Bosch DKE9305AUC/03, DKE9305AUC/02 Owner’s Manual

en Operating and

installation instructions

fr Notice de montage

et d’utilisation

es Instrucciones de uso

y montaje

DKE 93 . . AUC

a

Internet: http://www.bosch-hausgeraete.de

Bosch Info-Team: de Tel. 01 80/5 30 40 50 (E 0,12/Min. DTAG)

2

en

page 03–11

fr

page 12 – 20

es

página 21 – 29

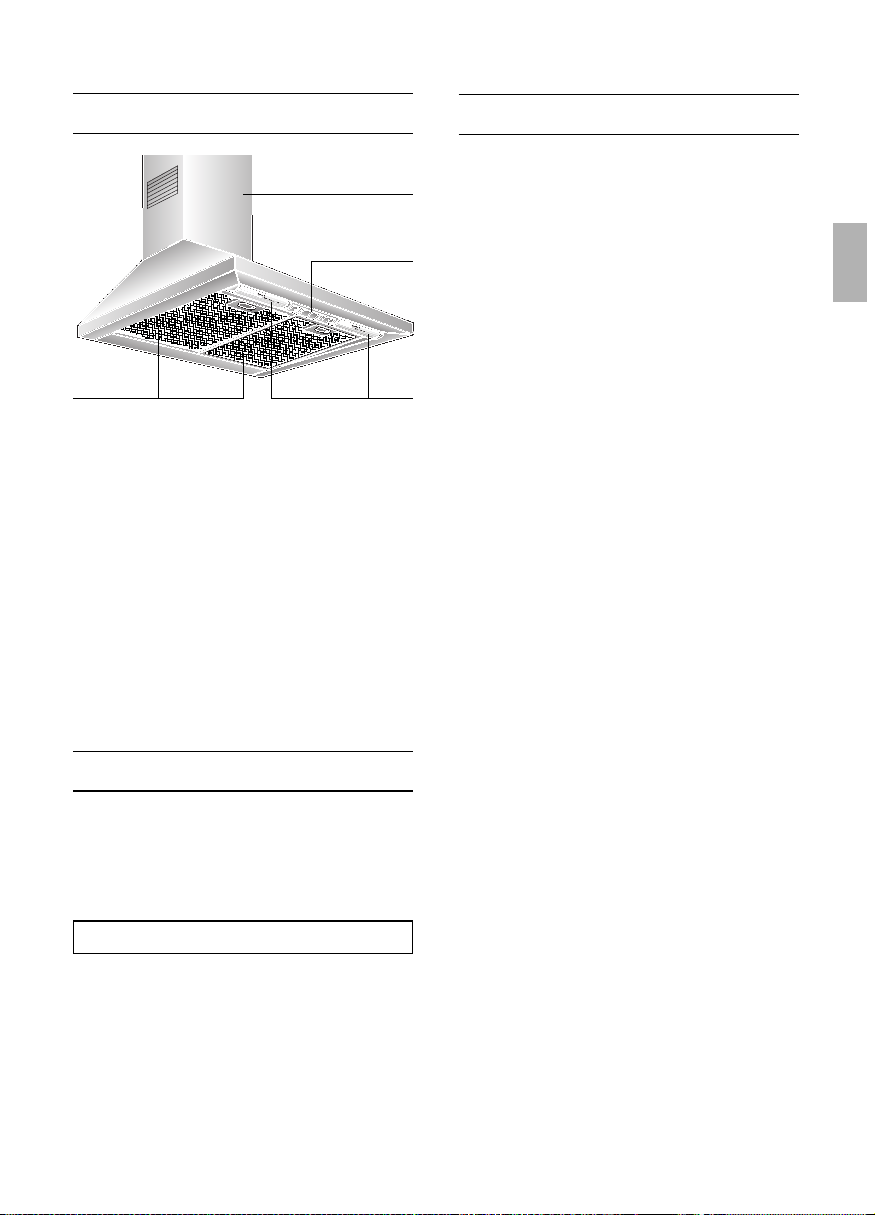

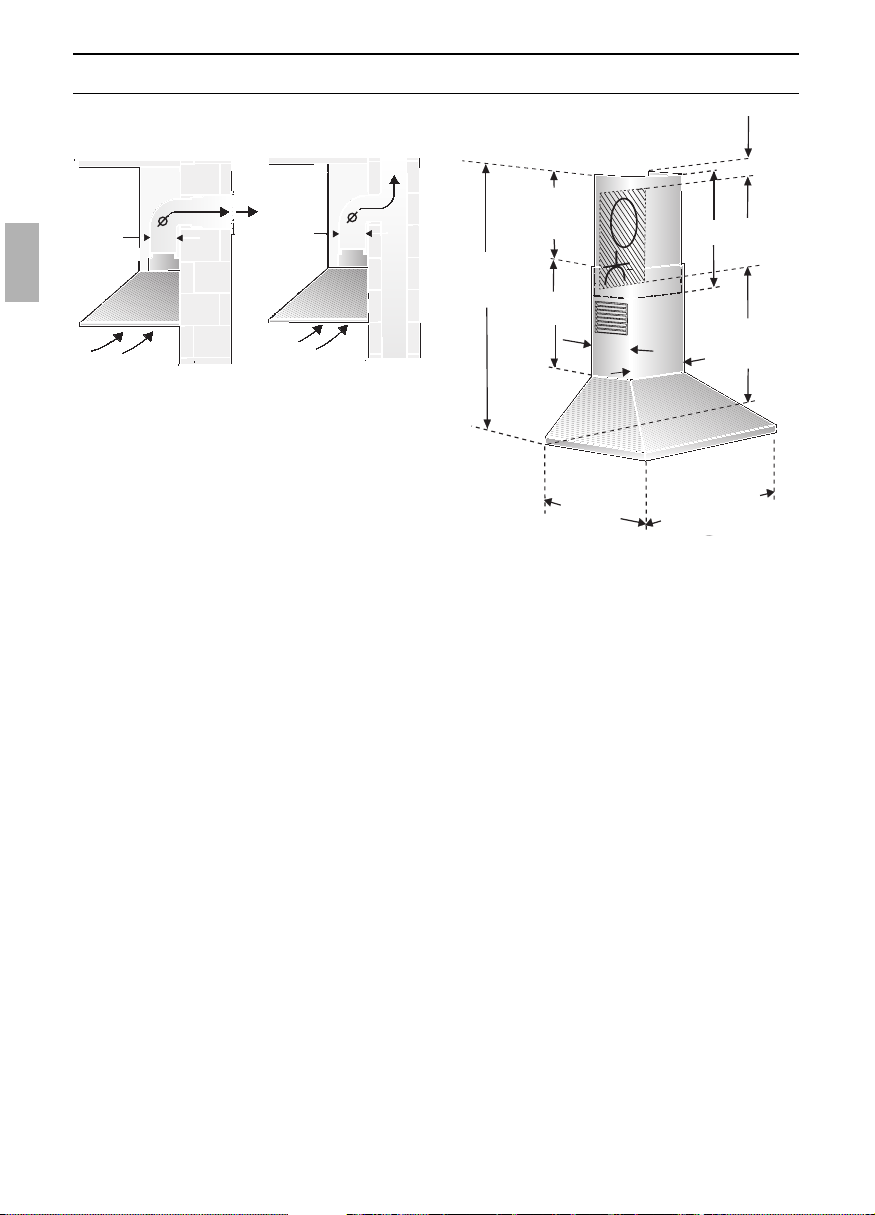

Fig. 1

MIN.

30”

3

Lighting

Light / fan

switches

Filter grill

Chimney

cover

Operation

❑ The hood fan extracts the kitchen

vapours and conveys them through the

grease filter into the atmosphere.

❑ The grease filter absorbs the solid

particles in the kitchen vapors.

❑ The kitchen is kept almost free of grease

and odors.

D

If the hood is in exhaust-air mode

and a flue-type heater is running at the

same time (e.g. gas, oil or solid-fuel

heaters, continuous-flow heaters, water

heaters), ensure that the fireplace has an

adequate air supply for combustion.

Safe operation requires that the low air

pressure in the room in which the fireplace

is located does not exceed 4 Pa (0.04

mbar).

This low air pressure can be obtained,

provided combustion air can escape

through non-lockable openings, e.g. in

doors, windows, air-intake/exhaust-air wall

boxes or by other technical procedures,

such as reciprocal interlocking, etc.

An air-intake/exhaust-air wall box by itself is

no guarantee that the limiting value will not

be exceeded.

Note: When assessing the air pressure, the

entire ventilation system in the house/

apartment must be taken into account. If

using cooking appliances, e.g. hob and/or

gas cooker, this rule does not apply.

Government regulations must be observed

for the conveyance of exhaust air.

If you encounter a problem

If you have any questions or if a fault

occurs, please call Customer Service:

1-800-735-4328

When you call, please quote the following:

E-Nr. FD

Enter the relevant numbers into the box

above. The E-Nr. (product no.) and FD

(production date) are shown on the

nameplate which can be seen inside the

extractor hood after the filter frame has

been detached.

Appliance description

Instructions for use:

4

Before using for the first time

Important notes:

❑ The Instructions for Use apply to several

versions of this appliance. Accordingly,

you may find descriptions of individual

features that do not apply to your

specific appliance.

❑ This hood complies with all

relevant safety regulations.

Repairs should only be carried out by

qualified technicians.

Improperly executed repairs can give

rise to significant hazards for the user.

❑ Before using your new appliance, please

read these Instructions for Use carefully.

They contain important information

concerning your personal safety as well

as on use and care of the appliance.

❑ Please keep the operating and

installation instructions in a safe place;

this important documentation may also

be of use to a possible subsequent

owner.

Do not use the appliance if it is

damaged in any way

The appliance is not intended for use

by young children without supervision.

Young children should be supervised to

ensure they do not play with the appliance.

Electrical connections should be made

by a qualified technician.

Dispose of packaging materials

properly (see Installation instructions).

Light bulbs must always be fitted when

the hood is in use.

Never operate the hood without a

grease filter.

Overheated fat or oil can easily catch

fire.

If you are cooking with fat or oil, e.g. chips,

etc., never leave food unattended.

Do not flambé food directly under the

hood.

Risk of grease filter catching fire due

! to flames.

WARNING – TO REDUCE THE RISK OF

INJURY TO PERSONS, IN THE EVENT

OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

SMOTHER FLAMES with a close-fitting

lid, cookie sheet, or other metal tray, then

turn off the gas burner or the electric element. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT

NEVER PICH UP A FLAMING PAN –

you may be burned.

DO NOT USE WATER, including wet

dishclothes or towels – a violent steam

explosion may result.

Use an extinguisher ONLY if:

1. You know you have a class ABC extin-

guisher, and you already know how to

operate it.

2. The fire is small and contained in the

area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to

an exit,

5

Cleaning the metal grease filters:

❑ In normal operation (1 to 2 hours daily),

the metal grease filter must be cleaned

after 8 to 10 weeks.

❑ The filters can be cleaned in a

dishwasher. It is however possible that

they will become slightly discolored.

Important:

Metal filters that are saturated with

grease should not be washed together

with other dishes etc.

❑ When cleaning the filters by hand, soak

them in hot soapy water first of all.

Then brush the filters clean, rinse them

thoroughly and leave the water to drain

off.

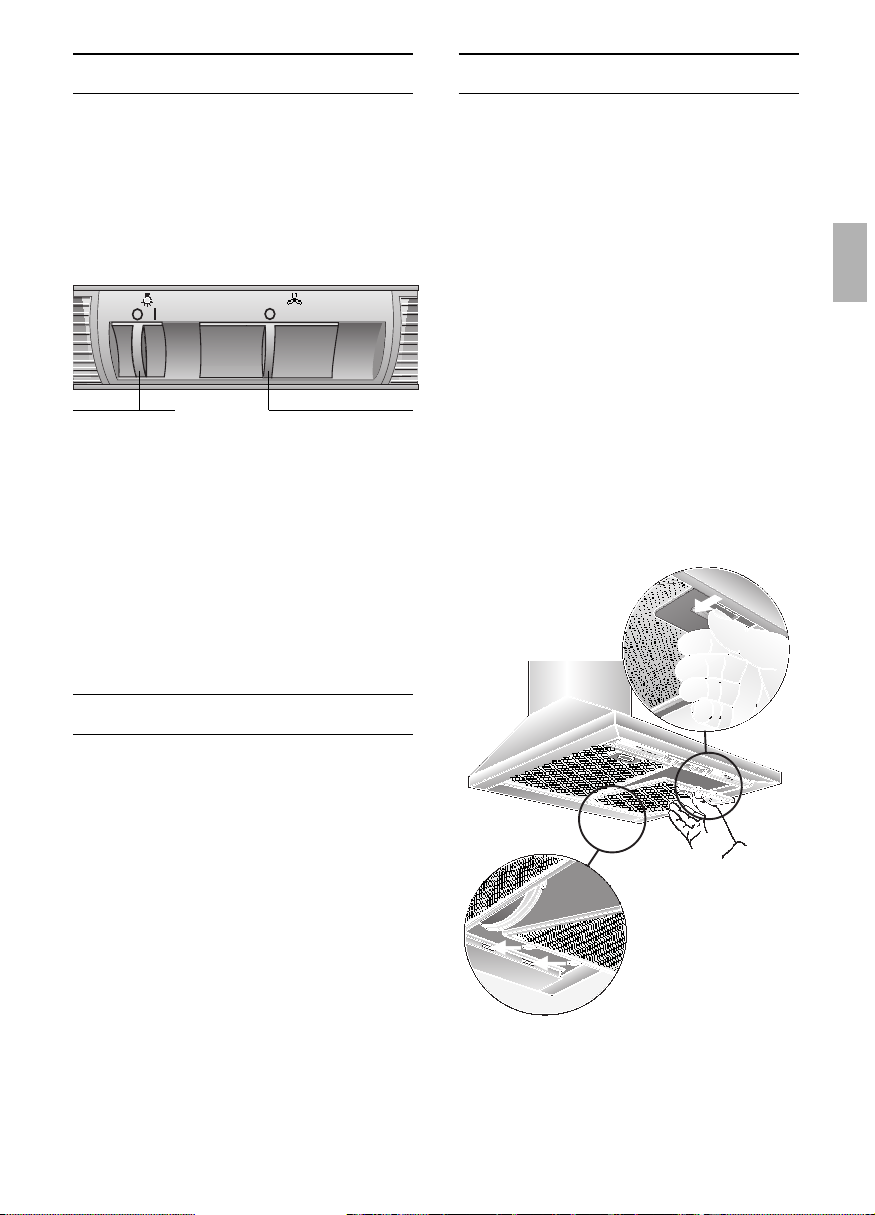

Removing and inserting the metal grease

filters:

1. Press the catch on the grease filters

inwards and fold the filters down.

Filters and maintenance

Filters and maintenance

Grease filters:

Metal filters are used to trap the grease

particles of the vapours that develop

during cooking.

The filter mats are made from noncombustible metal.

Caution:

As the filter becomes more and more

saturated with grease, not only does the

risk of it catching fire increase but the

efficiency of the hood can also be adversely

affected.

Important:

By cleaning the metal grease filters at

appropriate intervals, the possibility of them

catching fire as a result of a build-up of heat

such as occurs when deep-fat frying or

roasting is taking place, is reduced.

The most effective method of removing

vapours produced during cooking is to:

❑ Switch the ventilator ON

approximately 5 minutes before you

begin cooking.

❑ Switch the ventilator OFF

a few minutes after you have finished

cooking.

Operating procedure

Switching ON:

❑ Slide the right slide switch to the desired

fan setting.

Switching OFF:

❑ Slide the right slide switch back to 0.

Lighting:

❑ The light can be switched on at any

time, even though the fan is switched off.

Light Off/On

Ventilator settings

2. Clean the filters.

3. Insert the clean filters back into the

hood.

1

2

3

6

Replacing the light bulbsCleaning and care

Disconnect the hood from the electricity

supply by pulling out the AC plug or

switching it off at the fuse box.

❑ At the same time as you clean the

grease filters, clean off any grease from

all accessible parts of the housing.

This significantly reduces the fire hazard

and ensures that the hood performs as

effectively as possible.

❑ Use a hot detergent solution or a mild

window cleaner to clean the canopy of

the hood.

❑ Do not scrape off any dirt that has dried

on but loosen it up with a damp cloth.

❑ Do not use abrasive cleaning agents or

sponges that could cause scratches.

❑ Note: Do not use alcohol (spirit) on

plastic parts, otherwise the surface may

lose its glass.

Caution: Ensure that the kitchen is

adequately ventilated.

Clean the sliding switch with a soft,

damp cloth (mild detergent solution) only.

Do not use stainless steel polish on the

sliding switch.

Stainless steel surfaces:

❑ Use a mild non-abrasive stainless steel

cleaner.

❑ Clean the surface in the same direction

as it has been ground and polished.

Do not use any of the following to clean

stainless steel surfaces: abrasive sponges,

cleaning agents containing sand, soda,

acid or chloride!

1. Switch off the hood and pull out the

mains plug or switch off the

electricity supply at the fuse box.

2. Remove the grease filters (see Filters and

Maintenance).

3. Press down the bulb cover and

disconnect from the light strip.

5. Attach the lamp cover again.

6. Re-insert the grease filters.

7. Plug the appliance into the mains or

switch it on at the fuse box.

4. Replace the light bulb (commercially

available candle bulbs, max. 40 watt,

E12 base).

7

Important information

Installation Instructions:

The installation of the hood above

gas cooking devices, at a minimum

height of 30” – Fig. 1 – is permitted

provided that the following

nominal heat loads (Hs) are not exceeded:

❑

Gas cooktops

Load of one burner max. 04,5 kW

Load of all burners max. 14,1 kW

❑

Gas glass-ceramic cooktop

The data on nominal heat loads do not

apply to gas glass-ceramic hotplates.

Be sure to observe the instructions

provided by the manufacturer of the

hotplate.

Always turn hood ON when cooking at

high heat.

Burners should not be operated

without an appropriate cooking vessel in

place over the burners.

Your hood has a thermal overload

which will automatically shut off the motor if

it becomes overheated. The motor will

restart when it cools down. If the motor

continues to shut off and restart, please

have the hood serviced.

The smaller the gap between hood and

cooking appliance, the greater the

likelihood that rising steam will cause

condensation to form on the hood.

Suitable for use in residential cooking

area.

Always mount the hood over the center

of the cooking surface.

Distance between cooking surface and

bottom edge of hood. Should be min 30”

(Fig. 1).

Additional notes concerning cooking

appliances:

The relevant regulations and installation

notes provided by the manufacturer of the

gas cooker must be observed in all cases.

The hood may be installed next to only

one full-height cupboard or high wall.

Gap to be at least 2”.

8

Prior to installation

Exhaust-air mode

The exhaust air is discharged upwards

through a ventilation duct or directly

through the outside wall into the open.

D

Exhaust air should neither be directed

into a smoke or exhaust flue that is

currently used for other purposes, nor into

a shaft that is used for ventilating rooms in

which stoves or fireplaces are also located.

Exhaust air may be discharged in

accordance with official and statutory

regulations only (e.g. national building

regulations).

Local authority regulations must be

observed when discharging air into smoke

or exhaust flues that are not otherwise in

use.

Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel burning

equipment to prevent backdrafting. Follow

the heating equipment manufacturers

guideline and safety standards such as

those published by the National Fire

Protection Association (NFPA), the

American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE),

and the local code authorities.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

All legal requirements concerning the

discharge of exhaust air must be observed.

❑ Due to size and weight of this unit two

installers are recommended.

❑ When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

❑ To properly exhaust air, be sure to duct

air outside – do not vent exhaust air into

spaces within walls, ceilings, attics,

crawl spaces, or garages.

❑ WARNING – TO REDUCE THE RISK

OF FIRE, USE ONLY METAL DUCT

WORK.

❑ Install this hood in accordance with all

requirements specified.

6”

6”

MIN.

1

1

”

4

/

5

”

8

45

MAX.

MIN.

/

29”

1

”

18

2

/

5

6

”

8

/

7

9

5

19

/

8

”

18

”

8

/

30” / 36”

5

”

8

/

5

19

MIN.

1

/

2

”

8

/

”

8

9

Prior to installation

The two lightly sprung flaps must be

able to move upwards

If the exhaust air is going to be

discharged into the open, a telescopic

wall box should be fitted into the outside

wall.

For optimum hood efficiency:

❑ Short, smooth air exhaust duct.

❑ As few bends in the duct run as

possible.

❑ Diameter of duct to be as large as

possible and no tight bends in duct run.

❑ Round pipes:

We recommend

Internal diameter: 6”.

❑ Flat ducts must have an internal cross-

section that equates to that of round

pipes.

There should be no sharp bends.

minimum 3

1

/4” x 10” recommended.

❑ If pipes have different diameters:

Insert appropriate transition pieces.

❑ Always ensure that there is an adequa-

te supply of fresh air.

Connecting a l 6” exhaust-air pipe:

❑ Mount the pipe directly onto the air

outlet on the hood.

Preparing the wall

❑ The wall must be flat and perpendicular.

❑ Ensure that the wall is capable of

providing a firm hold for mounting

screws and plugs.

Weight in lbs:

2830”

36” 31

We reserve the right to change specifications or design

without prior notice.

Electrical connection

WARNING: THIS APPLIANCE MUST BE

CONNECTED TO GROUND

IMPORTANT: Fitting a Different Plug:

The wires in the power lead are coloured in

accordance with the following code:

Green – Ground

White – Neutral

Black – Live

If you fit your own plug, the colours of

these wires may not correspond with the

identifying marks on the plug terminals.

This is what you have to do:

1. Connect the green (Ground) wire to the

terminal in the plug marked ‘E’ or with

the symbol ( ).

2. Connect the white (Neutral) wire to the

terminal in the plug marked ‘N’.

3. Connect the black (Live) wire to the

terminal marked ‘L’.

The hood should only be connected to an

earthed socket that has been installed

according to relevant

regulations.

If possible, site the earthed socket directly

behind the chimney panelling.

Electrical data:

Are to be found on the name plate inside

the appliance after removal of the filter

frame.

Before undertaking any repairs,

always disconnect the hood from the

electricity supply.

Length of the connecting cable: 4 ft.

If it is necessary to wire the hood

directly into the mains:

The hood should only be connected to the

electricity supply by a properly qualified

electrician.

A separator must be installed in the household circuit. A suitable separator is a switch

that has a contact gap of more than 3 mm

and interrupts all poles. Such devices include circuit breakers and contactors.

If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his

customer service or a similarly qualified

person in order to prevent serious injury to

the user.

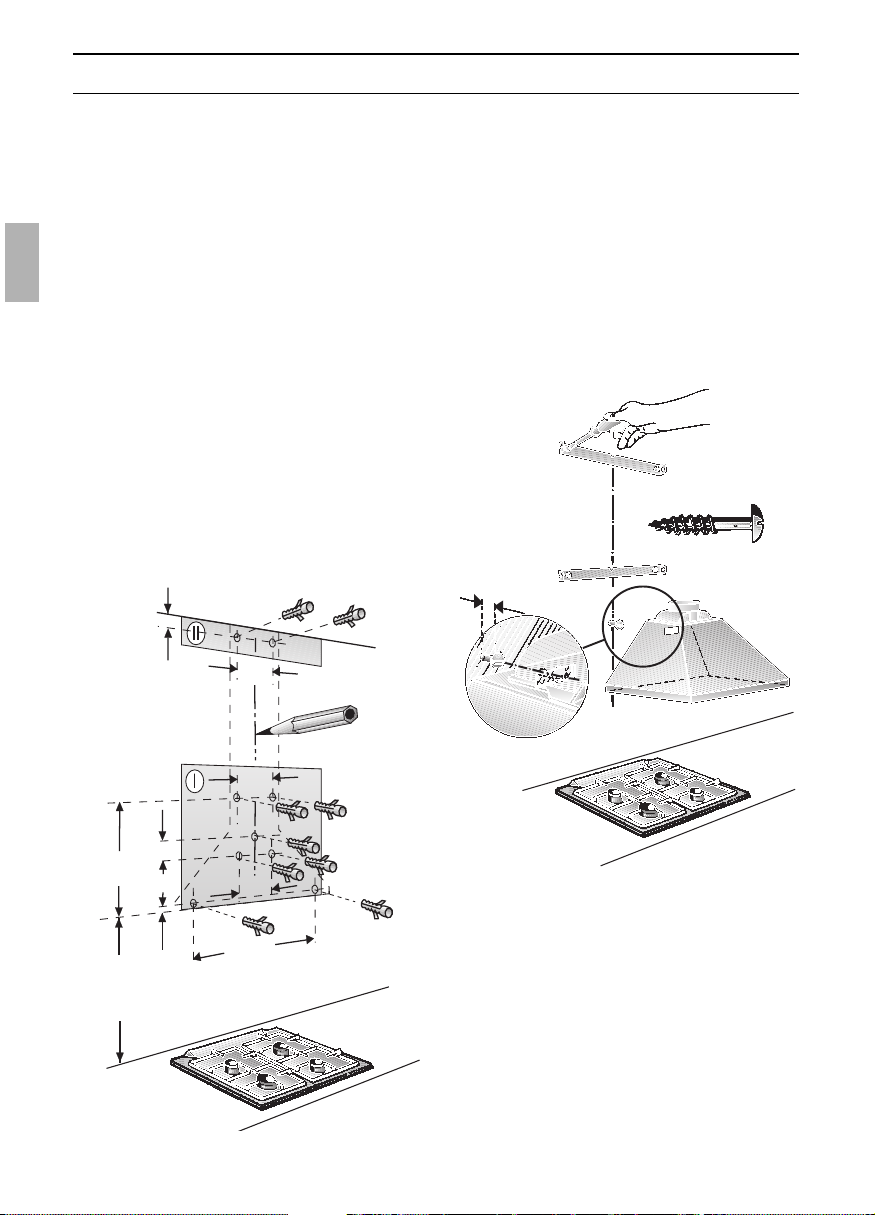

Installation

Note: Take into account any special

accessories that are going to be fitted.

5. Screw on the 2 brackets for fixing the

upper and lower flue ducts.

6. In order to help fix the hood onto the

wall, screw in the middle screw

(without a washer) until it protrudes by

approx. 1/4”.

7. Hook the hood over the screw in the

wall.

This hood is intended to be mounted onto

the kitchen wall.

1. Remove the grease filter

(see operating instructions).

2. Draw a line on the wall from the ceiling

to the lower edge of the hood at the

center of the location where the hood is

going to be mounted.

3. Using the template, mark positions on

the wall for the screws.

Ensure that the minimum distance

between the cooking surface and the hood

is maintained. The bottom edge of the

template equates to the lower edge of the

hood.

4. Drill 5 holes (dia.

1

/4”) for the

hood and 4 holes (dia. 1/4”) for the

brackets for fixing the flue ducts and

insert wall plugs flush with the wall.

Note: At least one screw must be

installed through a stud.

10

1

1

”

16

/

9”

CA. 7/32”

MIN.

18

1

/

30”

9”

5

2

”

8

/

”

4

1

”

4

2

/

1

1

”

5

/

15

5

”

8

/

8

3

”

4

/

Loading...

Loading...