Bosch DS1109I Installation Manual

Glass Break Detector

Door

Door Closed

Door

Frame

Door

Frame

Sensor A per tu re

Magnet

DS1109i

DS1109i

Door Open

DS1109i

en Installation and Operation Guide

1 Specifi cations

1.1 Coverage

10 ft (3 m) maximum to farthest point of glass being protected. For glass sizes over 12 in x 12 in (30 cm x 30 cm); types of

1/4 in (64 mm) Plate, Tempered, Laminated, and Wired glass;

and 1/8 in (32 mm) Plate glass (DSB).

1.2 Mounting

Directly (or using the supplied bracket) to a ceiling, wall, door

or window frame.

1.3 Input Power

12 VDC (6 VDC min to 15 VDC max), 23 mA nominal @ 12 VDC

(29 mA max in the LED Latch mode).

1.4 Standby Power

Connect to power sources capable of supplying standby power

of 23 mAh for each hr of required standby time. Four hr minimum standby time required for UL Listed Requirements.

1.5 Alarm Relay

Normally Closed (NC/C) reed relay contacts rated 3.5 Watts,

125 mA @ 28 VDC for DC resistive loads. Protected by a 10

ohm resistor in the common “C” leg. The contact opens for 3

sec upon a glassbreak alarm. For a magnetic contact alarm, the

contacts remain open as long as the magnet is more than 1 - 2

inches away from the detector.

1.6 Tamper

Normally Closed (NC/C) rated 125 mA @ 28 VDC maximum.

For UL Listed Requirements, the tamper switch must be connected to a 24 hr protection circuit.

1.7 Operating Temperature

-20° to +120°F (-29° to +49°C). For UL Listed Requirements,

the temperature range is +32° to +120°F (0° to +49°C).

1.8 Enclosure

ABS high impact plastic. 1.25 in H x 3.75 in W x 0.875 in D (32

mm H x 95 mm W x 23 mm D).

1.9 Accessories

DS1110i Glass Breakage Tester. mm) Plate glass (DSB).

If you must install the DS1109i in a zone that is armed •

when occupied:

Avoid acoustically live areas such as kitchens and bath-•

rooms.

Use a delay zone to allow time to acknowledge user caused •

false alarms.

Instruct users of the system how to respond to such an •

alarm.

Remember:

The best mounting location is less than 10 ft (3 m) from •

the glass, and in direct line of sight of the glass. Do not

exceed the maximum range.

Range will be reduced in areas that are acoustically soft. •

This may be due to carpeting, drapes, plants, or other

sound absorbing materials. The DS1110i Glass Breakage

Tester should be used to verify range in all installations.

Glass break detectors are intended only as a component of •

a perimeter protection system. They should always be used

in conjunction with motion sensors.

Glass breakage detectors are designed to detect the break-•

age of framed glass and may not detect such things as bullet holes, spontaneous breakage of glass (with no impact),

and removal of glass.

Maximum Range:

The maximum detection range is 10 ft (3 m) from the farthest

corner, for glass sizes 12 in x 12 in

(30 cm x 30 cm) and larger.

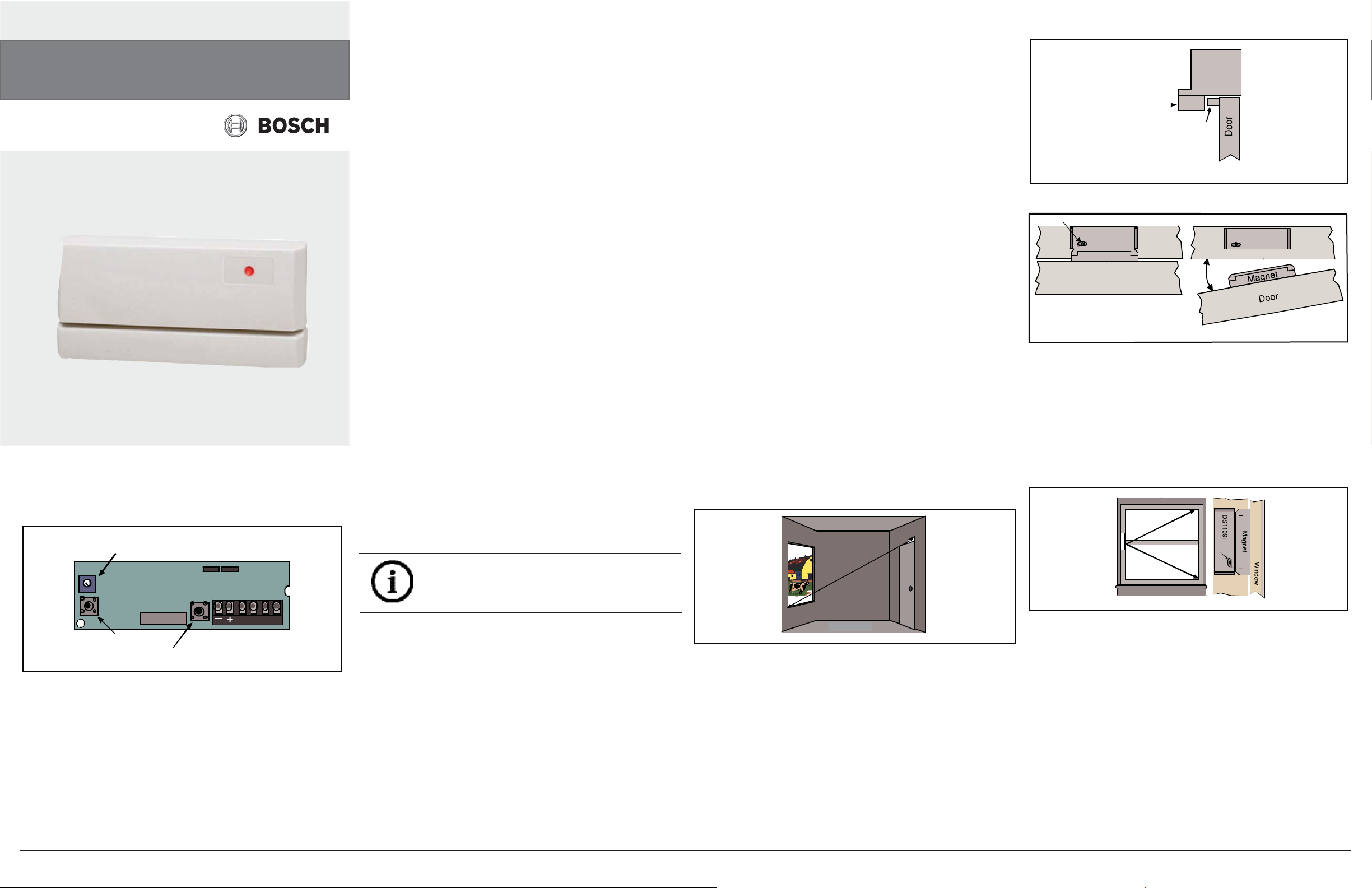

3 Selecting a Mounting Location

Opposite Wall Mounting Using the Door Contact

• Mount the detector where there are no objects between

itself and the glass.

Make sure the detector is no farther than 10 ft (3 m) from •

Top of

Door

Frame

DS1109i

Magnet

Side View

Figure 3.2: Side View

Figure 3.3: View Looking up from Floor

Single Window Coverage Using the Magnetic Contact

Mount the detector where there are no objects be-•

tween itself and the glass.

Make sure the detector is no farther than 10 ft (3 m) •

from the farthest corner of the glass (line A in Figure

3.4).

Do not mount the unit with the Sensor Aperture facing •

away from the window.

Do Not Adjust

Test Switch

Tamper Switch

Figure 1.1: Board Layout

© 2011 Bosch Security Systems, Inc.

P2 P3

2 Installation Considerations

NOTICE!

Always pretest the detector’s location using the

A

DS1110i Glass Breakage Tester.

NC C T T

Terminal

Block

Do Not:

Mount the detector on iron or steel surfaces if the mag-•

netic contact will be used. Aluminum and stainless stell

frames are acceptable.

Mount the detector with obstructions between the glass •

being protected and the detector.

Mount closer than 2 ft (61 cm) to heating or cooling out-•

lets; mount as far away as possible. If drafts from these

outlets blow on the detector, select a different location for

the detector. Use the environmental test (see Section 6) to

verify good installation locations.

Install alarm contacts on 24 hr protection circuits. •

Figure A

Figure 3.1: Opposite Wall Mounting Using Door Contact

any corner of the glass (line A in Figure 3.1).

Mounting Above Glass Doors

Mount the DS1109i at the top of the door frame with •

the Sensor Aperture pointing downward.

Mount the magnet to the top of the door. The magnet •

should be placed so that it aligns with the side of the

DS1109i. Do not allow the magnet to cover the front of

the detector. See Figure 3.2.

The detector must be mounted so that the door swings •

outward from the detector. See Figure 3.3.

Figure 3.4: Single Window Coverage Using the Magnetic Contact

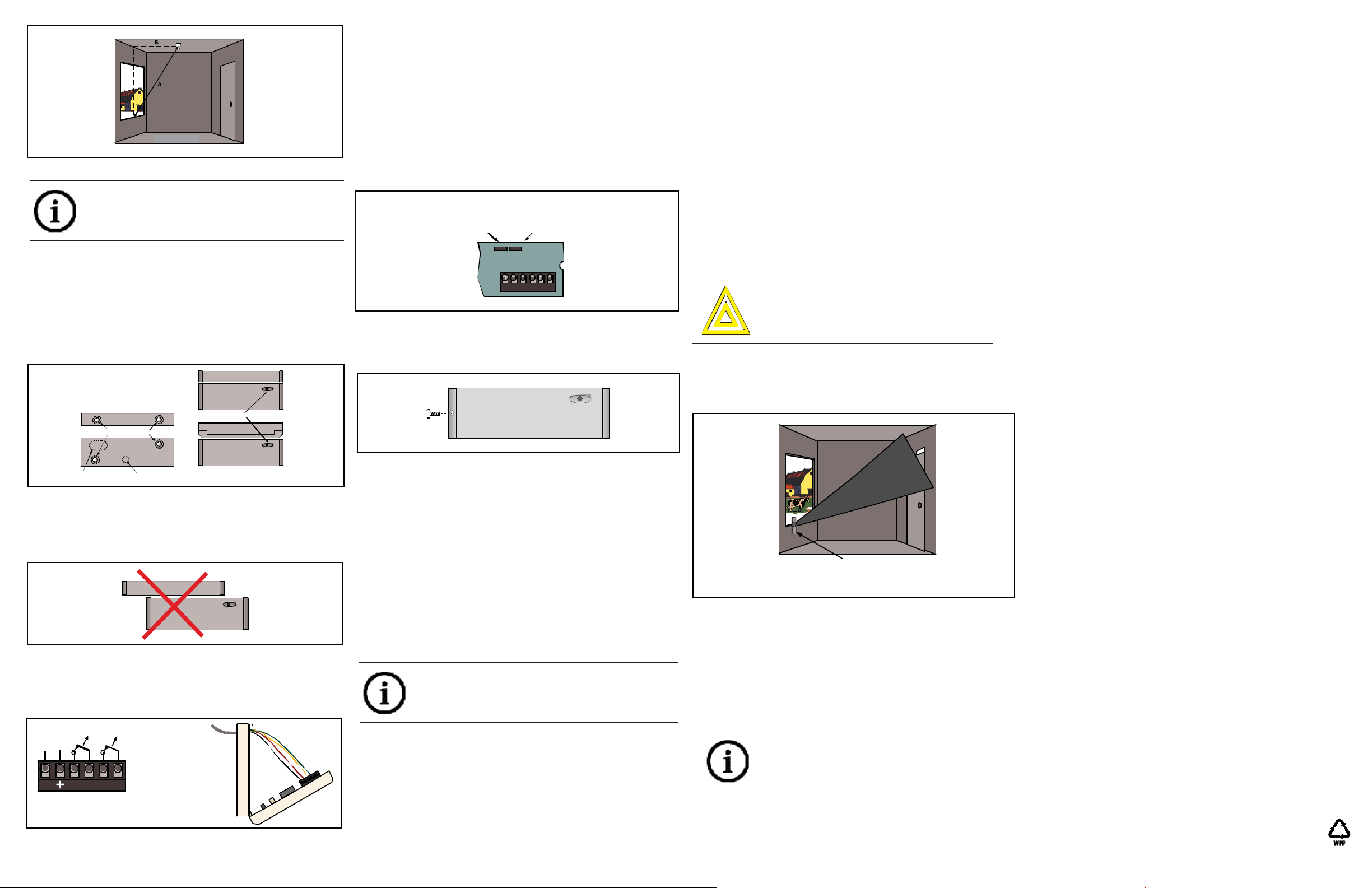

Ceiling Mounting Without the Magnetic Contact

The recommended location is half the distance be-•

tween the glass and the opposite wall or 7 ft (2.1 m)

whichever is smaller.

Mount the detector where there are no objects be-•

tween the glass and itself.

Make sure the detector is no further than 10 ft (3 m) •

from any corner of the glass (line A in fi gure 3.5).

The detector should be within ±30° of the center of •

the glass to be protected (line B in fi gure 3.5).

Jumper P3 must be installed to disable the magnetic •

contact. See Section 5.

A

A

Figure C

F01U069268 | 02 | 2011.10 | 1

Sensor

Aperture

Window

Frame

Side View

Figure 3.5: Ceiling Mounting Without the Magnetic Contact

5 Setting the Jumpers

The DS1109i has two jumpers located on the main board. P2

is used to allow the LED to latch on to a glass breakage alarm.

P3 is used to determine if the magnetic contact is used.

Remove the jumper from P2 if you do not want the LED •

to latch into alarm when a glass breakage occurs. The

relay contacts will only change state for approximately 3

sec upon a glass breakage alarm. The LED may be reset

by a momentary interruption of the power.

Remove the jumper from P3 if you want to use the mag-•

netic contact.

Turn on all sources of noise (e.g. forced air blowers, air •

conditioners, compressor motors, etc.).

The LED will fl ash 5 times per second each time a low •

frequency disturbance is detected. If the 5 fl ashes per

second occur more than once every 15 sec or if the unit

alarms, then do not mount in this location.

The LED will fl ash once each time a high frequency •

disturbance is detected. If any fl ashes occur more than

once every 15 sec, do not mount in this location.

Remember: If the detector happens to alarm during this

test, the alarm relay will activate as well.

During the last 10 sec of the detector’s test mode, its •

LED will pulse. To end the test mode before the 5 minute time-out period, press the Test Switch.

Automatic Sound Check

This detector features Automatic Sound Check, to allow the

end user to test the unit on a periodic basis. To perform the

test, simply clap your hands or create some other loud sound.

When the detector hears this sound the LED (but not the alarm

relay) will activate. This feature works in the normal operating mode and does not require that the detector be in the test

mode.

NOTICE!

Adjacent wall mounting is not recommended

for this detector.

Mounting the Detector

After verifying an acceptable location, permanently •

mount the detector. Use the two mounting holes in the

enclosure to secure it to the mounting surface.

Mount the detector and the Contact Magnet within 1 •

in (2.5 cm) of each other. The Contact Magnet must be

mounted facing the side of the detector with the Sensor Aperture. See Figure 3.6.

Magnet

DS1109i

Sensor Aperture

Magnet

DS1109i

Mounting Holes

Wire Knockouts

Magnet

DS1109i

Wall Tamper Sring

Knockout

Figure 3.6: Mounting the Detector

Do not mount the magnet so it covers the Sensor •

Aperture.

Avoid misaligning the detector and the magnet.•

Magnet

DS1109i

Figure 3.7: Alignment Caution

4 Wiring the Detector

Wire the detector as shown in Figure 4.1. Leave extra •

wire so the case can be opened for testing.

Alarm

Power

NC

Contacts shown with power on, no alarm

and Tamper Switch closed (cover on).

Figure 4.1: Wiring the Detector

C

Tamper

T

T

Latch

Jumper

Bypass

Jumper

P2 P3

Contact

NC C T T

+

-

Figure 5.1: Setting the Jumpers

6 Installing the Tamper Screw

Install the tamper screw as shown in Figure 6.1.

Figure 6.1: Installing the Tamper Screw

7 Testing

Testing the Location

Temporarily mount the detector using 2-sided tape.•

Power the detector using a 9 Volt battery.•

The detector will enter the test mode for fi ve min as •

soon as power is applied. The detector will indicate that

it is in the test mode by fl ashing the LED for 10 sec. At

the end of fi ve min the detector will fl ash the LED again

for 10 sec to indicate the test period is over. The test

mode can be restarted at any time by powering the unit

off and then on or by pressing the Test Switch (see the

Board Layout drawing). Pressing the Test Switch when

the unit is in the test mode will terminate the test.

NOTICE!

All testing should be done with the detector’s

cover in place.

Test #1 Environmental Test

Remember: The detector must be in test mode to perform this

test. During the 5 minute test mode, the LED will indicate low

or high frequency disturbances by fl ashing at specifi c rates.

Occasional (random) fl ashes of the LED are normal. To rule out

random fl ashes affecting this test, observethe LED for the full

5 min.

Test #2 Response Test

Remember: The detector must be in test mode to perform

this test.

This test should be performed using the DS1110i Glass Breakage Tester. The DS1110i produces a high frequency tone

designed to alarm the unit to further verify proper location.

CAUTION!

Don’t point the tester directly at your or anyone’s ear. Doing so could damage hearing.

Hold the DS1110i Glass Breakage Tester against the •

window being tested and point it at the detector.If

there are curtains or blinds covering the window, close

them over the Tester. See Figure 7.1.

DS1110i Tester

Hold against window and

point at detector.

Figure 7.1: Test #2 Response Test

Activate the tester. Setting the Tester to automatic •

mode causes it to activate every 6 sec. This will allow

you to better observe the detector’s LED.

For large windows, perform this test at different place-•

ments along the window.

The alarm/test LED and the alarm relay will activate for •

three sec if this is an acceptable detector placement.

NOTICE!

The low frequency response of the detector can

be tested (while still in the test mode) by opening a door about 1 inch and slamming it shut.

The detector should indicate an alarm.

It is recommended that a full Response Test (as outlined

above) and magnetic contact test (if used) be performed on an

annual basis.

Reading Bosch Security Systems, Inc. Product Date Codes

For Product Date Code information, refer to the Bosch Security Systems, Inc.

Web site at: http://www.boschsecurity.com/datecodes/.

© 2011 Bosch Security Systems, Inc.

F01U069268 | 02 | 2011.10 | 2

Loading...

Loading...