Bosch Power Tools FNA250-15 User Manual

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:00 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

FNA-250-15

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations et

les adresses de nos centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 15 Ver la página 28

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:00 AM Page 2

General Pneumatic Tool Safety Rules

!

WARNING

may result in electric shock, fire, serious personal injury or death.

ALL USERS AND EMPLOYERS/OWNERS MUST READ AND UNDERSTAND ALL INSTRUCTIONS IN THIS

MANUAL BEFORE OPERATING OR MAINTAINING THIS TOOL. Failure to follow all instructions listed below

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas increase the risks of accidents,

electric shock, fire, and injury to persons.

Do not operate pneumatic tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust. The tool is able to create sparks

which may ignite the dust or fumes. Never use the tool in

sites containing lacquer, paint, benzine, thinner, gasoline,

gases, adhesive agents, and other materials which are

combustible or explosive.

Keep bystanders, children, and visitors away while

operating a pneumatic tool. Distractions may cause loss

of control of the tool. Fragments of fasteners may cause

injury to bystanders.

Never engage in horseplay with the tool. Respect the

tool as a working implement.

Personal Safety

Do not remove, tamper with, or otherwise cause the tool

operating controls to become disabled or inoperable.

This will cause the tool to work irregularly and may result in

the risk of injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts and increases the risk of

injury.

Always wear eye and ear protection when using this

tool. Use additional personal protective equipment as

appropriate when operating this tool. Operators and

others in work area must wear safety glasses with side

shields and make sure all other personnel in the work area

wear safety glasses. Safety glasses must conform to the

requirements of American National Standards Institute,

ANSI Z87.1 and provide protection against flying particles

both from the front and side. Prolonged exposure to high

intensity noise is able to cause hearing loss. Dust mask,

non-skid safety shoes, hard hat and other personal

protective equipment, must be used for appropriate

conditions.

Keep handles dry, clean and free from oil and grease.

Slippery hands cannot safely control the tool.

Avoid directing exhaust air from the tool into your or a

bystander face and eyes. Exhaust air from a tool can

contain water, oil, metal particles or contaminants from the

compressor, which can be blown into the eyes or cause

serious injury. Use adjustable air vent to direct exhaust to

blow exhaust air away from user.

Stay alert. Watch what you are doing, and use common

sense when operating a pneumatic tool. Do not use the

tool while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating the

tool may result in serious personal injury.

Avoid unintentional operation. While connecting air

supply do not depress trigger. Do not carry the tool with

your finger on the trigger or connect the tool to the air

supply with the switch “on.”

Do not overreach. Keep proper footing and balance at

all times. Proper footing and balance enable better control

of the tool in unexpected situations.

Make sure air hose is free of snags and obstructions.

Do not attach an air hose or tool to your body.

Entangled or snarled hoses can cause a loss of balance or

footing in addition to unintentional tool operation. Attach the

hose to the structure to reduce the risk of loss of balance if

the hose shifts.

Tool Use and Care

Use this tool and accessories in accordance with the

instructions. Tools and accessories must be used for the

purpose for which they are designed. Use of the pneumatic

tool for operations different from what's described in this

manual can result in a hazardous situation.

Use only accessories that are recommended by BOSCH

for your particular model. Accessories that may be

recommended for a particular model tool may not be

suitable on other model tools and may result in personal

injury.

Before each use, inspect the tool. Do not operate if any

portion of the tool is loose, missing, damaged,

malfunctioning, disconnected or altered. If the tool

appears to be operating unusually and/or making strange

noises, stop using it immediately and contact your local

service center. There is a risk of bursting if the tool is

damaged.

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and safer

at the rate for which it is designed.

Do not operate the tool with any power source other

than that specified in the tool operating/safety

instructions. Use of alternative power sources may result

in malfunctions of the tool and the power source which may

lead to serious injury of you or others in your surroundings.

Disconnect tool from air supply when not in use.

Leaving the tool unattended with the air supply connected

can result in unintentional operation of the tool by users

unfamiliar with tool.

2.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:00 AM Page 3

Disconnect the tool from the air source before making

adjustments, clearing jams, unloading fasteners,

leaving the work area, performing tool maintenance or

storing the tool. Such precautionary safety measures

reduce the risk or unintentional tool operation.

Never carry the tool by the hose. The tool, air fittings and

the air hose may become damaged.

Use clamps or another practical way to secure and

support the work piece to a stable platform. Holding

work by hand or against your body is unstable and may lead

to loss of control or personal injury.

The correct pressure is the lowest pressure that will do

the job. Always follow recommendations for the particular

tool.

Maintain tools with care. Properly maintained tools are

less likely to break and cause injury. Any alteration or

modification is a misuse and may result in a dangerous

condition.

Service

Maintenance performed by unauthorized personnel may

result in misplacing of the internal components which

could cause serious hazard. We recommend that all tool

service be performed by a BOSCH factory service center or

authorized BOSCH service station.

Develop a periodic maintenance schedule for your tool.

When cleaning a tool be careful not to disassemble any

portion of the tool since internal components may be

misplaced or safety components may be improperly

mounted. Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage plastic parts and

o-rings.

When servicing the tool, use only recommended

BOSCH replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions can cause

a risk of injury.

Use only the air tool lubricants supplied with the tool or

specified by BOSCH. Do not use other lubricants as they

may damage the tool. See the "Lubrication" section for a list

of recommended air tool lubricants.

Replace missing or damaged warning labels. Refer to

tool schematic for correct placement and part number.

Keep the tool clean and lubricated. Clean the tool at least

daily and lubricate as required. Never operate a dirty or

malfunctioning tool.

When not in use, store the tool out of reach of children

and other personnel unfamiliar with tool operation.

When not in use, the tool should be disconnected and

stored in a dry place. Keep out of reach of children. Lock

the storage area. Tools are dangerous in the hands of users

unfamiliar with the tool.

Air Source

Never use oxygen or other bottled gases as a power

source. Explosion may occur. Combustible gases and other

bottled gases are dangerous and may cause the tool to

explode.

Use only clean, dry, regulated, compressed air within

the rated pressure range marked on the tool. Do not

exceed maximum recommended air pressure marked

on the tool. Verify prior to using the tool that the air source

has been adjusted within the rated air-pressure range. Be

sure the air pressure gauge is operating properly and check

it at least twice a day. Tools operated in excess of their

maximum pressure rating may operate abnormally or burst,

resulting in personal injury.

Never connect the tool to an air source that is capable

of producing air pressure exceeding 200 PSI. Excessive

pressure can cause abnormal operation or cause the tool to

burst, resulting in personal injury.

Do not abuse the air hose. Protect all hoses from kinks,

restrictions, solvents or sharp objects. Keep air hose

away from heat, oil, sharp edges or moving parts.

Replace damaged hoses immediately. Damaged hoses can

burst or whip around.

Check all fittings, hoses, pipes, connections and

compressor before each use of this tool. Repair or

replace damaged or leaking hoses and connections

immediately. Damage to a hose or connection can cause a

pressure hose to break and whip around the work area, and

can lead to injury.

Safety Rules for Pneumatic Nailer Tools

Always assume the tool contains nails. Check the

magazine for nails that may be left in the tool, even if you

think the tool is empty or disconnected.

Never point the tool at yourself or others in the work

area. Always assume the tool contains nails. If nails are

accidentally fired, it may result in injury. The tool is not a toy

and should not be used like one.

Remove finger from the trigger when not driving nails.

Always carry the tool by the handle only. Removing your

finger from the trigger when not operating the tool reduces

the risk of unintentionally firing a nail and injuring yourself or

someone else.

Do not disable or remove the work contact element.

This tool is equipped with a safety mechanism, the work

contact element, to reduce the risk of accidental firing.

Disabling this component can result in unintentional firing.

Do not use the tool unless the work contact element is

working properly. If the work contacting element is not

functioning correctly, the tool can fire unexpectedly.

Never use non relieving couplers and/or female quick

disconnect couplings on the tool. Non relieving couplings

and female couplings will trap high pressure air in the tool

when the air line is disconnected. This will leave the tool

charged with enough air after it has been disconnected to

drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in the

tool is vented to atmosphere as soon as the air line is

disconnected.

3.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:00 AM Page 4

Follow all recommendations for sizes of hoses, fittings

and other compressed air accessories. Improperly sized

or fitting components may result in the risk of injury or

property damage.

Check air supply lines for restrictions before adjusting

the tool. Air volume is as important as air pressure.

Restricted air flow will prevent the tool from operating as

designed, resulting in slow operation, nail misfeeding or

reduced driving power.

Always load nails into the tool's magazine before the air

supply is connected. Connecting the air supply after

loading nails reduces the risk of unintentionally driving a nail

and injuring yourself or someone else.

When loading nails ensure that nails are parallel with

nose of tool. If nails are not parallel with nose the tool will

misfire and nails can be deflected, cause the tool to react in

an unexpected manner, and damage the tool.

When loading the tool's magazine, check that the nail

follower slides smoothly by pulling with finger. If not

smooth, nails can be driven at irregular angle.

Use only the nails meeting the criteria listed in the

“Specification” section of this manual. Nails not

identified for use with this tool can cause the tool to

malfunction and result in the risk of injury and/or tool

damage.

Do not connect the air supply when the trigger or work

contact element is depressed. Keep the tool pointed

downward, away from yourself and bystanders when

connecting the hose to reduce the risk of accidental nail

firing.

Keep hands and feet away from work contact element

of the tool during use. Never place your hands or feet

closer than 8 inches (200 mm) to the work contact element

of the tool. Nails can be deflected by the work piece or

driven away from the point of entry.

Choice of triggering methods is important; understand

the operating characteristics of each option. There are

two possible firing modes; “sequential firing” and “bump

firing.” Read and understand section titled “Actuation

Systems” for details of each mode.

Do not use a frozen tool. Allow tool to thaw before using.

Moisture frozen in the tool may impede internal components

resulting in the risk of injury and/or tool damage.

Operate the tool only when properly positioned on the

work piece. If the tool is not held properly on the work

piece the nail can be deflected or the tool can react in an

unexpected manner.

Use sufficient grip to maintain control of the tool while

allowing tool to recoil away from work surface as nail is

driven. Do not attempt to prevent the recoil by holding

the tool with excessive force against the work piece.

The tool will recoil as the nail is driven. This is normal

function for the tool. Restriction to the recoil can result in

second nail being driven when the tool is in “bump firing”

mode.

Use caution when operating the tool in confined areas.

If the work contact element is allowed to re-contact the work

surface before trigger is released, an unwanted nail will be

fired if the tool is set in “bump firing” mode.

In order to avoid undesirable double fire, take the

following actions when the tool is in the following firing

modes:

Sequential firing:

. Ensure trigger is in sequential fire mode.

1

2. Pull the trigger firmly and release.

Bump firing:

1.Do not press the tool against the wood with

excessive force.

2.Allow the tool to separate from the wood as it

recoils after nailing.

Never drive nails near flammable materials. Some types

of nails can spark out of the nose during driving operation.

Know what is behind your work piece. Do not fire nails

into walls or floors without assuring the area on the

opposite side is clear. A nail could travel through the work

piece, striking someone.

Do not drive a nail on top of another nail. This could

cause the nail to be deflected or the tool to react in an

unexpected manner.

Do not attempt to drive nails at a steep angle. This could

cause the nail to be deflected or the tool to react in an

unexpected manner.

Use care when nailing thin material or when working

near the edges and corners of the work piece. Nails may

drive through or away from the work piece and injure

yourself or someone else. Be aware that the nail may follow

the grain of the wood causing it to protrude unexpectedly

from the side of the work material. Drive the nails

perpendicular to the grain.

Do not drive nails into walls, floors or other work areas

without knowing what may be damaged by the driven

nails. Nails driven into live electrical wires, plumbing, gas

piping, or other types of obstructions can result in

electrocution, explosion, personal injury and/or property

damage.

Make sure the pressure of the compressor is adjusted

so that nails are driven flush into the work piece and

not pushed completely through. The correct pressure is

the lowest pressure that will do the job.

Keep face and body parts away from back of the top

cap when working in restricted areas. Sudden recoil can

result in impact to the body especially when nailing into hard

or dense material.

Handle tool carefully. Because of high air pressure in the

tool, do not drop the tool or strike the tool against hard

surfaces; and do not scratch, stamp, nor engrave signs on

the tool. The tool may burst.

Always disconnect tool from air supply and remove

nails from magazine before leaving the area or passing

tool to another operator. This avoids the risk of

unintentional operation.

Do not disconnect air hose from the tool with finger on

trigger or the work contact element depressed. The tool

can fire when reconnected to air supply.

4.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:00 AM Page 5

Functional Description and Specifications

!

WARNING

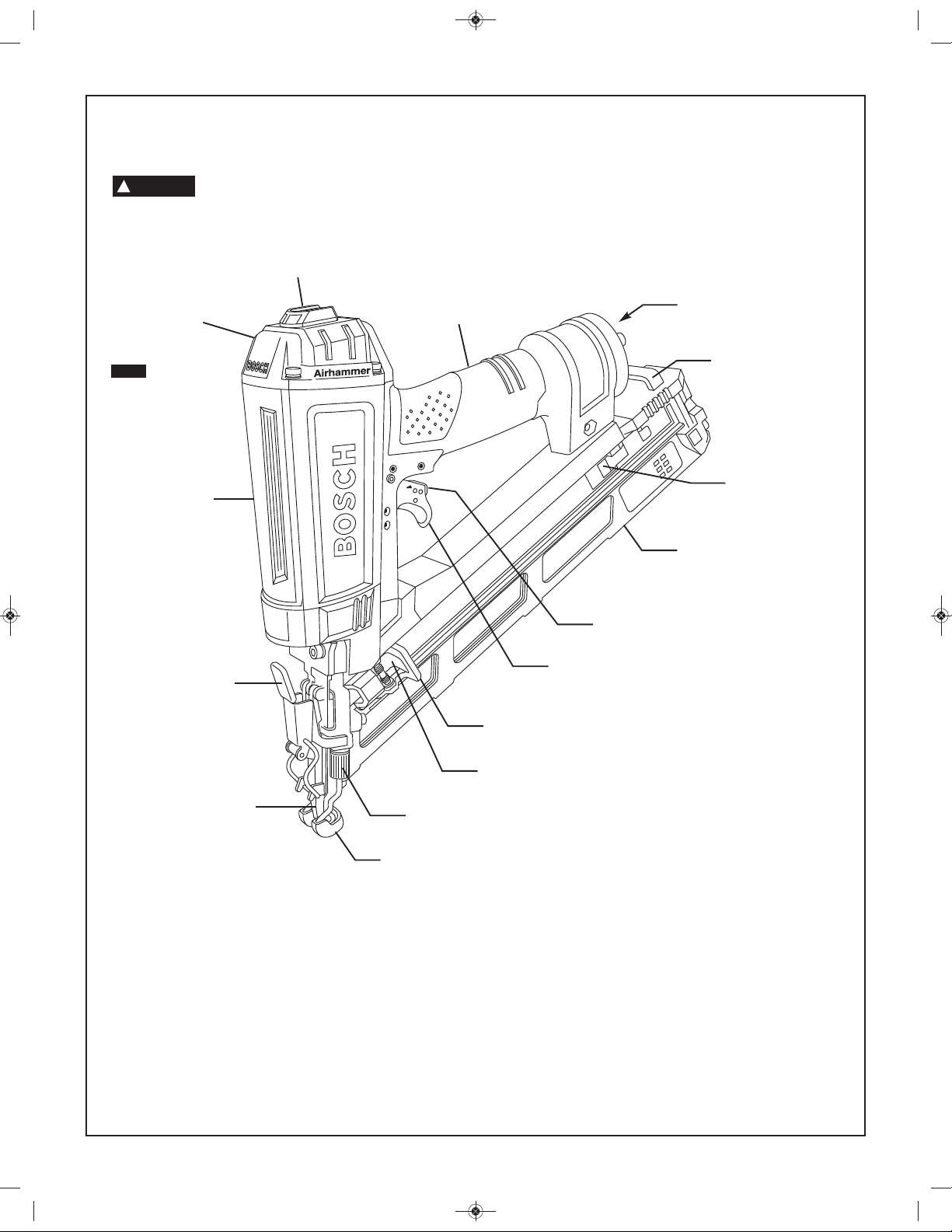

FIG. 1

Top Cap

Housing

Disconnect the tool from the air source before making any adjustments, changing accessories or

storing the tool. Such precautionary safety measures reduce the risk or unintentional tool operation.

Adjustable Exhaust

Deflector

Handle

Air Fitting

(Not Included)

No Mar Tip

Storage

Nail Hold

Back Spring

Magazine

Selectable Firing Mode Switch

Quick

Release

Lever

Work Contact

Element

Depth of Drive Adjustment

No-Mar Tip

Specifications

Product Size:

Height - 12.1 in.

Width - 3.1 in.

Weight: 4.1 lbs.

Normal Operating Pressure: 60 to 120 PSI

Magazine Capacity: 100 Nails

Maintenance: Oiling

Firing Modes: Bump Fire or Sequential Fire

Air Consumption, one shot per second @ 100 psi: 3.1 CFM

Trigger

Nail Follower

Bypass Lever

Maximum Capacities

Nails: Diameter 15 gage

Length (Range): 1-1/4 in. to 2-1/2 in.

Nail Loading & Change Out: Back

Additional Features

Tool-Less No-Mar Tip

5.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 6

Assembly / Installation

Follow the instructions below to prepare your tool for

operation.

1. All tool operators and their immediate supervisors must

become familiar with the operator safety instructions

before operating the tool. The instructions begin on page

3 of this manual.

2.Included with each tool are one copy of these

Operating/Safety Instructions and one copy of the Tool

Schematic. Keep these publications for future reference.

3. Install a filter, regulator, lubricator unit and moisture trap

on your air delivery system per the manufacturer's

instructions for these devices. Additionally, install a

pressure gauge as close as practical to the tool,

preferably within ten feet.

4. Select hoses with a minimum inner diameter of 3/8 inches

and a maximum length of 100 feet.

!

WARNING

least 200 PSI.

5. Select fittings that are appropriately sized for the selected

hoses. The tool and air hose must have a hose coupling

such that all pressure is removed from the tool when the

coupling joint is disconnected.

To reduce the risk of injury from a hose

bursting, select hoses that are rated at

!

WARNING

couplings on the tool. Non relieving couplings and

female couplings will trap high pressure air in the tool

when the air line is disconnected. This will leave the tool

charged with enough air after it has been disconnected to

drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in the

tool is vented to atmosphere as soon as the air line is

disconnected.

6. Set the regulator at the air delivery system to a PSI that

falls within the tool's operating range of 60 to 120 PSI.

The correct pressure is the lowest pressure that will do

the job.

7.If the operator is working at a bench or table, it is

recommended to run the air line underneath the bench. A

small tray under the bench top can hold the nail supply

and the tool when not in use.

Never use non relieving couplers

and/or female quick disconnect

Operation

Actuation System

Your tool is equipped with two devices that require actuation

before the tool will fire, the work contact element and the

finger trigger. There are two selectable modes, built into the

trigger, that determine how the tool fires nails.

“Sequential” Firing Mode: In “sequential” firing mode,

there is a predetermined sequence required to fire a nail.

The work contact element must first be depressed against

the work piece. A nail will then fire when the trigger is

depressed. To fire another faster, the work contact element

must be removed from the work piece, the trigger must be

released. The sequence can then be repeated.

“Bump” Firing Mode: In “Bump” firing mode, nails can be

fired each time the work contact element is depressed with

the trigger depressed. With the trigger continuously

depressed, a nail will fire each time the work contact

element is depressed against the work piece. This allows

for nails to be fired at a faster rate.

Each mode is described in detail in the “Firing Modes”

section of this manual.

!

WARNING

tool in an inappropriate mode may cause tool to react in an

unexpected manner and may result in personal injury.

!

WARNING

before verifying the actuation mode may cause tool to react

in an unexpected manner and may result in personal injury.

Understand the differences between

actuation modes for this tool. Using the

Verify the setting of the Selectable trigger

switch before using the tool. Using the tool

6.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 7

Operation

Lubrication

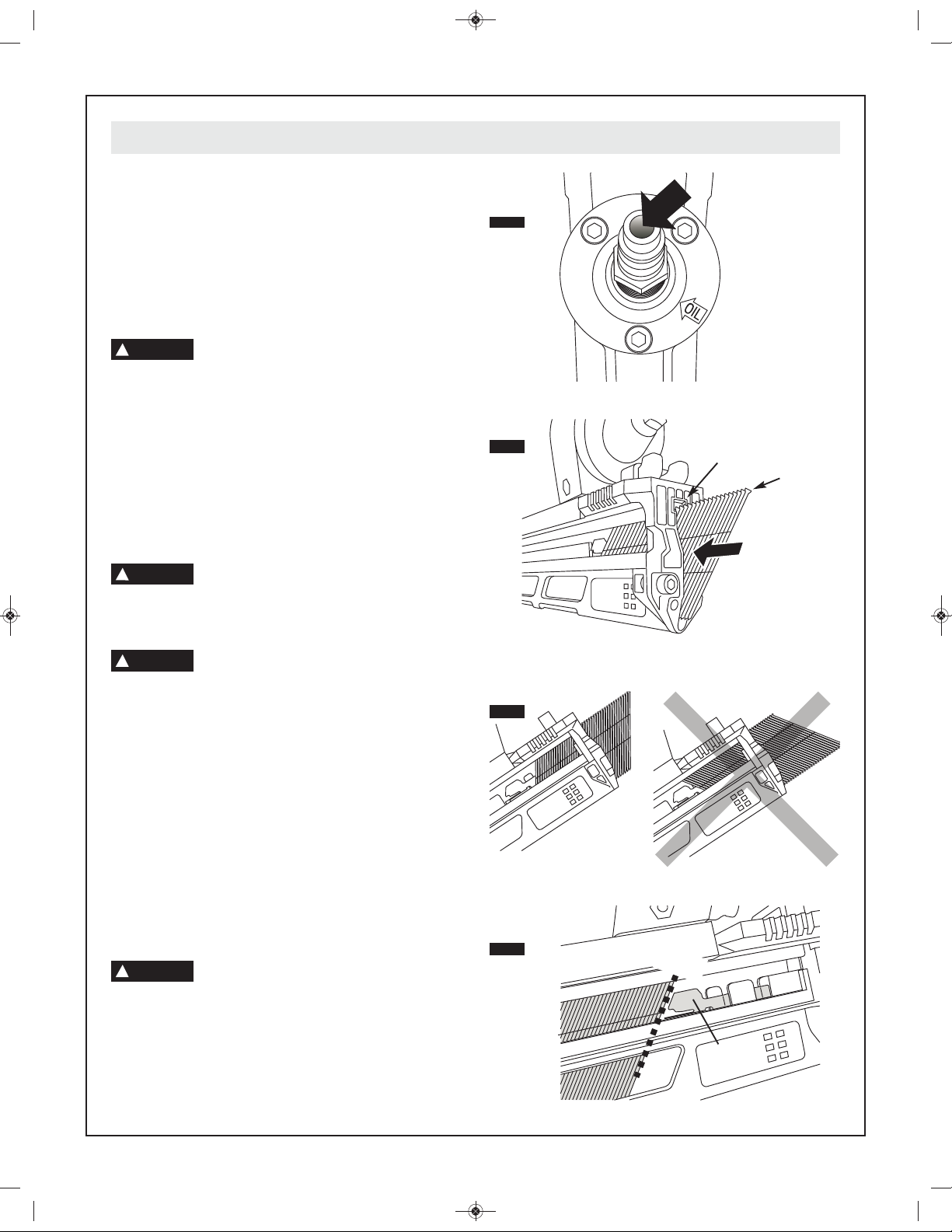

If the tool is not used with an in-line lubrication system on

the air supply it is necessary to periodically lubricate the tool

with air tool lubricant.

Under low use, lubricate once a day. Under heavy use,

lubricate twice a day. To lubricate, insert 2-3 drops of

lubricant into the air supply fitting attached to the tool

handle, see figure 2. Using to much oil will cause it to collect

in the tool and be noticeable in the exhaust.

!

WARNING

not use other lubricants as they may damage the tool.

Do not use detergent oil, WD-40, transmission fluid, motor

oil, or other lubricants not specifically designated as air tool

lubricants. These lubricants will cause accelerated wear to

the seals, o-rings, and bumpers in the tool, resulting in poor

tool performance and frequent maintenance.

BOSCH recommended lubricants: 10W Pneumatic Tool Oil,

Fuchs Air Lube 10W/NR.

Use only the air tool lubricants supplied

with the tool or specified by BOSCH. Do

Nail Loading

!

WARNING

Connecting the air supply after loading nails reduces the risk

of unintentionally driving a nail and injuring yourself or

someone else.

!

WARNING

pulling with finger. If not smooth, nails can be driven at

irregular angle.

1. Insert appropriate collated nail strips into loading slot in

back of magazine, see figure 3. See tool specifications to

determine appropriate nail sizes and angles.

2. Orient a strip of approved nails with the tips pointed down,

the nails should be inserted with the tips first into the slot,

see figure 4, and to align the head of the nail with the top

“T” portion of the slot. Insert nails fully into magazine

making sure that the last nail in the strip slides past the

Nail Hold Back Spring, see figure 5.

Note: The tool features a nail follower lockout that will

prevent the tool from firing when there are zero nails left

in the magazine. The tool will not allow the work contact

element to be depressed when there are no nails in the

tool.

!

WARNING

manual. Nails not identified for use with this tool can cause

the tool to malfunction and result in the risk of injury and/or

tool damage.

Always load nails into the tool's magazine

before the air supply is connected.

When loading the tool's magazine, check

that the nail follower slides smoothly by

Use only the nails meeting the criteria

listed in the “Specification” section of this

FIG. 2

FIG. 3

RIGHT WRONG

FIG. 4

FIG. 5

MAXIMUM

LOAD

2-3 Drops

of Air Tool

Lubricant

T-slot

INSERT

NAILS

Head of

nail

7.

Nail Hold

Back

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 8

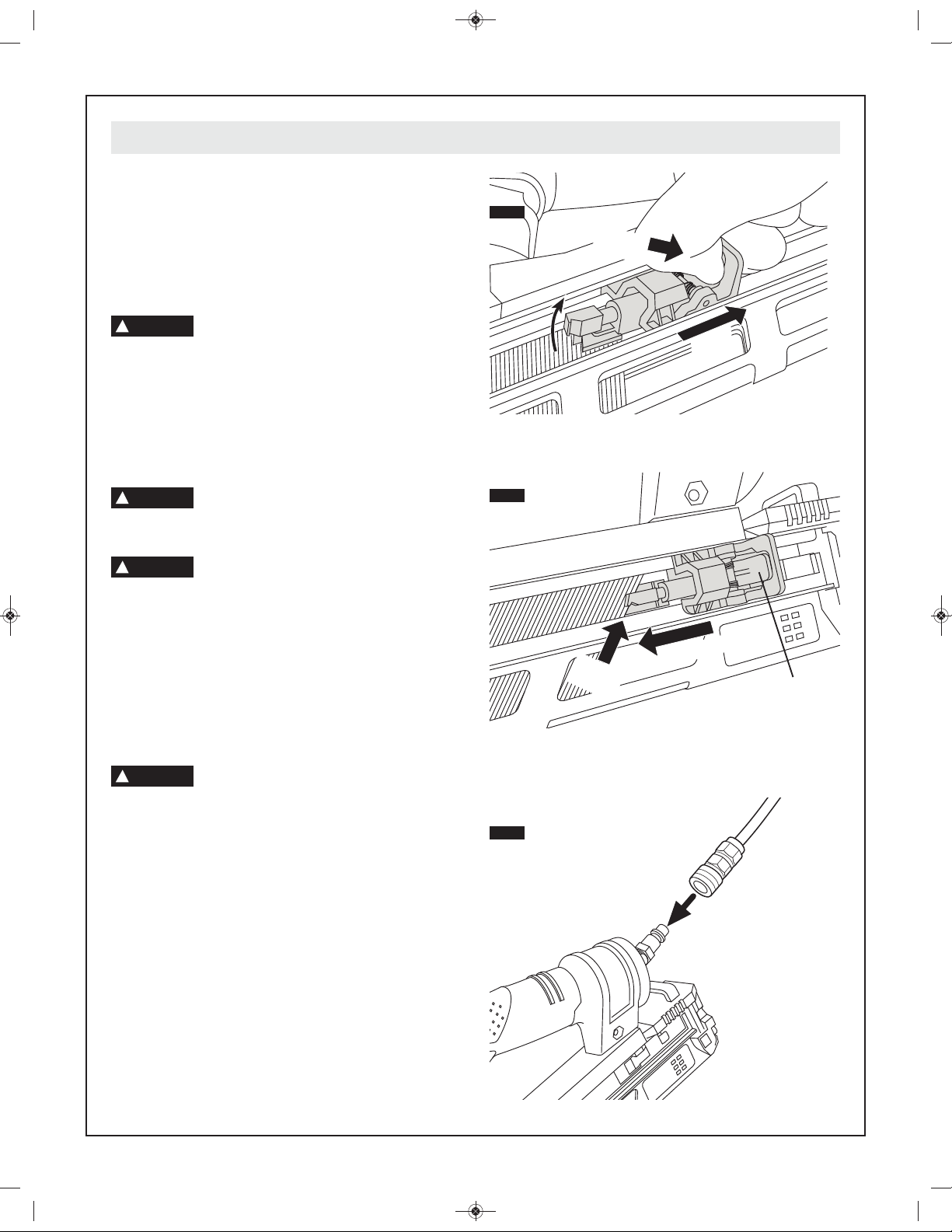

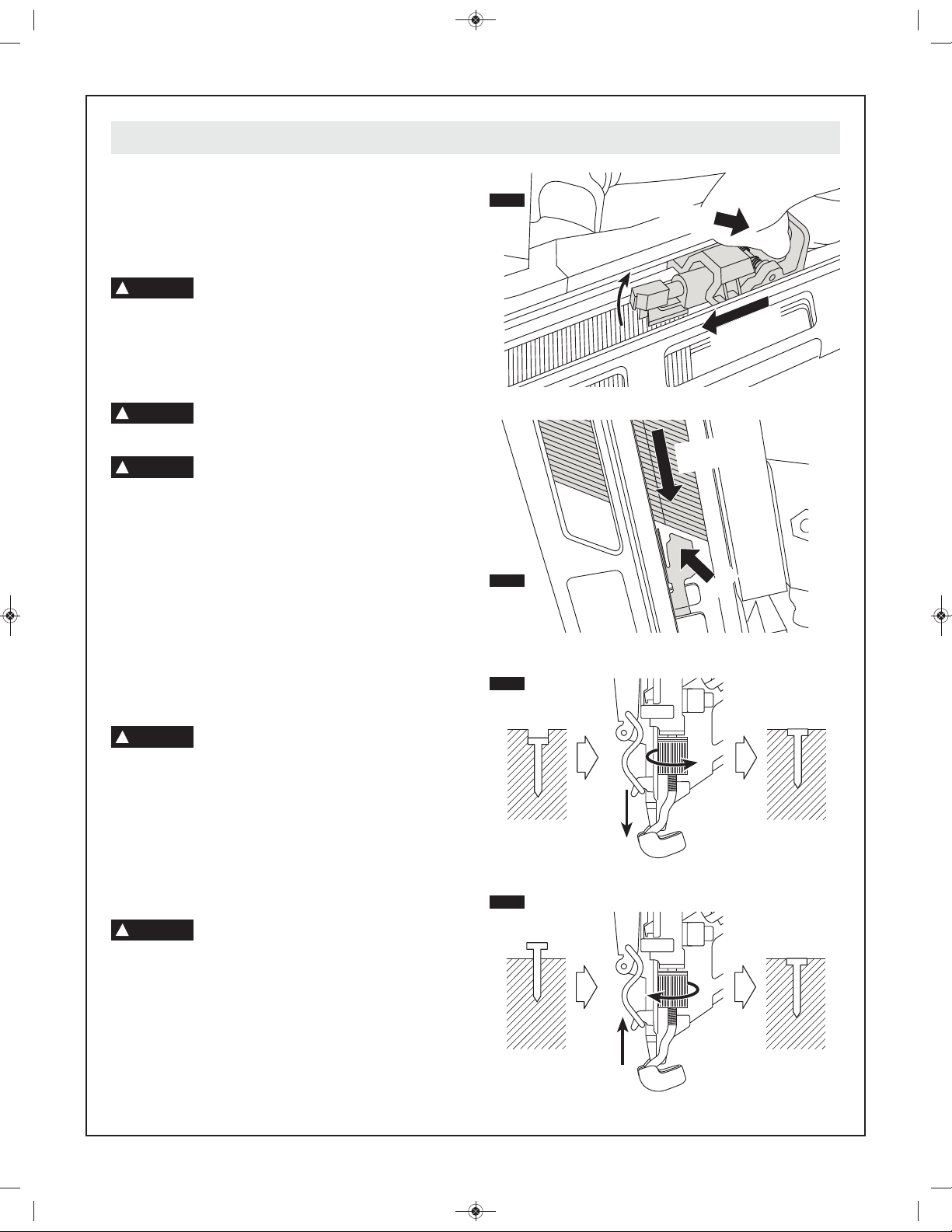

3. This tool uses a spring loaded bypass lever in order to

load and unload the nails. Once the nails are properly

inserted, pull the follower completely to the back of the

magazine, pressing against the bypass lever of the

follower, see figure 6.

4. Once the follower hits the back of the magazine, allow the

follower to slide forward and engage the nails, pushing

them to the nose of the tool, see figure 7.

!

WARNING

pinch point area. When loading nails consider where your

hand is located. If it is within a pinch point, strongly consider

an alternative position. Injuries occur when hands or fingers

are between moving and stationary parts during the pinching

movement.

Watch for pinch points with the follower.

Never place any part of your body in a

Connecting Air Supply

!

WARNING

Combustible gases and other bottled gases are dangerous

and may cause the tool to explode.

!

WARNING

exceeding 200 PSI. Excessive pressure can cause

abnormal operation or cause the tool to burst, resulting in

personal injury.

Use only clean, dry, regulated compressed air within the

pressure range as marked on the tool. The correct pressure

is the lowest pressure that will do the job.

Before connecting the tool to the air supply, check the air

compressor regulator gauge to be sure it is functioning

properly, and that the air pressure is within the operational

range of the tool, 60-120 psi.

!

WARNING

prior to using the tool that the air source has been adjusted

within the rated air-pressure range. Be sure the air pressure

gauge is operating properly and check it at least twice a day.

Tools operated in excess of their maximum pressure rating

may operate abnormally or burst resulting in personal injury

To connect the tool to the compressor only use pneumatic air

hoses that meet the following criteria:

• Minimum hose pressure rating, 200 psi

• Minimum hose inner diameter, 3/8 in.

• Maximum hose length, 100 ft.

To connect the air supply:

1. Snap the air hose onto the quick connector, see figure 8.

2. Check for air leakage. If leakage is noted, cease using the

tool immediately and contact your BOSCH service center.

3. Be sure the air pressure gauge is operating properly and

check it at least twice a day.

Never use oxygen or other bottled gases

as a power source. Explosion may occur.

Never connect the tool to an air source

that is capable of producing air pressure

Do not exceed maximum recommended

air pressure marked on the tool. Verify

Operation

FIG. 6

FIG. 7

FIG. 8

PRESS

Bypass Lever

ENGAGE

NAILS

SLIDE

BACK

SLIDE FORWARD

Release

Bypass Lever

8.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 9

Operation

Firing Modes

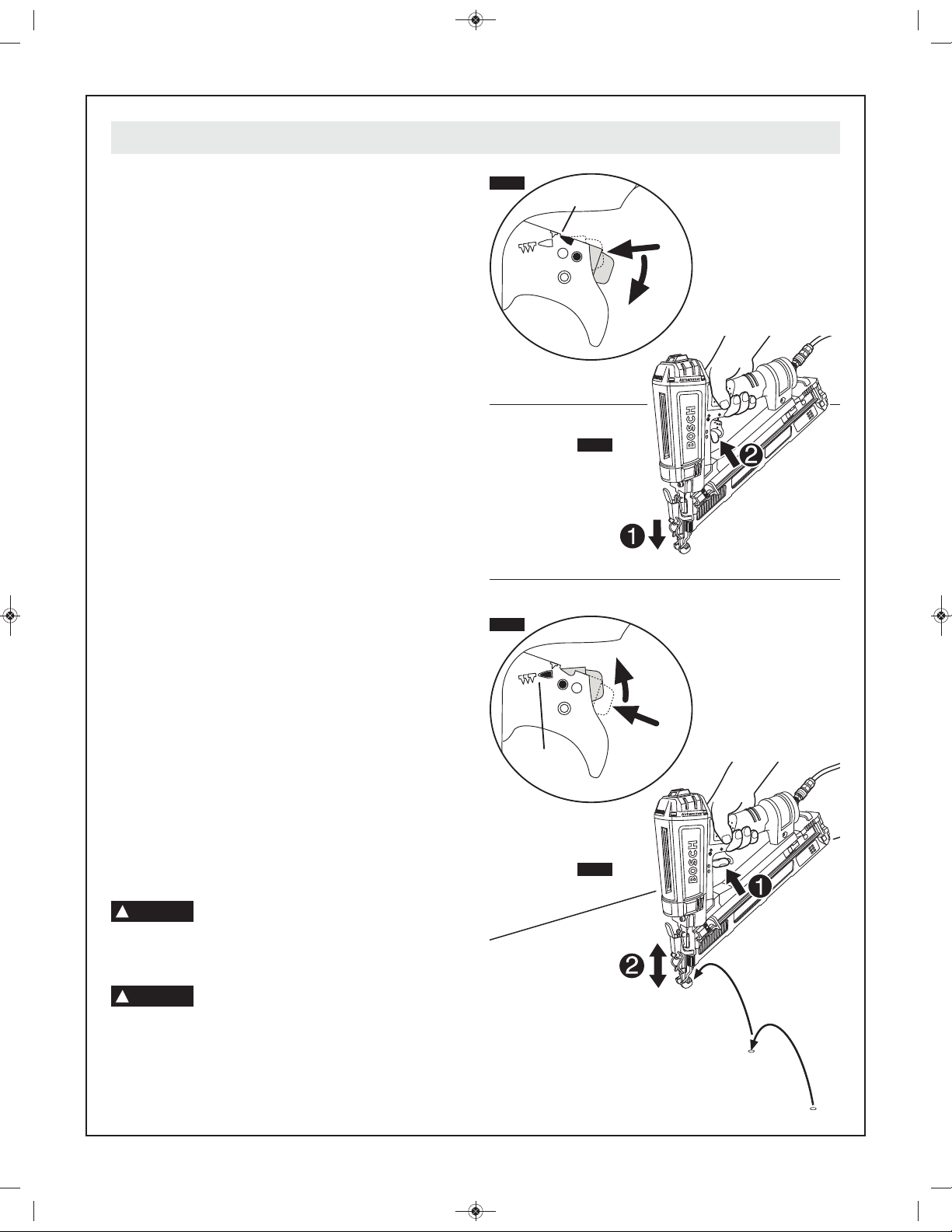

The tool is equipped with a trigger that can select one of two

firing modes.

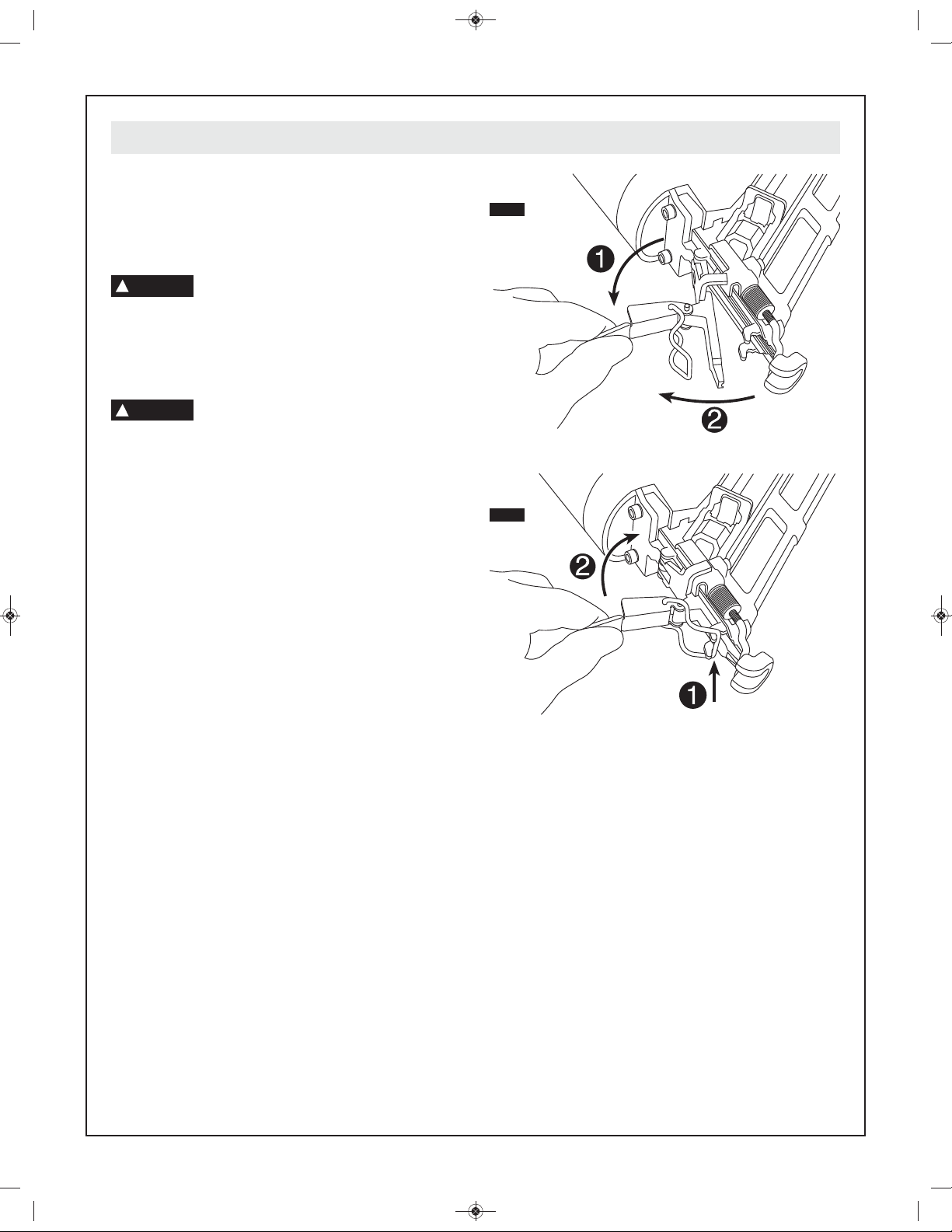

“Sequential” Firing Mode:

To use the tool to drive nails in this actuation mode, the

work contact element and trigger must be used in a specific

order:

1.Press and turn the selectable fire mode switch in the

downwards position. On the trigger, the firing mode

indicator should be pointing at the single nail icon, see

figure 9.

2. The work contact element must be completely depressed

by placing the nose of the tool against the work piece, see

figure 10.

3. The trigger must be pulled firmly and then released, see

figure 10.

4. The tool must be allowed to recoil away from the work

piece.

To continue operation in a separate location, move the tool

along the work piece, repeating steps 2 through 4 as

required.

“Bump” Firing Mode:

To use the tool to drive nails in this actuation mode the work

contact element and trigger can be actuated in any order.

1.Press and turn the selectable fire mode switch in the

upwards position. On the trigger the actuation mode

indicator should be pointing at the multi-nail icon, see

figure 11.

2. Pull and hold the trigger with the tool off the work piece.

3. Press the work contact element against the work piece. A

nail will be driven, see figure 12.

4. The tool must be allowed to recoil away from the work

piece.

5.Move the tool along the work piece with a bouncing

motion. Each time the work contact element is depressed

a nail will be driven, see figure 12.

6. As soon as the desired number of nails has been driven,

remove finger from trigger.

!

WARNING

handle only. Removing your finger from the trigger when

not operating the tool reduces the risk of unintentionally

firing a nail and injuring yourself or someone else.

!

WARNING

on top of another nail. If the tool is not moved before the

trigger is pulled again a second nail will be driven on top of

the previously driven nail. This could cause the nail to be

deflected or the tool to react in an unexpected manner.

Remove finger from the trigger when not

driving nails. Always carry the tool by the

The tool must be allowed to recoil away

from the work piece. Do not drive a nail

FIG. 9

FIG. 11

Fire Position

Trigger

Bump Fire

Position

Sequential

FIG. 10

FIG. 12

Press

then

turn

down

Press

then turn

up

9.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 10

Cold Weather Operation

When using the tool in cold conditions the tool will cycle

slower than usual while driving the first nails. The cycle rate

will increase as the tool warms up. Keep tool warm to avoid

reduced cycle rate.

!

WARNING

impede internal components resulting in the risk of injury

and/or tool damage.

Do not use a frozen tool. Allow tool to thaw

before using. Moisture frozen in the tool may

Nail Unloading

!

WARNING

This avoids the risk of unintentional operation.

!

WARNING

element depressed. The tool can fire when reconnected to

air supply.

1. Disconnect air supply.

2. Pull back follower, pressing bypass lever of the follower to

allow follower to bypass nails and slowly allow follower to

return to nose of the tool, see figure 13.

3. Tilt the tool with the magazine vertical and the nose facing

up, this will allow the nails to slide to the back of the

magazine.

4. Once the nails have slid back to the hold back spring,

press the tab on the hold back spring to push the spring

back and allow the nails to come out of the magazine, see

figure 14.

!

WARNING

reaches its full forward position. Free recoil of the

follower could result in damage to the follower and/or

magazine or your fingers could become pinched.

Always disconnect tool from air supply

before removing nails from magazine.

Do not disconnect air hose from the tool

with finger on trigger or work contact

Do not allow the nail follower to freely

recoil. Guide the follower by hand until it

Operation

FIG. 13

FIG. 14

FIG. 15

PRESS

Bypass Lever

RELEASE

NAILS

SLIDE

FORWARD

PRESS

FlushToo Deep

Depth of Drive Adjustment

The depth with which nails are driven into the work piece

can be adjusted using the depth adjustment on the nose

piece of the tool.

!

WARNING

precautionary safety measures reduce the risk or

unintentional tool operation.

1. Disconnect tool from air supply.

2.Remove nails from tool as described in the “Nail

Unloading” section of this manual.

3. Adjust tool driving depth:

• To reduce the nail depth, turn the adjustment knob

counter clockwise, see figure 15.

Disconnect the tool from the air source

before making adjustments. Such

Turn the adjustment knob counter clockwise.

FIG. 16

Too Shallow

Flush

Turn the adjustment knob clockwise.

10.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 11

• To drive the nail deeper, turn the adjustment knob

clockwise, see figure 16.

4. Reload nails as described in the “Nail Loading” section of

this manual.

5. Reconnect air supply

!

WARNING

without assuring the area on the opposite side is clear.

A nail could travel through the work piece, striking someone.

Know what is behind your work piece.

Do not fire nails into walls or floors

Jam Clearing

!

WARNING

Such precautionary safety measures reduce the risk or

unintentional tool operation.

If a nail becomes jammed in the nosepiece, follow these

instructions to remove the jammed nail:

1. Release the trigger.

2. Disconnect the air supply from the tool.

3. Remove nails from the magazine as described in “Nail

Unloading.”

4. Open the nose of the tool by pulling quick release lever

forward. Pull open the nose of the tool to access the nail

jam, see figure 17.

5. Remove the nail, using pliers if necessary.

6. Close the nose of the tool by hooking the spring of the

quick clear lever on the two hooks on the nose. Press the

lever closed, see figure 18.

7.Reinsert nails into the magazine as described in “Nail

Loading”.

8.Reconnect air supply as described in “Connecting Air

Supply”.

NOTE: If the driver blade does not return to its up position,

disconnect air supply and contact a Bosch factory service

center or authorized Bosch service station.

NOTE: If nails continue to jam frequently in the nose piece,

contact BOSCH service center for repair.

Disconnect the tool from the air source

before attempting to clear a jammed nail.

Operation

FIG. 17

FIG. 18

Adjustable Exhaust Deflector

This tool has an adjustable exhaust deflector that allows the

exhaust air to be blown away from user or workpiece.

11.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 12

Maintenance

Service

!

WARNING

internal components which could cause serious hazard.

We recommend that all tool service be performed by a

BOSCH factory service center or authorized BOSCH

service station.

Contact your BOSCH service center for instructions and the

following user replaceable parts; o-rings, bumpers, and

driver blades.

For all other repairs contact your BOSCH service center.

Maintenance performed by unauthorized

personnel may result in misplacing of the

Cleaning

!

WARNING

internal components may be misplaced or safety

components may be improperly mounted. Certain

cleaning agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts and o-rings.

!

WARNING

edges may damage internal components causing a serious

hazard.

Ventilation openings, the work contact element, and the

trigger must be kept clean and free of foreign matter.

Periodically clean the tool with compressed air.

Clean the magazine. Remove plastic or wooden chips

which may have accumulated in the magazine. Lubricate

the magazine with pneumatic tool lubricant.

When cleaning a tool be careful not to

disassemble any portion of the tool since

Do not attempt to clean by inserting

pointed objects through openings. Sharp

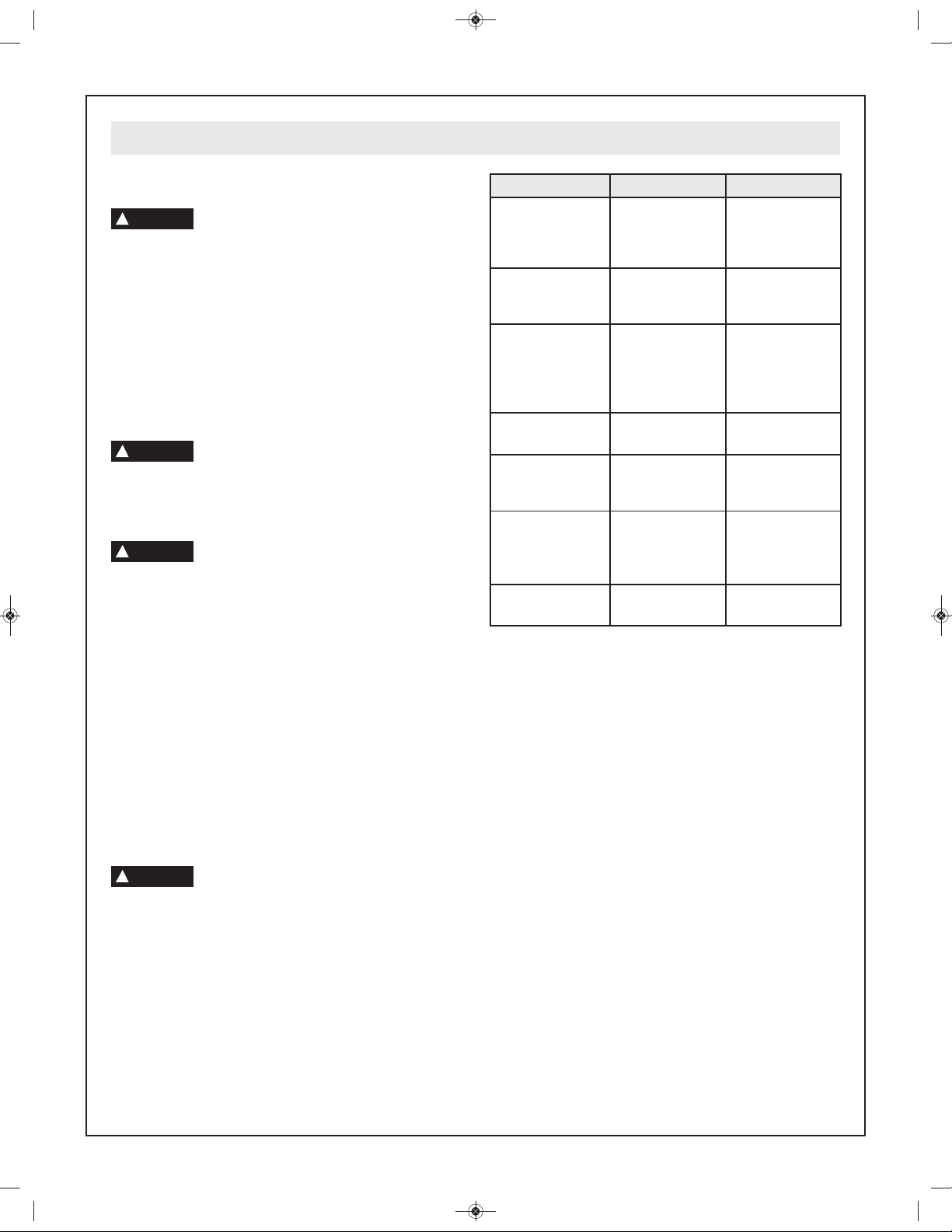

ACTION WHY HOW

Drain air line filter

daily.

Keep lubricator

filled

Clean filter element

- then blow air

through filter in

direction opposite

to normal flow.

Clean magazine

and feeder

Keep work contact

element working

properly

Lubricate the tool. Extend tool life. Place 2-3 drops of

Drain air

compressor.

Prevent

accumulation of

moisture

and dirt.

Keep the Nailer

lubricated

Prevent clogging

of filter with dirt.

Prevent a jam. Blow mechanism

Promote operator

safety and efficient

tool operation.

Keep water out of

tool.

Open manual

valve.

Fill with BOSCH

pneumatic tool

lubricant.

Follow

manufacturer's

instructions.

clean daily.

Blow clean daily.

lubricant

into the tool as

directed.

Open valve on air

compressor tank.

Storage

When not in use, the tool should be disconnected and

stored in the storage case in a warm and dry place. When

tool will not be in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

Do not store the tool in a cold weather environment.

!

WARNING

Lock the storage area. Tools are dangerous in the hands of

personnel unfamiliar with the tool.

Keep out of reach of children and

personnel unfamiliar with tool operation.

12.

BM 2610957377 02-09:BM FNA250 06-09 6/17/09 8:01 AM Page 13

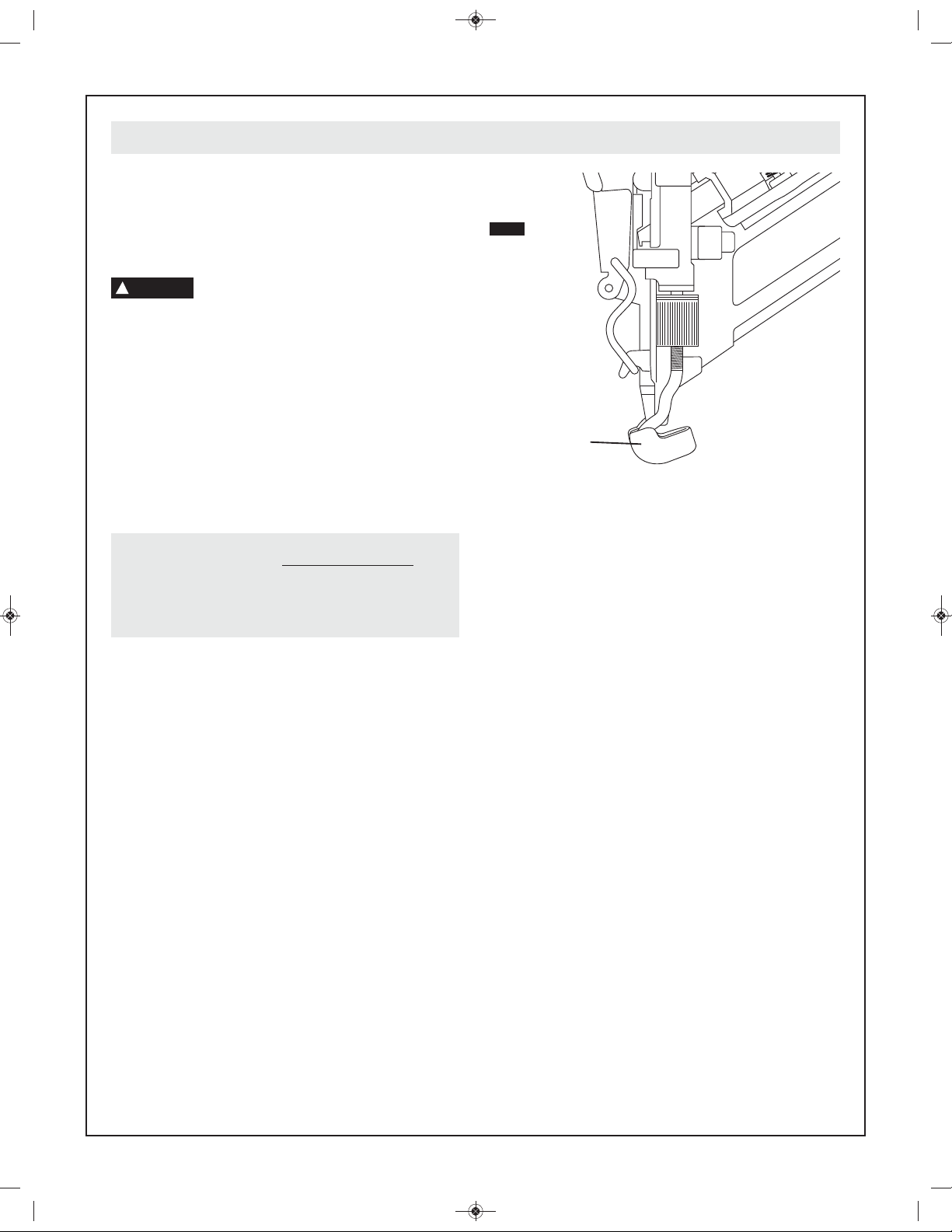

No-Mar Pad

The No-Mar Pad on the nose of the work contact element

protects the work piece from the work contact element toe

nailing teeth when the work piece contact is compressed

during actuation. The pad can be removed and replaced.

!

WARNING

or replacing no-mar pads. Such precautionary safety

measures reduce the risk or unintentional tool operation.

To remove the pad: Pull the no mar tip towards the back of

the tool following the bend of the wire nose.

To replace the pad. Push the no mar tip on to the tool

inserting the opening of the no mar tip on to the wire nose.

Disconnect the air supply from the tool

and remove nail strips before removing

Accessories

FIG. 19

Compressor

A correctly sized compressor is critical for maximum tool

performance. Use the following calculation to determine the

required compressor size.

Compressor size (CFM) =

x Shots per minute x Number of tools x 1.2

Air Consumption, one shot per second @ 100 psi: 3.1 CFM

Air Consumption(CFM)

60

No-Mar Pad

13.

Loading...

Loading...