Bosch MX30E Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 20 Ver la página 38

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

MX30E

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 1

-2-

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any ad apter p lugs w ith ea r thed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e common sense when operatin g a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in the off -position before

connecting to power source and / or battery

pa ck, picking up o r carrying the tool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unex pected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

can not be contr olled with the switch is

dangerous and must be repaired.

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

!

WARNING

General Power Tool Safety Warnings

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 2

-3-

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

s

tarting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Man y a ccide nts are cau s ed by poor l y

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

rep air per son usi ng only identi cal

replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety Rules for Oscillating Tools

Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a "live"

wire will make exposed metal parts of the tool

"live" and shock the operator.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Use a metal detector to determine if there

are gas or water pipes hidden in the work

area or call the local utility company for

assistance before beginning the operation.

Striking or cutting into a gas line will result in

explosion. Water entering an electrical device

may cause electrocution.

Always hold the tool firmly with both hands

for maximum control. Keep proper footing

and balance at all times. This enables better

control of t he powe r tool in un expe cted

situations.

Keep hands away from cutting area. Do

not reach under the material being cut. The

proximity of the blade to your hand is hidden

from your sight.

Do not use dull or damaged blades. Bent

blade can break easily or cause kickback.

Exercise extreme caution when handling

the accessories. The accessories are very

sharp.

Wear protective gloves when changing

cutting accessories. Accessories become

hot after prolonged usage.

Use thick cushioned gloves and limit the

exposure time by taking frequent rest

periods. Vibration caused by the tool may be

harmful to the hands and arms.

Before scraping, check workpiece for nails.

If there are nails, either remove them or set

them well below intended finished surface.

Striking a nail with accessory edge could

cause the tool to jump.

Do not wet sand with this tool. Liquids

entering the motor housing is an electrical

shock hazard.

Never work in area which is soaked with a

li quid , such as a s olve nt or water, or

dampened such as newl y app lied

wallpaper. There is an electrical shock

hazard when working in such conditions with a

power tool and heating of the liquid caused by

scraping action may cause harmful vapors to

be emitted from workpiece.

Always wear eye protection and a dust

mask for dusty applications and when

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 3

-4-

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool since in ternal wires may be

misplaced or pinched or safety guard return

sp rings may be imprope rly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Bosch Factory Service Center

or Autho rized Bosch Service Station.

Some dust created by power

sanding, sawing, grinding,

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

You r ri sk from t hese expos ures varies ,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Additional Safety Warnings

!

WARNING

sanding overhead. Sanding particles can be

absorbed by your eyes and inhaled easily

and may cause health complications.

Use special precautions when sanding

chemically pressure treated lumber, paint

that may be lead based, or a ny other

materials that may contain carcinogens. A

suitable breathing respirator and protective

clothing must be worn by all persons entering

the work area. Work area should be sealed by

plastic sheeting and persons not protected

should be kept out until work area is thoroughly

cleaned.

Do not use sandpaper intended for larger

sanding pads. Larger sandpaper will extend

beyond the sanding pad causing snagging,

tearing of the paper or kick-back. Extra paper

extending beyond the sanding pad can also

cause serious lacerations.

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 4

-5-

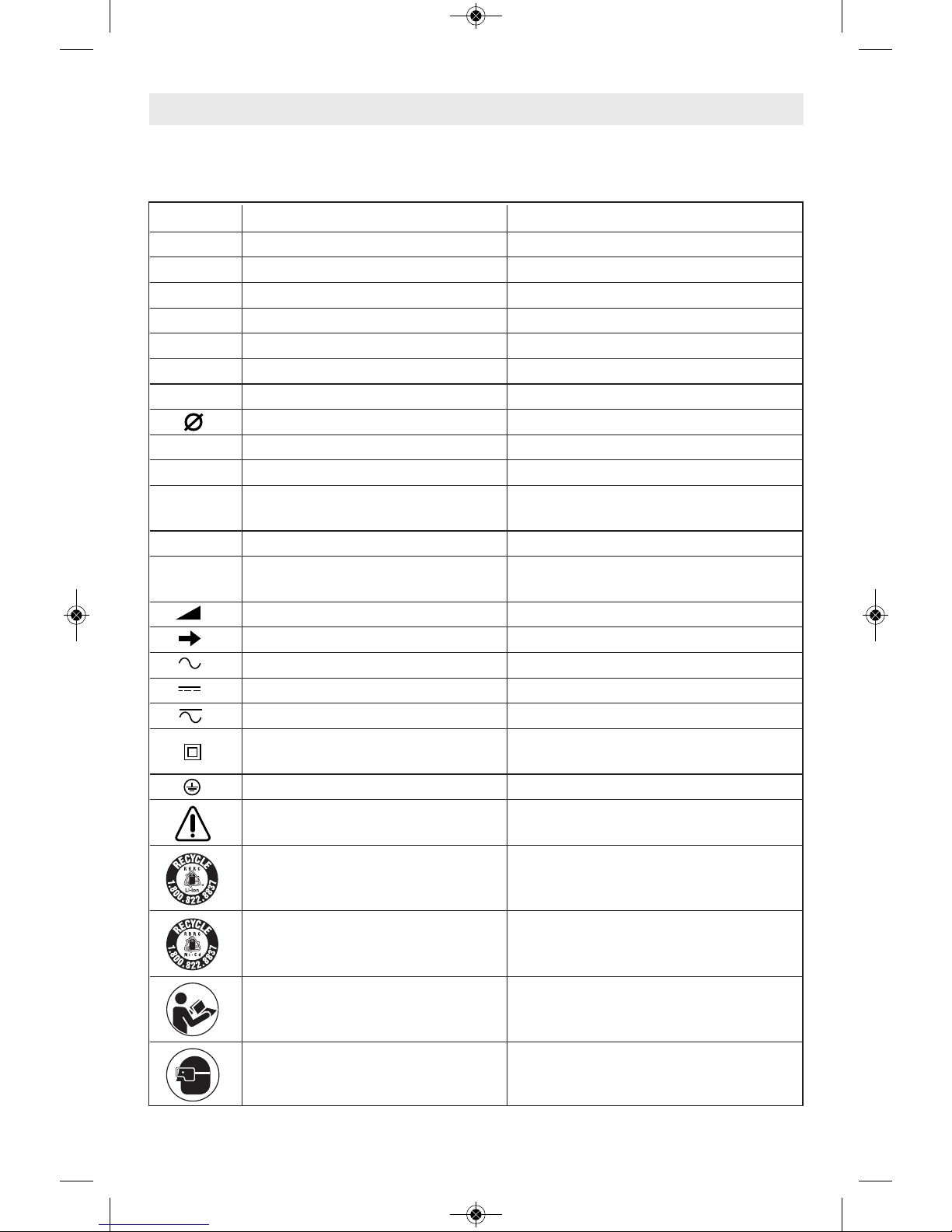

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

Symbols

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 5

-6-

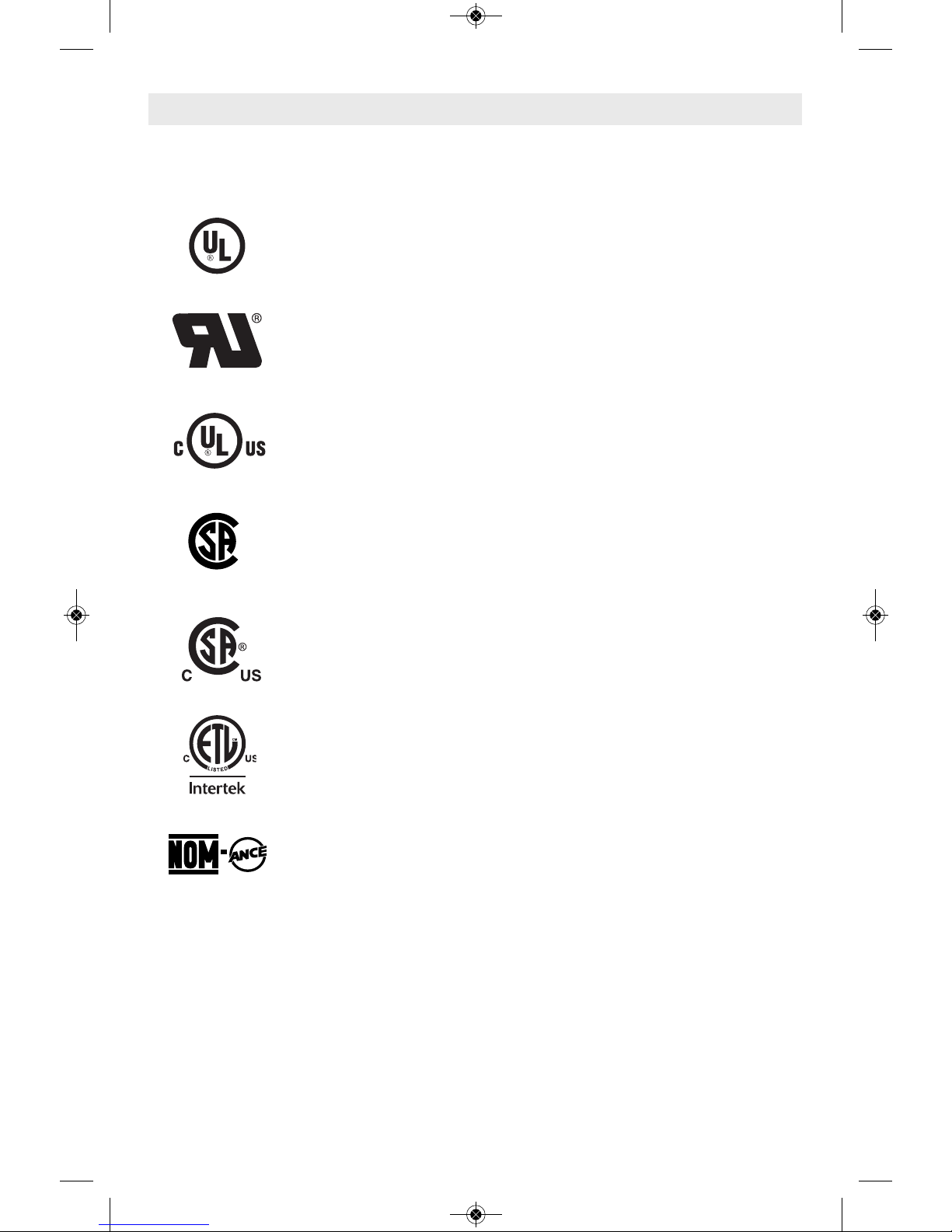

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 6

-7-

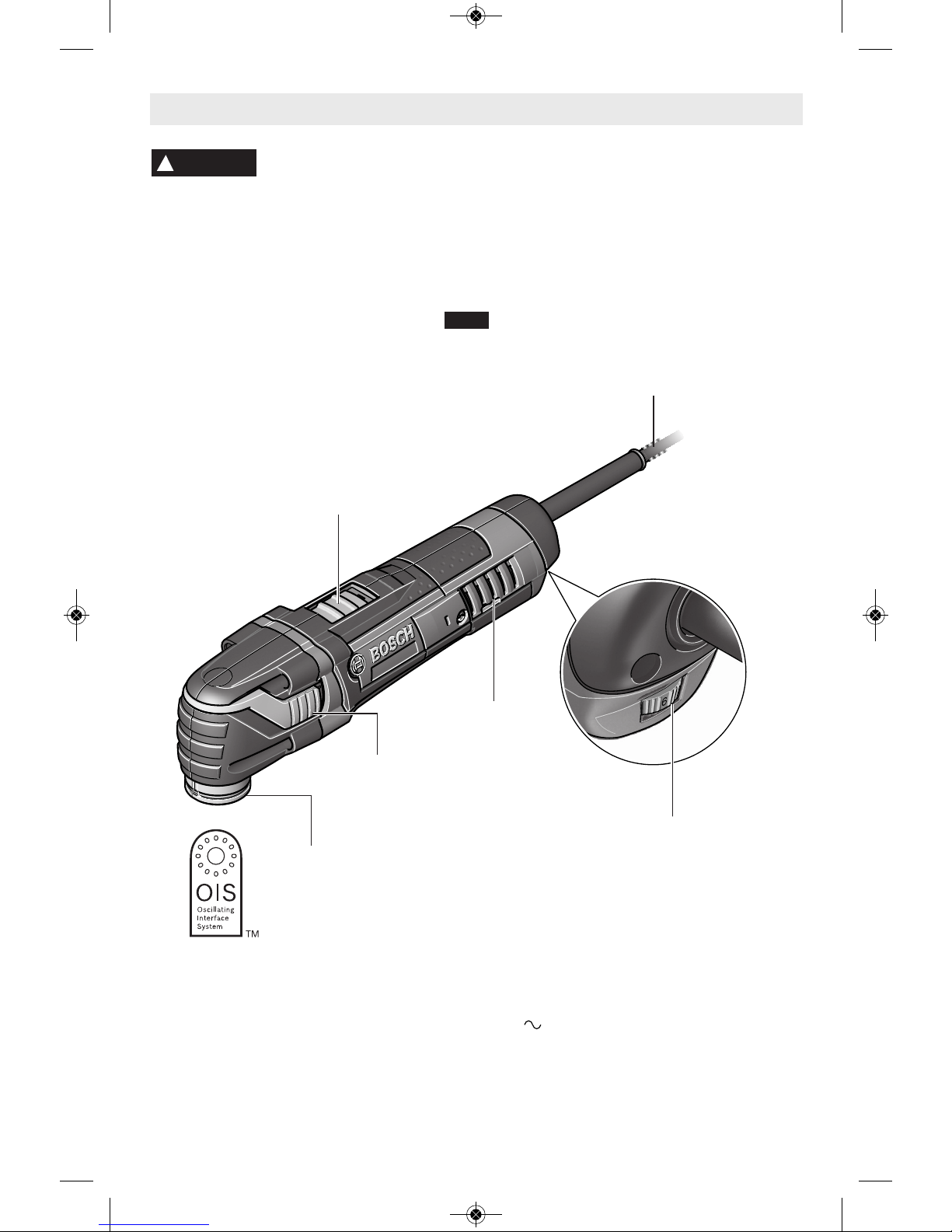

Functional Description and Specifications

Disconn ect the plu g from the powe r source be fore mak ing any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

NOTE: For tool specifications refer to the nameplate on your tool.

Multi-X Oscillating Power Tool

Model number MX30E

No load speed n

0

8,000-20,000/min

Voltage rating 120 V 60 Hz

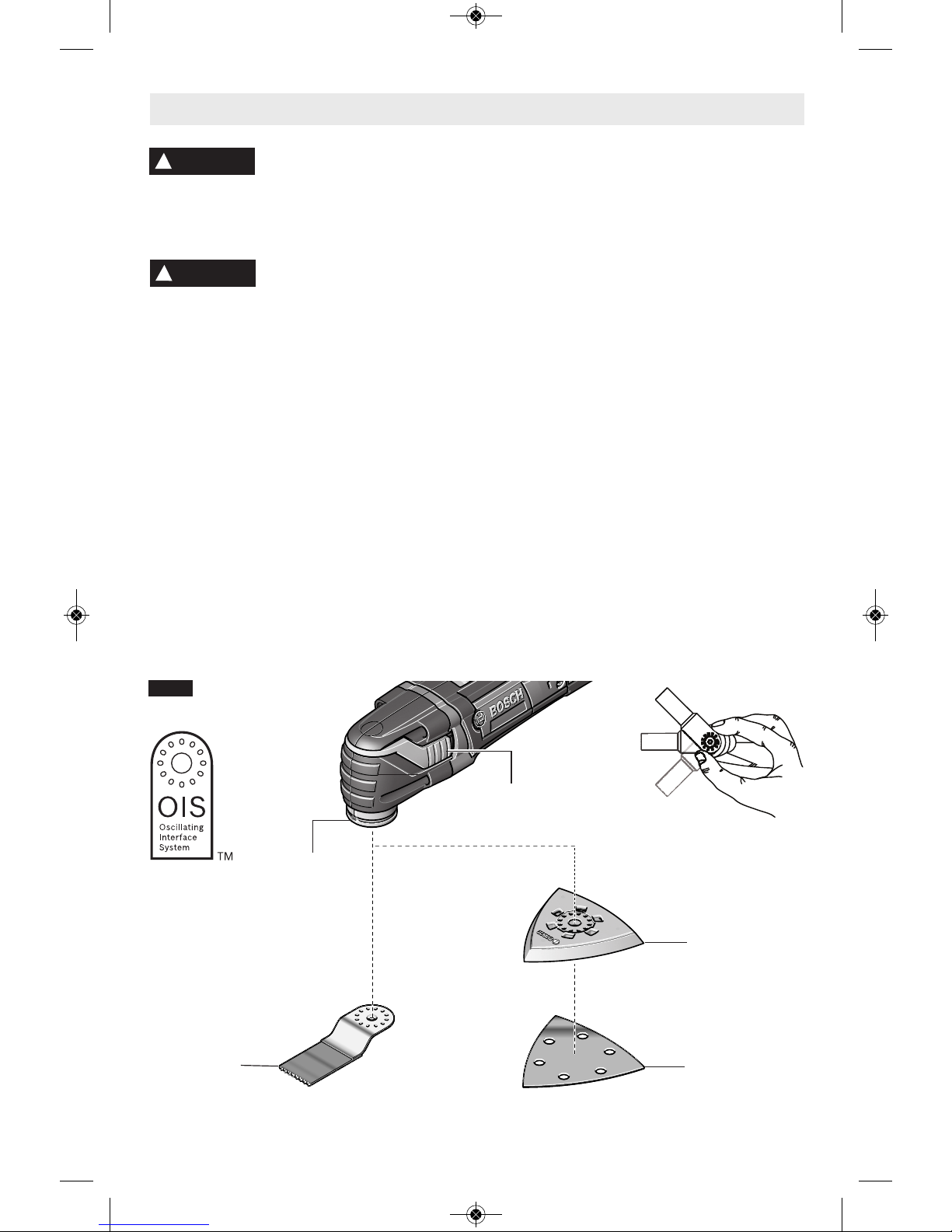

FIG. 1

OIS

ACCESSORY

HOLDER

SLIDE

"ON/OFF"

SWITCH

VENTILATION

OPENINGS

VARIABLE SPEED

CONTROL DIAL

POWER

CORD

ACCESSORY

CHANGE LEVER

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 7

-8-

Disconnect the plug from

the power source before

making any assembly, adjustments or

changing accessories. Such preventive

safety measures reduce the risk of starting the

tool accidentally.

For a ll work o r w hen

changing accessories

always wear protective gloves. Such

preventive safety measures reduce the risk of

injury from sharp edges of the accessories.

Application tools can become very hot while

working. Danger of burns!

INSTALLING AND REMOVING

ACCESSORIES

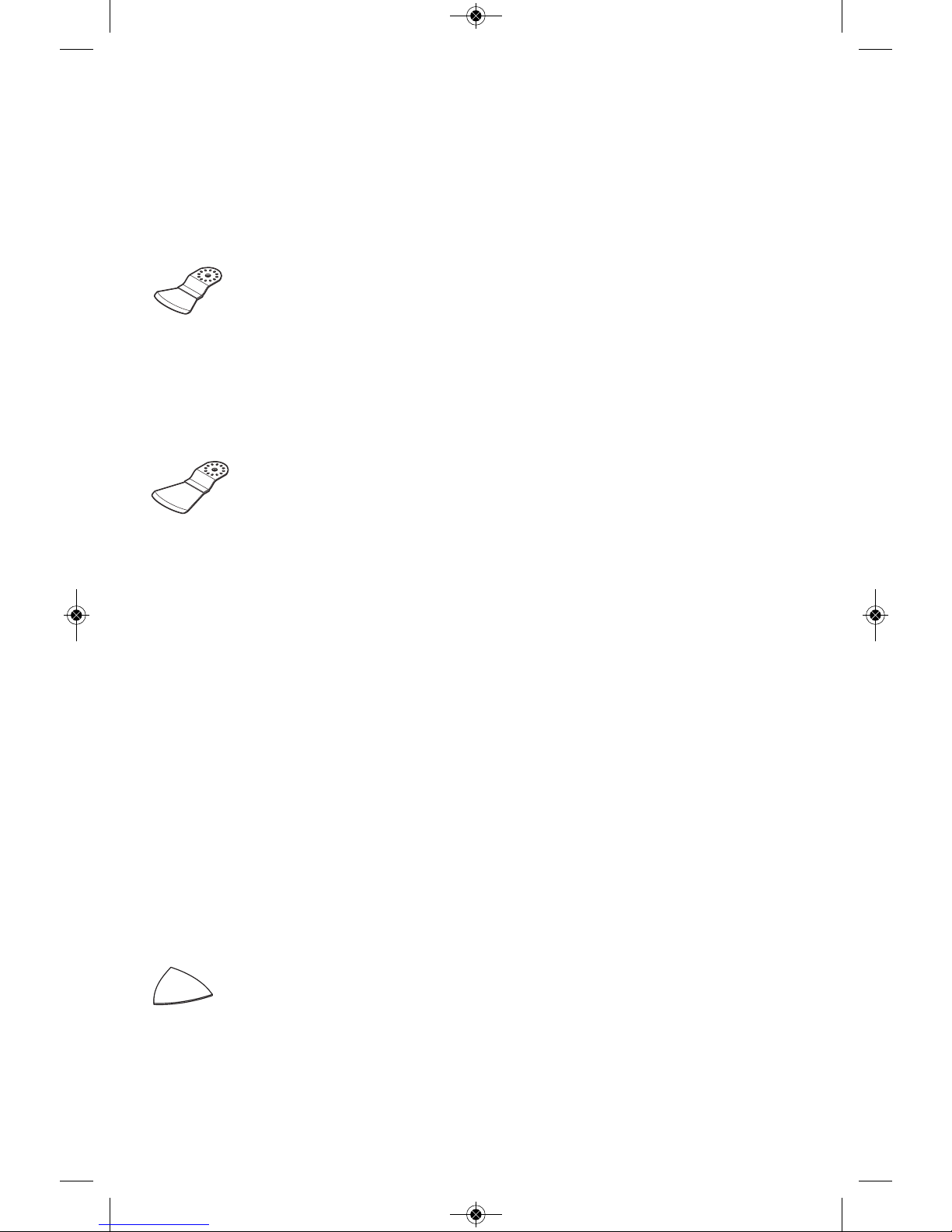

1. Open accessory change lever (Fig. 2).

2. Clean OIS accessory holder and accessory

with a clean cloth.

3. Place the accessory onto the OIS accessory

holder making sure the accessory engages

all pins in the holder and the accessory is

flush aganist the OIS accessory holder.

4. Close accessory change lever (Fig. 2).

5. To remove accessory, open accessory

change lever and take accessory off of OIS

accessory holder.

NOTE: Some accessories, such as scrapers or

blades, may be mounted either straight on the

tool, or at an angle to enhance usability (Fig. 2).

INSTALLING AND REMOVING

SANDING SHEETS

Your backing pad uses hook-and-loop backed

accessories, which firmly grip the backing pad

when applied with moderate pressure.

1. Align the sanding sheet and press it onto the

sanding plate by hand.

2. Firmly press the power tool with the sanding

sheet against a flat surface and briefly

switch the power tool on. This will promote

good adhesion and helps to prevent

premature wear.

3. To change, merely peel off the old sanding

sheet, remove dust from the backing pad if

necessary, and press the new sanding

sheet in place.

After considerable service the backing pad

surface will become worn, and the backing pad

must be replaced when it no longer offers a firm

grip. If you are experiencing premature wear

out of the backing pad facing, decrease the

amount of pressure you are applying during

operation of the tool.

For maximum use of abrasive, rotate pad 120

degrees when tip of abrasive becomes worn.

Assembly

!

WARNING

!

WARNING

RUBBER

BACKING PAD

SANDING

SHEET

OIS

ACCESSORY

HOLDER

PLUNGE CUT

BLADE

FIG. 2

ACCESSORY

CHANGE LEVER

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 8

-9-

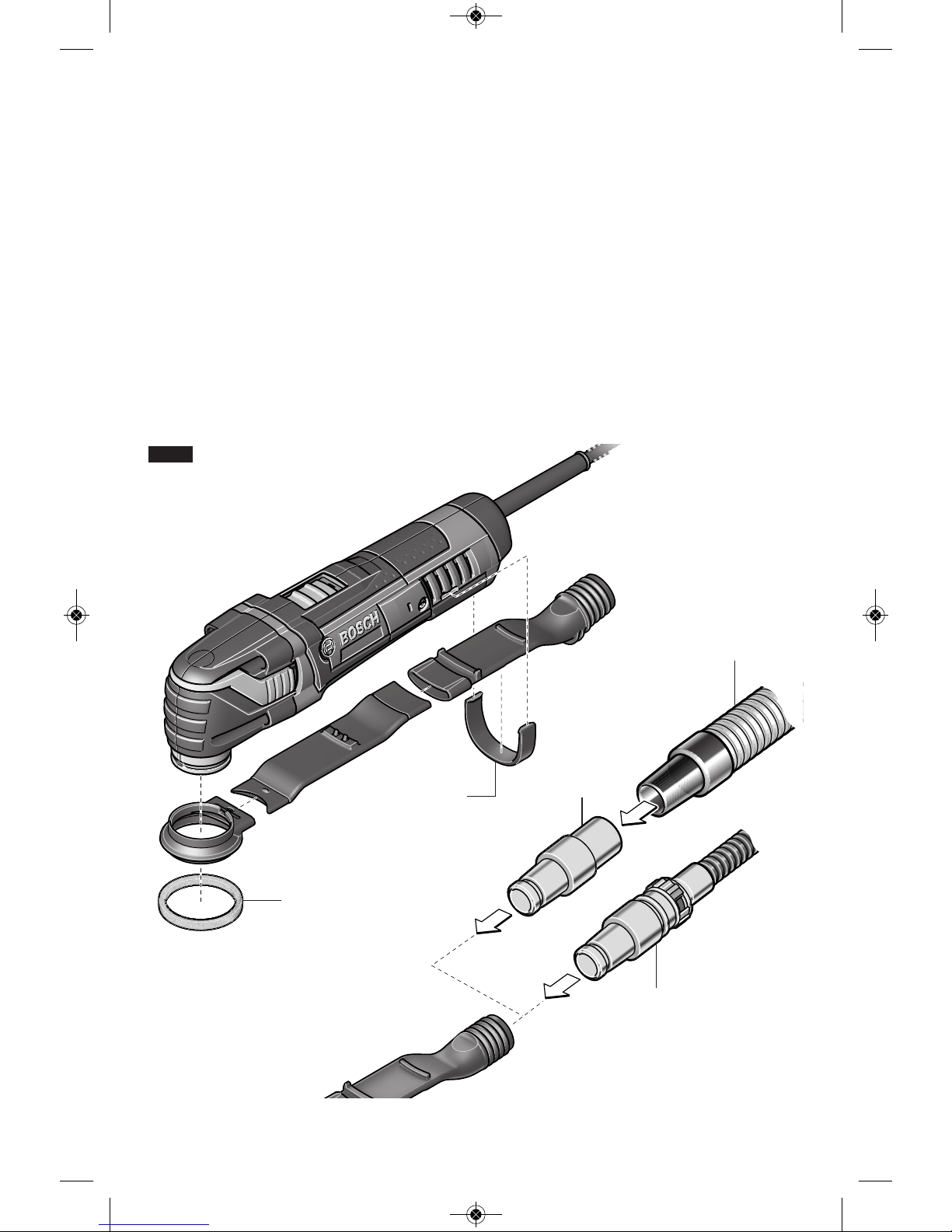

CONNECTING THE DUST EXTRACTION

ATTACHMENT

The opti onal O SC00 3 dust extra ctio n

attachment (sold separately) is only for use

when sanding. It is not designed for use when

c

utting, scraping or grinding.

Assemble and attach the parts of the dust

extraction as shown in figure 3.

1. Befo re moun ting the dus t e xtra ctio n

attachment pieces, remove any accessory

that is attached to the tool.

2. Make sure that the dust extraction hood's

felt ring is undamaged and faces tightly

against the sand ing plate. Replace a

damage felt ring immediately.

3. Attach the two parts of the dust extraction

tube to each other and to the dust extraction

hood.

4. Position the assembled dust extraction

attachment onto the tool over the accessory

attachment area.

5

. Secure the assembled dust extraction tube

onto the tool using the retaining clip as

shown in figure 3.

6. Attach the rubber backing pad and sanding

sheet.

7. Place a vacuum hose or vacuum cleaner

hose adapter onto the dust extraction tube.

8. Connect the vacuum hose to a vacuum

cleaner.

The vacuum cleaner must be suitable for the

material being worked. When vacuuming dry

dust that is especially detrimental to health or

carcinogenic, use a vacuum cleaner that is

specifically intended for that purpose.

FELT RING

RETAINING

CLIP

VAC024

1-1/4”

OR

1-1/2” HOSE

FIG. 3

BOSCH

VACUUM

HOSE

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 9

-10-

Operating Instructions

LEARNING TO USE THE TOOL

Getting the most out of your oscillating tool is a

matter of learning how to let the speed and the

feel of the tool in your hands work for you.

The first step in learning to use the tool is to

get the “feel” of it. Hold it in your hand and feel

its weight and balance (Fig. 4). Depending on

the application, you will need to adjust your

hand position to achieve optimum comfort and

control. The unique comfort grip on the body of

the tool allows for added comfort and control

during use.

When holding tool, do not cover the air vents

with your hand. Blocking the air vents could

cause the motor to overheat.

IMPORTANT! Practice on scrap material first

to see how th e t ool’s high-speed acti on

performs. Keep in mind that your tool will

perform best by allowing the speed, along with

the correct accessory, do the work for you. Be

careful not to apply too much pressure.

Instead, lower the oscillating accessory lightly

to the work surface and allow it to touch the

point at which you want to begin. Concentrate

on guiding the tool over the work using very

little pressure from your hand. Allow the

accessory to do the work.

Usually it is better to make a series of passes

with the tool rather than to do the entire job

with one pass. To make a cut, for example,

pass the tool back and forth over the work. Cut

a little material on each pass until you reach

the desired depth.

SLIDE "ON/OFF" SWITCH

The tool is switched "ON" by the slide switch

located on the topside of the motor housing

(Fig. 1).

TO TURN THE TOOL "ON" slide the switch

button forward to the “I” .

TO TURN THE TOOL "OFF" slide the switch

button backward the “0” .

ELECTRONIC FEEDBACK

Your tool is equipped with a n int erna l

electronic feedback system that provides a

“soft start”, which will reduce the stresses that

occur from a high torque start. The system

also helps to keep the preselected speed

virtually constant between no-load and load

conditions.

VARIABLE SPEED DIAL

This tool is equipped with a variable speed

dial. The speed may be controlled during

operation by presetting the dial in any one of

six positions (Fig. 1).

OPERATING SPEEDS

The Bosch Multi-X has a high oscillating

motion of 8,000 - 20,000 /min (OPM). The

high speed motion allows the Bosch Multi-X

to achieve with ex cellent results. The

oscillating motion allows the dust to fall to the

surface rather than slinging particles into the

air.

To achieve the best results when working

with different materials, set the variable

speed control to suit the job (See Speed

Chart on Page 12 for guidance) . To select

the right speed for the accessory in use,

practice with scrap material first.

FIG. 4

INTENDED USE

This Bosch Multi- X Os c i l l a ting Tool is

intended for dry sanding of surfaces, corners,

edges, for scraping, for sawing soft metals,

wood and plastic components, and for grout

rem o val u sing t he a p plicab l e to o ls a n d

accessories recommended by Bosch.

Introduction

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 10

-11-

NOTE: Speed is affected by voltages

changes. A reduced incoming voltage will

slow the OPM of the tool, especially at the

lowest setting. If your tool appears to be

running slowly, increase the speed setting

a

ccordingly. The tool may not start at the

lowest switch setting in areas where outlet

voltage is less than 120 volts. Simply move

the speed setting to a higher position to

begin operation.

The variable spee d contr ol s etti ngs are

marked on t h e speed control d i a l . The

settings for approximate /min (OPM) are:

Switch Setting Speed Range

/min (OPM)

1 8,000

2 10,400

3 12,800

4 15,200

5 17,600

6 20,000

You can refer to the charts on next page to

determine the proper speed, based on the

material and accessory being used. These

charts enable you to select both the correct

accessory and the optimum speed at a glance.

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 11

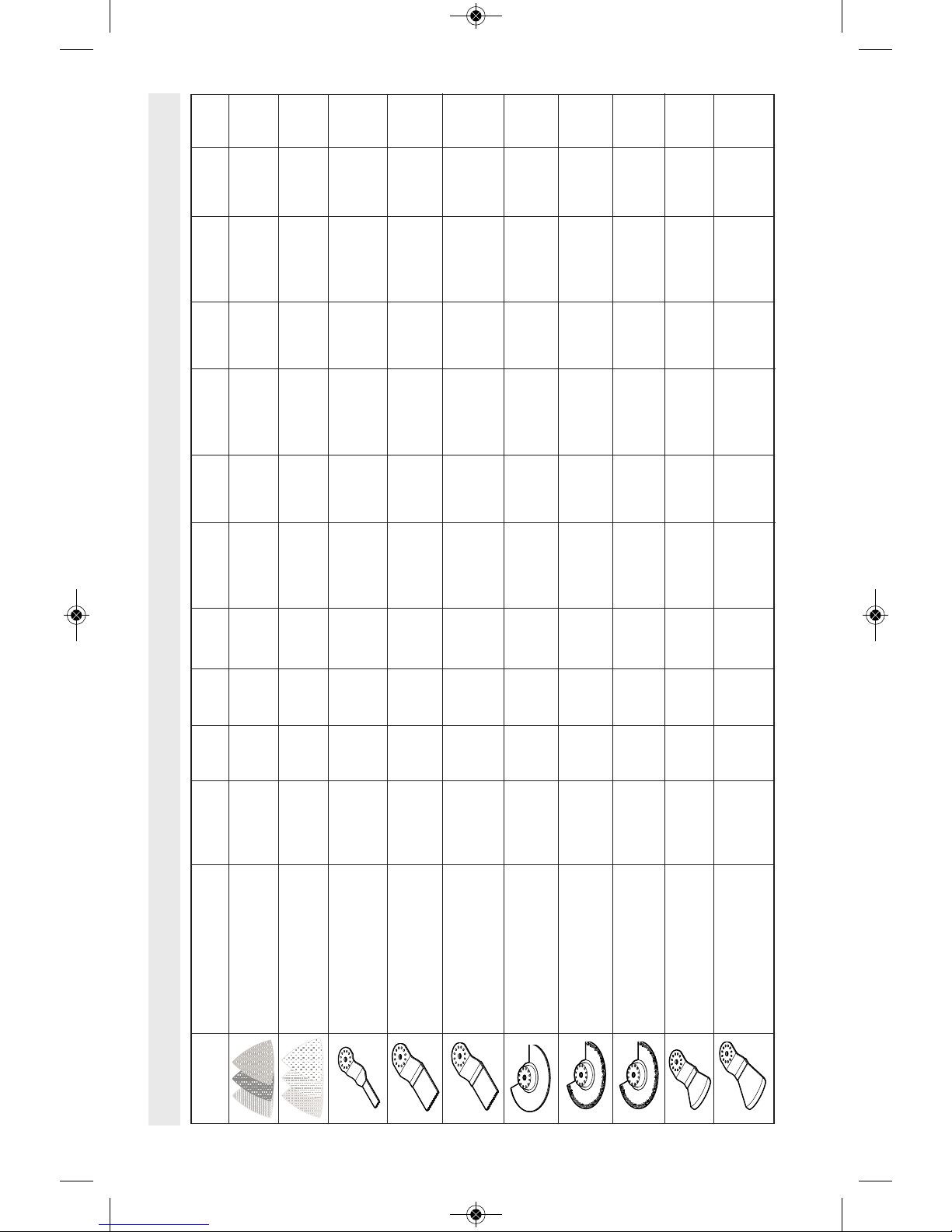

-12-

Multi-X Accessory Speed Settings

""'&

,#%##

""'&

,#%"'

##

, ("('

##

, ("('

##'

, ("('

*

%#('!#)

,

%#('!#)

,

%$%

+ %$%

"

!

"

DM 2610033449 02-14_MX30E 2/11/14 12:54 PM Page 12

-13-

APPLICATIONS

Your Bosch Multi-X oscillating tool is intended

f

or sanding and cutting wooden materials,

plastic, plaster and non-ferrous metals. It is

especially suitable for working close to edges,

in tight spaces, and for flush cutting.

Below are some typical uses for your Bosch

Multi-X oscillating tool.

For all accessories, work

with the accessory away

from the body. Never position hand near or

directly in front of working area. Always hold

the tool with both hands and wear protective

gloves.

Flush Cutting

Remove excess wood from door jamb, window

sill and/or toekick. Removing excess copper or

PVC pipe.

Removal work

e.g. carpets & backing, old tile adhesives,

caulking on maso nry, woo d and other

surfaces.

Removal of excess materials

e.g. plaster, mortar splatters, concrete on tiles,

sills.

Preparation of surfaces

e.g. for new floors and tiles.

Detail sanding

e.g. for sanding in extremely tight areas

otherwise difficult to reach and require hand

sanding

CUTTING

Saw blades are ideal for making precise cuts

in tight areas, close to edges or flush to a

surface.

Select a medium to high speed for making

initial plunge, start off at medium speed for

increased control. After making your initial cut,

you can increase speed for faster cutting

ability.

Flush cutting blades are

intended to make precise cuts to

allow for installation of flooring or

wall material. When flush cutting

it is important not to force the tool during the

plunge cut. If you experience a strong vibration

in your ha nd dur ing the plunge cut , this

indicates that you are applying too much

pressure. Back the tool out and let the speed

of the tool do the work. While keeping the teeth

of the blade in the work surface, move the

back of the tool in a slow sideways motion.

This motion will help expedite the cut.

When making a flush cut it is always a good

idea to have a piece of scrap material (tile or

wood) supporting the blade. If you need to rest

the flush cutting blade on a delicate surface,

you should protect the surface with cardboard

or masking tape.

The flat saw blade is ideal for

making pr ecis e c uts in woo d,

plaster, drywall material.

Ap plicati ons inclu de cuttin g open ings in

flooring for venting, repairin g dam aged

flooring, cutting openings for electrical boxes.

The blade works best on softer woods such as

pine. For harder woods, the blade life will be

limited.

Select a medium to high speed.

The fla t saw blad e can also be use d for

window restoration making glazing easy to

remove. The saw blade can be placed directly

against the edge of the window frame, guiding

the blade through the glazing.

GROUT REMOVAL

Grout removal blades are ideal

for removing d amaged or

cracked grout. Gr out blade s

come in different widths (1/16" and 1/8") to

tackle diffe rent grout line widths. Before

selecting a grout blade measure the grout line

width to pick the appropriate blade.

Select a medium to high speed.

To remove the grout, use a back and forth

motion, making several passes along the grout

line. The hardness of the grout will dictate how

many passes are needed. Try and keep the

grout blade aligned with the grout line and be

careful not to apply too much side pressure on

the grout blade during the process. To control

plunge depth use the carbide grit line on the

blade as an indicator. Be careful not to plunge

beyond the carbide grit line to avoid damage to

the backer board material.

The grout blades can handle both sanded and

un sand ed grou t. If you notic e the bla de

clogging during the grout removal process, you

can use a brass brush to clean the grit, thus

exposing the grit again.

The grout blade geometry is designed so that

the blade can remove all grout up to the

su rface of a wa ll or corner. Thi s can be

Operating Applications

!

WARNING

DM 2610033449 02-14_MX30E 2/11/14 12:55 PM Page 13

-14-

accomplished by ensuring that the segmented

portion of the blade is facing the wall or corner.

SCRAPING

Scrapers are suitable for removing old coats of

varnish or adhes ives, removing bond ed

carpeting, e.g. on stairs/steps and other

small/medium size surfaces.

Select low to medium speed.

Rigid scrapers are for large area

removal, and harder materials

such as vinyl flooring, carpeting

and t ile adhesive s. When

removing strong, tacky adhesives, grease the

scraper blade surface with (petroleum jelly

or silicone grease) to reduce gumming up.

The carpet/vinyl flooring removes easier if

it is scored prior to removal so the scraper

blade can move underneath the flooring

material.

Flexible scrapers are used for

hard to reach areas and softer

material such as caulk.

Mount the scraper blade with the logo side

facing up. With the flexible scraper, make sure

that the screw head does not make contact

with surface during the scraping process (a 30

- 45 degree pitch is recommend). This can be

accomplished by making sure that the tool is at

an angle to the blade. You should be able to

see the blade flex during the scraping process.

If you are removing caulk from a delicate

surface such as a bath tub or tile back splash,

we recomme nd taping o r protecting th e

surface that the blade will rest on. Use rubbing

alcohol to clean the surface after the caulk

and/or adhesive is removed.

Turn the tool on and place desired accessory

on the area where material is to be removed.

Begin with light pressure. The oscillating

motion of accessor y only occu rs when

pressure is applied to the material to be

removed.

Excessive pressure can gouge or damage the

background surfaces (e.g,. wood, plaster).

SANDING

Sanding accessories are suitable

for dry sanding of wood, metal,

surfaces, corners and edges and

hard to reach areas.

Work with the complete surface of the sanding

pad, not only with the tip.

Corners may be finished using the tip or edge

of the selected accessory, which should

occasionally be rotated during use to distribute

the wear on the accessory and backing pad

surface.

Sand with a continuous motion and light

pressure. DO NOT apply excessive pressure let the tool do the work. Excessive pressure

will result in poor handling, vibration, and

unwanted sanding marks and premature wear

on the sanding sheet.

Always be certain that smaller workpieces are

securely fastened to a bench or other support.

Larger panels may be held in place by hand on

a bench or sawhorses.

Open-coat aluminum oxide sanding sheets are

recommended for most wood or metal sanding

applications, as this synthetic material cuts

quickly and wears well. Some applications,

such as metal finishing or cleaning, require

special abrasive pads which are available from

your dealer. For best results, use Bosch

sanding accessories which are of superior

quality and are carefully selected to produce

professional quality results with your oscillating

tool.

The following suggestions may be used as a

general guide for abrasive selection, but the

best results will be obtained by sanding a test

sample of the workpiece first.

Grit Application

Coarse For rough wood or metal

sanding, and rust or old

finish removal.

Medium For general wood or metal

sanding

Fine For final finishing of wood,

metal, plaster and other

surfaces.

With the workpiece firmly secured, turn tool on

as described above. Contact the work with the

tool after the tool has reached its full speed,

and remove it from the work before switching

the tool off. Operating your oscillating tool in

this manner will prolong switch and motor life,

and greatly increase the quality of your work.

Move the oscillating tool in long steady strokes

parallel to the grain using some lateral motion

to overlap the strokes by as much as 75%.

DO NOT apply excessive pressure - let the

tool do the work. Excessive pressure will result

in poor handling, vibration, and unwanted

sanding marks.

DM 2610033449 02-14_MX30E 2/11/14 12:55 PM Page 14

-15-

Material Application Grit Size

All wooden materials (e.g.,

hardwood, softwood, chipboard,

building board) Metal materials–

Metal materials, fiberglass

and plastics

Paint, varnish, filling compound

and filler

Selecting Sanding/Grinding Sheets

For coarse-sanding, e.g. of

rough, unplanned beams and

boards

For face sanding and planing

small irregularities

For finish and fine sanding of

wood

For sanding off paint

For sanding primer (e.g., for

removing brush dashes, drops

of paint and paint run)

For final sanding of primers

before coating

Coarse

Medium

Fine

Coarse

Medium

Fine

40/60

80/120

180/240

40/60

80/120

180/240

Sand Paper (Red)

Sand Paper (White)

DM 2610033449 02-14_MX30E 2/11/14 12:55 PM Page 15

-16-

FIG. 6FIG. 5

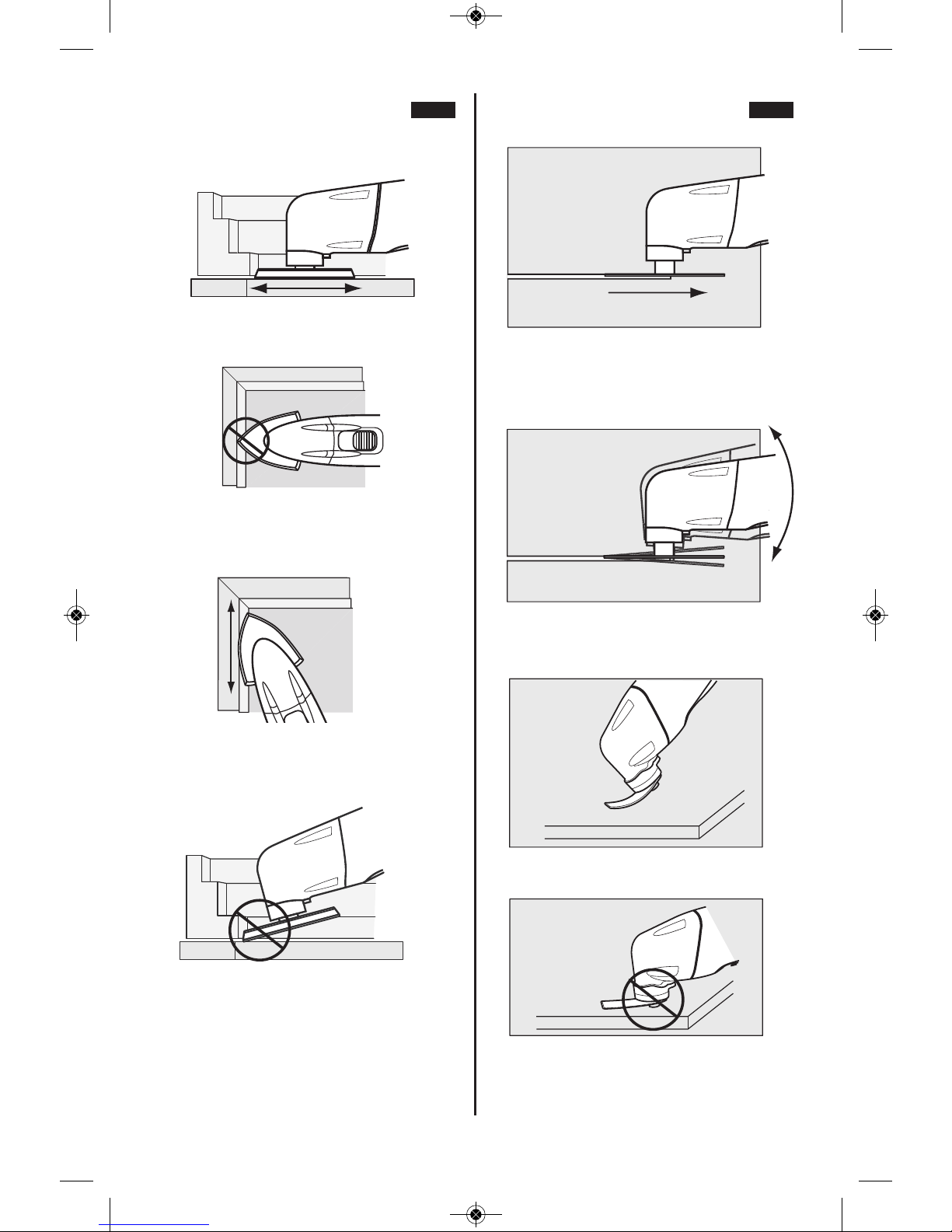

CORRECT: Sand with a smooth

back and forth motion, allowing the

weight of the tool to do the work.

INCORRECT: Avoid sanding with

only the tip of the pad. Keep as

much sand paper in touch with the

work surface as possible.

CORRECT: Always sand with the

pad and sandpaer flat against the

work surface. Work smoothly in a

back and forth motion.

INCORRECT: Avoid tipping the

pad. Always sand flat.

CORRECT: Always cut with a

smooth back and forth motion.

Never force the blade. Apply light

pressure to guide the tool.

INCORRECT: Do not twist the tool

while cutting.This can cause the

blade to bind.

CORRECT: Make sure flexible

scraper blade flexes enough

INCORRECT: Avoid screw head

touching surface with flexible

scraper blade.

DM 2610033449 02-14_MX30E 2/11/14 12:55 PM Page 16

-17-

Accessories & Attachments

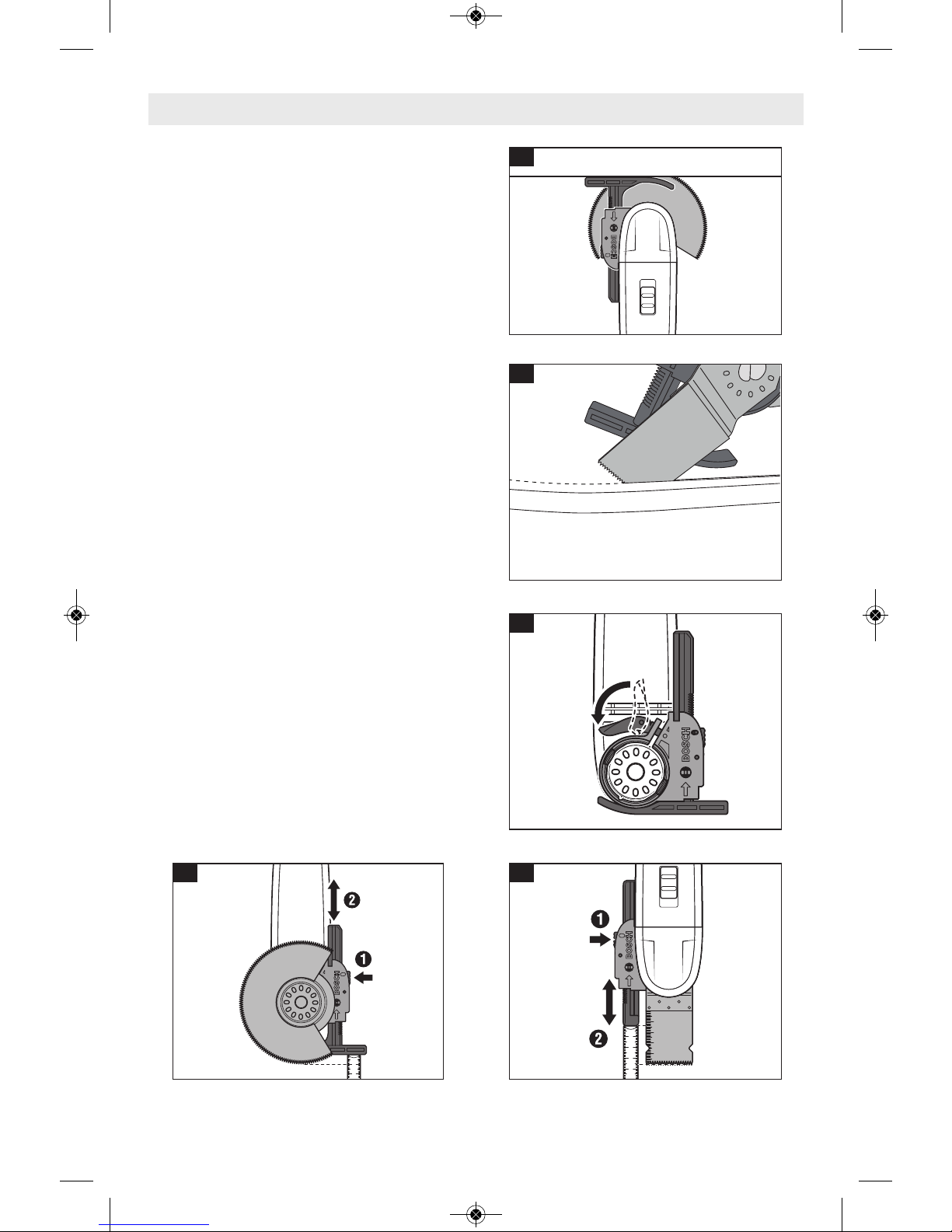

OSC004 Depth Stop Kit

(

Optional Accessory)

INTRODUCTION

The OSC004 Depth Stop Kit attachment is

comp a t ible w i th th e Bos c h MX3 0 E and

Bosch MXH180 Multi-X Oscillating Tools and

allows the depth of a cut to be limited to a

user-selected depth. (FIG.A) It can also be

used to provide guidance for other types of

cuts. (FIG. B)

INSTALLATION

Step 1: If an accessory has already been

installed on the tool, remove it.

Step 2: Place the bracket onto the nose of

the Multi-X tool such that the clamp

is facing the rear of the tool. (FIG. C)

Step 3: Press the clamp shut. (FIG. C)

Step 4: Push the appropriate guide into the

opening in the front of the bracket.

Step 5: Install the accessory onto the tool.

Step 6: Set the desired cutting depth using

the red button on the side of the

bracket. (FIG. C & D)

PLUNGE CUTS

• For plunge cutting using round blades,

such as “segment” blades, install the wide

stop as shown in figure D.

• F o r plunge-cu t blades u s ing st r a i g h t

blades, install the narrow stop as shown in

figure E.

OTHER TYPES OF GUIDED CUTS

• For other types of guided cuts, install the

wide stop as shown in figure B.

A

B

C

D

E

DM 2610033449 02-14_MX30E 2/11/14 12:55 PM Page 17

Loading...

Loading...