Bosch DSA-N2C7X8-12AT, DSA-N2E7X8-12AT, DSX-N1D6X8-12AT, DSX-N6D6X8-60AT Installation Manual

Page 1

DSA E-Series (E2700)

DSA-N2E7X2-08AT | DSA-N2E7Xx-12AT | DSA-N2C7Xx-12AT |

DSX-N1D6Xx-12AT | DSX-N6D6Xx-60AT | DSX-NRCK40-INT

en

Installation manual

Page 2

Page 3

DSA E-Series (E2700) Table of contents | en 3

Table of contents

1

1.1 Safety message explanation 5

1.2 Safety precautions 5

1.3 Important safety instructions 5

1.4 Warning Notices 7

1.5 Caution Notices 9

1.6 Notices 9

2

3

4

4.1 Key terms 13

4.2 Gathering items 13

4.2.1 Basic hardware 13

4.2.2 E2700 configuration cables and connectors 14

4.2.3 Tools and other items 15

4.3 Things to know – copper cables and sas cables 15

4.4 Things to know –taking a quick glance at the hardware in a E2700 controller-drive tray

5

6

6.1 Things to know – general installation 22

6.2 Procedure – installing the E2712 controller-drive tray 22

6.3 Procedure – installing drives in the E2712 controller-drive 26

7

7.1 Key terms 27

7.2 Things to know – storage array configuration specifications for the E2700 controller-

7.3 Things to know – host channels 27

7.4 Procedure – connecting the controller-drive tray to the expansion drive trays 29

7.5 Connecting to the network 31

7.6 Connecting to the management hosts 31

8

8.1 Things to know – general installation of drive trays with the E2700 controller-drive tray 33

8.2 Procedure – installing the DE1600 drive trays 33

8.3 Procedure – installing drives in the DE1600 drive trays 37

8.4 Procedure – installing the DE6600 drive tray 38

8.5 Procedure – installing drives on the de6600 drive tray 45

8.6 Things to know – connecting the power cords 47

8.7 Procedure – connecting the power cords 48

9

9.1 Key terms 49

9.2 Things to know – E2700 controller-drive tray 49

9.3 Things to know – drive trays 50

9.4 Things to know – drive tray cabling configurations for the E2712 controller-drive tray 50

10

10.1 Key terms 53

10.2 Things to know – connecting Ethernet cables 53

10.3 Procedure – connecting Ethernet cables 53

Safety 5

About this guide 11

Registering for E-Series 12

Preparing for an E2700 controller-drive tray installation 13

16

configuration

Ethernet network interface cards for the E2700 controller-drive tray 21

Installing the E2700 controller-drive tray 22

Connecting the E2700 controller-drive tray to the hosts 27

27

drive tray

Installing the drive trays for the E2700 controller-drive tray configurations 33

Connecting the E2700 controller-drive tray to the drive trays 49

Connecting the ethernet cables 53

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 4

4 en | Table of contents DSA E-Series (E2700)

11

Connecting the power cords 54

11.1 Things to know – AC power cords 54

11.2 Procedure – connecting AC power cords 54

12

Turning on the power and checking for problems in an E2700 controller-drive tray

55

configuration

12.1 Procedure –turning on the power to the storage array and checking for problems in a

55

E2700 controller-drive tray configuration

12.2 Things to know –LEDs on the E2712 controller-drive tray 56

12.3 Things to know – general behavior of the LEDs on the controller-drive tray 60

12.4 Things to know – service action allowed LEDs 62

12.5 Things to know –LEDs on the DE6600 drive tray 63

12.6 LEDs on the DE6600 drive drawers 66

12.7 LEDs on the DE6600 drives 67

12.8 General behavior of the LEDs on the drive trays 67

12.9 Things to know –seven segment display sequence code definitions on the E2700

69

controller-drive tray

12.10 Things to know –seven segment component failure identifications for the E2700

69

controller-drive tray

12.11 Things to Know – Lock-Down Codes for the Controller-Drive Tray 70

12.12 Things to know – seven-segment display use cases 72

12.13 Things to know – seven-segment display for the ESMs on the drive trays 74

13

14

15

Regulatory compliance statements 75

Trademark information 76

Additional documentation 77

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 5

DSA E-Series (E2700) Safety | en 5

!

!

!

!

1 Safety

1.1 Safety message explanation

Warning!

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Caution!

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Notice!

Indicates a situation which, if not avoided, could result in damage to the equipment or

environment, or data loss.

1.2 Safety precautions

Caution!

Installation should only be performed by qualified service personnel in accordance with

applicable local codes.

Caution!

The Low Voltage power supply unit must comply with EN/UL 60950. The power supply must

be a SELV-LPS unit or a SELV - Class 2 unit (Safety Extra Low Voltage - Limited Power

Source).

1.3 Important safety instructions

Read, follow, and retain for future reference all of the following safety instructions. Follow all

warnings before operating the device.

– Clean only with a dry cloth. Do not use liquid cleaners or aerosol cleaners.

– Do not install device near any heat sources such as radiators, heaters, stoves, or other

equipment (including amplifiers) that produce heat.

– Never spill liquid of any kind on the device.

– Take precautions to protect the device from power and lightning surges.

– Unless qualified, do not attempt to service a damaged device yourself. Refer all servicing

to qualified service personnel.

– Install in accordance with the manufacturer's instructions in accordance with applicable

local codes.

– Use only attachments/accessories specified by the manufacturer.

– Protect all connection cables from possible damage, particularly at connection points.

– Do not defeat the safety purpose of a polarized or ground‑type plug.

– Permanently connected devices must have an external, readily operable mains plug or

all‑pole mains switch in accordance with installation rules.

– Pluggable devices must have an easily accessible socket-outlet installed near the

equipment.

– Unplug the unit from the outlet before cleaning. Follow any instructions provided with the

unit.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 6

6 en | Safety DSA E-Series (E2700)

– Any openings in the unit enclosure are provided for ventilation to prevent overheating and

ensure reliable operation. Do not block or cover these openings.

– Do not place the unit in an enclosure unless proper ventilation is provided, or the

manufacturer's instructions have been adhered to.

– Install the unit only in a dry, weather-protected location.

– Do not use this unit near water, for example near a bathtub, washbowl, sink, laundry

basket, in a damp or wet basement, near a swimming pool, in an outdoor installation, or

in any area classified as a wet location.

– To reduce the risk of fire or electrical shock, do not expose this unit to rain or moisture.

– Never push objects of any kind into this unit through openings as they may touch

dangerous voltage points or short-out parts that could result in a fire or electrical shock.

– Power supply cords should be routed so that they are not likely to be walked on or

pinched by items placed upon or against them, playing particular attention to cords and

plugs, convenience receptacles, and the point where they exit from the appliance.

– Operate the unit only from the type of power source indicated on the label. Use only the

power supply provided or power supply units with UL approval and a power output

according to LPS or NEC Class 2.

– Do not open or remove the cover to service this unit yourself. Opening or removing covers

may expose you to dangerous voltage or other hazards. Refer all servicing to qualified

service personnel.

– Be sure the service technician uses replacement parts specified by the manufacturer.

Unauthorized substitutions could void the warranty and cause fire, electrical shock, or

other hazards.

– Safety checks should be performed upon completion of service or repairs to the unit to

ensure proper operating condition.

– Observe the relevant electrical engineering regulations.

– When installing in a switch cabinet, ensure that the unit and the power supply units have

sufficient grounding.

– Connect the unit to an earthed mains socket.

– Use proper CMOS/MOS-FET handling precautions to avoid electrostatic discharge (ESD).

– For protection of the device, the branch circuit protection must be secured with a

maximum fuse rating of 16A. This must be in accordance with NEC800 (CEC Section 60).

– Disconnect the power before moving the unit. Move the unit with care. Excessive force or

shock may damage the unit and the hard disk drives.

– All the input/output ports are Safety Extra Low Voltage (SELV) circuits. SELV circuits

should only be connected to other SELV circuits.

– If safe operation of the unit cannot be ensured, remove it from service and secure it to

prevent unauthorized operation. In such cases, have the unit checked by Bosch Security

Systems.

– Disconnect power supply and arrange for the device to be serviced by qualified personnel

in the following cases, because safe operation is no longer possible:

– The power cable/plug is damaged.

– Liquids or foreign bodies have entered the device.

– The device has been exposed to water or extreme environmental conditions.

– The device is faulty despite correct installation/operation.

– The device has fallen from a height, or the housing has been damaged.

– The device was stored over a long period under adverse conditions.

– The device performance is noticeably changed.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 7

DSA E-Series (E2700) Safety | en 7

!

!

!

!

!

!

!

!

1.4 Warning Notices

Warning!

Risk of electrical shock

If there is evidence of fire, water, or structural damage, never turn on the power to the

equipment.

Warning!

Risk of electrical shock

Before removing or installing a power supply, turn off the power switch, and unplug the

power cord.

Warning!

Risk of exposure to laser radiation

Do not disassemble or remove any part of a Small Form-factor Pluggable (SFP) transceiver

because you might be exposed to laser radiation.

Warning!

Risk of bodily injury

The battery can weigh up to 10.9 kg (24 lb). When you remove the battery, be prepared to

support its weight. If the battery is dropped, the impact might cause bodily injury, including

deep puncture wounds caused by the battery pins.

Warning!

Risk of bodily injury

If the bottom half of the cabinet is empty, do not install components in the top half of the

cabinet. If the top half of the cabinet is too heavy for the bottom half, the cabinet might fall

and cause bodily injury. Always install a component in the lowest available position in the

cabinet.

Warning!

Risk of bodily injury

Attach the stability foot before moving the cabinet. If you do not attach the stability foot, the

cabinet might become unstable, or it might fall. This problem is most likely to occur when the

cabinet is moved along inclined surfaces or over uneven surfaces.

Warning!

Risk of bodily injury

Only move a populated cabinet with a forklift or adequate help from other persons. Always

push the cabinet from the front to prevent it from falling over.

A fully populated cabinet can weigh more than 909 kg (2000 lb). The cabinet is difficult to

move, even on a flat surface. If you must move the cabinet along an inclined surface, remove

the components from the top half of the cabinet, and make sure that you have adequate help.

Warning!

Risk of fire or chemical burn

Before disposing of a used battery, review the battery warning label. The label reads: The

battery used in this device may present a risk of fire or chemical burn if mistreated. DO NOT

disassemble, heat above 60ºC (140ºF), crush or puncture, short circuit external contacts, or

dispose of in fire or water. Use appropriate charger only. Replace only with original batteries.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 8

8 en | Safety DSA E-Series (E2700)

!

!

!

!

!

!

!

!

Warning!

Risk of bodily injury

Only move a populated cabinet with a forklift or adequate help from other persons. Attach

the stability foot before moving the cabinet. If you do not attach the stability foot, the cabinet

might become unstable, or it might fall. Always push the cabinet from the front to prevent it

from falling over.

A fully populated cabinet can weigh more than 636 kg (1420 lb). The cabinet is difficult to

move, even on a flat surface. If you must move the cabinet along an inclined surface, remove

the components from the top half of the cabinet, and make sure that you have adequate help.

Warning!

Risk of bodily injury

A qualified service person is required to make the DC power connection according to NEC

and CEC guidelines.

Warning!

Risk of bodily injury

An empty tray weighs approximately 56.7 kg (125 lb). Three persons are required to safely

move an empty tray. If the tray is populated with components, a mechanized lift is required to

safely move the tray.

Warning!

Risk of bodily injury

Each tray has more than one power cord. To remove all electrical current from the devices,

make sure that all of the power cords are disconnected from the power source and that the

two-pole 20-amp circuit breaker for the storage array has been disconnected.

Warning!

Risk of bodily injury

Each tray has more than one power cord. To remove all electrical current from the devices,

make sure that all of the power cords are disconnected from the power source.

Warning!

Risk of bodily injury

Do not use equipment in the cabinet as a shelf or work space.

Warning!

Hazardous moving parts

Keep away from moving fan blades.

Warning!

Risk of bodily injury

High leakage current earth connection essential before connecting supply.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 9

DSA E-Series (E2700) Safety | en 9

1.5 Caution Notices

Caution!

Potentially hazardous material

The battery pack contains sealed lead acid batteries that might be considered hazardous

material. If you recycle a used battery pack that is not damaged, use the proper facilities.

Handle the battery pack according to all applicable regulations.

Caution!

Potentially hazardous material

If the used battery pack is physically damaged or is leaking, DO NOT ship the battery pack to

a recycling center. Handling a damaged battery pack exposes you and others to potentially

hazardous material. Dispose of the damaged battery pack according to all applicable

regulations.

Caution!

Pinching hazard

As you push the canister into the slot, ensure that your fingers are not pinched between the

lever and the canister. The lever automatically moves toward the closed position as the

canister is pushed into its slot.

Caution!

Potentially hazardous material

The battery pack contains sealed lithium ion batteries that might be considered hazardous

material. If the used battery pack is physically damaged and is leaking, DO NOT ship the

battery pack to a recycling center. Handling a damaged battery pack exposes you and others

to potentially hazardous material. Dispose of the damaged battery pack according to all

applicable regulations. If you recycle a used battery pack that is not damaged, use the proper

facilities. Handle the battery pack according to all applicable regulations.

Caution!

Electrical grounding hazard

This equipment is designed to permit the connection of the DC supply circuit to the earthing

conductor at the equipment.

Caution!

Possible hazard exists

Do not remove more than one canister from the enclosure while power to the enclosure is

turned on.

1.6 Notices

Notice!

This is a class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 10

10 en | Safety DSA E-Series (E2700)

!

Notice!

Video loss is inherent to digital video recording; therefore, Bosch Security Systems cannot be

held liable for any damage that results from missing video information.

To minimize the risk of losing information, we recommend multiple, redundant recording

systems, and a procedure to back up all analog and digital information.

Disposal

Your Bosch product has been developed and manufactured using highquality materials and components that can be reused.

This symbol means that electronic and electrical devices that have reached

the end of their working life must be disposed of separately from

household waste.

In the EU, separate collecting systems are already in place for used

electrical and electronic products. Please dispose of these devices at your

local communal waste collection point or at a recycling center.

Notice!

Do not dispose batteries in household waste. Dispose of batteries only at suitable collection

points and, in the case of lithium batteries, mask the poles.

Caution!

Battery replacement - For qualified service personnel only

A lithium battery is located inside the unit enclosure. To avoid danger of explosion, replace

the battery as per instructions. Replace only with the same or equivalent type recommended

by the manufacturer. Dispose of the replaced battery in an environmentally friendly way and

not with other solid waste. Refer all servicing to qualified service personnel.

Do not place this unit on an unstable stand, tripod, bracket, or mount. The

unit may fall, causing serious injury and/or serious damage to the unit.

Information on sales, delivery, storage, and working life period

No restrictions or conditions apply for the sale or delivery of this product.

If stored under the specified conditions, the storage period is not restricted.

If used for the specified purpose in compliance with the safety instructions and technical

specifications, the working life period of the product is in accordance with normal

expectations for this type of product.

Information on equipment use

Device is for professional installation only. Operation of the devices is not intended for

personal or household use. There are no restrictions to use the device in commercial and

industrial areas, except those mentioned in the Safety information.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 11

DSA E-Series (E2700) About this guide | en 11

2 About this guide

This manual is written for professional system integrators and PC technicians. It provides

information for the installation and use of the E2700 controller-drive tray running with

SANtricity® Storage Manager software version 11.20, including all attached drive trays.

To access the SANtricity® Storage Manager software, go to the online product catalogue.

Installation, configuration and maintenance should be performed by experienced and qualified

technicians only.

Conventions in this manual:

For simplicity, the following product names will be used for the following units also described

in this manual:

– DE1600 for the DSAE‑Series 12-bay expansion unit

– DE6600 for the DSAE‑Series 60-bay expansion unit

See also

– Additional documentation, page 77

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 12

12 en | Registering for E-Series DSA E-Series (E2700)

3 Registering for E-Series

Before you begin the installation, register your E-Series storage system by using the

registration form shipped with the system. The enclosure serial number is located on two

places on each enclosure: the large UL label attached to the top of an enclosure, and a silver

label attached to the front of the enclosure, either on the bottom lip or the right ear. In both

of these places, the enclosure serial number is identified by the text “Serial ” or “S/N ”.

Record the serial number of the integrated controller-drive tray for later use. This serial

number is required to initiate any support request for your system.

Notice!

The SANtricity® Storage Manager software is also referred to as the storage management

software.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 13

DSA E-Series (E2700) Preparing for an E2700 controller-drive tray installation | en 13

4 Preparing for an E2700 controller-drive tray

installation

Storage arrays consist of a E2700 controller-drive tray model and can have eight or twelve

drive trays in a cabinet:

Use this document to install the E2700 controller-drive tray model and all necessary drive

trays for your configuration.

Notice!

Possible hardware damage

To prevent electrostatic discharge damage to the tray, use proper antistatic protection when

handling tray components.

4.1 Key terms

storage array

A collection of both physical components and logical components for storing data. Physical

components include drives, controllers, fans, and power supplies. Logical components include

disk pools, volume groups, and volumes. These components are managed by the storage

management software.

controller-drive tray

One tray with drives, one or two controllers, fans, and power supplies. The controller-drive

tray provides the interface between a host and a storage array.

controller

A circuit board and firmware that is located within a controller tray or a controller-drive tray. A

controller manages the input/output (I/O) between the host system and data volumes.

drive tray

One tray with drives, one or two environmental services modules (ESMs), power supplies, and

fans. A drive tray does not contain controllers.

environmental services module (ESM)

A canister in the drive tray that monitors the status of the components. An ESM also serves as

the connection point to transfer data between the drive tray and the controller.

4.2 Gathering items

Before you start installing the controller-drive tray, you must have installed the cabinet in

which the controller-drive tray will be mounted.

Use the tables in this section to verify that you have all of the necessary items to install the

controller-drive tray.

Notice!

Possible hardware damage

To prevent electrostatic discharge damage to the tray, use proper antistatic protection when

handling tray components.

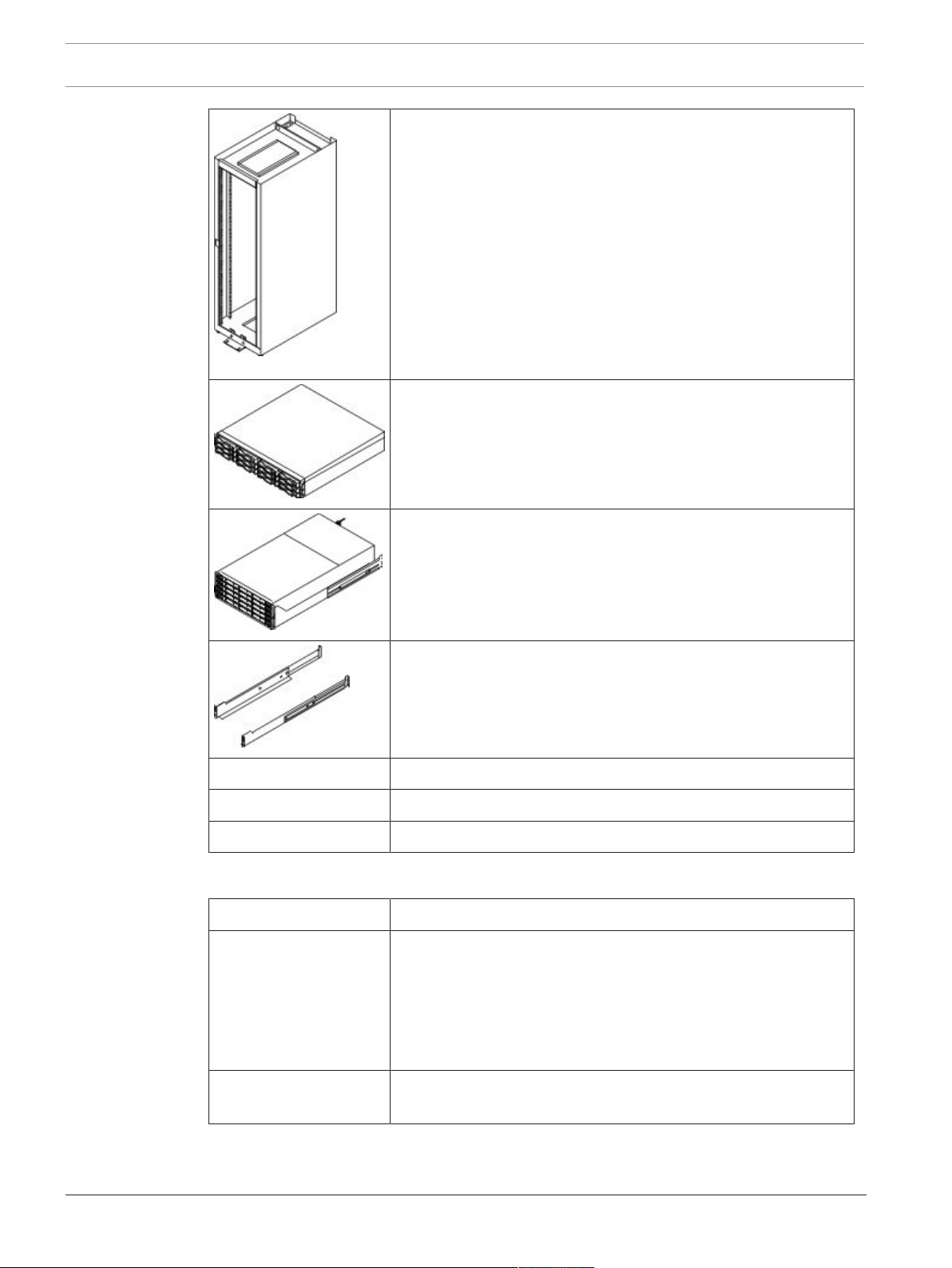

4.2.1 Basic hardware

Item

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 14

14 en | Preparing for an E2700 controller-drive tray installation DSA E-Series (E2700)

Cabinet

– Make sure that your cabinet meets the installation site

specifications of the E2700 storage array components.

For more information, refer to the “Storage System Site

Preparation Guide”.

– Depending on the power supply limitations of your cabinet,

you might need to install more than one cabinet to

accommodate the different components of the E2700

storage array.

For instructions on installing the cabinet , refer to the

installation guide for your cabinet for instructions on

installing the cabinet.

DE1600 drive tray with end caps that are packaged separately.

This drive tray can be used with all variations of the E2700

controller-drive tray.

DE6600 drive tray (shown with the separately packaged

mounting rails attached). This drive tray can be used with all

variations of the E2700 controller-drive tray.

Mounting rails and screws

The mounting rails that are available with the drive tray are

designed for an industry-standard cabinet.

iSCSI switch (optional)

Gigabit Ethernet switch for Management (optional)

IP cameras/encoders with iSCSI capabilities

4.2.2 E2700 configuration cables and connectors

AC power cords

The controller-drive tray and the drive trays ship with power

cords for connecting to an external power source, such as a wall

plug. Your cabinet might have special power cords that you use

instead of the power cords that ship with the controller-drive tray

and the drive trays.

RJ-45 Ethernet cable

This cable is used for 10-Gb/s iSCSI connections.

Item

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 15

DSA E-Series (E2700) Preparing for an E2700 controller-drive tray installation | en 15

Ethernet cable

SAS cables

The HD Mini-SAS (SFF-8644) to Mini-SAS (SFF-8088) SAS cables

connect each controller expansion port to the drive tray(s).

Serial cable

This cable is used for support only. You do not need to connect it

during initial installation.

DB9-to-PS2 adapter cable

This cable adapts the DB9 connector on commercially available

serial cables to the PS2 connector on the ESM for drive trays in

the storage array. This cable is used for support only. You do not

need to connect it during installation.

Mini-USB connector

This cable adapts the DB9 connector on commercially available

serial cables to the PS2 connector on the controller. This cable is

used for support only. You do not need to connect it during

installation.

4.2.3 Tools and other items

You may need the following equipment:

– Labels: Help you to identify cable connections and lets you more easily trace cables from

one tray to another.

– A cart: Holds the tray and components.

– A mechanical lift (optional)

– A Phillips screwdriver

– A flat-blade screwdriver

– An anti-static protection

– A flashlight

4.3 Things to know – copper cables and sas cables

The controller-drive tray supports SAS drive connections and SAS, or iSCSI host connections.

Notice!

Your cables might look slightly different from the ones shown. The differences do not affect

the performance.

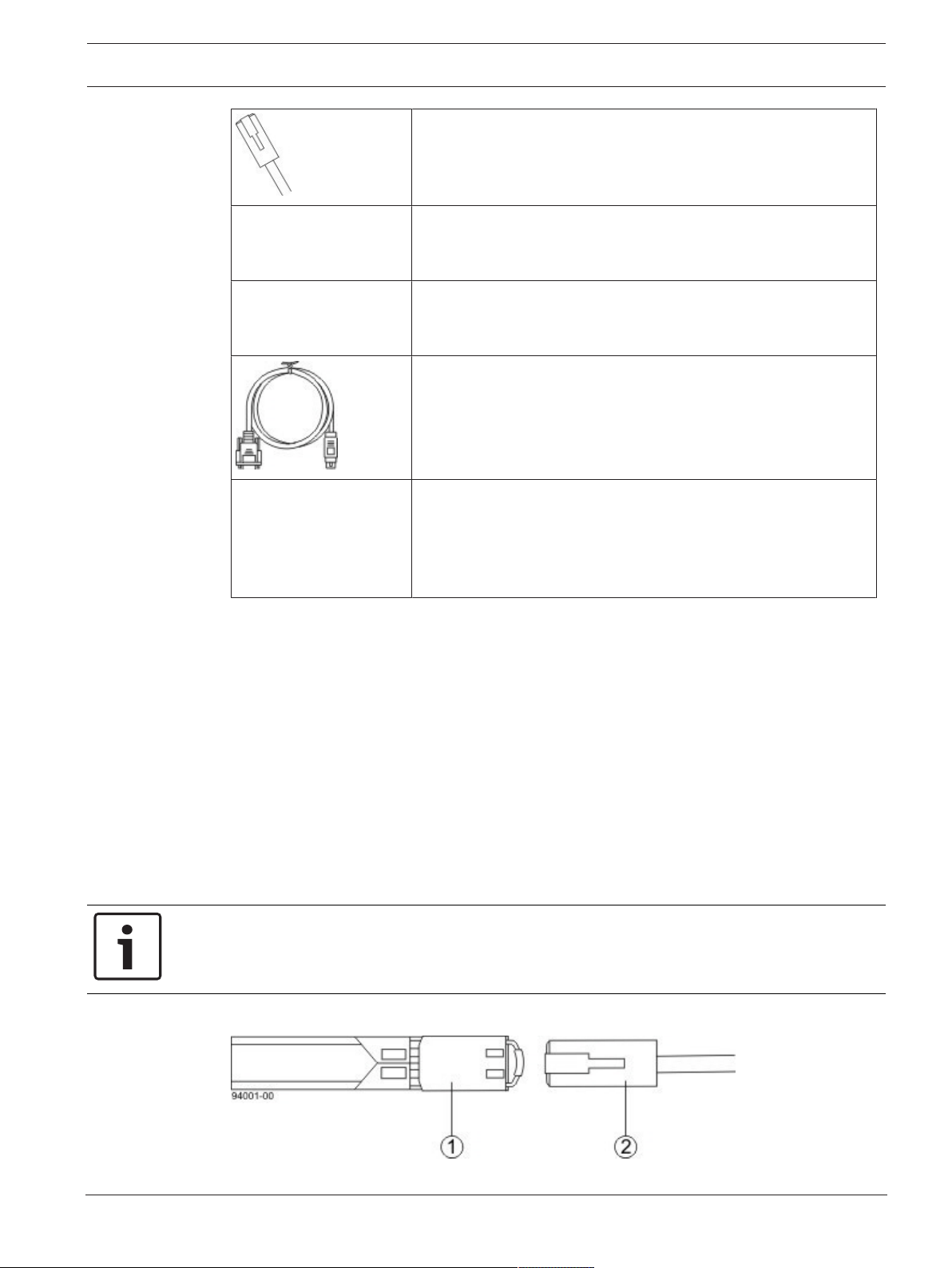

10-Gb/s iSCSI cable connection

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 16

16 en | Preparing for an E2700 controller-drive tray installation DSA E-Series (E2700)

970 01-03

!

1

2

3

4

5

6

1 Active SFP transceiver

2 Copper cable with RJ-45 connector

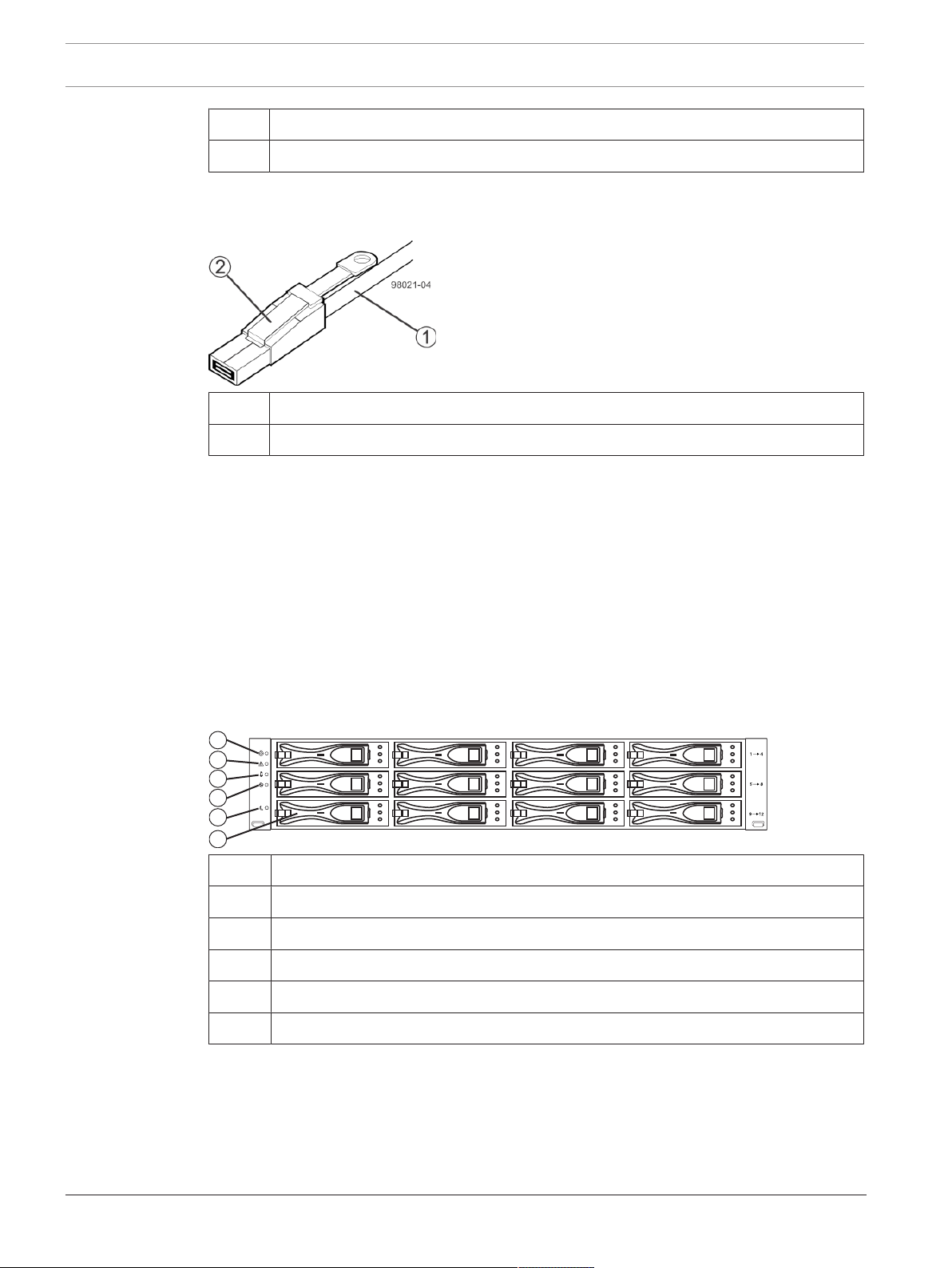

SAS cable connection with SFF-8644 connector

1 SAS cable

2 SFF-8644 connector

4.4 Things to know –taking a quick glance at the hardware in a E2700 controller-drive tray configuration

The E2700 systems always come with eight or twelve hard drives. At least two drives are

required for proper operation.

This section provides an overview of hardware described in this document.

Observe the following:

– The top of the controller-drive tray is the side with labels.

– The configuration of the host ports might appear different on your system depending on

which host interface card configuration is installed.

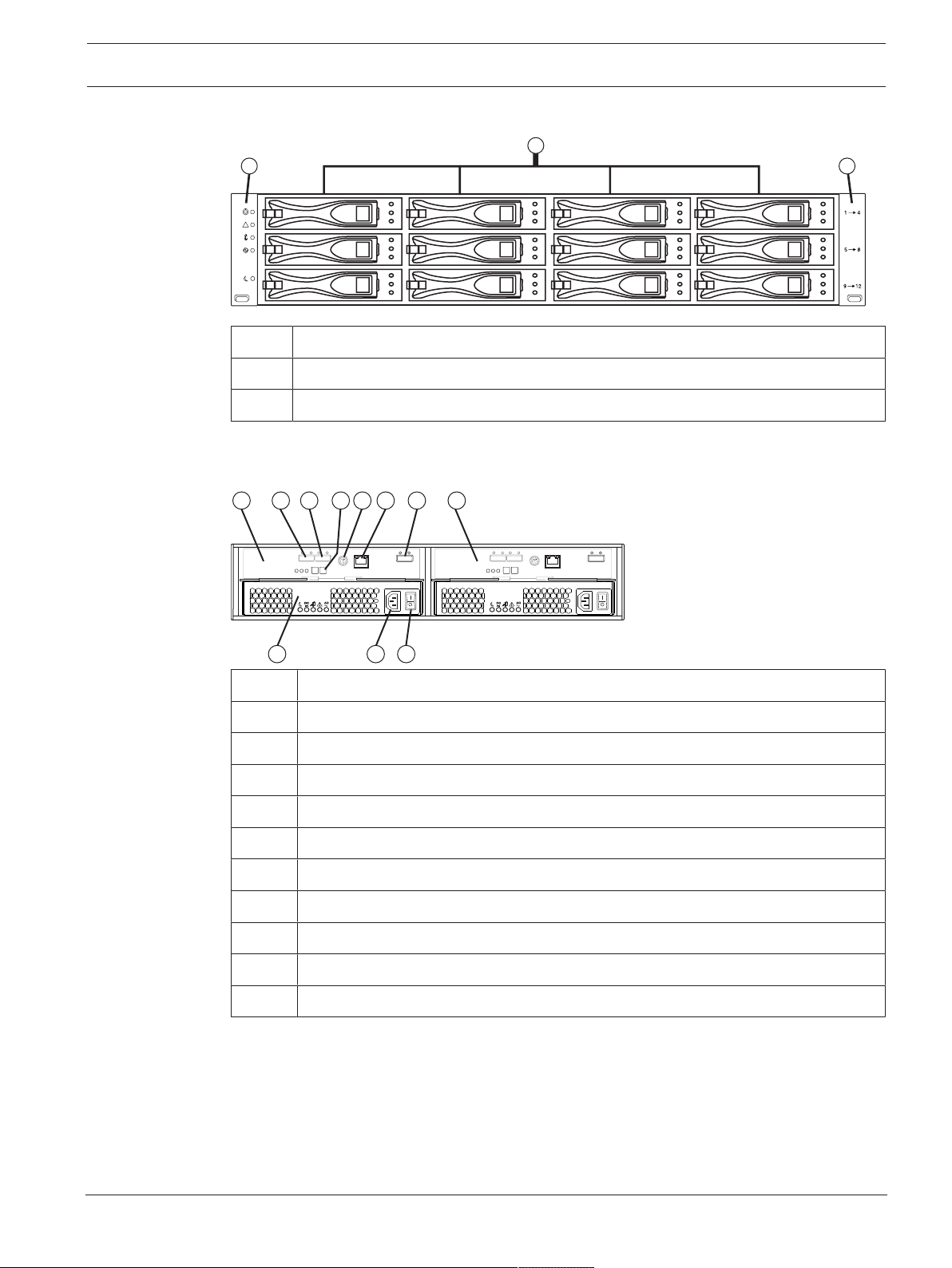

E2700 controller-drive tray – front view

1 End cap Locate LED

2 End cap Service action required LED

3 End cap over-temperature LED

4 End cap Power LED

5 End cap Standby power LED

6 Drive canister

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 17

DSA E-Series (E2700) Preparing for an E2700 controller-drive tray installation | en 17

17

11 12

13

8

1 2 5 7

9 10

6

23 24

25

4

3

18 19

20 21 22

iSCSI

Host

S

S

SL

S

A

Lnk Lnk

LnkLnk

Port 2Port 1

Ch 4

Ch 3

Drive Expansion

L

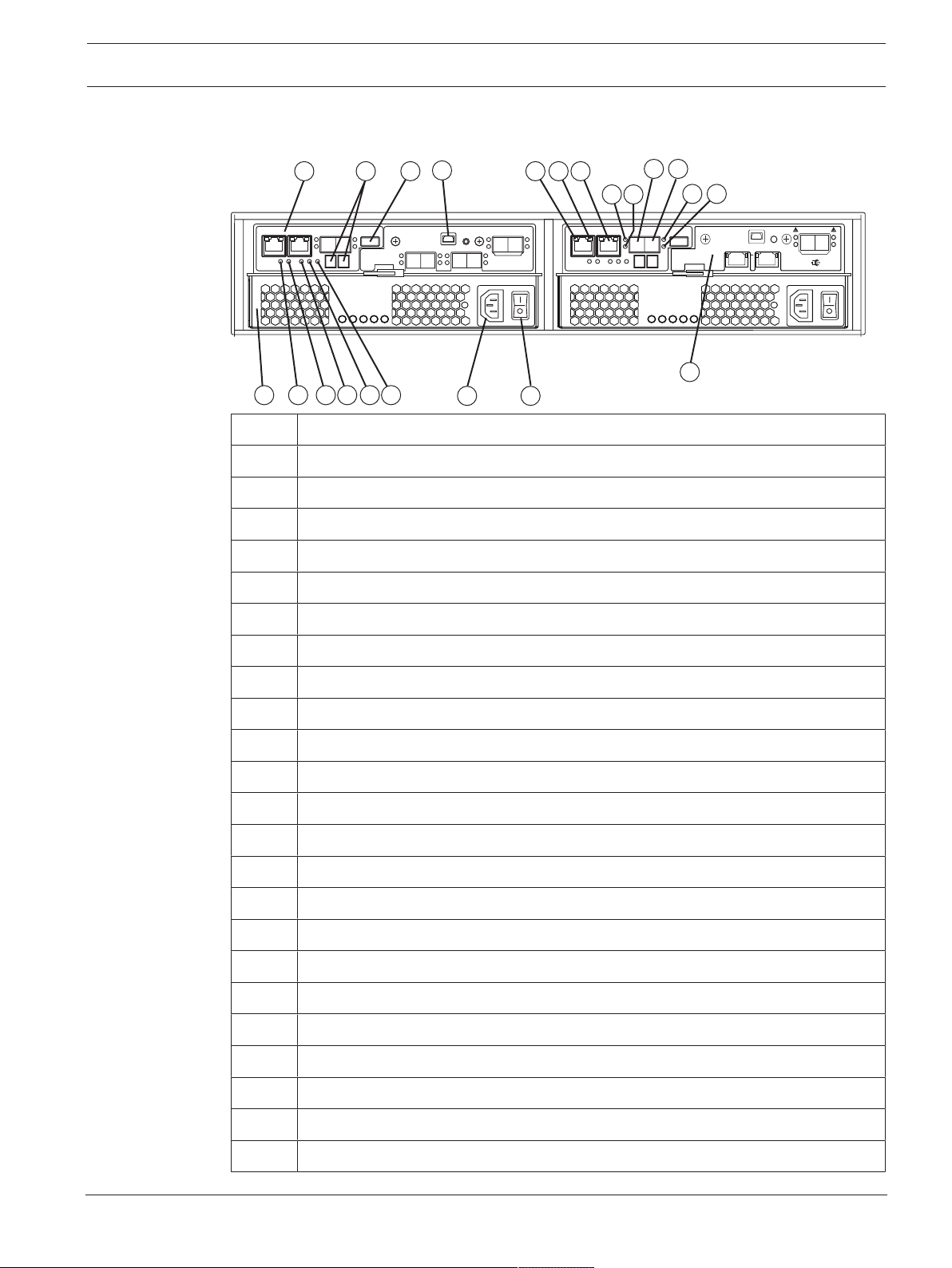

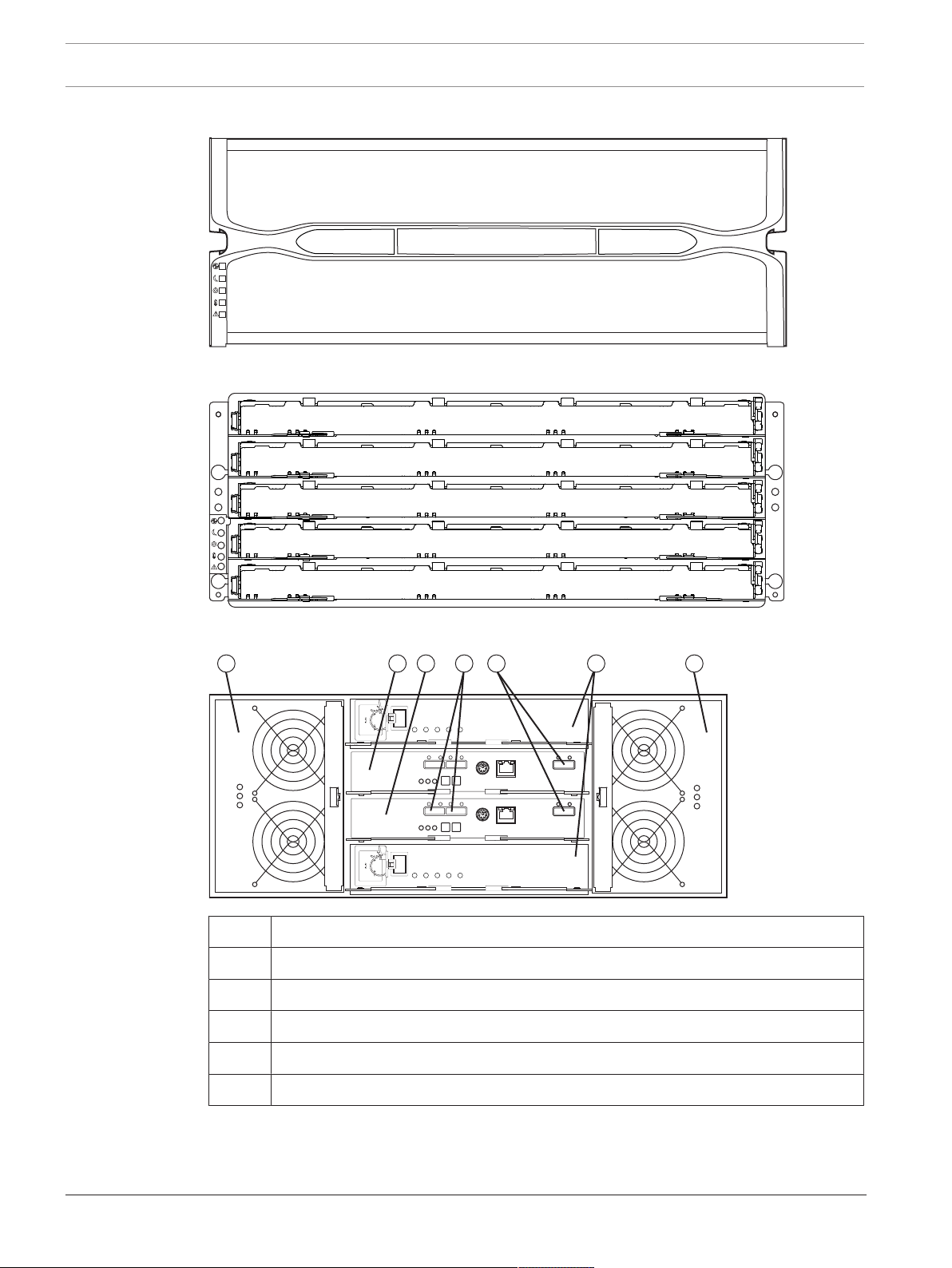

E2700 controller-drive tray – rear view

(right-rear sub plate with a two-port 1-Gb/s or 10-Gb/s iSCSI host interface card)

1 E2700 controller canister

2 Seven-segment display

3 USB port

4 Serial port

5 Ethernet port 1 link rate LED

6 Ethernet port 2 link active LED

7 1 GbE Ethernet management port 2

8 SFF-8644 SAS host connector 1

9 SAS host 1 link up LED

10 SAS host 1 link fault LED

11 SAS host 2 link up LED

12 SAS host 2 link fault LED

13 SFF-8466 SAS host connector 2

14 SAS expansion link 1 fault LED

15 SAS expansion link 1 up LED

16 SFF-8644 SAS connector 1 (expansion)

17 Power-fan canister

18 Battery service action required LED

19 Battery charging LED

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

20 Controller service action allowed LED

21 Controller service action required LED

22 Cache active LED

23 AC power connector

24 On/off switch

Page 18

18 en | Preparing for an E2700 controller-drive tray installation DSA E-Series (E2700)

49006-08

7

8 91 2

3

4 5

6

25 Right rear sub plate (see below)

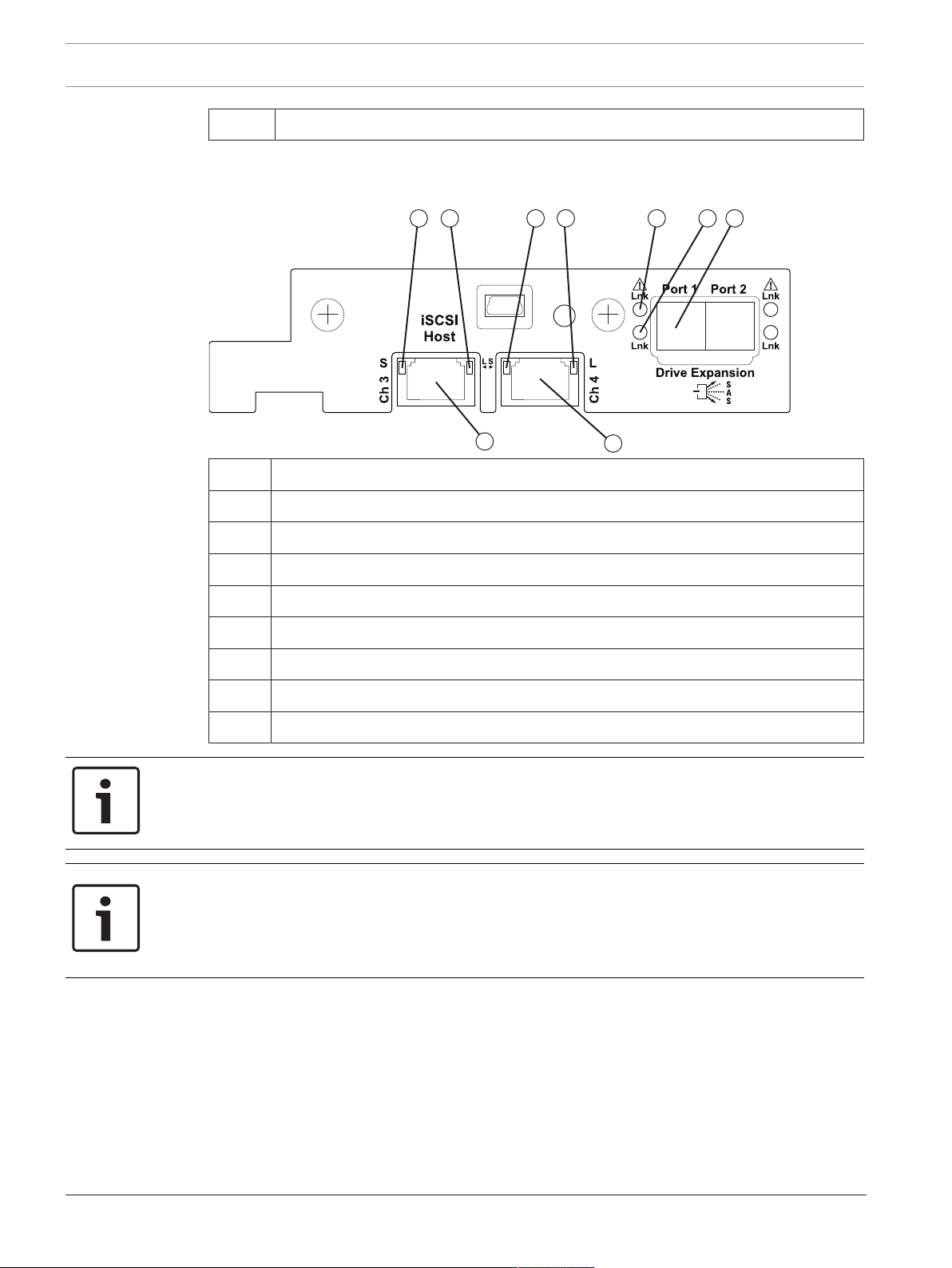

E2700 right-rear sub plate with a two-port 1-Gb/s or 10-Gb/s iSCSI host interface card

1 Host interface card channel 3 fault LED

2 Host interface card channel 3 link up LED

3 iSCSI host interface card channel 3

4 iSCSI host interface card channel 4 fault LED

5 Host interface card channel 4 link up LED

6 iSCSI host interface card channel 4

7 SAS expansion port 1 fault LED

8 SAS expansion port 1 link up LED

9 SFF-8644 SAS port 1 (expansion)

Notice!

Possible equipment damage

You must use the supported drives in the drive tray to ensure proper operation. For

information about supported drives, contact a Technical Support Representative.

Notice!

Risk of equipment malfunction

To avoid exceeding the functional and environmental limits, install only drives that have been

provided or approved by the original manufacturer. System integrators, resellers, system

administrators, or users of the controller-drive tray can install the drives.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 19

DSA E-Series (E2700) Preparing for an E2700 controller-drive tray installation | en 19

!

970 01- 01

31

2

970 02-01

AC

DC

!

AC

DC

!

2 3 4 5 761

98 10

11

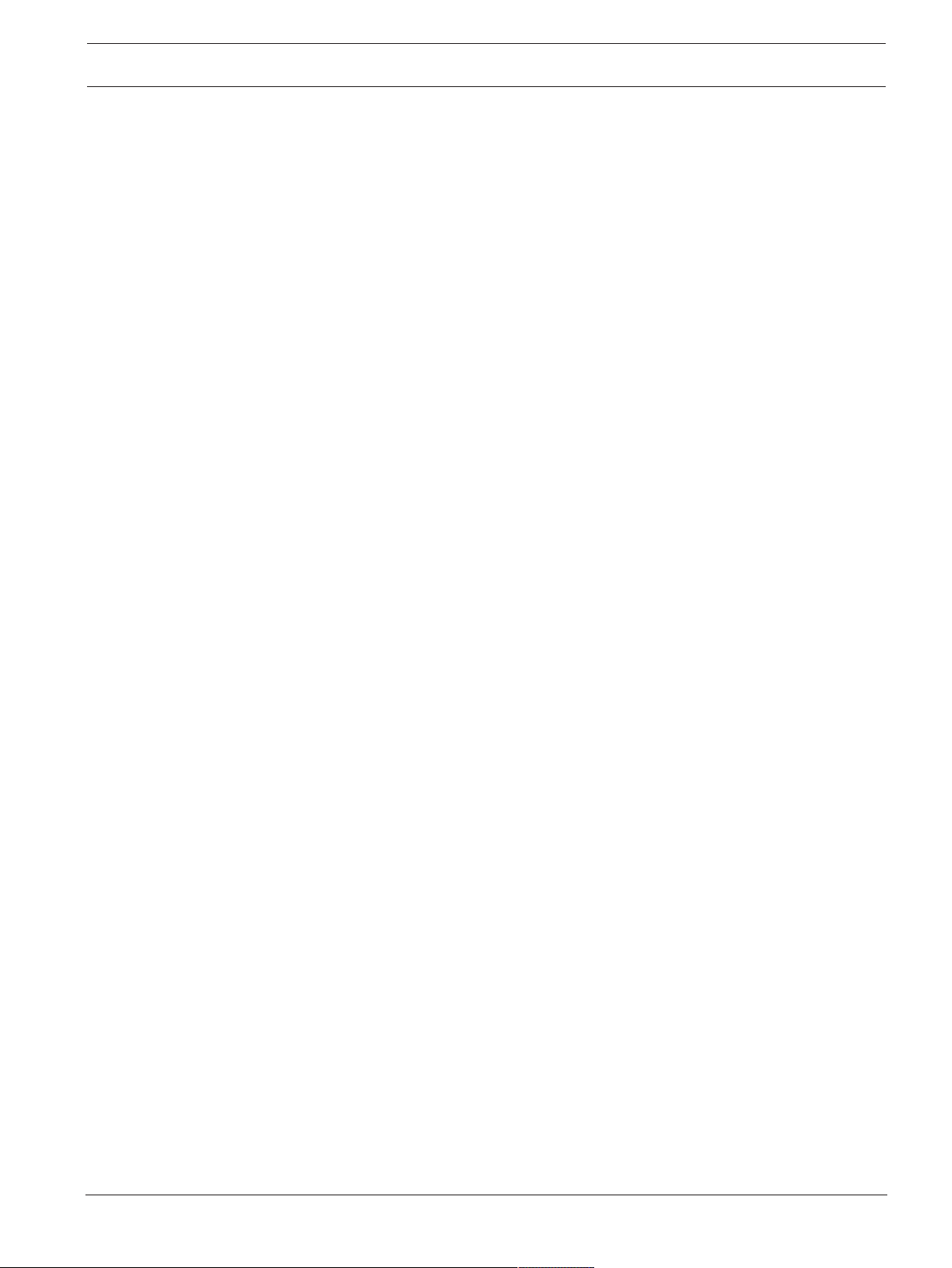

DE1600 drive tray – front view

1 Left end cap (has the drive tray LEDs)

2 Drives

3 Right end cap

DE1600 drive tray with AC power option - rear view

1 ESM A canister

2 Expansion port SFF-8088 connector 1 (IN)

3 Expansion port SFF-8088 connector 2 (IN)

4 Seven-segment display indicators

5 Serial connector

6 Ethernet connector

7 Expansion port SFF-8088 connector (OUT)

8 Power-fan canister

9 Power connector

10 Power switch

11 ESM B canister

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 20

20 en | Preparing for an E2700 controller-drive tray installation DSA E-Series (E2700)

!

92036-01

92034-04

!

92056-07

!

2 3 4 5 6 11

DE6600 drive tray – front view with bezel

DE6600 drive tray – front view with bezel removed

DE6600 drive tray – rear view

1 Fan canisters

2 ESM A

3 ESM B

4 Expansion port SFF-8088 connectors (IN)

5 Expansion port SFF-8088 connector (OUT)

6 Power canisters

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 21

DSA E-Series (E2700) Ethernet network interface cards for the E2700 controller-drive tray | en 21

5 Ethernet network interface cards for the E2700

controller-drive tray

The E2700 controller-drive tray supports a two-port 10-Gb/s iSCSI Base-T HIC host interface

cards.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 22

22 en | Installing the E2700 controller-drive tray DSA E-Series (E2700)

!

!

6 Installing the E2700 controller-drive tray

6.1 Things to know – general installation

The power supplies meet standard voltage requirements for both domestic and worldwide

operation.

Notice!

Make sure that the combined power requirements of your trays do not exceed the power

capacity of your cabinet. For power ratings on E2700 controller-drive trays and its related

drive trays, refer to the “Storage System Site Preparation Guide”.

6.2 Procedure – installing the E2712 controller-drive tray

This procedure describes how to install the mounting rails into an industry standard cabinet.

You can install the controller-drive tray into an industry standard cabinet.

Warning!

Risk of bodily injury

Two persons are required to safely lift the component.

Warning!

Risk of bodily injury

If the bottom half of the cabinet is empty, do not install components in the top half of the

cabinet. If the top half of the cabinet is too heavy for the bottom half, the cabinet might fall

and cause bodily injury. Always install a component in the lowest available position in the

cabinet.

Notice!

Possible hardware damage

To prevent electrostatic discharge damage to the tray, use proper antistatic protection when

handling tray components.

To install the controller-drive tray:

1. Make sure that the cabinet is in the final location. Make sure that the cabinet installation

site meets the clearance requirements.

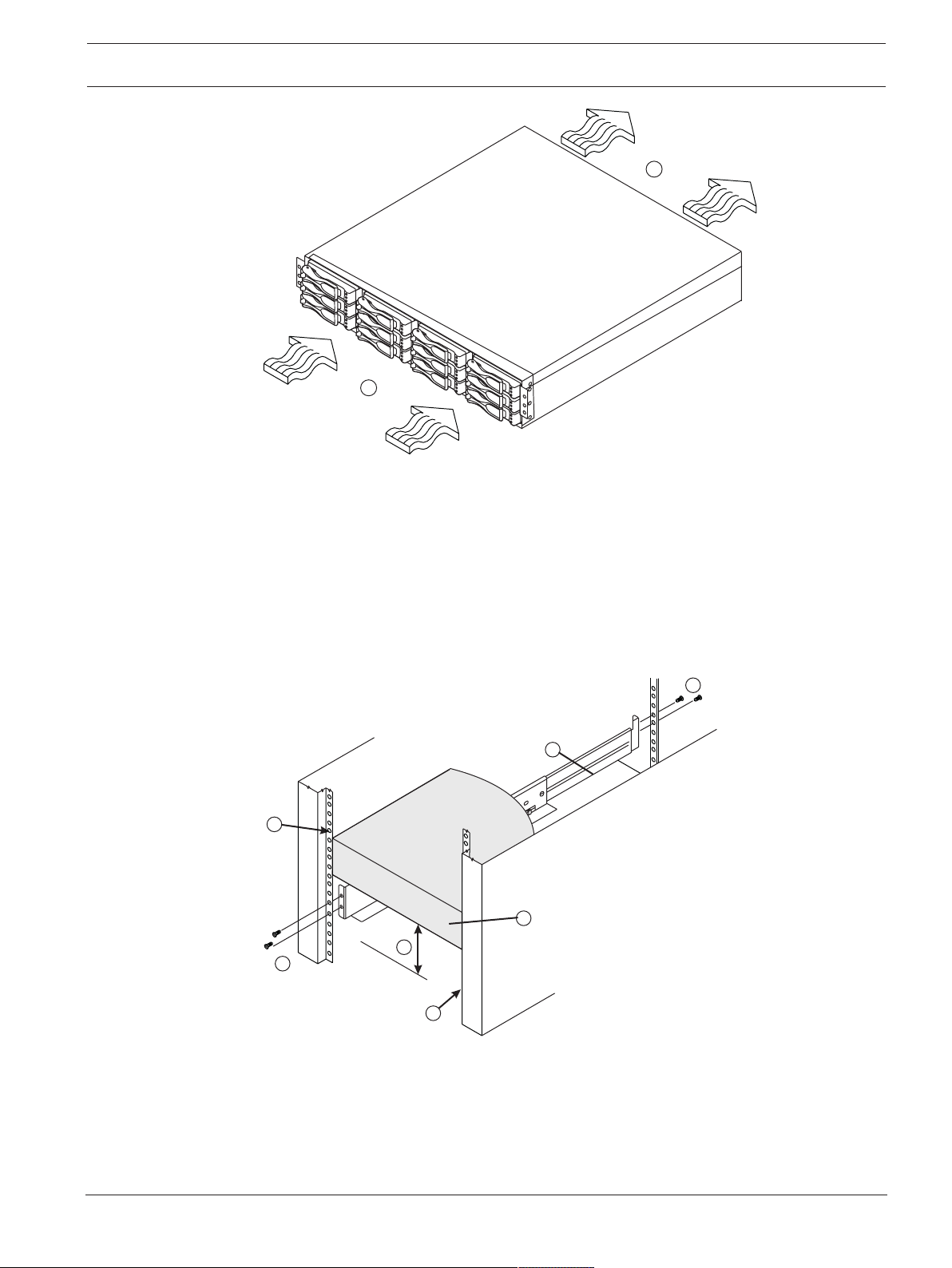

Note: Fans pull air through the tray from front to back across the drives.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 23

DSA E-Series (E2700) Installing the E2700 controller-drive tray | en 23

78014-02

1

2

1.

2.

1.

2.

2

3

4

5

78039-02

1

4

3

1 - 76 cm (30 in.) clearance in front of the cabinet

2 - 61 cm (24 in.) clearance behind the cabinet

2. Lower the feet on the cabinet, if required, to keep it from moving.

3. Remove the controller-drive tray and all contents from the shipping carton.

4. Install the mounting rails in the cabinet. For more information, refer to the installation

instructions that are included with your mounting rails.

– If you are installing the mounting rails above an existing tray, position the mounting

rails directly above the existing tray.

– If you are installing the mounting rails below an existing tray, allow 8.7-cm (3.4-in.)

vertical clearance.

1 - Mounting rail

2 - Existing tray

3 - Clearance above and below the existing tray

4 - Screws for securing the mounting rail to the cabinet (front and rear)

5 - Industry standard cabinet

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 24

24 en | Installing the E2700 controller-drive tray DSA E-Series (E2700)

78039-03

1

1

2

3

4

7803 9-04

1

Note: Risk of equipment malfunction - To avoid exceeding the functional and

environmental limits, install only drives that have been provided or approved by the

original manufacturer. Not all controller-drive trays or drive trays are shipped with prepopulated drives. System integrators, resellers, system administrators, or users of the

controller-drive tray or drive tray can install the drives.

5. Attach the mounting rails to the cabinet.

– Make sure that the adjustment screws on the mounting rail are loose so that the

mounting rail can extend or contract as needed.

1 - Cabinet mounting holes

2 - Adjustment screws for locking the mounting rail length

3 - Mounting rails

4 - Clip for securing the rear of the controller-drive tray

– Place the mounting rail inside the cabinet, and extend the mounting rail until the

flanges on the mounting rail touch the inside of the cabinet.

– Make sure that the alignment spacers on the front flange of the mounting rail fit into

the mounting holes in the cabinet.

The front flange of each mounting rail has two alignment spacers. The alignment

spacers are designed to fit into the mounting holes in the cabinet. The alignment

spacers help position and hold the mounting rail.

1 - Alignment spacers

– Insert one M5 screw through the front of the cabinet and into the top captured nut

in the mounting rail. Tighten the screw.

– Insert two M5 screws through the rear of the cabinet and into the captured nuts in

the rear flange in the mounting rail. Tighten the screws.

– Tighten the adjustment screws on the mounting rail.

– Repeat the substeps to install the second mounting rail.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 25

DSA E-Series (E2700) Installing the E2700 controller-drive tray | en 25

78039-01

1

2

3

4

6. With the help of one other person, slide the rear of the controller-drive tray onto the

mounting rails. The rear edge of the controller-drive tray must fit into the clip on the

mounting rail. The controller-drive tray is correctly aligned when these conditions are

met:

– The mounting holes on the front flanges of the controller-drive tray align with the

mounting holes on the front of the mounting rails. Refer to item 4 in the following

figure.

– The rear edge of the controller-drive tray sheet metal fits into the clip on the

mounting rail.

– The holes in the controller-drive tray sheet metal for the rear hold-down screws align

with the captured nuts in the side of the mounting rails.

1 - Mounting rail

2 - Clip

3 - Partial view of the controller-drive tray rear sheet metal

4 - Mounting holes

7. Secure the front of the controller-drive tray to the cabinet. Use the two screws to attach

the flange on each side of the front of the controller-drive tray to the mounting rails.

– Insert one M5 screw through the bottom hole of a flange on the controller-drive tray

so that the screw goes through the cabinet rail and engages the bottom captured nut

in the mounting rail. Tighten the screw.

– Repeat substep a for the second flange.

Note: The rear of the controller-drive tray contains two controllers. The top of the

controller-drive tray is the side with the labels.

8. Secure the side of the controller-drive tray to the mounting rails by performing these

substeps:

– Insert one M4 screw through the side sheet metal of the controller-drive tray into the

captured nut on the side of the mounting rail. Tighten the screw.

– Repeat substep a for the other side.

9. Attach the plastic end caps onto the front of the controller-drive tray.

– Put the top of the end cap on the hinge tab that is part of the controller-drive tray

mounting flange.

– Gently press on the bottom of the end cap until it snaps into place over the retainer

on the bottom of the controller-drive tray mounting flange.

10. Install the drive trays.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 26

26 en | Installing the E2700 controller-drive tray DSA E-Series (E2700)

97006-01

1

6.3 Procedure – installing drives in the E2712 controller-drive

In some situations, the controller-drive tray might be delivered without the drives installed.

Follow the steps in this procedure to install the drives. If your controller-drive tray already has

drives installed, you can skip this step.

Notice!

Risk of equipment malfunction

To avoid exceeding the functional and environmental limits, install only drives that have been

provided or approved by the original manufacturer. Drives might be shipped but not installed.

System integrators, resellers, system administrators, or users can install the drives.

Notice!

The installation order is from top to bottom and from left to right. The installation order is

important for tray loss protection because the drives might already contain configuration

information that depends upon the correct sequence of the drives in the tray.

To install drives in the controller-drive:

1. Beginning with the first drive slot in the upper-left side of the controller-drive tray, place

the drive on the slot guides, and slide the drive all the way into the slot.

2. Push the drive handle to the right to lock the drive securely in place.

Note: In some models, the drive handle might have the hinge on the right.

1 - Drive handle

3. Install the second drive beneath the first drive.

4. Install the other drives from top to bottom and then from left to right.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 27

DSA E-Series (E2700) Connecting the E2700 controller-drive tray to the hosts | en 27

7 Connecting the E2700 controller-drive tray to the

hosts

7.1 Key terms

topology

The logical layout of the components of a computer system or network and their

interconnections. Topology deals with questions of what components are directly connected

to other components from the standpoint of being able to communicate. It does not deal with

questions of physical location of components or interconnecting cables. (Dictionary of Storage

Networking Terminology.)

direct topology

A topology that does not use a switch.

switch topology

A topology that uses a switch.

7.2 Things to know – storage array configuration specifications for the E2700 controller-drive tray

Item Specification

Number of controllers Two

Number of host connectors Two iSCSI host connectors

Supported Combined Cache and Processor

GB Memory Sizes

Maximum number of drive slots supported 192

Maximum number of hosts per storage

partition

Maximum number of volumes per storage

array

Maximum number of storage partitions 128

Maximum number of volumes per storage

partition

7.3 Things to know – host channels

Notice!

Possible hardware damage

To prevent electrostatic discharge damage to the tray, use proper antistatic protection when

handling tray components.

8

256

512

256

Observe the following:

– Each controller has two native host ports.

– In addition, you can have additional host ports that are located on a host interface card

(HIC).

Two iSCSI Base-T connectors at 10 Gb/s are supported.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 28

28 en | Connecting the E2700 controller-drive tray to the hosts DSA E-Series (E2700)

490 02 -07

1 2

1 2

iSCSI

Host

S

S

SL

S

A

Lnk Lnk

LnkLnk

Port 2Port 1

Ch 4

Ch 3

Drive Expansion

L

Host channels on the E2712 and E2712 controllers with no HIC – rear view

1 HD mini-SAS native host channel 1 2 HD mini-SAS native host channel 2

Host channels on the E2712 and E2712 controllers with a two-port iSCSI HIC – rear view

1 iSCSI host interface card channel 3 2 - iSCSI host interface card channel 4

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 29

DSA E-Series (E2700) Connecting the E2700 controller-drive tray to the hosts | en 29

7.4 Procedure – connecting the controller-drive tray to the expansion drive trays

The DSAE‑Series expansion drive trays are shipped with the appropriate number of SAS

cables.

The following figures show valid host-to--controller-drive tray configurations when using an

E2700 controller- drive tray.

One expansion drive tray (simplex controller configuration)

One expansion drive tray (dual simplex controller configuration)

(recommended cabling for maximum throughput)

Two expansion drive trays (dual simplex controller configuration)

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 30

30 en | Connecting the E2700 controller-drive tray to the hosts DSA E-Series (E2700)

Maximum expansion (dual simplex controller configuration)

Example: for DE1600 (only 3expansions for DE6600)

Notice!

You can connect the E2700 controller-drive tray to a maximum of 7DE1600 expansion drive

trays or to a maximum of 3DE6600 expansion drive trays. No mixed configurations expansion

drive trays are allowed.

To connect the components:

1. Plug either the SAS cable or copper cables into the controller.

2. Plug the cable either into an HBA in the host (direct topology) or into a switch (fabric

topology).

3. Affix a label to each end of the cable with the relevant information. A label is very

important if you need to disconnect cables to service a controller. Include this

information on the labels:

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 31

DSA E-Series (E2700) Connecting the E2700 controller-drive tray to the hosts | en 31

1

2 3

– The host name and the HBA port (for direct topology)

– The switch name and the port (for fabric topology)

– The controller ID (for example, controller A)

– The host channel ID (for example, host channel 1)

Example label abbreviation – Assume that a cable is connected between port 1 in HBA 1

of a host named Engineering and host channel 1 of controller A.

A label abbreviation could be as follows.

4. Repeat step 1 through step 4 for each controller and host channel that you intend to use.

7.5 Connecting to the network

In case of a Bosch Video Recording Solution a host is an IP camera. To connect the controller

to the Ethernet one or two of two available iSCSI host ports must be connected to the

Ethernet. The iSCSI port connections will then be used by the IP cameras for video data

traffic.

Connect the cable from the iSCSI host port to a port on the switch and make sure that the

iSCSI ports of the controller and the relevant IP camera ports are in the same zone on the

switch.

Switch topology

1 Switch 2 Controller A – Host Ports

3 Controller B – Host Ports

7.6 Connecting to the management hosts

The management host directly manages storage arrays over an out-of-band network. This

section describes how to setup an out-of-band connection between the Ethernet port of a

controller and the management host.

To set up an out-of-band connection:

1. Connect Ethernet cables between port 1 of controller A and port 1 of controller B to an

external Ethernet switch or hub.

2. Connect the management host to the Ethernet switch or hub.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 32

32 en | Connecting the E2700 controller-drive tray to the hosts DSA E-Series (E2700)

1

5

2

6

3

7

4

Figure7.1: Connect to management host

1 Private network 2 Management station or personal

computer

3 Local Area Network (LAN) 4 Switch or hub

5 Controller-drive tray with ControllerA

6 Ethernet Port 1

and ControllerB

7 Ethernet Port 2 (reserved)

Notice!

Ethernet port 2 should be reserved for maintenance operations if your hardware contains a

second Ethernet port.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 33

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 33

!

!

!

8 Installing the drive trays for the E2700 controller-drive

tray configurations

8.1 Things to know – general installation of drive trays with the E2700 controller-drive tray

Notice!

If you are installing the drive tray in a cabinet with other trays, make sure that the combined

power requirements of the drive tray and the other trays do not exceed the power capacity of

your cabinet.

Notice!

For important considerations about cabinet installation, refer to the “Storage System Site

Preparation Guide”.

Warning!

Risk of bodily injury

An empty tray weighs approximately 56.7 kg (125 lb). Three persons are required to safely

move an empty tray. If the tray is populated with components, a mechanized lift is required to

safely move the tray.

If you are performing a hot add of a tray to an existing storage array, observe the following:

– Special site preparation is not required for any of these drive trays beyond what is

normally found in a computer lab environment.

– The power supplies meet standard voltage requirements for both domestic and

worldwide operation.

– Keep as much weight as possible in the bottom half of the cabinet.

-

8.2 Procedure – installing the DE1600 drive trays

Warning!

Risk of bodily injury

Two persons are required to safely lift the component.

Warning!

Risk of bodily injury

If the bottom half of the cabinet is empty, do not install components in the top half of the

cabinet. If the top half of the cabinet is too heavy for the bottom half, the cabinet might fall

and cause bodily injury. Always install a component in the lowest available position in the

cabinet.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 34

34 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

78014-02

1

2

Notice!

Possible hardware damage

To prevent electrostatic discharge damage to the tray, use proper antistatic protection when

handling tray components.

To install the DE1600 drive tray:

1. Make sure that the cabinet is in the final location. Make sure that the cabinet installation

site meets the clearance requirements.

Note: Fans pull air through the tray from front to back across the drives.

1 - 76 cm (30 in.) clearance in front of the cabinet

2 - 61 cm (24 in.) clearance behind the cabinet

2. Lower the feet on the cabinet, if required, to keep it from moving.

3. Remove the drive tray and all contents from the shipping carton.

4. Install the mounting rails in the cabinet. For more information, refer to the installation

instructions that are included with your mounting rails.

– If you are installing the mounting rails above an existing tray, position the mounting

rails directly above the existing tray.

– If you are installing the mounting rails below an existing tray, allow 8.7-cm (3.4-in.)

vertical clearance.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 35

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 35

1.

2.

1.

2.

2

3

4

5

78039-02

1

4

3

78039-03

1

1

2

3

4

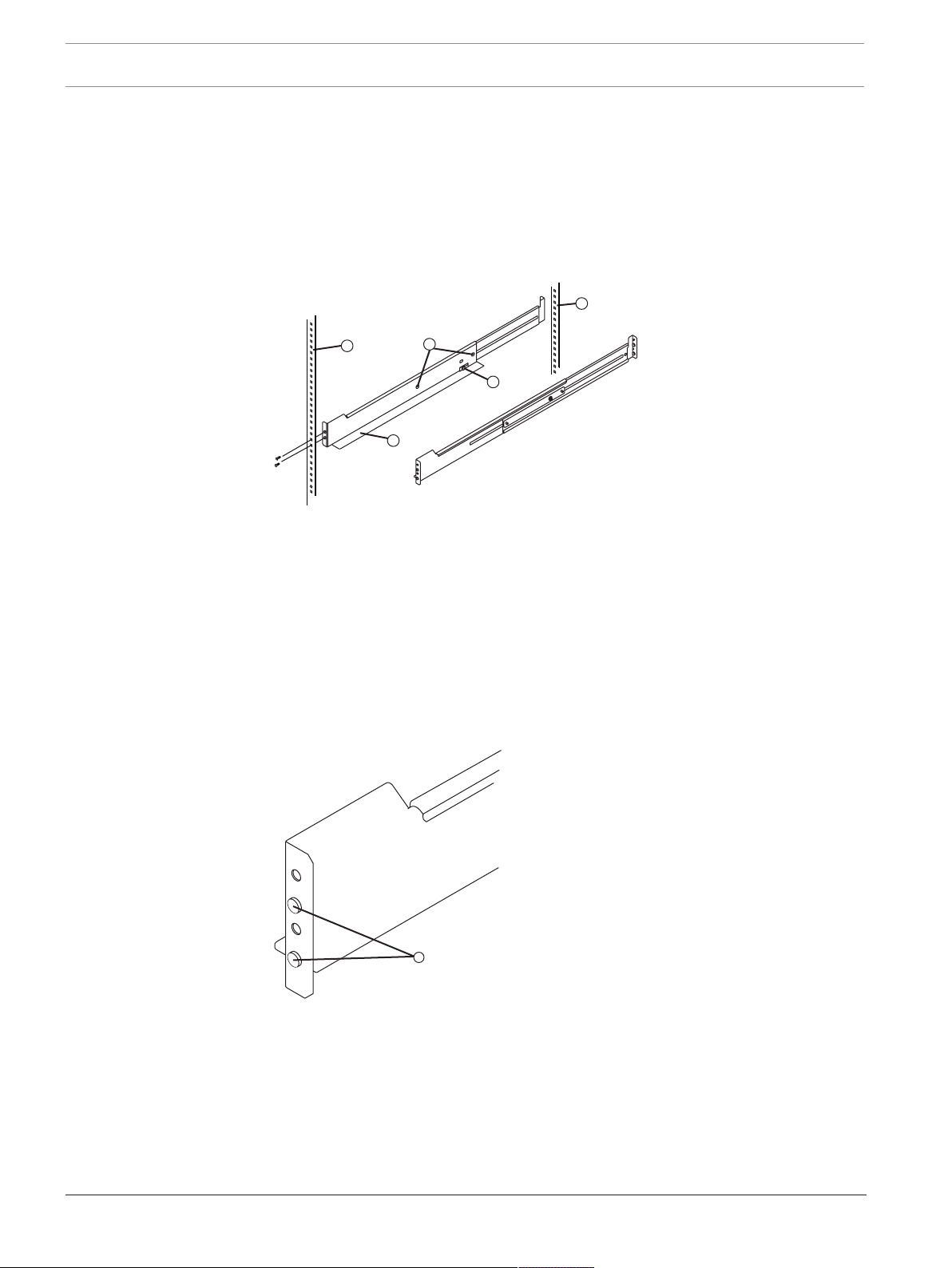

1 - Mounting rail

2 - Existing tray

3 - Clearance above and below the existing tray

4 - Screws for securing the mounting rail to the cabinet (front and rear)

5 - Industry standard cabinet

Note: Risk of equipment malfunction - To avoid exceeding the functional and

environmental limits, install only drives that have been provided or approved by the

original manufacturer. Not all controller-drive trays or drive trays are shipped with prepopulated drives. System integrators, resellers, system administrators, or users of the

controller-drive tray or drive tray can install the drives.

5. Attach the mounting rails to the cabinet.

– Make sure that the adjustment screws on the mounting rail are loose so that the

mounting rail can extend or contract as needed.

1 - Cabinet mounting holes

2 - Adjustment screws for locking the mounting rail length

3 - Mounting rails

4 - Clip for securing the rear of the controller-drive tray

– Place the mounting rail inside the cabinet, and extend the mounting rail until the

flanges on the mounting rail touch the inside of the cabinet.

– Make sure that the alignment spacers on the front flange of the mounting rail fit into

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

the mounting holes in the cabinet.

Page 36

36 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

7803 9-04

1

78039-01

1

2

3

4

The front flange of each mounting rail has two alignment spacers. The alignment

spacers are designed to fit into the mounting holes in the cabinet. The alignment

spacers help position and hold the mounting rail.

1 - Alignment spacers

– Insert one M5 screw through the front of the cabinet and into the top captured nut

in the mounting rail. Tighten the screw.

– Insert two M5 screws through the rear of the cabinet and into the captured nuts in

the rear flange in the mounting rail. Tighten the screws.

– Tighten the adjustment screws on the mounting rail.

– Repeat the substeps to install the second mounting rail.

6. With the help of one other person, slide the rear of the drive tray onto the mounting rails.

The rear edge of the drive tray must fit into the clip on the mounting rail. The drive tray is

correctly aligned when these conditions are met:

– The mounting holes on the front flanges of the drive tray align with the mounting

holes on the front of the mounting rails. Refer to item 4 in the following figure.

– The rear edge of the drive tray sheet metal fits into the clip on the mounting rail.

– The holes in the drive tray sheet metal for the rear hold-down screws align with the

captured nuts in the side of the mounting rails.

1 - Mounting rail

2 - Clip

3 - Partial view of the drive tray rear sheet metal

7. Secure the front of the drive tray to the cabinet. Use the two screws to attach the flange

4 - Mounting holes

on each side of the front of the drive tray to the mounting rails.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 37

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 37

98009-00

2

1

1

2

– Insert one M5 screw through the bottom hole of a flange on the drive tray so that the

screw goes through the cabinet rail and engages the bottom captured nut in the

mounting rail. Tighten the screw.

– Repeat the substep for the second flange.

1 - Screw

2 - Mounting Hole

Note: The rear of the controller-drive tray contains two controllers. The top of the

controller-drive tray is the side with the labels.

8. Secure the side of the drive tray to the mounting rails by performing these substeps:

– Insert one M4 screw through the side sheet metal of the drive tray into the captured

nut on the side of the mounting rail. Tighten the screw.

– Repeat the substep for the other side.

9. Attach the plastic end caps onto the front of the drive tray.

– Put the top of the end cap on the hinge tab that is part of the drive tray mounting

flange.

– Gently press on the bottom of the end cap until it snaps into place over the retainer

on the bottom of the drive tray mounting flange.

8.3 Procedure – installing drives in the DE1600 drive trays

In some situations it might be required to install drives in the DE1600 drive trays.

Follow the steps in this procedure to install the drives.

Notice!

Risk of equipment malfunction

To avoid exceeding the functional and environmental limits, install only drives that have been

provided or approved by the original manufacturer. Drives might be shipped but not installed.

System integrators, resellers, system administrators, or users can install the drives.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Notice!

The installation order is from top to bottom and from left to right. The installation order is

important for tray loss protection because the drives might already contain configuration

information that depends upon the correct sequence of the drives in the tray.

Page 38

38 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

97006-01

1

!

!

To install drives in the DE1600 drive tray:

1. Beginning with first drive slot in the upper-left side of the DE1600 drive tray, place the

drive on the slot guides, and slide the drive all the way into the slot.

2. Push the drive handle to the right to lock the drive securely in place.

Note: In some models, the drive handle might have the hinge on the right.

1 - Drive handle

3. Install the second drive beneath the first drive.

4. Install the other drives from top to bottom and then from left to right.

8.4 Procedure – installing the DE6600 drive tray

You can install the high-density, 6-Gb SAS SBB 2.0-compliant DE6600 drive tray into an

Industry-standard cabinet, provided it has a depth of 100 cm (40 in.).

A minimum depth of 76 cm (30 in.) between the front EIA support rails and the rear EIA

support rails is required.

Warning!

Risk of bodily injury

Three persons are required to safely lift the component.

Warning!

Risk of bodily injury

An empty tray weighs approximately 56.7 kg (125 lb). Three persons are required to safely

move an empty tray. If the tray is populated with components, a mechanized lift is required to

safely move the tray.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 39

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 39

92003-02

1

2

Notice!

Risk of equipment malfunction

To avoid possible equipment damage and ensure safe and efficient servicing of the

equipment, install 60 drive trays towards the bottom of a cabinet.

Notice!

Type and source of hazard

Consequences

Notice!

If you are mounting the DE6600 drive tray in a cabinet with square holes, use the eight

shoulder washers in the rail kit to align the screws in the holes (see step 4 through step 7).

To install the DE6600 drive-tray:

1. Make sure that the cabinet is in the final location. Make sure that you meet the clearance

requirements shown in the following figure.

Note: Fans pull air through the drive tray from front to back across the drives.

1 - 91 cm (36 in.) clearance in front of the cabinet

2 - 61 cm (24 in.) clearance behind the cabinet

2. Lower the feet on the cabinet to keep the cabinet from moving.

3. Before removing the drive tray and all of the contents from the shipping carton, locate the

tray handles and attach them to the drive tray.

– Align the handle just under the thumb latch.

– Push the handle up until it clicks in place with the thumb latch.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 40

40 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

92015-00

1

1

2

2

2

2

1

1

92015-02

4. With the help of at least two other persons, remove the drive tray and all of the contents

from the shipping carton, using the four drive tray handles (two to a side) as shown in the

following figure. Set the drive tray aside.

5. Position the mounting rails in the cabinet.

– If you are installing the mounting rails above an existing tray, position the mounting

rails directly above the tray.

– If you are installing the mounting rails below an existing tray, allow 17.8 cm (7 in.)

vertical clearance.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 41

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 41

2

3

92011-01

1

4

92011-00

3

1

2

6

7

8

5

4

9

1 - Screws for securing the mounting rail to the cabinet (front)

2 - Screws for securing the mounting rail to the cabinet (rear)

3 - Existing tray

4 - Industry standard cabinet

6. To attach the mounting rails to the cabinet, do one of the following: If you are using the

long fixed-size mounting rails, go to step 7.

If you are using the shorter adjustable mounting rails, go to step 8.

7. Attach the long fixed-size mounting rails to the cabinet.

– Make sure that the adjustment screws on the mounting rail are loose so that the

mounting rail can extend or contract as needed.

1 - Front of the mounting rail

2 - Two M5 screws for the rear EIA support rail

3 - Front of the cabinet

4 - Two M5 screws for the front EIA support rail

5 - Adjustable rail tightening screws

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 42

42 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

92042-01

UP

1

2

3

4

5

6

6 - Rear hold-down screw

7 - Cabinet mounting holes on the front EIA support rail

8 - Cabinet mounting holes on the rear EIA support rail

9 - Mounting rail lip

– Remove the rear hold-down screw. It protrudes from the inside of the rail and

prevents you from sliding the drive tray onto the rails.

– Place the mounting rail inside the cabinet, and extend the mounting rail until the

flanges on the mounting rail touch the inside of the cabinet.

– Insert one M5 screw through the front of the cabinet, and screw it into the top

captured nut in the mounting rail.

– Insert two M5 screws through the rear of the cabinet, and screw them into the

captured nuts in the rear flange in the mounting rail.

– Counting up from the bottom of the mounting rail, place the bottom of the rear

bracket in the 8th hole of the cabinet, so that the top of the rear bracket is in the

11th hole. The distance between the two holes should be 1U or 4.45 cm (1.75 in).

– Tighten the adjustment screws on the mounting rail.

– Repeat the sub steps to install the second mounting rail.

– Insert one M5 screw through the front of the mounting rail. You use this screw to

attach the drive tray to the cabinet.

8. Attach the shorter, adjustable size mounting rails to the cabinet.

1 - Front of the mounting rail

2 - Rear of the mounting rail

3 - Rail fix bar

4 - Two M5 screws for the front EIA support rail

5 - Two clips for the front EIA support rail

6 - Rear bracket

– Make sure that the adjustment screws on the mounting rail are loose so that the

mounting rail can extend or contract as needed. The adjustment screws are on the

other side of the previous figure.

– Place the mounting rail inside the cabinet, and extend the mounting rail until the

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

flanges on the mounting rail touch the inside of the cabinet.

Page 43

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 43

92011-05

1

1

1

2

92042-03

UP

– Insert one M5 screw through the front of the cabinet, and screw it into the top

captured nut in the mounting rail.

1 - M5 screws

– Insert two M5 screws through the rear of the cabinet, and screw them into the

captured nuts in the rear flange in the mounting rail.

– Counting up from the bottom of the mounting rail, place the bottom of the rear

bracket in the 8th hole of the cabinet, so that the top of the rear bracket is in the

11th hole. The distance between the two holes should be 1U or 4.45 cm (1.75 in).

– Tighten the adjustment screws on the mounting rail.

– Repeat the substeps to install the second mounting rail.

1 - Top cabinet mounting hole on the rear EIA support rail

2 - Bottom cabinet mounting hole on the rear EIA support rail

9. Remove the bezel from the front of the drive tray.

WARNING (W09) Risk of bodily injury – Three persons are required to safely lift the

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

component.

Page 44

44 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

92015-01

1

2

3

1

10. With the help of at least two other persons, slide the rear of the drive tray onto the

mounting rails. The drive tray is correctly aligned when the mounting holes on the front

flanges of the drive tray align with the mounting holes on the front of the mounting rails.

WARNING (W15) Risk of bodily injury – An empty tray weighs approximately 56.7 kg

(125 lb). Three persons are required to safely move an empty tray. If the tray is populated

with components, a mechanized lift is required to safely move the tray.

11. After the controller-drive tray is correctly aligned, remove the enclosure lift handles as

shown in the following figure:

– Use your thumb to unlatch and remove the rear enclosure lift handles (two to a

side).

– Use the front enclosure lift handles to slide the drive tray all the way into the

cabinet.

– After the drive tray is secure in the cabinet, use your thumb to unlatch and remove

the front enclosure lift handles (two to a side).

1 - Pull the thumb latch away from the drive tray to detach the hook.

2 - Shift the handle down to release the other four hooks.

3 - Move the handle away from the drive tray.

12. Secure the front of the drive tray to the cabinet. Use the four screws to attach the flange

on each side of the front of the drive tray to the mounting rails.

– Insert two M5 screws through the bottom holes of a flange on the drive tray so that

the screws go through the EIA support rail and engage the bottom captured nuts in

the mounting rail. Tighten the screws.

You had attached the second and fourth threaded holes in step 8c.

– Repeat the sub-step a for the second flange.

13. Secure the side of the drive tray to the mounting rails.

– Tighten the thumbscrew on the rear mounting bracket that you installed in step 8e to

secure the drive tray to the mounting rails.

– Repeat the sub-step for the other side.

Note: Make sure that each drive drawer in the drive tray is securely fastened to

ensure proper air flow to the drives.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 45

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 45

92014-00

!

4

5

6

7

8

9

1

0

11

12

1

2

3

!

4

5

6

7

8

9

1

0

11

1

2

1

2

3

!

4

5

6

7

8

9

1

0

11

1

2

1

2

3

!

4

5

6

7

8

9

1

0

11

1

2

1

2

3

!

4

5

6

7

8

9

1

0

11

1

2

1

2

3

F

r

o

nt

1

2

3

69

12

5

4 7

8

11

10

F

r

ont

1

2

3

6

9

12

5

4 7

8

11

10

F

r

o

n

t

1

2

3

6

9

12

5

4

7

8

11

10

F

r

o

n

t

1

2

3

6

9

12

5

4 7

8

11

10

F

r

o

n

t

1

2

3

6

9

12

5

4 7

8

11

10

14. Attach the bezel onto the front of the drive tray.

Note: You must remove the bezel when installing drives on the DE6600 Drive Tray.

8.5 Procedure – installing drives on the de6600 drive tray

The DE6600 drive tray is shipped with the drive drawers installed, but the drives are not

installed. Follow the steps in this procedure to install the drives.

Notice!

Risk of equipment malfunction

To avoid exceeding the functional and environmental limits, install only drives that have been

provided or approved by the original manufacturer. Drives might be shipped but not installed.

System integrators, resellers, system administrators, or users can install the drives.

The installation order within each drawer is from left to right in rows. Slots 1, 4, 7, and 10

must have a drive installed in these locations to make sure there is sufficient air flow to the

drives. To verify these slots, consult the overlay on the front of each of the five drive drawers.

Make sure the four drives in each row are adjacent to each other. The long edge of each drive

should touch the drive next to it. To maintain a uniform airflow across all drive drawers, the

drive tray must be configured with a minimum of 20 drives, with four drives in the front row of

each of the five drive drawers.

Notice!

Risk of equipment malfunction

All 60-drive trays have a limit of five solid state drives (SSDs) per drawer. If you exceed this

limit for SSDs in a particular drawer, the power source in the drawer could fail.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 46

46 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

92004- 01

1

7

10

4

1

92034-02

1

92037-03

DE6600 drive drawer with required slots filled

1 DE6600 Drive Tray with Slots 1, 4, 7, and 10

Notice!

Risk of equipment malfunctio

For the DE6600 drive tray, you can replace only one canister or drive at a time. Make sure you

have the replacement drive in hand before starting the task. Refer to your storage vendor for

information about obtaining additional SANtricity Storage Manager documentation.

To install the drives in the DE6600 drive tray:

1. Beginning with the top drawer in the drive tray, release the levers on each side of the

drawer by pulling both towards the center.

1 - Levers to release the drive drawer

2. Pull on the extended levers to pull the drive drawer out to its full extension without

removing it from the drive tray.

3. Starting with the first drive, raise the drive handle to the vertical position.

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

4. Align the two raised buttons on each side over the matching gap in the drive channel on

the drawer.

Page 47

DSA E-Series (E2700) Installing the drive trays for the E2700 controller-drive tray configurations | en 47

92012-00

1

2

92004-0 0

5. Lower the drive straight down, and then rotate the drive handle down until the drive

snaps into place under the drive release lever as shown in the following figure.

1 - Drive release lever

2 - Drive handle

6. Install the other drives in rows from left to right until the drive drawer contains at least

four drives in the front row of each drawer.

7. Push the drive drawer all the way back into the drive tray, closing the levers on each side

of the drive drawer.

Note: Risk of equipment malfunction – Make sure you push both levers to each side so

the drive drawer is completely closed. The drive drawer must be completely closed to

prevent excess airflow, which has the potential to damage the drives.

8. Continue onto the next drive drawer, repeating step 1 through step 7 for each drive

drawer in the configuration.

8.6 Things to know – connecting the power cords

Observe the following:

– For each AC power connector on the drive tray, make sure that you use a separate power

source in the cabinet. Connecting to independent power sources maintains power

redundancy.

– To ensure proper cooling and assure availability, the drive tray always uses two power

supplies.

– You can use the power cords shipped with the drive tray with typical outlets used in the

destination country, such as a wall receptacle or an uninterrupted power supply (UPS).

These power cords, however, are not intended for use in most EIA-compliant cabinets.

Bosch Sicherheitssysteme GmbH Installation manual 2016.12 | V2.1 | DOC

Page 48

48 en | Installing the drive trays for the E2700 controller-drive tray configurations DSA E-Series (E2700)

92056.03

!

1

Notice!

Make sure that you do not turn on the power to the drive tray until this installation guide

instructs you to do so.

8.7 Procedure – connecting the power cords

To connect the power cords:

1. Make sure that the circuit breakers in the cabinet are turned off.

2. Make sure that both of the Power switches on the drive trays are turned off.

3. Connect the primary power cords from the cabinet to the external power source.

1 - Power switches

2016.12 | V2.1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

Page 49

DSA E-Series (E2700) Connecting the E2700 controller-drive tray to the drive trays | en 49

490 02- 04

4

iSCSI

Host

S

S

SL

S

A

Lnk Lnk

LnkLnk

Port 2Port 1

Ch 4

Ch 3

Drive Expansion

L

iSCSI

Host

S

S

SL

S

A

Lnk Lnk

LnkLnk

Port 2Port 1

Ch 4

Ch 3

Drive Expansion

L

321

49006-16

9 Connecting the E2700 controller-drive tray to the drive

trays

9.1 Key terms

drive channel

The path for the transfer of data between the controllers and the drives in the storage array.

9.2 Things to know – E2700 controller-drive tray

Observe the following:

– The E2700 controller-drive trays supports the DE1600 drive tray and the DE6600 drive

tray for expansion.

– For any one controller-drive tray, you must not exceed the limit of 7 connected drive trays

or the limit for the total number of drives in the storage array, which is 192. The drive

limit includes drives installed in the controller-drive tray.

Notice!

Make sure that you do not turn on the power to the drive tray until this installation guide

instructs you to do so.

Base Host Ports on the E2712 Controller-Drive Tray

1 Controller canister A 3 Controller canister B

2 iSCSI host interface card channels

(channel1/channel2)

4 iSCSI host interface card channels

(channel3/channel4)

E2700 controller with base host channel ports (CH1 and CH2)

See also

– Procedure –turning on the power to the storage array and checking for problems in a E2700