Page 1

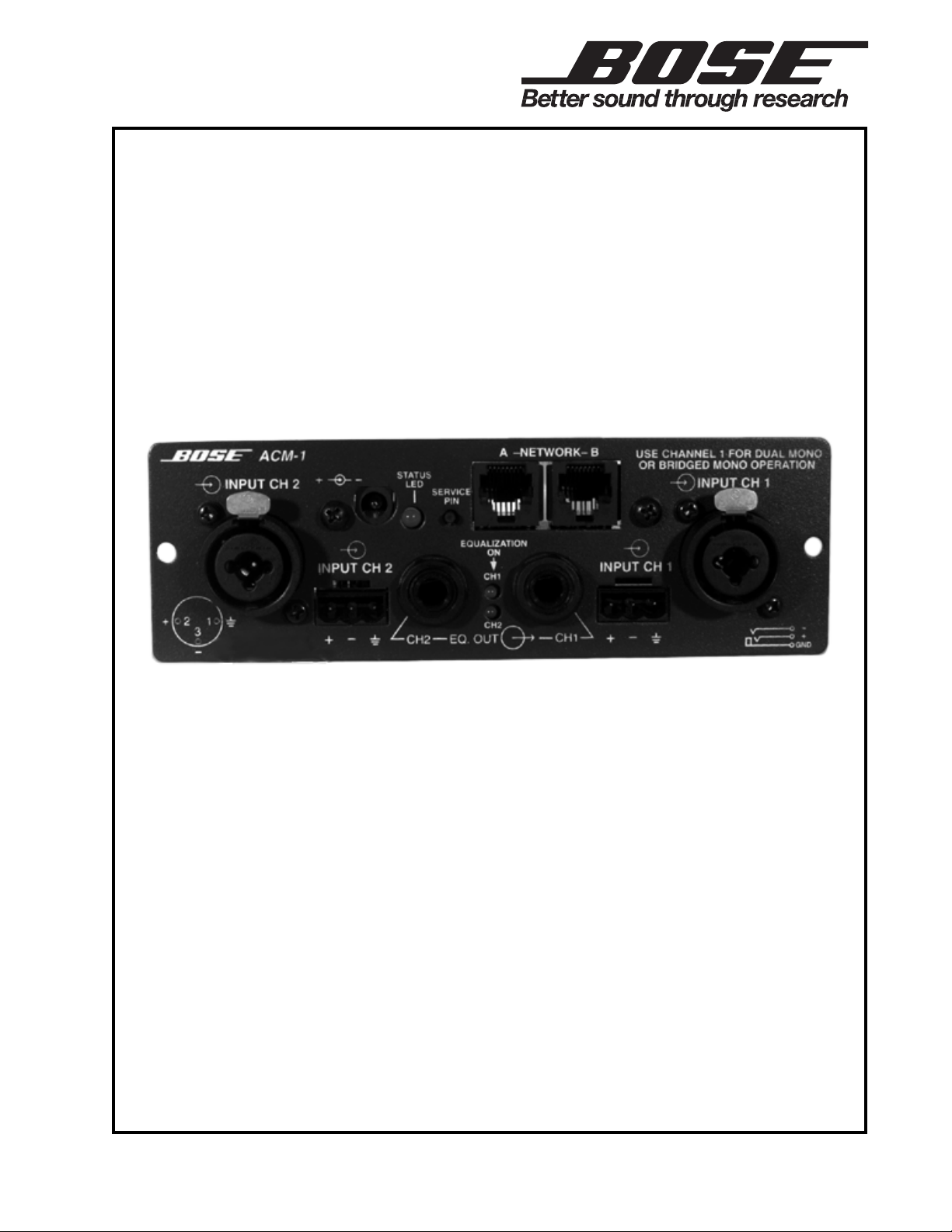

ACM-1 Amplifier Control Module

®

®

©

1999 Bose Corporation

Service Manual

Part Number 199746 Rev. 00

Page 2

CONTENTS

Safety Information............................................................................................................................ 3

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 4

Warranty Information....................................................................................................................... 4

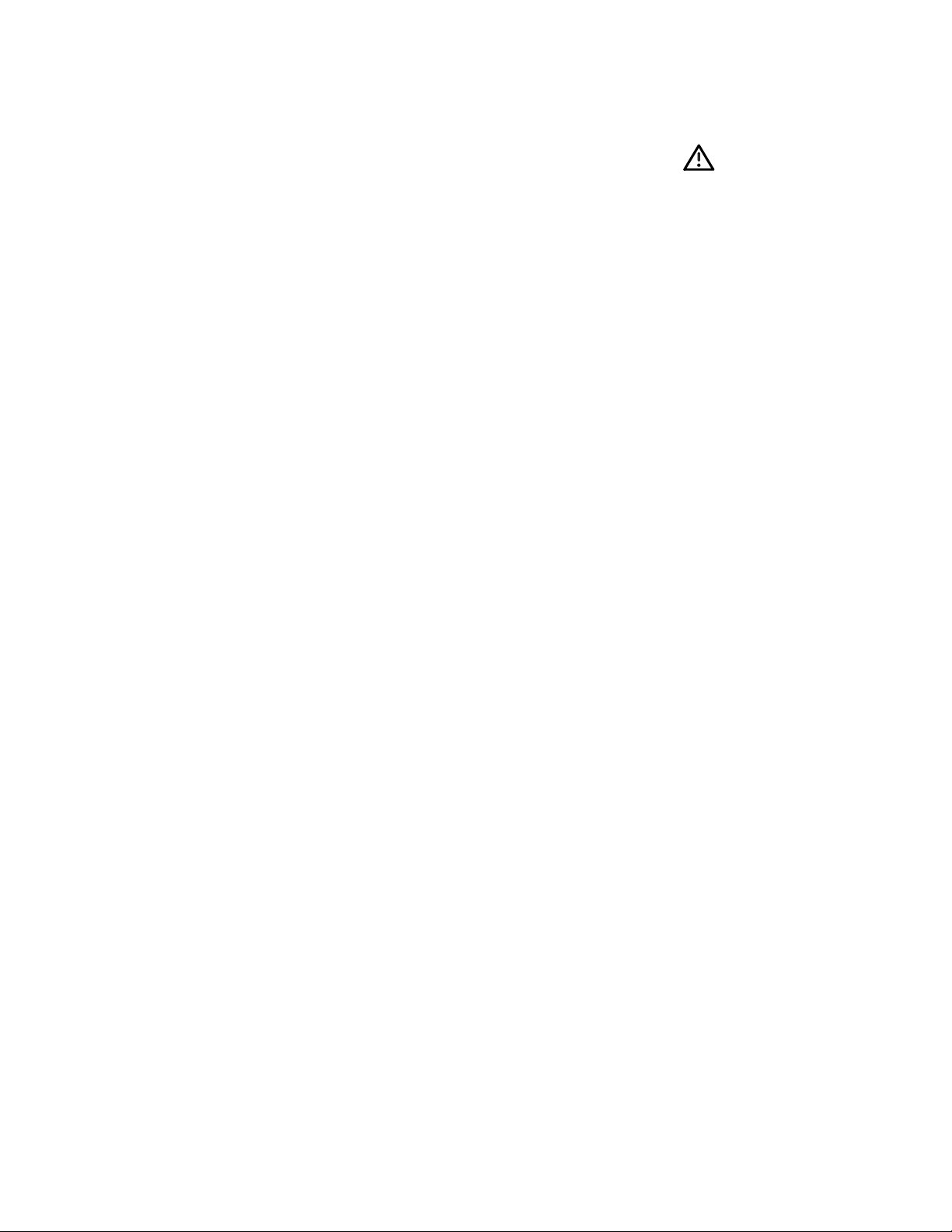

Figure 1. ACM-1 Audio Section Block Diagram................................................................................ 5

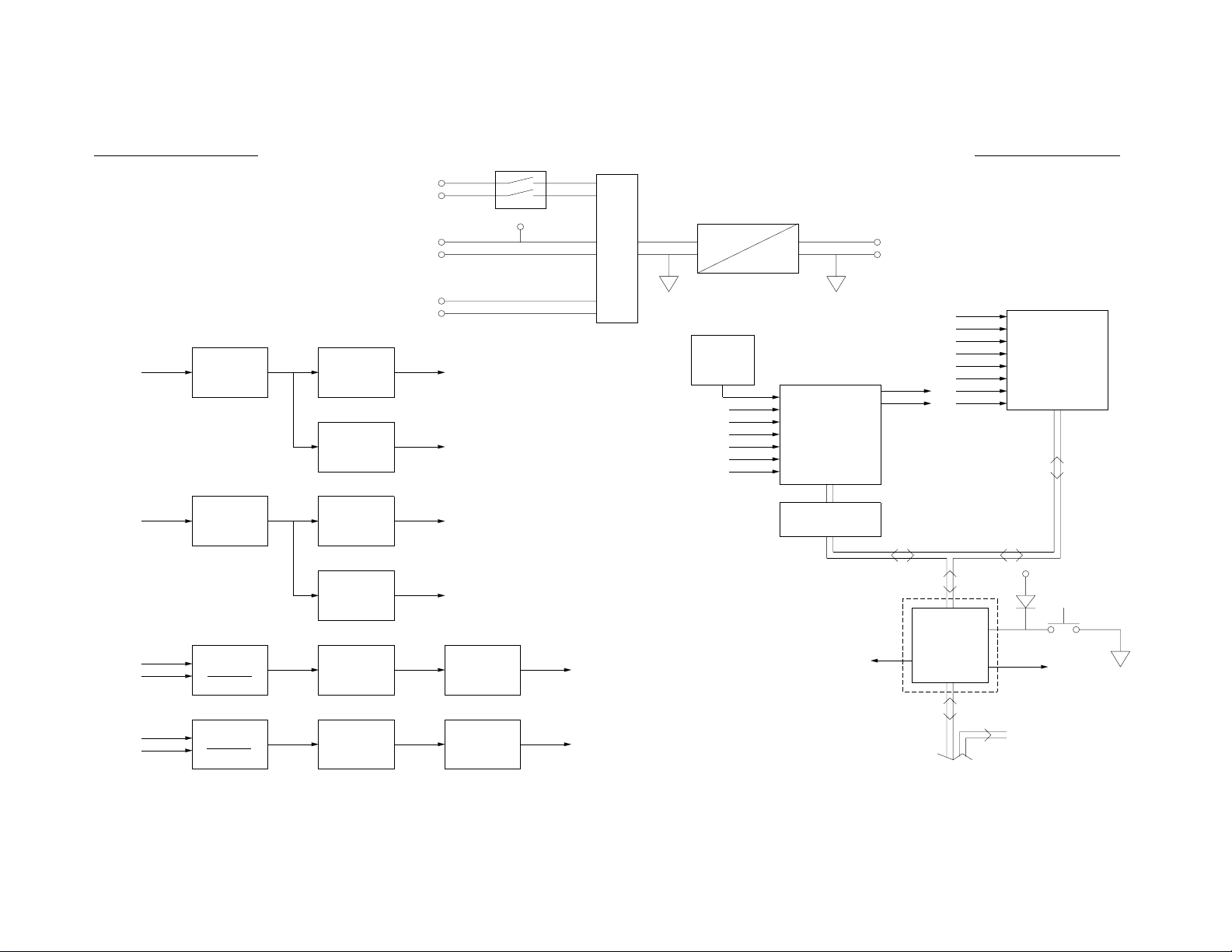

Figure 2. ACM-1 Monitoring Section Block Diagram........................................................................ 6

Theory of Operation.................................................................................................................... 7-10

Disassembly/Assembly Procedures ....................................................................................... 11-12

Figure 3. Input Module Screw Removal..........................................................................................11

Figure 4. ACM-1 Default Switch Settings....................................................................................... 11

Figure 5. 1800VI Ribbon Cable Connector Location (ACM-1 J8 to 1800VI J2) ............................ 11

Figure 6. ACM-1 J1 Ribbon Cable Connection .............................................................................. 12

Test Procedures ........................................................................................................................ 13-19

Table 1. ACM-1 Input, Output, and Power Connections................................................................. 13

Table 2. PS71 Power Supply List................................................................................................... 13

Figure 7. ACM-1 Switch Settings ................................................................................................... 14

Figure 8. 1800VI Rear Panel Switch Settings................................................................................ 14

Figure 9. ACM-1 Graphical User Interface Control Panel .............................................................. 15

Table 3. Amplifier Output Performance Tests................................................................................. 16

Test Cable Construction ............................................................................................................... 19

Part List Notes................................................................................................................................ 19

Main and Packaging Part list, ACM-1 Amplifier Control Module (see Figure 10)..................... 20

Figure 10. ACM-1 Amplifier Control Module Exploded View.......................................................... 20

Electrical part list ...................................................................................................................... 21-25

Figure 11. Daughterboard Topside Etch Layout Diagram .............................................................. 26

Figure 12. Daughterboard Internal Etch Layout Diagram .............................................................. 26

Figure 13. Daughterboard Bottom Etch Layout Diagram ............................................................... 26

Integrated Circuit Pinout Diagrams......................................................................................... 27-29

CAUTION: The ACM-1 Amplifier Control Module contains

no user serviceable parts. To prevent warranty infractions,

refer servicing to warranty service centers or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY

FOR THE PURPOSE OF SERVICING THE IDENTIFIED BOSE

PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR

OWNER OF THE BOSE PRODUCT, AND SHALL NOT BE

REPRODUCED OR USED FOR ANY OTHER PURPOSE.

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check

(1) With the unit completely reassembled, plug the AC line cord directly

into a 120V AC outlet. Do not use an isolation transformer during

this test. Use a leakage current tester or a metering system that

complies with American National Standards Institute (ANSI) C101.1

"Leakage Current for Appliances" and Underwriters Laboratories

(UL) 1492 (71).

(2) With the unit AC switch first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the unit (antennas, handle bracket, metal cabinet,

screwheads, metallic overlays, control shafts, etc.), especially any

exposed metal parts that offer an electrical return path to the chassis.

(3) Any current measured must not exceed 0.5 milliamp.

(4) Reverse the unit power cord plug in the outlet and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check

(1) Unplug the power supply and connect a jumper wire between the two

prongs of the plug.

(2) Turn on the power switch of the unit.

(3) Measure the resistance with an ohmmeter between the jumpered AC plug

and each exposed metallic cabinet part on the unit. When the exposed

metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 Megohms. When there is no return path to the chassis,

the reading must be "infinite". If it is not within the limits specified, there is the

possibility of a shock hazard, and the unit must be repaired and rechecked

before it is returned to the customer.

3

Page 4

ELECTROSTATIC DISCHARGE SENSITIVE

(ESDS) DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing, or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap, or plastic trays.

WARRANTY INFORMATION

• The ACM-1 Amplifier Control Module is covered by a 5-year transferable limited warranty.

4

Page 5

GND

IN1+

IN1-

IN2+

IN2-

GND

A

Circuitry

2

Unbalanced

Figure 1. ACM-1 Audio Section Block Diagram

Mode Switch

SW1A SW1B MODE

0

011 1

don't care

don't care

Truth Table

bridged

0

dual mono

normal

normal

SW2B

SW1B

Protection

3

Balanced

U16

6

A

Protection

Circuitry

HF Switch

5

2

0

U10

Selector

2

3

U15

Balanced

Unbalanced

6

1

SW1A

SW2

HF2

Eq Card 2

2

7

0

1

Selector

U12

5

2

U13

1

7

Selector

SW2A

1

Switchable

Inverter

U11

5

1

SW1B

SW2B

HF1

J6-4

Eq Card 1

J6-5

7

1

2

A

5

Buffer

Driver

U7

7

Protection

Circuitry

CH. 2 EQ

OUTPUT

5

21

U14

22

5

Buffer

Driver

U8

7

Protection

Circuitry

P2

J1-20

AMP IN 2

ENABLE I07

Attenuator

0 -100 dB

Digital

12

14

8VCLK

Clock Logic

U21

4

3

13

A

3

Buffer

Driver

U7

1

Protection

Circuitry

CH. 1 EQ

OUTPUT

P3

DATA I08

3

Buffer

Driver

U8

1

Protection

Circuitry

J1-16

AMP IN 1

5

Page 6

Signals from Amplifier

Therm 1

Therm 2

Rail Voltage

+I Out 1

-I Out 1

+I Out 2

-I Out 2

Protect 1

Protect 2

I Out +1

Rectification

Network Power (dc / dc)

Adapter Power (ac / dc)

Amplifier Power (dc)

Mean

Peak

V1_Mean

V1_Peak

Jumper

Standby

Wired 'OR'

D

Rectifier

Thermal

Sensor

Therm 1

Therm 2

106 dc

Standby

Protect 1

Protect 2

Regulator

A

Multiplexer

+5Vdc

Gnd.

V1_Mean

V1_Peak

V2_Mean

V2_Peak

I1_Mean

I2_Mean

Aux 1

Aux 2

Signals to Amplifier

Amp In 1

Amp In 2

Power-up

LED

Analog to Digital

Converter

10-bit Serial

6

I Out +2

I Out 1+

I Out 1-

I Out 2+

I Out 2-

Rectification

Current

Sense

Divider

Current

Sense

Divider

Mean

Peak

V2_Mean

V2_Peak

Rectification Mean

Rectification Mean

Figure 2. ACM-1 Monitoring Section Block Diagram

I1_Mean

I2_Mean

Level Shifting

Power-up

Data Bus

Neuron

Micro-

processor

Network (LonWorks®)

Service LED

Service Pin

Amplifier

Data

Activity

LED

Network Power

Gnd.

Page 7

G

eneral Description:

THEORY OF OPERATION

The Bose

®

ACM-1 Amplifier Control Module is an optional replacement for the standard

Input Module that is delivered with the Bose 1600 and 1800 Series VI Power Amplifiers.

This module, which installs into the back of the amplifier in place of the standard input

module, adds a network interface to the power amplifier; allowing the user to control and

monitor the amplifier(s) remotely and simultaneously. This can be done only when the

amplifier is in standby or 'sequence' mode, which is set on the front of the amplifier. The

network topology used by the ACM-1 Amplifier Control Module is the LonWorks

standard which is a registered trademark of Echelon

the amplifier(s) may be a personal computer or any other 'smart' device that incorporates

a LonWorks

Neuron® module.

®

Corporation. The device controlling

®

network

The Bose ACM-1 uses a LonWorks Neuron module to translate network polls into

addressing, reading and writing commands used to control the amplifier. This device

contains a network transceiver and a micro-controller interacting with on-board flashmemory. On the main PCB of the ACM-1, an Analog to Digital Converter (ADC)

translates amplifier operating conditions such as output level, temperature and clipping

level inside the amplifier to digital information to be passed to and from the Neuron module

and ultimately, the network. This information can be monitored with a computer either

locally, tied directly to the control network of the installation, or remotely, provided that the

remote computer has a network connection such as a modem (Internet), Ethernet, or LAN,

and the required software. The amplifier itself is controlled by setting a digital/analog signal

attenuator to manipulate volume level, as well as to switch the amplifier from stand-by

mode to operate mode and vice versa.

The ACM-1 is normally fed stand-by power by an external 12 Vrms AC power adapter

when the amplifier is off or in stand-by (sequence) mode. This allows the amplifier to be

turned on remotely by providing a constant power source to the Neuron module and the

Analog to Digital Converter. The amplifier cannot supply power to the Neuron module

when the amplifier is switched off, which is why the AC adapter is required. Without this

keep-alive voltage, the amplifier would not be able to be powered up remotely. Once the

amplifier is operating, the keep-alive voltage could fail and still have the amplifier operate.

Once the amplifier is shut off again, however, the keep-alive voltage must again be

present to allow remote turn-on of the amplifier. The recommended AC power adapter is

the Bose PS71. See Table 2 on page 12 for part numbers for the various models.

The keep-alive voltage input circuitry of the ACM-1 is designed to also allow the use of a

DC external stand-by power source. The nominal power requirements for a DC source

are +12 Vdc at 100 mA. Furthermore, it is also possible to power the ACM-1 via the

network cable. This must be a DC source. Although this mode of powering has its

limitations due to wire length and thickness, this option might be very useful in smaller or

highly segmented applications. To use network power, jumpers at JB1 on the daughterboard must be set. Place jumpers across pins 1 & 2 and across pins 5 & 6 at JB1. Refer

to sheet 2 of the schematic diagram at coordinates [D5]. The daughterboard is the small

board mounted to the faceplate with the RJ45 connectors on it. Refer to the daughterboard

layout diagrams on page 23. The ACM-1 is shipped with the jumpers uninstalled in order

to avoid RFI noise coupling onto the network wire, which may degrade amplifier

performance when this mode is not used.

Refer to the ACM-1 Schematic Diagram, Sheet 2 of 2, for the following information.

Note: The designators inside the brackets "[ ]" are the schematic grid coordinates which

are provided in order to make it easier to locate components on the schematic sheet

indicated in the description.

7

Page 8

THEORY OF OPERATION

Power Supply Section:

The required keep-alive voltage for the ACM-1 enters the unit at J11 [C7] as V_IN. This

input voltage is rectified, if necessary, by D32 and C44 [C7]. The DC voltage is regulated

by the +5V regulator U18 [C7]. This keep-alive power is required by the components that

allow the amplifier to be powered up remotely, the Neuron

schematic], and the Analog to Digital Converter U9 [Sheet 1, B3]. D31 and D30 [C7]

together form a wired 'OR' gate. This means that if the amplifier is powered-up, the ACM1 receives power from it, which is +15 Vdc regulated down to +5 Vdc by U18. If not, the

ACM-1 is powered from the standby power source, which could be an AC adapter, a DC

adapter, or a DC voltage supplied through the network cable. STANDBY [B4] is the

network power source which is passed through R97 [B4] to make STBYOK, which is

passed on to the ADC Multiplexer U17 [Sheet 1, C1/2], and is used to detect if there is

adapter power available, even when the amplifier is turned on. Note that digital ground is

used for the power supply reference in order to keep the analog ground after the +5V

regulator as clean as possible.

The ACM-1 consists of a power supply section, an analog section, which is the audio

signal path to the power amplifier, and a digital section which controls and monitors the

amplifier.

Note: The schematics and theory of operation of the neuron module will not be covered in

detail in this section.

®

module [not shown on

Refer to the ACM-1 Schematic Diagram, Sheet 1 of 2, for the following information.

Audio signal path:

The input stage is a balanced input receiver composed of U15 and U16 [C/D7]. The input

is taken from either the combi input connectors [D2/3] or the euro screw terminal inputs at

J4 and 5 [Sheet 2, B7]. The shield ground is decoupled from the analog ground by

capacitors C14 and C15. All inputs have spark gaps to avoid possible damage due to

static electricity. All input legs have RFI low-pass filters [C/D 7/8] and diode clamps to

protect the op-amps against overload. The input impedance in each leg is approximately

25k Ohms and is laser trimmed for good common-mode rejection.

After the input signal is converted from balanced to unbalanced, the signal enters

switchable op-amps U10 and U12 [C/D6]. These op-amps are used to route the signal

through the optional loudspeaker equalizer cards that can be installed on the ACM-1

motherboard. The presence of the EQ cards is detected automatically. If the EQ card is

plugged into its socket, the EQ1USED or EQ2USED at J6-6 or J7-6 [Sheet 2, B7] signal

is grounded causing U10 and/or U12 to route the audio signal through the EQ-cards, by

pulling the SW1A and SW2A signals at U10 or U12 low. Also, the appropriate section of

the green dual LED D50 [Sheet 2, A4] will be turned on to indicate the card is installed.

Further, the high-pass filter available on the EQ cards can be activated by setting switch

SW2 [Sheet 2, D7] to the correct position. This causes signal HF1 and HF2, which are

routed to the EQ cards via J6 and J7 [Sheet 2, B7] to be grounded.

After the signal is equalized, the audio signal is passed on to a second set of switchable

op-amps, U11 and U13 [C/D6]. The function of this op-amp pair is to set the mode of

operation of the amplifier: normal (stereo) mode, bridged mode or dual-mono mode. If

SW2B is high, the amplifier is in normal mode regardless of the state of the SW1B signal.

SW2B basically routes the signal of channel 1 into channel 2 if it is pulled low. By doing

this, the amplifier is configured in bridged mode or dual mono mode, depending on SW1B,

which inverts the signal going into channel 2, or not. When SW1B is high, the signal is not

inverted and the amplifier is in dual mono mode; if it is pulled low, the amplifier is in bridged

mode. The configuration of the mode of the amplifier is done by setting the SW1 to the

correct position [Sheet 2, D7].

8

Page 9

THEORY OF OPERATION

The equalized signal is also routed to U7 [C/D6] which forms output line drivers. The

output of the EQ card is then available to link to the next amplifier, minimizing the need for

additional EQ cards. This signal is available at the female EQ output jacks P2 and P3

[C/D4] on the frontplate of the ACM-1 module. These outputs are also equipped with RFI

low-pass T-filters, diode clamps and spark-gaps. The output impedance at audio

frequencies is approximately 400 Ohms, making it possible to drive long cable lengths

without oscillation.

After the audio signals are equalized and composed in such a way as to set the correct

mode of the amplifier, they are routed into a software controlled attenuator U14 [D5]. With

this attenuator, the level of the audio signal can be attenuated in steps of 1 dB from 0 dB

all the way down to -100 dB. The lowest attenuation level is a full mute. The attenuation

level is set by the serial data stream IO9 (DATA) from the Neuron

addressed with I07 (ENABLE) with the timing signal supplied by IO8 (CLOCK), which is

generated by the Neuron. The 3.16 k Ohms resistors R40, 41, and 42, protect U14 from

damage when the ACM-1 is in standby mode. In this mode, the attenuator is off, but the

Neuron is still powered. The quad-NAND U21 [Sheet 2, C4/5] generates VCLK from the

ENABLE and CLOCK signal. This logic is used by the TC9412F attenuator. After the

level is set with the attenuator, signal buffer U8 [C/D4] routes the signal out through J1

pins 16 and 20 [Sheet 2, B7] to the power stages of the amplifier.

Monitoring and control, digital section:

Refer to the ACM-1 Schematic Diagram, Sheet 1 of 2, for the following information.

®

. The attenuator is

The monitoring and control of the amplifier is performed by the plug-in LonWorks

module (not shown on schematic) which plugs into the ACM-1 motherboard at J9 and J10

[Sheet 2, A/B7]. This module incorporates a network transceiver which is connected to the

system's control network by means of RJ-45 connectors J12 and J13 [Sheet 2, D4],

which are located on the daughterboard.

The Neuron module switches the amplifier to operate mode by pulling low the IO6 signal

on transistor Q1 [Sheet 2, A4]. This transistor causes current to flow into the opto coupler,

located inside the amplifier which fires the TRIAC in the amplifier's power supply. Refer to

the 1600VI/1800VI service manual, Bose

the amplifiers.

Each Neuron module is assigned its own unique identification number when it is

manufactured. It can only be activated and controlled by this unique address. If the

address number for a Neuron module is lost, the unit can identify itself on the network by

toggling its service pin. This pin is connected to the momentary switch on the front-panel

of the ACM-1 module. When this switch is depressed, the SERV pin is grounded and the

yellow LED lights up. The LED is also used to indicate network activity in the ACM-1. In

this mode the LED is lit constantly. The LED blinks with a 50% duty-cycle when the

neuron module is not yet configured on the network.

The amplifier is equipped with an LED on the front of the amplifier, located in the center of

the front panel, used to indicate network activity. It is triggered by Q4 [Sheet 2, A4], which

is turned on and off via the IO5 pin from the Neuron's micro-processor.

The Neuron gets its status information via the Analog to Digital Converter U9 [B3]. This is

a serial 10-bit ADC with 8 inputs. It communicates with the Neuron on the same DATA

line. The serial timing is delivered via the IO8 CLOCK signal and the IO1 signal which

basically functions as a control signal (the control clock for successive approximation

circuitry inside the chip) for the ADC. IO0 toggles the chip select pin and the output

enable pin. When they are both low, the falling edge of the IO8 shifts out the conversion

data out of the output pin connected to IO10. IO9 shift serial data into the converter. For

detailed timing information, consult the National Semiconductor datasheet on the ADC1038.

®

part number 199747, for more information on

®

Neuron

9

Page 10

THEORY OF OPERATION

The ADC inputs are all equipped with diode clamps to protect its inputs from damage due

to a 15V input signal. This failure could occur if one of the components connected to the

ADC fails and shorts one of the 15V rails to the inputs. The resistors on the inputs of the

ADC protect the input stages of the converter against excessive currents due to fault

signals.

Six of the inputs directly sample six status signals. The other two are connected to a dual

4 channel multiplexer U17 [C1] which makes it possible to sample eight more different

status signals. V1_PEAK, V2_PEAK, V1_MEAN, V2_MEAN, I1_MEAN and I2_MEAN are

the mean and peak voltage and current levels directly measured at the output of the

power amplifier. With these signals, output signal levels can be displayed and the load

impedances can be calculated and used in the User Interface(s) connected via the

network.

The peak and mean output voltage levels are generated with U1, U2 and U3. U1 [C7]

divides down the +IOUT1 80 Vpk signal from the amplifier's output. After this, the signal

undergoes double sided rectification. From the rectified signal, the mean voltage is created

by a RC filter section, N14 [C6] and C24 [C6] and buffered with an op-amp. The

V1_MEAN output is taken from U1 pin 14 [C6]. In another op-amp stage, U3 [C5], the

peak signal is derived with a peak-hold circuit. The peak level is stored in C28 [B5].

V1_PEAK is taken off of U3 at Pin 7 [C5]. +IOUT2 is processed in the same way using

U2 and U3.

The mean current level is generated with U4 and U5 [A5-7]. Because the output current is

measured across the 20 milliOhm resistor that is installed inside the amplifier, the signal

needs to be divided down before it is routed into the balanced input stage formed by U4

and U5. The division is done by the 5 kOhms resistor arrays N16-19 [A/B7]. After

converting the signal into an unbalanced signal, the signal is double sided rectified. RC

filters R5/C26 [A5] and R6/C27 [A5] filter the signal and produce the scaled mean of the

output current for both amplifiers. U4 and U5 buffer this signal before it is routed into the

ADC [B3].

The dual multiplexer U17 together with U6 [C1] produce two extra buffered signals which

are routed into the remaining two inputs of the ADC. With the multiplexer, the Neuron

select which parameter should be sampled. These parameters are connected to the 8

inputs of the mutiplexer and can be selected with IO2A and IO3A. These 2 signals are

level shifted to +15V and inverted with transistors Q2 and Q3 [Sheet 2, A5]. Two inputs

are selected at the same time and fed to the ADC. XTEMP is the temperature on the ACM1 motherboard and is generated with temperature sensor U20 [C2]. 316ADD1 and

316ADD2 are generated by the amplifier and indicate that the relays at the outputs of the

amplifier are open due to a short circuit condition or due to DC offset caused by amplifier

failure. These signals are also supplied to the User Interface(s) to indicate that impedance

measurement is then invalid due to the opened relays.

The 106VDC (1800VI), 90VDC (1600VI) signal indicates the presence of the power

amplifier rail voltage. It is a divided down version of the rail voltage, and is used by the

User Interface(s) to detect proper operation of the amplifier.

THERM1 and THERM2 are voltages generated by the temperature sensors on the power

amplifier stage's heatsinks. With these scaled voltages the temperature of these stages

can be measured and displayed on the User Interface.

STDBYOK is the voltage derived from the standby power from the mains adapter or the

network. It is used to indicate if the amplifier can be turned back on after it is powered

down.

®

can

10

Page 11

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: In order to test the ACM-1 Amplifier

Control Module, you must first remove the

standard input module that is supplied by

the factory from the rear of the amplifier.

1. Input Module Removal

1.1 Use a phillips-head screwdriver to

remove the two screws from the input

module connector panel. The input module

is located on the rear of the amplifier.

See Figure 3.

1.2 Pull the input module partially out of

the chassis.

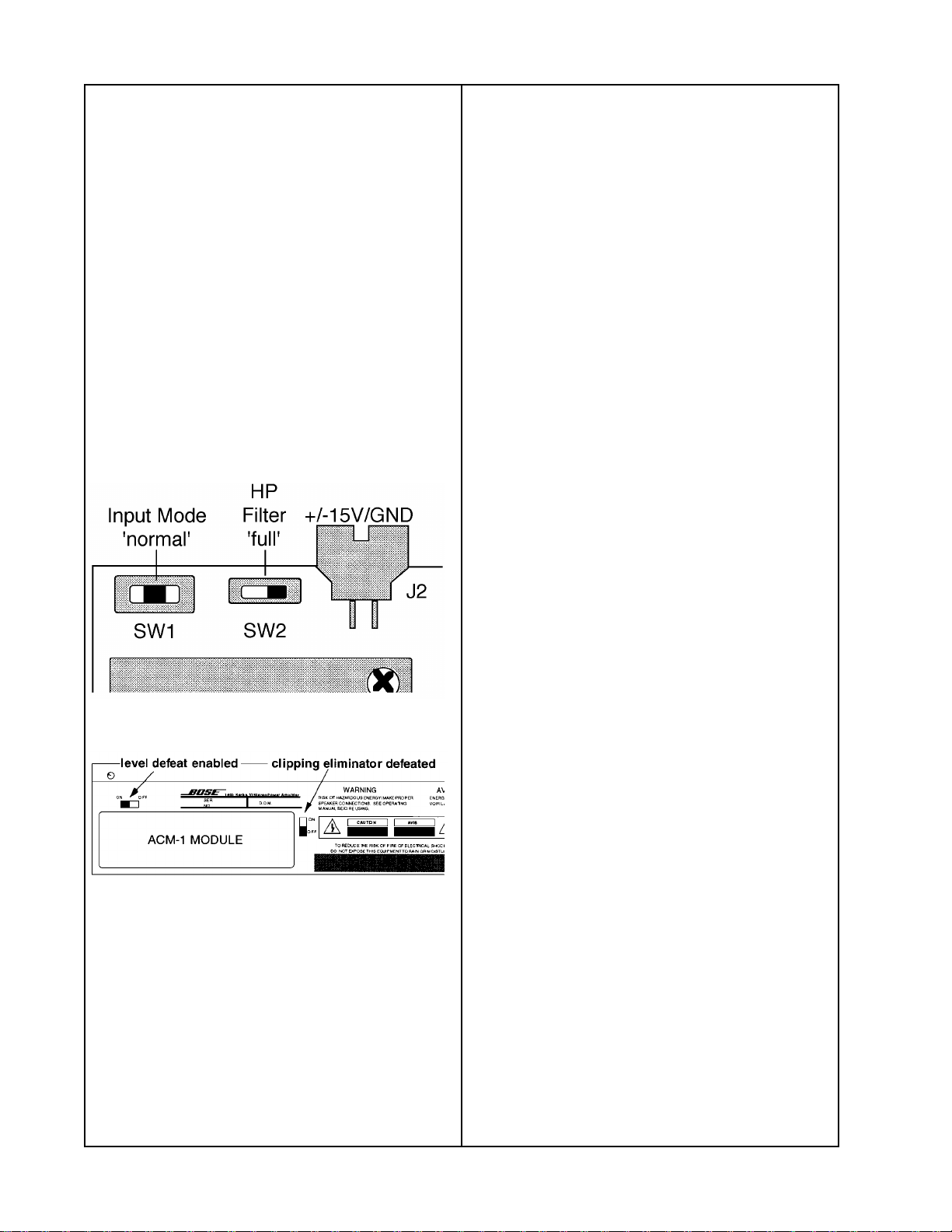

Figure 4. ACM-1 Default Switch Settings

1.3 Disconnect the amplifier ribbon cable

from the input module J1 connector.

Figure 3. Input Module Screw Removal

Note: Before installing the ACM-1 module

into the amplifier, you must set the switches

on the ACM-1 to the default settings.

Note: DO NOT install any EQ cards into

the ACM-1 module that may have been

installed in the standard input module.

Installing these cards will change the

response of the ACM-1 and make the tests

invalid.

2. ACM-1 Module Installation

2.1 Connect the ribbon cable from the

J8 connector of the ACM-1 to the J2

connector located on the I/O board of the

amplifier. This connector is fairly difficult to

insert. Pin 1 (red stripe) of the ribbon cable

is to the right. See Figure 5.

Default switch settings:

On the ACM-1 Module, place the Input

Mode Switch SW1 to the NORMAL (center)

position. Place the HF/Full Range Switch

SW2 to the FULL (right) position.

See Figure 4.

Figure 5. Amplifier Ribbon Cable Connector

Location (ACM-1 J8 to amplifier J2)

11

Page 12

DISASSEMBLY/ASSEMBLY PROCEDURES

2.2 Connect the amplifier's ribbon cable to

the ACM-1 module J1 connector. Pin 1 (red

stripe) of the ribbon cable is to the right.

See Figure 6.

Figure 6. ACM-1 J1 Ribbon

Cable Connection

3.4 Disconnect the ACM-1's ribbon cable

from the amplifier's J2 connector.

4. Input Module Replacement

4.1 Connect the amplifier's ribbon cable

to the input module connector at J1.

Pin 1 (red stripe) of the ribbon cable is

to the right.

4.2 Slide the input module into the

chassis slot until the input module J2

connector is completely seated into the

amplifier's two-pin harness connector.

The input module should be flush with

the chassis back panel.

4.3 Secure the input module to the

amplifier chassis with the two screws

using a phillips-head screwdriver.

2.3 Slide the ACM-1 module into the

chassis slot until the module's J2 connector

is completely seated into the amplifier twopin harness connector. The module should

be flush with the chassis back panel.

2.4 Secure the ACM-1 module to the

amplifier chassis with two screws using a

phillips-head screwdriver.

Note: The ACM-1 Module will not operate

properly unless at least one screw is used

to secure it to the amplifier. The faceplate

of the ACM-1 is used to provide a ground

connection to the amplifier.

3. ACM-1 Module Removal

3.1 Use a phillips-head screwdriver to

remove the two screws from the ACM-1

module connector panel.

3.2 Pull the input module partially out of

the chassis.

3.3 Disconnect the amplifier's ribbon cable

from the input module's J1 connector.

12

Page 13

TEST PROCEDURES

Function PCB Location Type of Connection

Source Input Ch. 1 P4 Balanced TRS; tie LO to ring, tie HI to tip,

tie ground to sleeve.

Source Input Ch. 2 P1 Balanced TRS; tie LO to ring, tie HI to tip,

tie ground to sleeve.

Source Input Ch. 1 (Euro) J4 Three position connector; tie LO to -, tie HI

to +, tie ground to GND.

Source Input Ch. 2 (Euro) J5 Three position connector; tie LO to -, tie HI

to +, tie ground to GND.

External Power Supply (PS71) J11 Co-axial; connect LO (gnd) to sleeve,

connect HI (12VAC) to tip.

LonWorks® Network Connector

(for monitoring and control)

EQ Output Ch. 1 P3 Balanced TRS; tie LO to ring, tie HI to tip,

EQ Output Ch. 2 P2 Balanced TRS; tie LO to ring, tie HI to tip,

J12 or J13 RJ45; use standard CAT-5 network cable

with crimped RJ45 connectors.

tie ground to sleeve.

tie ground to sleeve.

Table 1. ACM-1 Input, Output, and Power Connections

Test Setup Parameters

1. In order to be able to perform these

tests, you will need the following:

• A Microsoft® Windows® compatible

computer with at least 40Mbytes of hard

disk space, 32Mbytes of RAM and a CD

ROM drive.

• Bose® Entero™ software (CD ROM)

• Windows 95 or Windows NT 4.0.

• Network Interface Card, such as the

Echelon PCNSI for desktops or the

PCC-10 for laptops.

• The Echelon LNS (LonWorks® Network

Services) software must be installed on

the computer you are using for testing.

This enables management of the

LonWorks database and direct

communication with nodes on the

network.

• Bose 1600VI or 1800VI power amplifier.

• Bose PS71 external power supply as

listed in Table 2 below.

Power Supply Bose Part Number

UL 120 VAC 178371

230V Euro 178375

230V UK/Singapore 178374

240V Australia 178373

100V Japan 178372

Table 2. PS71 Power Supply List

13

Page 14

TEST PROCEDURES

Test Setup Parameters (continued)

2. Default switch settings: On the ACM-1

Module, place the Input Mode Switch SW1

to the NORMAL (center) position.

Place the HF/Full Range Switch SW2 to the

FULL (right) position. See Figure 7.

On the amplifier rear panel, place the Level

Defeat Switch to the ENABLED (on) position. This disables the volume controls on

the amplifier front panel.

Place the Clipping Eliminator Switch to the

DISABLED (off) position, and the Power

Switch to the STANDBY position. See

Figure 8.

3. Install the ACM-1 Module into the rear

of the amplifier using Disassembly/

Assembly procedures 1 & 2.

4. Connect the PS71 external power

supply to an AC Mains connection and to

the Standby Power connector at J11 on the

ACM-1 Module. This will provide power to

allow the module to be controlled by the

network before the amplifier is powered up.

5. Connect the CAT-5 network cable

between the network interface card located

in the computer and the ACM-1 module.

6. Four signal paths are used during

testing. They are as follows:

• Source Input Ch.1 to EQ output Ch.1.

• Source Input Ch.2 to EQ output Ch.2.

• Source Input Ch.1 to amp output Ch.1.

• Source Input Ch.2 to amp output Ch.2.

Figure 7. ACM-1 Switch Settings

Figure 8. Amplifier Rear Panel Switch

Settings

Note: If the Power Switch on the front

panel of the amplifier is not in the

STANDBY position, you will not be able to

control the amplifier using the network.

7. For each signal path there are two basic

input/output terminations to be used.

• Noise Test Termination - Noise is

measured in a bandwidth of 20 Hz to 22

kHz with no weighting function. The

source inputs (+ and -) are not to be

driven with signal, but terminated with 50

Ohms. Power amplifier outputs are

measured across an 8 Ohm, 500 Watt

load connected across the outputs.

The EQ outputs of the ACM-1 are

measured across a 10 kOhm load

terminating the unbalanced outputs

(each leg to ground).

• Gain, Response and Distortion Test

Termination - The inputs are to be driven

from a 50 Ohm source. EQ outputs are

measured across a 10 kOhm load

terminating the unbalanced outputs.

Power amplifier outputs are measured

across an 8 Ohm, 500 Watt load

connected across the outputs.

Note: If there are any EQ PCBs installed in

the ACM-1 at J6 or J7, be sure to remove

them before testing.

14

Page 15

TEST PROCEDURES

Adding a Bose® 1600VI or 1800VI

amplifier to a network using the

Entero™ software.

1. Install the ACM-1 Amplifier Control

Module into the amplifier using

Disassembly/Assembly procedures 1 & 2.

2. Connect the network cable to J12 or J14

of the ACM-1.

3. Plug the PS71 standby power supply into

J11 of the ACM-1. Connect the power cord

of the PS71 to the AC mains.

4. Make all required audio input and output

connections.

5. Open the Entero software on the

computer screen.

6. Click on the Device Finder tab. You

should see all of the previously configured

devices (if any) on the left-hand side of the

screen.

7. Pull down the Tools menu, scroll down to

Add Device, and click the mouse. A dialog

box will open with folders listing different

types of devices.

8. Double-click on the Amplifiers folder.

9. There will be four files listed to choose

from. They are: Bose 1600 Bridge.dev;

Bose 1600 Stereo.dev; Bose 1800

Bridge.dev; and Bose 1800 Stereo.dev.

Click on the Bose 1600 Stereo.dev or the

Bose 1800 Stereo.dev file, according to

which amplifier you are using for testing.

Click on Open. The device will appear

grayed-out on the left-hand side of the

screen.

Electrical Tests

Note: Refer to Figure 9 for the following

tests.

Figure 9. ACM-1 Graphical User Interface

Control Panel

1. Network Power Up Test

1.1 Open the Entero software by double-

clicking on the icon. When the program

opens enter the password, if required, and

click OK. Click on the Device Finder tab.

The amplifier to be used for the test should

be listed in the column on the left. If the

amplifier is not listed, refer to the Appendix

in the back of this manual for information

on how to add and configure it.

1.2 Click on the icon for the amplifier, the

controls for the amplifier should appear in

the box on the right.

10. Pull down the Tools menu, scroll down

to Attach, and click the mouse. You will be

prompted to press the service pin switch on

the panel of the ACM-1. Press the service

pin switch. The device will be added to the

database and will no longer be grayed-out.

1.3 In the box to the right, you will see

several controls for the amplifier. At the

bottom left, you will see the Power button.

Click on the Power button using the mouse.

The amplifier should power up.

15

Page 16

TEST PROCEDURES

1.4 Verify that the amplifier powers up, and

that on the computer screen, the green

status light located in the controls section

next to the gain sliders lights green to

indicate proper operation of the amplifier.

2. EQ Audio Output Gain Test

2.1 Open the Entero™ software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to -100.0 dB.

2.2 Apply a 1 Vrms, 1 kHz signal to the

Channel 1 input of the ACM-1.

2.3 Measure the ouput level at the

Channel 1 ACM-1 EQ output at P3.

It should be 0 dBV ± 1 dB.

4. EQ Audio Output Noise Test

4.1 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to -100.0 dB.

4.2 Terminate the ACM-1 Channel 1 audio

input at P4 (or J4) with 50 Ohms. Measure

the ACM-1 Channel 1 output at P3 across

10k Ohms, terminating each unbalanced

output leg to ground.

4.3 Measure the noise level at P3 within a

bandwidth of 20 Hz - 22 kHz with no

weighting function. It should be

-95 dBV ≤ -90 dBV.

4.4 Repeat this procedure for Channel 2.

2.4 Repeat this procedure for Channel 2.

3. EQ Audio Output THD Test

3.1 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to -100.0 dB.

3.2 Apply a 1 Vrms, 1 kHz signal to the

Channel 1 input of the ACM-1.

3.3 Measure the THD level at the

Channel 1 ACM-1 EQ output at P3.

It should be 0.05% ± 0.1%.

3.4 Repeat this procedure for Channel 2.

5. Amplifier Output Gain Test

5.1 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

5.2 Apply a 775 mVrms, 1 kHz signal to

the ACM-1 Channel 1 input at P4 (or J4).

5.3 Reference a dB meter to the output.

5.4 Measure the output level at the

amplifier channel 1 output. For the 1600VI

amplifier, it should be +27.6 dBr ± 1.0 dB

for low sensitivity units and +33.3 dBr ±

1.0 dB for high sensitivity units. For the

1800VI amplifier, it should be +30.3 dBr ±

1.0 dB for low sensitivity units and 36.0 dBr

± 1.0 dB for high sensitivity units.

16

5.5 Repeat this procedure for Channel 2.

Page 17

TEST PROCEDURES

6. Amplifier Output Relative Gain Tests

6.1 Open the Entero™ software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

6.2 Apply a 100 mV, 1 kHz signal to the

ACM-1 Channel 1 input at P4 (or J4).

6.3 Reference a dB meter to the amplifier

channel 1 output. This is the reference

level.

6.4 Perform the tests in Table 3 below.

Test Name Freq. Output

Gain 20 Hz 20 Hz 0 dBr ± 1.0 dBr

Reference 1 kHz 0 dBr ± 1.0 dBr

Gain 100 Hz 100 Hz 0 dBr ± 1.0 dBr

Gain 500 Hz 500 Hz 0 dBr ± 1.0 dBr

Gain 5 kHz 5 kHz 0 dBr ± 1.0 dBr

Gain 20 kHz 20 kHz 0 dBr ± 1.0 dBr

Table 3. Amplifier Output Performance Tests

6.5 Repeat this procedure for Channel 2.

7. Amplifier Output THD Test

8. Amplifier Output Noise Test

8.1 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

8.2 Terminate the ACM-1 Channel 1 audio

input at P4 (or J4) with 50 Ohms. Measure

the ACM-1 Channel 1 output at P3 across

10k Ohms, terminating each unbalanced

output leg to ground.

8.3 Measure the noise level at the

amplifier channel 1 output within a bandwidth of 20 Hz - 22 kHz with no weighting

function. It should be -60 dBV ≤ -55 dBV.

8.4 Repeat this procedure for Channel 2.

9. Voltage Controlled Amplifier Tests

9.1 On the Entero Graphical User

Interface Control Panel, set the sliders to

-40.0 dB. You can do this by sliding the

sliders or by clicking on the box above the

slider. A dialog box will open that will allow

you to type in the level you want.

7.1 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

7.2 Apply a 500 mV, 1 kHz signal to the

ACM-1 Channel 1 input at P4 (or J4).

7.3 Measure the THD level at the amplifier

channel 1 output. It should be

0.05% ≤ 0.2%.

7.5 Repeat this procedure for Channel 2.

9.2 Apply a 775 mVrms, 1 kHz signal to the

Channel 1 input of the ACM-1 module.

9.3 Measure the output at the Channel 1

output of the amplifier. For the 1600VI

amplifier it should be -14.25 dBV ± 1.0 dB.

For the 1800VI amplifier it should be

-6.4 dBV ± 1.0 dB.

9.4 Repeat this procedure for Channel 2.

17

Page 18

TEST PROCEDURES

10. Monitoring Functions Test

10.1 Open the Entero™ software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

10.2 Apply a 200 mVrms, 1 kHz signal to

the ACM-1 channel 1 and 2 inputs at P4

and P1. Verify that the GUI Display for Z1

and Z2 reads 8 Ohms ± 1 Ohm.

10.3 While the 200 mVrms, 1 kHz signal

is applied, check the GUI display at for

Temp1 and Temp2. They should read

between 20° C and 60° C, or 68° F and

140° F, depending on how long the

amplifier has been operating and what

the ambient temperature of the test

environment is.

12. Dual Mono Test

12.1 Place the Amplifier Mode Switch SW1

on the ACM-1 to the DUAL MONO position

(full right).

12.2 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

12.3 Apply a 100 mVrms, 1 kHz signal to

the ACM-1 Channel 2 input only.

12.4 Measure the output level at the

Channel 1 output of the amplifier. For the

1600VI amplifier it should be 7.35 dBV ±

1.0 dB. For the 1800VI amplifier it should

be 15.6 dBV ± 1.0 dB.

11. Bridged Mono Test

11.1 Place the Amplifier Mode Switch SW1

on the ACM-1 to the BRIDGED position

(full left).

11.2 Open the Entero software on the

computer, and select the device finder tab.

Click on the icon for the amplifier in the

left-hand column. On the right-hand side of

the screen, click on the Power button using

the mouse. The amplifier should power up.

Set the gain slider for the channel under

test to 0.0 dB.

11.3 Apply a 100 mVrms, 1 kHz signal to

the ACM-1 Channel 2 input only.

11.4 Measure the output level at the

Channel 1 output of the amplifier. For the

1600VI amplifier it should be 7.35 dBV ±

1.0 dB. For the 1800VI amplifier it should

be 15.6 dBV ± 1.0 dB.

18

Page 19

TEST PROCEDURES

Test Cable Construction

If you need to troubleshoot an ACM-1

outside of the amplifier chassis, you will

need to make a test cable.

You can do this by unsoldering the 4-pin

Molex connector at J2 from the rear of the

ACM-1 board and soldering a twisted-pair

of wires on to pins 1 and 2. These are the

terminals that are the closest to the connector and correspond to the bottom pins

of the connector itself. It's recommended

to use two different color wires to avoid

errors. Refer to the component layout

diagram for location.

Solder the other ends of the wires to the

corresponding pads on the board.

The +15Vdc terminal at J2 pin 2 is tied to

D40 and C92. The -15Vdc terminal at J2

pin 1 is tied to D41 and C93. Be sure to

solder the wires to the correct terminals or

you will destroy the PCB.

This cable will allow you to plug the into

the Molex connector in the card slot of the

1600/1800VI amplifier and operate the

ACM-1 outside of the amplifier chassis.

Note: Be sure to connect a ground wire

from the front panel of the ACM-1 to the

chassis of the amplifier. The ACM-1 will

not operate without this ground wire.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with

the same safety characteristics as the recommended replacement part might create shock,

fire, and/or other hazards.

19

Page 20

MAIN AND PACKAGING PART LIST

ACM-1 Amplifier Control Module (see Figure 10)

Item

Description Part Number Qty.

Number

1 SCREW, MACH, 6-32X.25, PAN, XREC 107343-04 4

2 MODULE, NEURON, TPFT-10F,

193966-01 1

ECHELON P/N: 55020-10

3 CHIP, FLASH, EXTENSOR 193965-01 1

4 PCB ASSY, DAUGHTERBOARD 196387 1

5 PANEL, FRONT 188663 1

6 SCREW, MACH, M3X0.5X5.0, PAN, XREC 183435-05 4

7 PCB ASSY, MOTHERBOARD 196343 1

8 SPACER, HEX, STEEL, 6-32X.5 196392-08 2

9 MANUAL, OWNER'S GUIDE 193962 1

10 CARTON, RSC VENDOR

SUPPLIED

4X

1

3

2

4

5

6

1

7

2X

8

1

6

9

10

Figure 10. ACM-1 Amplifier Control Module Exploded View

20

Page 21

ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 100K, 0805, 1/10W, 1% 133625-1003

R2 100K, 0805, 1/10W, 1% 133625-1003

R3 100K, 0805, 1/10W, 1% 133625-1003

R4 100K, 0805, 1/10W, 1% 133625-1003

R5 100K, 0805, 1/10W, 1% 133625-1003

R6 100K, 0805, 1/10W, 1% 133625-1003

R43 100K, 0805, 1/10W, 1% 133625-1003

R44 100K, 0805, 1/10W, 1% 133625-1003

R40 3.16K, 0805, 1/10W, 1% 133625-3161

R41 3.16K, 0805, 1/10W, 1% 133625-3161

R42 3.16K, 0805, 1/10W, 1% 133625-3161

R45 JUMPER CHIP, 0805 133627

R47 JUMPER CHIP, 0805 133627

R60 392K, 0805, 1/10W, 1% 133625-3923

R61 392K, 0805, 1/10W, 1% 133625-3923

R62 392K, 0805, 1/10W, 1% 133625-3923

R63 392K, 0805, 1/10W, 1% 133625-3923

R70 12.1Ω, 0805, 1/10W, 1% 133625-12R1

R76 330K, 0805, 1/10W, 5% 133626-3345

R77 330K, 0805, 1/10W, 5% 133626-3345

R78 330K, 0805, 1/10W, 5% 133626-3345

R79 330K, 0805, 1/10W, 5% 133626-3345

R80 1.0K, 0805, MF, 1% 181896-1001

R81 1.0K, 0805, MF, 1% 181896-1001

R82 1.0K, 0805, MF, 1% 181896-1001

R83 1.0K, 0805, MF, 1% 181896-1001

R98 1.0K, 0805, MF, 1% 181896-1001

R90 4.99K, 0805, 1/10W, 1% 133625-4991

R91 4.99K, 0805, 1/10W, 1% 133625-4991

R92 100K, 0805, 1/10W, 1% 133625-1003

R93 100K, 0805, 1/10W, 1% 133625-1003

R94 4.22K, 0805, 1/10W, 1% 173767-4221

R95 4.22K, 0805, 1/10W, 1% 173767-4221

R97 5.10K, 0805, 1/10W, 1% 133626-5125

R96 332Ω, 0805, 1/10W, 1% 173767-332R

R99 330K, 0805, 1/10W, 5% 133626-3345

R101 330K, 0805, 1/10W, 5% 133626-3345

R100 33.2K, 0805, 1/10W, 1% 173767-3322

R102 33.2K, 0805, 1/10W, 1% 173767-3322

N1 10K, RES NET, 1/10W, 2%, X4 196347-1002

N2 10K, RES NET, 1/10W, 2%, X4 196347-1002

N3 10K, RES NET, 1/10W, 2%, X4 196347-1002

N4 10K, RES NET, 1/10W, 2%, X4 196347-1002

N5 2.7K, RES NET, 1/10W, 2%, X4 196347-2701

N24 2.7K, RES NET, 1/10W, 2%, X4 196347-2701

N6 10K, RES NET, 1/10W, 2%, X3 196346-1002

N9 10K, RES NET, 1/10W, 2%, X3 196346-1002

N7 20K, RES NET, 1/10W, 2%, X5 196345-2002

N8 20K, RES NET, 1/10W, 2%, X5 196345-2002

N10 200Ω, RES NET, 1/10W, 2%, X4 196347-2000

N11 200Ω, RES NET, 1/10W, 2%, X4 196347-2000

N12 47K, RES NET, 1/10W, 2%, X4 196347-4702

Description Part Number Note

21

Page 22

ELECTRICAL PART LIST

Resistors

Reference

Designator

N13 47K, RES NET, 1/10W, 2%, X4 196347-4702

N14 100K, RES NET, 1/10W, 2%, X4 196347-1003

N15 100K, RES NET, 1/10W, 2%, X4 196347-1003

N16 5.00K, RES NET, 1/10W, 0.1%, X8 181482-5001

N17 5.00K, RES NET, 1/10W, 0.1%, X8 181482-5001

N18 5.00K, RES NET, 1/10W, 0.1%, X8 181482-5001

N19 5.00K, RES NET, 1/10W, 0.1%, X8 181482-5001

N20 470Ω, RES NET, 1/10W, 2%, X4 196347-4700

N21 470Ω, RES NET, 1/10W, 2%, X4 196347-4700

N22 470Ω, RES NET, 1/10W, 2%, X4 196347-4700

N23 470Ω, RES NET, 1/10W, 2%, X4 196347-4700

Reference

Designator

C 2 1000pF, 0805, COG, 50V, 5% 133622-102

C 3 16pF, 0805, COG, 50V, 5% 133622-160

C 4 16pF, 0805, COG, 50V, 5% 133622-160

C 5 330pF, 0805, COG, 50V, 5% 133622-331

C 6 330pF, 0805, COG, 50V, 5% 133622-331

C 7 330pF, 0805, COG, 50V, 5% 133622-331

C 8 330pF, 0805, COG, 50V, 5% 133622-331

C1 0 5600pf, 1206, COG, 50V, 5% 177214-562

C1 1 5600pf, 1206, COG, 50V, 5% 177214-562

C14 .01uF, 0805, X7R, 50V, 10% 133623-103

C15 .01uF, 0805, X7R, 50V, 10% 133623-103

C16 .01uF, 0805, X7R, 50V, 10% 133623-103

C22 1uF, 1206, Y5V, 16V, 80% 173383-105

C23 1uF, 1206, Y5V, 16V, 80% 173383-105

C24 1uF, 1206, Y5V, 16V, 80% 173383-105

C25 1uF, 1206, Y5V, 16V, 80% 173383-105

C26 1uF, 1206, Y5V, 16V, 80% 173383-105

C27 1uF, 1206, Y5V, 16V, 80% 173383-105

C28 1uF, 1206, Y5V, 16V, 80% 173383-105

C29 1uF, 1206, Y5V, 16V, 80% 173383-105

C3 0 47 pF, 0805, COG, 50V, 5% 133622-470

C3 1 47 pF, 0805, COG, 50V, 5% 133622-470

C32 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C33 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C34 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C35 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C36 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C37 2.2 uF, EL, 85, 50V, 20% 149947-2R2H

C42 1.0 uF, EL, 85, 50V, 20% 149948-1R0H

C43 .10uF, 0805, Y5V, 25V, 80% 133624

C45 .10uF, 0805, Y5V, 25V, 80% 133624

C47 .10uF, 0805, Y5V, 25V, 80% 133624

C49 .10uF, 0805, Y5V, 25V, 80% 133624

C50 .10uF, 0805, Y5V, 25V, 80% 133624

C51 .10uF, 0805, Y5V, 25V, 80% 133624

C52 .10uF, 0805, Y5V, 25V, 80% 133624

Description Part Number Note

Capacitors

Description Part Number Note

22

Page 23

ELECTRICAL PART LIST

Capacitors

Reference

Designator

C54 .10uF, 0805, Y5V, 25V, 80% 133624

C55 .10uF, 0805, Y5V, 25V, 80% 133624

C56 .10uF, 0805, Y5V, 25V, 80% 133624

C57 .10uF, 0805, Y5V, 25V, 80% 133624

C58 .10uF, 0805, Y5V, 25V, 80% 133624

C59 .10uF, 0805, Y5V, 25V, 80% 133624

C60 .10uF, 0805, Y5V, 25V, 80% 133624

C61 .10uF, 0805, Y5V, 25V, 80% 133624

C62 .10uF, 0805, Y5V, 25V, 80% 133624

C63 .10uF, 0805, Y5V, 25V, 80% 133624

C65 .10uF, 0805, Y5V, 25V, 80% 133624

C66 .10uF, 0805, Y5V, 25V, 80% 133624

C67 .10uF, 0805, Y5V, 25V, 80% 133624

C71 .10uF, 0805, Y5V, 25V, 80% 133624

C44 330 uF, EL, 85, 25V, 20% 149948-331E

C92 100 uF, EL, 105, 50V, 20% 144000-101H

C93 100 uF, EL, 105, 50V, 20% 144000-101H

Reference

Designator

D1 DUAL, SOT-23, BAV 99R-R 147239

D2 DUAL, SOT-23, BAV 99R-R 147239

D3 DUAL, SOT-23, BAV 99R-R 147239

D4 DUAL, SOT-23, BAV 99R-R 147239

D5 DUAL, SOT-23, BAV 99R-R 147239

D6 DUAL, SOT-23, BAV 99R-R 147239

D7 DUAL, SOT-23, BAV 99R-R 147239

D8 DUAL, SOT-23, BAV 99R-R 147239

D9 DUAL, SOT-23, BAV 99R-R 147239

D10 DUAL, SOT-23, BAV 99R-R 147239

D11 DUAL, SOT-23, BAV 99R-R 147239

D12 DUAL, SOT-23, BAV 99R-R 147239

D13 DUAL, SOT-23, BAV 99R-R 147239

D14 DUAL, SOT-23, BAV 99R-R 147239

D15 DUAL, SOT-23, BAV 99R-R 147239

D16 DUAL, SOT-23, BAV 99R-R 147239

D17 DUAL, SOT-23, BAV 99R-R 147239

D18 DUAL, SOT-23, BAV 99R-R 147239

D19 DUAL, SOT-23, BAV 99R-R 147239

D20 DUAL, SOT-23, BAV 99R-R 147239

D30 AXIAL, 500V, 35A, 1N4004 146515-4

D31 AXIAL, 500V, 35A, 1N4004 146515-4

D32 AXIAL, 500V, 35A, 1N4004 146515-4

D40 ZENER, 18V, 1W, 5%, 1N4746 116995-4746A

D41 ZENER, 18V, 1W, 5%, 1N4746 116995-4746A

D42 ZENER, .5W, 12V 174265-5242

D43 ZENER, .5W, 12V 174265-5242

D50 DIODE, LED, DUAL GREEN 196355

D51 DIODE, LED, LUMEX, SINGLE 196356

Description Part Number Note

Diodes

Description Part Number Note

23

Page 24

ELECTRICAL PART LIST

Transistors

Reference

Designator

Q1 BPLR, P, 40V, 200mA, SOT23 148596

Q2 BPLR, N, 40V, 200mA, SOT23 146819

Q3 BPLR, N, 40V, 200mA, SOT23 146819

Q4 BPLR, N, 40V, 200mA, SOT23 146819

Reference

Designator

U1 OP-AMP, QUAD, SOIC-14, NJM2059 187472

U2 OP-AMP, QUAD, SOIC-14, NJM2059 187472

U3 OP-AMP, QUAD, SOIC-14, NJM2059 187472

U4 OP-AMP, QUAD, SOIC-14, NJM2059 187472

U5 OP-AMP, QUAD, SOIC-14, NJM2059 187472

U6 OP-AMP, DUAL, SOIC-8, NJM4559 187473

U7 OP-AMP, DUAL, SOIC-8, NJM4559 187473

U8 OP-AMP, DUAL, SOIC-8, NJM4559 187473

U9 ADC, 10 BIT / 8 IN, ADC1038, SO20 196360

U10 OP-AMP SWITCH, SOIC-8, NJM2120 187474

U11 OP-AMP SWITCH, SOIC-8, NJM2120 187474

U12 OP-AMP SWITCH, SOIC-8, NJM2120 187474

U13 OP-AMP SWITCH, SOIC-8, NJM2120 187474

U14 VOL CTL, ST, TC9412AF 196350

U15 OP-AMP, SSM2141S, SOIC-8 196348

U16 OP-AMP, SSM2141S, SOIC-8 196348

U17 MUX, 2X4IN/1OUT, CD4052BCM, SO16 196351

U18 REG, ISOPKG, +5V, L7805CP, TO220 196361

U20 TEMP SENSOR, LM50C1M3, SOT23 196352

U21 NAND, DUAL 2 IN NAND, SMD, MM74HC00M 186065

Description Part Number Note

Integrated Circuits

Description Part Number Note

24

Page 25

ELECTRICAL PART LIST

Miscellaneous

Reference

Designator

J1 CONN, 10X2 ROWS, .1 GRID, MALE 196364

J2 CONN, MOLEX, PCB MT,

4 PIN

J3A CONN, HEADER, W/ SPACER, 8 PIN 196359

J3 B CONN, HEADER, BTM INSERT, 4x2 PIN GRID 196358

J4 CONN, RTANG, 3 POS, BLK 177291-03

J5 CONN, RTANG, 3 POS, BLK 177291-03

J6 CONN, TOP ENTRY, 12 POS 170250

J7 CONN, TOP ENTRY, 12 POS 170250

J8 CABLE, RIBBON, 20 PIN 196366

J9 CONN, SOCKET, PCB MNT 196367

J10 CONN, SOCKET, PCB MNT 196368

J11 CONN, DC PWR JACK, 1 POS, FEMALE 147540

J12 CONN, RJ45, PCB MNT,

AMP 520251-4 OR EQUIV.

J13 CONN, RJ45, PCB MNT,

AMP 520251-4 OR EQUIV.

JB 1 CONN, JUMPER BLOCK, 3x2 ROW, .1 GRID 196369

P1 CONN. DUAL, XLR/ 1/4 PLUG 196363

P4 CONN. DUAL, XLR/ 1/4 PLUG 196363

P2 CONN, TRS, 1/4, PCB MT 196349

P3 CONN, TRS, 1/4, PCB MT 196349

S1 SCREW TERM, PCB HORIZ, 6-32 187504

S2 SCREW TERM, PCB HORIZ, 6-32 187504

SW1 2P3T, E SW EG2301 196353

SW2 2P2T, E SW EG2209A 196354

SW 3 SPST, PB, PCB MNT, HRZ GRID 196362

- JUMPER, SHORTING, GOLD, SULLINS P/N

SSC02SYAN

Description Part Number Note

196365

196357

196357

-

25

Page 26

Figure 11. Daughterboard Topside Etch Layout Diagram

Figure 12. Daughterboard Internal Etch Layout Diagram

Figure 13. Daughterboard Bottom Etch Layout Diagram

26

Page 27

INTEGRATED CIRCUIT PINOUT DIAGRAMS

PIN FUNCTION

A

B

Y

1

A1

2

B1

3

Y1

4

A2

5

B2

Y2

6

Vcc

B4

A4

Y4

B3

A3

14

13

12

11

10

1

2

- +

3

4

5

9

- +

6

14

13

- +

12

11

10

- +

9

1. A OUTPUT

2. A -INPUT

3. A +INPUT

4. V+

5. B +INPUT

6. B -INPUT

7. B OUTPUT

8. C OUTPUT

9. C -INPUT

10. C +INPUT

11. V-

Y3

7

GND

8

7 8

12. D +INPUT

13. D -INPUT

14. D OUTPUT

Bose® P/N: 186065, Device Type 74HC00

Quad Nand Gate.

1

A

- +

2

B

3

- +

4 5

8

7

6

PIN FUNCTION

1. A OUTPUT

2. A -INPUT

3. A +INPUT

4. V-

5. B +INPUT

6. B -INPUT

7. B OUTPUT

8. V+

Bose P/N: 187473, Device Type NJM4559

Dual Op-Amp.

Bose P/N: 187472, Device Type NJM2059

Quad Op-Amp.

PIN

FUNCTION

1

2

- + + -

3

8

7

6

1. SWITCH

CONTROL

2. A +INPUT

3. A -INPUT

4. V-

5. OUTPUT

4 5

6. B -INPUT

7. B +INPUT

8. V+

Bose P/N: 187474, Device Type NJM2120

Op-Amp Switch.

25k Ohm

1

25k Ohm

2

25k Ohm

3

4 5

-

+

25k Ohm

1. Reference

8

2. Inverting input

3. Non-inverting input

7

4. -Vcc

5. Sense

6

6. Output

7. +Vcc

8. NC

Bose P/N: 196348, Device Type SSM2141S

Op-Amp.

3

PIN FUNCTION

1. +V Source

2. V Output

1 2

3. GND

Bose P/N: 196352, Device Type LM50C1M3

Temp Sensor.

27

Page 28

INTEGRATED CIRCUIT PINOUT DIAGRAMS

1

Y0

2

Y2

3

Y

4

Y3

5

Y1

6

INHIBIT

VEE

7

8 9

VSS

VDD

X2

X1

X

X0

X3

A

B

16

15

14

13

12

11

10

CONTROLS

SWITCHES

IN/OUT

6

10

9

12

14

15

11

1

5

2

4

Inhibit

A

B

X0

X1

X2

X3

Y0

Y1

Y2

Y3

X

VDD = PIN 16

VSS = PIN 8

VEE = PIN 7

Y

Bose® P/N: 196351, Device Type CD4052 2x4 in/ 1 Out Multiplexer

13

3

COMMONS

OUT/IN

Bose P/N: 196350, Device Type TC9412AF Volume Control

28

Page 29

INTEGRATED CIRCUIT PINOUT DIAGRAMS

Bose® P/N: 196360, Device Type ADC1038 10-Bit Analog to Digital Converter with Analog

Multiplexer and Track/Hold Function.

29

Page 30

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

®

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N: 199746 Rev. 00 3/99 FOR TECHNICAL ASSISTANCE OR PART ORDERS, CALL 1-800-367-4008

Loading...

Loading...