Page 1

Service and

Maintenance

Manual

210 DUS JD4045

IT4 74HP

Air Compressor

This manual must be read carefully before using your Boss Industries, Inc. Air Compressor. Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website:

http://www.bossair.com

309416

05-03-2013 ARB

Page 2

01/31/2012

2 309416

Page 3

Contents

Manual Change History................................................................................................7

1.1 Revision List....................................................................................................7

Welcome........................................................................................................................8

2.1 General Information..........................................................................................8

2.2 Overview .........................................................................................................8

Safety...................................................................................................................9-13

3.1 General Safety Overview...................................................................................9

3.2 Safety Precautions..........................................................................................10

3.3 Safety and Information Decals..........................................................................12

Specifications..............................................................................................................14

4.1 Specification Sheet........................................................................................14

Description of Components..............................................................................15-18

5.1 Engine............................................................................................................15

5.2 Drive Coupling...............................................................................................15

5.3 Compressor Airend.......................................................................................15

5.4 Separator System..........................................................................................15

Separator Tank.........................................................................................15

Separator Element......................................................................................15

5.5 Pressure Relief Valve.....................................................................................16

5.6 Engine Air Filter..........................................................................................16

5.7 Compressor Air Filter.................................................................................16

5.8 Cooling Systems...........................................................................................16

Engine Radiator..........................................................................................16

Compressor Oil Cooler...............................................................................16

5.9 Compressor Oil Filter..................................................................................16

5.10 Compressor Oil Thermal Valve......................................................................16

5.11 Compressor Inlet Valve.................................................................................17

5.12 Minimum Pressure Valve...............................................................................17

5.13 Blowdown Valve..........................................................................................17

5.14 Blowdown Switch........................................................................................17

5.15 Discharge Pressure Regulator Valve...............................................................17

5.16 Instrument Panel...........................................................................................18

Engine Oil Pressure Gauge..........................................................................18

Engine Coolant Temperature Gauge............................................................18

Compressor Discharge Pressure Gauge......................................................18

Compressor Discharge Temperature Gauge................................................18

01/31/2012

3 309416

Page 4

Contents

Description of Components (continued)............................................................15-18

5.15 Instrument Panel (continued).....................................................................18

Hourmeter.......................................................................................18

Tachometer.........................................................................................18

Voltmeter.................................................................................18

Unloader Valve...........................................................................................18

Emergency Stop Switch.............................................................................18

Bypass Switch...........................................................................................18

Ignition Switch...........................................................................................18

Installation.............................................................................................19-23

6.1 System Installation Overview...........................................................................19

6.2 Placing the Machine........................................................................................19

6.3 Connecting the System Fuel Supply.................................................................19

6.4 Fuel Specifications..........................................................................................20

High Altitude and Low Temperature Fuel....................................................20

Cold Weather Fuel.....................................................................................20

6.5 Connecting the Air Discharge Lines...............................................................20

6.6 Pre-Startup Inspection .................................................................................20

6.7 Machine Documentation...............................................................................21

6.8 Check Fluid Levels.......................................................................................21

6.9 Initial Startup Preparation..............................................................................21

6.10 Initial Startup.................................................................................................22

Operation.............................................................................................................23-24

7.1 Routine Operating Procedures........................................................................23

Routine Startup Preparation........................................................................23

Routine Startup Procedure.........................................................................23

Routine Shutdown Procedure.....................................................................23

7.2 Emergency Shutdown Procedure..........................................................24

Maintenance........................................................................................................25-36

8.1 Maintenance Overview....................................................................................25

8.2 Maintenance Schedule....................................................................................25

8.3 Recommended Spare Parts List......................................................................26

8.4 Parts and Service Contact Information............................................................26

8.5 Maintenance Log............................................................................................27

01/31/2012

4 309416

Page 5

Contents

Maintenance (continued)....................................................................................25-36

8.6 Separator Element Replacement......................................................................28

8.7 Engine Air Filter Replacement..........................................................................29

8.8 Compressor Air Filter Replacement.................................................................30

8.9 Compressor Oil..............................................................................................31

Specifications.......................................................................................31

Adding Compressor Oil.............................................................................32

Changing Compressor Oil..........................................................................32

8.10 Compressor Oil Cooler.................................................................................33

8.11 Compressor Oil Filter....................................................................................33

8.12 Engine Cooling System Maintenance..............................................................34

Engine Coolant...........................................................................................34

Engine Radiator..........................................................................................34

Engine Fan.................................................................................................35

Engine Serpentine Belt...............................................................................35

8.13 Battery..........................................................................................................35

8.14 Standby Pressure Adjustment (For 100 PSI System).....................................35

8.15 Idle Speed Adjustment..................................................................................36

8.16 Rated Speed Adjustment...............................................................................36

Troubleshooting...................................................................................................37-40

9.1 Troubleshooting Chart....................................................................................37

9.2 Parts and Service Contact Information............................................................40

Warranty..............................................................................................................41-45

10.1 Warranty Policy............................................................................................41

10.2 Summary of Main Warranty Provisions..........................................................42

10.3 Warranty/Return Goods Instructions.............................................................43

10.4 Warranty Claims - Preparation of Part Return.................................................43

10.5 Return or Warranty Claims - Filing Procedures...............................................43

10.6 Warranty Claims Provisions..........................................................................44

10.7 Damage in Transit..........................................................................................44

10.8 Screw Compressor Airend Exchange Program..............................................45

Parts and Illustration Section...........................................................................46-63

11.1 Frame System...............................................................................................46

11.2 Engine System..............................................................................................48

11.3 Compressor System.....................................................................................50

11.4 Discharge System..........................................................................................52

01/31/2012

5 309416

Page 6

Contents

Parts and Illustration Section (continued)........................................................46-63

11.5 Cooling System..........................................................................................54

11.6 Electrical System.......................................................................................56

11.7 Canopy System.......................................................................................58

11.8 Decal System..............................................................................................60

11.9 Hose System......................................................................................62

11.10 System Wiring Diagram..............................................................................63

01/31/2012

6 309416

Page 7

Manual Change History

ETAD NOITACOL EGNAHCFONOITPIRCSED SLAITINI

1.1 Revision List

01/31/2012

7 309416

Page 8

Welcome

This manual must be read carefully before using your Boss Industries, Inc. Air Compressor. Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website:

http://www.bossair.com

Service and

Maintenance

Manual

210 DUS JD4045

IT4 74HP

Air Compressor

309416

01/31/2012

2.1 General Information

Thank you for choosing the 210 DUS Air Compressor. Before operating

this system, read over this manual and become well acquainted with your

new machine. Doing this will increase your safety and maximize the life

of the machine.

While this manual is written to be as accurate as possible, Boss Industries, Inc. strives to continually improve the efficiency and performance of

its machines. As a result, sometimes there may be slight differences

between a given version of the manual and the machine.

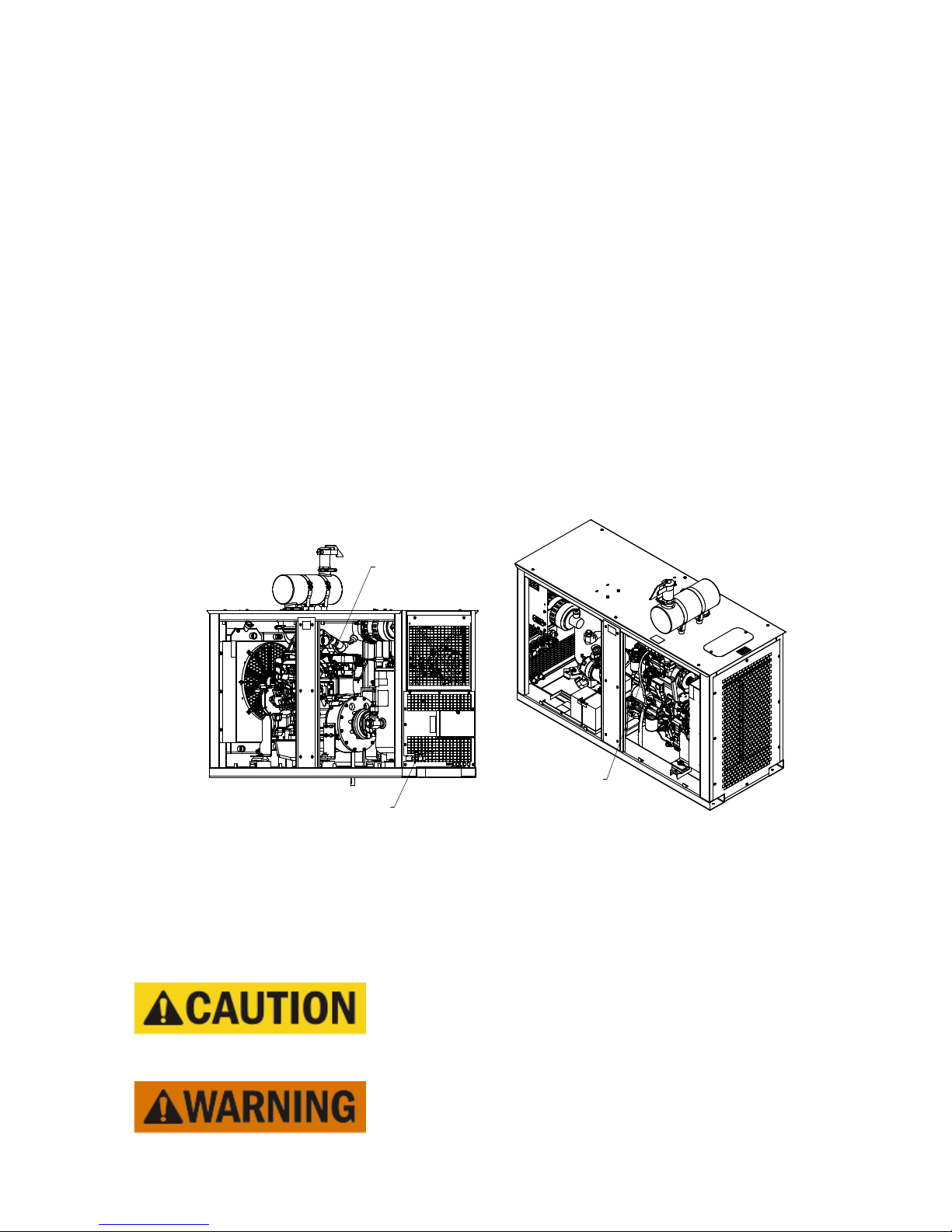

2.2 Overview

The 210 DUS Air Compressor is a compact, strategically designed system. It integrates all major

components on a single frame, which is enclosed in a tough, weather-resistant canopy.

The 210 DUS Air Compressor’s rotary screw

design guarantees continuous air output of up to

210 CFM (cubic feet per minute) at 100 PSI

(pounds per square inch). With remote fluid

drains and removable doors, virtually all

components are accessible for maintenance and

service. The instrument panel clearly displays

pressures, temperatures, and hours of operation.

Other features, including a spin-on compressor oil

filter and a drop-in separator element, reduce the

time and costs associated with routine

maintenance.

The 210 DUS Air Compressor also has enhanced

safety features to protect your valuable resources:

minimum pressure valve, high compressor oil

temperature shutdown, high discharge pressure

shutdown, automatic blowdown device, pressure

relief valve, high engine coolant temperature, low

engine oil pressure, and clearly displayed warning/

information decals.

01/31/2012

8 309416

Page 9

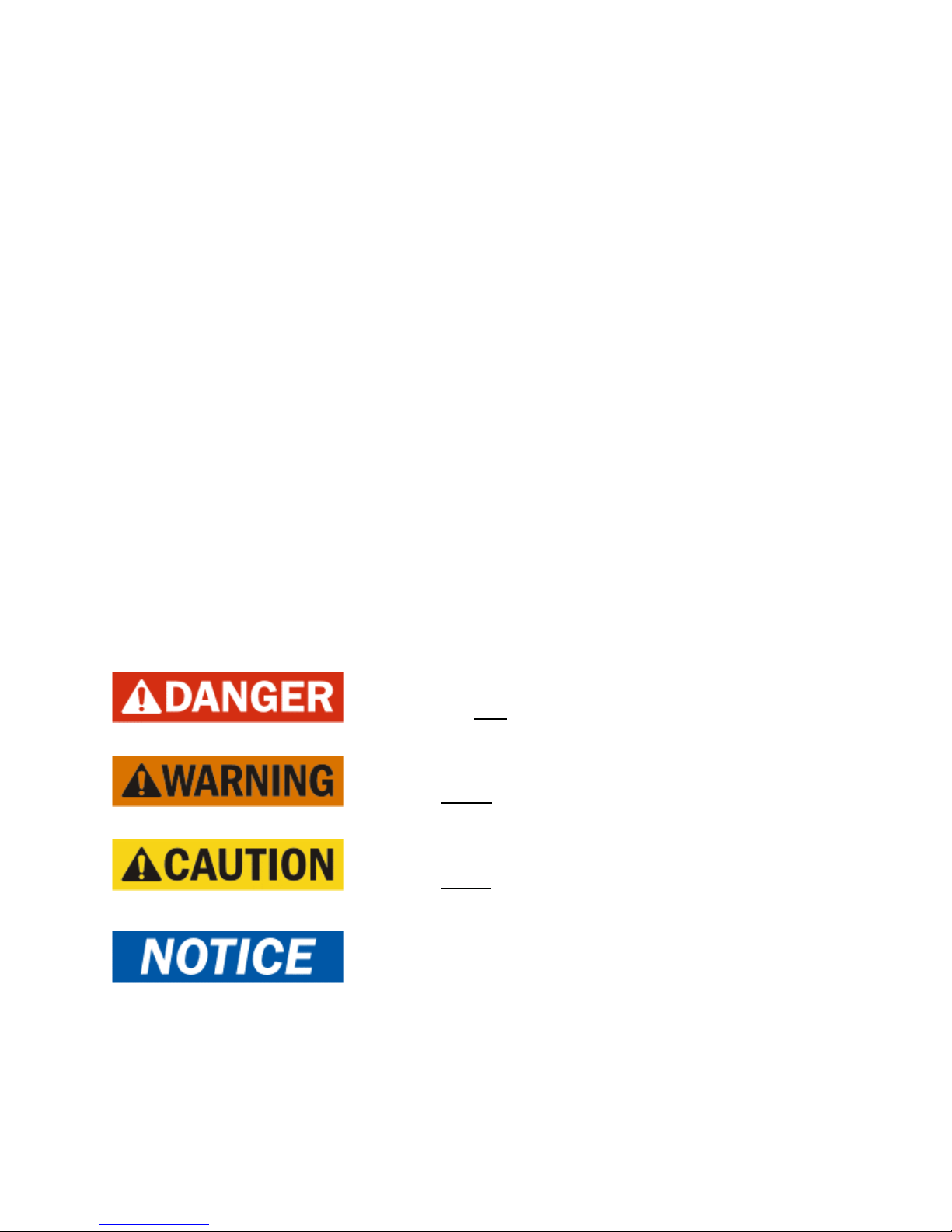

Safety

3.1 General Safety Overview

Remember, safety is basically common sense. While there are standard safety rules, each situation has

its own peculiarities that cannot always be covered by rules. Therefore with your experience and

common sense, you are in a position to ensure the safety of yourself and others. Lack of attention to

safety can result in: accidents, personal injury, reduction in efficiency, and worst of all – Loss of Life.

Watch for safety hazards and correct them promptly.

Understanding the proper operation of this equipment is critical to its safe operation. The owner, lessor,

and/or operator of this equipment is hereby notified and forewarned that any failure to observe the

safety and operating guidelines may result in injury and/or damage. Boss Industries, Inc. expressly

disclaims responsibility or liability for any injury or damage caused by failure to observe these specified

precautions or by failure to exercise the ordinary caution and due care required while operating or

handling this equipment, even though not expressly specified.

In addition to following these safety guidelines, the operator should follow any company specific guidelines and procedures. Consult your immediate supervisor for specific company safety guidelines and/or

procedures.

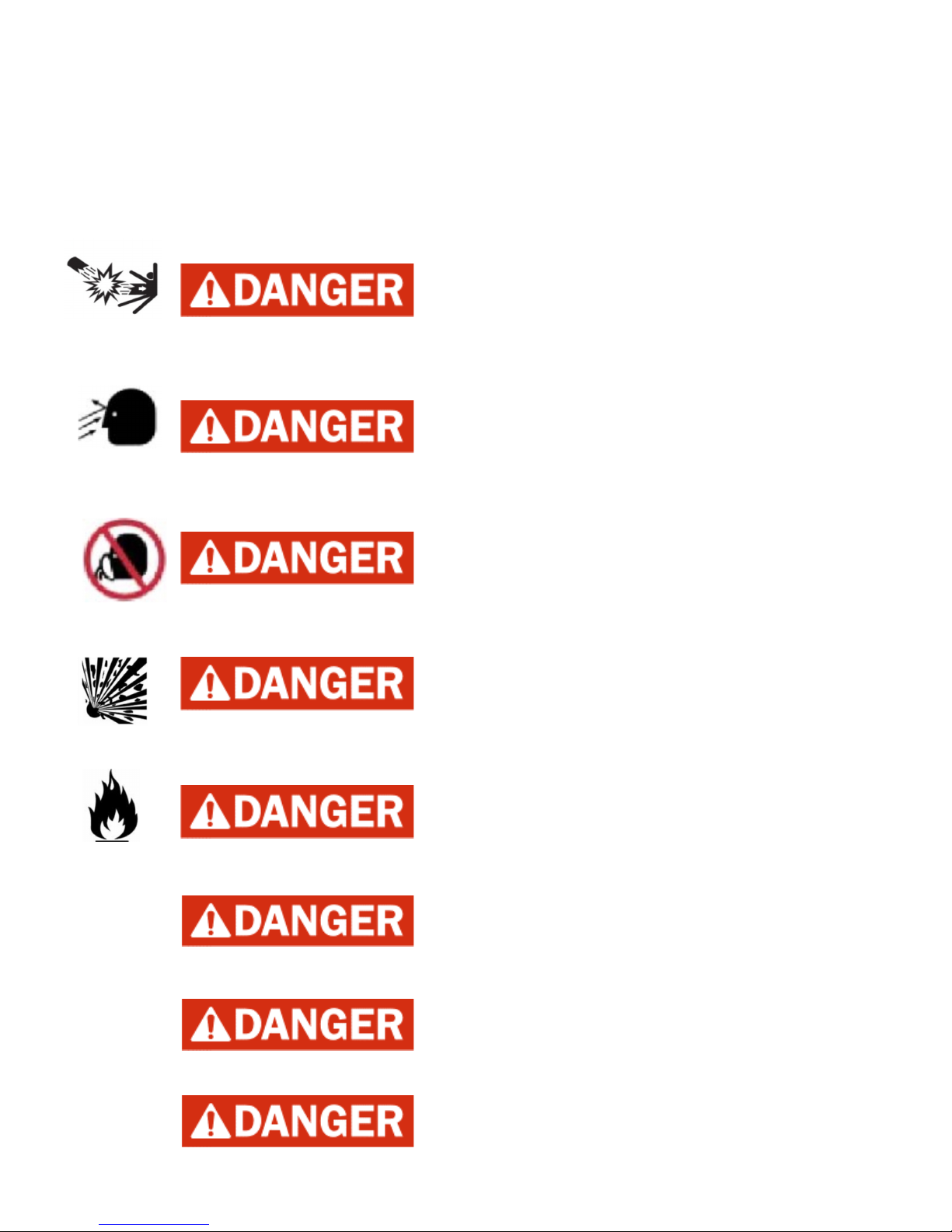

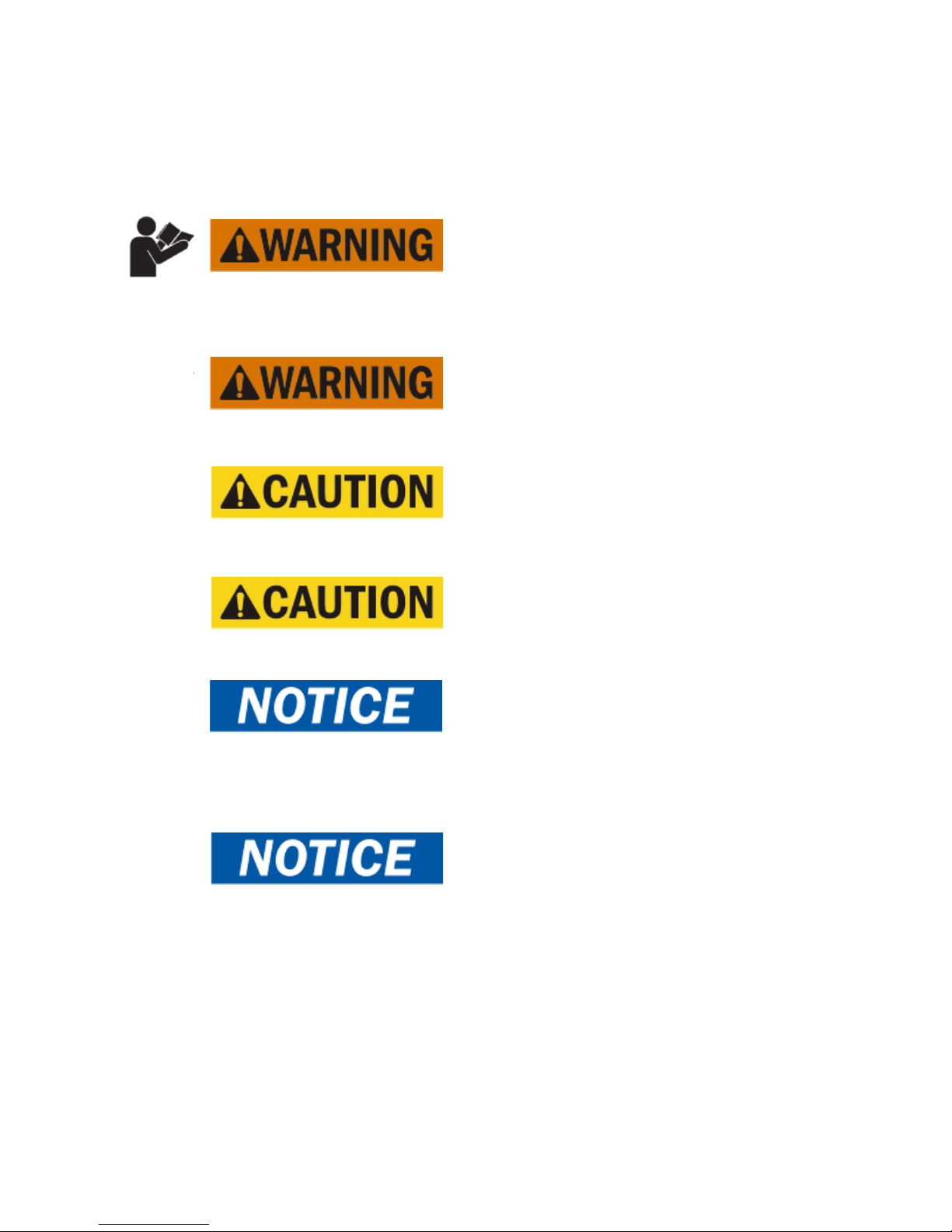

The following safety symbols are used throughout this manual to draw attention to important information.

If the information is not carefully read and the instructions are not followed, severe injury, death, and/or

damage to property and equipment may occur.

Indicate[s] an imminently hazardous situation, which, if

not avoided, will result in death or serious injury.

Indicate[s] a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

Indicate[s] a potentially hazardous situation, which, if not

avoided, could result in minor or moderate injury.

Indicate[s] a potentially unsafe situation or practice,

which, if not avoided, can result in property and/or

equipment damage only.

01/31/2012

9 309416

Page 10

Safety

3.2 Safety Precautions

The following safety precautions are a general guide to safe operation of the equipment.

This is a pressurized system. Do not attempt to remove

any part of this machine without first completely relieving

entire system of pressure. Do not attempt to service any

part of the equipment while in operation. Never attempt

to repair or modify any pressure vessel or device.

System contains hot oil. The system must be shut off prior

to servicing. Then permit system to cool down prior to

adding compressor oil or servicing the unit.

Do not use air from this system for breathing or food

processing. Air from this system will cause severe injury

or death if used for breathing or food processing.

The system is designed to compress air. Do not attempt

to compress other gases. Compression of other gases

may create a situation where an explosion or fire may

occur.

Do not use flammable solvents for cleaning system components as this can cause the unit to ignite or explode

during operation. Keep combustibles out of and away

from system inlets and any associated enclosures.

Never disable, override, or remove safeties, either temporarily or permanently.

Do not modify systems to operate equipment at a higher

pressure than specified.

01/31/2012

Never operate the machine in an enclosed area.

10 309416

Page 11

3.2 Safety Precautions (continued)

Safety

Read and understand this manual and all other safety

instructions before using this equipment. Failure to follow

operating instructions and/or failure to follow maintenance

procedures and intervals could result in personal injury,

death, and/or damage to equipment and property.

Use only Boss Industries, Inc. approved replacement

parts.

Never place machine on a grade more than 15 degrees.

Keep doors closed on the machine during operation.

Check engine’s operator manual for required service

and maintenance intervals.

This machine is equipped with safety unloading

system to prevent damage to the compressor drive

coupling. Should an attempt be made to start this

system improperly, the machine will run unloaded for

60 seconds. Likewise, if an attempt is made to

shutdown the system improperly, the unit will continue to run until the compressor system pressure

unloads below 50 PSI.

01/31/2012

11 309416

Page 12

Safety

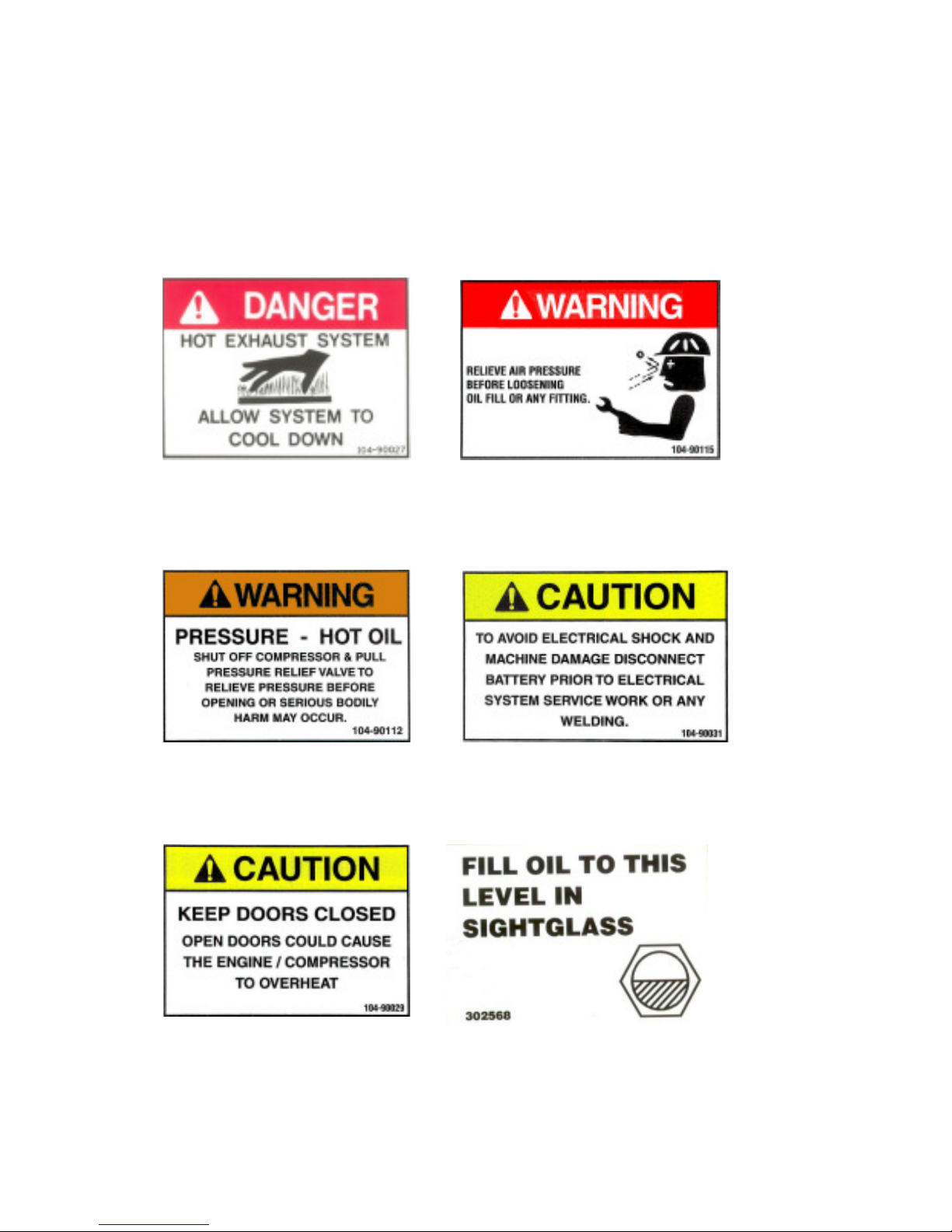

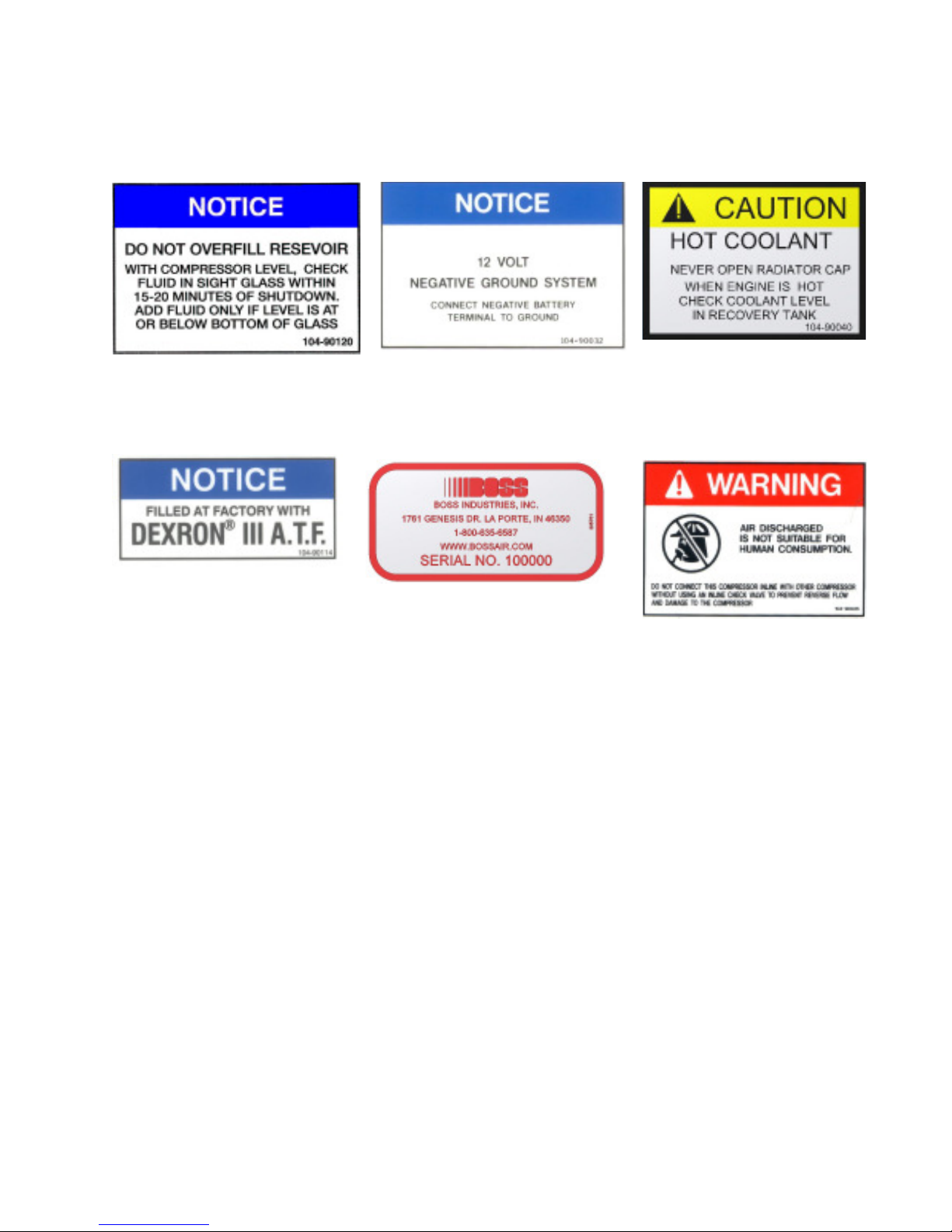

3.3 Safety and Information Decals

This machine is supplied with a full complement of safety and identification decals. These decals are

affixed to the unit during final assembly. These decals must be clearly visible and undamaged. Should

any of these decals become illegible or damaged, immediately replace the decal.

Hot Exhaust Pressurized System

Electrical ShockHot Pressurized Oil

Close Doors Oil Level

12 309416

01/31/2012

Page 13

Safety

3.3 Safety and Information Decals (continued)

Overfill Negative Ground System

Compressor Oil

Hot Coolant

Serial Tag

Breathing Air

01/31/2012

13 309416

Page 14

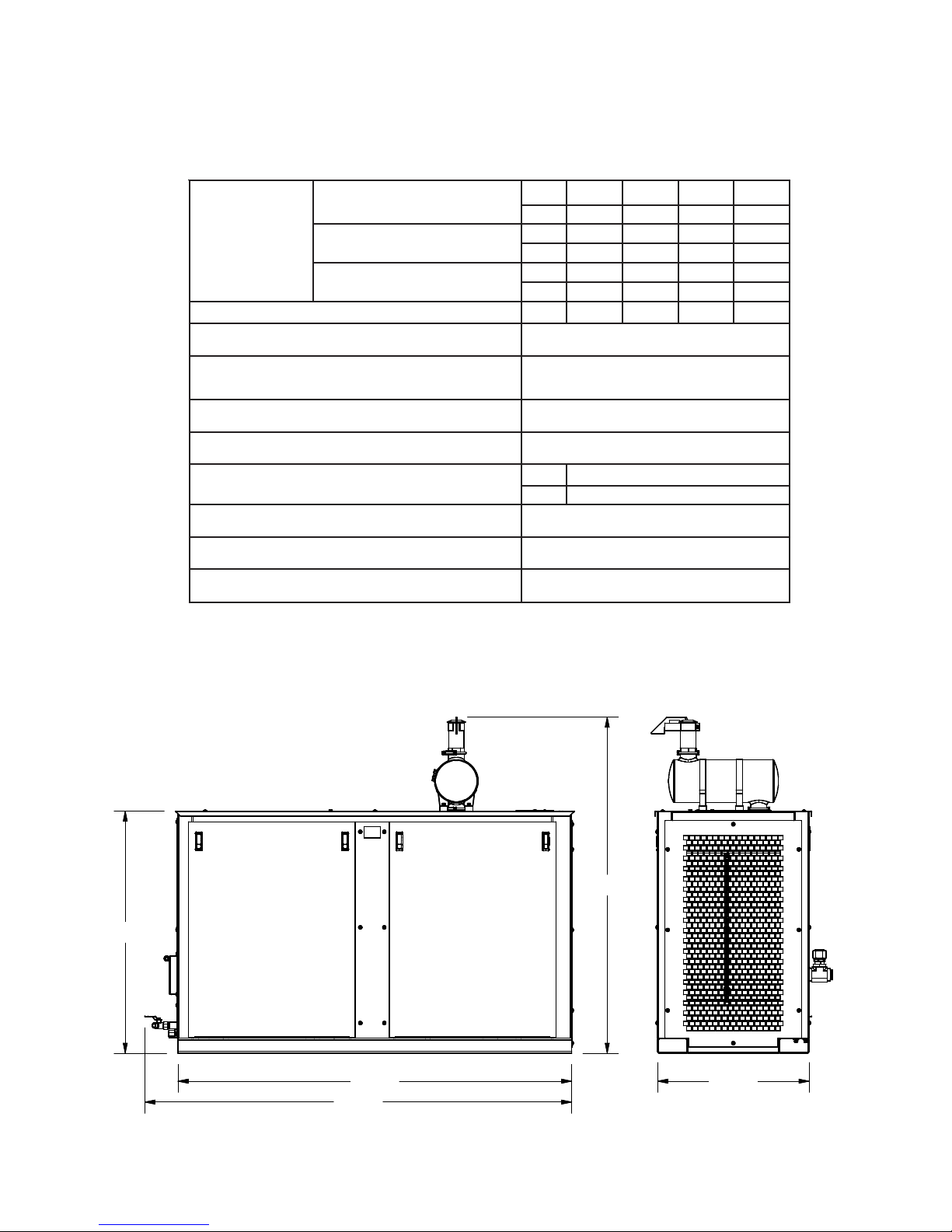

4.1 Specification Sheet

yticapaC

ISP001@

MFC 571 581 002 012

PH 83 14 54 74

ISP521@

MFC 471 481 991 902

PH 44 74 25 55

ISP061@

MFC 071 181 891 402

PH 84 15 65 75

deepStupnIrosserpmoC

MPR 0002 5212 5232 0042

dneriArosserpmoC oitaRraeG50.3htiwG01ACS

enignE

47

PH

DJ

5404

MIRTNI

REIT

4

EAS/W

B

EVIRDXUA

metsySlacirtcelEenignE CDV21

snoisnemiDesaB "2/107X"03X"8/548

knaTleuFleseiDlanoitpO

PAC L041,.LAG73

MID "5.6X"03X"87

elgnAgnitarepOenihcaM mumixam°51

elcyCytuD suounitnoC

snoitidnoCtneibmA F°521otF°04-

66.77

48.07

78.00

84.55

30.00

Specifications

*SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE*

01/31/2012

14 309416

Page 15

Description of Components

5.1Engine

The 210 DUS Air Compressor contains a John Deere, 4 cylinder diesel engine. This engine has been

selected to handle the rugged duty required for its operation. The engine speed is regulated by a

pneumatic throttle control.

5.2Drive Coupling

Power from the engine is transmitted to the compressor input shaft through a specially designed drive

coupling. The drive coupling consists of a highly torsionally flexible rubber disc that mates with an

engine flywheel flange. The coupling provides a torque limitation to protect from system overloads.

5.3 Compressor Airend

The Boss Industries, Inc. compressor airend is a positive displacement, oil flooded, rotary screw type

unit employing one stage of compression to achieve the desired pressure. Components include a

housing (stator), two screws (rotors), bearings, and bearing supports. Power from the engine flywheel

is transferred through a gear set to the male rotor. The female rotor is driven by the male rotor. There

are five lobes on the male rotor while the female rotor has six roots.

rotors mesh to compress air. Inlet air is trapped as the male lobes roll down the female grooves,

pushing trapped air along, compressing it until it reaches the discharge port at the end of the stator which

delivers smooth-flowing, pulse-free air. Being an oil flooded system, the oil serves three purposes:

lubricates the rotating parts and bearings, serves as a cooling agent for the compressed air, and seals the

running clearances.

In operation, two helical grooved

5.4 Separator System

I. Separator Tank

From the compressor airend, the compressed air and hot oil flow into a steel, ASME coded,

pressure vessel, rated at 250 PSI, that acts as an oil reservoir. This tank is the first of two stages in

separating the oil and compressed air mixture. From the bottom of the separator tank, oil is forced

to the oil filter.

II. Separator Element

At the top of the separator tank is the separator element. The separator element removes the oil

mist from the air as it is passed on to the minimum pressure valve. As the air/oil mist passes through

the outside of the media, oil gathers on the interior walls and settles to the bottom of the element.

Collected oil is returned to the compressor airend through the oil return line. The separator will filter

the oil concentration in the air to less than 3 parts per million.

15 309416

01/31/2012

Page 16

Description of Components

5.5 Pressure Relief Valve

This valve vents separator tank pressure to atmosphere should the pressure inside the tank exceed 200

PSI.

5.6 Engine Air Filter

The engine air filter is a two stage, dry type intake filter with a gravity evacuator and replaceable internal

element. On the outlet of the engine air filter is an air filter restriction indicator. This indicator serves as

a maintenance tool.

5.7 Compressor Air Filter

The compressor air filter is a two stage, dry type intake filter with a gravity evacuator and replaceable

internal element. On the outlet of the compressor air filter is an air filter restriction indicator. This

indicator serves as a maintenance tool.

5.8 Cooling Systems

I. Engine Radiator

The radiator is designed to dissipate the heat load of the engine and is mounted in front of the

specially selected engine fan. Hot engine coolant is passed through the interior of the radiator and

heat is transferred to the air that passes across the cooling fins.

II. Compressor Oil Cooler

The compressor oil cooler is designed to dissipate the heat created during the compression of air.

The oil cooler is mounted beside the engine radiator. This works similar to the engine radiator but is

designed to withstand the full compressor system working pressure.

5.9 Compressor Oil Filter

The compressor oil filter is a full flow, spin-on canister. It has been specially designed to handle 200

PSI. The oil filter is mounted downstream of the separator tank to ensure all contaminants are prevented from being passed on to the compressor oil cooler.

5.10 Compressor Oil Thermal Valve

The compressor oil thermal valve is a thermostatically controlled by-pass valve that allows varying

amounts of oil, depending upon the temperature, to by-pass the oil cooler. The oil thermal valve directs

oil flow back to the compressor airend until the system reaches 170°F. Once at system operating

temperature, the valve shifts, directing the flow through the oil cooler before returning to the compressor

airend.

01/31/2012

16 309416

Page 17

Description of Components

5.11 Compressor Inlet Valve

The compressor inlet valve is a normally open air intake valve bolted to the compressor airend. When

the system is shut down, this valve also acts as a check valve that prevents the air/oil mixture within the

compressor airend from entering the inlet piping.

5.12 Minimum Pressure Valve

To ensure there is adequate pressure to produce proper oil flow throughout the system, a spring loaded,

normally closed minimum pressure valve is set to maintain at least 80 PSI in the separator tank.

5.13 Blowdown Valve

The blowdown valve is a shuttle valve that vents system pressure to atmosphere when the system is shut

down. This is done to prevent the high torque load that would be required to overcome the static

pressure. The blowdown valve is stamped with an “I” and a “P”. The “I” side is connected to dry air

from the separator tank, and the “P” side is the pilot signal coming from the compressor inlet valve.

5.14 Blowdown Switch

The system is equipped with a blowdown switch. This switch will sense pressure in the pilot signal to

the blowdown valve. If the system contains pressure, the switch will prevent the machine from starting.

This will prevent premature damage to the drive coupling.

5.15 Discharge Pressure Regulator Valve

This valve, located downstream of the separator element, is used to set the desired discharge pressure.

This valve will send a pneumatic signal to the inlet valve to start closing when the pressure exceeds the

setpoint. This signal will also adjust the speed of the engine. This system has a maximum operating

pressure of 160 PSI.

Most air tools operating pressure range is between 90 and 125

PSI. Operating above the tools recommended pressures will

decrease the life of the tool. Strictly adhere to tool operating

pressures and torque standards set forth by the tool

manufacturer.

01/31/2012

17 309416

Page 18

Description of Components

5.16 Instrument Panel

The 210 DUS Air Compressor incorporates an instrument panel that includes numerous gauges and

controls in a single, easy to access location.

I. Engine Oil Pressure Gauge

This feature displays the oil pressure inside the engine block. When the pressure drops below 20

PSI, the system will shut down. During operation, the engine oil pressure should be approximately

60 PSI to 80 PSI.

II. Engine Coolant Temperature Gauge

This feature displays the temperature of the engine coolant. When the temperature reaches 235°F,

the system will shut down. During operation, the temperature should be approximately 190°F to

210°F.

III. Compressor Discharge Pressure Gauge

This feature displays the pressure downstream of the airend.

IV. Compressor Discharge Temperature Gauge

This feature displays the compressor discharge temperature. When the temperature reaches 245°F,

the system will shut down. During operation, the discharge temperature should be approximately

170°F to 190°F.

V. Hourmeter

The hourmeter records the total number of operating hours. It serves as a guide in following the

recommended maintenance schedule. The hourmeter will only run when the engine is operating.

VI. Voltmeter

This feature displays the voltage of the battery. The voltmeter will display when the ignition switch is

in the “RUN” position. During operation, the voltmeter should be approximately 14 VDC.

VII. Unloader Valve

This turn valve is used to limit the compressor system pressure. When the valve is in the loaded

position, the system will build to the regulator setting. If the valve is set to unloaded, the system will

build to approximately 45 PSI.

VIII. Emergency Stop Switch

The system is equipped with an emergency stop switch to immediately shutdown the machine.

IX. Bypass Switch

The bypass switch will temporarily disable the engine oil pressure shutdown during startup.

X. Ignition Switch

The ignition switch is used for starting and stopping the machine.

01/31/2012

18 309416

Page 19

Installation

1/4" TUBE

FUEL SUPPLY

(2) 3/4" MNPT AIR

SERVICE VALVES

5/16" TUBE

FUEL RETURN

6.1 System Installation Overview

The 210 DUS Air Compressor should be installed only by those who have been delegated to do so,

trained, and who have read and understand this manual. Failure to follow the instructions, procedures,

and safety precautions in this manual may result in accidents and injuries.

Install, use, and operate this system only in full compliance with all pertinent O.S.H.A., Federal, State,

and Local codes or requirements, in addition to Boss Industries, Inc. and any company’s regulations.

Do not modify this system except with written factory approval.

6.2 Placing The Machine

The first step in installing the 210 DUS Air Compressor is placing the system on a solid, level surface.

This machine is designed to run at up to a 15° grade maximum. The machine must be supplied ample

ambient air, as the system will overheat if the cooling air intake’s temperature exceeds ambient conditions.

6.3 Connecting the System Fuel Supply

Connect the fuel supply line to the 1/4” tube port on the starter side of the engine. Connect the fuel

return line to the 5/16” tube port, near the air inlet side of the turbo. Both tubes need to be SAE

30R7 rated fuel lines.

01/31/2012

Due to the precise tolerances of diesel injection systems, it is

extremely important that the fuel be kept clean and free from

dirt or water. Dirt or water in the system can cause severe

damage to both the injection pump and the injection nozzle.

Do not mix gasoline or alcohol with diesel fuel. This mixture can cause an explosion.

19 309416

Page 20

6.4 Fuel Specifications

I. High Altitude and Low Temperature Fuels

Fuels with cetane numbers higher than 40 may be needed in high altitudes or extremely low ambient

temperatures to prevent misfires and excessive smoke.

II. Cold Weather Fuel

At operating temperatures below 32° F, use a blend of No. 1D and No. 2D fuels, also known as

“Winterized” No. 2D.

Use a low sulfur content fuel having a cloud point that is at least 10 degrees below the lowest

excepted fuel temperature. Cloud point is the temperature at which wax crystals begin to form in

diesel fuel.

The viscosity of the fuel must be kept above 1.3 centistoke to provide adequate fuel system lubrication.

Use ASTM No. 2D fuel with a minimum cetane number of 40.

No. 2 diesel fuel gives the best economy and performance

under most operating conditions. See engine manufactures

operators/instruction manual for the proper engine fuel for the

brand engine in your Boss Industries, Inc. Air Compressor.

Installation

No. 1D fuel can be used; however, fuel economy will suffer.

6.5 Connecting the Air Discharge Lines

Connect the customer supplied air discharge lines, designed to handle a minimum of 200 PSI continuously, to the two 3/4” MNPT air discharge ports.

6.6 Pre-Startup Inspection

This inspection must be done prior to initial system startup.

I. Check

tied and secured.

II. Remove all tools, rags, and installation equipment from the area.

III. Verify the air discharge valves are closed.

all assemblies, clamps, fittings, hose connections, nuts, and bolts to ensure they are properly

01/31/2012

20 309416

Page 21

HOURMETER

COOLANT

TEMPERATURE

OIL PRESSURE

COMPRESSOR

TEMPERATURE

AIR PRESSURE

VOLTMETER

BYPASS SWITCH

IGNITION

SWITCH

EMERGENCY

STOP SWITCH

Installation

6.7 Machine Documentation

Record serial numbers for main components in the system.

I. Machine Serial Number __________________________________________

II. Compressor Airend Serial Number __________________________________________

III. Engine Serial Number __________________________________________

IV. Separator Tank Serial Number __________________________________________

6.8 Check Fluid Levels

The machine is factory filled prior to shipment. The proper fluid levels are also listed in the maintenance

section.

I. Separator Tank Oil Level = Halfway on the separator tank sightglass.

II. Engine Radiator Coolant Level = Bottom of the radiator fill neck.

III. Engine Coolant Recovery Bottle = Fill to the cold line.

IV. Engine Crankcase Oil Level = Full on the dipstick.

6.9 Initial Startup Preparation

I. Reconnect battery terminals. Ensure the red cable is connected to the battery’s positive terminal,

and the black cable is connected to the battery’s negative terminal.

II. Check the system for fuel, oil, and/or coolant leaks.

01/31/2012

21 309416

Page 22

Installation

This machine is equipped with safety unloading system to

prevent damage to the compressor drive coupling. Should an

attempt be made to start this system improperly, the machine

will run unloaded for 60 seconds. Likewise, if an attempt is

made to shutdown the system improperly, the unit will continue

to run until the compressor system pressure unloads below 50

PSI.

In the case of an emergency, this system is equipped with an

emergency shutdown switch. See section 7.2 for operating

instructions.

6.10 Initial Startup

At this point the system is ready to test functionality. Be sure to have completed all of the previous steps

prior to continuing.

I. Rotate the unloader valve to “UNLOAD”.

II. Hold the bypass switch and turn the ignition switch to the “START” position. If engine fails to

start, DO NOT attempt to restart until cranking motor stops rotating and the separator tank has

blown down.

III. When engine starts, release the ignition switch. Once the oil pressure has exceeded 30 PSI

release the bypass switch. Maintain the unloader valve in the “UNLOAD” position until the

engine is warm and operating smoothly, then rotate the valve to “LOAD”.

IV. Check system for leaks.

V. Allow system to run until engine coolant temperature reaches 190°F.

VI. Check for leaks again.

VII. Verify the engine speed is 1800 RPM.

VIII. Open an air service valve and verify the speed increases to 2400 RPM.

IX. Close the service valve.

X. Rotate the unloader valve to “UNLOAD”.

XI. Allow engine to idle until the air pressure has dropped below 50 PSI.

XII. Turn the ignition switch to the “OFF” position.

XIII. Initial startup testing is complete.

01/31/2012

22 309416

Page 23

Operation

7.1 Routine Operating Procedures

The 210 DUS Air Compressor should only be operated by those who have been delegated to do so,

trained, and who have read and understand this manual. Failure to follow the instructions, procedures,

and safety precautions in this manual may result in accidents and injuries.

Operate this system only in full compliance with all pertinent O.S.H.A., Federal, State, and Local codes

or requirements, in addition to Boss Industries, Inc. and any company’s regulations.

I. Routine Startup Preparation

A. Verify machine is on a level surface. Maximum allowable tilt in any direction is 15°.

B. Verify fluid levels and refill if necessary.

C. Check engine air filter’s indicator, element, clamps, and hoses.

D. Check compressor air filter’s indicator, element, clamps, and hoses.

E. Check battery cable connections for corrosion.

F. Check the condition of the engine fan belt.

G. Check for fuel, oil, and/or coolant leaks.

II. Routine Startup Procedure

A. Verify the unloader valve is in the “UNLOAD” position and all service valves are closed.

B. Hold down the bypass switch and turn the ignition switch to “START”.

C. When engine starts, release the ignition switch and continue holding bypass switch until the oil

pressure has exceeded 30PSI

D. Leave the unloader valve in the “UNLOAD” position for a minimum of 60 seconds and until the

engine temperature has reached 160°F.

E. Turn the unloader valve to the “LOAD” position.

F. Check for leaks again.

G. Open service valves for air usage.

III. Routine Shutdown Procedure

A. Close all service valves.

B. Rotate the unloader turn valve to “UNLOAD”.

C. Allow engine to idle until the air pressure has dropped below 50 PSI.

D. Turn the ignition switch to the “OFF” position.

Shutting down the machine under load will damage the engine,

drive coupling, and/or the airend. Follow normal shutdown

procedure at all times.

01/31/2012

23 309416

Page 24

Operation

7.2 Emergency Shutdown Procedure

In the event of an emergency and the 210 DUS Air Compressor must be stopped suddenly without first

unloading the compressor, the machine is equipped with an emergency shutdown switch. Do not shut

the machine off loaded except in an emergency situation. Do not operate this machine again until the

problem has been properly resolved.

I. Emergency Shutdown Procedure

A. Flip up the red emergency stop switch cover on the instrument panel.

B. Flip the toggle switch up to immediately shutdown the machine.

C. Once the machine has stopped, flip the shutdown switch and cover back down.

D. Fix the problem that required the emergency shutdown.

E. Remove the side panel and replace the 20 amp fuse on the rear of the instrument panel.

Shutting down the machine under load will damage the engine,

drive coupling, and/or the airend. Follow normal shutdown

procedure at all times.

01/31/2012

24 309416

Page 25

Maintenance

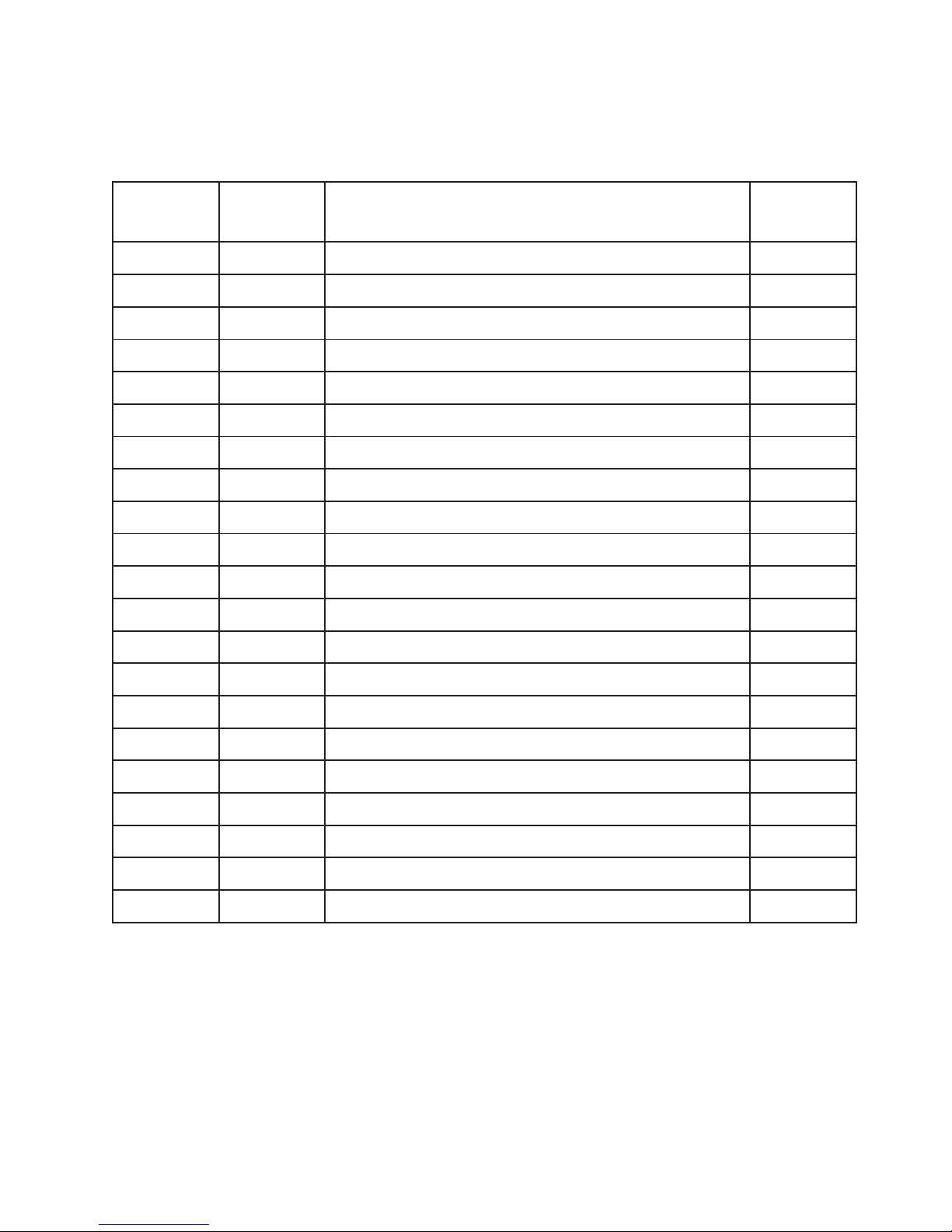

INTERVAL REQUIRED MAINTENANCE

1. Check separator tank oil level.

2. Check engine coolant level in coolant recovery bottle.

3. Check engine air filter maintenance indicator.

4. Check for fuel, oil, air, and coolant leaks.

5. Check compressor air filter maintenance indicator.

6. Check battery hold down for security.

1. Drain water from separator tank. More frequent draining may be required

under high humidity conditions.

2. Inspect lifting frame.

1. Change compressor oil and oil filter element.

2. Clean battery terminals.

3. Check battery hold-down and cables for wear.

4. Check engine air filter connections, fittings, and clamps.

5. Check compressor air filter connections, fittings, and clamps.

6. Check radiator hoses and clamps.

7. Check integrity of engine mounts.

1. Install new air filter elements. (compressor and engine)

2. Check all door gaskets, hinges, and latches.

3. Clean and flush engine cooling system

4. Check separator tank pressure relief valve.

5. Clean cooler fins on all coolers.

6. Install new fuel filter and water separator elements.

EVERY 10

HOURS OR

DAILY

EVERY 50

HOURS OR

WEEKLY

EVERY 500

HOURS OR 6

MONTHS

EVERY 1000

HOURS OR 1

YEAR

8.1 Maintenance Overview

This section contains instructions for performing the inspection, lubrication, and maintenance procedures

required to ensure the system is in proper operating condition. The importance of performing the

maintenance described herein cannot be over emphasized. A planned program of periodic inspection

and maintenance will help avoid premature failure and costly repairs. Keep an accurate logbook for

maintenance, service, and operating hours. The maintenance schedule intervals on this system are

maximum intervals. The factory recommended maintenance schedule is based on favorable operating

conditions. For continuous duty, extreme temperature, etc., service more frequently. Neglecting routine

maintenance can result in machine failure or permanent damage.

This system should be maintained only by those who have been delegated to do so, trained, and who

have read and understand this manual. Failure to follow the instructions, procedures, and safety

precautions in this manual may result in accidents and injuries.

8.2 Maintenance Schedule

01/31/2012

25 309416

Page 26

Maintenance

REBMUNTIK REBMUNTRAP NOITPIRCSED

77208

39082-421 retliFliOrosserpmoC

86219-421 tnemelErotarapeS

014903 tnemelEretliFriAenignE

014903 tnemelEretliFriArosserpmoC

590703 tiKriapeRlaeStfahSG01ACS

Compressor oil and oil filter is to be changed after the first 50

hours of operation. After this, normal intervals are to be

followed.

Check engine’s operator manual for required service and

maintenance intervals.

8.3 Recommended Spare Parts List

8.4 Parts and Service Contact Information

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website: http://www.bossair.com

01/31/2012

26 309416

Page 27

Maintenance

Accum.

Hours Date Service Performed Parts Replaced Service Work By

8.5 Maintenance Log

01/31/2012

27 309416

Page 28

Maintenance

8.6 Separator Element Replacement

When the oil vapor in the discharge air becomes excessive, the separator element may need replacing.

This should not be necessary more than once a year under normal operating conditions.

I. Replacement Procedure.

A. Shut down machine and allow to cool for approximately 10 minutes.

B. Verify entire system pressure is relieved before proceeding.

When disconnecting hose and tube, be sure to note the

location to ensure there is no confusion when

reconnecting.

C. Disconnect the 1” hose from the minimum pressure valve.

D. Disconnect the 1/4” tube from the elbow on the separator tank lid.

E. Disconnect the 1/4” tube from the elbow on the discharge pressure regulator valve.

F. Disconnect the 1/4” tube from the elbow on the blowdown valve.

G. Disconnect the 1/4” tube from the straight connector on the oil return line.

Note the location of the separator tank lid so that it can

be reinstalled in the same orientation.

H. Remove the eight 5/8” bolts holding the separator tank lid in place.

The separator tank lid has a pick-up tube installed and

damaging or moving the tube will affect the machines.

I. Lift and remove the lid from the package.

J. Remove the separator element.

Substitute filters may have inadequate working pressure

limits, resulting in filter leakage or rupture. Replacement

filters must be the same quality and type as the original Boss

Industries, Inc. separator element.

The separator element flange must have a gasket on each side

to seal the lid on one side and the vessel on the other. The

staple in each gasket acts as a static ground and must not be

removed.

K. Install a new element.

L. Reinstall the separator tank lid.

M. Reinstall the eight 5/8” bolts.

N. Uniformly tighten the bolts in a crisscross pattern to a torque of 220ft-lb.

O. Reconnect hose and tubes and ensure they are correctly located and tightened properly.

P. Start machine and check for any leaks.

01/31/2012

28 309416

Page 29

Maintenance

8.7 Engine Air Filter Replacement

Loosen the clamps that secure the engine air filter’s rear cover to the filter housing.

I.

II. Remove and clean the rear cover.

III. Remove the air filter element.

IV. Clean the canister with a damp cloth inside and out. DO NOT blow dirt out with compressed air.

Never blow dirt out of the interior of the filter housing. This

may introduce dust downstream of the filter. Instead, use a

clean damp cloth.

V. Prior to cleaning an element, check the element for damage. Damaged air filter elements must be

replaced.

A. Place a bright light inside the element to inspect for damages or leaks.

B. Inspect all seals and seal contact surfaces on the housing. Should faulty seals be evident, correct

the condition immediately.

VI. If element is undamaged, clean the air filter element.

A. The maximum number of times that an element should be cleaned is twice; however, the element

should be used no longer than a period of 1 year without changing.

Do not strike the element against any hard surfaces for cleaning as it may possibly rupture the element. Do not oil element.

B. When cleaning the element with compressed air, never let the air pressure exceed 30 PSI.

Reverse flush the element by directing the compressed air up and down the pleats in the filter

media from the inside of the element. Continue reverse flushing until all dust is removed. Should

any oil or greasy dirt remain on the filter surface, the element should be replaced.

When cleaning an element, the element will be damaged if you

exceed the recommended maximum air pressure of 30 PSI.

C. If the cleaned element is to be stored for later use, it must be stored in a clean container.

VII. Install the air filter element.

VIII. Install the rear cover and tighten clamp.

IX. Reset the air filter restriction indicator and the machine will be ready for operation.

01/31/2012

29 309416

Page 30

Maintenance

8.8 Compressor Air Filter Replacement

Loosen the wing nut that secures the compressor air filter’s cover to the filter housing.

I.

II. Remove and clean the cover.

III. Remove the air filter element.

IV. Clean the canister with a damp cloth inside and out. DO NOT blow dirt out with compressed air.

Never blow dirt out of the interior of the filter housing. This

may introduce dust downstream of the filter. Instead, use a

clean damp cloth.

V. Prior to cleaning an element, check the element for damage. Damaged air filter elements must be

replaced.

A. Place a bright light inside the element to inspect for damages or leaks.

B. Inspect all seals and seal contact surfaces on the housing. Should faulty seals be evident, correct

the condition immediately.

VI. If element is undamaged, clean the air filter element.

A. The maximum number of times that an element should be cleaned is twice; however, the element

should be used no longer than a period of 1 year without changing.

Do not strike the element against any hard surfaces for cleaning as it may possibly rupture the element. Do not oil element.

B. When cleaning the element with compressed air, never let the air pressure exceed 30 PSI.

Reverse flush the element by directing the compressed air up and down the pleats in the filter

media from the inside of the element. Continue reverse flushing until all dust is removed. Should

any oil or greasy dirt remain on the filter surface, the element should be replaced.

When cleaning an element, the element will be damaged if you

exceed the recommended maximum air pressure of 30 PSI.

C. If the cleaned element is to be stored for later use, it must be stored in a clean container.

VII. Install the air filter element.

VIII. Install the rear cover and tighten clamps. Install rubber evacuator cup facing down.

IX. Reset the air filter restriction indicator and the machine will be ready for operation.

01/31/2012

30 309416

Page 31

Maintenance

8.9 Compressor Oil

It is important that the compressor oil be of a recommended

type, and inspected and replaced as started in this manual.

The combination of a separator element loaded with dirt

and oxidized oil products together with increased air velocity as a result of this clogged conditions may produce a

critical point while the machine is in operation where ignition can take place and could cause a fire in the separator

tank.

The following are general characteristics for a rotary screw lubricant. Due to the impossibility of establishing

limits on all physical and chemical properties of lubricants which can affect their performance in the

compressor over a broad range of environmental influences, the responsibility for recommending and

consistently furnishing a suitable heavy duty lubricant must rest with the individual supplier if they choose not

to use the recommended Boss Industries, Inc. rotary screw lubricant. The lubricant supplier’s

recommendation must, therefore, be based upon not only the following general characteristics, but also upon

his own knowledge of the suitability of the recommended lubricant in helical screw type air compressors

operating in the particular environment involved.

Mixing different types or brands of lubricants is not recommended due to the possibility of a dilution of the additives

or a reaction between additives or different types.

Boss Recommended Compressor Lubricant: DEXRON® III ATF

I. Specifications

1. Flash point 400°F minimum.

2. Pour point -40°F.

3. Contains rust and corrosion inhibitors.

4. Contains foam suppressors.

5. Contains oxidation stabilizer.

Due to environmental factors, the useful life of all “extended life” lubricants may be shorter than quoted by the

lubricant supplier. Boss Industries, Inc. encourages the

user to closely monitor the lubricant condition and to participate in an oil analysis program with the supplier.

01/31/2012

No lubricant, however good and/or expensive, can replace

proper maintenance and attention. Select and use it wisely.

31 309416

Page 32

8.9 Compressor Oil (continued)

II. Adding Compressor Oil

A. Verify the machine is level to ensure oil level in sightglass will be accurate.

B. Remove any dirt around the separator tank fill cap to prevent contamination from entering the

system.

C. Remove the separator tank fill cap.

D. Inspect and clean the fill cap. Replace if necessary.

E. Dexron® III ATF can then be added until the oil level reaches halfway in the sightglass. Do not

over fill the separator tank. This will cause oil carryover in the discharge line and at blowdown.

Maintenance

Do not remove caps, plugs, or other components when the

system is running or pressurized. Stop system and relieve

all internal pressure before doing so. Failure to comply

with this warning will cause damage to property and serious

bodily harm.

Do not replace fill cap with a pipe cap; serious injury or damage could result. Replacement filters must be the same

quality and type as the original Boss Industries, Inc. fill cap.

F. Replace fill cap and tighten immediately.

III. Changing Compressor Oil

Initially the compressor oil and oil filter should be replaced after the first 50 hours of operation then

every 500 hours or 6 months. If the oil appears dirty or has a foul smell, it should be replaced

immediately.

A. Verify the machine is level to ensure oil level sightglass will be accurate.

B. Remove any dirt around the separator tank fill cap to prevent contamination from entering the

system.

Do not remove caps, plugs, or other components when the

system is running or pressurized. Stop system and relieve all

internal pressure before doing so. Failure to comply with this

warning will cause damage to property and serious bodily

harm.

C. Remove the separator tank fill cap.

D. Inspect and clean the fill cap. Replace if necessary.

E. Drain oil from the bottom of the separator tank.

F. If compressor oil filter change is required, proceed to section 8.11, “Compressor Oil Filter”.

01/31/2012

32 309416

Page 33

Maintenance

8.9 Compressor Oil (continued)

III. Changing Compressor Oil (continued)

G. Dexron III® ATF can now be added until the oil level reaches halfway in the sightglass. Do not

over fill the separator tank. This will cause oil carryover in the discharge line and at blowdown.

Do not replace fill cap with a pipe cap; serious injury or damage could result. Replacement filters must be the same

quality and type as the original Boss Industries, Inc. fill cap.

H. Replace fill cap and tighten immediately.

I. Run system briefly to see if more oil needs to be added and to ensure there are no leaks.

8.10 Compressor Oil Cooler

Any sign of leakage from the compressor oil cooler justifies a pressure test to ensure its integrity.

Cooler leaks should only be repaired by qualified service technicians. Dirt that clogs the cooling fins of

the cooler should be removed. The use of an air stream or high-pressure steam cleaner should be done

with caution so as to not damage the delicate fins. Bent cooling fins will reduce the cooling capability of

the compressor oil cooler.

8.11 Compressor Oil Filter

Initially the filter should be replaced after the first 50 hours of operation, then every 500 hours or 6

months. A dirty filter can restrict oil flow, causing high oil temperature, which will result in a system

shutdown.

I. Compressor Oil Filter Replacement

A. Verify the compressor oil system is drained.

B. Using a strap wrench, remove the oil filter and o-ring.

C. Clean o-ring seating surface on the oil filter head.

Substitute filters may have inadequate working pressure

limits, resulting in filter leakage or rupture. Replacement

filters must be the same quality and type as the original Boss

Industries, Inc. oil filter.

D. Apply a light film of oil to the new o-ring.

E. Hand tighten new filter until o-ring is seated in o-ring groove.

Mechanical over-tightening may distort the threads or damage

the filter element seal.

F. Continue tightening filter by hand an additional 1/2 to 3/4 turn.

G. Continue with Changing the Compressor Oil steps.

01/31/2012

33 309416

Page 34

Maintenance

8.12 Engine Cooling System Maintenance

The 210 DUS Air Compressor’s engine has a pressurized cooling system that contains a 50/50 mixture

of water and ethylene glycol. Maintenance of the system includes the engine coolant, belt tension, fan

integrity, and radiator. Further cooling system maintenance is defined in the engine manual.

I. Engine Coolant

A. Specifications

This diesel engine requires a balanced coolant mixture of water and ethylene glycol base

antifreeze. This protects the engine cooling system from corrosion as well as freezing damage.

The 210 DUS Air Compressor is shipped from the factory with a 50/50 mixture of water and

ethylene glycol. In tropical climates where freeze protection is not required, glycol engine

coolant should still be used to help prevent corrosion and pitting of cylinder liners.

B. Mixtures

Antifreeze concentration level should not exceed recommended levels. To do so can cause

cooling system failure.

1. A mixture of 50% antifreeze and 50% water is required for temperatures above -34° F.

2. A mixture of 60% antifreeze and 40% water is required for temperatures below -34° F.

This provides protection to -65° F.

3. Never exceed a 60% overall antifreeze mix.

C. Coolant Level

Before each start-up, when radiator is cold, the coolant level should be checked. When

needed, refill with a 50/50 solution of water and ethylene glycol, DO NOT use 100% antifreeze. The proper level for coolant in the system is to the bottom of the radiator fill neck and to

the cold line of the recovery bottle.

II. Engine Radiator

A. Radiator Core

Any sign of leakage from the engine radiator may justify a pressure test to assure its integrity.

Radiator leaks should only be repaired by qualified service technicians. Dirt that clogs the

cooling fins of the radiator should be removed. The use of an air stream or high-pressure steam

cleaner should be done with caution so as to not damage the delicate fins. Bent cooling fins will

reduce the cooling capability of the radiator.

Check the coolant level only when the engine is stopped and

the temperature is below 160° F. Failure to do so can cause

personal injury from heated coolant spray.

01/31/2012

34 309416

Page 35

Maintenance

8.12 Engine Cooling System Maintenance (continued)

II. Engine Radiator (continued)

B. Radiator Pressure Cap

If coolant continually spills from radiator through the overflow, the radiator cap should be tested

and/or replaced with a 13 PSI rated cap. Be sure cap is tightened to the proper secure position.

III. Engine Fan

Check the engine fan for cracks, loose bolts, and bent or damaged blades. Replace damaged fans

immediately. Do not run system if any of the conditions exist. Make sure the hex head bolts

mounting the fan to the water pump pulley are properly torqued to 29 ft-lbs.

Never use the fan to rotate the engine. The blade(s) can be

damaged causing a fan failure, which can result in personal

injury or property damage.

Engine Serpentine Belt

IV.

Visually inspect the engine serpentine belt. Replace belt if cracked or frayed. Check engine manual

for proper belt tension.

8.13 Battery

The battery supplied with the 210 DUS Air Compressor has been selected to have ample cold cranking

amperes for quick starts in cold weather. Keep the battery fully charged and if replacement is necessary

the new battery must be of equal or greater capacity.

Battery gas can explode causing acid burn to skin and blindness. Do not overcharge or jump the battery incorrectly.

8.14 Standby Pressure Adjustment (For 100 PSI system)

A. Close all service valves.

B. Start the machine.

C. Allow the engine to warm up.

D. The air pressure will build to 120 PSIG.

E. If the air pressure is less than 120 PSIG.

1. Adjust the discharge pressure regulator up by loosening the locknut.

2. Turn the adjusting screw clockwise.

F. If the air pressure is greater than 120 PSIG.

1. Adjust the discharge pressure regulator up by loosening the locknut.

2. Turn the adjusting screw counter-clockwise.

G. After the air pressure is set, tighten the locknut.

01/31/2012

35 309416

Page 36

Maintenance

DISCHARGE PRESSURE

REGULATOR BLEED HOLE

If your unit is rated at a higher pressure, add 20 PSI to the

working pressure for unload pressure: 160 PSI working = 180

PSI standby.

8.15 Idle Speed Adjustment

If engine speed is below 1800 RPM, contact Boss Industries, Inc.’s service department for further

assistance.

8.16 Rated Speed Adjustment

I. Rotate the unloader valve to “UNLOAD”.

II. Turn the ignition switch to the “START” position. If engine fails to start, DO NOT attempt to

restart until cranking motor stops rotating and the separator tank has blown down.

III. When engine starts, release the ignition switch. Maintain the unloader valve in the “UNLOAD”

position until the engine is warm and operating smoothly, then rotate the valve to “LOAD”.

IV. Allow system to run until engine coolant temperature reaches 190°F.

V. Open the air service valve until the discharge pressure gauge reads the desired working pressure.

Verify that air is not bleeding out of the bottom of the discharge pressure regulator. If air is bleed-

ing out, the standby pressure is set too high. Follow the steps in section 8.14 for reducing the

standby pressure.

VI. Loosen the adjustment locknut on the adjustment screw towards the front of the engine.

VII. Turn the adjustment screw clockwise to increase the speed.

VIII. Turn the adjustment screw counter-clockwise to decrease the speed.

IX. If the proper speed cannot be obtained with the adjustment screw, it may require loosening the

locknut on the air cylinder shaft and adjusting the clevis.

X. By turning the clevis onto the shaft, the engine speed will increase.

XI. By turning the clevis out, the engine speed will decrease.

XII. After proper speed is set, tighten all locknuts.

XIII. Close service valve and allow compressor to unload and the engine to return to idle.

Air Cylinder

Adjustment

Screw

Adjustment

Locknut

01/31/2012

Clevis

Locknut

36 309416

Page 37

Troubleshooting

MOTPMYS ESUAC YDEMER

tonlliwenihcaM

knarc

.snoitcennocyrettabytluaF

rofslanimretyrettabehtkcehC

.noisorrocdnassenthgit

.egatlovyrettabwoL .yrettabehtecalperroegrahC

.hctiwsnoitingiytluaF .hctiwsehtecalpeR

esoolerasnoitcennocdionelosretratS

.dedorrocro

.snoitcennocnethgitdnanaelC

.retratsrodionelosretratsytluaF

ytluafehtecalperroriapeR

.stnenopmoc

tub,sknarcenihcaM

tratstonlliw

.leufoN

tileuffotuonursahtinufI.leufddA

leufehtemirpotyrassecenebyam

.metsys

.metsysleufehtniriA

dnasnoitcennocenilleufkcehC.a

.riaperronethgit

.metsysleufehtemirP.b

.evitareponidionelosleuF

kcehc;enigneehtgniknarcelihW.a

.dionelosehttaegatlovrof

.sehctiwsytefaskcehC.b

nwodstuhsenihcaM

dnamedriahtiw

tneserp

.leuffotuO

tileuffotuonursahtinufI.leufddA

leufehtemirpotyrassecenebyam

.metsys

.detcirtserretlifleuF .retlifleufegnahC

.detavitcanwodtuhsytefaS

;detcirtserretlifliorosserpmoC.a

.retlifehtegnahc

egrahcsid/tnaloocenignehgiH.b

naelc;nwodtuhserutarepmet

.snifrelooclio/rotaidar

riaper;nekorbrognippilstlebnaF.c

.ecalperro

.liodda;wollevelliorosserpmoC.d

.liodda;wollevellioenignE.e

9.1 Troubleshooting Chart

01/31/2012

37 309416

Page 38

Troubleshooting

MOTPMYS ESUAC YDEMER

nwodstuhsenihcaM

dnamedriahtiw

)deunitnoc(tneserp

)deunitnoc(.detavitcanwodtuhsytefaS

egnahc;detcirtserretliflioenignE.f

.retlif

.eguagnwodtuhsytefasevitcefeD .eguagnwodtuhsehtkcehC

.gninoitcnuflamevlavcitatsomrehT

citatsomrehtehtecalperronaelC

.tnemele

tonlliwenihcaM

erusserppudliub

.eguagevitcefeD .eguagehtecalpeR

.taergootdnamedriA

neporoskaelrofsenilecivreskcehC

.sevlav

.nepoevlavnwodwolB

nwodwolbehtfieesotkcehC.a

.langistolipagnittegsievlav

.evlavecivresroriapeR.b

.gnilpuocevirdytluaF .gnilpuocehtecalpeR

eht,dnamedonhtiW

sdliubrosserpmoc

erusserpevissecxe

.eguagevitcefeD .eguagehtecalpeR

tonrotalugererusserpegrahcsiD

.ytluafrodetsujdaylreporp

.rotalugerehttsujdA.a

.rotalugerehtecalperroriapeR.b

riatneiciffusnI

yreviled

riaehtrofdezisrednurosserpmoC

.tnemeriuqer

.tnemeriuqerriamumixamkcehceR

.woldeepsenignE .yrassecensatsujdadnadeepskcehC

.detcirtserekatniriA

ekamdnatridrofretlifriakcehC.a

.gnikrowsirotacidniehterus

retlifehtnisnoitcurtsborofkooL.b

.gnipiptelnidna

sievlavtelniehttahtkcehC.c

.yllufgninepo

.gnilpuocevirdytluaF .gnilpuocehtecalpeR

9.1 Troubleshooting Chart (continued)

01/31/2012

38 309416

Page 39

Troubleshooting

MOTPMYS ESUAC YDEMER

evissecxE

liorosserpmoc

noitpmusnoc

.dellifrevoknatrotarapeS .levelreporpotniarD

.metsysliorosserpmocehtnikaeL

;snoitcennocdnasenilgnipipllakcehC

.yrassecensariaper

lioehtgnivomertonenilnruterliO

.tnemelerotarapesehtmorf

kcehcstidnaenilnruterliokcehC.a

saraelc;snoitcirtserrofevlav

.yrassecen

enilnruterlioehttahterusekaM.b

rotarapesehtfomottobehtsehcaer

.tnemele

.degamadtnemelerotarapeS .tnemeleehtecalpeR

riaehtrofdezisrednurosserpmoC

.tnemeriuqer

esaercniserusserpwoltagnitarepO

daolehtkcehcer;revoyrraclioeht

.stnemeriuqer

rosserpmoC

gnitaehrevo

htiwaerananidetarepogniebtinU

.riahserfdetimil

ehtpuneporotinuehtnoitisopeR

.tnemenifnoc

.nekorbroesoolsitlebnaF .ecalperronethgiT

.sreloocehtnopudliubtriD

eB.ylhguorohtreloocehtnaelC

.snifehtegamadottonluferac

.wollevelliorosserpmoC .levelreporpotllifdnakcehC

.ytridretlifliorosserpmoC .retlifehtecalpeR

.gninoitcnuflamevlavcitatsomrehT .tnemeleehtecalperronaelC

.senilliorosserpmocehtninoitcirtseR .senilehtecalperronaelC

.relooclioehtninoitcirtseR .reloocehtfosebutlanretninaelC

ehthtiwrosserpmocehtgnitarepO

.ffosrood

.nosroodtuP

.wolleveltnaloocenignE .levelreporpehtottnaloocddA

leufhgiH

noitpmusnoc

.metsysleufehtniskaeL

dnasenilleufehtllakcehC

saecalperroriaper;snoitcennoc

.yrassecen

.deepsgnitarepotcerroctatonenignE .deepsreporpstiotenigneehttsujdA

9.1 Troubleshooting Chart (continued)

01/31/2012

39 309416

Page 40

Troubleshooting

MOTPMYS ESUAC YDEMER

leufhgiH

noitpmusnoc

)deunitnoc(

.hgihoottesevlavtelnioterusserP

erusserptcerrocotrotalugertsujdA

.tinuehtrof

.detcirtsersiekatniriaenignE

gnikcehc,metsysekatniriaehttcepsnI

ro,riaper,naelc;noitcirtserynarof

.yrassecensaecalper

.gnimitnoitcejnitcerrocnI

enigneehtnisnoitacificepsottsujdA

.launam

9.1 Troubleshooting Chart (continued)

9.2 Parts and Service Contact Information

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website: http://www.bossair.com

When calling for technical support, please have machine

serial number and this manual available.

01/31/2012

40 309416

Page 41

WARRANTY

Warranty

10.1 Warranty Policy

Boss Industries, Inc. (BOSS) warrants that this Rotary Screw Compressor unit conforms to applicable

drawings and specifications approved in writing by BOSS. The unit assembly will be free from defects in

material and workmanship for a period of two (2) years from the date of initial operation or thirty (30)

months from the date of shipment, whichever period first expires. All other components and parts of BOSS

manufacture, will be free from defects in material and workmanship for a period of one (1) year from the

date of initial operation or eighteen (18) months from the date of shipment, whichever period first expires. If

within such period BOSS receives from the Buyer written notice of and alleged defect in or nonconformance of the unit, all other components and parts of BOSS manufacture and if in the judgment of

BOSS these items do not conform or are found to be defective in material of workmanship, BOSS will at its

option either, (a) furnish a Service Representative to correct defective workmanship, or (b) upon return of

the item F.O.B. BOSS original shipping point, repair or replace the item or issue credit for the replacement

item ordered by Buyer, (Defective material must be returned within thirty (30) days of return shipping

instructions from BOSS. Failure to do so within specified time will result in forfeiture of claim), or (c) refund

the full purchase price for the item without interest. Factory installed units will also include warranty on

installation for a period of one (1) year. This warranty does not cover damage caused by accident, misuse

or negligence. If the compressor unit is disassembled the warranty is void. BOSS’s sole responsibility and

Buyer’s exclusive remedy hereunder is limited to such repair, replacement, or repayment of the purchase

price. Parts not of BOSS manufacture are warranted only to the extent that they are warranted by the

original manufacture. BOSS shall have no responsibility for any cost or expense incurred by Buyer from

inability of BOSS to repair under said warranty when such inability is beyond the control of BOSS or

caused solely by Buyer.

There are no other warranties, express, statutory or implied, including those

of merchantability and of fitness of purpose; nor any affirmation of fact or

representation which extends beyond the description of the face hereof.

This warranty shall be void and BOSS shall have no responsibility to repair, replace, or repay the purchase

price of defective or damaged parts or components resulting directly or indirectly from the use of repair or

replacement parts not of BOSS manufacture or approved by BOSS or from Buyer’s failure to store, install,

maintain, and operate the compressor according to the recommendations contained in the Operating and

Parts Manual and good engineering practice. The total responsibility of BOSS for claims, losses, liabilities

or damages, whether in contract or tort, arising out of or related to its products shall not exceed the

purchase price. In no event shall BOSS be liable for any special, indirect, incidental or consequential

damages of any charter, including, but not limited to, loss of use of productive facilities or equipment, loss of

profits, property damage, expenses incurred in reliance on the performance of BOSS, or lost production,

whether suffered by Buyer or any third party.

BOSS INDUSTRIES, INC.

1761 GENESIS DRIVE

LAPORTE, IN 46350

(219) 324-7776 Phone

(219) 324-7470 Fax

41 309416

01/31/2012

Page 42

Warranty

10.2 Summary of Main Warranty Provisions

As claims, policies and procedures are governed by the terms of the BOSS Industries, Inc. (BOSS)

warranty, it is necessary to outline some of the more important provisions.

The BOSS warranty applies only to new and unused products, which, after shipment from the factory,

have not been altered, changed, repaired or mistreated in any manner whatsoever. Normal maintenance

items such as lubricants and filters are not warrantable items.

Parts not of BOSS manufacture are warranted only to the extent they are warranted by the original

manufacturer.

Damage resulting from abuse, neglect, misapplication or overloading of a machine, accessory or part is

not covered under warranty.

Deterioration or wear occasioned by chemical and/or abrasive action or excessive heat shall not

constitute defects.

Parts replacement and/or correction of defective workmanship will normally be handled by BOSS

Industries, Inc. or their authorized distributor.

Failure to file a detailed warranty claim/service report for each occurrence of material defect of

defective workmanship will cause warranty claim to be rejected.

Defective material must be returned within 30 days of receipt of shipping instructions. Failure to do so

within specified time will result in forfeiture of claim.

The distributor is responsible for the initial investigation and write up of the warranty claim.

Distributor shall be allowed no more than 30 days from date of repair to file a warranty claim/service

report.

Warranty for failure of BOSS replacement parts covers the net cost of the part only, not labor and

mileage.

The BOSS warranty does not cover diagnostic calls and travel. That is time spent traveling to the

machine to analyze the problem and returning with the proper tools and parts to correct the problem.

Boss will deduct from allowable credits for excess freight caused by sender failing to follow return

shipping instructions.

Distributors or end-user automatically deducting the value of a warranty claim from outstanding balances

due and payable to BOSS prior to receiving written notification of BOSS approval of the warranty

claim may be subject to forfeiture of the entire claim.

01/31/2012

42 309416

Page 43

Warranty

10.3 Warranty/Return Goods Instructions

The warranty/return procedure outlined below is provided to give the claimant the information necessary

to file a warranty/return claim, and enable BOSS INDUSTRIES the ability to best serve its’ customers.

Please see the following instructions to initiate a return:

Contact BOSS INDUSTRIES Returns Department by telephone at 219.324.7776 or via email at

service@bossair.com. You may also send a fax at 219.324.7470.

10.4 Warranty Claims - Preparation of Parts Return

Parts returned to the factory must be properly packaged to prevent damage during shipment. Damage to

a part as a result of improper handling or packing could be cause for denial. When addressing the package

for shipment, the following information must be on the outside of, or tagged clearly, to the package.

1. Return Goods Authorization #.

2. Distributor or end-users return address.

3. Correct factory address.

4. Number of packages pertaining to each claim.

NOTE: Our warranty requires that all defective parts be returned to BOSS INDUSTRIES freight

prepaid. Items sent without RGA number will not be accepted. Unauthorized Returns Will Immediately

Be Refused At Dock.

10.5 Return or Warranty Claims - Filing Procedures

1. Initiate through a purchase order for warranty part or request for credit.

2. RGA will accompany replacement part.

3. BOSS INDUSTRIES will confirm disposition of failed part within 30 days of receipt and or request

additional information.

4. Claim denial will result in issuance of a letter of denial.

5. BOSS INDUSTRIES will consider each claim on its’ own merit and reserves the right to accept or

reject claim request. In case of air-ends, these will be returned to the manufacturer for their analysis/

input.

6. Send Warranty Claim to:

BOSS INDUSTRIES, INC.

1761 Genesis Drive

LaPorte, IN 46350

Attn: Returns Dept.

01/31/2012

43 309416

Page 44

Warranty

10.6 Warranty Claims Provisions

An approved claim depends on the following provision:

1. An RGA # must be issued by BOSS INDUSTRIES. (See filing procedures.)

2. Failed part must be returned within 30 days of original invoice date, freight prepaid, with RGA #.

3. Part is determined to be defective.

4. Workmanship is determined to be defective.