Page 1

ISP-SM90-120

(en) Seismic detector

(de) Körperschallmelder

11/2016

1

2

3

4 5

F.01U.331.565-01 1 © 2016 Bosch Security Systems, Inc.

6

Page 2

7

F.01U.331.565-01 2 © 2016 Bosch Security Systems, Inc.

Page 3

en

1. EC declaration of conformity

Hereby Bosch Security Systems, Inc. declares that this

equipment type is in compliance with all relevant EU

Directives for CE marking. From 20/04/2016 it is in

compliance with Directive 2014/30/EU (Electromagnetic

Compatibility Directive).

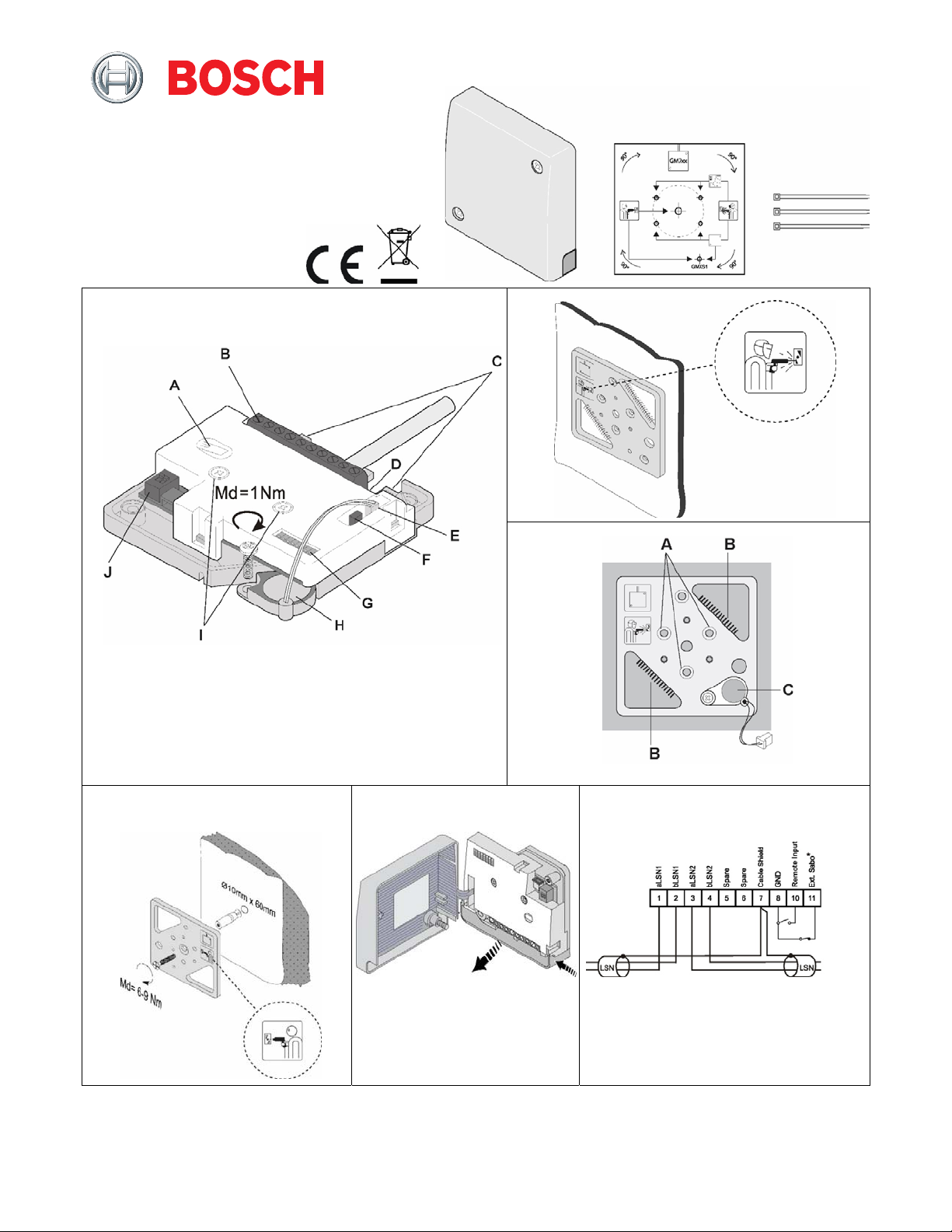

2. Application

The ISP-SM90-120 seismic detector is compatible with both

types of local security network LSNi & LSN and has a loop

connection to the control panel. The detector reliably

detects attempted break-ins to safes, ATMs, night deposits,

lightweight safes, strong rooms and modular steel or

concrete vaults. Intelligent signal processing enables

detection sensitivity to be set individually and therefore

reliably ensures no false alarms. The anti-tamper system for

the cover (Fig. 1, item A) and on the back of the ISP-SM90120 will detect the opening or the forcible removal of the

detector.

Installation, programming and commissioning must

be performed by specialists.

3. Contents

• 1 x ISP-SM90-120 seismic detector

• 1 x ISP-SM90-120 drill template

• 3 x cable ties

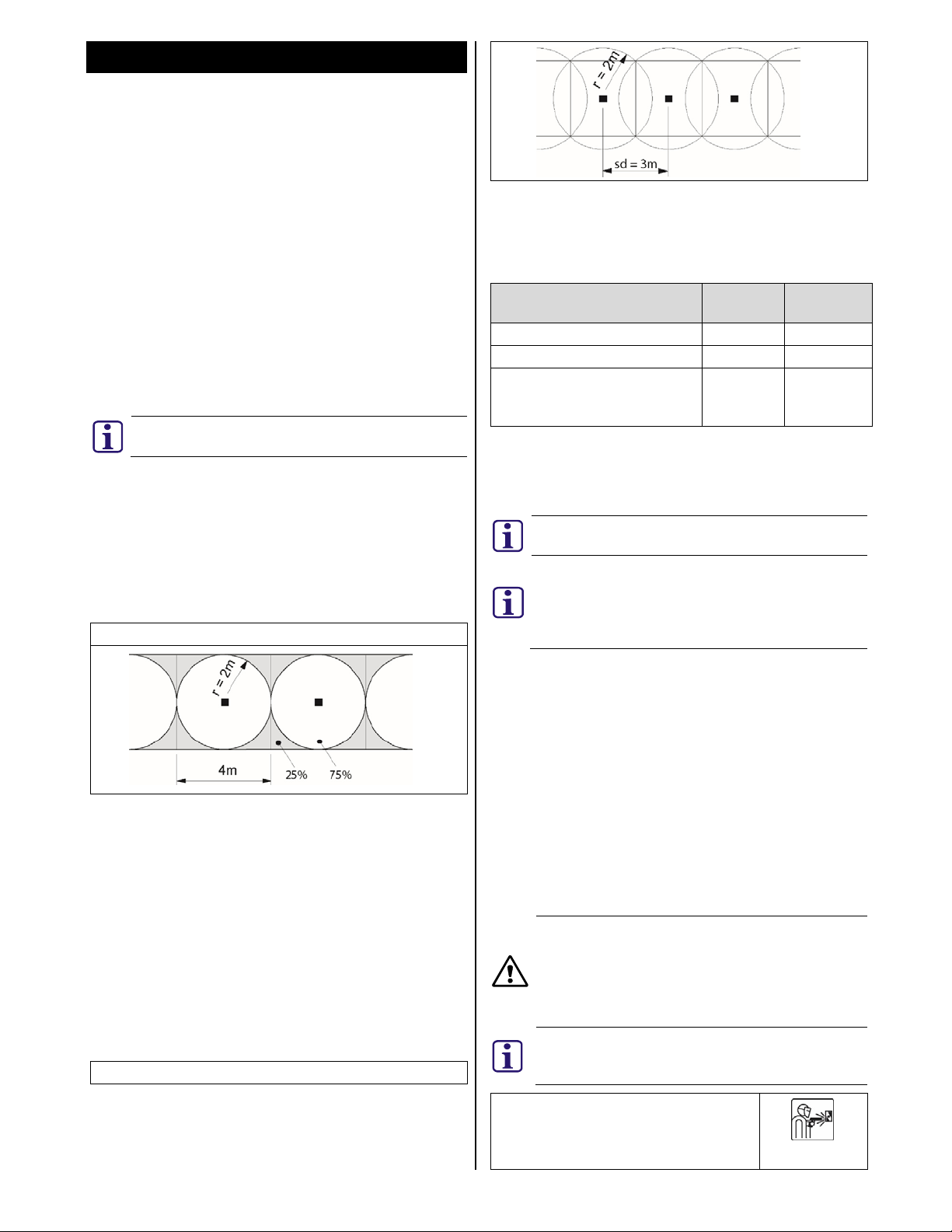

4. Coverage area

The area monitored by the detector is referred to as the

coverage area. It covers the area around the detector with an

operating radius (r).

Detector coverage

Joints in the construction of the vault may impair the

transmission of the signal. Doors must have their own

detector installed to provide the correct coverage.

Tightly sealed corners and edges may reduce the operating

radius (r) by >25%, therefore, corners and edges on steel

vaults must be seamlessly welded. Incorrect positioning can

reduce the coverage area. It is recommended that detectors

are installed on each plane (walls, floor, and ceiling) of the

protected area. Coverage from adjoining planes should not

form part of a comprehensive protection strategy.

4.1. Detector spacing distance

Detectors should be positioned so that they cover the entire

area to be monitored. The distance between detectors is

referred to as the spacing distance (sd).

Detector spacing distance (sd)

To ensure complete coverage of the protected area, the

following formula should be applied to determine the correct

spacing distance between seismic detectors.

Spacing distance (sd) = operating radius(r) x 2 x 0.75

Example:

Material Operating

radius

Spacing

distance

Steel 2m 3m

Concrete 4m 6m

LWS (Systems of armour plating

1.5m 2.25m

with synthetic/composite

materials)

5. Installation

5.1. Direct Installation on steel

The ISP-SM90-120 seismic detector can be installed directly

onto a flat, even metal surface.

Take note of the orientation of the ISP-SM90-120

seismic detector and the required drill pattern.

There must be a direct connection between the

detector and the mounting surface. Paint, varnish,

dirt, silicone or similar materials will impede the

acoustics. Remove these materials from the

mounting location before installation.

Use the ISP-SM90-120 drilling template (provided) to

determine the location of the required holes.

1. Drill 3 x 3.2mm holes, 6mm deep. 2 holes for the

detector and 1 hole for the ISN-GMX-S1 internal test

transmitter (Fig. 1, item H).

2. Remove the drilling template.

3. Thread all holes to M4.

4. Secure the detector and the test transmitter to the

mounting surface.

5.2. Installation on steel using the ISN-GMX-P0 mounting

plate

Use the weld symbol side of the ISN-GMX-P0 mounting plate

(Fig. 2) to install the detector on uneven or reinforced steel

surfaces.

The ISN-GMX-P0 mounting plate can be used for

installing a seismic detector on a steel surface. It is

essential to use the correct side and mounting

methods. The ISN-GMX-P0 displays a detector

symbol to indicate the direction of the cable access

to the detector.

Take note of the orientation of the ISP-SM90-120

seismic detector and the required orientation of

the ISN-GMX-P0 mounting plate.

ISN-GMX-P0 weld symbol

F.01U.331.565-01 3 © 2016 Bosch Security Systems, Inc.

Page 4

Detector symbol showing cable access at

top

1. With the weld symbol visible, attach the ISN-GMX-P0 to

the mounting surface using two fillet welds as shown

(Fig. 3, item B).

If welding is not possible, use the ISN-GMX-P0 as a drill

template.

• Mark the 3 centrally located countersunk holes (Fig.

3, item A).

• Drill 3 x 3.2mm Ø holes (depth to be determined by

the thickness of the mounting surface).

• Thread to M4.

• Secure the ISN-GMX-P0 using 3 x M4 countersunk

screws (provided with ISN-GMX-P0).

2. Mount the detector on to the ISN-GMX-P0.

3. Mount the ISN-GMX-S1 internal test transmitter on the

designated location on the ISN-GMX-P0 (Fig. 3, item C)

and connect to the detector (Fig. 1, item E).

5.3. Installation on concrete using the ISN-GMX-P0

mounting plate

Use the drill symbol side of the ISN-GMX-P0 mounting plate

(Fig. 4) to install the detector on concrete surfaces.

The ISN-GMX-P0 mounting plate can be used for

installing a seismic detector on a concrete surface.

It is essential to use the correct side and mounting

methods. The ISN-GMX-P0 displays a detector

symbol to indicate the direction of the cable access

to the detector.

Take note of the orientation of the ISP-SM90-120

seismic detector and the required orientation of

the ISN-GMX-P0 mounting plate.

ISN-GMX-P0 drill symbol

Detector symbol showing cable access at

top

1. Use the ISP-SM90-120 drilling template (provided) to

determine the location of the required holes.

2. Drill a 10mm Ø x 60mm hole and insert the steel

expansion plug.

3. Drill a 5mm Ø x >22mm hole and insert the ISN-GMX-S1

brass expansion plug.

When installing on concrete, the ISN-GMX-S1 must

not have any contact with the ISN-GMX-P0

mounting plate. The ISN-GMX-S1 must be attached

to the concrete using the M4 x 21mm screw and the

associated brass expansion plug.

4. Secure the ISN-GMX-P0 to the steel expansion plug with

the M6 x 47mm screw.

5. Secure the ISN-GMX-S1 to the brass expansion plug with

the M4 x 21mm screw.

6. Mount the detector on to the ISN-GMX-P0.

6. Mounting the detector

1. Remove the cover from the detector.

2. Attach the detector to the prepared mounting base using

the two mounting screws (Fig. 1, items I).

3. Remove the cable access skirt (Fig. 5).

4. Wire the connection cables to the terminal (Fig. 1, item

B) as shown in diagram (Fig. 6).

5. Secure the cable to a cable anchor (Fig. 1, items C) with

a cable tie (provided).

6. Connect the accessories and program the detector.

7. Remove the pre-formed cable access points as required

to enable cable access through the skirt (Fig. 5).

8. Replace the cable access skirt.

The cables connected to terminals 8, 10 and 11

must not exceed 3m in length.

The polarity of the LSN Bus must be maintained.

The screen from the LSN cables must be connected

into terminal 7.

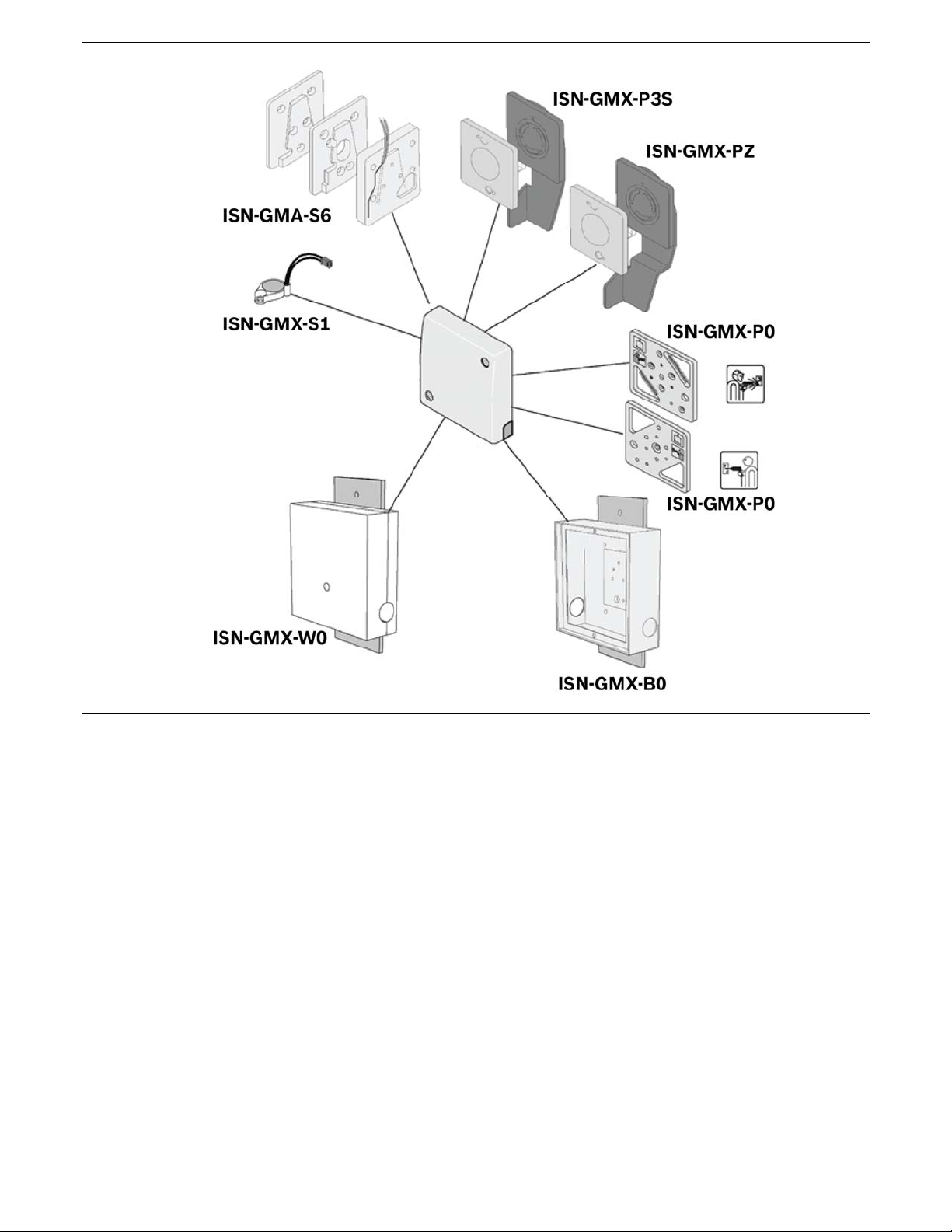

7. Accessories

All of the accessories (Fig. 7) have their own installation

instructions, which are supplied with each accessory. These

installation instructions should be followed for the correct

installation and optimum performance from this seismic

detector. For ordering information, see section 16.

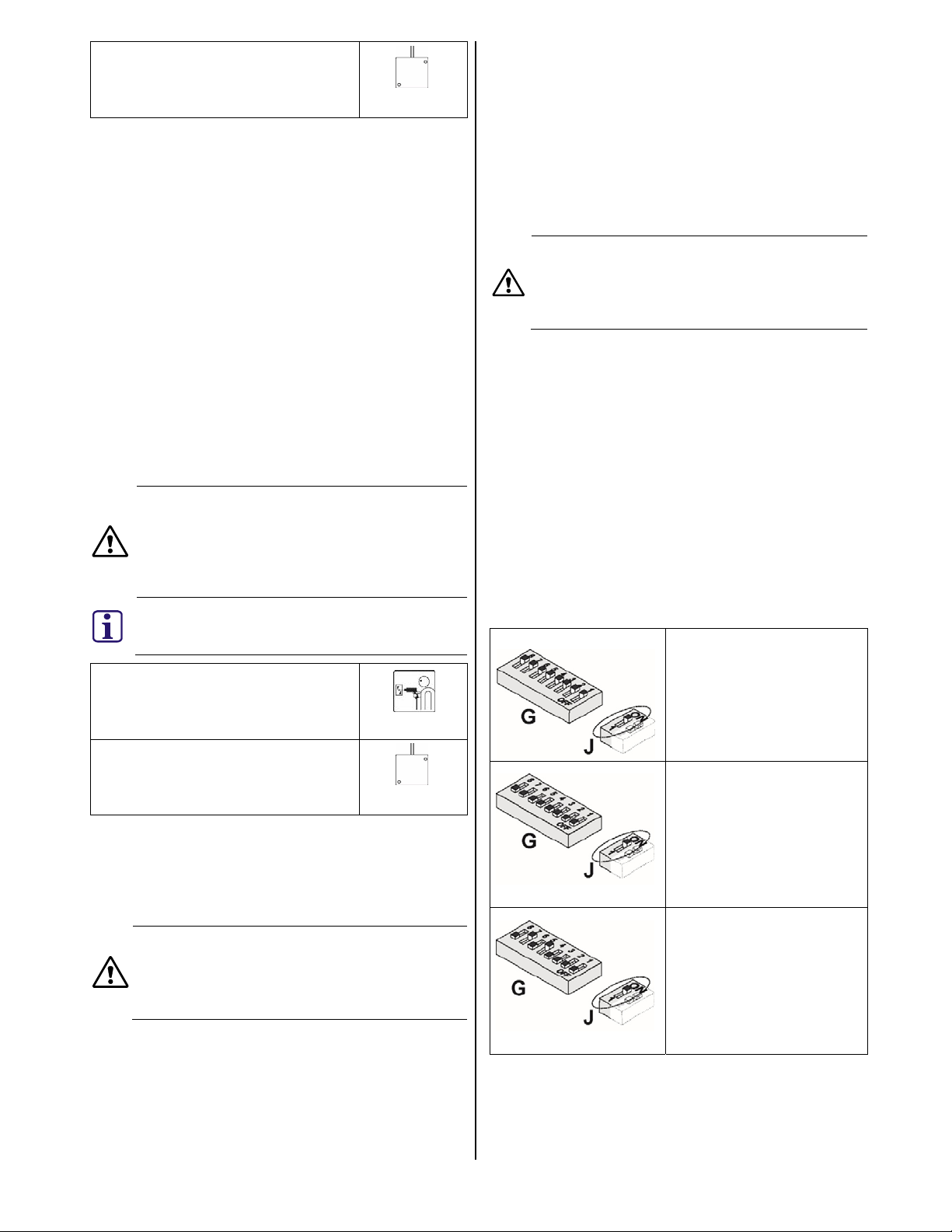

8. Configuration (addressing LSNi/LSN)

ISP-SM90-120 supports LSNi (LSN improved) and LSN (LSN

classic). The detector must be configured using the two DIP

switches (Fig. 1, items G and J) before the power supply is

connected via the LSNi/LSN bus. The DIP switches are used

for configuration and addressing as follows:

• Fig. 1, item G – Addressing

• Fig. 1, item J – Material and coverage application

The following configurations are possible:

LSN application

Fig. 1, item G all in ON

position

Fig. 1, item J in ON position

(default setting)

LSNi application with

automatic addressing

Fig. 1, item G all in OFF

position

Fig. 1, item J in ON position

LSNi application with

manual addressing

Fig. 1, item G set to the

corresponding address (see

the table in the Appendix at

the end of this document).

Fig. 1, item J ON position

F.01U.331.565-01 4 © 2016 Bosch Security Systems, Inc.

Page 5

LSN application in GM570LSN

compatibility mode

This mode enables compatible

use of ISP-SM90-120 in

existing installations to replace

a GM570LSN detector.

The detection characteristics

are identical in all

8.1. External tamper contact

The detector provides the option of connecting an

additional, external tamper contact (for example, the ISNGMA-S6 or the ISN-GMX-P3S). Connect the external tamper

contact to terminal 11 Ext. Sabo and terminal 8 GND (Fig.

6).

The external tamper contact is enabled via the DIP switch

(Fig. 1, item J) with switch 2 in the ON position as follows:

ON

OFF

8.2. Remote sensitivity input (Fig. 6, terminal 10)

When this input is active, the sensitivity of the

detector is reduced. The sensitivity input should

only be applied under special circumstances, and

only for short periods of time. Any reduction in

sensitivity must comply with applicable regulations

such as VdS in Germany. Remote sensitivity is

activated by linking terminal 8 to terminal 10.

Sensitivity is reduced to 12.5% of the original setting for the

duration of the remote sensitivity input. A potential

application is the prevention of alarm triggering where loud

functional noises prevail

configurations.

Fig. 1, item G any position

Fig. 1, item J in OFF position

Switch 2 ON = Internal tamper

contacts only

Switch 2 OFF = Internal and

external tamper contacts

Link terminal 8 to terminal

11 to prevent a tamper

signal (Fig. 6)

9. Programming via LSNi/LSN control panel

The detector is programmed using the configuration

software of the corresponding control panel.

10. Effective operating radius

The specified operating radius applies to an attack with an

oxygen lance. If attacked with a mechanical tool (e.g. a drill)

the value may be as much as three times higher. The

specified operating radius is a guideline which is heavily

influenced by the characteristics of the material and the type

of construction.

11. Shock sensitivity

Shock sensitivity defines how the detector responds to

individual strikes to the substructure of the detector. It is

only possible to set the shock sensitivity for the mode and

effective radius independently in USER MODE with the

LSNi/LSN control panel.

Mode Effective

radius

Concrete 5m* High Vault

Shock

sensitivity*

Example of use

Mode Effective

radius

Concrete 4m. High Vault, modular vault

Concrete 2.5m. High Vault, modular vault

Steel 2m. Medium

Steel 1.5m. Medium

Steel 1m* Low ATM, safe, vault door

LWS 2m. High

LWS 1.5m. High

*Modes not available in GM570LSN compatibility mode

*Availability of these options depends on the ability of the

control panel to identify the detector as a ISP-SM90-120.

Some control panels may identify the ISP-SM90-120 as a

GM570LSN.

11.1. Function test

The LSNi/LSN control panel can trigger a function test in

conjunction with an installed ISN-GMX-S1 internal test

transmitter. The ISN-GMX-S1 is activated through the control

panel using a seismic test function. An alarm is activated if

the detector is working correctly (activation time <3s).

11.2. Automatic self-test

The LSNi/LSN control panel can set the time interval

(hour/day/week) for automatic self-test. The control panel

identifies any unsuccessful self-test.

The detector must be fitted with a ISN-GMX-S1 internal test

transmitter.

Shock

sensitivity*

Example of use

Armor-plated safe,

vault door

Armor-plated safe,

vault door, ATM

Systems of armour

plating with

synthetic /

composite materials

Systems of armour

plating with

synthetic /

composite materials

12. Commissioning

1. Initialize the LSNi/LSN bus

2. Wait 60 seconds.

The detector is now operational.

3. Verify the correct radius and material type have been

selected by the control panel.

Using a multimeter (Ri ≥ 20 kΩ) at terminal 1 (0 V) and TP

(Fig. 1, item D) to monitor for the analogue integration

signal:

Quiescent level 0 V

Integration start 1 V

Alarm threshold (w/o load) 3 V

12.1. Functional checks

Functional checks can be performed as follows:

• With the cover removed, scratch the metal case of the

detector with a screw driver.

• Activate the ISN-GMX-S1 internal test transmitter

through the control panel using a seismic test function.

• Apply the required input to activate the GMXS5 external

test transmitter, if provided.

• Simulate an attack on the protected space.

• Carefully replace the cover and secure it in place.

F.01U.331.565-01 5 © 2016 Bosch Security Systems, Inc.

Page 6

13. Service

The function of the detector and its mounting should be

checked at least once a year as follows:

• Functionally test the detector as detailed in section 12.1.

• Verify the settings of the detector by the control panel

menu options.

• Check the mounting of the detector to ensure that the

detector is securely attached.

• Check that there is a direct connection between the

detector and the mounting surface. Paint, varnish, dirt,

silicone or similar materials will impede the acoustics.

Refer to local approvals for guidance on this matter.

14. Modular vaults

The following principles must be strictly observed when

using seismic detectors on modular vaults made from steel

or concrete:

• Thickness from 100 to 400mm

• Width up to 1000mm

• Length up to 6500mm

Modules with detector

arrangement

1 2 3 4 5 1 2 3 4 5 . . . .

Recommended setting

On maximum 5 modules at a

maximum height of 6.5m

On maximum 3 modules at a

maximum height of 4m

On doors Steel 2m

Concrete 4m

Concrete 2.5m

15. Technical data

Dimensions 89mm x 89mm x 23mm

Supply voltage (LSNi/LSN) Vmax. = 33 V DC

Current consumption

(LSNi/LSN)

Tamper monitoring:

• Microswitch, cover +

removal

• External tamper contact

(Fig.6, terminal 11)

o Closed resistor < 20 kΩ

o Open resistor > 650 kΩ

• Anti-drilling foil in cover

(optional)

Ityp. = 1.2 mA

Imax. = 1.625 mA

Opens on sabotage

Damage = sabotage

• For sensitivity reduction LOW < 1.5 V DC

Operating temperature -25 ºC to +70 ºC

Storage temperature -50 ºC to +70 ºC

Air humidity (EN 60721),

non-condensing

Approvals See the type plate inside the

< 95%

detector cover (Fig. 5).

Corner joints between walls

seamlessly welded

Always 1 detector on

doors

16. Ordering information

1. One detector for a maximum of 5 wall modules. The

detector must be mounted on the middle module.

2. In addition to being bolted together, all of the joints

between the modules must be welded every 400 −

500mm with a 30 − 40mm seam.

3. Corner joints between wall modules must be seamlessly

welded if the coverage area is to extend beyond the

corners.

4. In the case of wall modules equipped with detectors, the

immediately adjoining floor and/or ceiling modules can

be included in the coverage area if the corresponding

butt joints are seamlessly welded.

5. Where building vaults use modules of varying thickness,

the butt joints must be seamlessly welded.

6. Avoid mounting detectors on modules to which guide

rails for cassette transport lifts, ventilators or other

mechanical equipment are attached.

7. Always equip modules which have a pay-in/withdrawal

slot with a detector. This will also be able to monitor the

adjacent modules.

8. All doors must always be equipped with a detector.

9. Programming:

F.01U.331.565-01 6 © 2016 Bosch Security Systems, Inc.

ISP-SM90-120

Seismic detector

ISN-GMX-P0

Mounting

ISN-GMX-S1

Internal test transmitter

ISN-GMX-W0

Wall/Ceiling recess box

ISN-GMX-B0

Floor recess box

ISN-GMX-P3S

Swivel plate

ISN-GMX-P3SZ

Swivel plate

ISN-GMA-S6

Movable mounting kit

ISN-GMX-D7

Anti-drill foil (10x)

F.01U.173.560

F.01U.003.366

F.01U.003.371

F.01U.003.372

F.01U.003.365

F.01U.003.368

F.01U.003.370

F.01U.003.363

F.01U.004.305

de

1. EG-Konformitätserklärung

Hiermit erklärt Bosch Security Systems, Inc. dass dieser

Gerätetyp den Anforderungen aller relevanten EU-Richtlinien

für die CE-Kennzeichnung entspricht. Ab dem 20.04.2016

Page 7

entspricht er der Richtlinie 2014/30/EU (Richtlinie über

elektromagnetische Verträglichkeit).

2. Anwendung

Der Körperschallmelder ISP-SM90-120 ist geeignet für den

Einsatz im lokalen Sicherheitsnetzwerk LSNi (oder LSN) und

hat eine Schleifenverbindung zur Zentrale. Der Melder

erkennt zuverlässig Aufbruchversuche bei Safes,

Geldautomaten, Nachttresoren, Leichtbausafes,

Stahlkammern und modularen Tresor-räumen aus Stahl oder

Beton. Die intelligente Signalverarbeitung erlaubt eine

individuelle Einstellung der Detektionsempfindlichkeit und

somit eine hohe Sicherheit gegen Falschalarm. Der

Sabotageschutz in der Melderabdeckung (Abb. 1, Element A)

und auf der Rückseite des ISP-SM90-120 erkennt ein Öffnen

und ein gewaltsames Entfernen des Melders.

Die Montage, Programmierung und Inbetriebnahme

müssen durch Fachpersonen erfolgen.

3. Inhalt

• 1 Körperschallmelder ISP-SM90-120

• 1 Bohrschablone ISP-SM90-120

• 3 Kabelbinder

4. Wirkbereich

Die vom Melder überwachte Fläche wird als Wirkbereich

bezeichnet. Dieser breitet sich kreisförmig vom Melder mit

einem Wirkradius (r) aus.

Melderwirkung

Verbindungsstellen in der Tresorkonstruktion können die

Signalübertragung beeinträchtigen. Türen müssen über einen

eigenen Melder verfügen, um eine ordnungsgemäße

Melderwirkung zu erzielen.

Gut abgedichtete Ecken und Kanten könnten den Wirkradius

(r) um > 25 % verringern, weshalb Ecken und Kanten bei

Stahltresoren durchgehend verschweißt sein müssen. Eine

falsche Positionierung kann den Wirkbereich reduzieren. Es

wird empfohlen, auf jeder Fläche (Wände, Boden und Decke)

des zu schützenden Bereichs Melder zu montieren. Eine

Erfassung von angrenzenden Flächen aus sollte nicht

Bestandtteil einer umfassenden Schutzstrategie sein.

4.1. Melderabstand

Melder müssen so positioniert werden, dass sie den

gesamten zu überwachenden Bereich abdecken. Der Abstand

zwischen den Meldern wird als Melderabstand bezeichnet

(sd – engl. spacing distance).

Melderabstand (sd)

Für eine vollständige Abdeckung des zu schützenden

Bereichs sollte die folgende Formel angewendet werden, um

den korrekten Abstand zwischen den Körperschallmeldern zu

bestimmen.

Melderabstand (sd) = Wirkradius (r) × 2 × 0,75

Beispiel:

Material Wirkradius Melderabstand

Stahl 2m 3m

Beton 4m 6m

LWS (Panzerungssysteme mit

1,5m 2,25m

Kunststoffen/Verbundwerkstoffen)

5. Montage

5.1. Direkte Montage auf Stahl

Der Körperschallmelder ISP-SM90-120 kann direkt auf einer

flachen, ebenen Metallfläche montiert werden.

Achten Sie darauf, dass der Körperschallmelder ISPSM90-120 und das passende Bohrmuster

aufeinander ausgerichtet sind.

Zwischen Melder und Montagefläche muss eine

direkte Verbindung bestehen. Farben, Lacke,

Schmutz, Silikon o. Ä. behindern die

Schallübertragung. Entfernen Sie diese Materialien

von der Montagefläche, bevor Sie mit der Montage

beginnen.

Verwenden Sie die beiliegende Bohrschablone ISP-SM90120, um die Position der erforderlichen Bohrungen zu

bestimmen.

1. Bohren Sie drei Löcher mit einem Durchmesser von

3,2 mm und einer Tiefe von 6 mm. Zwei Löcher für den

Melder und ein Loch für den internen Prüfsender ISNGMX-S1 (Abb. 1, Element H).

2. Entfernen Sie die Bohrschablone.

3. Schneiden Sie in alle Bohrungen ein M4-Gewinde.

4. Befestigen Sie den Melder und den Prüfsender auf der

Montagefläche.

5.2. Montage auf Stahl mithilfe der Montageplatte ISN-

GMX-P0

Verwenden Sie die Seite der Montageplatte ISN-GMX-P0 mit

dem Schweißsymbol (Abb. 2), um den Melder auf unebenen

oder verstärkten Stahlflächen zu montieren.

Die Montageplatte ISN-GMX-P0 kann für die

Montage eines Körperschallmelders auf einer

Stahlfläche verwendet werden. Es ist

ausschlaggebend, dass die richtige Seite und die

korrekten Montagemethoden verwendet werden.

Die ISN-GMX-P0 trägt ein Meldersymbol, das die

Ausrichtung der Kabelzuführung zum Melder

anzeigt.

Achten Sie darauf, dass der

Körperschallmelder ISP-SM90-120 und die

Montageplatte ISN-GMX-P0 zueinander

ausgerichtet sind.

ISN-GMX-P0-Schweißsymbol

F.01U.331.565-01 7 © 2016 Bosch Security Systems, Inc.

Page 8

Meldersymbol mit Kabelzuführung auf

Oberseite

1. Befestigen Sie die Montageplatte ISN-GMX-P0 mit zwei

Kehlnähten auf der Montagefläche. Das Schweißsymbol

muss sichtbar sein (siehe Abb. 3, Element B).

Wenn kein Schweißen möglich ist, verwenden Sie die

ISN-GMX-P0 als Bohrschablone.

• Markieren Sie die drei mittig liegenden

Senkbohrungen (Abb. 3, Element A).

• Bohren Sie drei Löcher mit einem Durchmesser von

3,2 mm (die Tiefe der Bohrung muss abhängig von

der Stärke der Montagefläche bestimmt werden).

• Schneiden Sie anschließend M4-Gewinde in alle

Bohrungen.

• Befestigen Sie die ISN-GMX-P0 mithilfe von

Senkkopfschrauben (3 × M4, im Lieferumfang der

ISN-GMX-P0 enthalten).

2. Montieren Sie den Melder auf der ISN-GMX-P0.

3. Montieren Sie den internen Prüfsender ISN-GMX-S1 an

der angegebenen Position auf der ISN-GMX-P0 (Abb. 3,

Element C), und schließen Sie ihn an den Melder an

(Abb. 1, Element E).

5.3. Montage auf Beton mithilfe der Montageplatte ISN-

GMX-P0

Verwenden Sie die Seite der Montageplatte ISN-GMX-P0 mit

dem Bohrsymbol (Abb. 4), um den Melder auf Betonflächen

zu montieren.

Die Montageplatte ISN-GMX-P0 kann für die

Montage eines Körperschallmelders auf einer

Betonfläche verwendet werden. Es ist

ausschlaggebend, dass die richtige Seite und die

korrekten Montagemethoden verwendet werden.

Die ISN-GMX-P0 trägt ein Meldersymbol, das die

Ausrichtung der Kabelzuführung zum Melder

anzeigt.

Achten Sie darauf, dass der

Körperschallmelder ISP-SM90-120 und die

Montageplatte ISN-GMX-P0 zueinander

ausgerichtet sind.

ISN-GMX-P0-Bohrsymbol

Meldersymbol mit Kabelzuführung auf

Oberseite

1. Verwenden Sie die beiliegende Bohrschablone ISP-

SM90-120, um die Position der erforderlichen

Bohrungen zu bestimmen.

2. Bohren Sie ein Loch mit einem Durchmesser von 10 mm

und einer Tiefe von 60 mm, und setzen Sie den

Stahlspreizdübel ein.

3. Bohren Sie ein Loch mit einem Durchmesser von 5 mm

und einer Tiefe von > 22 mm, und setzen Sie den ISNGMX-S1-Messingspreizdübel ein.

Bei der Montage auf Beton darf der ISN-GMX-S1

keinen Kontakt mit der Montageplatte ISN-GMX-P0

haben. Der ISN-GMX-S1 muss mithilfe der Schraube

(M4 × 21 mm) und dem dazugehörigen

Messingspreizdübel am Beton befestigt werden.

4. Befestigen Sie die ISN-GMX-P0 mithilfe der Schraube

(M6 × 47 mm) am Stahlspreizdübel.

5. Befestigen Sie den ISN-GMX-S1 mit der Schraube

(M4 × 21 mm) am Messingspreizdübel.

6. Montieren Sie den Melder auf der ISN-GMX-P0.

6. Montage des Melders

1. Entfernen Sie die Abdeckung vom Melder.

2. Befestigen Sie den Melder mithilfe der zwei

Befestigungsschrauben auf der vorbereiteten

Montageplatte (Abb. 1, Element I).

3. Entfernen Sie die Verkleidung der Kabelzuführung

(Abb. 5).

4. Führen Sie die Verbindungskabel zur Zentrale (Abb. 1,

Element B) wie in der Abbildung dargestellt (Abb. 6).

5. Befestigen Sie das Kabel mit einem (beiliegenden)

Kabelbinder an einer Kabelklemme (Abb. 1, Element C).

6. Schließen Sie das Zubehör an und programmieren Sie

den Melder.

7. Entfernen Sie die vorgestanzten Abdeckungen an den

Kabelzuführungsaussparungen wie erforderlich, um die

Kabelzuführung durch die Verkleidung zu ermöglichen

(Abb. 5).

8. Bringen Sie die Verkleidung der Kabelzuführung wieder

an.

Die mit den Klemmen 8, 10 und 11 verbundenen

Kabel dürfen nicht länger als 3 m sein.

Die Polarität des LSN-Busses muss erhalten bleiben.

Die Abschirmung der LSN-Kabel muss mit Klemme 7

verbunden werden.

7. Zubehör

Für alle Zubehörteile (Abb. 7) gelten eigene

Montageanweisungen, die jedem Zubehörteil beiliegen.

Diese Montageanweisungen müssen für die korrekte

Montage und eine optimale Leistung dieses

Körperschallmelders befolgt werden. Bestellangaben siehe

Abschnitt 16.

8. Konfiguration (LSNi/LSN-Adressierung)

Der ISP-SM90-120 unterstützt LSNi (LSN improved) und LSN

(LSN classic). Der Melder muss mithilfe der zwei DIPSchalter konfiguriert werden (Abb. 1, Elemente G und J),

bevor die Stromversorgung über den LSNi/LSN-Bus

angeschlossen wird. Die DIP-Schalter werden wie folgt für

die Konfiguration und Adressierung verwendet:

• Abb. 1, Element G – Adressierung

• Abb. 1, Element J – Material- und

Abdeckungsanwendung

Folgende Konfigurationen sind möglich:

LSN-Anwendung

Abb. 1, Element G alle in EINPosition

Abb. 1, Element J in EINPosition

(Werkseinstellung)

F.01U.331.565-01 8 © 2016 Bosch Security Systems, Inc.

Page 9

LSNi-Anwendung mit

automatischer Adressierung

Abb. 1, Element G alle in AUSPosition

Abb. 1, Element J in EINPosition

8.1. Externer Sabotagekontakt

Der Melder bietet die Möglichkeit, einen zusätzlichen,

externen Sabotagekontakt (z. B. ISN-GMA-S6 oder ISN-GMX-

P3S) anzuschließen. Schließen Sie den externen

Sabotagekontakt an Klemme 11 Ext. Sabo und Klemme 8

GND (Abb. 6) an.

Der externe Sabotagekontakt wird über den DIP-Schalter

(Abb. 1, Element J) mit Schalter 2 in der EIN-Position wie

folgt aktiviert:

EIN

AUS

8.2. Fernempfindlichkeitseingang (Abb. 6, Klemme 10)

Wenn dieser Eingang aktiv ist, wird die

Melderempfindlichkeit verringert. Der

Empfindlichkeitseingang darf nur unter bestimmtem

Umständen angewendet werden, und das nur für

kurze Zeiträume. Die Reduzierung der

Empfindlichkeit muss in Übereinstimmung mit den

geltenden Vorschriften (z. B. gemäß VdS) erfolgen.

Die Fernempfindlichkeit wird durch Verbindung der

Klemme 8 mit Klemme 10 aktiviert.

LSNi-Anwendung mit

manueller Adressierung

Einstellung von Element G in

Abb. 1 auf die entsprechende

Adresse (siehe Tabelle im

Anhang am Ende des

Dokuments).

Abb. 1, Element J EIN-Position

LSN-Anwendung im

GM570LSNKompatibilitätsmodus

Dieser Modus ermöglicht den

kompatiblen Einsatz des ISPSM90-120 in bestehenden

Installationen als Ersatz eines

GM570LSN-Melders.

Die Detektionseigenschaften

sind in allen Konfigurationen

identisch.

Abb. 1, Element G beliebige

Position

Abb. 1, Element J in AUSPosition

Schalter 2 EIN = Nur interne

Sabotagekontakte

Schalter 2 AUS = Interne und

externe Sabotagekontakte

Verbinden Sie Klemme 8

mit Klemme 11, um ein

Sabotagesignal zu

verhindern (Abb. 6).

Die Empfindlichkeit wird für die Dauer des Signals am

Fernempfindlichkeitseingang auf 12,5 % der

Originaleinstellung reduziert. Eine potentielle Anwendung ist

die Verhinderung der Alarmauslösung bei starken

funktionsbedingten Geräuschen.

9. Programmierung über LSNi/LSN-Zentrale

Die Programmierung des Melders erfolgt über die

Konfigurationssoftware der entsprechenden Zentrale.

10. Wirkradius

Der angegebene Wirkradius gilt für einen Angriff mit

Sauerstofflanze. Bei einem Angriff mit mechanischem

Werkzeug (z. B. Bohrer) kann sich der Wert bis auf das

Dreifache erhöhen. Der angegebene Wirkradius ist ein

Richtwert, der stark von der Beschaffenheit des Untergrunds

beeinflusst wird.

11. Schlagempfindlichkeit

Die Schlagempfindlichkeit definiert, wie der Melder auf

einzelne Schläge auf den Untergrund des Melders reagiert.

Die unabhängige Einstellung der Schlagempfindlichkeit von

Modus und Wirkradius ist nur im USER MODE über die

LSNi/LSN-Zentrale möglich.

Modus Wirkradius

Beton 5m* Hoch Tresorraum

Beton 4m Hoch

Beton 2,5m Hoch

Stahl 2m Mittel

Stahl 1,5m Mittel

Stahl 1m* Niedrig

LWS 2m Hoch

LWS 1,5m Hoch

*Modi nicht im GM570LSN-Kompatibilitätsmodus verfügbar

*Ob diese Optionen verfügbar sind, hängt davon ab,

inwiefern die Zentrale den Melder als einen ISP-SM90-120

erkennt. Einige Zentralen könnten den ISP-SM90-120 als ein

GM570LSN identifizieren.

11.1. Funktionstest

Die LSNi/LSN-Zentrale kann zusammen mit einem

montierten internen Prüfsender ISN-GMX-S1 einen

Funktionstest auslösen. Der ISN-GMX-S1 wird über die

Zentrale mithilfe einer Schallmeldetestfunktion aktiviert. Bei

korrekt funktionierendem Melder löst dieser Alarm aus

(Auslösezeit < 3 s).

11.2. Automatischer Selbsttest

Mit der LSNi/LSN-Zentrale kann das Zeitintervall

(Stunde/Tag/Woche) für den automatischen Selbsttest

Schlag-

empfindlichkeit*

Anwendungsbeispiel

Tresorraum,

Elementtresor

Tresorraum,

Elementtresor

Panzer-Geldschrank,

Tresorraumtür

Panzer-Geldschrank,

Tresorraumtür,

Geldautomat

Geldautomat, Safe,

Tresortür

Panzerungssysteme

mit

Kunststoffen/Verbun

dwerkstoffen

Panzerungssysteme

mit

Kunststoffen/Verbun

dwerkstoffen

F.01U.331.565-01 9 © 2016 Bosch Security Systems, Inc.

Page 10

festgelegt werden. Die Zentrale erkennt jeden

fehlgeschlagenen Selbsttest.

Der Melder muss mit einem internen Prüfsender ISN-GMX-S1

ausgestattet sein.

12. Inbetriebnahme

1. Initialisieren Sie den LSNi/LSN-Bus.

2. Warten Sie 60 Sekunden.

Der Melder ist nun betriebsbereit.

3. Überprüfen Sie, ob der korrekte Radius und Materialtyp

mithilfe der Zentrale gewählt wurden.

Überprüfen Sie mithilfe eines Multimeters (Ri ≥ 20 kΩ) an

Klemme 1 (0 V) und Testpunkt (Abb. 1, Element D) das

analoge Integrationssignal:

Ruhepegel 0 V

Integrationsstart 1 V

Alarmschwelle (unbelastet) 3 V

12.1. Funktionsprüfungen

Funktionsprüfungen können wie folgt ausgeführt werden:

• Nehmen Sie die Abdeckung ab und kratzen Sie das

Metallgehäuse des Melders mit einem Schraubendreher

an.

• Aktivieren Sie den internen Prüfsender ISN-GMX-S1 über

die Zentrale mithilfe einer Schallmeldetestfunktion.

• Legen Sie das erforderliche Eingangssignal an, um den

externen Prüfsender GMXS5 (falls vorhanden) zu

aktivieren.

• Simulieren Sie einen Angriff auf den zu schützenden

Bereich.

• Setzen Sie die Abdeckung wieder auf und sichern Sie

sie.

13. Service

Die Funktion des Melders und dessen Montage müssen

mindestens einmal jährlich wie folgt geprüft werden:

• Testen Sie den Melder auf eine ordnungsgemäße

Funktion entsprechend Abschnitt 12.1.

• Überprüfen Sie die Einstellungen des Melders mithilfe

der Menüoptionen der Zentrale.

• Überprüfen Sie die Montage des Melders, um

sicherzustellen, dass er sicher befestigt ist.

• Überprüfen Sie, ob ein direkter Kontakt zwischen dem

Melder und der Montagefläche besteht. Farben, Lacke,

Schmutz, Silikon o. Ä. behindern die Schallübertragung.

Siehe lokale Zulassungen für weitere Informationen zu

diesem Thema.

14. Elementtresore

Beim Einsatz des Körperschallmelders in und an

Elementtresoren aus Stahl und Betonmaterial sind folgende

Grundsätze unbedingt zu beachten:

• Stärke von 100 bis 400 mm

• Breite bis 1.000 mm

• Länge bis 6.500 mm

Elemente mit Melderanordnung

1 2 3 4 5 1 2 3 4 5 . . . .

Eckverbindung Wand/Wand

durchgehend verschweißt

Immer 1 Melder an

Türen

1. Ein Melder für jeweils maximal 5 Wandelemente. Der

Melder muss auf dem mittleren Element montiert

werden.

2. Alle Fugen zwischen den Elementen müssen zusätzlich

zu einer Verschraubung punktuell alle 400 bis 500 mm

mit einer 30 bis 40 mm langen Schweißnaht verschweißt

sein.

3. Eckverbindungen bei Wandelementen müssen

durchgehend verschweißt werden, wenn der

Wirkbereich sich auch über die Ecken erstrecken soll.

4. Werden Wandelemente mit Meldern bestückt, kann das

direkt angrenzende Boden- und/oder Deckenelement in

den Wirkbereich mit einbezogen werden, wenn die

entsprechende Stoßstelle durchgehend verschweißt

wird.

5. Wenn in Tresoren unterschiedliche Elementdicken

kombiniert werden, müssen die Stoßstellen

durchgehend verschweißt werden.

6. Bringen Sie Melder soweit möglich nicht auf Elementen

an, an denen Führungsschienen von KassettenTransportlifts, Ventilatoren oder andere mechanische

Einrichtungen befestigt sind.

7. Verwenden Sie immer Elemente, die mit einer Ein-

/Ausgabeöffnung mit Melder ausgestattet sind. Dadurch

können auch die angrenzenden Elemente überwacht

werden.

8. Alle Türen müssen mit einem eigenen Melder

ausgestattet sein.

9. Programmierung:

Empfohlene Einstellung

Auf max. 5 Elementen mit

Beton 4m

max. Höhe von 6,5 m

Auf max. 3 Elementen mit

Beton 2,5m

max. Höhe von 4 m

Auf Türen Stahl, 2m

15. Technische Daten

Abmessungen 89mm × 89mm × 23mm

Versorgungsspannung

(LSNi/LSN)

Stromaufnahme (LSNi/LSN) Ityp. = 1,2 mA

Sabotageüberwachung:

• Mikroschalter,

Abdeckung + Entfernung

• Externer

Sabotagekontakt

(Abb. 6, Klemme 11)

Vmax. = 33 V DC

Imax. = 1,625 mA

Öffnet bei Sabotage

F.01U.331.565-01 10 © 2016 Bosch Security Systems, Inc.

Page 11

o Widerstand

geschlossen

o Widerstand

offen

• Bohrschutzfolie auf der

Innenseite der

Abdeckung (optional)

• Für Absenkung der

Empfindlichkeit

Betriebstemperatur –25 °C bis +70 °C

Lagertemperatur –50 °C bis +70 °C

Luftfeuchtigkeit (EN 60721),

nicht kondensierend

Zulassungen Siehe Typenschild auf

< 20 kΩ

> 650 kΩ

Beschädigung = Sabotage

LOW < 1,5 V DC

< 95 %

Innenseite der Abdeckung

(Abb. 5)

16. Bestellangaben

ISP-SM90-120

Körperschallmelder

ISN-GMX-P0

Montageplatte

ISN-GMX-S1

Interner Prüfsender

ISN-GMX-W0

Wand-/Deckeneinbaudose

ISN-GMX-B0

Bodeneinbaudose

ISN-GMX-P3S

Schlossschutz

ISN-GMX-P3SZ

Schlossschutz

GMAS6

Bewegliches Montagekit

ISN-GMX-D7

Bohrschutzfolie (10×)

F.01U.173.560

F.01U.003.366

F.01U.003.371

F.01U.003.372

F.01U.003.365

F.01U.003.368

F.01U.003.370

F.01U.003.363

F.01U.004.305

F.01U.331.565-01 11 © 2016 Bosch Security Systems, Inc.

Page 12

Appendix Anhang

Settings for the LSNi operating mode with manual addressing

Einstellungen für die Betriebsart LSNi mit manueller Adressierung

Switch setting Fig. 1, item G Schalterstellung Fig. 1, item G

O = OFF 1 = ON O = OFF 1 = ON

87654321 A87654321 A87654321

Adresse

LSNi auto

LSN classic

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

00000000

00000001

00000010

00000011

00000100

00000101

00000110

00000111

00001000

00001001

00001010

00001011

00001100

00001101

00001110

00001111

00010000

00010001

00010010

00010011

00010100

00010101

00010110

00010111

00011000

00011001

00011010

00011011

00011100

00011101

00011110

00011111

00100000

00100001

00100010

00100011

00100100

00100101

00100110

00100111

00101000

00101001

00101010

00101011

00101100

00101101

00101110

00101111

00110000

00110001

00110010

00110011

00110100

00110101

00110110

00110111

00111000

00111001

00111010

00111011

00111100

00111101

00111110

00111111

01000000

01000001

01000010

01000011

01000100

01000101

01000110

01000111

01001000

01001001

01001010

01001011

01001100

01001101

01001110

01001111

01010000

01010001

01010010

01010011

01010100

85

01010101

86

01010110

87

01010111

88

01011000

89

01011001

90

01011010

91

01011011

92

01011100

93

01011101

94

01011110

95

01011111

96

01100000

97

01100001

98

01100010

99

01100011

100

01100100

101

01100101

102

01100110

103

01100111

104

01101000

105

01101001

106

01101010

107

01101011

108

01101100

109

01101101

110

01101110

111

01101111

112

01110000

113

01110001

114

01110010

115

01110011

116

01110100

117

01110101

118

01110110

119

01110111

120

01111 0 00

121

01111 0 01

122

01111 0 10

123

01111 0 11

124

01111100

125

01111101

126

01111110

127

01111111

128

10000000

129

10000001

130

10000010

131

10000011

132

10000100

133

10000101

134

10000110

135

10000111

136

10001000

137

10001001

138

10001010

139

10001011

140

10001100

141

10001101

142

10001110

143

10001111

144

10010000

145

10010001

146

10010010

147

10010011

148

10010100

149

10010101

150

10010110

151

10010111

152

10011000

153

10011001

154

10011010

155

10011011

156

10011100

157

10011101

158

10011110

159

10011111

160

10100000

161

10100001

162

10100010

163

10100011

164

10100100

165

10100101

166

10100110

167

10100111

168

10101000

169

10101001

170

10101010

171

10101011

172

10101100

173

10101101

174

10101110

175

10101111

176

10110000

177

10110001

178

10110010

179

10110011

180

10110100

181

10110101

182

10110110

183

10110111

184

10111000

185

10111001

186

10111010

187

10111011

188

10111100

189

10111101

190

10111110

191

10111111

192

11000000

193

11000001

194

11000010

195

11000011

196

11000100

197

11000101

198

11000110

199

11000111

200

11001000

201

11001001

202

11001010

203

11001011

204

11001100

205

11001101

206

11001110

207

11001111

208

11010000

209

11010001

210

11010010

211

11010011

212

11010100

213

11010101

214

11010110

215

11010111

216

11011000

217

11011001

218

11011010

219

11011011

220

11011100

221

11011101

222

11011110

223

11011111

224

11100000

225

11100001

226

11100010

227

11100011

228

11100100

229

11100101

230

11100110

231

11100111

232

11101000

233

11101001

234

11101010

235

11101011

236

11101100

237

11101101

238

11101110

239

11101111

240

11110000

241

11110001

242

11110010

243

11110011

244

11110100

245

11110101

246

11110110

247

11110111

248

11111000

249

11111001

250

11111010

251

11111011

252

11111100

253

11111101

254

11111110

F.01U.331.565-01 12 © 2016 Bosch Security Systems, Inc.

Loading...

Loading...