Page 1

Robert Bosch Power Tools GmbH

1 609 92A 4AJ

70538 Stuttgart

GERMANY

www.bosch-pt.com

GEX Professional

1 609 92A 4AJ (2018.05) O / 45

125-1 A | 125-1 AE

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

ต้นแบบ

id Petunjuk-Petunjuk untuk Penggun-

aan Orisinal

vi Bản gốc hướng dẫn sử dụng

Page 2

2 |

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. page 6

中文 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. 页次 13

繁體中文. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .頁次 17

한국어 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. 페이지 22

ไทย. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . หน้า 27

Bahasa Indonesia. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. Halaman 33

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. .. Trang 38

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 3

2 608 000 349

2 608 000 351

2 608 000 352

Ø 19 mm

2 600 793 009 (3 m)

1 610 793 002 (5 m)

1 609 200 933

Ø 19 mm

2 607 002 161 (3 m)

2 607 002 162 (5 m)

GAS 25

GAS 50

GAS 50 M

GAS 25

GAS 50

GAS 50 M

| 3

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 4

A

B

(1)

(2)

(3)

(4)

(4)

(5)

(5)

(5)

(6)

(7)

GEX 125-1 AE

Professional

4 |

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 5

| 5

C1

C2

C3

C3

D E

(3)

(3)

(3)

(8)

(9)

(8)

(10)

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 6

6 | English

English

Safety instructions

General Power Tool Safety Warnings

WARNING

tions provided with this power tool. Failure to follow all in-

structions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

Read all safety warnings, instructions, illustrations and specifica-

tion while operating power tools may result in serious personal injury.

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as a dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair and clothing away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

u Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe in-

jury within a fraction of a second.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or re-

move the battery pack, if detachable, from the power

tool before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools and accessories. Check for mis-

alignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 7

English | 7

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

u Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety Warnings for Sander

u Only use the power tool for dry sanding. Water entering

a power tool will increase the risk of electric shock.

u Ensure that no persons are at risk due to flying sparks.

Remove combustible materials from the surrounding

area. Flying sparks are created when sanding metals.

u Warning: Danger of fire! Avoid overheating the work-

piece and the sander. Always empty the dust collector

before taking a break from work. Sanding dust in the

dust bag, microfilter, paper bag (or in the filter bag or vacuum cleaner filter) can spontaneously combust under

certain conditions, for example if flying sparks are created when sanding metals. This risk is increased if the

sanding dust is mixed with paint or polyurethane residue

or with other chemical substances and if the workpiece is

hot as a result of prolonged work.

u Clean the air vents on your power tool regularly. The

motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric

plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

u Always wait until the power tool has come to a com-

plete stop before placing it down.

u Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than by

hand.

Product description and specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended Use

The power tool is intended for dry sanding of wood, plastic,

metal, filler and varnished surfaces.

Power tools with electronic control are also suitable for polishing.

Product Features

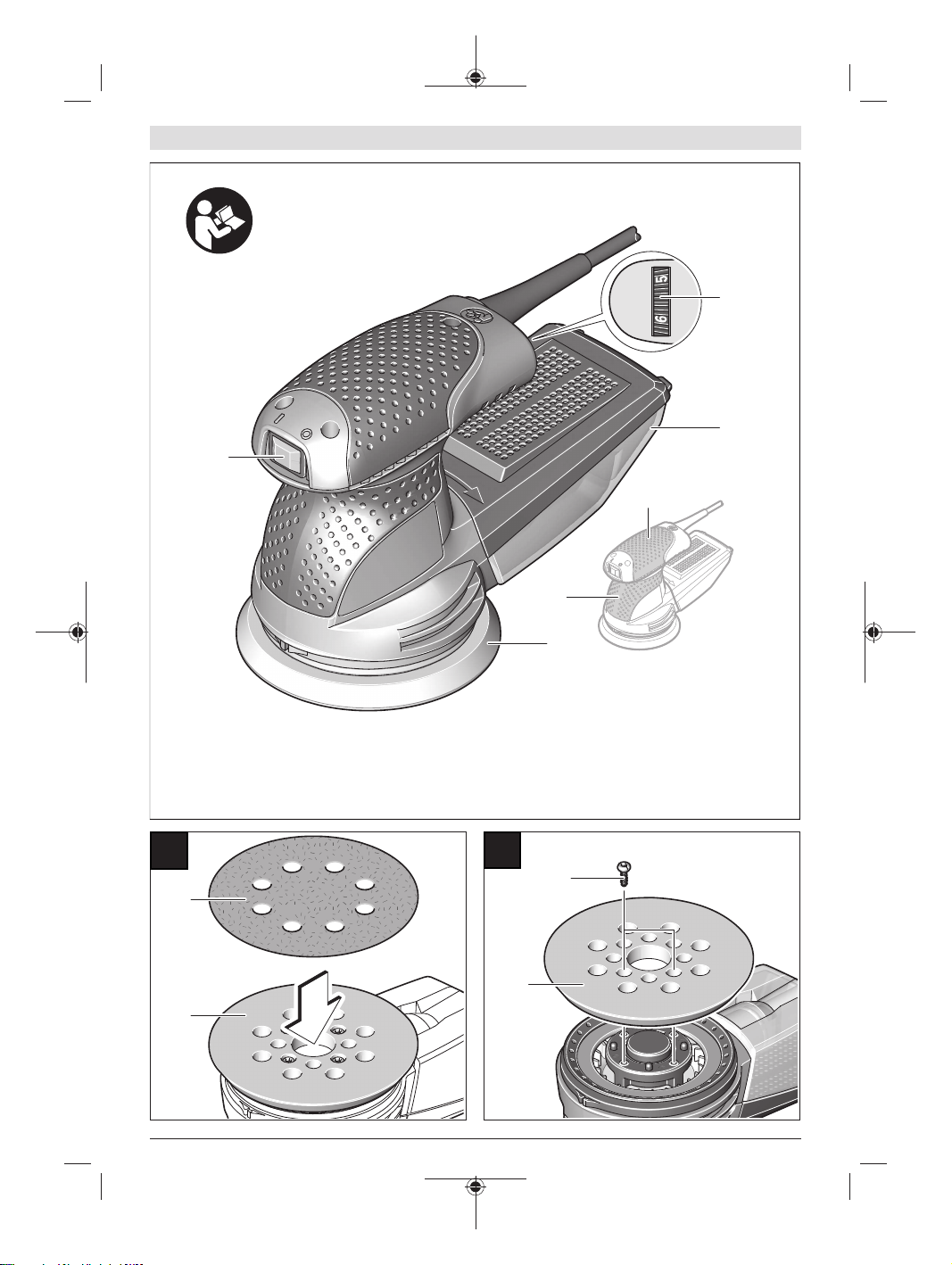

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

On/off switch

(1)

Orbital stroke rate preselection thumbwheel

(2)

(GEX125-1AE)

Complete dust box (Microfilter system)

(3)

Handle (insulated gripping surface)

(4)

Sanding pad

(5)

Sanding sheet

(6)

Screws for sanding pad

(7)

Extraction outlet

(8)

Filter element (Microfilter system)

(9)

Dust extraction hose

(10)

Accessories shown or described are not included with the

A)

product as standard. You can find the complete selection of

accessories in our accessories range.

A)

A)

Technical Data

Random orbit sanders GEX 125-1 A

Professional

Article number

3 601 C87 0.. 3 601 C87 5..

Orbital stroke rate preselection – ●

Rated power input W 250 250

No-load speed n

0

rpm 12,000 7500–12000

No-load orbital stroke rate rpm 24,000 15,000–24,000

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

GEX 125-1 AE

Professional

Page 8

8 | English

Random orbit sanders GEX 125-1 A

Professional

Orbit diameter mm 2.5 2.5

Sanding pad diameter mm 125 125

Weight according to EPTA-Procedure 01:2014 kg 1.3 1.3

Protection class / II / II

The specifications apply to a rated voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

GEX 125-1 AE

Professional

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

Selecting the Sanding Sheet

Different sanding sheets are available, depending on the material you are working with and the required surface removal rate:

Material Application Grit

– Paint

– Varnish

– Filler

– Bodyfiller

Expert for Wood

– All wood and wood-based ma-

terials (e.g. hardwood, softwood, chipboard, construction

boards)

Best for Wood

– Hardwood

– Chipboard

– Construction boards

– Metal materials

For sanding down paint Coarse 40

For sanding undercoats (e.g. removing brushstrokes, paint drips and paint runs)

For final sanding of primers prior to painting Fine 180

For pre-sanding, e.g. of rough and uneven

beams and boards

For surface sanding and levelling of slight irregularities

For finish-sanding and fine sanding of wood Fine 180

Medium 80

100

120

240

320

400

Coarse 40

Medium 80

100

120

240

320

400

60

60

– Car paint

– Stone

– Marble

– Granite

– Ceramic

– Glass

– Perspex

– Fibreglass reinforced plastics

Changing the sanding sheet (see figure A)

To remove the sanding sheet (6), lift it from the side and pull

it from the sanding pad (5).

Remove dirt and dust from the sanding pad (5), e.g. with a

paintbrush, before attaching a new sanding sheet.

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

For pre-sanding Coarse 80

For shaping and edge chamfering Medium 100

120

For fine sanding during shaping Fine 180

240

320

400

Buffing and edge rounding Very fine 600

1200

The surface of the sanding pad (5) is fitted with a hook-andloop fastening, allowing sanding sheets with a similar backing to be secured quickly and easily.

Press the sanding sheet (6) firmly onto the underside of the

sanding pad (5).

Page 9

English | 9

To ensure optimum dust extraction, make sure that the

punched holes in the sanding sheet are aligned with the

drilled holes in the sanding pad.

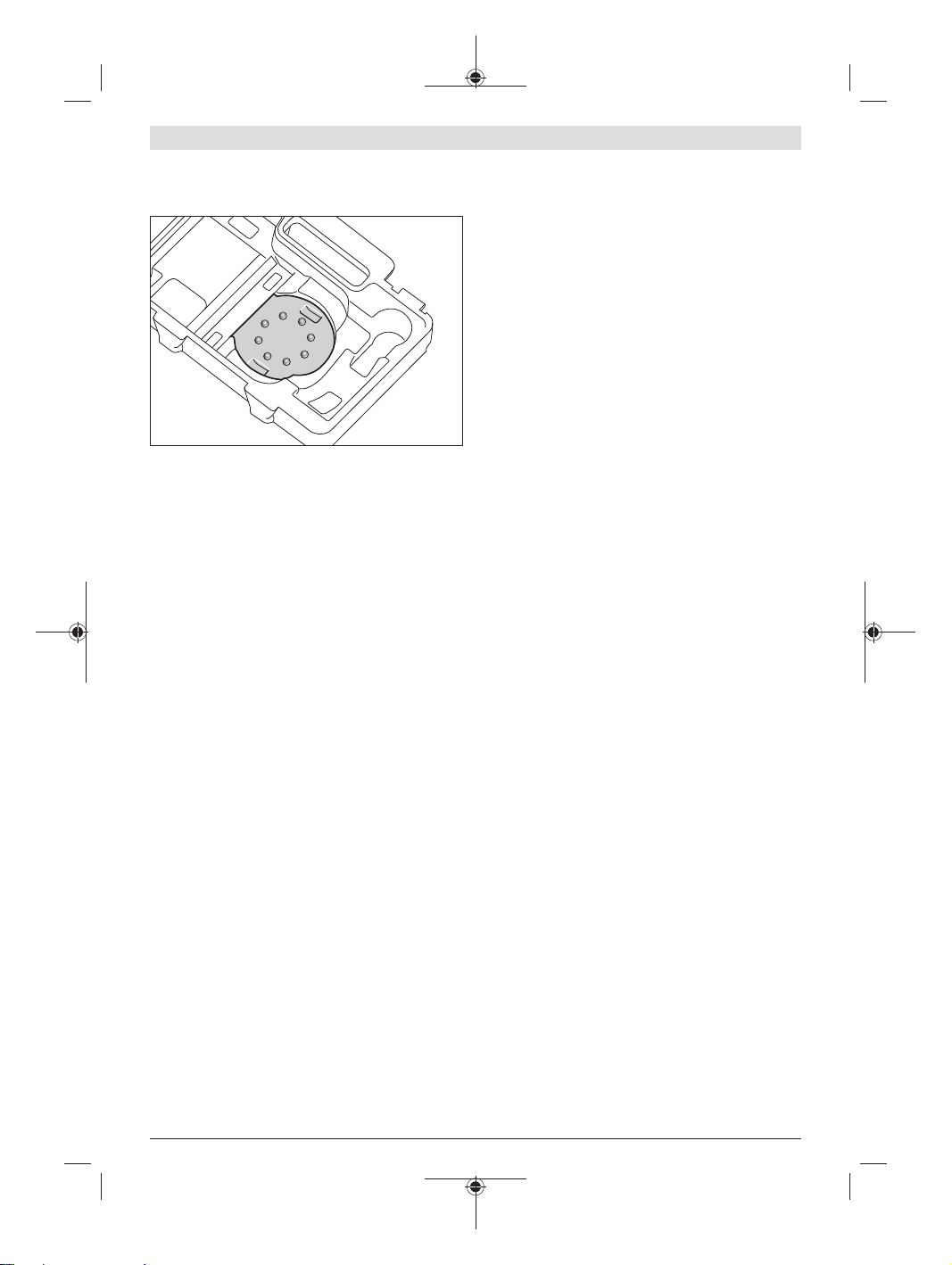

The alignment aid that is in the tool box and shown in the figure enables easy alignment of the sanding sheet (6) on the

sanding pad (5). Place the sanding sheet into the alignment

aid with the hook-and-loop fastening facing upwards and

press the power tool with the sanding pad firmly onto it.

Selection of the Sanding Plate

The power tool can be fitted with sanding pads of various

hardnesses, depending on the application:

– Extra soft sanding pad: Suitable for polishing and sensit-

ive sanding, even on curved surfaces.

– Medium hard sanding pad: Suitable for all sanding work,

universal application.

– Hard sanding pad: Suitable for heavy sanding on flat sur-

faces.

Changing the sanding pad (see figure B)

Note: Replace damaged sanding pads (5) immediately.

Remove the sanding sheet or polishing tool. Unscrew the

four screws completely (7) and remove the sanding pad (5).

Attach the new sanding pad (5) and retighten the screws.

Note: When attaching the sanding pad, make sure that the

teeth of the catch mate with the recesses in the sanding pad.

Note: Damaged sanding pads must only be replaced by an

after-sales service centre authorised to work with Bosch

power tools.

Dust/chip extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

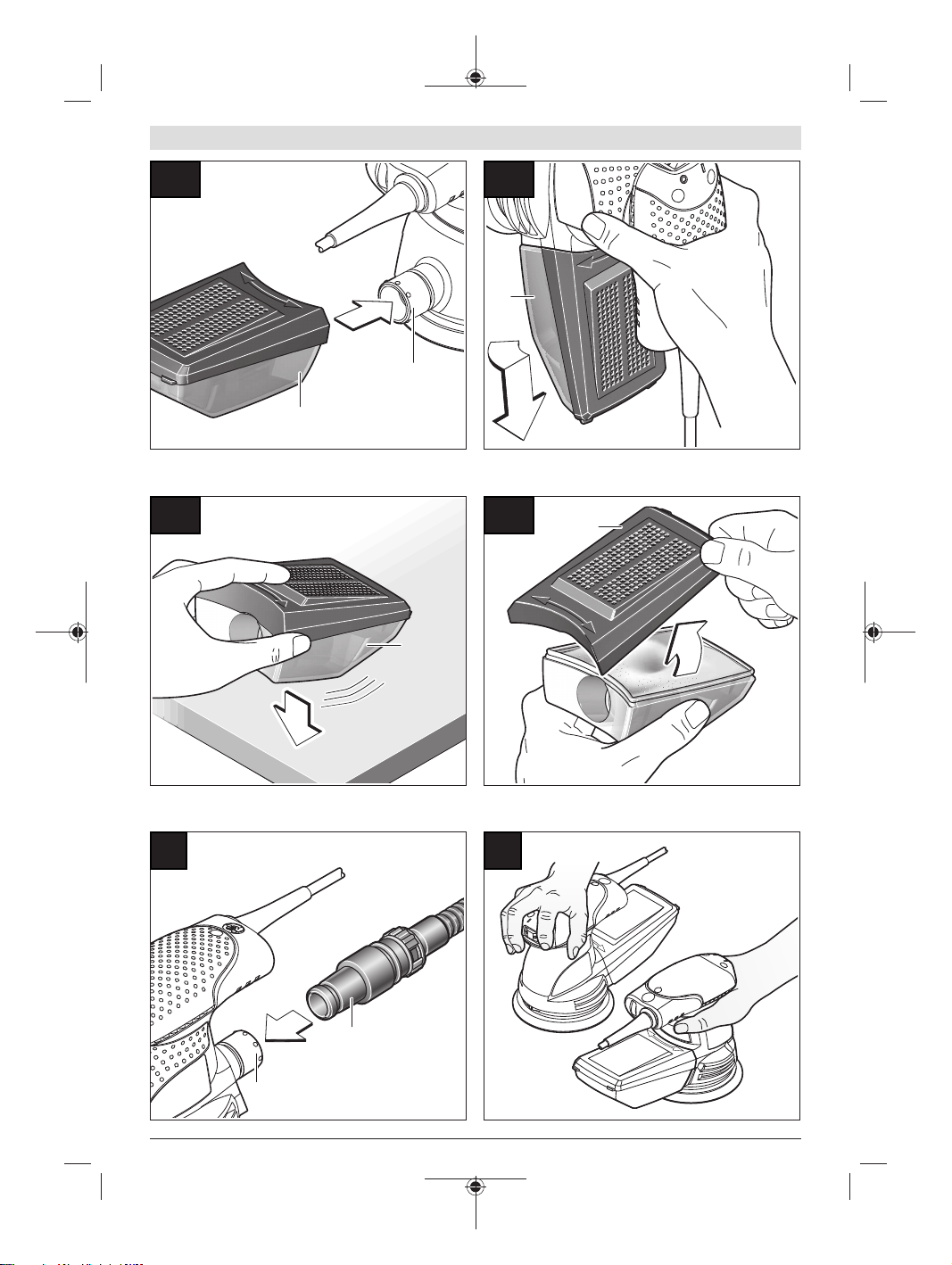

Self-generated dust extraction with dust box (see figure C1–C4)

Place the dust box (3) onto the extraction outlet (8) until it

clicks into place.

You can easily check the filling level of the dust box (3)

through the transparent container.

To empty the dust box (3), rotate and pull it downwards.

Before opening the dust box (3), knock the dust box against

a firm surface as shown in the figure to loosen the dust from

the filter element.

Holding the dust box (3) firmly, flap the filter element (9)

upwards out of the way and empty the dust box. Use a soft

brush to clean the flaps of the filter element (9).

External dust extraction (see figure D)

Fit a dust extraction hose (10) onto the extraction outlet (8).

Connect the dust extraction hose (10) to an extractor. You

will find an overview of connecting to various dust extractors

at the beginning of these operating instructions.

The dust extractor must be suitable for the material being

worked.

When extracting dry dust that is especially detrimental to

health or carcinogenic, use a special dust extractor.

Operation

Starting Operation

u Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

230 V can also be operated at 220 V.

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Switching On/Off

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To switch on the power tool, tilt the on/off switch (1) toward the right to the “I” position.

To switch off the power tool, tilt the on/off switch (1) toward the left to the “O” position.

Preselecting the orbital stroke rate (GEX 125-1 AE)

You can even preselect the orbital stroke rate during operation using the necessary orbital stroke rate preselection

thumbwheel (2).

1–2 Low orbital stroke rate

3–4 Medium orbital stroke rate

5–6 High orbital stroke rate

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 10

10 | English

The required orbital stroke rate is dependent on the material

and the work conditions and can be determined using practical tests.

After working at a low orbital stoke rate for an extended

period, you should operate the power tool at the maximum

orbital stroke rate for approximately three minutes without

load to cool it down.

Sanding Plate Brake

An integrated sanding pad brake reduces the orbital stroke

rate when running without load to prevent scoring when the

power tool is placed on the workpiece.

If the no-load orbital stroke rate constantly increases over

time, this means that the sanding pad is damaged and must

be replaced, or that the sanding pad brake is worn. A worn

sanding pad brake must be replaced by an after-sales service centre authorised to work with Bosch power tools.

Working Advice

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Always wait until the power tool has come to a com-

plete stop before placing it down.

u This power tool is not suitable for bench-mounted use.

It must not be clamped into a vice or fastened to a workbench, for example.

For fatigue-free work, you can hold the power tool from

above, from the side or from the front, depending on the application (see figure E).

Sanding Surfaces

Switch the power tool on, place the entire sanding surface

against the surface of the workpiece and apply moderate

pressure as you move the sander over the workpiece.

The material removal rate and sanding result are primarily

determined by the choice of sanding sheet, the preselected

orbital stroke rate level and the contact pressure.

Only immaculate sanding sheets achieve good sanding performance and make the power tool last longer.

Be sure to apply consistent contact pressure in order to increase the lifetime of the sanding sheets.

Excessively increasing the contact pressure will not lead to

increased sanding performance, rather it will cause more

severe wear of the power tool and of the sanding sheet.

Do not use a sanding sheet for other materials after it has

been used to work on metal.

Use only original Bosch sanding accessories.

Rough Sanding

Attach a coarse grit sanding sheet.

Apply only light pressure to the power tool so that it runs at a

higher orbital stroke rate and a higher material removal rate

is achieved.

Fine Sanding

Attach a fine grit sanding sheet.

You can reduce the sanding plate orbital stroke rate by

lightly varying the contact pressure or changing the orbital

stroke rate level; the random orbit motion will be retained.

Move the power tool with moderate pressure flat on the

workpiece in a circular motion or alternately along and

across it. Do not tilt the power tool in order to avoid sanding

through the workpiece, e.g. veneers.

Switch the power tool off after completing operation.

Polishing

For polishing weathered lacquers and redressing scratches

(e.g. acrylic glass), the power tool can be fitted with an appropriate polishing tool, e.g. lambswool bonnet, polishing

felt or polishing sponge (accessory).

Select a low orbital stroke rate (level 1–2) when polishing in

order to avoid heating up the surface excessively.

Apply the polish to an area slightly smaller than the area

which you intend to polish. Using the appropriate polishing

tool, work in the polish with either linear or circular movements and with moderate pressure.

Do not allow the polish to dry out on the surface; this may

damage the surface. Do not expose the surface which you intend to polish to direct sunlight.

Clean the polishing tool regularly to ensure good polishing

results. Wash the polishing tools with mild detergent and

warm water; do not use thinning agents.

Maintenance and Service

Maintenance and cleaning

u Pull the plug out of the socket before carrying out any

work on the power tool.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by Bosch or by a

customer service centre that is authorised to repair Bosch

power tools.

After-sales service and advice on using products

Our after-sales service can answer questions concerning

product maintenance and repair, as well as spare parts. You

can find exploded drawings and information on spare parts

at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

www.powertool-portal.de, the internet portal for tradespeople and DIY enthusiasts.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the type plate of

the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 11

English | 11

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People’s Republic of China

China Mainland

Bosch Power Tool (China) Co. Ltd.

Bosch Service Center

567, Bin Kang Road

Bin Kang District

Hangzhou, Zhejiang Province

China 310052

Tel.: (0571) 8887 5566 / 5588

Fax: (0571) 8887 6688 x 5566# / 5588#

E-Mail: bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

India

Bosch Service Center

69, Habibullah Road, (Next to PSBB School), T. Nagar

Chennai–600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi–110001

Phone: (011) 43166190

Bosch Service Center

79, Crystal Bldg., Dr. Annie Besant Road, Worli

Mumbai–400018

Phone: (022) 39569936 / (022 )39569959 /

(022) 39569967 / (022) 24952071

Indonesia

PT Robert Bosch

Palma Tower 10th Floor

Jalan RA Kartini II-S Kaveling 6

Pondok Pinang, Kebayoran Lama

Jakarta Selatan 12310

Tel.: (21) 3005-5800

www.bosch-pt.co.id

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-Mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

Pakistan

Robert Bosch Middle East FZE – Pakistan Liaison Office

2nd Floor Plaza # 10, CCA Block, DHA Phase 5

Lahore, 54810

Phone: +92(303)4444311

Email: Faisal.Khan@bosch.com

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio, Global City,

1634 Taguig City

Tel.: (632) 8703871

Fax: (632) 8703870

www.bosch-pt.com.ph

Singapore

Powerwell Service Centre Ptd Ltd

Bosch Authorised Service Centre (Power Tools)

4012 Ang Mo Kio Ave 10, #01-02 TECHplace

Singapore 569628

Tel.: 6452 1770

Fax: 6452 1760

E-Mail: ask@powerwellsc.com

www.powerwellsc.com

www.bosch-pt.com.sg

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: 02 6393111

Fax: 02 2384783

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Tel.: 02 7587555

Fax: 02 7587525

Vietnam

Branch of Bosch Vietnam Co., Ltd in HCMC

Floor 10, 194 Golden Building

473 Dien Bien Phu Street

Ward 25, Binh Thanh District, Ho Chi Minh City

Tel.: (08) 6258 3690

Fax: (08) 6258 3692

Hotline: (08) 6250 8555

www.bosch-pt.com.vn

Armenia, Azerbaijan, Georgia, Kyrgyzstan, Mongolia,

Tajikistan, Turkmenistan, Uzbekistan

TOO “Robert Bosch” Power Tools, After Sales Service

Rayimbek Ave., 169/1

050050, Almaty, Kazakhstan

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 12

12 | English

Service Email: service.pt.ka@bosch.com

Official Website: www.bosch.com, www.bosch-pt.com

Bahrain

Hatem Al Juffali Technical Equipment Establishment.

Kingdom of Bahrain, Setra Highway, Al Aker Area

Phone: +966126971777-311

Fax: +97317704257

Email: h.berjas@eajb.com.sa

Egypt

Unimar

20 Markaz kadmat

El tagmoa EL Aoul – New Cairo

Phone: +20 2224 76091-95

Phone: +20 2224 78072-73

Fax: +20222478075

Email: adelzaki@unimaregypt.com

Iran

Robert Bosch Iran

3rd Floor, No 3, Maadiran Building

Aftab St., Khodami St., Vanak Sq.

Tehran 1994834571

Phone: +9821 86092057

Iraq

Sahba Technology Group

Al Muthana airport road

Baghdad

Phone: +9647901906953

Phone Dubai: +97143973851

Email: bosch@sahbatechnology.com

Jordan

Roots Arabia – Jordan

Nasser Bin Jameel street, Building 37 Al Rabiah

11194 Amman

Phone: +962 6 5545778

Email: bosch@rootsjordan.com

Kuwait

Al Qurain Automotive Trading Company

Shuwaikh Industrial Area, Block 1, Plot 16, Street 3rd

P.O. Box 164 – Safat 13002

Phone: 24810844

Fax: 24810879

E-mail: josephkr@aaalmutawa.com

Lebanon

Tehini Hana & Co. S.A.R.L.

P.O. Box 90-449

Jdeideh

Dora-Beirut

Phone: +9611255211

Email: service-pt@tehini-hana.com

Libya

El Naser for Workshop Tools

Swanee Road, Alfalah Area

Tripoli

Phone: +218 21 4811184

Oman

Malatan Trading & Contracting LLC

P.O. Box 131

Ruwi, 112 Sultanate of Oman

Phone: +968 99886794

Email: malatanpowertools@malatan.net

Qatar

International Construction Solutions W L L

P. O. Box 51,

Doha Phone: +974 40065458

Fax: +974 4453 8585

Email: csd@icsdoha.com

Saudi Arabia

Juffali Technical Equipment Co. (JTECO)

Kilo 14, Madinah Road, Al Bawadi District

Jeddah 21431

Phone: +966 2 6672222 Ext. 1528

Fax: +966 2 6676308

Email: roland@eajb.com.sa

Syria

Dallal Establishment for Power Tools

P.O. Box 1030

Aleppo

Phone: +963212116083

Email: rita.dallal@hotmail.com

United Arab Emirates

Central Motors & Equipment LLC, P.O. Box 1984

Al-Wahda Street – Old Sana Building

Sharjah

Phone: +971 6 593 2777

Fax: +971 6 533 2269

Email: powertools@centralmotors.ae

Yemen

Abualrejal Trading Corporation

Sana’a Zubiery St. Front to new Parliament Building

Phone: +967-1-202010

Fax: +967-1-279029

Email: tech-tools@abualrejal.com

Ethiopia

Forever plc

Kebele 2,754, BP 4806,

Addis Ababa

Phone: +251 111 560 600

Email: foreverplc@ethionet.et

Ghana

C.WOERMANN LTD.

Nsawam Road/Avenor Junction, P.O. Box 1779

Accra Phone: +233 302 225 141

Kenya

Robert Bosch East Africa Ltd

Mpaka Road P.O. Box 856

00606 Nairobi

Nigeria

Robert Bosch Nigeria Ltd.

52–54 Isaac John Street P.O. Box

GRA Ikeja – Lagos

Republic of South Africa

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 13

中文 | 13

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-Mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-Mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-Mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-Mail: rbsa-hq.pts@za.bosch.com

Tanzania

Diesel & Autoelectric Service Ltd.

117 Nyerere Rd., P.O. Box 70839

Vingunguti 12109, Dar Es Salaam

Phone: +255 222 861 793/794

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

Disposal

The power tool, accessories and packaging should be recycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

中文

安全规章

电动工具通用安全警告

警告!

会导致电击、着火和/或严重伤 害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语" 电动工具" 指市电驱动

(有线)电动工具或电池驱动(无线)电动工具。

工作场地的安全

保持工作场地清洁和明亮。

u

引 发事故。

不要在易爆环境,如有易燃液体、气体或粉尘的

u

环 境下操作电动工具。

燃粉 尘或气体。

让儿童和旁观者离开后操作电动工具。

u

集 中会使操作者失去对工具的控制。

电气安全

电动工具插头必须与插座相配。绝不能以任何方

u

式 改装插头。需接地的电动工具不能使用任何转

换插 头。

击危 险。

避免人体接触接地表面,如管道、散热片和冰

u

箱。

如果你身体接地会增加电击危险。

不得将电动工具暴露在雨中或潮湿环境中。

u

入 电动工具将增加电击危险。

不得滥用电线。绝不能用电线搬运、拉动电动工

u

具 或拔出其插头。使电线远离热源、油、锐边或

运动 部件。

当在户外使用电动工具时,使用适合户外使用的

u

外 接软线。

险。

如果在潮湿环境下操作电动工具是不可避免的,

u

应 使用剩余电流动作保护器(

可减 小电击危险。

人身安全

保持警觉,当操作电动工具时关注所从事的操作

u

并 保持清醒。当你感到疲倦,或在有药物、酒精

或治 疗反应时,不要操作电动工具。

工具时 瞬间的疏忽会导致严重人身伤害。

使用个人防护装置。始终佩戴护目镜。

u

置, 诸如适当条件下使用防尘面具、防滑安全

鞋、安全 帽、听力防护等装置能减少人身伤害。

防止意外起动。确保开关在连接电源和/ 或电池

u

盒、拿起或搬运工具时处于关断位置。

已 接通电源的开关上或开关处于接通时插入插头

可能 会导致危险。

在电动工具接通之前,拿掉所有调节钥匙或扳

u

手。

遗留在电动工具旋转零件上的扳手或钥匙会

导致人 身伤害。

警告! 阅读所有警告和所有说

明!

不遵照以下警 告和说明

混乱和黑暗的场地会

电动工具产生的火花会点

注意力不

未经改装的插头和相配的插座将减少电

水进

受损或缠绕的软线会增加电击危险。

适合户外使用的软线将减少电击危

RCD)。 使用RCD

在操作电动

安全装

手指放在

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 14

14 | 中文

手不要伸展得太长。时刻注意立足点和身体平

u

衡。

这样在意外情况下能很好地控制电动工具。

着装适当。不要穿宽松衣服或佩戴饰品。让衣

u

服、 手套和头发远离运动部件。

宽松衣服、佩饰

或长发 可能会卷入运动部件中。

如果提供了与排屑、集尘设备连接用的装置,要

u

确 保他们连接完好且使用得当。

使用这些装置可

减少 尘屑引起的危险。

即使由于经常使用电动工具而对此非常熟悉,也

u

不要就认为可以高枕无忧而忽略工具的安全规

定。

粗心大意的行为可能在瞬间就造成严重的伤

害。

电动工具使用和注意事项电动工具使用和注意事项

不要滥用电动工具,根据用途使用适当的电动工

u

具。

选用适当设计的电动工具会使你工作更有

效、 更安全。

如果开关不能接通或关断工具电源,则不能使用

u

该 电动工具。

如果开关不能接通或关断工具电

源,则不能使用该 电动工具。

在进行任何调节、更换附件或贮存电动工具之

u

前, 必须从电源上拔掉插头和/ 或使电池盒与工

具脱 开。

这种防护性措施将减少工具意外起动的

危险。

将闲置不用的电动工具贮存在儿童所及范围之

u

外, 并且不要让不熟悉电动工具或对这些说明不

了解的 人操作电动工具。

电动工具在未经培训的

用户手中 是危险的。

保养电动工具。检查运动件是否调整到位或卡

u

住, 检查零件破损情况和影响电动工具运行的其

他状 况。如有损坏,电动工具应在使用前修理

好。

许多 事故由维护不良的电动工具引发。

保持切削刀具锋利和清洁。

u

保养良好的有锋利切

削 刃的刀具不易卡住而且容易控制。

按照使用说明书,考虑作业条件和进行的作业来

u

使 用电动工具、附件和工具的刀头等。

将电动工

具用 于那些与其用途不符的操作可能会导致危

险。

保持手柄和握持表面干燥、清洁、无油污。

u

在突

发情况下,滑溜的手柄和握持表面无法确保安全

地握持和控制工具。

维修

将电动工具用 于那些与其用途不符的操作可能会

u

导致危险。

. 这样将确保所维修的电动工具的安全

性。

针对研磨机的安全规章

本电动工具仅可用于干法研磨。

u

水进入电动工具

将增加电击危险。

要注意确保飞溅的火花不会伤到人。清除附近的

u

可燃材料。

注意火灾危险!应避免磨料和研磨机过热。每次

u

工作休息前都要清空集尘腔。

研磨金属时会有火花飞溅。

集尘袋、微过滤

器、纸袋(或者吸尘器的过滤袋或过滤器)内的

磨削粉尘可能会在不良条件下(例如研磨金属时

火花飞溅)被点燃。如果磨削粉尘与油漆或聚氨

酯残余物或者其他化学原料混合,且磨料在长时

间作业后产生高温时,会产生极大危险。

定期清洁电动工具的通风间隙。

u

电动机风扇会将

灰尘吸进机壳,过多的金属粉末沉积会导致电气

危险。

等待电动工具完全静止后才能够放下机器。

u

固定好工件。

u

使用固定装置或老虎钳固定工件,

会比用手持握工件更牢固。

产品和性能说明

请阅读所有安全规章和指示。

下警告和说明可能导致电击、着火和/

或严重伤害。

请注意本使用说明书开头部分的图示。

按照规定使用

本电动工具适合在木材,塑料,金属,填隙料和涂

了油漆的表面上干磨。

配备了电动调节装置的电动工具也可以进行抛光。

插图上的机件

机件的编号和电动工具详解图上的编号一致。

起停开关

(1)

振荡次数预选调节轮(GEX 125-1 AE)

(2)

集尘盒(Microfilter System)

(3)

手柄(绝缘握柄)

(4)

磨垫

(5)

(6)

(7)

(8)

(9)

(10)

A)

A)

砂纸

磨垫的固定螺丝

排气孔接头

过滤组件(Microfilter System)

集尘软管

图表或说明上提到的附件,并不包含在基本的供货范围

中。本公司的附件清单中有完整的附件供应项目。

A)

不遵照以

技术数据

偏心研磨机

物品代码

设定振荡次数 – ●

额定输入功率 W 250 250

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

GEX 125-1 A

专业版

GEX 125-1 AE

专业版

3 601 C87 0.. 3 601 C87 5..

Page 15

中文 | 15

偏心研磨机

空载转速n

0

rpm 12000 7500 –12000

GEX 125-1 A

专业版

GEX 125-1 AE

专业版

空载轨道速率 rpm 24000 15000 –24000

振荡回路直径 mm 2.5 2.5

磨垫直径 mm 125 125

重量符合EPTA-Procedure 01:2014 kg 1.3 1.3

保护等级 / II / II

本说明书提供的参数是以230V为依据,于低电压地区,此数据有可能不同。

安装

维修电动工具或换装零、配件之前,务必从插座

u

上拔出插头。

选择砂纸

根据工件的物料和希望的物表研磨效果,选择合适的砂纸:

物料 用途 目数

– 颜料

– 油漆

– 填料

– 填隙料

Expert for Wood

– 所有木材(比如硬木、软

木、刨花板、人造板)

Best for Wood

– 硬木

– 木屑板

– 建筑板材

– 金属

磨除颜料层 粗略 40

用于打磨底漆(比如磨除刷子痕迹、滴

状油漆和条状油漆)

中 80

100

120

磨平底料以方便上漆 精细 180

240

320

400

对于初磨,例如粗糙、未磨光的横梁和木板粗略 40

用于平面磨削和磨平轻微的凹凸不平点 中 80

100

120

粗磨和细磨木材 精细 180

240

320

400

60

60

– 汽车漆

– 石材

– 大理石

– 花岗岩

– 陶材

– 玻璃

– 安全玻璃

– 玻璃纤维塑料

更换砂纸(参见插图A)

取下砂纸

下。

(6)

时,将其一侧抬起,然后从磨盘

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

进行粗加工 粗略 80

成形和去边 中 100

成形后的细加工 精细 180

去边后的抛光工作 极细 600

(5)

上的脏污和灰

(5)

上拉

装入新砂纸前,用刷子清除磨盘

尘。

(5)

磨盘

表面由尼龙织物组成,因此可通过魔术贴快

速便捷地固定砂纸。

120

240

320

400

1200

Page 16

16 | 中文

(6)

将砂纸

注意将砂纸的冲孔与磨盘上的孔重叠,以确保最佳

的集尘效果。

为方便校准磨垫

图所示的校准辅助工具。将砂纸和魔术贴向上装入

校准辅助工具,并用磨垫牢牢压紧电动工具。

牢固地按压到磨盘

(5)

上的砂纸

(5)

底面。

(6)

,可使用工具箱中如

选择磨垫

可以根据用途在电动工具上安装不同硬度的磨垫:

– 超软磨垫:适用于抛光或操作时必须凭借触感的

研磨工作,另外也可以在凸起的表面研磨。

– 中硬度磨垫:适合所有的研磨工作,是通用型磨

垫。

– 硬磨垫:适合在平坦的表面进行高效率的研磨。

更换磨垫(参见插图B)

提示:

请立即更换损坏的磨盘

拆下砂纸或抛光工具。小心地旋出4颗螺栓

取下磨垫

提示:

凹槽中。

提示:

权的客户服务处更换。

(5)

。装上新磨垫

安装磨盘时应注意从动件的齿轮进入磨盘的

损坏的磨盘支架必须由博世电动工具公司授

(5)

。

(5)

,然后重新拧紧螺栓。

(7)

,然后

吸锯尘/吸锯屑

含铅的颜料以及某些木材、矿物和金属的加工废尘

有害健康。机器操作者或者工地附近的人如果接

触、吸入这些废尘,可能会有过敏反应或者感染呼

吸道疾病。

某些尘埃(例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理 木材的添加剂(例如木材的防腐

剂等)结合之后。只有经过专业训练的人才能够加

工含石棉的物料。

– 尽可能使用适合物料的吸尘装置。

– 工作场所要保持空气流通。

– 最好佩戴P2滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

避免让工作场所堆积过多的尘垢。

u

燃。

利用集尘盒自集尘(参见插图C1–C4)

将集尘盒

(3)

装到排气孔接头

(8)

尘埃容易被点

上,直至卡止。

可通过一个透明的容器轻松控制集尘盒

清空集尘盒

打开集尘盒

尘盒,使灰尘从滤芯脱落。

固定住集尘盒

用一支软刷清洁滤芯

外部集尘(参见插图D)

将集尘软管

将集尘软管

可以找到各种集尘器的连接概览。

根据工件的物料选择合适的吸尘装置。

吸集可能危害健康,可能导致癌症或干燥的废尘

时,务必使用特殊的吸尘装置。

(3)

时,请将其转动向下拔下。

(3)

前,请如图所示在固定底座上敲击集

(3)

,向上翻开滤芯

(9)

膜片。

(10)

插到排气孔接头

(10)

与吸尘器连接。在本使用说明的开头

(3)

(9)

并清空集尘盒。

(8)

上。

集尘量。

工作

投入使用

注意电源电压!电源的电压必须和电动工具铭牌

u

上标示的电压一致。标记为

的电压可以驱动。

V

接通/关闭

请确保握住手柄时可以开启/关闭开关。

u

接通

电动工具时,将起停开关

“I”

置

。

关闭

电动工具时,将起停开关

“O”

置

。

预选振荡次数(GEX 125-1 AE)

利用振荡次数预选调节轮

选所需的振荡次数。

1 – 2 低振荡次数

3 – 4 中振荡次数

5 – 6 高振荡次数

正确的振荡次数是由工件和工作条件决定,唯有实

际操作才能够找出最合适的振荡次数。

使用低振荡次数长期操作之后,应该让电动工具以

最大振荡次数空转约3分钟来帮助机器冷却。

磨盘缓速器

机器空转时,它内部的磨盘缓速器会降低磨盘的振

荡次数,以避免将电动工具放在工件上时造成不必

要的凹槽。

如果空转振荡次数不断上升,代表磨盘已经损坏了

必须更换,或是磨盘缓速器磨损了。损坏的磨盘缓

速器必须由博世电动工具公司授权的客户服务处更

换。

(2)

工作提示

维修电动工具或换装零、配件之前,务必从插座

u

上拔出插头。

等待电动工具完全静止后才能够放下机器。

u

本电动工具不适合固定式应用。

u

虎钳上或固定在工作台上。

电动工具用

230 V

(1)

向右翻到位

(1)

向左翻到位

也可以在运行过程中预

例如不允许夹在

220

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 17

为确保无疲劳作业,可从上方、侧面或前部固定住

电动工具,具体固定位置视应用情况而定(参见插

图E)。

研磨平面

开动电动工具,把整个研磨面平贴在待研磨的表面

上,并均匀地在工件上移动机器。

磨除功率和研磨的效果原则上是由所选择的砂纸、

设定的振荡级和操作机器时施压的大小来决定的。

只有完好的砂纸才能够提高研磨功率,並且保护电

动工具。

操作机器时要均匀施压,如此才能够提高砂纸的使

用寿命。

在机器上过度施压,不仅无法提高研磨功率,反而

容易损坏机器並提高砂纸的耗损率。

不可以使用研磨过金属的砂纸研磨其它的物料。

只能使用博世原厂的研磨附件。

粗磨

安装粒度粗的砂纸。

只能轻按电动工具,这样它才能够以较高的振荡次

数运转,并达到较高的材料磨除效果。

细磨

安装粒度细的砂纸。

稍微改变接触压力或更改振荡次数等级,可以在保

持偏心运动的同时减少磨盘振荡次数。

坝高采用绕圈或纵向、横向互相交换的方式,在工

件上均匀地移动电动工具。勿让研磨机歪斜了,以

避免磨穿工件,例如胶合板。

工作完备后随手关闭电动工具。

抛光

在电动工具上安装合适的抛光工具,例如羊毛罩,

抛光绒布或抛光海绵(附件) 等,也可以使用本电

动工具抛光受气候侵蚀的油漆和刮痕(例如有机玻

璃)。

抛光时请选择较少的振荡次数(等级1–2),以避

免表面过热。

抛光时,先在一处小面积上涂抹抛光剂,接着再使

用合适的抛光工具,采纵横交错或绕圈的方式,均

匀地涂抹抛光剂。

不可让涂抹在抛光表面的抛光剂干掉,这样会损坏

抛光表面。不可以让阳光直接照射待抛光的表面。

定期清洁抛光工具,以确保出色的抛光效果。使用

温和的清洁剂和温水清洗抛光工具。勿使用稀释

剂。

繁體中文 | 17

如果必须更换连接线,务必把这项工作交给博世或

者经授权的博世电动工具顾客服务执行,以避免危

害机器的安全性能。

客户服务和应用咨询

本公司顾客服务处负责回答有关本公司产品的修

理,维护和备件的问题。备件的分解图和信息也可

www.bosch-pt.com

查看:

博世应用咨询团队乐于就我们的产品及其附件问题

提供帮助。

www.powertool-portal.de

网门户网站。

如需查询和订购备件,请务必提供产品型号铭牌上

的10位数货号。

羅伯特 · 博世有限公司

香港北角英皇道625 號21 樓

客戶服務熱線:+852 2101 0235

傳真:+852 2590 9762

電郵:info@hk.bosch.com

網站:www.bosch-pt.com.hk

制造商地址:

Robert Bosch Power Tools GmbH

罗伯特· 博世电动工具有限公司

70538 Stuttgart / GERMANY

70538 斯图加特 / 德国

中国大陆

博世电动工具(中国)

有限公司 中国 浙江省 杭州市

滨江区 滨康路567号

102/1F 服务中心

邮政编码:310052

电话:(0571)8887 5566 / 5588

传真:(0571)8887 6688 x 5566# / 5588#

电邮:bsc.hz@cn.bosch.com

,适合工匠和DIY者的互联

处理废弃物

必须以符合环保的方式,回收再利用损坏的机器、

附件和废弃的包装材料。

不可以把电动工具丢入家庭垃圾中!

繁體中文

安全注意事項

维修和服务

维修和清洁

维修电动工具或换装零、配件之前,务必从插座

u

上拔出插头。

电动工具和通风间隙都必须保持清洁,这样才能

u

够提高工作品质和安全性。

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

電動工具一般安全注意事項

警告

遵照以下列出的指示,將可能導致電擊、著火和/

或人員重傷。

保存所有警告和說明書以備查閱。

在所有警告中,「電動工具」此一名詞泛指:以市

電驅動的(有線)電動工具或是以電池驅動的(無

線)電動工具。

請詳讀工作臺及電動工具的所

有安全警告與使用說明。

若不

Page 18

18 | 繁體中文

工作場地的安全

保持工作場地清潔和明亮。

u

混亂和黑暗的場地會

引發事故。

不要在易爆環境,如有易燃液體、氣體或粉塵的

u

環境下操作電動工具。

電動工具產生的火花會點

燃粉塵或氣體。

讓兒童和旁觀者離開後操作電動工具。

u

注意力不

集中會使您失去對工具的控制。

電氣安全

電動工具插頭必須與插座相配。 絕不能以任何方

u

式改裝插頭。 需接地的電動工具不能使用任何轉

換插頭。

未經改裝的插頭和相配的插座將減少電

擊危險。

避免人體接觸接地表面,如管道、散熱片和冰

u

箱。

如果您身體接地會增加電擊危險。

不得將電動工具暴露在雨中或潮濕環境中。

u

入電動工具將增加電擊危險。

不得濫用電線。 絕不能用電線搬運、拉動電動工

u

具或拔出其插頭。 使電線遠離熱源、油、銳利邊

緣或移動零件。

受損或纏繞的軟線會增加電擊危

險。

當在戶外使用電動工具時,使用適合戶外使用的

u

延長線。

適合戶外使用的軟線,將減少電擊危

險。

如果在潮濕環境下操作電動工具是不可避免的,

u

應使用剩餘電流動作保護器(

RCD)。使用RCD可

降低電擊危險。

人身安全

保持警覺,當操作電動工具時關注所從事的操作

u

並保持清醒。 當您感到疲倦,或在有藥物、酒精

或治療反應時,不要操作電動工具。

在操作電動

工具時瞬間的疏忽會導致嚴重人身傷害。

使用個人防護裝置。 始終佩戴護目鏡。

u

安全裝

置,諸如適當條件下使用防塵面具、防滑安全

鞋、安全帽、聽力防護等裝置能減少人身傷害。

防止意外起動。 確保開關在連接電源和/或電池

u

盒、拿起或搬運工具時處於關閉位置。

手指放在

已接通電源的開關上或開關處於接通時插入插頭

可能會導致危險。

在電動工具接通之前,拿掉所有調節鑰匙或扳

u

手。

遺留在電動工具旋轉零件上的扳手或鑰匙會

導致人身傷害。

手不要伸展得太長。 時刻注意立足點和身體平

u

衡。

這樣在意外情況下能很好地控制電動工具。

著裝適當。 不要穿寬鬆衣服或佩戴飾品。 讓您的

u

衣物及頭髮遠離運動部件。

寬鬆衣服、佩飾或長

髮可能會捲入運動部件中。

如果提供了與排屑、集塵設備連接用的裝置,要

u

確保他們連接完好且使用得當。

使用這些裝置可

減少塵屑引起的危險。

切勿因經常使用工具所累積的熟練感而過度自

u

信,輕忽工具的安全守則。

任何一個魯莽的舉動

都可能瞬間造成人員重傷。

水進

電動工具使用和注意事項

不要濫用電動工具, 根據用途使用適當的電動工

u

具。

選用適當設計的電動工具會使您工作更有

效、更安全。

如果開關不能開啟或關閉工具電源,則不能使用

u

該電動工具。

不能用開關來控制的電動工具是危

險的且必須進行修理。

在進行任何調整、更換配件或貯存電動工具之

u

前,必須從電源上拔掉插頭並/或取出電池盒。

這種防護性措施將減少工具意外起動的危險。

將閒置不用的電動工具貯存在兒童所及範圍之

u

外,並且不要讓不熟悉電動工具或對這些說明不

瞭解的人操作電動工具。

電動工具在未經培訓的

用戶手中是危險的。

保養電動工具與配備。 檢查運動件是否調整到位

u

或卡住,檢查零件破損情況和影響電動工具運行

的其他狀況。 如有損壞,電動工具應在使用前修

理好。

許多事故由維護不良的電動工具引發。

保持切削刀具鋒利和清潔。

u

保養良好的有鋒利切

削刃的刀具不易卡住而且容易控制。

按照使用說明書,考慮作業條件和進行的作業來

u

使用電動工具、配件和工具的刀頭等。

將電動工

具用於那些與其用途不符的操作可能會導致危

險。

把手及握持區應保持乾燥、潔淨,且不得沾染任

u

何油液或油脂。

易滑脫的把手及握持區將無法讓

您在發生意外狀況時安全地抓緊並控制工具。

檢修

將您的電動工具送交專業維修人員,必須使用同

u

樣的備件進行更換。

這樣將確保所維修的電動工

具的安全性。

砂磨機安全注意事項

本電動工具僅適用於乾式研磨。

u

將增加電擊危險。

請注意:噴濺的火花不會波及任何人。請將附近

u

的易燃材料清走。

請注意:有失火之虞!請避免砂磨材料或砂帶機

u

研磨材料時會有火花噴濺。

過熱。暫停作業之前請務必清空集塵容器。

袋、超微細過濾器、紙袋內(或吸塵器過濾袋/

濾材內)的研磨粉塵可能在不利條件下自行點

燃,例如研磨金屬時所產生的火花。尤其是當研

磨粉塵若混入殘留的烤漆、聚胺酯或其他化學物

質,而且在經過長時間運轉後砂磨材料的溫度又

極高時,這種情形特別具危險性。

請定期清潔電動工具的通風口。

u

灰塵吸進機殼,過多的金屬粉末沉積會導致電氣

危險。

等待電動工具完全靜止後才能夠放下機器。

u

固定好工件。

u

使用固定裝置或老虎鉗固定工件,

會比用手持握工件更牢固。

水進入電動工具

電動機風扇會將

集塵

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 19

繁體中文 | 19

起停開關

產品和功率描述

請詳讀所有安全注意事項和指示。

遵守安全注意事項與指示,可能導致火

災、人員遭受電擊及/或重傷。

請留意操作說明書中最前面的圖示。

依規定使用機器

本電動工具適合在木材、塑膠、金屬、填縫泥及上

漆表面上進行乾式研磨。

電子調控的電動工具也可進行拋光。

插圖上的機件

機件的編號和電動工具詳解圖上的編號一致。

如未

(1)

振蕩次數設定轉鈕(GEX 125-1 AE)

(2)

集塵盒全套件(超微細過濾器系統)

(3)

把手(絕緣握柄)

(4)

磨盤

(5)

(6)

(7)

(8)

(9)

(10)

A)

A)

研磨片

磨盤螺栓

排放接管

濾芯(超微細過濾器系統)

A)

吸塵管

圖表或說明上提到的配件,並不包含在基本的供貨範圍

中。本公司的配件清單中有完整的配件供應項目。

技術性數據

偏心研磨機

零件編號

設定振蕩次數 – ●

額定輸入功率 W 250 250

無負載轉速 n

0

次/分 12000 7500 –12000

無負載振蕩次數 次/分 24000 15000 –24000

振蕩繞圈直徑 mm 2.5 2.5

磨盤直徑 mm 125 125

重量符合 EPTA-Procedure 01:2014 kg 1.3 1.3

絕緣等級 / II / II

本說明書提供的參數是以 230 伏特為依據,於低電壓地區,此數據有可能不同。

GEX 125-1 A

Professional

GEX 125-1 AE

Professional

3 601 C87 0.. 3 601 C87 5..

安裝

維修電動工具或換裝零、配件之前,務必從插座

u

上拔出插頭。

選用研磨片

本公司特別針對欲進行加工之各種材質以及所需之表面材料去除比率,推出各式研磨片供您選購:

材料 用途 粒度

– 顏料

– 漆料

– 補填材料

– 填縫泥

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

磨除顏料層 粗 40

研磨先前塗上的顏料(例如磨除某一條

筆刷痕跡、滴落的色點和蜿蜒垂流的顏

料)

中 80

100

120

磨平底料以方便上漆 細 180

240

320

400

60

Page 20

20 | 繁體中文

材料 用途 粒度

Expert for Wood

– 所有種類的木質材料(例如

硬木、軟木、塑合板、建築

板材)

Best for Wood

– 硬木

– 塑合板

– 建築板材

– 金屬材料

粗加工研磨,例如未刨平的粗糙木樑及木板粗 40

平面磨整以及整平凹凸不平處 中 80

精磨與細磨木材 細 180

60

100

120

240

320

400

– 車漆

– 石材

– 大理石

– 花崗岩

– 陶瓷

– 玻璃

– 安全玻璃

– 玻璃纖維塑膠材料

進行粗磨 粗 80

成形和去邊 中 100

成形後的細磨 細 180

拋光作業和磨圓銳邊 超細 600

更換研磨片(請參考圖 A)

若要取下研磨片

它從磨盤

裝上新的研磨片之前,請用例如刷子清除磨盤

上的髒污與粉塵。

(5)

磨盤

的表面材質是魔鬼氈,可以很便利地快速

固定研磨片。

將研磨片

請注意:為確保最佳吸塵效果,研磨片上的沖孔請

對準磨盤開孔位置。

若要輕鬆在磨盤上

可使用工具箱裡的校正輔助工具 (如圖中所示)。

研磨片的魔鬼氈那一面朝上,將它放進校正輔助工

具中,接著再將電動工具上的磨盤用力按壓上去。

(6)

(5)

(6)

,請從側邊將它抬起,接著再將

拔下。

牢牢按壓到磨盤

(5)

對準研磨片

(5)

底部上。

(6)

(5)

的位置,您

120

240

320

400

1200

選用磨盤

本電動工具可以依據用途安裝不同硬度的磨盤:

– 超軟磨盤:適用於拋光或操作時必須憑藉觸感的

研磨作業,此外也可研磨凸起表面。

– 中硬度磨盤:適合所有的研磨工作,是通用型磨

盤。

– 硬磨盤:適合在平坦的表面進行高效率的研磨。

更換磨盤(請參考圖 B)

提示:

卸下研磨片或拋光工具。將 4 顆螺栓

出,並取下磨盤

螺栓。

提示:

進磨盤的凹槽內。

提示:

司授權的客戶服務處更換。

(5)

磨盤

如有受損請立即換掉。

(7)

(5)

。裝上新的磨盤

裝上磨盤時請注意從動部件的囓合齒應要卡

磨盤座如果損壞,必須交由博世電動工具公

完全旋

(5)

,然後旋緊

吸除廢塵/料屑

含鉛顏料、部分木材種類、礦石和金屬的加工廢塵

有害健康。機器操作者或施工現場附近的人員如果

接觸、吸入這些廢塵,可能會引發過敏反應或感染

呼吸道疾病。

某些塵埃(例如加工橡木或山毛櫸的廢塵)可能致

癌,特別是與處理木材的添加劑(例如木材的防腐

劑等)結合之後。唯有受過專業訓練的人才能夠進

行含石棉物料的加工。

– 儘可能使用適合物料的吸塵裝置。

– 工作場所要保持空氣流通。

– 建議佩戴 P2 過濾等級的口罩。

請留意並遵守貴國的物料加工相關法規。

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 21

避免讓工作場所堆積過多的塵垢。

u

塵埃容易被點

燃。

機器本身的吸塵裝備,含集塵盒(請參考圖 C1– C4)

將集塵盒

(3)

套到排放接管

(8)

上,直到卡緊為

止。

因為採用的是透明容器,因此很容易掌握集塵盒

的裝填狀態。

若要清空集塵盒

打開集塵盒

(3)

,請將它往下旋轉即可拔出。

(3)

之前,應如圖所示將集塵盒往穩固

平面上敲一敲,以便將濾芯上的塵垢抖鬆。

拿穩集塵盒

(3)

,將濾芯

盒倒空。用柔軟的刷子清潔濾芯

(9)

往上翻開,接著將集塵

(9)

上的濾網層。

外接的吸塵裝備(請參考圖 D)

將吸塵管

將吸塵管

(10)

插到排放接管

(10)

與吸塵器連接起來。本手冊的最前面

(8)

上。

另外刊錄了連接不同類型吸塵器的操作概覽。

根據工件材質選擇合適的吸塵裝置。

吸集可能危害健康、可能致癌或乾燥的廢塵時,務

必使用特殊吸塵裝置。

操作

操作機器

請注意電源電壓!電源的電壓必須和電動工具銘

u

牌上標示的電壓一致。標示為

亦可接上

220V

電源。

啟動/關閉

請確定您不用放開把手,就能操作起停開關。

u

若要啟動電動工具:請將起停開關

「I」

為

位置。

若要關閉電動工具:請將起停開關

「O」

為

位置。

設定振蕩次數(GEX 125-1 AE)

利用振蕩次數設定轉鈕

(2)

,即使是在工具運作期

間,亦可按照需求設定振蕩次數。

1 – 2 低振蕩次數

3 – 4 中振蕩次數

5 – 6 高振蕩次數

正確的振蕩次數是由加工材質和工作條件決定,唯

有實際操作才能夠找出最合適的振蕩次數。

使用低振蕩次數長期操作之後,應該讓電動工具以

最大振蕩次數空轉約 3 分鐘來幫助機器冷卻。

磨盤緩速器

機器空轉時,它內部的磨盤緩速器會降低磨盤的振

蕩次數,以避免將電動工具放在工件上時造成不必

要的凹槽。

如果空轉振蕩次數不斷上升,代表磨盤已經損壞了

必須更換,或是磨盤緩速器完全磨損了。已完全磨

損的磨盤緩速器必須交由博世電動工具公司授權的

客戶服務處更換。

230V

(1)

(1)

的電動工具

往右扳,設

往左扳,設

作業注意事項

維修電動工具或換裝零、配件之前,務必從插座

u

上拔出插頭。

等待電動工具完全靜止後才能夠放下機器。

u

本電動工具並不適用於以不移動的方式進行加

u

工。

(3)

不得將它夾入老虎鉗或固定在工作桌上。

本電動工具可配合實際應用情況從上方、側面或前

方拿握(請參閱圖 E),以最省力的方式進行作

業。

研磨平面

啟動電動工具,把整個研磨面平貼在待研磨的表面

上,並均力地在工件上移動機器。

磨除效率與研磨效果原則上取決於所選用的研磨

片、設定的振蕩級以及操作機器時施力的大小。

只有完好的研磨片才能夠提高研磨效率,並且保護

電動工具。

操作機器時要均力施壓,如此才能夠提高研磨片的

使用壽命。

在機器上施力過度,不僅無法提高研磨效率,機器

反而容易損壞並加速研磨片耗損。

不可以使用研磨過金屬的研磨片來研磨其它材質。

僅可使用博世原廠研磨配件。

粗磨

安裝粒度粗的研磨片。

只能輕按電動工具,這樣它才能夠以較高的振蕩次

數運轉,並達到較高的材料磨除率。

細磨

安裝粒度細的研磨片。

藉由稍微變換施壓力道或變更振蕩次數的設定檔

速,即可降低磨盤振蕩次數但機器偏心運作的移動

方式維持不變。

採用繞圈或縱向、橫向輪流的方式,力道均勻地在

工件上移動電動工具。勿讓研磨機歪斜,以避免磨

穿工件,例如木工貼皮。

工作完成後隨手關閉電動工具。

拋光

在電動工具上安裝合適的拋光工具後,例如羊毛

罩,拋光絨布或拋光海綿(配件)等,也可以使用

本電動工具拋光受氣候侵蝕的漆層和刮痕(例如安

全玻璃)。

拋光時請選擇較低振蕩次數(檔速 1-2),以免表

面過熱。

拋光時,先在一處小面積上塗抹拋光劑,接著再使

用合適的拋光工具,採縱橫交錯或繞圈的方式,力

道均勻地推抹拋光劑。

不可讓塗在拋光表面上的拋光劑乾掉,這樣會損壞

拋光表面。不可以讓陽光直接照射待拋光的表面。

請定期清潔拋光工具,以確保拋光效果良好。使用

溫和的清潔劑和溫水清洗拋光工具。勿使用稀釋

劑。

繁體中文 | 21

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 22

22 | 한국어

維修和服務

維修和清潔

維修電動工具或換裝零、配件之前,務必從插座

u

上拔出插頭。

電動工具和通風口都必須保持清潔,這樣才能夠

u

提高工作品質和安全性。

如果必須更換連接線,請務必交由博世或者經授權

的博世電動工具顧客服務執行,以避免危害機器的

安全性能。

顧客服務處和顧客咨詢中心

本公司顧客服務處負責回答有關本公司產品的維

修、維護和備用零件的問題。如需分解圖和備件的

資料,請至以下網頁:

若對本公司產品及其配件有任何疑問,博世應用諮

詢小組很樂意為您提供協助。

工匠與 DIY 玩家網路平台入口:

portal.de

單元 鉛

開關

電容器

馬達

電源線

外殼( 塑料)

備考 1. " 超出 0.1 wt %" 及" 超出 0.01 wt %" 係指限用物質之百分比含量超出百分比含量基準值。

備考 2. "O" 係指該項限用物質之百分比含量未超出百分比含量基準值。

備考 3. " − " 係指該項限用物質為排除項目。

www.bosch-pt.com

www.powertool-

設備名稱 : 偏心研磨機 , 型號 : GEX 125-1 AE

限用物質及其符號

汞

(Pb)

O O O O O O

O O O O O O

– O O O O O

O O O O O O

O O O O O O

(Hg)

當您需要諮詢或訂購備用零件時,請務必提供本產

品銘牌上的 10 位零件編號。

台灣

台灣羅伯特博世股份有限公司

建國北路一段90 號6 樓

台北市10491

電話: (02) 2515 5388

傳真: (02) 2516 1176

www.bosch-pt.com.tw

制造商地址:

Robert Bosch Power Tools GmbH

羅伯特· 博世電動工具有限公司

70538 Stuttgart / GERMANY

70538 斯圖加特/ 德國

廢棄物處理

必須以符合環保的方式,回收再利用損壞的機器、

配件和廢棄的包裝材料。

不可以把電動工具丟入家庭垃圾中。

鎘

(Cd)

六價鉻

(Cr+6)

多溴聯苯

(PBB)

多溴二苯醚

(PBDE)

터리를 사용하는 (전선이 없는) 전동 기기를 의미

한국어

안전 수칙

전동공구 일반 안전 수칙

경고

림 및 사양을 숙지하십시오. 다음의 지시 사항

을 준수하지 않으면 감전, 화재, 또는 심각한 부

상을 초래할 수 있습니다.

앞으로 참고할 수 있도록 이 안전수칙과 사용 설

명서를 잘 보관하십시오.

다음에서 사용되는 "전동공구"라는 개념은 전원에

연결하여 사용하는 (전선이 있는) 전동 기기나 배

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

본 전동공구와 함께 제공된

모든 안전경고, 지시사항, 그

합니다.

작업장 안전

작업장을 항상 깨끗이 하고 조명을 밝게 하십시오

u

작업장 환경이 어수선하거나 어두우면 사고를 초

래할 수 있습니다.

가연성 유체, 가스 또는 분진이 있어 폭발 위험이 있

u

는 환경에서 전동공구를 사용하지 마십시오

공구는 분진이나 증기에 점화하는 스파크를 일으

킬 수 있습니다.

전동공구를 사용할 때 구경꾼이나 어린이 혹은 다

u

른 사람이 작업장에 접근하지 못하게 하십시오

른 사람이 주의를 산만하게 하면 기기에 대한 통제

력을 잃기 쉽습니다.

. 전동

. 다

.

Page 23

전기에 관한 안전

전동공구의 전원 플러그가 전원 콘센트에 잘 맞아

u

야 합니다

다

를 사용하지 마십시오

플러그를 절대 변경시켜서는 안 됩니

.

접지된) 전동공구를 사용할 때 어댑터 플러그

. (

. 변형되지 않은 플러그와 잘

맞는 콘센트를 사용하면 감전의 위험을 줄일 수 있

습니다.

파이프 관, 라디에이터, 레인지, 냉장고와 같은 접

u

지 표면에 몸이 닿지 않도록 하십시오

. 몸에 닿을

경우 감전될 위험이 높습니다.

전동공구를 비에 맞지 않게 하고 습기 있는 곳에 두

u

지 마십시오

. 전동공구에 물이 들어가면 감전될 위

험이 높습니다.

전원 코드를 잘못 사용하는 일이 없도록 하십시오

u

전원 코드를 잡고 전동공구를 운반해서는 안 되며

콘센트에서 전원 플러그를 뽑을 때 전원 코드를 잡

아 당겨서는 절대로 안 됩니다

. 전원

코드가 열과

오일에 접촉하는 것을 피하고, 날카로운 모서리나

기기의 가동 부위에 닿지 않도록 주의하십시오

상되거나 엉킨 전원 코드는 감전을 유발할 수 있습

니다.

실외에서 전동공구로 작업할 때는 실외용으로 적

u

당한 연장 전원 코드만을 사용하십시오

. 실외용 연

장 전원 코드를 사용하면 감전의 위험을 줄일 수 있

습니다.

전동공구를 습기 찬 곳에서 사용해야 할 경우에는

u

누전 차단기를 사용하십시오

. 누전 차단기를 사용

하면 감전 위험을 줄일 수 있습니다.

사용자 안전

신중하게 작업하며, 전동공구를 사용할 때 경솔하

u

게 행동하지 마십시오

피로한 상태이거나 약물 복

.

용 및 음주한 후에는 전동공구를 사용하지 마십시

오

. 전동공구를 사용할 때 잠시라도 주의가 산만해

지면 중상을 입을 수 있습니다.

작업자 안전을 위한 장치를 사용하십시오

u

안경을 착용하십시오

. 전동공구의 종류와 사용에

. 항상

따라 먼지 보호 마스크, 미끄러지지 않는 안전화,

안전모 또는 귀마개 등의 안전한 복장을 하면 상해

의 위험을 줄일 수 있습니다.

실수로 기기가 작동되지 않도록 주의하십시오

u

동공구를 전원에 연결하거나 배터리를 끼우기 전

에, 혹은 기기를 들거나 운반하기 전에, 전원 스위

치가 꺼져 있는지 다시 확인하십시오

. 전동공구를

운반할 때 전원 스위치에 손가락을 대거나 전원 스

위치가 켜진 상태에서 전원을 연결하면 사고 위험

이 높습니다.

전동공구를 사용하기 전에 조절하는 툴이나 키 등

u

을 빼 놓으십시오

. 회전하는 부위에 있는 툴이나 키

로 인해 상처를 입을 수 있습니다.

자신을 과신하지 마십시오

u

고 항상 평형을 이룬 상태로 작업하십시오

불안정한 자세를 피하

.

. 안정된

자세와 평형한 상태로 작업해야만이 의외의 상황

에서도 전동공구를 안전하게 사용할 수 있습니다.

알맞은 작업복을 입으십시오

u

나 장신구를 착용하지 마십시오

헐렁한 복장을 하거

.

머리나 옷이 가동

.

하는 기기 부위에 가까이 닿지 않도록 주의하십시

오

. 헐렁한 복장, 장신구 혹은 긴 머리는 가동 부위

에 말려 사고를 초래할 수 있습니다.

분진 추출장치나 수거장치의 조립이 가능한 경우

u

이 장치가 연결되어 있는지, 제대로 작동이 되는지

확인하십시오

분진으로 인한 사고 위험을 줄일 수 있습니다.

툴을 자주 사용한다고 해서 안주하는 일이 없게 하

u

고 공구의 안전 수칙을 무시하지 않도록 하십시오

부주의하게 취급하여 순간적으로 심각한 부상을

입을 수 있습니다.

전동공구의 올바른 사용과 취급

기기를 과부하 상태에서 사용하지 마십시오

u

할 때 이에 적당한 전동공구를 사용하십시오

.

은 전동공구를 사용하면 지정된 성능 한도 내에서

,

더 효율적으로 안전하게 작업할 수 있습니다.

전원 스위치가 고장 난 전동공구를 사용하지 마십

u

시오

. 전원 스위치가 작동되지 않는 전동공구는 위

. 손

험하므로, 반드시 수리를 해야 합니다.

전동공구를 조정하거나 액세서리 부품 교환 혹은

u

공구를 보관할 때, 항상 전원 콘센트에서 플러그를

미리 빼어 놓거나 배터리를 분리하십시오

조치는 실수로 전동공구가 작동하게 되는 것을 예

방합니다.

사용하지 않는 전동공구는 어린이 손이 닿지 않는

u

곳에 보관하고, 전동공구 사용에 익숙지 않거나 이

사용 설명서를 읽지 않은 사람은 기기를 사용해서

는 안됩니다

하면 위험합니다.

전동공구 및 액세서리를 조심스럽게 관리하십시

u

오

부위가 하자 없이 정상적인 기능을 하는

. 가동

지, 걸리는 부위가 있는지, 혹은 전동공구의 기능에

중요한 부품이 손상되지 않았는지 확인하십시오

손상된 기기의 부품은 전동공구를 다시 사용하기

전에 반드시 수리를 맡기십시오

보

않은 전동공구의 경우 많은 사고를 유발합니다.

절단 공구를 날카롭고 깨끗하게 관리하십시오

u

카로운 절단면이 있고 잘 관리된 절단공구는 걸리

는 경우가 드물고 조절하기도 쉽습니다.

.

때, 이 지시 사항과 특별히 기종 별로 나와있는 사용

전동공구, 액세서리, 장착하는 공구 등을 사용할

u

전

방법을 준수하십시오. 이때 작업 조건과 실시하려

는 작업 내용을 고려하십시오

닌 다른 작업에 전동공구를 사용할 경우 위험한 상

황을 초래할 수 있습니다.

손잡이 및 잡는 면을 건조하게 유지하고, 오일 및 그

u

리스가 묻어 있지 않도록 깨끗하게 하십시오

이 또는 잡는 면이 미끄러우면 예상치 못한 상황에

서 안전한 취급 및 제어가 어려워집니다.

서비스

전동공구 수리는 반드시 전문 인력에게 맡기고

u

리 정비 시 보쉬 순정 부품만을 사용하십시오

게 함으로써 기기의 안전성을 오래 유지할 수 있습

니다.

한국어 | 23

. 이러한 분진 추출장치를 사용하면

작업

.

. 알맞

. 이러한

. 경험이 없는 사람이 전동공구를 사용

. 제대로 관리하지

. 날

. 원래 사용 분야가 아

. 손잡

수

,

. 그렇

,

.

.

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 24

24 | 한국어

그라인더 관련 안전 수칙

본 전동공구는 건식 작업에만 사용하십시오

u

공구에 물이 들어가면 감전될 위험이 높습니다.

불꽃이 튀어 부상을 입는 사람이 없도록 유의하십

u

시오. 근처에 가연성 물질이 남아 있지 않도록 하십

시오

. 금속 소재를 샌딩 작업할 경우 불꽃이 발생할

수 있습니다.

주의 화재위험! 가공물과 그라인더가 과열되지 않

u

도록 하십시오. 작업을 중단하기 전에 항상 먼지 용

기를 비우십시오

. 먼지백, 마이크로 필터, 종이백

(또는 필터 주머니 또는 집진기의 필터)에 있는 그

라인딩 분진은 금속 그라인딩 작업 시 불꽃을 발생

시키거나 자체적으로 점화될 수 있습니다. 특히 그

라인딩 분진이 페인트 잔여물, 폴리우레탄 잔여물

또는 기타 화학물질과 섞이고, 오랜 작업 후 가공물

이 뜨거워진 상황에서는 훨씬 위험합니다.

전동공구의 통풍구를 정기적으로 깨끗이 닦으십시

u

오

. 모터 팬이 하우징 안으로 분진을 끌어 들이며,

금속 분진이 많이 쌓이면 전기적인 위험을 야기할

수 있습니다.

전동공구를 내려놓기 전에 기기가 완전히 멈추었

u

는지 확인하십시오

작업물을 잘 고정하십시오

u

.

. 고정장치나 기계 바이

스에 끼워서 작업하면 손으로 잡는 것보다 더 안전

합니다.

제품 및 성능 설명

모든 안전 수칙과 지침을 숙지하십시

오. 다음의 안전 수칙과 지침을 준수

하지 않으면 화재 위험이 있으며 감전

혹은 중상을 입을 수 있습니다.

. 전동

사용 설명서 앞 부분에 제시된 그림을 확인하십

시오.

규정에 따른 사용

본 전동공구는 목재, 플라스틱, 금속, 충전물 그

리고 각종 도장된 표면에 건식 샌딩 작업을 하는

데 사용해야 합니다.

전자 제어장치가 있는 전동공구는 폴리싱 작업도

가능합니다.

제품의 주요 명칭

제품의 주요 명칭에 표기되어 있는 번호는 기기

그림이 나와있는 면을 참고하십시오.

전원 스위치

(1)

진동수 사전 선택 조정 휠(GEX 125-1 AE)

(2)

분진 박스 세트(Microfilter System)

(3)

손잡이(절연된 손잡이 부위)

(4)

샌딩판

(5)

샌딩 페이퍼

(6)

샌딩판용 나사

(7)

연결 부위

(8)

필터 부위(Microfilter System)

(9)

흡입 호스

(10)

도면이나 설명서에 나와있는 액세서리는 표준 공급부품

A)

에 속하지 않습니다. 전체 액세서리는 저희 액세서리 프

로그램을 참고하십시오

A)

A)

.

제품 사양

원형 샌더

제품 번호

진동수 선택 – ●

소비 전력 W 250 250

무부하 속도 n

0

rpm 12000 7500 –12000

무부하 진동수 rpm 24000 15000 –24000

진동 직경 mm 2.5 2.5

샌딩판 직경 mm 125 125

EPTA-Procedure 01:2014 에 따른 중량 kg 1.3 1.3

보호 등급 / II / II

자료는 정격 전압 [U] 230V를 기준으로 한 것입니다. 전압이 다른 경우 및 국가별 사양에 따라 변동이 있을 수 있습니다.

GEX 125-1 A

Professional

GEX 125-1 AE

Professional

3 601 C87 0.. 3 601 C87 5..

조립

전동공구를 보수 정비하기 전에 반드시 콘센트에

u

서 전원 플러그를 빼십시오

샌딩 페이퍼의 선택

작업하려는 소재와 표면의 깎임 정도에 따라 다양한 샌딩 페이퍼가 있습니다:

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

.

Page 25

한국어 | 25

작업 소재 사용 분야 입자 크

– 페인트

– 니스

– 충전재

– 충전물

Expert for Wood

– 전체 목재(예: 경목, 연목, 칩

보드, 건축용 패널)

Best for Wood

– 경목

– 칩 보드

– 건축용 패널

– 금속 소재

– 자동차 도료

– 석재

– 대리석

– 화강암

– 세라믹

– 유리

– 플렉시 유리

– 유리 섬유 플라스틱

페인트 연마 작업용 기본 40

초벌칠에 샌딩 작업용(예: 브러시 칠, 페

인트 방울 및 흐른 자국)

도장하기 전 프라이머에 최종 연마 작업용미세 180

초벌 샌딩 작업용(예: 대패질 전의 거친 들

보 및 널빤지)

작고 고르지 않은 부위에 매끄럽게 연마

하거나 고르게 연마할 때

목재에 최종 연마 및 미세 연마 작업용 미세 180

초벌 샌딩용 기본 80

성형 연마 및 모서리 깎는 작업용 중간 100

성형 작업 시 미세 연마용 미세 180

광택 연마 및 모서리 마무리 작업용 아주 미

기

중간 80

기본 40

중간 80

세

60

100

120

240

320

400

60

100

120

240

320

400

120

240

320

400

600

1200

샌딩 페이퍼 교체하기(그림 A 참조)

샌딩 페이퍼 (6) 교환 시 샌딩판 (5) 옆면을 잡

고 당겨 빼십시오.

새로운 샌딩 페이퍼를 끼우기 전에 브러시 등을

이용해 샌딩판의 (5) 이물질 및 분진을 제거하십

시오.

샌딩판 (5) 의 표면은 벨크로 조직으로 되어있어

샌딩 페이퍼를 쉽고 간단히 고정할 수 있습니다.

샌딩 페이퍼 (6) 를 샌딩판 (5) 아랫면에 대고

단단히 누르십시오.

효과적으로 분진을 제거하기 위해서는 샌딩 페이

퍼의 구멍과 샌딩판의 구멍이 일치해야 합니다.

샌딩 페이퍼 (6) 를 샌딩판 (5) 에 손쉽게 맞추

기 위해 공구 가방 안에 그림과 같은 보조 조절

장치 를 사용할 수 있습니다. 샌딩 페이퍼의 벨

크로 접착 부분이 위로 향하게 하여 보조 조절장

치 안으로 끼우고 샌딩판이 있는 전동공구를 그

위로 꽉 누르십시오.

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 26

26 | 한국어

샌딩판의 선택

본 전동공구는 작업 용도에 따라 다양한 강도의

샌딩판을 적용할 수 있습니다:

– 부드러운 샌딩판: 폴리싱 작업과 섬세한 샌딩 작업

및 휘어진 표면에 적합.

– 중간 강도의 샌딩판: 범용적이며 모든 샌딩 작업 가

능.

– 경질의 샌딩판: 평평한 표면에 높은 강도의 작업에

적합.

샌딩판 교체하기(그림 B 참조)

지침: 샌딩판 (5) 이 손상된 경우 즉시 교체하십

시오.

샌딩판에 부착되어 있는 샌딩 페이퍼나 폴리싱

공구를 빼십시오. 4개 볼트 (7) 를 돌려 완전히

빼낸 후 샌딩판 (5) 을 분리하십시오. 새로운 샌

딩판 (5) 을 끼우고 볼트를 다시 체결하십시오.

지침: 샌딩판을 끼울 때 샌딩판 뒤쪽에 구동 부

분과 맞물리는 톱니형 홀더가 있는데 이를 맞추

어 끼워 주어야 합니다.

지침: 손상된 샌딩판 베이스는 반드시 보쉬 지정

전동공구 전문 서비스 센터에 맡겨 교환하십시

오.

분진 및 톱밥 추출장치

납 성분을 포함한 페인트나 몇몇 나무 종류, 또

는 광물 성분 그리고 철과 같은 재료의 분진은

건강을 해칠 수 있습니다. 이 분진을 만지거나

호흡할 경우, 사용자나 주변 사람들이 알레르기

반응이나 호흡기 장애를 일으킬 수 있습니다.

떡갈나무나 너도밤나무와 같은 특정한 분진은 암

을 유발시키며, 특히 목재 처리용으로 사용되는

부가 원료 (크로마트, 목재 보호제)와 혼합되면

암을 유발시키게 됩니다. 석면 성분을 포함한 재

료는 전문가만 작업할 수 있습니다.

– 가능하면 작업물 소재에 적당한 분진 추출장치를

사용하십시오.

– 작업장의 통풍이 잘 되도록 하십시오.

– 필터등급 P2가 장착된 호흡 마스크를 사용하십시

오.

작업용 재료에 관해 국가가 지정한 규정을 고려

하십시오.

작업장에 분진이 쌓이지 않도록 하십시오

u

쉽게 발화할 수 있습니다.

분진 박스를 통한 자체 분진 처리(그림 C1–C4 참조)

분진 박스 세트 (3) 가 맞물려 고정될 때까지 연

결 부위 (8) 쪽으로 미십시오.

분진 박스 (3) 가 투명한 용기로 되어있어 분진

의 수위 상태를 쉽게 확인할 수 있습니다.

분진 박스 (3) 를 비우려면 박스를 회전시켜 아

래쪽으로 빼내십시오.

분진 박스 (3) 를 열기 전에 그림에 나와 있는

것처럼 단단한 바닥에 두드려 필터 부위에 있는

분진을 분리하는 것이 좋습니다.

. 분진이

분진 박스 (3) 를 꽉 잡은 채, 필터 (9) 를 위로

당긴 후 분진 박스를 비웁니다. 필터 (9) 의 겉

면을 부드러운 솔로 깨끗이 닦으십시오.

외부 분진 처리(그림 D 참조)

흡입 호스 (10) 를 연결 부위에 (8) 끼우십시오.

흡입 호스 (10) 를 진공 청소기에 연결하십시오.

다양한 진공 청소기 연결에 관한 정보는 본 설명

서의 첫 부분에서 확인할 수 있습니다.

진공 청소기는 작업하는 소재에 적당한 것이어야

합니다.

특히 건강에 유해한 발암성 혹은 건조한 분진을

처리해야 할 경우에는 특수한 청소기를 사용해야

합니다.

작동

기계 시동

전원의 전압에 유의하십시오! 공급되는 전원의 전

u

압은 전동공구의 명판에 표기된 전압과 동일해야

합니다

동이 가능합니다

전원 스위치 작동

손잡이에서 손을 떼지 않고 전원 스위치를 작동할

u

수 있는지 확인하십시오

전동공구의 전원을 켜려면 전원 스위치 (1) 를

우측 “I” 위치로 기울이십시오.

전동공구의 전원을 끄려면 전원 스위치 (1) 를

좌측 “O” 위치로 기울이십시오.

진동수 선택하기 (GEX 125-1 AE)

기기가 작동 중에도 진동수 선택 섬휠 (2) 로 필

요한 진동수를 선택할 수 있습니다.

1 – 2 낮은 속도

3 – 4 중간 속도

5 – 6 높은 속도

필요한 진동수는 작업하려는 소재와 작업 조건에

따라 달라지므로 직접 시험을 통해 결정할 수 있

습니다.

느린 속도로 장시간 연속 작업을 했을 경우 전동

공구를 식히기 위해 약 3분간 무부하 상태의 최

고 속도로 작동하여 주십시오.

샌딩판 제동장치

전동공구를 작업물 표면에 댈 때 긁히지 않도록

하기 위해 무부하 시에는 내장된 샌딩판 제동장

치에 의해 속도가 감소됩니다.

시간이 지나면서 무부하 속도가 상승하면, 샌딩

판이 손상되어 이를 교체해야 하거나 샌딩판 제

동장치가 마모됩니다. 마모된 샌딩판 제동장치는

반드시 보쉬 지정 전동공구 전문 서비스 센터에

맡겨 교환하십시오.

사용방법

전동공구를 보수 정비하기 전에 반드시 콘센트에

u

서 전원 플러그를 빼십시오

표시된 전동공구는

. 230 로

에서도 작

.

.

220 V

.

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 27

전동공구를 내려놓기 전에 기기가 완전히 멈추었

u

는지 확인하십시오

본 전동공구는 고정시켜 작업하는 용도로는 적합

u

하지 않습니다

작업 거치대에 고정시켜 사용할 수 없습니다.

작업 시 피로하지 않도록 전동공구를 사용 분야

에 따라 위나 옆에서 혹은 앞에서 잡을 수 있습

니다(그림 E 참조).

표면 샌딩 작업

전동공구의 스위치를 켜고 기기의 전체 샌딩 면

을 작업하려는 바닥에 놓고 일정한 압력을 가하

여 작업하도록 하십시오.

샌딩작업의 성공 여부와 결과는 대체로 샌딩 페

이퍼의 선택, 설정한 진동 단계 그리고 누르는

힘에 따라 좌우됩니다.

아무런 하자가 없는 샌딩 페이퍼를 사용해야 훌

륭한 샌딩 작업 결과를 얻을 수 있고 전동공구를

보호할 수 있습니다.

일정한 압력으로 작업을 하면 샌딩 페이퍼의 수

명을 연장할 수 있습니다.

지나치게 눌러 작업을 하면, 샌딩 효과가 좋아지

는 것이 아니라 전동공구와 샌딩 페이퍼가 더 빨

리 소모됩니다.

금속 소재에 사용했던 샌딩 페이퍼를 다른 소재

에 사용해서는 안 됩니다.

보쉬 순정 샌딩 액세서리만 사용하십시오.

조도 연마

굵은 입방수의 샌딩 페이퍼를 끼웁니다.

높은 속도로 작동하여 피드가 많이 생기도록 전

동공구를 가볍게 눌러 주십시오.

미세 연마

미세한 입방수의 샌딩 페이퍼를 끼웁니다.

기기에 가하는 힘을 약간 변경하거나 작업 속도

단계를 조정하면 원형 동작을 그대로 유지하면서

진동수를 줄일 수 있습니다.

작업물 표면에 적당한 압력을 가하면서 원형으로

혹은 가로세로로 번갈아가며 전동공구를 움직입

니다. 베니어 판 등 작업물이 뚫어지는 경우를

피하기 위하여 전동공구를 기울여 작동하지 마십

시오.

작업을 마치고 나서 전동공구의 스위치를 끕니

다.

폴리싱 작업

비바람에 바랜 페인트 도장 부위를 폴리싱 하거

나 아크릴 유리 등의 긁힌 부분을 다시 폴리싱

해야 할 때 전동공구에 양털이나 폴리싱 펠트 또

는 스펀지(별매 액세서리) 등 적당한 폴리싱 부품

을 장착하여 작업할 수 있습니다.

폴리싱 작업을 할 때는 표면이 과열되지 않도록

낮은 속도(1 – 2단)를 선택하십시오.

폴리싱 작업을 하려는 부위보다 약간 작은 표면

에 연마제를 바르십시오. 적합한 폴리싱 공구를

사용하여 연마제를 십자선으로 교차하며 혹은 원

을 그리듯이 움직이며 살짝 누르면서 작업하십시

오.

.

. 예를 들어 바이스에 고정시키거나

ไทย | 27

연마제를 표면 위에서 건조시키지 마십시오. 표

면이 손상될 수 있습니다. 폴리싱 작업해야 할

표면이 직사광선에 노출되지 않게 하십시오.

폴리싱 작업 결과가 잘 나오도록 폴리싱 공구를

주기적으로 세척하십시오. 폴리싱 공구는 중성

세제와 온수로 세척해야 하며 희석제를 사용해서

는 안 됩니다.

보수 정비 및 서비스

보수 정비 및 유지

전동공구를 보수 정비하기 전에 반드시 콘센트에

u

서 전원 플러그를 빼십시오

안전하고 올바른 작동을 위하여 전동공구와 전동

u

공구의 통풍구를 항상 깨끗이 하십시오

연결 코드를 교환해야 할 경우 안전을 기하기 위

해 보쉬사나 보쉬 지정 전동공구 서비스 센터에

맡겨야 합니다.

.

.

AS 센터 및 사용 문의

AS 센터에서는 귀하 제품의 수리 및 보수정비,

그리고 부품에 관한 문의를 받고 있습니다. 대체

부품에 관한 분해 조립도 및 정보는 인터넷에서

도 찾아 볼 수 있습니다 - www.bosch-

pt.com

보쉬 사용 문의 팀에서는 보쉬의 제품 및 해당

액세서리에 관한 질문에 기꺼이 답변 드릴 것입

니다.

전문 작업자 및 개인 작업자를 위한 인터넷 포털

www.powertool-portal.de도 참조할 수 있

습니다.

문의나 대체 부품 주문 시에는 반드시 제품 네임

플레이트에 있는 10자리의 부품번호를 알려 주십

시오.

콜센터

080-955-0909

처리

기기와 액세서리 및 포장 등은 환경 친화적인 방

법으로 재생할 수 있도록 분류하십시오.

전동공구를 가정용 쓰레기로 처리하지

마십시오!

ไทย

คำเตือนเพื่อความปลอดภัย

คำเตือนเพื่อความปลอดภัยทั่วไปสำหรับเครื่องมือ ไฟฟ้า

คำเตือน

จำเพาะทั้งหมดที่จัดส่งมาพร้อมกับเครื่องมือไฟฟ้า

อ่านคำเตือนเพื่อความปลอดภัย คำ

แนะนำ ภาพประกอบ และข้อมูล

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

Page 28

28 | ไทย

การไม่ปฏิบัติตามคําแนะนําทั้งหมดที่ระบุไว้ด้าน

ล่างนี้อาจทำให้ถูกไฟฟ้าดูด เกิดไฟไหม้ และ/หรือได้รับบาด

เจ็บอย่างร้ายแรง

เก็บรักษาคำเตือนและคำสั่งทั้งหมดสำหรับเปิดอ่านในภาย

หลัง

คำว่า "เครื่องมือไฟฟ้า" ในคำเตือนหมายถึง เครื่องมือไฟฟ้า

ของท่านที่ทำงานด้วยพลังงานไฟฟ้าจากแหล่งจ่ายไฟหลัก (มี

สายไฟฟ้า) และเครื่องมือไฟฟ้าที่ทำงานด้วยพลังงานไฟฟ้า

จากแบตเตอรี่ (ไร้สาย)

ความปลอดภัยในสถานที่ทำงาน

รักษาสถานที่ทำงานให้สะอาดและมีไฟส่องสว่างดี

u

สถานที่ที่มืดหรือรกรุงรังนำมาซึ่งอุบัติเหตุ

อย่าใช้เครื่องมือไฟฟ้าทำงานในสภาพบรรยากาศที่จุด

u

ติดไฟได้ เช่น ในที่ที่มีของเหลวไวไฟ ก๊าซ หรือฝุ่น

เมื่อใช้เครื่อง

มือไฟฟ้าจะเกิดประกายไฟซึ่งอาจจุดฝุ่นหรือไอให้ลุกเ

ป็นไฟได้

ขณะใช้เครื่องมือไฟฟ้าทำงาน ต้องกันเด็กและผู้ยืนดู

u

ให้ออกห่าง

การหันเหความสนใจอาจทำให้ท่านขาดการควบคุมเค

รื่องได้

ความปลอดภัยเกี่ยวกับไฟฟ้า

ปลั๊กของเครื่องมือไฟฟ้าต้องเหมาะพอดีกับเต้าเสียบ

u

อย่าดัดแปลงปลั๊กไม่ว่าในลักษณะใดๆ อย่างเด็ดขาด

อย่าใช้ปลั๊กพ่วงต่อใดๆ กับเครื่องมือไฟฟ้าที่มีสายดิน

ปลั๊กที่ไม่ดัดแปลงและเต้าเสียบที่เข้ากันช่วยลดความ

เสี่ยงจากการถูกไฟฟ้าดูด

หลีกเลี่ยงอย่าให้ร่างกายสัมผัสกับพื้นผิวที่ต่อสายดิน

u

หรือลงกราวด์ไว้ เช่น ท่อ เครื่องทำความร้อน เตา และตู้

เย็น

จะเสี่ยงอันตรายจากการถูกไฟฟ้าดูดมาก

ขึ้นหากกระแสไฟฟ้าวิ่งผ่านร่างกายของท่านลงดิน

อย่าให้เครื่องมือไฟฟ้าถูกฝนหรืออยู่ในสภาพเปียกชื้น

u

หากน้ำเข้าในเครื่องมือไฟฟ้า จะเพิ่มความเสี่ยงจากการ

ถูกไฟฟ้าดูด

อย่าใช้สายไฟฟ้าในทางที่ผิด อย่าใช้สายไฟฟ้าเพื่อยก

u

ดึง หรือถอดปลั๊กเครื่องมือไฟฟ้า กันสายไฟฟ้าออกห่าง

จากความร้อน น้ำมัน ขอบแหลมคม หรือชิ้นส่วนที่

เคลื่อนที่

สายไฟฟ้าที่ชำรุดหรือพันกันยุ่งเพิ่มความ

เสี่ยงจากการถูกไฟฟ้าดูด

เมื่อใช้เครื่องมือไฟฟ้าทำงานกลางแจ้ง ให้ใช้สายไฟต่อ

u

ที่เหมาะสำหรับการใช้งานกลางแจ้ง

การใช้สาย

ไฟต่อที่เหมาะสมสำหรับงานกลาง

แจ้งช่วยลดอันตรายจากการถูกไฟฟ้าดูด

หากไม่สามารถหลีกเลี่ยงการใช้เครื่องมือไฟฟ้าทำงาน

u

ในสถานที่เปียกชื้นได้ ให้ใช้สวิ

ทช์ตัดวงจรเมื่อเกิดการรั่วไหลของไฟฟ้าจากสายดิน

(RCD) การใช้สวิทช์ตัดวงจรเมื่อเกิดการรั่ว

ไหลของไฟฟ้าจากสายดินช่วยลดความเสี่ยงต่อการถูก

ไฟฟ้าดูด

ความปลอดภัยของบุคคล

ท่านต้องอยู่ในสภาพเตรียมพร้อม ระมัดระวังในสิ่งที่

u

ท่านกำลังทำอยู่ และมีสติขณะใช้เครื่องมือไฟฟ้าทำงาน

อย่าใช้เครื่องมือไฟฟ้าขณะที่ท่านกำลังเหนื่อย หรืออยู่

ภายใต้การครอบงำของฤทธิ์ของยาเสพติด แอลกอฮอล์

และยา

เมื่อใช้เครื่องมือไฟฟ้าทำงาน

ในชั่วนาทีที่ท่านขาดความเอาใจ

ใส่อาจทำให้บุคคลบาดเจ็บอย่างรุนแรงได้

ใช้อุปกรณ์ปกป้องร่างกาย สวมแว่นตาป้องกันเสมอ

u

อุปกรณ์ปกป้อง เช่น หน้ากากกันฝุ่น รองเท้ากันลื่น

หมวกแข็ง หรือประกบหูกันเสียงดังที่ใช้ตามความ

เหมาะสมกับสภาพการทำงาน จะลดการบาดเจ็บทาง

ร่างกาย

ป้องกันการติดเครื่องโดยไม่ตั้งใจ ตรวจสอบให้แน่ใจว่า

u

สวิทช์อยู่ในตำแหน่งปิดก่อนเชื่อมต่อเข้ากับแหล่งจ่าย

ไฟ และ/หรือแบตเตอรี่แพ็ค ยกหรือถือเครื่องมือ

ถือเครื่องโดยใช้นิ้วหิ้วที่สวิทช์ หรือเสียบพลัง

ไฟฟ้าขณะสวิทช์เปิดอยู่ อาจนำไปสู่อุบัติเหตุที่ร้าย

แรงได้

นำเครื่องมือปรับแต่งหรือประแจปากตายออกก่อนเปิดส

u

วิทช์เครื่องมือไฟฟ้า

เครื่องมือหรือประแจปาก

ตายที่วางอยู่กับส่วนของเครื่องที่กำลังหมุนจะทำให้บุค

คลบาดเจ็บได้

อย่าเอื้อมไกลเกินไป ตั้งท่ายืนที่มั่นคงและวางน้ำหนัก

u

ให้สมดุลตลอดเวลา

ในลักษณะนี้ท่านสามารถควบคุมเครื่อง

มือไฟฟ้าในสถานการณ์ที่ไม่คาดคิดได้ดีกว่า

แต่งกายอย่างเหมาะสม อย่าใส่เสื้อผ้าหลวมหรือสวม

u

เครื่องประดับ เอาผมและเสื้อผ้าออกห่างจากชิ้นส่วนที่

เคลื่อนที่

เสื้อผ้าหลวม เครื่องประดับ และผม

ยาวอาจเข้าไปติดในชิ้นส่วนที่เคลื่อนที่

หากเครื่องมือไฟฟ้ามีข้อเชื่อมต่อกับเครื่องดูดฝุ่นหรือ

u

เครื่องเก็บผง ให้ตรวจสอบให้แน่ใจว่าได้เชื่อมต่อและ

ใช้งานอย่างถูกต้อง

การใช้อุปกรณ์ดูด

ฝุ่นช่วยลดอันตรายที่เกิดจากฝุ่นได้

เมื่อใช้งานเครื่องบ่อยครั้งจะเกิดความคุ้นเคย อย่าให้

u

ความคุ้นเคยทำให้ท่านเกิดความชะล่าใจและละเลยกฎ

เกณฑ์ด้านความปลอดภัยในการใช้งานเครื่อง

การ

ทำงานอย่างไม่ระมัดระวังอาจทำให้เกิดการบาด

เจ็บอย่างร้ายแรงภายในเสี้ยววินาที

การใช้และการดูแลรักษาเครื่องมือไฟฟ้า

อย่างฝืนกำลังเครื่องมือไฟฟ้า ใช้เครื่องมือไฟฟ้าที่ถูก

u

ต้องตรงตามลักษณะงานของท่าน

เครื่องมือไฟฟ้าที่ถูก

ต้องจะทำงานได้ดี

กว่าและปลอดภัยกว่าในระดับสมรรถภาพที่ออกแบบไว้

อย่าใช้เครื่องมือไฟฟ้าถ้าสวิทช์ไม่สามารถเปิดปิดได้

u

เครื่องมือไฟฟ้าที่ไม่สามารถควบคุมการเปิดปิดด้วยสวิ

ทช์ได้ เป็นเครื่อง

มือไฟฟ้าที่ไม่ปลอดภัยและต้องส่งซ่อมแซม

ก่อนปรับแต่งเครื่อง เปลี่ยนอุปกรณ์ประกอบ หรือเก็บ

u

เครื่องเข้าที่ ต้องถอดปลั๊กออกจากแหล่งจ่ายไฟ และ

หรือถอดแบตเตอรี่แพ็คออกจากเครื่องมือไฟฟ้าหาก

ถอดออกได้

มาตรการป้องกันเพื่อความปลอดภัยนี้ช่วยลดความ

เสี่ยงจากการติดเครื่องโดยไม่ได้ตั้งใจ

เมื่อเลิกใช้งานเครื่องมือไฟฟ้า ให้เก็บเครื่องไว้ในที่ที่

u

เด็กหยิบไม่ถึง และไม่อนุญาตให้บุคคลที่ไม่คุ้นเคยกับ

เครื่องหรือบุคคลที่ไม่ได้อ่านคำแนะนำเหล่านี้ใช้เครื่อง

เครื่องมือไฟฟ้าเป็นของอันตรายหากตกอยู่ในมือของผู้

ใช้ที่ไม่ได้รับการฝึกฝน

บำรุงรักษาเครื่องมือไฟฟ้าและอุปกรณ์ประกอบ ตรวจ

u

สอบชิ้นส่วนที่เคลื่อนที่ว่าวางไม่ตรงแนวหรือติดขัดหรือ

การ

/

1 609 92A 4AJ | (24.05.2018) Bosch Power Tools

Page 29

ไทย | 29

ไม่ ตรวจหาการแตกหักของชิ้นส่วนและสภาพอื่นใดที่

อาจมีผลต่อการทำงานของเครื่องมือไฟฟ้า หากชำรุด

ต้องส่งเครื่องมือไฟฟ้าไปซ่อมแซมก่อนใช้งาน

อุบัติเหตุหลายอย่างเกิด

ขึ้นเนื่องจากดูแลรักษาเครื่องไม่ดีพอ

รักษาเครื่องมือตัดให้คมและสะอาด

u

หากบำรุงรักษาเครื่องมือที่มีขอบตัดแหลมคมอย่างถูก

ต้อง

จะสามารถตัดได้ลื่นไม่ติดขัดและควบคุมได้ง่ายกว่า

ใช้เครื่องมือไฟฟ้า อุปกรณ์ประกอบ เครื่องมือ และอุปก

u

รณ์อื่นๆ ตรงตามคำแนะนำเหล่านี้ โดยคำนึงถึงเงื่อนไข

การทำงานและงานที่จะทำ

การใช้เครื่อง

มือไฟฟ้าทำงานที่ต่างไปจากวัตถุประสงค์การ

ใช้งานของเครื่อง

อาจนำไปสู่สถานการณ์ที่เป็นอันตรายได้

ดูแลด้ามจับและพื้นผิวจับให้แห้ง สะอาด และปราศจาก

u

คราบน้ำมันและจาระบี

ด้ามจับและพื้นผิว

จับที่ลื่นทำให้หยิบจับได้ไม่ปลอดภัย

และไม่สามารถควบคุมเครื่อง

มือในสถานการณ์ที่ไม่คาดคิด

การบริการ

ส่งเครื่องมือไฟฟ้าของท่านเข้ารับบริการจากช่างซ่อมที่

u

มีคุณสมบัติเหมาะสม โดยใช้อะไหล่ที่เหมือนกันเท่านั้น

ในลักษณะนี้ท่านจะแน่ใจได้ว่าเครื่อง

มือไฟฟ้าอยู่ในสภาพที่ปลอดภัย

คำเตือนเพื่อความปลอดภัยสำหรับเครื่องขัด

ใช้เครื่องมือไฟฟ้าสำหรับการขัดแห้งเท่านั้น

u

หากน้ำเข้าในเครื่องมือไฟฟ้า จะเพิ่มความเสี่ยงต่อการ

ถูกไฟฟ้าดูด

ตรวจสอบให้แน่ใจว่าจะไม่มีบุคคลใดได้

u

รับอันตรายจากประกายไฟ นำวัตถุใดๆ

ที่ติดไฟได้ในบริเวณใกล้เคียงออกไป

ไฟเมื่อขัดโลหะ

ระวังอันตรายจากไฟไหม้! หลีกเลี่ยงการทำให้วัสดุชิ้น

u

งานและเครื่องขัดร้อนเกินไป ถ่ายผงออกจากกล่องเก็บ

ผงก่อนพักงานทุกครั้ง

ในสถานการณ์ที่ไม่เหมาะสม ต.

ย. เช่น เมื่อเกิดประกายไฟขณะขัดโลหะ เศษผงที่

ได้จากการขัดที่อยู่ในถุงเก็บผง เครื่องกรองไมโคร

หรือถุงกระดาษ (หรือในถุงกรอง หรือตัว

กรองของเครื่องดูดฝุ่น) อาจจุดลุกเป็นไฟขึ้นเองได้ จะ

เป็นอันตรายอย่างยิ่งเมื่อเมื่อเศษผงผสมปน

กับเศษสารเคลือบเงา เศษโพลียูรีเทน

หรือเศษวัสดุเคมีอื่นๆ และเมื่อเศษผงขัดเกิดร้อนขึ้นหลัง

จากใช้เครื่องทำงานเป็นเวลานาน

จะเกิดประกาย

ทำความสะอาดช่องระบายอากาศของเครื่องมือไฟฟ้า

u

อย่างสม่ำเสมอ

พัดลมของมอเตอร์จะดูดผง

ฝุ่นเข้าในหม้อครอบ และผงโลหะที่พอกสะสมกันมากๆ

อาจทำให้เกิดอันตรายจากไฟฟ้าได้

รอให้เครื่องมือไฟฟ้าหยุดนิ่งอยู่กับที่ก่อนวางเครื่องลง

u

บนพื้น

ยึดชิ้นงานให้แน่น

u

การยึดชิ้นงานด้วยเครื่อง

หนีบหรือแท่นจับจะมั่นคงกว่าการยึดด้วยมือ

รายละเอียดผลิตภัณฑ์และข้อมูล จำเพาะ

อ่านคำเตือนเพื่อความปลอดภัยและคำ

แนะนำทั้งหมด การไม่ปฏิบัติตามคำเตือนและ

คำสั่งอาจเป็นสาเหตุให้ถูกไฟฟ้าดูด เกิดไฟไหม้

และ/หรือได้รับบาดเจ็บอย่างร้ายแรง

กรุณาดูภาพประกอบในส่วนหน้าของคู่มือการใช้งาน

ประโยชน์การใช้งานของเครื่อง

เครื่องมือไฟฟ้านี้ใช้สำหรับขัดแห้งบนไม้ พลาสติก โลหะ วัสดุ

อุดแทรก และผิวเคลือบเงา

เครื่องมือไฟฟ้าที่ควบคุมด้วยระบบอิเล็กทรอนิกส์ใช้สำหรับขัด

เงาได้ด้วย

ส่วนประกอบผลิตภัณฑ์

ลำดับเลขของส่วนประกอบผลิตภัณฑ์อ้างถึงส่วน

ประกอบของเครื่องที่แสดงในหน้าภาพประกอบ

สวิทช์เปิด-ปิด

(1)

สวิทช์ตั้งอัตราแกว่งสั่นสะเทือนล่วงหน้า (GEX

(2)

125-1 AE)

กล่องเก็บผง สมบูรณ์แบบ (Microfilter System)

(3)

ด้ามจับ (พื้นผิวจับหุ้มฉนวน)

(4)

จานรองขัด

(5)

กระดาษทราย

(6)

สกรูสำหรับจานรองขัด

(7)

ท่อระบายออก

(8)

ตัวกรอง (Microfilter System)

(9)

ท่อดูดฝุ่น

(10)

อุปกรณ์ประกอบที่แสดงภาพหรืออธิบายไม่รวมอยู่ในการ

A)

จัดส่งมาตรฐาน

กรุณาดูอุปกรณ์ประกอบทั้งหมดในรายการแสดงอุปกรณ์ประ

กอบของเรา

A)

A)

ข้อมูลทางเทคนิค

เครื่องขัดแบบลูกเบี้ยว

หมายเลขสินค้า

การตั้งอัตราแกว่งสั่นสะเทือนล่วงหน้า – ●

กำลังไฟฟ้าเข้ากำหนด วัตต์ 250 250

ความเร็วรอบเดินตัวเปล่า n

0

รอบ/นาที 12000 7500 –12000

อัตราแกว่งสั่นสะเทือนเดินตัวเปล่า รอบ/นาที 24000 15000 –24000

Bosch Power Tools 1 609 92A 4AJ | (24.05.2018)

GEX 125-1 A

Professional

GEX 125-1 AE

Professional

3 601 C87 0.. 3 601 C87 5..

Page 30

30 | ไทย

เครื่องขัดแบบลูกเบี้ยว

เส้นผ่าศูนย์กลางระยะแกว่งสะเทือน มม. 2.5 2.5

เส้นผ่าศูนย์กลางจานรองขัด มม. 125 125

น้ำหนักตามระเบียบการ-EPTA-Procedure

01:2014

ระดับความปลอดภัย / II / II

ค่าที่ให้นี้ใช้ได้กับแรงดันไฟฟ้านอมินอล [U] 230 โวลท์ค่าเหล่านี้อาจเปลี่ยนแปลงไปสำหรับแรงดันไฟฟ้าที่แตกต่างกัน

และโมเดลที่ผลิตสำหรับเฉพาะประเทศ

กก. 1.3 1.3

GEX 125-1 A

Professional

GEX 125-1 AE

Professional

การติดตั้ง

ดึงปลั๊กไฟออกจากเต้าเสียบก่อนปรับแต่งเครื่อง

u

การเลือกกระดาษทราย