Page 1

ControlSpace® ESP-88

Engineered Sound Processor,

CC-16 and CC-64 Controllers

(US and non-US units)

©2009 Bose Corporation

Service Manual

Reference Number 286448-SM Rev. 03

Electronic Copy Only

Page 2

CONTENTS

Safety Information ...........................................................................................................................................3

Warranty...........................................................................................................................................................3

Product Descriptions ...................................................................................................................................4-7

Specifications .............................................................................................................................................8-10

Electrostatic Discharge Sensitive (ESDS) Device Handling....................................................................... 11

Part List Notes ............................................................................................................................................... 11

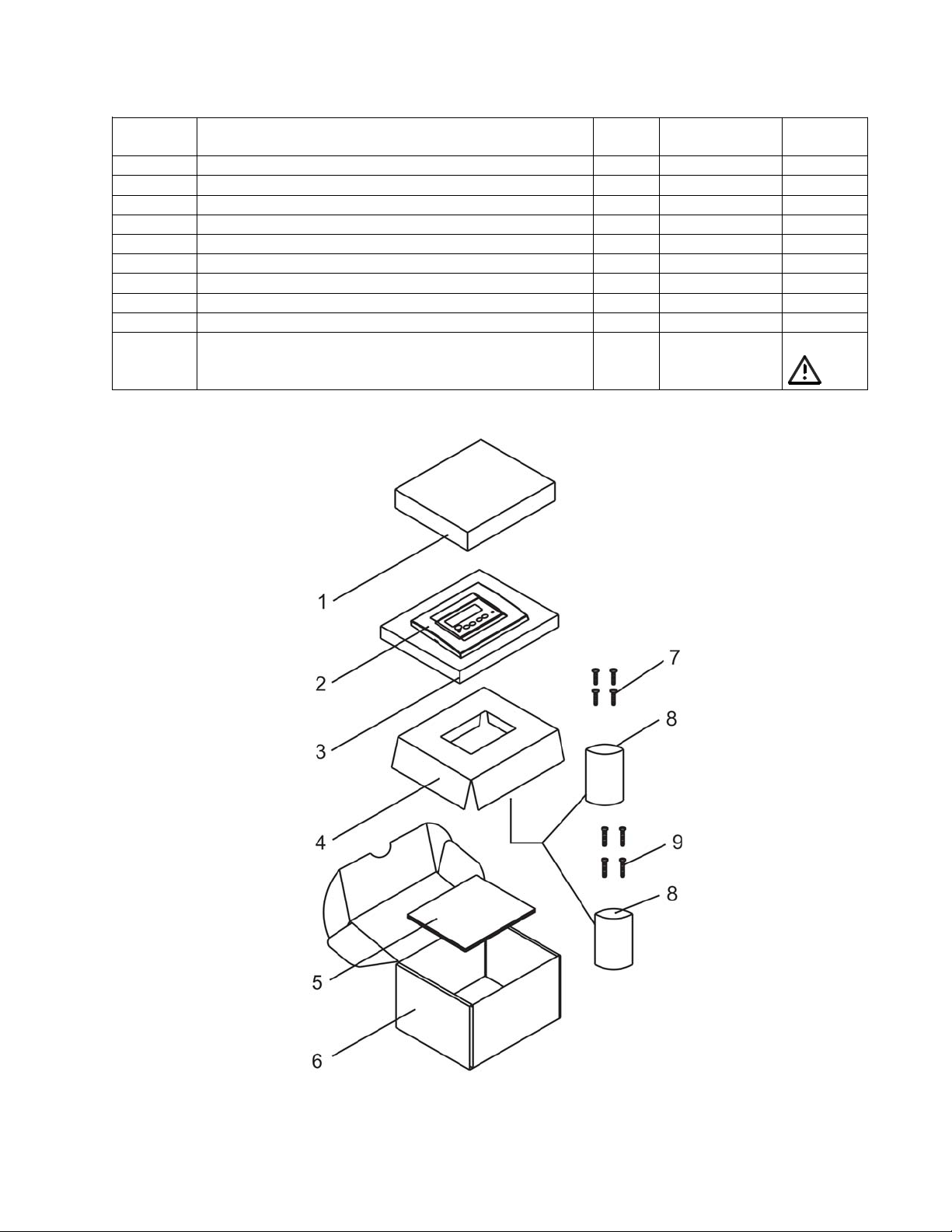

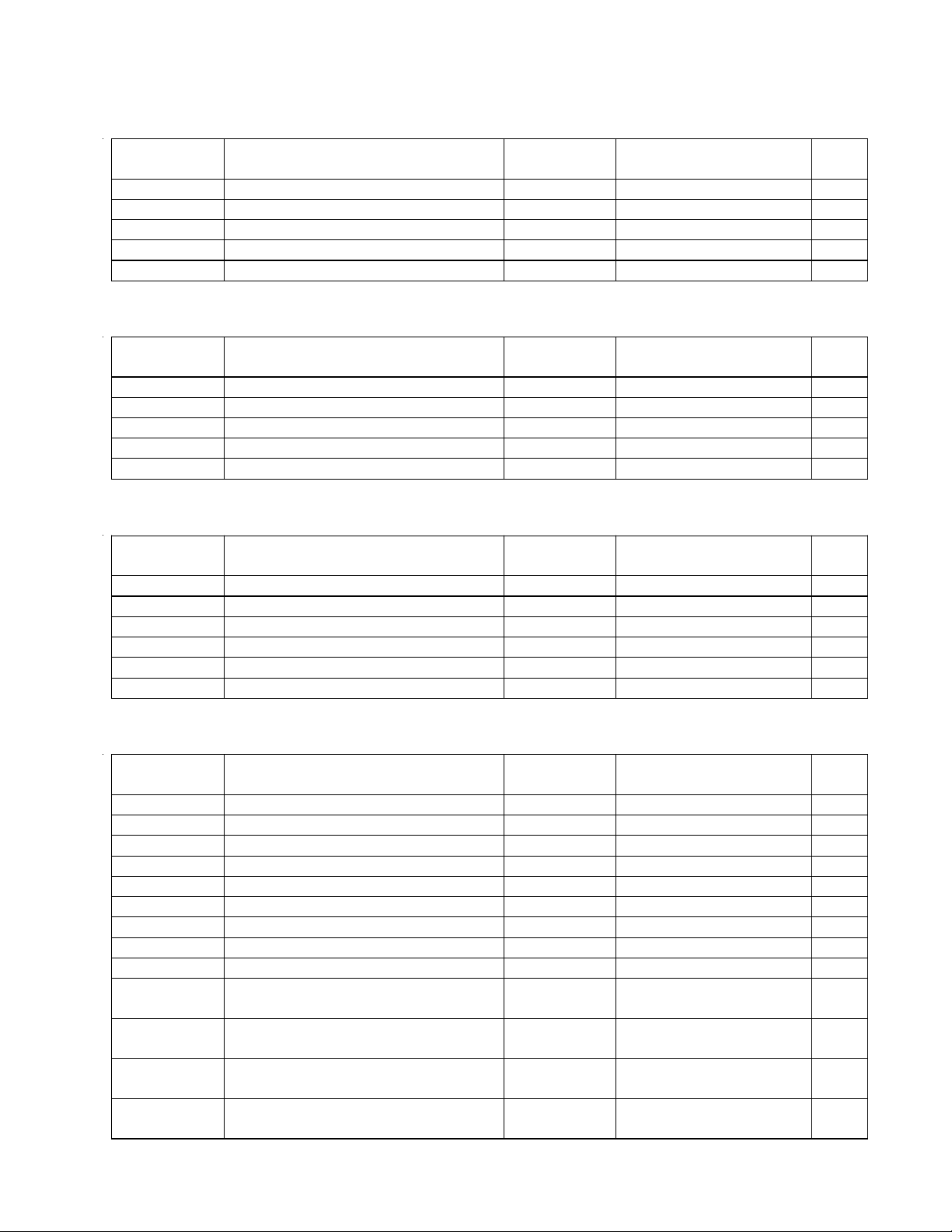

Packaging Part List, ControlSpace® ESP-88 Chassis ................................................................................. 12

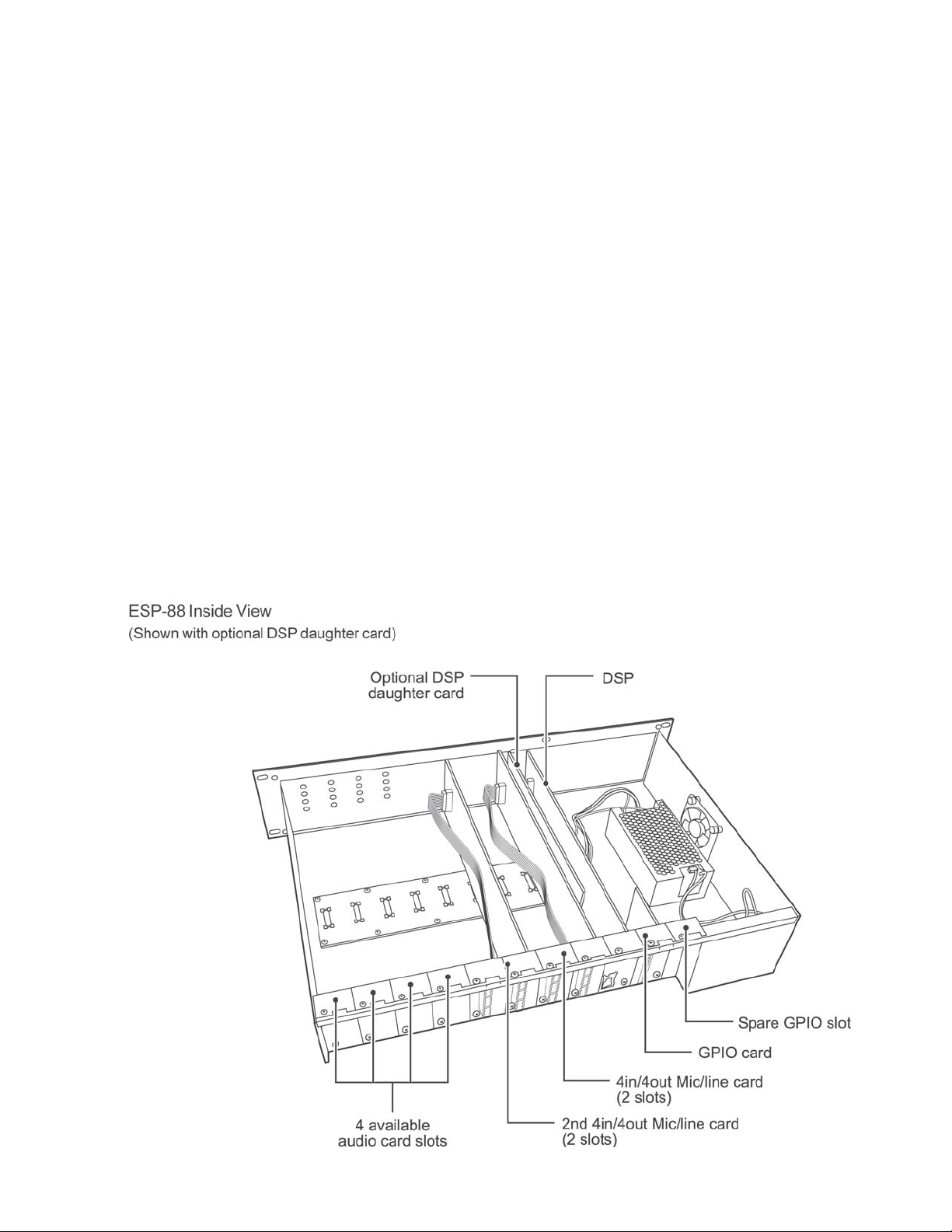

Figure 1. ESP-88 Chassis Packing View.......................................................................................................12

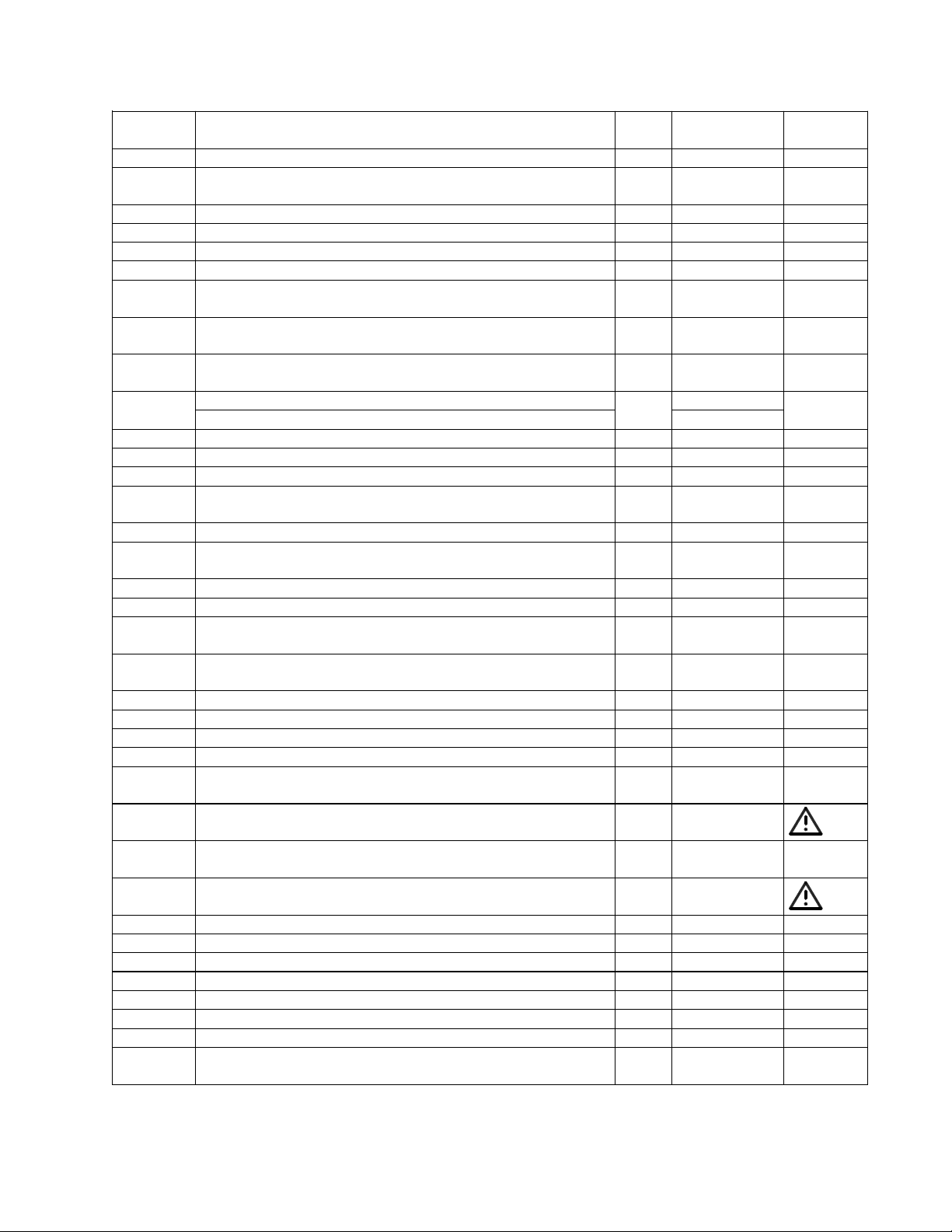

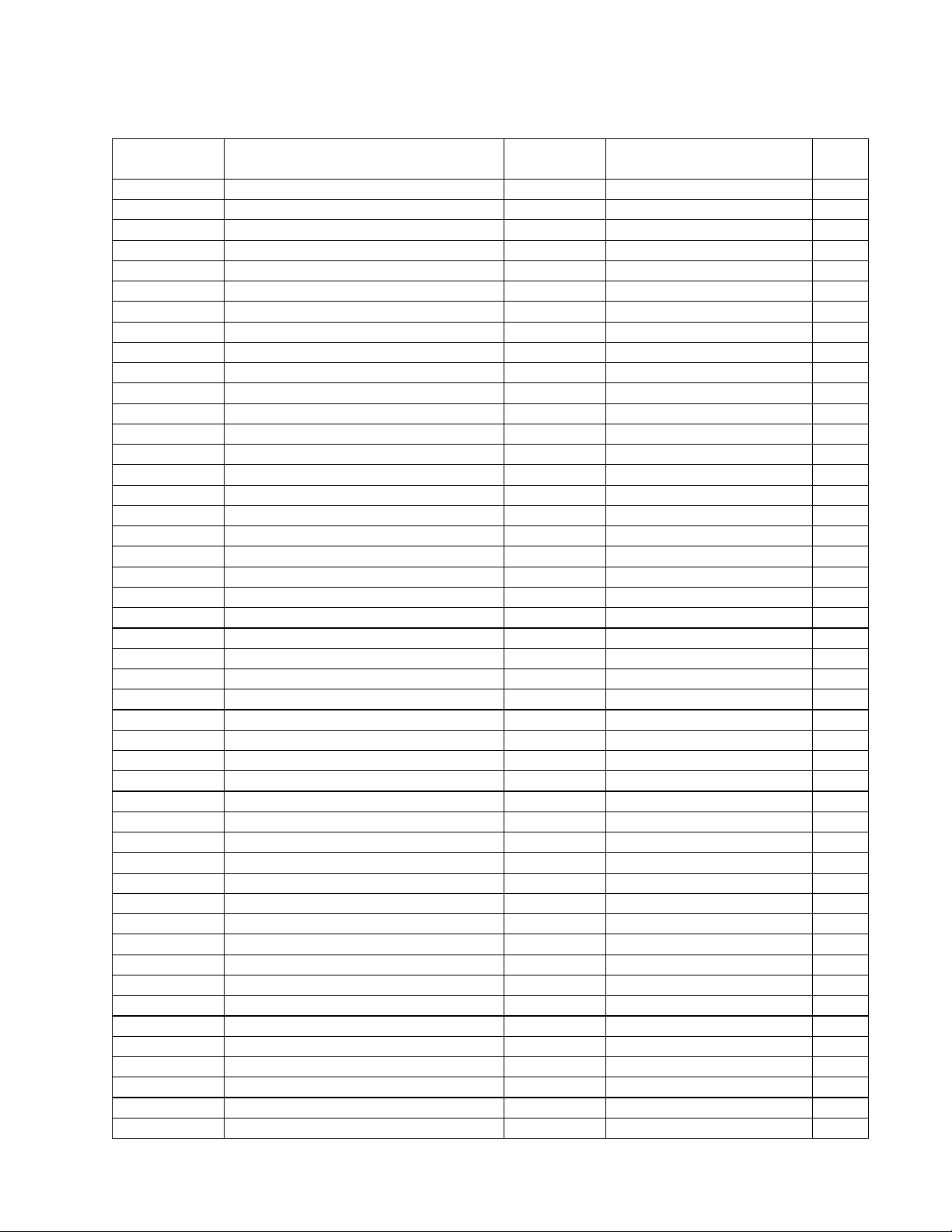

Packaging Part List, ControlSpace CC-16 Controller .................................................................................13

Figure 2. CC-16 Controller Packing View......................................................................................................13

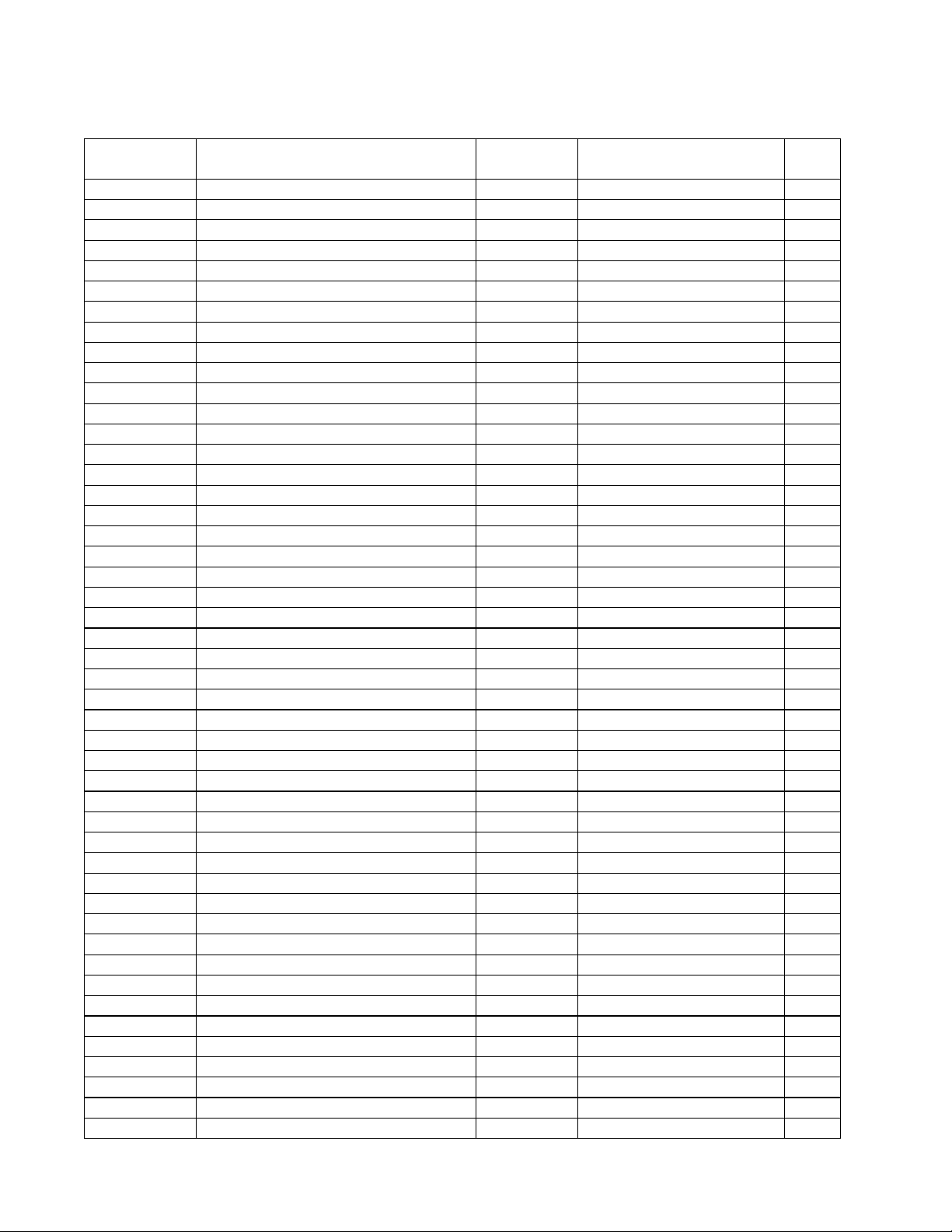

Packaging Part List, ControlSpace CC-64 Controller .................................................................................14

Figure 3. CC-64 Controller Packing View......................................................................................................14

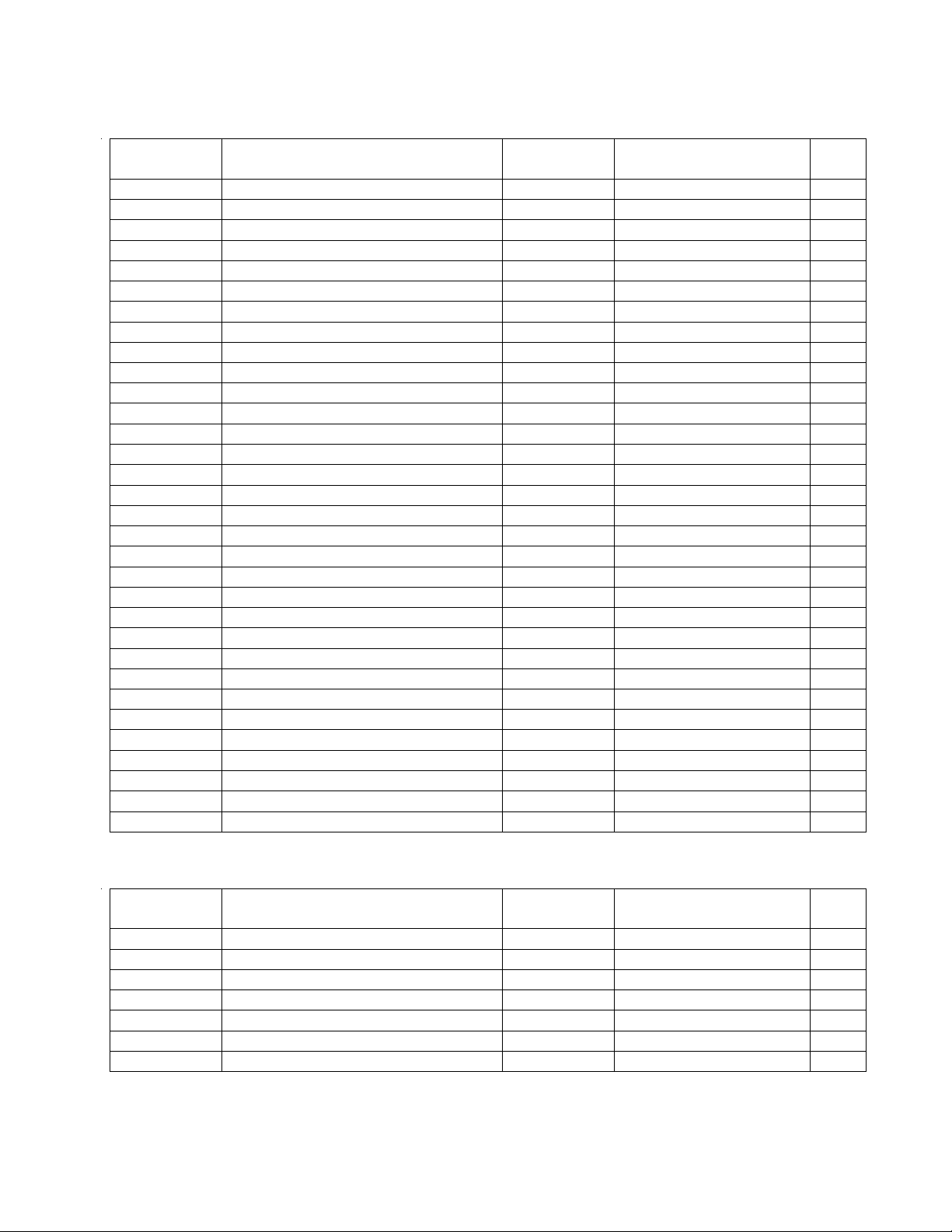

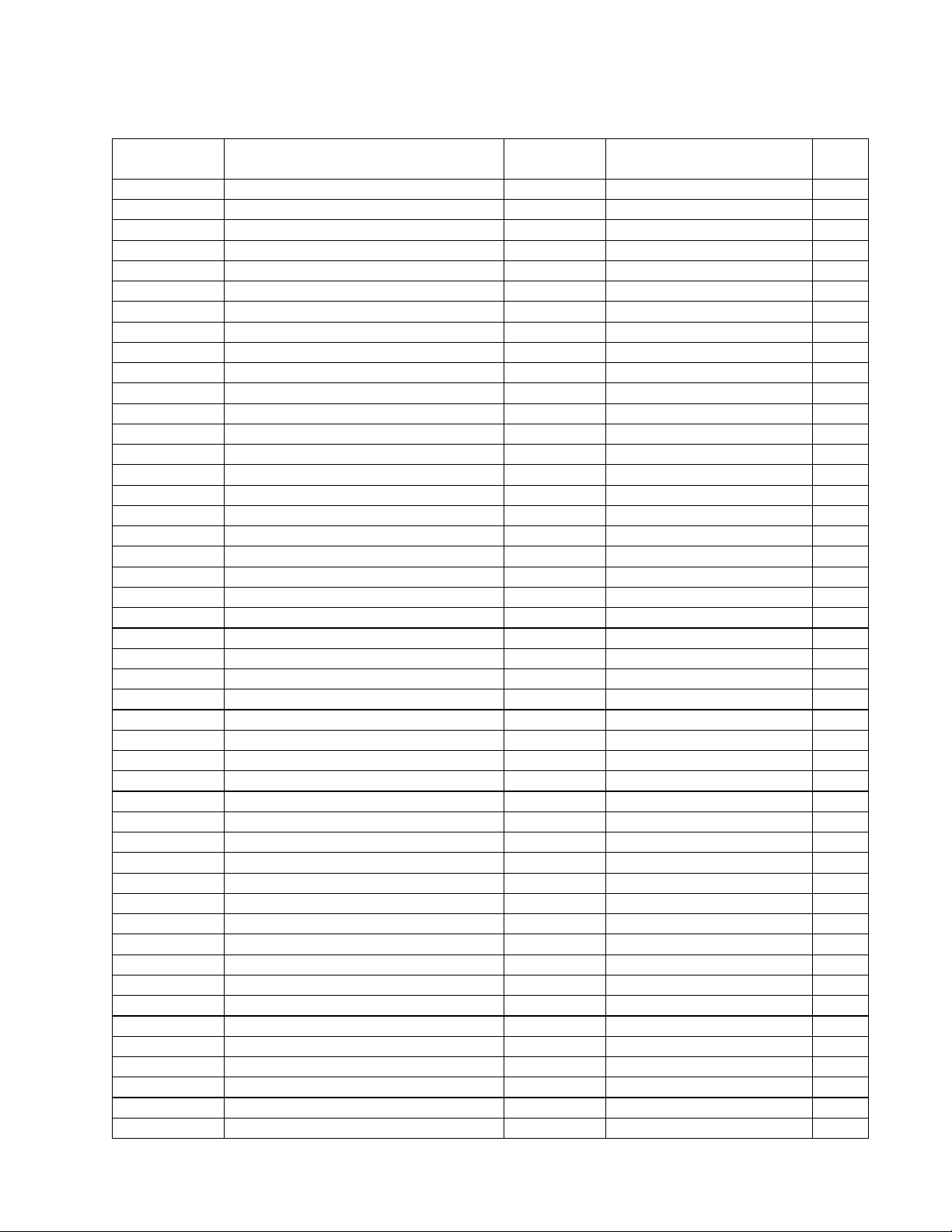

Main Part List, Control Space ESP-88 Chassis (see Figure 4) ..............................................................15-16

Figure 4. ControlSp ace ESP-88 Chassis Exploded View .............................................................................. 16

Main Part List, ControlSpace CC-16 Controller...........................................................................................17

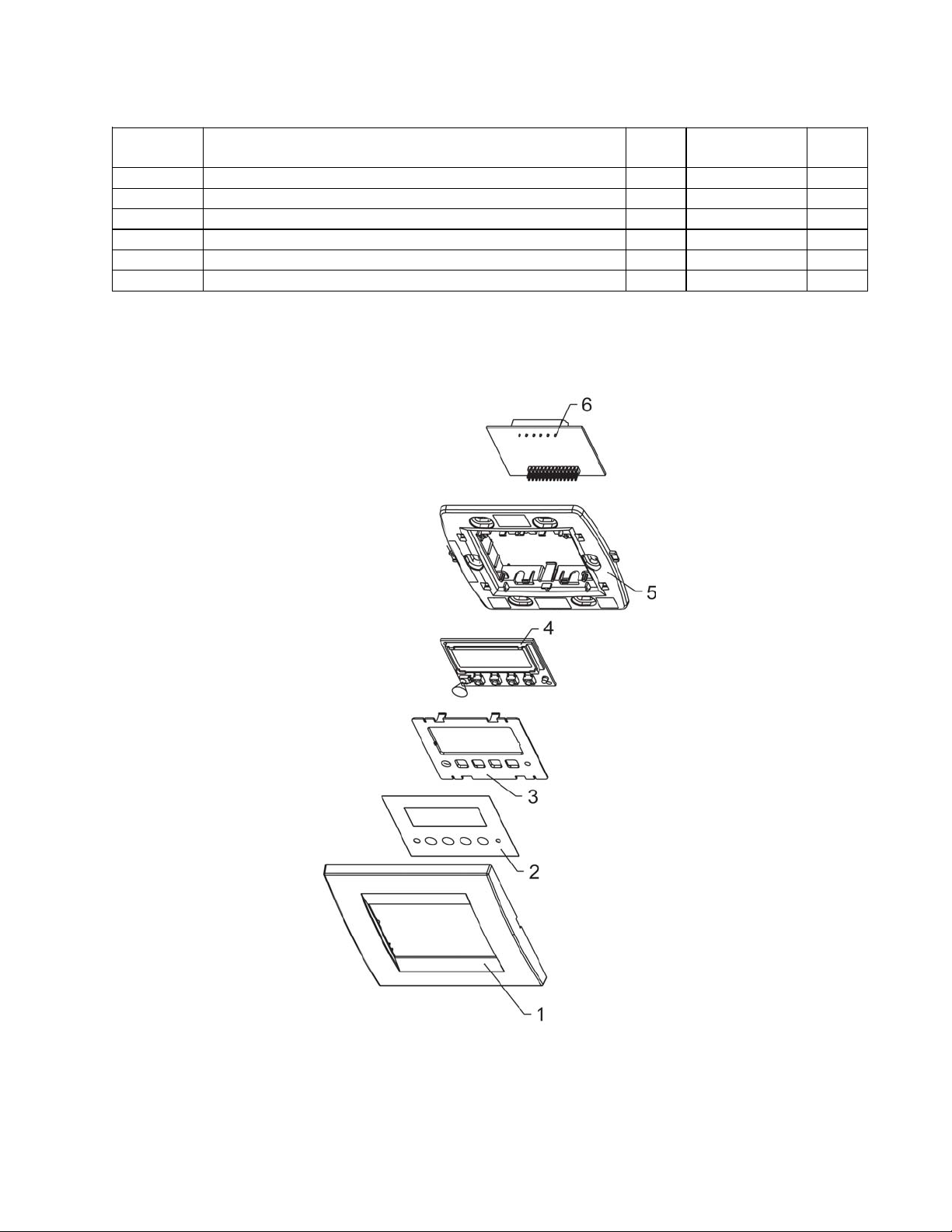

Figure 5. ControlSpace CC-16 Controller Exploded V iew..............................................................................17

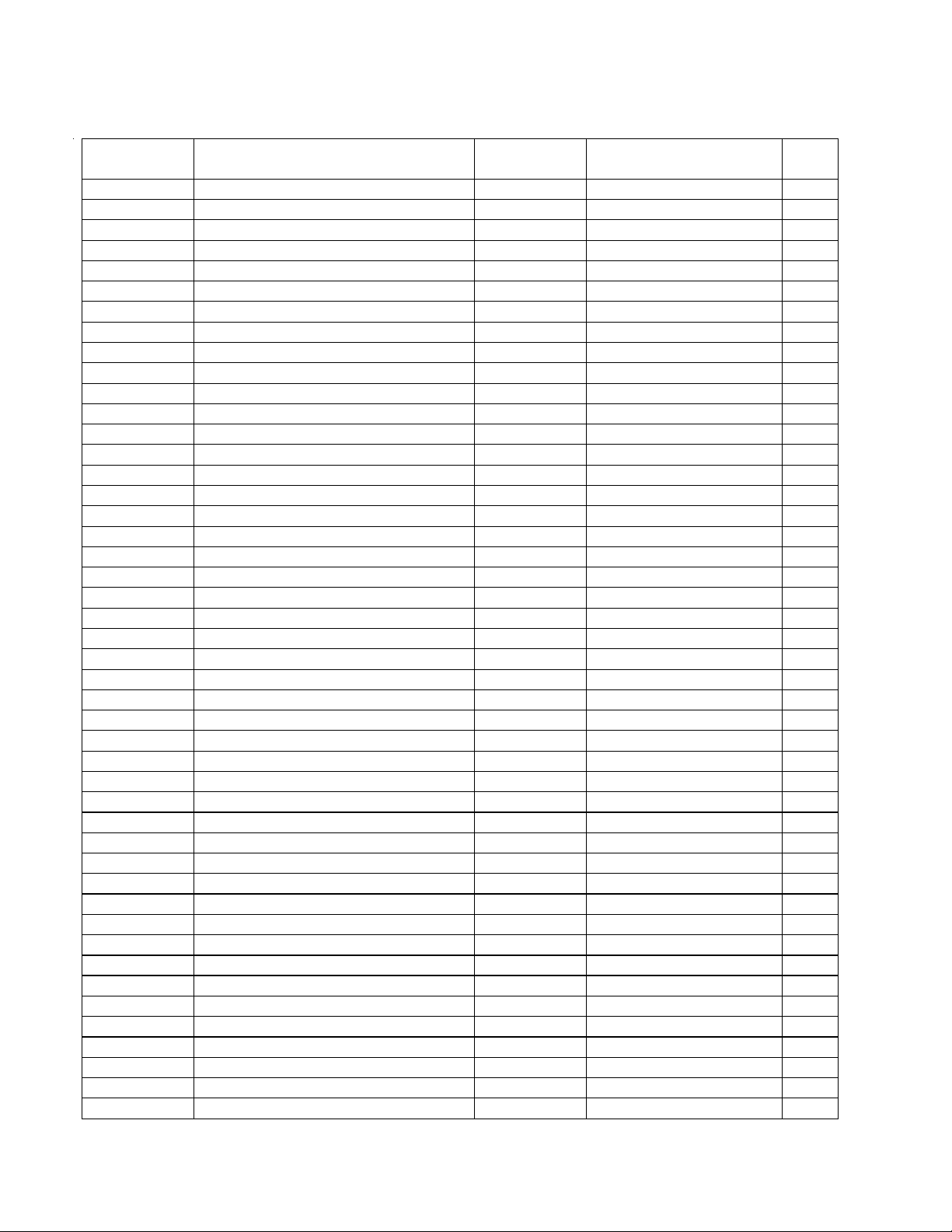

Main Part List, ControlSpaceTM CC-64 Controller .....................................................................................18

Figure 6. ControlSpace CC-64 Controller Exploded V iew..............................................................................18

Electrical Part Lists ..................................................................................................................................19-64

ESP-88 Chassis Motherboard PCB Assembly........................................................................................19-25

ESP-88 Chassis 4x4 PCB Assembly........................................................................................................26-42

ESP-88 Digital Signal Processor (DSP) PCB Assembly.........................................................................43-56

ESP-88 Output PCB Assembly .....................................................................................................................57

ESP-88 LED PCB Assembly..........................................................................................................................57

CC-64 Control Center ...............................................................................................................................58-62

CC-16 Zone Controller .............................................................................................................................63-64

Disassembly Procedures .........................................................................................................................65-67

ControlSpace ESP-88 Chassis ..................................................................................................................... 65

ControlSpace CC-16 Control Center ............................................................................................................66

ControlSpace CC-64 Control Center ............................................................................................................67

Front Panel Indicators and Features............................................................................................................68

Rear Panel Controls and Connections ........................................................................................................ 69

T est Procedures, Audio Processor ESP-88 St d Version........................................................................ 71-96

Figure 7. ATS-2, ESP-88 and AuBit Switchbox Test Setup Diagram .............................................................73

Figure 8. Motherboard Top Etch Layout Diagram ..........................................................................................97

Figure 9. Motherboard VCC Etch Layout Diagram ........................................................................................97

Figure 10. Motherboard GND Etch Layout Diagram......................................................................................98

Figure 1 1. Motherboard Bottom Etch Layout Diagram ................................................................................... 98

Figure 12. MIC/Line Input PCB Topside Etch Layout Diagram ......................................................................99

Figure 13. MIC/Line Input PCB VCC Etch Layout Diagram...........................................................................99

Figure 14. MIC/Line Input PCB GND Etch Layout Diagram ........................................................................ 100

Figure 15. MIC/Line Input PCB Bottom Etch Layout Diagram ..................................................................... 100

Figure 16. DSP PCB Topside Etch Layout Diagram ....................................................................................101

Figure 17. DSP PCB VCC Etch Layout Diagram......................................................................................... 101

Figure 18. DSP PCB GND Etch Layout Diagram ........................................................................................102

Figure 19. DSP PCB Bottom Etch Layout Diagram.....................................................................................102

Figure 20. GPIO PCB Topside Etch Layout Diagram .................................................................................. 103

Figure 21. GPIO PCB VCC Etch Layout Diagram .......................................................................................103

Figure 22. GPIO PCB GND Etch Layout Diagram.......................................................................................103

Figure 23. GPIO PCB Bottom Etch Layout Diagram ................................................................................... 103

Figure 24. Output PCB Topside Etch Layout Diagram.................................................................................104

Figure 25. Output PCB Bottom Etch Layout Diagram ................................................................................. 104

Figure 26. LED PCB Topside Etch Layout Diagram .................................................................................... 104

Figure 27. LED PCB Bottom Etch Layout Diagram .....................................................................................104

Power Supply +5VDC V oltage Adjustment Procedures..................................................................... 105-106

Troubleshooting .......................................................................................................................................... 107

Service Manual Revision History ...............................................................................................................108

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® ControlSpace® ESP-88 System, CC-16 and CC-64 Controllers

contains no user-serviceable parts. To prevent warranty infractions, refer servicing

to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose ControlSpace ESP-88 System and CC-16 and CC-64 Controllers are covered by a

limited 5-year transferable warranty.

3

Page 4

PRODUCT DESCRIPTION

ESP-88 Chassis Overview:

The Bose

high quality audio signal processor for engineered sound applications such as churches, theaters, auditoriums, and sports venues.

The base model (ESP-88) includes eight inputs (microphone or line-level selectable) and eight

line level outputs. Four available audio slots allow the addition of up to 16 more analog audio

channels – inputs, outputs or a combination – or up to 32 more digital audio channels (AES3) as

inputs, outputs or a combination.

For large applications, multiple ESP-88s can be used per system. Multiple choices of user

controllers are available to provide end-users with simple, easy-to-use control of their

ControlSpace system.

The Bose ControlSpace Designer software is used to design systems and configure the

ESP-88 and user controllers. The software runs on a PC and communicates to the ESP-88 over

Ethernet.

Features and functions:

• Expandable and flexible cardframe architecture

• Eight mic/line analog audio input channels

• Eight line level analog audio output channels

• Four open audio expansion slots allow up to 32 analog audio channels total in a 2U chassis

• DSP expansion slot allows DSP processing power and delay times to increase fourfold

• Eight general purpose control inputs and eight general purpose control outputs (GPIO)

• GPIO expansion slot allows up to 16 control inputs and 16 control outputs

• All audio input and input channels feature tricolor level LEDs

• Design, control and configuration via PCbased software and Ethernet connection.

• Large set of signal processing modules including: Bose speaker EQs, Bose crossovers,

graphic and parametric EQs, routers, delays, matrix mixers, signal generators,

meters, compressors/Limiters, duckers, automatic gain controls, gate and source selectors.

®

ControlSpace® ESP-88 engineered sound processor is a flexible, expandable and

Modularity and Expansion

Flexible Architecture

The ESP-88 employs a flexible, modular architecture. The flexible architecture provides two

levels of DSP performance – up to 32 general-purpose I/O and up to 64 digital audio channels –

or up to 32 analog audio channels.

The base model ESP-88, includes a DSP card, two 4x4 Mic/Line cards and one GPIO card. In

this configuration, four audio and one GPIO slot are available for expansion.

Three types of optional cards are available: DSP expansion; GPIO; and Audio.

DSP Expansion Card - Daughter card for main DSP card. Increases performance by 300%.

One card can be added to an ESP-88.

GPIO Card

Fits in one of the two GPIO slots. Eight control inputs and eight control outputs. One GPIO card

can be added to an ESP-88.

4

Page 5

PRODUCT DESCRIPTION

ESP-88 Chassis Overview (continued):

Optional Cards

Audio Cards:

4x4 Mic/Line Card (Series I)

4x4 Mic/Line Card (Series II)

Occupies two audio slots. Four microphone or line level inputs (software selectable), and four

line level outputs. The ESP-88 includes two 4x4 Mic/line cards. Two 4x4 cards can be added.

EDR Line Level Output Card

Occupies one audio slot. Four highest-quality, line level outputs.

EDR Line Level Input Card

Occupies one audio slot. Four highest-quality, line level inputs.

AES3 Output Card

Occupies one audio slot. Eight AES3 outputs (two per output connector).

AES3 Input Card

Occupies one audio slot. Eight AES3 inputs (two per input connector).

Surround Sound Card

Occupies one audio slot. One optical and one coaxial digital audio inputs.

5

Page 6

CC-16 Zone Controller

PRODUCT DESCRIPTION

The Bose

mounted device designed to provide end-user control of ControlSpace

systems. Custom programming allows the CC-16 to control a variety of

the system elements, from switching audio sources to selecting

“scenes” or system configurations. The CC-16 features a bitmap LCD

and four buttons for displaying and controlling the system settings.

The CC-16 connects to the ControlSpace Engineered Sound Processor (ESP-88) at the RS-485 port. Up to fifteen CC-16 units can be

used per each ESP-88 to provide localized control of the system. The

maximum distance from ESP-88 to CC-16 is 2000 feet. As a networked device, remote reprogramming is possible at any time.

Features and Functions

• 122 x 32 pixel backlit blue LCD

• LCD displays volume level and source/scene/preset setting

• Select up/down buttons for selecting sources or scenes

• Volume up/down buttons for controlling one or more gain controls

• IR receiver (for IR remote controls)

• RS-485 network supports up to fifteen CC-16 units per ESP-88

• DIP-switch for specifying network address and termination

• Universal mounting bracket

• UL and CE listed

®

ControlSpace® CC-16 zone controller is an elegant wall-

CC-64 Control Center

The Bose ControlSpace CC-64 control center is an

elegant, programmable, networked controller that

provides users with a simple and logical interface to

their ControlSpace system. Because the controller is

completely programmable, you can customize the

ControlSpace system, making only certain controls

available, and simplifying user interaction with the

system.

The CC-64 provides four rotary encoders with

circular LED arrays for a userfriendly method of

managing gain settings or scene selections. A fifth encoder provides control over programmed

“scenes” or presets. Four bank switch buttons redefine the four Gain/Selector control knobs,

providing quick access for up to 16 system gain controls or selectors. A large, 2-line by 40character backlit LCD provides the user with the names of the system elements they are controlling (gains, presets, etc.).

Using custom programming, the CC-64 can manage a variety of system elements, including

audio sources, scene selection settings, and specific system configurations. Each gain control

can be ganged so that a single control can be mapped to as many as sixteen system gains. The

CC-64 also supports a “custom mode” – intended for installers, not end users – in which any

parameter in the system can be viewed and changed using the LCD display and control knobs.

6

Page 7

PRODUCT DESCRIPTION

CC-64 Control Center (continued)

The CC-64 is a 10Base-T Ethernet device. Up to sixteen CC-64s can be used per

ControlSpace

Features

• 2-line by 40-character backlit LCD

• Sixteen Gain/Selector controls (four banks of four)

- Four rotary encoders for changing the gain level or selecting scenes/sources

- Each encoder includes a 15-segment LED array for indicating the control’s current level or

state

- The encoders feature push buttons for muting gain controls or making selections

- Ten character descriptions of the gain controls appear on the LCD above the encoder

• Four bank switch buttons with label area

• Lock function in software prevents local changes

• 10Base-T Ethernet network based

• Sixteen CC-64s per ControlSpace system

• Power over Ethernet cable or separate cable

• LEDs for status, link and network transmit/receive

• Fits standard 5-gang electrical box

• UL6500 listed and CE approved

Functions

1. LCD

2. Preset/Scene selector

- Rotate to view presets. Push to select.

- Push and hold for 5 seconds to enter Custom mode.

3. Network link indicator

4. Network receive indicator

5. Network transmit indicator

6. Bank select buttons (4). Press to select one of four bank controls

7. Bank select indicators (4). Indicates the currently selected bank

8. Bank select label area. 1.25" (31.75 mm) x .35" (9 mm) area for custom labels.

- Accepts standard 3/8" (9 mm) label stock.

9. Gain/Selector control knob. Rotary encoder (no stops). Push to mute.

10. Gain/Selector level indicators (15 levels/selections)

®

system.

7

Page 8

SPECIFICATIONS

Inputs

T ype: 8 analog, electronically balanced, microphone/line level

(software selectable)

Connectors: Phoenix/Euroblock 2-piece, 3-pin

Nominal Input Level: +4dBu/-10dBu/-20dBu/-38dBu/-44dBu/-50dBu/-60dBu

Frequency Response: 20 to 20kHz (+0.5dB / -2.0dB) at +4dBu nominal input level

Input Impedance: 2.4k ohm @ 1kHz (with or without phantom power active)

Maximum Input Level: +24dBu @ +4dBu nominal input power

Equivalent Input Noise: -115dB at -60dBu nominal input level (A-weighted/20-20kHz)

Phantom Power: +15V nominal, selectable per input

THD+N: 0.01% at +4dBu nominal input and output level

(A-weighted/20-20kHz)

Digital Resolution: 24-bit

Outputs

T ype: 8 analog, electronically balanced

Connectors: Phoenix/Euroblock 2-piece, 3-pin

Nominal Output Level: +4dBu

Output Impedance: 200 Ohms (600 Ohm load expected)

Frequency Response: 20 to 20kHz (+0.5dB/-2.0dB) at +4dBu nominal output level

Maximum Output Level: +24dBu at +4dBu nominal output level

Digital Resolution: 24-bit

Signal to Noise Ratio (SNR): 80dB at +4dBu nominal output level (A-weighted/20-20kHz)

Residual Output Noise: -110dBu at output muted (A-weighted/20-20kHz)

THD+N: 0.01% at +4dBu nominal input and output level

(A-weighted/20-20kHz)

Crosstalk: < -90dB at +4dBu nominal input and output level at 1kHz

8

Page 9

SPECIFICATIONS

Signal Processing

T ype: 32-bit floating-point digital signal processor(s)

Clock Speed: 200MHz

Maximum Calculation: 1600 MIPS/1200 MFLOPS

(6400 MIPS/4800 MFLOPS with DSP option card)

Delay Memory: 16MByte/72s (maximum)

(64MByte/288s maximum with DSP option card)

Audio Latency: 610us (analog in to analog out) (860us with DSP option card)

Sampling Rate: 48kHz

Control Inputs

T ype: 8 analog or digital inputs, 5.1k ohms internal pull-up resistor

to 5V

Connectors: Phoenix/Euroblock 2-piece, 9-pin 3.81mm pitch

Analog Input: 0V to 3.3V (max 5V; suitable for 10k ohm variable resistor)

Digital Input Voltage Range: 0V to 3.3V (threshold voltage = 1.6V; internal 5.1k ohms pulled

up to 5V)

Control Outputs

T ype: 8 digital outputs, 10k ohms internal pull-up resistors to 5V

Connectors: Phoenix/Euroblock 2-piece, 9-pin 3.81mm pitch

Output Voltage: 0V to 5V open collector

Output Current: 0.5mA (source)/10mA max (sink)

Communication Ports

LAN: 10Base-T (RJ-45)

RS-232C: D-sub 9 pin, male; DTE

RS-485: Phoenix/Euroblock 2-piece, 3-pin

Indicators

Status: Power/Status/Ethernet/Serial (RS232C + RS485)

Audio: Signal (Present/Normal/Clip) for each audio input and output

9

Page 10

SPECIFICATIONS

Expansion Slots

Audio I/O: 8 slots (4 slots occupied)

Control I/O: 2 slots (1 slot occupied) Max 16 inputs/16 outputs

DSP: 1 slot

Audio Channels

Analog: 32 max (all slots full)

Digital (AES3): 64 (all slots full)

Mechanical

Dimensions: 18.9”W x 3.5”H x 12.6”D (482 x 88 x 320mm)

Weight: 14 lb. (5.3 kg)

Electrical

Mains Voltage: 85 - 264 VAC 50/60 Hz with PFC

Power Consumption: < 35VA

Maximum Power < 70VA (at <35 degrees C ambient)

Consumption:

Environmental

Operating Temperature: < 50 degrees C at less than 35VA / < 40 degrees C at

less than 70VA

Humidity: 80% relative humidity (without condensation)

10

Page 11

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

11

Page 12

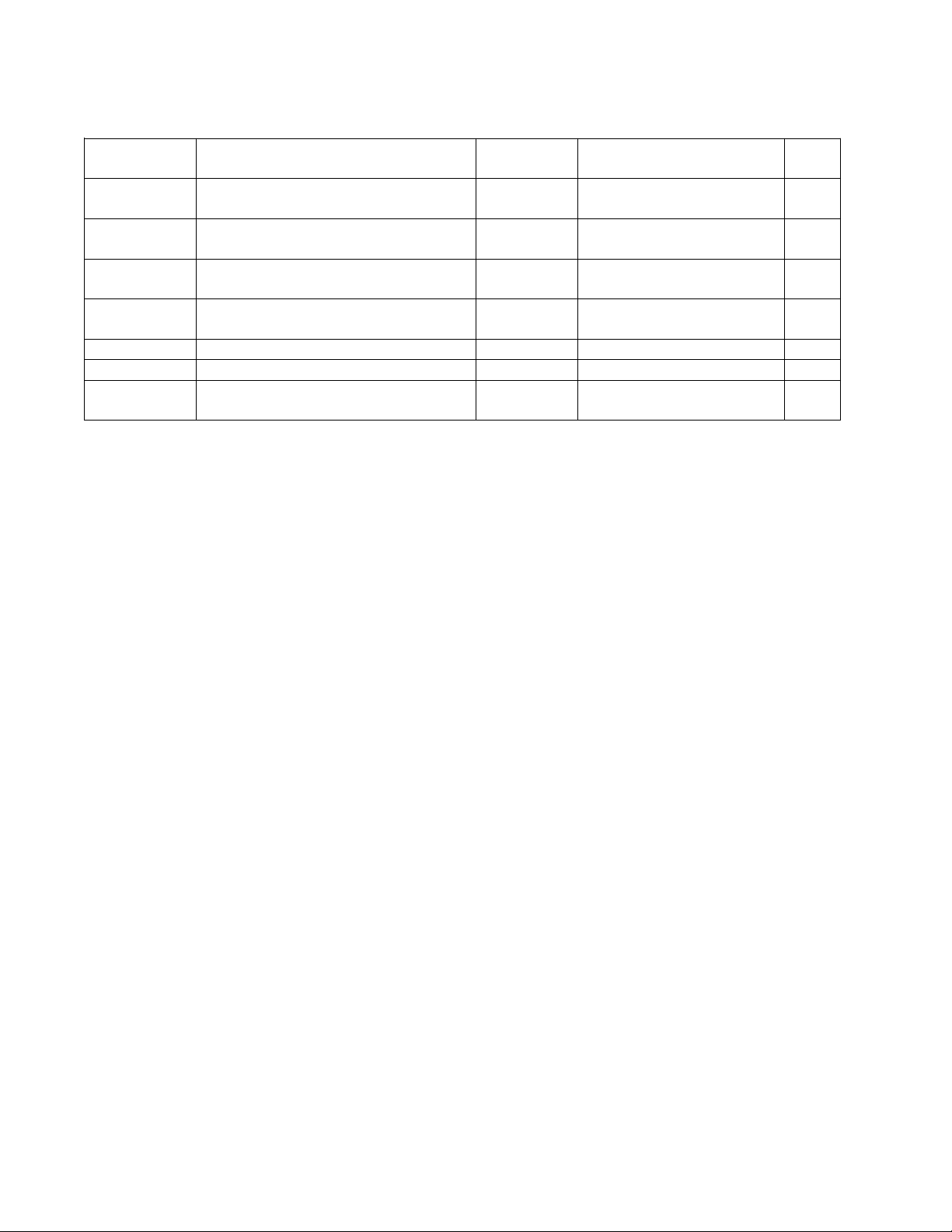

PACKAGING PART LIST

Item

Description Qty. Part

Note

ControlSpace® ESP-88 Chassis

Number

1 EPE FOAM 2 312474

2 ESP-88 Chassis, US/CAN

ESP-88 Chassis, EURO

ESP-88 Chassis, UK

ESP-88 Chassis, JAPAN

ESP-88 Chassis, AUS

3 POLYBAG, L550xW600MM 1 - 4

4 CONTROLSPACE S/W CD 1 - 4

5 CD SLEEVE 1 - 4

6 POLYBAG, L300xW150MM 1 - 4

7 POWER CORD, 120V, US/ C A N

POWER CO RD, 220V, EURO

POWER CORD, 24 0V, U K

POWER CO RD, 100V, JAPA N

POWER CO RD, 240V, AUS

8 CAT-5 ETHERNET CABLE 1 - 4

9 POLYBAG, 100x60MM 3 - 4

10 TERMINAL BLOCK, 9 POS 2 305532

11 TERM BLOCK, PLUG, ORANGE 8 305535

12 TERM BLOCK, PLUG, GREEN 9 305536

13 USER MANUAL 1 275800

14 CARTON 1 275797

1 041755

1 298165

Number

041756

041758

041757

041759

298166

298168

298167

298169

3

Figure 1. ESP-88 Chassis Packing View

12

Page 13

PACKAGING PART LIST

Item

Description Qty. Part Number Note

ControlSpace® CC-16 Controller

Number

1 Foam, White EPE 1 - 4

2 CC-16 Controller 1 041761 2

3 Anti-static bag, 150 x 180 x 0.03MM 1 - 4

4 Paper Tray 1 - 4

5 Installation Manual, English Language 1 285042

6 White box 1 - 4

7 Screw, #6-32x0.7", Phillips, ZINC (US/J apan) 4 - 4

8 Bag, Poly, 40 x 60MM 2 - 4

9 Screw, M4.0x18, Phillips, ZINC (Europe) 4 - 4

- Power Supply, 15VDC, 5W, 100-240VAC Input

(not packaged w/CC-16)

1 041762 3

Figure 2. CC-16 Controller Packing View

13

Page 14

PACKAGING PART LIST

ControlSpace® CC-64 Controller

Item

Number

1 Install Guide, CC-64 1 285041

2 EPE Foam, 330X180X15MM 1 - 4

3 Bag, PE, Anti-Static, 330X180X0.03 MM 1 - 4

4 CC-64 Controller 1 041760 2

5 Screw, US, MSF, #6-32X0.7, MS, ZN-WH 4 - 4

6 Bag, Poly, 40X60MM 1 - 4

7 Tray, Foam, EPE, 330x180x45MM 1 - 4

8 Terminal Block, 2P, P5.08, 2ESDV-02P 1 - 4

9 Bag, Poly, 100X60MM 1 - 4

10 White Box, W9B 1 - 4

11 Computer UTP LAN Cable, 2M, CAT 5 1 - 4

- Power Supply, 15VDC, 5W, 100-240VAC Input

(not packaged w/CC-64)

Description Qty. Part Number Note

1 041762 3

Figure 3. CC-64 Controller Packing View

14

Page 15

MAIN PART LIST

Item

Description Qty. Part

Note

ControlSpace® ESP-88 Chassis (see Figure 4)

Number

1 TOP COVER 1 278505-001

2 M3x4 SCREW, MSF, MS-BK

(FOR CHASSIS/COVER)

3 M3x4 SCREW, SI, MSB, MS-BK 62 - 4

4 GIO REAR PANEL, SECC-T1, T=1.0MM 1 278516-001

5 PANEL, REAR, BLANK, SECC-T1 T=1.0MM 5 278518-001

6 DSP REAR PANEL, SECC-T1, T=1.0MM 1 278515-001

7 4CH REAR PANEL (LINE OUTPUT) SECC-T1

8 4CH REAR PANEL (MIC/LINE INPUT) SECC-T1

9 4x4 LINE OUTPUT PCB ASSY

10 4X4 MIC/LINE SERIES I I/O PCB 2 041767 2

4X4 MIC/LINE SERIES II I/O PCB 041915

11 PCB FIXED STICK, ABOVE 2 278503-001

12 MOTHERBOARD PCB ASSY 1 275796 2

13 M3x6 SCREW, MSB, M3x6mm, MS-BK 5 - 4

14 INTERNAL TOOTH WASHER,

15 LED LENS, PMMA, MF001 9 278522-001

16 FRONT ENDCAP, RIGHT, PC/ABS, C2950 (M3x3

17 DOOR, ALUMINUM 1 278520-001

18 FRONT PANEL, ALUM, FIXED 1 278519-001

19 FRONT ENDCAP, MID, PC/ABS, C2950, (M3x2

20 FRONT ENDCAP, LEFT, PC/ABS, C2950 (M3x3

21 FRONT PANEL, SECC-T1 1 278507-001

22 CHASSIS 1 278506-001

23 PCB FIXED STICK, BELOW 1 278504-001

24 SCREW, US, MSF, 4#-40x0.236, MS, BLACK 4 - 4

25 LED PCB ASSEMBLY (PART OF MIC/LINE IN/O UT

26 POWER SUPPLY , 70W, REL-70-300227 M4x12 SCREW, SI, MSB, MS-BK

28 DC FAN, +5VDC, 60MM,

29 M4x3 HEX NUT W/NYLON INSERT, SI, SS 4 - 4

30 DSP PCB ASSEMBLY 1 275794 2

31 GPIO PCB ASSEMBLY 1 041768 2

32 STAY, SECC-T1, T=1.0MM 1 278508-001

- D SP EX PAN SION CA RD - 041769

- 8-CH DIGITAL IN EXP PCB - 041765

- 8-CH DIGITAL OUT EXP PCB - 041766

- 4-CH ANALOG IN EXP PCB

T=1.0MM

T=1.0MM

(PART OF ITEM 10 BELOW)

OD 6.4xID3xT0.45MM

NUT)

NUT)

NUT)

MAIN PCB)

F-CHCO

(FOR F AN )

F6010AP-05LCW

(EDR Line Level Input Card)

4 - 4

2 278512-003

2 278512-002

2 -

7 - 4

1 278521-002

1 278521-003

1 278521-001

2 - 2

1 295622 3

4 - 4

1 295621 3

- 041764

Number

15

Page 16

MAIN PART LIST

Item

Description Qty. Part

Note

ControlSpace® ESP-88 Chassis (continued)

Number

- 4-CH ANALOG OUT EXP PCB

(EDR Line Level Output Card)

- 4-CH SDR OUTPUT PCB - 041916

- 4-CH MIC/LINE INPUT PCB - 041917

- SURROUND DECODER INPUT PCB - 302210

- AC POWER SWITCH, ROCKER, SPST, 125V/15A 1 - 3, 4

- AC SOCKET, IEC, 250V/10A 1 - 3, 4

- Power Supply Harness, Improved, ESP-88C / ESP00 (used with the Astec power supply)

- Power Supply Harness, Improved, ESP-88 / ESP88C (used with the IPD power supply)

- 041763

1 3189351 318938-

Number

001S

001S

3

3

Figure 4. ControlSpace ESP-88 Chassis Exploded View

16

Page 17

MAIN PART LIST

Item

Description Qty.

Note

ControlSpace® CC-16 Controller

Part Number

Number

1 Front plate, PC, GE, LEXAN, 241R, White 1 275432

2 Overlay, PC sheet, w/adhesive, 0.18mm 1 277488

3 Insert, plate, PC, GE, LEXAN, 241R, White 1 275434 4

4 LCD PCB Assembly 1 275817-002

5 Mounting Frame, PC, GE, LEXAN, 241R, White 1 275433 4

6 Main PCB Assembly 1 275817-001

Figure 5. ControlSpace CC-16 Controller Exploded View

17

Page 18

MAIN PART LIST

ControlSpace® CC-64 Controller

Item

Number

1 Metal EMC Shield, Case, SECC-T1, T=0.50MM 1 275816 4

2 Front Panel 1 275814 4

3 Knob 5 278523-002

4 Nylon Washer, OD=6.1MM, ID=2.95MM, T=2MM 6 - 4

5 Keyboard Overlay, Plastic, W/S, Adhesive 1 277485

6 LCM Module, STN, Blue, 12 Clock,

YMC402-11AAABUCL

7 LED PCB Assembly 1 278524-001

8 Main PCB Assembly 1 278523-001

9 Metal Panel, Aluminum 1 275815 4

10 Screw, SI, MSP, M3X11.5MM 4 - 4

11 Screw, MSB, M3X6, NI 14 - 4

12 Spacer, Support, K33-7 4 - 4

13 Sponge 1 - 4

14 PVC Washer, ID=3.1MM, T=0.3MM 4 - 4

Description Qty

Part Number

1 323977-001S

Note

Figure 6. ControlSpace CC-64 Controller Exploded View

18

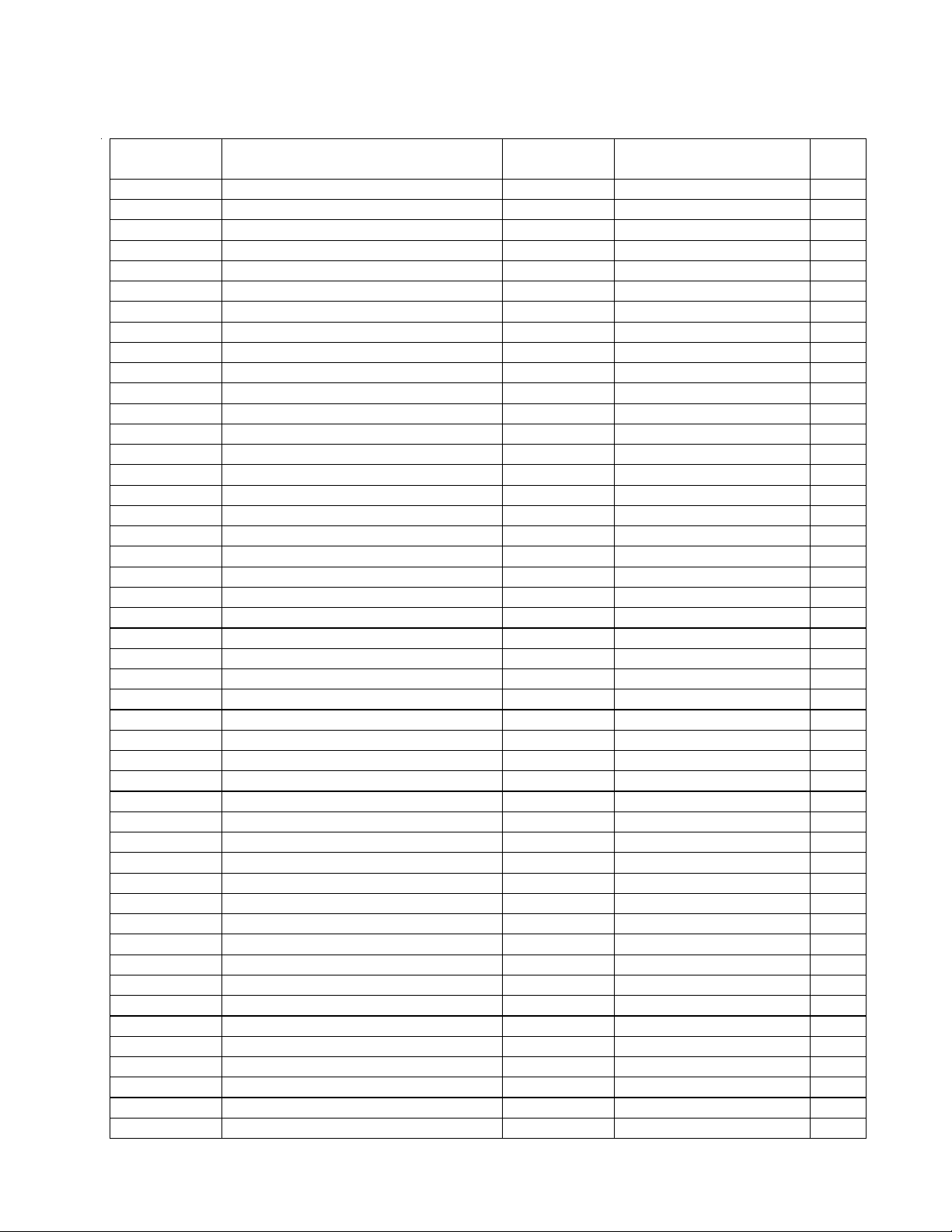

Page 19

Reference

Description Vendor Vendor Part Number Note

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Resistors

Designator

JP200 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP201 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP202 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP203 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

R100 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R101 1K, 0603, 1/10W, 1% Yageo RC0603FR-071K 4

R102 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R103 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R104 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R105 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R200 220K, 0603, 1/10W, 1% Yageo RC0603FR-07220K 4

R201 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R202 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R204 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R205 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R208 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R209 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R210 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR- 07 R00 4

R211 1K, 0603, 1/10W, 1% Yageo RC0603FR-071K 4

R213 1K, 0603, 1/10W, 1% Yageo RC0603FR-071K 4

R214 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R215 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R216 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R220 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R221 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R236 220K, 0603, 1/10W, 1% Yageo RC0603FR-07220K 4

R238 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R239 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R240 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R241 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R300 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R301 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R302 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R303 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R304 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R305 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R306 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R307 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R308 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R309 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R310 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R311 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R312 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R313 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R314 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R315 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R316 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

19

Page 20

Reference

Designator

Description Vendor Vendor Part Number Note

R317 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R318 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R319 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R320 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R321 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R322 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R323 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R324 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R325 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R326 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R327 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R328 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R329 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R330 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R331 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R332 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R333 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R334 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R335 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R336 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R337 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R338 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R339 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R340 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R341 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R342 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R343 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R344 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R345 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R346 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R347 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R348 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R349 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R350 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R351 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R352 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R353 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R354 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R355 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R356 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R357 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R358 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R359 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R360 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R361 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R362 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R363 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Resistors (continued)

20

Page 21

Reference

Description Vendor Vendor Part Number Note

Reference

Description Vendor Vendor Part Number Note

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Resistors (continued)

Designator

R364 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R365 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R366 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R367 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R368 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R369 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R370 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R371 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R372 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R373 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R374 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R375 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R376 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R377 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R378 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R379 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R380 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R381 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R382 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R383 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R384 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R385 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R386 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R387 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R388 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R389 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R390 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R391 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R392 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R393 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R394 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R395 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

Resistor Arrays

Designator

RA100 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA101 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA102 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA103 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA104 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA105 33 OHM, 8 PIN, 1/16W, ISO, 5% Yageo YC164-JR-0733R 4

RA106 10K, 10 PIN, 8R, 1/16W, ISO, 5% Yageo YC158TJR-0710K 4

21

Page 22

Reference

Designator

Description Vendor Vendor Part Number Note

C100 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C101 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C102 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C103 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C104 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C105 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C106 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C107 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C108 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C109 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C110 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C111 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C112 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C113 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C114 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C115 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C116 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C117 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C118 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C119 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C120 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C121 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C122 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C123 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C124 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C125 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C126 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C127 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C200 47uF, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C201 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C202 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C203 47uF, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C204 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C205 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C206 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C207 47uF, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C208 10uF, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C209 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C210 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C211 10uF, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C212 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C220 47uF, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C221 47uF, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C222 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C223 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C300 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Capacitors

22

Page 23

Reference

Description Vendor Vendor Part Number Note

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Capacitors (continued)

Designator

C301 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C302 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C303 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C304 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C305 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C306 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C307 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C308 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C309 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C310 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C311 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C312 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C313 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C314 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C315 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C316 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C317 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C318 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C319 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C320 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C321 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C322 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C323 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C324 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C325 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C326 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C327 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C328 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C329 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C330 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C331 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C332 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C333 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C334 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C335 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C336 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C337 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C338 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C339 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C340 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C341 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C342 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C343 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C344 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C345 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C346 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C347 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

23

Page 24

Reference

Designator

Description Vendor Vendor Part Number Note

C348 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C349 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C350 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C351 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C352 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C353 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C354 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C355 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C356 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C357 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C358 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C359 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C360 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C361 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C362 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C363 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C364 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C365 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C366 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C367 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C368 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C369 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C370 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C371 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C372 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C373 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C374 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C375 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C376 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C377 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C378 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C379 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C380 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C381 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C382 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C383 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C384 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C385 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C386 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C387 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C388 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C389 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C390 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C391 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C392 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C393 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C394 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

C395 47pF, 0603, 50V, 55C, NPO, 5% Samsung CL10C470JBNC 4

ELECTRICAL PART LIST

ESP-88 Chassis Motherboard PCB Assembly

Capacitors (continued)

24

Page 25

ELECTRICAL PART LIST

Reference

Description Vendor Vendor Part Number Note

Reference

Description Vendor Vendor Part Number Note

Reference

Description Vendor Vendor Part Number Note

Reference

Description Vendor Vendor Part Number Note

ESP-88 Chassis Motherboard PCB Assembly

Diodes

Designator

D200 400V, 1A, 1SR154-400, SOD-106 ROHM 1SR154-400 4

D201 400V, 1A, 1SR154-400, SOD-106 ROHM 1SR154-400 4

D202 400V, 1A, 1SR154-400, SOD-106 ROHM 1SR154-400 4

D207 400V, 1A, 1SR154-400, SOD-106 ROHM 1SR154-400 4

D208 400V, 1A, 1SR154-400, SOD-106 ROHM 1SR154-400 4

Transistors

Designator

Q100 PNP, 50V, 100mA, SOT-23 KEC KRA102S 4

Q202 PNP, 60V, 1A, SOT-89 KEC KTA1668Y 4

Q203 NPN, 50V, 100mA, SOT-23 KEC KRC102S 4

Q205 NPN, 50V, 100mA, SOT-23 KEC KRC102S 4

Q211 PNP, 50V, 100mA, SOT-23 KEC KRA102S 4

Integrated Circuits

Designator

M100 DECODER, TSSOP-16 ONSEMI MC74VHC138DT 4

M101 OCTAL BUS BUFFER, TSSOP-20 ONSEMI MC74VHC541DT 4

M102 OCTAL BUS BUFFER, TSSOP-20 ONSEMI MC74VHC541DT 4

M103 OCTAL BUS BUFFER, TSSOP-20 ONSEMI MC74VHC541DT 4

M104 DECODER, TSSOP-16 ONSEMI MC74VHC138DT 4

M200 REGULATOR, 3.3V, 1A, TO-252 NEC UPC2933T 4

Miscellaneous

Designator

CN100 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN101 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN102 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN103 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN104 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN105 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN106 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN107 CONN, P1.0MM, 30 PIN, MALE KEL Corp. 87BMN-030S 4

CN108 CONN, P1.0MM, 100 PIN, MALE KEL Corp. 87BMN-100S 4

CN200 W IRE TO BOARD HEADER,

CN202 W IRE TO BOARD HEADER,

CN203 W IRE TO BOARD HEADER,

CN205 W IRE TO BOARD HEADER,

CompuTime 4024406-----0N19 4

P3.96MM, 6 POLES, 2114S-06

CompuTime 4024208-----0N19 4

P2.5MM, 8 POLES, 2317SJ-08

P2.5MM, 8 POLES, 2317SJ-08

P2.5MM, 3 POLES, 2317SJ-03

CompuTime 4024208-----0N19 4

CompuTime 4024203-----0N19 4

25

Page 26

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors

Designator

JP100 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP101 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP102 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP103 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP104 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP200 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP201 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP202 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP203 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP204 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP300 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP301 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP400 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP401 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP500 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP501 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP550 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

JP551 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

R100 100K, 0603, 1/10W, 1% Yageo RC0603FR-0710 0K 4

R101 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R102 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R103 100K, 0603, 1/10W, 1% Yageo RC0603FR-0710 0K 4

R110 1.3K, 0603, 1/10W, 1% Yageo RC0603FR-071K3 4

R112 5.1K, 0603, 1/10W, 1% Yageo RC0603FR-075K1 4

R115 82 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0782R 4

R117 68 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0768R 4

R120 1.3K, 0603, 1/10W, 1% Yageo RC0603FR-071K3 4

R122 5.1K, 0603, 1/10W, 1% Yageo RC0603FR-075K1 4

R125 82 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0782R 4

R127 68 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0768R 4

R131 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R132 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R133 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R134 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R135 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R136 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R137 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R138 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R141 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R142 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R143 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R144 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R145 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R146 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R147 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R148 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R149 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

Name

26

Page 27

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R150 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R151 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R152 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R153 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R156 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R157 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R158 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R159 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R160 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R161 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R162 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R163 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R164 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R165 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R166 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R167 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R168 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R169 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R170 1.8K, 0603, 1/10W, 1% Yageo RC0603FR-071K8 4

R171 1.2K, 0603, 1/10W, 1% Yageo RC0603FR-071K2 4

R172 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R173 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R174 1.8K, 0603, 1/10W, 1% Yageo RC0603FR-071K8 4

R175 1.2K, 0603, 1/10W, 1% Yageo RC0603FR-071K2 4

R176 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R200 100K, 0603, 1/10W, 1% Yageo RC0603FR-0710 0K 4

R201 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R202 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R203 100K, 0603, 1/10W, 1% Yageo RC0603FR-0710 0K 4

R210 1.3K, 0603, 1/10W, 1% Yageo RC0603FR-071K3 4

R212 5.1K, 0603, 1/10W, 1% Yageo RC0603FR-075K1 4

R215 82 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0782R 4

R217 68 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0768R 4

R220 1.3K, 0603, 1/10W, 1% Yageo RC0603FR-071K3 4

R222 5.1K, 0603, 1/10W, 1% Yageo RC0603FR-075K1 4

R225 82 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0782R 4

R227 68 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0768R 4

R231 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R232 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R233 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R234 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R235 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R236 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R237 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R238 680 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07680R 4

R241 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R242 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

27

Name

Page 28

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R243 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R244 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R245 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R246 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R247 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R248 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R249 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R250 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R251 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R252 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R253 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R256 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R257 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R258 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R259 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R260 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R261 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R262 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R263 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R264 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R265 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R266 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R267 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R268 39K, 0603, 1/10W, 1% Yageo RC0603FR-0739K 4

R269 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R270 1.8K, 0603, 1/10W, 1% Yageo RC0603FR-071K8 4

R271 1.2K, 0603, 1/10W, 1% Yageo RC0603FR-071K2 4

R272 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R273 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R274 1.8K, 0603, 1/10W, 1% Yageo RC0603FR-071K8 4

R275 1.2K, 0603, 1/10W, 1% Yageo RC0603FR-071K2 4

R276 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R300 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R301 47K, 0603, 1/10W, 1% Yageo RC0603FR-0747K 4

R302 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R303 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R304 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R305 47K, 0603, 1/10W, 1% Yageo RC0603FR-0747K 4

R307 16K, 0603, 1/10W, 1% Yageo RC0603FR-0716K 4

R308 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R309 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R310 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R311 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R312 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R313 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R314 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R315 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

Name

28

Page 29

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R316 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R317 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R318 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R319 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R320 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R321 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R322 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R323 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R324 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R325 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R326 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R327 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R328 5.6K, 0603, 1/10W, 1% Yageo RC0603FR-075K6 4

R329 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R330 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R331 1.5K, 0603, 1/10W, 1% Yageo RC0603FR-071K5 4

R332 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R333 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R334 2.7K, 0603, 1/10W, 1% Yageo RC0603FR-072K7 4

R336 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R337 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R338 16K, 0603, 1/10W, 1% Yageo RC0603FR-0716K 4

R339 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R340 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R341 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R342 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R343 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R344 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R345 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R346 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R347 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R348 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R349 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R350 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R351 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R352 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R353 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R354 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R355 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R356 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R357 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R358 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R359 5.6K, 0603, 1/10W, 1% Yageo RC0603FR-075K6 4

R360 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R361 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R362 1.5K, 0603, 1/10W, 1% Yageo RC0603FR-071K5 4

R363 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

29

Name

Page 30

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R364 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R365 2.7K, 0603, 1/10W, 1% Yageo RC0603FR-072K7 4

R366 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R367 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R368 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R369 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R370 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R371 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R400 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R401 47K, 0603, 1/10W, 1% Yageo RC0603FR-0747K 4

R402 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R403 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R404 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R405 47K, 0603, 1/10W, 1% Yageo RC0603FR-0747K 4

R407 16K, 0603, 1/10W, 1% Yageo RC0603FR-0716K 4

R408 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R409 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R410 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R411 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R412 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R413 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R414 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R415 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R416 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R417 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R418 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R419 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R420 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R421 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R422 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R423 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R424 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R425 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R426 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R427 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R428 5.6K, 0603, 1/10W, 1% Yageo RC0603FR-075K6 4

R429 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R430 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R431 1.5K, 0603, 1/10W, 1% Yageo RC0603FR-071K5 4

R432 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R433 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R434 2.7K, 0603, 1/10W, 1% Yageo RC0603FR-072K7 4

R436 16K, 0603, 1/10W, 1% Yageo RC0603FR-0716K 4

R437 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R438 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R439 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R440 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

Name

30

Page 31

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R441 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R442 18 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0718R 4

R443 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R444 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R445 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R446 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R447 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R448 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R449 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R450 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R451 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R452 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R453 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R454 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R455 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R456 100 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07100R 4

R457 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R458 6.8K, 0603, 1/10W, 1% Yageo RC0603FR-076K8 4

R459 5.6K, 0603, 1/10W, 1% Yageo RC0603FR-075K6 4

R460 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R461 8.2K, 0603, 1/10W, 1% Yageo RC0603FR-078K2 4

R462 1.5K, 0603, 1/10W, 1% Yageo RC0603FR-071K5 4

R463 2.2K, 0603, 1/10W, 1% Yageo RC0603FR-072K2 4

R464 12K, 0603, 1/10W, 1% Yageo RC0603FR-0712K 4

R465 2.7K, 0603, 1/10W, 1% Yageo RC0603FR-072K7 4

R466 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R467 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R468 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R469 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R470 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R471 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R504 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R505 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R506 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R507 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R508 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R509 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R510 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R511 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R512 5.1 OHM, 0603, 1/10W, 1% Yageo RC0603FR-075R1 4

R515 5.1 OHM, 0603, 1/10W, 1% Yageo RC0603FR-075R1 4

R516 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R517 3.3K, 0603, 1/10W, 1% Yageo RC0603FR-073K3 4

R518 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R519 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R520 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

R521 470 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07470R 4

31

Name

Page 32

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R522 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R523 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R524 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R525 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R526 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R527 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R552 5.1 OHM, 0603, 1/10W, 1% Yageo RC0603FR-075R1 4

R555 5.1 OHM, 0603, 1/10W, 1% Yageo RC0603FR-075R1 4

R556 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R557 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R558 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R559 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R560 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R561 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R562 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R563 180 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07180R 4

R700 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R702 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R703 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R706 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R707 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R708 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R709 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R710 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R711 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R712 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R713 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R714 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R716 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R719 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R720 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R721 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R722 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R723 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R724 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R725 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R726 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R727 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R728 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R730 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R731 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R732 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R733 10K, 0603, 1/10W, 1% Yageo RC0603FR-0710K 4

R734 4.7K, 0603, 1/10W, 1% Yageo RC0603FR-074K7 4

R735 0 OHM, 0603, 1/10W, 5% Yag eo RC0603JR-07R00 4

R736 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

R737 33 OHM, 0603, 1/10W, 1% Yageo RC0603FR-0733R 4

Name

32

Page 33

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

Reference

Description Vendor

Vendor Part Number Note

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Resistors (continued)

Designator

R738 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

R740 0 OHM, 0603, 1/10W, 5% Yageo RC0603JR-07R00 4

R741 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

R742 330 OHM, 0603, 1/10W, 1% Yageo RC0603FR-07330R 4

Designator

RA550 10K, 10 PIN, 8R, 5% Yageo YC158TJR-0710K 4

RA700 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA701 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA702 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA703 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA704 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA705 33 OHM, 8 PIN, 1/16W, 5% Yageo YC164-JR-0733R 4

RA706 10K, 10 PIN, 8R, 5% Yageo YC158TJR-0710K 4

Designator

C100 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C101 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C102 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C103 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C104 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C105 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C108 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C109 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C110 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C111 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C112 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C113 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C114 0.1uF, 0603, Y5V, 50V, 20% Sams ung CL10F104ZBNC 4

C115 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C116 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C117 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C118 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C119 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C120 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C121 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C122 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C123 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C124 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C125 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C126 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C127 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C128 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

Resistor Arrays

Capacitors

33

Name

Name

Name

Page 34

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Capacitors (continued)

Designator

C129 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C130 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C131 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C132 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C133 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C134 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C135 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C136 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C139 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C140 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C141 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C142 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C143 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C144 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C145 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C146 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C147 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C148 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C149 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C200 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C201 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C202 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C203 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C204 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C205 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C208 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C209 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C210 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C211 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C212 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C213 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C214 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C215 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C216 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C217 0.1uF, 0603, Y5V, 50V, 20% Samsung CL10F104ZBNC 4

C218 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C219 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C220 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C221 47uF, ELEC, 16V, 40C, 20% NICHICON UZT1C470MCR1GB 4

C222 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C223 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C224 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C225 10uF, ELEC, 16V, 40C, 20% NICHICON UZT1C100MCR1GB 4

C226 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C227 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C228 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

C229 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4

Name

34

Page 35

ELECTRICAL PART LIST

Reference

Description Vendor

Vendor Part Number Note

ESP-88 Chassis 4x4 PCB Assembly

Capacitors (continued)

Designator

C230 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C231 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C232 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C233 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C234 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C235 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C236 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C239 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C240 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C241 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C242 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C243 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C244 47pF, 0603, NPO, 50V, 5% Samsung CL10C470JBNC 4

C245 10uF, BI-POLAR, 16V, 40C, 20% ELNA RVB16V100M-R 4

C246 100pF, 0603, NPO, 50V, 5% Samsung CL10C101JBNC 4