Bosch GKF12V-25 Owner's Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

GKF12V-25

For English Version Version française Versión en español

See page 2 Voir page 14 Ver la página 27

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

160992A400_GKF12V-25 10/9/17 2:58 PM Page 1

-2-

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapt e r p lugs wi t h e arthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e c o mmon sen se w hen operati ng a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in the off- posi tion be fore

connecting to power source and / or battery

pa ck, pic king up or car ryin g t he tool.

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

General Power Tool Safety Warnings

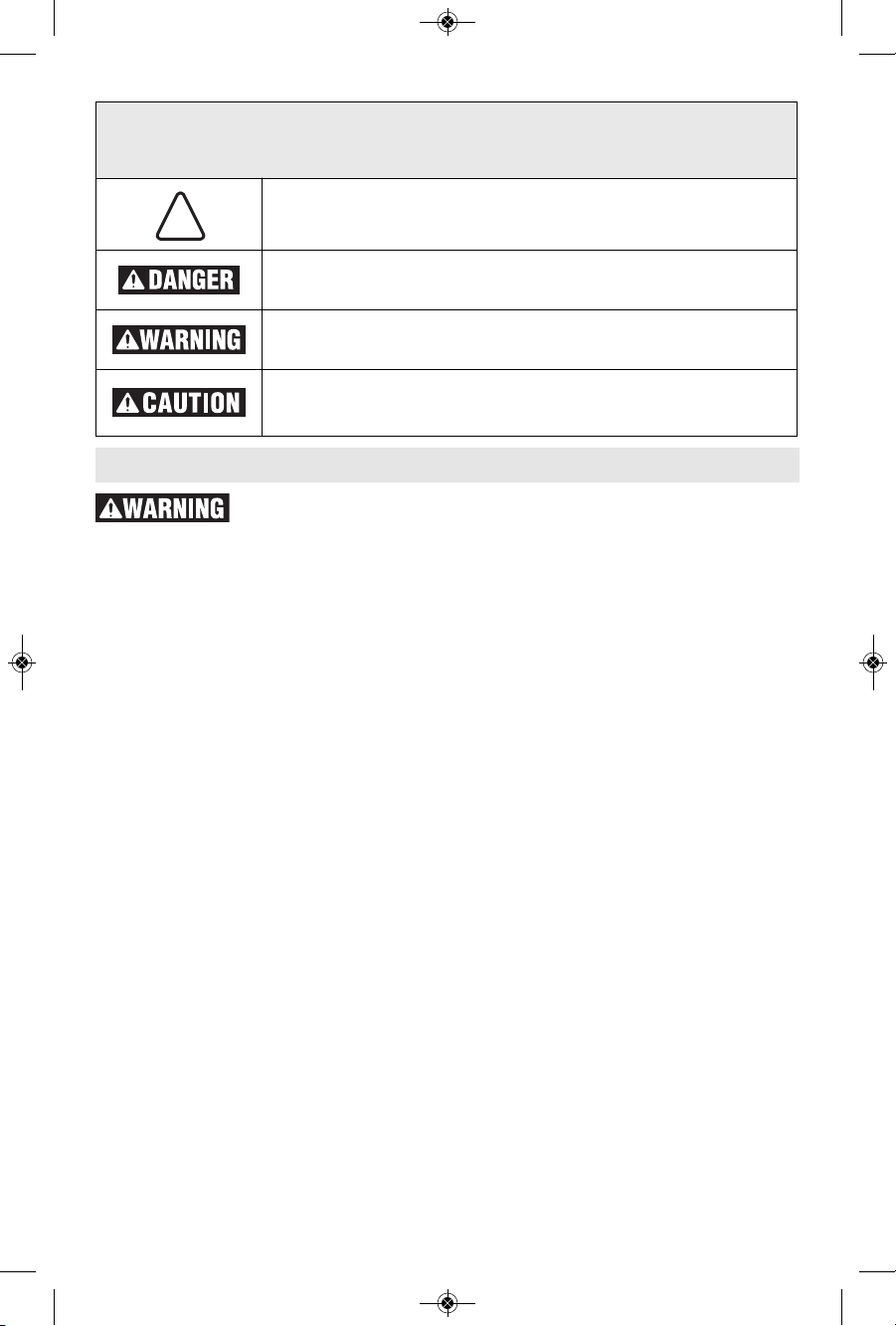

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual

and pay attention to these symbols.

!

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

160992A400_GKF12V-25 10/9/17 2:58 PM Page 2

-3-

Safety Rules for Routers

Use c lamp s o r a noth er prac tica l w ay to

secure and support the workpiece to a stable

platform. Holding the work by your hand or

against the body leaves it unstable and may lead

to loss of control.

If cutting into existing walls or other blind

areas where electrical wiring may exist is

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Always make sure the work surface is free

from nails and other foreign objects. Cutting

into a nail can cause the bit and the tool to

jump and damage the bit.

C

arrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co n trol of the pow er t o ol i n une x p ected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not for ce the pow e r too l . Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca n n o t be control l e d with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

p

arts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma n y a c c i dents are caused by poo r l y

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Battery tool use and care

Recharge only with the charger specified

by th e ma nufa ctur er. A c harg er t hat is

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

Use po wer tools only with sp ecificall y

designated battery packs. Use of any other

battery packs may create a risk of injury and

fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small m e t a l objects that c a n make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified

re p a i r pe r s o n us i n g onl y ident i c a l

replacement parts. This will ensure that the

safety of the power tool is maintained.

160992A400_GKF12V-25 10/9/17 2:58 PM Page 3

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding the

tool with both hands is safer.

Never la y wo r k p iece on to p of hard

surfaces, li k e concr e t e , stone, et c . . .

Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust mask.

Us e only in w e l l ventilated a r e a . Usi n g

personal safety devices and working in safe

environment reduces risk of injury.

After c h a n g i n g t he bits or m a k i n g a n y

adjustments, make sure the collet nut and

any other adjustment devices are securely

tigh t e n e d . Loose adjustment d e v i c e can

unexpectedly shift, ca using loss of control,

loose rotating compo nents wi ll be violently

thrown.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the m ater ial cau sing los s o f co ntro l of th e

cutter.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

the to o l fr o m t h e t o p , the bit rotates

clockwise. Feed direction of cutting must be

counter-clockwise. NOTE: inside and outside

c

uts will require different feed direction, refer to

section on feeding the router. Feeding the tool

in the wrong direction, causes the cutting edge

of the bit to climb out of the work and pull the

tool in the direction of this feed.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits can

snap during use. Dull bits require more force to

push the tool, possibly causing the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

bit can grab the surface and pull the tool out of

your control.

Cutter diameter must be at least 1/4” smaller

than opening for the bit and cutter.

-4-

Additional Safety Warnings

Use this tool with Bosch recommended

batteries only. Use of any other battery pack

may create a risk of injury and fire.

Use only router bits with rated speed at

least equal to the maximum no load speed

marked on the router. Router bits running

faster than their rated speed can break and fly

apart.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Use clamps or other practical way to secure

and su pport the workpiece to a stable

platform. Holding the work by hand or against

your body leaves it unstable and may lead to

loss of control.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool sinc e inter nal wire s may be

misplaced or pinched or safety guard return

sp ring s may be improp erly mount ed.

Certain cleaning agents such as gasoline,

carbon tetrachloride, am mon ia, etc. ma y

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Bosch Factory Service Center

or Autho rized Bosch Service Station.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

ca use ca ncer , bi r t h de f e cts or ot h er

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Yo u r risk fr o m these e x p o sures v a r i es,

depending on how often you do this type of

work. To re duc e y our exposu re to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

160992A400_GKF12V-25 10/9/17 2:58 PM Page 4

-5-

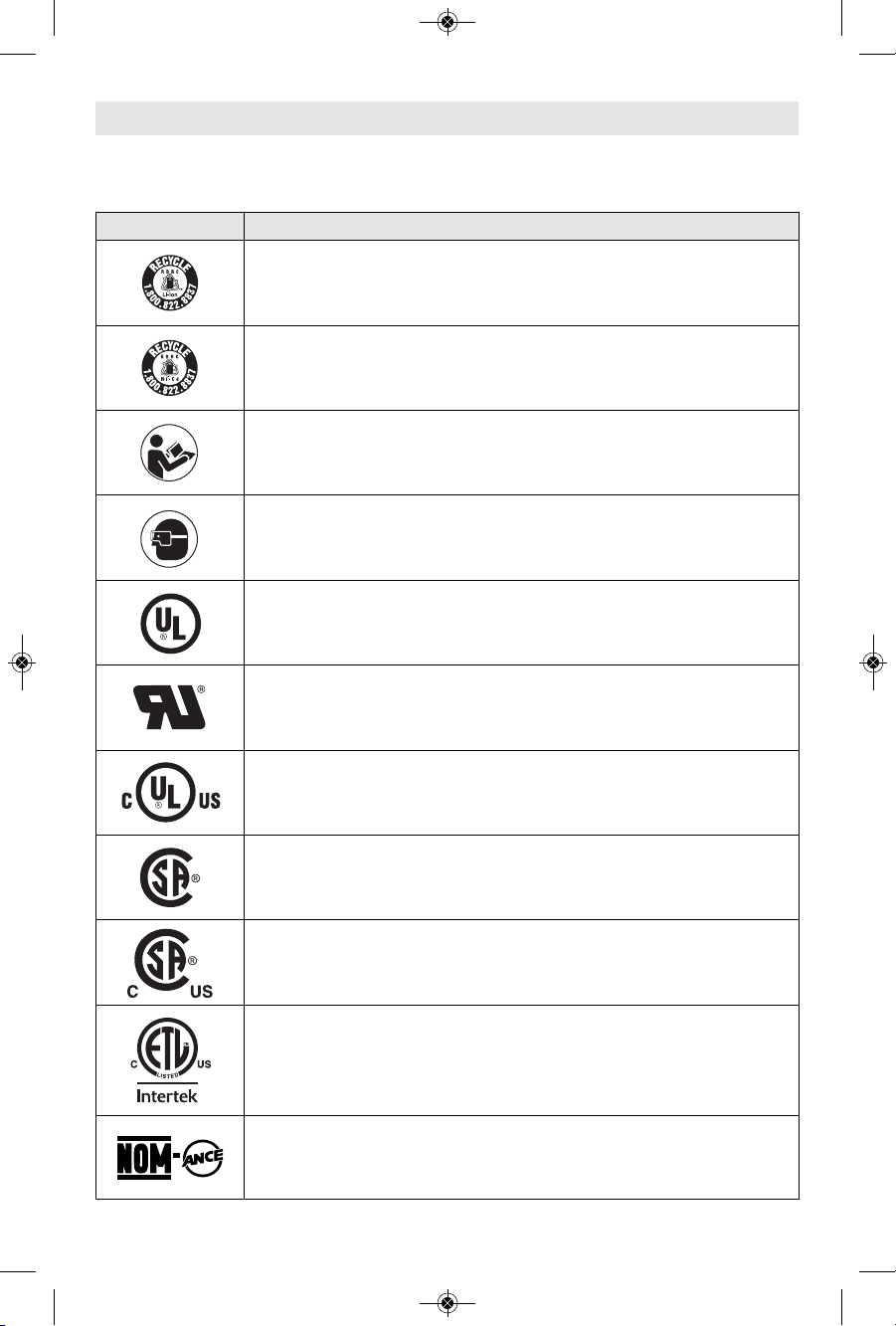

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

V Volts (voltage)

A Amperes (current)

Ah Amp-hour (measurement of battery capacity)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

⌀

Diameter (size of drill bits, grinding wheels, etc.)

n

0

No load speed (rotational speed at no load)

n Rated speed (maximum attainable speed)

.../min

Revolutions or reciprocation per minute (revolutions, strokes, surface speed,

orbits etc. per minute)

0 Off position (zero speed, zero torque...)

1, 2, 3, ...

I, II, III,

Selector settings (speed, torque or position settings. Higher number means

greater speed)

0

Infinitely variable selector with off (speed is increasing from 0 setting)

Arrow (action in the direction of arrow)

Alternating current (type or a characteristic of current)

Direct current (type or a characteristic of current)

Alternating or direct current (type or a characteristic of current)

Class II construction (designates double insulated construction tools)

Earthing terminal (grounding terminal)

160992A400_GKF12V-25 10/9/17 2:58 PM Page 5

-6-

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

Designates Li-ion battery recycling program

Designates Ni-Cad battery recycling program

Alerts user to read manual

Alerts user to wear eye protection

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

160992A400_GKF12V-25 10/9/17 2:58 PM Page 6

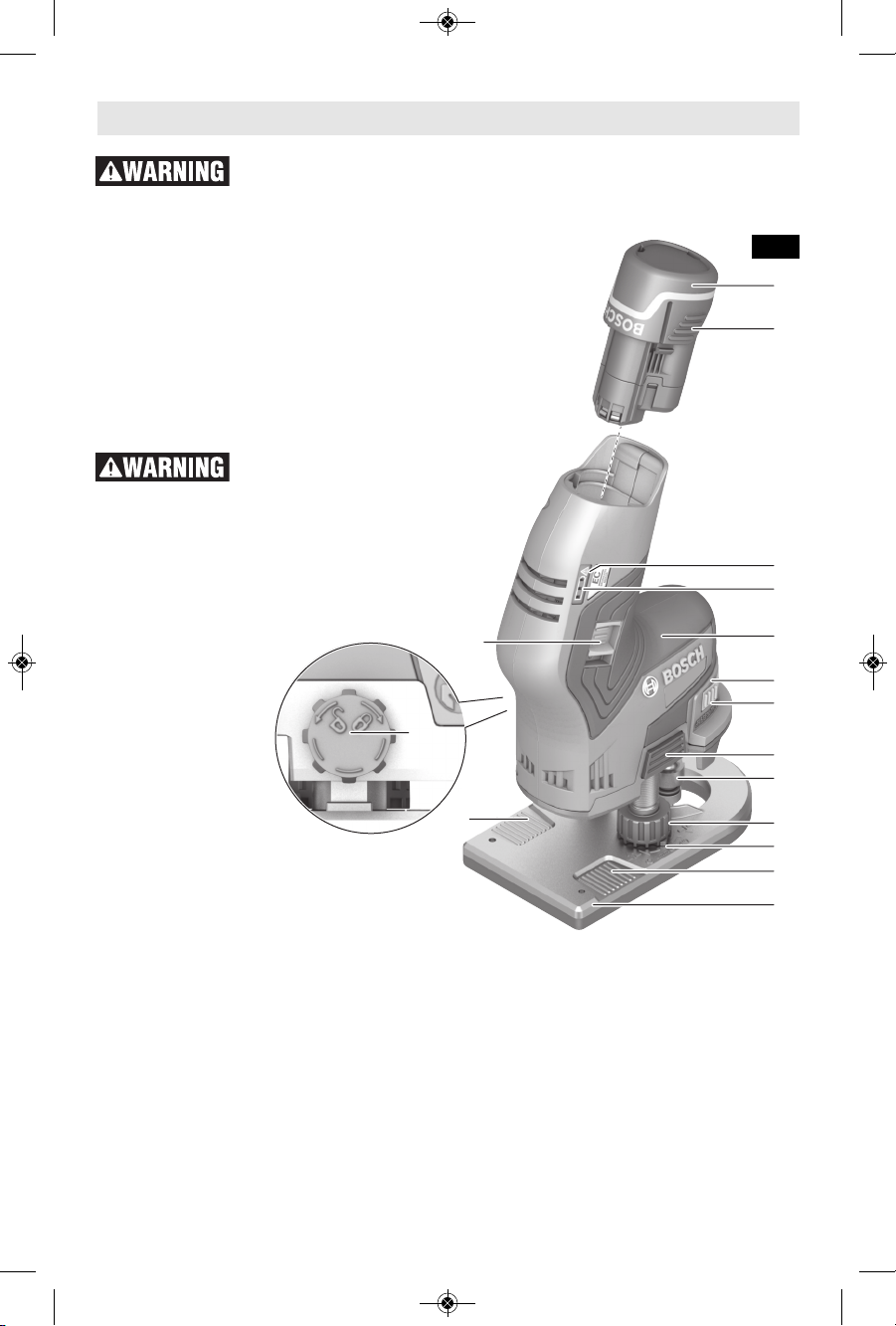

1

2

3

4

13

7

6

8

9

10

11

20

12

14

20

5

-7-

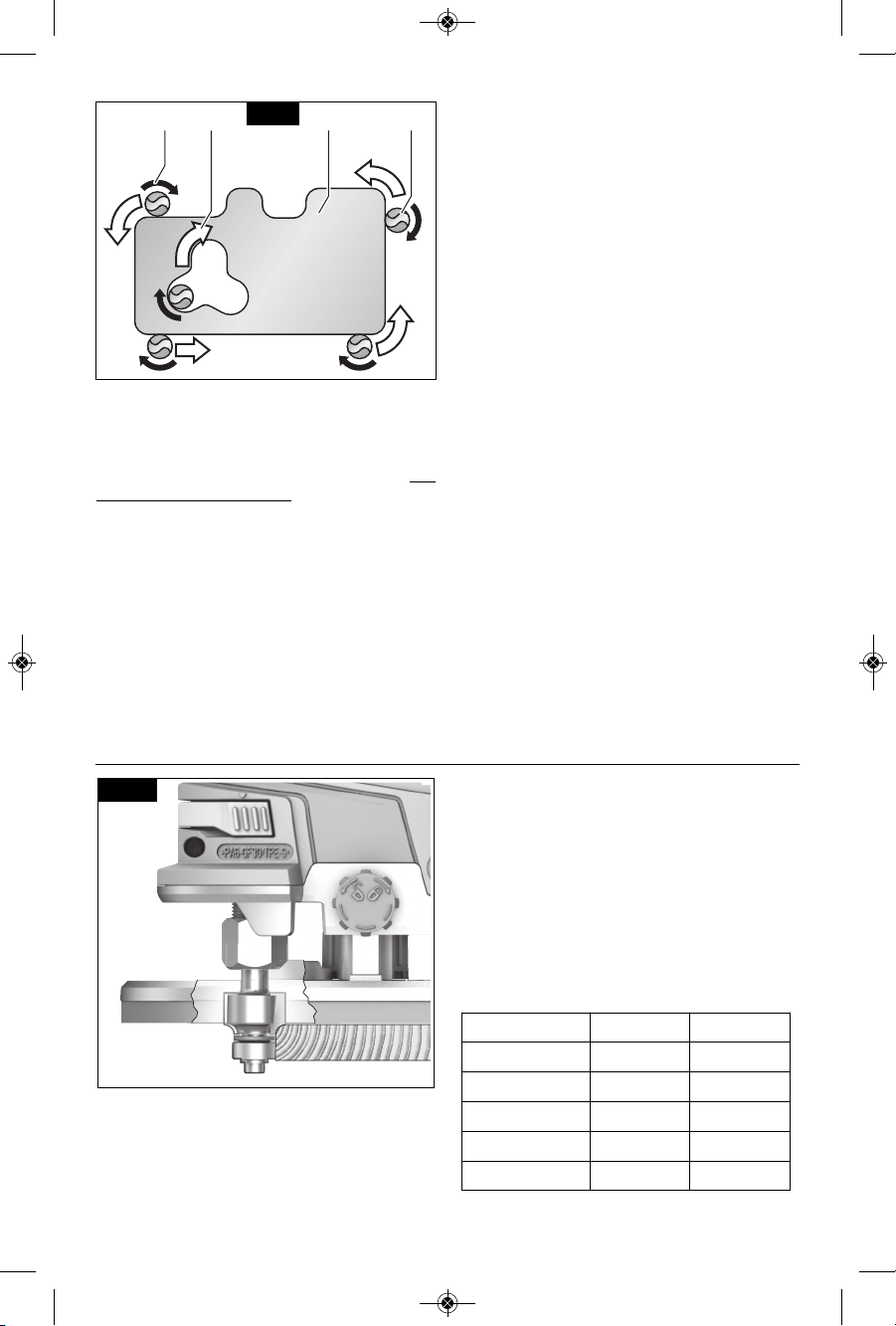

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Palm Router

FIG. 1

Model Number . . . . . . . . . . . . . . . . . . . .GKF12V-25

Bit Capacity . . . . . . . . . . . . . . . . . . . . .1/4" shank

Max. Router Bit / Cutter Diameter . . . .1-5/16"

NOTE: For tool specifications refer to the nameplate on

your tool.

Battery Packs/Chargers

Us e th i s to o l wi t h Bo sch

recommended batteries only. Use

of any other batteries may create a risk of injury and

fire.

Please refer to the Charger Manual included with your

tool for Bosch recommended battery packs.

1 Battery pack*

2 Battery release tabs

3 Temperature control/overload protection

indicator

4 Battery charge condition indicator

5 On/Off switch

6 Marking arrow for spindle lock

7 Spindle lock bar

8 Depth-of-cut adjustment button

9 Collet nut with collet

10 Depth-of-cut adjustment thumbwheel

11 Depth-of-cut adjustment fixing screw

12 Base plate

13 Rubberized gripping area

14 Depth-of-cut locking wheel

15 Collet**

16 Spindle**

17 Router bit* **

18 Open-end wrench (17 mm)**

19 Smooth guide column**

20 Finger support pockets

* Sold separately

** Not shown in this picture

160992A400_GKF12V-25 10/9/17 2:58 PM Page 7

SELECTING BITS

Your Bosch palm router is designed for a wide

variety of routing applications that use 1/4"

sh a nk bi t s. Th e se in c lude woo d workin g

applications such as edge forming, grooving,

and sign making. This router is also ideal for

trimming la minat es, phenolics, and oth er

ma t erial s that h a ve bee n bonde d to a

substrate overhang the substrate typically by

about 1/8" (3 mm).

A wide assortment of router bits with different

profiles are available as accessories. Only use

good quality bits.

Use only router bits with

rated speed at least equal

to the maximum no load speed marked on

the router. Router bits running faster than their

rated speed can break and fly apart.

NOTE: The bit shank and chuck should be

clean and free of dust, wood, residue, and

grease before assembling.

To pre v ent p erson a l

in j ury, alwa y s re m ove

battery pack from the tool before removing

or installing bits or accessories.

INSTALLING A ROUTER BIT

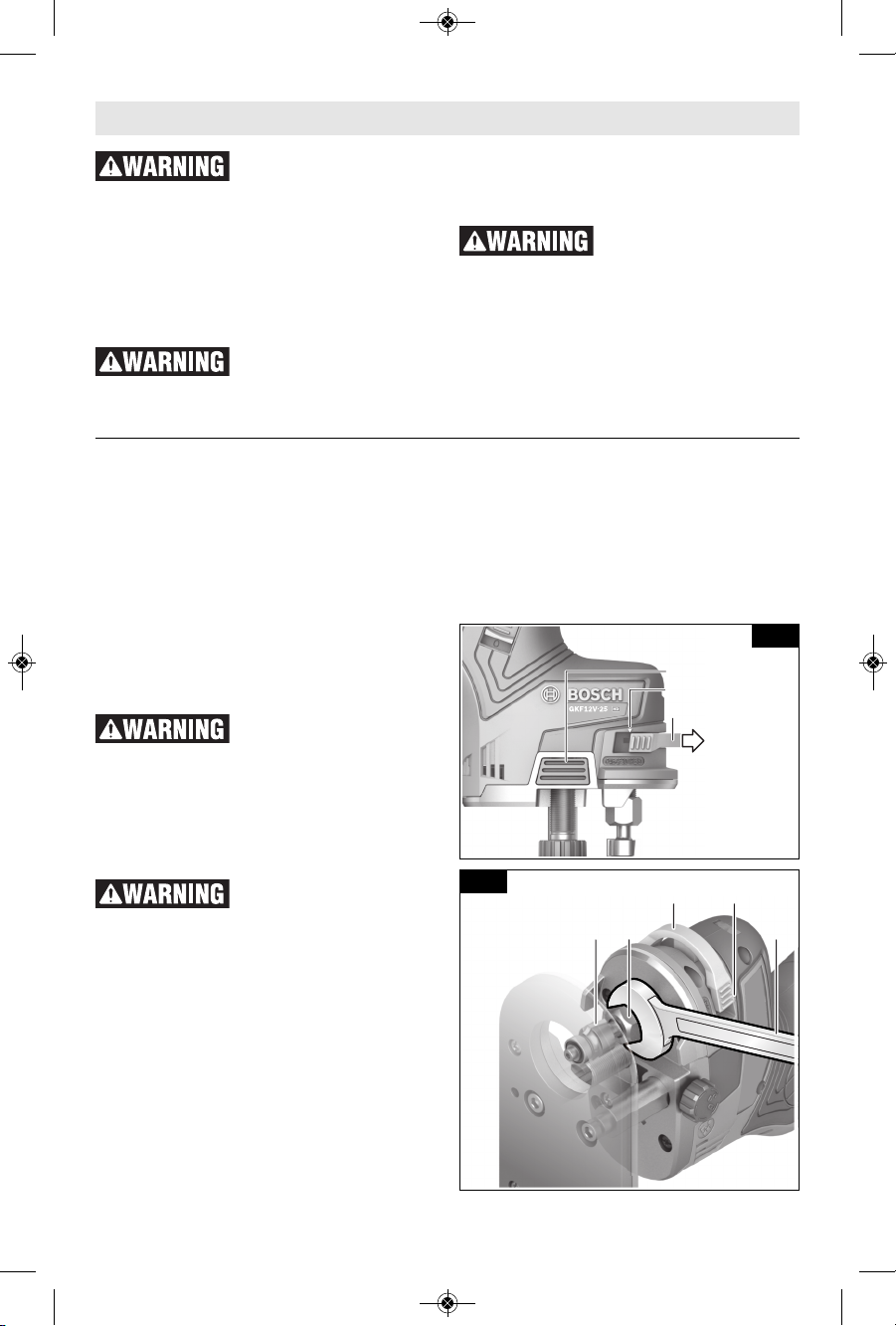

1. Press and hold the button 8 to raise the

router unit as high as possible from the

base.

2. Pull out the spindle locking bar 7 up to the

ma r king arrow 6 on th e hous i ng. If

necessary, turn the spindle manually until it

is lock e d in pla c e. Th e re ar e six loc k

positions offset by 60° (Fig. 2).

3. Next, use the collet wrench 18 to loosen the

collet nut 9 in a counter-clockwise direction

as viewed from bottom of router (Fig. 3).

4. Insert the shank of the router bit 17 into the

collet chuck assembly as far as it will go,

then back the shank out until the cutters are

approximately 1/8" to 1/4" away from the

collet nut 9 face (Fig. 3).

5. With the route r bit 17 inser ted and the

spindle lock engaged, use the collet wrench

18 to firmly tighten the collet nut 9 in a

-8-

Assembly

INSERTING AND RELEASING

BATTERY PACK

- R e l e a s e b a t t e r y pack f r o m to o l by

pressing on both s ide s o f the b att ery

release tabs 2 and pull the battery out

(Fig. 1).

If battery release tabs are

cr a cked o r othe r wise

damaged, do not insert into tool. Battery can

fall out during operation.

Make sure the tool is in

the OFF position before

inserting the battery pack. Inserting the

battery pack into power tool that has the

switch ON invites accidents.

- To insert battery, align battery and slide

battery pack into tool until it locks into

position. Do not force.

Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

7

6

8

FIG. 2

9

76

17 18

FIG. 3

160992A400_GKF12V-25 10/9/17 2:58 PM Page 8

c

lockwise direction as viewed from bottom

of router (Fig. 3).

6. Push the spindle locking bar 7 back into

disengaged position.

To ensure proper gripping of the router bit and

minimize run-out, the shank of the router bit

must be inserted at least 5/8".

To p revent dam age to

tool, do not tighten collet

without a bit.

REMOVING THE ROUTER BIT

1. Pull out the spindle locking bar 7 up to the

ma r king a rrow 6 on the housi n g. If

necessary, turn the spindle manually until it

is lock e d in pla c e. Th e re ar e six loc k

positions offset by 60° (Fig. 2).

2. Next, use the collet wrench 18 to loosen the

collet nut 9 in a counter-clockwise direction

as viewed from bottom of router. (Fig. 3).

3. Continue to turn the collet chuck assembly 9

until it pulls the col let 15 free from the

spindle 16, and the router bit 17 can be

removed.

NOTE: The collet chuck is self-extracting; it is

NOT necessary to strike the collet chuck to

free the router bit.

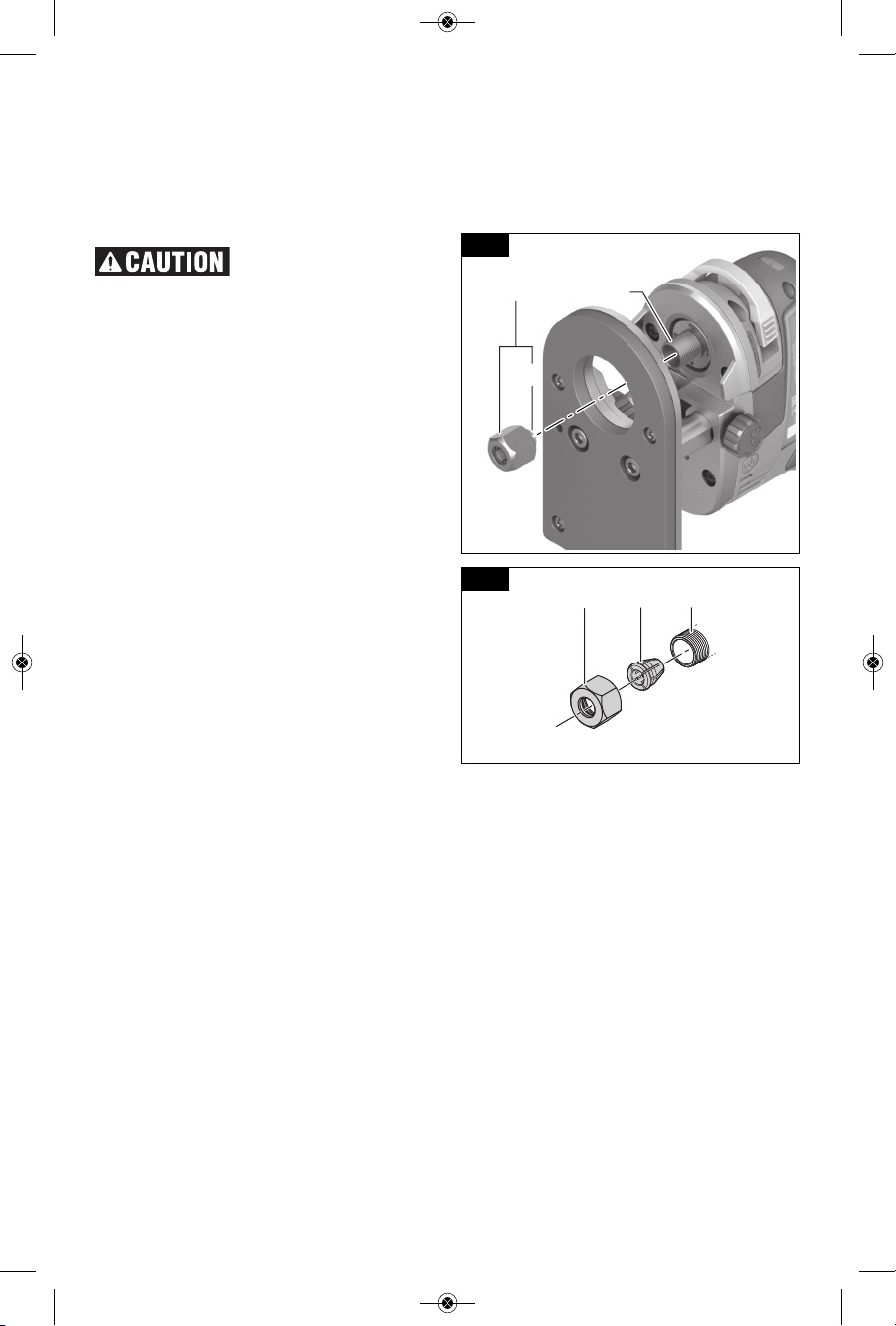

COLLET CHUCK CARE

To assure a firm grip, occasionally blow out the

collet chuck with compressed air, and clean

the taper in the spindle assembly shaft with a

tissue or fine brush.

The collet chuck is made up of two component

p

arts that snap together (Fig. 5); check to see

that the collet 15 is properly seated in the collet

chuck nut 9 and lightly thread the collet chuck

back onto the spindle.

Repla ce worn o r d amag ed col let chu cks

immediately.

-9-

169

15

FIG. 4

9

1615

FIG. 5

160992A400_GKF12V-25 10/9/17 2:58 PM Page 9

-10-

Disconnect battery pack

from tool before making

any assembly, adjustments or changing

ac c e s sories. Such preve n t i ve s a f e ty

measures reduce the risk of starting the tool

accidentally.

TURNING TOOL ON AND OFF

Make sure that the spindle locking bar 7 is

pressed into disengaged position.

To switch the power tool ON, slide the

On/Off switch 5 down so that “I” appears on

the switch.

To switch the power tool OFF, slide the

On/Off switch 5 up so that “O” appears on the

switch (Fig. 1).

SETTING THE DEPTH OF CUT

Adjust the depth-of-cut only when the motor is

switched off.

Remove the battery pack and make

sure the switch 5 is in the “O” (off)

position.

1. Install desired router bit according to the

instructions on page 8.

2. Place the router on the workpiece.

3. Turn the depth-of-cut locking wheel 14

co u nterc l ockwi s e (t o wards )

approximately half a revolution to unlock

depth-of-cut adjustment (Fig. 6).

4. Press depth-of-cut adjustment button 8 and

slowly lower the router to approximately

desired depth of cut. Release the button 8

(Fig. 6).

5. Use the thumbwheel 10 to set the exact

cutting depth required. Each revolution of

the thumbwheel changes the cutting depth

by 0.04 in (1 mm).

6. Turn the lock ing whee l 14 cl ockwi se

(towards ) to securely lock the depth-ofcut adjustment.

7. Insert the battery pack. Check the adjusted

depth with a trial cut. If necessary, remove

the battery pack and re-adjust the depth of

cut.

8. If you want to keep the tool fixed at the

cutting depth you have set, you can screw

the fixing screw 11 into the depth-of-cut

adjustment thumbwheel 10. You will need

a flat head screwdriver (not included) with

5/32” (4mm) maximum width (Fig. 7).

BATTERY CHARGE CONDITION

INDICATOR

Your tool is equipped with charge condition

indicator lights 4 (Fig. 1). The indicator lights

show the charge condition of the battery for a

few seconds the tool activation.

LED Capacity

3 continuous green lights > 2/3

2 continuous green lights > 1/3

1 continuous green light < 1/3

1 flashing green light reserve

Operating Instructions

8

10

11

14

FIG. 6

10

11

FIG. 7

160992A400_GKF12V-25 10/9/17 2:58 PM Page 10

T

EMPERATURE CONTROL / OVERLOAD

PROTECTION INDICATOR

The red LED indicator 3 helps you to protect

the battery against overheating and the drive

against overheating and overload (Fig. 1).

If the LED indicator 3 is lit up permanently

in red, the temperature of the battery or drive

unit is too high. The power tool switches off

automatically. When this happens:

– Turn swi tch the s witch 5 to “O” (OFF)

position.

– Allow the battery and power tool to cool

down before you resume working.

T

he LED indicator 3 flashes red, the power

tool is jammed and switches off automatically.

When this happens:

– Turn Switch the switch 5 to “O” (OFF)

position.

– Remove the power tool from the workpiece.

– Un lock the sp indle lo cking ba r 7 i f

necessary.

As soon as the jam has been cleared and the

motor spindle is able to turn freely again, you

can switch the power tool back on.

-11-

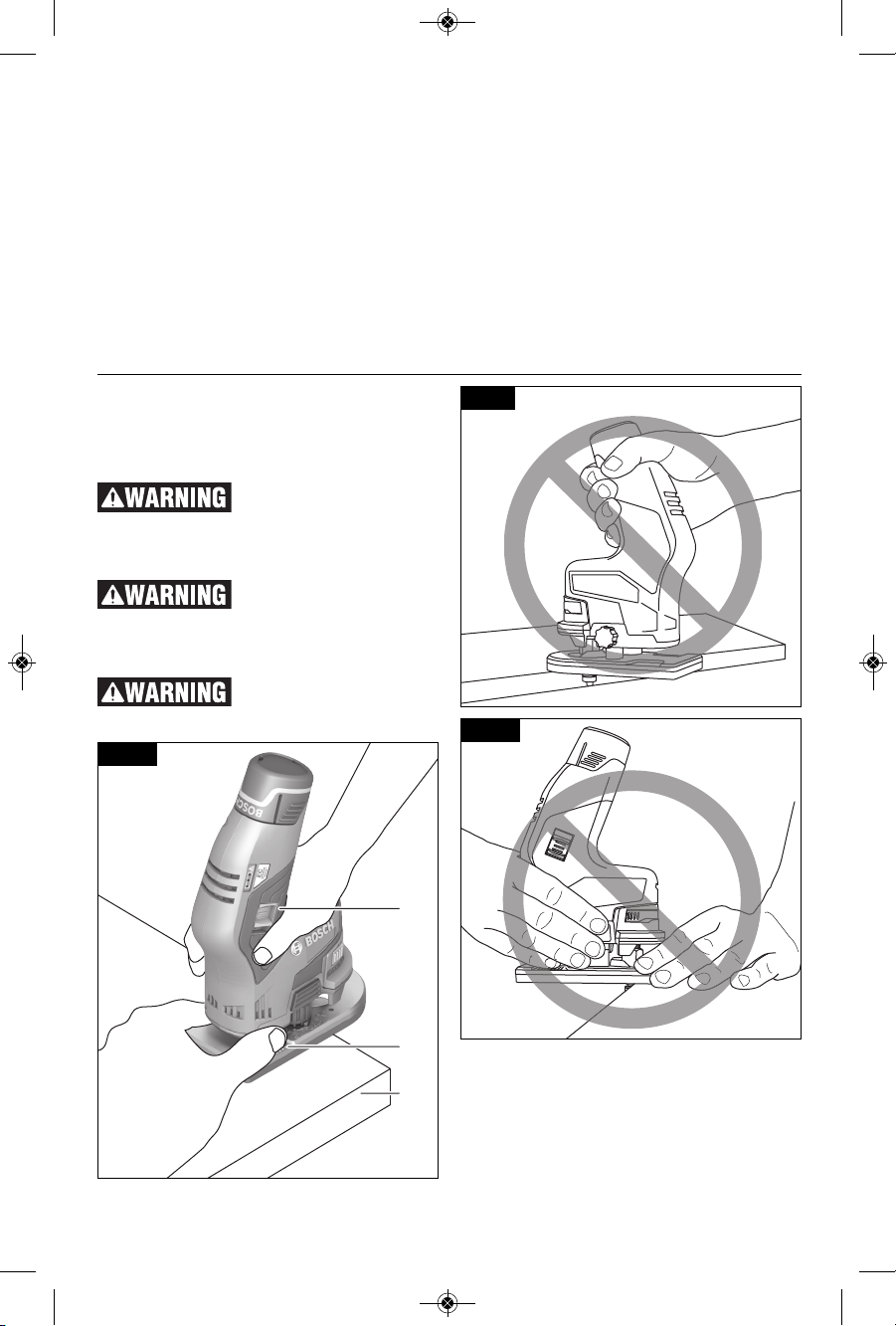

FEEDING THE ROUTER

In addition to the main gripping area 13, the

base has Bosch -excl usive finger suppo rt

pockets 20 to provide additional stability for the

router (Fig. 8).

Always hold the router

with b oth hands. Keep

fingers away from router bits and cutters.

Hands contacting with rotating router bit can

cause serious personal injury.

Always place both finger

po c kets o ver the

workpiece and always hold the router in a

way that allows you to see your fingers and

thumb.

Ne ver hold the too l in

ot h er way s , such a s

those shown in figures 9 and 10.

20

21

13

FIG. 8

FIG. 10

FIG. 9

160992A400_GKF12V-25 10/9/17 2:58 PM Page 11

USING SELF-PILOTED BITS

Self-piloted bits have an integral round tip or

ball bearing which rides against the work

surface above or below the cutter to control

horizontal cutting depth (Fig. 12). When using

these bits, n either the roller g uide or the

straight gu ide is requi red . W hen gu idi ng

against a laminated surface, use wax or other

lubricant and do not apply excess pressure or

the piloted end may mar the work. Bearing

pilots must be kept clean and free of adhesive

or oth er re sidue. Rou ter b it be aring s are

sealed and permanently lubricated, and should

be replaced when they no longer turn freely to

avoid damaging the work surface.

The following maximum workpiece dimensions

apply for edge and profile routing operations:

Material Radius Chamfer

Hardwood 3/8” / 10mm 1/4” / 6mm

Softwood 1/2” / 12mm 3/8” / 10mm

MDF sheets 1/2” / 12mm 3/8” / 10mm

Plastic 1/2” / 12mm 3/8” / 10mm

Plywood sheets 3/8” / 10mm 1/4” / 6mm

As seen from the top of the router, the bit 17

turns clockwise (23) and the bit’s cutting edges

are positioned to best cut into the workpiece

21. Therefore, the most efficient cut is made by

feeding (22) the router so that the bit turns into

the workpiece, not away. Figure 11 shows

proper feed for various cuts. How fast you feed

depends on the hardness of the material and

the size of the cut. For some materials, it is

best to make several cuts of increasing depth.

If the router is hard to control, heats up, runs

ve r y slo wly or leaves an impe rfect cut,

consider these causes:

1. Wrong direction of feed — hard to control.

2. Feeding too fast — overloads motor.

3. Dull bit — overloads motor.

4. Cut is too large for one pass — overloads

motor.

5

. Feeding too slow — leaves friction burns on

work.

Feed smoothly and steadily (do not force). You

will soon learn how the router sounds and feels

when it is working best.

Always hold the router off the workpiece 21

when turning the switch on or off. Contact

the workpiece with the router after the

router has reached full speed, and remove

it from the workpiece before turning the

switch off. Operating in this manner will

prolong switch and motor life and will greatly

increase the quality of your work.

RATE OF FEED

When routing or doing related work in wood

and plastics, the best finishes will result if the

depth of cut and feed rate are regulated to

keep the motor operating at high speed. Feed

the router at a moderate rate. Soft materials

require a faster feed rate than hard materials.

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool. Always be sure

the collet chuck is tightened securely before

use. Always use router bits with the shortest

cu ttin g l engt h ne cess ary to prod uce the

desired cut. This will minimize router bit run-out

and chatter.

It may be necessary to make the cut in more

than o ne pass with prog ressi vely deeper

settings to avoid overloading the motor. If the

bit cuts freely and the motor does not slow

down, the cutting depth is generally correct.

FIG. 12

-12-

17212223

FIG. 11

160992A400_GKF12V-25 10/9/17 2:58 PM Page 12

Loading...

Loading...