Page 1

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

GKF125CE

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

IMPORTANT

Read Before Using

●

IMPORTANT

Lire avant usage

●

IMPORTANTE

Leer antes de usar

For English Version

See page 2

●

Version française

Voir page 26

●

Versión en español

Ver la página 53

Call Toll Free for Consumer Information and Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

2610052572_GKF125CE 9/18/18 12:11 PM Page 1

Page 2

2

Work area safety

Keep work a r e a clean and w e l l lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any ad a p t e r plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

Avoid body contact with ea r t h e d or

grounded s u r f a c e s such a s pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp

location is unavoidable, use a Ground

Fault Circuit Interrupter (GFCI) protected

supply. Use of an GFCI reduces the risk of

electric shock.

Personal safety

Stay alert, watch what you are doing and

use common sense w hen oper ating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools

may result in serious personal injury.

Use personal protective eq u i p m e n t .

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

General Power Tool Safety Warnings

Read and understand all instructions before using this appliance.

Failure to follow all instructions listed below, may result in electric

shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

2610052572_GKF125CE 9/18/18 12:11 PM Page 2

Page 3

3

Safety Rules for Routers

Hold power tool by insulated gripping

surfaces, because the cutter may contact

its own cord. Cutting a ”live” wire may

make exposed metal parts of the power

tool ”live” and shock the operator.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by your

hand or against the body leaves it unstable

and may lead to loss of control.

If cutting into existing walls or other blind

areas where electrical wiring may exist is

unavoidable, d i s c o n n e c t all fuses or

circuit breakers feeding this worksite.

Always make sure the work surface is free

fr om na ils a nd ot her f oreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding

the tool with both hands is safer.

Never lay workpiece on top of ha r d

surfaces, like concrete, s t o n e , etc...

Protruding cutting bit may cause tool to

jump.

Al ways wear safety goggl es and dust

Prevent unintentional starting. Ensure the

switch is in the off-position before

con necting to power source and / or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energizing power tools

that have the switch on invites accidents.

Rem ove any adjustin g key or wren ch

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power to o l may result in

personal injury.

Do not overreach. Keep proper footing

and balance at all times. This enables

better c o n t r o l of t h e power t o o l in

unexpected situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught

in moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

Power tool use and care

Do not force the power t ool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it was

designed.

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect t h e plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of

children an d do not al l o w persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that m a y affect the p o w e r tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power

tools.

Keep cutting tools sharp and cl e a n .

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool

bits et c . in accordance with th e s e

ins t ructions, taking i n t o accoun t the

working conditions and the work to be

per f ormed. U se of the powe r tool for

operations different from those intended

could result in a hazardous situation.

Service

Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

2610052572_GKF125CE 9/18/18 12:11 PM Page 3

Page 4

4

mask. Use only in well ventilated area.

Using personal safety devices and working

in safe environment reduces risk of injury.

A

fter changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment device can

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

the tool from the top, the bit rotates

clockwise. Feed direction of cutting must

be counter-clockwise. NOTE: inside and

outside cuts will require different feed

direction, refer to section on feeding the

rout e r . Feeding the tool in the wrong

direction, causes the cutting edge of the bit

to climb out of the work and pull the tool in

t

he direction of this feed.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits

can snap during use. Dull bits require more

force to push the tool, possibly causing the

bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to

be touched by bare hands.

Never lay the tool down until the motor

has come to a complete standstill. The

spinning bit can grab the surface and pull

the tool out of your control.

Cutter diameter must be at least 1/4”

smal l e r than o p e n i ng for t h e bit a n d

cutter.

Additional Safety Warnings

Use only router b its that have shank

diameters that match the installed collet.

Using a router bit that has a smaller shank

could cause the bit to come loose during

operation and become a projectile.

Never operate router bits at speeds that

ar e higher than their maxim um rat ed

speed. Router bits running faster than their

rated speed can break and fly apart.

GFCI and personal protection devices like

electrician’s rubber gloves and footwear

will further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a

hazard to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Us e cla mps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body leaves it unstable and

may lead to loss of control.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

the tool since internal wires may be

misplaced or pinched or safety guard return

springs may be improperly mounted. Certain

cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

Risk of injury to user. The power cord must

only be serviced by a Bosch Factory Service

Center or Autho rized Bosch Service Station.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or ot her

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposu res varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

2610052572_GKF125CE 9/18/18 12:11 PM Page 4

Page 5

5

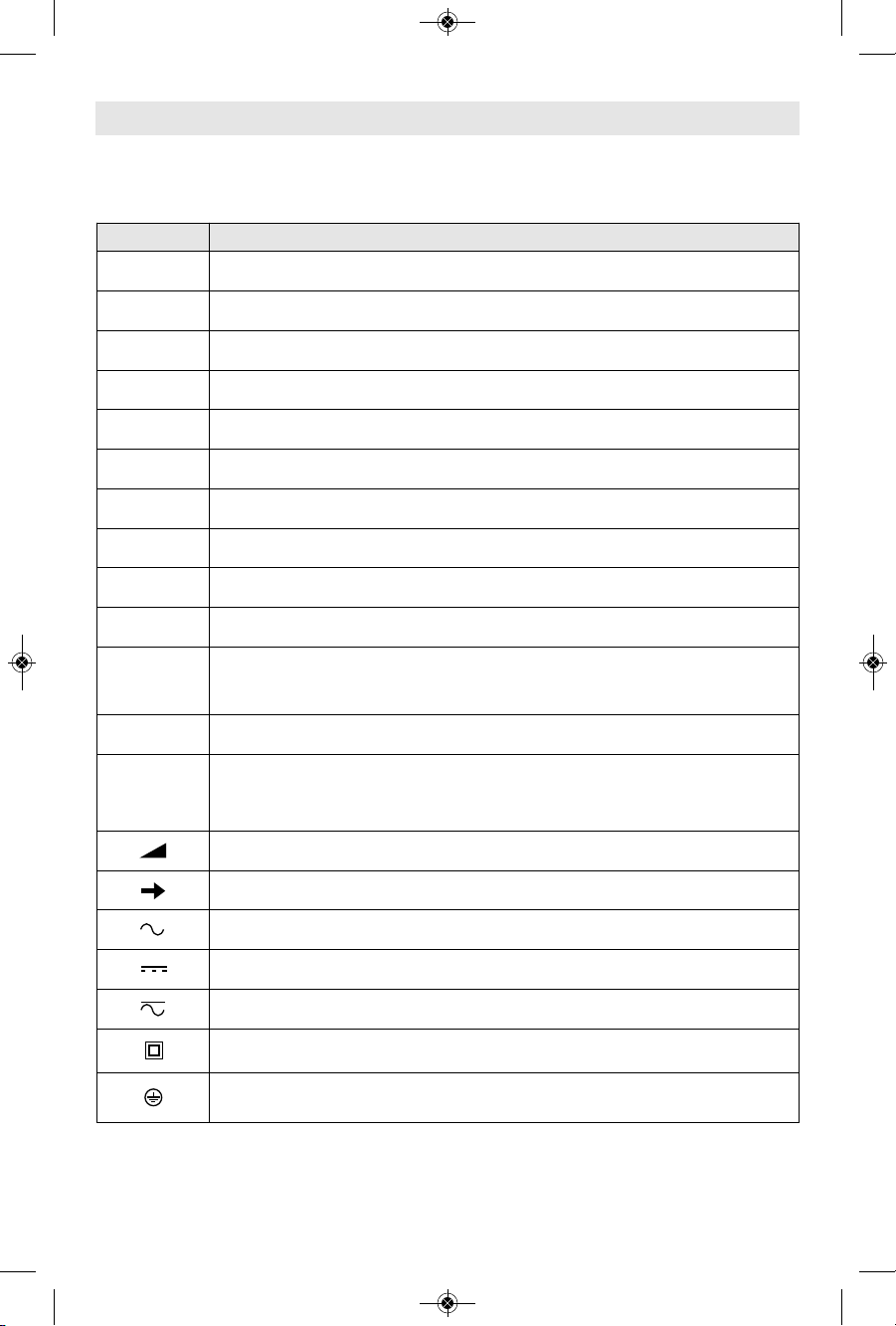

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you

to operate the tool better and safer.

Symbol Designation ⁄ Explanation

V Volts (voltage)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

Diameter (size of drill bits, grinding wheels, etc.)

n

No load speed (rotational speed at no load)

n Rated speed (maximum attainable speed)

...⁄min

Revolutions or reciprocation per minute (revolutions, strokes, surface

speed, orbits etc. per minute)

Off position (zero speed, zero torque...)

, , , ...

I, II, III,

Selector settings (speed, torque or position settings. Higher number

means greater speed)

0

Infinitely variable selector with off (speed is increasing from setting)

Arrow (action in the direction of arrow)

Alternating current (type or a characteristic of current)

Direct current (type or a characteristic of current)

Alternating or direct current (type or a characteristic of current)

Class II construction (designates double insulated construction tools)

Earthing terminal (grounding terminal)

2610052572_GKF125CE 9/18/18 12:11 PM Page 5

Page 6

6

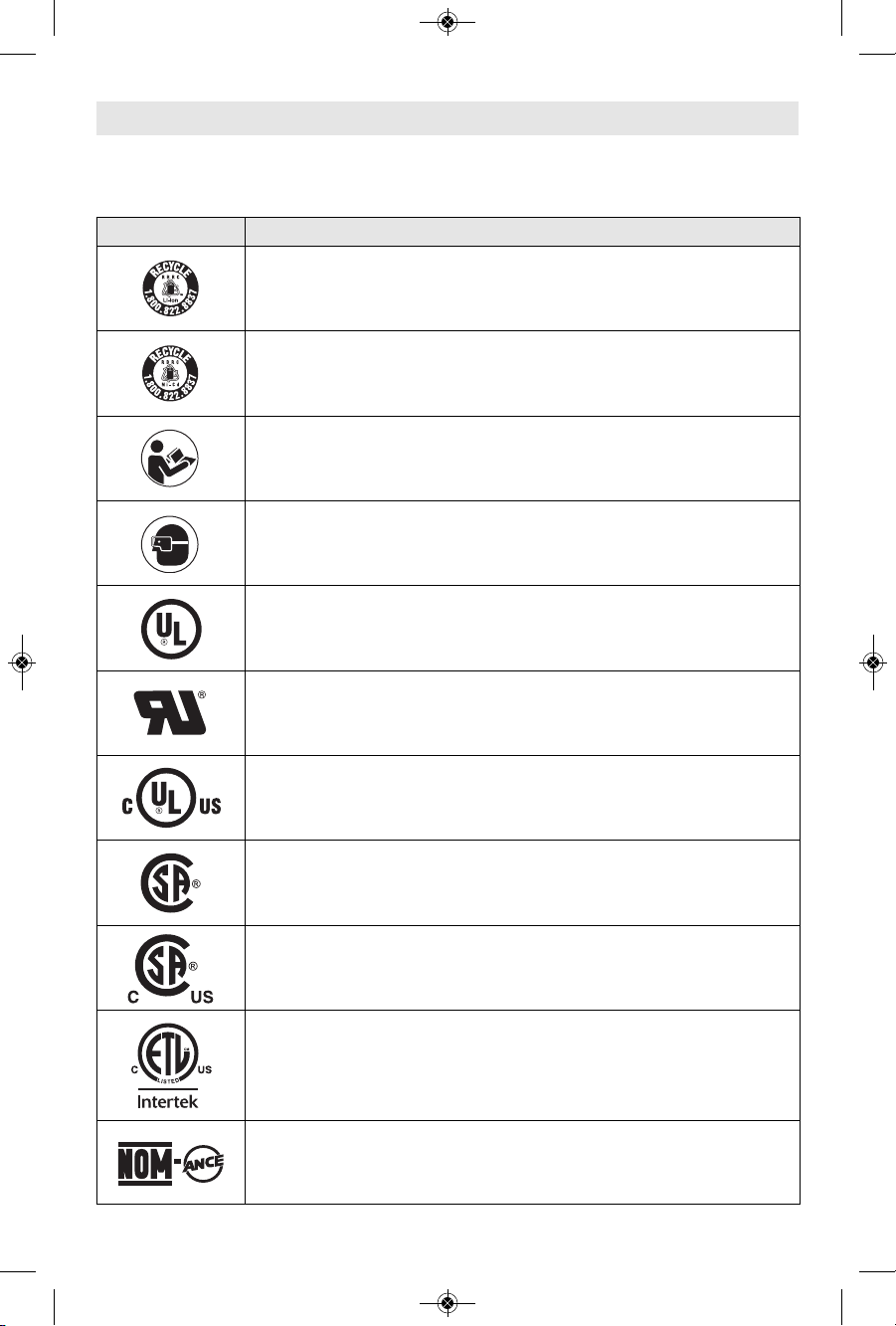

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you

to operate the tool better and safer.

Symbol Designation / Explanation

Designates Li-ion battery recycling program

Designates Ni-Cad battery recycling program

Alerts user to read manual

Alerts user to wear eye protection

This symbol designates that this tool is listed by Underwriters

Laboratories.

This symbol designates that this component is recognized by

Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

2610052572_GKF125CE 9/18/18 12:11 PM Page 6

Page 7

7

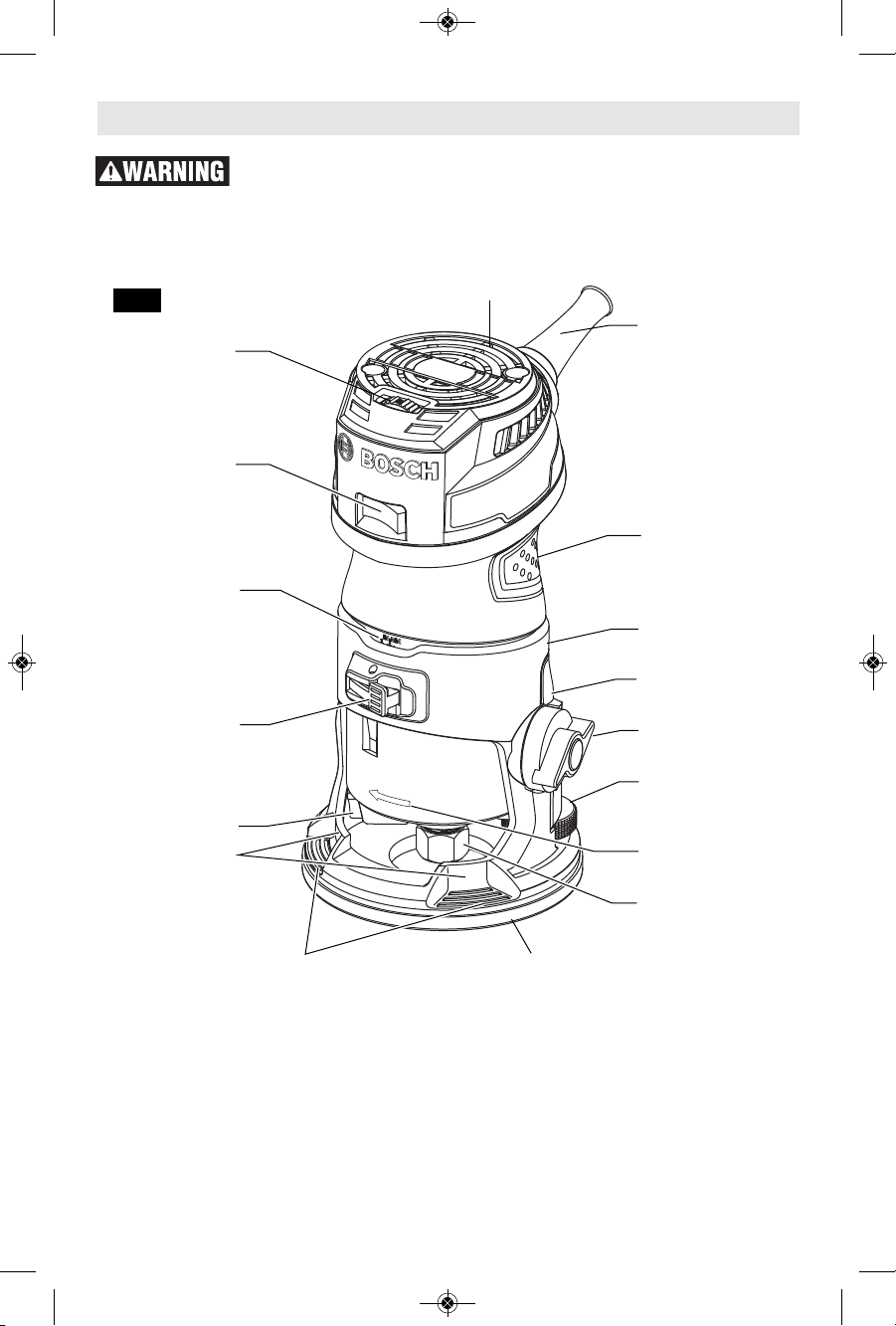

Functional Description and Specifications

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive

safety measures reduce the risk of starting the tool accidentally.

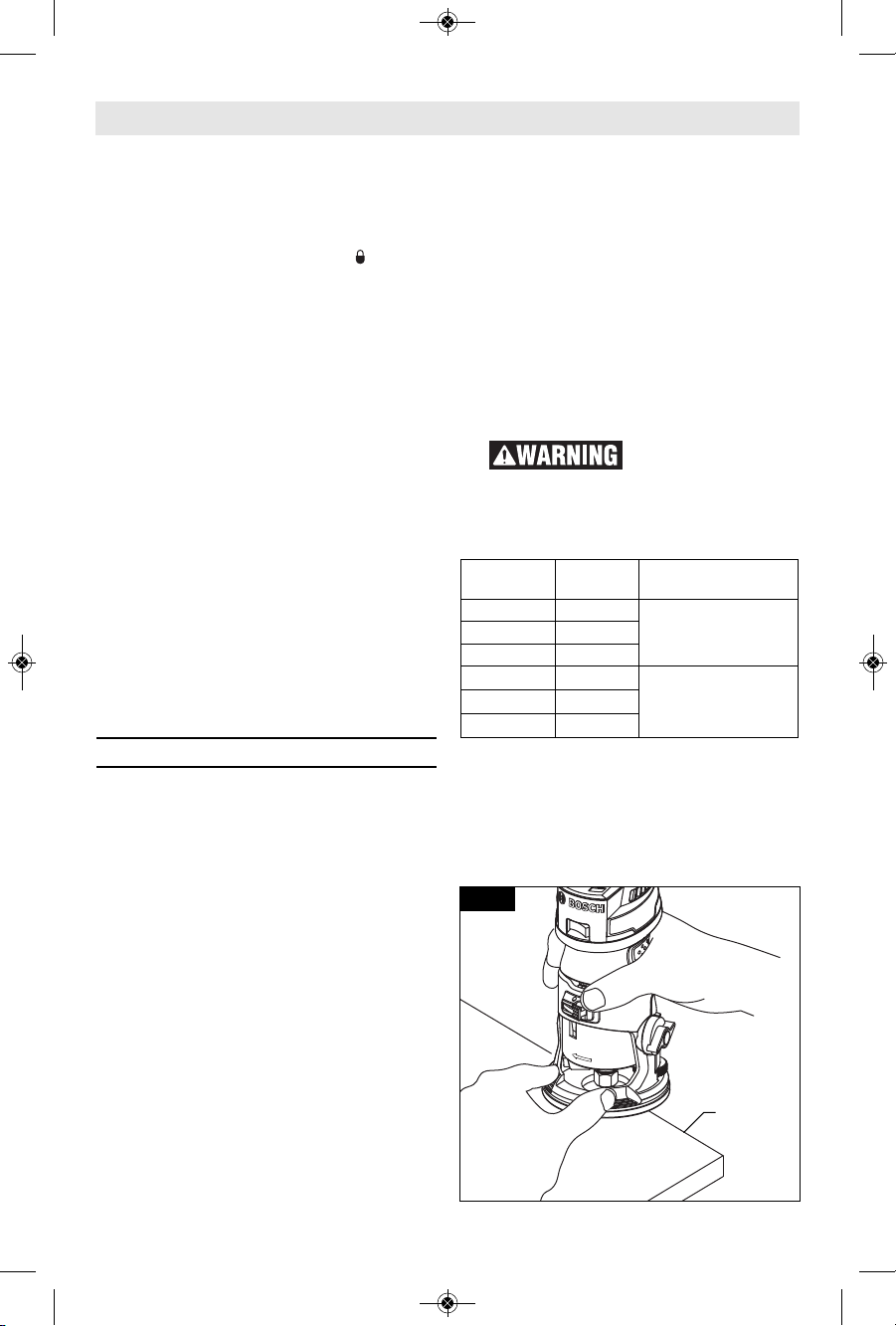

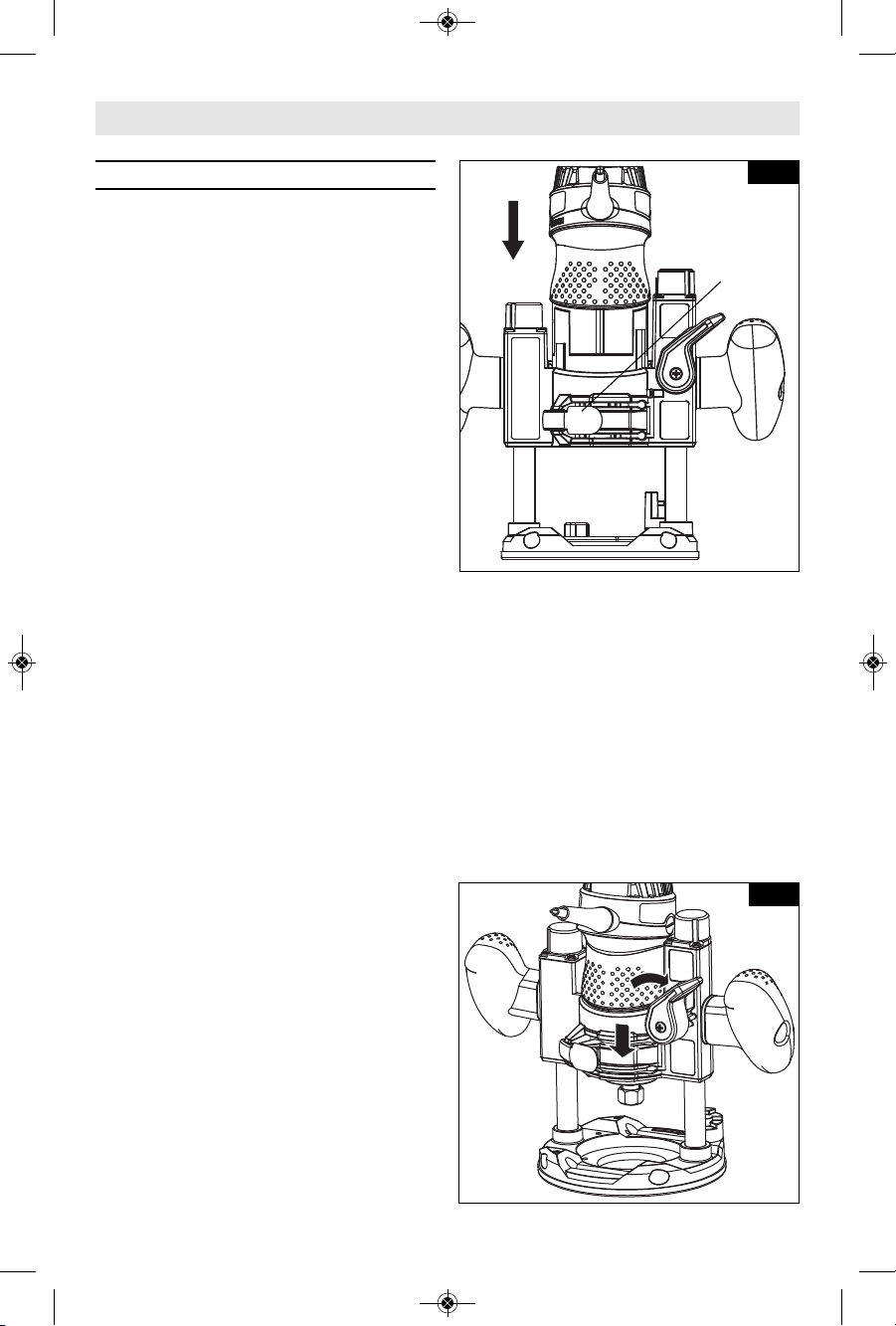

Fixed-Base Palm Router

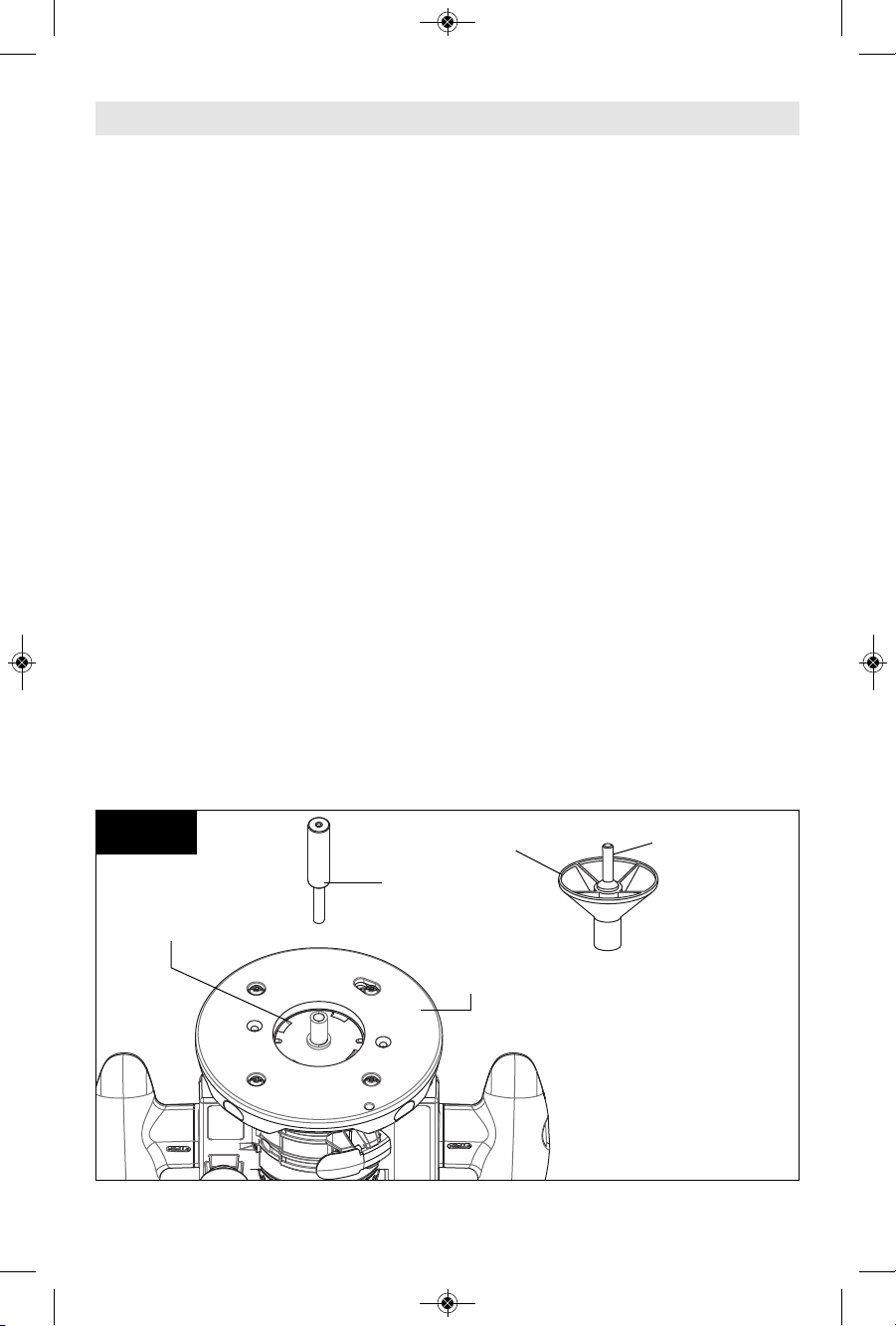

KNURLED WHEEL

BIT ROTATION ARROW

COLLET NUT

CONTOURED

GRIP AREA

VARIABLE-SPEED

DIAL

FINGER SUPPORT

POCKETS

FINGER GUARDS

POWER CORD

MOTOR RELEASE

BUTTON

DEPTH SCALES

(IMPERIAL AND

METRIC)

SPINDLE LOCK

SUBBASE

RUGGED ALUMINUM

BASE (PR101)

CLAMPING KNOB

FLAP

ROCKER

ON/OFF

SWITCH

AIR VENTS

FIG. 1

Model Number GKF125CE

Bit Capacity 1/4" shank

Max. Cutter Diameter *

* Cutter diameter must be at least 1/4" smaller than opening for

the bit and cutter.

NOTE: For tool specifications refer to the nameplate on your tool.

2610052572_GKF125CE 9/18/18 12:11 PM Page 7

Page 8

8

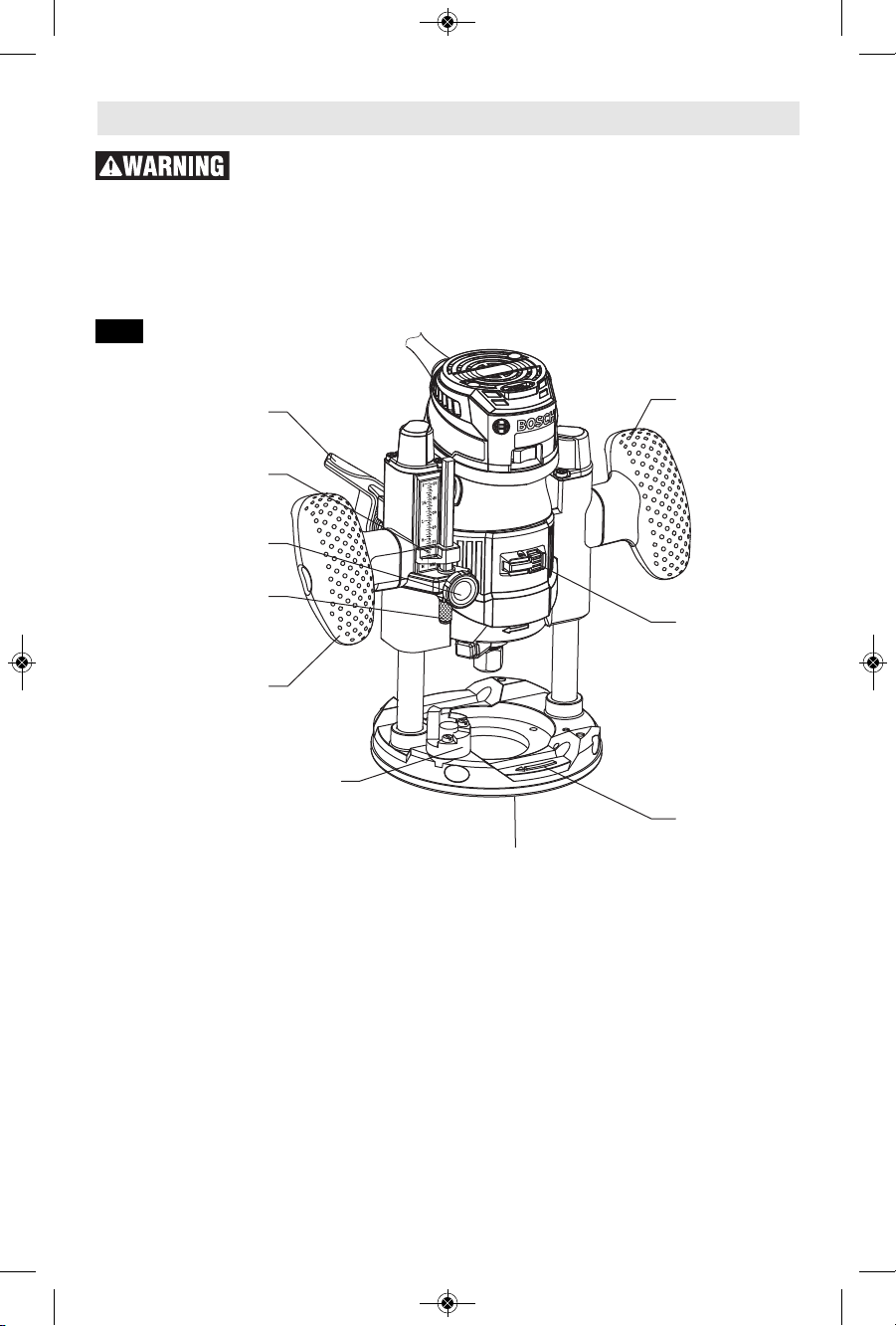

Functional Description and Specifications

Disconnect the plug from the p ow er source before making any

assembly, adjustments or changing accessories. Such preventive

safety measures reduce the risk of starting the tool accidentally.

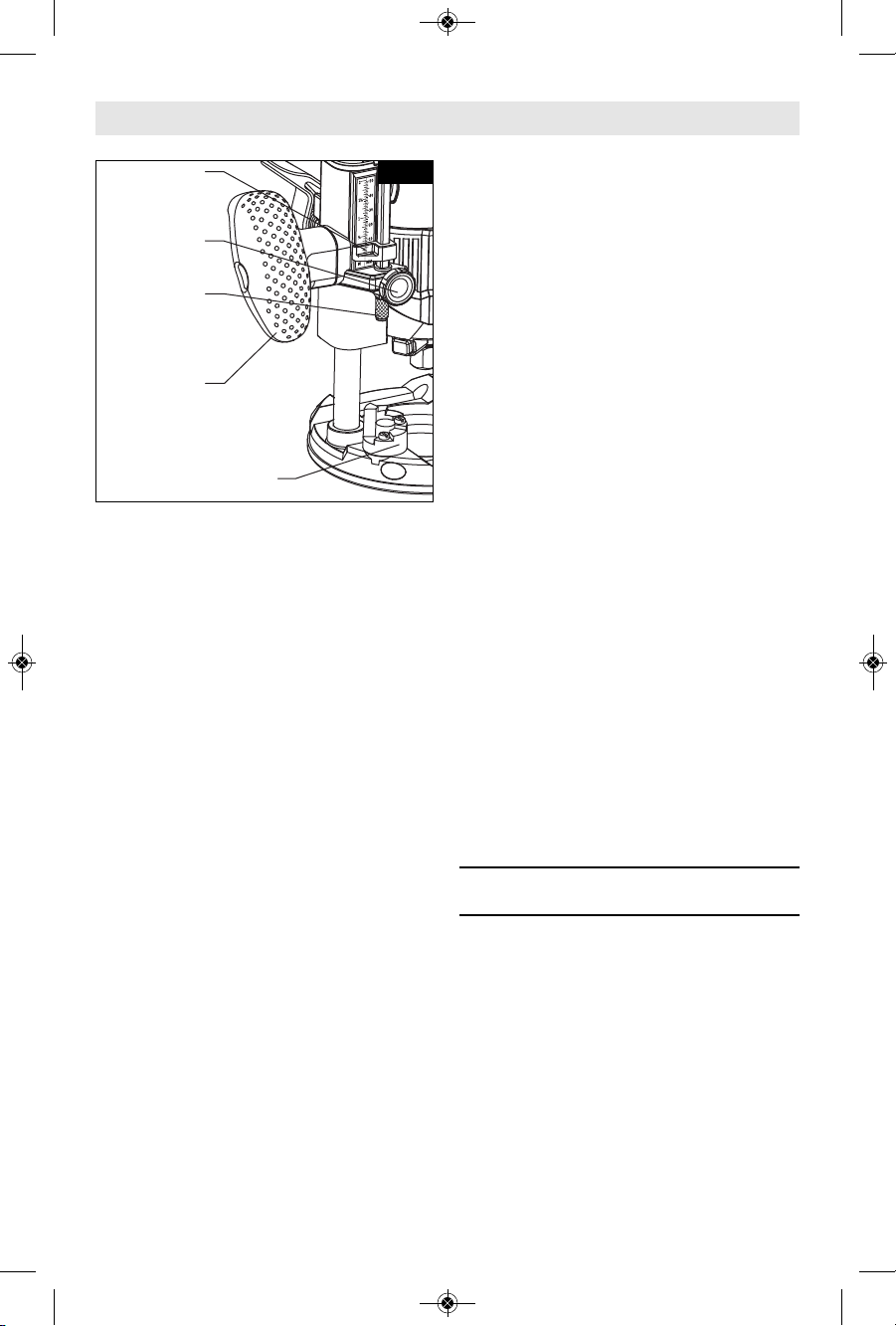

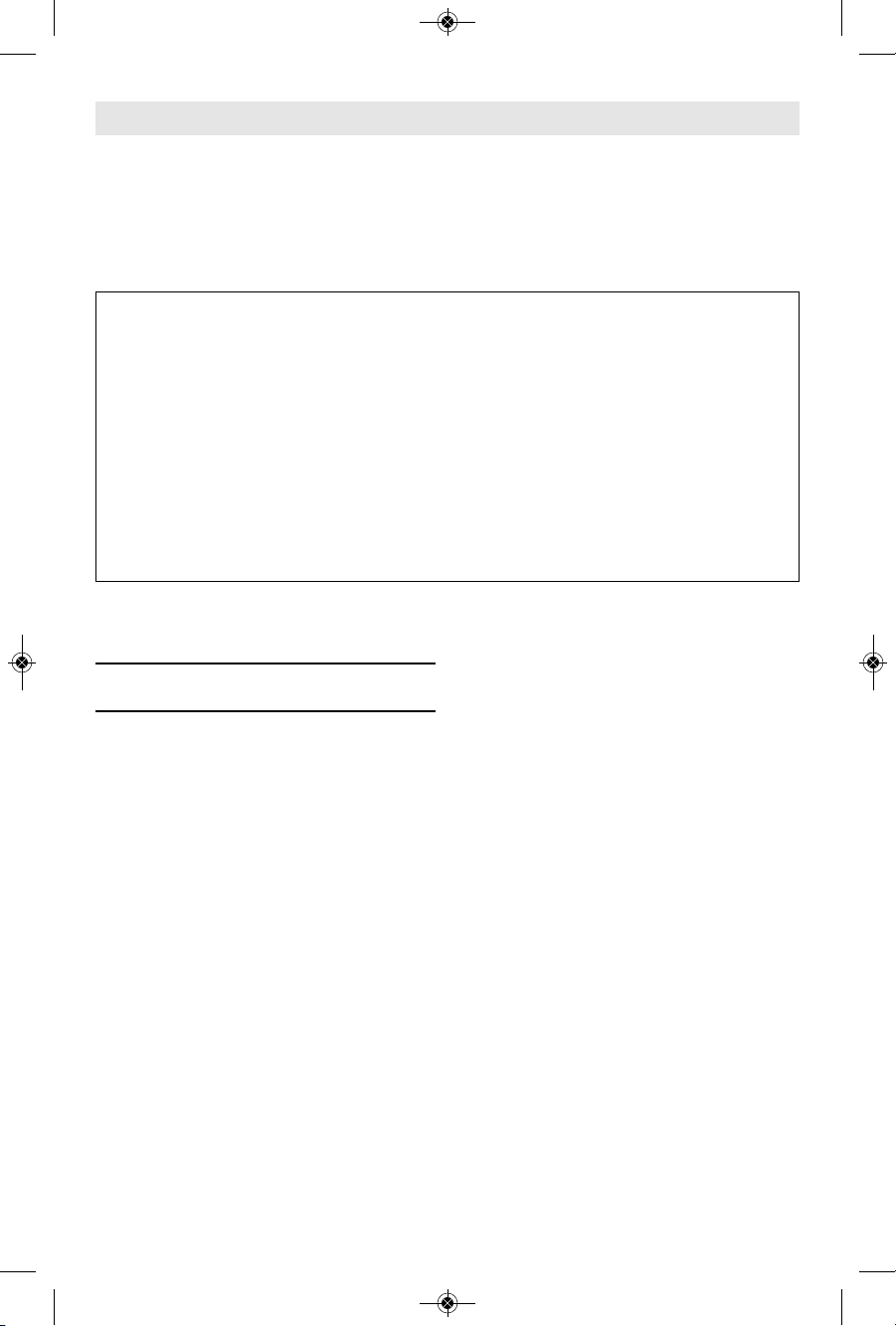

DEPTH

INDICATOR

PLUNGE LOCK

LEVER

LEFT

GRIPPING

HANDLE

DEPTH

INDICATOR

KNOB

DEPTH ROD FINE

ADJUSTMENT

KNOB

DEPTH STOP

TURRET

MOTOR RELEASE

BUTTON

RIGHT GRIPPING

HANDLE

SUBBASE

BIT ROTATION

ARROW

Plunge-Base Palm Router Configuration

FIG. 2

2610052572_GKF125CE 9/18/18 12:11 PM Page 8

Page 9

9

Selecting Bits

Your Bosch palm router is designed

for a wide variety of ro u t i n g

applications that use 1/4" shank bits.

These include woodworking

applications such as edge forming,

grooving, and sign making. This router

is also ideal for trimming laminates,

phenolics, and other materials that

ha ve been bonded to a su bstrate

overhang the substrate typically by

about 1/8" (3 mm).

A wide assortment of router bits with

different profiles are availab le a s

accessories. Only use good quality

bits.

Use only router bits

that h a v e shank

diameters that match the installed

collet. Using a router bit that has a

smaller shank could cause the bit to

co me loose du ring operat ion a nd

become a projectile.

Never operate

router bits at

speeds that are higher than their

maximum rated speed. Router bits

running faster than their rated speed

can break and fly apart.

To prevent personal

injury, always

remove the plug from power source

before removing or in stal ling bits or

accessories.

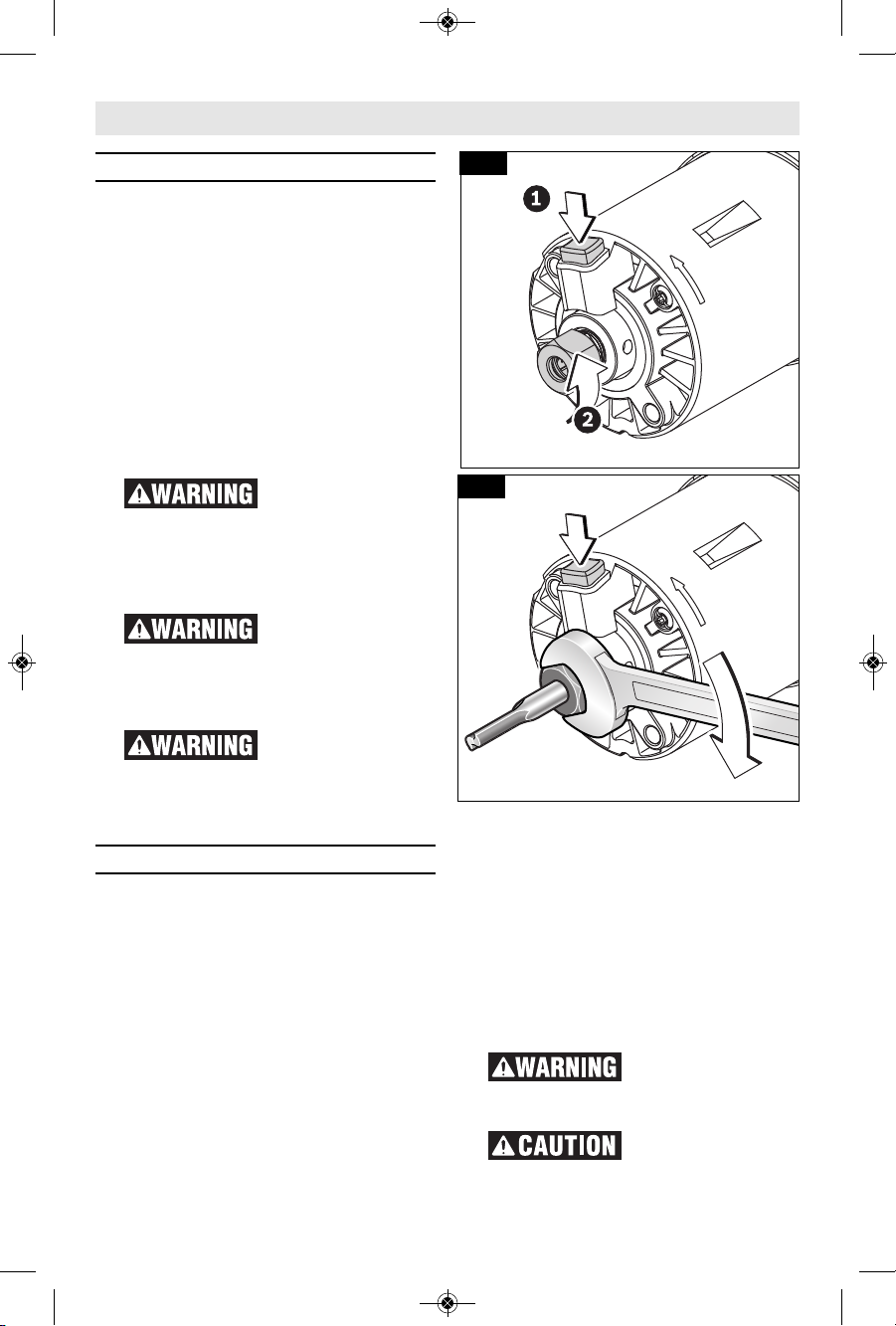

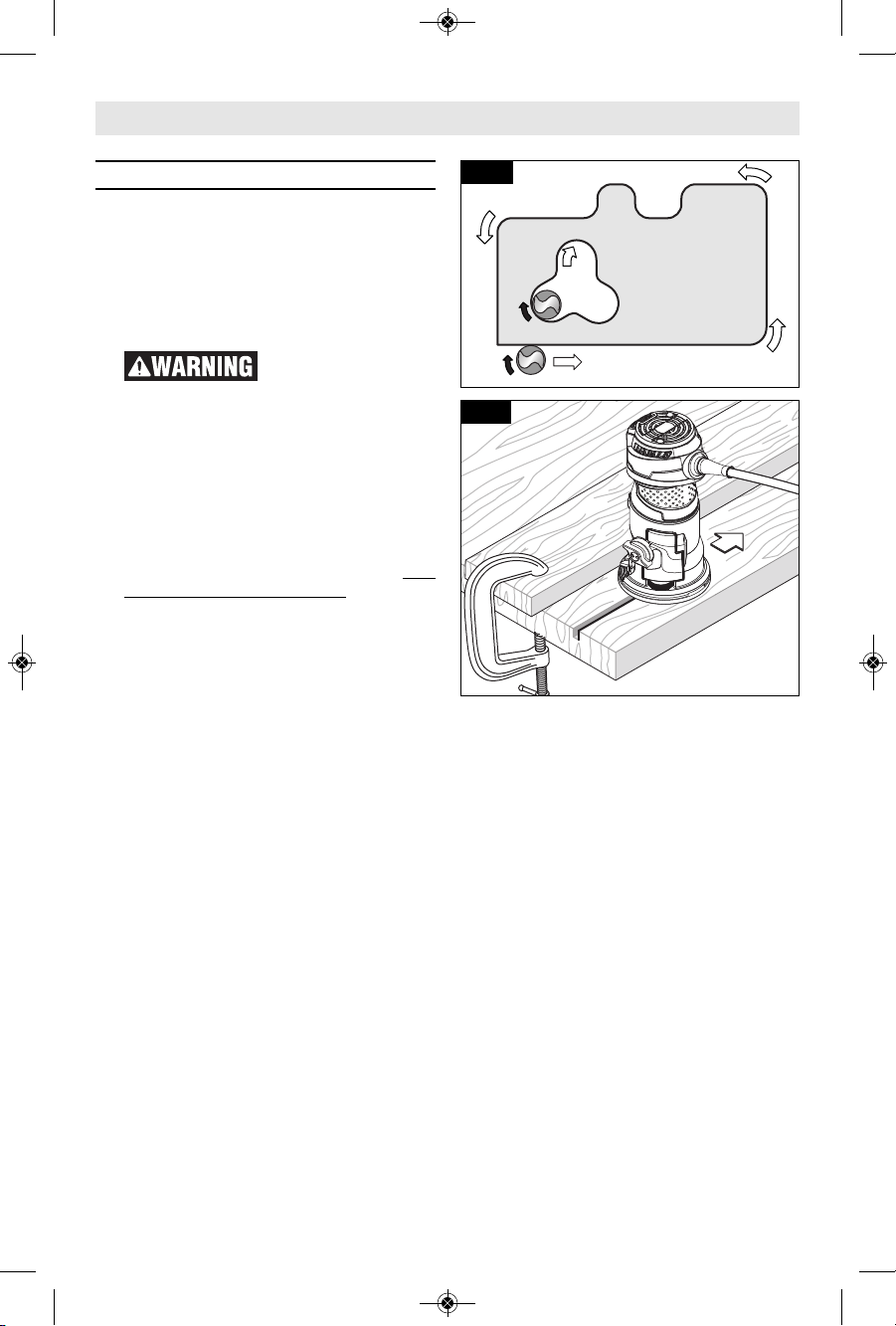

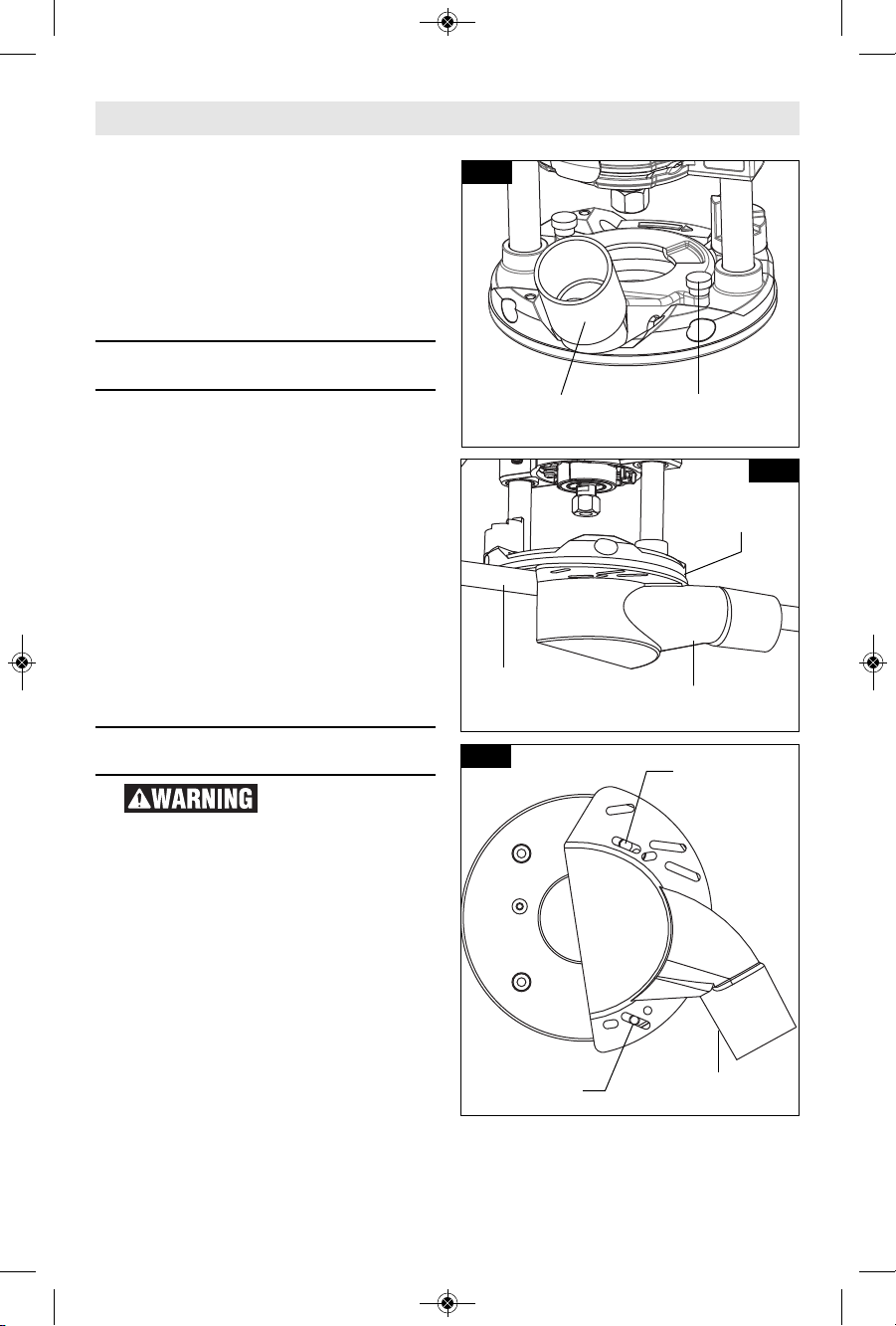

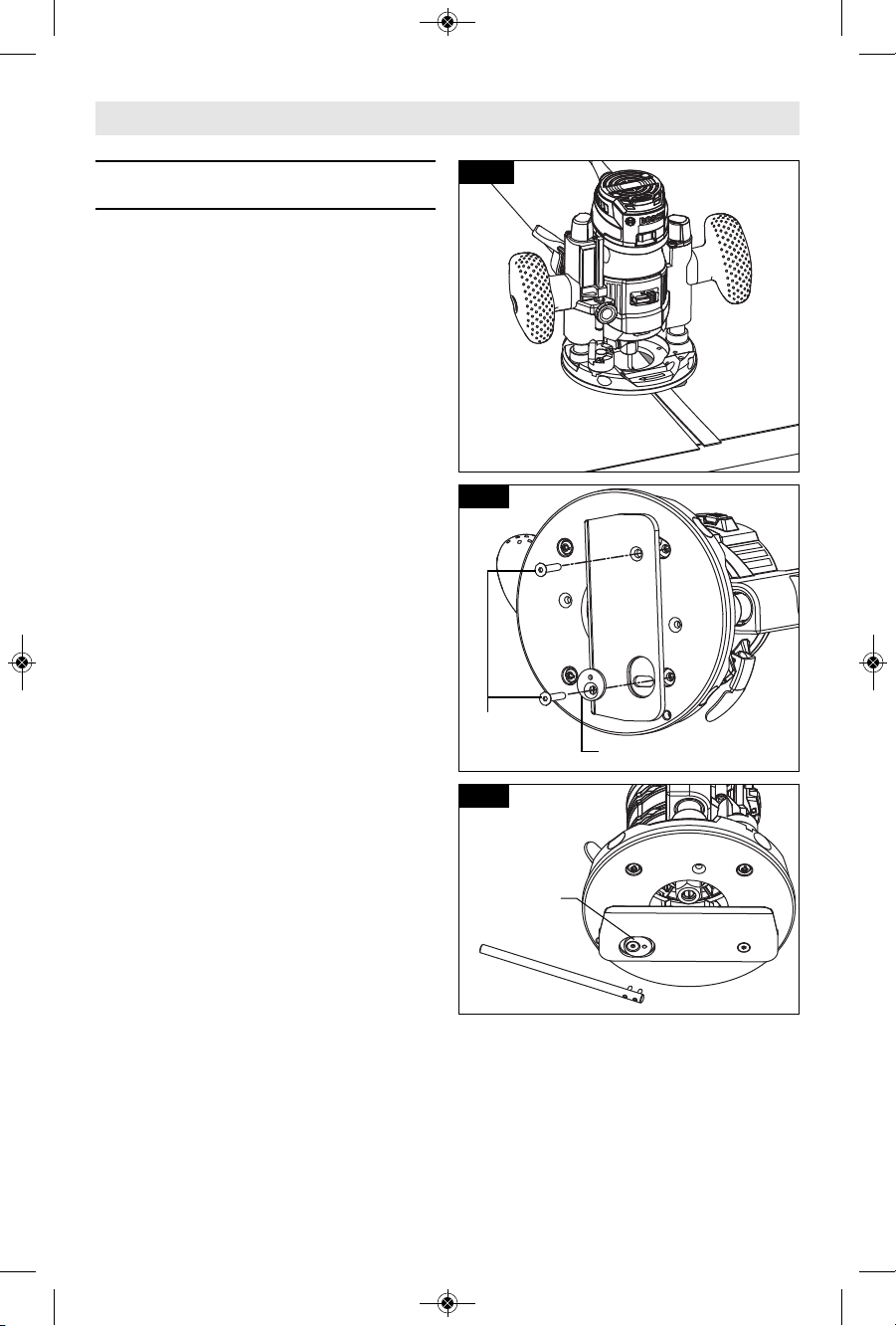

Installing a Router Bit

1. Lay the router or motor on its side.

The router can also be stood "on its

head" for bit changes.

2. Press spindle lock to prev ent

rotation of collet chuck. NOTE: it

may be necessary to rotate collet

nut to engage spindle lock

(Fig. 3).

3. Next, use the collet wrench to

loosen the collet chuck assembly in

a coun ter-c lockw ise direction

(viewed from bottom of router).

4. Insert the shank of the router bit

into the collet chuck assembly as

far as it will go, then back the

shank out until the cutters are

approximately 1/8" to 1/4" away

from the collet nut face.

5. With the router bit inserted and the

spindle loc k engaged, use the

collet wrench to firmly tighten the

collet chuck assembly in a

clockwise direction (viewed from

bottom of router) (Fig. 4).

To ensure prope r grip ping o f the

router bit and minimize run-out, the

shank of the router bit mu s t be

inserted at least 5/8".

Cutter diameter

must be at least

1/4” smaller than opening for the bit

and cutter.

To prevent damage

to tool, d o no t

tighten collet without a bit.

Assembly

FIG. 3

FIG. 4

SPINDLE LOCK

SPINDLE LOCK

(BASE REMOVED FOR CLARITY)

(BASE REMOVED FOR CLARITY)

2610052572_GKF125CE 9/18/18 12:11 PM Page 9

Page 10

10

NOTE: The bi t shank an d chuck

should be clean and free of dust,

wood, residue, and grease before

assembling.

Removing the Router Bit

1. Press spindle lock to prev ent

rotation of collet chuck and turn

the collet chuck assembly in a

counter-clockwise direction.

2. Once the collet chuck assembly is

loosened, continue to turn the

collet chuck assembly until it pulls

the collet free from the spindle,

and the router bit can be removed.

NOTE: The collet chuck is selfextracting; it is NOT necessary to

strike the collet chuck to free the

router bit.

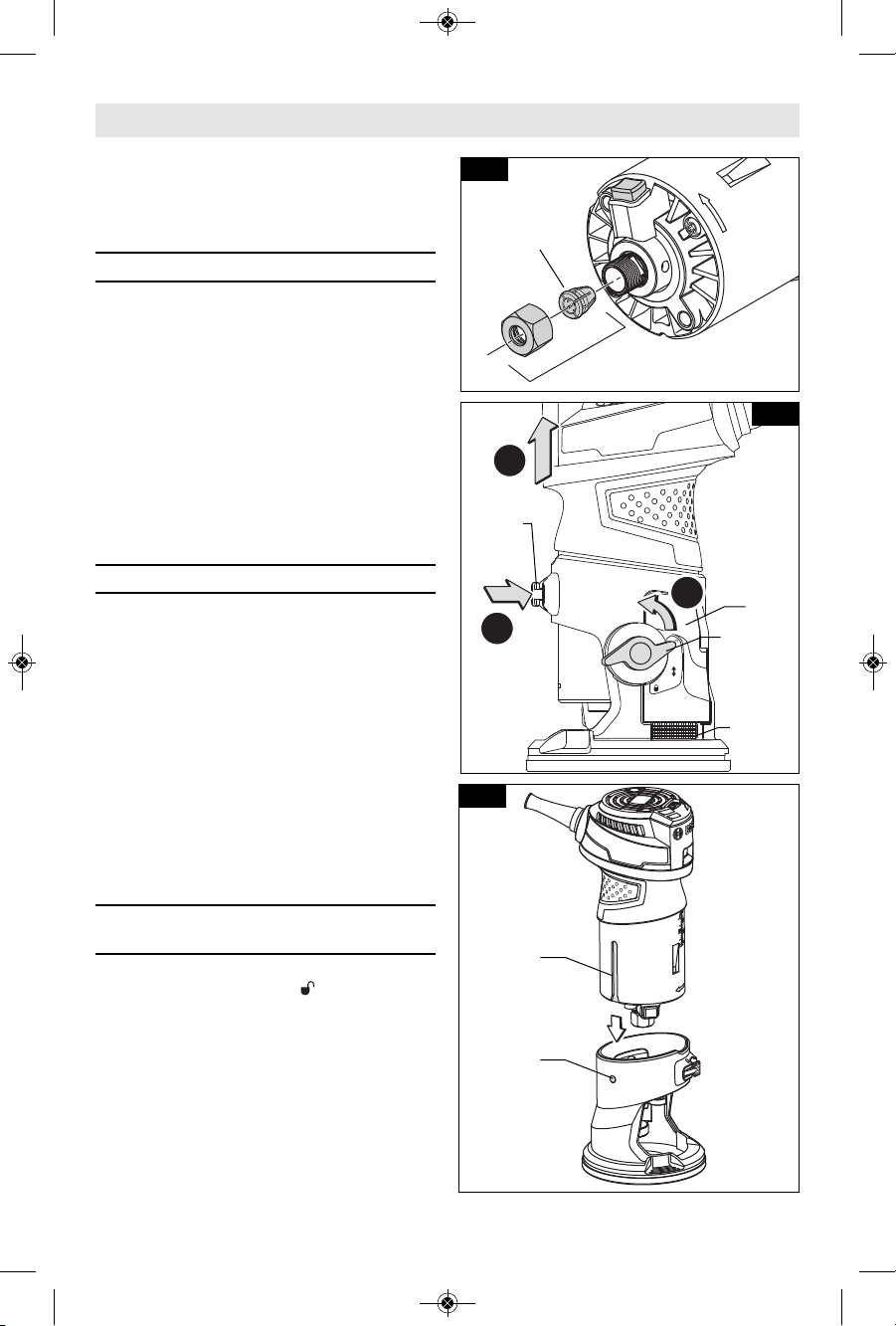

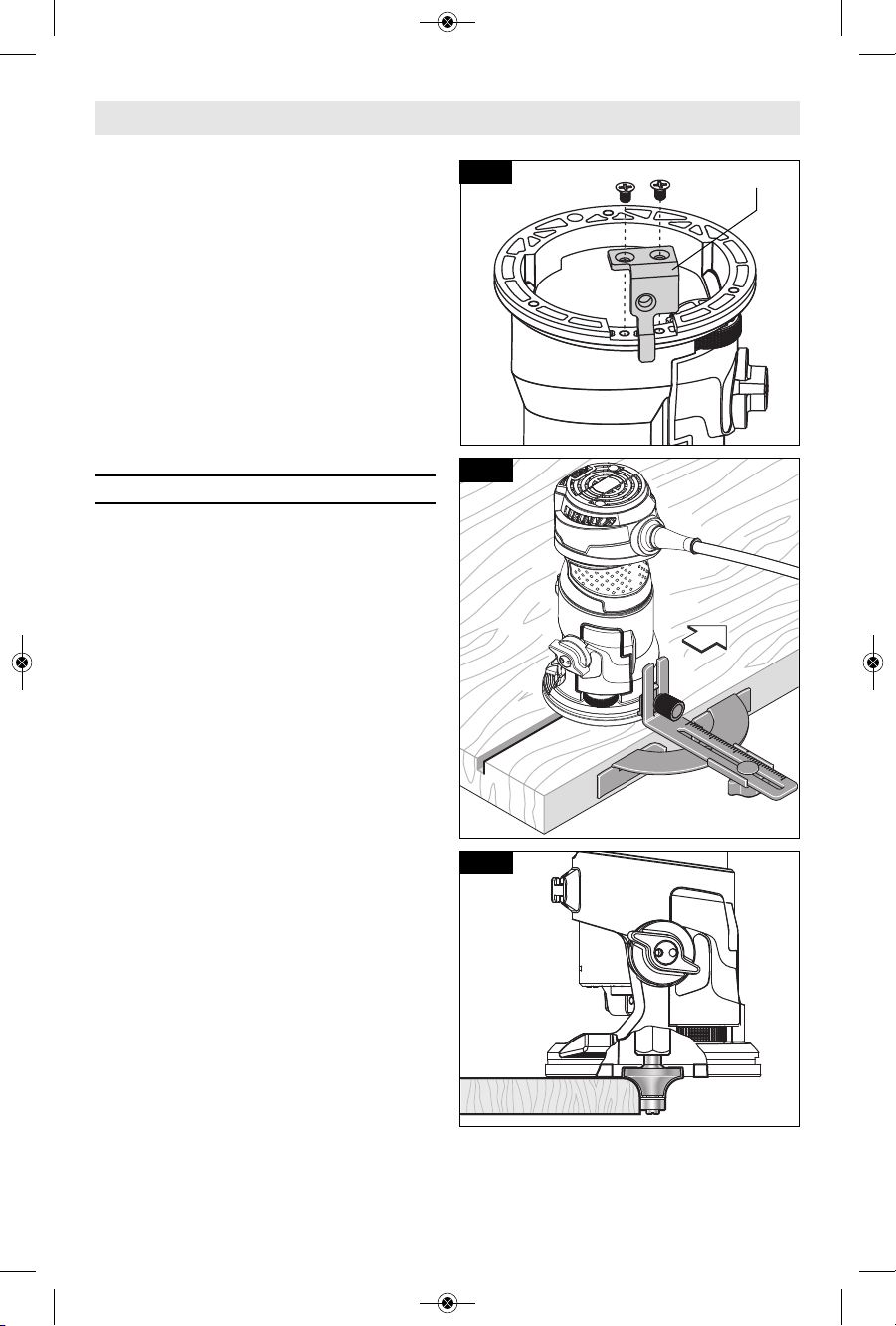

Collet Chuck Care

With the router bit removed, continue

to turn the col let ch u ck cou nterclockwise until it is free of the shaft.

To assure a firm grip, occasionally

blow out t h e collet chuck w i t h

compressed air, and clean the taper

in the armature assembly shaft with a

tissue or fine brush. The collet chuck

is made up of two component parts

that snap together (Fig. 5); check to

see that the collet is properly seated

in the collet chuck nut and lightly

thread the collet chuck back onto the

armature shaft. Replace w o r n or

damaged collet chucks immediately.

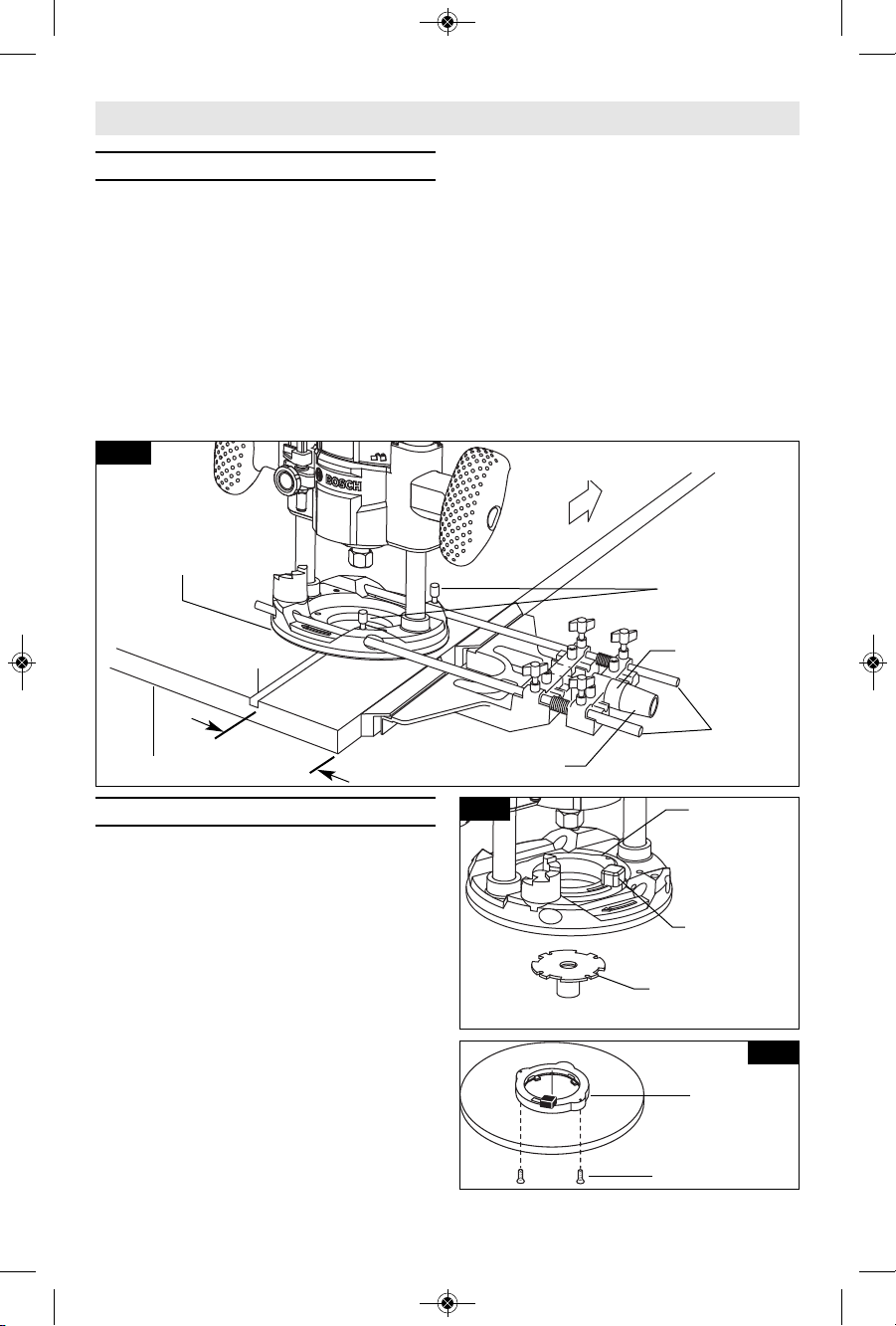

Removing Motor from

PR101 Fixed Base

1. Turn the clamping knob to the

unlocked position (A, Fig. 6).

2. Pull the motor away from base until

it stops. (Do not press on the flap

in the base whi le pulling the

motor.) (C, Fig. 6).

3. Press and hold the motor release

button. (B, Fig. 6).

4. Pull motor out of base (C, Fig. 6).

COLLET

(with Retainer)

COLLET

CHUCK

NUT

F

IG. 5

B

C

A

CLAMPING

KNOB

SLOT

PIN

MOTOR

RELEASE

BUTTON

FLAP

KNURLED

WHEEL

FIG. 6

FIG. 7

Assembly

2610052572_GKF125CE 9/18/18 12:11 PM Page 10

Page 11

Disconnect the plug

from t h e power

source before making any assembly,

adjustments or changing

accessories. Such preventive safety

measures reduce the risk of starting

the tool accidentally.

Bosch routers are designed for speed,

accuracy and con venience in

pe rformi ng ca binet wor k, fluting,

beading, c o v e - c u t t i n g , rounding

ed ges, d ovetailing, etc. They w ill

enable you to accomplish inlay work,

decorative edges and many types of

special routing.

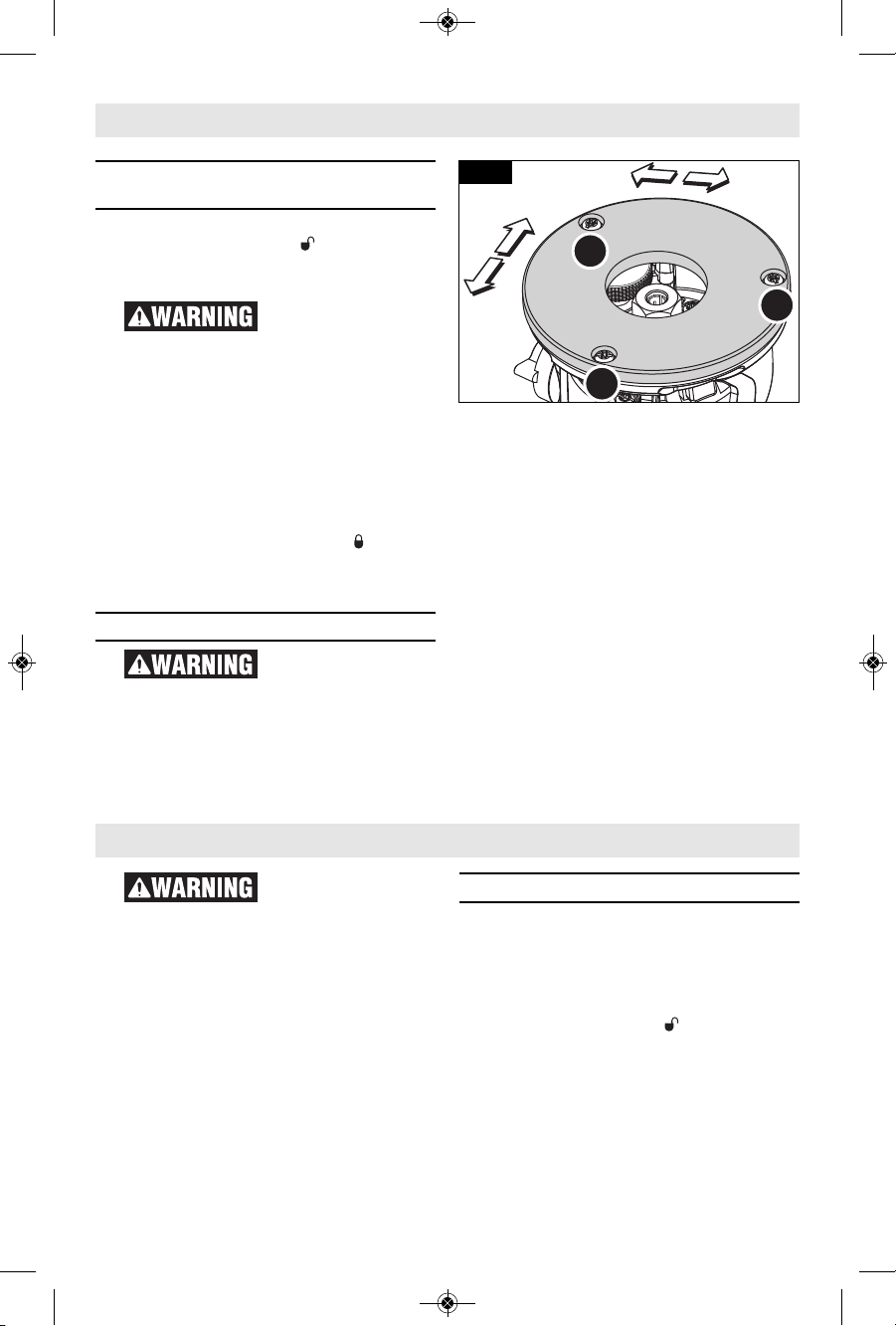

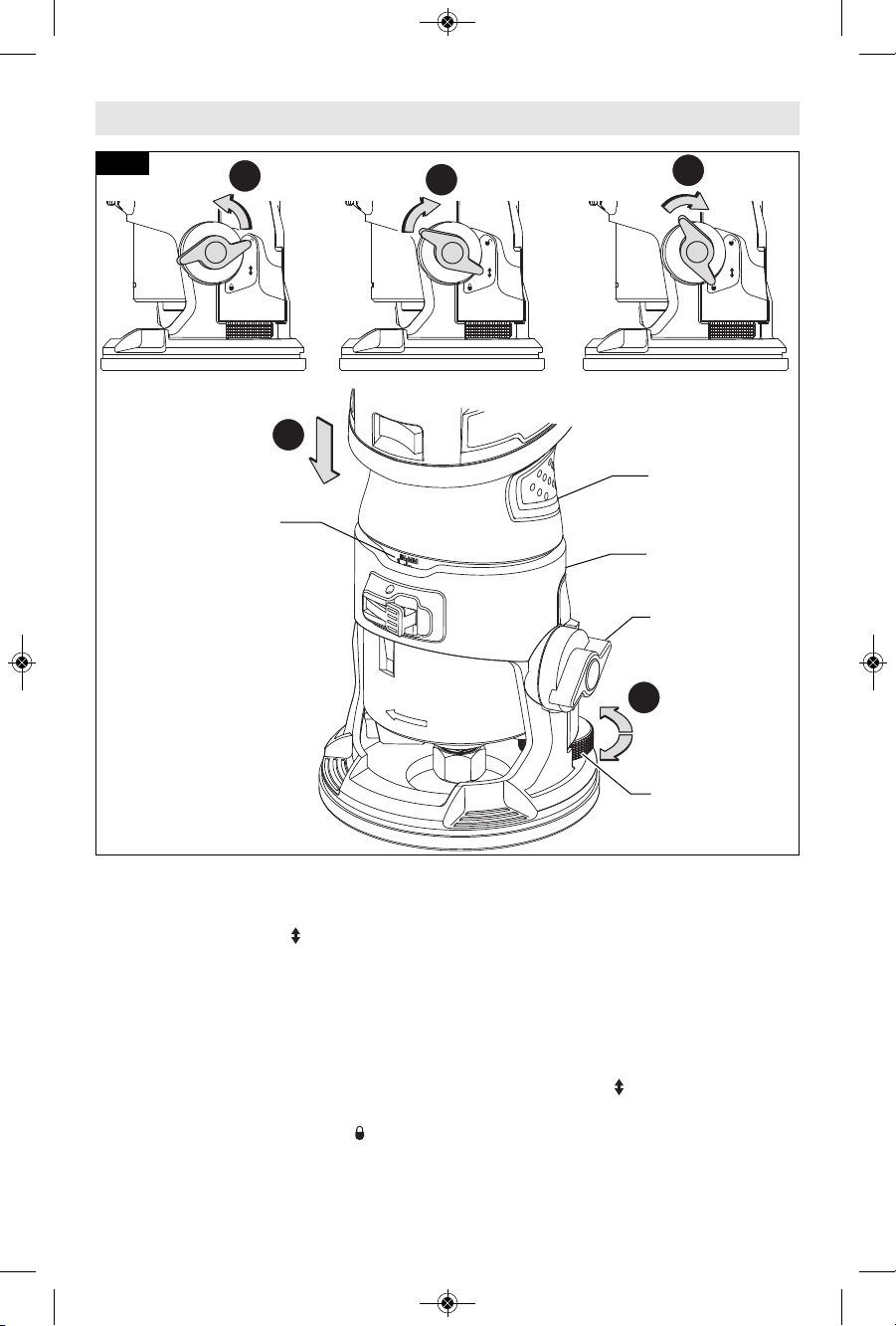

Setting the Depth of Cut

Adjust the depth-of-cut only when the

motor is switched off.

1. Install desired router bit.

2. Place the router on the workpiece.

3. Turn the clamping knob to the top,

unlocked position (A, Fig. 9).

4. Slowly lower the motor until the

router bit touches the workpiece (

B

,

Fig. 9)

5. Note the reading on th e scale

(above the motor release button)

and add the desired depth-of-cut to

this value to determine the target

scale value.

Operating Instructions

Installing the Motor into

PR101 Fixed Base

1. Open the clamping knob to the

unlocked position (A, Fig. 6).

2. Align the slot on the motor with the

pin on the base (Fig. 7)

To avoid pinchi n g

injury, keep all parts

of your hands away from the top rim

of the base and away f rom m etal

section of the motor when pushing

motor into base.

3. Push the motor into the base to the

approximate desired position has

been reached. Do not press on the

flap in the base while installing the

motor.

4. Turn the clamping knob to the

bottom, locked position (E, Fig.

9). Always make sure the motor

sits tightly in the base.

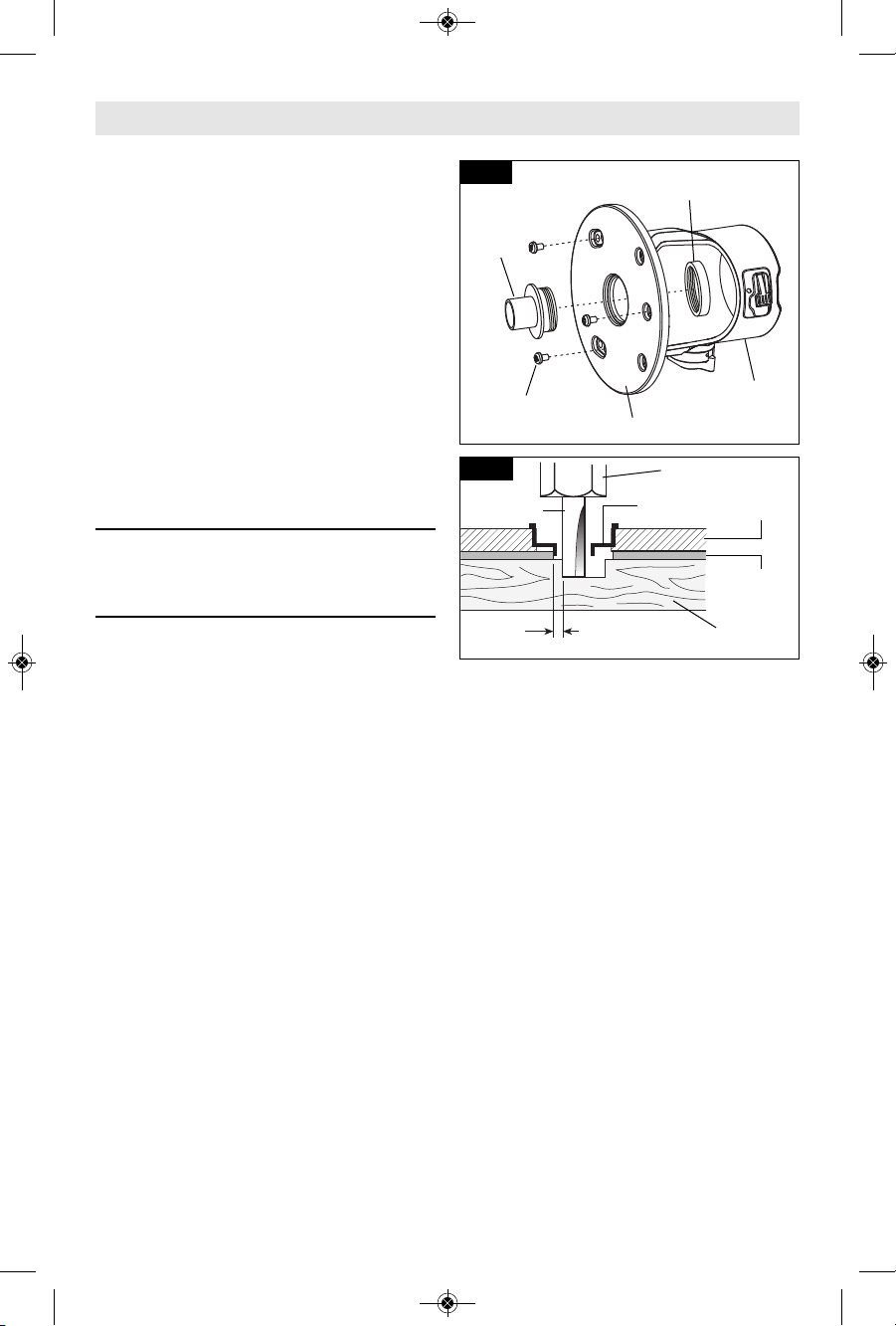

Check Subbase Location

Cutter diameter

must be at least

1/4” smaller than opening for the bit

and cutter.

Make sure that the bit and its cutter

are centered in the subbase opening.

If necessary, adjust the location of the

subbase as follows:

1. Loosen the three screws that hold

the subbase.

2. Adjust the location of the subbase

as needed so that the bit and its

cutter are centered in the subbase

opening. The optional RA11 51

centering device makes this easy.

3. Tighten the three screws that hold

the subbase (Fig. 8).

When the subbase has been centered

in this ma n n e r , a n y part of the

subbase can be used as a guiding

surface wit hout worrying about a

difference in t h e cut line. See

"Guiding The Router" on page 13.

Note: This subbase is not designed

for use with template guides. The

optional PR110 Attachment allows

use of template guides with this palm

router.

11

1

2

3

FIG. 8

Assembly

2610052572_GKF125CE 9/18/18 12:11 PM Page 11

Page 12

12

B

A

C

D

E

FIG. 9

6. Lower the motor until the target

scale value is reached.

7. Turn the clamping knob to the

middle position symbol, for fine

adjustment (C, Fig. 9). Always

make sure the motor is held tightly

in the base.

8. Check the depth-of-cut and make

fine adjustment if necessary (D,

Fig. 9). See FINE DEPTH

ADJUSTMENT section below for

details.

9. Turn the clamping knob to the

bottom, locked position (E, Fig.

9). Always make sure the motor

sits tightly in the base.

Note: the depth of the motor and bit

may shift very slightly when the

clamping knob is turned to the locked

position.

10. Make a trial cut to verify that the

router is set to make the cut as

desired.

FINE DEPTH ADJUSTMENT

Adjust the depth-of-cut only when the

motor is switched off.

1. Turn the clamping to the middle

position symbol, for fi ne

adjustment (C, Fig. 9).

2. Adjust the desired depth-of-cut

with the knurled wheel on back of

base (D, Fig. 9). Rotate the knurled

wheel clockwise to increase the

KNURLED WHEEL

DEPTH SCALE

CLAMPING KNOB

MOTOR

BASE

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 12

Page 13

13

Operating Instructions

r

outing depth, counterclockwise to

decrease the cutting depth. Each

complete rotation of the dial equals

1.25 mm (approximately 3/64").

3. Turn the clamping knob to the

bottom, locked position (E, Fig.

9). Always make sure the motor

sits tightly in the base.

4. Check the depth-of-cut and make

an additional fine adjustment if

necessary.

Note: the depth of the motor and bit

may shift very slightly when the

clamping knob is turned to the locked

position.

5. Make a trial cut to verify that the

router is set to make the cut as

desired.

DEEP CUTS

For dee p cut s, ma ke se veral

progressively deeper cuts by starting at

one d epth and then m ake several

subsequent passes, increasing the

cutting depth with each pass.

To be certain that your depth settings

are as desired, you may want to make

test cuts in scrap material before

beginning work.

Rocker “On/Off” Switch

Your tool can b e turned “ON” or

“OFF” by the rocker switch located on

the motor housing. One side of the

switch is marked “I” for “ON“, and the

other side of switch is marked “O” for

“OFF“.

TO TURN THE TOOL “ON”: Push the

side of the switch marked “I”.

TO TURN THE TOOL “OFF”: Push the

side of the switch marked “O”.

SOFT START FEATURE

Electronic feedback control minimizes

torque twist customary in routers by

limiting the speed at which motor

starts.

ELECTRONIC VARIABLE SPEED

CONTROL

The electronic speed control feature

allows motor speed to be matched to

cutter size and material hardness for

improved finish, extended bit life, and

h

igher performance. Speed changes

are achieved by rotating the Control

Dial RIGHT to increase speed or LEFT

to decrease as indicated on housing

(Fig. 1). Speed may be changed while

tool is on. The reference numbers on

the dial facilitate re-setting control to

desired speed.

The speed c h a r t i n d i c a t e s the

relationship between settings and

application, exact settings are

determined by operator experience

and preference. The bit manufacturer

may also have a speed

recommendation.

Never operate

router bits at

speeds that are higher than their

maximum rated speed. Router bits

running faster than their rated speed

can break and fly apart.

CONSTANT RESPONSE™

CIRCUITRY

The router's Constant Response™

Circuitry monitors and adjusts power

to m a i n t a i n the desired RPM f o r

consistent performance and control.

DIAL

SETTING

RPM APPLICATION

1

16000

Larger-diameter

bits and cutters.

2

18000

3

20000

4

22500

Softwoods,

plastics, laminates,

smaller diameter

bits and cutters

5

27500

6

35000

FIG. 10

WORKPIECE

WORKPIECE

EDGE

2610052572_GKF125CE 9/18/18 12:11 PM Page 13

Page 14

14

Operating Instructions

Feeding the Router

I

n addition to the main palm-grip area

at the back of the motor housing and

base, the base has Bosch-exclusive

finger support pockets to provide

additional stability for the router. The

pockets feature finger g u a r d s to

provide a barrier between the finger

pockets and the bit area (Fig 10).

Wh en us ing finger

pockets, always

place both finger pockets over the

workpiece and always hold the router

in a way that allows you to see your

finger and thumb.

As seen from the top of the router,

the bit turns clockwise and the bit’s

cutting edges are positioned to best

cut into the workpiece. Therefore, the

most efficient cut is made by feeding

the router so that the bit turns into

the workpiece, not away. Figure 11

shows proper feed for various cuts.

How fast you feed depends on the

hardness of the material and the size

of the cut. For some materials, it is

best t o make se v e r a l cuts of

increasing depth.

If the router is hard to control, heats

up , runs very slowl y or leaves an

imperfect cut, consider these causes:

1. Wrong direction of feed — hard to

control.

2. Feeding too fast — overloads motor.

3. Dull bit — overloads motor.

4. Cut is too large for one pass —

overloads motor.

5. Feeding too slow — leaves friction

burns on work.

Feed smoothly and steadily (do not

force). You will soon learn how the

router sounds and feels when it is

working best.

Always hold the router off the work

when turning the switch on or off.

Contact the work with the router after

the router has reached full speed, and

remove it fr o m the wo r k before

turning the switch off. Operating in

this manner will prolong switch and

motor life and will greatly increase

the quality of your work.

RATE OF FEED

When routing or doing related work in

wood and plastics, the best finishes

will result if the depth of cut and feed

rate are regulated to keep the motor

operating at high speed. Feed the

router at a moderate rate. Soft

materials require a faster feed rate

than hard materials.

The router may s

tall if improperly used

or overloaded. Reduce the feed rate to

prevent possible damage to the tool.

Alwa y s be su r e the c o l let chuck is

tightened securely before use. Always

use router bits with the shortest cutting

length necessary to produce the desired

cut. This will minimize router bit run-out

and chatter.

It may be necessary to make the cut in

more than one pass with progressively

deeper settings to avoid overloading the

motor. If the bit cuts freely and the

motor does not slow down, the cutting

depth is generally correct.

FIG. 12

FIG. 11

WORKPIECE

DIRECTION OF ROUTER FEED

2610052572_GKF125CE 9/18/18 12:11 PM Page 14

Page 15

GUIDING THE ROUTER

T

he router can be guided through the

wor k in a ny of several ways. T he

method you use depends, of course,

on the demands of the particular job

and on convenience.

For r o u t i n g operations su c h as

grooving or dadoing, it is often

necessary to guide the tool in a line

parallel to a straight edge. On e

method of obtaining a straight cut is

to securely clamp a board or other

straightedge to the work surface, and

guide the edge of the router sub-base

along this path (Fig. 12).

PR102 Edge Guide

The edge g u i d e is an o p t i o n a l

accessory that will guide the router

parallel to a straight edge (Fig. 14).

The edge guide is supplied in two

parts held together with a bolt, wing

nut and washer.

ATTACHING THE EDGE GUIDE

1. Remove the subbase by

unscrewing the three screws.

2. Position the adapter in the gap in

the base.

3. Fasten the adapter using the two

Philips screws (Fig. 13).

4. Reattach the subbase.

Note: See “Check S u b b a b s e

Location” section on how to center

the subbase.

5. Attach the edge guide to the

adapter using the knurled screw

with two washers (Fig. 14).

The guide features a sc a l e f o r

accurately positioning the edge guide

relative to the bit. With the guide

installed and adjusted, the router

should be fed normally, keeping the

guide in contact with the edge of the

workpiece at all times.

The e d g e g u i d e can also be

positioned directly under the router

base for operations where a cut is

needed close to or at the edge of the

work, such as when rounding off deck

planks.

15

FIG. 13

FIG. 14

FIG. 15

ADAPTER

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 15

Page 16

16

USING SELF-PILOTED BITS

S

elf -pilote d bits have an int egral

round tip or ball bearing which rides

against the work surface above or

below the cutter to control horizontal

cutting depth (Fig. 15). When using

these bits, neither the roller guide or

the straight guide is required. When

guiding against a laminated surface,

use wax or other lubricant and do not

apply excess pressure or the piloted

end may mar the work. Bearing pilots

must be kept clean and fr e e of

adhesive or other residue. Router bit

bearings are sealed and permanently

lubricated, and should be replaced

when they no longer turn freely to

avoid damaging the work surface.

PR110 Round Subbase and

Use of Template Guide

Bushings with PR101 Fixed

base

(Available as optional accessories)

Optional large round subbases are

available separately and allow various

template guide bushings to be used

with the palm routers.

Template guide bushings are used to

guide the router to repeatedly make

consistent openings and inlays using

various templates (also referred to as

pa tterns and jigs). Temp lates for

standa rd r outing applications are

available commercially and templates

for specialty applications are typically

made by users for their specific

needs.

The PR110 Round Subbase accepts

threaded template guide adapters.

PR110 ATTACHMENT ROUND

SUBBASE OF THREADED

TEMPLATE GUIDE (Fig. 16)

1. Remove regular subbase.

2. Loosely attach round subbase

using panhead screws that come

with that accessory.

3. Attach the threaded template guide

by putting the template guide

through the bottom and attaching

the ring from the top.

4. Center the template guide around

the bit. ( The o ption al Bosch

RA1151 Centering device can be

used to ensure that the template

guide is properly centered.)

5. Tighten the panhead screws to

hold the template guide an d

subbase in position.

CREATING TEMPLATES

Template patterns can be made of

plywood, hardboard, metal or even

plastic. The design can be cut with a

router, jigsaw, or other suitable

cutting t o o l . Remember that the

pattern will have to be made to

compensate for the distance between

the router bit and the template guide

(the “offset”), as the final workpiece

will differ in size from the template

pattern by that amount, due to the bit

position (Fig. 17).

WORKPIECE

ROUTER BIT

OFFSET

TEMPLATE

GUIDE

TEMPLATE

PATTERN

ROUTER

SUBBASE

FIG. 16

FIG. 17

PR110 SUBBASE

TEMPLATE

GUIDE RING

ROUTER

BASE

PANHEAD

SCREWS

TEMPLATE

GUIDE

COLLET CHUCK

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 16

Page 17

17

PR111 Plunge Base

(

Included with GKF125CEPK and sold

separately)

To install motor in plunge base:

1. Release the base clamp lever (Fig.

18).

2. Push the motor into the base as far

as it will go.

3. Fasten the base clamp lever.

If additi onal clamping force is

desired: using a 8 mm wrench,

rotate cl amp nut clockwise

SLIGHTLY (1/8 turn or less), then

test clamp. Do not over-tighten.

To remove motor from plunge base:

1. Release the base clamp lever.

2. Press and hold the motor release

button.

3. Pull motor up and out of base.

DEPTH ADJUSTMENT

The plunge feature simplifies depth

adjustments and will allow the cutting

bit to easily and accurately enter the

workpiece.

1. To lower, push plunge lock lever to

the left, apply downward pressure

until you reach desired depth, and

release pressure on lever to lock

(Fig. 19). The plunge lock lever is

spring lo aded an d retur ns

automatically to the locked

position.

2. To raise the router, push plunge

lock lev er to the left, release

pressure on router and the router

will automatically retract the bit

from the workpiece. It is advisable

to retract the bit whenever it is not

engaged in work piece.

DEPTH ROD AND TURRET

The depth rod and the depth stop

turret are used to control cutting

depth as follows;

1. With the bit installed, gently lower

the motor until the tip of the router

bit just contacts the level surface

the router is sitting on. This is the

“zero” position, from which further

depth ad justm ents c an be

accurately made.

2. Rotate depth stop turret until the

lowest step is aligned with the

depth rod. Loosen depth indicator

knob and lower the depth rod until

it contacts the lowest step of the

turret. Slide the depth indicator

until the red line indicates zero on

the depth scale, indicating the

point at which the bit just contacts

the work (Fig. 20).

3. Slide the depth rod up until the red

depth indicator line attains the desired

cutting depth, and secure the rod in

position by firmly tightening the depth

indicator knob.

BASE

CLAMP

LEVER

FIG. 18

FIG. 19

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 17

Page 18

4. The desired depth of cut may now

be achieved by plunging the router

until the depth rod contacts the

lowest stop on the turret.

ALTERNATE SET-UP FOR DEPTH

ROD AND TURRET

1. An alternative to place a jig of the

desired routing depth (such as a

hinge which needs to be mortised)

on the bottom step of the turret.

2. Next, lower the depth rod until it

contacts the jig.

3. Secure the rod in position by firmly

tightening the depth in dicator

knob.

4. Finally, remove the jig.

DEEP CUTS

For deeper c u t s , make s e v e r a l

progressively deeper cuts by starting

with the highest step on the depth

turret, and after each cut, rotate the

depth turret to progressively lower

steps as desired, until the final depth

(lowest step or flat) is reached. Steps

progress by 1/8” increments.

To be certain that your depth settings

are as desired, you may want to make

test cuts in scrap material before

beginning work.

FINE ADJUSTMENT

The PR111 plunge base is equipped

with a fine adjustment system that

allows you to micro adjust the plunge

depth of the router bit for superior

routing accuracy.

Each complete revolution of the fine

adjustment knob adjusts the plunging

depth by 1/32”, and each of the four

indicator marks on the kn o b

represents 1/128”.

To use the fine adjustment knob, once

the depth rod and turret have been

set, check the final depth setting and

fine-adjust as follows:

To micro-increase the plunge depth,

raise the fine adjustment stop by

turning it counter-clockwise by the

desired amount.

To micro-reduce the plunge depth,

lower the fine adjustment stop by

turning it clockwise by the desired

amount.

Notes:

• When micro-adjusting the plunge

depth, it is more convenient to

move the fine adjustment stop up

than down. Before setting th e

depth rod and turret, make sure

the fine adjustment stop has been

turned several revolutions down

from its top position so that it can

be adjusted upward.

• The fine adjustment stop cannot be

used to reduce the plunge depth

when the depth rod is already

touching the depth stop turret.

The router must be raised before such

an adjustment can be made.

Using the Router in the

Plunge Base

Grip both of t h e pl u n g e ba s e ’ s

gripping handles while operating (see

Fig. 2).

1. Turn the router on

2. Allow router bit to reach the full

speed as set on the dial before

plunging the cutter head into the

workpiece.

3. Press down on the plunge lock

lever to allow it to be plunged.

4. Plunge the router down until the

bit reaches the set depth.

5. Lock the plunge lock lever.

18

DEPTH

INDICATOR

DEPTH

INDICATOR

KNOB

DEPTH STOP

TURRET

DEPTH ROD

FINE

ADJUSMENT

KNOB

FIG. 20

Operating Instructions

LEFT GRIPPING

HANDLE

2610052572_GKF125CE 9/18/18 12:11 PM Page 18

Page 19

19

6. Perform the routing operation,

following the instructions in the

“Feeding the Router” section that

begins on page 14 of this manual.

7. Unlock the plunge lock lever. This

will allow the router bit to

disengage the work.

8. Turn the router off.

The PR012 Router Dust

Collection for Plunge Base

This dust extraction hood is designed

for use the plung e base ( P R111)

when routing is done in the middle of

the workpiece, such as when creating

slots or routing patterns for inlays. If

you have a shop vacuum system, you

can attach the dust extraction hood

for improved visibility, accuracy and

utility, particularly i n freehand

routing.

To attach, positio n as shown and

secure adapter t o base with the

thumbscrews provided (Fig. 21).

The dust extraction hood can also be

installed with the hose outlet facing

the front of the tool.

Edgeforming Dust Extraction

Hood RA1175

Do not reach in area

of the bit while the

router is ON or plugged in. To avoid

entangling hoses, do not use this

dust extraction hood at the same

time as any other dust extraction

hood.

This dust extraction hood (optional

accessory) is used for dust collection

when edge-forming (Fig. 22).

ATTACHING DUST EXTRACTION

HOOD

You can attach the edge-forming hood

in several places according to your

needs or preferences. The dust hood

is attached to the plunge base using

two M4 thumb screws Two auxiliary

holes are provided in the plunge base

for attachment. At t a c h the dust

extraction hood — over the router’s

sub-base — using the screws provided

with the hood. Securely tighten the

screws. (Figures 22 and 23).

DUST EXTRACTION

HOOD

WORKPIECE

EDGE

ROUTER

SUBBASE

Dust Extraction Hood

(Optional Accessory)

M4 Thumb

Screws

FIG. 21

FIG. 22

M4 x 16mm

SCREW

SUBBASE

M4 x 16mm

SCREW

DUST EXTRACTION

HOOD

FIG. 23

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 19

Page 20

Template Guides

This plunge base can also be used

with the optional Bosch-exclusive

quick-change template guide system,

which firmly grips the guides with a

spring-loaded ring. Unlike conven tio n al thread e d templa t e guides,

there is no threaded ring that can

come loose while routing (Fig. 25).

INSTALLING TEMPLATE GUIDE

ADAPTER

(Not included, available as accessory)

Place template guide adapter over the

holes in the center of the sub-base,

and align the two threaded holes in

the bo t t o m of adapter wi t h the

countersunk holes in subbase. Fasten

adapter with the screws provided.

TEMPLATE GUIDE

ADAPTER

(optional accessory)

MOUNTING SCREWS

FIG. 26

TEMPLATE

GUIDE ADAPTER

TEMPLATE GUIDE

RELEASE LEVER

TEMPLATE GUIDE

(optional accessory)

FIG. 25

20

BASE

CUT

DESIRED

WIDTH

M6 WING SCREW

ROUTER

GUIDE RODS

FINE ADJUSTMENT

KNOB

FINE

ADJUSTMENT

INDICATOR

WORKPIECE

FEED

DIRECTION

FIG. 24

Operating Instructions

Deluxe Router Guide

(Not included, available as accessory)

The Bosch deluxe router guide is an

optional accessory that will guide the

router parallel to a straight edge or

allow you to create circles and arcs.

The deluxe router guide is supplied

with two rods and screws to fasten

the guide (Fig. 24). In addition, it

features a fine adjustment knob and

indicator for accurately positioning the

edge guide relative to the bit. With the

guide installed and a d j u s t e d , the

r

outer should be fed normally, keeping

the guide in contact with the edge of

the workpiece at all times. The deluxe

router guide may also be positioned

directly under the r outer base for

op eration s wher e a cut is neede d

close to or at the edge of the work.

The deluxe router guide includes a

dust extraction hood and the VAC002

vacuum hose adapter.

For c o m p l e t e instructions on

installation and operation, please

refer to the instructions which are

included with this accessory.

2610052572_GKF125CE 9/18/18 12:11 PM Page 20

Page 21

N

ote that the adapter is reversible, so

the release lever may be positioned as

desired. (Fig. 26)

CENTERING THE SUB-BASE OR

TEMPLATE GUIDES

Your PR111 plunge base features the

Bosch “Precision Centering Design”.

Its subbase is precisely centered at

the factory. This positions the bit at

the ce n t e r of the s u b b a s e and

optional template guides.

Precision centering allows you to use

the edge of the subbase or template

guides to closely follow jigs such as

straight g u i d e s , templates, an d

dovetail fixtures without worrying

about bit walk-off from the intended

cut line for any reason, including the

orientation of the router’s handles

relative to the jig.

To mo s t precisely re-center the

subbase or template guides, attach

the subbase using the optional Bosch

RA 1151 Cente ring Devic e. Follow

steps 1-8 (Fig. 27).

1. If a template guide is to be

centered, Install the template guide

adapter and template guide

(optional atta chmen ts) as

described elsewhere in this

manual.

2. Loosen the four screws that hold

t

he subbase to the base.

3. Prepare the Centering Device:

•

Use narrow end of steel shaft.

• When cente ring subbase or

template guide that has opening of

more than 1/2”, slide the wide

plastic sleeve over the steel shaft.

4. Slide centering sleeve through the

subbase or template guide and into

collet. Tighten collet nut with

fingers to put slight grip o n

centering cone.

5. Lightly press centering sleeve into

sub-base or template guide to

center.

6. Tighten the pan-head screws.

Remove centering sleeve.

7. The precision centering of the

subbase or template gu ide is

complete.

CENTERING CO N E – Used when

centering the subbase itself or wide

template guides.

MAXIMUM BIT/CUTTER SIZE FOR

TEMPLATE GUIDES

When using a template guide, use

only router bit with cutters that are

1/16” less than the internal diameter

of the template guide, such as in the

table below.

Operating Instructions

21

CENTERING SHAFT

(optional accessory)

TEMPLATE GUIDE

(optional accessory)

SUBBASE

CENTERING CONE

(optional accessory)

FIG. 27

PLUNGE BASE

CENTERING SHAFT

(optional accessory)

2610052572_GKF125CE 9/18/18 12:11 PM Page 21

Page 22

22

Operating Instructions

Attaching a Vacuum / Dust

Extractor Hose

The hose ports on the PR012, RA1175

and RA1054 will accept the typical

nozzles from 35 mm vacuum cleaner

hoses, such as the VX120 nozzle that

is included with the Bosch VH-Series

hoses.

To connect them to a 1-1/4 in. or

1-1/2 ho se, the Bosch VAC002 or

VAC024 vacuum hose adapters (both

sold separately) can be used.

To connect them to a 2-1/2 in. hose,

the Bosch VAC020 (sold separately)

can be used.

Bosch Bushing External Internal Max

Template Depth Diameter Diameter Bit/Cutter

Guide Diameter

ABB

RA1101 3/16” 5/16” 1/4” 3/16”

RA1103 9/64” 5/16” 17/64” 13/64”

RA1105 9/64” 7/16” 3/8” 5/16”

RA1107 5/16” 7/16” 3/8” 5/16”

RA1109 7/16” 1/2” 13/32” 11/32”

RA1111 3/16” 5/8” 17/32” 15/32”

RA1113 1/2” 5/8” 17/32” 15/32”

RA1115 3/16” 3/4” 21/32” 19/32”

RA1117 31/64” 13/16” 5/8” 9/16”

RA1119 31/64” 1” 25/32” 21/32”

RA1121 7/16” 1-3/8” 1-19/64” 1-15/64”

USE WITH THREADED TEMPLATE

GUIDES

Also available as an op t i o n a l

accessory is an additional adapter,

the RA1100, that allows u s e of

conventional threaded t e m p l a t e

guides with the Bosch quick-release

system.

2610052572_GKF125CE 9/18/18 12:11 PM Page 22

Page 23

23

PR006 Underscribe

Attachment

(Available as optional accessory)

The PR006 Underscribe Attachment is

used to create precision-fit seams

between two sheets of laminate (Fig.

28), such a s stile and r a i l

constructions and very large surfaces.

It is attached to the bottom of the

PR111 Plunge Base.

INSTALLATION (FIG. 29)

1. Remove rear screws used to hold

subbase onto PR111 Plunge Base.

2. Attach infeed side of PR006 to the

Plunge Base using hex screw.

3. Insert eccent ric adjuster into

pocket on outfeed side of PR006.

4. Attach outfeed side of PR006 to

the Plunge Base using hex screw.

BIT INSTALLATION

• The recommend bit for use with

the Underscribe Attachment is the

Bosch 85213M with 1/8” cutting

diameter.

• It should be installed according to

the instructions on page 9.

BIT HEIGHT ADJUSTMENT

After installing the bit, the height

should be adjusted as follows:

1. Lower bit until it just enters the

recess that is machined in the

underscribe attachment’s

aluminum plate.

2. The tool is now ready for making a

test cut.

FRONT-TO-BACK ADJUSTMENT

If necessary, the cutting point can be

ad justed front -to-back as fol lows

(Fig. 30):

1. Loosen the two screws holding the

aluminum plate.

2. Using the pin wrench, adjust the

eccentric adjuster as follows:

• For a t ighte r seam, turn the

eccentric adjuster clockwise (as

viewed from under the base)

• For a loos er seam, turn the

eccentric adjuster co unter clockwise, (as viewed from under

the base)

3. Retighten the screws

4. Make a test cut

5. Repeat steps 1-4 as necessary

FIG. 28

FIG. 29

FIG. 30

PIN

WRENCH

ECCENTRIC ADJUSTER

ECCENTRIC

ADJUSTER

HEX

SCREW

Operating Instructions

2610052572_GKF125CE 9/18/18 12:11 PM Page 23

Page 24

24

Service

Preventive ma i n -

tenance performed

by unauthorized personnel may

result in misplacing of internal wires

and components which could cause

serious hazard. We recommend that

all tool service be performed by a

Bosch Factory Service C e n t e r or

Autho rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly

lubricated and is ready to use. It is

recommended that tools with gears

be regr e ased wi t h a s pecial g ear

lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your

tool have been engineered for many

hours of d e p e n d a b l e service. To

maintain peak efficiency of the motor,

we recommend every two to six

months the brush es be examined.

Onl y genuine Bosch replace me n t

brushes specially designed for your

tool should be used.

BEARINGS

Bearings which become noisy (due to

heavy load or very abrasive material

cut ting) should be replaced at once to

avoid overheating or motor failure.

Cleaning

To avoid accidents

always dis connect

the tool from t h e power supply

before cleaning or performing any

main tenance. The tool m a y be

cleaned mo s t effectively with

compressed dry air. Always wear

safety gog gles when cleaning tools

with compressed air.

Ventilation openings and sw i t c h

levers must be kept clean and free of

foreign matter. Do not at tempt to

clean by inserting pointed objects

through openings.

Certain cleaning

agents and sol vents

damage plastic parts. Some of these

are: gasoline, carbon tetrachlo ride,

chlo rinated cl e a n i n g s o l v e n t s ,

ammonia and house hold detergents

that contain ammonia.

Maintenance

Operating Instructions

CREATING A SEAM

1

. To create a precision seam, make

sure he guiding piece of laminate

has a clean, straight edge, because

it will serve as the guide for the

underscribe attachment.

2. Contact cement should be applied

to the substrate core material and

the guiding piece of laminate up to

1” from its guiding edge.

2610052572_GKF125CE 9/18/18 12:11 PM Page 24

Page 25

25

The use of other acces sories and attach ments not specified in this

manual may create a hazard.

If an extension cord

is necessary, a cord

with adequate size conductors that

is capable of carrying the current

necessary for your tool must be

us ed. T his w ill p revent excessive

voltage d r o p , loss of power o r

overheating. Grounded tools must use

3-wire extension cords that have 3prong plugs and receptacles.

NOTE: The smaller the gauge number,

the heavier the cord.

RECOMMENDED SIZES OF

EXTENSION CORDS

120 VOLT ALTERNATING CURRENT

TOOLS

Extension Cords

Tool’s

Ampere

R

ating

C

ord Size in A.W.G.

W

ire Sizes in mm

2

C

ord Length in Feet

C

ord Length in Meters

25501001501530601

20

3

-6

6-8

8-10

1

0-12

12-16

1

8

18

18

1

6

14

1

6

16

16

1

6

12

1

6

14

14

1

4

–

1

4

12

12

1

2

–

0

.75

0.75

0.75

1

.0

–

0

.75

1.0

1.0

2

.5

–

1

.5

2.5

2.5

4

.0

–

2

.5

4.0

4.0

–

–

- PR101 Fixed Base*

†‡

- PR102 Edge Guide

†‡

- PR110 Round Subbase for Threaded

Template Guide

- PR111 Plunge Base

‡

- Router Bits

- Case

†‡

- 17 mm Collet Nut Wrench*

†‡

- RA1151 Centering Device

- PR006 Underscribe Attachment for

Plunge Base

- PR012 Dust Hood for Plunge Base

- RA1175 Edge-Forming Dust Hood for

Plunge Base

- RA1054 Deluxe Router Guide for Plunge

Base

- Vacuum Hoses

- Vacuum Hose Adapters

* Included with GKF125CEN

† Included with GKF125CEK

‡ Included with GKF125CEPK

Accessories and Attachments

2610052572_GKF125CE 9/18/18 12:11 PM Page 25

Page 26

26

Veuillez lire tous les avertissements et toutes les consignes

de sécurité. Si l'on n'observe pas ces avertissements et ces

consignes de sécurité, il existe un risque de choc électrique, d'incendie et/ou de

blessures corporelles graves.

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil

branché sur le secteur (avec fil) ou à votre outil alimenté par piles (sans fil).

Avertissements généraux concernant la sécurité des outils

électroportatifs

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien

éclairé. Les risques d’accident sont plus

élevés quand on travaille dans un endroit

encombré ou sombre.

N’utilisez pas d’outils électroportatifs

dans des atmosphères explosives,

comme par exemple en présence de gaz,

de poussières ou de liquides

inflammables. Les outils électroportatifs

produisent des étincelles qui risquent

d’enflammer les poussières ou les vapeurs.

Éloignez les enfants et les visiteurs quand

vous vous servez d’un outil

électroportatif. Vous risquez une perte de

contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs

doivent correspondre à la prise. Il ne faut

absolument jamais modifier la fiche.

N’utilisez pas d’adaptateur de prise avec

des outils électroportatifs munis d’une

fiche de terre. Le risque de ch oc

électrique est moindre si on utilise une

fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des

surfaces reliées à la terre tels que tuyaux,

radiateurs, gazinières ou réfrigérateurs.

Le risque de choc électrique augmente si

votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à

la pluie ou à l’humidité. Si de l’eau

pénètre dans un outil électroportatif, le

risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en

servez jamais pour transporter l’outil

électroportatif, pour le tirer ou pour le

débrancher. Éloignez le cordon de la

Symboles relatifs à la sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour chaque terme signalant un

danger. Veuillez lire le mode d’emploi et lire la signification de ces symboles.

C’est le symbole d’alerte relatif à la sécurité. Il est utilisé

pour vous avertir de l’existence possible d’un danger de

lésion corporelle. Obéissez à tous les messages relatifs à

la sécurité qui suivent ce symbole pour éviter tout risque

de blessure ou même de mort.

DANGER indique une situation dangereuse qui, si elle

n’est pas évitée, causera la mort d’une personne ou

une blessure grave.

AVERTISSEMENT indique une situation dangereuse

qui, si elle n’est pas évitée, pourrait causer la mort

d’une personne ou une blessure grave.

MISE EN GARDE indique une situation dangereuse

qui, si elle n'est pas évitée, causera une blessure

légère ou modérée.

2610052572_GKF125CE 9/18/18 12:12 PM Page 26

Page 27

27

chaleur, des huiles, des arêtes coupantes

ou des pièces mobiles. Les cordons

abîmés ou emmêlés augmentent les

risques de choc électrique.

Si vous utilisez un outil électroportatif à

l’extérieur, employez une rallonge conçue

pour l’extérieur. Ces rallonges sont faites

pour l’extérieur et réduisent le risque de

choc électrique.

S'il est absolument nécessaire d'utiliser

l'outil électroportatif dans un endroit

humide, utilisez une alimentation

protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur

GFCI réduit les risques de choc électrique.

Sécurité personnelle

Restez concentré, faites attention à ce

que vous faites, et servez-vous de votre

bon sens lorsque vous utilisez un outil

électroportatif. N'employez pas d’outils

électroportatifs quand vous êtes fatigué

ou sous l’emprise de drogues, d’alcool ou

de médicaments. Quand on utilise des

outils électroportatifs, il suffit d’un

moment d’inattention pour causer des

blessures corporelles graves.

Utilisez des équipements de sécurité

personnelle. Portez toujours un e

protection oculaire. Le port

d'équipements de sécurité tels que des

masques antipoussières, des chaussures

de sécurité antidérapantes, des casques

de chantier et des protecteurs d'oreilles

dans des conditions appropriées réduira le

risque de blessure corporelle.

Évitez les démarrages intempestifs.

Assurez-vous que l'interrupteur est dans

la position arrêt (Off) avant de brancher

l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le

transporter. Le transport d'un outil

électroportatif avec le doigt sur la gâchette

ou le branchement de cet outil quand

l'interrupteur est en position de marche

(ON) est une invite aux accidents.

Enlevez toutes les clés de réglage avant

de mettr e l’outil électroportatif en

marche. Si on laisse une clé sur une pièce

tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pa s. Conse rvez

toujours une bonne assise et un bon

équilibre. Ceci vous permettra de mieux

maîtriser l’outil électroportatif dans des

situations inattendues.

Habillez-vous de manière appropriée. Ne

portez pas de vêtements amples ou de

bijoux. Attachez les cheveux longs.

N’approchez pas les cheveux, les

vêtements ou les gants des pièces en

mouvement. Les vêtements amples, les

bijoux ou les cheveux longs risquent d’être

happés par les pièces en mouvement.

Si l’ou til est muni de dispositifs

permettant le raccordement d’un système

d’aspiration et de collecte des

poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés

correctement. L'utilisation d'un

dépoussiéreur peut réduire les dangers

associés à l'accumulation de poussière.

Utilisation et entretien des

outils électroportatifs

Ne forcez pas sur l’outil électroportatif.

Utilisez l’outil électroportatif qui convient

à la tâche à effectuer. L’outil qui convient

à la tâche fait un meilleur travail et est plus

sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’ outil

électroportatif si son interrupteur ne

parvient pas à le mettre en marche ou à

l’arrêter. Tout outil électroportatif qui ne

peut pas être comm andé par so n

interrupteur est dangereux et doit être

réparé.

Débranchez la fiche de la prise ou enlevez

le bloc-pile de l’outil électroportatif avant

tout réglage, changement d’accessoires

ou avant de ranger l’outil électroportatif.

De telles mesures de sécurité préventive

réduisent le risqu e de d émarr age

intempestif de l’outil électroportatif.

Rangez les outils électroportatifs dont

vous ne vous servez pas hors de portée

des enfants et ne permettez pas à des

personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces

consignes de s’en servir. Les outils

électroportatifs sont dangereux dans les

mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs.

Vérifiez que les pièces mobiles sont

alignées correctement et ne coincent pas.

Vérifiez qu’il n’y a pas de pièces cassées

ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil

électroportatif. Si l’outil est abîmé,

faites-le réparer avant de l’utiliser. De

nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

2610052572_GKF125CE 9/18/18 12:12 PM Page 27

Page 28

28

Tenez l’outil électroportatif par ses

surfaces de préhension isolées parce que

l’accessoire de coupe risque d’entrer en

contact avec un fil caché. Tout contact de

l’accessoire de coupe avec un fil sous

tension risque de mettre aussi sous

tension les parties métalliques exposées

de l’outil électroportatif, ce qui pourrait

causer un choc électrique pour l’opérateur.

Utilisez des brides ou d’autres moyens

pratiques de brider ou de supporter la

pièce sur une plate-forme stable. Tenir la

pièce à la main ou contre le corps la rend

instable et risque de résulter en une perte

de contrôle.

Pour couper dans des murs existants ou

autres endroits a veugl es pouvant

dissimuler des fils électriques,

débranchez tous les fusi bles ou les

disjoncteurs alimentant ce lieu de travail.

Assurez-vous toujours que la surface de

travail est exempte de clous et autres

objets étrangers. La coupe dans un clou

peut faire sauter la lame et l'outil, et ainsi

abîmer la lame.

Ne tenez jamais le matériau d'une main et

l'outil de l'autre lorsque vous en faites

usage. Ne placez jamais les mains sous la

surface de coupe ou à proximité de celleci. Il est plus sûr de cramponner le

matériau et de guider l'outil des deux

mains.

Ne posez jamais le matériau sur des

surfaces dures telles que le béton, la

pierre, etc. ... La lame de coupe en saillie

peut faire sauter l'outil.

Portez toujours des lunettes de sécurité

et un masque anti-poussières. N'utilisez

l'outil qu'à un endroit bien aéré.

L'utilisation de dispositifs de sécurité

personnelle et le trava il d ans un

environnement sûr réduisent les risques de

blessures.

Après avoir changé les lames ou effectué

quelque réglage que ce soit, assurez-vous

que l'écrou de la douille et tout autre

dispositif de réglage sont bien serrés. Un

dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de

contrôle avec projection violente des

composants en rotation.

Ne mettez jamais l'outil en marche alors

que la lame est enfoncée dans le

matériau. Le tranchant de la lame peut se

coincer dans le matériau et vous faire

perdre le contrôle du couteau.

Tenez toujours le couteau des deux mains

durant la mise en marche. Le couple de

réaction du moteur peut faire tordre l'outil.

Le sens d'introduction de la lame dans le

matériau est très important, et il est lié au

sens d'introduction de la lame. Lorsque

vous regardez l'outil depuis le dessus, la

lame tourne en sens horaire. Le sens

d'introduction du couteau doit être antihoraire. REMARQUE : Les c oupes

intérieures et extérieures nécessiteront

des sens de déplacement différents référez-vous à la section consacrée au sens

de déplacement de la toupie. Si l'outil est

introduit dans le mauvais sens, le

tranchant de la lame peut sortir du

matériau et tirer l'outil dans le sens de

cette introduction.

N'utilisez jamais de lames émoussées ou

abîmées. Les lames affilées doivent être

maniées soigneusement. Les mèches

abîmées peuvent se rompre brusquement

Règles de sécurité concernant les toupies

Maintenez les outils coupants affûtés et

propres. Les outils coupants entretenus

correctement et dotés de bords tranchants

a

ffûtés sont moins susceptibles de coincer

et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les

a

ccessoires et les embouts d'outil, etc.

conformément à ces instructions, en

tenant compte des conditions de travail

et des travaux à réaliser. L'emploi

d’outils électroportatifs pour des tâches

différentes de celles pour lesquelles ils ont

été prévus peut résulter en une situation

dangereuse.

Entretien

Faites réparer votre outil électroportatif

par un agent de service qualifié n’utilisant

que des pièces de rechange identiques.

Ceci assure que la sécurité de l’outil

électroportatif est préservée.

2610052572_GKF125CE 9/18/18 12:12 PM Page 28

Page 29

29

Avertissements supplémentaires concernant la sécurité

Utilisez uniquement des fers de toupie

dont le diamètre de la tige correspond à

celui de la douille installée. L'utilisation

d'un fer de toupie dont la tige est plus

petite peut entraîner le détachement du fer

pendant s o n fonctionnement, et il

risquerait de devenir un projectile.

N'utilisez jamais des fers de toupie à des

vitesses s u p é r i e u r e s à le u r vitesse

nominale maximale. Des fers de toupie

fonctionnant à une vitesse supérieure à leur

vitesse nominale risqueraient de se casser

et d’être projetés dans l’air.

L’emploi d’un GFCI et de dispositifs de

protection personnelle tels que gants et

chaussures d’électricien en caoutchouc

améliorent votre sécurité personnelle.

N’utilisez pas un outil conçu uniquement

pour le C.A. sur une alimentation en C.C.

Même si l’outil semble fonctionner, les

composants électriques d’un outil prévu

pour le C.A. tomberont probablement en

panne et risquent de créer un danger pour

l’utilisateur.

Maintenez les poignées sèches et

exemptes d’huile et de graisse. On ne pas

maîtriser un outil électroportatif en toute

sécurité quand on a les mains glissantes.

Utilisez des brides ou d’autres moyens

pratiques de brider ou de supporter la

pièce sur une plate-forme stable. Tenir la

pièce à la main ou contre le corps est

instable et risque de résulter en une perte

de contrôle.

Créez un agenda d’entretien périodique

pour votre outil. Quand vous nettoyez un

outil, faites attention de n’en démonter

aucune pièce car il est toujours possible

de mal remonter ou de pincer les fils

internes ou de remonter incorrectement

les ressorts de rappel des capots de

protection. Certains agents de nettoyage

tels que l’essence, le tétrachlorure de

carbone, l’ammoniaque, etc. risquent

d’abîmer les plastiques.

Risque de blessure pour l'utilisateur. Le

cordon d'alimentation électrique ne doit

être réparé que par un Centre de service

usine de Bosch ou par une Station service

agréée de Bosch.

Les travaux à la

machine tel que

ponçage, sciage, meulage, perçage et

autres travaux du bâtiment peuvent créer

des poussières contenant des produits

chimiques qui sont des causes reconnues

de cancer, de malformation congénitale

ou d’autres problèmes reproductifs. Ces

produits chimiques sont, par exemple :

• Le plomb provenant des peintures à base

de plomb,

• Les cristaux de silices provenant des

briques et du ciment et d’autres produits

de maçonnerie, et

• L’arsenic et le chrome provenant des bois

traités chimiquement.

Le niveau de risque dû à cette exposition

varie avec la fréquence de ces types de

travaux. Pour réduire l’exposition à ces

produits chimiques, il faut travailler dans

un lieu bien ven tilé et porter un

équipement de sécurité approprié tel que

certains masques à poussière conçus

spécialement pour filtrer les particules

microscopiques.

durant l'usage. Les lames émoussées

nécessitent plus de force pour pousser

l'outil, causant éventuellement un bris de la

lame.

Ne touchez jamais la lame durant ou

immédiatement après l'usage. Après

usage, la lame est trop chaude pour être

touchée à main nue.

Ne posez jamais l'outil avant que le

moteur ne se soit arrêté complètement.

La lame en rotation peut saisir la surface et

vous faire perdre le contrôle de l'outil.

Le diamètre du tranchant doit être d’au

moins 1/4 po inférieur à celui de

l'ouverture pour le fer et le tranchant.

2610052572_GKF125CE 9/18/18 12:12 PM Page 29

Page 30

30

Symboles

Imp

or

ta

nt

:

C

e

rt

ai

n

s

de

s

s

y

m

bo

l

e

s

s

u

i

v

an

t

s

pe

u

v

e

n

t

ê

t

re

u

t

i

l

i

s

é

s

s

u

r

v

o

t

re

o

u

t

i

l

.

V

eu

illez

les ét

u

d

ier

et

a

p

p

r

en

d

r

e leu

r

sig

n

ific

a

t

io

n

.

U

n

e in

t

er

p

r

ét

a

t

io

n

a

p

p

r

o

p

r

iée d

e

c

es

sym

b

o

les

vo

u

s

p

er

m

et

t

r

a

d

'

u

t

iliser

l'

o

u

t

il

d

e

fa

ç

o

n

p

lu

s

effic

a

c

e

et

p

lu

s

sû

r

e.

Symbole Désignation ⁄ Explication

V Volts (voltage)

A Ampéres (courant)

Hz Hertz (fréquence, cycles par seconde)

W Watt (puissance)

kg Kilogrammes (poids)

min Minutes (temps)

s Seconds (temps)

Diamétre (taille des mèches de perceuse, meules, etc.)

n

Vitesse à vide (vitesse de rotation, à vide)

n Vitesse nominale (vitesse maximum pouvant être atteinte)

...⁄min

Tours ou mouvement alternatif par minute (tours, coups, vitesse en

surface, orbites, etc., par minute)

Position d'arrêt (vitesse zéro, couple zéro ...)

, , , ...

I, II, III,

Réglages du sélecteur (Réglages de vitesse, de couple ou de position. Un

nombre plus élevé signifie une vitesse plus grande)

0

Sélecteur variable à l'infini avec arrêt (La vitesse augmente depuis le

réglage )