Bradley Corporation S19-320EXP120, S19-320EXP220 Installation Manual

Installation

DISCONTINUED

Installation

S19-320EXP120

S19-320EXP220

Flow Switch Alarm System, Class I,

Division 2, Groups B, C and D ExplosionProof

Système d'alarme du commutateur de débit,

Classe I, Division 2, Antidéflagrants groupes

B, C et D

Sistema de alarma del interruptor de flujo,

Clase I, Divisi

prueba de explosiones

120V y 220/240V)

(includes 120V and 220/240V versions)

(inclut les versions 120V et 220/240V)

ó

n 2, Grupos B, C y D, a

(incluye las versiones de

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . . . . . .2

Flow Switch Alarm System Components . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Table des matières

Avant l’installation . . . . . . . . . . . . . . . . . . . . . . . . . .8

Eléments du système d’alarme . . . . . . . . . . . . . . . . .9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Contenido

Información previa a la instalación . . . . . . . . . . . . .14

Componentes del sistema de alarma . . . . . . . . . . . .15

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-18

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

215-1083 Rev. H; ECM 10-05-011B

© 2011 Bradley Corporation

Page 1 of 19 4/12/11

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

S19-320EXP120, S19-320EXP220 Installation

DISCONTINUED

IMPORTANT

Installation

R

WI 53051

alls,

HENTLICH ZU

WEEK

WÖC

P.O. Box 309, Menomonee F

DAIRE

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

TEST THIS

hrift. Jeglic

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Test le fonctionnement des v

signe en bas. S'il y à quelqu

un rappor

Date

Datum

Date

114-051

PRÜFEN.

Testbetrieb prüfen,

he Störung sofor

Signed

Unterschrift

below.

bestätigt

t melden.

y.

alves chaque semaine et

e chose qui ne v

Date Signed

Signe

THIS

SIDE

UP

a pas fait

Signed

Signed

Date

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

Read this installation manual completely to ensure proper installation, then file it

with the owner or maintenance department. Compliance and conformity to drain

requirements and other local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before

Packing List

•

•

•

discarding any packaging material. If any parts are missing, do not begin installation

•

until you obtain the missing parts.

Flush the water supply lines before beginning installation and after installation is

complete. Test the unit for leaks and adequate water flow. Main water supply to the

eyewash should be “ON” at all times. Provisions shall be made to prevent unauthorized

shutoff.

The ANSI Z358.1 standard requires an uninterruptible supply of flushing fluid at a

minimum 30 PSI (0.21 MPa) flowing pressure. Flushing fluid should be tepid per ANSI

Z358.1.

The inspection and testing results of this equipment should be recorded weekly to verify

proper operation. This equipment should be inspected annually to ensure compliance

with ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be

trained regarding the placement and proper operation of emergency equipment per ANSI

Z358.1.

For questions regarding the operation or installation of this product, visit www.

bradleycorp.com or call 1-800-BRADLEY.

Product warranties and parts information may also be found under ”Products” on our

web site at www.bradleycorp.com.

2

4/12/11 Bradley Corporation • 215-1083 Rev. H; ECM 10-05-011B

Installation S19-320EXP120, S19-320EXP220

DISCONTINUED

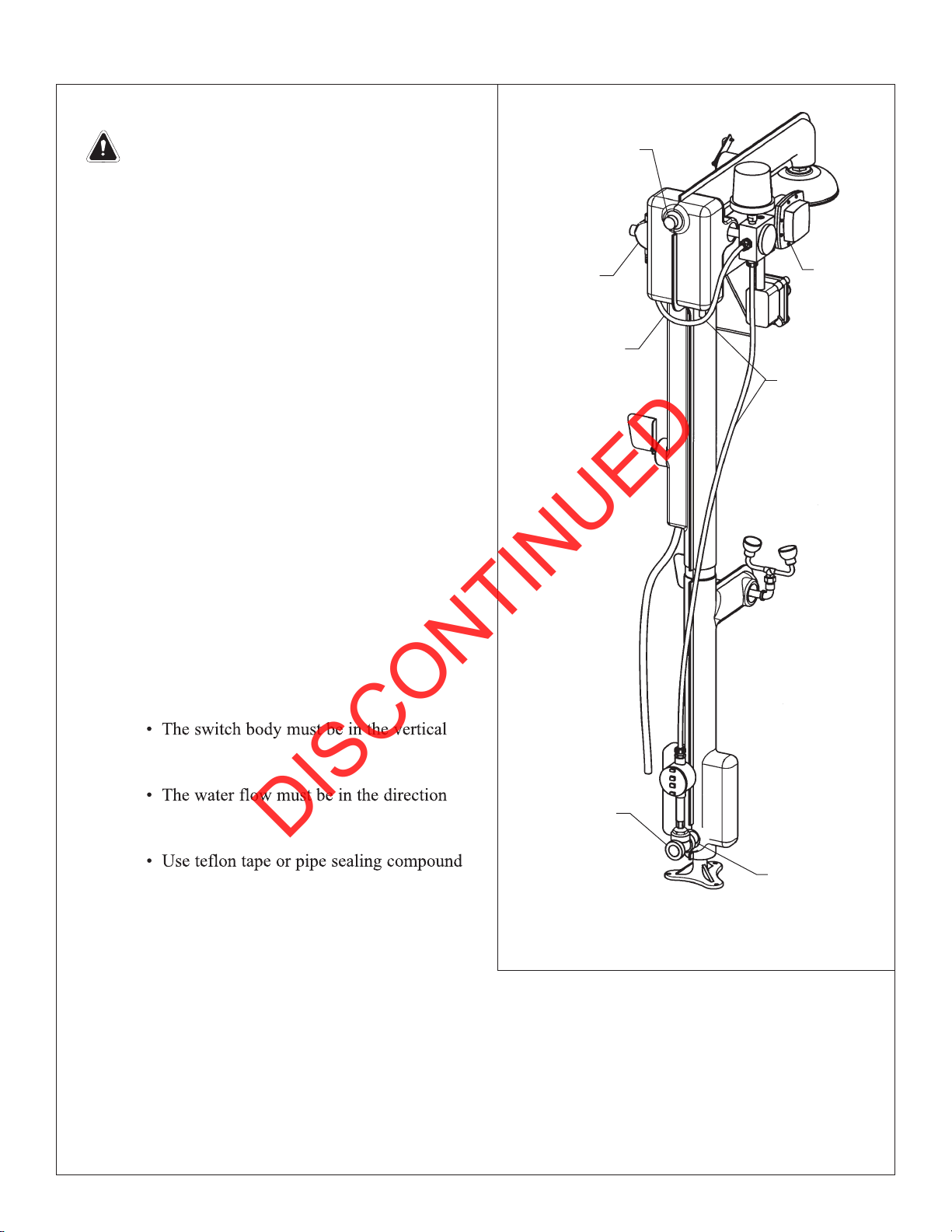

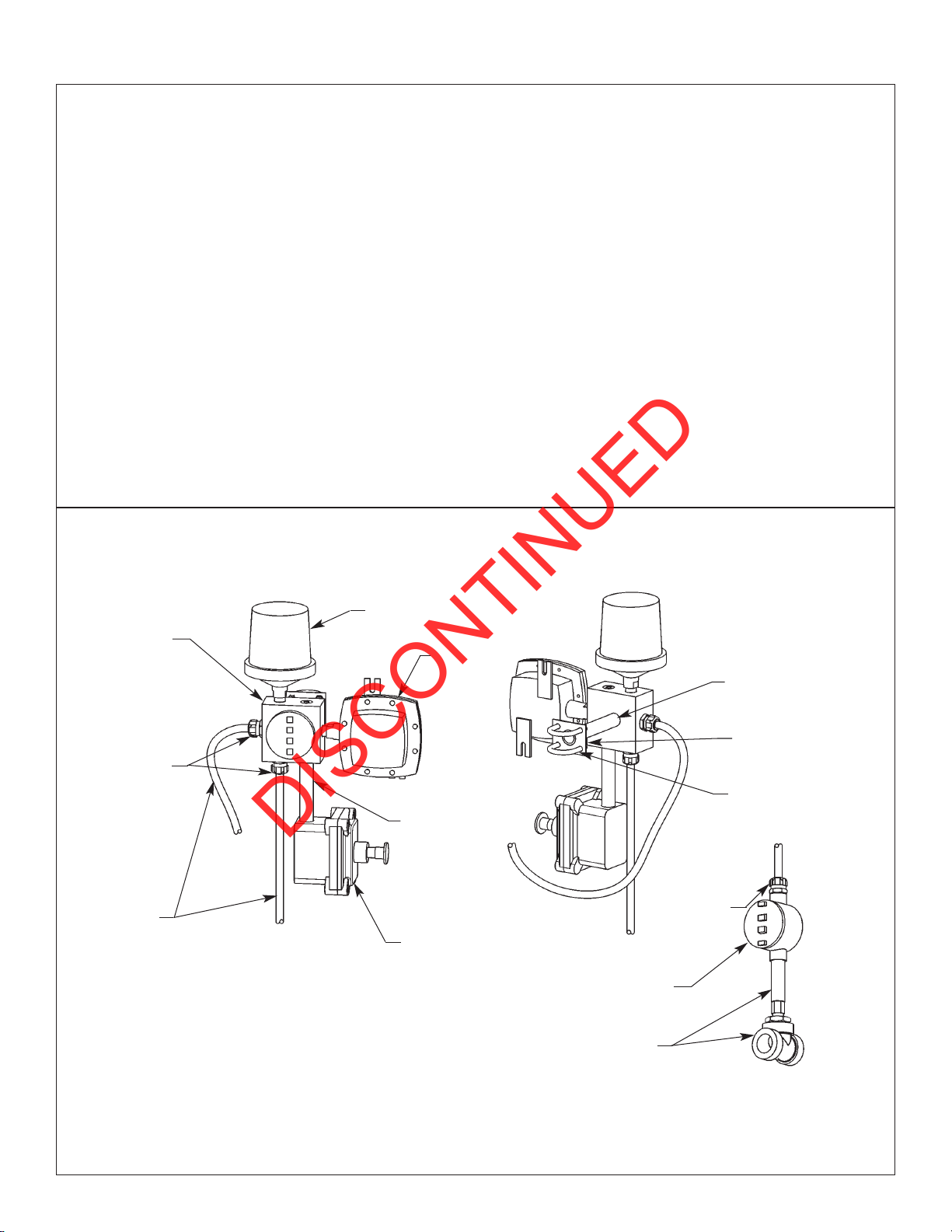

Assembly of Components and Parts List

NOTE: If the alarm system is ordered with the model S19-300T or S19-300B Heat Trace Shower and Eye

Wash, the mounting bracket will be attached to the unit.

STROBE LIGHT

269-1305 (120V)

269-1305A (220/240V)

JUNCTION

BOX

269-1314

CONDUIT

CONNECTOR

269-1308

TO POWER

SUPPLY

PIPE PLUG

269-1294

NIPPLE

269-1316

HORN

269-1306

NIPPLE

269-1342

MOUNTING BRACKET

ASSEMBLY

S70-156

U-BOLT (qty. 2)

269-587

NUT (qty. 4)

161-065

FLEXIBLE

CONDUIT

269-1588

TO FLOW

SWITCH

CUT-OUT

SWITCH BOX

269-1928

Parts not shown:

Supplies required for installation:

CONDUIT

CONNECTOR

269-1308

JUNCTION

BOX

269-1312

FLOW

SWITCH

269-1421

Bradley Corporation •

215-1083 Rev. H; ECM 10-05-011B 4/12/11

3

S19-320EXP120, S19-320EXP220 Installation

DISCONTINUED

Installation

IMPORTANT: Power should be supplied

to the alarm by no larger than a 15 amp

branch circuit with a dedicated circuit

breaker or fuse and should not supply

power to any other device. Compliance

and conformity to local codes and

ordinances is the responsibility of the

installer.

Step 1: Install the flow switch in the water

supply line

NOTE: Because the flow switch will attach to the

mounted alarm via a 7-foot waterproof cable, the

installer must keep the location for mounting the

alarm in mind when choosing the flow switch location (see Figure 1).

1. Choose a location for mounting the flow

switch in a horizontal run of the water supply

line. The inlet and outlet ports of the flow

switch must be a minimum of 6 inches from

any tees or elbows in the water supply line

(see Figure 1).

NOTE: If the water supply line will be exposed to

temperatures at or below freezing, the inlet supply

must be freeze-protected 6 inches above the flow

switch tee (freeze protection by others).

TOP SUPPLY

JUNCTION

BOX

120 VAC

POWER

SUPPLY

INLET

ALARM

SYSTEM

WATERPROOF

CABLE

2. Mount the flow switch assembly in the water

supply line.

position with the water pipe in the

horizontal position.

marked by the arrow on the flow switch

body.

(supplied by installer) on all water pipe

connections.

NOTE: The alarm system is designed to work properly even if both the eyewash and drench shower are

used simultaneously. The alarm will continue to

operate as long as either the eye wash or drench

shower is still in use.

FLOW

SWITCH

BOTTOM

SUPPLY

INLET

Figure 1

4

4/12/11 Bradley Corporation • 215-1083 Rev. H; ECM 10-05-011B

Installation S19-320EXP120, S19-320EXP220

DISCONTINUED

Installation

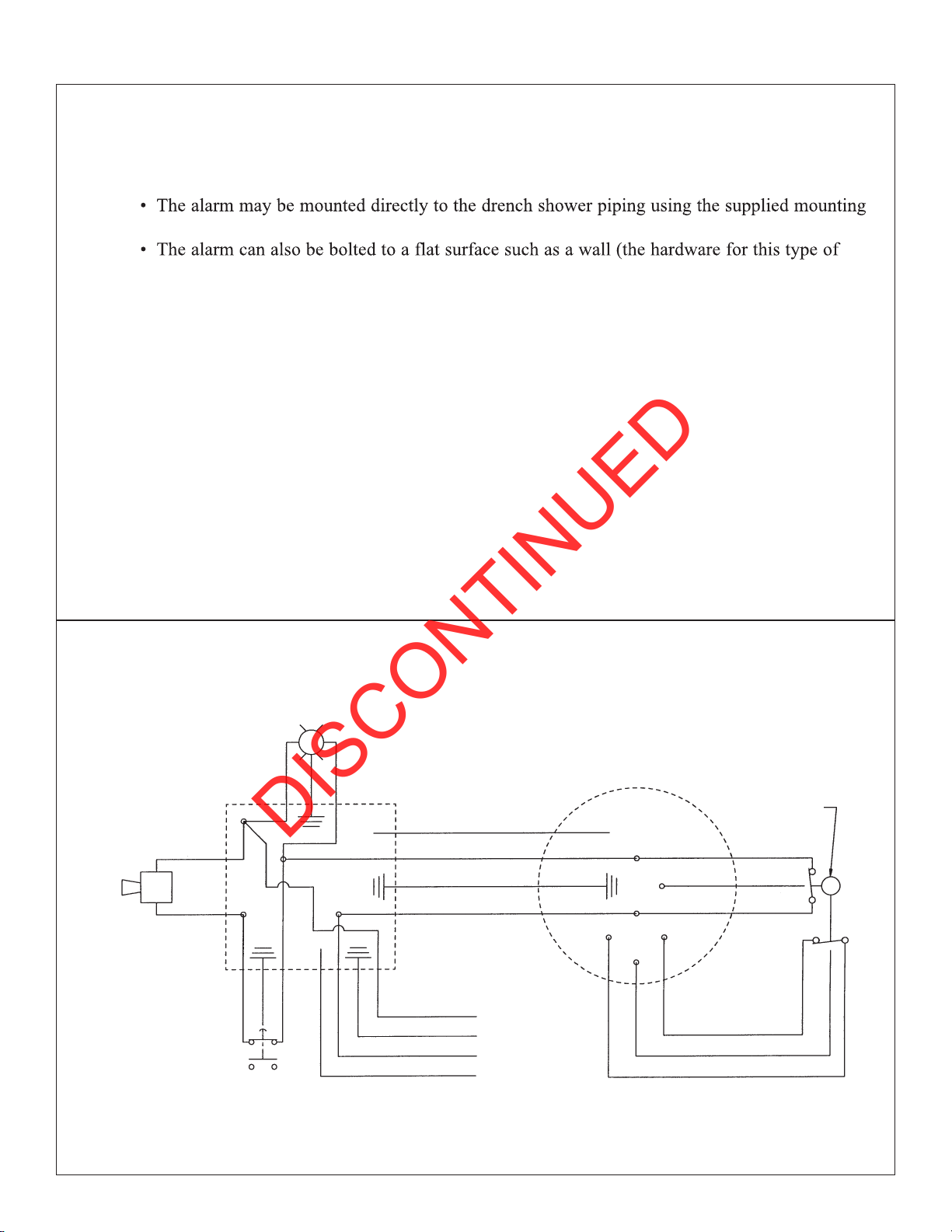

Step 2: Mount alarm assembly to unit

1. Choose a location for mounting the alarm assembly. The alarm should be mounted at least 7 feet

above ground level for best visibility.

hardware (see Figure 1 on page 4).

installation is NOT supplied).

Step 3: Make electrical connections—alarm to flow switch

1. Connect the flow switch to the alarm by installing a conduit connector to the end of the 7-foot

waterproof cable and into the flow switch junction box (see Figure 1 on page 4 and Figure 2

below).

NOTE: The cable may be cut to any length required.

NOTE: To prevent water condensation from dripping onto the flow switch, make sure the cable is not

taut.

NOTE: Refer to the instruction manual supplied with the conduit connector for assembly information.

Step 4: Complete electrical supply connections

1. Connect the alarm system to the power source using the shorter length of waterproof cable.

2. Follow the same procedure as in Step

3 for completing the electrical supply connection.

Figure 2

WHITE

BLACK

BLACK BLACK

WHITE

GREEN

PUSH BUTTON

ALARM LIGHT

GREEN

BLACK

RED (NOT USED)

BLUE

GREEN (GROUND)

BLACK

RED

GREEN

(GROUND)

BLACK

BLUE (NOT USED)

BLACK

POWER IN

RED

BLUE

BLUE

RED

BLACK

REMOTE

LOCATION

SENSING

FLOW

SWITCH

Bradley Corporation •

215-1083 Rev. H; ECM 10-05-011B 4/12/11

5

S19-320EXP120, S19-320EXP220 Installation

DISCONTINUED

Installation

Step 5: Test the alarm system

NOTE: Testing the alarm for the first time using the drench shower may expose the flow switch to an

unnecessary water hammer since the downstream piping may be empty of water. The flow switch is designed to

withstand such a water hammer, but using the smaller eye wash flow is recommended. Refer to Figure 3 when

testing the alarm system.

1. Apply power to the alarm branch circuit. The alarm should remain off.

2. Make sure the alarm horn cut-out switch is in the “ON” position (pull the button out).

3. Open the eye wash valve. The alarm should sound and the strobelight flash shortly after water flows

from the system.

4. Use the alarm horn cut-off switch to silence the horn. Pushing the button should shut off the horn but

allow the strobelight to keep flashing.

5. Shut off the eye wash flow valve. The strobelight should stop flashing.

6. Reset the alarm horn cut-out switch by pulling the button out.

7. Repeat the tests in procedures 1-6 above, this time using the drench shower only.

JUNCTION

BOX

CONDUIT

CONNECTOR

FLEXIBLE

CONDUIT

TO POWER

SUPPLY

TO FLOW

SWITCH

STROBE LIGHT

HORN

NIPPLE

CUT-OUT

SWITCH BOX

NIPPLE

MOUNTING BRACKET

ASSEMBLY

U-BOLT (qty. 2)

NUT (qty. 4)

CONDUIT

CONNECTOR

JUNCTION

BOX

FLOW

SWITCH

Figure 3

6

4/12/11 Bradley Corporation • 215-1083 Rev. H; ECM 10-05-011B

Loading...

Loading...