Bosch DIP-6043-4HD User Manual

DIVAR IP 6000 1U

DIP-6040-00N, DIP-6042-4HD

en Installation manual

DIVAR IP 6000 1U Table of Contents | en 3

Table of contents

1

1.1 General safety precautions 5

1.2 Electrical safety precautions 6

1.3 ESD precautions 7

1.4 Operating precautions 7

1.5 Important notices 8

1.6 FCC and ICES compliance 8

2

2.1 Chassis features 9

2.2 Chassis components 9

2.2.1 Chassis 9

2.2.2 Backplane 10

2.2.3 Fans 10

2.2.4 Mounting rails 10

2.2.5 Power supply 10

2.2.6 Air shroud 10

2.3 System interface 10

2.3.1 Control panel buttons 11

2.3.2 Control panel LEDs 11

2.3.3 Drive carrier LEDs 12

2.3.4 Power supply LEDs and overheat indicators 12

2.3.5 Overheating 13

3

3.1 Removing the chassis cover 14

3.2 Installing hard drives 14

3.2.1 Removing hard drive trays 14

3.2.2 Installing a hard drive 15

3.3 Installing a DVD-ROM or floppy drive 17

3.4 Replacing the internal transcoder device 17

3.5 Installing the motherboard 18

3.6 Installing the air shroud 18

3.7 System fans 19

3.8 Power supply 20

3.8.1 Power supply failure 20

4

4.1 Unpacking the system 22

4.2 Preparing for setup 22

4.2.1 Choosing a setup location 22

4.2.2 Rack precautions 22

4.2.3 General system precautions 23

4.2.4 Rack mounting considerations 23

4.3 Rack mounting instructions 23

4.3.1 Identifying the sections of the rack rails 24

4.3.2 Installing the inner rails 24

4.3.3 Assembling the outer rails 25

4.3.4 Installing the outer rails to the rack 25

4.3.5 Installing the chassis into the rack 26

Safety precaution 5

System overview 9

Chassis setup and maintenance 14

Rack installation 22

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

4 en | Table of Contents DIVAR IP 6000 1U

4.3.6 Installing the chassis into a Telco rack 27

4.4 Turning on the system 27

5

Appendix 28

5.1 Motherboard 28

5.1.1 Motherboard layout 28

5.1.2 Motherboard component overview 29

5.1.3 Motherboard features 31

5.1.4 Block diagram 33

5.2 Chipset overview 33

5.3 PC health monitoring 34

5.4 Power configuration settings 34

5.5 Power supply 35

5.6 Super I/O 35

5.7 iSCSI support 35

5.8 Overview of the Nuvoton BMC controller 36

5.9 RAID disaster recovery 36

5.9.1 Multiple disks failed - theory 37

5.9.2 Multiple disks failed - practice 42

5.9.3 Foreign configuration disk appears in the Windows GUI after booting 45

5.9.4 MegaCLI Commandline Utility 46

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

!

!

!

DIVAR IP 6000 1U Safety precaution | en 5

1

1.1

Safety precaution

Observe the safety precautions in this chapter.

General safety precautions

Follow these rules to ensure general safety:

– Keep the area around the system clean and free of clutter.

– Place the chassis top cover and any system components that have been removed away

from the system or on a table so that they won't accidentally be stepped on.

– While working on the system, do not wear loose clothing such as neckties and

unbuttoned shirt sleeves, which can come into contact with electrical circuits or be

pulled into a cooling fan.

– Remove any jewelry or metal objects from your body, which are excellent metal

conductors that can create short circuits and harm you if they come into contact with

printed circuit boards or areas where power is present.

– After accessing the inside of the system, close the system back up and secure it to the

rack unit after ensuring that all connections have been made.

– The system weighs approximately 38.5 lbs. (17.5 kg) when fully loaded. When lifting the

system, two people at either end should lift slowly with their feet spread out to distribute

the weight. Always keep your back straight and lift with your legs.

Warning!

Interruption of mains supply:

Voltage is applied as soon as the mains plug is inserted into the mains socket.

However, for devices with a mains switch, the device is only ready for operation when the

mains switch (ON/OFF) is in the ON position. When the mains plug is pulled out of the

socket, the supply of power to the device is completely interrupted.

Warning!

Removing the housing:

To avoid electric shock, the housing must only be removed by qualified service personnel.

Before removing the housing, the plug must always be removed from the mains socket and

remain disconnected while the housing is removed. Servicing must only be carried out by

qualified service personnel. The user must not carry out any repairs.

Warning!

Power cable and AC adapter:

When installing the product, use the provided or designated connection cables, power cables

and AC adaptors. Using any other cables and adaptors could cause a malfunction or a fire.

Electrical Appliance and Material Safety Law prohibits the use of UL or CSA-certified cables

(that have UL/CSA shown on the code) for any other electrical devices.

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

!

!

6 en | Safety precaution DIVAR IP 6000 1U

Warning!

Lithium battery:

Batteries that have been inserted wrongly can cause an explosion. Always replace empty

batteries with batteries of the same type or a similar type recommended by the manufacturer.

Handle used batteries carefully. Do not damage the battery in any way. A damaged battery

may release hazardous materials into the environment.

Dispose of empty batteries according to the manufacturer's instructions.

Warning!

Handling of lead solder materials used in this product may expose you to lead, a chemical

known to the State of California to cause birth defects and other reproductive harm.

Notice!

Electrostatically sensitive device:

To avoid electrostatic discharges, the CMOS/MOSFET protection measures must be carried

out correctly.

When handling electrostatically sensitive printed circuits, grounded anti-static wrist bands

must be worn and the ESD safety precautions observed.

1.2

Notice!

Installation should only be carried out by qualified customer service personnel in accordance

with the applicable electrical regulations.

Disposal

Your Bosch product has been developed and manufactured using highquality materials and components that can be reused.

This symbol means that electronic and electrical devices that have reached

the end of their working life must be disposed of separately from

household waste.

In the EU, separate collecting systems are already in place for used

electrical and electronic products. Please dispose of these devices at your

local communal waste collection point or at a recycling center.

Electrical safety precautions

Basic electrical safety precautions should be followed to protect you from harm and the

system from damage:

– Be aware of the locations of the power on/off switch on the chassis as well as the room's

emergency power-off switch, disconnection switch or electrical outlet. If an electrical

accident occurs, you can then quickly remove power from the system.

– Do not work alone when working with high voltage components.

– Power should always be disconnected from the system when removing or installing main

system components, such as the motherboard or memory modules. When disconnecting

power, you should first turn off the system and then unplug the power cords from all the

power supply modules in the system.

– When working around exposed electrical circuits, another person who is familiar with the

power-off controls should be nearby to switch off the power if necessary.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

!

!

DIVAR IP 6000 1U Safety precaution | en 7

– Use only one hand when working with powered-on electrical equipment. This is to avoid

making a complete circuit, which will cause electrical shock. Use extreme caution when

using metal tools, which can easily damage any electrical components or circuit boards

they come into contact with.

– The power supply power cords must include a grounding plug and must be plugged into

grounded electrical outlets. The unit has more than one power supply cord. Disconnect

both power supply cords before servicing to avoid electrical shock.

– Mainboard replaceable soldered-in fuses: Self-resetting PTC (Positive Temperature

Coefficient) fuses on the mainboard must be replaced by trained service technicians only.

The new fuse must be the same or equivalent as the one replaced. Contact technical

support for details and support.

Caution!

Mainboard Battery: There is a danger of explosion if the onboard battery is installed upside

down, which will reverse its polarities. This battery must be replaced only with the same or

an equivalent type recommended by the manufacturer (CR2032). Dispose of used batteries

according to the manufacturer's instructions.

Caution!

DVD-ROM Laser: This system comes without a DVD-ROM drive but if added: To prevent direct

exposure to the laser beam and hazardous radiation exposure, do not open the enclosure or

use the unit in any unconventional way.

1.3

ESD precautions

Electrostatic Discharge (ESD) is generated by two objects with different electrical charges

coming into contact with each other. An electrical discharge is created to neutralize this

difference, which can damage electronic components and printed circuit boards. The

following measures are generally sufficient to neutralize this difference before contact is made

to protect your equipment from ESD:

– Do not use mats designed to decrease electrostatic discharge as protection from

electrical shock. Instead, use rubber mats that have been specifically designed as

electrical insulators.

– Use a grounded wrist strap designed to prevent static discharge.

– Keep all components and printed circuit boards (PCBs) in their antistatic bags until ready

for use.

– Touch a grounded metal object before removing the board from the antistatic bag.

– Do not let components or printed circuit boards come into contact with your clothing,

which may retain a charge even if you are wearing a wrist strap.

– Handle a board by its edges only. Do not touch its components, peripheral chips, memory

modules or contacts.

– When handling chips or modules, avoid touching their pins.

– Put the mainboard and peripherals back into their antistatic bags when not in use.

– For grounding purposes, make sure your computer chassis provides excellent

conductivity between the power supply, the case, the mounting fasteners and the

mainboard.

1.4

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

Operating precautions

The chassis cover must be in place when the system is operating to assure proper cooling. Out

of warranty damage to the system can occur if this practice is not strictly followed.

8 en | Safety precaution DIVAR IP 6000 1U

Note:

Please handle used batteries carefully. Do not damage the battery in any way. A damaged

battery may release hazardous materials into the environment. Do not discard a used battery

in the garbage or a public landfill. Please comply with the regulations set up by your local

hazardous waste management agency to dispose of your used battery properly.

1.5

1.6

Important notices

Accessories - Do not place this unit on an unstable stand, tripod, bracket,

or mount. The unit may fall, causing serious injury and/or serious damage to

the unit. Use only with the cart, stand, tripod, bracket, or table specified by

the manufacturer. When a cart is used, use caution and care when moving

the cart/apparatus combination to avoid injury from tip-over. Quick stops,

excessive force, or uneven surfaces may cause the cart/unit combination to

overturn. Mount the unit per the manufacturer's instructions.

FCC and ICES compliance

(only for U.S.A. and Canada)

This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the manufacturer’s instruction manual, may cause

harmful interference with radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case you will be required to correct the

interference at your own expense.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

DIVAR IP 6000 1U System overview | en 9

2

System overview

DIVAR IP 6000 is an affordable, simple and reliable all-in-one recording management solution

for network surveillance systems of up to 64 cameras. Powered by VRM (Video Recording

Manager) software, the system is an intelligent IP storage device that eliminates the need for

separate NVR (Network Video Recorder) server and storage hardware.

The 1U rack mount unit combines advanced recording management and state-of-the-art iSCSI

storage into a single cost-effective, plug and play IP recording appliance for IT-minded

customers seeking for a state-of-the-art “second generation” NVR recording solution.

The DIVAR IP 6000 1U chassis features a unique and highly-optimized design. The chassis is

equipped with high efficiency power supply.

High performance fans provide ample optimized cooling for memory modules. Hot-swap drive

bays offer maximum storage capacity in a 1U form factor.

DIVAR IP 6000 features:

– Instant real time access to video

View high quality HD video despite low or limited bandwidth connections. Dynamic

Transcoding technology ensures that you can view your video immediately — anytime,

anywhere.

– Remote viewing

DIVAR IP 6000 comes with our advanced Video Client for remote viewing. Video Client is a

Windows PC application for live viewing and playback including Configuration Manager.

Configuration Manager allows the settings of the DIVAR IP 6000 be configured. A stand-

alone archive player will allow archive playback and authentication without any other

workstation software.

For information on supported hardware, see the datasheet for DIVAR IP 6000 in the Bosch

Online Product Catalog.

2.1

2.2

2.2.1

Chassis features

The DIVAR IP 6000 1U high performance chassis includes the following features:

– CPU

The chassis supports a Dual-core Xeon processor.

– Hard Drives

The chassis features 4 slots for SATA drives. These drives are hot swappable. Once setup

correctly, these drives can be removed without turning off the unit. In addition, these

drives support SES2 (SAS/SATA).

– Other Features

Other onboard features are included to promote system health. These include various

4 cooling fans, a convenient power switch, reset button, and 5 LED indicators.

Chassis components

This chapter describes the most common components included with your chassis. For more

information, see the installation instructions detailed later in this manual.

Chassis

The chassis includes 1 slim CD-ROM bay and 4 hard drive bays. The chassis accepts a 1U

backplane, 4 fans and 2 power supplies.

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

!

10 en | System overview DIVAR IP 6000 1U

2.2.2

2.2.3

2.2.4

2.2.5

Backplane

Each chassis comes with a 1U backplane. The backplane accepts SAS/SATA or SCSI hard

drives.

Warning!

Use caution when servicing and working around the backplane. Hazardous voltage or energy

is present on the backplane when the system is operating. Do not touch the backplane with

any metal objects and make sure no ribbon cables touch the backplane.

Fans

The chassis supports 4 system fans that are powered from the motherboard. These fans are

1U high and are powered by 3-pin connectors.

Mounting rails

The unit can be placed in a rack for secure storage and use. To setup your rack, follow the

step-by-step instructions included in this manual.

Power supply

Each chassis model includes 2 high-efficiency power supplies (redundant). In the unlikely

event your power supply fails, replacement is simple and can be accomplished without tools.

2.2.6

2.3

Air shroud

Air shrouds are shields, usually plastic, which conduct the airflow directly to where it is

needed. Always use the air shroud included with your chassis.

System interface

There are several LEDs on the front and rear of the chassis. The LEDs show the over-all status

of the system and the activity and health of specific components.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

DIVAR IP 6000 1U System overview | en 11

2.3.1

2.3.2

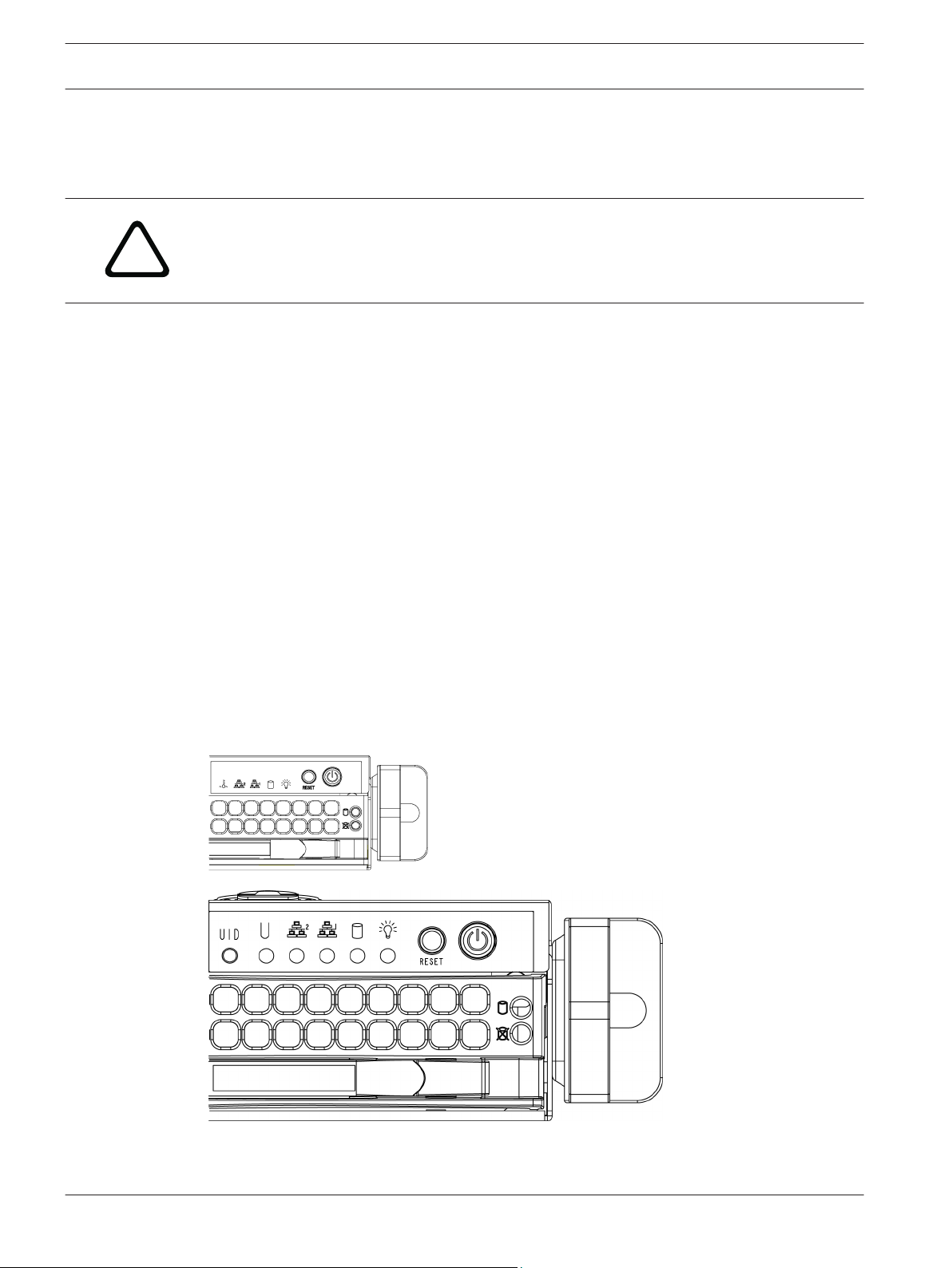

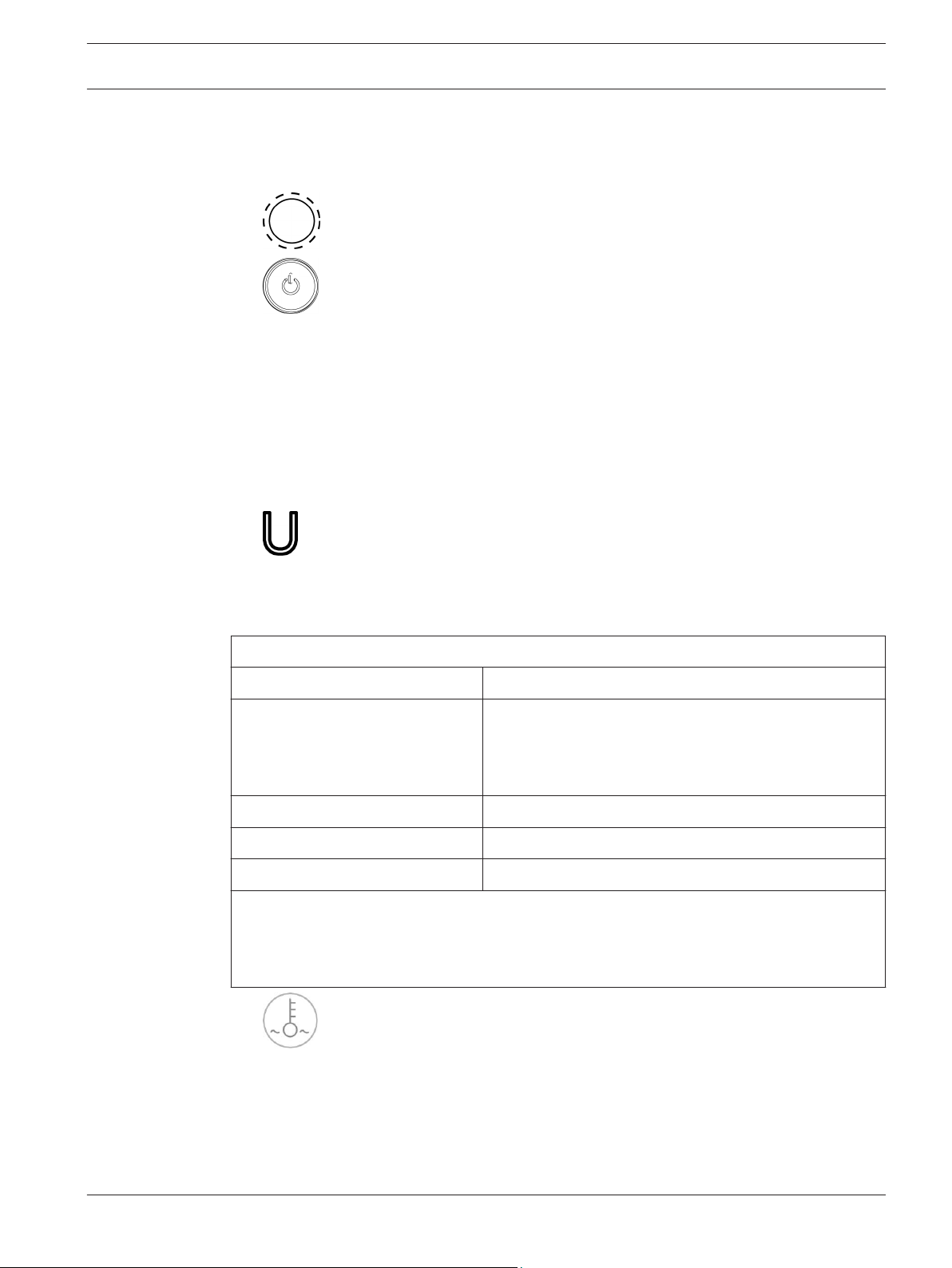

Control panel buttons

The chassis includes two or three push-buttons located on the front panel: a reset button, a

power on/off button, and a UID button.

–

–

supply to the server system. Turning off system power with this button removes the main

power but keeps standby power supplied to the system. Therefore, you must unplug

system before servicing.

Reset: The reset button is used to reboot the system.

Power: The main power switch is used to apply or remove power from the power

Control panel LEDs

The control panel located on the front of the chassis has up to 5 LEDs. These LEDs provide

critical information related to different parts of the system. This section explains what each

LED indicates when illuminated and any action that may be required.

–

Universal Information LED: The Universal Information LED is used to indicate fan

failure, power failure, overheat condition, or to identify the unit within a large rack

installation. The feature requires a motherboard that supports the Universal Information

LED.

Universal Information LED States

Fast blinking red (1x/sec) Fan failure

Solid red CPU overheat

Note: Can be caused by cables obstructing the airflow in

the system or the ambient room temperature being too

warm.

Slow blinking red (1x/4 sec) Power failure

Solid blue Local UID button depressed

Blinking blue IPMI-activated UID

Note:

Deactivating the UID LED must be performed in the same way it was activated. If the UID

LED was activated via IPMI, you can only turn the LED off via IPMI and not with the UID

button.

– Overheat/fan fail: A flashing LED indicates a fan failure.

When continuously on (not flashing) the LED indicates an overheat condition, which may

be caused by cables obstructing the airflow in the system or the ambient room

temperature being too warm. Check the routing of the cables and make sure all fans are

present and operating normally. You should also check to make sure that the chassis

covers are installed. Finally, verify that the heat sinks are installed properly.

This LED will remain flashing or on as long as the fan failure/overheat condition exists.

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

12 en | System overview DIVAR IP 6000 1U

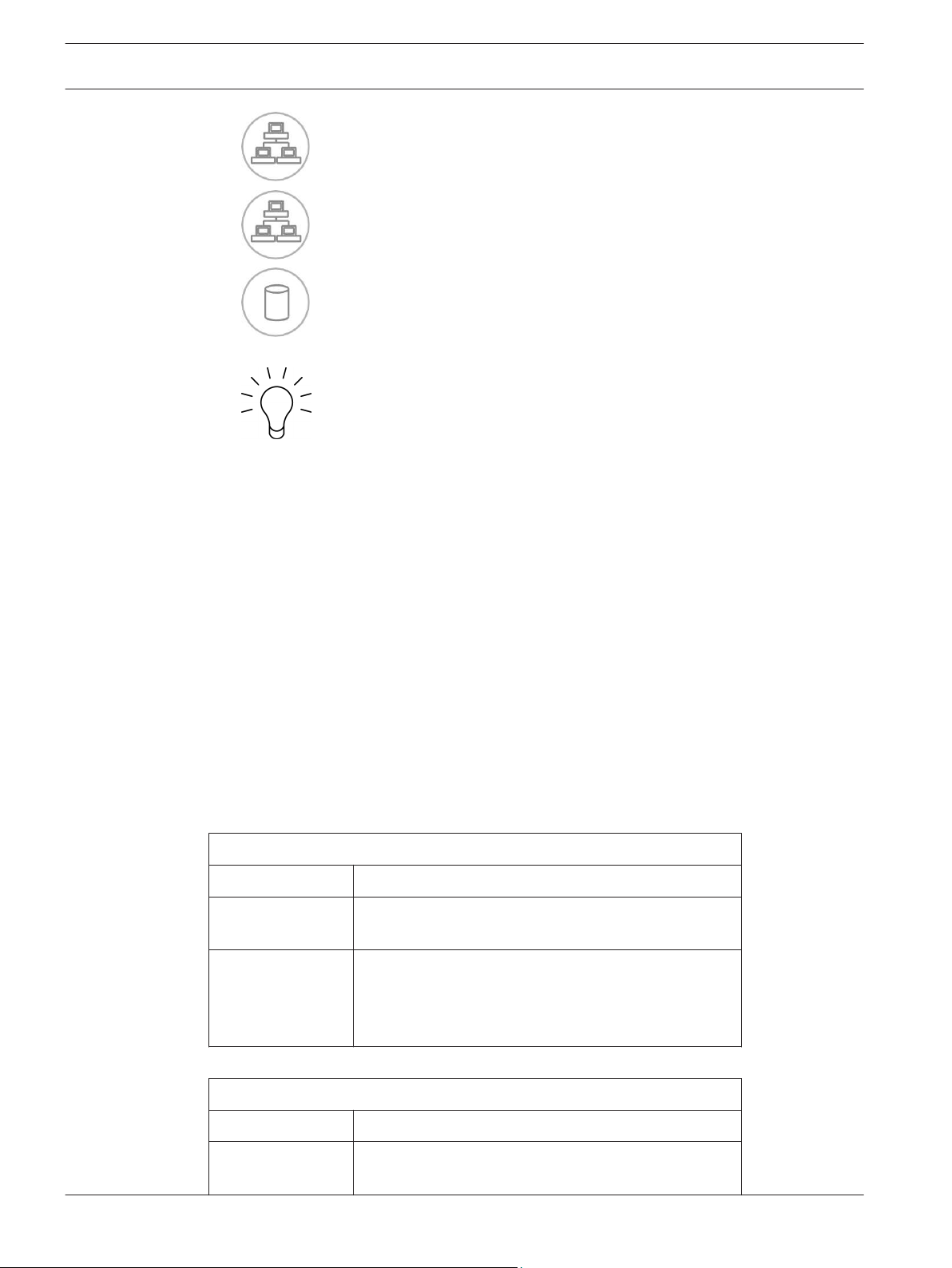

– NiC2: A flashing LED indicates network activity on GLAN2.

2.3.3

–

– HDD: A flashing LED indicates IDE channel activity in the SAS/SATA drive, SCSI

drive, and/or DVD-ROM drive activity.

– Power: Indicates power is being supplied to the system's power supply units.

This LED should normally be illuminated when the system is operating.

NIC1: A flashing LED indicates network activity on GLAN1.

Drive carrier LEDs

Your chassis uses SAS/SATA.

SAS/SATA drives

Each SAS/SATA drive carrier has two LEDs.

– Green: Each Serial ATA drive carrier has a green LED. When illuminated, this green LED

(on the front of the SATA drive carrier) indicates drive activity. A connection to the SATA

backplane enables this LED to blink on and off when that particular drive is being

accessed.

– Red: The red LED indicates a SAS/SATA drive failure. If one of the SAS/SATA drives fail,

you should be notified by your system management software.

2.3.4

Power supply LEDs and overheat indicators

This chassis provides several options which may include hot-swappable, cold-swappable, and

redundant power supplies. Some power supplies include an LED in the rear with the following

definitions:

450 W and 650 W power supplies

450 W and 650 W power supply LEDs

Solid green Power supply is on.

Solid amber The power supply is plugged in and turned off, or the

system is off but in an abnormal state.

Blinking amber Power supply temperature has reached to 63” C. The

system automatically turns off when the power supply

temperature reaches 70” C and restarts when the

power supply temperature is below 60” C.

All other power supplies

All other power supply LEDs

Solid green Power supply is on.

Solid amber The power supply is plugged in and turned off, or the

system is off but in an abnormal state.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

DIVAR IP 6000 1U System overview | en 13

2.3.5

Overheating

The section lists actions that should be taken in the unlikely event the server overheats.

Overheat temperature setting

Some backplanes allow the overheat temperature to be set at 45, 50, or 55 by changing a

jumper setting.

If the server overheats, do the following:

1. Use the LEDs to determine the nature of the overheating condition.

2. Confirm that the chassis covers are installed properly.

3. Check the routing of the cables and make sure all fans are present and operating

normally.

4. Verify that the heatsinks are installed properly.

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

!

14 en | Chassis setup and maintenance DIVAR IP 6000 1U

3

3.1

Chassis setup and maintenance

This chapter covers the steps required to install components and perform maintenance on the

chassis.

Caution!

Review the warnings and precautions listed in the manual before setting up or servicing this

chassis.

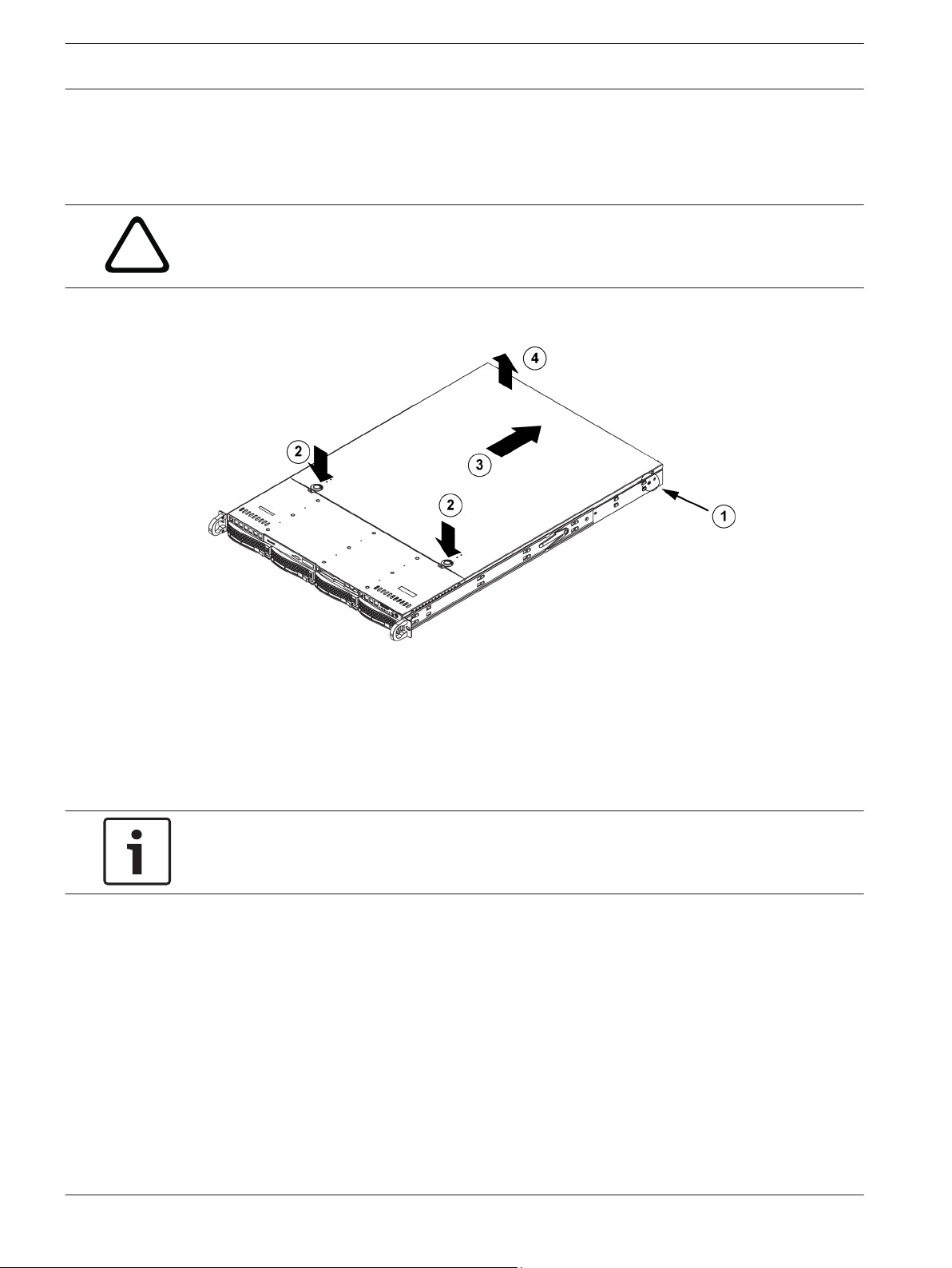

Removing the chassis cover

3.2

3.2.1

To remove the chassis cover:

1. Remove the two screws on each side of the cover, which secure the cover to the chassis.

2. Press the release tabs to remove the cover from the locked position. Press both tabs at

the same time.

3. Once the top cover is released from the locked position, slide the cover toward the rear

of the chassis.

4. Lift the cover off the chassis.

Notice!

Except for short periods of time, do NOT operate the server without the cover in place. The

chassis cover must be in place to allow proper airflow and prevent overheating.

Installing hard drives

This chapter describes the removing and installing of hard drives.

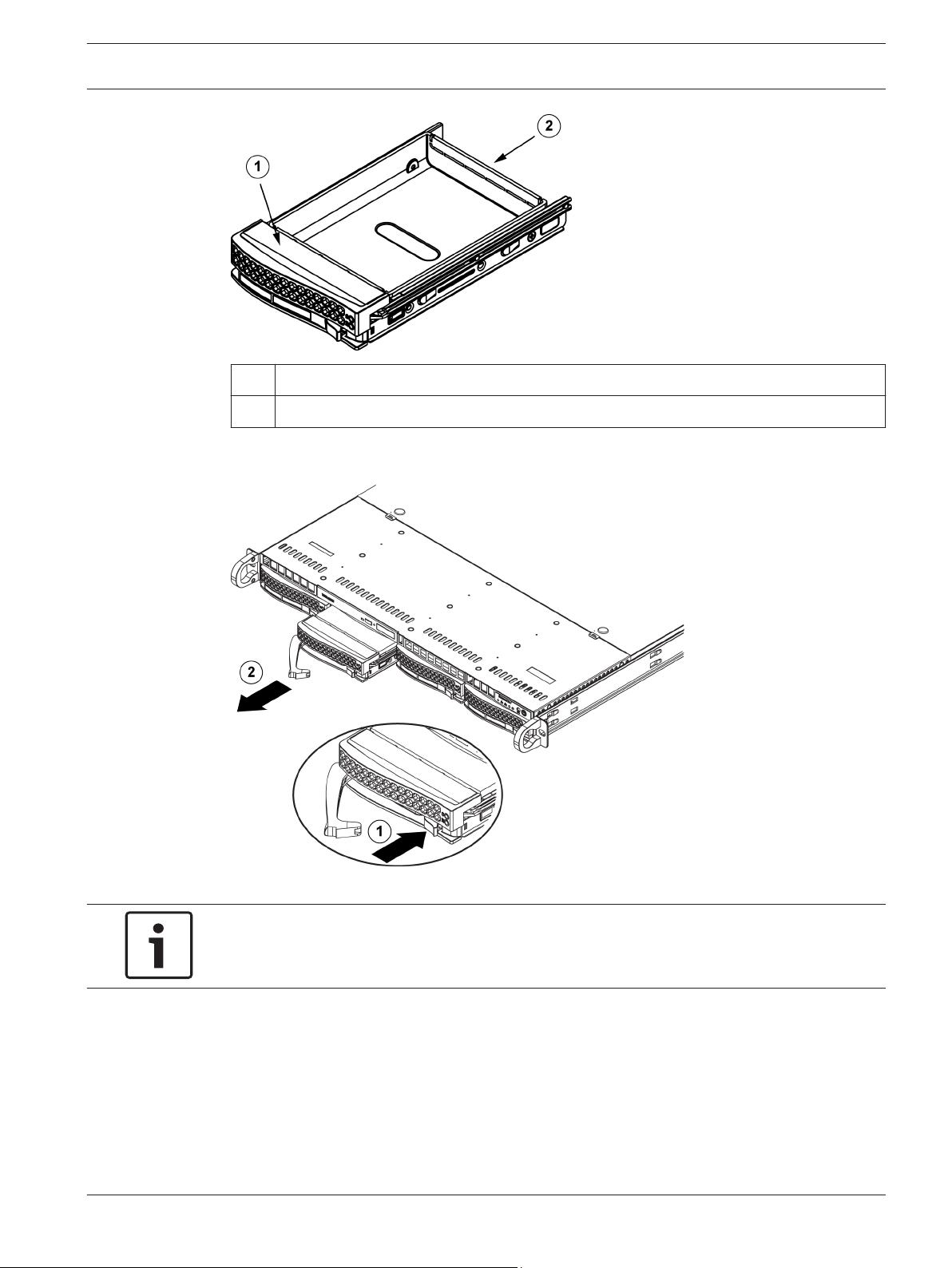

Removing hard drive trays

The drives are mounted in drive carriers to simplify their installation and removal from the

chassis. These carriers also help promote proper airflow for the drive bays.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

DIVAR IP 6000 1U Chassis setup and maintenance | en 15

1 Drive carrier

2 Dummy drive

To remove hard drive trays from the chassis:

1. Press the release button on the drive carrier. This extends the drive carrier handle.

2. Use the handle to pull the drive out of the chassis.

Notice!

Except for short periods of time (swapping hard drives), do not operate the unit with the

hard drives removed from the bays.

3.2.2

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

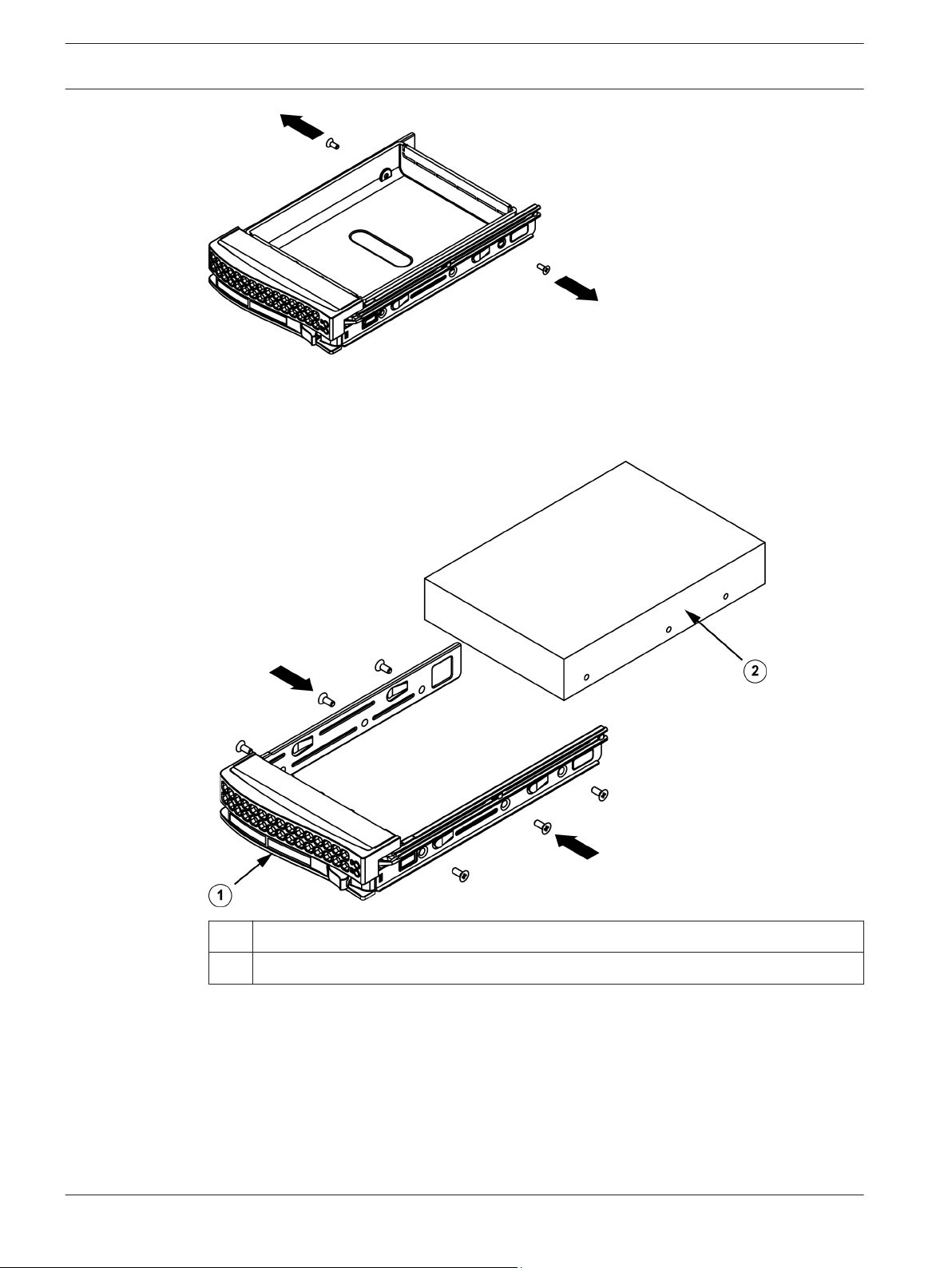

Installing a hard drive

The drives are mounted in drive carriers.

To install a hard drive to the hard drive carrier:

1. Remove the screws securing the dummy drive to the carrier.

en | Chassis setup and maintenance DIVAR IP 6000 1U

16

2. Remove the dummy drive from the carrier.

3. Install a new drive into the carrier with the printed circuit board side facing down so that

the mounting holes align with those in the carrier.

4. Secure the hard drive by tightening all 6 screws.

1

Drive carrier

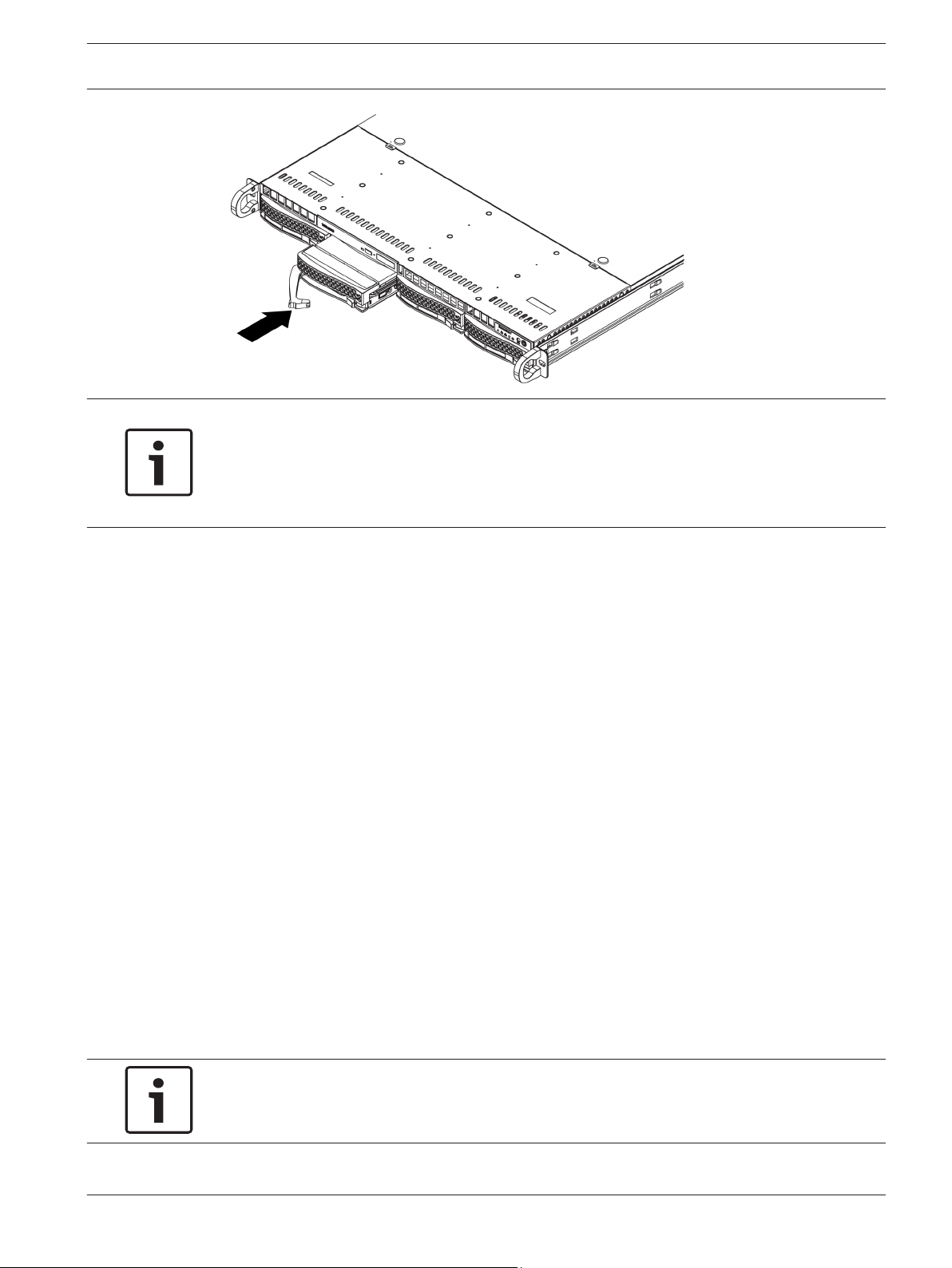

2 SAS/SATA hard drive

5. Replace the drive carrier into the chassis bay. Make sure that the drive carrier handle is

completely closed.

2013.05 | V1 | DOC Installation manual Bosch Sicherheitssysteme GmbH

DIVAR IP 6000 1U Chassis setup and maintenance | en 17

Notice!

We recommend using the respective Bosch hard disk drives. The hard disk drives as one of

the critical component are carefully selected by Bosch based on available failure rates. HDD –

not delivered from Bosch – are not supported. Information on supported HDDs can be found

in the datasheet in the Bosch Online Product Catalog.

3.3

3.4

Installing a DVD-ROM or floppy drive

The Bosch models come without a DVD-ROM. Due to the Bosch specific setup a DVD-ROM

drive is not needed for operations and / or maintenance.

To install or replace a DVD-ROM or floppy drive:

1. Turn off the system and if necessary, remove the unit from the rack and the front bezel

from the chassis.

2. Remove the chassis cover.

3. Unplug the drives power and data cables from the motherboard and/or backplane.

4. If you are adding a new drive:

Remove the mini-bezel (grate) from the drive bay. The bezel can be removed by pulling

out the hard drive beneath the DVD-ROM or floppy drive bay, then pulling the mini-bezel

forward.

If you are replacing a drive:

Locate the locking tab at the rear (left hand side when viewed from the front) of the DVDROM or floppy drive. Push the tab toward the drive and push the drive unit out the front

of the chassis.

5. Insert the new drive unit in the slot until the tab locks in place.

6. Reconnect the data and power cables.

7. Replace the chassis cover. replace the unit in the rack, if necessary, then turn on the

system.

Replacing the internal transcoder device

The chassis model includes an internal USB transcoder device.

Notice!

To replace or install the transcoder device, please apply to one of the Bosch RMA helpdesks.

Bosch Sicherheitssysteme GmbH Installation manual 2013.05 | V1 | DOC

Loading...

Loading...