Page 1

Fire Alarm Control Panels

FPD-7024

en Installation and Operation Manual

Page 2

Page 3

Fire Alarm Control Panels Table of Contents | en 3

Table of contents

1

1.1 FCC Compliance Notice 6

1.2 FCC Phone Connection to Users 6

1.3 Industry Canada Notice 7

1.4 Trademarks 7

2

2.1 System overview 8

2.2 Components 9

2.2.1 On-board conventional points 9

2.2.2 Off-board addressable points (with D7039 Multiplex Expansion Module) 9

2.2.3 Enclosure Housing 10

2.2.4 Remote LCD Keypads 10

2.2.5 Remote LED Annunciators 10

2.2.6 D7032 - use with the D7030X 10

2.2.7 Communicator 12

2.2.8 Users 13

2.2.9 Lightning protection 13

2.2.10 Battery backup calculation 13

2.2.11 Required batteries for existing load 16

2.2.12 Compatible devices 17

2.3 Parts List 19

3

3.1 Smoke detector layout 20

3.1.1 General considerations 20

3.1.2 Family residences 20

3.2 Having and practicing an escape plan 21

4

4.1 Installation guide for UL Listed systems 22

4.1.1 FPD‑7024 UL Listings 22

4.1.2 Installation considerations 22

4.1.3 UL requirements 22

4.2 Installing the enclosure 25

4.3 Installing the FPD‑7024 26

4.4 Installing optional equipment 27

5

5.1 FACP terminal connection 29

5.2 Power supply connection 33

5.3 Option bus wiring requirements 34

6

6.1 Modes of Operation 36

6.1.1 Normal 36

6.1.2 Off-normal Displays 36

6.1.3 Acknowledge 36

6.1.4 Alarm 36

6.1.5 Supervisory 36

6.1.6 Trouble 37

6.1.7 Fire Silence/Reset 37

Notices 6

Overview 8

Fire Safety 20

Installation 22

Connection 29

System Operation 36

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 4

4 en | Table of Contents Fire Alarm Control Panels

6.2 Basic System Use 38

6.2.1 Function keys 38

6.2.2 Selecting menu items 38

6.2.3 After a Main Menu item is selected 38

6.2.4 Returning to an earlier screen 38

6.2.5 Entering data 38

6.2.6 Drill 38

6.2.7 Disable 38

6.2.8 History 39

6.2.9 Remote Programming 40

6.3 Keypads 40

6.3.1 Built-in keypad 40

6.3.2 FMR-7033 keypad 42

6.4 Testing 43

6.4.1 Walk test 43

6.4.2 Communicator test 43

6.4.3 Battery/NAC circuits test 44

6.4.4 Activate ouputs test 44

6.4.5 Zone input level test 44

6.4.6 Addressable point test (MUX test) 44

6.4.7 Sensitivity test 45

6.5 Point/Zone Mapping 45

6.6 Personal Identification Numbers (PINs) 47

6.7 Communicator Operation 47

7

Programming 49

7.1 Programming features 49

7.2 Point programming 50

7.3 Alpha programming 51

7.4 Format programming 53

7.5 Program menu tree 55

7.6 Shortcuts 56

7.7 Remote programming 57

8

Control Panel Programming 59

8.1 PROG TIME 59

8.1.1 Program time 59

8.1.2 Automatic test 59

8.1.3 Daylight saving time 60

8.2 SECURITY 60

8.2.1 Personal Identification Numbers (PINs) 61

8.2.2 Authority 61

8.3 PROG SYSTEM 62

8.3.1 Program timers 62

8.3.2 AC line synch 64

8.3.3 Option bus 64

8.3.4 PIN required 65

8.3.5 NAC silence mode 66

8.3.6 Remote programming 67

8.4 PROG INPUTS 67

8.4.1 Point number 67

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 5

Fire Alarm Control Panels Table of Contents | en 5

8.4.2 Point function 70

8.4.3 Point copy 72

8.5 PROG OUTPUTS 73

8.5.1 Programming NACs 73

8.5.2 Programming relays 76

8.6 PROG ACCOUNTS 77

8.6.1 Phone Numbers/IP Addresses 78

8.6.2 Phone Control 82

8.6.3 Report Steering 83

8.6.4 Ring Count 84

8.6.5 Communication Tries 85

8.6.6 Machine Bypass 85

8.6.7 ALT. COMM 85

8.7 PROG FORMATS 85

8.7.1 4/2 Zone Report 86

8.7.2 4/2 Report Codes 87

8.7.3 BFSK Report Codes 88

8.8 HISTORY DEFAULTS 88

8.8.1 Clear History 88

8.8.2 Default EE 89

8.8.3 Alternate 4/2 Codes 89

8.9 Program MUX 89

8.9.1 MUX Edit 90

8.9.2 MUX Program 90

8.9.3 MUX Bus Type 92

8.9.4 AUTO PROGRAM 93

8.9.5 Removing MUX Devices 96

9

10

Specifications 98

Appendices 99

10.1 Appendix A: Abbreviations on Control Panel Display 99

10.2 Appendix B: Control Panel Display Descriptions 100

10.3 Appendix C: Reporting Summary for Fire Communicator 102

10.4 Appendix D: Programming Defaults List 110

10.5 Appendix E: Phone Monitor Troubleshooting 118

10.5.1 COMM FLT/DATA LOST 118

10.5.2 Trouble Phone 119

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 6

6 en | Notices Fire Alarm Control Panels

1

1.1

1.2

Notices

FCC Compliance Notice

This equipment was tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy, and if not installed and used in accordance with

the instructions, might cause harmful interference to radio communications. There is no

guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, that can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

– Re-orient or relocate the receiving antenna.

– Increase the separation between the equipment and the receiver.

– Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

– Consult the dealer or an experienced radio or TV technician for help.

FCC Phone Connection to Users

This control panel complies with Part 68 of the FCC rules.

On the inside of the enclosure is a label that contains, among other information, the ringer

equivalence number (REN) for this equipment. You must, upon request, provide this

information to your local telephone company.

The REN is useful to determine the quantity of devices that can be connected to your

telephone line and still have all of those devices ring when your telephone number is called. In

most, but not all areas, the sum of the RENs of all devices connected to one line should not

exceed five. To ascertain the number of devices that you can connect to your line, contact

your local telephone company to determine the maximum REN for your local calling area.

This equipment can not be used on coin service provided by the telephone company. Do not

connect this control panel to party lines. If this equipment causes harm to the telephone

network, the telephone company might discontinue your service temporarily. If possible, they

will notify you in advance. But if advance notice isn’t practical, you will be notified as soon as

possible.

You will be informed of your right to file a complaint with the FCC. The telephone company

might make changes in its facilities, equipment, operations, or procedures that could affect

the proper functioning of your equipment. If they do, you will be notified in advance to give

you an opportunity to maintain uninterrupted telephone service.

If you experience trouble with this equipment, contact the manufacturer for information on

obtaining service or repairs.

The telephone company might ask that you disconnect this equipment from the network until

the problem is corrected or until you are sure that the equipment is not malfunctioning. The

manufacturer, not the user, must make the repairs to this equipment. To guard against

accidental disconnection, there is ample room to mount the telco jack inside of the control

panel cabinet.

The operation of this control panel might also be affected if events such as accidents or acts

of God cause an interruption in telephone service.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 7

Fire Alarm Control Panels Notices | en 7

1.3

1.4

Industry Canada Notice

The Industry Canada label identifies certified equipment. This certification means that the

equipment meets certain telecommunications network protective, operational, and safety

requirements. Industry Canada does not guarantee the equipment will operate to the user’s

satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to

the facilities of the local telecommunications company. The equipment must also be installed

using an acceptable method of connection. The customer should be aware that compliance

with the above conditions might not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance

facility designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, might give the telecommunications company cause to

request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the

power utility, telephone lines, and internal metallic water pipe system, if present, are

connected together. Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or electrician.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Microsoft, Windows, and Windows NT are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

CYCOLOY is a registered trademark of Sabic Plastic.

POLYLAC is a registered trademark of CHI MEI Industrial Corporation, LTD.

CleanMe is a trademark of GE Interlogix, Inc. in the United States and/or other countries.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 8

8 en | Overview Fire Alarm Control Panels

2

2.1

Overview

System overview

The FPD‑7024 Fire Alarm Control Panel is a fully integrated hard-wire fire alarm system. It can

support four input points (expandable to 255 using D7039 Multiplex Expansion Module and

the FPC‑7034 Four-Point Expander) and 16 individual users (expandable to 100 with the

D7039). The control panel has a built-in LCD keypad. Up to four additional keypads can be

used to provide user interface with the system and programming access for the installer. The

FPD‑7024 also includes the following features:

– Built-in dual-line communicator

– Menu driven keypad programming

– Freely programmable alphanumeric/alphabetical display

– 99 event history buffer

– 16 user codes

– UL Listed, CSFM, MEA Approved

When the D7039 Multiplex Expansion Module is installed, these additional features are

available:

– 247 additional addressable input points (255 total points)

– 499 Non-volatile event history buffer

– 100 user codes

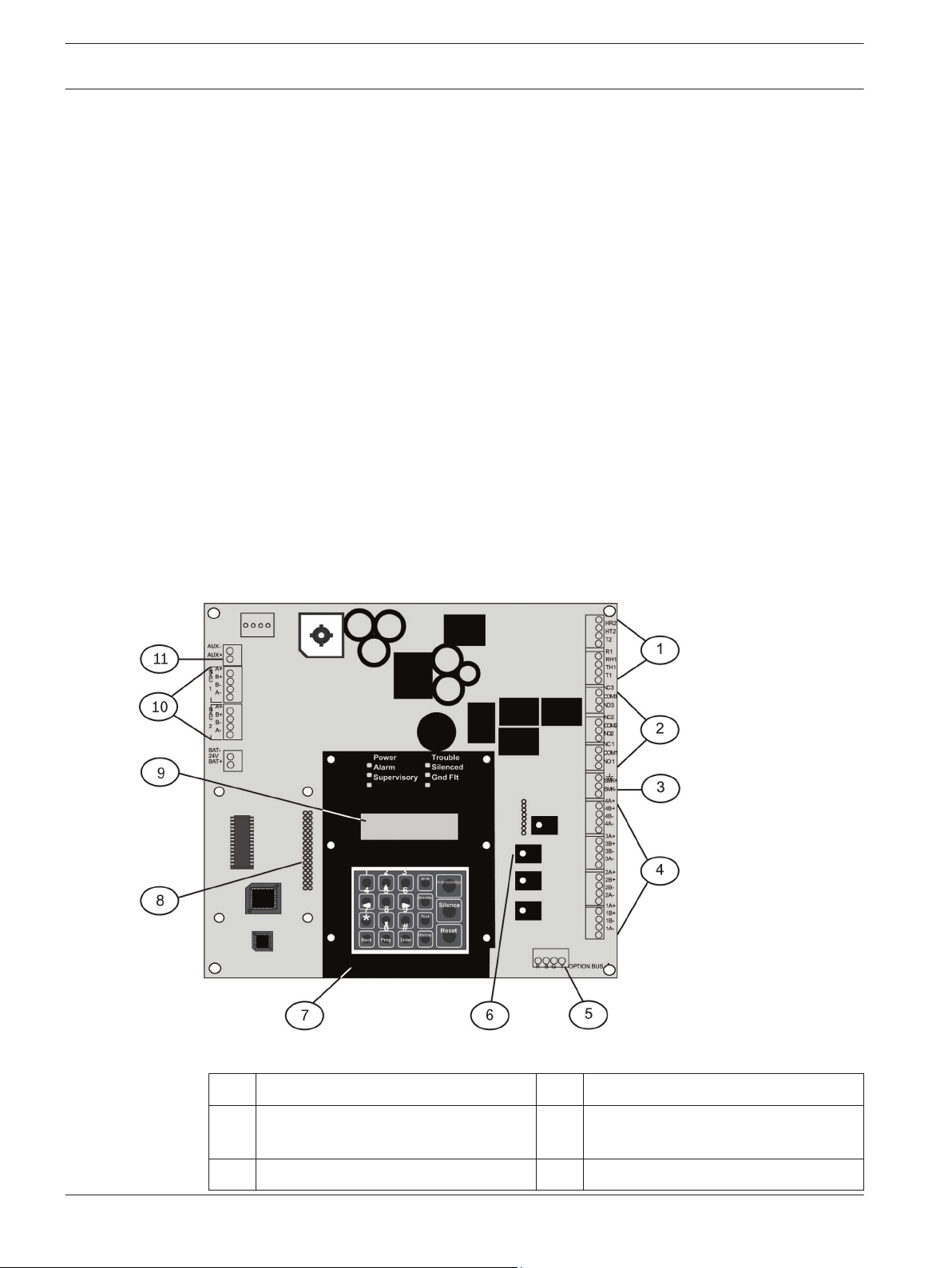

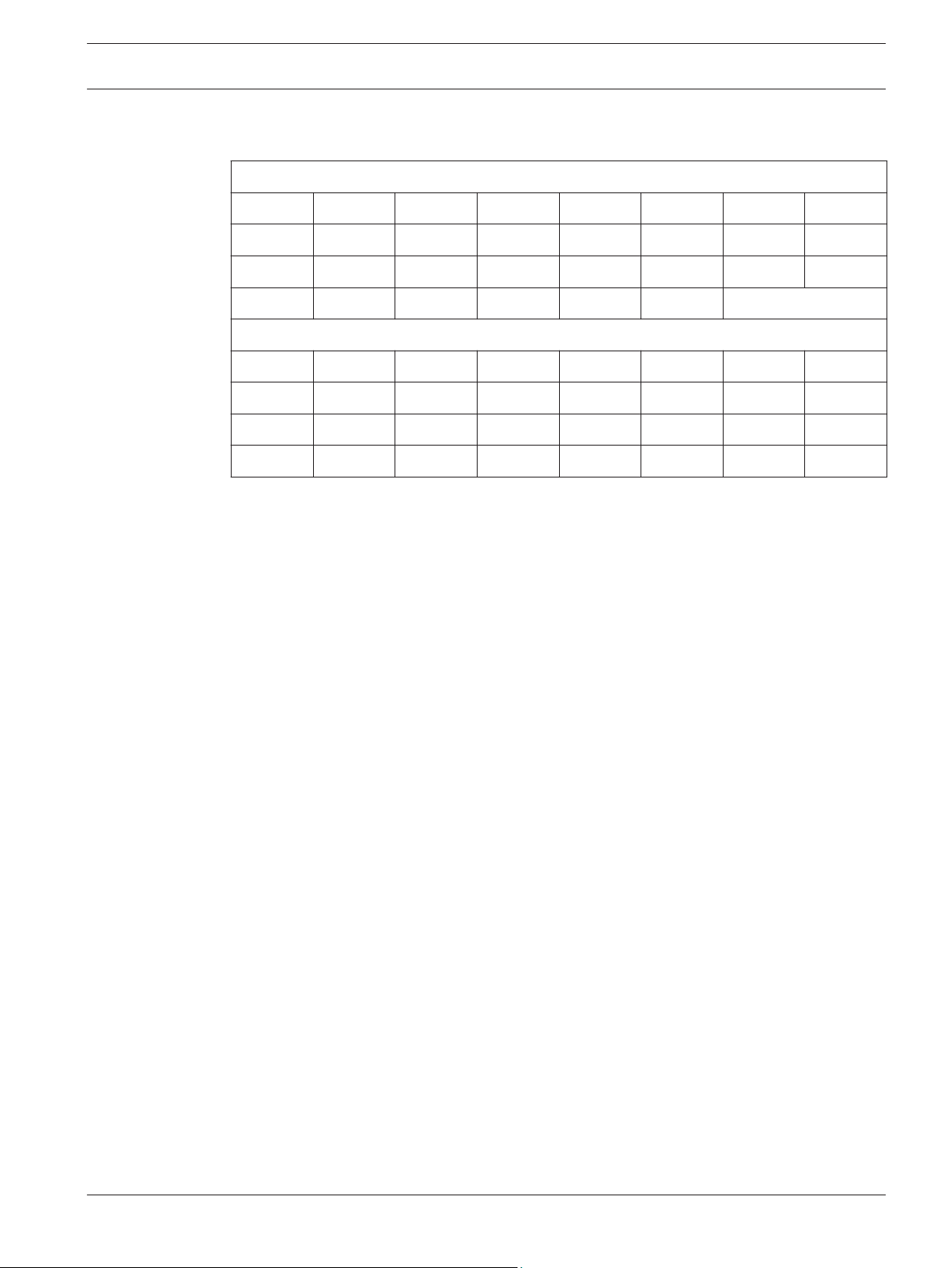

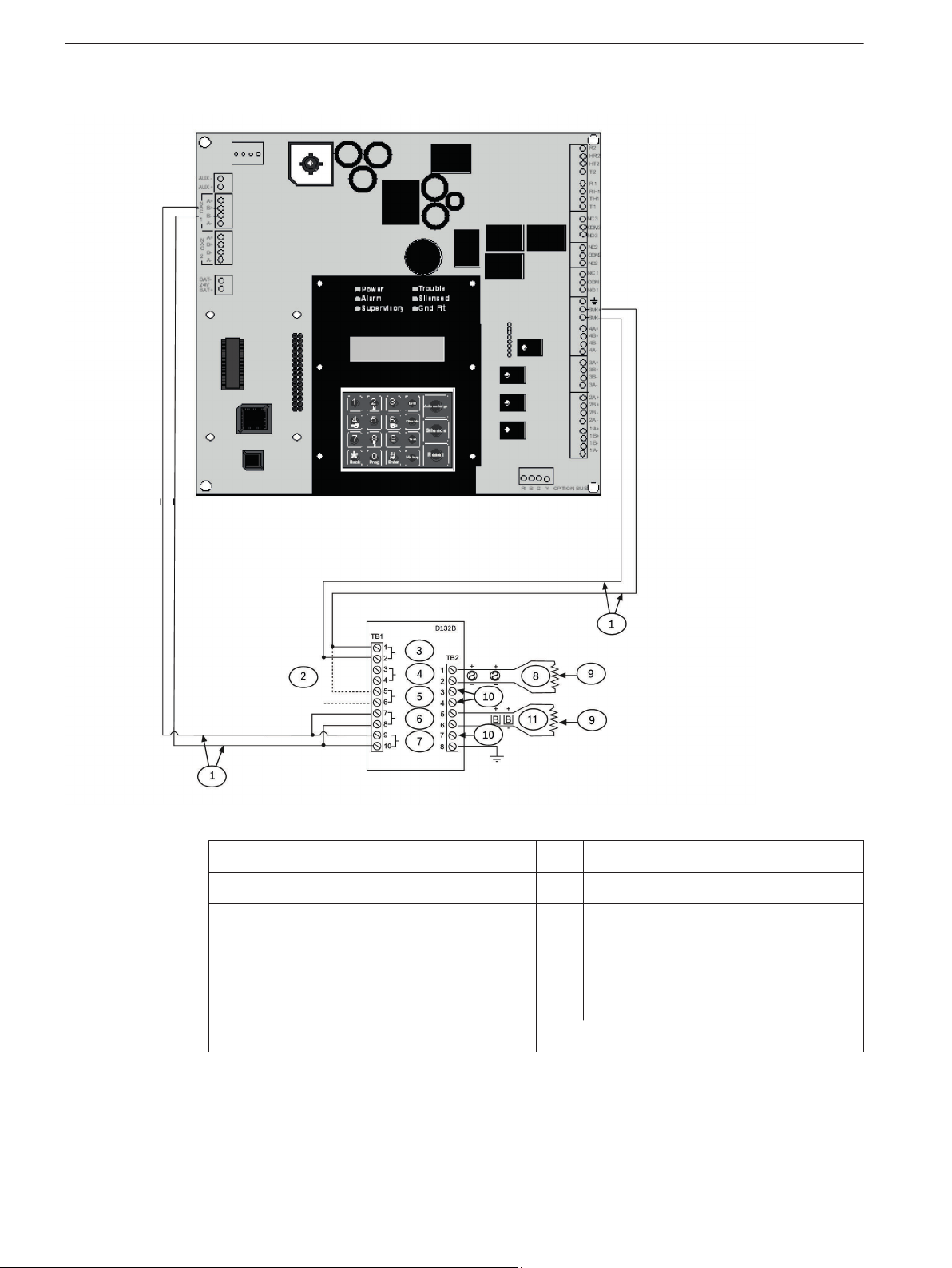

For the location of the major items on the FPD‑7024 Control Board, see the following figure:

Figure 2.1: FPD-7024 ControlBoard

1 TELCO terminal strip 7 Keypad

2 Relay terminal strip 8 D7039 MUX expansion module

connector pins

3 Smoke power terminal strip 9 LCD display

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 9

Fire Alarm Control Panels Overview | en 9

4 Zone input terminal strip 10 NAC terminal strip

5 Option bus terminal strip 11 Auxiliary power terminal strip

2.2

2.2.1

6 FPC-7034 point expander connector

pins

Components

On-board conventional points

All on-board points and points implemented with the FPC-7034 work with two- or four-wire

detectors. The system has an optional alarm verification feature.

Number of two-wire circuits Four circuits, expandable to eight using an

FPC-7034 Expander

Type of Circuit Class B, Style B and Class A, Style D as

needed)

EOL Resistor 2.21 kΩ (P/N: 25899 or F01U034504), UL

listed

Supervisory Existing 8 mA to 20 mA

Required Existing for Alarm 25 mA

Maximum Short Circuit Existing 45 mA

Maximum Line Resistance 150 Ω

Circuit Voltage Range 20.4 VDC to 28.2 VDC

2.2.2

Maximum Detectors per Point 20 detectors (two-wire)

Total Detector Standby Existing 3 mA maximum

Response Time

Dirty Detector Monitoring Implements Bosch Security Systems, Inc.

1

See , 24

Table 2.1: Two-wire circuits

All on-board points, and points activated with the FPC‑7034 Four Point Expander, are

continuously monitored for detectors signaling a dirty condition using the Bosch Security

Systems, Inc. Chamber Check and GE Interlogix, Inc. CleanMe protocols. To prevent nuisance

reports, a two-minute delay occurs before a dirty detector is annunciated. A six-minute delay

occurs after the detector restores from the dirty condition before the control panel restores

the condition.

1

Either fast (500 ms) or programmable (from

1 second to 89 seconds)

Chamber Check and GE Interlogix, Inc.

CleanMe protocol to monitor conventional

loops for dirty detectors.

Off-board addressable points (with D7039 Multiplex Expansion Module)

The D7039 Multiplex Expansion Module adds:

– Two Class B, Style 4 or one Class A, Style 6 Signaling Line Circuits (SLCs)

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 10

i

i

10 en | Overview Fire Alarm Control Panels

– Each point is individually supervised for proper connection to the common bus (when

over ten points are troubled, up to ten troubles are shown per bus and the balance of the

troubles is indicated by a common bus failure message).

– Response time can be set to fast, or programmed from 1 to 89 seconds.

– Input points on the SLCs are implemented with a D7042 Eight Input Remote Module.

2.2.3

2.2.4

2.2.5

2.2.6

Enclosure Housing

The standard enclosure is 18 ga., cold-rolled steel, and measures 20.75 in. x 15 in. x 4.25 in.

(52.7 cm x 38.1 cm x 10.8 cm). A keyed lock is included, and the LEDs and LCD display are

visible through the door.

Remote LCD Keypads

Maximum number of keypads: Four FMR‑7033 LCD Fire Keypads.

For wiring Requirements, see Option bus wiring requirements, 34

Remote LED Annunciators

Maximum number of annunciators: Eight D7030 eight-zone LED Annunciators.

For wiring Requirements, see Option bus wiring requirements, 34

D7032 - use with the D7030X

When a D7032 Eight-Zone LED Annunciator Expander is connected to the D7030X, eight

additional LED zones appear. This allows the D7030X/D7032 combination to show 16 LED

zones. Up to eight D7030X/D7032 combinations can be connected to the FPD‑7024 Fire Alarm

Control Panel.

Notice!

Each D7030X processes 16 zones of information. If no D7032 is attached, only the lower eight

zones are shown.

Notice!

The column labeled “shown on D7030X” in the LED assignments table below applies regard-

less if an attachment of a D7032 to any D7030X is made.

For LED assignments when up to eight D7030X/D7032 combinations are used, see the

following table:

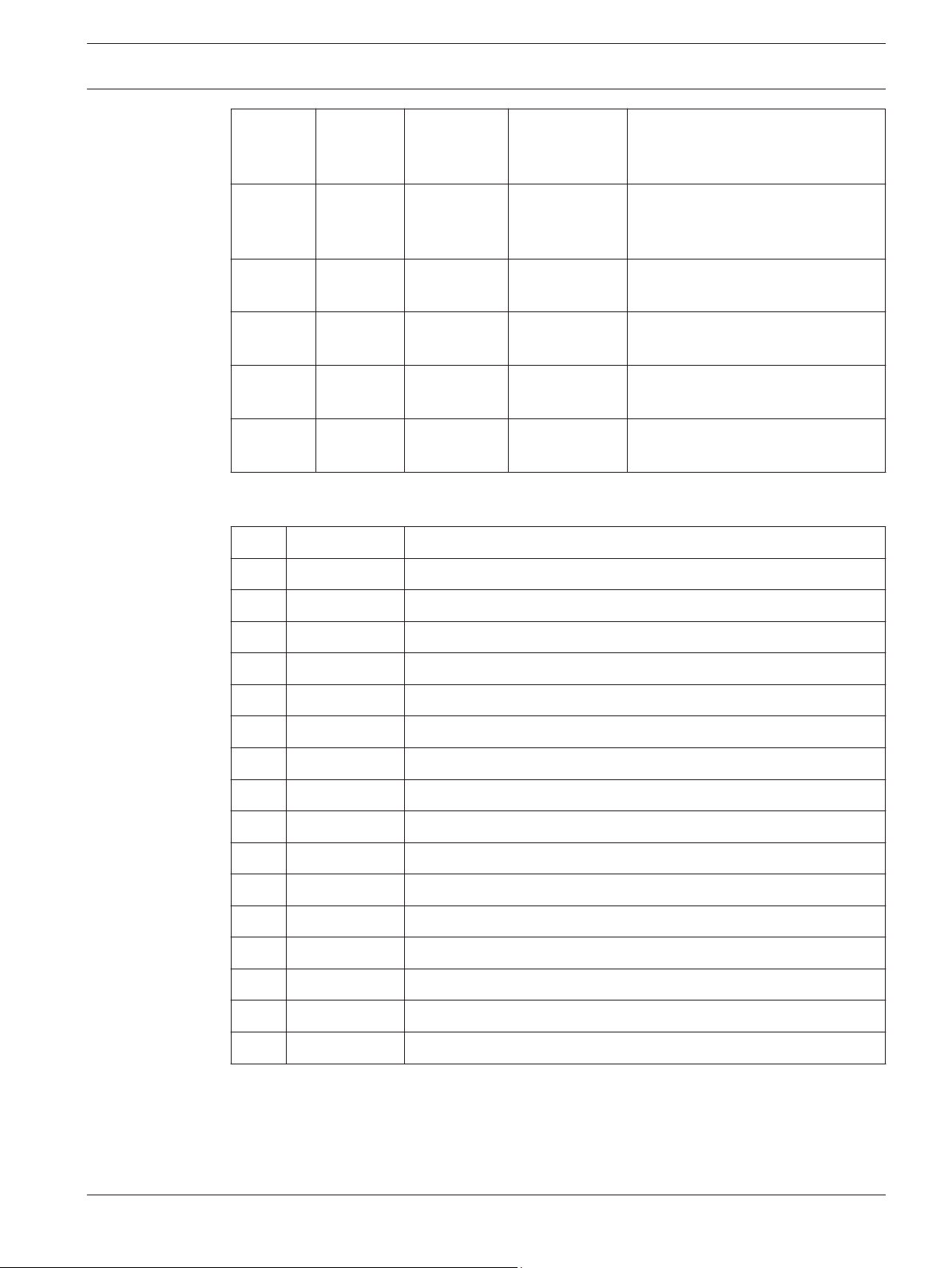

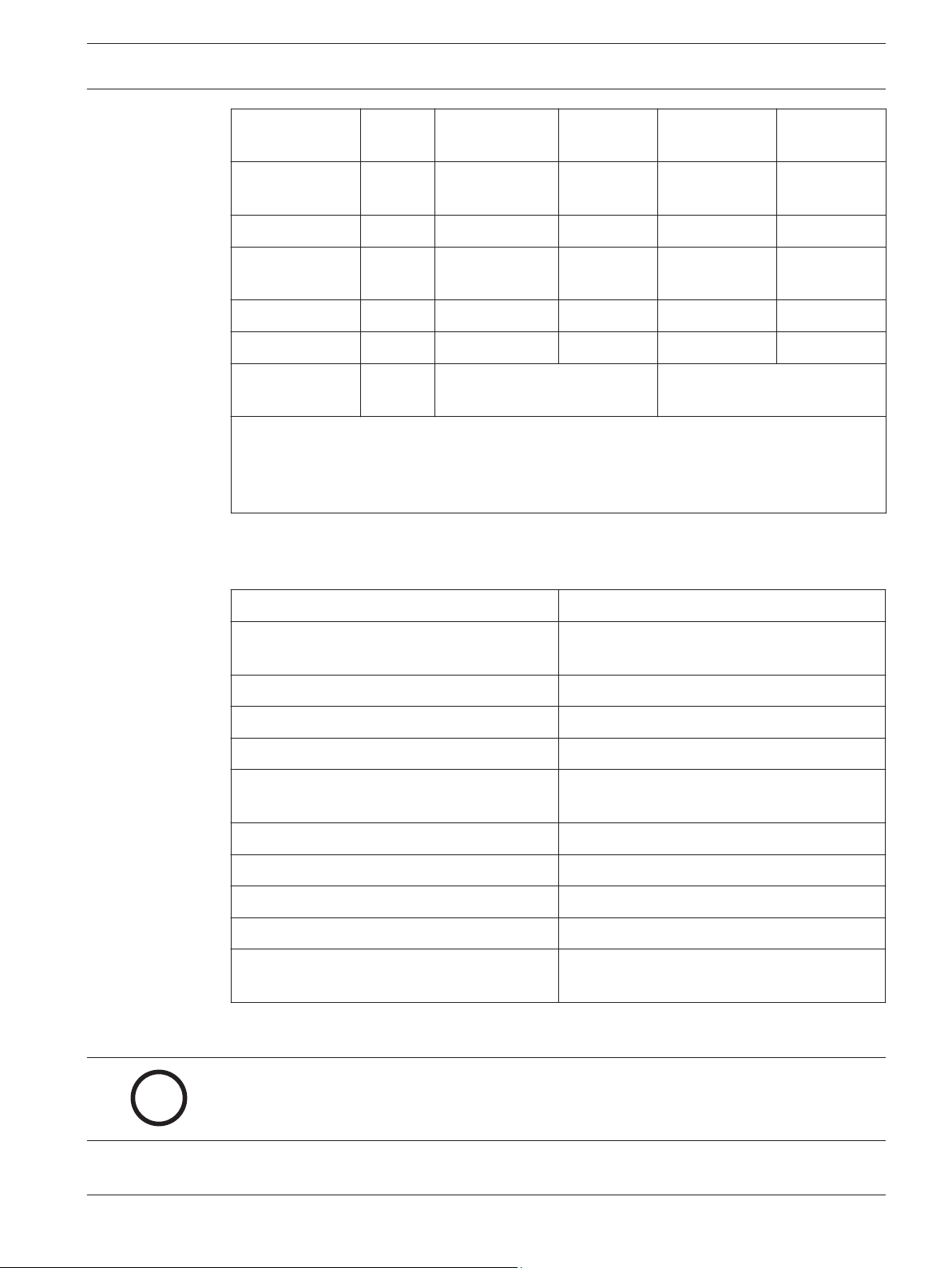

D7030X zones

covered

1 1 to 16 1 to 8 9 to 16 Combination with lowest option

2 17 to 32 17 to 24 25 to 32 Combination with second lowest

3 33 to 48 33 to 40 41 to 48 Combination with third lowest

shown on

D7030X

shown on

D7032 (if

attached)

comments

bus address (such as Address 1)

option bus address (such as

Address 2)

option bus address (such as

Address 3)

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 11

Fire Alarm Control Panels

Overview | en 11

D7030X zones

covered

shown on

D7030X

shown on

D7032 (if

comments

attached)

4 49 to 64 49 to 56 57 to 64 Combination with fourth lowest

option bus address (such as

Address 4)

5 1 to 16 1 to 8 9 to 16 Fifth combination repeats first

combination

6 17 to 32 17 to 24 25 to 32 Sixth combination repeats second

combination

7 33 to 48 33 to 40 41 to 48 Seventh combination repeats third

combination

8 49 to 64 49 to 56 57 to 64 Eighth combination repeats fourth

combination

Table 2.2: LED assignments for LED Annunciators

For the LED display for Zones 49 to 64, see the following table.

LED

Zone Description

1 49 User defined

2 50 User defined

3 (reserved)

4 52 General fire alarm monitor waterflow (non-silencable)

5 53 General fire alarm monitor (silencable)

6 (reserved)

7 55 General Supervisory (silencable)

8 56 General Waterflow (silencable)

9 (reserved)

10 58 General supervisory alarm (non-silencable)

11 (reserved)

12 (reserved)

13 61 General waterflow alarm (non-silencable)

14 (reserved)

15 63 General alarm monitor waterflow (non-silencable)

16 (reserved)

Table 2.3: LED display for Zones 49 to 64

See also

– D7032 - use with the D7030X, 10

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 12

i

i

12 en | Overview Fire Alarm Control Panels

2.2.7

Communicator

The communicator can report to two phone numbers or IP addresses with full single, double,

and back-up reporting. Communicates in SIA, Modem IIIa2, Contact ID, BFSK, and 3/1 and 4/2

Tone burst formats (available communication formats depend on phone or IP connection).

Notice!

The communicator must be enabled and configured to operate. The communicator and phone

line monitors are disabled in the default factory configuration.

Phone Line and Phone Number/IP Selection: To ensure the delivery of critical reports, the fire

panel has two phone lines and two phone numbers or IP addresses that can be used for

reporting. Reports can be directed to one or both of two phone numbers or IP addresses

using the Report Steering feature in the control panel programming. Note that Account

Number 1 is used with Phone Number/IP 1, and Account Number 2 is used with Phone

Number/IP 2. Except for test reports, the control panel automatically selects the phone line or

IP address to use. If the report is not successful after two attempts on Line 1, the control

panel automatically switches and uses Phone Line 2. One exception is when test reports

(manual or automatic) are sent. Test reports are sent every 4 hours to 28 days. Each time a

test report is sent, the control panel alternates phone lines. This happens even if the monitor

says the line is bad. If the user sends two manual test reports, both phone lines can be tested.

The first report uses one line, and the second uses the other line. During normal operation,

the automatic test uses a different line each day. Because the control panel automatically

selects which line to use, both phone lines must use the same dialing sequences for sending

reports. For example, a line that requires a 9 to be dialed for an outside line cannot be paired

with a line that does not require a 9.

For more information on report steering, see Report Steering, 83.

Notice!

PBX lines and ground start lines do not comply with NFPA requirements for digital communi-

cation.

While the control panel is idle, the FACP monitors the primary and alternate telephone lines by

monitoring the line for trouble. The FACP monitors each line every 12 seconds. When a trouble

still exists after three samples (36 seconds), the FACP sends a trouble report and activates

the yellow trouble LED and trouble relay.

Danger!

If the central station receives the automatic test report only every other day, this indicates

that one phone line at the protected premises is inoperative.

Correct this condition immediately, because other critical reports can be delayed when the

communicator is trying to send the test signal through the inoperative phone line (once each

48 hours).

Supplemental Reporting: While two independent phone lines are required for UL864 Central

Station service, the FACP can be configured with one phone line if the control panel is used

only for supplemental reporting on a local, remote station or auxiliary system.

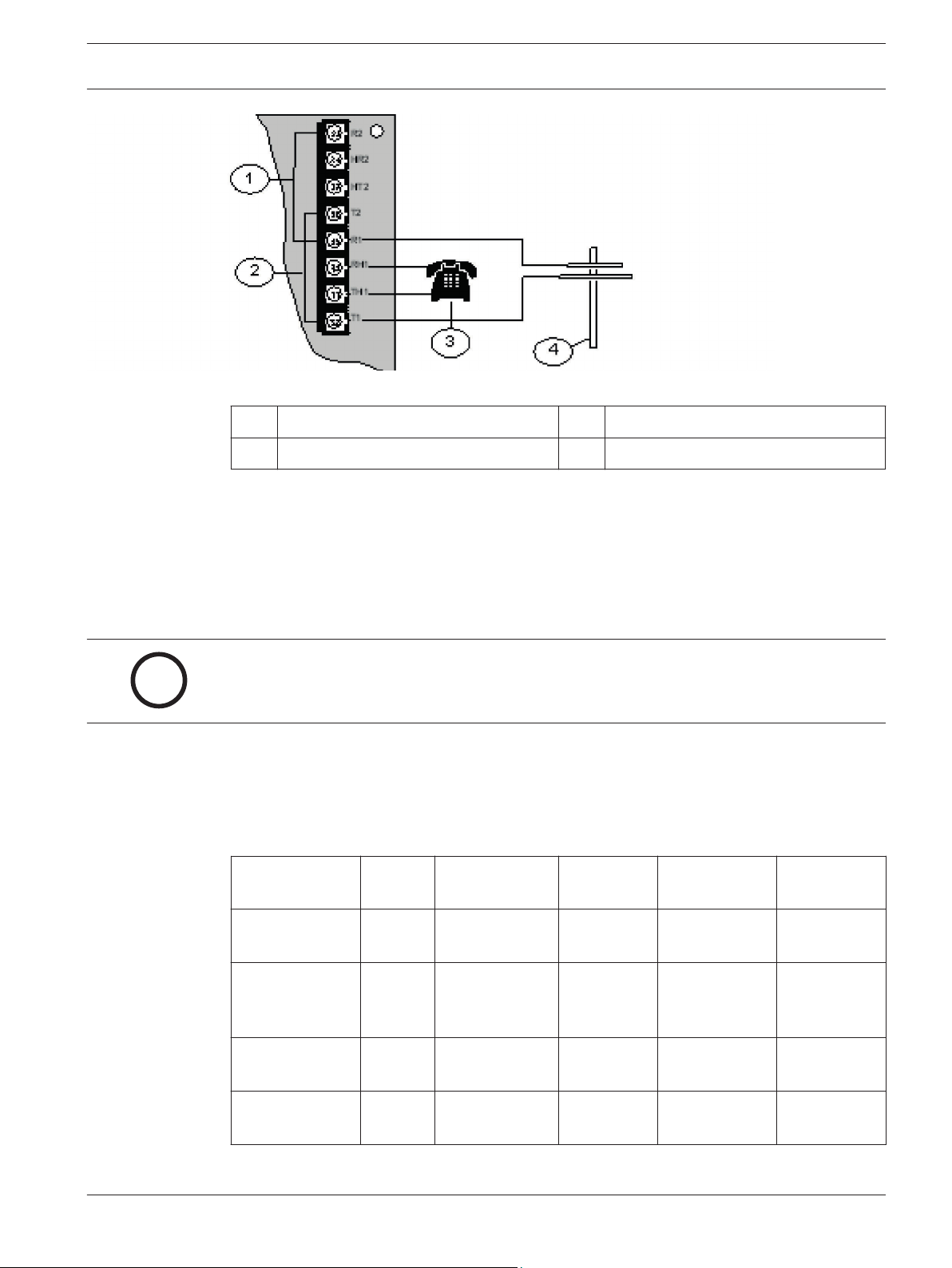

To install the control panel with only one phone line, connect a jumper from T1 to T2 and a

jumper from R1 to R2. These jumper connections are shown in the following figure:

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 13

i

Fire Alarm Control Panels Overview | en 13

Figure 2.2: Supplemental Reporting

1 Jumper from R1 to R2 3 House phone

2 Jumper from T1 to T2 4 TELCO line

2.2.8

2.2.9

2.2.10

Users

The system allows up to 16 individual users, or up to 100 users when the D7039 is installed. A

personal identification number (PIN, the four-digit code entered at the keypads) and an

authority level to determine which functions can be performed can be assigned to each user.

For PINs, see Personal identification numbers (PINs), 47.

Lightning protection

Notice!

This system is intended for installation entirely within one building.

Metal-oxide varistors (MOVs) and spark gaps provide protection from lightning surges and

static discharges.

Battery backup calculation

To calculate the standby battery capacity required by NFPA when using the FPD‑7024, see the

two following tables:

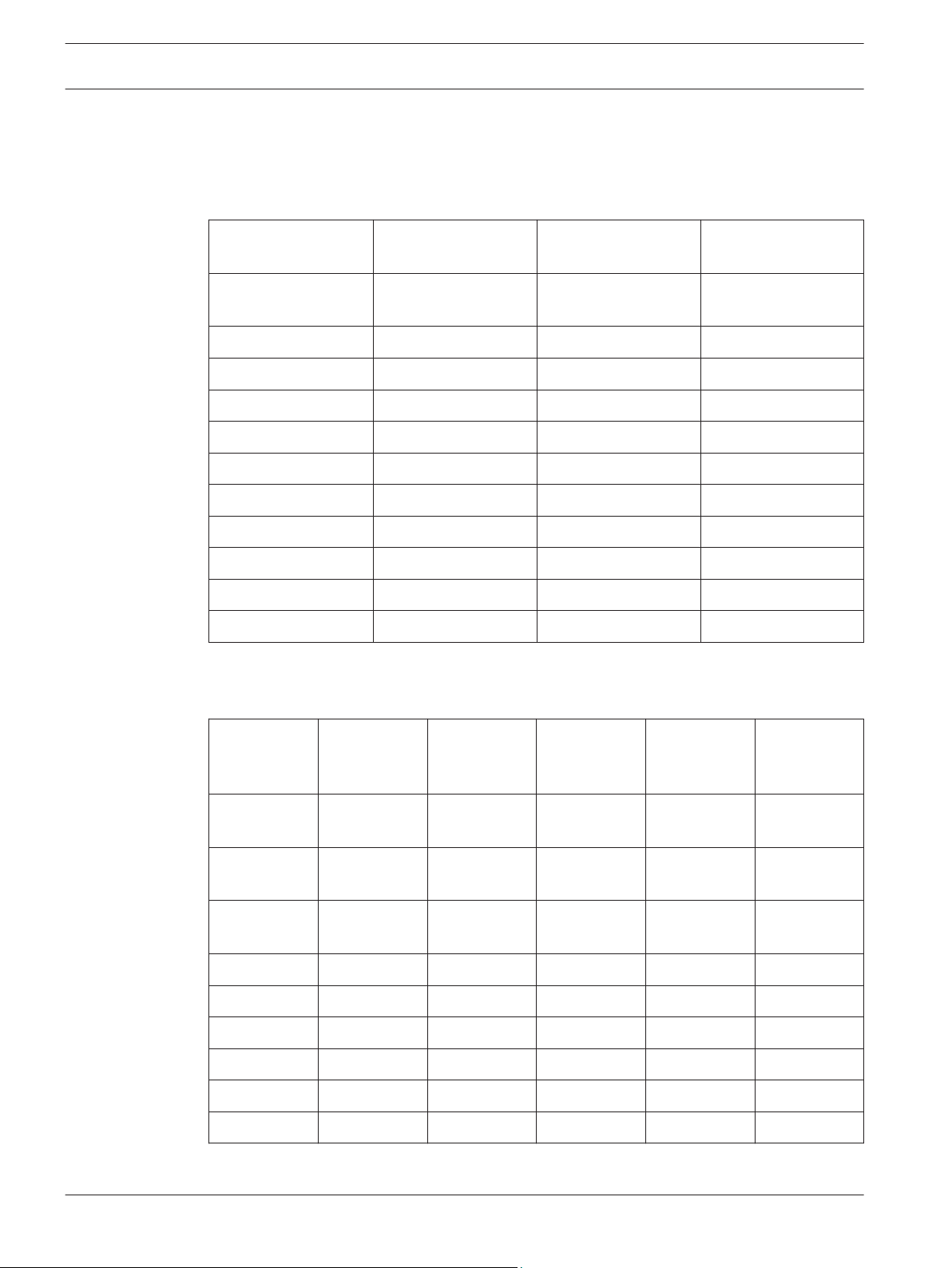

Device Quantity Standby

existing/device

FPD‑7024

Control Panel

1 200 mA 200 mA 380 mA 380 mA

Total

standby

Alarm existing/

device

Total alarm

FPC‑7034

Four‑Point

Expander

D7035/B Octal

1

Relay

D7048/B Octal

Driver Module

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

44 mA 156 mA

8 mA + 30 mA 2 8 mA + 30 mA 2

10 mA 10 mA

Page 14

14 en | Overview Fire Alarm Control Panels

Device Quantity Standby

existing/device

FMR‑7036

80 mA 100 mA

Annunciator

Keypad

D7030X

27 mA 132 mA

Eight‑Point LED

Annunciator

D7030X‑S2

1

35 mA 175 mA

Eight‑Point LED

Annunciator

D7030X‑S8

35 mA 175 mA

Eight-Point LED

Annunciator

D7032 Eight‑

1 mA 90 mA

Point LED

Annunciator

Expander

FMR‑7033

Keypad

1

80 mA 100 mA

Total

standby

Alarm existing/

device

Total alarm

D7039 MUX

Expansion

Module

D7042/B

Addressable

Eight Point Input

D7050 MUX

Photoelectric

Smoke Detector

D7050TH MUX

Photoelectric

Smoke Detector

FMM-7045 MUX

Pull Station

D7044 MUX

Single Input Fire

D7044M MUX

Mini Contact

Module

150 mA 150 mA

18 mA 18 mA

0.50 mA 0.56 mA

0.50 mA 0.56 mA

0.55 mA 0.55 mA

0.55 mA 0.55 mA

0.55 mA 0.55 mA

D7052 MUX Dual

0.55 mA 0.55 mA

Input Fire

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 15

i

Fire Alarm Control Panels Overview | en 15

Device Quantity Standby

existing/device

D7053 MUX I/ O

0.70 mA 0.70 mA

Total

standby

Alarm existing/

device

Total alarm

Module Fire

Smoke Detectors

Bells, Horns, and

so on

Other Sensors

Other

Grand Total

Standby Existing

1

The 24 VDC existing requirements for the D7030X, FMR-7033 and D7035 are shown at 75%

Grand Total

Alarm Existing

of the 12 VDC level shown on the specification sheets for these models. The FPD-7024

regulates 24 VDC power from the battery to 12 VDC for these accessories.

2

Add 30 mA for each relay activated

Table 2.4: Standby battery capacity calculations

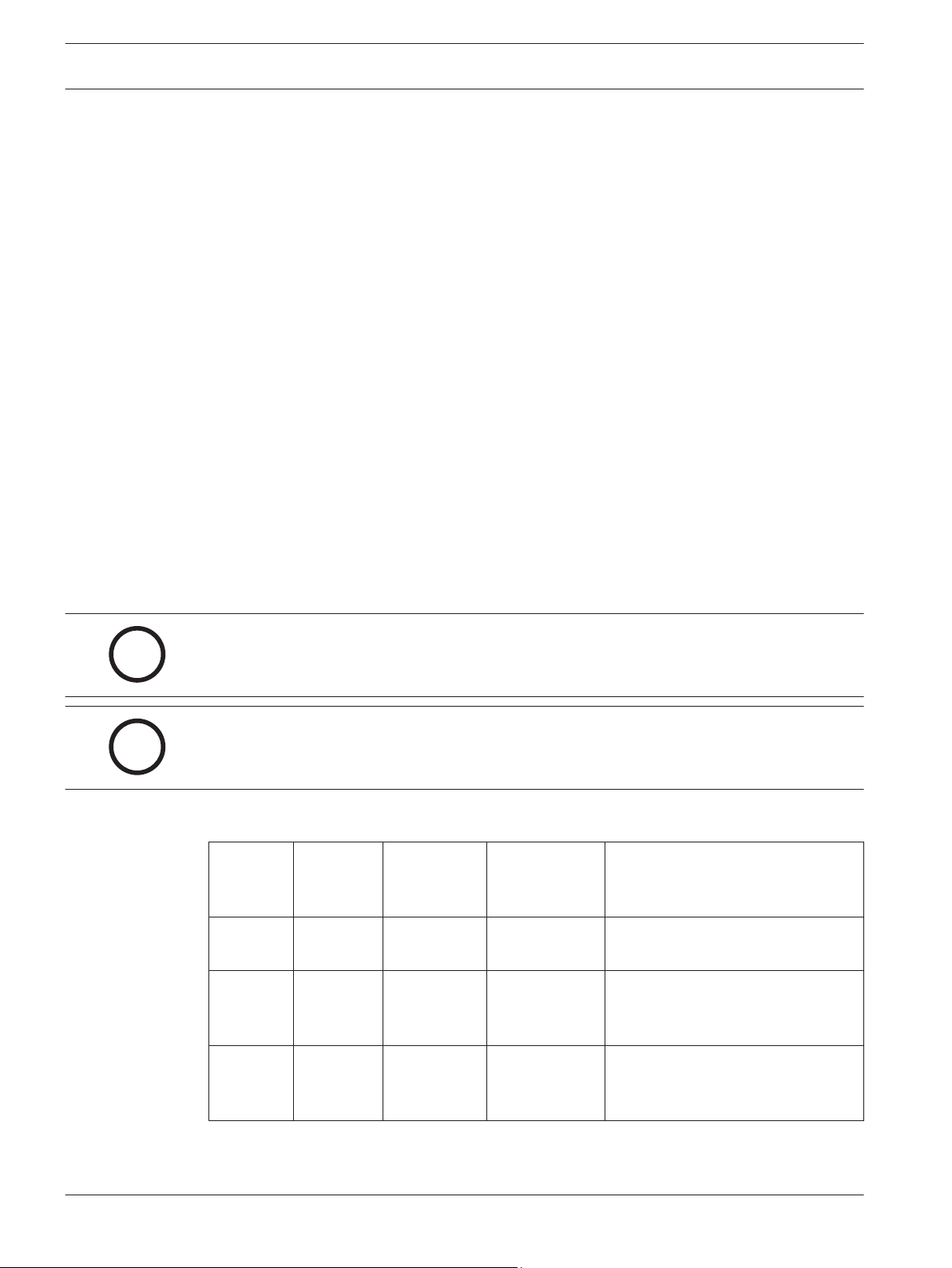

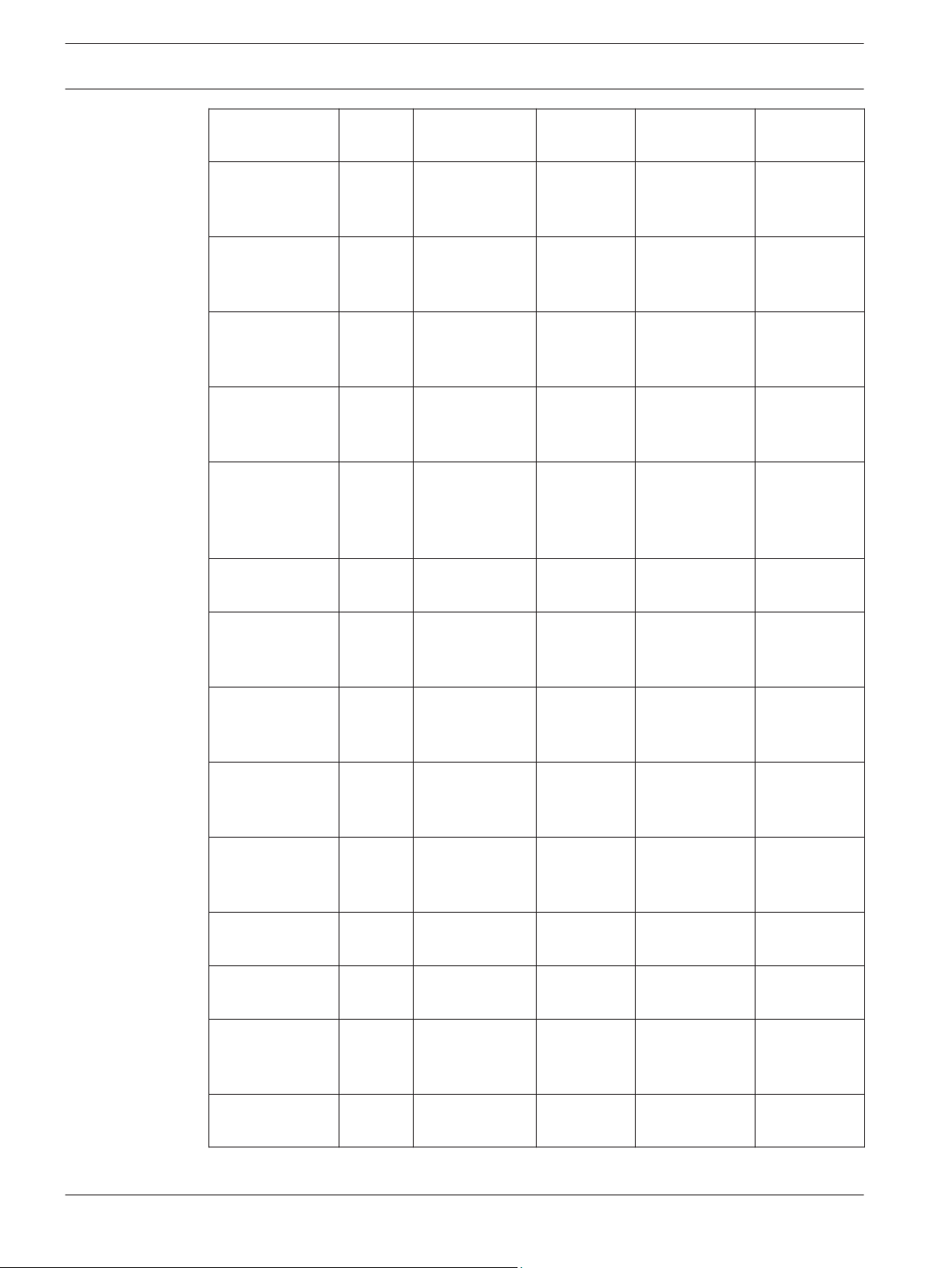

The units shown in the following table are Amp hours (Ah), and the calculations include a 20%

derating factor.

Grand Total Standby Existing (in amps)

Total Hours of Standby Required

CS

HS

(usually 24 or 60):

Total Standby Capacity (multiply CS x HS) TS= CS x HS

Grand Total Alarm Existing (in amps) CA

Total Hours of Alarm Time Required

HA

(usually 0.083 o 0.25):

Total Standby Capacity (multiply CA x HA) TA= CA x HA

Total Capacity Required (add TA + TS): TC = TA + TS

Required Capacity with 20% Derating

C = TC x 1.2

(TC x 1.2)

Table 2.5: Required battery size calculation

Notice!

The required battery size to support the system can be calculated using the tables for Stand-

by load battery size, 16 and Alarm load battery size, 16.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 16

16 en | Overview Fire Alarm Control Panels

2.2.11

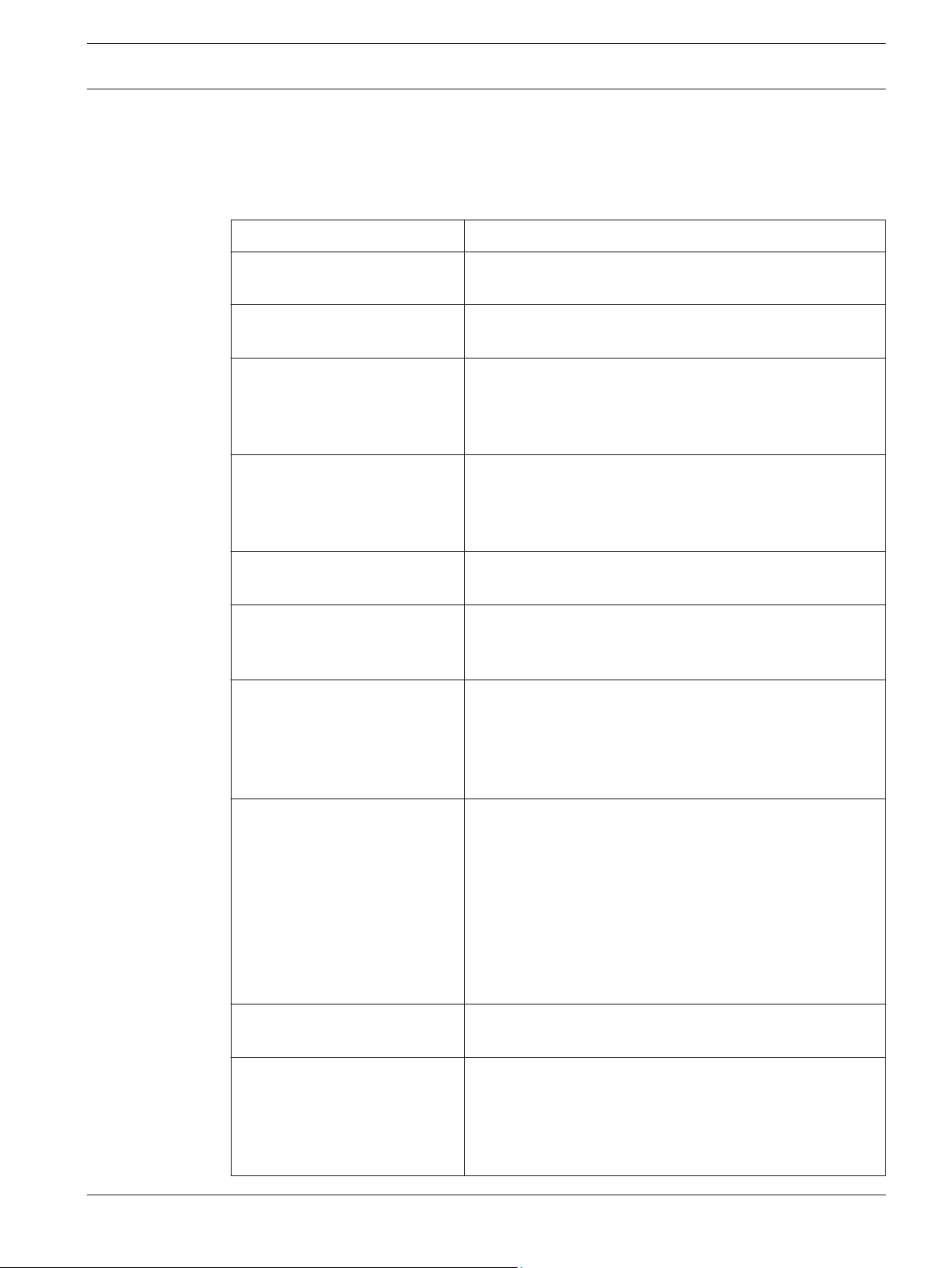

Required batteries for existing load

Use the following procedure to determine the battery requirements for your system:

– Estimate the size of the battery required to support the standby load using the following

table:

Standby load battery

size chart

Grand Total Standby

Existing

100 to 200 mA 5.8 11.5 14.4

201 to 300 mA 8.6 17.3 21.6

301 to 400 mA 11.5 23.0 28.8

401 to 500 mA 14.4 28.8 36.0

501 to 600 mA 17.3 34.6 X

601 to 700 mA 20.2 X X

701 to 800 mA 23.0 X X

801 to 900 mA 25.9 X X

901 to 1000 mA 28.8 X X

Capacityr required

for 24 hours

Capacity required for

48 hours

Capacity required for

60 hours

1001 to 1100 mA 31.7 X X

Table 2.6: Standby load battery size (Ah)

– Estimate the size of the battery required to support the alarm load using the following

table:

Alarm load

battery size

chart

Grand Total

Capacity

required for

5 minutes

Capacity

required for

10 minutes

Capacity

required for

15 minutes

Capacity

required for

30 minutes

Capacity

required for

45 minutes

Alarm Existing

250 to

0.1 0.1 0.2 0.3 0.5

500 mA

501 to

0.1 0.2 0.3 0.6 0.9

999 mA

1.0 to 1.5 A 0.2 0.3 0.5 0.9 1.4

1.6 to 2.0 A 0.2 0.4 0.6 1.2 1.8

2.1 to 2.5 A 0.3 0.5 0.8 1.5 2.3

2.6 to 3.0 A 0.3 0.6 0.9 1.8 2.7

3.1 to 3.5 A 0.4 0.7 1.1 2.1 3.2

3.6 to 4.0 A 0.4 0.8 1.2 2.4 3.6

Table 2.7: Alarm load battery size (Ah)

– Add the results together for the total battery size.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 17

Fire Alarm Control Panels Overview | en 17

– Select the next larger standard battery for the system.

If the results show a requirement for a battery over 40 Ah, reduce the existing load or add an

external regulated fire protective signaling power supply.

2.2.12

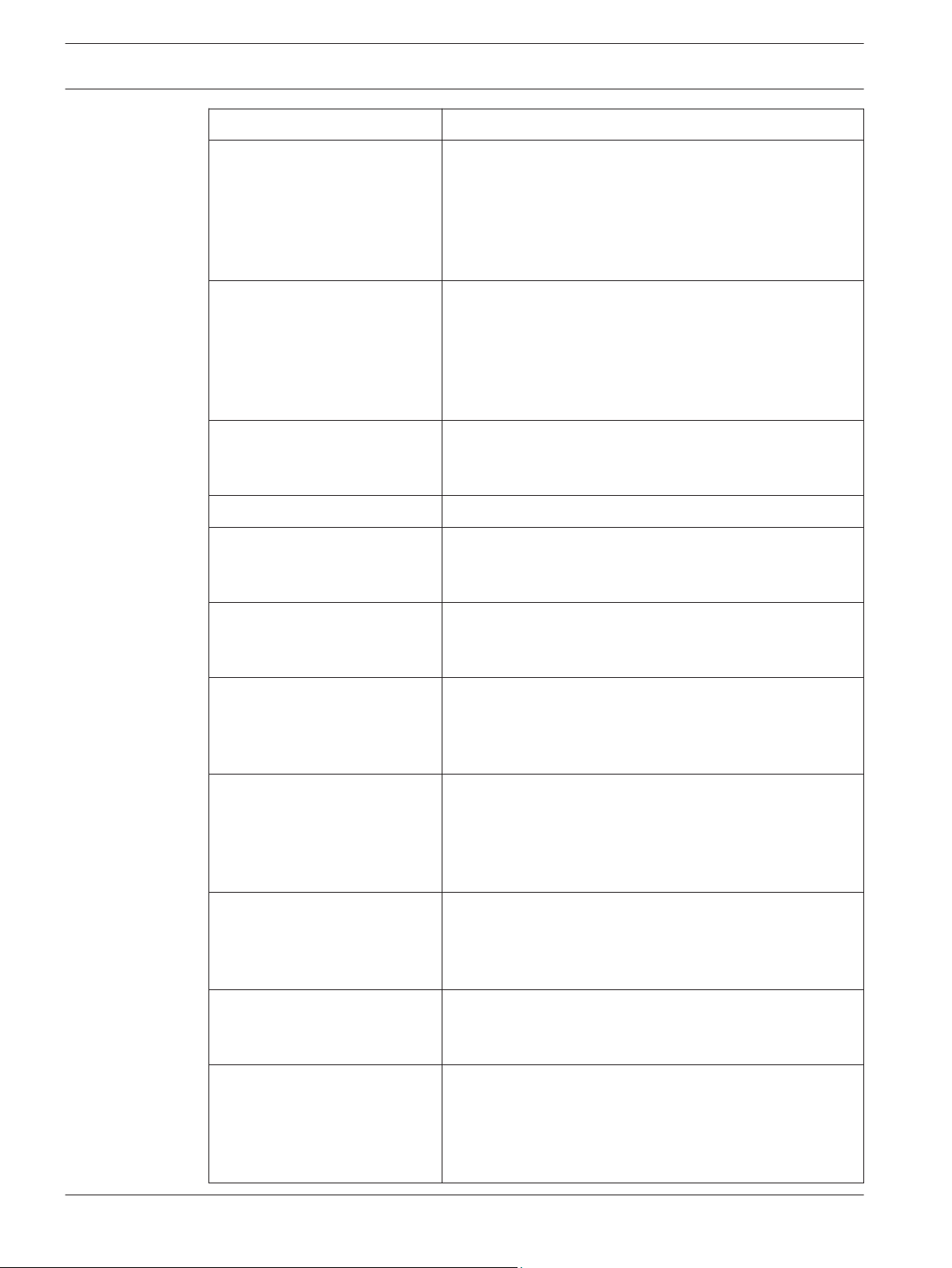

Compatible devices

Device Function

D7030 Eight Point LED

Annunciator

D7030X Eight Point LED

Annunciator

D7030X‑S2 Eight Point LED

Annunciator

D7030X‑S8 Eight Point LED

Annunciator

D7032 Eight Point LED

Annunciator Expander

FMR‑7033 Alphanumeric LCD

Keypad

Identifies the location of a fire alarm for up to eight zones

allowed per system.

Identifies the location of a fire alarm for up to eight zones

allowed per system.

An eight zone LED annunciator, of which two zones are

reserved for supervisory functions. It has Power and

Trouble LEDs plus eight zone LEDs that can be labeled

individually.

An eight-zone LED annunciator, of which all eight zones are

reserved for supervisory functions. It has Power and

Trouble LEDs plus eight-zone LEDs that can be labeled

individually.

Attaches to a D7030X and identifies the location of a fire

alarm for eight additional zones.

The FMR‑7033 LCD Keypad combines remote annunciator

and controller functions for the FPD‑7024. Up to four

keypads can be connected.

FPC‑7034 Four Point Expander Allows the FPD‑7024 Control Panel to support four

additional loops. The FPC‑7034 plugs into the control panel

and provides four Class B, Style 4 loops that are identical

in characteristics to the loops on the control panel. One

FPC‑7034 is allowed per system.

D7035/B Octal Relay Module Provides eight Form C relay outputs for addition to the

system. The outputs are programmable and can be

activated by system events. Each output operates

independently of the other seven outputs for complete

flexibility. The D7035 connects to the option bus; up to

two are allowed per system. The D7035B comes installed

on a mounting skirt.

For required enclosure modification, see also the D7035

Installation Guide.

FMR‑7036 Fire Annunciator

Keypad

FPP‑RNAC‑8A‑4C Remote NAC

Power Supply

Establishes the location of a fire alarm.

Adds four NFPA 72 Class B, Style Y Notification Appliance

Circuits through the option bus and is supervised by the

control panel. The FPP‑RNAC‑8A‑4C connects to the option

bus of the FPD‑7024 control panel and up to four are

allowed per system.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 18

18 en | Overview Fire Alarm Control Panels

Device Function

D7039 Multiplex Expansion

Module

Provides either 2 two-wire (Class B, Style 4) multiplex

buses or 1 four-wire (Class A, Style 6) multiplex bus. In

Class A mode, up to 120 addressable points can be added.

In Class B Mode, up to 247 addressable points can be

added. The D7039 connects directly to the control panel.

One is allowed per system.

D7042/B Eight‑Input Remote

Module

Provides eight Class B, Style 4 input points. Connect up to

15 modules to MUX Bus A, and 15 on MUX Bus B. The

D7042 is powered by 12 VDC supplied by the option bus

power terminals, in addition to the two‑wire data

connection. The D7042 can not be used on a signal line

circuit (SLC) configured for Class A, Style 6 operation.

D7048/B Octal Driver Module Provides eight open‑collector transistor outputs for

addition to the FPD‑7024 Fire Alarm Control panels. It

connects to the control panels through the option bus.

FMM-7045 MUX Pull Station UL Listed fire alarm initiating device.

D7044 MUX Single Input

Module

Connects a normally‑open contact device to the multiplex

bus of the FPD‑7024 with a supervised local loop. The

D7044 draws operating power from the FPD‑7024.

D7044M MUX Mini Contact

Module

Connects a contact device to the multiplex bus of the

FPD‑7024 with a supervised input loop. The D7044 draws

operating power from the FPD‑7024.

D7052 MUX Dual Input Fire Connects to the multiplex bus of the FPD‑ 7024 and

provides two supervised input zones for connecting

conventional normally-open inputs. The D7052 draws

operating power from the FPD‑7024.

D7053 MUX I/O Module Fire Connects to the multiplex bus of the FPD‑7024 and

implements a supervised local loop, and a Form C relay

output. Up to 20 modules can be connected to each MUX

bus. The D7053 draws operating power from the

FPD‑7024.

D7050/TH MUX Smoke Detector The D7050/TH is a photo-electric smoke detector with a

heat option. It connects to the multiplex bus of the

FPD‑7024. The D7050 draws operating power from the

FPD‑7024.

DX4020 / B420 models The Conettix DX4020 and B420 models are communication

devices that manages secure, two-way IP communications

over Ethernet networks.

ITS‑DX4020‑G The ITS-DX4020-G enables two-way IP or dialed

communications over a commercial GPRS/GSM network.

Typical applications are event reporting to a central

monitoring station and remote access to Bosch control

panels.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 19

Fire Alarm Control Panels Overview | en 19

Table 2.8: Compatible devices

Install D7042 modules only at addresses:

9 17 25 33 41 49 57 65

73 81 89 97 105 113 121 129

137 145 153 161 169 177 185 193

201 209 217 225 233 241

Do not install D7052 and D7053 modules at these addresses:

16 24 32 40 48 56 64 72

80 88 96 104 112 120 128 136

144 152 160 168 176 184 192 200

208 216 224 232 240 248 255

Table 2.9: Address restrictions for the D7042, D7052, and D7053

2.3

Parts List

The FPD‑7024 comes with:

– One FPD-7024 Control/Communicator in static-resistant bag

– One enclosure with transformer

– One hardware pack containing the hardware necessary for installing the control panel in

the enclosure

– One enclosure lock, washer, and keys

– Six end-of-line (EOL) resistors

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 20

i

i

20 en | Fire Safety Fire Alarm Control Panels

3

3.1

3.1.1

Fire Safety

Danger!

No fire detection device or system is 100% foolproof.

This fire alarm system can provide early warning of a developing fire. Such a system, however,

does not ensure protection against property damage or loss of life resulting from a fire. Any

fire alarm system can fail to warn for any number of reasons (such as smoke not reaching a

detector that is behind a closed door).

Notice!

This system must be regularly tested (when installed, when modified, and at least annually

thereafter) to ensure continued performance.

When considering detectors for residential applications, refer to NFPA Standard 72, The

National Fire Alarm Code. This standard is available at a nominal cost from: The National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

Smoke detector layout

General considerations

Proper location of detection devices is one of the most critical factors in a fire alarm system.

Smoke detectors should not be installed in dead air spaces or close to ventilating or air

conditioning outlets because smoke can be circulated away from the detector. Locations near

air inlets are favored.

Avoid areas subject to normal smoke concentrations such as kitchens, garages, or near

fireplaces.

Do not install smoke detectors where normal area temperatures are above +100°F (+38°C) or

below +32°F (0°C).

Avoid areas of high humidity and dust concentrations.

Place the edge of ceiling mounted detectors no closer than 4 in. (10 cm) from any wall.

Place the top edge of wall-mounted detectors between 4 in. and 12 in. (10 cm and 30 cm)

from the ceiling.

For exact mounting information, refer to the instructions provided with the smoke detectors.

3.1.2

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Family residences

Providing a Fire Warning System: Most fire deaths occur in the home, especially during

sleeping hours. The minimum level of protection requires smoke detectors to be installed

outside of each separate sleeping area and on each additional story of the dwelling.

Notice!

For added early warning protection, install detectors in all separate areas including the base-

ment, bedrooms, dining room, utility room, furnace room, and hallways.

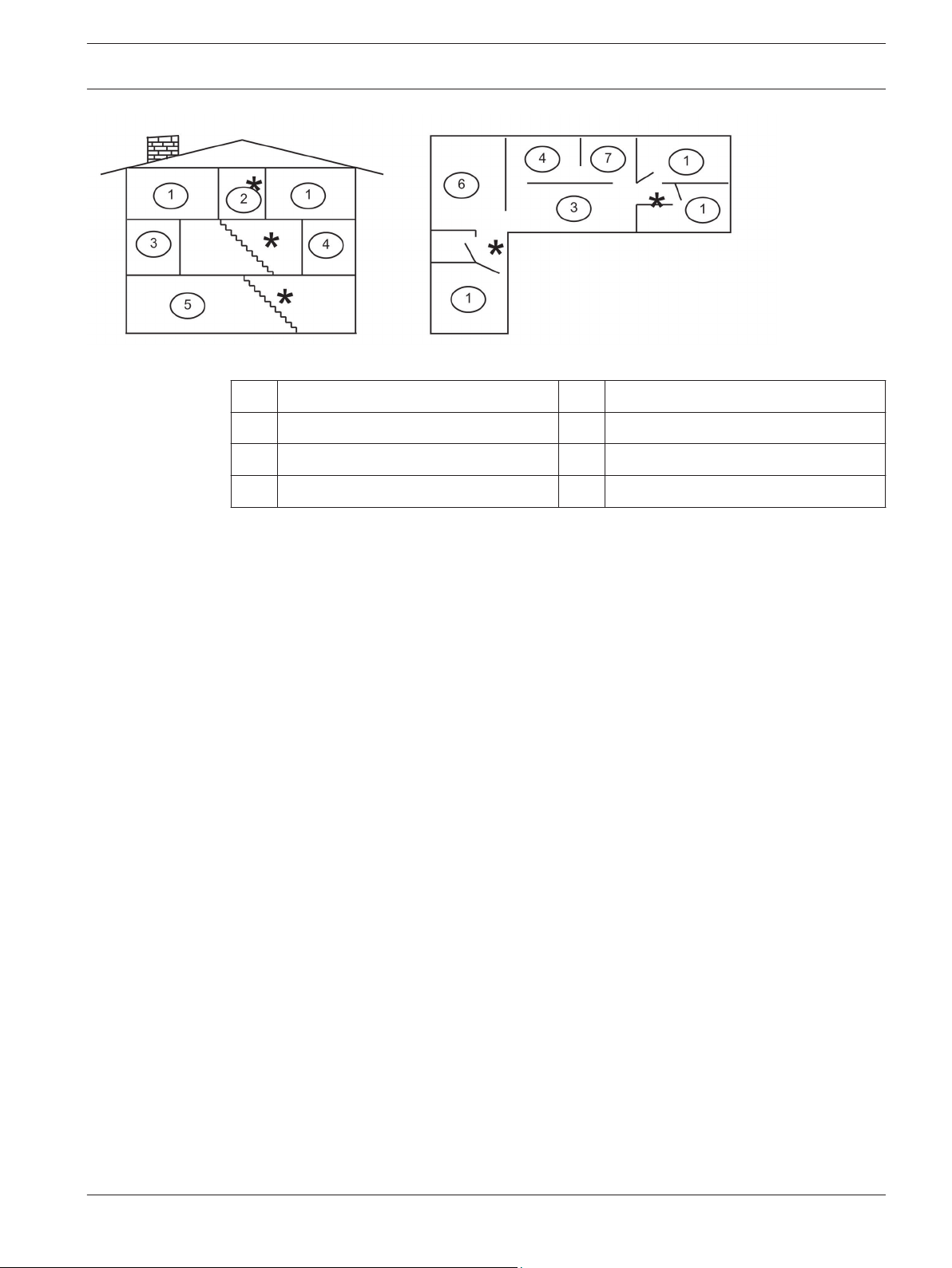

For residential smoke detector locations, see the following figure:

Page 21

Fire Alarm Control Panels Fire Safety | en 21

Figure 3.1: Smoke detector locations in residential settings

1 Bedroom 5 Basement

2 Hall 6 Recreation room

3 Living room 7 Kitchen

4 Dining room * Smoke detector

3.2

Having and practicing an escape plan

A fire warning can be wasted unless the personnel planned in advance for a rapid and safe exit

from the building.

Draw a floor plan of the entire building showing two exits from each sleeping area and two

from the building. Since stairwells and hallways can be blocked during a fire, provide exits

from sleeping area windows. Make copies of the plan and practice it with all personnel.

Arrange a meeting place outside and away from the building. Once out of the building, all

occupants should immediately go to the pre-selected location to be accounted for.

Provide a barricade between personnel and fire, smoke, and toxic gases (such as closing all

sleeping area doors before retiring).

Instruct children on opening their bedroom windows and exiting safely from the building. If

exiting is not possible, teach them to stay at the open window and shout for help until it

arrives.

If a fire alarm occurs after retiring, wake the children by shouting to them from behind your

closed door. Tell them to keep their bedroom doors closed.

If the top of your bedroom door is uncomfortably hot, do not open it. There is most likely fire,

intolerable heat, or smoke on the other side. Shout to all family members to keep their

bedroom doors closed and to exit the building by alternate routes.

If the top of the door is not uncomfortably hot, brace the bottom of the door with your foot,

and the top with one hand, then open the door about one inch. Be prepared to slam the door

shut if there is any pressure against the door or if any hot air rushes in.

If there is no evidence of excessive heat or pressure, leave the room and close the door

behind you. Shout appropriate instructions to all family members and immediately leave the

building by the planned routes. If heavy smoke is present, drop to your hands and knees, or

crawl to remain below the smoke level.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 22

i

22 en | Installation Fire Alarm Control Panels

4

4.1

4.1.1

4.1.2

Installation

Installation guide for UL Listed systems

FPD‑7024 UL Listings

The FPD‑7024 is UL Listed for the following:

– Commercial Fire Alarm (UL Standard UL864)

– Type Service: Auxiliary, Local, Central Station, and Remote Station

– Type Initiating: Automatic, Manual, Sprinkler Supervisory, and Waterflow

Install the control panel according to NFPA 72 for Commercial Fire installations.

Installation considerations

Failure to install and program the control panel according to the requirements in this section

voids the listing mark of Underwriters Laboratories.

– The standby battery capacity is 40 Ah at 24 VDC.

– The total nominal existing must not exceed 1.25 A in standby or 4 A when in alarm.

– The control panel must be mounted indoors and within the protected area.

– Grounding must be according to article 250 of the NEC (NFPA 70).

– Points must be connected to UL Listed, compatible devices.

– The ground wire provided with the enclosure must be connected between the door and

the enclosure using the supplied nuts.

– Do not program the ground start feature.

– Select Phone Monitoring if the digital alarm communicator transmitter (DACT) feature is

used.

4.1.3

UL requirements

Notice!

The system must be tested after installation and after any re-programming, including pro-

gramming performed by downloading.

When used in UL Listed installations, the control panel must conform to certain programming

requirements. For a list of the required program entries specific UL Listed installations, see

the Programming features for UL864 table, 49.

Commercial Fire Alarm (Central Station [DACT] and Local)

Required Accessories

– At least one Bosch Security Systems, Inc. Model F220‑P Smoke Detector with an F220

Family Base; or another UL Listed compatible smoke detector.

– At least one Horn Strobe or Bell (provides 85 dB for UL985 and NFPA 72 requirements;

other UL Listed compatible devices listed for regulated 24 V can be used) is required for

this application and must be installed inside the protected area.

– Four-wire detectors must be used with UL Listed power supervision devices. A

compatible UL Listed four-wire detector is the Bosch Security Systems, Inc. F220‑P in an

F220‑B6 Family Base. A compatible UL Listed relay is the Bosch Security Systems, Inc.

D275.

– All points must be used with the resistor provided.

Report Programming

– Program non-supervisory and supervisory reports for those points used.

– Program trouble reports.

– Set AC Failure Report Delay for a delay of 1 hour to 3 hours.

– Set automatic test report frequency to occur at least every 24 hours.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 23

Fire Alarm Control Panels

Installation | en 23

Timer Programming

– Program Auto Silence Time for not less than five minutes, or to “0” to disable auto-silence

operation.

Point Programming

– For fire points: open = trouble, latching.

Alarm Output Programming

– Program notification appliance circuits to activate from the appropriate input points.

Communications Programming

– If used for Central Station Service, select a communication format compatible with the

central station. Enable monitoring of both phone lines.

UL Listed Accessory Devices

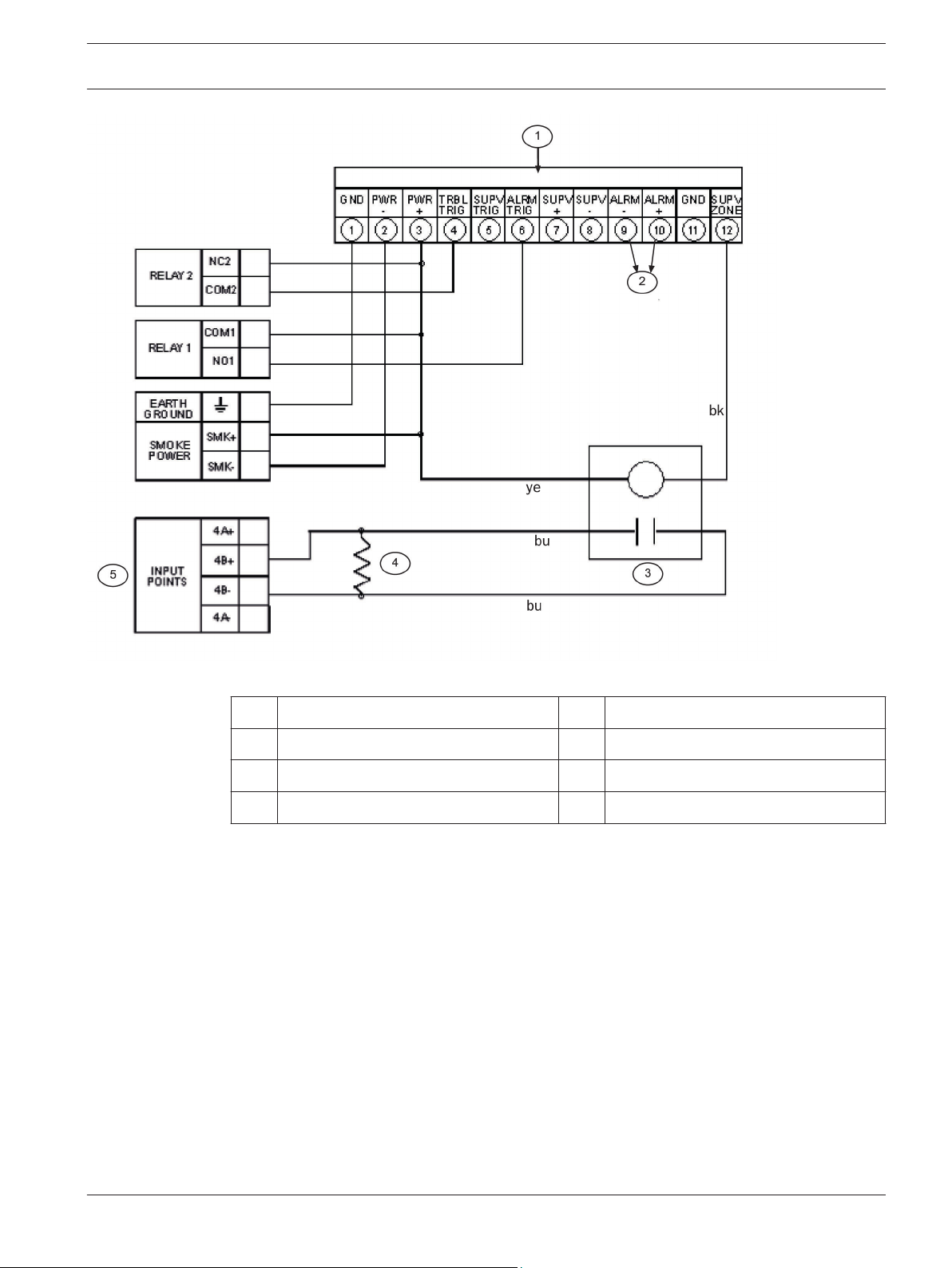

D132B Multi-use Reversing Relay Module

The D132B is a multi-purpose, fully configurable, smoke power-reversing module for activating

detectors with local annunciation. The D132B operates both two-wire and four-wire circuits

and also works with Class A or Class B initiating circuits. An alarm latch connection is

provided to allow an initiating loop to be held in alarm after the detector loop power is

reversed to activate any sounders. The D132B does not affect compatibility between the FACP

and detectors, or the FACP and Notification Appliance Circuits (NACs).

See also the D132B Installation Guide for detailed installation instructions for the D132B

module. One of the installation options shown in the D132B Installation Guide is also shown in

the following figure:

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 24

24 en | Installation Fire Alarm Control Panels

Figure 4.1: Wiring the D132B smoke power reversing module

1 Power limited and supervised 7 12/24 VDC

2 Optional alarm latch 8 24 V reversing detectors

3 Loop 9 2.2 kΩ EOL (power limited and

supervised)

4 Class A 10 Not used

5 Latch 11 24 V NACs

6 NAC

D185 Reverse Polarity Module

The D185 Reverse Polarity Module is a UL Listed module that connects the control panel with

either a single set or a pair of leased telephone company (TELCO) lines in NFPA 72 remote

station applications. It relays system alarm status information from the control panel to a

monitoring station. The D185 operates with either 12 VDC or 24 VDC supply.

For typical wiring of the D185 module, see the following figure:

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 25

Fire Alarm Control Panels Installation | en 25

Figure 4.2: Wiring the D185

The module can signal alarm, trouble, and supervisory conditions. The Wiring the D185 figure,

24 shows the module being used to signal alarm and trouble conditions only. With a third relay

(available from the eight-relay expansion module) and an additional leased line, supervisory

conditions can also be signaled.

In the example in the Wiring the D185 figure, Relay 1 must be programmed to operate on

Alarm (Zone 63) and Relay 2 must be programmed to operate on Trouble (Zone 62). Program

Input 4 to operate as a Supervisory point. Any alarm causes the voltage to the monitoring

station to be interrupted. Placing the D185 in test mode causes a SUPERVISORY TROUBLE.

See also the D185 Installation Manual.

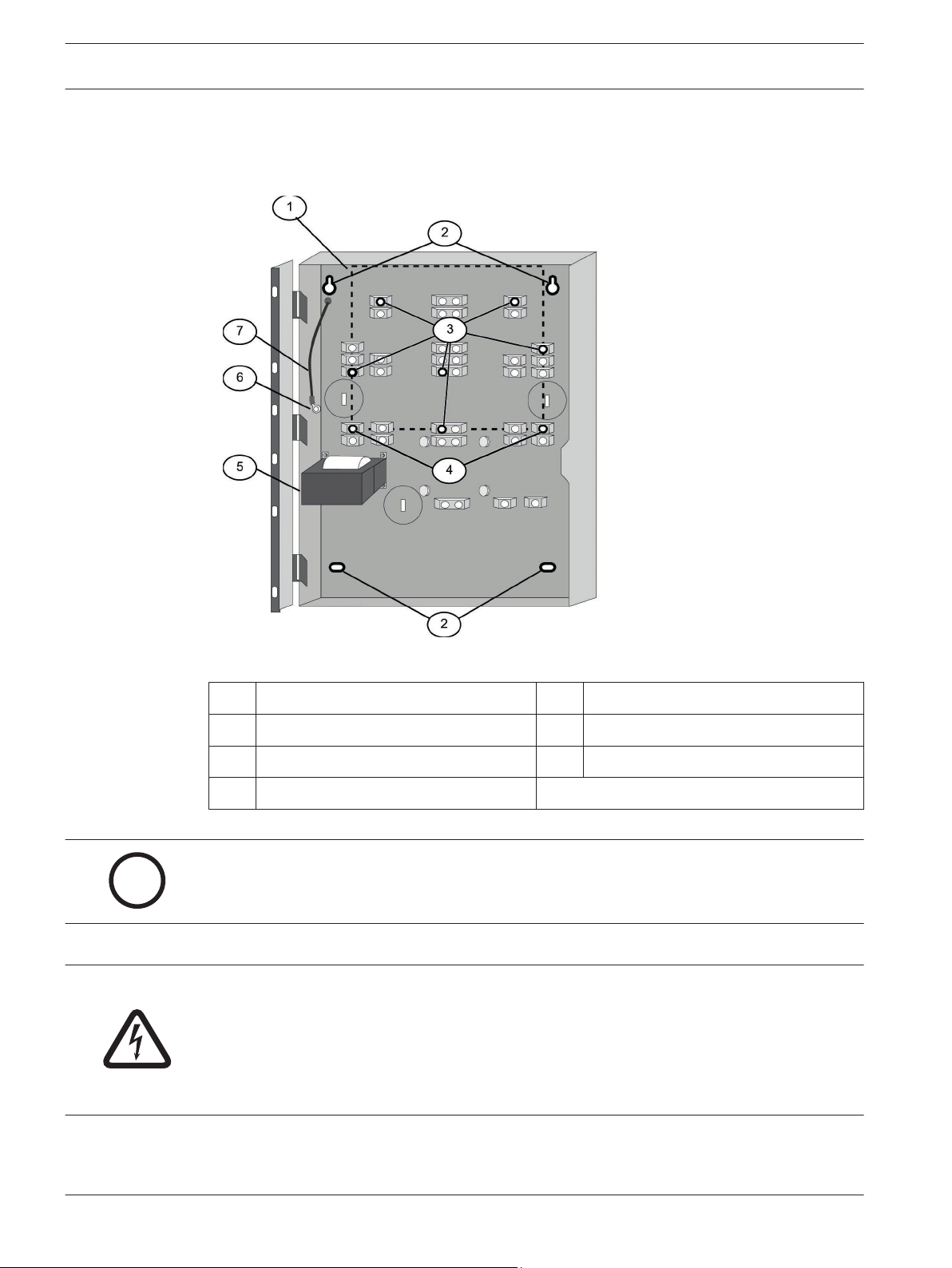

4.2

Installing the enclosure

To install the enclosure, follow these instructions:

1. Using the enclosure as a template, mark the top mounting holes on the mounting surface.

2. Start the mounting screws (not supplied) for these two holes.

3. Slide the enclosure onto these screws so that the screws rest on the thinner section of

4. Tighten the screws.

1 D185 module 5 Fire control panel

2 To monitoring station bk black

3 D275 bu blue

4 2.2 kΩ EOL ye yellow

the holes.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 26

i

26 en | Installation Fire Alarm Control Panels

5. Install and tighten the remaining two screws in the bottom mounting holes.

6. Knock out the desired wire entrances on the enclosure.

For mounting hole locations, see the following figure:

Figure 4.3: Enclosure iInstallation

1 Control panel location 5 Transformer

2 Mounting holes 6 Stud

3 Retainer holes for standoffs 7 Ground wire

4 Retainer holes for support posts

Notice!

If using the knockouts located at the bottom of the enclosure, install batteries in a separate

enclosure.

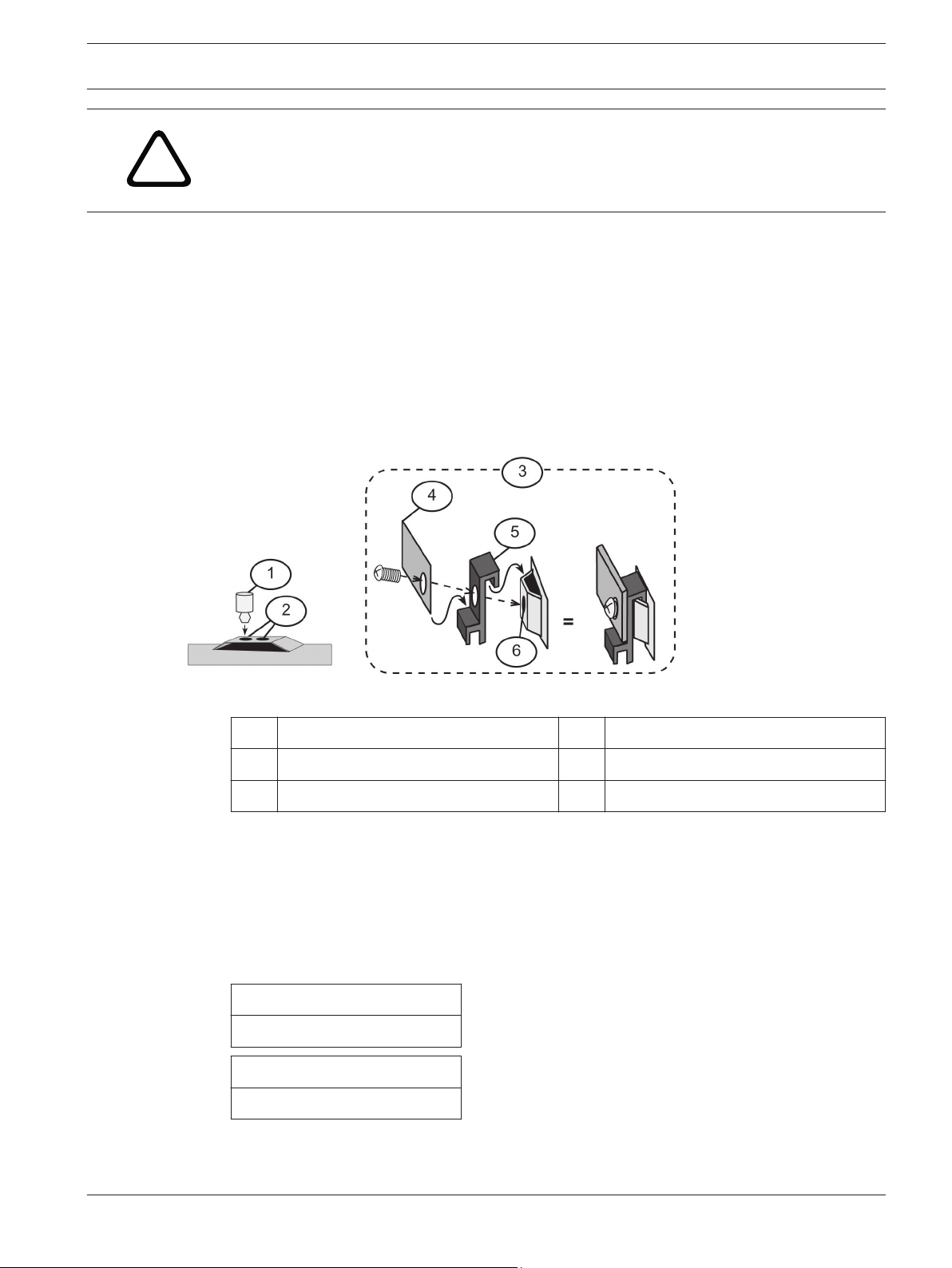

4.3

Installing the FPD‑7024

Danger!

The control circuit board in the FPD-7024 is static sensitive.

To avoid damage to sensitive components, touch ground before handling the control board.

This discharges any static electricity in your body. For example, run the ground wire to the en-

closure before handling the control circuit board. Continue touching the enclosure while in-

stalling the control board.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 27

!

Fire Alarm Control Panels Installation | en 27

Warning!

Before the circuit board is installed, connect the supplied ground wires between the door and

the enclosure and from the transformer to the enclosure using the supplied nuts. Both

grounds connect to the stud in the enclosure to the left of the circuit board.

For installation illustrations, see the figures for Enclosue installation, 26 and for Standoff and

support post installation, 27.

1. Insert the three support posts in the enclosure’s retainer holes.

2. Press the 1/8 in. nylon standoffs (P/N: F01U034705) into the retainer holes.

3. Slide the top of the control panel onto the retainer tabs (the slots under the top of the

frame). When the control panel is in the retainer tabs, it rests on the posts.

4. Secure the bottom of the circuit board by inserting and tightening the screws at the two

bottom corners through the support posts and the retainer holes.

For installing standoffs and support posts, see the following figure:

Figure 4.4: Standoff and support post installation

1 1/8 in. nylon standoff 4 Corner of circuit board

2 Retainer holes 5 Support post

3 Support post assembly 6 Retainer hole in enclosure

4.4

Installing optional equipment

Two expansion options connect directly to the control panel, and are automatically detected

and supervised when the control panel is powered:

– FPC-7034 Four Point Expander

– D7039 Multiplex Expansion Module

When the control panel is powered after installing one of these options, the control panel

displays one of the following windows:

4Z EXP DETECTED

PRESS BACK KEY

MUX DETECTED

PRESS BACK KEY

Press the [*/BACK] key to confirm the installation of the device and automatically set it up for

supervision.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 28

!

i

i

28 en | Installation Fire Alarm Control Panels

If the [*/BACK] key is not pressed during the power-up time-out period, the control panel

resumes operation using the last confirmed status of the affected expander and displays an

installation error condition.

Warning!

Expansion devices such as point expanders and multiplex expanders are disabled if they are

removed from the control panel configuration after installation. You cannot disable supervi-

sion of these devices when they are installed.

For additional information, see the installation instructions for the specific expanders.

Notice!

EEPROM fault at first installation

When the D7039 Multiplex Expansion Module is first installed, the system displays an EE-

PROM fault. Execute the default procedure to synchronize the EEPROM on the expansion

module to the EEPROM in the control panel. Remove power to the control panel, then reapply

power and re-install option bus devices after the default procedure.

Notice!

Loss of programming

Replacing a D7039 Multiplex Expansion Module causes the loss of programming of expansion

points and PINs. Reprogram all multiplex point and PINs if you replace the D7039.

When the D7039 is first installed, or anytime the control panel is powered with a D7039 that

has no points programmed, the system automatically starts the multiplex auto-programming

process:

AUTO PROGRAM?

_______:YES(1) NO(0)

Pressing the [1] key starts auto-programming, and pressing [0/Prog] allows the control panel

to continue normal startup. The menu automatically closes with NO selected if no key is

pressed after several minutes.

For detailed instructions on the auto-programming mode, see Auto Program, 93.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 29

!

i

Fire Alarm Control Panels Connection | en 29

5

5.1

Connection

FACP terminal connection

Danger!

Incorrect connections may result in damage to the unit and personal injury.

Warning!

Before servicing this equipment, remove all power including the transformer, battery and

phone lines.

Notice!

Shared cable is not recommended for option bus, telephone or NAC wiring.

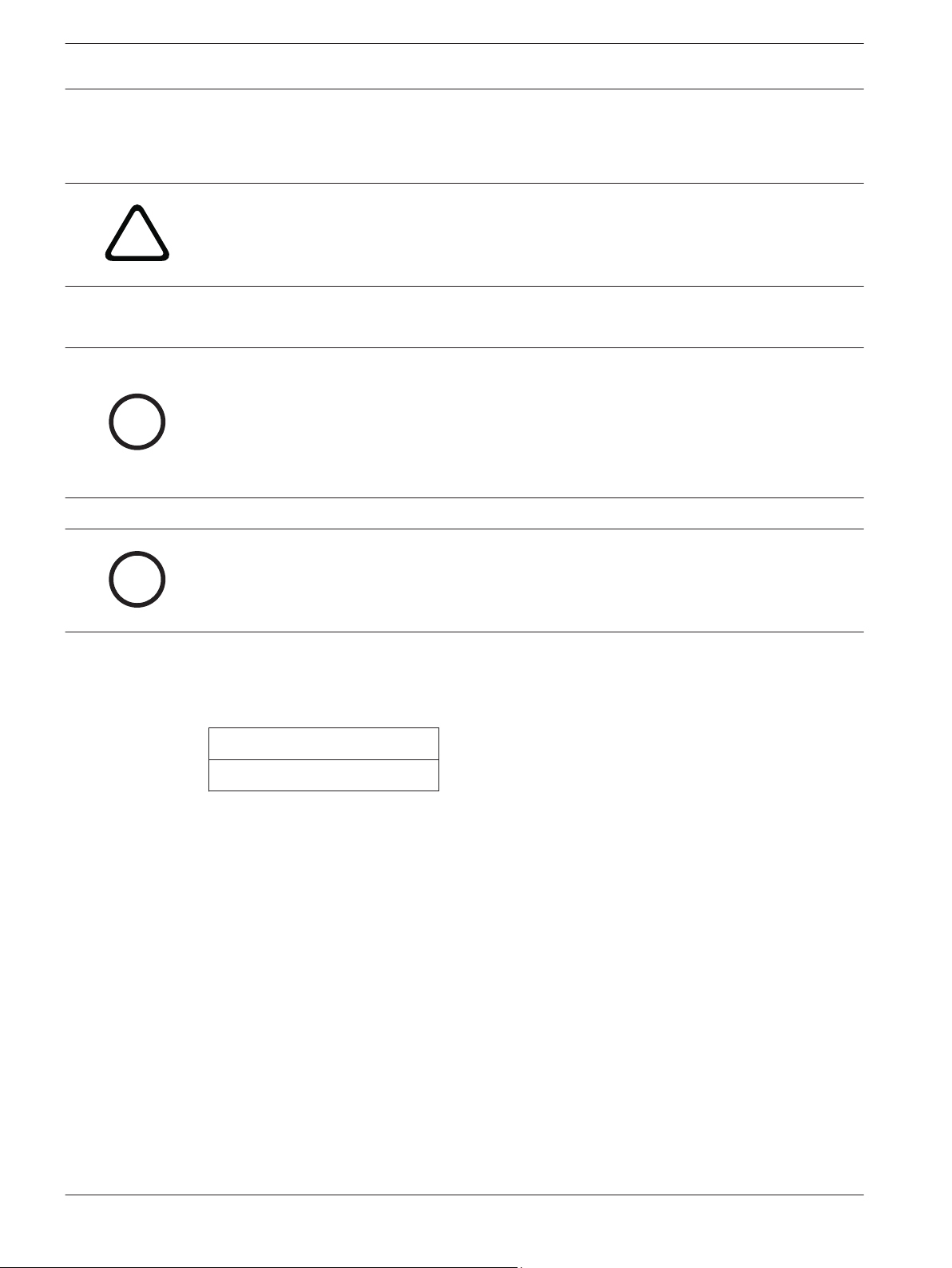

Figure 5.1: Typical 2-wire smoke detector wirin (supervised)g

1 Class A, Style D 3 EOL resistor

2 Class B, Style B

Figure 5.2: Typical 4-wire smoke detector wiring

1 Class A, Style D 4 EOL resistor

2 Class B, Style B 5 Smoke detector

3 EOL relay

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 30

i

30 en | Connection Fire Alarm Control Panels

Notice!

All wiring except battery terminal and primary AC power is power-limited. Primary AC and bat-

tery wires must be separated from other wires by at least ¼ in. (64 mm) and tied to prevent

movement.

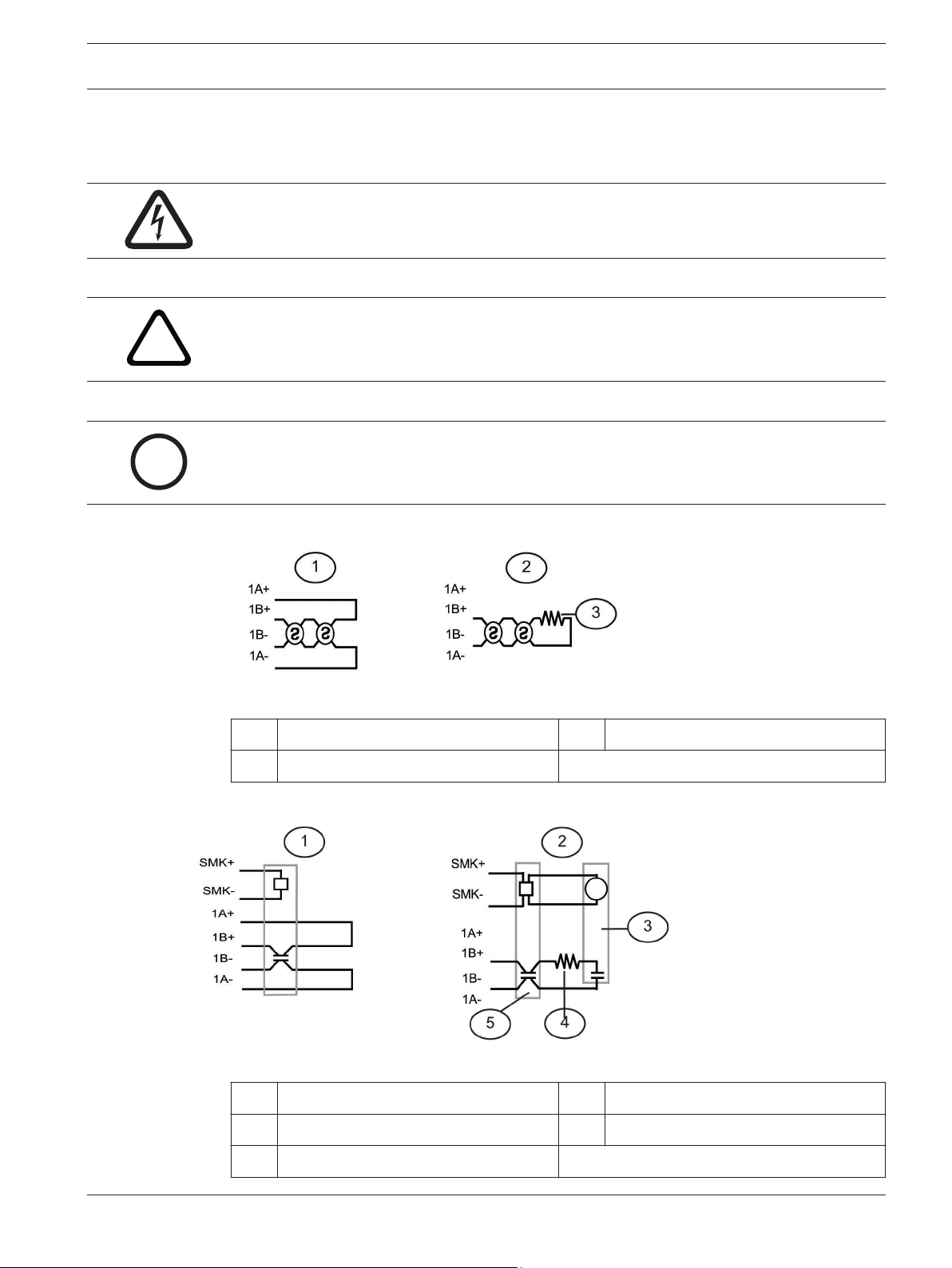

Figure 5.3: Transformer

RD red

BN brown

supervised:

YE yellow

WH white

BK black

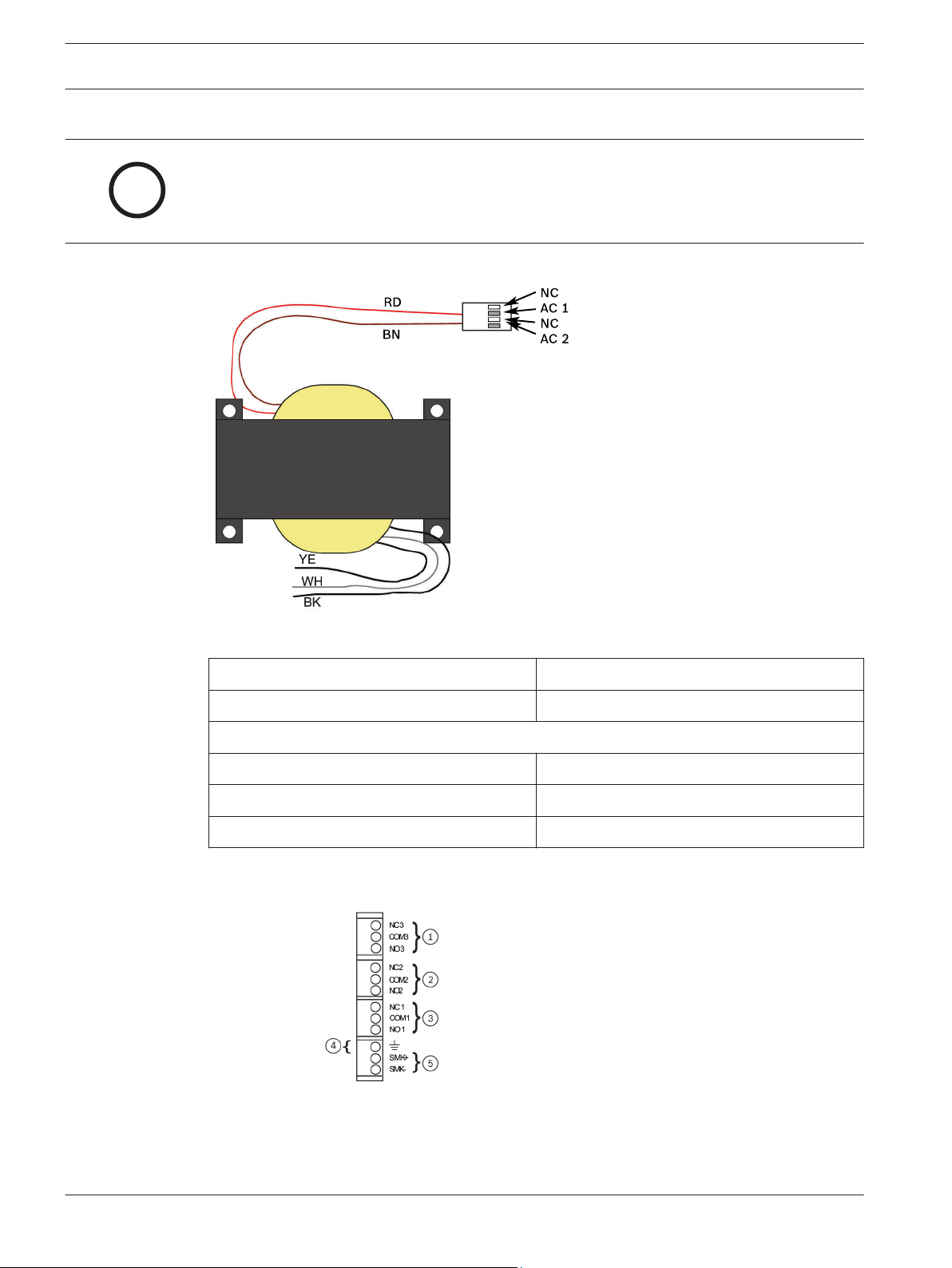

Figure 5.4: Input Points

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 31

i

i

Fire Alarm Control Panels Connection | en 31

Unsupervised: Switched unsupervised:

1 Relay 1 4 Earth ground

2 Relay 2 5 Smoke detector

3 Relay 3

Input Points 1-4:

(supervised) Points are intended for connection of normally-open/normally-closed alarm

contacts. They may also be used for compatible two-wire smoke detectors. All EOL resistors

are 2.21 kΩ, P/N: 25899 Bosch, UL listed. Initiating devices are Class B, Style B or Class A,

Style D. Two‑wire Compatibility Identifier "A".

Notice!

For connection to listed power limited Class 2 or Class 3 sources only. Contacts rated at

5.0 A, 24 V.

Notice!

Smoke Power: 24 V, 1.0 A maimum (filtered).

For compatible devices, see also Technogram P/N: F01U0790.

Figure 5.5: Telephone lines 1 and 2

1 Phone Line 2 (supervised) 2 Phone Line 1 (supervised)

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 32

DX4020,

B420 models,

ITS-DX4020-G

i

32 en | Connection Fire Alarm Control Panels

Figure 5.6: Keypad Connection (supervised, Class B, Style 4, 500 mA maximum)

Figure 5.7: Backup Batteries

1 Class B, Style Y supervised:

2 Class A, Style Z BAT Battery

3 Backup batteries BK black

EOL End of line RD red

Notice!

Unswitched unsupervised Auxiliary Power: 24 V, 1.0 A maximum (unfiltered).

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 33

Fire Alarm Control Panels Connection | en 33

Danger!

Explosion and burn hazard!

Do not short terminals!

Notification appliance circuit:

5.2

NAC 1+

NAC 1-

+24 V while in alarm; ground while in standby.

Ground while in alarm; supervisory voltage while in standby.

Notification appliance circuit:

NAC 2+

NAC 2-

+24 V while in alarm; ground while in standby.

Ground while in alarm; supervisory voltage while in standby.

Batteries:

BAT BAT +

Requires two 12 V batteries in series, for a combined voltage of 24 V.

Charge current = 1.1 A, maximum

Use only indicating devices as listed on Technogram P/N. F01U010791.

Power supply connection

Use wire nuts to connect the primary side of the transformer in one of the following ways:

– black and white wires to an unswitched 120 V, 60 Hz, or

– yellow and white wires to an unswitched 240 V, 50 Hz circuit.

Danger!

Shock Risk!

Do to risk of shock and/or damage to the transformer a wire mut must be in place over the

unused black or yellow wire.

Connect the earth ground to the threaded ground stud on the left side of the enclosure.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 34

i

i

34 en | Connection Fire Alarm Control Panels

Figure 5.8: Transformer Connections

Primary:

YE yellow WH white

BK black

5.3

Option bus wiring requirements

Use 18 AWG (1.2 mm) or larger wire to connect option bus devices to the FACP. The total

length of wire connected to the option bus terminals must not exceed 4 000 ft (1 219 m),

regardless of the wire gauge wire used.

Notice!

Shared cable is not recommended for option bus, addressable points bus, telephone, or NAC

wiring.

Notice!

To comply with UL, do not share supplementary devices with primary device on the option

bus.

Avoid shielded or twisted pair-wire except for special applications where a reduced length of

wiring (approximately 50%) is acceptable for tolerating a harsh electrical environment.

The length of wire allowed between the control panel and the last device on a wiring run

depends on the existing current draw on that wiring run. Reducing the number of devices on a

wiring run allows the individual runs to be longer.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 35

i

Fire Alarm Control Panels Connection | en 35

Add together the alarm existing current draw by all the devices on the wiring run to determine

the maximum allowed distance between the option bus terminals on the control panel and the

last device on the wire run (the device farthest from the control panel).

To determine the maximum allowed length for the run, add up the total alarm load for option

bus devices on the wire run. For example, if the total load of option bus devices on a

particular run is 400 mA, the maximum length of the run can be up to 500 ft (152 m). No more

than 4 000 ft (1 219 m) of wire can be connected to the option bus terminals, even if the

individual lengths of the runs are all within limit.

For the allowed lengths for18 AWG (1.2 mm) wire, see the following figure:

Figure 5.9: 18 AWG cable length for existing current draw

Notice!

The graph is for 18 AWG cable!

For16 AWG (1.5 mm) wire, cable lengths can be 1.5 times longer. For14 AWG (1.8 mm) wire,

cable lengths can be 2.5 times longer. The 4 000 ft (1 219 m) maximum length of connected

wire still applies.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 36

36 en | System Operation Fire Alarm Control Panels

6

6.1

6.1.1

6.1.2

System Operation

Modes of Operation

There are four modes of system operation for the FPD‑7024: normal, alarm, supervisory, and

trouble.

Normal

When the system operates normally, it shows SYSTEM NORMAL on the top line of the display,

the Power LED lights steadily, and no other LEDs are lit. The bottom line indicates the existing

date MM/DD/YY and time HH:MM. If the system is programmed to require a PIN, the second

line of the LCD screen shows ENTER PIN.

Off-normal Displays

Control panel alarms and problems are indicated on the top line of the display. Contact your

installing company if problems persist.

For the alarm/problem messages, see the following table:

Off-Normal Display Description

XXX/XXX FIR: XXXXX One or more fire or waterflow points are in alarm.

XXX/XXX SUP: XXXXX One or more supervisory conditions exist.

XXX/XXX TRB: XXXXX A trouble condition exists (AC power failure, phone line

trouble, and so on).

6.1.3

6.1.4

6.1.5

Table 6.1: Off-normal displays

Acknowledge

When the control panel is off-normal, the control panel’s piezo (buzzer) can be silenced

without silencing the NACs or resetting the control panel. Press the [ACK] button on the local

or remote keypad to silence only the piezo.

Alarm

When an alarm occurs, the top line shows the number of alarms and the point that is in alarm.

The bottom line alternates between the instructions and the programmed description for the

affected point. When you back out of the detail view and go to the group view by pushing the

[4/<] key, the top line of the display shows ALARM (XXX), where XXX indicates the number of

alarms. This display overrides any other system display. The built-in sounder turns on with a

steady tone, and outputs programmed to activate with the existing alarm condition(s)

activate.

When the control panel is not scanning the inputs, as during smoke power reset, alarm

verification delay, or on-site programming, the trouble LED flashes to indicate this condition.

Supervisory

When a Supervisory condition occurs, the top line shows the number of supervisories and the

point that is in the supervisory condition. The bottom line alternates between the instructions

and the programmed description for the affected point. When you back out of the detail view

and go to the group view by pushing the [4/<] key, the top line of the display shows

supervisory (XXX), where XXX indicates the number of supervisory conditions. The bottom line

indicates more instructions. The built‑in sounder beeps. Outputs programmed to activate with

the existing condition(s) then activate.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 37

i

Fire Alarm Control Panels System Operation | en 37

6.1.6

6.1.7

Trouble

When a trouble condition occurs (such as cut wiring for a point or AC power fails), the

sounder beeps every 10 seconds. The Trouble LED lights and the LCD shows the trouble

condition. When you back out of the detailed screen when the [4/<] key is pressed the group

is entered and shows TROUBLE (XXX). The system can diagnose and show a variety of trouble

conditions, including those affecting the input points, NAC circuits, power, battery, system

grounding, and internal operations of the fire control panel. Notify your installing company

immediately if the system trouble message appears.

Press the [Acknowledge] key to silence the system trouble beep.

Fire Silence/Reset

Danger!

Fire Alarm!

During a fire alarm, exit from the premises immediately. Do not enter the premises unless ac-

companied by the appropriate emergency services' personnel, or until they have given the OK

to enter.

DANGER!

When it is determined that there is no fire, you can silence the horns or bells to allow more

investigation of the devices that initiated the alarm, or you can reset the system to return it to

normal operation.

Notice!

Before resetting fire alarms

Before using the [Reset] key, determine which smoke detector sounded the alarm so that the

monitoring company can check that the system is operating correctly. If the control panel is

being used as an addressable control panel, use the [History] key to determine which address

is in alarm.

NOTICE!

If the system is configured to allow alarm silencing, the [Silence] key turns off the horns or

bells, but does not reset the alarm status and does not return the activated input to normal

service. Detectors that were activated stay in alarm and can be checked (usually by observing

an LED on the device) to see which detector caused the alarm. When the detectors causing

the alarm are identified, reset the system to return it to normal service.

The [Reset] key clears the system alarm status, and briefly turns off power to the detectors to

reset them. This command is required after any fire alarm affecting a point programmed for

latching operation (which is the normal configuration). This operation is also required to reset

Class A, Style 6 multiplex (SLC) wiring fault troubles.

The software automatically supervises the system software for proper operation. If the system

fails, a CPU FAULT message appears, and the nature of the failure can be optionally recorded

in the history buffer. To enable history buffer recording for CPU faults, program Output Zone

D of onboard Relay 2 to Zone 51 (unused). The history buffer message, if enabled, shows

CPUFLTxxx, where xxx is an error code. If the display shows CPU FAULT, contact Bosch

Security Systems, Inc. Technical Support and report the history buffer code along with a

description of the operations that caused the fault. Unusual conditions during programming

and debugging operations can result in a CPUFLT message in the history buffer. If, this occurs

when the control panel is in service, report it to Technical Service.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 38

38 en | System Operation Fire Alarm Control Panels

6.2

6.2.1

6.2.2

Basic System Use

Function keys

A keypad that does not require a PIN number shows (under normal conditions) SYSTEM

NORMAL on the top line, and existing date and time on the bottom line. On a keypad that

does require a PIN number, enter the PIN number first. This enables the function keys.

Selecting menu items

Depending on which level in the system, (menu, sub-menu, sub-sub-menu), you can select an

item three different ways:

1. In the main menu, TEST, HISTORY, DISABLE, and DRILL each have an exclusive key on the

keypad. To select one of these menu items, press the corresponding key. For example, to

select TEST, press the [TEST] button.

2. The [PROG] and [ENTER] keys are not exclusive, but are shared with other characters.

The character sharing the corresponding key appears in the second line following a

forward slash (\). To select one of these items, press the corresponding key. For

example, the [PROG] key is also 0.

3. The key corresponding to a sub-menu item might appear in the second line preceding a

dash. Press the corresponding key to select that item. For example, press [1] to select

PROG TIMES.

While a menu is active, you do not need to wait for the desired menu item to appear before

making your selection. You can select any item on the existing menu rotation at any time.

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

After a Main Menu item is selected

When a main menu item is selected, the keypad might prompt you to enter your PIN. If so,

enter the number (factory default is 9876) and press the [#/Enter] key (or press the key

labeled with the desired command directly). The display automatically retrieves the sub-menu

display.

Returning to an earlier screen

To return to a previous screen at any time, press the [*/Back] key. To return to the SYSTEM

NORMAL display, press the [*/Back] repeatedly until you reach SYSTEM NORMAL. When you

reach SYSTEM NORMAL, you cannot go any farther.

Entering data

When a sub-menu item asks you to enter data, enter the data and press the [#/Enter] key. If

data already exists at a particular location, you can either accept that data or enter new data.

When you press the [#/Enter] key to enter the data, the display returns you to the previous

sub-menu display.

Drill

The drill command activates all NACs and no relays. It creates a history log entry and, as an

option, can be reported to the central station.

Disable

Use the disable command to disable input points, outputs, or the dialer. When any device is

disabled, the system shows this condition on the LCD and on the system trouble LED. The

Disable All Inputs operation takes several seconds to perform, during which time the system

display remains fixed.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 39

i

Fire Alarm Control Panels System Operation | en 39

6.2.8

History

Notice!

If a system without a D7039 Multiplex Expansion Module loses all power (AC and standby bat-

tery), all history events are cleared.

The HISTORY option is a chronological list of system events that occurred. Press the [History]

key to HISTORY select from the Main Menu (SYSTEM NORMAL display).

On an FPD-7024 FACP with a D7039 Multiplex Expansion Module, up to 499 History events are

supported.

On an FPD-7024 FACP without a D7039 Multiplex Expansion Module, up to 99 History events

are supported.

After you press the [History] key, the most recent system event appears on the top line of the

LCD with the time and date below it.

Example: (Assume you pressed the [History] key at the Main Menu):

While the first event shows, the bottom line toggles every four seconds between the time and

date that the event occurred.

To return to a previous screen in the history buffer, press [2/▲].To scroll to the next event

record, press [8/▼].

For abbreviations used in history events, see the following table:

Abbreviation

Meaning Abbreviation Meaning

ALRM Alarm OFFNORM Off Normal at Test

ARST Alarm Restore PH1 Phone Line 1

AUTOTST Auto Test PH2 Phone Line 2

BATT:LOW Battery Low RSTR Restore

BAT:RSTR Battery Restore S Supervisory

CPUFLT Internal Error SMK:FLT Smoke Power Fault

DBL Disable SYSRESET System Reset

DRILL:BEG Drill Begin SYSRST System Restore

DRILL:OVR Drill Over SYSTRB System Trouble

DRST Dirty Restore SYS:WDOG Automatic CPU Reset

(Watchdog)

DRTY Dirty TRBL Trouble

DSBL Disable TRST Trouble Restore

EE2 EEPROM TST:BEG Test Begin

ENBL Enable TST:OVR Test Over

F Fire W Waterflow

MANULTST Manual Test

Table 6.2: History event abbreviations

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 40

40 en | System Operation Fire Alarm Control Panels

For additional history log ID information, see the Modem IIIa2 reporting table, 105.

6.2.9

6.3

6.3.1

Remote Programming

Call for remote programming

Phone Numbers 1 and 3 must be programmed, along with Account Code 1. The control panel

calls Phone Number 3 and attempts to connect for downloading. If the control panel is already

using the phone line, it sounds the three-beep error tone. This function requires an access

code with programming authority (Level 1).

Answer for remote programming

The control panel immediately seizes the phone line to answer a remote programming call.

While programming is underway, the Trouble LED flashes. This also allows on-site PC

downloading. If the control panel already uses the phone line for a report communication, it

sounds the three-beep error tone. This function requires an access code with programming

authority (Level 1).

Keypads

Built-in keypad

The keypad built into the control/communicator is an alphanumeric LCD keypad. It has a twoline by 16-character display to provide information on various control panel functions. Usually,

the first line shows the off-normal condition, while the second line describes specific details

that might be relevant to the existing system status. A built-in sounder annunciates keystroke

entries and acts as a warning device.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 41

Fire Alarm Control Panels System Operation | en 41

Figure 6.1: Built-in Keypad

1 Green Power LED - is on when the AC

power is present, and flashes when

the unit is operating from battery

power.

2 Yellow Trouble LED - lights when the

system detects a problem with wiring

or internal circuitry. The Trouble LED

flashes while programming mode is

active and whenever inputs are not

active, such as during smoke power

reset or alarm verification.

3 Red Alarm LED - lights when the

system registers an alarm and was not

reset.

9 [#/Enter] key - to accept data when in

the programming mode.

10 [History] key - to view system events.

11 [Reset] key - briefly (programmable

from 1 to 16 seconds) turns off power

to the detectors to reset them and

clears any off- normal conditions.

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Page 42

42 en | System Operation Fire Alarm Control Panels

4 Yellow Silenced LED - lights when the

user manually silences an alarm

condition (fire or water flow), turns off

12 [Silence] key - mutes the bell or sirens

for an alarm condition, if the system is

so configured.

when the condition that was silenced

is corrected.

5 [Disable] key - used to disable or

re‑enable inputs, NACs or relays

(outputs), and the dialer.

13 [Drill] key – used to activate the NACs

manually. It creates a history log entry

and as an option reports to the central

station.

6 [Test] key - used to select one of seven

special test modes.

1

14 Yellow Supervisory LED - lights

whenever the system registers a

supervisory condition.

7 [*/Back] key - used during

programming to exit from menus or to

exit from the programming mode

15 Yellow GND Fault LED - lights

whenever the system detects a ground

fault condition.

entirely.

8 [0/Prog] key – for selecting the

programming mode.

16 [Acknowledge] key to silence local

keypad sounders and to step through

the groups of off-normal conditions.

1 For test modes, see Testing, 43.

For abbreviations on the keypad and control panel, see Control Panel Display Descriptions,

100.

6.3.2

FMR-7033 keypad

The FMR-7033 Keypad is an alphanumeric LCD keypad. Up to four of these keypads can be

mounted apart from the main control panel to provide additional locations for system status

and control. The LCD display and keys operate identically to those of the built-in keypad on

the control panel.

For operation, see Built-in Keypad callouts, 40.

2012.08 | 04 | F01U008458 Installation and Operation Manual Bosch Security System, Inc.

Page 43

Fire Alarm Control Panels System Operation | en 43

Figure 6.2: FMR-7033 Keypad

6.4

6.4.1

Testing

Select any of seven special test modes using the [Test] key on the built‑in and FMR‑7033

keypads.

Walk test

The Walk Test allows a technician to alarm each point manually to ensure that detectors

connected to a point send an Alarm report to the control panel. While in this mode, the LCD

shows the system test status and the trouble sounder sounds every 10 sec. NAC outputs

activate during this test as points are alarmed and restored based on the following settings:

– SHORT ACTIVE:1 second activation

– LONG ACTIVE:5 second activation

– NO ACTIVE:outputs do not activate

As each point is alarmed, the outputs activate once (if selected) and power is reset. As each

point is activated, alarms and restorals are logged in the control panel’s history log. When the

point returns to standby, the outputs activate twice. The control panel attempts to reset

points ten times to restore them. Points remaining alarmed when exiting from the walk test

mode cause an immediate alarm.

1 LEDs 3 Keys

2 Keypad Display

6.4.2

Bosch Security System, Inc. Installation and Operation Manual 2012.08 | 04 | F01U008458

Communicator test

The communicator sends a test report. While communication is in progress, the Power LED

flashes. When the communication succeeds, a long keypad beep sounds, the Power LED

returns to normal, and the display returns to normal.

Page 44

i

!

44 en | System Operation Fire Alarm Control Panels

Notice!

This test is available only if your system sends alarms and system information to a monitoring

service, and was programmed by the security installing company to permit communicator

tests.

NOTICE!

Warning!

Reset upon termination of test

Terminating the communicator test function (with the [*/Back] key) resets the communicator

and discards all unsent reports. When an off-normal condition occurs during a Communicator

test, the test automatically resets, clearing all reports, so the off-normal conditions are sent

normally.

6.4.3

6.4.4

6.4.5

6.4.6

Battery/NAC circuits test

If a power failure occurs, your control panel has a built-in battery that continues to power the

system for several hours. The control panel automatically recharges the battery when power is

restored. In this test mode, the system operates the local NAC circuits and tests the battery

for two seconds. The test results are shown at the end of the test, and are not reported to the

central station. Pressing the [*/Back] key or the [#/Enter] key returns the display to standby

mode, or the unit times out after three minutes.

Activate ouputs test

This test turns a selected output on and off manually.

Zone input level test

This test shows the status of a selected on-board point. The loop existing through the point is

shown. Normal loops show 11 mA to 15 mA. Loops in alarm show over 25 mA, and loops in

trouble show less than 6 mA.

Addressable point test (MUX test)

This test allows activation of the special test mode for addressable (multiplex) devices. This

applies only if the optional D7039 Addressable Point Bus Expander module is installed. When

this test mode is selected, the system asks which bus to test, 1 or 2. Select 1 to test points 9