Bosch GST 140 CE, GST 140 BCE User Manual

GST 140 BCE

Professional

Robert Bosch Power Tools GmbH

1 609 92A 50K

70538 Stuttgart

GERMANY

www.bosch-pt.com

GST Professional

1 609 92A 50K (2019.05) T / 57

140 CE | 140 BCE

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

id Petunjuk-Petunjuk untuk Penggun

vi Bản gốc hướng dẫn sử dụng

ต้นแบบ

aan Orisinal

2 |

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. Page 7

中文 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 页 15

繁體中文. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. . 頁 19

한국어 .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 페이지 24

ไทย. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . หน้า 30

Bahasa Indonesia. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. Halaman 36

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. .. Trang 43

1 609 92A 50K | (10.05.2019) Bosch Power Tools

GST 140 CE

GST 140 BCE

(1)

(3)

(4)

(2)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(1)

(3)

(4)

(12)

(14)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(12)

| 3

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

+ 40°

–

40°

A

B

(15)

(11)

(10)

(13)

(9)

E

(5)

(6)

(19)

D

C

(16)

(11)

(18)

(17)

(15)

(11)

(6)

T 144 D

T 244 D

4 |

1 609 92A 50K | (10.05.2019) Bosch Power Tools

| 5

H I

J K

(21)

(22)

(23)

(6)

(17)

(21)

(15)

(6)

(13)

G

(20)

F

(16)

(6)

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

L

6 |

1 609 92A 50K | (10.05.2019) Bosch Power Tools

English

Safety instructions

General Power Tool Safety Warnings

WARNING

tions provided with this power tool. Failure to follow all in-

structions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

Read all safety warnings, instructions, illustrations and specifica-

English | 7

tion while operating power tools may result in serious personal injury.

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as a dust mask,

non-skid safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair and clothing away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

u Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe in-

jury within a fraction of a second.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or re-

move the battery pack, if detachable, from the power

tool before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools and accessories. Check for mis-

alignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

8 | English

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

u Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety instructions for jigsaws

u Hold the power tool by insulated gripping surfaces,

when performing an operation where the cutting accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give

the operator an electric shock.

u Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the workpiece by hand or against your body leaves it unstable and may lead to loss of control.

u Keep hands away from the sawing area. Do not reach

under the workpiece. Contact with the saw blade can

lead to injuries.

u Only bring the power tool into contact with the work-

piece when switched on. Otherwise there is danger of

kickback if the cutting tool jams in the workpiece.

u Ensure that the footplate always rests securely while

sawing. A jammed saw blade can break or lead to kickback.

u When the cut is completed, switch off the power tool

and then pull the saw blade out of the cut only after it

has come to a standstill. In this manner you can avoid

kickback and can place down the power tool securely.

u Always wait until the power tool has come to a com-

plete stop before placing it down. The application tool

can jam and cause you to lose control of the power tool.

u Use only undamaged saw blades that are in perfect

condition. Bent or dull saw blades can break, negatively

influence the cut, or lead to kickback.

u Do not brake the saw blade to a stop by applying side

pressure after switching off. The saw blade can be damaged, break or cause kickback.

u Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead

to fire and electric shock. Damaging a gas line can lead to

explosion. Penetrating a water line causes property damage or may cause an electric shock.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric

plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

Product Description and Specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended Use

The power tool is intended for making separating cuts and

cut-outs in wood, plastic, metal, ceramic plates and rubber

while resting firmly on the workpiece. It is suitable for

straight and curved cuts with mitre/bevel angles of up to

45°. Note the saw blade recommendations.

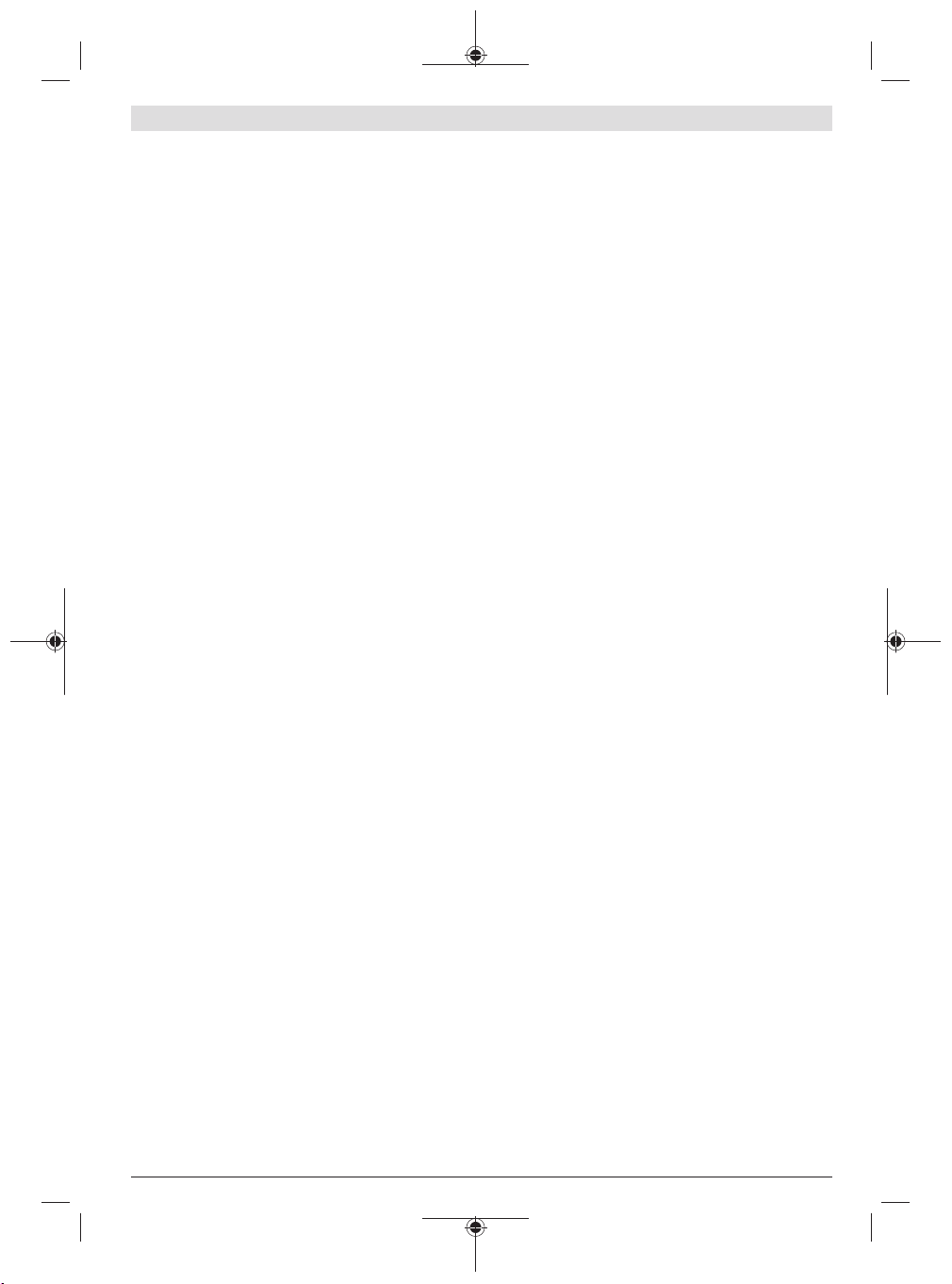

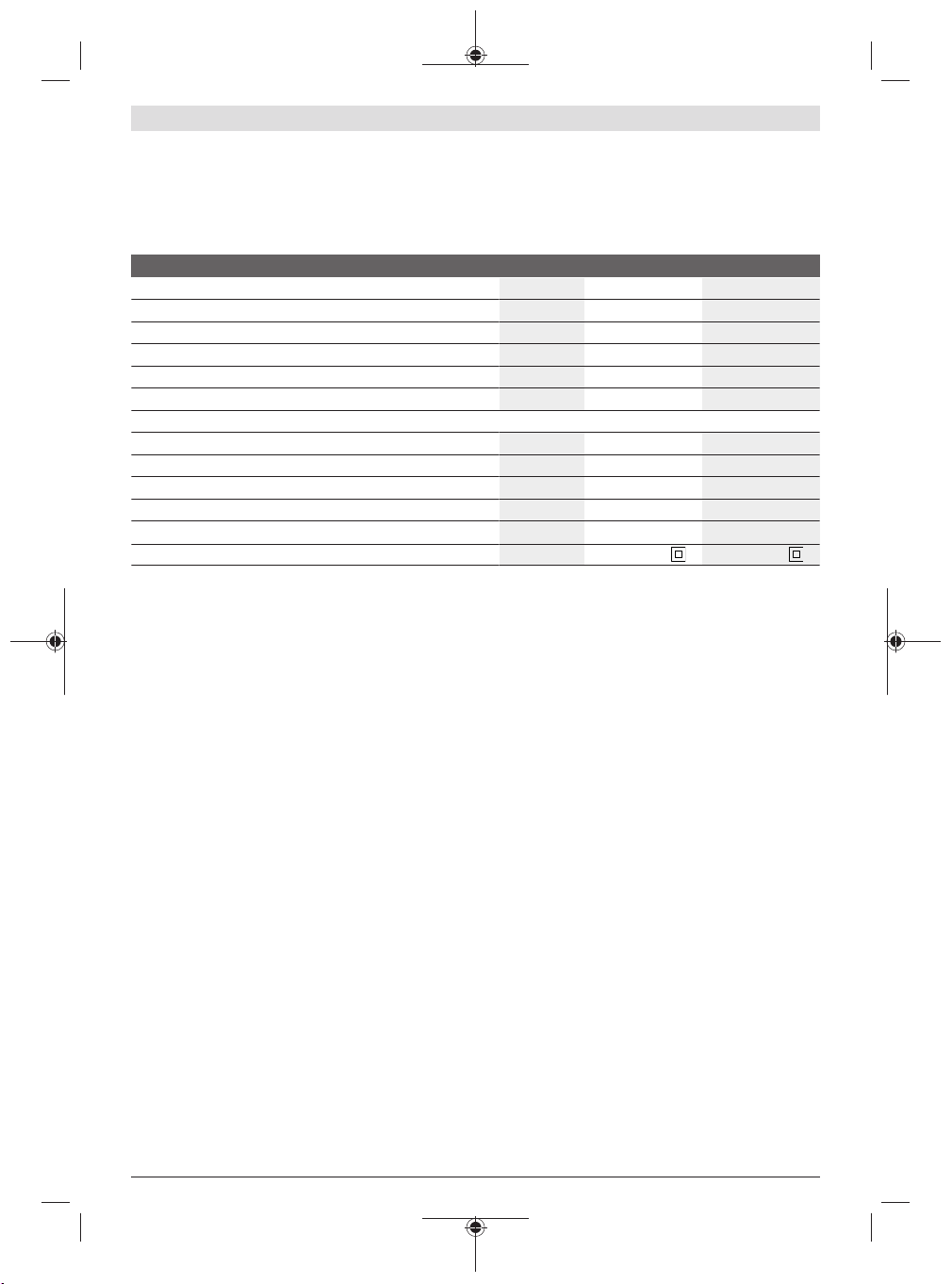

Product Features

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

Worklight button

(1)

On/off switch locking mechanism (GST140BCE)

(2)

On/off switch

(3)

Stroke rate preselection thumbwheel

(4)

Plastic guide plate

(5)

Base plate

(6)

Sawdust blower device switch

(7)

Orbital action adjusting lever

(8)

SDS lever for saw blade release

(9)

Guide roller

(10)

Saw blade

(11)

Worklight

(12)

Shock protection guard

(13)

Handle (insulated gripping surface)

(14)

Saw blade receptacle

(15)

Anti-splinter guard

(16)

Base plate clamping lever

(17)

Base plate screw

(18)

Steel glide shoe

(19)

Hood for dust extraction

(20)

A)

A)

1 609 92A 50K | (10.05.2019) Bosch Power Tools

English | 9

Extraction outlet

(21)

Extraction hose

(22)

A)

Scale for mitre/bevel angles

(23)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

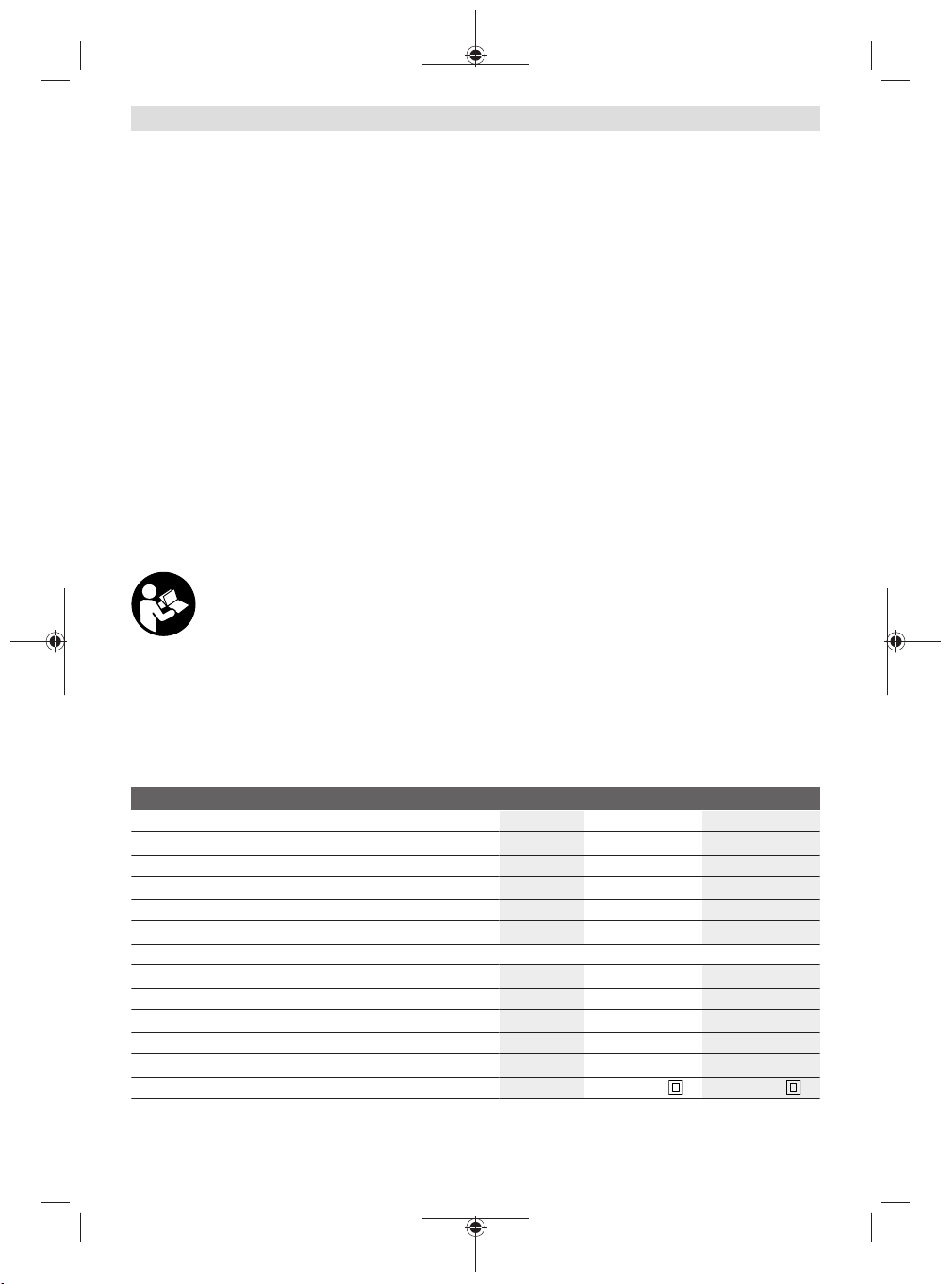

Technical Data

Jigsaw GST 140 CE GST 140 BCE

Article number

Stroke rate control ● ●

Constant electronic control ● ●

Rated power input W 720 720

No-load stroke rate n

0

min

Stroke mm 26 26

Max. cutting depth

– In wood mm 140 140

– In aluminium mm 20 20

– In steel (unalloyed) mm 10 10

Max. cutting angle (left/right) ° 45 45

Weight according to EPTA-Procedure 01:2014 kg 2.2 2.3

Protection class

The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

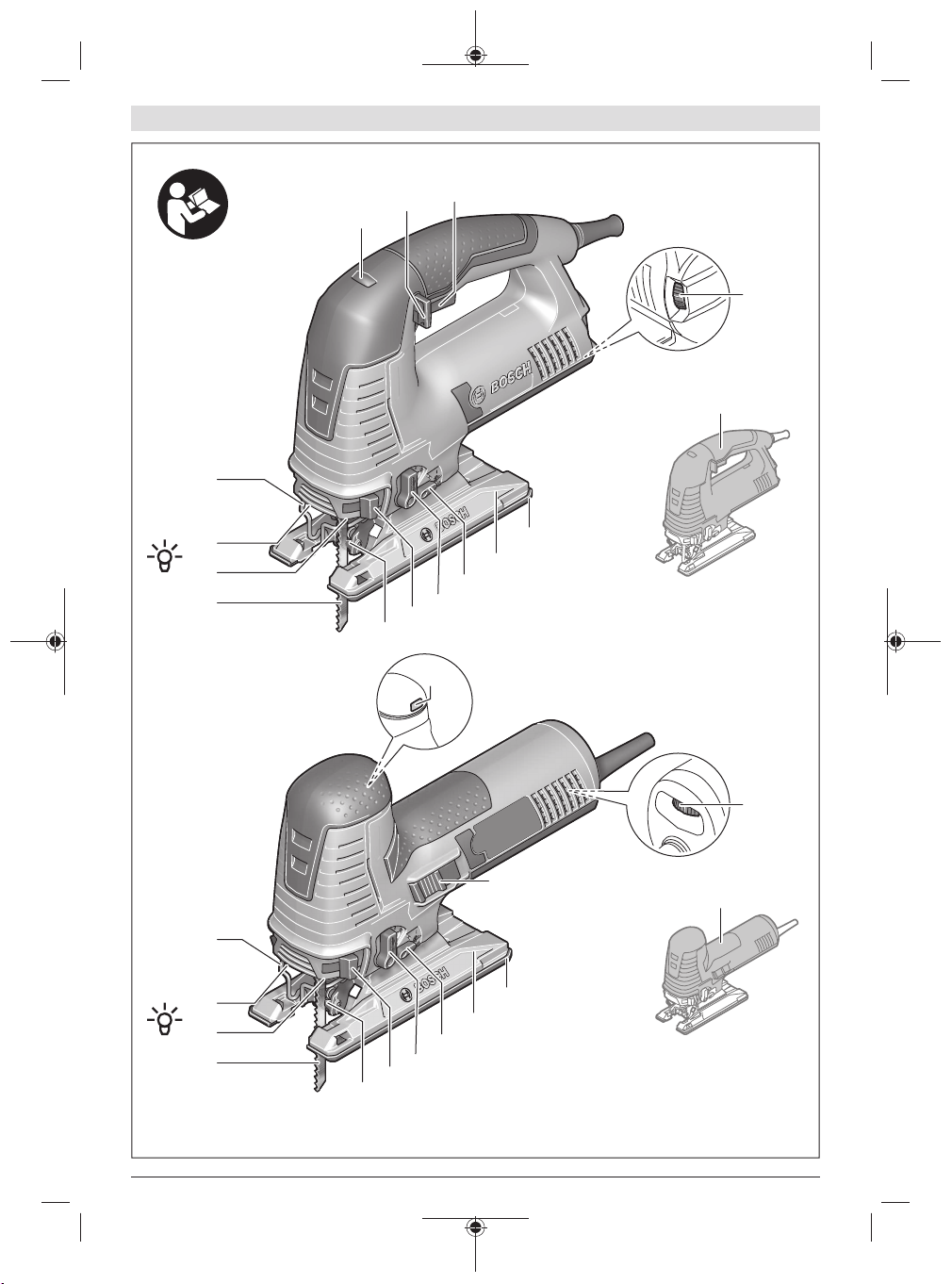

Inserting/changing the saw blade

u When fitting or changing the saw blade, wear protect-

ive gloves. Blades are sharp and can become hot when

used for prolonged periods of time.

Selecting the saw blade

You will find an overview of recommended saw blades at the

end of these operating instructions. Only use saw blades

with single lug shank (T shank). The saw blade should not be

longer than required for the intended cut.

Use a narrow saw blade when sawing tight curves.

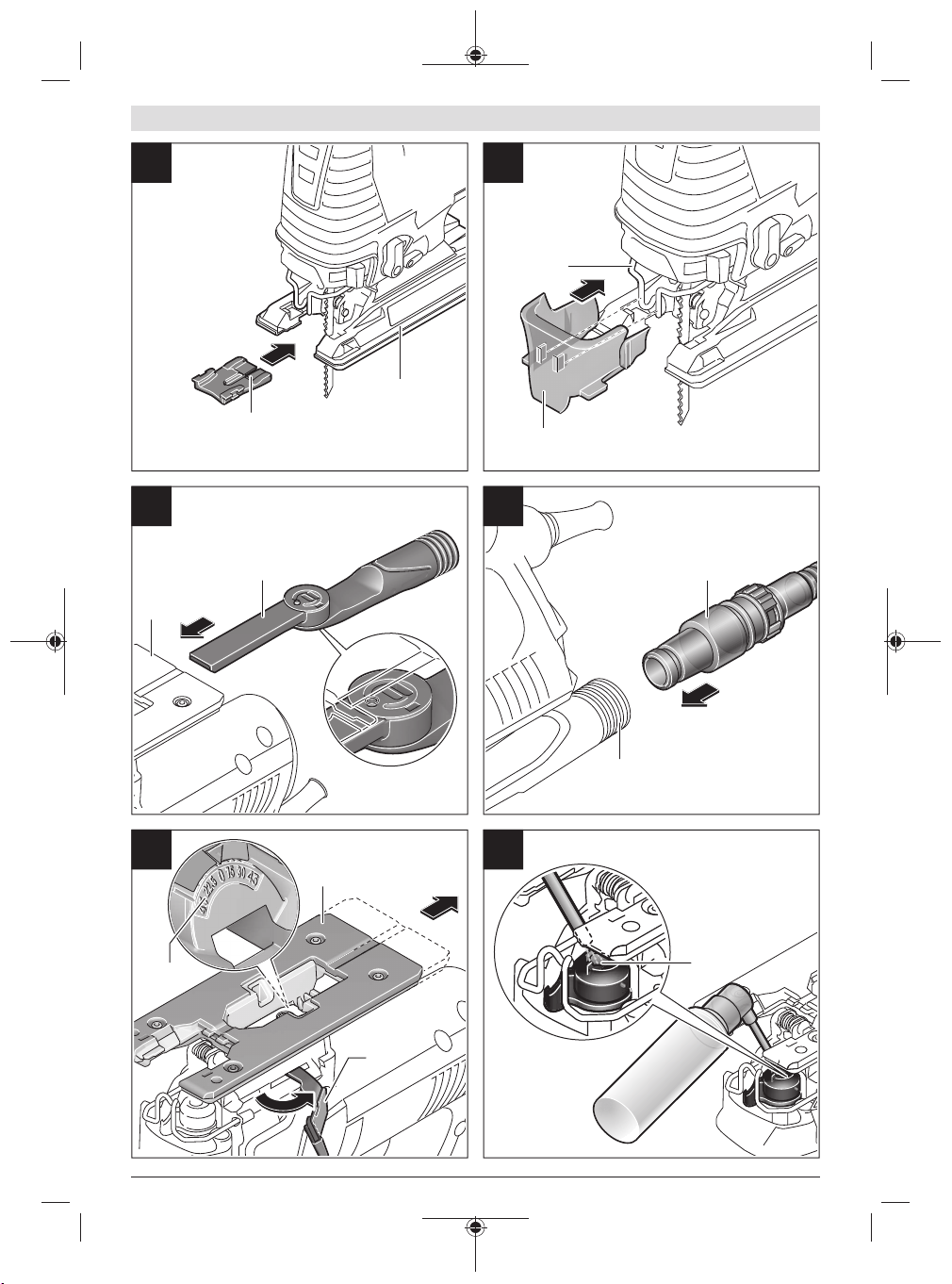

Inserting the saw blade (seefigure A)

u Clean the shaft on the saw blade before inserting it.

Adirty shaft cannot be securely fixed in place.

Push the saw blade (11), with the teeth in the cutting direction, into the saw blade receptacle (15) until it clicks into

place.

Make sure when inserting the saw blade that the back of the

saw blade is in the groove on the guide roller (10).

u Check that the saw blade is seated securely. A loose

saw blade can fall out and lead to injuries.

Ejecting the saw blade (seefigure B)

u When ejecting the saw blade, hold the power tool in

such a manner that no persons or animals can be injured by the ejected saw blade.

Turn the SDS lever (9) as far as it will go in the direction of

the shock protection guard (13). The saw blade is released

and ejected.

Adjusting the base plate (seefiguresC−D)

When sawing with a mitre/bevel angle of 0°, if the base

plate(6) is not precisely at a right angle to the saw

blade(11), the base plate will need to be readjusted:

– Insert a saw blade(11) into the saw blade recept-

acle(15).

– Slide the anti-splinter guard(16) into the base plate(6)

from the front.

– Insert an additional short saw blade(11) into the front re-

cess of the anti-splinter guard as shown in the figureC.

– Open the clamping lever(17) of the base plate.

– Turn the screw(18) of the base plate clockwise or anti-

clockwise until both inserted saw blades are in a line one

after the other.

– Close the clamping lever(17) of the base plate.

– Remove the saw blade(11) from the anti-splinter

guard(16).

Glide shoe (see figure E)

The plastic guide plate(5) of the base plate(6) reduces

scratching on sensitive surfaces. Use the steel glide

shoe(19) when machining metal.

Fit the steel glide shoe(19) by sliding it onto the base

plate(6) from the front.

The plastic guide plate(5) should be replaced if it is worn.

3601E140.. 3601E150..

−1

800–2800 800–2800

/II /II

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

10 | English

Anti-splinter guard (see figureF)

The anti-splinter guard (16) (accessory) can prevent splintering of the surface while sawing wood. The anti-splinter

guard can only be used with certain saw blade types and only

at a cutting angle of 0°. When sawing with the anti-splinter

guard, the base plate (6) must not be moved to the rear for

sawing close to edges.

Slide the anti-splinter guard (16) into the base plate (6)

from the front.

Dust/Chip Extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

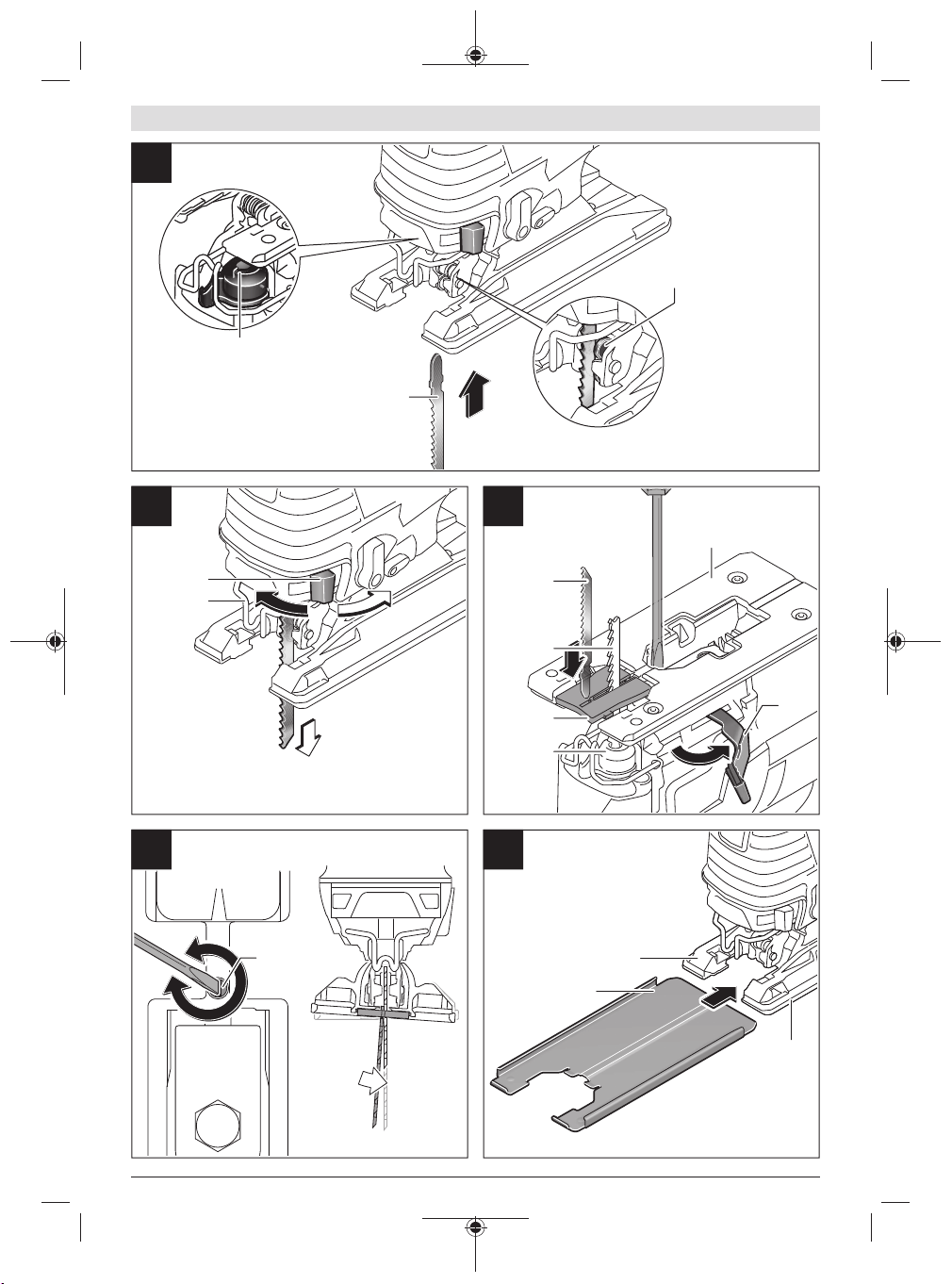

Hood (see figureG)

Fit the hood (20) before you connect the power tool to the

dust extraction system.

Attach the hood(20) to the power tool so that the bracket

locks into place on the shock protection guard(13).

Remove the hood(20) when working without a dust extraction system and for mitre/bevel cuts. To do this, pull the

hood forwards off the shock protection guard(13).

Connecting the dust extraction (seefiguresH–I)

Fit the extraction outlet(21) in the recesses of the base

plate(6).

Ensure that the cam on the extraction outlet slots into the

corresponding recess of the base plate(6) as shown in the

figureH.

Connect a dust extraction hose (22) (accessory) to the extraction outlet (21). Connect the dust extraction hose (22)

to a dust extractor (accessory).

You will find an overview of connecting to various dust extractors at the end of these operating instructions.

For optimum dust extraction, where possible use the antisplinter guard (16).

Switch off the sawdust blower device when you have connected the dust extraction system.

The dust extractor must be suitable for the material being

worked.

When extracting dry dust that is especially detrimental to

health or carcinogenic, use a special dust extractor.

Operation

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Operating modes

u Pull the plug out of the socket before carrying out any

work on the power tool.

Pendulum action settings

The pendulum action can be adjusted using four different

settings, allowing the cutting speed, cutting capacity and the

cut itself to be optimally adapted to the material that you

want to cut.

You can also adjust the pendulum action during operation

using the adjusting lever (8).

Level 0 No pendulum action

LevelI Low pendulum action

LevelII Moderate pendulum action

LevelIII High pendulum action

The optimum pendulum level for each application can be determined by a practical test. Note the following recommendations:

– Select a lower pendulum level or switch off the pendulum

action completely if you wish to produce a finer or cleaner

cutting edge.

– Switch off the pendulum action when machining thin ma-

terials (e.g. sheets).

– Work on hard materials (e.g. steel) with low pendulum ac-

tion.

– You can work on soft materials and saw wood in the direc-

tion of the grain using maximum pendulum action.

Adjusting the mitre/bevel angle (seefigureJ)

The base plate (6) can be swivelled to the right or left to

make mitre cuts up to 45°.

The hood(20), the extraction outlet(21) and the antisplinter guard(16) cannot be used while mitre/bevel cuts

are being made.

– Push the extraction outlet(21) gently upwards and pull it

out of the base plate(6).

– Remove the hood(20) and the anti-splinter guard(16).

– Open the base plate clamping lever(17) and push the

base plate(6) slightly towards the power cable.

– The base plate has lock-in points on the left and right so

that precise mitre/bevel angles can be set. Swivel the

base plate(6) to the required position according to the

scale(23). Other mitre/bevel angles can be adjusted us-

ing a protractor.

– Then push the base plate(6) towards the saw blade(11)

as far as it will go.

– Close the clamping lever(17) to lock the base plate in the

set position.

1 609 92A 50K | (10.05.2019) Bosch Power Tools

English | 11

Moving the base plate (seefigureJ)

You can move the base plate (6) back for sawing close to

edges.

Open the base plate clamping lever(17) and push the base

plate(6) towards the power cable as far as it will go. Close

the clamping lever to lock the base plate.

Sawing with an offset base plate (6) is only possible with a

mitre angle of 0°. In all other cases the anti-splinter guard

(16) may not be used. Sawdust blower device

The cutting line can be kept clear of chips using the airflow

from the sawdust blower device.

Switch on the sawdust blower device for work in wood,

plastic, etc. with a high level of material removal. Do this by

sliding the switch(7) to the "I" position.

Switch off the sawdust blower device when working in metal

or with a dust extraction system connected. Do this by sliding the switch(7) to the "0" position.

Starting Operation

u Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230V can also be operated with 220V.

Switching on the LED worklight

To switch the worklight(12) on or off, press the worklight

button(1).

u Do not look directly into the worklight; it can blind

you.

Switching on and off (GST140CE)

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To switch on the power tool, slide the on/off switch(3) forwards so that "I" appears on the switch.

To switch off the power tool, slide the on/off switch(3)

backwards so that "0" appears on the switch.

Switching on and off (GST140BCE)

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To switch on the power tool, press the on/off switch (3).

To lock the on/off switch (3), keep it pressed down and

push the locking mechanism (2) to the right or left.

To switch off the power tool, release the on/off switch (3).

If the on/off switch (3) is locked, press the switch first and

then release it.

Restart protection

The restart protection feature prevents the power tool from

uncontrolled starting after the power supply to it has been

interrupted.

To restart the tool, set the on/off switch(3) to the off position and then switch the power tool on again.

Constant Electronic control

The Constant Electronic control keeps the stroke rate at no

load and under load virtually consistent, guaranteeing uniform performance.

Controlling the stroke rate (GST140BCE)

You can variably adjust the stroke rate of the power tool

when it is on by pressing in the on/off switch (3) to varying

extents.

Applying light pressure to the on/off switch (3) results in a

low stroke rate. Applying increasing pressure to the switch

increases the stroke rate.

Preselect the stroke rate

You can also preselect the stroke rate and change it during

operation using the stroke rate preselection thumbwheel

(4).

The required stroke rate is dependent on the material and

the work conditions and can be determined using practical

tests.

It is recommended that you reduce the stroke rate when

placing the saw blade on the workpiece and when sawing

plastic and aluminium.

During prolonged periods of use at a low stroke rate, the

power tool may heat up significantly. Remove the saw blade

and let the power tool run at the maximum stroke rate for

around three minutes to cool down.

Working Advice

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Switch the power tool off immediately if the saw blade

becomes blocked.

u When machining small or thin workpieces, always use

a stable base or saw table (accessory).

Before sawing into wood, chipboard, building materials,

etc., check for and remove any foreign objects such as nails,

screws, etc.

Plunge cutting (see figureL)

u Plunge cuts may only be applied to soft materials,

such as wood, gypsum board, etc.

For plunge cutting, use only short saw blades. Plunge cutting

is possible only with a mitre angle of 0°.

Place the power tool so that the front edge of the base plate

(6) rests on the workpiece, without the saw blade (11)

touching the workpiece, and switch it on. On power tools

with stroke rate control, select the maximum stroke rate.

Press the power tool firmly against the workpiece and allow

the saw blade to plunge slowly into the workpiece.

As soon as the base plate (6) rests fully on the workpiece,

continue sawing along the required cutting line.

Coolant/lubricant

As the material heats up along the cutting line when cutting

metal, you should apply coolant or lubricant.

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

12 | English

Maintenance and Service

Maintenance and Cleaning

u Pull the plug out of the socket before carrying out any

work on the power tool.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by Bosch or by an

after-sales service centre that is authorised to repair Bosch

power tools.

Clean the saw blade receptacle regularly. For this, remove

the saw blade from the power tool and lightly tap out the

power tool on a level surface.

If the power tool becomes very dirty, this can lead to serious

faults. For this reason, do not cut materials which generate

large quantities of dust from below or overhead.

u In extreme conditions, always use a dust extractor if

possible. Blow out ventilation slots frequently and install a residual current device (RCD) upstream. When

machining metals, conductive dust can settle inside the

power tool, which can affect its protective insulation.

If the dust outlet becomes blocked, switch off the power

tool, disconnect the dust extraction system and remove the

dust and chips.

Apply a drop of oil to the guide roller (10) from time to time.

Check the guide roller(10) regularly. If worn, it must be re-

placed through an authorised Bosch after-sales service

centre.

Regularly spray the saw blade receptacle(15) with penetrating oil (see figureK).

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. You can find explosion drawings and information on

spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the nameplate

of the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People’s Republic of China

China Mainland

Bosch Power Tool (China) Co. Ltd.

Bosch Service Center

567, Bin Kang Road

Bin Kang District

Hangzhou, Zhejiang Province

China 310052

Tel.: (0571) 8887 5566 / 5588

Fax: (0571) 8887 6688 x 5566# / 5588#

E-Mail: bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

India

Bosch Service Center

69, Habibullah Road, (next to PSBB School), T. Nagar

Chennai–600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi–110001

Phone: (011) 43166190

Bosch Service Center 79,

Crystal Bldg., Dr. Annie Besant Road, Worli

Mumbai–400018

Phone: (022) 39569936 / (022 )39569959 /

(022) 39569967 / (022) 24952071

Indonesia

PT Robert Bosch

Palma Tower 10th Floor

Jalan RA Kartini II-S Kaveling 6

Pondok Pinang, Kebayoran Lama

Jakarta Selatan 12310

Tel.: (21) 3005-5800

www.bosch-pt.co.id

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-Mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

Pakistan

Robert Bosch Middle East FZE – Pakistan Liaison Office

2nd Floor Plaza # 10, CCA Block, DHA Phase 5

Lahore, 54810

1 609 92A 50K | (10.05.2019) Bosch Power Tools

English | 13

Phone: +92(303)4444311

Email: Faisal.Khan@bosch.com

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio, Global City,

1634 Taguig City

Tel.: (632) 8703871

Fax: (632) 8703870

www.bosch-pt.com.ph

Singapore

Powerwell Service Centre Ptd Ltd

Bosch Authorised Service Centre (Power Tools)

4012 Ang Mo Kio Ave 10, #01-02 TECHplace

Singapore 569628

Tel.: 6452 1770

Fax: 6452 1760

E-Mail: ask@powerwellsc.com

www.powerwellsc.com

www.bosch-pt.com.sg

Thailand

Robert Bosch Ltd.

FYI Center Tower 1, 5th Floor,

2525 Rama IV Road, Klongtoei,

Bangkok 10110

Tel.: 02 0128888

Fax: 02 0645802

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Tel.: 02 7587555

Fax: 02 7587525

Vietnam

Branch of Bosch Vietnam Co., Ltd in HCMC

14th floor, Deutsches Haus, 33 Le Duan

Ben Nghe Ward, District 1, Ho Chi Minh City

Tel.: (028) 6258 3690

Fax: (028) 6258 3692 - 6258 3694

Hotline: (028) 6250 8555

Email: tuvankhachhang-pt@vn.bosch.com

www.bosch-pt.com.vn

Armenia, Azerbaijan, Georgia, Kyrgyzstan, Mongolia,

Tajikistan, Turkmenistan, Uzbekistan

TOO “Robert Bosch” Power Tools, After Sales Service

Muratbaev Ave., 180

050012, Almaty, Kazakhstan

Service Email: service.pt.ka@bosch.com

Official Website: www.bosch.com, www.bosch-pt.com

Bahrain

EA Juffali and Brothers for Technical Equipment Company.

Kingdom of Bahrain, Al Aker - Block 0624 - Road 2403 -

Building 0055D

Phone: +97317704537

Fax: +973177045257

Email: h.berjas@eajb.com.sa

Egypt

RBEG-LLC

22 Kamal Eldin Hussein

Sheraton Heliopolis

11799 Cairo

E-mail: boschegypt.powertools@eg.bosch.com

Iran

Robert Bosch Iran

3rd Floor, No 3, Maadiran Building

Aftab St., Khodami St., Vanak Sq.

Tehran 1994834571

Phone: +9821- 86092057

Iraq

Sahba Technology Group

Al Muthana airport road

Baghdad

Phone Bagdad: +964 (0) 7 901 930366

Phone Dubai: +971 (0) 4 422 1898

Email: duraid@sahbatechnology.com

Jordan

Roots Arabia – Jordan

Al-Hurriyah Street, Al-Muqabalein

Amman 11623, Jordan

P.O. Box: 110068

Tel. : +962 6 4398990

E-mail: bosch@rootsjordan.com

Kuwait

Shuwaikh Industrial Area, Block 1, Plot 16, Street 3rd

P.O. Box 164 – Safat 13002

Phone: +965 - 2496 88 88

Fax: +965 - 2481 08 79

E-mail: josephkr@aaalmutawa.com

Lebanon

Tehini Hana & Co. S.A.R.L.

P.O. Box 90-449

Jdeideh 1202 2040

Dora-Beirut

Phone: +9611255211

Email: service-pt@tehini-hana.com

Libya

El Naser for Workshop Tools

Swanee Road, Alfalah Area

Tripoli

Phone: +218 21 4811184

Oman

Malatan Trading & Contracting LLC

P.O. Box 131, Ruwi, Muscat

Postal Code: 112, Sultanate of Oman

Phone: +968 2479 4035/4089/4901

Mob: +968-91315465

Fax: +968 2479 4058

E-Mail: sudhirkumar@malatan.net

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

14 | English

Qatar

International Construction Solutions W L L

P. O. Box 51, Doha

Phone: +974 40065458

Fax: +974 4453 8585

Email: csd@icsdoha.com

Saudi Arabia

Juffali Technical Equipment Co. (JTECO)

P.O.Box: 1049 – Jeddah 21431 – KSA

Jeddah: 00966(0)126920770 – Ext433

Riyadh: 00966(0)114093976 – Ext-30/34/39

Dammam: 00966(0)138339565

E-mail: M.Zreik@eajb.com.sa

Syria

Dallal Establishment for Power Tools

Damascus. Baramkeh street - Ibn Amer street,

Phone: +963112241006 or 009631122414009

Mobile: 00963991141005

Email: rita.dallal@hotmail.com

United Arab Emirates

Central Motors & Equipment,

P.O. Box 26255, Dubai

Dubai: 00971(0)43090920/3090930

Abu Dhabi: 00971(0)24017745

Sharjah: 00971(0)65932777

Al Ain: 00971(0)37157419

E- Mail: Mallappa.Madari@centralmotors.ae

Yemen

Abu Alrejal Trading Corporation

P.O. Box : 17024 , Zubeiry St.

Sana'a, Yemen

Tel: +967-1-20 20 10

Fax: +967-1-47 19 17

E-mail: tech-tools@abualrejal.com/yahya@abualrejal.com

Ethiopia

Forever plc

Kebele 2,754, BP 4806,

Addis Ababa

Phone: +251 111 560 600

Email: foreverplc@ethionet.et

Ghana

Peew-Williams Services Company Ltd

Mile 7, Plot 331, Before Achimota Mall.

Accra

Tel. +233552352511

E-mail: info@peew-williams.com

Kenya

Robert Bosch East Africa Ltd

Mpaka Road P.O. Box 856

00606 Nairobi

Nigeria

Robert Bosch Nigeria Ltd.

52–54 Isaac John Street P.O. Box

GRA Ikeja – Lagos

Republic of South Africa

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-Mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-Mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-Mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-Mail: rbsa-hq.pts@za.bosch.com

Tanzania

Diesel & Autoelectric Service Ltd.

117 Nyerere Rd., P.O. Box 70839

Vingunguti 12109, Dar Es Salaam

Phone: +255 222 861 793/794

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

Disposal

The power tool, accessories and packaging should be recycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

1 609 92A 50K | (10.05.2019) Bosch Power Tools

中文

安全规章

电动工具通用安全警告

警告!

导致电击、着火和/或严重伤 害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语" 电动工具" 指市电驱动

(有线)电动工具或电池驱动(无线)电动工具。

工作场地的安全

u 保持工作场地清洁和明亮。 混乱和黑暗的场地会

引 发事故。

u 不要在易爆环境,如有易燃液体、气体或粉尘的

环 境下操作电动工具。 电动工具产生的火花会点

燃粉 尘或气体。

u 让儿童和旁观者离开后操作电动工具。 注意力不

集 中会使操作者失去对工具的控制。

电气安全

u 电动工具插头必须与插座相配。绝不能以任何方

式 改装插头。需接地的电动工具不能使用任何转

换插 头。 未经改装的插头和相配的插座将减少电

击危 险。

u 避免人体接触接地表面,如管道、散热片和冰

箱。 如果你身体接地会增加电击危险。

u 不得将电动工具暴露在雨中或潮湿环境中。 水进

入 电动工具将增加电击危险。

u 不得滥用电线。绝不能用电线搬运、拉动电动工

具 或拔出其插头。使电线远离热源、油、锐边或

运动 部件。 受损或缠绕的软线会增加电击危险。

u 当在户外使用电动工具时,使用适合户外使用的

外 接软线。 适合户外使用的软线将减少电击危

险。

u 如果在潮湿环境下操作电动工具是不可避免的,

应 使用剩余电流动作保护器(RCD)。 使用

RCD 可减 小电击危险。

人身安全

u 保持警觉,当操作电动工具时关注所从事的操作

并 保持清醒。当你感到疲倦,或在有药物、酒精

或治 疗反应时,不要操作电动工具。在操作电动

工具时 瞬间的疏忽会导致严重人身伤害。

u 使用个人防护装置。始终佩戴护目镜。 安全装

置, 诸如适当条件下使用防尘面具、防滑安全

鞋、安全 帽、听力防护等装置能减少人身伤害。

u 防止意外起动。确保开关在连接电源和/ 或电池

盒、拿起或搬运工具时处于关断位置。 手指放在

已 接通电源的开关上或开关处于接通时插入插头

可能 会导致危险。

u 在电动工具接通之前,拿掉所有调节钥匙或扳

手。 遗留在电动工具旋转零件上的扳手或钥匙会

导致人 身伤害。

警告! 阅读所有警告和所有说

明! 不遵照以下警 告和说明会

中文 | 15

u 手不要伸展得太长。时刻注意立足点和身体平

衡。 这样在意外情况下能很好地控制电动工具。

u 着装适当。不要穿宽松衣服或佩戴饰品。让衣

服、 手套和头发远离运动部件。 宽松衣服、佩饰

或长发 可能会卷入运动部件中。

u 如果提供了与排屑、集尘设备连接用的装置,要

确 保他们连接完好且使用得当。 使用这些装置可

减少 尘屑引起的危险。

u 即使由于经常使用电动工具而对此非常熟悉,也

不要就认为可以高枕无忧而忽略工具的安全规

定。粗心大意的行为可能在瞬间就造成严重的伤

害。

电动工具使用和注意事项电动工具使用和注意事项

u 不要滥用电动工具,根据用途使用适当的电动工

具。 选用适当设计的电动工具会使你工作更有

效、 更安全。

u 如果开关不能接通或关断工具电源,则不能使用

该 电动工具。 如果开关不能接通或关断工具电

源,则不能使用该 电动工具。

u 在进行任何调节、更换附件或贮存电动工具之

前, 必须从电源上拔掉插头和/ 或使电池盒与工

具脱 开。 这种防护性措施将减少工具意外起动的

危险。

u 将闲置不用的电动工具贮存在儿童所及范围之

外, 并且不要让不熟悉电动工具或对这些说明不

了解的 人操作电动工具。 电动工具在未经培训的

用户手中 是危险的。

u 保养电动工具。检查运动件是否调整到位或卡

住, 检查零件破损情况和影响电动工具运行的其

他状 况。如有损坏,电动工具应在使用前修理

好。 许多 事故由维护不良的电动工具引发。

u 保持切削刀具锋利和清洁。 保养良好的有锋利切

削 刃的刀具不易卡住而且容易控制。

u 按照使用说明书,考虑作业条件和进行的作业来

使 用电动工具、附件和工具的刀头等。 将电动工

具用 于那些与其用途不符的操作可能会导致危

险。

u 保持手柄和握持表面干燥、清洁、无油污。 在突

发情况下,滑溜的手柄和握持表面无法确保安全

地握持和控制工具。

维修

u 将电动工具用 于那些与其用途不符的操作可能会

导致危险。. 这样将确保所维修的电动工具的安全

性。

针对线锯的安全规章

u 在切削附件可能触及暗线或其自身软线之处进行

操作时,要通过绝缘握持面来握持工具。 切削附

件碰到带电导线会使工具外露的金属零件带电从

而使操作者受到电击。

u 使用夹箍或其他实用方式将加工件固定和支承到

一个稳定的平台上。 用手握住或用身体顶住加工

件会导致不稳定,从而引起失控。

u 双手必须远离锯割范围,手不可以握在工件下

端。如果不小心碰触了锯片可能被割伤。

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

16 | 中文

u 先开动电动工具后再把工具放置在工件上切割。

如果电动工具被夹在工件中,会有反弹的危险。

u 注意锯割时把底盘正确安稳地放置。锯片如果歪

斜了,可能断裂或者造成反弹。

u 工作告一段落时,必须先关闭电动工具并等待机

器完全静止后,才可以从锯缝中拔出锯刀。如此

不但可以防止反弹,而且可以防止放置机器时发

生危险。

u 等待电动工具完全静止后才能够放下机器。 机器

上的工具可能在工作中被夹住,而令您无法控制

电动工具。

u 只能使用未受损的功能正常的锯片。弯曲或变钝

的锯片可能断裂,对锯痕造成负面影响或导致反

弹。

u 关机后不可以侧压刀片来制止仍然继续转动的刀

片。锯刀可能因此受损、断裂或者造成反击。

u 使用合适的侦测装置侦察隐藏的电线,或者向当

地的相关单位寻求支援。 接触电线可能引起火灾

並让操作者触电。损坏了瓦斯管会引起爆炸。凿

穿水管不仅会造成严重的财物损失,也可能导致

触电。

产品和性能说明

请阅读所有安全规章和指示。不遵照以

下警告和说明可能导致电击、着火和/或

严重伤害。

请注意本使用说明书开头部分的图示。

按照规定使用

本机器可以在稳固的底垫上,进行切割、挖割。适

用的材料包括木材、塑胶、金属、陶片和橡胶等。

本机器不仅能够直锯,也可以锯弯角,最大弯角角

度可达45°。请使用本公司推荐的锯条。

插图上的机件

机件的编号和电动工具详解图上的编号一致。

工作灯按钮

(1)

电源开关止动件(GST140BCE)

(2)

电源开关

(3)

冲击次数预选调节轮

(4)

塑料滑板

(5)

底板

(6)

锯屑吹净装置开关

(7)

振荡调整杆

(8)

锯片解锁SDS杆

(9)

导引轮

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

A) 图表或说明上提到的附件,并不包含在基本的供货范围

A)

锯片

工作灯

防割伤装置

手柄(绝缘握柄)

锯片架

防毛边压板

底板夹紧杆

底板螺栓

A)

钢滑座

集尘装置盖罩

抽吸套管

集尘软管

A)

斜切角度的刻度

中。本公司的附件清单中有完整的附件供应项目。

技术数据

曲线锯

物品代码

冲击次数控制装置

恒定电子装置

额定输入功率

空载转速n

0

冲程

瓦 720 720

转/分 800–2800 800–2800

毫米 26 26

最大切割深度

– 木材

– 铝材

– 钢材(非合金)

最大切割角度(左/右)

重量符合EPTA-Procedure 01:2014

毫米 140 140

毫米 20 20

毫米 10 10

度 45 45

千克 2.2 2.3

保护等级

所有参数适用于230伏的额定电压[U],对于其他不同的电压和国际规格,数据有可能不同。

1 609 92A 50K | (10.05.2019) Bosch Power Tools

GST 140 CE GST 140 BCE

3601E140.. 3601E150..

● ●

● ●

/ II / II

中文 | 17

安装

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

安装/更换锯片

u 安装或更换工具刀头时务必佩戴保护手套。工具

刀头非常锋利,长时间使用后会变热。

选择锯片

在本说明书的最后有锯片的一览表。请只安装单凸

轮轴(T型刀柄)的锯片。锯片长度不得超过预定锯

线所需的数值。

在狭小的弯角上锯割时要使用窄的锯片。

安装锯片(参见插图A)

u 安装前,请清洁锯片的柄部。脏污的柄部无法牢

牢固定。

推动锯片(11),使锯齿朝向切割方向,直至卡入锯

片架(15)。

在安装锯片时注意,锯片背位于导引轮(10)的槽

内。

u 检查锯片是否牢固固定。松脱的锯片会从接头掉

落并伤害您。

抛出锯片(参见插图B)

u 抛出锯片时千万要握好电动工具,不可以让弹出

的锯片伤害旁人或动物。

沿防割伤装置(13)方向向前转动SDS杆(9),直至极

限位置。接着锯片会被松开,并被抛出。

校准底板(参见图片C−D)

当斜切角度为0度时,如果底板(6)与锯片(11)不完

全成直角,则必须重新校准底板:

– 将锯片(11)装入锯片架(15)。

– 将防毛边压板(16)从前部推入底板(6)。

– 将另一块短锯片(11)装入防毛边压板前部的凹槽

中,如图C所示。

– 打开底板的夹紧杆(17)。

– 沿顺时针或逆时针尽可能地转动底板螺栓(18),

直至两个装入的锯片在一条线上。

– 关上底板的夹紧杆(17)。

– 将锯片(11)从防毛边压板(16)中取出。

滑座(参见插图E)

底板(6)的塑料滑板(5)可以减少敏感表面上的划

痕。加工金属时,请使用钢滑座(19)。

安装钢滑座(19)时,请将其从前部推到底板(6)上。

塑料滑板(5)磨损后,请更换。

防毛边压板(见图片 F)

防毛边压板 (16)(附件)可以在锯割木材时防止表

面裂开。防毛边压板只能用于特定的锯片类型,并

且只能用于0°锯角。使用防毛边压板锯切时,不得

向后移动底板 (6) 以靠近边缘锯切。

将防毛边压板(16)从前部推入底板(6)。

吸锯尘/吸锯屑

含铅的颜料以及某些木材、矿物和金属的加工废尘

有害健康。机器操作者或者工地附近的人如果接

触、吸入这些废尘,可能会有过敏反应或者感染呼

吸道疾病。

某些尘埃(例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理 木材的添加剂(例如木材的防腐

剂等)结合之后。只有经过专业训练的人才能够加

工含石棉的物料。

– 尽可能使用适合物料的吸尘装置。

– 工作场所要保持空气流通。

– 最好佩戴P2滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

u 避免让工作场所堆积过多的尘垢。尘埃容易被点

燃。

盖罩(参见插图G)

将电动工具连接到集尘装置上前,请装好盖罩

(20)。

将盖罩(20) 放到电动工具上,以便支架卡入防割伤

装置(13)。

执行不需要集尘的操作或斜切时,请拆下盖

罩(20)。为此,将盖罩向前从防割伤装置(13) 上

拉下。

连接集尘装置(参见插图H–I)

将抽吸套管(21)装到底板(6)的凹槽中。

注意抽吸套管上的凸轮应如图H所示卡入底板(6)相

应的凹槽中。

将集尘软管(22)(附件)插到抽吸套管(21)上。将

集尘软管(22)与吸尘器(附件)连接。

在本使用说明的末尾可以找到各种集尘器的连接概

览。

为确保最佳集尘效果,如果可以的话,请安装防毛

边压板(16)。

连接好集尘装置后,请关闭锯屑吹净装置。

根据工件的物料选择合适的吸尘装置。

吸集可能危害健康、可能导致癌症或干燥的废尘

时,务必使用特殊的吸尘装置。

操作

运行模式

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

调整振荡功能

本机器有四个振荡档位,因此可以根据加工物料适

度配合锯割速度、锯割功率并产生最好的锯割效

果。

使用调节杆 (8) 也能在运行期间调整振荡。

档位0 无振荡

档位I 小振荡

档位II 中振荡

档位III 大振荡

Bosch Power Tools 1 609 92A 50K | (10.05.2019)

18 | 中文

通过实际试验来确定各个应用的最佳振荡档位。以

下各设定建议仅供参考:

– 振荡档位越小,甚至完全关闭振荡功能,锯缘越

细越干净。

– 在加工较薄的材料(例如板材)时请关闭振荡功

能。

– 在加工硬纸材料(例如钢)时使用小振荡。

– 锯割较软的材料或顺着木纹锯割木材时必须设定

最大的振荡档位。

调整斜切角度(参见插图J)

斜切角度在45°以下时,可将底板 (6) 向右或向左摆

动。

斜切时,无法安装盖罩(20)、抽吸套管(21) 和防

毛边压板(16)。

– 将抽吸套管(21)轻轻向上压,然后将其从底板(6)

中拉出。

– 取下盖罩(20)和防毛边压板(16)。

– 打开底板夹紧杆(17),将底板(6)朝电源线方向轻

轻推动。

– 精确调整斜切角度时,底板在左右侧有多个卡入

点。根据刻度(23),将底板(6)摆动到所需的位

置。此外也可以使用量角规设定其它的角度。

– 然后沿锯片(11)方向推动底板(6),直至限位。

– 关闭夹紧杆(17),以便将底板锁定在设定位置。

移动底板(参见插图J)

可向后移动底板 (6),以便贴着边缘锯切。

打开底板夹紧杆(17),将底板(6)朝电源线方向推

动,直至限位。关闭夹紧杆,以锁定底板。

仅可在斜切角度为0度时利用移动后的底板(6)锯

切。此外,不得使用防毛边压板(16)。

锯屑吹净装置

利用锯屑吹净装置的气流可以清除切线上的锯屑。

加工像木材、塑料等切屑去除量较大的材料时请接

通锯屑吹净装置。为此,将开关(7)推到位置“I”。

在连接有集尘装置的情况下加工金属时请关闭锯屑

吹净装置。为此,将开关(7)推到位置“0”。

投入使用

u 注意电源电压!电源的电压必须和电动工具铭牌

上标示的电压一致。标记为230伏电动工具用220

伏的电压可以驱动。

接通LED工作灯

接通或关闭工作灯(12)时,请按压工作灯(1)按钮。

u 勿直视工作灯,强光会刺眼。

接通/关闭(GST140CE)

u 请确保握住手柄时可以开启/关闭开关。

接通电动工具时,需要向前推动电源开关(3),使开

关上出现“I”符号。

关闭电动工具时,需要向后推动电源开关(3),使开

关上出现“0”符号。

接通/关闭(GST140BCE)

u 请确保握住手柄时可以开启/关闭开关。

要 接通 电动工具,按压起停开关 (3)。

要 锁定 起停开关 (3),按住起停开关并向左或向右

推动止动件 (2)。

要关闭电动工具,松开起停开关 (3)。起停开关 (3)

锁住时,请先按压,然后再松开。

重启保护

重启保护功能可以避免电动工具在供电中断之后突

然失控地重新起动。

如需再次使用,请将电源开关(3)置于已关闭的位

置,然后重新接通电动工具。

恒定电子装置

有了恒定电子装置,机器的冲击次数能够在空转和

负载时都保持恒定。如此能够确保均匀的运作功

率。

控制冲击次数(GST140BCE)

可以无级调节已接通电动工具的冲击次数,视按压

起停开关 (3) 的力道程度决定。

以较小的力按压起停开关 (3)时,冲击次数较低。逐

渐在开关上加压,冲击次数也会跟着提高。

预选冲击次数

利用冲击次数预选调节轮 (4) 也可以在运行过程中

预选所需的冲击次数。

正确的冲击次数必须视工件物料和工作状况而定。

唯有实际操作才能找出最合适的冲击次数。

起锯时,或者锯割塑料、铝片时最好降低冲击次

数。

以小的冲击次数长期工作之后,电动工具会变得很

热。拆下锯片,让电动工具以最高冲击次数运作3分

钟以加速冷却。

工作提示

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

u 当锯片被夹住时,请立即关闭电动工具。

u 锯割小的或薄的工件时必须使用牢固的垫架或者

使用锯台 (附件)。

锯切木材、刨花板、建筑材料等材料前应检查是否

有异物,比如钉子、螺栓等类似物质,如果有的

话,请清除。

潜锯(见图片 L)

u 在切入式锯切工艺中,仅允许加工软材料,比如

木材、石膏板等类似材料!

潜锯时只能使用短的锯片。仅可在斜切角度为0°时

进行潜锯。

将电动工具底板 (6)的前边缘放到工件上,锯片

(11) 不要触碰到工件,然后接通。如果电动工具有

冲击次数设定功能的话,必须选择最高冲击次数。

用力地把电动工具压向工件,并让锯刀慢慢地潜入

工件中。

底板 (6) 齐平地贴着工件后,就可沿着所需的切线

继续切割。

1 609 92A 50K | (10.05.2019) Bosch Power Tools

Loading...

Loading...