Page 1

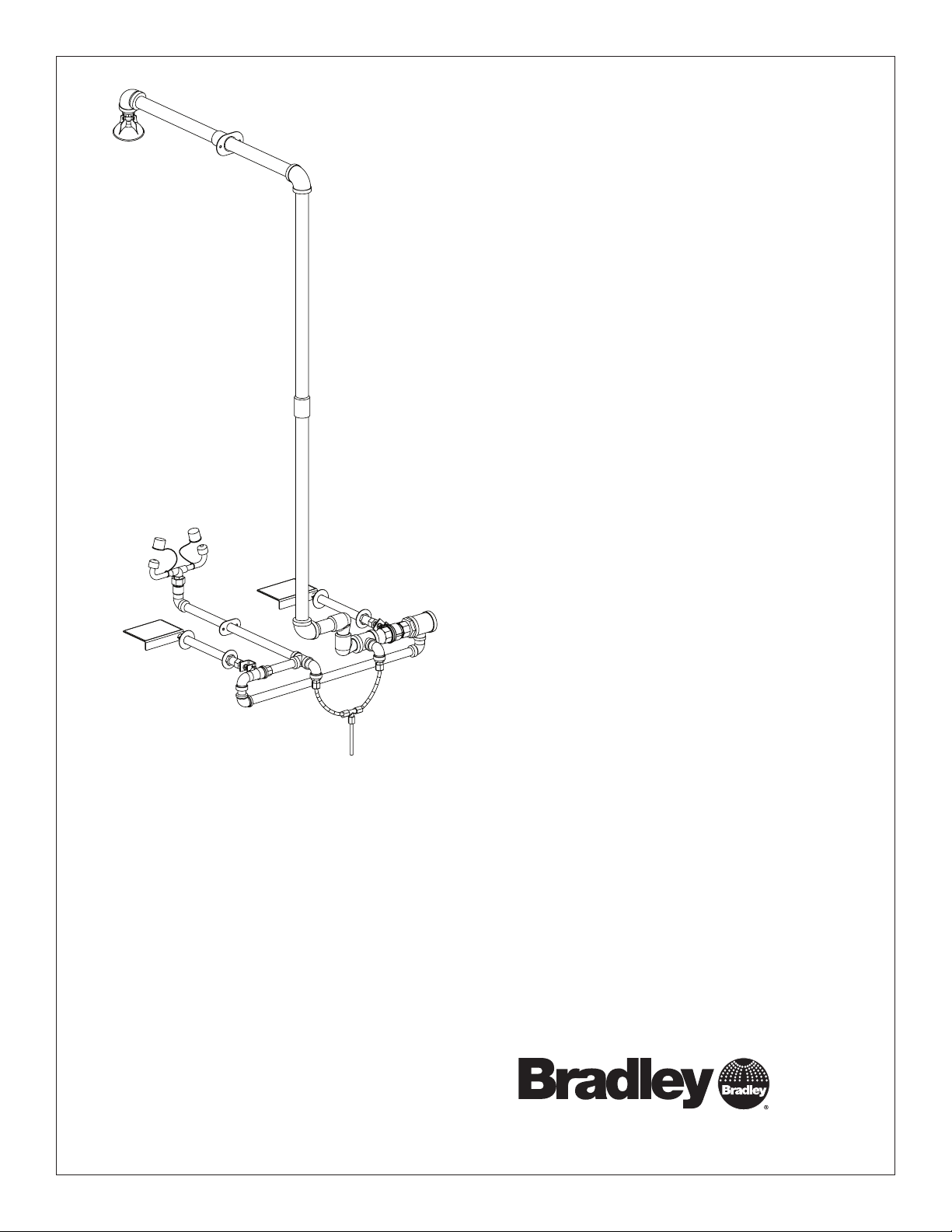

Installation

S19-310TW8

S19-310TW12

S19-310TW18

Frostproof Combination Drench

Shower and Eyewash

Table of Contents

Pre-Installation Information ..........................2

Dimensions ......................................3

Installation .......................................4

Assembly of Components ...........................5

Parts List ........................................6

215-1474 Rev. J; ECN 12-05-016G

© 2012 Bradley

Page 1 of 6 11/20/2012

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

Page 2

S19-310TW8, S19-310TW12, S19-310TW18 Installation

IMPORTANT

Installation

R

WI 53051

alls,

HENTLICH ZU

WEEK

WÖC

P.O. Box 309, Menomonee F

DAIRE

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

TEST THIS

hrift. Jeglic

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Test le fonctionnement des v

signe en bas. S'il y à quelqu

un rappor

Date

Datum

Date

114-051

PRÜFEN.

Testbetrieb prüfen,

he Störung sofor

Signed

Unterschrift

below.

bestätigt

t melden.

y.

alves chaque semaine et

e chose qui ne v

Date Signed

Signe

THIS

SIDE

UP

a pas fait

Signed

Signed

Date

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

Packing List

•

•

•

•

Read this installation manual completely to ensure proper installation, then file it with the

owner or maintenance department. Compliance and conformity to drain requirements and

other local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain the

missing parts.

Flush the water supply lines before beginning installation and after installation is complete.

Test the unit for leaks and adequate water flow. Main water supply to the eyewash should be

“ON” at all times. Provisions shall be made to prevent unauthorized shutoff.

The ANSI Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed

emergency fixtures require a minimum of 30 PSI (0.21 MPa) flowing pressure. Flushing fluid

should be tepid per ANSI Z358.1.

The inspection and testing results of this equipment should be recorded weekly to verify

proper operation. This equipment should be inspected annually to ensure compliance with

ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be trained

regarding the placement and proper operation of emergency equipment per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.

com or call 1-800-BRADLEY.

Product warranties and service parts information may also be found under ”Products” on our

web site at www.bradleycorp.com.

2

11/20/2012 Bradley • 215-1474 Rev. J; ECN 12-05-016G

Page 3

Installation S19-310TW8, S19-310TW12, S19-310TW18

S19-310TW Dimensions

Ø 3.1"

(78.7mm)

16"

(406mm)

53¼"

(1352mm)

3⁷⁄₈"

(98mm)

(dimension will

increase with

varying wall

thicknesses)

Wall Thickness Model No.

0"−8" S19-310TW8

8"−12" S19-310TW12

12"−18" S19-310TW18

Use valve sub-assembly (Item 15)

to mark and drill valve stem holes.

8"

(203mm)

1¼" NPT

Supply Inlet

12"

(305mm)

48¾"

(1238mm)

36"

(914mm)

to floor

5⁵⁄₈"

(143mm)

All dimensions assume standard thread

engagement. Variations in manufacturing

allow for +/- 1⁄8" (3mm) per threaded joint.

To find the tolerance of a dimension, add

the number of thread joints in between a

dimension and multiply it by 1⁄8" (3mm).

Bradley • 215-1474 Rev. J; ECN 12-05-016G 11/20/2012

3

Page 4

S19-310TW8, S19-310TW12, S19-310TW18 Installation

Installation

Supplies Required:

• Teflon tape and pipe sealant

• Piping to 1¼" NPT water supply inlet

• Adequate supply pipe supports

• Minimum 4" (102mm) drain to accommodate 30 gallons (115 liters) per minute discharge for drench

shower waste

• OPTIONAL: Sign-mounting hardware

Local codes may require the installation of a backflow prevention valve to complete proper installation.

Compliance with local codes is the responsibility of the installer. Valve must be tested annually to verify that

it is functioning properly. Backflow prevention valves are not included with the fixture and may be supplied by

the contractor or purchased from Bradley Corporation.

IMPORTANT! Do not rely on Bradley’s Combination Unit to support supply piping.

Step 1: Assemble drench shower and eyewash components

1. From the outside of the building, drill a 1" dia. hole in the wall 36" up from the ground floor for the eyewash

piping. Use the sub-assembly (Item 15) to measure, mark and drill two 1³⁄₈" dia. holes for the valve operating

stems.

This unit has been designed to accommodate varying wall thicknesses. When installing the operating stem

support sleeve (Item 27), make sure that a minimum 5⁄8" of threaded pipe protrudes from the wall.

2. Assemble the two valve stems as shown on page 5 and connect the stems to the assembly through the holes

in the wall.

3. Secure the assembly to the wall with adequate supports supplied by installer. Make sure that Item 14 is pitched

a minimum of ½" toward the building to allow for proper weep valve drainage.

4. Connect Items 4, 8, 9 and another Item 9 (as shown on page 5) and attach them to Item 15.2.

5. Mark and drill a 1³⁄₈" dia. hole for the shower pipe.

6. Assemble the rest of the unit as shown on page 5.

Step 2: Connect water supply

1. Connect water supply piping to the 1¼" NPT inlet (piping supplied by installer). Provide adequate supports

(supplied by installer) for supply pipe using pipe hangers or other means.

2. Run the drain’s ⁵⁄₁₆" tubing to an adequate drain containment.

3. Hang the safety sign from the unit with the curtain hooks provided (or mount it to the wall using sign-mounting

hardware by installer).

4

11/20/2012 Bradley • 215-1474 Rev. J; ECN 12-05-016G

Page 5

Installation S19-310TW8, S19-310TW12, S19-310TW18

Assembly of Components

8

3

1

4

5

7

NOTE: Use

teflon tape

only.

2

12

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

9

34

33

22

23

26.1

24

16

25

27

26

29

25

35

36

14

6

24

26.1

21

23

22

20

15.41

19

15.4

15.11

15.13

15.14

15.2

15.15

8

9

4

15.3

15.12

15.5

17

15.1

15.7

22

23

26.1

24

25

27

26

15.10

15.9

15.6

15.8

13

13

30

30

31

18

25

15.11

24

26.1

28

11

29

23

22

32

15.61

Bradley • 215-1474 Rev. J; ECN 12-05-016G 11/20/2012

5

Page 6

S19-310TW8, S19-310TW12, S19-310TW18 Installation

Parts List

Item Part No. Qty. Description

1 S24-188 1 Showerhead, Plastic

2 151-001 2 Hook

3 113-1107 1 Pipe, 1" NPT x 14"

4 169-1027 2 Coupling, 1" NPT

5 150-212 1 Escutcheon, Shower Pipe

6 150-213 1 Escutcheon, Eyewash Pipe

7 113-1108 1 Pipe, 1" NPT x 11½"

(S19-10TW8)

113-1109 1 Pipe, 1" NPT x 15½"

(S19-10TW12)

113-1110 1 Pipe, 1" NPT x 21½"

(S19-10TW18)

8 169-847 2 Elbow, 1" NPT

9 113-1112 2 Pipe, 1" NPT x 24"

11 140-720 1 Bracket, 1" Ball Valve Adapter

12 114-052 1 Safety Sign

13 S29-068 2 Weep Valve Assembly

14 113-1116 1 Pipe, ½" NPT x 18¾"

(S19-10TW8)

113-1117 1 Pipe, ½" NPT x 22¾"

(S19-10TW12)

113-1118 1 Pipe, ½" NPT x 28¾"

(S19-10TW18)

15 S08-369 1 Valve Sub-Assy, Eyewash/

Shower

15.1 169-723 2 1" Street Elbow 90°

15.2 169-847 1 Elbow, 1" NPT

15.3 113-1113 1 Pipe, 1" x 3"

15.4 S27-282 1 ½" Ball Valve with Nut

15.41 110-215 1 Nut (only)

15.5 169-838 1 Tee, ½" NPT

15.6 S27-278 1 1" Ball Valve with Nut

15.61 110-214 1 Nut (only)

15.7 169-840 1 Tee, 1" x 1" x ½"

15.8 113-935 2 Pipe, 1" NPT x 1½"

15.9 269-1721 1 Reduc’g Bushing, 1¼" x 1"

15.10 169-841 1 Tee, 1¼" x ½"

Item Part No. Qty. Description

15.11 169-025 2 90° Street Elbow ½" NPT

15.12 113-1114 1

15.13 113-1084 1 Pipe, ½" NPT x 1½"

15.14 169-839 1 Elbow ½" NPT

15.15 113-1115 1 Pipe, ½" NPT x 4¼"

16 S08-361 1 Handle, Eyewash

17 S08-360 1 Handle, Shower

18 269-1720 1

19 153-372R 1 Adapter, ½" Ball Valve

20 142-002DA 1

21 128-151 1 Adapter, ½" Ball Valve Handle

22 161-036 4

23 142-002BK 4

24 110-191 4 Nut, ½"-14 NPS Connector

25 142-002CB 4

26 S21-067 2 Rod, Operating (S19-310TW8)

S21-067A 2 Rod, Operating (S19-310TW12)

S21-067B 2 Rod, Operating (S19-310TW18)

26.1 132-042 4 Clip, Retaining

27 113-006NN 2 Sleeve, Operating Rod

113-006NR 2 Sleeve, Operating Rod

113-006NU 2 Sleeve, Operating Rod

28 128-164 1 Adapter, 1" Ball Valve Handle

29 110-115 2 Nut, ½" NSPM

30 269-881 2

31 R68-600015 4 ft.

32 142-002DC 1

33 S05-091 1 Eyewash Yoke

34 107-371 2 Tethered Dust Cover

35 S21-077 1 Stem

36 169-1069 1

Pipe, ½" NPT x 23¹⁷⁄₃₂"

Tee, ⁵⁄₁₆"Hose, Nylon Union

Lockwasher, ⁵⁄₁₆" Internal Tooth

Nut, Hex ⁵⁄₁₆"-18 Stn. Steel

Lockwasher, ⁵⁄₁₆" Stn. Steel

Washer, ⁷⁄₈" x 2" Stainless Steel

(S19-310TW8)

(S19-310TW12)

(S19-310TW18)

ElbowConnector, ¼" NPT, ⁵⁄₁₆"

Tube

Tube, ⁵⁄₁₆" Polyethylene

Lockwasher, ³⁄₈" Internal Tooth

Elbow, ½" x ³⁄₈"

6

11/20/2012 Bradley • 215-1474 Rev. J; ECN 12-05-016G

Loading...

Loading...