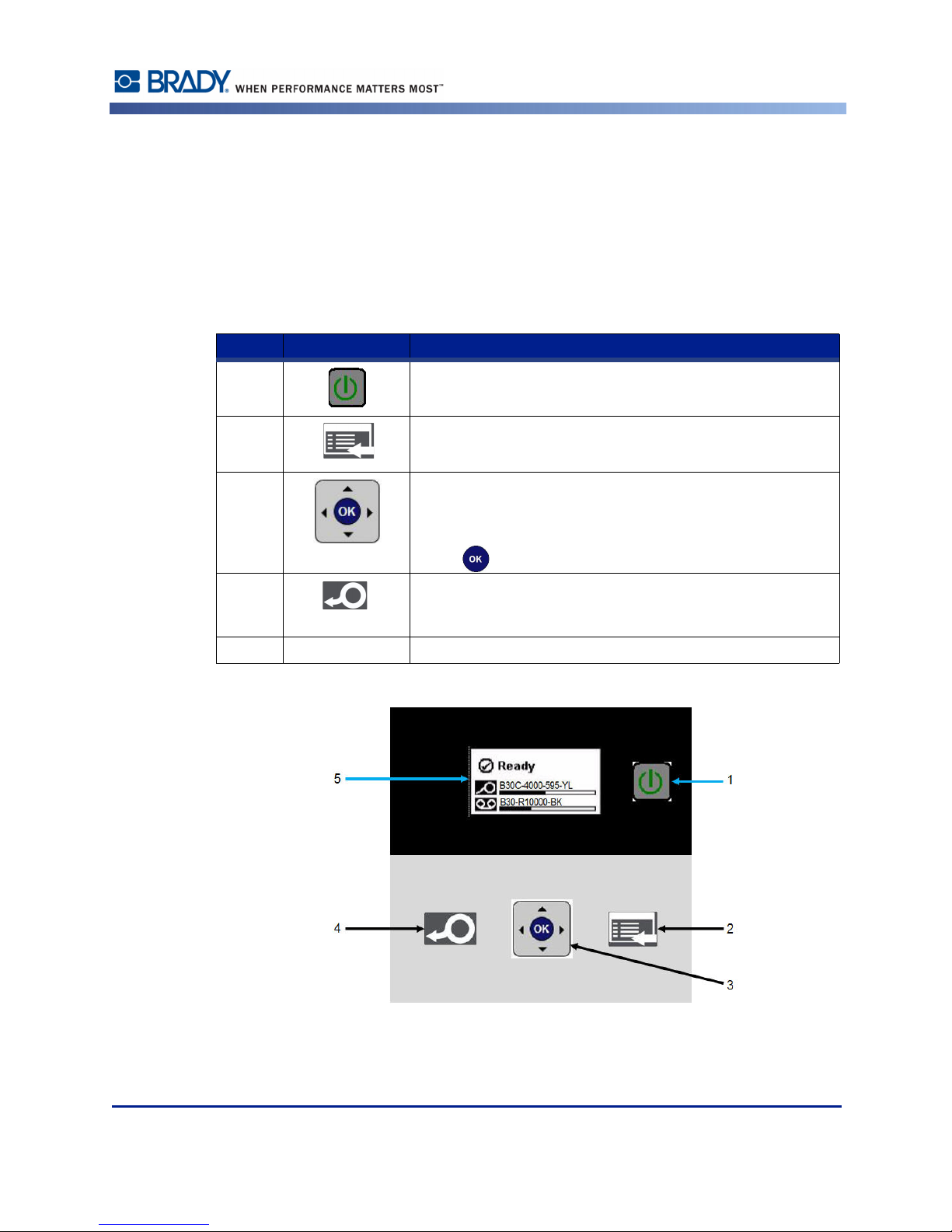

Keypad and Menu Functions

Keypad and Menu Functions

The following describes the keys, buttons and display screen that are used to navigate through

and use the BBP

User Interface

The user interface (UI) contains the keypad and buttons for using the printer. The main

functions are as follows:

Item # Icon Description

1 Power Button: Turns the printer on and off.

2 Menu: The display screen.

3 Keypad:

4 Feed: Feeds the labels through the printer to the next notch

5 -- Display Screen: See “Display Screenn page 4 for details.

®

30 Label Printer.

Press or to move through primary menu.

Press to exit or move up a menu.

Press for menu support functions.

Press to accept a selection or move through submenus.

on the liner. Feeds a full label for die cut; 0.5-inch (12.7 mm)

for continuous.

Rev A 3 BBP®30 User’s Manual

Page 14

Keypad and Menu Functions

Display Screen

The display screen has two modes:

•

Ready Mode: Indicates printer status and displays estimated remaining media and

estimated remaining ribbon. Also indicates the media and ribbon installed.

Menu Selection Mode: Lets you configure system defaults, view and set printer

•

information, perform input and output operations and perform diagnostics.

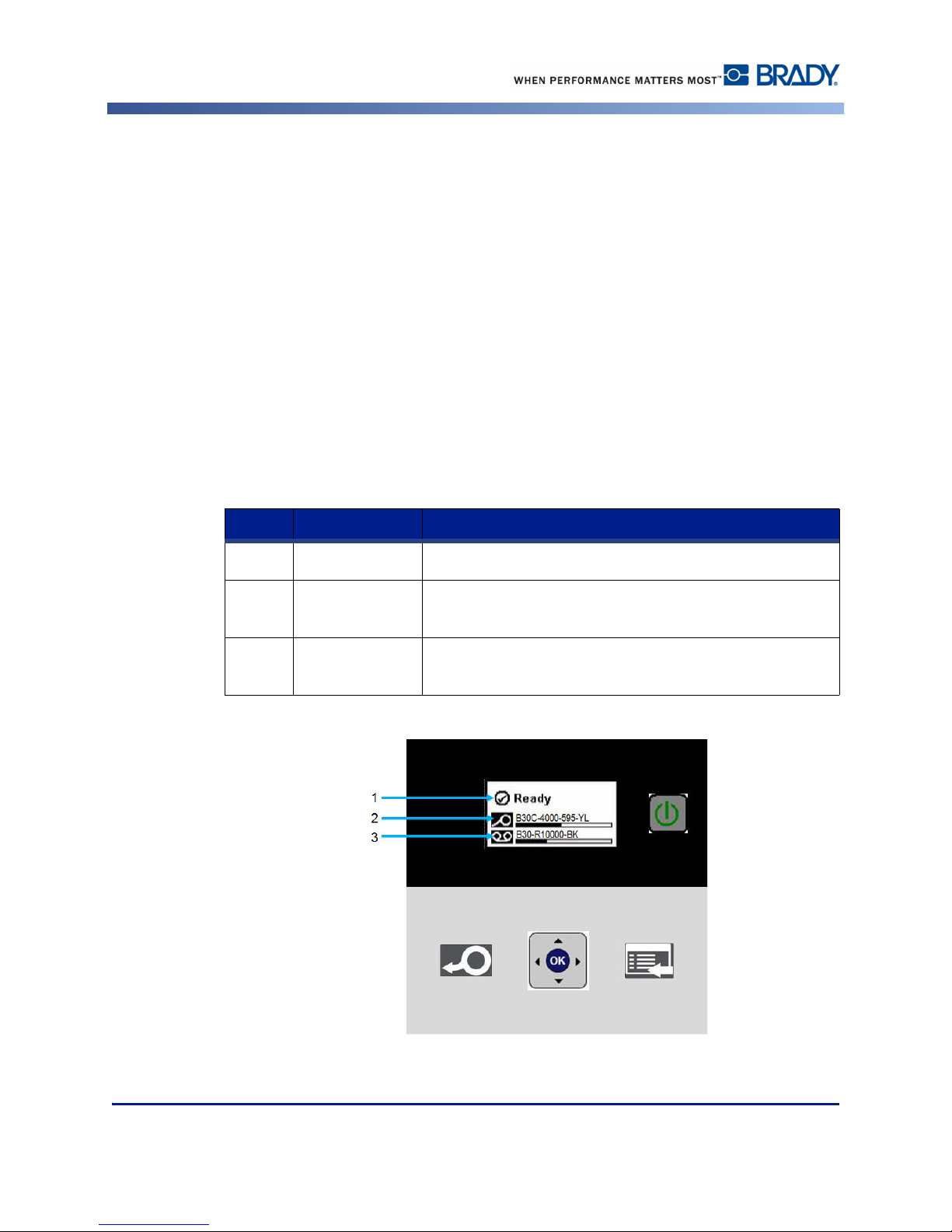

Ready Mode

The printer has three ready modes:

Initializing

•

• Ready

• Ready - USB Only

The table describes the display screen when in idle (Ready) mode.

Item # Condition Description

1 Printer Status Displays the online printer status.

2 Media Status Displays media part number and estimated amount of

remaining media.

3 Ribbon Status Displays ribbon part number and estimated amount of

remaining ribbon.

BBP®30 User’s Manual 4 Rev A

Page 15

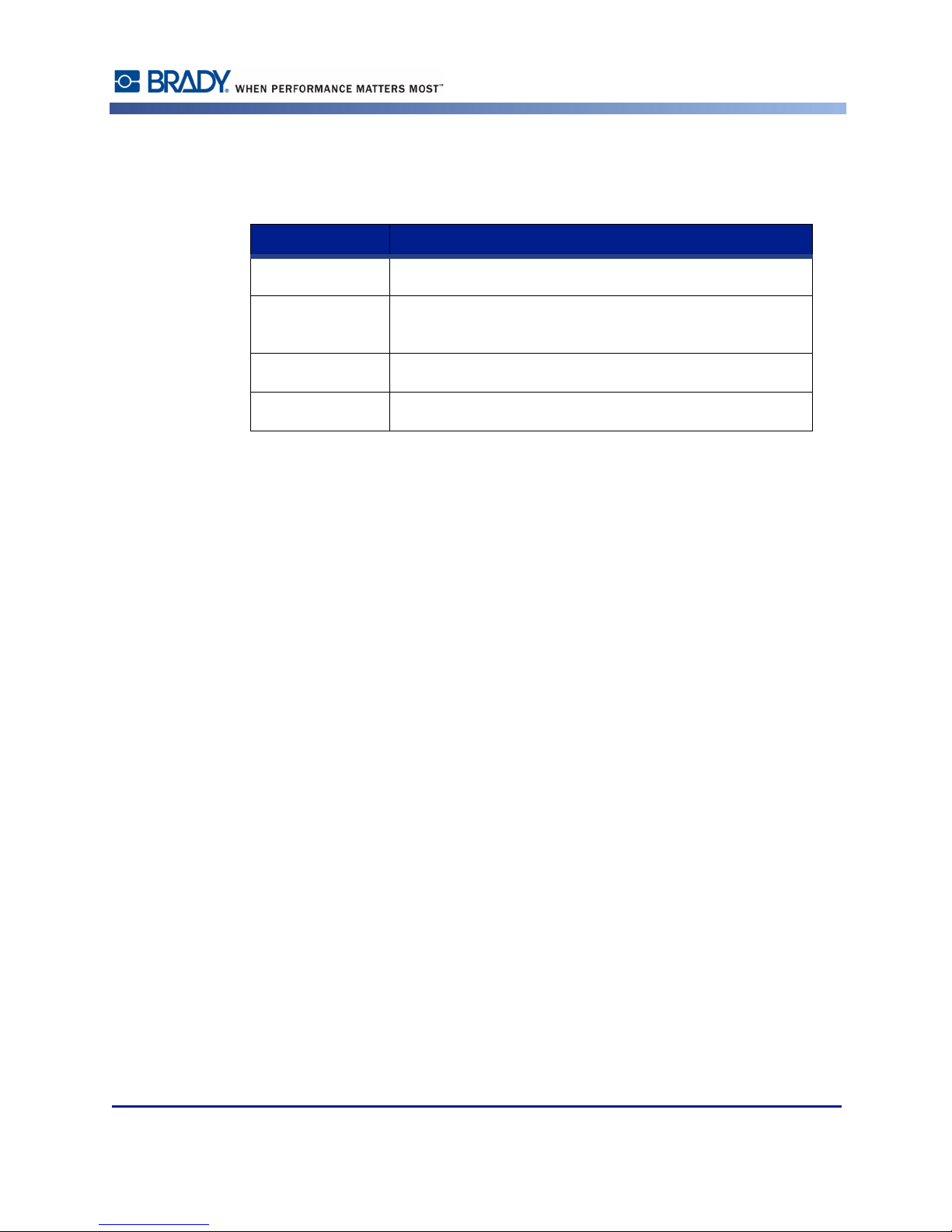

Menu Selection Mode

The table describes the main options of the display screen when in menu selection mode. See

page 6 for a list of all the menu options.

Menu Item Description

Cut Media Used to automatically cut the media.

Status Info Options to display or print status and configuration

Printer Settings Options to set up printer defaults for language.

Tools Upgrade from a USB device.

Keypad and Menu Functions

information, font list and/or graphic list.

Rev A 5 BBP®30 User’s Manual

Page 16

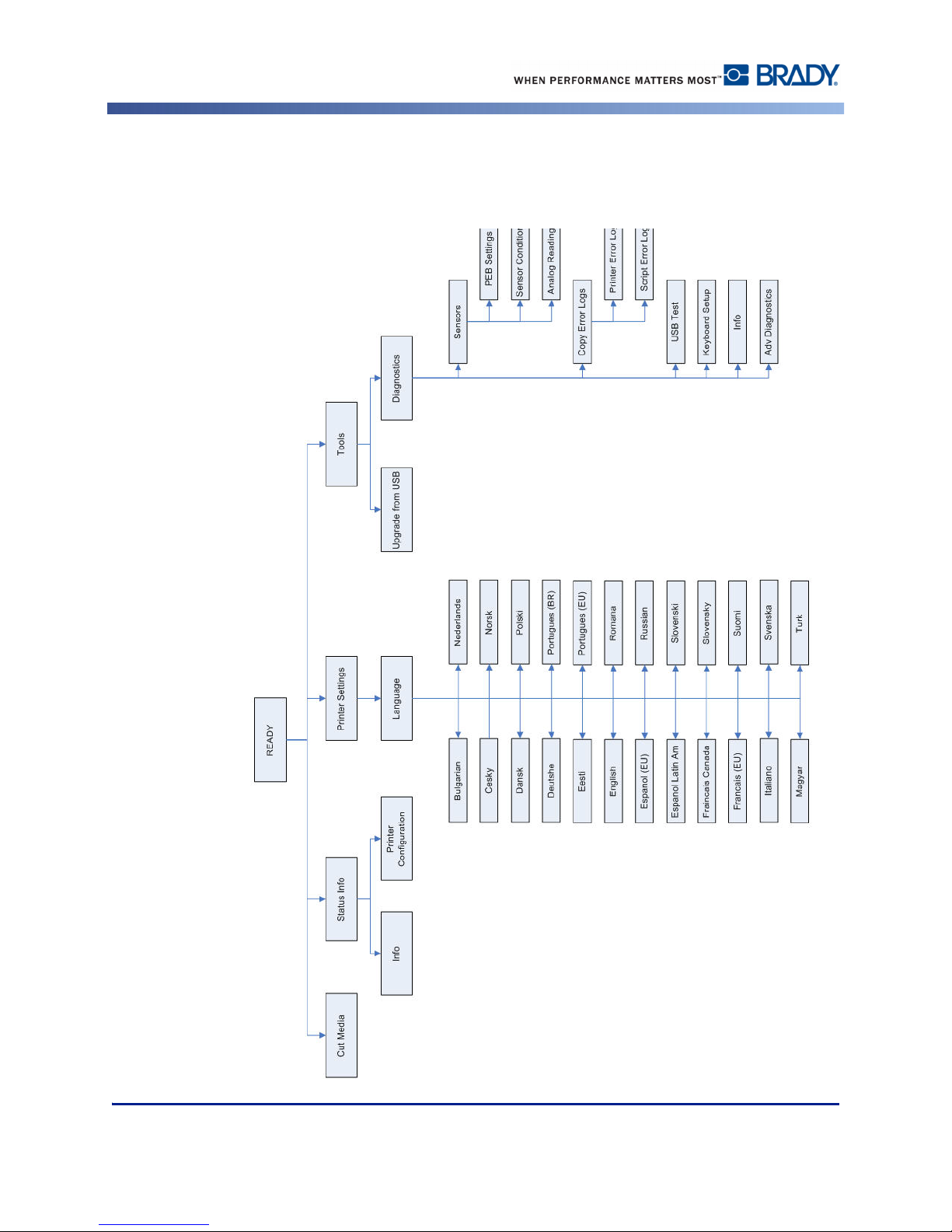

User Interface Menu Structure

User Interface Menu Structure

BBP®30 User’s Manual 6 Rev A

Page 17

Printer Set Up

Unpack and Set up Printer

Carefully unpack and inspect the printer surfaces (interior and exterior) and the labeling

system for possible damage during shipping.

Note: Be sure to remove any transportation protection from around the printhead

and inside the enclosure cover.

What’s in the Box

•BBP®30 Label Printer

•Power Cord

• USB Type B Cable

Printer Set Up

• Printed Quick Start Guide

• Product CD including: electronic Quick Start Guide, electronic User’s Manual and web

links

• Cleaning Kit (Cat # B31-CCT), not available in all regions - includes foam swabs,

adhesive scraping tool, plastic bottle

Note: Please keep the original packaging, including the box, in case the printer

must be returned.

Rev A 7 BBP®30 User’s Manual

Page 18

Printer Set Up

System Components

Figure 1 • Printer Components

1 Enclosure cover 6 Media guides

2 Label exit chute/auto cutter 7 Ribbon cartridge

3 Power button 8 Ribbon cover latch

4 Media 9 Ribbon cover

5 Media wiper 10 Ribbon cartridge latch

BBP®30 User’s Manual 8 Rev A

Page 19

Set up the Printer

Connect Printer Power

To setup the printer:

1. Plug the power cord into the printer at the location shown.

2. Plug the other end of the power cord into an AC power outlet. The printer automatically

turns on and displays the printer status and the size and color of the currently installed

media.

Printer Set Up

Rev A 9 BBP®30 User’s Manual

Page 20

Printer Set Up

Install or Change Supplies

The media and ribbon supply cartridges use a “smart cell” to define and track the supply

information. The system automatically recognizes the supply information for the installed

media and ribbon.

Note: The printer can be either on or off when changing supplies.

To install or change ribbon:

1. Open the enclosure cover 2. Release the latch on the ribbon cover and

swing open.

3. Release the ribbon cartridge latch and lift the ribbon cartridge up and out.

BBP®30 User’s Manual 10 Rev A

Page 21

To install a ribbon:

Printer Set Up

1. Place the ribbon cartridge with the ribbon

over the print head and the product label

toward machine, then snap into place.

3. Close the enclosure cover.

2. Close and latch the ribbon cover.

4. If printer was off, press . The system

detects the media and ribbon colors and

sets the amount of remaining supplies.

Rev A 11 BBP®30 User’s Manual

Page 22

Printer Set Up

To install or change media:

1. Open the enclosure cover. 2. Release the latch on the ribbon cover and

swing open.

3. If engaged, swing yellow media wiper to

the back.

5. Remove existing media, if installed, by pulling the cartridge from printer.

4. Slide yellow media guides out to the sides

to fully open.

BBP®30 User’s Manual 12 Rev A

Page 23

Printer Set Up

6. Insert the media cartridge until spindle

ends rest in slots of media holder. Media

unwinds from the top of the roll and the

smart cell should be on the left side of the

spindle.

8. Slide the media guides inward from the

sides until they touch the edge of the

media liner, with the media under the

guides.

7. Feed media from the top of the roll until it

sits just past the black rubber roller.

9. Move the media wiper into position so it

rests on the media.

Note: Not all media requires the use of the media wiper. Engage the media wiper

only if continuous media is installed.

Rev A 13 BBP®30 User’s Manual

Page 24

Printer Set Up

Feeding and Cutting Label Stock

10. Close and latch the ribbon cover. 11 . Close the enclosure cover.

If printer was off, press . The system

detects the media and ribbon colors and

sets the amount of remaining supplies.

Use this procedure to advance the media to the cut position, and (optionally) cut the media.

Note: For die-cut media, the media is advanced to the cut position which is the

next die-cut label. For continuous media, the media advances until you release the

Feed button.

To feed and cut the label stock:

1. With printer power on, press and hold Feed until the length of media you want

exits the printer.

To cut the media:

2. Press Menu to go to the navigation menu.

3. Press or to scroll to Cut Media, then press . The media is cut.

BBP®30 User’s Manual 14 Rev A

Page 25

System Power

These procedures describe how to power-up the printer when starting from a non-powered

state (i.e., printer has been unplugged) and how to remove power from the printer.

Note: With power removed (i.e., printer disconnected from power source), the

system clock retains its settings for about 30 days.

Starting Printer

1. To start printer from a cold state: Plug the printer into a power source. The system

automatically recognizes the supply information for the installed media and ribbon and the

display panel indicates

System Power

Ready.

Note: The

2. To turn on the backlight: Press any button.

backlight for the display panel turns off after a pre-defined period of time.

Powering Off the Printer

When the system is shut down, the display turns off.

To completely remove printer power:

1. Disconnect the power cord from the printer.

To perform a soft power down:

2. Press and release the Power button . The screen goes blank and the backlight goes

off.

Rebooting the Printer

Use this procedure to reboot the printer (e.g., if the screen freezes).

To reset the printer:

1. Press and hold the Power button for at least 5 seconds. The system performs the

initialization process and restarts the printer.

2. When the Ready displays, you can continue printing your labels.

Rev A 15 BBP®30 User’s Manual

Page 26

Connect Printer to a PC via USB

Connect Printer to a PC via USB

Unless you are using Brady Workstation and Direct Print, to use your PC with the BBP®30

Sign and Label printer, you must have the USB device driver installed on your PC.

Note: See Compatible Applications (page 1) for a list of software applications that

®

are compatible with the BBP

for instructions about installing and using the software.

30. Refer to your labeling software documentation

BBP®30 User’s Manual 16 Rev A

Page 27

User Interface Menu

The User Interface (UI) menu provides feedback and also allows you to access and change

printer settings, printer status and tools. A 5-way navigation keypad lets you navigate through

the menu structure to choose the option(s) you want.

User Interface Menu

In Ready mode, the UI menu indicates

and ribbon.

Navigation is divided into 4 major functions:

• Cut Media

• Status Info

• Printer Settings

• Tools

Cut Media

Selecting Cut Media from the menu sends a signal to the printer telling it to cut the media.

To set the cut option:

1. Press Menu to go to the navigation menu. Cut Media is the first option.

2. When you are ready to cut, press . The printer cuts at the current position of the

media.

printer status and displays estimated remaining material

In Menu Selection mode, the display changes to a navigation-type menu.

Note: The menu stays on Cut Media until you exit the menu.

3. When done, press to exit to the main menu.

Rev A 17 BBP®30 User’s Manual

Page 28

User Interface Menu

Status Info

Status Info includes information about the printer configuration and fonts. From this menu,

you can print a configuration label.

To view system information:

1. Press Menu to go to the navigation menu.

2. Press or to scroll to Status Info, then press .

3. Press or and choose from one of the following options, then press :

Note: Press to exit a menu at any time.

Note: For print options, use continuous media to get the best results.

Info: Displays the current application and firmware version.

•

• Print Configuration: Prints current printer configuration.

4. When done, press twice to exit to the main menu.

BBP®30 User’s Manual 18 Rev A

Page 29

Printer Settings

The Printer Settings menu lets you set the default values for the printer. Defaults are common

settings that are pre-assigned to make the system usable as soon as power is applied (e.g., set

date and time to your local date and time). By changing the defaults, you can set the printer to

your specific requirements.

Any defaults set here will stay in effect even when power is removed from the printer, and also

during upgrades.

Note: If password protection has been implemented, you will need to enter a

password to have access to these functions.

Language

To change language setting:

User Interface Menu

1. Press Menu to go to the navigation menu.

2. Press or to scroll to Printer Settings, then press .

3. Press to scroll to Language, then press .

4. Press or to scroll to the language you want.

5. Press to accept the change. It takes a few moments for the settings to take effect.

6. When done, press twice to exit to the main menu.

Rev A 19 BBP®30 User’s Manual

Page 30

User Interface Menu

CAUTI ONCAUTI ON

Tools

Upgrade from USB Flash Drive

Use this procedure to upgrade the firmware or software from a USB flash drive that contains

the upgrade. The system will support only one USB device at a time.

To upgrade software from a USB flash drive:

1. Copy the upgrade files to the root directory of your USB flash drive.

2. Connect the USB flash drive to any available USB port on the printer.

Do not interrupt power during an upgrade from a USB flash drive.

3. Press Menu

4. Press or to scroll to Tools, then press .

5. Press to scroll to Upgrade from USB, then press . The printer automatically

to go to the navigation menu.

downloads and installs the firmware/software from the root directory of the USB flash

drive.

Note: During the upgrade, the screen goes blank. It may take a few moments for

the upgrade to complete. When done, the printer returns to the Ready menu.

BBP®30 User’s Manual 20 Rev A

Page 31

Diagnostics

Some diagnostics are not available for users. Advanced diagnostics are password protected

and to be used only with Brady Technical Support. The password is assigned by Brady.

Enter Diagnostic Mode

Use this procedure to access any of the diagnostics menus.

To enter diagnostics mode:

Diagnostics

Note: A password is required to access the Advanced Diagnostics menus.

1. Press

2. Press or to scroll to Tools, the press to go to the submenu.

3. Press to scroll to Diagnostics, then press to go to the diagnostics list.

4. When done, press

to go to the navigation menu.

to exit the test.

Sensors

Print Engine Base (PEB) Settings

This procedure displays the PEB settings on the printer.

To view the PEB settings:

1. Access Diagnostic mode (see “Enter Diagnostic Moden page 21).

2. Press to select Sensors.

3. Press to select PEB Settings. The PEB settings display results for the following:

4. Press repeatedly to exit to the main menu or to return to the PEB Settings menu.

Rev A 21 BBP®30 User’s Manual

CutLine - Lead.

Leading - Print

Print - Diecut

Diecut - Tapeout

Rocker Steps

Print - Center

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

Page 32

Diagnostics

Sensor Conditions

This diagnostic detects the sensor conditions for ribbon motion, door, cutter, leading (edge),

diecut, tapeout, wiper, and center.

Conditions are:

BL (blocked)

•

•

Clos (closed) or Open

• Hom (home position)

• Eng (engaged)

•

UnB (unblocked)

To view the PEB settings:

1. Access Diagnostic mode (see page 21).

2. Press to scroll to Sensor Conditions, then press . The sensor settings display

results for the following:

RibbonMotion

Door

Cutter

Leading

Diecut

TapeOut

Wiper

Center

3. Press repeatedly to exit to the main menu or to return to the Sensor Conditions

BL

Clos/Open

Hom

BL

BL

BL

Eng

BL

menu.

BBP®30 User’s Manual 22 Rev A

Page 33

Analog Readings

This diagnostic detects the analog readings for the diecut analog/digital converter, head

voltage and thermistor temperature.

To view the analog readings:

1. Access Diagnostic mode (see page 21).

2. Press to scroll to Analog Readings, then press . The readings display for the

following:

Diagnostics

3. Press repeatedly to exit to the main menu or to return to the Analog Readings

menu.

Copy Error Logs

Printer Error Log

1. Insert a USB drive into any available port on the printer.

2. Access Diagnostic mode (see page 21).

3. Press to go to Copy Error Logs, then press .

4. Press to select Printer Error Log, then press . The error log is written to the

USB drive and the message Successfully Copied Error Log displays.

Note: A message will display if no USB device is detected.

Diecut A/D

Head Voltage

Thermistor

xxxx

xxxx

xxxx

5. Press repeatedly to exit to the main menu.

To view the error log:

6. Remove the USB drive from the printer and insert into your PC.

7. In Windows Explorer, navigate to the USB drive and open the folder BBP30 Error Logs.

8. Double-click the file PRINTER_ERROR_LOG.txt to view the log.

Rev A 23 BBP®30 User’s Manual

Page 34

Diagnostics

Script Error Log

1. Access Diagnostic mode (see page 21).

2. Press to go to Copy Error Logs, then press .

3. Press to go to Script Error Log.

4. Press . The error log is written to the USB drive and the message Successfully Copied

BPL Error Log and Successfully Copied SM Error Log displays.

Note: A message will display if no USB device is detected.

5. Press repeatedly to exit to the main menu.

To view the error log:

6. Remove the USB drive from the printer and insert into your PC.

7. In Windows Explorer, navigate to the USB drive and open the folder BBP30 Error Logs.

8. Double-click either of the following files to view the logs:

•

BPL_ERROR_LOG.txt

• SCRIPT_ERROR_LOG.txt

BBP®30 User’s Manual 24 Rev A

Page 35

USB Test

The USB test verifies that the USB ports are active. The tests can be performed with a flash

drive or a type-B cable.

USB Flash Drive Test

To perform a USB test:

1. Access Diagnostic mode (see page 21).

2. Press or to go to USB Test, then press to select the test.

3. Press to start the test.

4. Insert a USB flash drive into the Lower USB port. The display indicates

DSK2: attached.

5. Remove the USB flash drive. The display indicates DSK2: removed.

Diagnostics

6. Repeat steps 4 and 5 for the Upper USB port.

7. When done, press

to exit the test.

USB Type-B Cable Test

To perform a USB test with a type-B cable:

1. Access Diagnostic mode (see page 21).

2. Press or to go to USB Test, then press to select the test. The USB Test Status

screen displays.

3. Insert a USB type-B cable from the Lower Host port to the Function port. The display

indicates LPT1: attached.

4. Remove the USB type-B cable. The display indicates LPT1: removed.

5. Repeat Steps 3 and 4 for the Upper Host port.

6. When done, press

to exit the test.

Rev A 25 BBP®30 User’s Manual

Page 36

Diagnostics

Keyboard Setup

Info

This procedure configures the printer to use the selected regional USB keyboard.

To configure a keyboard:

1. Access Diagnostic mode (see page 21).

2. Press or to go to Keyboard Setup, then press . The list of keyboard options

displays.

3. Press or to select the regional configuration you want, then press . The printer is

configured for use with the selected keyboard.

4. Press repeatedly to exit to the main menu.

Lists the length of label media printed, number of cuts made and the last errors displayed.

To view printer information:

1. Access Diagnostic mode (see page 21).

2. Press or to go to Info, then press .

3. Press or to select the information you want displayed:

•

Printed: Displays the number of ft (mm) of media printed to date.

• Cuts: Displays the total number of cuts made to date. (Note: The number actually

reflects the number of times the printer has retracted the material for a new print.)

Last Errors: Displays the last 15 printer error message numbers.

•

4. Press to display the error messages.

Note: The errors displayed are for actual messages received. So, if you get the

same error multiple times, the screen will display that error once for each

occurrence (up to 15).

5. Press repeatedly to exit to the main menu.

Advanced Diagnostics

A password is required to enter the advanced diagnostic procedures. Contact your Brady

Technical Support contact for help with these diagnostics.

BBP®30 User’s Manual 26 Rev A

Page 37

Printer Maintenance

Removing Power and Media from Printer

Before performing any maintenance procedure that involves opening the enclosure cover, you

should remove the power and media from the printer.

To remove printer power and media:

1. Remove the power plug from the printer.

Printer Maintenance

2. Open the enclosure cover.

3. Release the latch on the ribbon cover and swing open.

4. Release the ribbon cartridge latch and lift the ribbon cartridge up and out.

Rev A 27 BBP®30 User’s Manual

Page 38

Printer Maintenance

5. Move yellow media wiper to the back.

6. Move yellow media guides to full-open.

7. Remove media cartridge from the slots of media holder.

BBP®30 User’s Manual 28 Rev A

Page 39

Cleaning the Printer

CAUTI ONCAUTI ON

Remove Dust

Dust generated by media cuts can accumulate in the unit. If a significant amount of dust is

built up, clean the unit using this procedure.

Materials Required

• Isopropyl Alcohol

• Compressed Air Bottle, purchased locally (e.g., HOSA AIR-464 Gear Duster)

To clean dust from the printer:

Always wear safety glasses when using compressed air.

Printer Maintenance

1. Remove power and media from the printer (see page 27).

2. Using compressed air, spray all visible areas inside the printer to remove accumulated

dust.

3. Using a cloth moistened with isopropyl alcohol, wipe any remaining dust from inside the

printer.

4. Wipe exterior cover and frame of printer for dirt and residue.

Rev A 29 BBP®30 User’s Manual

Page 40

Printer Maintenance

CAUTI ONCAUTI ON

Clean Printer and Keypad Residue

Whenever performing any maintenance on the printer, you should also clean any residue

caused by the media.

Materials Required

• Compressed Air Bottle, purchased locally (e.g., HOSA AIR-464 Gear Duster)

• Lint-free Cloth

• Isopropyl Alcohol

• Safety Glasses

To clean residue from the printer:

Always wear safety glasses when using compressed air.

1. Remove power and media from the printer (see page 27).

2. With safety glasses on, spray compressed air on any parts of the printer that have built-up

residue.

Note: If compressed air is not available, use a lint-free cloth lightly moistened

with isopropyl alcohol and wipe off residue.

3. If necessary, use a moistened, lint-free cloth to clean the keypad.

4. Replace the ribbon and tape.

5. Close all covers and plug in the power cord.

BBP®30 User’s Manual 30 Rev A

Page 41

Printer Maintenance

Clean LCD Screen

Materials Required

• Lint-free Cloth, non-abrasive

• Isopropyl Alcohol

- or -

• Pre-moistened Cloth (appropriate for cleaning PC screens)

To clean the LCD screen:

Note: Normal cleaners with ammonia, soaps, or any acids can damage the screen.

Use only a lint-free cloth dampened with isopropyl alchohol.

1. Lightly moisten a lint-free cloth with isopropyl alcohol, or use a pre-moistened cloth

suitable for cleaning a PC screen.

2. Gently rub the damp cloth across the screen until all of the residue is removed.

Rev A 31 BBP®30 User’s Manual

Page 42

Printer Maintenance

Clean Auto-Cutter Blade

Materials Required

• Isopropyl Alcohol

• Cleaning Kit (Cat # B31-CCT), includes foam swabs, adhesive scraping tool, plastic bottle

To clean the cutter:

1. Remove power and media from the printer.

2. Squeeze the two yellow cutter tabs [2a] to release the cutter. The cutter mechanism and

Note: When cleaning the cutter, you should also clean the media and cutter

sensors (see page 34).

(not available in all regions)

exit chute [2b] will slide down behind the ribbon cover.

3. Fill the plastic bottle from the cleaning kit with isopropyl alcohol.

BBP®30 User’s Manual 32 Rev A

Page 43

Printer Maintenance

4. Clean metal cutting blade:

• If the cutting blade shows significant residue, use the adhesive scraping tool from the

cleaning kit, or other flat-edged tool, to gently scrape the reside off the cutting blade.

• Moisten one of the foam swabs from the cleaning kit with the alcohol. Do not allow

the alcohol to drip from the swab.

• Clean cutting blade with moistened swab until all residue is removed.

5. Close the cutting blade by pushing up on the exit chute until the cutter tabs snap into

place.

Note: You may need to hold ribbon cover up slightly to access the exit chute.

6. Replace the ribbon and tape.

7. Close all covers and plug in the power cord.

Rev A 33 BBP®30 User’s Manual

Page 44

Printer Maintenance

CAUTI ONCAUTI ON

Clean Sensors

The sensors are located inside the printer and may be covered with dust that results from

cutting the media. The media sensor is located under the yellow media guide.

Materials Required

• Cleaning Kit (Cat # B31-CCT), includes foam swabs, adhesive scraping tool, plastic bottle

• Isopropyl Alcohol

To clean the sensors:

1. If necessary, remove power and media from the printer (see page 27).

2. With the ribbon cover open, use a pre-moistened swab and thoroughly clean the surface of

(not available in all regions)

the sensors

at the locations shown:

Do not allow the alcohol to drip from the swab

.

• Center die-cut sensor [2a]

• Tape out/die-cut sensors [2b]

Note: Sensor is located under the yellow media guide.)

(

BBP®30 User’s Manual 34 Rev A

Page 45

Printer Maintenance

CAUTI ONCAUTI ON

CAUTI ONCAUTI ON

Clean Tape Entrance

This procedure cleans the tape entrance, exit area and exit chute. The tape entrance can

become sticky because of adhesive buildup

Note: Clean the exit area after cleaning the sensors (see page 34). The cleaning

swab may be damaged when cleaning the exit area.

Materials Required

• Cleaning Kit (Cat # B31-CCT), includes foam swabs, adhesive scraping tool, plastic bottle

(not available in all regions)

®

•Kimwipes

• Isopropyl Alcohol

• Compressed Air Bottle, purchased locally (e.g., HOSA AIR-464 Gear Duster)

or other non-abrasive cloth

Always wear safety glasses when using compressed air.

To clean the tape entrance:

1. Lightly moisten a lint-free cloth with isopropyl alcohol.

Do not use isopropyl alcohol on the print head! Isopropyl alcohol may

permanently damage the print head.

2. At the top of the tape entrance, rub along entire length of the tape entrance to remove the

adhesive residue [2]. If necessary, use the adhesive scraping tool or other flat-edged tool,

covered with the Kimwipe, to push against the tape entrance to clean all of the residue

from the entrance.

Rev A 35 BBP®30 User’s Manual

Page 46

Printer Maintenance

CAUTI ONCAUTI ON

3. Wet a cotton swab with isopropyl alcohol and thoroughly clean along the entire media

entrance area.

When cleaning, don’t pinch or gouge the platen roller. Use only compressed air

.

4. Use compressed air to clean off dust on the entire printer, including the platen roller.

BBP®30 User’s Manual 36 Rev A

Page 47

Printer Maintenance

Clean the Cutter Blade Exit Area

This procedure cleans the cutter blade exit area and the exit chute.

Note: You should clean the exit area after cleaning the cutter blade and sensors.

The cleaning swab may be damaged when cleaning the exit area.

Materials Required

• Cleaning Kit (Cat # B31-CCT), includes foam swabs, adhesive scraping tool, plastic bottle

(not available in all regions)

• Isopropyl Alcohol

To clean the exit chute:

1. If necessary, remove power and media from the printer (see page 27).

2. Close the ribbon cover. It does not need to snap into place.

3. Using a swab pre-moistened with alcohol, clean the exit chute entrance [3a] and exit chute

ramp [3b].

Note: To reach all areas of the exit chute, you can close the enclosure cover and

tilt the printer up.

4. Replace the ribbon and tape.

5. Close covers and plug in the power cord.

Rev A 37 BBP®30 User’s Manual

Page 48

Printer Maintenance

CAUTI ONCAUTI ON

CAUTI ONCAUTI ON

Clean Printhead

Materials Required

• Cleaning Kit (Cat # B31-CCT), includes foam swabs, adhesive scraping tool, plastic bottle

• Isopropyl Alcohol

To clean the printhead:

1. Remove power and media from the printer (see page 27).

2. Fill the plastic bottle from the cleaning kit with isopropyl alcohol.

(not available in all regions)

Use only the materials supplied in the cleaning kit. Using other materials may

permanently damage the printhead.

Do not rub the swab over the bronze-colored area of the printhead. This

may permanently damage the printhead.

3. Moisten one of the foam swabs from the cleaning kit with the alcohol and gently rub

across the

4. Replace the ribbon and tape.

5. Close all covers and plug in the power cord.

green and black area only of the printhead [3].

BBP®30 User’s Manual 38 Rev A

Page 49

Replacing the Media Wiper

Materials Required

• Media Wiper (5 pack) Kit, Cat #B31-WIPER (sold separately)

To replace the media wiper:

1. Remove power and media from the printer (see page 27).

2. LIft and hold the wiper arm while grasping the tab of the wiper insert [2].

3. Pull the tab slightly forward and then slide the wiper insert out of the wiper arm.

4. To replace the wiper, insert the lip of the wiper insert into the slot [4] of the wiper arm and

slide in until the tab snaps into place.

Printer Maintenance

5. Replace the ribbon and tape.

6. Close all covers and plug in the power cord.

Clearing Jams

To clear jams from the printer:

1. Remove all damaged ribbon and/or media from the printer.

2. Check that there is no damage to the print head, sensors, or any other parts.

3. Check whether any cleaning is needed. If cleaning is required, see page 29 for details.

4. Reload ribbon and media and clear all error messages.

Replacing/Adjust Media End Caps

In the unlikely even that your tape roll comes apart, contact Tech Support for assistance in

replacing or adjusting the end caps. See page v for details.

Rev A 39 BBP®30 User’s Manual

Page 50

Printer Maintenance

BBP®30 User’s Manual 40 Rev A

Page 51

Troubleshooting

Messages

The BBP®30 Label Printer contains error messages that describe what action you should take

to resolve any messages or errors.

Messages indicate the problem for the task being performed and also provide a possible

corrective action.

Printing Errors

Problem Cause Corrective Action

Troubleshooting

Printer not ready.

Error: 15

Printer Error.

Error: 16

Printer Error

Error: 21

Printer Error

Error: 22

Poor print quality.

Error: 1024

The ribbon cover is open or

the cutter is not in operating

position.

Ribbon cover was opened

during printing.

Media wiper is not

engaged.

Media wiper is engaged but

should not be used on this

media.

Printhead needs cleaning. Clean printhead with

Close and latch ribbon

cover or move cutter to

operational position.

Close ribbon cover.

Engage media wiper arm.

Disengage the media wiper

arm.

isopropyl alcohol and swab.

Rev A 41 BBP®30 User’s Manual

Page 52

Troubleshooting

Hardware Errors

Problem Cause Corrective Action

Printer too warm. Print job

canceled.

Error: 18

Printer too cold. Print job

canceled.

Error: 20

Media jam. Print job

canceled.

Errors: 45, 80, 85, 87

Cut quality poor.

Error: 1025

Residue on labels.

Error: 1027

The printhead is too hot. The printhead has reached

maximum operating

temperature. Allow printer

to cool down

approximately 10 minutes,

then re-initiate the print job.

The printhead has not

reached operating

temperature.

Normal operating range is

between

50-104°F (10-40°C). Allow

printer to warm up to

operating temperature

before printing.

Media is jammed in the

printer [45]; Media is in the

media guides, but not

Clear media path and

reinstall media, then re-

initiate the print job.

detected by the cutter

home sensor [80]; Media is

in the home position but

not detected by the media

If error persists, contact

Technical Support.

out notch sensor [85];

Media is in the printer but

not detected by the leading

edge sensor [87].

Cutter needs cleaning

because of adhesive build

up on the cutter.

• Unlatch cutter and push

down away from roller.

• Remove residue from

blades with flat-edged tool,

then clean with isopropyl

alcohol.

• Close cutter and printer.

• From exit chute, swab

back of blades with

isopropyl alcohol.

Media wiper needs to be

replaced.

• Swing media wiper arm to

upright position.

• Slide wiper out of wiper

arm toward left side of the

printer.

• Slide replacement wiper

into slot on wiper arm.

Poor media detection on

the printer, or print

registration problems.

BBP®30 User’s Manual 42 Rev A

Media end cap not

centered on spindle.

Adjust the center position

of the media roll.

Page 53

Media Errors

Troubleshooting

Problem Cause Corrective Action

Error reading media

memory cell. Reload or

replace media.

Errors: 48, 49, 50, 51, 52

Media out.

Error: 53

Media is jammed.

Error: 54

Media not detected.

Error: 55

Printer cannot read the

media memory cell: media

validation failed [48];

cannot read media cell

[49]; cannot read memory

CRC [50]; cell is wrong

version [51]; media counter

shows no media remaining

[52].

Media sensor shows end

of media. Print job

canceled.

Media is jammed

somewhere in the printer.

Print job canceled.

Media is not loaded

correctly.

Replace media. If problem

persists, contact Technical

support.

Verify media guides are

positioned correctly at the

edge of the media or

replace roll if empty.

Clear the media path and

re-initiate the print job.

Reload media:

1. Insert media.

2. Feed media between

guides to middle of black

roller.

3. Verify guides are

positioned to media

edge.

Rev A 43 BBP®30 User’s Manual

Page 54

Troubleshooting

Ribbon Errors

Problem Cause Corrective Action

Ribbon Out.

Error: 58

Ribbon too narrow.

Error: 62

Error reading ribbon

memory cell.

Errors: 64, 65, 66, 67, 68

Media mismatch.

Error: 69

The ribbon ran out or broke

during the print job.

The installed ribbon is

narrower than the installed

media.

The printer cannot read the

ribbon memory cell:

memory cell code incorrect

[64], cannot read cell [65],

data in cell is corrupted

[66], cell is wrong version

[67], ribbon counter shows

no ribbon remaining [68].

The installed ribbon is not

recommended for use with

the current media.

Replace ribbon and close

inside printer cover. Reinitiate the print job.

Replace the ribbon

cartridge with wider ribbon.

- or -

Replace the media with a

width that matches the

ribbon.

Replace the ribbon. If

problem persists, contact

Technical Support.

Replace the ribbon with a

type that is compatible with

the media.

- or -

Replace the media with a

type that is compatible with

the ribbon.

BBP®30 User’s Manual 44 Rev A

Page 55

Page 56

© 2015 Brady Worldwide, Inc. All Rights Reserved.

Y4181115

Loading...

Loading...