Page 1

SUPPLEMENT – VENTING INSTRUCTIONS FOR INSTALLATION AND OPERATING INSTRUCTION MANUALS

WARNING

The venting system must be properly installed. Failure to properly install the vent system could result in property

damage, personal injury, or death.

DO NOT install damaged venting system components. If damage is evident then please contact the supplier where

the water heater or venting system components were purchased for replacement parts.

Use only the vent terminals provided or factory authorized terminals for venting this water heater.

The water heater requires its own separate venting system. Do not connect the exhaust vent into an existing vent pipe

or chimney.

All of the exhaust venting connections must be leak checked with a soap solution upon initial start-up of the water

heater. Any leaks must be repaired before continuing operation of the water heater.

Do not terminate the venting where noise from the exhaust or intake will be objectionable. This includes locations

close to or across from windows and doors. Avoid anchoring the vent and intake pipes directly to framed walls, floors,

or ceilings unless rubber isolation pipe hangers are used. This prevents any vibrations from being transmitted into the

living spaces.

Do not exceed the venting distances or the number of elbows listed in the instruction manual supplied with the water

heater. Exceeding the maximum venting distances may cause the water heater to malfunction or cause an unsafe

condition.

DO NOT operate this water heater until the venting installation is complete and the piping completed. Failure to

complete installation before operation can result in property damage, personal injury, or death.

DO NOT install Duravent Polypro venting components with any other manufacturer’s vent components. Duravent

components must be used exclusively throughout the entire venting system from the water heater coupling or vent

connection to the outside wall or ceiling near the vent terminal location.

This supplement is intended only for additional information for installing Duravent Polypro single wall venting system

and the instruction manual supplied with the water heater must be followed for the detailed information provided for the

venting system installation.

238-48384-00, 238-44727-00, 238-44445-00, 238-48144-00, 238-47936-00, 238-45917-00, 238-45637-00,

238-47448-00, 238-48071-00, 238-49060-00, AND 238-47707-00 FOR HIGH EFFICIENCY CONDENSING

COMMERCIAL, COMMERCIAL POWER DIRECT VENT, COMMERCIAL POWER VENT, RESIDENTIAL POWER

DIRECT VENT, and RESIDENTIAL POWER VENT MODEL SERIES

INSTALLATION OF DURAVENT POLYPRO® SINGLE WALL POLYPROPYLENE VENTING SYSTEMS

This supplement is for the installation of polypropylene single wall venting system manufactured by M&G DuraVent, Inc.

The DuraVent Polypro venting system is a CSA approved alternative to the PVC, ABS, and CPVC venting components for

the High Efficiency Commercial Condensing, Commercial Power Direct Vent, Residential Power Direct Vent, Commercial

Power Vent and Residential Power Vent model series.

The DuraVent venting system components are ULC S636 approved and listed by a recognized agency and may be

installed in the U.S. and Canada. All components used must be from the same manufacturer and are designed for use

with the above noted products. The DuraVent components may be purchased from plumbing supply distributors. The

vent size diameter and maximum vent lengths must be followed as detailed in the Installation and Operating Instruction

Manual that was supplied with the water heater. Thoroughly read and understand the venting section of the instruction

manual supplied with the water heater before proceeding with the following instructions in this supplement. The vent

terminals supplied with the water heater or the factory approved accessory vent terminal kits must be used with this

venting system.

1 238-50320-00A 3/13

Page 2

Step 1: Thoroughly read and understand the venting section of the Installation and Operating Instruction Manual that

WARNING

Use only water for lubricating the gaskets and pipe ends to allow easy insertion. DO NOT use any other kind of

lubricant, since deterioration of the gasket may result, which may allow dangerous flue gases to leak into the room.

If the vent pipe needs to be disassembled after the gasket has dried, wet the joint thoroughly to loosen the

connection.

was supplied with the water heater before determining the location of the water heater and the vent terminals. Locate

the water heater for the shortest practical vent length to the outside. Measure the total venting distance required to

reach the outside wall or roof. Determine the diameter of the venting components to use for the length of vent pipe

(and combustion air supply for direct vent models) required by referring to the venting tables in the instruction manual

for the maximum vent length for each diameter pipe size. Obtain all the necessary venting system components for the

installation.

Step 2: Before installation, inspect each vent component for damage making sure the gaskets for each component are

fully intact and in undamaged condition. Do not attempt to install or repair damaged components. If a gasket is

damaged, these are available from the supplier of DuraVent components. Do not use gaskets from another

manufacturer and do not try to repair the gasket.

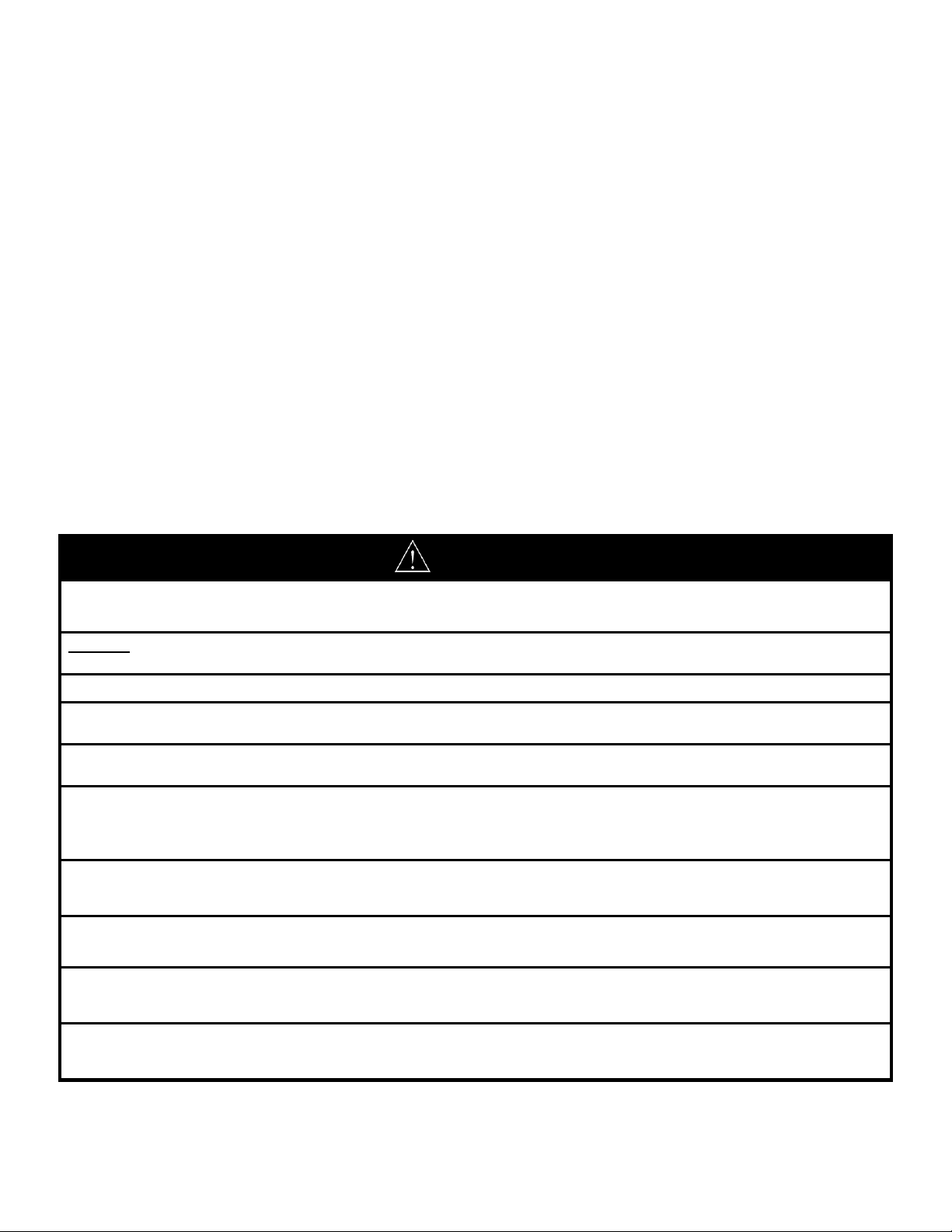

Step 3: A DuraVent PVC to Polypropylene adapter (referred by DuraVent as Appliance Adapters, 2PPS-AD, 3PPS-AD, or

4PPS-AD) must be used to connect into a PVC coupling or tee (Commercial and Residential Power Direct Vent air intake

connections), condensate elbow (High Efficiency Commercial Condensing models) or the exhaust outlet adapter for

Commercial Power Vent and Residential Power Vent models. To make the insertion of the gasketed fittings into the

coupling easier, rotate the joints slightly and use water to lubricate the gaskets. DO NOT use any other kind of lubricant.

Wet the gasket surface and inside of the coupling using your finger or wet paper towel and insert the male end of the

adapter with the exterior gasket into the coupling, condensate elbow or exhaust outlet adapter connection. If a larger

vent diameter size is to be used, use the appropriately sized reducer coupling first on the water heater intake or exhaust

vent connection as detailed in the installation manual supplied with the water heater. See the following photos.

High Efficiency Condensing Commercial Models: Use the appropriate primer and cement (refer to venting section of

instruction manual with water heater) for cementing a PVC coupling (not supplied with water heater) to the end of the

PVC air intake pipe connection. Using your finger, wet with water the male gasketed end of the DuraVent PVC to

PolyPro adapter and fully insert into the air intake coupling. Loosen the DuraVent adapter connector clamp (PPS-PAC)

and install over the PVC coupling. See following photos.

2 238-50320-00A 3/13

Page 3

Install PVC pipe coupling over air intake pipe connection

WARNING

DuraVent Adapter Connector Clamps (p/n: PPS-PAC) MUST be properly

installed to secure the PVC Vent Adapter. DO NOT operate the vent system

without first installing the Flue Adapter Connector Clamps.

Water Heater PVC Air Intake

Pipe. Use appropriate

solvent and cement to

cement coupling to pipe.

PVC Pipe Coupling (not

supplied with water heater)

Wet gasket using water

with finger

Male Gasketed end of PVC

adapter

Flue Clamp band fit over PVC Adapter

shoulder and PVC Coupling. Tighten

clamp screws securely with screwdriver.

and cement to pipe using appropriate solvent and cement. Wet gaskets of DuraVent PVC Adapter using finger.

Insert male gasketed end of DuraVent

PVC adapter into PVC pipe coupling. Install DuraVent Adapter Connector Clamp (PPS-PAC) over the

PVC coupling so that clamp brackets secure the shoulder of PVC

adapter fitting. Tighten clamp screws securely.

3 238-50320-00A 3/13

Page 4

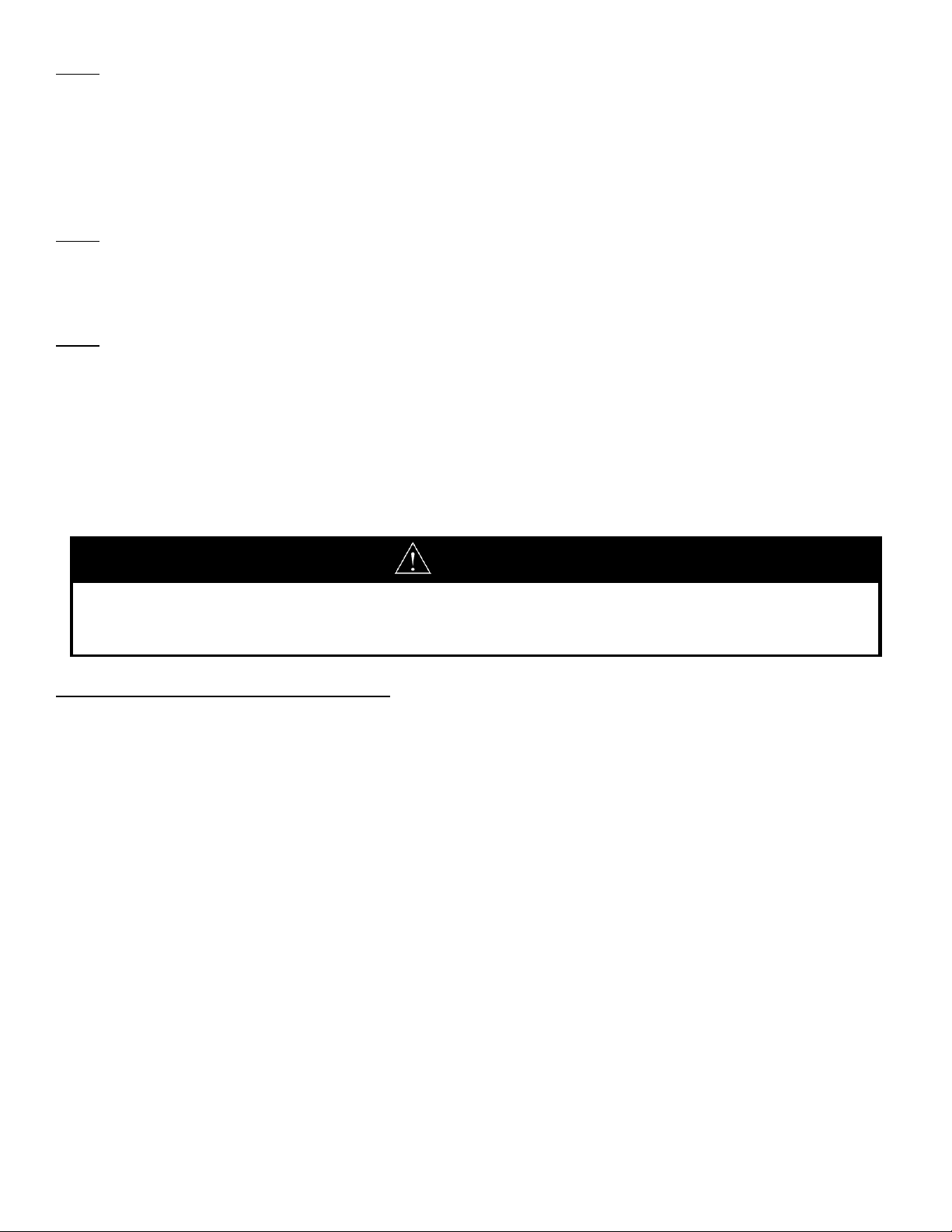

Condensate Elbow

Tighten Connector Clamp

Wet gasket with water using finger of PVC Adapter

PVC Adapter into Elbow

Connector Clamp

around PP pipe

Install Connector Clamp over Condensate Elbow

For High Efficiency Commercial Model series exhaust connection, wet outside gasket with finger and insert PVC adapter

into the condensate elbow. Insert DuraVent PVC Adapter fitting into Condensate Elbow as shown.

Install DuraVent Connector Clamp around outside of Tighten Connector Clamp Screw to secure PVC Adapter and

Condensate Elbow as shown. Adapter and Vent Pipe into condensate Elbow.

4 238-50320-00A 3/13

Page 5

Commercial and Residential Power Direct Vent / Power Vent Models:

For installation of commercial and residential power

vent models, install the male end of the PVC to

PolypPro adapter into the air intake pipe tee as shown.

Install the adapter connector clamp over the PVC adapter.

Then install the elbow or vent pipe section into the PVC

adapter. Tighten the clamp bands of the adapter connector

to the air intake tee and pipe elbow or straight pipe section to

secure vent pipe to the water heater air intake tee as shown

below.

Air Intake Pipe Tee

Adapter Connector Clamp – Fits over Air Intake

Tee and next vent pipe section as shown.

PVC Adapter

Fitting

5 238-50320-00A 3/13

Page 6

For the exhaust venting for all power vent and power direct For Commercial Power Direct Vent models, insert

Install the Adapter Connector Clamp over the PVC adapter and install the elbow or next section of straight pipe into

the PVC adapter. Then tighten the clamp bands of the Adapter Connector around the Exhaust Outlet Adapter and

Elbow to secure venting system.

Exhaust Outlet Adapter with

clamp for residential power

vented models. Tighten clamp.

Exhaust Outlet Adapter for

Power Direct Vent Commercials.

Tighten clamp screws to secure

vent pipe elbow to exhaust

outlet adapter.

vent models, insert the PVC Adapter into the Exhaust Outlet PVC Adapter into Exhaust Outlet Adapter.

Adapter. On residential models, tighten the clamp to secure

the PVC Adapter.

6 238-50320-00A 3/13

Page 7

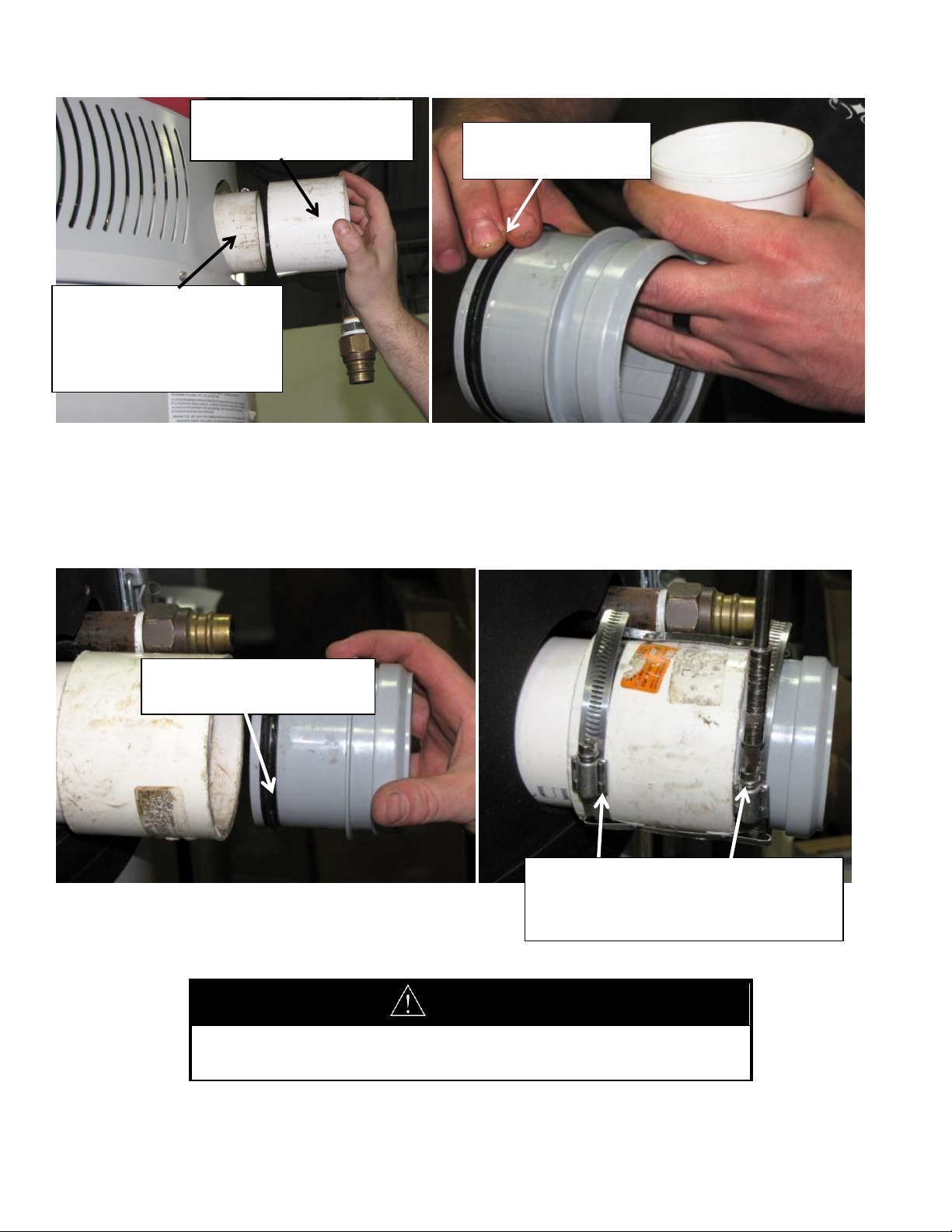

Step 4: Using a finger or paper towel, wet with water the inside gasket of the PVC adapter and the male end (without

WARNING

DO NOT operate vent system without

properly installing Locking Bands.

PVC Adapter

Locking Band first inserted over end of

vent pipe section

Use a twisting motion to insert male end of

vent pipe section into PVC Adapter

Push hook of Locking Band over the lip of

the joint to secure the vent pipe

gasket) of the elbow or straight section of pipe for running the exhaust or intake pipe from the water heater.

Steel joint Locking Bands (available from DuraVent supplier) must be used at each pipe joint. The connector rings ensure

that the joints do not separate under heavy loads. These connector rings must be used to comply with ULC-S636

requirements. See following photo with the joint connector attached to the pipe sections.

Insert a Locking Band over the male end of the vent pipe section with the hook and leg facing the joint. Insert the male

end of the elbow or straight section into the PVC adapter. Use a twisting motion while pushing the male end of the pipe

or elbow into the PVC adapter to fully seat into the gasket. The male end of the pipe or elbow must always point toward

the water heater.

Secure Locking Band to connection joint by sliding the hook over the lip of the joint as shown below.

7 238-50320-00A 3/13

Page 8

WARNING

Make sure pipe sections are fully inserted into the PVC adapter and/or gasketed end of DuraVent fitting. Insertion

depth is no less than 2 inches.

Plastic clamp latched around

body of vent pipe

Lag Bolt screws into wall

stud and clamp screws

onto bolt. Clamp then

fastens around vent pipe.

Step 5: DuraVent supplied support brackets must be used to support the pipe sections. The vent pipe sections must be

supported a minimum of every 10 feet (3 meters) of vertical run or on every horizontal pipe section. Consult local codes

for additional requirements.

DuraVent supplies two types of approved clamps available for hanging the vent pipe. The Polypropylene snap style

clamp can be attached at either the male or female end of the pipe. Determine the location for the anchor bolt

mounting to the wall or framing member. Mount the anchor bolt supplied with the clamp. Align the encapsulated nut

of the clamp with the anchor bolt and rotate the body of clamp with the nut onto the threads of the anchor bolt. With

the vent pipe in place, the clamp is then snapped together by closing the clamp around the vent pipe body or female

end of the pipe.

The metal Wall Strap type clamp can only be mounted on the body of the vent pipe. Open the metal clamp to fit around

the body of the vent pipe and slide into the desired location to secure to the wall or ceiling. Secure to the wall or

structural member by using (2) 1 ½” #8 wood screws or equivalent (not supplied with clamp). Secure the clamp around

the vent pipe by tightening the nuts and bolts of the clamp.

8 238-50320-00A 3/13

Page 9

Position clamp to fit between raised

“bump” on female flange as shown

Plastic Clamp also fits over Female Flange of DuraVent Vent Pipe Sections

Plastic Clamp opening allows room for Locking Bands to hook over flared female joint

9 238-50320-00A 3/13

Page 10

WARNING

Cut pipe edges must be properly deburred. Damage to the gasket from not deburring the edges of the cut male

end may result in the release of dangerous flue products.

Tighten Metal Clamp around body of vent pipe. Metal clamp fastens to wall with wood screws

High Efficiency Commercial Condensing Models:

For horizontal sections of flue pipe, the pipe must be installed with a slight upward slope of approximately ¼ inch per

foot (20 mm per meter) toward the water heater to allow condensate to drain into the condensate elbow.

Residential and Commercial Power Direct Vent / Power Vent Models:

To prevent condensate from accumulating in the exhaust blower, install the horizontal vent pipe with a downward slope

toward the vent terminal of ¼ inch per foot (20 mm per meter) of horizontal vent pipe. An optional condensate kit is

available for residential power vent models or a tee fitting with a condensate drain loop may be used on commercial

power direct vent models to prevent condensate accumulation in the blower for long vertical runs of vent pipe. Refer to

the venting section of the Installation and Operating Instructions supplied with the water heater.

Step 6: If any of the straight pipe sections need to be cut, use a hack saw and make a straight cut on the male

(ungasketed) end of the pipe. When making the cut, allow for the 2” minimum (51 mm) insertion distance inside the

female end of the pipe. Make sure the cuts are made square and use a razor knife to deburr the edges of the cut pipe to

avoid any sharp edges that may damage the gasket.

DuraVent has adjustable vent pipe sections available, which allow 4.5 inches (114 mm) of adjustment to the length.

10 238-50320-00A 3/13

Page 11

Deburr cut pipe with razor knife to remove

sharp edges.

Cut end of pipe to length using a hacksaw. Cut male Deburring cut pipe edge with razor knife to remove

end only and allow for 2” insertion depth into female end of sharp edges to prevent gasket damage.

fitting.

Step 7: Continue installing straight sections of pipe and elbows and support with pipe support clamps as previously

shown on every horizontal pipe section or at least every 10 feet (3 meters) for vertical runs. Run the vent pipe near the

outside wall or roof to be terminated. A DuraVent PVC to PolyPro Adapter (2”, 3” or 4” diameters) must be used to

connect the DuraVent polypropylene vent pipe to PVC pipe first before exiting the wall or roof. The female flared end

(inside gasket) of the last DuraVent pipe section must be cut off at the proper length needed. Connect the female end of

the PVC Adpater into the end of the last pipe. Connect the PVC coupling over the male gasketed end of the PVC

Termination Adapter. Secure the PVC pipe coupling to the DuraVent PVC adapter with the Adapter Connector Clamp

and detailed previously. Cut the PVC pipe to the length needed to exit the wall or roof. Refer to the installation

instruction manual supplied with the water heater for information regarding the location of the vent terminals.

Cut the male end of the last piece of pipe to the length as needed to get near the exiting wall or ceiling

of the desired outside vent terminal location. Install this last section of pipe.

11 238-50320-00A 3/13

Page 12

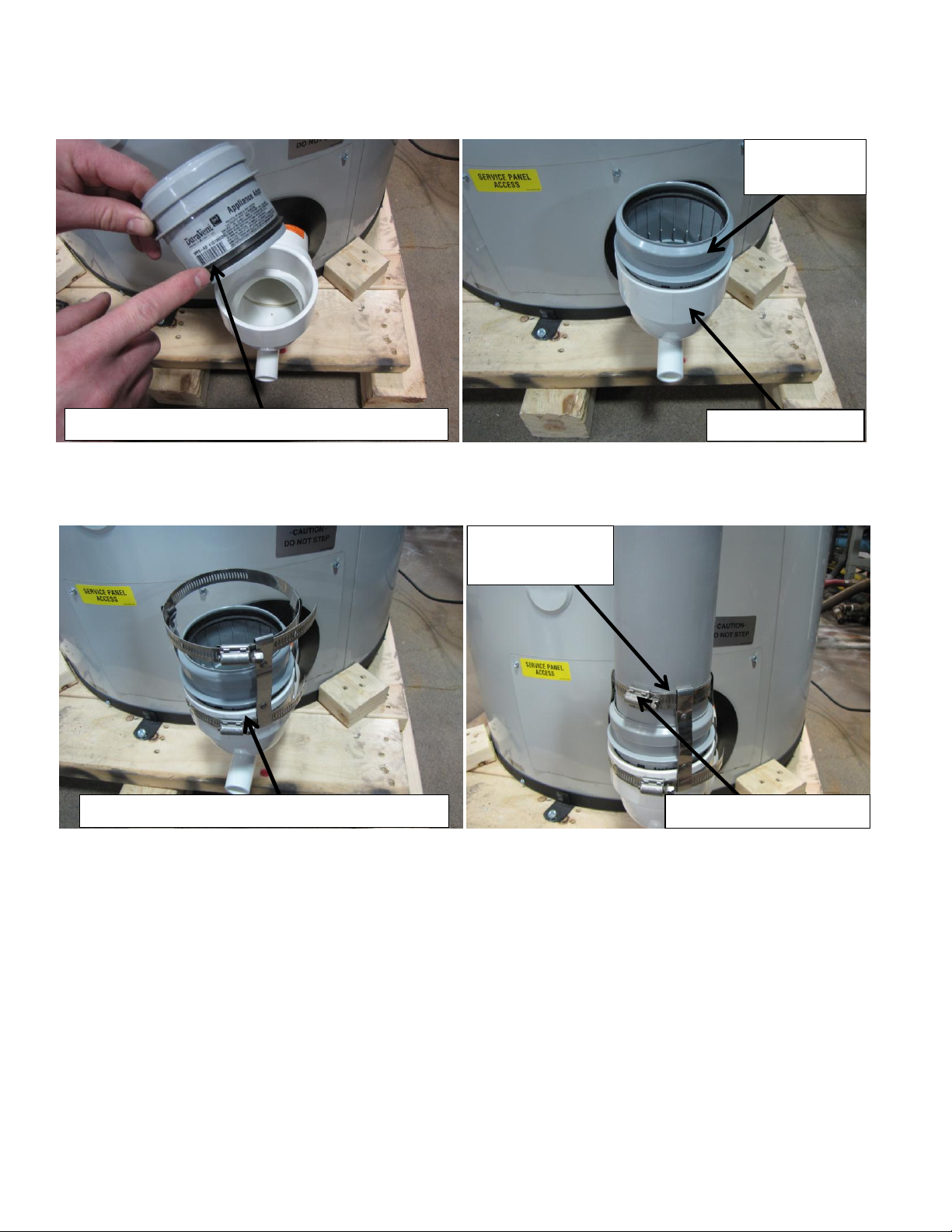

Cut end of vent pipe

PVC Coupling attaches to

DuraVent Adapter.

DuraVent PVC to PolyPro adapter attaches

to cut male end of last pipe section.

Install the appropriate diameter DuraVent PVC Adapter on the end of the last pipe.

Install a PVC coupling onto the male gasketed end of the DuraVent PVC Adapter. A reducer coupling may be needed to

use the supplied vent terminals if a larger pipe diameter size was used. Cement the straight section of PVC pipe to the

PVC pipe coupling. Install the PVC pipe to exit the wall or roof, and then cement the vent terminal onto the PVC or CPVC

pipe. Refer to the venting section of the water heater Installation and Operating Instruction manual for the appropriate

solvent and cement to use. The exhaust vent terminal for the EF model series is shown. Use the vent terminals supplied

with the water heater. See the following photos.

Install PVC Pipe Coupling (not supplied) over the male end of DuraVent PVC Adapter.

12 238-50320-00A 3/13

Page 13

WARNING

All of the exhaust venting connections must be leak checked with a soap solution upon initial start-up of the water

heater. Any leaks must be repaired before continuing operation of the water heater.

Periodically check all venting system connections for leakage. Replace any defective venting components. Refer

to the maintenance section of the Installation and Operating Instructions for further details.

Supplied Air Intake Terminal

Cement PVC Pipe Coupling and Vent Terminal to

PVC pipe using approved solvent and cement.

Secure PVC Pipe Coupling to PVC

Adapter with Adapter Connector

Clamp.

Secure the PVC coupling to the PVC Terminal Adapter with the DuraVent Flue Pipe Clamp. Cement a short section of

PVC pipe into the PVC pipe coupling. Cement the supplied PVC exhaust terminal coupling onto the PVC pipe.

Step 8: After the venting system installation is completed, start the water heater and check all joints for leaks using a

soapy water solution. Any leaks found must be repaired. If a gasket is damaged, replacement gaskets may be obtained

from the local DuraVent supplier.

13 238-50320-00A 3/13

Loading...

Loading...