Page 1

L1® Compact

Portable Line Array System

©2009 Bose Corporation

Service Manual

Reference Number 318882-SM Rev. 01

Electronic Copy Only

Page 2

Contents

Safety Information.............................................................................................................................3

Warranty .............................................................................................................................................3

Specifications....................................................................................................................................4

Electrostatic Discharge Sensitive (ESDS) Device Handling....................................................... 5

Part List Notes ..................................................................................................................................5

L1 Compact Accessory Pack...........................................................................................................5

Product Description ..................................................................................................................... 6-8

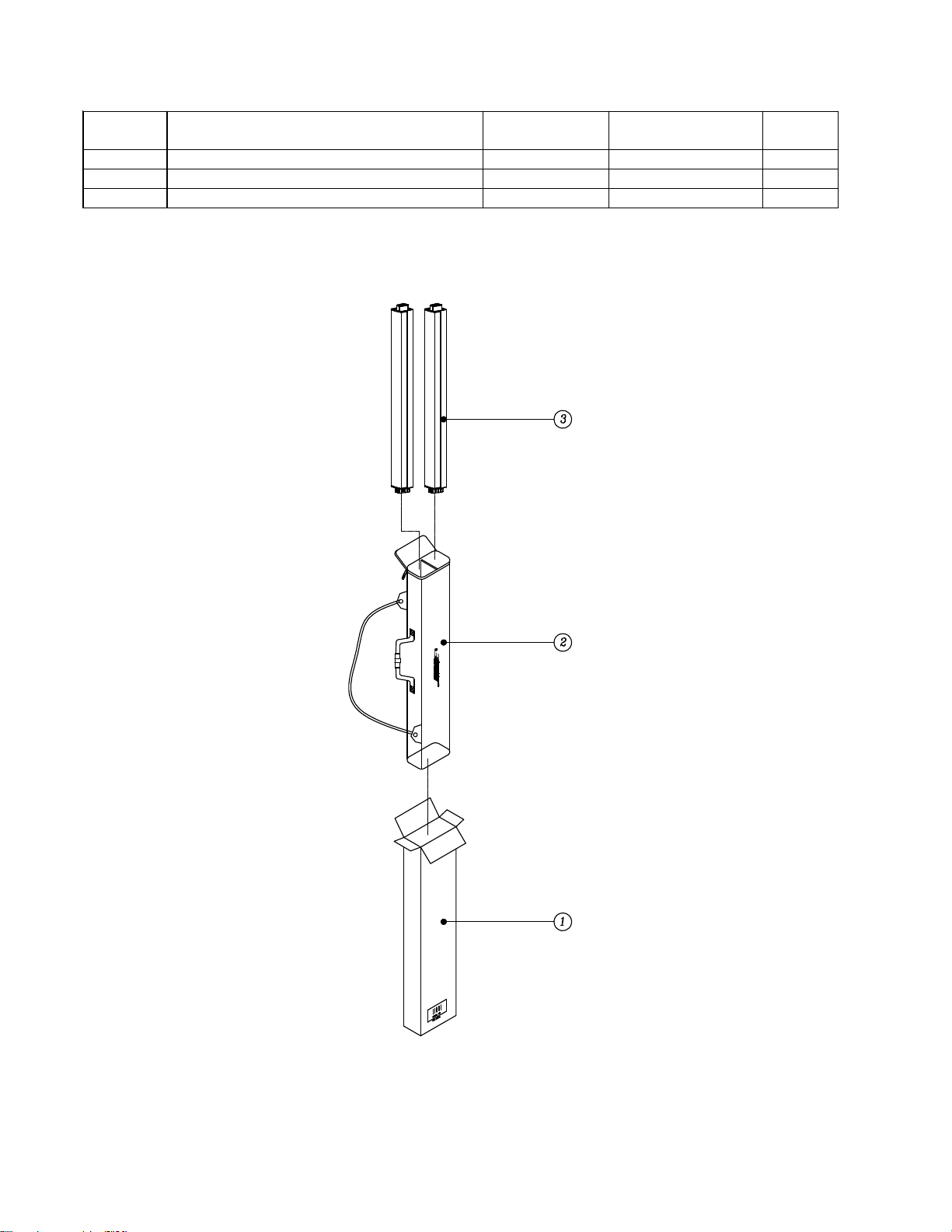

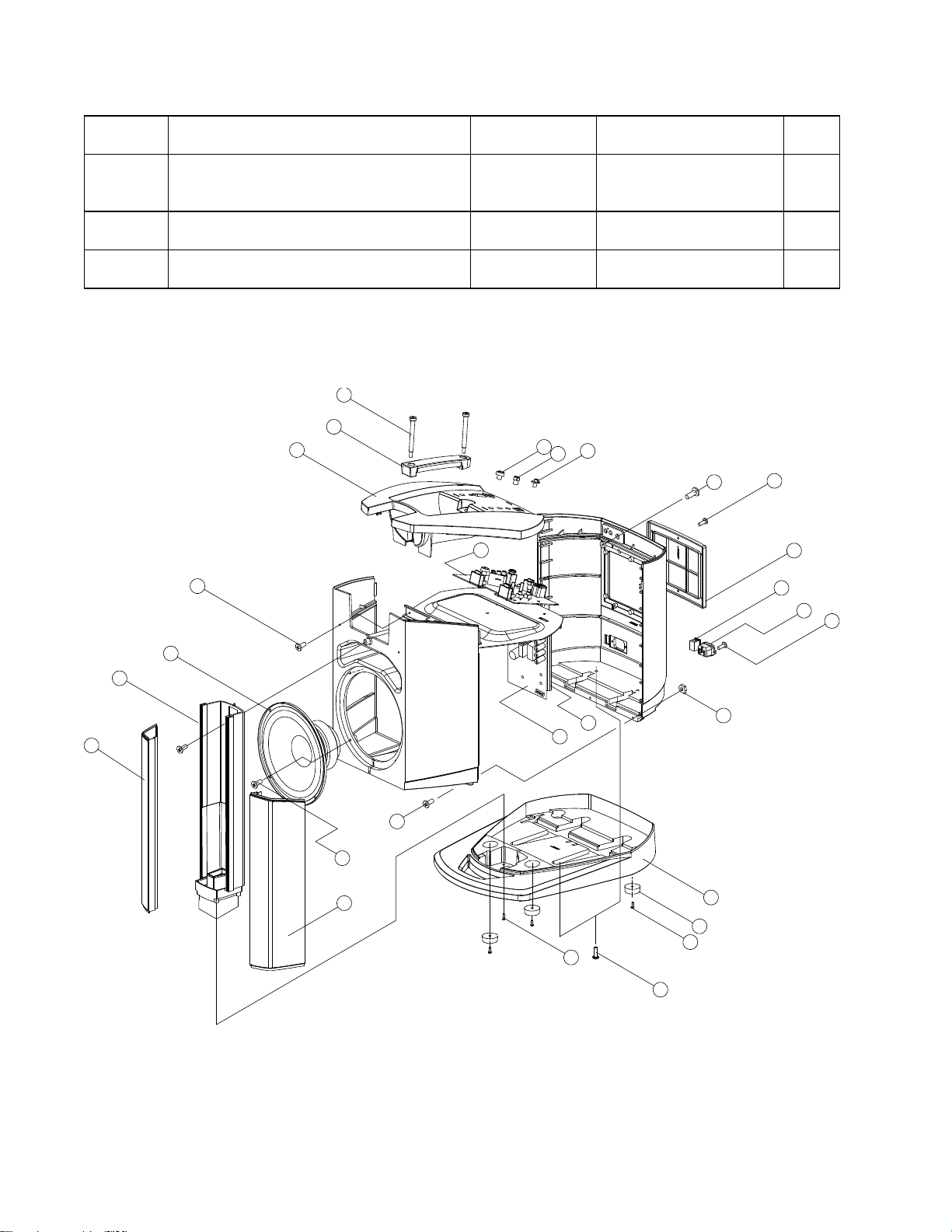

Packaging Part List, L1 Compact Power Stand (includes Array) (see Figure 1) ........................9

Figure 1. L1 Compact Power Stand Packaging View ..........................................................................9

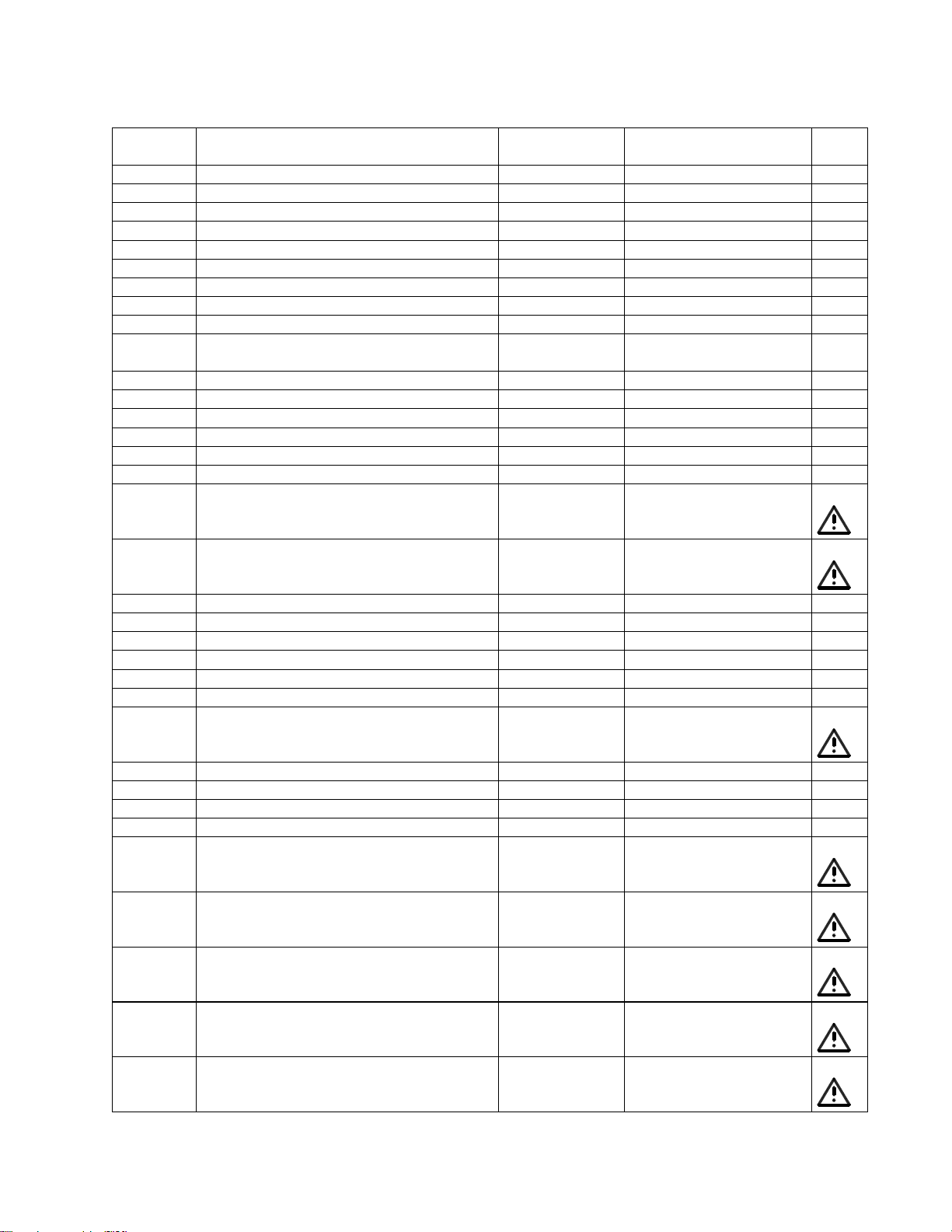

Packaging Part List, L1 Compact Array Extensions (see Figure 2) ..........................................10

Figure 2. L1 Compact Array Extensions Packaging View .................................................................10

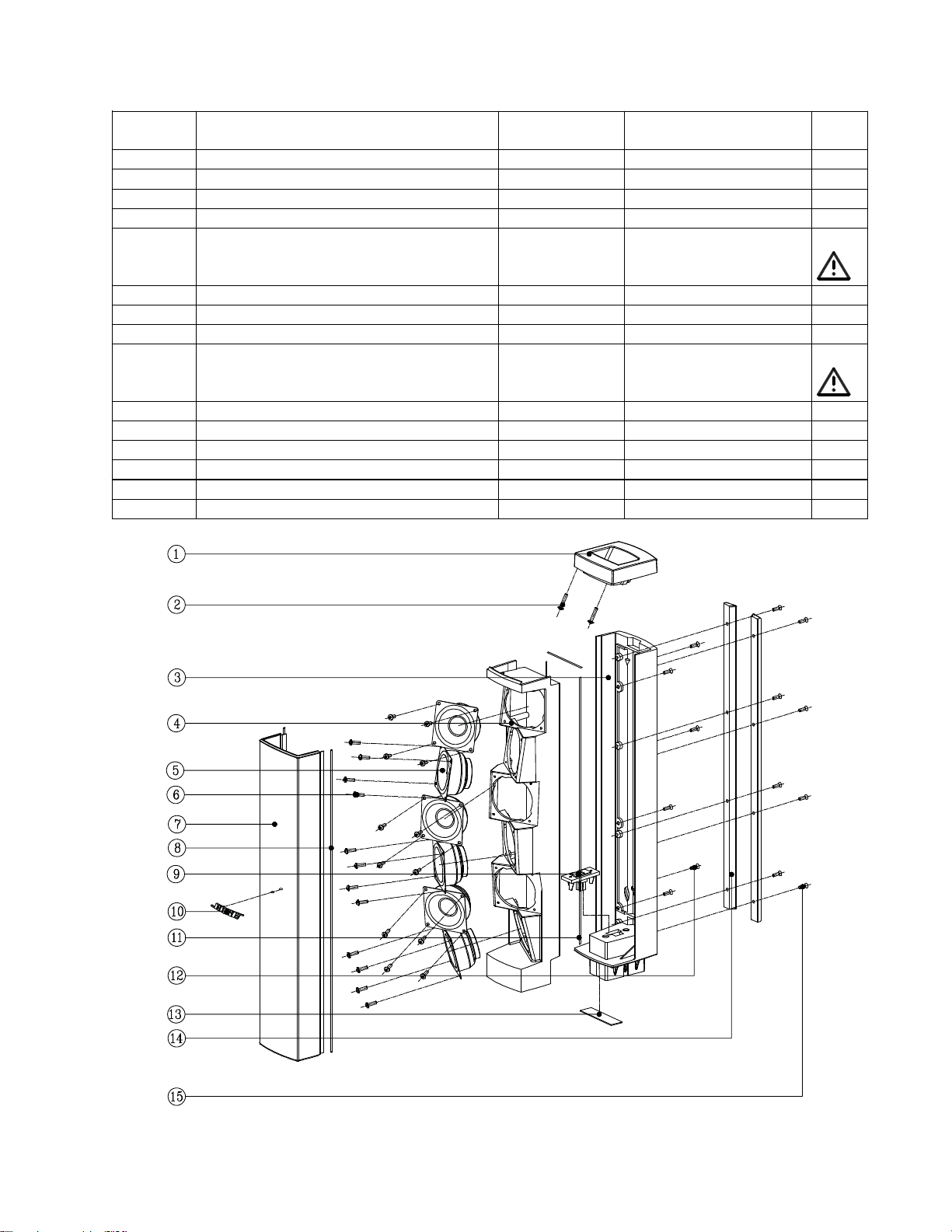

Main Part List, L1 Compact Power Stand (see Figure 3).......................................................11-12

Figure 3. L1 Compact Power Stand Exploded View .......................................................................... 12

Main Part List, L1 Compact Array Speaker (see Figure 4)..........................................................13

Figure 4. L1 Compact Array Speaker Exploded View ........................................................................ 13

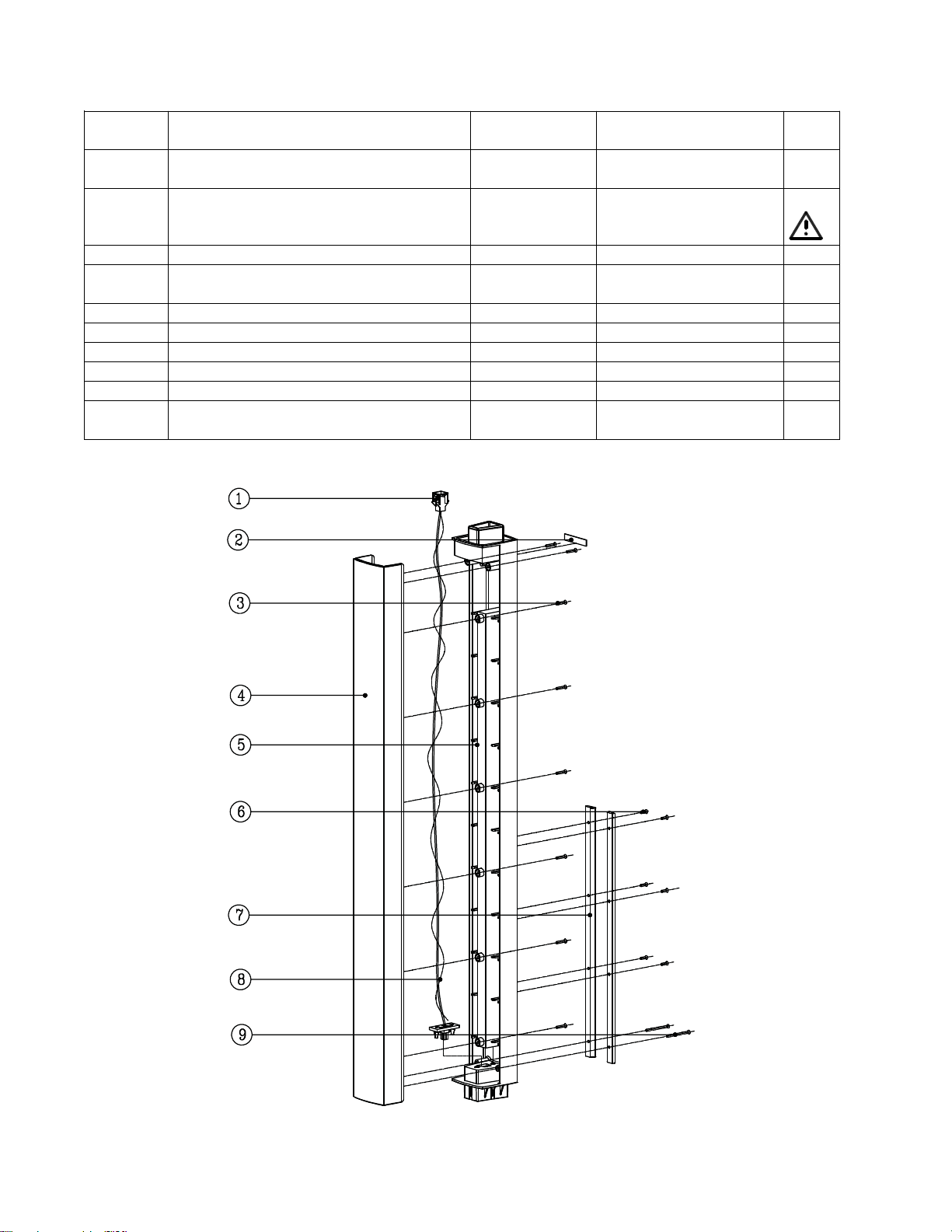

Main Part List, L1 Compact Array Extension Exploded View (see Figure 5) ............................14

Figure 5. L1 Compact Array Extension Exploded View ..................................................................... 14

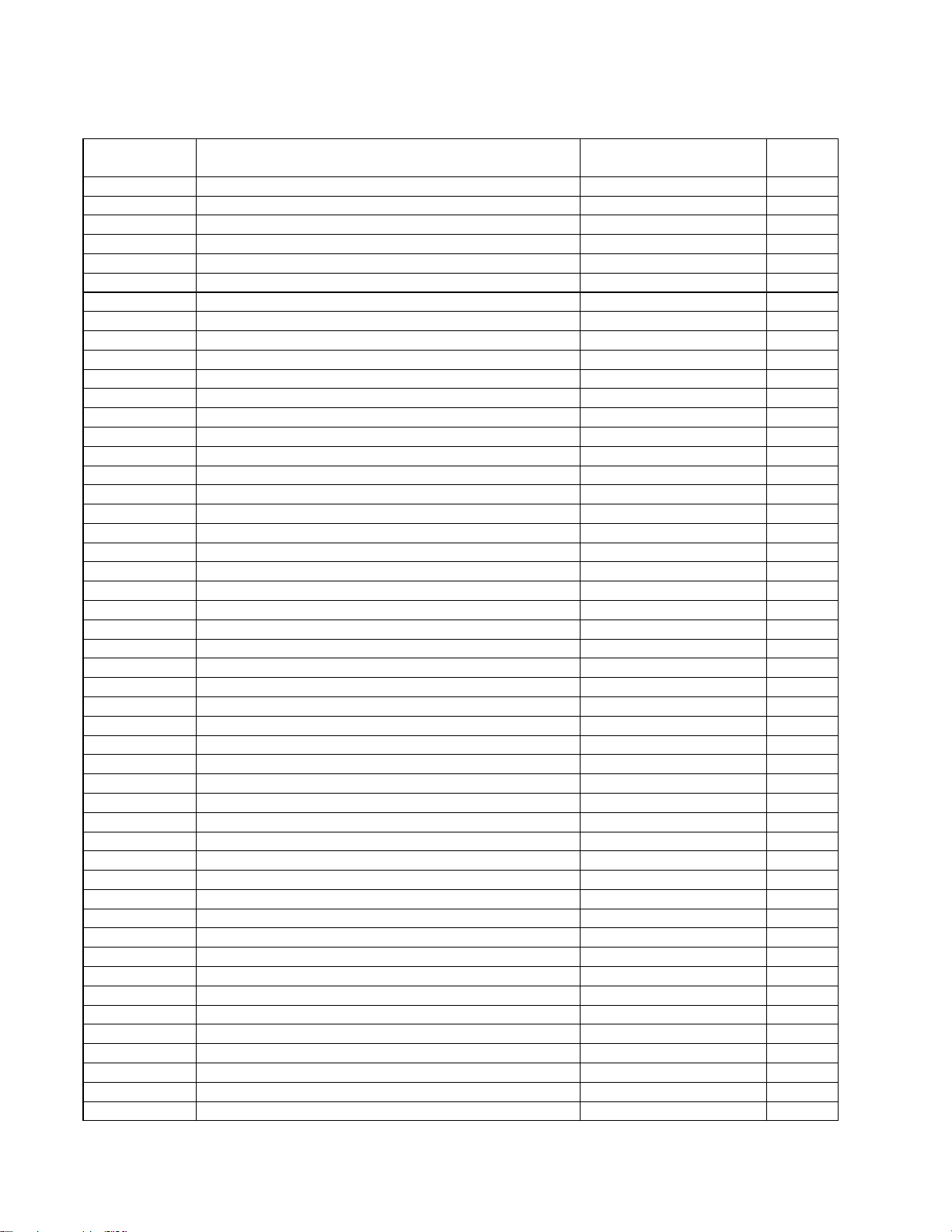

Electrical Part List .................................................................................................................... 15-37

Input/Output PCB Assembly .................................................................................................... 15-29

3.5mm Line Input PCB Assembly ...................................................................................................29

Output PCB Assembly .............................................................................................................. 29-30

Power Amplifier PCB Assembly ............................................................................................... 31-37

Disassembly Procedures ......................................................................................................... 38-44

Test Procedures ....................................................................................................................... 45-48

IC Diagrams ............................................................................................................................... 49-50

Service Manual Revision History .................................................................................................51

2

Page 3

Safety Information

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

6500 / IEC 60056 paragraph 9.1.1. With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads, metallic

overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the unit

power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® L1® Compact system contains

no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

W arranty

The Bose L1 Compact Power Stand is covered by a limited 2-year transferable warranty.

The L1 Compact Array and the Power Stand woofer are covered by a 5-year limited warranty.

3

Page 4

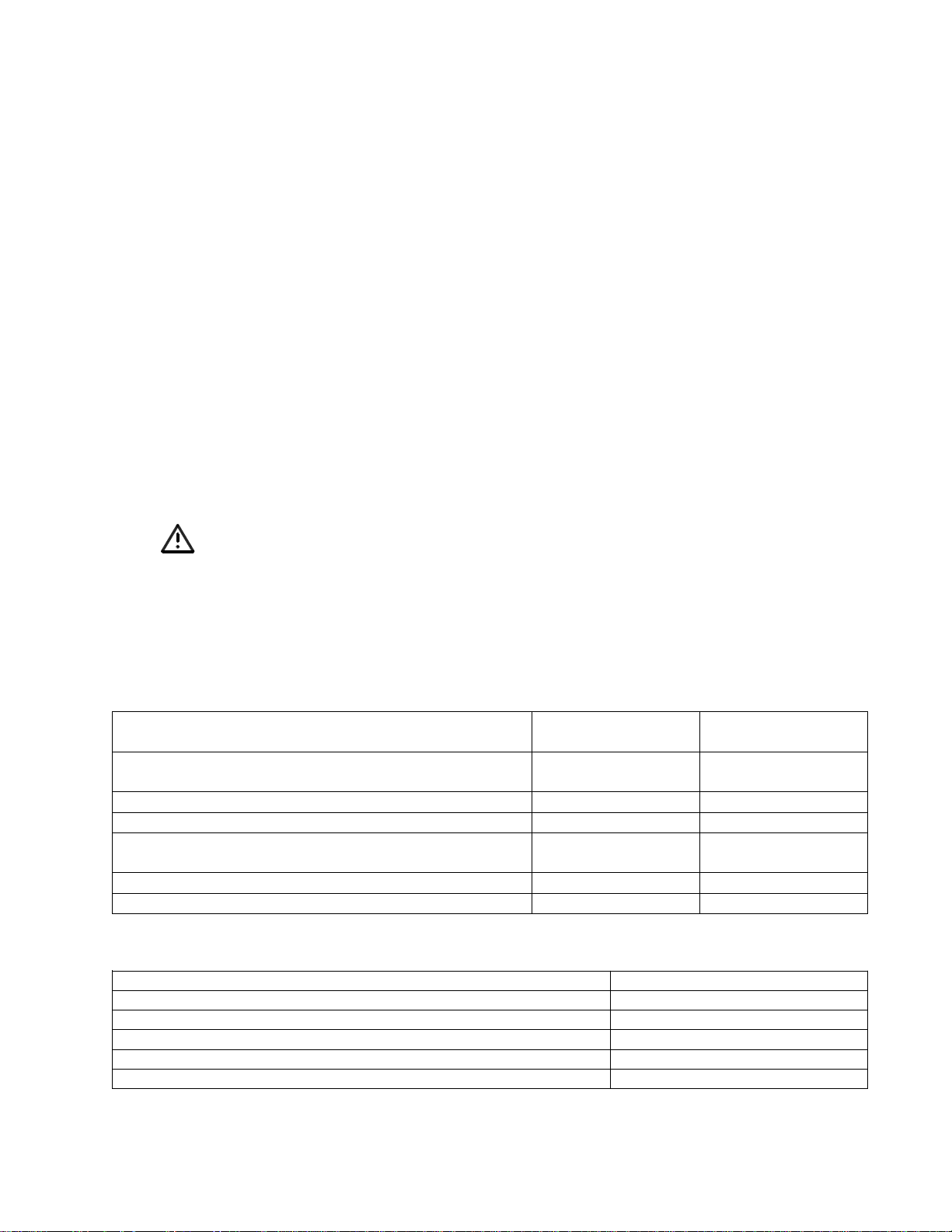

Specifications

Mechanical

Part Dimensions Weight

L1 Compact Power Stand with 16.5” H x 13.25” W x 16.75” D 24.6 lbs (11.2 kg)

Loudpseaker Array (41.8 cm x 33.9 cm x 42.6 cm)

L1 Compact Loudpseaker Array 16” H x 2.75” W x 2.75” D 3.0 lbs (1.35 kg)

(40.8 cm x 7 cm x 7.1 cm)

L1 Compact Extensions (2) 32.5” H x 2.75” W x 2.75” D 2.3 lbs (1.05 kg) each

Collapsed Position 16.5” H x 13.25” W x 16.75” D 24.6 lbs (11.2 kg)

(assembled) (41.8 cm x 33.9 cm x 42.6 cm)

Extended Position 78.5” H x 13.25” W x 16.75” D 29.2 lbs (13.3 kg)

(assembled) (199.5 cm x 33.9 cm x 42.6 cm)

Shipping Cartons Weight

L1 Compact System (no extensions) 30.4 lbs (13.8 kg)

L1 Compact Extensions 7.5 lbs (3.4 kg)

Electrical

AC Power Rating

100 - 240 VAC ~ 50/60 Hz, 200W max

Peak Inrush Current

230V: 18.2 Amps

120V: 9.7 Amps

4

Page 5

Electrostatic Discharge Sensitive (ESDS)

Description Bose®

Vendor Part

Description Bose® Part Number

Device Handling

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

Part List Notes

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

L1 Compact Accessory Pack

Part Number

L1 Microphone Accessory Pack,

Includes all items below

Audix OM3 Cardioid Dynamic Vocal Microphone 318884-0000 OM3

20' XLR Microphone Cable 318885-0000 CBL-20

Carton, L1 Microphone Accessory Pack, RSC,

10.50x8.50x5.75"

Cable, Audio, Dual, RCA 185931-01 N/A

Cable, Input, 3.5mm, 6ft, Black 271994-001 N/A

322711-0000 -

318886-0000 N/A

Number

L1 Compact System Versions

L1 Compact Power Stand, 120V (US) 318882-1100

L1 Compact Power Stand, 220V (China) 318882-2100

L1 Compact Power Stand, 100V (Japan) 318882-3100

L1 Compact Power Stand, 230V (Euro) 318882-4100

L1 Compact Power Stand, 240V (UK) 318882-5100

5

Page 6

Product Description

Loudspeaker

Array

Whether you are a musician amplifying your instruments, a mobile DJ entertaining an audience,

or the host of your own special event, the Bose® L1® Compact Portable Line Array System will

provide quality sound for audiences of approximately 100 people.

Features Include

• Carry it in one trip – The entire system is light enough to be carried in a single trip.

• Set it up in one minute – The interlocking components of the L1 Compact system allow system

setup in less than a minute. There are no external speaker wires required. An integrated bass

enclosure with an intuitive user interface eliminates the need for separate components.

• Fill the room with one loudspeaker – Whether you’re performing live or playing back prerecorded music, whether you’re performing in a coffeehouse or a 100-seat room, Bose Spatial

Dispersion™ loudspeaker technology provides nearly 180º of tonally balanced sound coverage

so there are no dead spots.

• PA and monitor combined – Audience members enjoy a more consistent and intimate listening

experience because the system sets up behind the performer and serves as both the monitor for

the stage and amplification system for the audience. The performer alone controls the sound.

• Versatility – In addition to musical performances, the L1 Compact provides quality sound for a

wide variety of general-purpose uses including presentations, celebrations, speeches, and

music playback for about 100 people.

• Integrated ToneMatch® signal processing – Provides a high level of tone customization on your

microphone or acoustic guitar to provide a listening experience that most musicians only achieve

using a recording studio.

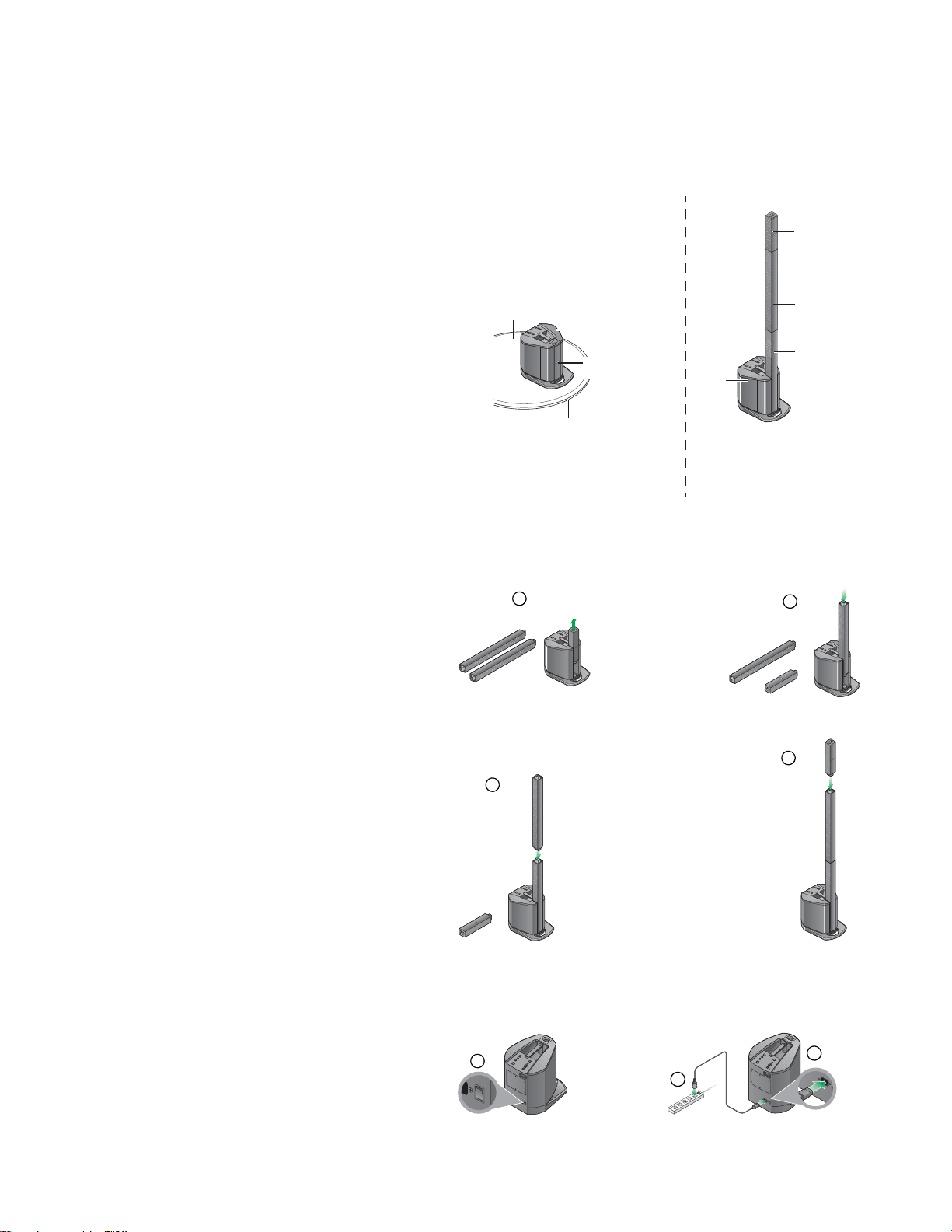

• Two setup options – The L1 Compact system can be used in either the collapsed position for

smaller audiences or extended positions for larger audiences.

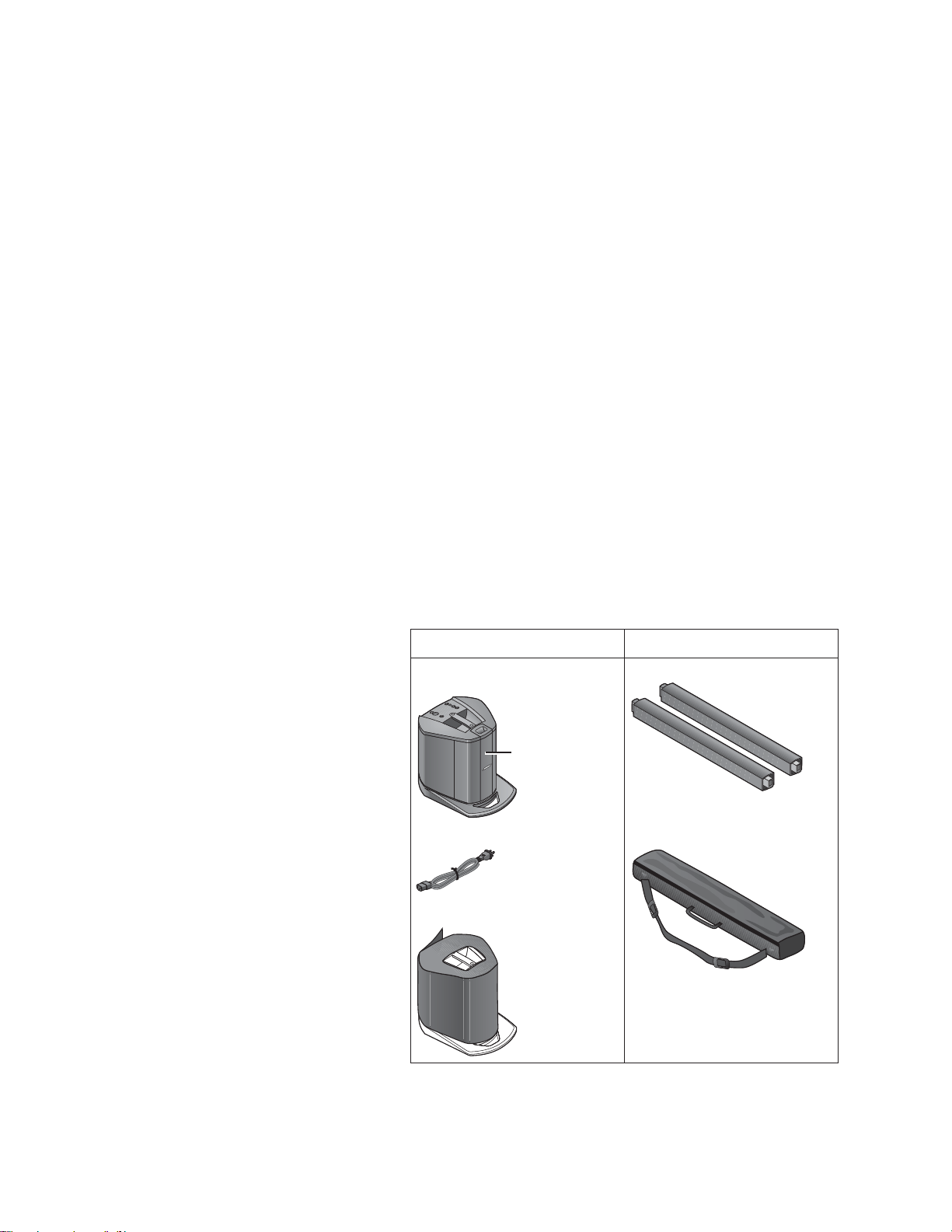

The L1 Compact Portable Line Array

System is shipped in two cartons.

The L1 Compact system consists of:

• L1 Compact Power Stand

• L1 Compact Loudspeaker Array

• L1 Compact Extensions

The L1 Compact system comes with

a slipcover for the Power Stand and

a padded carry bag for the L1 Compact Extensions.

Power stand carton Extensions carton

L1®Compact Power Stand

with Loudspeaker Array

AC power cord

Power Stand slipcover

L1®Compact Extensions

Extensions carry bag

6

Page 7

Product Description

Smaller audiences

• Intimate acoustic performances

• Music playback

• Presentations

• Speeches

Larger audiences

•Musical pe

rformances

–

auditorium/coeehouse

• DJ events

• Announcements

–

larger spaces

Collapsed position

Loudspeaker

Power

Extended position

Power Stand

Array

Extension

Extension

Stand

Ta b l e t o p

Array

Loudspeaker

2

3

System configurations

You can set up the L1

®

Compact system in two unique positions. The examples below will help

you quickly identify the position that can

work best for you.

The L1 Compact Extensions are not required when using the L1 Compact Portable

Line Array System in the collapsed position.

They are included for situations where you

need to elevate the Loudspeaker Array to

project sound to larger audiences.

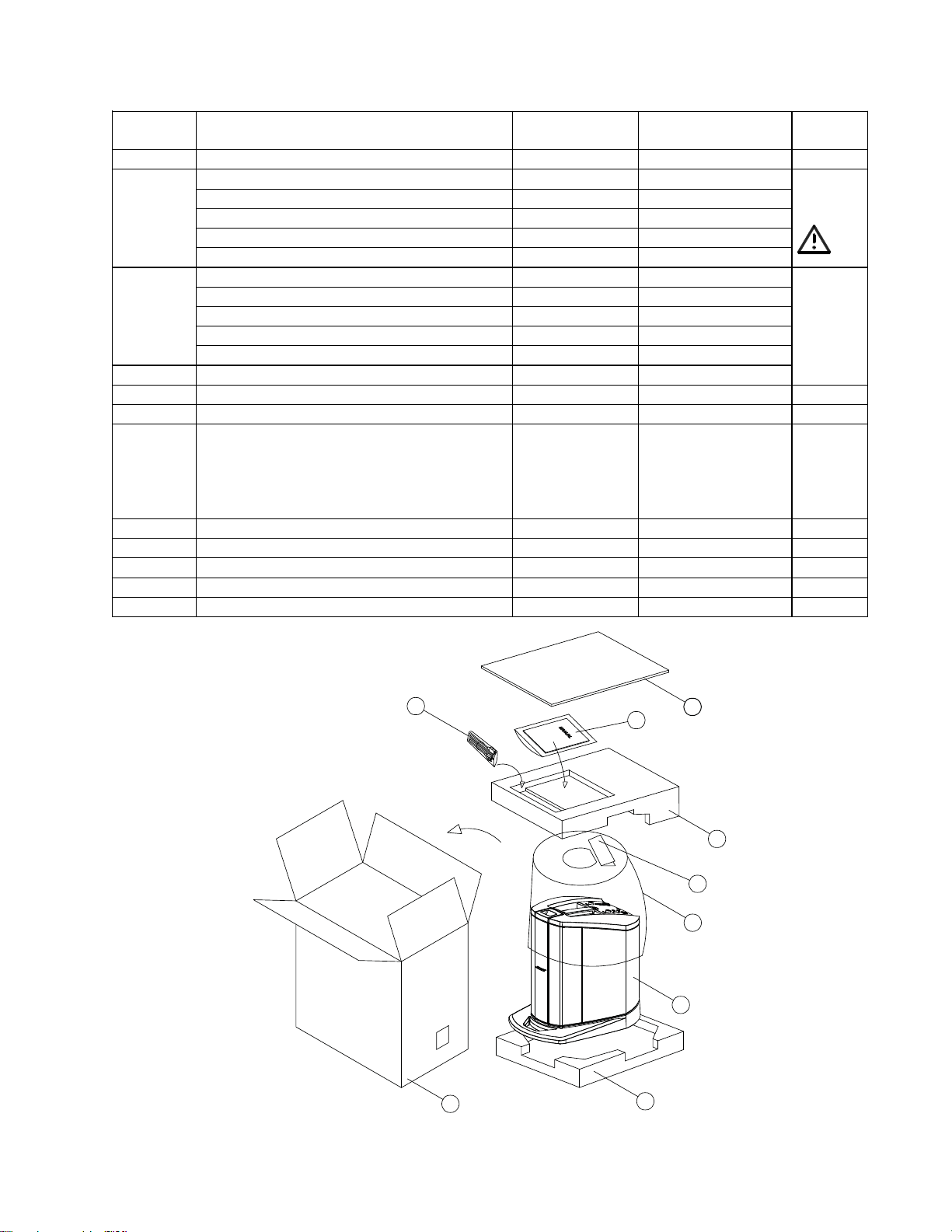

Extending the Loudspeaker Array

Once you have set the system in place:

1.Slide the Loudspeaker Array up and

out of the Power Stand and temporarily lay it aside.

Note: The two L1 Compact Extensions are identical to each other.

1

2

2.Align the plug on the bottom of the

Extension with the socket on the

Power Stand, then slide the extension

into the power stand.

3.Align the remaining Extension and

push it firmly in place.

4.Align the Loudspeaker Array and

push it firmly in place.

Connecting power to the system

1.Make sure the power switch is off

(down position).

2.Plug one end of the power cord into

the connector on the power stand.

3.Plug the other end into a live electrical receptacle.

4.Before turning the system on,

connect your sound sources.

4

3

1

7

Page 8

Product Description

Channel 1

Channel 2

1

2

3

4

5

6

7

8

9

10

11

12

Connections and controls

The power stand control panel provides all the necessary connectors, controls, and indicators

for operation.

(Microphone input)

The channel 1 input is for use only with a

microphone. Integrated ToneMatch

®

signal

processing provides a high level of tone

customization to provide a listening experience

that most musicians can only achieve using a

recording studio.

1. S igna l/Clip indic ator – Displays the input

signal status in color.

• Green: Input signal present

• Red: Input signal clipping

2. V olume contr ol – Adjusts the volume of your

microphone.

3. Treble control – Adjusts the amount of treble

on your microphone.

4. B ass c ontr ol – Adjusts the amount bass on

your microphone.

5. Microphone input – Analog input for

connecting a balanced XLR microphone cable. A

ToneMatch microphone preset is built in.

(Utilit y cha nne l – multip le input)

6. S igna l/Clip indicator – Displays the input

signal status in color.

• Green: Input signal present

• Red: Input signal clipping

7.V olume contr ol – Adjusts the overall volume of

all input sources connected to Channel 2.

8. 1/8-inch stereo input – Stereo analog input

for connecting audio sources such as portable

mp3 players, satellite radio, laptop computers,

video projectors, and smart boards. Left and right

inputs are summed by the power stand.

9. RCA stereo input – Analog input for

connecting audio sources such as DVD players,

VCR players, video game consoles, DJ mixers,

Keyboards and other instruments. For best

results, connect both the left and right signals.

Left and right inputs are summed by the power

stand.

10. 1/4-inch input – Balanced analog input for

connecting guitars and other instruments.

Accepts either 1/4-inch TRS balanced or TS

unbalanced cables.

11. ToneMatch switch – When connecting an

acoustic guitar to the 1/4-inch input, move the

switch to the position to enable a ToneMatch

preset. When connecting anything other than an

acoustic guitar to the 1/4-inch input, move the

switch down to the Line Level position.

12. Power LED – Indicates power status.

Blue: Power on

8

Page 9

Packaging Part List

L1 Compact Power Stand (includes Array) (see Figure 1)

Item

Number

Description Bose® Part

Number

Vendor Part

Number

Note

1 Inner Sheet, Cardboard 324116-001S 1451-0340+0

2 Power Cord, 120V, (US) 298165 7012-7340+0 3

Power Cord, 220V (China) 318882-210S 7013-0580+0

Power Cord, 100V, (Japan) 298167 7012-5530+0

Power Cord, 230V (Euro) 298166 7012-6980+0

Power Cord, 240V (UK) 298168 7012-6603+0

3 Owner’s Guide, 3 Lang (US/UK) 317638-0010 4301-7353+0

Owner’s Guide (Euro) 320042-0010 4301-7354+0

Owner’s Guide (China) 320043-0010 4301-7356+0

Owner’s Guide (Japan) 320044-0010 4301-7352+0

2YR Warranty Card, Registration 320561-0010 3050-4571+0

4 Filler, Top, Power Stand 317383-000S 1493-2001+0

5 Quick Start Guide Card 317639-0010 3050-4561+0

6 Power Stand Slip Cover 317403-010S 4201-1180+0

7 L1 Compact Power Stand, 120V (US) REF -

L1 Compact Power Stand, 220V (China) REF -

L1 Compact Power Stand, 100V (Japan) REF -

L1 Compact Power Stand, 230V (Euro) REF -

L1 Compact Power Stand, 240V (UK) REF -

8 Filler, Bottom, Power Stand 317384-000S 1493-2011+0

9 Carton, Powerstand 317382-000S 1481-4801+0

- L1 Compact Loudspeaker Array 318880-0100 svc-cajun11+arra

- Warranty Card, English Language 307430 3050-3531+0

- Poly Bag 320228-0000 1497-4122+0

2

9

3

7

8

Figure 1. L1 Compact Power Stand Packaging View

1

4

5

6

9

Page 10

Packaging Part List

Item

Description Bose® Part

Vendor Part

Note

L1 Compact Array Extensions (see Figure 2)

Number

1 Carton, Extensions 317385-000S 1481-4701+0

2 Extensions Carry Bag 317404-010S 4201-1170+0

3 L1 Compact Extension 318881-010S svc-cajun11+exte

Number

Number

Figure 2. L1 Compact Array Extensions Packaging View

10

Page 11

Main Part List

Item

Description Bose® Part

Vendor Part Number Note

L1 Compact Power Stand (see Figure 3)

Number

1 Grille, Power Stand, Left 317363-010S 4135+8921+0

2 Grille, Power Stand, Right 317364-010S 4135-8931+0

3 Guide, Array, ABS, Blk - 4155-3811+0

4 Woofer, 8 inch 317370-000S SVC-8900-6980+0

5 Screw, M4x25mm - 2900-4025+3000 4

6 Screw, M4x14 - 2904-4014+3000 4

7 Enclosure, Top, Silk Screened 317346-010S 1468-5501+0

8 Carry Handle, Power Stand 317353-010S 4155-3781+0

9 Bolt, Power Stand Carry Handle, M6 317359-010S 4135-8951+0

10 PCB Assy, IO COM

(Pre-amp PCB ASSY)

11 Knob, Channel 1/2 317349-010S 2447-8401+0

12 Knob, Volume/Treble 317350-010S 2447-8501+0

13 Knob, Line Level 317351-010S 2447-8601+0

14 Screw, Machine, Flat, CS, M4x12 - 2901-4012+3000 4

15 Screw, CSH, Blk - 2901-3012+3000 4

16 Panel, Access 317348-010S 1468-5701+0

17 Switch, Power, DPST, 250V, 10A 317373-000S 5200-4969+0 3

18 Inlet, AC, UL/CSA/VDE, 250V - 2113-1144+0 3

19 Screw, M3x12, CSH, Blk - 2901-3012+3000 4

20 Nut, M4 - 2640-4030+0703 4

21 Heatsink, Amplifier PCB, 160x120mm - 5401-0191+0 4

22 PCB Assy, Amp/SMPS 317372-000S SVC-CAJUN01+PAMP 2

23 Screw, Machine, M4 - 2904-4020+3000 4

24 Enclosure, Bottom 317347-010S 1468-5601+0

25 Foot, Rubber, 31x31x10 - 4157-1191+0 3

26 Screw, B-tite, Bind, M4x12 - 2954-4012+3000 4

27 Screw, Machine, M4x25, 7.8mm - 2900-4025+3000 4

28 Screw, B-tite, Flat-CS, M3x12 - 2951-3012+0000 4

- Guide Track, Bass 317358-010S 4155-3841+0

- FUSE, 5A, 250V, 8X8.5,

VDE/PSE/CCC, RLT LITTELFUSE,

JAPAN/EURO/UK

- FUSE, 5A, 250V, 8X8.5 UL/CSA

RLT LITTELFUSE, US/CAN

- Ribbon Cable, I/O Board to

AMP/SMPS, WIRE-CONN, 10P, P2.0,

#26, UL2468 F/F

- Cable Assy, AMP/SMPS to Woofer,

WIRE-SPK, 2P, VH3.96-2Y, #20,

UL2468, L400, R/B, 205/110T

- Cable Assy, AMP/SMPS to Twiddler

Conn., WIRE, 2P, VH3.96-3Y, #20, UL

2468, L=500, R/B, WM17700ND

Number

319966-000S SVC-CAJUN01+I/O 2

317381-000S 5120-1136+0-L 3

319970-000S 5120-1140+0-L 3

319983-000S 7013-0590+0 3

319984-000S 7013-0780+0 3

319985-000S 7013-0730+0 3

11

Page 12

Main Part List

Item

Description Bose® Part

Vendor Part Number Note

L1 Compact Power Stand, continued (see Figure 3)

Number

- PCB Assy, COB COM

(Includes: PRE-AMP ASSY/3.5MM

Jack Input Card/Line Output Card)

- PCB Assy, IN COM

(3.5MM Jack Input Card)

- PCB Assy, OUT COM

(Line Output Card)

6

Number

317371-000S SVC-CAJUN01+COB 2

319967-000S SVC-CAJUN01+IN 2

319968-000S SVC-CAJUN01+OUT 2

9

8

7

10

11

13

12

14

15

17

16

18

19

4

3

21

1

23

5

2

22

28

27

20

24

25

26

Figure 3. L1 Compact Power Stand Exploded View

12

Page 13

Main Part List

Item

Description Bose® Part

Vendor Part Number Note

L1 Compact Array Speaker (see Figure 4)

Number

1 Handle, Array - 4155-3851+0 4

2 Screw, B-tite, Bind, M3x16, CS-Recess - 2954-3016+3000 4

3 Enclosure, Array, ABS - 4155-3801+0 4

4 Baffle, Array, ABS, Black - 4155-3791+0 4

5 Twiddler, 2.5 inch 291636-001 1525-2120+0 3

6 Screw, M3x10, BT, ZN, Blk - 2934-3010+3000 4

7 Grille, Array (W/Logo) 317365-010S svc-cajun01+gril

8 Butyl Tape - 9500-1101+0 4

9 Wire, Spk, 2P, #20, UL1007,

L=250/180, RD/BLK

10 Array Logo 317407-010S 2150-7311+0

11 EVA Gasket, Baffle - 4149-1121+0 4

12 Screw, M3x13, 5.6MM, BK-ZN/CR HD - 2931-3013+3000 4

13 Label, Serial Number, 30x7mm - - 4

14 Guide Strip, Array 317366-010S 4155-3861+0

15 Screw, M3x12, CSH, BK - 2901-3012+3000 4

Number

- 7013-0760+0 3, 4

Figure 4. L1 Compact Array Speaker Exploded View

13

Page 14

Main Part List

Item

Description Bose® Part

Vendor Part Number Note

L1 Compact Array Extension Exploded View (see Figure 5)

Number

- Array Extension, Complete Assembly,

Consists of below items

1 Wire, 2P, #20, UL2468, L=850

Red/Blk, Molex MDI

2 Label, Serial Number, 30x7mm - - 4

3 Screw, B-tite, Flat-CS, M3x16, CS-

Recess, BZ

4 Extension Front, ABS, Blk - 4155-3821+0 4

5 Extension Rear, ABS, Blk - 4155-3831+0 4

6 MS Screw, M3x12, CSH, BK - 2901-3012+3000 4

7 Guide Strip, POM, Blk - 4155-3861+0 4

8 Gasket - 4153-3431+0 4

9 Screw, Machine, Flat-CS, M3x40, CS-

Recess, BZ

Note: The array extensions are not repairable. The above parts are listed for reference only.

Number

318881-010S svc-cajun11+exte

- 7013-0750+0 3, 4

- 2951-3016+3000 4

- 2901-3040+3000 4

Figure 5. L1 Compact Array Extension Exploded View

14

Page 15

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors

Designator

R100 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R101 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R102 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R103 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R104 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R105 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R106 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R107 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R108 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R109 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R110 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R111 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R112 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R113 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R114 150 OHM, RMG, 1/16W, 1%, 0603 4723-151A+P-R 4

R115 150 OHM, RMG, 1/16W, 1%, 0603 4723-151A+P-R 4

R116 2.2K, RMG, 1/16W, 1%, 0603/1608 4723-222A+P 4

R117 150 OHM, RMG, 1/16W, 1%, 0603 4723-151A+P 4

R118 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R119 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R120 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R122 39K, RMG, 1/10W, 1%, 0603 4720-393A+P 4

R123 39K, RMG, 1/10W, 1%, 0603 4720-393A+P 4

R124 12K, RMG, 1/16W, 1%, 0603 4723-123A+P 4

R125 150 OHM, RMG, 1/16W, 1%, 0603 4723-154A+P-R 4

R126 75K, RMG, 1/16W, 1%, 0603 4723-753A+P 4

R127 8.87K, RMG, 1/16W, 1%, 0603/1608 4723-8871+P 4

R128 47K, RMG, 1/16W, 1%, 0603/1608 4723-473A+P 4

R129 60.4K, RMG, 1/16W, 1%, 0603/1608 4723-6042+P 4

R130 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R131 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R132 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R133 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R134 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R135 97.6K, RMG, 1/10W, 1%, 0603 4720-9762+P 4

R136 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R137 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R138 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R139 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R140 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R141 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R142 43.2K, RMG, 1/10W, 1%, 0603 4720-4322+P 4

R143 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R144 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R145 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R146 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R147 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

15

Page 16

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors (continued)

Designator

R148 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R149 270 OHM, RMG, 1/16W, 1%, 0603 4723-271A+P-R 4

R150 270 OHM, RMG, 1/16W, 1%, 0603 4723-271A+P-R 4

R151 34.8K, RMG, 1/10W, 1%, 0603 4720-3482+P 4

R152 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R153 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R154 48.7K, RMG, 1/10W, 1%, 0603 4720-4872+P 4

R155 17.8K, RMG, 1/16W, 1%, 0603/1608 4723-1782+P 4

R156 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R157 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R158 6.81K, RMG, 1/10W, 1%, 0603 4720-6811+P 4

R159 13.7K, RMG, 1/10W, 1%, 0603 4720-1372+P 4

R160 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R161 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R162 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R163 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R164 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R165 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R166 22K, RMG, 1/16W, 1%, 0603 4723-223A+P-R 4

R167 8.87K, RMG, 1/16W, 1%, 0603/1608 4723-8872+P 4

R168 12K, RMG, 1/16W, 1%, 0603 4723-123A+P 4

R169 3K, RMG, 1/16W, 1%, 0603 4723-302A+P 4

R170 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R172 820 OHM, RMG, 1/16W, 1%, 0603/1608 4723-821A+P 4

R173 820 OHM, RMG, 1/16W, 1%, 0603/1608 4723-821A+P 4

R174 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R175 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R177 510 OHM, RMG, 1/4W, 5%, 1206 4725-511J+6 4

R178 510 OHM, RMG, 1/4W, 5%, 1206 4725-511J+6 4

R179 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R180 15.8K, RMG, 1/10W, 1%, 0603 4720-1582+P 4

R181 470K, RMG, 1/16W, 1%, 0603 4723-474A+P 4

R182 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R183 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R184 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R186 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R188 10 OHM, RMG, 1/16W, 1%, 0603 4723-100A+P-R 4

R189 10 OHM, RMG, 1/16W, 1%, 0603 4723-100A+P-R 4

R190 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R199 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R200 45.3K, RMG, 1/10W, 1%, 0603 4720-4532+P 4

R201 95.3K, RMG, 1/10W, 1%, 0603 4720-9532+P 4

R202 59K, RMG, 1/10W, 1%, 0603 4720-593A+P 4

R203 12K, RMG, 1/16W, 1%, 0603 4723-123A+P 4

R204 7.87K, RMG, 1/10W, 1%, 0603 4720-7871+P 4

R205 9.76K, RMG, 1/16W, 1%, 0603 4723-9761+P 4

R206 9.76K, RMG, 1/16W, 1%, 0603 4723-9761+P 4

R207 95.3K, RMG, 1/10W, 1%, 0603 4720-9532+P 4

R208 7.87K, RMG, 1/10W, 1%, 0603 4720-7871+P 4

16

Page 17

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors (continued)

Designator

R209 12K, RMG, 1/16W, 1%, 0603 4723-123A+P 4

R210 150 OHM, RMG, 1/16W, 1%, 0603 4723-154A+P-R 4

R211 75K, RMG, 1/16W, 1%, 0603 4723-753A+P 4

R213 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R214 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R215 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R216 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R217 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R218 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R219 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R220 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R222 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R223 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R224 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R225 1.8M, RMG, 1/16W, 1%, 0603 4723-185A+P 4

R226 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R227 1.8M, RMG, 1/16W, 1%, 0603 4723-185A+P 4

R228 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R229 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R230 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R231 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R232 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R234 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R236 3.9K, RMG, 1/16W, 1%, 0603/1608 4723-392A+P 4

R238 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R239 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R240 3.9K, RMG, 1/16W, 1%, 0603/1608 4723-392A+P 4

R241 3.9K, RMG, 1/16W, 1%, 0603/1608 4723-392A+P 4

R243 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R244 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R245 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R246 1.8M, RMG, 1/16W, 1%, 0603 4723-185A+P 4

R247 59K, RMG, 1/10W, 1%, 0603 4720-593A+P 4

R248 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R249 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R250 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R251 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R254 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R255 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R257 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R258 10 OHM, RMG, 1/16W, 1%, 0603 4723-100A+P-R 4

R260 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R262 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R264 1.8M, RMG, 1/16W, 1%, 0603 4723-185A+P 4

R265 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R266 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R267 22.6K, RMG, 1/10W, 1%, 0603 4720-2262+P 4

R271 510 OHM, RMG, 1/4W, 5%, 1206 4725-511J+6 4

17

Page 18

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors (continued)

Designator

R272 510 OHM, RMG, 1/4W, 5%, 1206 4725-511J+6 4

R275 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R276 15.8K, RMG, 1/10W, 1%, 0603 4720-1582+P 4

R277 470K, RMG, 1/16W, 1%, 0603 4723-474A+P 4

R278 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P-R 4

R279 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R280 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R282 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R283 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R285 2.2K, RMG, 1/16W, 1%, 0603/1608 4723-222A+P 4

R287 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R288 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R289 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R290 15.8K, RMG, 1/10W, 1%, 0603 4720-1582+P 4

R300 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R301 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R302 91K, RMG, 1/10W, 1%, 0603 4720-913A+P 4

R303 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R304 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R305 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R306 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R307 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R308 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R309 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R311 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R312 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R313 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R314 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R315 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R316 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R317 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R318 13.7K, RMG, 1/10W, 1%, 0603 4720-1372+P 4

R319 13.7K, RMG, 1/10W, 1%, 0603 4720-1372+P 4

R320 200K, RMG, 1/16W, 1%, 0603/1608 4723-204A+P 4

R321 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R322 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R325 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R326 330 OHM, RMG, 1/16W, 1%, 0603 4723-331A+P 4

R327 10 OHM, RMG, 1/16W, 1%, 0603 4723-100A+P-R 4

R328 470 OHM, RMG, 1/16W, 1%, 0603 4723-471A+P-R 4

R329 470 OHM, RMG, 1/16W, 1%, 0603 4723-471A+P-R 4

R332 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R333 80.6K, RMG, 1/10W, 1%, 0603 4720-8062+P 4

R334 3K, RMG, 1/16W, 1%, 0603 4723-302A+P 4

R335 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R336 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R337 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R338 39K, RMG, 1/16W, 1%, 0603/1608 4723-393A+P 4

R339 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

18

Page 19

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors (continued)

Designator

R340 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R341 158K, RMG, 1/10W, 1%, 0603 4720-1583+P 4

R342 23.2K, RMG, 1/16W, 1%, 0603/1608 4723-2322+P 4

R343 24.3K, RMG, 1/10W, 1%, 0603 4720-2432+P 4

R344 24.3K, RMG, 1/10W, 1%, 0603 4720-2432+P 4

R345 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R346 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R347 14K, RMG, 1/16W, 1%, 0603/1608 4723-143A+P 4

R348 7.15K, RMG, 1/16W, 1%, 0603/1608 4723-7151+P 4

R349 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R351 80.6K, RMG, 1/10W, 1%, 0603 4720-8062+P 4

R352 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R353 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R354 4.99K, RMG, 1/16W, 1%, 0603 4723-4991+P 4

R356 5.36K, RMG, 1/10W, 1%, 0603 4720-5361+P 4

R357 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R358 1.96K, RMG, 1/10W, 1%, 0603 4720-1961+P 4

R359 14K, RMG, 1/16W, 1%, 0603 4723-143A+P 4

R366 107K, RMG, 1/10W, 1%, 0603 4720-1073+P 4

R367 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R368 53.6K, RMG, 1/10W, 1%, 0603 4720-5362+P 4

R369 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R373 8.45K, RMG, 1/10W, 1%, 0603 4720-8451+P 4

R376 23.2K, RMG, 1/16W, 1%, 0603/1608 4723-2322+P 4

R378 107K, RMG, 1/10W, 1%, 0603 4720-1073+P 4

R381 97.6K, RMG, 1/10W, 1%, 0603 4720-9762+P 4

R386 470K, RMG, 1/16W, 1%, 0603 4723-474A+P 4

R391 470K, RMG, 1/16W, 1%, 0603 4723-474A+P 4

R392 47K, RMG, 1/16W, 1%, 0603 4723-473A+P-R 4

R393 24K, RMG, 1/16W, 1%, 0603 4723-243A+P 4

R394 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R395 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R396 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R397 47K, RMG, 1/16W, 1%, 0603 4723-473A+P-R 4

R399 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R400 33K, RMG, 1/16W, 1%, 0603 4723-333A+P-R 4

R401 47 OHM, RMG, 1/2W, 1%, 2010 4727-470A+W 4

R402 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R403 4.7M, RMG, 1/10W, 1%, 0603 4720-475A+P 4

R404 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R405 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R406 47 OHM, RMG, 1/2W, 1%, 2010 4727-470A+W 4

R407 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R408 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R409 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R410 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R411 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R412 158K, RMG, 1/10W, 1%, 0603 4720-1583+P 4

19

Page 20

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Resistors (continued)

Designator

R413 24.3K, RMG, 1/10W, 1%, 0603 4720-2432+P 4

R414 24.3K, RMG, 1/10W, 1%, 0603 4720-2432+P 4

R424 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R425 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R426 510 OHM, RMG, 1/4W, 5%, 1206 4725-511J+6 4

R427 68K, RMG, 1/16W, 1%, 0603 4723-683A+P-R 4

R428 82K, RMG, 1/10W, 1%, 0603 4720-823A+P 4

R432 200K, RMG, 1/16W, 1%, 0603/1608 4723-204A+P 4

R433 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R435 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R440 4.7M, RMG, 1/10W, 1%, 0603 4720-475A+P 4

R441 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R449 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R450 34K, RMG, 1/10W, 1%, 0603 4720-343A+P 4

R451 12K, RMG, 1/16W, 1%, 0603 4723-123A+P-R 4

R452 200K, RMG, 1/16W, 1%, 0603/1608 4723-204A+P 4

R453 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R500 200K, RMG, 1/16W, 1%, 0603/1608 4723-204A+P 4

R501 47 OHM, RMG, 1/2W, 1%, 2010 4727-470A+W 4

R502 47 OHM, RMG, 1/2W, 1%, 2010 4727-470A+W 4

R503 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R504 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R505 270 OHM, RMG, 1/16W, 1%, 0603 4723-271A+P-R 4

R506 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R507 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R508 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R509 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R510 2.2K, RMG, 1/16W, 1%, 0603/1608 4723-222A+P 4

R511 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R512 3.3K, RMG, 1/16W, 1%, 0603/1608 4723-332A+P 4

R513 3.3K, RMG, 1/16W, 1%, 0603/1608 4723-332A+P 4

R514 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R515 10K, RMG, 1/16W, 1%, 0603 4723-103A+P-R 4

R517 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R518 270 OHM, RMG, 1/16W, 1%, 0603 4723-271A+P-R 4

R519 150 OHM, RMG, 1/16W, 1%, 0603 4723-154A+P-R 4

R521 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R525 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

20

Page 21

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Capacitors

Designator

C100 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C101 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C102 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C103 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C105 22uF, CE, 16V, 20%, RLT, 4X7, RC2 157D-226M+K-GME 4

C106 22uF, CE, 16V, 20%, RLT, 4X7, RC2 157D-226M+K-GME 4

C107 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C108 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C109 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C110 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C111 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C112 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C113 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C114 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C115 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C116 220uF, CE, 6.3V, 20%, RLT, 5X11 157B-227M+K-IUI 4

C117 220uF, CE, 6.3V, 20%, RLT, 5X11 157B-227M+K-IUI 4

C118 220uF, CE, 6.3V, 20%, RLT, 5X11 157B-227M+K-IUI 4

C119 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C120 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C121 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C122 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C123 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C124 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C125 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C126 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C127 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C128 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C129 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C130 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C131 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C132 220uF, CE, 6.3V, 20%, RLT, 5X11 157B-227M+K-IUI 4

C133 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C134 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C135 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C136 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C137 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C138 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C139 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C140 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C141 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C142 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C143 470pF, CC, 50V, 5%, 0603 150F-471J+P-AC 4

C144 470pF, CC, 50V, 5%, 0603 150F-471J+P-AC 4

C145 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C146 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C147 1200pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-122J+P-AC 4

21

Page 22

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Capacitors (continued)

Designator

C148 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C149 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C151 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C152 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C153 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C154 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C156 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C157 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C158 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C159 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C160 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C161 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C162 470pF, CC, 50V, 5%, 0603 150F-471J+P-AC 4

C166 2000pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-202J+P-AC 4

C169 1uF, CC, 25V, 5%, 0805, 1.25X2 150E-105J+J-BD 4

C170 1800pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-182J+P-AC 4

C171 0.47uF, CC, 25V, 5%, 0805, 1.25X2 150E-474J+J-BD 4

C172 1uF, CE, 50V, 20%, RLT, 4X7, ELNA 157F-105M+K-GME 4

C173 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C174 47uF, CE, 16V, 20%, RLT, 5X7 157D-476M+K-IME 4

C175 47uF, CE, 16V, 20%, RLT, 5X7 157D-476M+K-IME 4

C200 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C201 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C202 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C208 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C209 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C210 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C211 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C212 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C213 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C214 0.022uF, CC, 50V, 10%, 0603 150F-223K+P-AC 4

C215 0.022uF, CC, 50V, 10%, 0603 150F-223K+P-AC 4

C216 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C217 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C218 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C219 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C220 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C221 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C222 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C225 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C226 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C231 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C233 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C235 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C236 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C237 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C238 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C239 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

22

Page 23

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Capacitors (continued)

Designator

C240 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C242 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C243 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C244 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C245 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C250 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C251 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C253 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C254 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C255 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C256 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C258 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C259 3300pF, CC, 50V, 5%, 0603, (0.8X1.6) 150F-332J+P-AC 4

C260 1uF, CE, 50V, 20%, RLT, 4X7, ELNA 157F-105M+K-GME 4

C300 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C301 10uF, CE, 50V, 20%, RLT, 5X11 157F-106M+K-IU 4

C302 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C303 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C306 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C308 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C309 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C310 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C311 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C312 4700pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-472J+P-AC 4

C313 68pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-680J+P-AC 4

C314 68pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-680J+P-AC 4

C315 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C316 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C317 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C318 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C319 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C320 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C321 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C322 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C323 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C324 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C325 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C326 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C327 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C328 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C329 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C330 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C331 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C332 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C333 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C334 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C335 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C336 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

23

Page 24

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Capacitors (continued)

Designator

C337 0.1F, CC, 25V, 10%, 0603, X7R 150E-104K+P-AC 4

C338 0.1F, CC, 25V, 10%, 0603, X7R 150E-104K+P-AC 4

C339 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C340 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C341 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C342 4700pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-472J+P-AC 4

C345 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C346 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C347 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C348 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C349 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C350 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C352 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C353 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C354 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C355 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C356 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C360 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C363 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C364 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C365 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C366 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C367 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C368 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C369 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C370 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C371 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C372 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C373 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C374 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C375 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C376 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C377 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C378 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C383 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C386 10uF, CE, 16V, 20%, RLT, 4X7, ELNA 157D-106M+K-GME 4

C387 0.022uF, CC, 50V, 10%, 0603 150F-223K+P-AC 4

C388 0.022uF, CC, 50V, 10%, 0603 150F-223K+P-AC 4

C389 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C390 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C397 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C400 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C401 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C402 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C403 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C404 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C405 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C406 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

24

Page 25

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Capacitors (continued)

Designator

C407 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C408 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C409 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C410 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C411 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C415 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C416 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C417 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C418 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C419 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C422 68pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-680J+P-AC 4

C424 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C425 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C426 0.027uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-273J+P-AC 4

C427 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C428 0.027uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-273J+P-AC 4

C434 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C435 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C436 100uF, CE, 25V, 20%, RLT, 6.3X11, 105C,

LOW ESR

C437 100uF, CE, 25V, 20%, RLT, 6.3X11, 105C,

LOW ESR

C438 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C439 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C440 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C441 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C442 10uF, CE, 50V, 20%, RLT, 5X11 157F-106M+K-IU 4

C444 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C445 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C446 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C448 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C451 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C452 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C453 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C454 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C500 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C501 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C502 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C503 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C504 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C505 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C506 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C507 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C508 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C509 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C510 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C511 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C512 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C513 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

157E-107M+K-LURT 4

157E-107M+K-LURT 4

25

Page 26

Electrical Part List

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Input/Output PCB Assembly

Capacitors (continued)

Designator

C515 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C518 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C519 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C520 47uF, CE, 16V, 20%, RLT, 5X7 157D-476M+K-IME 4

C521 47uF, CE, 16V, 20%, RLT, 5X7 157D-476M+K-IME 4

C522 0.047uF, CC, 50V, 5%, 0603, 0.8X1.6 150F-473J+P-AC 4

C523 68pF, CC, 50V, 5%, 0603, 0.8X1.6 150F-680J+P-AC 4

C524 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

Designator

L300 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L301 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

Inductors

Diodes

Designator

D100 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D101 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D102 LED, SMD, 1.6X0.8X0.75, GN, HIGH, 525NM,

KINGBRIGHT

D103 LED, SMD, 1.6X0.8X0.75, GN, HIGH, 525NM,

KINGBRIGHT

D104 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D105 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D106 ZENER, 0.2W, UDZS5.1B, ROHM, SM 483H-5V11+3 4

D107 LOW CURRENT SMD LED, RED 2mA 3700-7829+R 4

D108 LOW CURRENT SMD LED, RED 2mA 3700-7829+R 4

D109 ZENER, 0.2W, UDZS5.1B, ROHM, SM 483H-5V11+3 4

D110 ZENER, 0.2W, UDZS5.1B, ROHM, SM 483H-5V11+3 4

D202 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D203 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D204 LED, SMD, 1.6X0.8X0.75, GN, HIGH, 525NM,

KINGBRIGHT

D205 LED, SMD, 1.6X0.8X0.75, GN, HIGH, 525NM,

KINGBRIGHT

D206 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D207 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D208 ZENER, 0.2W, UDZS5.1B, ROHM, SM 483H-5V11+3 4

D209 LOW CURRENT SMD LED, RED 2mA 3700-7829+R 4

D210 LOW CURRENT SMD LED, RED 2mA 3700-7829+R 4

D300 LED, SMD, 1.6X0.8X0.6, 469NM, BL,

WAVELENGTH464NM-476NM

D301 LED, SMD, 1.6X0.8X0.6, 469NM, BL,

WAVELENGHT464NM-476NM

D302 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D303 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

26

3700-7851+G 4

3700-7851+G 4

3700-7851+G 4

3700-7851+G 4

3700-7848+B 4

3700-7848+B 4

Page 27

Electrical Part List

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Input/Output PCB Assembly

Diodes (continued)

Designator

D304 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D305 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D306 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D401 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D402 DIODE, BAV99, SOT23, PHILIPS 4840-8970+3 4

D500 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D501 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D502 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D503 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D504 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D505 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D506 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D507 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D508 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D509 DIODE, 1SS355TE-17, ROHM 4840-1660+0 4

D510 ZENER, 1/2W, 5.1V, MMSZ5231B, SOD-123,

SMD, PANJIT

D512 ZENER, 1/2W, 5.1V, MMSZ5231B, SOD-123,

SMD, PANJIT

4837-5V18+3 4

4837-5V18+3 4

Transistors

Designator

Q100 MMBT4403LT1G, SMD 4854-4030+3 4

Q101 MMBT4403LT1G, SMD 4854-4030+3 4

Q102 MMBT4403LT1G, SMD 4854-4030+3 4

Q103 MMBT4403LT1G, SMD 4854-4030+3 4

Q104 MMBT4403LT1G, SMD 4854-4030+3 4

Q105 MMBT4403LT1G, SMD 4854-4030+3 4

Q106 MMBT4403LT1G, SMD 4854-4030+3 4

Q107 MMBT4403LT1G, SMD 4854-4030+3 4

Q108 NPN, MMBT4401, SOT-23, HFE:20-300, SM 4854-4010+3 4

Q109 NPN, MMBT4401, SOT-23, HFE:20-300, SM 4854-4010+3 4

Q110 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

Q112 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

Q200 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

Q202 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

27

Page 28

Reference

Description Vendor Part Number Note

Electrical Part List

Input/Output PCB Assembly

Integrated Circuits

Designator

U100 NJM2068M-#ZZZB, DUAL OP AMP 3130-6890+0 4

U101 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U102 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U103 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U104 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U106 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U107 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U200 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U201 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U202 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U204 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U205 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U206 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U207 OP AMP SWITCH, NJM2120M, SOIC8, JRC 3132-3711+0 4

U300 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U301 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U302 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U303 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U304 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U305 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U306 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U307 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U308 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U309 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U310 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U312 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U313 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U314 LM13700M/NOPB, TRANSCOND. AMP 3132-1981+0 4

U315 VOLT REG, +15V, L7815ACD2T, D2PAK, ST 3132-3881+0 4

U316 VOLT REG, -15V, L7915CD2T, D2PAK, ST 3132-3891+0 4

U317 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U391 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U500 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U501 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

U502 TL072CDR, DUAL J-FET INPUT, OP-AMP 3130-8020+0 4

28

Page 29

Electrical Part List

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Input/Output PCB Assembly

Miscellaneous

Designator

CN300A WAFER, 10 PIN, P2 2102-100S+003 4

CN302A WIRE-CONN, 10P, P2.0, #26, UL2468, L=110,

F/M

CN308A CONNECTOR, 5 PIN, P2.5 (JST 05JQ-BT) 2101-1371+0 4

J100 XLR, FEMALE CONN, NC3FAV1-0 2113-1337+1 4

J200 JACK, RCA, 2P, UPRIGHT, W/R, SILVER 2113-3131+1 4

J202 JACK, PHONE, 5P, 6.4MM, BLACK, W/SW 2113-3269+0 4

SW200 SWITCH, SLIDE, DPDT, 50V, 0.3A, L=12,

16X6.5X8

VR100 VR, ROTARY, 10K/10CX2, 20%, V, L=15, D

SHAFT, ALPHA

VR101 VR, 50KBX1, XV09203, PVBN25F, NOBLE 4750-9655+0 4

VR102 VR, 50KBX1, XV09203, PVBN25F, NOBLE 4750-9655+0 4

VR200 VR, 20KAX2, RD902-40-15F, ALPHA 4751-0750+0 4

3.5mm Line Input PCB Assembly

Miscellaneous

7012-7033+0 4

5200-4984+0 4

4751-1849+0 4

Designator

CN308B WAFER, 5P, P2.5, RA, M, S5B-XH-A 2101-3255+0 4

J801 JACK, PHONE, 3.5MM, STEREO, 3P 2113-3335+0 4

Designator

R330 330 OHM, RMG, 1/16W, 1%, 0603 4723-331A+P 4

R331 330 OHM, RMG, 1/16W, 1%, 0603 4723-331A+P 4

R454 330 OHM, RMG, 1/16W, 1%, 0603 4723-331A+P 4

R455 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R801 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

R802 6.8K, RMG, 1/16W, 1%, 0603/1608 4723-682A+P 4

Output PCB Assembly

Resistors

29

Page 30

Electrical Part List

Reference

Description Vendor Part Number Note

Reference

Description Vendor Part Number Note

Output PCB Assembly

Capacitors

Designator

C351 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C361 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C362 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C447 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C449 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C450 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C701 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C702 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C801 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

C802 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C803 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C804 0.1uF, CC, 50V, 5%, 0603 150F-104J+P-AC 4

Designator

CN302B WAFER, 10 PIN, P2 2102-100S+003 4

J300 JACK, RCA, 2P, W/R, SILVER 2113-1801+2 4

J301 JACK, SOCKET, NRJ6HF (STEREO) 2113-3085+0 4

Miscellaneous

30

Page 31

Electrical Part List

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Resistors

Designator

R1 110K, RMG, 1/4W, 5%, 1206 4725-114J+6 4

R2 10 OHM, RMG, 1/8W, 1%, 1206 4721-100A+6 4

R3 49.9 OHM, RMG, 1/4W, 1%, 1206 4725-49R9+6 4

R4 20 OHM, RMG, 1/4W, 1%, 1206 4725-200A+6 4

R5 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R6 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R7 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R8 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R9 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R10 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R11 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R12 2M, RMG, 1/4W, 1%, 1206 4725-205A+6 4

R13 1.8M, RMG, 1/8W, 1%, 1206 4721-185A+6 4

R14 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R15 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R16 0 OHM, RMG, 1/16W, 1%, 0603 4723-000A+P 4

R18 6.8 OHM, RMG, 1/16W, 1%, 0603 4723-6R8A+P 4

R19 1K, RMG, 1/10W, 1%, 0805 4720-102A+J 4

R20 0 OHM, RMG, 1/16W, 1%, 0603 4723-000A+P 4

R21 22 OHM, RMG, 1W, 5%, 2512 4728-220J+3 4

R22 22 OHM, RMG, 1W, 5%, 2512 4728-220J+3 4

R23 10 OHM, RMG, 1/4W, 5%, 1206 4725-100J+6 4

R24 10 OHM, RMG, 1/4W, 5%, 1206 4725-100J+6 4

R25 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R26 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R27 180 OHM, RMG, 1/16W, 1%, 0603/1608 4723-181A+P 4

R28 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R29 16 OHM, RMG, 1/4W, 1%, 1206 4725-160A+6 4

R30 3.3K, RMG, 1/16W, 1%, 0603/1608 4723-332A+P 4

R31 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R32 402K, RMG, 1/16W, 1%, 0603 4723-4023+P 4

R33 10 OHM, RMG, 1/4W, 5%, 1206 4725-100J+6 4

R34 24 OHM, RMG, 1/4W, 1%, 1206 4725-240A+6 4

R35 24 OHM, RMG, 1/4W, 1%, 1206 4725-240A+6 4

R36 49.9 OHM, RMG, 1/4W, 1%, 1206 4725-49R9+6 4

R37 49.9 OHM, RMG, 1/4W, 1%, 1206 4725-49R9+6 4

R38 210K, RMG, 1/16W, 1%, 0603 4723-214A+P 4

R39 16 OHM, RMG, 1/4W, 1%, 1206 4725-160A+6 4

R40 4.7K, RMG, 1/16W, 1%, 0603/1608 4723-472A+P 4

R41 49.9 OHM, RMG, 1/4W, 1%, 1206 4725-49R9+6 4

R42 49.9 OHM, RMG, 1/4W, 1%, 1206 4725-49R9+6 4

R43 4.7K, RMG, 1/16W, 1%, 0603/1608 4723-472A+P 4

R44 10 OHM, RMG, 1/4W, 5%, 1206 4725-100J+6 4

R45 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R46 5.6K, RMG, 1/16W, 1%, 0603/1608 4723-562A+P 4

R47 39K, RMG, 1/10W, 1%, 0603 4720-393A+P 4

Number

31

Page 32

Electrical Part List

Reference

Description Vendor Part

Note

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Resistors (continued)

Designator

R48 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R49 5.6K, RMG, 1/16W, 1%, 0603/1608 4723-562A+P 4

R50 39K, RMG, 1/16W, 5%, 0603 4723-393J+P-R 4

R51 100K, RMG, 1/16W, 1%, 0603 4723-104A+P-R 4

R52 5.6K, RMG, 1/16W, 1%, 0603/1608 4723-562A+P 4

R53 39K, RMG, 1/10W, 1%, 0603 4720-393A+P 4

R54 100 OHM, RMG, 1/16W, 1%, 0603 4723-101A+P 4

R55 30K, RMG, 1/16W, 1%, 0603/1608 4723-303A+P 4

R56 5.6K, RMG, 1/16W, 1%, 0603/1608 4723-562A+P 4

R57 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R58 4.7K, RMG, 1/16W, 1%, 0603/1608 4723-472A+P 4

R59 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R60 820K, RMG, 1/8W, 5%, 1206 4721-824J+6 4

R62 20 OHM, RMG, 1/4W, 1%, 1206 4725-200A+6 4

R63 4.7K, RMG, 1/16W, 1%, 0603/1608 4723-472A+P 4

R66 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R100 0 OHM, RMG, 1/4W, 5%, 1206 4725-000J+6 4

R535 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R538 4.7K, RMG, 1/16W, 1%, 0603/1608 4723-472A+P 4

Capacitors

Number

Designator

C1 470uF, CE, 250V, 20%, RL, 25X40, 105C 157R-477M+5-&^T 4

C2 3300pF, CC, 1000V, 10%, RLT, 10X4, X7R,

125C

C3 470uF, CE, 250V, 20%, RL, 25X40, 105C 157R-477M+5-&^T 4

C4 47uF, CE, 10V, 20%, RLT, 5X11, 105C 157C-476M+K-IUT 4

C5 4.7uF, CE, 63V, 20%, RLT, 5X11, LOW ESR,

105C

C6 0.1uF, CC, 100V, 10%, 1206, AVX 150H-104K+6-CFD 4

C7 2200pF, CC, 1000V, 10%, RLT, 6X3, X7R, 125C 150N-222K+K-KE 4

C8 0.68uF, CM, 100V, 5%, RBT, 7.5X11.5, MKS2,

WIMA

C9 0.68uF, CM, 100V, 5%, RBT, 7.5X11.5, MKS2,

WIMA

C10 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+J-BD 4

C11 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C12 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

LOW ESR

C13 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C14 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C15 47uF, CE, 100V, 20%, RLT10X16, LOW ESR,

105C

C16 470uF, CE, 35V, 20%, RLT, 10X20, 105C, LOW

ESR

C17 470uF, CE, 35V, 20%, RLT, 10X20, 105C, LOW

ESR

32

Number

150N-332K+K-SG 4

157I-475M+K-IURT

153H-684J+V-NVU 4

153H-684J+V-NVU 4

157Q-108M+K-

157H-476M+K-

157Q-477M+K-

157Q-477M+K-

4

4

X&TR

4

S5RT

4

S9RT

4

S9RT

Page 33

Electrical Part List

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Capacitors (continued)

Designator

C18 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

LOW ESR

C19 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C20 1000pF, CC, 1000V, 10%, RLT, 6X3, 125C, X7R 1511-102K+K-0N 4

C21 1000pF, CC, 1000V, 10%, RLT, 6X3, 125C, X7R 1511-102K+K-0N 4

C22 0.015uF, CC, 50V, 10%, 0603 150F-153K+P-AC 4

C23 0.015uF, CC, 50V, 10%, 0603 150F-153K+P-AC 4

C24 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C25 0.1uF, CC, 100V, 10%, RLT, 5X5, X7R 150H-104K+K-II 4

C26 0.1uF, CC, 100V, 10%, RLT, 5X5, X7R 150H-104K+K-II 4

C27 10uF, CE, 50V, 20%, RLT, 5X11, 105C 157F-106M+K-IUTI 4

C28 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C29 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

C30 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

C31 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C32 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C33 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

C34 100uF, CE, 35V, 20%, RLT, 6.3X11, 105C, LOW

C35 1000uF, CE, 35V, 20%, RLT, 12.5X25, 105C,

C36 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C37 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C38 100uF, CE, 35V, 20%, RLT, 6.3X11, 105C, LOW

C39 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C40 47uF, CE, 10V, 20%, RLT, 5X11, 105C 157C-476M+K-IUT 4

C41 3300pF, CC, 1000V, 10%, RLT, 10X4, X7R,

C42 47pF, CC, 1000V, 10%, RLT, 6X3, X7R, 125C 150N-470K+K-KE 4

C44 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C47 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C48 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C49 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C51 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C53 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C55 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C56 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C57 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C58 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C60 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C61 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C62 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

LOW ESR

LOW ESR

LOW ESR

ESR

LOW ESR

ESR

125C

Number

157Q-108M+K-

X&TR

157Q-108M+K-

X&TR

157Q-108M+K-

X&TR

157Q-108M+K-

X&TR

157Q-107M+K-

LUTR

157Q-108M+K-

X&TR

157Q-107M+K-

LUTR

150N-332K+K-SG 4

4

4

4

4

4

4

4

33

Page 34

Electrical Part List

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Capacitors (continued)

Designator

C63 0.1uF, CC, 100V, 10%, 1206, AVX 150H-104K+6-CFD 4

C64 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C65 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C66 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C67 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C68 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C69 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+J-BD 4

C70 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C71 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C72 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C73 0.01uF, CC, 50V, 5%, 0603 150F-103J+P-AC 4

C74 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C75 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C76 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C77 0.47uF, CC, 25V, 5%, 0805, 1.25X2 150E-474J+J-BD 4

C78 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C80 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C81 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C82 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C83 1000pF, CC, 250V, 5%, 0805 150R-102J+J-BD 4

C85 1000pF, CC, 250V, 5%, 0805 150R-102J+J-BD 4

C86 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C87 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C88 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C89 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C90 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C91 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C92 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C93 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C94 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C95 0.1uF, CC, 100V, 10%, 1206, AVX 150H-104K+6-CFD 4

C96 0.1uF, CC, 100V, 10%, 1206, AVX 150H-104K+6-CFD 4

C97 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C98 1uF, CC, 50V, 10%, 0805 150F-105K+J-BD 4

C99 1uF, CC, 50V, 10%, 0805 150F-105K+J-BD 4

C100 0.1uF, CC, 50V, 10%, 0805, 1.2X2.0 150F-104K+J-BD 4

C101 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C102 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C103 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C104 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

C105 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C106 220pF, CC, 50V, 5%, 0603 150F-221J+P-AC 4

C107 1uF, CC, 50V, 10%, 0805 150F-105K+J-BD 4

C108 1uF, CC, 50V, 10%, 0805 150F-105K+J-BD 4

C109 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C110 0.1uF, CC, 50V, 5%, 0805, 1.25X2 150F-104J+P-AC 4

Number

34

Page 35

Electrical Part List

Reference

Description Vendor Part

Note

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Capacitors (continued)

Designator

XYC1 680pF, CC, 400V, 10%, RL, 10X8 150T-681K+5-SO 4

XYC3 680pF, CC, 400V, 10%, RL, 10X8 150T-681K+5-SO 4

XYC5 1000pF, CC, 400V, 20%, RL, Y5, U, 9.5X8,

AH09E102MLO

YC6 1000pF, CC, 400V, 20%, RL, Y5, U, 9.5X8,

AH09E102MLO

YC7 1000pF, CC, 400V, 20%, RL, Y5, U, 9.5X8,

AH09E102MLO

Designator

L1 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L2 CHOKE-COMMON MODE, 10MH MIN, AC,

240V, 2A, AL

L3 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L4 CHOKE-COMMON MODE, 10MH MIN, AC,

240V, 2A, AL

L5 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L6 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L7 CHOKE-COMMON MODE, 2X16UH, 8A, FT50-

L8 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

L10 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

L11 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

L12 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

L13 CHOKE-COMMON MODE, 2X16UH, 8A, FT50-

L14 FERRITE COIL, 22uH, 20%, BL19.2 1807-220M+9 4

L15 FERRITE COIL, 22uH, 20%, BL19.2 1807-220M+9 4

L19 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L21 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L22 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L23 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L24 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L25 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L26 FERRITE BEAD, INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L27 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

43

43

Inductors

Number

150T-102M+5-RO 4

150T-102M+5-RO 4

150T-102M+5-RO 4

Number

1806-4037+0000 3, 4

1806-4037+0000 3, 4

1806-3913+0 4

1806-3913+0 4

35

Page 36

Electrical Part List

Reference

Description Vendor Part

Note

Reference

Description Vendor Part

Note

Reference

Description Vendor Part

Note

Power Amplifier PCB Assembly

Diodes

Designator

B1 DIODE BRIDGE, 800V, 8A, GBU8K, RL 4840-9218+5 3, 4

D1 BAV21W, 200V, 0.2A, SOD-123, SMD 480V-21W0+3 4

D2 RECTIFIER, UF4006-T GI, AT 4840-8530+2 4

D3 MUR1640, ULTRA, 400V, 16A, TO-220AB 4801-6400+9 4

D4 MUR1640, ULTRA, 400V, 16A, TO-220AB 4801-6400+9 4

D5 RECTIFIER, ES1D, 200V, 1.1A, SMD 4840-9190+3 4

D6 RECTIFIER, ES1D, 200V, 1.1A, SMD 4840-9190+3 4

D7 LL4148, SM 4804-1480+3 4

DZ1 P6KE200A, SUPPRESSOR, 200V, AT 4802-00A0+2 4

Z1 ZENER, 5W, 10V, 2%, AXIAL, AT 483B-1009+2 4

Z2 ZENER, 5W, 10V, 2%, AXIAL, AT 483B-1009+2 4

Z3 ZENER, 1/2W, 30V, 5%, SM 4837-3009+3 4

Z4 ZENER, 1/2W, 22VD, RLZTE-1122D, LL-34,

ROHM

Z5 ZENER, 1/2W, 5.6V, SMD 4837-5V69+3 4

Z6 ZENER, 1/2W, 15V, 5%, SOD-123C,

MMSZ5245BT1G

Z7 ZENER, 5W, 10V, 2%, AXIAL, AT 483B-1009+2 4

Transistors

Number

4837-22D1+3 4

4837-15V9+3 4

Designator

Q1 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

Q2 2N2222, SMD, MMBT2222ALT1G 4860-5410+3 4

Number

Integrated Circuits

Designator

U1 PWM CONT, TOP258YN, TO-220-7C, PI 3132-7241+0-35 3, 4

U2 PHOTOCOUPLER, EL817, EVERLIGHT 481E-L817+3 3, 4

U3 PWR AMP, TDA8920BTH/N2, SOT566-3,

PHILIPS

U3 MICA SHEET, INSULATOR, 16.5X12 3100-6701+0 3, 4

U4 REGULATOR, TL432BIDBZR, SOT-23-3, TI 3132-7691+0-16 3, 4

36

Number

3132-2641+0 3, 4

Page 37

Electrical Part List