Page 1

P.O. BOX 309

MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

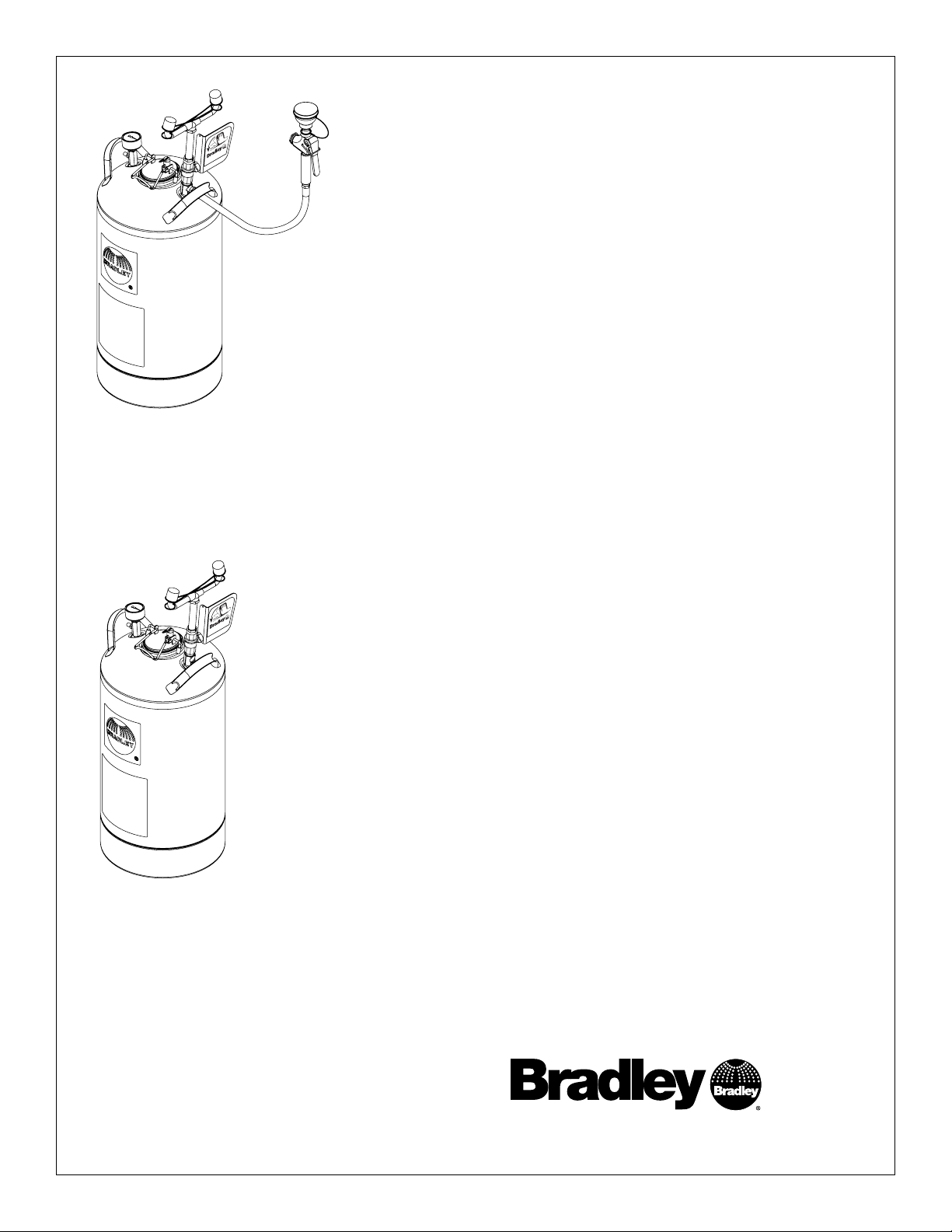

Installation

S19-690

10-Gallon Tank with Eyewash and

Hose Spray

Réservoir de 10 gallons avec

douche oculaire et douchette

S19-690

Depósito de 10 galones con

lavaojos y manguera de aspersión

S19-690LHS

10-Gallon Tank with Eyewash

Réservoir de 10 gallons avec

douche oculaire

Depósito de 10 galones con

lavaojos

P.O. BOX 309

MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

S19-690LHS

Table of Contents

Pre-Installation Information ...................... 2

Dimensions ..................................3

Eyewasy Installation ........................... 3

Filling the Tank................................4

Maintenance & Troubleshooting .................. 5

S19-690 Components & Parts List ................ 6

S19-690LHS Components & Parts List............. 7

Table des matières

Avant l’installation ............................. 8

Dimensions ..................................9

Installation de la douche oculaire ................. 9

Remplissage du réservoir ......................10

Entretien et dépannage ........................ 11

S19-690 Composantes et liste des pièces ......... 12

S19-690LHS Composantes et liste des pièces...... 13

Contenido

Información previa a la instalación ............... 14

Dimensiones ................................15

Instalación del lavaojos ........................ 15

Llenar el tanque..............................16

Mantenimiento y resolución de problemas ......... 17

S19-690 Componentes y lista de piezas........... 18

S19-690LHS Componentes y lista de piezas ....... 19

215-321C Rev. V; ECN 14-05-015

© 2014 Bradley

Page 1 of 19 7/29/2014

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

Page 2

S19-690, S19-690LHS Installation

F

IMPORTANT

Installation

P.O. Box 309, Menomonee F

UNIT EACH

TEST THIS

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

durch Untersc

60˚ F

Read this installation manual completely to ensure proper installation, then file it with the

owner or maintenance department. Compliance and conformity to drain requirements and

other local codes and ordinances is the responsibility of the installer.

Packing List

•

•

•

THIS

SIDE

•

UP

Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain

the missing parts.

R

WI 53051

alls,

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

Signed

e chose qui ne v

Signed

Date Signed

y malfunctions immediatel

hentlich im

hrift. Jeglic

Date

Date

t immédiatement.

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

The inspection and testing results of this equipment should be recorded weekly to verify

proper operation. This equipment should be inspected annually to ensure compliance with

ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be trained

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

regarding the placement and proper operation of emergency equipment per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.

com or call 1-800-BRADLEY.

Product warranties and service parts information may also be found under ”Products” on our

web site at www.bradleycorp.com.

100˚

This unit is to be used with tepid, potable water as defined by ANSI Z358.1. (Note: avoid

prolonged exposure to ambient heat sources above 100° F, or below 60° F).

Failure to lift unit by the provided handles may damage unit.

NOTICE! Avoid cleaners containing organic solvents, alcohols, and hydrocarbons.

Rinse with water after cleaning.

Supplies Required:

• Pipe sealant

• Air pressure equipment or supply (clean and free of oil contaminants) capable of up to 100 psi

• Sign-mounting hardware

• Adjustable wrench

2

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 3

Installation S19-690, S19-690LHS

Dimensions

6"

(152mm)

34"

(864mm)

24³⁄₈"

(619mm)

1

Eyewash installation

Remove the plastic dust plug from the bottom of

the yoke assembly and discard.

Hose spray for S19-690 model only. Do not

attach body wash spray head at this time.

26"

(660mm)

12¼"

(311mm)

Body Wash Spray Head

Attach the pressure gauge to

the adapter on the pressure

side of the tank with pipe

C

sealant (by installer).

NOTICE: When attaching the pressure

gauge and hose spray to the tank

outlet, hold the adapter (item 3) with a

wrench to prevent stripping. Failure to

do so may damage the seal and cause

leakage. Max. torque 150 in-lbs.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

Attach the eyewash yoke assembly

A

to the tank. Max. torque 150 In-Lbs.

Connect the hose with appropriate

pipe sealant (by installer). Do not

B

use sealant tape.

3

Page 4

S19-690, S19-690LHS Installation

2

Filling the Tank

Fill tank and pressurize

CAUTION! DO NOT open the cover until the pressure gauge reads “0.”

1. Open the tank by pulling up on the wire handle located on top of the Quick-lock cover. Push down, rotate and remove. Make

sure that the interior of the container is clean. Fill the container with 8 gallons of tepid potable water.

2. Replace the cover and secure by pulling up on the cover and down on the wire handle.

3. After filling the tank with tepid water and before pressurizing the unit, open the activation valve to the full open position and

remove the dust covers from the eyewash heads.

4. Located beneath the pressure gauge is an air valve. Remove protective cover and begin to pressurize the unit by applying

pressured air through the valve. As soon as water begins discharging from the eyewash heads, close the activation lever

completely. Finish pressurizing the tank to 90 psi and replace the air valves protective cover.

If this is the initial startup of this unit or if the unit has been unfilled and/or un-pressurized for a prolonged period of time the

unit should be flushed out per the procedure below.

Prior to placing unit in service let unit stand for one hour. If there is a noticeable pressure drop, re-pressurize and let

stand for an additional hour. If unit continues to exhibit pressure loss DO NOT place unit in service and consult the

Troubleshooting guide found on page 5 of this manual.

CAUTION! Relief valve is designed to vent automatically at 100-130 psi to prevent the tank from over pressurizing.

If the gauge ever reads more then 130 psi immediately open the pressure relief valve manually by pulling

up on the relief valve tab until the pressure reads zero. Remove the unit from service and consult the

troubleshooting guide found on page 5 in this manual for steps to correct the problem. Return the unit to

service only when over-pressurization issue is corrected.

Flush tank

1. Be sure the unit is assembled, filled and pressurized according to Steps 1 & 2 above, (If this is the initial start up of the unit

the body wash spray head will not be attached to the drench hose activation valve at this time.)

2. Discharge the water through the eyewash and hose spray (if provided with unit) for at least five minutes to flush the system.

3. Flush all remaining fluid in the tank.

4. Attach the body wash sprayhead (S19-690).

5. Refill the tank and pressurize as described in Step 2 above.

4

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 5

Installation S19-690, S19-690LHS

Maintenance

WARNING! Follow instructions of the preservative manufacturer for the proper use of water preservative.

Inspect eyewash unit

1. Visually inspect the pressure gauge weekly to ensure the unit is maintaining the proper pressure. If the unit is not working

properly, remove it from the hazard area immediately and refer to the troubleshooting instructions. For further assistance,

contact the Bradley Corporation.

Clean eyewash unit

When using potable water only:

1. Empty the tank any time from once per week to once per month, depending on the quality of your water supply. The

manufacturer is not responsible for variations in the water supply.

2. Clean the inside of the tank using warm water and mild soap. Rinse the tank thoroughly with warm water.

3. Refill the eyewash tank with tepid potable water.

When using potable water and water preservative (recommended):

1. Clean the inside of the tank using warm water and mild soap. Rinse the tank thoroughly with warm water.

2. Refill the eyewash tank with tepid potable water. Follow instructions of the preservative manufacturer for the proper use of

water preservative.

Troubleshooting

1. If pressure relief valve relieves prior to the required pressure, do the following (when in the unpressurized condition):

• Tighten the valve completely into the cap by turning the gray hex head portion of the pressure relief valve clockwise.

Do not use a wrench.

• ull up on the relief valve ring and ensure that the ring is not preventing the valve from closing completely. Push on the

center pin of the relief valve to ensure that it is completely closed. Repressurize tank to required pressure. This may

have to be done several times to get the valve to seat completely.

2. If the pressurized tank loses pressure over time, check the connections with diluted liquid dish soap or children’s bubbles to

identify the leak location. Tighten the connection slightly and test again.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

5

Page 6

S19-690, S19-690LHS Installation

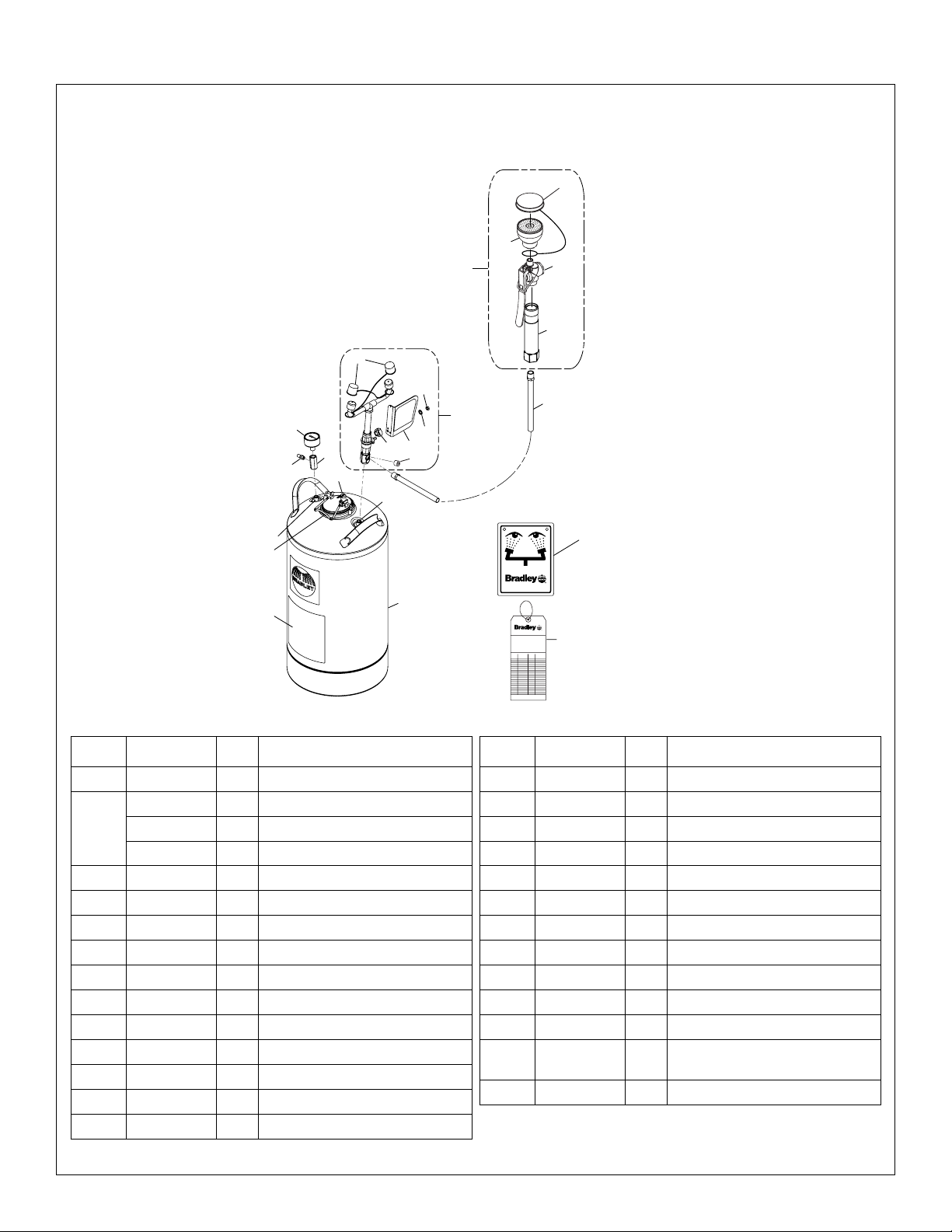

Assembly of Components and Parts List - S19-690

9.4

9.3

9

2.1

9.1

9.2

2.3

1.3, 1.5

1.2, 1.21

4

3

5

1.22

1.1

1.3, 1.4

2.5

2.2

2.4

2.6

1

Item Part No. Qty. Description

1 S39-785 1 Tank, 10-Gallon

1.1 204-641 1 Operating Instr. Label, English

204-641FC 1 Operating Instr. Label, French

204-641M 1 Operating Instr. Label, Spanish

1.2 S44-024 1 Lid Assembly

1.21 269-1410 1 Gasket

1.22 269-1642 1 Relief Valve

1.3 269-1411 2 O-Ring

1.4 269-1516 1 Draw Tube

1.5 269-1515 1 Level Indicator Tube

2 S05-182 1 Eyewash Valve Assembly

2.1 107-371 2 Tethered Dust Cover

2.2 S08-336 1 Handle/Label Assembly

2.3 110-215 1 Nut

2.4 153-372R 1 Adapter

114-051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Datum

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

P.O. Box 309, Menomonee Falls, WI 53051

Signed

Unterschrift

Signe

8

7

R

6

Date Signed

Date

Signed

Date

Signed

2

Item Part No. Qty. Description

2.5 142-002DA 1 Lockwasher

2.6 169-043 1 Plug (do not save)

3 153-451 1 Adapter

4 169-786 1 Pressure Gauge

5 S27-320 1 Tank Valve Assembly

6 204-421 1 Emergency Inspection Tag

7 114-051 1 Safety Sign

8 S89-002 1 3/8" Yellow Tube

9 S39-817 1 Hose Spray

9.1 S27-332 1 Valve, Hose Spray

9.2 128-182 1 Handle

9.3 S45-2453 1 Service Kit EFW - Black

9.4 S53-063 1 Tethered Dust Cover

Sprayheads

S45-2410 includes Items 1.21, 1.3

6

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 7

Installation S19-690, S19-690LHS

Assembly of Components and Parts List - S19-690LHS

1.3, 1.5

1.2, 1.21

1.1

2.1

2.3

2

4

3

5

1.22

1.3, 1.4

2.4

2.5

2.2

2.6

1

6

7

Item Part No. Qty. Description

1 S39-785 1 Tank, 10-Gallon

1.1 204-641 1 Operating Instr. Label, English

204-641FC 1 Operating Instr. Label, French

204-641M 1 Operating Instr. Label, Spanish

1.2 S44-024 1 Lid Assembly

1.21 269-1410 1 Gasket

1.22 269-1642 1 Relief Valve

1.3 269-1411 2 O-Ring

1.4 269-1516 1 Draw Tube

1.5 269-1515 1 Level Indicator Tube

2 S05-182 1 Eyewash Valve Assembly

Item Part No. Qty. Description

2.1 107-371 2 Tethered Dust Cover

2.2 S08-336 1 Handle/Label Assembly

2.3 110-215 1 Nut

2.4 153-372R 1 Adapter

2.5 142-002DA 1 Lockwasher

2.6 169-043 1 Pipe Plug, 3/8"

3 153-451 1 Adapter

4 169-786 1 Pressure Gauge

5 S27-320 1 Tank Valve Assembly

6 114-051 1 Safety Sign

7 204-421 1 Emergency Inspection Tag

S45-2410 includes Items 1.21, 1.3

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

7

Page 8

S19-690, S19-690LHS Installation

IMPORTANT

Installation

P.O. Box 309, Menomonee F

UNIT EACH

TEST THIS

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

durch Untersc

60˚ F

Lire ce manuel d’installation dans son intégralité pour garantir une installation appropriée.

Une fois celle-ci terminée, classer ce manuel auprès du service à la clientèle ou d’entretien.

L’installateur est responsable de la conformité de l’installation aux codes pour des drain et

codes et règlements en vigueur.

Packing List

•

•

•

THIS

SIDE

•

UP

R

WI 53051

alls,

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

Signed

e chose qui ne v

Signed

Date Signed

y malfunctions immediatel

hentlich im

hrift. Jeglic

Date

Date

t immédiatement.

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en manque

aucune avant de jeter l’emballage. Ne commencez pas l’assemblage avant de recevoir les

pièces manquantes.

Inspectez et testez cet équipement une fois par semaine pour en assurer le bon

fonctionement. Notez les dates d’inspection. Ce matériel doit être inspecté une fois par an

pour assurer sa conformité à la norme ANSI Z358.1.

Les ouvriers susceptibles d’entrer en contact avec des matières potentiellement

dangereuses doivent recevoir une formation sur la mise en place et le bon fonctionnement

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

du matériel d’urgence conformément à la norme ANSI Z358.1.

Pour toute question concernant le fonctionnement ou l’installation de ce produit, consulter le

site www.bradleycorp.com ou appeler le 1-800-BRADLEY.

Les garanties de produits figurent sous la rubrique « Informations techniques » sur notre

site Internet à www.bradleycorp.com.

100˚ F

Cet appareil doit être utilisé avec de l’eau potable tiède telle que définie par la norme

ANSI Z358.1. (Remarque : éviter l’exposition prolongée à des sources de chaleur ambiante

supérieures à 38 °C ou inférieures à 16°C).

Le levage de l’appareil autrement que par les poignées prévues peut endommager l’appareil.

AVIS ! Éviter les nettoyants qui contiennent des solvants organiques, de l’alcool et de l’hydrocarbure.

Rincer avec de l’eau après le nettoyage.

Equipements nécessaires :

• Enduit d’étanchéité pour tuyau

• Compresseur ou alimentation en air comprimé pur tolère jusqu’à 100 livres par pouce carré (psi) de pression

• Quincaillerie pour l’installation de l’enseigne

• Clé à molette

8

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 9

Installation S19-690, S19-690LHS

Dimensions

6"

(152mm)

34"

(864mm)

24³⁄₈"

(619mm)

12¼"

(311mm)

1

Installation de la douche oculaire

Enlevez le bouchon de la bas de l’assemblage de

cadre de douche oculaire (ne gardent pas).

Tuyau de lavage pour le modèle S19-690 seulement.

Ne pas fixer l’érogateur la douche oculaire/visage.

26"

(660mm)

Tête de douche corporelle

Monter le manomètre à

l’adaptateur avec un enduit

d’étanchéité pour tuyau (à fournir),

C

côté pression du réservoir.

AVIS : Lors de la pose le manomètre

et de la douchette, maintenir la

adaptateur (pièce 3) avec une clé

pour éviter d’arracher les filets. Une

mauvaise utilisation peut occasionner

des dommages au joint d’étanchéité

et causer des fuites. Couple maximum

150 in-lbs.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

Monter la douche oculaire sur

l’orifice de sortie du réservoir.

A

Couple maximum 150 in-lbs.

Raccorder le tuyau en utilisant une

pâte d’étanchéité adaptée (par

l’installateur). Ne pas utiliser de

B

ruban d’étanchéité.

9

Page 10

S19-690, S19-690LHS Installation

2

Remplissage du réservoir

Remplissage et mise sous pression du réservoir

ATTENTION ! NE PAS ouvrir le couvercle tant que le manomètre n’indique pas «0».

1. Pour ouvrir le réservoir, tirer sur la poignée au sommet du couvercle à verrouillage instantané. Enfoncer le couvercle,

le tourner et le retirer. Vérifier que l’intérieur du réservoir est propre. Remplir le réservoir de 30.3 litres (8 gallons) d’eau

potable tiède.

2. Remettre le couvercle en place et l’attacher en tirant le couvercle vers le haut et la poignée vers le bas.

3. Après avoir rempli le réservoir d’eau tiède et avant de mettre l’appareil sous pression, ouvrir complètement la vanne

d’activation et retirer les cache-poussière des têtes de douche oculaire.

4. Sous le manomètre se trouve une valve d’air. Retirer le capuchon protecteur et mettre progressivement l’appareil sous

pression par l’application d’air comprimé à travers la valve. Dès que l’eau commence à sortir par les têtes de douche

oculaire, fermer complètement la manette d’activation. Poursuivre la pressurisation du réservoir jusqu’à 90 livres/po2 et

remettre le capuchon protecteur en place sur la valve.

Si s’agit de la mise en service initiale de l’appareil ou si l’appareil a été non rempli et/ou hors pression pendant une durée

prolongée, le système doit être purgé comme indiqué ci-dessous.

Avant de mettre l’appareil en service, le laisser au repos pendant une heure. S’il se produit une chute de pression notable,

le remettre sous pression et attendre une heure supplémentaire. Si l’appareil continue de présenter une perte de pression,

NE PAS le mettre en service et de consulter le guide de dépannage à la page 11 de ce manuel.

ATTENTION ! La soupape de sécurité est conçue pour s’ouvrir automatiquement sous 100 à 130 livres/po

une surpression du réservoir. Si le manomètre indique plus de 130 livres/po

soupape à la main en tirant sur la bague de soupape jusqu’à afficher une pression nulle. Mettre l’appareil

hors service et voir les mesures de correction du problème dans le guide de dépannage à la page 11 de

ce manuel. Ne remettre l’appareil en service que si le problème de surpression est corrigé.

2

, ouvrir immédiatement la

2

afin d’éviter

Vidanger le réservoir

1. Vérifier que l’appareil a été assemblé, rempli et mis sous pression conformément aux étapes 1 et 2 ci-dessus (s’il s’agit de

la mise en service initiale de l’appareil, la tête de douche corporelle n’est pas encore raccordée à la vanne d’activation de

la douche d’urgence).

2. Laisser l’eau s’écouler par la douche oculaire et le tuyau de lavage (le cas échéant) pendant au moins cinq minutes pour

purger le système.

3. Purger tout le liquide restant dans le réservoir.

4. Fixer la douche oculaire/visage à érogateur (S19-690).

5. Remplir le réservoir et mettre sous pression, tel qu’expliqué à l’étape 2 ci-dessus.

10

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 11

Installation S19-690, S19-690LHS

Entretien

AVERTISSEMENT ! Suivre les instructions d’utilisation de l’agent de conservation de l’eau fournies avec ce produit.

Inspection de la douche oculaire

1. Examinez visuellement l’manomètre pour assurer l’unité met à jour la pression appropriée. Si l’unité ne fonctionne

pas correctement, retirez-la de la zone de risque immédiatement et référez-vous aux instructions de dépannage. Pour

davantage d’aide, contactez Bradley Corporation.

Nettoyage de la douche oculaire

En utilisant l’eau potable seulement :

1. Videz le réservoir n’importe quand de une fois par semaine à une fois par mois selon la qualité de votre approvisionnement

en eau. Le constructeur n’est pas responsable des variations de l’approvisionnement en eau.

2. Nettoyez l’intérieur du réservoir en utilisant l’eau chaude et un produit doux de savon. Rincez le réservoir complètement

avec de l’eau chaud.

3. Refaire le plein du réservoir de douche oculaire avec de l’eau potable tiède.

En utilisant l’eau potable et le préservatif de l’eau (recommandés) :

1. Nettoyez l’intérieur du réservoir en utilisant l’eau chaude et un produit doux de savon. Rincez le réservoir complètement

avec de l’eau chaud.

2. Refaire le plein du réservoir de douche oculaire avec de l’eau potable tiède. Suivre les instructions d’utilisation de l’agent de

conservation de l’eau fournies avec ce produit.

Dépannage

1. Si la valve de sécurité s’actionne avant que la pression requise ne soit atteinte, effectuer ce qui suit (lorsque non

pressurisé) :

• Bien serrer la valve dans le couvercle en tournant la partie grise hexagonale de la valve de sécurité dans le sens des

aiguilles d’une montre. Ne pas utiliser une clé.

• Tirer sur l’anneau de la valve de sécurité et s’assurer que l’anneau n’empêche pas la fermeture complète de la valve.

Pousser sur la cheville au centre de la valve de sécurité afin de vous assurer que celle-ci est complètement fermée.

Remettre le réservoir sous pression jusqu’au niveau requis. Cette opération pourrait devoir être accomplie plusieurs

fois pour permettre un siège complet de la valve.

2. Si, avec le temps, le réservoir pressurisé perd sa pression, vérifier les raccordements à l’aide de savon à vaisselle dilué

dans de l’eau ou de savon à bulle afin de déterminer l’emplacement de la fuite. Resserrer légèrement les raccordements et

tester à nouveau.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

11

Page 12

S19-690, S19-690LHS Installation

Assemblage des composantes/Liste des pièces - S19-690

9.4

9.3

9

2.1

9.1

9.2

2.3

1.3, 1.5

1.2, 1.21

4

3

5

1.22

1.1

1.3, 1.4

2.5

2.2

2.4

2.6

1

Pièce Réf. Qté. Description

1 S39-785 1 Réservoir, 10 gallons

1.1 204-641 1 Étiquette, d’utilisation, anglais

204-641FC 1 Étiquette, d’utilisation, français

204-641M 1 Étiquette, d’utilisation, espagnol

1.2 S44-024 1 Couverture

1.21 269-1410 1 Joint

1.22 269-1642 1 Soupape de sécurité

1.3 269-1411 2 Bague

1.4 269-1516 1 Tube d’aspiration

1.5 269-1515 1 Tube de niveau

2 S05-182 1 Valve de douche oculaire

2.1 107-371 2 Cache-poussière ancré

2.2 S08-336 1 Manette

2.3 110-215 1 Écrou

2.4 153-372R 1 Adaptateur

114-051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Datum

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

P.O. Box 309, Menomonee Falls, WI 53051

Signed

Unterschrift

Signe

8

7

R

6

Date Signed

Date

Signed

Date

Signed

2

Pièce Réf. Qté. Description

2.5 142-002DA 1 Rondelle de blocage

2.6 169-043 1 Bouchon (ne gardent pas)

3 153-451 1 Adaptateur

4 169-786 1 Manomètre

5 S27-320 1 Valve de Réservoir

6 204-421 1 Etiquette d’urgence

7 114-051 1 Enseigne de sécurité

8 S89-002 1 Tuyau jaune 3/8"

9 S39-817 1 Douchette

9.1 S27-332 1 Robinet

9.2 128-182 1 Manette

9.3 S45-2453 1 Trousse d’entretien EFW -

9.4 S53-063 1 Cache-poussière ancré

Diffuseurs noirs

Paquet S45-2410 comprend les éléments 1.21, 1.3

12

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 13

Installation S19-690, S19-690LHS

Assemblage des composantes/Liste des pièces - S19-690LHS

1.3, 1.5

1.2, 1.21

1.1

2.1

2.3

2

4

3

5

1.22

1.3, 1.4

2.4

2.5

2.2

2.6

1

6

7

Pièce Réf. Qté. Description

1 S39-785 1 Réservoir, 10 gallons

1.1 204-641 1 Étiquette, d’utilisation, anglais

204-641FC 1 Étiquette, d’utilisation, français

204-641M 1 Étiquette, d’utilisation, espagnol

1.2 S44-024 1 Couverture

1.21 269-1410 1 Joint

1.22 269-1642 1 Soupape de sécurité

1.3 269-1411 2 Bague

1.4 269-1516 1 Tube d’aspiration

1.5 269-1515 1 Tube de niveau

2 S05-182 1 Valve de douche oculaire

Pièce Réf. Qté. Description

2.1 107-371 2 Cache-poussière ancré

2.2 S08-336 1 Manette

2.3 110-215 1 Écrou

2.4 153-372R 1 Adaptateur

2.5 142-002DA 1 Rondelle de blocage

2.6 169-043 1 Bouchon, 3/8"

3 153-451 1 Adaptateur

4 169-786 1 Manomètre

5 S27-320 1 Valve de Réservoir

6 114-051 1 Enseigne de sécurité

7 204-421 1 Etiquette d’urgence

Paquet S45-2410 comprend les éléments 1.21, 1.3

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

13

Page 14

S19-690, S19-690LHS Installation

IMPORTANTE

60˚ F

P.O. Box 309, Menomonee F

TEST THIS

DIESES GERÄT 1ST

Installation

R

WI 53051

alls,

PRÜFEN.

y.

HENTLICH ZU

WEEK

WÖC

DAIRE

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

hrift. Jeglic

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Signed

Test le fonctionnement des v

Unterschrift

signe en bas. S'il y à quelqu

Signe

un rappor

Date

Datum

Date

114-051

below.

bestätigt

t melden.

e chose qui ne v

Date Signed

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

THIS

SIDE

UP

a pas fait

Signed

Date

Date

TEL: 1-800-BRADLEY FAX: (262-251-5817)

Lea en su totalidad este manual de instalación para garantizar una instalación adecuada.

Una vez que termine la instalación, entregue este manual al propietario o al Departamento

de Mantenimiento. Es responsabilidad de quien instale el equipo cumplir con los códigos

para desagüe y otra códigos y ordenanzas locales.

Packing List

•

•

•

•

Separar todas las piezas del material de embalaje y asegurarse que todas las piezas estén

incluídas antes de desechar cualquier material de embalaje. Si faltase alguna pieza, no

intentar instalar la unidad combinada Bradley hasta obtener las piezas faltantes.

Este equipo se debe inspeccionar, probar y anotar semanalmente para mantener un

Signed

funcionamiento adecuado. Se debe revisar este equipo anualmente para asegurarse de que

cumpla con la norma ANSI Z358.1.

Los trabajadores que puedan tener contacto con materiales potencialmente peligrosos

deben recibir capacitación sobre la ubicación y operación adecuada de los equipos de

http://www.bradleycorp.com

emergencia en conformidad con la norma ANSI Z358.1.

Para consultas sobre la operación o instalación de este producto, visite www.bradleycorp.

com o llame al 1-800-BRADLEY.

Las garantías del producto se pueden encontrar e n “Información del producto” o en nuestro

sitio Web, www.bradleycorp.com.

100˚ F

Esta unidad se debe utilizar con agua potable tibia, como conforme a la norma ANSI Z358.1

(Nota: evite la exposición prolongada a fuentes de calor ambiental por sobre los 38 ºC [100

ºF] y bajo los 16º C [60 ºF]).

No levantar la unidad con las manillas que se proporcionan puede dañar la unidad.

¡AVISO! Evite los limpiadores que contengan solventes orgánicos, alcoholes e hidrocarburos.

Enjuague con agua después de limpiar.

Materiales necesarios:

• Compuesto sellador para tubos

• Equipo o suministro de presión de aire limpio capaz de hasta 100 psi

• Tornillería para montar el letrero de seguridad

• Llave ajustable

14

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 15

Installation S19-690, S19-690LHS

Dimensiones

6"

(152mm)

34"

(864mm)

24³⁄₈"

(619mm)

(311mm)

1

Instalación del lavaojos

Quite el tapón de la parte inferior del conjunto de

la horquilla del lavaojos (no guardan).

Rociador de manguera solo para modelo S19-690.

No conecte el cabezal del lavaojos/lavarostros.

26"

(660mm)

12¼"

Cabezal de rociado

para lavado corporal

Adjuntar el manómetro al

adaptador en el lado de presión

del déposito con un sellador

C

para tubos (suministrado por el

instalador).

AVISO: Al montar el manómetro y la

manguera de aspersión a la salida

del depósito, sujetar los adaptador

(artículo 3) con una llave de tuercas

para evitar daño a las roscas. De otra

forma, puede usted dañar el sello y

provocar fugas. Esfuerzo de torsión

máximo 150 in-lbs.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

Montar el conjunto de la horquilla

del lavaojos al tanque. Esfuerzo de

A

torsión máximo 150 in-lbs.

Conecte la manguera con un

sellador para tubos adecuado (que

proporciona el instalador). No use

B

cinta obturadora.

15

Page 16

S19-690, S19-690LHS Installation

2

Llenar el tanque

Llenar el tanque y presurizar

¡ATENCIÓN! NO abrir la cubierta hasta que el manómetro lea “0”.

1. Abrir el tanque jalando hacia arriba el asa metálica situada en la parte superior de la cubierta de bloqueo rápido. Empujar

hacia abajo, girar y retirar. Asegúrese de que el interior del recipiente esté limpio. Llene el recipiente con 30.3 litros (8

galones) de agua potable tibia.

2. Volver a colocar la cubierta y, para fijarla, jalar hacia arriba la cubierta y hacia abajo el asa metálica.

3. Después de llenar el tanque con agua tibia y antes de presurizar la unidad, abrir la válvula de activación hasta la posición

de abertura completa y quitar las cubiertas de los cabezales lavaojos.

4. Hay una válvula de aire debajo del manómetro. Quitar la cubierta protectora y comience a presurizar la unidad mediante la

aplicación de aire a presión a través de la válvula. Tan pronto como el agua comience a salir desde los cabezales lavaojos,

cerrar completamente la palanca de activación. Finalizar la presurización del tanque en 90 psi y volver a colocar la cubierta

protectora de las válvulas de aire.

Si este es el arranque inicial de la unidad o si la unidad ha permanecido vacía o sin presurización por un período de

tiempo prolongado, se debe purgar la unidad según el procedimiento que se indica a continuación.

Antes de poner la unidad en servicio, déjela reposar por una hora. Si hay una caída de presión evidente, vuelva a

presurizarla y déjela reposar por una hora más. Si la unidad sigue exhibiendo pérdida de presión, NO la ponga en servicio;

consulte la guía de Solución de problemas que se encuentra en la página 17 de este manual.

ATENCIÓN! La válvula de alivio está diseñada para ventilar automáticamente de 100 a 130 psi para evitar que el tanque

se sobrepresurice. Si en el manómetro se leen más de 130 psi, tire de la lengüeta de la válvula de alivio

para abrir manualmente y de inmediato la válvula de alivio de presión, hasta que la presión llegue a cero.

Ponga la unidad fuera de servicio y consulte la guía de solución de problemas que se encuentra en la

página 17 de este manual, para conocer los pasos para corregir el problema. Vuelva a poner la unidad en

servicio solo si se logra corregir el problema de exceso de presurización.

Vaciar el tanque

1. Asegúrese de que la unidad está montada, llena y presurizada según lo descrito en los pasos 1 y 2 mencionados

anteriormente (si este es el arranque inicial de la unidad, el cabezal de rociado para lavado corporal no estará conectado

en ese momento a la válvula de activación de la manguera).

2. Para purgar el sistema, descargue el agua a través del lavaojos y del rociador de la manguera (si se proporciona con la

unidad) durante, al menos, cinco minutos.

3. Purgue todo el líquido restante del tanque.

4. Conectar el cabezal del lavaojos/lavarostros (S19-690).

5. Volver a llenar el depósito y presurizarlo siguiendo el Paso 2.

16

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 17

Installation S19-690, S19-690LHS

Mantenimiento

¡ADVERTENCIA! Para darle el uso adecuado al conservante de agua, siga las instrucciones del fabricante del producto.

Inspección de la unidad lavadora de ojos

1. Examine visualmente el manometro para asegurar la unidad está manteniendo la presión apropiada. Si la unidad no está

trabajando correctamente, quítela de la zona de peligro inmediatamente y refiera a las instrucciones de la localización de

resolución de problemas. Para la ayuda adicional, entre en contacto con al Bradley Corporation.

Limpieza de la unidad lavadora de ojos

Al usar el agua potable solamente:

1. Vacie el tanque en caulquier momento de una vez por semana a una vez por mes dependiendo de la calidad de su

abastecimiento de agua. El fabricante no es responsable de variaciones en el abastecimiento de agua.

2. Limpie el interior del tanque usando el agua caliente y un producto suave del jabón. Aclare el tanque a conciencia con

agua caliente.

3. Vuelva a llenar el tanque lavaojos con agua potable tibia.

Al usar el agua potable y el preservativo del agua (recomendados):

1. Limpie el interior del tanque usando el agua caliente y un producto suave del jabón. Aclare el tanque a conciencia con agua caliente.

2. Vuelva a llenar el tanque lavaojos con agua potable tibia. Para darle el uso adecuado al conservante de agua, siga las instrucciones

del fabricante del producto.

Resolución de Problemas

1. Si la válvula de descarga de la presión se descarga antes de alcanzar la presión requerida, haga lo siguiente (cuando no

haya presión):

• Ajuste la válvula perfectamente dentro de la tapa, girando hacia la derecha la parte gris hexagonal de la válvula de

descarga. No use una llave de tuercas.

• Tire del anillo de la válvula de descarga y asegúrese de que el anillo no impida que la válvula se cierre por

completo. Empuje el seguro que se encuentra en el centro de la válvula de descarga para asegurarse de que esté

completamente cerrada. Vuelva a presurizar el tanque a la presión requerida. Quizás tenga que hacer esto varias

veces para que la válvula se asiente perfectamente.

2. Si el tanque presurizado pierde presión con el tiempo, revise las conexiones con una solución de jabón para platos o con

burbujas para niños para identificar la ubicación de la fuga. Apriete un poco más las conexiones y pruebe otra vez.

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

17

Page 18

S19-690, S19-690LHS Installation

Montaje de los componentes/Lista de piezas - S19-690

9.4

9.3

9

2.1

9.1

9.2

2.3

1.3, 1.5

1.2, 1.21

4

3

5

1.22

1.1

1.3, 1.4

2.5

2.2

2.4

2.6

1

Art. No. de pza Ctd. Descripción

1 S39-785 1 Deposito, 10-galones

1.1 204-641 1 Etiqueta de instrucciones,

204-641FC 1 Etiqueta de instrucciones,

204-641M 1 Etiqueta de instrucciones,

1.2 S44-024 1 Conjunto del cubierto

1.21 269-1410 1 Junta

1.22 269-1642 1 Válvula de seguridad

1.3 269-1411 2 Arosello

1.4 269-1516 1 Tubo del drenaje

1.5 269-1515 1 Tubo del indicator

2 S05-182 1 Válvula del Lavaojos

2.1 107-371 2 Cubiertas contra el polvo con

2.2 S08-336 1 Manija

2.3 110-215 1 Tuerca

inglés

francés

español

ligaduras

114-051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Datum

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

P.O. Box 309, Menomonee Falls, WI 53051

Signed

Unterschrift

Signe

8

7

R

6

Date Signed

Date

Signed

Date

Signed

2

Art. No. de pza Ctd. Descripción

2.4 153-372R 1 Adaptador

2.5 142-002DA 1 Arandela de seguridad

2.6 169-043 1 Tapón (no guardan)

3 153-451 1 Adaptador

4 169-786 1 Manometro

5 S27-320 1 Válvula del deposito

6 204-421 1 Etiqueta de inspeccion

7 114-051 1 Letrero de seguridad

8 S89-002 1 Tubo Amarillo 3/8"

9 S39-817 1 Manguera de aspersion

9.1 S27-332 1 Conjunto de válvula

9.2 128-182 1 Manija

9.3 S45-2453 1 Kit de mantenimiento para

9.4 S53-063 1 Cubiertas contra el polvo con

lavado de ojos y cara: Boquillas

rociadoras negras

ligaduras

Paquete S45-2410 incluye art. 1.21, 1.3

18

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Page 19

Installation S19-690, S19-690LHS

Montaje de los componentes/Lista de piezas - S19-690LHS

1.3, 1.5

1.2, 1.21

1.1

2.1

2.3

2

4

3

5

1.22

1.3, 1.4

2.4

2.5

2.2

2.6

1

6

7

Art. No. de pza Ctd. Descripción

1 S39-785 1 Deposito, 10-galones

1.1 204-641 1 Etiqueta de instrucciones,

inglés

204-641FC 1 Etiqueta de instrucciones,

francés

204-641M 1 Etiqueta de instrucciones,

español

1.2 S44-024 1 Conjunto del cubierto

1.21 269-1410 1 Junta

1.22 269-1642 1 Válvula de seguridad

1.3 269-1411 2 Arosello

1.4 269-1516 1 Tubo del drenaje

1.5 269-1515 1 Tubo del indicator

2 S05-182 1 Válvula del Lavaojos

Paquete S45-2410 incluye art. 1.21, 1.3

Art. No. de pza Ctd. Descripción

2.1 107-371 2 Cubiertas contra el polvo con

ligaduras

2.2 S08-336 1 Manija

2.3 110-215 1 Tuerca

2.4 153-372R 1 Adaptador

2.5 142-002DA 1 Arandela de seguridad

2.6 169-043 1 Tapón (no guardan)

3 153-451 1 Adaptador

4 169-786 1 Manometro

5 S27-320 1 Válvula del deposito

6 114-051 1 Letrero de seguridad

7 204-421 1 Etiqueta de inspeccion

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

19

Loading...

Loading...