Page 1

CONTENTS

Safety Information.............................................................................................................................2

Warranty .............................................................................................................................................2

Product Description ..........................................................................................................................3

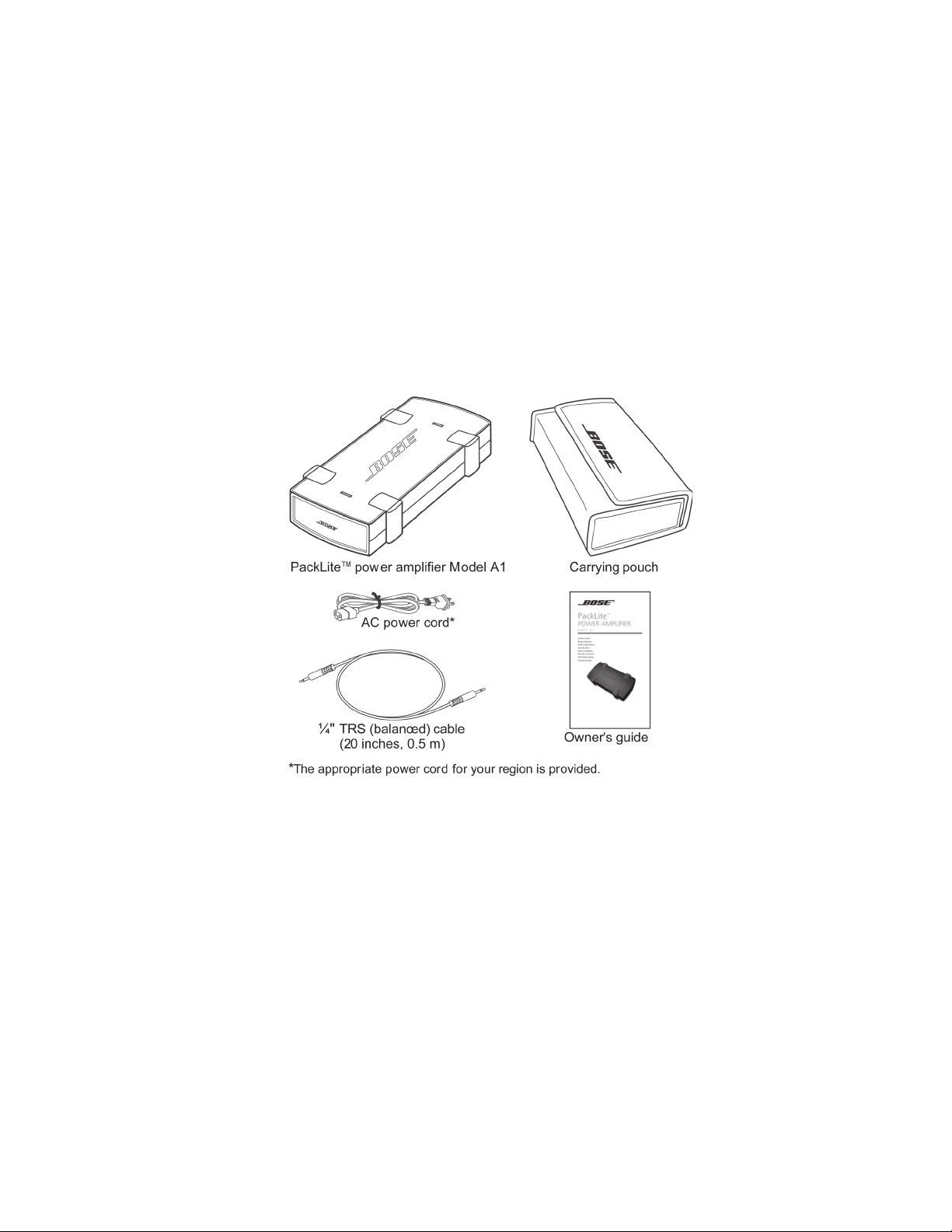

Carton Contents ................................................................................................................................3

Amplifier Rear Panel Connections and Controls ...........................................................................4

Top Panel Indicators .........................................................................................................................4

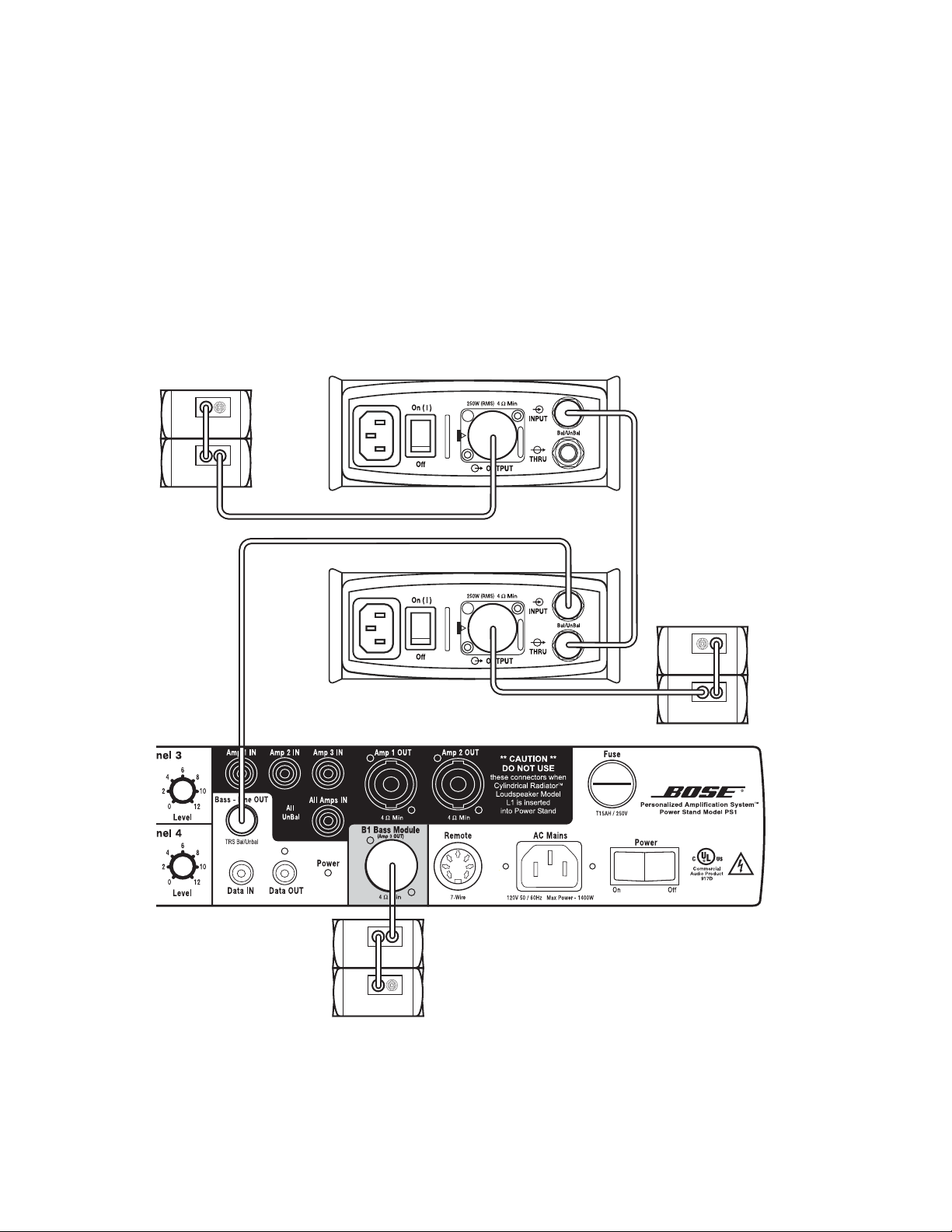

Setting Up a Single A1 Amplifier .....................................................................................................5

Using Multiple A1 Amplifiers ............................................................................................................ 6

Using the A1 in other applications ..................................................................................................7

Setting up the A1 for use with other systems: ...............................................................................7

Specifications .................................................................................................................................... 8

Production Notes ..............................................................................................................................9

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................9

Part List Notes ................................................................................................................................... 9

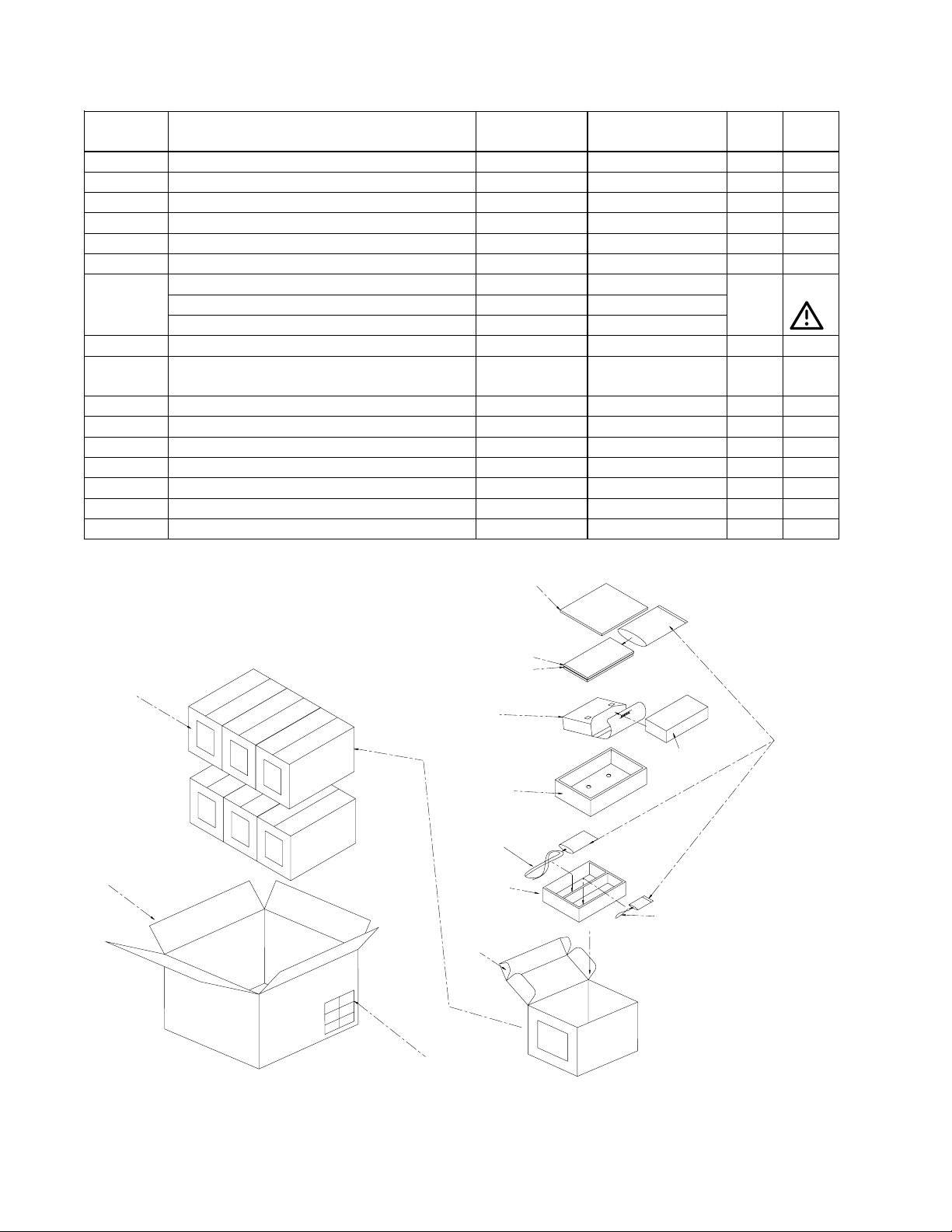

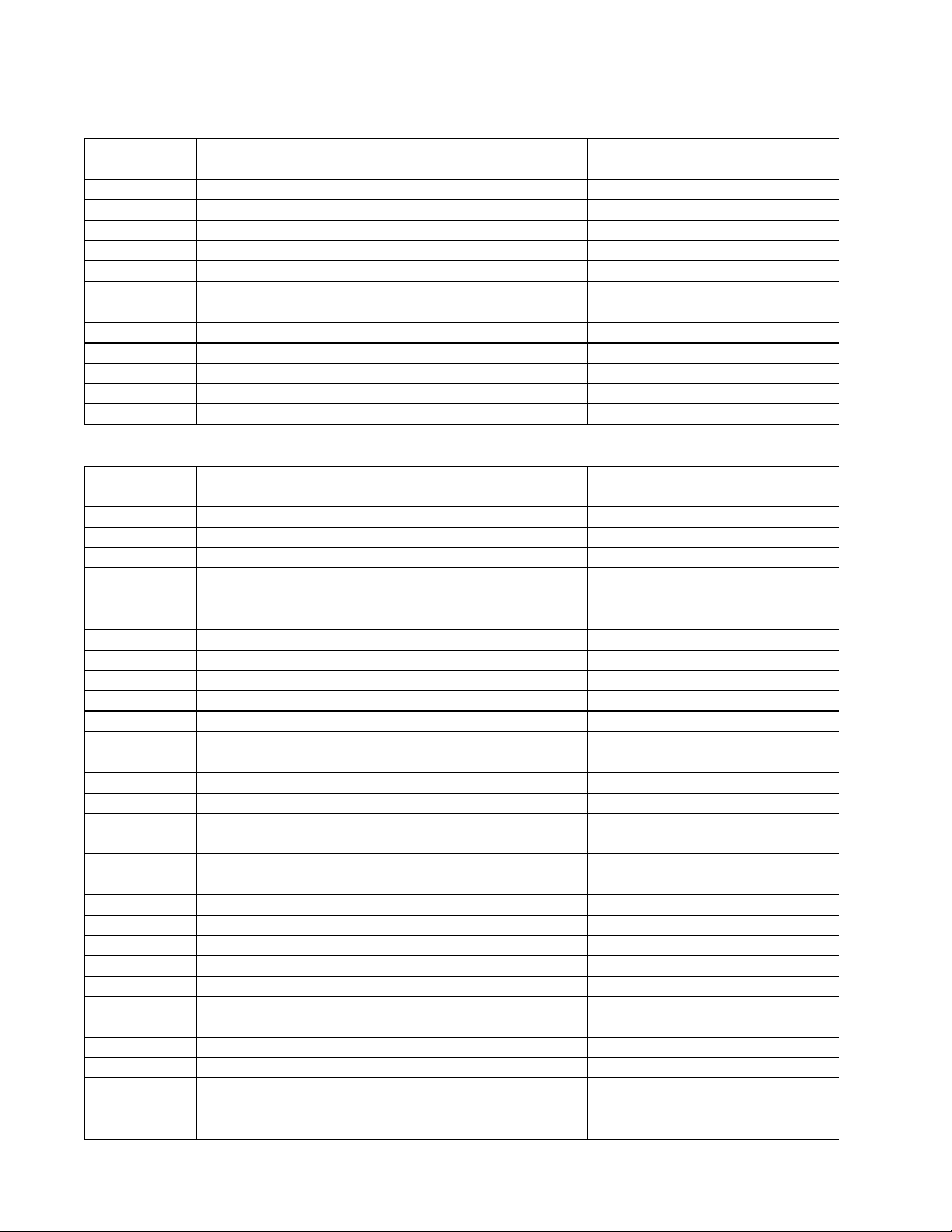

Packaging Part List, PackLite

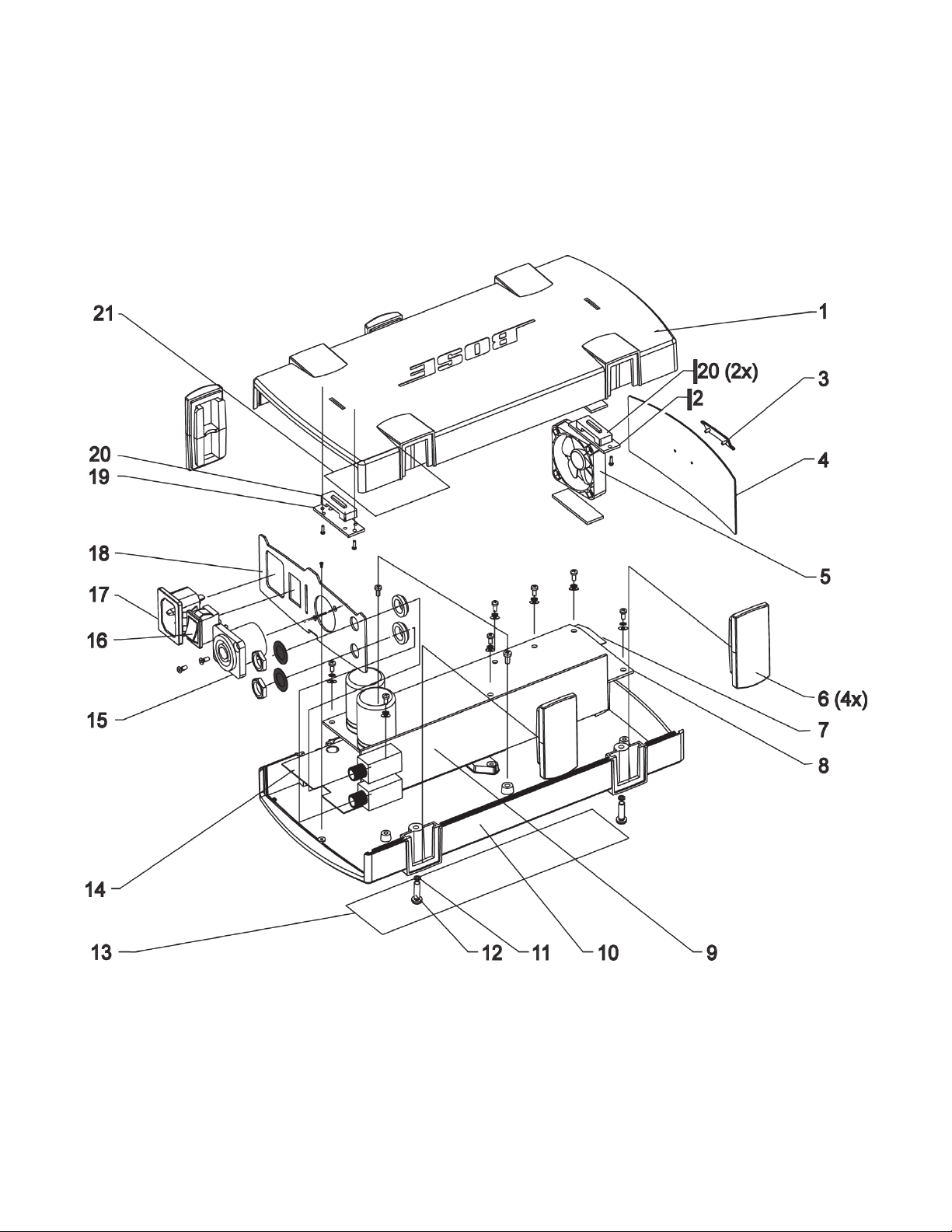

Figure 1. PackLite A1 Amplifier Assembly Packaging View............................................................10

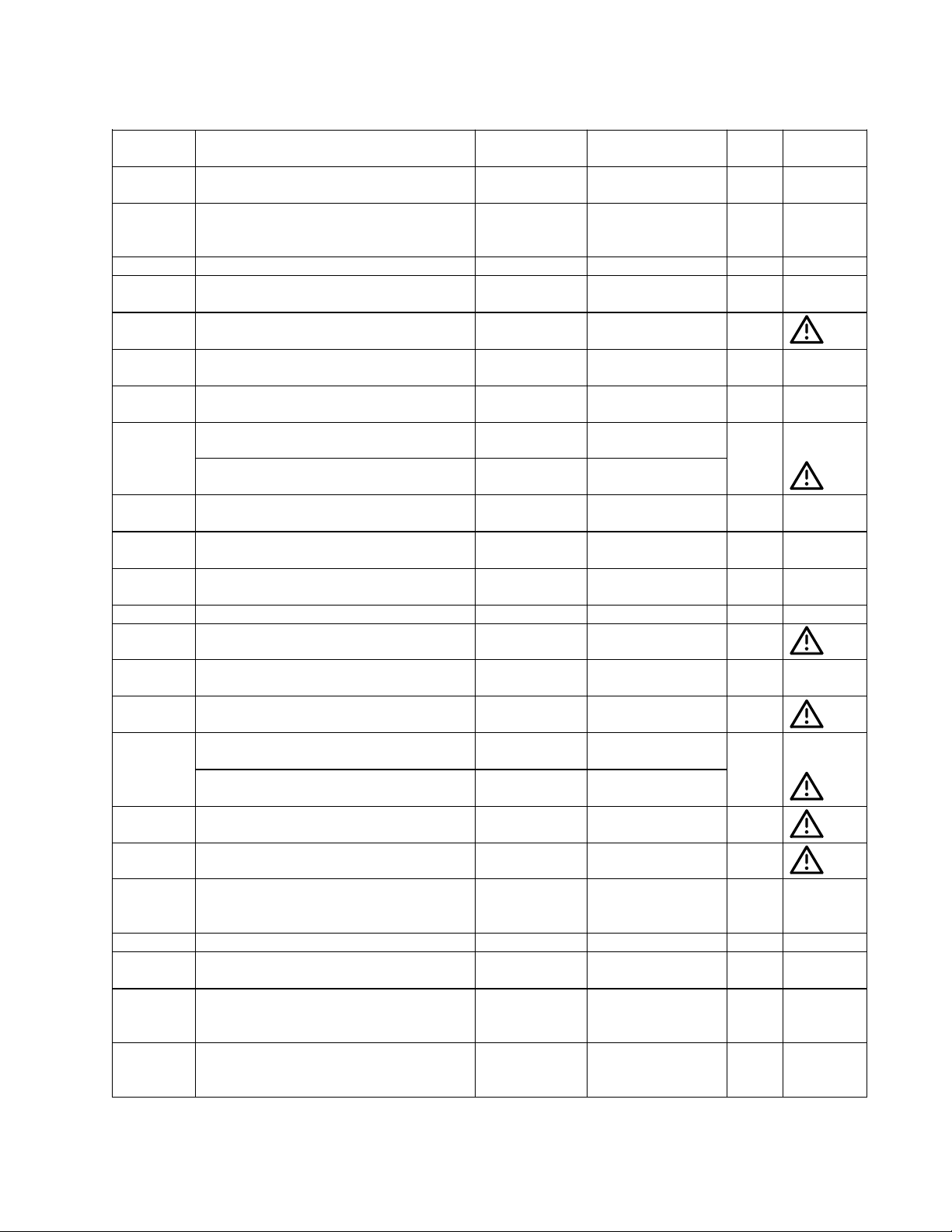

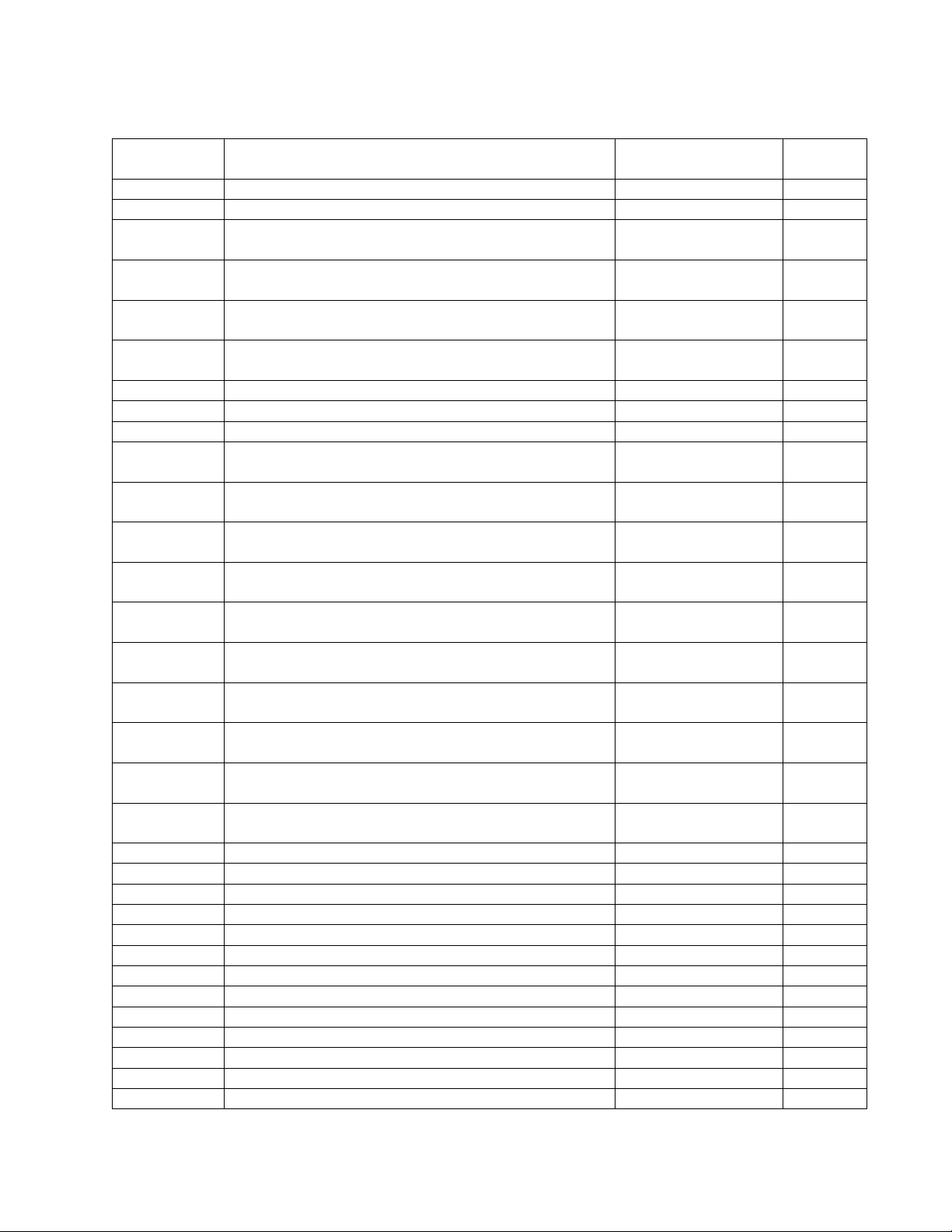

Main Part List, PackLite A1 Amplifier Assembly (see Figure 2).................................................. 11

Figure 2. PackLite A1 Amplifier Exploded View .............................................................................. 12

Electrical Part Lists ................................................................................................................... 13-29

Power Supply / Amplifier PCB Assembly................................................................................ 13-22

Input / Limiter PCB Assembly .................................................................................................. 23-28

Signal LED PCB Assembly ............................................................................................................. 29

Power / Fault LED PCB Assembly .................................................................................................29

Disassembly Procedures ......................................................................................................... 30-33

Test Procedures ........................................................................................................................ 33-34

Figure 3. Amplifier/SMPS PCB (Non-RoHS) Topside Etch Layout ................................................. 35

Figure 4. Amplifier/SMPS PCB (Non-RoHS) Internal Etch Layer 1 Layout ....................................35

Figure 5. Amplifier/SMPS PCB (Non-RoHS) Internal Etch Layer 2 Layout ....................................36

Figure 6. Amplifier/SMPS PCB (Non-RoHS) Bottom Etch Layout..................................................36

Figure 7. Amplifier/SMPS PCB (RoHS) Topside Etch Layout.........................................................37

Figure 8. Amplifier/SMPS PCB (RoHS) Internal Etch Layer 1 Layout ............................................37

Figure 9. Amplifier/SMPS PCB (RoHS) Internal Etch Layer 2 Layout ............................................38

Figure 10. Amplifier/SMPS PCB (RoHS) Bottom Etch Layout........................................................ 38

Figure 11. Input/Limiter PCB (Non-RoHS) Top Side Etch Layout...................................................39

Figure 12. Input/Limiter PCB (Non-RoHS) Bottom Side Etch Layout ............................................. 39

Figure 13. Input/Limiter PCB (RoHS) Top Side Etch Layout ..........................................................40

Figure 14. Input/Limiter PCB (RoHS) Bottom Side Etch Layout.....................................................40

Figure 15. Power/Fault LED PCB Etch Layout ...............................................................................41

Figure 16. Signal/Overload LED PCB Etch Layout ........................................................................41

Test Cable Wiring Diagrams...........................................................................................................41

Troubleshooting .............................................................................................................................. 42

Theory of Operation, PackLite Model A1 Amplifier ................................................................ 43-50

Integrated Circuit Diagrams ..................................................................................................... 51-53

Service Manual Revision History...................................................................................................54

TM

A1 Amplifier Assembly (see Figure 1) ..................................... 10

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® PackLiteTM Model A1 Amplifier

contains no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose PackLite Model A1 Amplifier is covered by a limited 1-year transferable warranty.

2

Page 3

Product Description

TM

The PackLite

amplifier that interfaces quickly with the Bose® PS1 power stand and B1 bass modules to

provide high bass output for demanding instruments such as bass guitar and drums. The connections are quick and easy: plug in the AC cord, connect the A1 to the PS1 power stand, and

play. When the A1 is used together with the Cylindrical Radiator

ing adjustments are required. The components act as a system and automatically adjust bass

output for more level and headroom, while maintaining consistent tone regardless of how many

B1 bass modules are being used.

In addition, the A1 can drive other passive loudspeakers such as bass guitar cabinets,

subwoofers, studio monitors, and floor monitors.

Model A1 power amplifier is a small, lightweight, powerful, and easy-to-use

®

loudspeaker, no time-consum-

Carton Contents

• Carrying pouch

• PackLite power amplifier Model A1

• AC power cord

• ¼" TRS (balanced) cable (20 inches, 0.5 m)

• Owner’s guide

3

Page 4

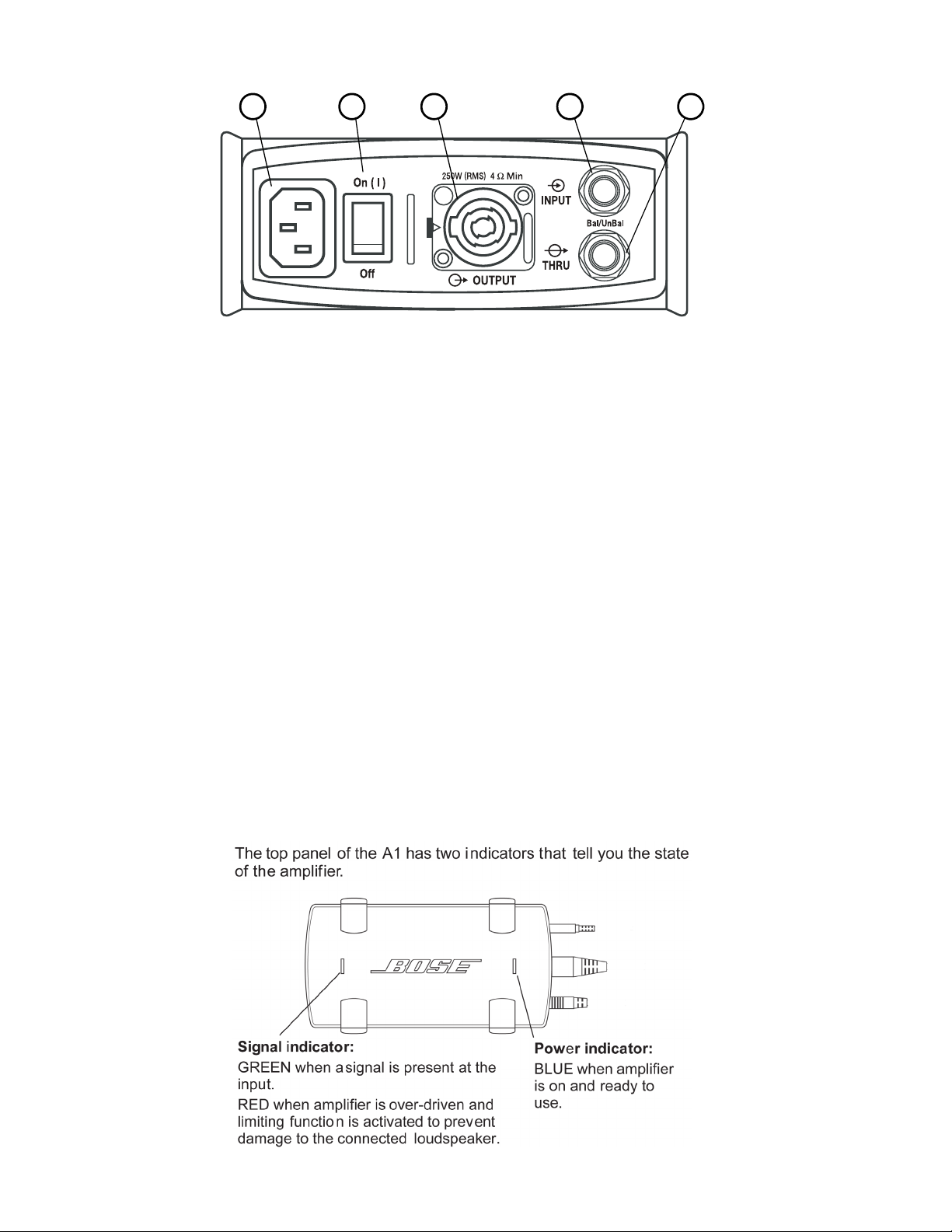

Amplifier Rear Panel Connections and Controls

1 2 3 4 5

1 - AC power connector: Accommodates the supplied AC power cord to connect your amplifier

to the appropriate AC (mains) outlet. Check the product label of your amplifier for the voltage

rating: 120V or 220-240V.

2 - Power switch: In the ON (l) position, applies power to your amplifier. When ON, the power

indicator (see diagram below) should be BLUE.

3 - OUTPUT connector: Accommodates both 2 and 4-wire Neutrik® Speakon® connectors.

OUTPUT can be connected to any of the following:

• B1 bass module.

• 4-ohm loudspeaker with a power rating of at least 250W RMS.

• 8-ohm loudspeaker with a power rating of at least 125W RMS.

4 - INPUT connector: Accommodates a ¼" TRS (balanced) or TS (unbalanced) plug.

INPUT can be connected to either of the following:

• Bass-Line OUT jack on the PS1 power stand using the supplied ¼" TRS cable.

• THRU connector of an “upstream” A1 amplifier when used in series.

• Other line-level source output using either a ¼" TRS or TS cable.

5 - THRU connector: Accommodates a ¼" TRS or TS connection. Used for sending the INPUT

signal to another A1 amplifier.

Notes:

1. Do not use the THRU connector as a second input, as it could damage any interconnected

equipment. Use THRU only as an output to another A1 amplifier.

2. The THRU connector will only relay the type of input (balanced or unbalanced) present at the

INPUT connector.

Top Panel Indicators

4

Page 5

Setting Up a Single A1 Amplifier

The A1 amplifier is designed to add more bass output to a system that already has two B1 bass

modules connected to the Amp 3 OUT connector on the PS1 power stand. The A1 amplifier can

power up to two additional B1 bass modules.

Follow these steps to set up the A1 as shown below.

1. Connect the AC power cord to an AC (mains) outlet.

2. Make sure the A1 amplifier Power switch is OFF.

3. Using the supplied ¼" TRS cable, connect the Bass-Line OUT connector on the PS1 power

stand to the INPUT connector on the A1 amplifier.

4. Connect a B1 bass module cable from the OUTPUT connector on the A1 to a B1 bass module. If desired, connect a second B1 to the first B1.

5. Set the A1 power switch to ON (I).

INPUT

OUTPUT

Bass-Line

OUT

A1 amplifier

B1 bass

modules

PS1 power stand

B1 bass

modules

CAUTION: Do not connect more than two B1 bass modules to an A1 amplifier.

CAUTION: Be careful not to connect the A1 amplifier to a B1 bass module that is already

connected to the Amp 3 OUT connector of a PS1 power stand, or to another A1 amplifier.

Note: Using the supplied ¼" TRS cable with your A1 amplifier is recommended. Using

balanced cabling prevents common interconnect noise problems.

Note: Up to four (maximum) B1 bass modules can be stacked in a column. Stacking may

improve acoustic output.

5

Page 6

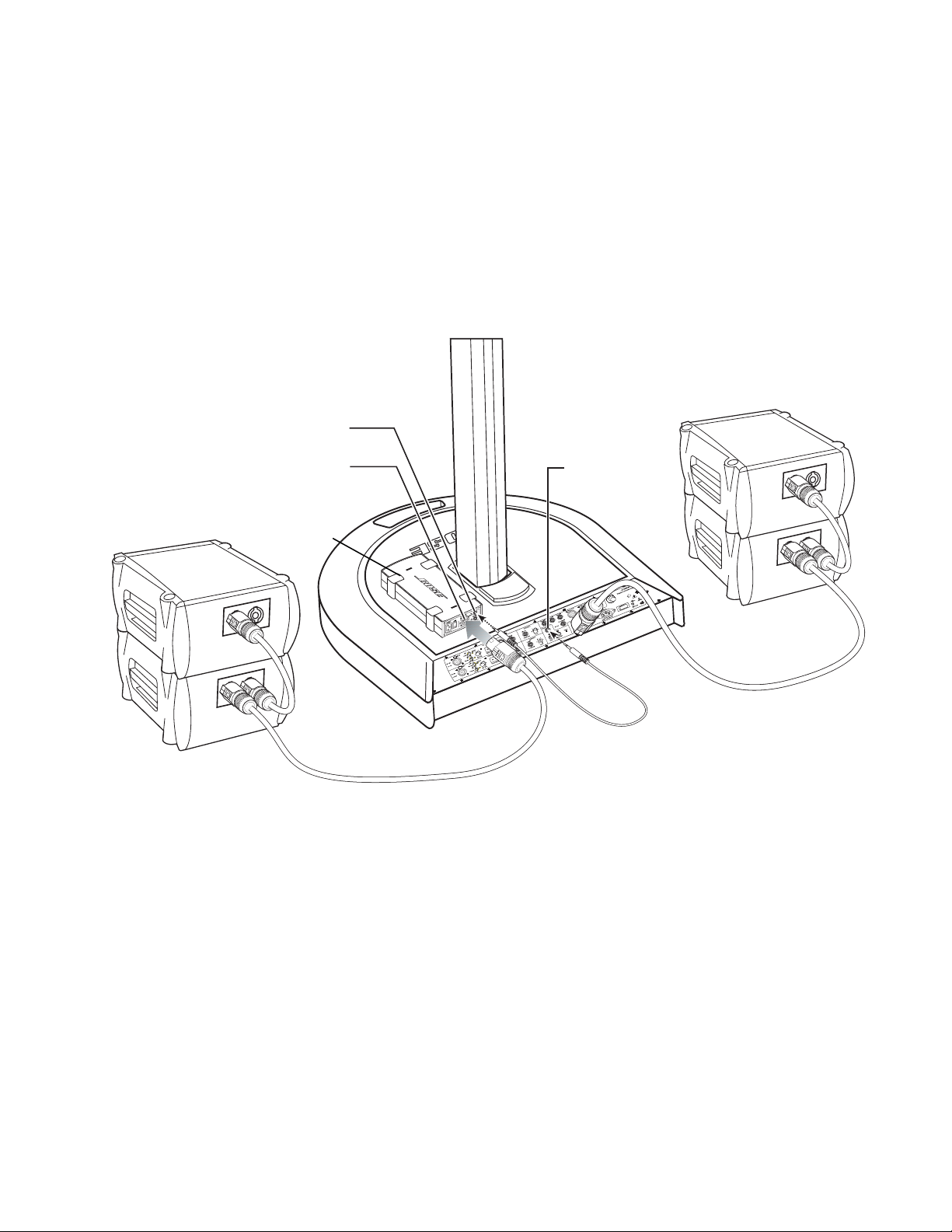

Using Multiple A1 Amplifiers

To add more bass capability to your system, you can connect multiple A1 amplifiers as shown

below.

1. Connect the AC power cord to an AC (mains) outlet.

2. Make sure the Power switch is OFF.

3. Using the supplied ¼" TRS cable, connect the Bass-Line OUT connector on the PS1 power

stand to the INPUT connector on the first A1 amplifier.

4. Using another ¼" TRS cable, connect the THRU connector on the first A1 amplifier to the

INPUT connector of the next A1 amplifier.

5. Connect a B1 bass module to the OUTPUT connector on each A1 amplifier. If desired,

connect a second B1 to the first B1.

6. Set power switch on both A1 amplifiers to ON (I).

B1 bass

modules

2nd

A1

1st

A1

B1 bass

modules

B1 bass

modules

PS1 power stand

CAUTION: Be careful not to connect the A1 amplifier to a B1 bass module that is already

connected to the Amp 3 OUT connector of a PS1 power stand or to another A1 amplifier.

Note: Up to four (maximum) B1 bass modules can be stacked in a column. Stacking may

improve acoustic output.

6

Page 7

Using the A1 in other applications

The A1 amplifier can be used as a power amplifier in other system configurations.

The A1 can drive other passive loudspeakers including subwoofers, floor monitors, studio

monitors, and guitar cabinets. The A1 can amplify a balanced or unbalanced signal from a linelevel device, such as a mixing console, and drive any loudspeaker load (4-ohm minimum) that is

capable of handling 250W.

Setting up the A1 for use with other systems:

1. Make sure the A1 amplifier Power switch is OFF.

2. Connect a line-level output connector from your source device to the INPUT connector of the

A1 amplifier.

• This could be the line-level output from an electronic crossover, mixing console, electric

bass/electric guitar amplifier head unit, preamp, digital modeler, or studio console line

output.

• You can use either a balanced (TRS) or unbalanced (TS) connection. The amplifier will sense

the type of connection and automatically adjust the overall level.

3. Connect the OUTPUT of the A1 amplifier to:

• Any 4-ohm loudspeaker load capable of handling at least 250 watts RMS.

• Any 8-ohm loudspeaker load capable of handling at least 125 watts RMS.

4. If you want to add an additional A1 for more bass, connect the THRU connector of the first A1

to the INPUT connector of another A1 amplifier using a ¼" TRS cable.

5. Set the A1 power switch to ON (I).

6. Adjust the source level so that the A1 signal indicator flashes green. At a maximum source

level, the A1 signal indicator occasionally flashes red. If the indicator is constantly red,

reduce the source level.

Note: Using the A1 amplifier and its connected B1 bass modules with any source device other

than the PS1 power stand is not recommended.

7

Page 8

Specifications

Electrical

Power, 4-ohm load: 250 watts RMS (1 kHz, 0.1% THD)

Power, 8-ohm load: 125 watts RMS (1 kHz, 0.1% THD)

Minimum loudspeaker load: 4 Ohms

Signal to noise: 100 dB (20 Hz to 20 kHz)

Voltage gain: 30 dB

Input sensitivity: 1.15 V (+3.4 dBu)

Input sensing: Automatic, balanced/unbalanced level adjust

Input impedance: 55k ohms unbalanced, 110k ohms balanced

Input clipping: 10 Vrms (+22 dBu)

Frequency response: 20 Hz to 20 kHz ± 0.5 dB

THRU output type: Balanced/unbalanced, dependent on

INPUT connection type

Output circuitry: Class D

Protection types: Self-resetting thermal, output short circuit,

and over-current

Typical AC power requirements: 1.8A, 120VAC; 0.9A, 220-240VAC

Peak inrush current: 28A (120VAC)

Mechanical

Dimensions: 5.6" W x 2.3" H x 10.3" D;

140 mm W x 56 mm H x 258 mm D

Weight: 3.0 lbs (1.4 kg)

Packaged Shipping Weight: 5.0 lbs (2.3 kg)

Max. operating temperature: 122°F (50°C)

8

Page 9

PRODUCTION NOTES

The PackLiteTM A1 amplifier has been manufactured in two versions, a 120V version (product

code 039057) and a 220-240V version (product code 039058).

The early 120V units, serial numbers 039057Z52620201AC to 039057Z52621200AC, are nonRoHS compliant units. 120V units built after the 5262 Julian date (9/19/2005) are fully RoHS

compliant.

The 220-240V version, product code 039058, is fully RoHS compliant from the initial production

units onward.

The Electrical Parts Lists have non-RoHS and RoHS compliant part numbers in cases where

these parts are different for the two versions of the amplifier. Be sure to use ONLY RoHS compliant repair parts in RoHS compliant products.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

9

Page 10

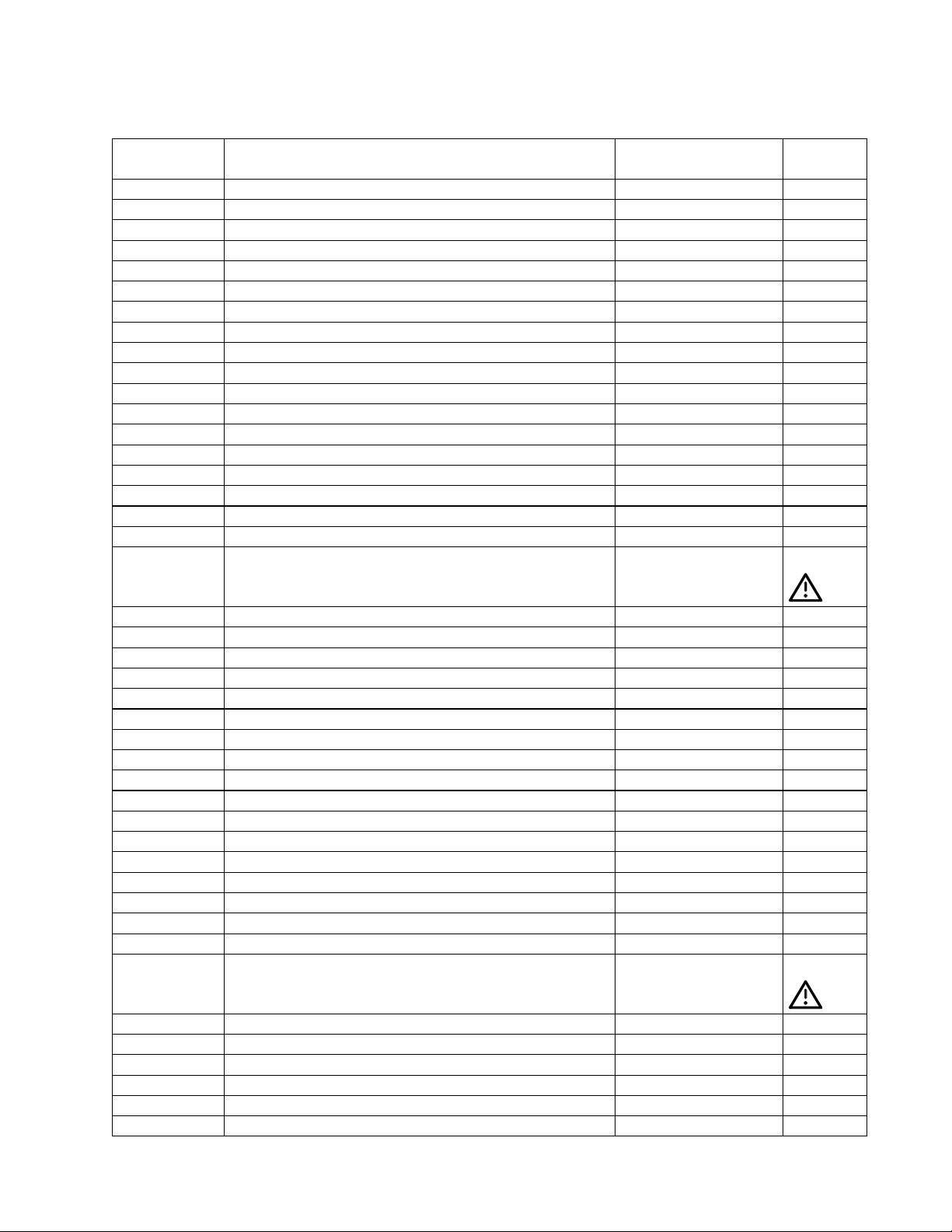

PACKAGING PART LIST

PackLiteTM A1 Amplifier Assembly (see Figure 1)

Item

Number

Description Bose® Part

Number

Vendor Part

Number

Qty. Note

1 Filler, Sheet, 295x168x6, A=B 291589 1450-8830+0 1

2 Owners Manual 287546 4301-7207+0 1

3 Sheet, Warranty / Welcome 287553 3050-3681 1

4 Carry Bag, Nylon 280x150x70 287554 4201-1000+1 1

5 PackLite Amplifier Assembly REF - 1

6 Filler, Lower, 292x167x46 291588 1450-8840+1 1

7 Power Cord, 120V (US/Canada) 263453 - 1 3

Power Cord, L=2.5M, 230V (Europe) 173352 7012-6980+0

Power Cord, 240V (Australia) 264357 -

8 Filler, Upper, 292x167x81 291587 1450-8850+1 1

9 Cable Assy, 1/4" to 1/4", TRS, Stereo

287556 7012-7130+0 1

Signal Input, L=500mm

10 Carton, Single, 4 Color Printed 287550 1480-8201+0 1

11 Carton, Master, 527x304x264mm - 1437-6401+0-2 -

- PE BAG, 8.5x14x0.05 - 1497-4412+0 1

- PE BAG 350x120x0.05 (MIC Cable) - 1497-7762+0 1

- PE BAG 350x120x0.05 (AC Cord) - 1497-7762+0 1

- PE BAG 250x140x0.05 (Manual) - 1497-7772+0 1

- Sheet, Notice - 3050-3701+0 1

INDIVIDUAL AMPS

IN GIFT BOXES

11

1

2

3

4

PE BAGS

5

6

7

8

9

10

Figure 1. PackLite

SKU LABELS (6 UNITS IN

ONE MASTER CARTON)

TM

A1 Amplifier Assembly Packaging View

10

Page 11

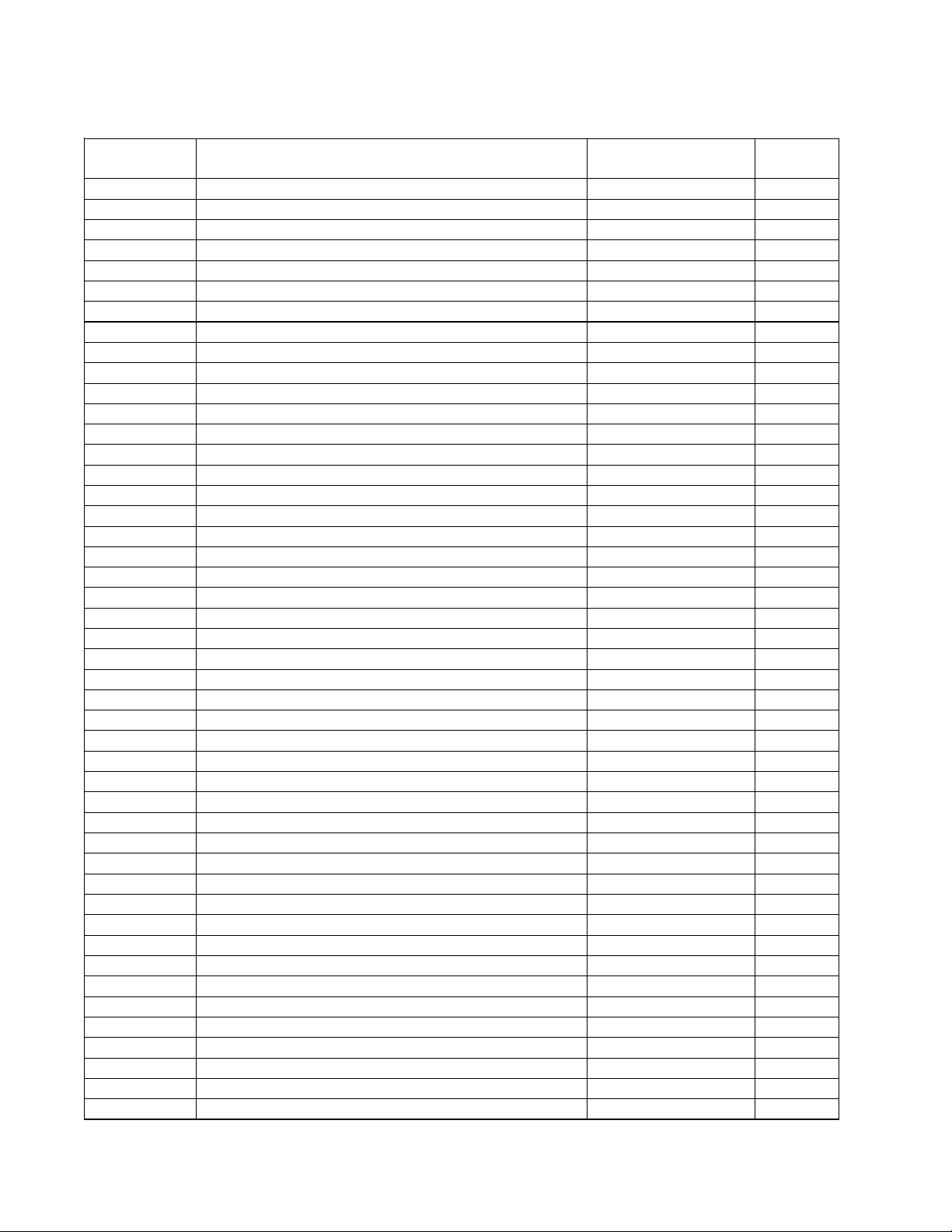

MAIN PART LIST

PackLiteTM A1 Amplifier Assembly (see Figure 2)

Item

Number

1 HOUSING, CHASSIS, UPPER,

ALUM, 266x140x28mm

2 INPUT SIGNAL AND LIMITING LED

PCB ASSY,

(PART OF INPUT/LIMITER PCB)

3 BOSE LOGO, ALUM, 40x9.8x1.3mm 288677 2150-7161+0 1

4 FRONT GRILLE, PERFORATED

STEEL, 124x48x0.8mm

5 FAN, DC, 12V, 40x40x10mm 291332 8913-0002+0 1 3

6 FOOT, RUBBER, MOLDED, BLK,

54x26x12mm

7 HEAT TRANSFER PAD, MICA

SHEET, 103x43x0.2mm

8 SMPS/AMPLIFIER PCB ASSEMBLY

(120V Units only)

SMPS/AMPLIFIER PCB ASSEMBLY

(220-240V Units only)

9 INPUT/LIMITER PCB ASSEMBLY 287555 SVC-BS90C11-

10 HOUSING, CHASSIS, LOWER,

ALUM, 266x140x28mm

11 WASHER, SPRING, M3X0.9X5.5, YZ,

(AMP/PS PCB)

12 SCREW, CHASSIS - 2944-3012-3000 4 4

13 LABEL, SAFETY, 120V Units

LABEL, SAFETY, 220-240V Units

14 PC SHEET 1, INSULATING,

128X80X8, T=0.5

15 CONN, NEUTRIK, SPEAKON,

NL4MD-V, (J 117, J118, J119)

16 SWITCH, AC POWER, SPST, TV5,

10A, 250V (120V UNITS)

SWITCH, AC POWER, SPST, 10A,

250V, TV-5 (220-240V UNITS)

17 IEC INLET, AC, 3P, 250V, 15A - 2113-3135+0 1 3

18 I/O PANEL, REAR, BLK, SECC,

123x48x1.2mm

19 POWER AND FAULT LED PCB

ASSEMBLY (PART OF INPUT

/LIMITER PCB)

20 LENS, LED - 3717-2506+0 2

21 PC SHEET 2, INSULATING, UPPER

CHASSIS, 80X65X0.43

- WIRE-CONN 4P P3.96 #18 UL1015

L=200 F (POWER AND FAULT LED

PCB)

- WIRE-CONN 3P P7.92/11.88 #18

UL1015 L=170 F (SIGNAL AND

LIMITING LED PCB)

Description Bose® Part

Number

- 1405-6801+0 1 4

- PCB-

288675 1405-6901+0 1

288673 4157-0981+0 4

291331 3100-6751+1 1

283302 SVC-BS90C11-

291337 SVC-BS90C21-

- 1405-6601+0 1 4

- 2607-3009+0550 4 4

- 3001-0899+0

- 4155-1771+0 1 4

275446 2113-1336+1 1 3

291333 5200-4926 1 3

291335 5200-4926+0

288674 1405-7001+0 1 3

- PCB-

- 4155-1781+0 1 4

- 7012-7042+0 1 4

- 7012-7150+0 1 4

Vendor Part

Number

BS91C21+LED2

AMP

AMP

INP

3001-0900+0

BS91C21+LED1

Qty. Note

1 2, 4

1 2, 3

1 2

1 3

2 2, 4

11

Page 12

Figure 2. PackLite

TM

A1 Amplifier Exploded View

12

Page 13

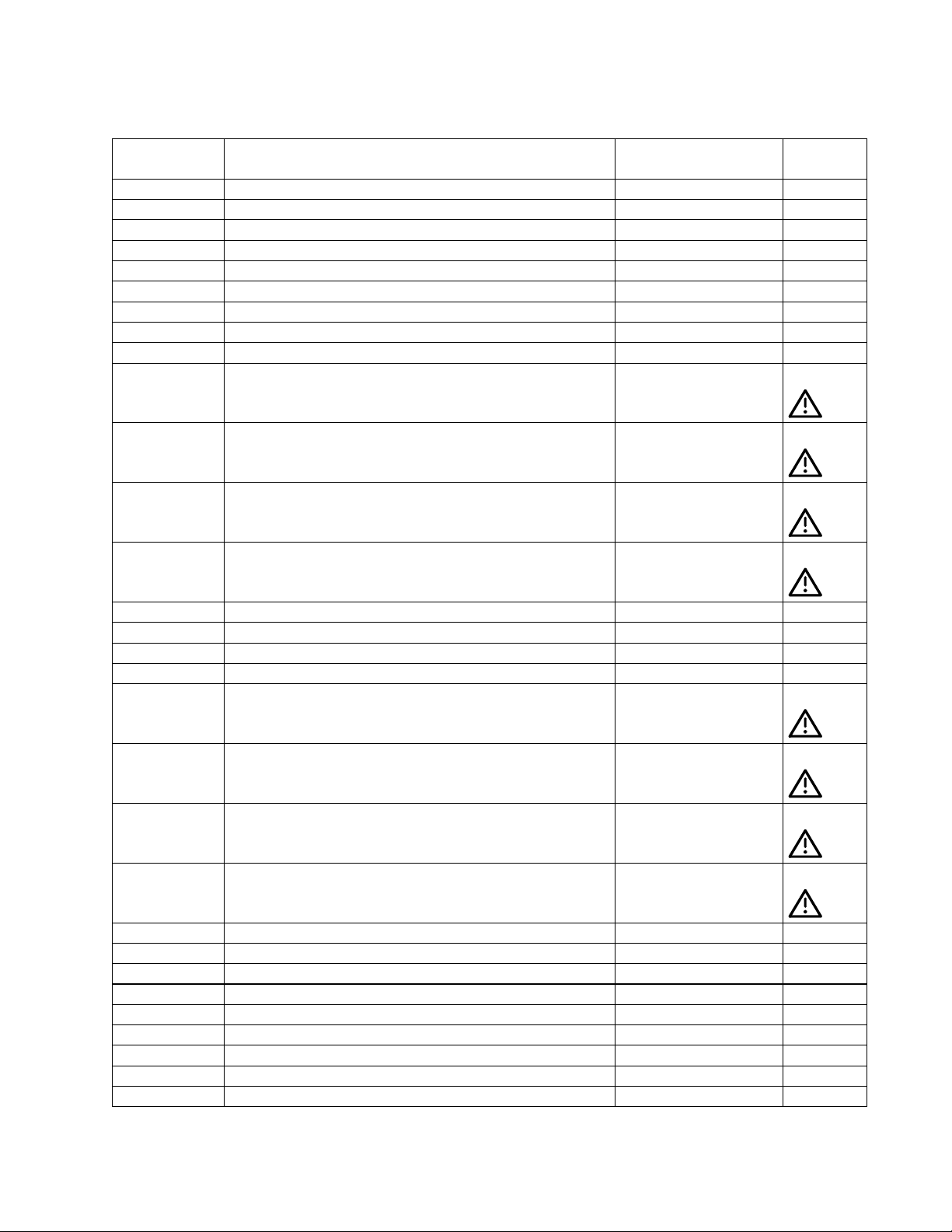

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Resistors

Reference

Designator

R1 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R3 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R4 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A-P 4

R5 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R6 4.7K, RMG, 0603/1608, 1/16W, 1% 4723-472A-P 4

R7 16K, RMG, 0805, 1/10W, 1% 4720-163A-J 4

R8 12K, RMG, 1206, 1/4W, 1% 4725-123A+6 4

R9 9.1K, RMG, 0805, 1/10W, 1% 4720-912A-J 4

R10 9.1K, RMG, 0805, 1/10W, 1% 4720-912A-J 4

R11 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R12 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R13 1M, RMG, 0603/1608, 1/16W, 5% 4723-105J-P 4

R14 1M, RMG, 0603/1608, 1/16W, 5% 4723-105J-P 4

R15 1.5K, RMG, 0603/1608, 1/16W, 1% 4723-152A-P 4

R16 0 OHM, RMG, 0805, 1/10W, 5% 4720-000J+J 4

R17 8.2K, RMG, 0603/1608, 1/16W, 5% 4723-822J+P 4

R18 6.8K, RMG, 0603/1608, 1/16W, 1% 4723-682A-P 4

R19 9.1K, RMG, 0805, 1/10W, 1% 4720-912A-J 4

R20 4.7 OHM, RWR, 5W, 5%, RL 474B-4R7J+5 3, 4

R21 64.9K, RMG, 0603, 1/16W, 1% 4723-6492+P 4

R22 0 OHM, RMG, 0805, 1/10W, 5% 4720-000J+J 4

R23 9.1K, RMG, 0805, 1/10W, 1% 4720-912A-J 4

R24 3.3K, RMG, 0603/1608, 1/16W, 1% 4723-332A-P 4

R25 3.3K, RMG, 0603/1608, 1/16W, 1% 4723-332A-P 4

R26 64.9K, RMG, 0603, 1/16W, 1% 4723-6492+P 4

R27 4.7K, RMG, 0603/1608, 1/16W, 1% 4723-472A-P 4

R28 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R29 12K, RMG, 1206, 1/4W, 1% 4725-123A+6 4

R30 16K, RMG, 0805, 1/10W, 1% 4720-163A-J 4

R31 1.5K, RMG, 0603/1608, 1/16W, 1% 4723-152A-P 4

R32 8.2K, RMG, 0603/1608, 1/16W, 5% 4723-822J+P 4

R34 10 OHM, RMG, 1206, 1/4W, 5% 4725-100J-6 4

R35 10 OHM, RMG, 1206, 1/4W, 5% 4725-100J-6 4

R36 0 OHM, RMG, 0603/1608, 1/16W, 5% 4723-000J-P 4

R38 10 OHM, RMG, 0805, 1/10W, 1% 4720-100A+J 4

R39 10 OHM, RMG, 0805, 1/10W, 1% 4720-100A+J 4

R41 4.7 OHM, RWR, 5W, 5%, RL 474B-4R7J+5 3, 4

R44 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A-P 4

R45 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R46 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R47 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R48 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R49 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

Description Vendor Part

Number

Note

13

Page 14

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Resistors (continued)

Reference

Designator

R50 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R51 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R52 1.8K, RMG, 0603/1608, 1/16W, 1% 4723-182A-P 4

R53 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R54 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R55 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R56 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R57 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R58 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R59 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R60 1.8K, RMG, 0603/1608, 1/16W, 1% 4723-182A-P 4

R61 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R62 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R63 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R64 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R65 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R66 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R67 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R68 560 OHM, RMG, 0603, 1/16W, 1% 4723-561A-P 4

R69 2.7K, RMG, 0603/1608, 1/16W, 1% 4723-272A+P 4

R70 2.7K, RMG, 0603/1608, 1/16W, 1% 4723-272A+P 4

R71 2.7K, RMG, 0603/1608, 1/16W, 1% 4723-272A+P 4

R72 2.7K, RMG, 0603/1608, 1/16W, 1% 4723-272A+P 4

R75 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R76 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R77 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R78 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R79 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R80 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R81 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R83 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R84 560 OHM, RMG, 0603, 1/16W, 1% 4723-561A-P 4

R85 560 OHM, RMG, 0603, 1/16W, 1% 4723-561A-P 4

R86 560 OHM, RMG, 0603, 1/16W, 1% 4723-561A-P 4

R87 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R88 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R89 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R90 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R91 2.2 OHM, RMG, 0603/1608, 1/16W, 5% 4723-2R2J-P 4

R92 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R93 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R94 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R95 2.2K, RMG, 0603/1608, 1/16W, 1% 4723-222A-P 4

R100 100K, RMG, 0805, 1/10W, 1% 4720-104A-J 4

R101 100K, RMG, 0805, 1/10W, 1% 4720-104A-J 4

R102 820K, RMG, 0805, 1/10W, 5% 4720-824J-J 4

Description Vendor Part

Number

Note

14

Page 15

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Resistors (continued)

Reference

Designator

R103 820K, RMG, 0805, 1/10W, 5% 4720-824J-J 4

R104 820K, RMG, 0805, 1/10W, 5% 4720-824J-J 4

R105 82K, RMG, 0805, 1/10W, 5% 4720-823J-J 4

R106 82K, RMG, 0805, 1/10W, 5% 4720-823J-J 4

R200 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A-P 4

R202 1.5K, RMG, 0603/1608, 1/16W, 1% 4723-152A-P 4

R203 470 OHM, RMG, 0603/1608, 1/16W, 5% 4723-471J-P 4

R204 22 OHM, RMG, 0805, 1/10W, 5% 4720-220J-J 4

R205 22 OHM, RMG, 0805, 1/10W, 5% 4720-220J-J 4

R206 0.15 OHM, 1206, RMG, 1/4W, 5%

(NON-ROHS UNITS)

R206 0.12 OHM, RMG, 1206, 1/4W, 5%

(ROHS COMPLIANT UNITS)

R207 0.15 OHM, 1206, RMG, 1/4W, 5%

(NON-ROHS UNITS)

R207 0.12 OHM, RMG, 1206, 1/4W, 5%

(ROHS COMPLIANT UNITS)

R208 47K, RMG, 0805, 1/10W, 5% 4720-473J-J 4

R209 47K, RMG, 0805, 1/10W, 5% 4720-473J-J 4

R210 47K, RMG, 0805, 1/10W, 5% 4720-473J-J 4

R212 100 OHM, RMG, 0805, 1/10W, 5% 4720-101J-J 4

R213 0.15 OHM, 1206, RMG, 1/4W, 5%

(NON-ROHS UNITS)

R213 0.12 OHM, RMG, 1206, 1/4W, 5%

(ROHS COMPLIANT UNITS)

R214 0.15 OHM, 1206, RMG, 1/4W, 5%

(NON-ROHS UNITS)

R214 0.12 OHM, RMG, 1206, 1/4W, 5%

(ROHS COMPLIANT UNITS)

R215 47K, RMG, 0805, 1/10W, 5% 4720-473J-J 4

R217 470 OHM, RMG, 0603/1608, 1/16W, 5% 4723-471J-P 4

R218 10 OHM, RMG, 0805, 1/10W, 1% 4720-100J+J 4

R219 10 OHM, RMG, 0805, 1/10W, 1% 4720-100J+J 4

R222 1 OHM, RMG, 0603, 1/16W, 5% 4723-1R0J-P 4

R223 1 OHM, RMG, 0603, 1/16W, 5% 4723-1R0J-P 4

R230 10 OHM, RMG, 0805, 1/10W, 1% 4720-100A+J 4

R231 10 OHM, RMG, 0805, 1/10W, 1% 4720-100A+J 4

R232 36K, RMG, 0603, 1/16W, 1% 4723-363A+P 4

Description Vendor Part

Number

4725-R15J+6 3, 4

4725-R12J+6 3, 4

4725-R15J+6 3, 4

4725-R12J+6 3, 4

4725-R15J+6 3, 4

4725-R12J+6 3, 4

4725-R15J+6 3, 4

4725-R12J+6 3, 4

Note

15

Page 16

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Resistors (continued)

Reference

Designator

R233 36K, RMG, 0603, 1/16W, 1% 4723-363A+P 4

R234 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A-P 4

R236 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A-P 4

R238 36K, RMG, 0603, 1/16W, 1% 4723-363A+P 4

R239 36K, RMG, 0603, 1/16W, 1% 4723-363A+P 4

R240 47K, RMG, 0603/1608, 1/16W, 1% 4723-473A-P 4

R241 36K, RMG, 0603, 1/16W, 1% 4723-363A+P 4

R242 5.1K, RMG, 0603/1608, 1/16W, 1% 4723-512A+P 4

R243 5.1K, RMG, 0603/1608, 1/16W, 1% 4723-512A+P 4

R290 100K, RMG, 0603, 1/16W, 1% 4723-104A-P 4

R291 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R300 10K, RMG, 1206, 1/8W, 5% 4721-103J+6 4

Reference

Designator

C1 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C2 0.47uF, CC, 0805/2012, 16V, 10%, 1.5X2.5 150D-474K+J-BDL 4

C3 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C4 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C5 2700pF, CC, 0805, 50V, 10%, 1.2X2.0 150F-272K+J-BD 4

C6 47pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-470J-P-AC 4

C7 330pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-331J+P-AC 4

C8 0.22uF, CC, 0805, 16V 10%, 1.2X2.0 150D-224K+J-BD 4

C9 220pF, CTC, 1206, 0/30, 100V, 5% 15CG-221J+6-CFH 4

C10 3300pF, CC, 0805, 50V, 10%, 1.2x2.0 150F-332K-J-BD 4

C11 680pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-681J+J-BD 4

C12 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C13 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C14 4.7uF, CC, 1206, Y5V, 16V, +80/-20% 150D-475Z+6-CF 4

C15 0.47uF, CM, 100V, 10%, RB, 7.5X8 153H-474K+9-NO 4

C16 0.33uF, CM, 100V, 5%, RBT, 7.5X9.5, MKS2,

WIMA

C17 3300pF, CC, 0805, 50V, 10%, 1.2x2.0 150F-332K-J-BD 4

C18 2700pF, CC, 0805, 50V, 10%, 1.2X2.0 150F-272K+J-BD 4

C19 680pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-681J+J-BD 4

C20 0.22uF, CC, 0805, 16V 10%, 1.2X2.0 150D-224K+J-BD 4

C21 4.7uF, CC, 1206, Y5V, 16V, +80/-20% 150D-475Z+6-CF 4

C22 0.47uF, CM, 100V, 10%, RB, 7.5X8 153H-474K+9-NO 4

C23 220pF, CTC, 1206, 0/30, 100V, 5% 15CG-221J+6-CFH 4

C24 0.33uF, CM, 100V, 5%, RBT, 7.5X9.5, MKS2,

WIMA

C25 2200pF, CC, 0603, 50V, 10%, 0.8x1.6 150F-222K+P-AC 4

C26 2200pF, CC, 0603, 50V, 10%, 0.8x1.6 150F-222K+P-AC 4

C27 47pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-470J-P-AC 4

C28 330pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-331J+P-AC 4

C29 0.47uF, CC, 0805/2012, 16V, 10%, 1.5X2.5 150D-474K+J-BDL 4

Description Vendor Part

Number

Capacitors

Description Vendor Part

Number

153H-334J+V-NRU 4

153H-334J+V-NRU 4

16

Note

Note

Page 17

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Capacitors (continued)

Reference

Designator

C31 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA 150F-225K+6-CFM 4

C32 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA 150F-225K+6-CFM 4

C33 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C33 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C34 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C34 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C35 0.01uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-103M-J-BD 4

C36 0.01uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-103M-J-BD 4

C37 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA 150F-225K+6-CFM 4

C38 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C38 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C39 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C39 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C40 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C40 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C43 2200uF, 105C, CE, RL, 50V, 20%, 22X25

(NON-ROHS UNITS)

C43 2200uF, CE, 50V, 105C, 20%, RL, 18X31

(ROHS COMPLIANT UNITS)

C44 2200uF, 105C, CE, RL, 50V, 20%, 22X25

(NON-ROHS UNITS)

C44 2200uF, CE, 50V, 105C, 20%, RL, 18X31

(ROHS COMPLIANT UNITS)

C45 220pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-221J+P-AC 4

C46 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C47 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C48 2.2uF, CM, 50V, 5%, 10X8, METALLIZED 153F-225J+K-SOM 4

C49 2.2uF, CM, 50V, 5%, 10X8, METALLIZED 153F-225J+K-SOM 4

C51 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C52 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C53 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C54 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C56 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C57 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C58 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C59 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

Description Vendor Part

Number

150F-105K+6-CFM 4

150F-225K+6-CFM 4

150F-105K+6-CFM 4

150F-225K+6-CFM 4

150F-105K+6-CFM 4

150F-225K+6-CFM 4

150F-105K+6-CFM 4

150F-225K+6-CFM 4

150F-105K+6-CFM 4

150F-225K+6-CFM 4

157F-228M+5-+&T 4

157F-228M+5-7$T 4

157F-228M+5-+&T 4

157F-228M+5-7$T 4

Note

17

Page 18

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Capacitors (continued)

Reference

Designator

C60 220pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-221J+P-AC 4

C61 220pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-221J+P-AC 4

C62 220pF, CTC, 0603, 0/60, 5%, 0.8X1.6 15CH-221J+P-AC 4

C63 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C68 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K-P-AC 4

C100 0.33uF, CM, 300V, 10%, RB, 18X15.5X10 1511-334K+9-03Z 3, 4

C103 0.015uF, CC, 1206, X7R, 630V, 10% 150M-153K+6-CF 4

C104 0.015uF, CC, 1206, X7R, 630V, 10% 150M-153K+6-CF 4

C105 0.015uF, CC, 1206, X7R, 630V, 10% 150M-153K+6-CF 4

C106 0.015uF, CC, 1206, X7R, 630V, 10% 150M-153K+6-CF 4

C107 680uF, CE, 200V, 105C, 20%, RL, 25X35 157U-687M+5-&^T 4

C108 680uF, CE, 200V, 105C, 20%, RL, 25X35 157U-687M+5-&^T 4

C109 1000pF, CC, 400V, 20%, RL, 9X6 150T-102M+5-QK 3, 4

C110 1000pF, CC, 400V, 20%, RL, 9X6 150T-102M+5-QK 3, 4

C111 2200pF, CC, 400V, 20%, RL, 10X6 150T-222M+5-SK 3, 4

C112 0.33uF, CM, 300V, 10%, RB, 18X15.5X10 1511-334K+9-03Z 3, 4

C200 680pF, CTC, 0603, 0/60, 5% 15CH-681J+P-AC 4

C201 0.22uF, CC, 0805, 16V 10%, 1.2X2.0 150D-224K+J-BD 4

C202 0.47uF, CM, 400VDC, 5%, RB, 18X17.5X9 1511-474J+9-0T 4

C203 0.47uF, CM, 400VDC, 5%, RB, 18X17.5X9 1511-474J+9-0T 4

C204 1uF, CC, 0805, 25V, 10% 150E-105K+J-BD 4

C205 1uF, CC, 0805, 25V, 10% 150E-105K+J-BD 4

C206 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C206 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C207 1uF, 1206, X7R, CC, 50V, 10%, MURATA

(NON-ROHS UNITS)

C207 2.2uF, CC, 1206, 50V, 10%, X7R, MURATA

(ROHS COMPLIANT UNITS)

C208 1uF, CC, 1206, X7R, 50V, 10%, MURATA 150F-105K+6-CFM 4

C210 470pF, CC, 2211, 250VAC, 10%, 2.8X5.7 150R-471K+Y-EKZ 3, 4

C211 1uF, CC, 1206, X7R, 50V, 10%, MURATA 150F-105K+6-CFM 4

Description Vendor Part

Number

150F-105K+6-CFM 4

150F-225K+6-CFM 4

150F-105K+6-CFM 4

150F-225K+6-CFM 4

Note

18

Page 19

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Capacitors (continued)

Reference

Designator

C212 470pF, CC, 2211, 250VAC, 10%, 2.8X5.7 150R-471K+Y-EKZ 3, 4

C213 470pF, CC, 2211, 250VAC, 10%, 2.8X5.7 150R-471K+Y-EKZ 3, 4

C214 100pF, CC, 0603/1608, 50V, 5%, 1X2 150F-101J-P-AC 4

C215 100pF, CC, 0603/1608, 50V, 5%, 1X2 150F-101J-P-AC 4

C216 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C217 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J-J-BD 4

C218 470pF, CC, 2211, 250VAC, 10%, 2.8X5.7 150R-471K+Y-EKZ 3, 4

C219 1uF, CC, 1206, X7R, 50V, 10%, MURATA 150F-105K+6-CFM 4

C220 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C221 1uF, CC, 0603, 10V, +80/-20% 150C-105Z-P-AC 4

C222 470uF, CE, 35V, 105C, 20%, RL, 10X20 157Q-477M+5-S9T 4

C223 470uF, CE, 35V, 105C, 20%, RL, 10X20 157Q-477M+5-S9T 4

C226 0.15uF, CC, 0805, 50V, 10% 150F-154K+J-BD 4

C227 0.15uF, CC, 0805, 50V, 10% 150F-154K+J-BD 4

C300 0.01uF, CC, 1206, 50V, 10%, 1.6x3.2 150F-103K-6-CF 4

Description Vendor Part

Number

Inductors

Note

Reference

Designator

L1 CHOKE, COIL, 10uH, 10%, 7A, T94-2 1806-3899+0 4

L3 CHOKE, COIL, 10uH, 10%, 7A, T94-2 1806-3899+0 4

L6 FERRITE BEAD INDUCTOR, BL01RN1A1F1J 1808-0680-0 4

L7 FERRITE BEAD INDUCTOR, BL01RN1A1F1J 1808-0680-0 4

L8 CHOKE, COMMON MODE, 2X16uH, 8A, FT50-

43

L100 CHOKE, COMMON MODE, 3A, 2X15MH, TC-

2510 (NON-ROHS UNITS)

L100 CHOKE, COMMON MODE, 2X10mH, 3A, TC-

2510 (ROHS COMPLIANT UNITS)

L101 CHOKE, COMMON MODE, 2X10mH, 3A, TC-

2510

L200 INDUCTOR, 10uH, 500MA, SMD, 1210 1803-0092+0 4

L201 INDUCTOR, 10uH, 500MA, SMD, 1210 1803-0092+0 4

Description Vendor Part

Number

1806-3913+0 4

1806-3901+1 3, 4

1806-3934+0 3, 4

1806-3934+0 3, 4

Note

19

Page 20

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Diodes

Reference

Designator

D1 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D2 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D3 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D4 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D5 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D6 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D7 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D8 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D9 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D10 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D14 BAS321, 200V, 250MA, 50NS, SOD323 480S-3210+3 4

D100 BRIDGE, GBU8J, 600V, 8A, RL

(NON-ROHS UNITS)

D100 DIODE BRIDGE, 800V, 8A, GBU8K, RL

(ROHS COMPLIANT UNITS)

D200 US1J, 600V, 1A, 75NS, SOD124 480U-S1J0+3 4

D201 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D202 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D203 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D204 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D205 12CWQ10FNTRBF, RECTIFIER, 100V, 12A,

DPAK, SMDIR

D206 12CWQ10FNTRBF, RECTIFIER, 100V, 12A,

DPAK, SMDIR

D207 12CWQ10FNTRBF, RECTIFIER, 100V, 12A,

DPAK, SMDIR

D208 12CWQ10FNTRBF, RECTIFIER, 100V, 12A,

DPAK, SMDIR

D209 RS1D, RECTIFIER, 200V, 1A, SOD124 4840-9212+3 4

D210 RS1D, RECTIFIER, 200V, 1A, SOD124 4840-9212+3 4

D211 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D212 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D216 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D217 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D218 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

D290 BAS216, 75V, 250MA, 4NS, SOD110 480S-2160+3 4

Z200 ZENER, 15V, 0.4W, BZX284-B15 4840-9230+0 4

Z201 ZENER, BZX284-C11@115, 11V, 1/2W, DZ,

SOD110

Description Vendor Part

Number

4840-9211+5 3, 4

4840-9218+5 3, 4

4840-9213+3 4

4840-9213+3 4

4840-9213+3 4

4840-9213+3 4

4837-1109+3 4

Note

20

Page 21

ELECTRICAL PART LIST

Reference

Description Vendor Part

Note

Reference

Description Vendor Part

Note

Power Supply / Amplifier PCB Assembly

Transistors

Designator

Q1 FDD368, MOSFET, N-CHANNEL, 2_NL, 100V,

32A, TO-252AA (Bose

Q2 FDD368, MOSFET, N-CHANNEL, 2_NL, 100V,

32A, TO-252AA (Bose part number 291330)

Q3 FDD368, MOSFET, N-CHANNEL, 2_NL, 100V,

32A, TO-252AA (Bose part number 291330)

Q4 FDD368, MOSFET, N-CHANNEL, 2_NL, 100V,

32A, TO-252AA (Bose part number 291330)

Q5 BC856S, PNP PAIR, 60V, SOT363 4858-56S0+3 4

Q6 BC856S, PNP PAIR, 60V, SOT363 4858-56S0+3 4

Q200 STB12NM50FD, MOSFET, N-CHANNEL,

D2PAK (Bose part number 291329)

Q201 STB12NM50FD, MOSFET, N-CHANNEL,

D2PAK (Bose part number 291329)

Q202 REGULATOR, 5V, LM78L05ACM, SO-8 3131-3390+0 4

Q203 BCP56-10, NPN, SOT223 485C-P560+3 4

Q204 REGULATOR, 250MA, LM79L05, SO8 3132-3091+0 4

Q205 FFB2227A, NPN/PNP PAIR, SC70-6 4852-27A0+3 4

Q206 FFB2227A, NPN/PNP PAIR, SC70-6 4852-27A0+3 4

Q207 BC856S, PNP PAIR, 60V, SOT363 4858-56S0+3 4

Q208 2N7002MTF, MOSFET, N-CHANNEL, SOT-23 4902-MTF0- 3 4

Q209 2N7002MTF, MOSFET, N-CHANNEL, SOT-23 4902-MTF0- 3 4

Q210 BC856S, PNP PAIR, 60V, SOT363 4858-56S0+3 4

Q211 BC846B, SOT23, PHILIPS, SMD 4858-46B0+3 4

Q290 PUMZ1, NPN/PNP PAIR, SOT363 485U-MZ10+3 4

®

part number 291330)

Number

4903-6820+3

4903-6820+3

4903-6820+3

4903-6820+3

4905-0FD0+3

4905-0FD0+3

Integrated Circuits

Designator

IC1 HALF BRIDGE DRIVER, LV4970M, SO-16 3132-3051+0 4

IC2 HALF BRIDGE DRIVER, LV4970M, SO-16 3132-3051+0 4

IC3 ANALOG 2CH CONTROLLER, LV4930M,

QUAD44

IC4 OP-AMP, MC33078DR2G, SO-8 3132-2711+0 4

IC200 HALF BRIDGE DRIVER, L6571BD013TR, SO8

(Bose part number 291328)

Number

3132-3061+0 4

3132-3071+0

21

Page 22

ELECTRICAL PART LIST

Power Supply / Amplifier PCB Assembly

Miscellaneous

Reference

Designator

F100 FUSE, T6.3A/125V, TE5-T, PSE/UL

(120V UNITS)

F100 FUSE, T3.15A, 250V, 8.5X8, VDE/UL/SEMKO,

TR5-T (220-240V UNITS)

F200 0 OHM, RMG, 1206, 1/8W, 1% 4721-000A+6 3, 4

MOV1 VARISTOR, 175V, SIOV-S05K175

(NON-ROHS UNITS)

MOV2 VARISTOR, 175V, SIOV-S05K175

(NON-ROHS UNITS)

MOV VARISTOR, 320V, 10%, SIOV-S10K320

(ROHS COMPLIANT UNITS)

N1 THERMISTOR, NTC, 100K, 5,% B5,

7620C0104J162, 0805, EPCOS

N100 NTC THERMISTOR, 5 0HM, 4A, NIOSP005L,

UL/CSA/VDE

N101 NTC THERMISTOR, 5 0HM, 4A, NIOSP005L,

UL/CSA/VDE

N200 THERMISTOR, PTC, 1K, 0805, 90 DEG, EPCOS 5202-0011+0 4

N201 THERMISTOR, PTC, 1K, 130 DEG, 0805,

EPCOS

S100 WJ, #23, 120/220-240V SELECTOR JUMPER.

(USED ON 120V UNITS ONLY)

S302 WJ, #23 635N-0001-0 4

TRAFO200 TRANSFORMER, SWITCHING, ETD29 1806-3898+0 3, 4

CON300 WAFER, 3P, P7.92/11.88, STRAIGHT 2101-3097+0 3, 4

CON301 WAFER, 4P, P3.96 (NON-ROHS UNITS) 2101-3053-0 4

CON301 WAFER, 4P, P3.96 (ROHS COMPLIANT UNITS) 2101-3053+0 4

J301 6 PIN, WF 2102-060S+003 4

J302 6 PIN, WF 2102-060S+003 4

J303 WAFER, 3P, P2.0, ST, MALE 2101-3008+0 4

JP1 WIRE JUMPER, ROLLER FORM, D=0.6MM

(ROHS COMPLIANT UNITS)

JP2 WIRE JUMPER, ROLLER FORM, D=0.6MM

(ROHS COMPLIANT UNITS)

Description Vendor Part

Number

5120-1094+0 3, 4

5120-0087+0 3, 4

4735-0002+0 3, 4

4735-0002+0 3, 4

4735-0003+0 3, 4

5202-0019+0 4

5202-0010+0 3, 4

5202-0010+0 3, 4

5202-0021+0 4

635N-0001-0 4

635N-0002+0 4

635N-0002+0 4

Note

22

Page 23

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Resistors

Reference

Designator

R301 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R302 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R303 24K, RMG, 0805, 1/10W, 5% 4720-243J+J 4

R304 100 OHM, RMG, 0805, 1/10W, 5% 4720-101J+J 4

R305 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R306 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R307 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R308 82K, RMG, 0805, 1/10W, 1% 4720-823A+J 4

R309 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R310 200K, RMG, 0805, 1/10W, 5% 4720-204J+J 4

R311 20K, RMG, 0805, 1/10W, 1% 4720-203A+J 4

R312 82K, RMG, 0805, 1/10W, 1% 4720-823A+J 4

R313 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R314 24K, RMG, 0805, 1/10W, 5% 4720-243J+J 4

R315 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R316 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R317 7.5K, RMG, 0805, 1/10W, 1% 4720-752A+J 4

R318 33K, RMG, 0805, 1/10W, 5% 4720-333J+J 4

R319 100K, RMG, 0805, 1/10W, 5% 4720-104J+J 4

R320 200K, RMG, 0805, 1/10W, 5% 4720-204J+J 4

R321 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R322 100 OHM, RMG, 0805, 1/10W, 5% 4720-101J+J 4

R323 22 OHM, RMG, 0805, 1/10W, 5% 4720-220J+J 4

R324 20K, RMG, 0805, 1/10W, 1% 4720-203J+J 4

R325 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R326 100K, RMG, 0805, 1/10W, 5% 4720-104J+J 4

R327 47K, RMG, 0805, 1/10W, 5% 4720-473J+J 4

R328 1K, RMG, 0805, 1/10W, 5% 4720-102J+J 4

R329 36K, RMG, 0805, 1/10W, 5% 4720-363J+J 4

R330 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R331 22 OHM, RMG, 0805, 1/10W, 5% 4720-220J+J 4

R333 750K, RMG, 0805, 1/10W, 5% 4720-754J+J 4

R334 510 OHM, RMG, 0805, 1/10W, 5% 4720-511J+J 4

R335 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R336 20K, RMG, 0805, 1/10W, 1% 4720-203J+J 4

R337 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R338 22K, RMG, 0805, 1/10W, 5% 4720-223J+J 4

R339 30K, RMG, 0805, 1/10W, 1% 4720-303J+J 4

R340 200K, RMG, 0805, 1/10W, 5% 4720-204J+J 4

R341 200K, RMG, 0805, 1/10W, 5% 4720-204J+J 4

R342 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R343 150K, RMG, 0805, 1/10W, 5% 4720-154J+J 4

R344 91K, RMG, 0805, 1/10W, 1% 4720-913A+J 4

R345 30K, RMG, 0805, 1/10W, 1% 4720-303J+J 4

R346 510 OHM, RMG, 0805, 1/10W, 5% 4720-511J+J 4

R347 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

Description Vendor Part

Number

Note

23

Page 24

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Resistors (continued)

Reference

Designator

R348 2.7K, RMG, 0805, 1/10W, 1% 4720-272A+J 4

R349 750K, RMG, 0805, 1/10W, 5% 4720-754J+J 4

R350 30K, RMG, 0805, 1/10W, 1% 4720-303A+J 4

R351 0 OHM, RMG, 0805, 1/10W, 5% 4720-000J+J 4

R352 51 OHM, RCF, 1/4W, 5%, AT 4705-510J+2 4

R355 5.1K, RMG, 0805, 1/10W, 5% 4720-512J+J 4

R356 2.2K, RMG, 0805, 1/10W, 1% 4720-222J+J 4

R360 100 OHM, RMG, 0805, 1/10W, 5% 4720-101J+J 4

R361 49.9K, RMG, 0805, 1/10W, 1% 4720-4992+J 4

R362 510 OHM, RMG, 0805, 1/10W, 5% 4720-511J+J 4

R363 510 OHM, RMG, 0805, 1/10W, 5% 4720-511J+J 4

R364 1K, RMG, 0805, 1/10W, 5% 4720-102J+J 4

R365 10K, RMG, 0805, 1/10W, 5% 4720-103J+J 4

R366 150K, RMG, 0805, 1/10W, 5% 4720-154J+J 4

R367 51 OHM, RCF, 1/4W, 5%, AT 4705-510J+2 4

R368 39K, RMG, 0805, 1/10W, 1% 4720-393A+J 4

R369 12K, RMG, 0805, 1/10W, 1% 4720-123A+J 4

R370 2.2K, RMG, 0805, 1/10W, 1% 4720-222A+J 4

R377 510K, RMG, 0805, 1/10W, 5% 4720-514J+J 4

R378 2.2K, RMG, 0805, 1/10W, 1% 4720-222A+J 4

R379 39K, RMG, 0805, 1/10W, 1%

(ROHS COMPLIANT UNITS)

Description Vendor Part

Number

4720-393A+J 4

Capacitors

Note

Reference

Designator

C301 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C302 27pF, CTC, 0805, 0/30, 5%, 1.2X2.5 15CG-270J+J-BD 4

C303 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C304 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C305 68pF, CC, 0805, 50V, 5%, 1.25X2.0, MURATA 150F-680J+J-BDM 4

C306 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C307 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C308 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C309 68pF, CC, 0805, 50V, 5%, 1.25X2.0, MURATA 150F-680J+J-BDM 4

C310 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C311 27pF, CTC, 0805, 0/30, 5%, 1.2X2.5 15CG-270J+J-BD 4

C312 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C313 47pF, CTC, 0805, 0/60, 5%, 1.2X2.5, 100V 15CH-470J+J-BD 4

C314 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C315 20pF, 0805, CTC, 0/30, 5%, 1.2x2.5

(NON-ROHS UNITS)

C315 22pF, CTC, 0805, 0/60, 5%, 1.2X2.5

(ROHS COMPLIANT UNITS)

C316 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C317 220pF, CC, 0805, 50V, 10%, 1.2x2.0 150F-221K+J-BD 4

C318 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

Description Vendor Part

Number

15CG-200J-J-BD 4

15CH-220J+J-BD 4

Note

24

Page 25

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Capacitors (continued)

Reference

Designator

C319 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C320 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C321 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C322 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C323 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C324 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C328 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C329 1.0pF, CTC, 0805, 0/30, 50V, 1.2X2.5 15CG-1R0C+J-

C330 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C331 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C332 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C333 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C334 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C335 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C336 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C337 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C338 1000pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-102J+J-BD 4

C343 2.2uF, CE, 50V, 20%, RLT, 4X7, ELNA 157F-225M+K-

C344 1uF, CC, 0805, 25V, 10% 150E-105K+J-BD 4

C345 1uF, CE, 50V, 20%, RLT, 4X7 157F-105M+K-GM 4

C346 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C347 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C350 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C352 0.1uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-104M+J-BD 4

C353 22uF, CE, 25V, 20%, RLT, 5X11 157E-226M+K-IU 4

C354 0.1uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-104M+J-BD 4

C355 22uF, CE, 25V, 20%, RLT, 5X11 157E-226M+K-IU 4

C356 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C357 0.1uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-104M+J-BD 4

C358 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C359 0.1uF, CC, 0805, 50V, 20%, 1.2x2.0 150F-104M+J-BD 4

C360 100pF, CTC, 0805, 0/30, 5%, 1.2x2.5 15CG-101J+J-BD 4

C361 10uF, CE, 50V, 20%, RLT, 4X7 157F-106M+K-GM 4

C362 0.47uF, CC, 0805, 25V, 20% 150E-474M+J-BD 4

C363 47uF, CE, 25V, 20%, RLT, 5X11, ELNA 157E-476M+K-IUE 4

C364 1000pF, 50V, 0805, CC, 10%, 1.2x2.0

(NON-ROHS UNITS)

C365 1000pF, 50V, 0805, CC, 10%, 1.2x2.0

(NON-ROHS UNITS)

C366 1000pF, 50V, 0805, CC, 10%, 1.2x2.0

(NON-ROHS UNITS)

C367 1000pF, 50V, 0805, CC, 10%, 1.2x2.0

(NON-ROHS UNITS)

C368 220uF, CE, 16V, 20%, RLT, 6.3X11, SC, SHOEI 157D-227M+K-LUI 4

C369 2.2uF, CE, 50V, 20%, RLT, 4X7, ELNA 157F-225M+K- 4

Description Vendor Part

Number

BDF

GMK

150F-102K-J-BD 4

150F-102K-J-BD 4

150F-102K-J-BD 4

150F-102K-J-BD 4

Note

4

4

25

Page 26

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Diodes

Reference

Designator

D301 1N4148T, AT 4804-1480+2 4

D302 1N4148T, AT 4804-1480+2 4

D303 1N4148T, AT 4804-1480+2 4

D304 1N4148T, AT 4804-1480+2 4

D305 1N4148, AT (NON-ROHS UNITS) 4804-1480-2 4

D305 ZENER, 12V, 1/2W, 5%, AT, TEMIC

(ROHS COMPLIANT UNITS)

D306 1N4148, AT (NON-ROHS UNITS) 4804-1480-2 4

D306 ZENER, 12V, 1/2W, 5%, AT, TEMIC

(ROHS COMPLIANT UNITS)

D307 ZENER, 5.1V, 1/2W, AT, TEMIC 4837-5V16+2 4

D308 SCHOTTKY, BAT42-T, DO-35, AT 480A-T420+2 4

D309 1N4148T, AT 4804-1480+2 4

D310 ZENER, 12V, 1/2W, 5%, AT, TEMIC 4837-1206+2 4

D319 ZENER, 3V, 1/2W, 5%, MMSZ4683T1, SOD-123 4837-3V09+3 4

D320 ZENER, 3V, 1/2W, 5%, MMSZ4683T1, SOD-123 4837-3V09+3 4

Reference

Designator

Q301 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q301 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q302 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q302 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q303 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q303 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q304 2N3906, RLT, TO92, PHILIPS

(NON-ROHS UNITS)

Q304 2N3906, RLT, TO92, PHILIPS

(ROHS COMPLIANT UNITS)

Q305 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q305 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q306 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q306 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q307 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q307 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q308 2N3906, RLT, TO92, PHILIPS

(NON-ROHS UNITS)

Q308 2N3906, RLT, TO92, PHILIPS

(ROHS COMPLIANT UNITS)

Q309 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q309 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q310 2N3906, RLT, TO92, PHILIPS

(NON-ROHS UNITS)

Q310 2N3906, RLT, TO92, PHILIPS

(ROHS COMPLIANT UNITS)

Description Vendor Part

Number

4837-1206+2 4

4837-1206+2 4

Transistors

Description Vendor Part

Number

4860-2390-K 4

4860-2390+K 4

4860-2390-K 4

4860-2390+K 4

4860-2390-K 4

4860-2390-K 4

Note

Note

26

Page 27

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Transistors (continued)

Reference

Designator

Q311 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q311 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q312 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q312 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Q313 2N3904, RLT (NON-ROHS UNITS) 4853-9040-K 4

Q313 2N3904TA, RLT (ROHS COMPLIANT UNITS) 4853-9040+K 4

Reference

Designator

U301 OP-AMP, NJM2068M, JRC (NON-ROHS UNITS) 3130-6890-0 4

U301 NJM2068M-#ZZZB, DUAL OP AMP

(ROHS COMPLIANT UNITS)

U302 OP-AMP, NJM2068M, JRC (NON-ROHS UNITS) 3130-6890-0 4

U302 NJM2068M-#ZZZB, DUAL OP AMP

(ROHS COMPLIANT UNITS)

U303 OP-AMP, NJM2068M, JRC (NON-ROHS UNITS) 3130-6890-0 4

U303 NJM2068M-#ZZZB, DUAL OP AMP

(ROHS COMPLIANT UNITS)

U304 LM311M, VOLTAGE COMPARATOR 3130-9240+0 4

U305 LM13700M, TRANSCONDUCTANCE AMP 3132-1981+0 4

U306 OP-AMP, NJM2068M, JRC (NON-ROHS UNITS) 3130-6890-0 4

U306 NJM2068M-#ZZZB, DUAL OP AMP

(ROHS COMPLIANT UNITS)

U310 L7815CV, REGULATOR, ST 3130-3030+0 4

U311 REGULATOR, -15V, 0.1A, 79L15, TO-92 3132-3041+0 4

Description Vendor Part

Number

Integrated Circuits

Description Vendor Part

Number

3130-6890+0 4

3130-6890+0 4

3130-6890+0 4

3130-6890+0 4

Miscellaneous

Note

Note

Reference

Designator

N300 THERMISTOR, NTC, 22K, 5%,

NCP21XW223J03, 0805, MURATA

J1 PHONE JACK, ST, 6.35MM 2113-1955+0 4

J2 PHONE JACK, ST, 6.35MM 2113-1955+0 4

CN101 WIRE-CONN, 6P, P2.0, #26, UL1007, L=150,

F/M

CN102 WIRE-CONN, 6P, P2.0, #26, UL1007, L=150,

F/M

CN103 WIRE-CONN, 3P, P2.0, #26, UL1007, L=50, F/M 7012-7061+0 4

CN104 WIRE-CONN, 4P, P2.0, #26, UL1007, L=160,

F/M

CN105 WIRE-CONN, 3P, P2.0, #26, UL1007, L=120,

F/M

CN106 WAFER, 2P, P2.0, RA, MALE 2101-3012+0 4

JP1 WIRE JUMPER, ROLLER FORM, D=0.6MM

(ROHS COMPLIANT UNITS)

Description Vendor Part

Number

5202-0022+0 3, 4

7012-7063+0 4

7012-7063+0 4

7012-7062+0 4

7012-7061+1 4

635N-0002+0 4

Note

27

Page 28

ELECTRICAL PART LIST

Input / Limiter PCB Assembly

Miscellaneous (continued)

Reference

Designator

JP2 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP3 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP4 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP5 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP6 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP7 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP8 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP9 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP10 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP11 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP12 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP13 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP14 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP15 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP16 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP17 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP18 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP19 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP20 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP21 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP22 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP23 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP24 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP25 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP26 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP28 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP29 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP30 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP31 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP32 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP34 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP35 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP36 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

JP37 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

Description Vendor Part

Number

Note

28

Page 29

ELECTRICAL PART LIST

Signal LED PCB Assembly

Diodes

Reference

Designator

D315 LOW CURRENT LED, SMD, RED, 2mA, 3700-7829+R 4

D316 LOW CURRENT LED, SMD, RED, 2mA, 3700-7829+R 4

D317 LED, OS, GN, LOW CURRENT, 525NM, 0603 3700-7834+G 4

D318 LED, OS, GN, LOW CURRENT, 525NM, 0603 3700-7834+G 4

Reference

Designator

CN205 CONN, 3 PIN, P2.0, ST, 25056457, 2002P0300T

(NON-ROHS UNITS)

CN205 PLUG NPLG-3P350 25055367

(ROHS COMPLIANT UNITS)

Description Vendor Part

Number

Miscellaneous

Description Vendor Part

Number

2101-3008-0 4

2101-1516+0 4

Note

Note

Power / Fault LED PCB Assembly

Diodes

Reference

Designator

D311 LOW CURRENT SMD LED, RED, 2mA 3700-7829+R 4

D312 LOW CURRENT SMD LED, RED, 2mA 3700-7829+R 4

D313 LOW CURRENT SMD LED, BLUE 3700-7830+B 4

D314 LOW CURRENT SMD LED, BLUE 3700-7830+B 4

Description Vendor Part

Number

Miscellaneous

Note

Reference

Designator

CN204 WAFER, 4P, P2.0, STRAIGHT 2102-040S+003 4

Description Vendor Part

Number

Note

29

Page 30

DISASSEMBLY PROCEDURES

The PackLiteTM A1 amplifier is housed in a

die-cast metal chassis. It is held together in

a clam-shell type configuration using four

screws.

Note: Refer to the photos at right or Figure 2

for the following information.

1. Top Chassis Housing Removal

1.1 Place the unit, top cover down, onto a

soft surface.

1.2 Using a Phillips-head screwdriver,

remove the four screws (12) that hold the

upper (1) and lower (10) chassis housings

together.

1.3 Turn the unit back over and carefully lift

the top chassis housing straight up.

Re-assembly Note: When re-installing the

top chassis housing, be sure that all four

rubber feet (6) are aligned with the grooves

in the upper chassis housing.

2. Input / Limiter PCB Assembly Removal

2.1 Perform procedure 1.

2.2 Using a pair of diagonal cutters, cut the

three wire ties that secure the various wire

harnesses to the input / limiter PCB (9).

2.3 Unplug the input / limiter PCB wiring

harnesses from the power supply / amplifier

PCB (8) at J301, J302 and J303.

2.4 Unplug the wiring harnesses at the two

LED PCBs (2 & 19) that are mounted in the

top housing.

2.5 Unplug the fan (5) wiring harness at

CN106.

2.6 Using a 1/2” nut driver, remove the nuts

that secure the INPUT and THRU 1/4” TRS

jacks to the rear panel.

2.7 Lift up the back corner of the input /

limiter PCB assembly and slide it away from

the rear panel. Lift out the PCB assembly.

30

Page 31

DISASSEMBLY PROCEDURES

3. Power Supply / Amplifier PCB Assembly

Removal

3.1 Perform procedure 1.

3.2 Unplug the input / limiter PCB (9) wiring

harnesses from the power supply / amplifier

PCB (8) at J301, J302 and J303.

3.3 Unplug the wiring harnesses at CON300

and CON301 on the power supply / amplifier

PCB assembly.

3.4 Using a Phillips-head screwdriver,

remove the eight screws that secure the

power supply / amplifier PCB assembly to

the lower housing (10). Lift the PCB assembly out of the lower housing.

Re-assembly Notes:

1. Be sure to retain the washers and lock

washers located under seven of the screws

for use during re-assembly.

2. The silver colored screw located near

C223 is used for grounding the PCB assembly to the lower housing. Be sure to use only

the silver colored star washer under it to

ensure a good ground connection.

3. Note the location of the thermal sil-pad (7)

under the power supply / amplifier PCB

assembly. Be sure it is in the proper location

when re-installing the PCB assembly. See

the photo at right.

4. Fan Removal

4.1 Perform procedure 1.

4.2 Unplug the fan assembly (5) wiring

harness at CN106 on the input / limiter PCB

assembly (9).

4.3 Lift the fan assembly out of the upper

housing.

Re-assembly Note: Be sure to note the

orientation of the fan when removing it from

the housing. It will need to be replaced

facing the same direction to ensure that the

outside air is pulled into the amplifier during

operation.

31

Page 32

DISASSEMBLY PROCEDURES

5. LED PCB Removal

5.1 Perform procedure 1.

5.2 Unplug the wiring harness from the input

/ limiter PCB (9) for the LED PCB (2 or 19)

that you wish to remove. These harnesses

unplug from the connector at the LED PCB

end of the harness.

5.3 Using a small Phillips-head screwdriver,

remove the two screws that secure the LED

PCB to the upper housing. Lift the PCB off of

the LED lens (20).

Re-assembly Notes:

1. Be sure to align the light pipe with the

upper housing and to align the LED PCB

with the four tabs on the LED lens.

2. Make a note of the direction that the LED

PCB mounts to the upper housing. If you reinstall it backward, the LED harness will

interfere with the power supply caps during

re-assembly.

6. Rear Panel Removal

6.1 Perform procedure 1.

6.2 Unplug the AC wiring harness from the

power supply / amplifier PCB (8) at CON300.

6.3 Using a Phillips-head screwdriver,

remove the screw that secures the AC wiring

harness ground lug to the lower chassis

housing. Retain the screw and washer for

re-use.

32

Page 33

DISASSEMBLY PROCEDURES

6.4 Unplug the audio output wiring harness

from the power supply / amplifier PCB (8) at

CON301.

6.5. Using a small Phillips-head screwdriver,

remove the one screw that secures the rear

panel (18) to the lower chassis housing (10).

Lift out the rear panel.

7. Front Panel Removal

7.1 Perform procedure 1.

7.2 Lift out the front panel (4).

Re-assembly Note: Be sure to align the

front panel so that the Bose® logo is facing

the correct direction.

Test Procedures

Required Equipment:

• dB meter

• Audio Signal Generator w/balanced output

• Distortion meter

• 4 Ohm, 250 Watt load resistor

• Digital Multimeter

• 4 Ohm full range speaker

• 1/4” TRS 600 Ohm test plug (see page 41)

• 1/4” TRS balanced input cable

• 1/4” TS unbalanced input cable

• Amplifier output test cable (see page 41)

Test Setup Notes:

1. Make measurements on the output using

an 80 kHz Low Pass Filter.

2. Remove the input signal after tests with

high levels to avoid overheating the amplifier

and load.

3. There are 120V and 220-240V versions of

this product. The voltage version is indicated

on the amplifier’s product label.

1. DC Offset Test

1.3 Measure the DC voltage across the load.

It should be less than +/- 30 mV.

2. Gain and Signal LED Balanced

Input Test

2.1 Connect the signal generator to either of

the A1 input jacks with a balanced, 1/4” TRS

cable.

2.2 Connect the output of the A1 to the 4

Ohm load.

2.3 Power on the unit

2.4 Apply a 1 kHz, -10 dBV (Tip to Ring)

signal to the input.

2.5 Reference a dB meter (80 kHz LPF) to

the input level. Measure the gain output at

the load. It should be +24.0 +4.0 dB.

3. Gain and Signal LED Unbalanced

Input Test

1.1 Connect the output of the A1 to the 4

Ohm load.

1.2 Power on the unit, with no input signal

present.

3.1 Connect the signal generator to either

of the A1 input jacks with an unbalanced,

1/4” Tip-Sleeve (TS) cable

33

Page 34

TEST PROCEDURES

3.2 Connect the output of the A1 to the

4 Ohm load resistor.

3.3 Power on the unit.

3.4 Apply a 1 kHz, -10 dBV (T to S) signal to

the input.

3.5 Reference a dB meter to the input level.

Measure the gain output at the load.

It should be +30.0 +4.0 dB.

4. Signal LED Test

4.1 Confirm that the green signal LED is on.

4.2 Lower the input signal to less than -25

dBV. Confirm that the green LED turns off.

4.3 Raise the input signal to over 1 dBV.

The LED should turn red.

Caution: Remove the input signal after this

test to avoid overheating the amplifier and

load.

6. Signal to Noise Test

6.1 Remove the signal generator and insert

a TRS test plug with a 600 Ohm termination

between tip and ring. See page 37.

6.2 Measure the output voltage across the

load resistor. It should read less than -60 dB

A-weighted, (referenced to 1 Volt).

7. Power / Fault LED Test

7.1 Connect the output of the A1 to the 4

Ohm load resistor.

7.2 Power on the unit.

7.3 Confirm that the blue LED comes on.

7.4 Apply a 1 kHz, -10 dBV (T to R) signal to

the input.

7.5 Short the loudspeaker output jack

(plus + to minus -).

5. Frequency Response & Distortion

5.1 Connect the signal generator to either

of the A1 input jacks with an unbalanced,

1/4” TS cable.

5.2 Connect the output of the A1 to the

4 Ohm load resistor.

5.3 Power on the unit.

5.4 Apply a 1 kHz, -10 dBV (T to S) signal to

the input.

5.5 Reference a dB meter to the input level.

Measure the frequency response at the load.

It should be 0.0 dB + 1.0 dB from 20 Hz to

20 kHz.

5.6 Measure the Total Harmonic Distortion

(THD) at the load. It should be less than

0.1% (0.02% typical) at 1 kHz.

7.6 Confirm that the blue power LED

changes to red. It will briefly change back

to blue every second or so as long as the

short is maintained.

7.7 Remove the short and power down the

unit.

8. Listening Test

8.1 Connect a line-level audio source (such

as a CD player) to the input jack.

8.2 Connect the output to a 4 Ohm fullrange speaker.

8.3 The audio output should sound clean

and undistorted.

8.4 Raise the input level until the green

signal LED turns red occasionally. The

audio output should still sound clean, although some limiting may be heard.

34

Page 35

Figure 3. Amplifier/SMPS PCB (Non-RoHS)

Topside Etch Layout

Figure 4. Amplifier/SMPS PCB (Non-RoHS)

Internal Etch Layer 1 Layout

35

Page 36

Figure 5. Amplifier/SMPS PCB (Non-RoHS)

Internal Etch Layer 2 Layout

Figure 6. Amplifier/SMPS PCB (Non-RoHS)

Bottom Etch Layout

36

Page 37

Figure 7. Amplifier/SMPS PCB (RoHS)

Topside Etch Layout

Figure 8. Amplifier/SMPS PCB (RoHS)

Internal Etch Layer 1 Layout

37

Page 38

Figure 9. Amplifier/SMPS PCB (RoHS)

Internal Etch Layer 2 Layout

Figure 10. Amplifier/SMPS PCB (RoHS)

Bottom Etch Layout

38

Page 39

Figure 11. Input/Limiter PCB (Non-RoHS) Top

Side Etch Layout

Figure 12. Input/Limiter PCB (Non-RoHS)

Bottom Side Etch Layout

39

Page 40

Figure 13. Input/Limiter PCB (RoHS)

Top Side Etch Layout

Figure 14. Input/Limiter PCB (RoHS)

Bottom Side Etch Layout

40

Page 41

Figure 15. Power/Fault LED PCB Etch Layout

Test Cable Wiring Diagrams

Twisted-pair wiring

4 Ohm, 250 Watt

load resistor

Neutrik

Speakon

R

R

4-pole plug

2-

1+

1-

2+

Figure 16. Signal/Overload LED PCB

Etch Layout

600 OHM, 1/4 WATT

RESISTOR CONNECTED

BETWEEN TIP AND RING

TIP RING SLEEVE

Part List

• Neutrik Speakon NL4FX connector

• 2 feet (1/2m) of 18 AWG twisted-pair

stranded wire.

• 4 Ohm, 250 Watt load resistor

Part List

• Tip-Ring-Sleeve (TRS) 1/4” male plug

• 600 Ohm, 1/4 Watt resistor

41

Page 42

Troubleshooting

Problem What to do

Power LED is not

lit; the amplifier

does not seem to

operate.

Power LED is

RED, not BLUE.

Signal LED is

flashing RED.

No audio, signal

LED is GREEN.

No audio, signal

LED not lit.

A hum or buzz can

be heard from the

loudspeaker.

• Be sure power switch is ON.

• Make sure the power cord is fully inserted into the unit and an AC outlet.

• Be sure the AC outlet is live. Try operating a lamp or other equipment

from the same AC outlet or test the outlet using an AC outlet tester.

• Amplifier is in the Protect mode:

– Thermal overload: Lower the level of the input signal. Be sure the

amplifier is on a hard, flat surface to aid in heat dissipation.

– Output is short-circuited: Check output connections/wires.

– Driving too many speakers in parallel: Make sure you connected no more

than two B1 bass modules to one A1 amplifier.

– Impedance is too low: Make sure you connected only one 4-ohm or up to

two 8-ohm speakers of other brands.

– Input level is too high: Lower the level of the input signal.

• The red light should no longer illuminate when a fault condition is

removed. In the case of thermal overload, the amplifier

may have to cool for a few minutes.

• The input signal is near limit. Lower the input level so the red

light flashes only occasionally, at peak volumes.

• Speaker not connected properly. Check that output connections

are correct and connectors are fully seated.

• Power not connected. Check the power LED. It will shine BLUE when

power is connected and the unit is turned on.

• No signal going into the amplifier. Check input connections and input

level.

• Replace input cable.

• If you are using a ¼" TS (unbalanced) cable, use a ¼" TRS cable

(supplied with the A1 amplifier) between the source device and the A1

amplifier.

• Plug the power cord of the PS1 or source device into the same AC

(mains) power circuit as the A1.

42

Page 43

THEORY OF OPERATION

PackLite™ Model A1 Amplifier

1. General Overview

The Personalized Amplification System™ family of products currently consists of the PS1 power

stand, the L1 Cylindrical Radiator

can power up to two B1 bass modules. This is sufficient for most instruments with the exception

of some applications of bass guitar, drums (kick drum) and some types of recorded music

playback. For these types of instruments, an attractive solution is to provide an additional power

amplifier that can power two additional bass modules, and can be “daisy-chained” to power

additional modules. The A1 PackLite power amplifier is designed primarily for this application,

but also has the features required to be applicable as a general purpose power amplifier, specifically, input limiting and signal/clip LED indication.

The amplifier contains a line level input, a pass-through line-level output, and a switching power

amplifier optimized for a 4 ohm load. In its normal use, the amplifier drives one or two (8 ohm)

B1 bass modules. There are 120 and 230V versions for sale in the US and Europe/Australia.

2. Amplifier PCB Architecture

Note: Refer to the Amplifier Block Diagram, sheet 1 of 1 for the following. The information

inside the brackets [ ] is the schematic grid location on the sheet.

The amplifier comprises two PCB’s, a Switch Mode Power Supply (SMPS)/Amplifier PCB and

an Input/Limiter PCB. The SMPS/Amplifier PCB filters the AC mains power, converts it to the

DC voltages required by the audio amplifier and the input/limiter PCB, and provides a switching

audio amplifier with 30 dB of gain.

®

loudspeaker and the B1 bass module. The PS1 power stand

The block diagram shows the amplifier board PCB architecture. The amplifier uses a three-wire,

grounded AC power configuration, with the cast aluminum chassis connected to earth ground.

Connectors

The amp pcb has connectors for AC power (con300) [C1], line-level audio in (J301) [C4],

speaker out (con301) [D4], control signals (J302) [B/C4], and DC voltage output (J303) [B4].

Switches

S301 [A3] is a DC bypass option for the ground connection, left open in production for best EMC

performance. S302 [A1] was a design option to allow a second grounding point on the board,

left closed in production for best EMC performance.

3. AC Power Input Filter Section

Note: Refer to the SMPS/Amplifier PCB Schematic Diagram, sheet 1 of 3 for the following.

L100, L101, C100, C109, C110, C111, and C112 [all located at B/C2] provide filtering to keep