Page 1

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

CL400

BOSCH REXROTH

Page 2

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

Page 3

Automationstechnik

Antriebs- und Steuerungstechnik

CL400

Manual

CL400

101

Version

Page 4

CL400

CL400

Manual

1070 072 143-101 (95.04) GB

E 1995

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 20.– DM

Page 5

Safety instructions and reading help

V

1070 072 143-101

Safety instructions and reading help

Read this instruction manual before you use the CL400. Keep this manual in

a place where it is always accessible to all users.

Standard operation

This instruction manual contains all of the information required for standard

operation of the described products.

The products described were developed, manufactured, tested and do

cumented in accordance with the relevant safety standards. There should

be no risk of danger to personnel or property if the specifications and safety

instructions relating to the project phase and installation and correct oper

ation of the product are followed.

Qualified personnel

This instruction manual is designed for specially trained PLC personnel.

The relevant requirements are based on the job specifications as described

by the ZVEI, see:

Anforderungsprofile für SPSFachkräfte

I + K SPEKTRUM 19

Hrsg.: ZVEI

Stresemannallee 19

60596 Frankfurt

Federal Republic of Germany

ISSN 0932-5018

This instruction manual is designed for PLC engineer.

Interventions in the hardware and software of our products which are not

described in this instruction manual may only be performed by our skilled

personnel.

Unqualified interventions in the hardware or software or noncompliance

with the warnings listed in this instruction manual or indicated on the prod

uct may result in serious personal injury or damage to property.

Page 6

Safety instructions and reading help

VI

1070 072 143-101

Qualified personnel are persons who

D as planning personnel, are familiar with the safety guidelines used

in electrical engineering and automation technology.

D as operating personnel, are familiar with the equipment used in the

field of automation technology and are thus familiar with the operat

ing instructions in this manual.

D as commissioning personnel, are authorized to commission,

ground and classify electric circuits and devices/systems in accord

ance with the relevant safety standards.

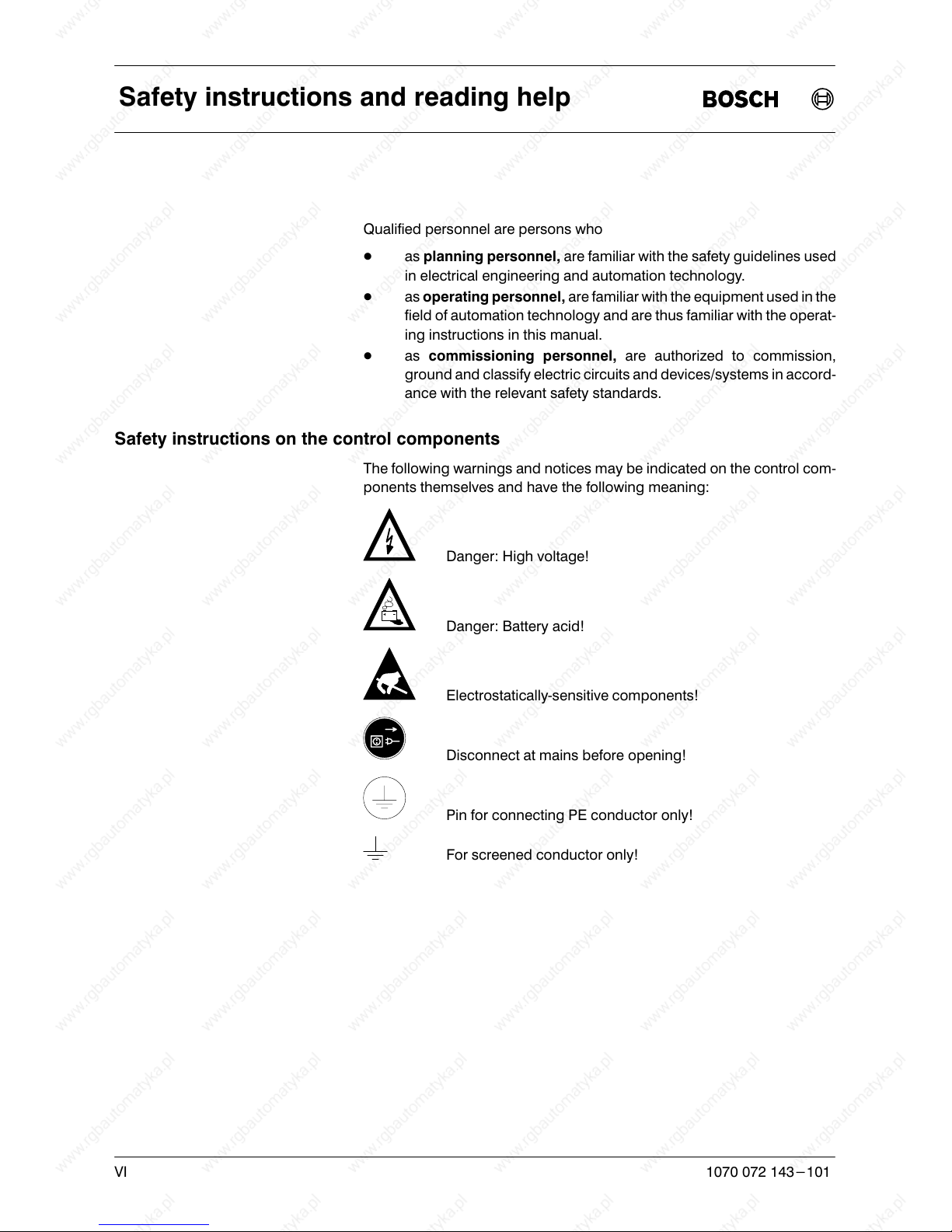

Safety instructions on the control components

The following warnings and notices may be indicated on the control com

ponents themselves and have the following meaning:

Danger: High voltage!

Danger: Battery acid!

Electrostaticallysensitive components!

Disconnect at mains before opening!

Pin for connecting PE conductor only!

For screened conductor only!

Page 7

Safety instructions and reading help

VII

1070 072 143-101

Safety instructions in this manual

!

.

These symbols are used throughout this manual subject to the following

conditions.

DANGER

This symbol is used to warn of the presence of dangerous electrical cur

rent. Insufficient or lacking compliance with these instructions can result in

personal injury.

Safety instructions accompanied by this symbol are serially numbered, for

example 0.1. The appendix provides translations of the safety notes shown

here in all the official EC languages.

DANGER

This symbol is used wherever an insufficient or lacking compliance with in

structions can result in personal injury.

Safety instructions accompanied by this symbol are serially numbered, for

example 0.1. The appendix provides translations of the safety notes shown

here in all the official EC languages.

CAUTION

This symbol is used wherever an insufficient or lacking compliance with in

structions can result in damage to equipment or files.

Safety instructions accompanied by this symbol are serially numbered, for

example 0.1. The appendix provides translations of the safety notes shown

here in all the official EC languages.

.

This symbol is used to inform the user of special features.

!

Page 8

Safety instructions and reading help

VIII

1070 072 143-101

Symbols used

L

This sign shows that the manual is describing an activity which you have to

perform, e.g.:

L Insert disk 1 into the floppy disk drive.

. We would greatly appreciate any contributions to improve this manual.

If you have any suggestions, please fill out the page provided at the

end of this manual.

Page 9

Safety instructions and reading help

IX

1070 072 143-101

Safety instructions

DANGER 0.1

Danger to persons and equipment!

Test every new program before operating the system!

CAUTION 0.2

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

CAUTION 0.3

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

Observe the following protective measures for electrostatically endan

gered modules! (EEM)!

D The employees responsible for the storage, transport and handling

must be trained in ESD protection.

D EEMs must be stored and transported in the protective packaging

specified.

D EEMs may basically only be handled at special ESD work places set

up specifically for this purpose.

D Employees, work surfaces and all devices and tools, which could

come into contact with EEMs must be same potential (e.g. earthed).

D Wear an approved earthing strap around your wrist. The grounding

bracelet must be connected via a cable with integrated 1 M7resis

tance with the work surface.

D EEMs may on no account come into contact with chargeable ob

jects, these include most plastics.

D When inserting EEMs into devices and removing them, the power

source of the device must be switched off.

. These operating instructions apply to the following versions:

ZS400:

Firmware: 101

Hardware: Daughter board version: 0

Basic PCB version: 0

!

Page 10

Safety instructions and reading help

X

1070 072 143-101

Page 11

Contents

XI1070 072 143-101

Contents

Page

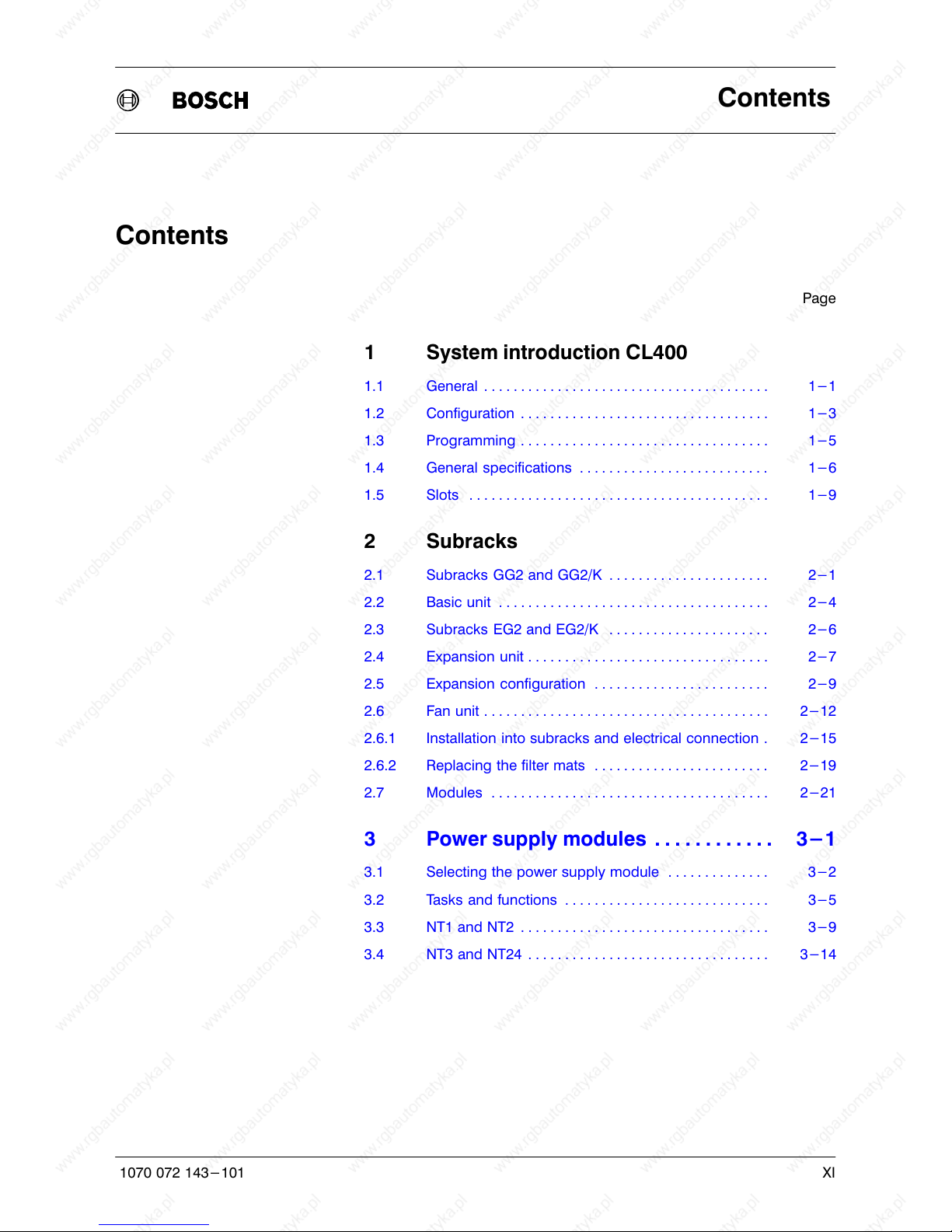

1 System introduction CL400

1.1 General 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Configuration 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Programming 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 General specifications 1-6. . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Slots 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Subracks

2.1 Subracks GG2 and GG2/K 2-1. . . . . . . . . . . . . . . . . . . . . .

2.2 Basic unit 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Subracks EG2 and EG2/K 2-6. . . . . . . . . . . . . . . . . . . . . .

2.4 Expansion unit 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Expansion configuration 2-9. . . . . . . . . . . . . . . . . . . . . . . .

2.6 Fan unit 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Installation into subracks and electrical connection 2-15.

2.6.2 Replacing the filter mats 2-19. . . . . . . . . . . . . . . . . . . . . . . .

2.7 Modules 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Power supply modules 3-1. . . . . . . . . . . .

3.1 Selecting the power supply module 3-2. . . . . . . . . . . . . .

3.2 Tasks and functions 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 NT1 and NT2 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 NT3 and NT24 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Contents

XII 1070 072 143-101

Page

4 Central processing unit ZS400 4-1. . . . .

4.1 Display and control elements 4-5. . . . . . . . . . . . . . . . . . . .

4.1.1 Status and rolling 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Reset key, Fix LED 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Retention switch 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 Lock output states switch 4-14. . . . . . . . . . . . . . . . . . . . . . .

4.2 Interface X31 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Memory card 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Operating states 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Stop 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Run 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Lock output states 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Firmware update 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Loading the PLC program from a memory card 4-22. . . .

4.4.6 Storing the PLC program on a memory card 4-24. . . . . .

4.5 Operating modes 4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Operation with buffer battery 4-28. . . . . . . . . . . . . . . . . . . .

4.5.2 Operation without buffer battery, with memory card 4-29

4.6 ZS400 startup 4-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 ZS400 program execution 4-32. . . . . . . . . . . . . . . . . . . . . . .

4.8 ZS400 monitor functions 4-33. . . . . . . . . . . . . . . . . . . . . . . .

5 System modules 5-1. . . . . . . . . . . . . . . . . .

5.1 ZAT1/2, ZAT1/10, ZAT2/2 and ZAT2/10 5-3. . . . . . . . . . .

5.2 Computer interface module R500 5-4. . . . . . . . . . . . . . . .

5.3 Computer Interface Module R500P 5-5. . . . . . . . . . . . . . .

5.4 Diagnostic Module DB500 5-6. . . . . . . . . . . . . . . . . . . . . .

Page 13

Contents

XIII1070 072 143-101

Page

6 Installation

6.1 Fan unit and assembly of the subracks 6-1. . . . . . . . . . .

6.2 Electrical installation 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 24 V load power supplies 6-5. . . . . . . . . . . . . . . . . . . . . . .

6.4 Power input from 24 V power supply 6-6. . . . . . . . . . . . .

A Appendix

A.1 Abbreviations A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Index A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Safety instructions A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.1 Dansk A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.2 Deutsch A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.3 %LLHNIK¼ A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.4 Español A-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.5 Français A-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.6 Italiano A-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.7 Nederlands A-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.8 Português A-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.9 Suomi A-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3.10 Svenska A-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 14

Contents

XIV 1070 072 143-101

Page 15

Illustrations

I1070 072 143-101

List of illustrations

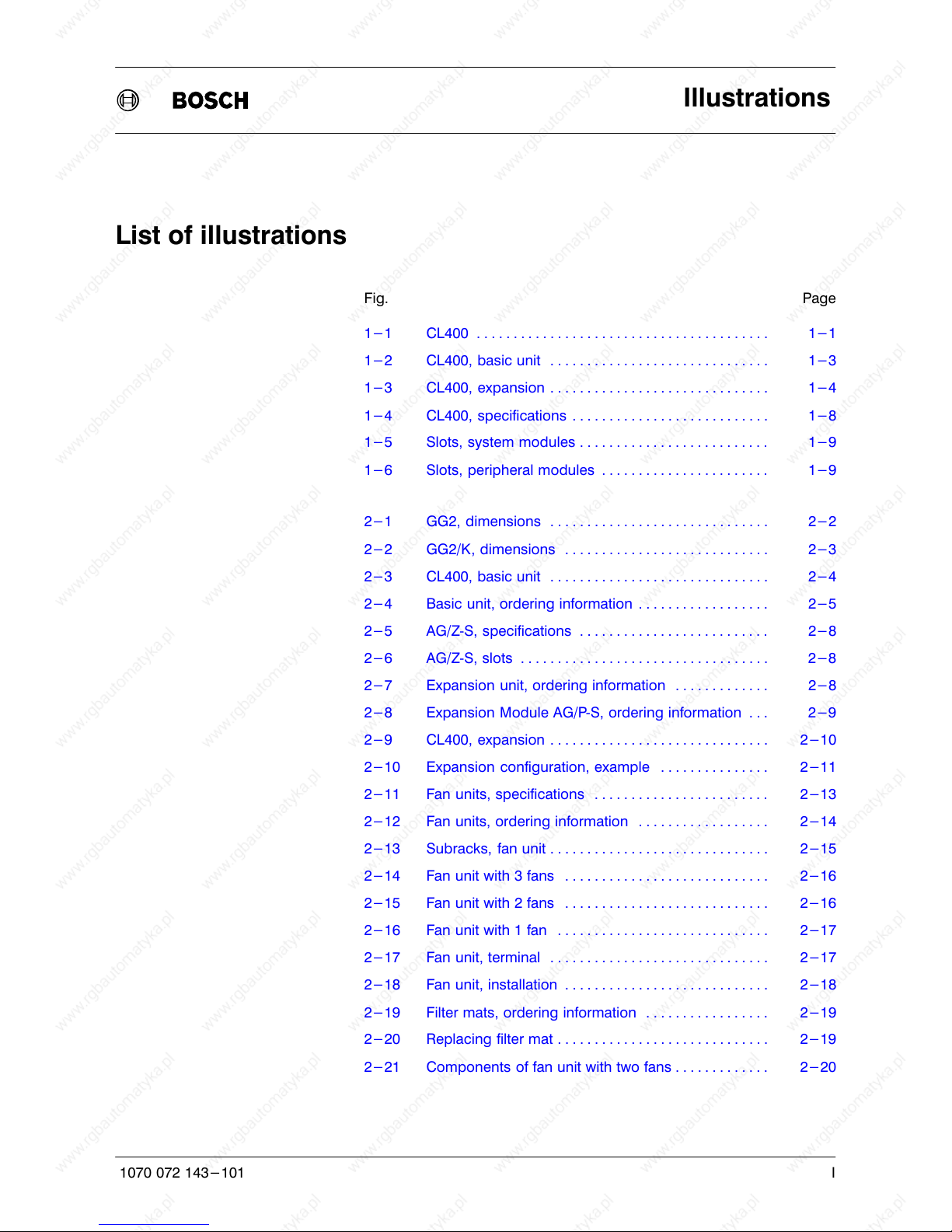

Fig. Page

1-1 CL400 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 CL400, basic unit 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 CL400, expansion 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 CL400, specifications 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Slots, system modules 1-9. . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Slots, peripheral modules 1-9. . . . . . . . . . . . . . . . . . . . . . .

2-1 GG2, dimensions 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 GG2/K, dimensions 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 CL400, basic unit 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Basic unit, ordering information 2-5. . . . . . . . . . . . . . . . . .

2-5 AG/ZS, specifications 2-8. . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 AG/ZS, slots 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Expansion unit, ordering information 2-8. . . . . . . . . . . . .

2-8 Expansion Module AG/PS, ordering information 2-9. . .

2-9 CL400, expansion 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 Expansion configuration, example 2-11. . . . . . . . . . . . . . .

2-11 Fan units, specifications 2-13. . . . . . . . . . . . . . . . . . . . . . . .

2-12 Fan units, ordering information 2-14. . . . . . . . . . . . . . . . . .

2-13 Subracks, fan unit 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-14 Fan unit with 3 fans 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-15 Fan unit with 2 fans 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16 Fan unit with 1 fan 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-17 Fan unit, terminal 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-18 Fan unit, installation 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-19 Filter mats, ordering information 2-19. . . . . . . . . . . . . . . . .

2-20 Replacing filter mat 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-21 Components of fan unit with two fans 2-20. . . . . . . . . . . . .

Page 16

Illustrations

II 1070 072 143-101

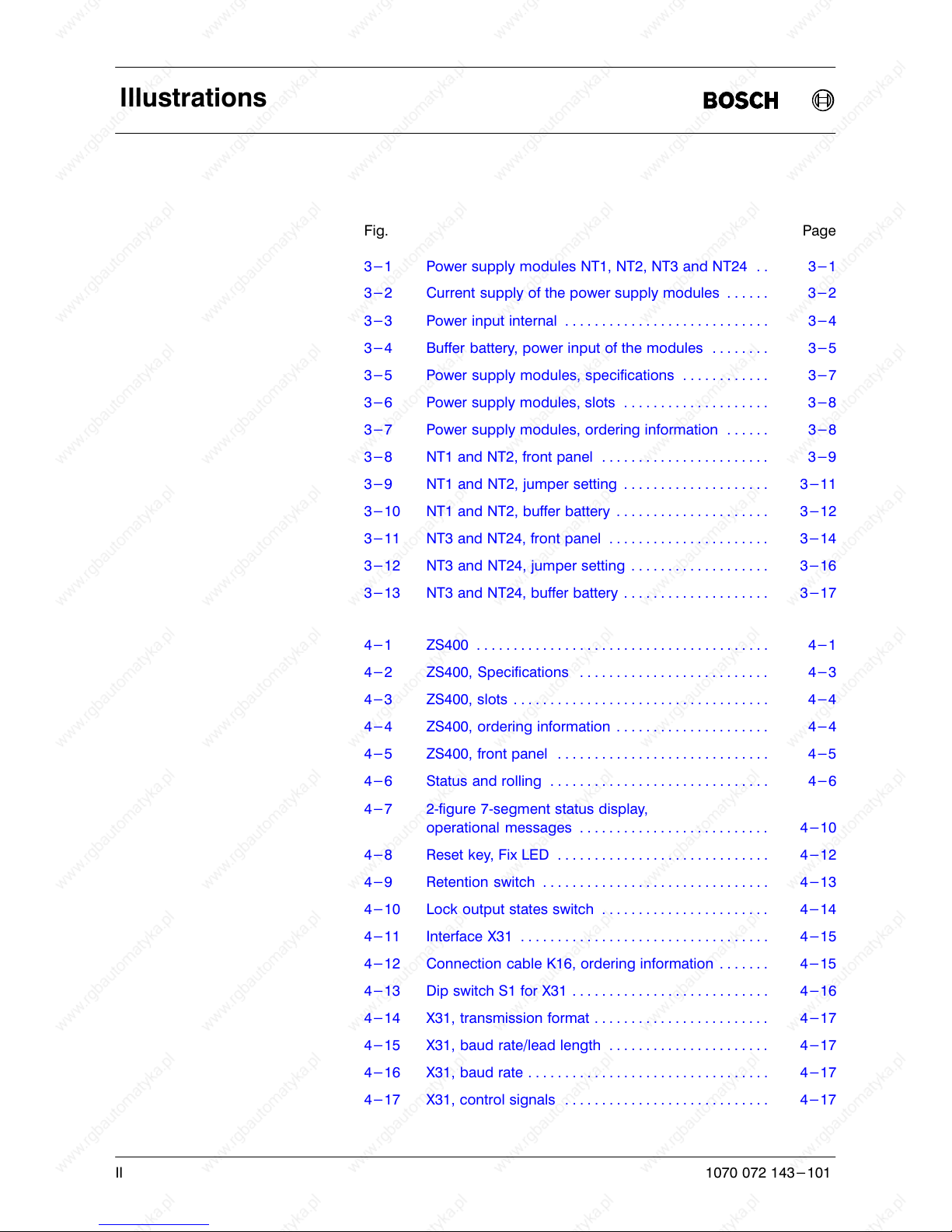

Fig. Page

3-1 Power supply modules NT1, NT2, NT3 and NT24 3-1. .

3-2 Current supply of the power supply modules 3-2. . . . . .

3-3 Power input internal 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Buffer battery, power input of the modules 3-5. . . . . . . .

3-5 Power supply modules, specifications 3-7. . . . . . . . . . . .

3-6 Power supply modules, slots 3-8. . . . . . . . . . . . . . . . . . . .

3-7 Power supply modules, ordering information 3-8. . . . . .

3-8 NT1 and NT2, front panel 3-9. . . . . . . . . . . . . . . . . . . . . . .

3-9 NT1 and NT2, jumper setting 3-11. . . . . . . . . . . . . . . . . . . .

3-10 NT1 and NT2, buffer battery 3-12. . . . . . . . . . . . . . . . . . . . .

3-11 NT3 and NT24, front panel 3-14. . . . . . . . . . . . . . . . . . . . . .

3-12 NT3 and NT24, jumper setting 3-16. . . . . . . . . . . . . . . . . . .

3-13 NT3 and NT24, buffer battery 3-17. . . . . . . . . . . . . . . . . . . .

4-1 ZS400 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 ZS400, Specifications 4-3. . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 ZS400, slots 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 ZS400, ordering information 4-4. . . . . . . . . . . . . . . . . . . . .

4-5 ZS400, front panel 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Status and rolling 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 2figure 7segment status display,

operational messages 4-10. . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Reset key, Fix LED 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Retention switch 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Lock output states switch 4-14. . . . . . . . . . . . . . . . . . . . . . .

4-11 Interface X31 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 Connection cable K16, ordering information 4-15. . . . . . .

4-13 Dip switch S1 for X31 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14 X31, transmission format 4-17. . . . . . . . . . . . . . . . . . . . . . . .

4-15 X31, baud rate/lead length 4-17. . . . . . . . . . . . . . . . . . . . . .

4-16 X31, baud rate 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-17 X31, control signals 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 17

Illustrations

III1070 072 143-101

Fig. Page

4-18 Memory card 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-19 Error messages when loading 4-23. . . . . . . . . . . . . . . . . . .

4-20 Error messages when storing 4-25. . . . . . . . . . . . . . . . . . .

4-21 Operating modes 4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-22 ZS400, Startup 4-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Version 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 System modules, slots 5-2. . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 ZAT, ordering information 5-3. . . . . . . . . . . . . . . . . . . . . . .

5-4 R500, ordering information 5-4. . . . . . . . . . . . . . . . . . . . . .

5-5 R500P, ordering information 5-5. . . . . . . . . . . . . . . . . . . . .

5-6 DB500, ordering information 5-6. . . . . . . . . . . . . . . . . . . . .

6-1 Basic unit 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Possible configuration of the subracks 6-2. . . . . . . . . . . .

6-3 Subracks and fan units, examples 6-3. . . . . . . . . . . . . . .

6-4 PE terminal 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 24 V load power supplies, specifications 6-5. . . . . . . . . .

6-6 24 V load power supplies, ordering information 6-5. . . .

6-7 Power input from 24 V power supply 6-6. . . . . . . . . . . . .

Page 18

Illustrations

IV 1070 072 143-101

Page 19

Flexible Automation

System introduction CL400

1-1

1070 072 143-101

1 System introduction CL400

1.1 General

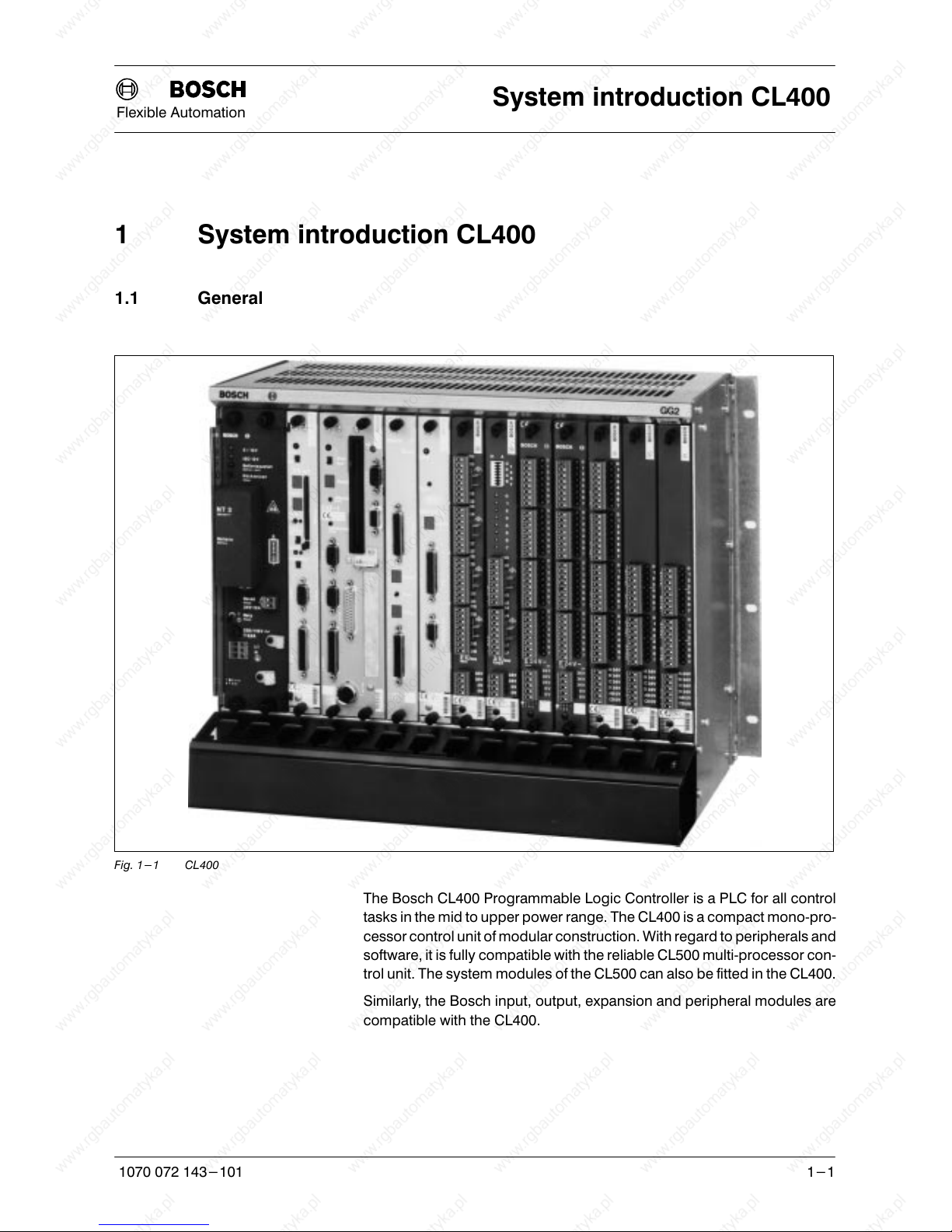

Fig. 1-1 CL400

The Bosch CL400 Programmable Logic Controller is a PLC for all control

tasks in the mid to upper power range. The CL400 is a compact monopro

cessor control unit of modular construction. With regard to peripherals and

software, it is fully compatible with the reliable CL500 multiprocessor con

trol unit. The system modules of the CL500 can also be fitted in the CL400.

Similarly, the Bosch input, output, expansion and peripheral modules are

compatible with the CL400.

Page 20

Flexible Automation

System introduction CL400

1-2

1070 072 143-101

Furthermore, the CL400 with COMNETDP represents an innovative sol

ution to the problem of decentralised installation.

COMNETDP combines the advantages of the DESI system with the bene

fits of networking via PROFIBUS. The Bosch COMNETDP is the realisation

of PROFIBUSDP and is based on DIN 19 245 part 3.

The CL400 operations set is compatible with CL500.

Memory card

The CL400 offers for the first time the possibly of operation with a memory

card in addition to operation with RAM memory and buffer battery.

Expansion capability

Possible expansions:

D central and parallel expansion units

D COMNETDP

Possible functional expansions:

D System modules

D Peripheral modules

Communication capability, interface capability

The standard interfaces

D R500

D R500P (PROFIBUSFMS)

make the CL400 capable of communicating and interfacing with

D other control systems

D computers

D standard peripheral devices

Additional functionalities

D PC modules ZAT1 and ZAT2

D Diagnostic module DB500

D Process visualisation software PV2

Peripheral modules

D Power source module SQ16

D Temperature controller module RT6

D Counter module EZ50

D Peripheral Bus Interface Module PBK

D Positioning module CC10

D Robot control system rho3.0

D Cycle time analysis module TZA

Page 21

Flexible Automation

System introduction CL400

1-3

1070 072 143-101

1.2 Configuration

Basic unit

The CL400 always consists of a basic unit first and foremost. Two subracks

are available for the basic unit,

D Subrack GG2 with 14 slots and

D Subrack GG2/K with 8 slots.

The basic unit contains

D the power supply module and

D the ZS400 central processing unit.

The remaining slots can be fitted with additional system or peripheral mod

ules.

Fig. 1-2 CL400, basic unit

If the maximum 14 basic unit slots are insufficient for control unit configur

ation, then additional peripheral modules can be fitted in expansion units.

Page 22

Flexible Automation

System introduction CL400

1-4

1070 072 143-101

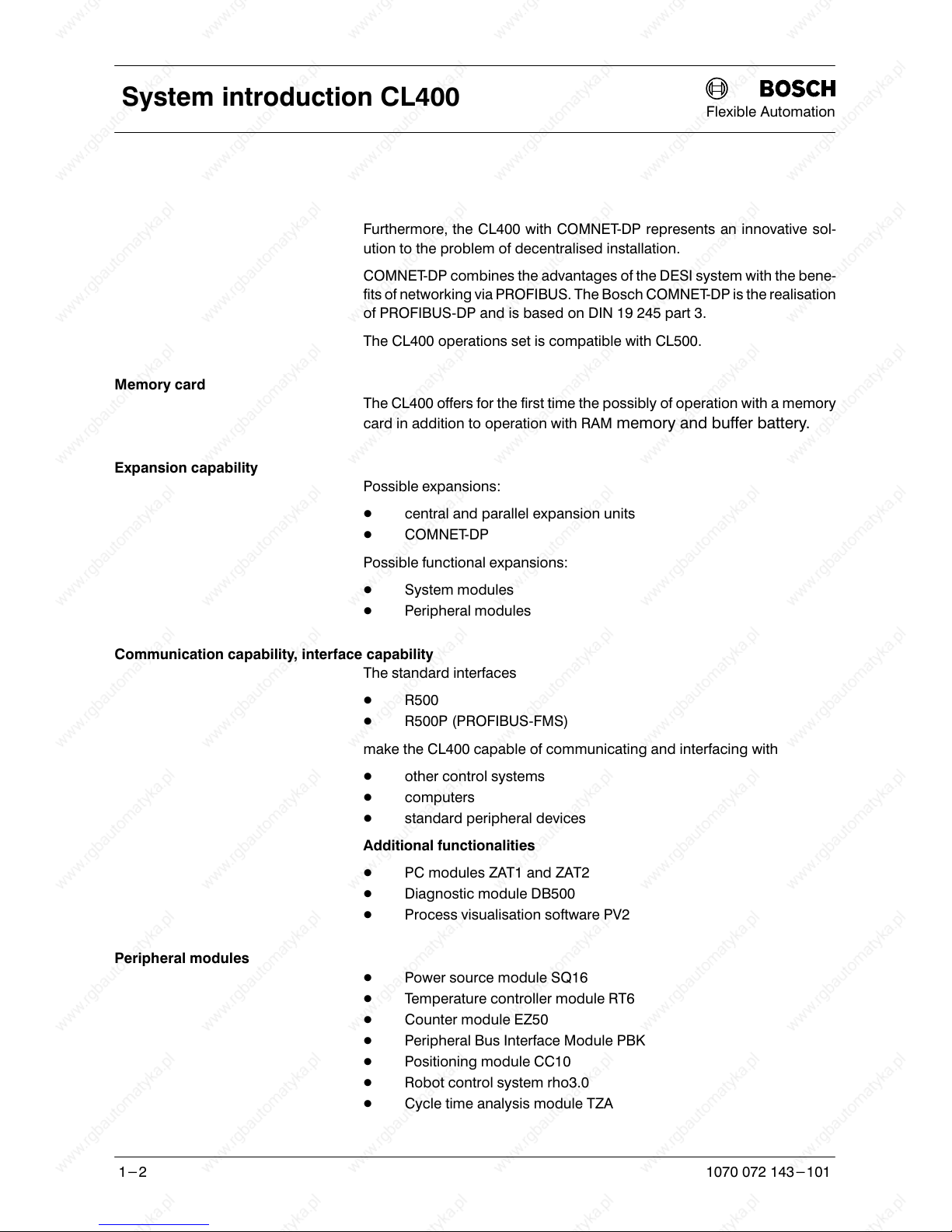

Expansion unit

Two subracks are available for the expansion unit,

D Subrack EG2 with 14 slots and

D Subrack EG2/K with 8 slots.

The expansion unit contains

D the expansion module AG/ZS and

D a maximum of 13 or 7 definable peripheral modules.

Expansion unit EG2

Basic unit GG2

NT

Fig. 1-3 CL400, expansion

. See also section 2.4 Expansion unit.

Page 23

Flexible Automation

System introduction CL400

1-5

1070 072 143-101

1.3 Programming

Programming the CL400 is carried out with Bosch programming units, an

AT compatible PC or a ZAT module.

The PLC program can be generated with the programming unit alone and

without the control unit. The PLC program is stored in a buffered RAM mem

ory in the CL400. In addition, the CL400 offers for the first time the possibility

of storing the PLC program on a memory card.

The programming language is based on DIN 19 239.

Program structure

The PLC program is divided into clear, technologically assigned program

modules.

Programming

The PLC program is created with the Bosch PLC service program. If

COMNETDP is used, the COMNETDP service program will also be re

quired.

PLC program generation can be carried out as

D IL instruction list,

D LD ladder diagram or

D SFC sequential function chart

with symbolic or absolute operands as desired.

PLC program documentation

A clear and easily comprehensible PLC program documentation with

crossreference lists support the user in fast commissioning or system fault

remedy, as well as when adapting to new applications.

The PLC program documentation on the programming unit screen and as a

printout permits a large amount of commentary.

Page 24

Flexible Automation

System introduction CL400

1-6

1070 072 143-101

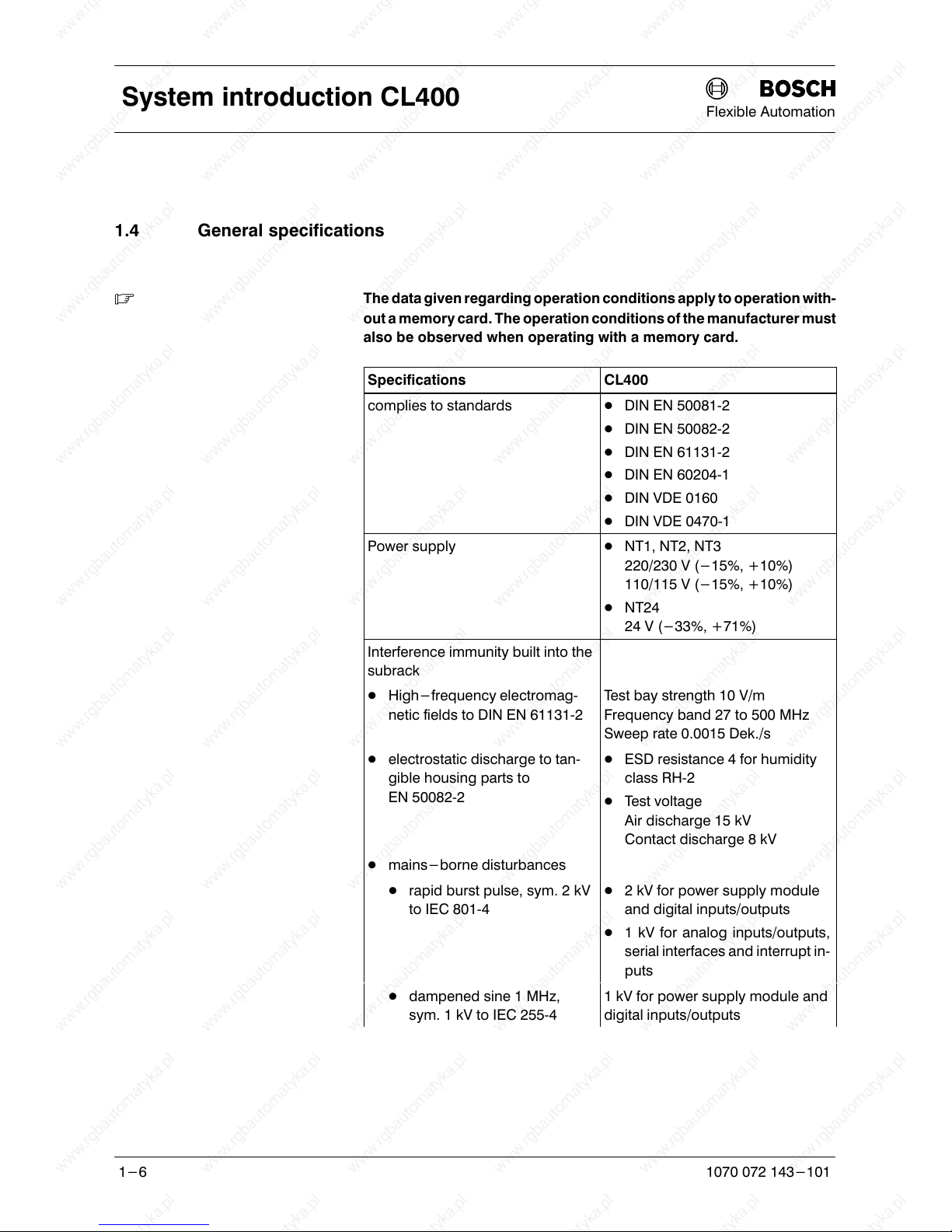

1.4 General specifications

. The data given regarding operation conditions apply to operation with

out a memory card. The operation conditions of the manufacturer must

also be observed when operating with a memory card.

Specifications

CL400

complies to standards D DIN EN 500812

D DIN EN 500822

D DIN EN 611312

D DIN EN 602041

D DIN VDE 0160

D DIN VDE 04701

Power supply D NT1, NT2, NT3

220/230 V (-15%, +10%)

110/115 V (-15%, +10%)

D NT24

24 V (-33%, +71%)

Interference immunity built into the

subrack

D High-frequency electromag

netic fields to DIN EN 611312

Test bay strength 10 V/m

Frequency band 27 to 500 MHz

Sweep rate 0.0015 Dek./s

D electrostatic discharge to tan

gible housing parts to

EN 500822

D ESD resistance 4 for humidity

class RH2

D Test voltage

Air discharge 15 kV

Contact discharge 8 kV

D mains-borne disturbances

D rapid burst pulse, sym. 2 kV

to IEC 8014

D 2 kV for power supply module

and digital inputs/outputs

D 1 kV for analog inputs/outputs,

serial interfaces and interrupt in

puts

D dampened sine 1 MHz,

sym. 1 kV to IEC 2554

1 kV for power supply module and

digital inputs/outputs

Page 25

Flexible Automation

System introduction CL400

1-7

1070 072 143-101

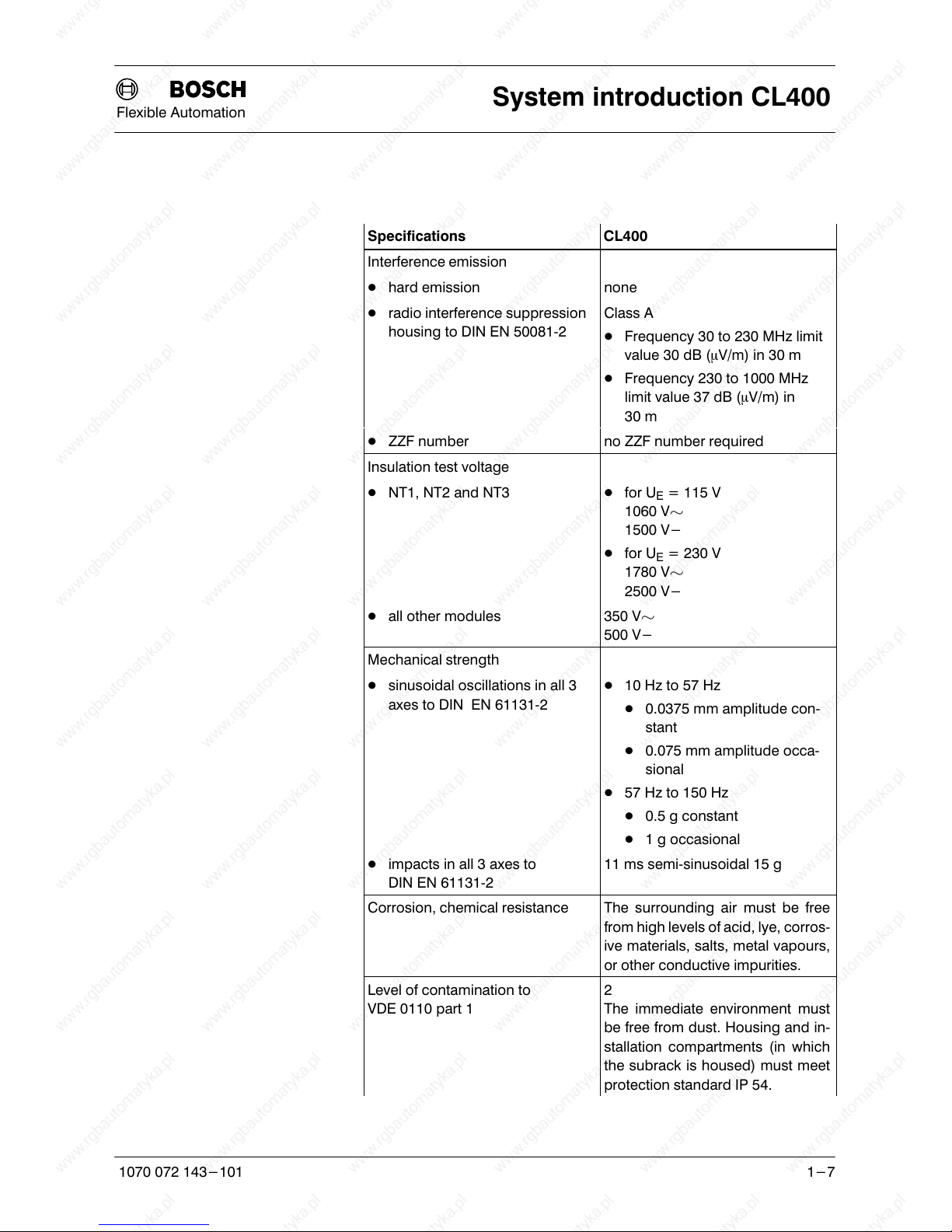

Specifications CL400

Interference emission

D hard emission none

D radio interference suppression

housing to DIN EN 500812

Class A

D Frequency 30 to 230 MHz limit

value 30 dB (MV/m) in 30 m

D Frequency 230 to 1000 MHz

limit value 37 dB (MV/m) in

30 m

D ZZF number no ZZF number required

Insulation test voltage

D NT1, NT2 and NT3 D for UE = 115 V

1060 V

1500 V-

D for U

E

= 230 V

1780 V

2500 V-

D all other modules 350 V

500 V-

Mechanical strength

D sinusoidal oscillations in all 3

axes to DIN EN 611312

D 10 Hz to 57 Hz

D 0.0375 mm amplitude con

stant

D 0.075 mm amplitude occa

sional

D 57 Hz to 150 Hz

D 0.5 g constant

D 1 g occasional

D impacts in all 3 axes to

DIN EN 611312

11 ms semisinusoidal 15 g

Corrosion, chemical resistance The surrounding air must be free

from high levels of acid, lye, corros

ive materials, salts, metal vapours,

or other conductive impurities.

Level of contamination to

VDE 0110 part 1

2

The immediate environment must

be free from dust. Housing and in

stallation compartments (in which

the subrack is housed) must meet

protection standard IP 54.

Page 26

Flexible Automation

System introduction CL400

1-8

1070 072 143-101

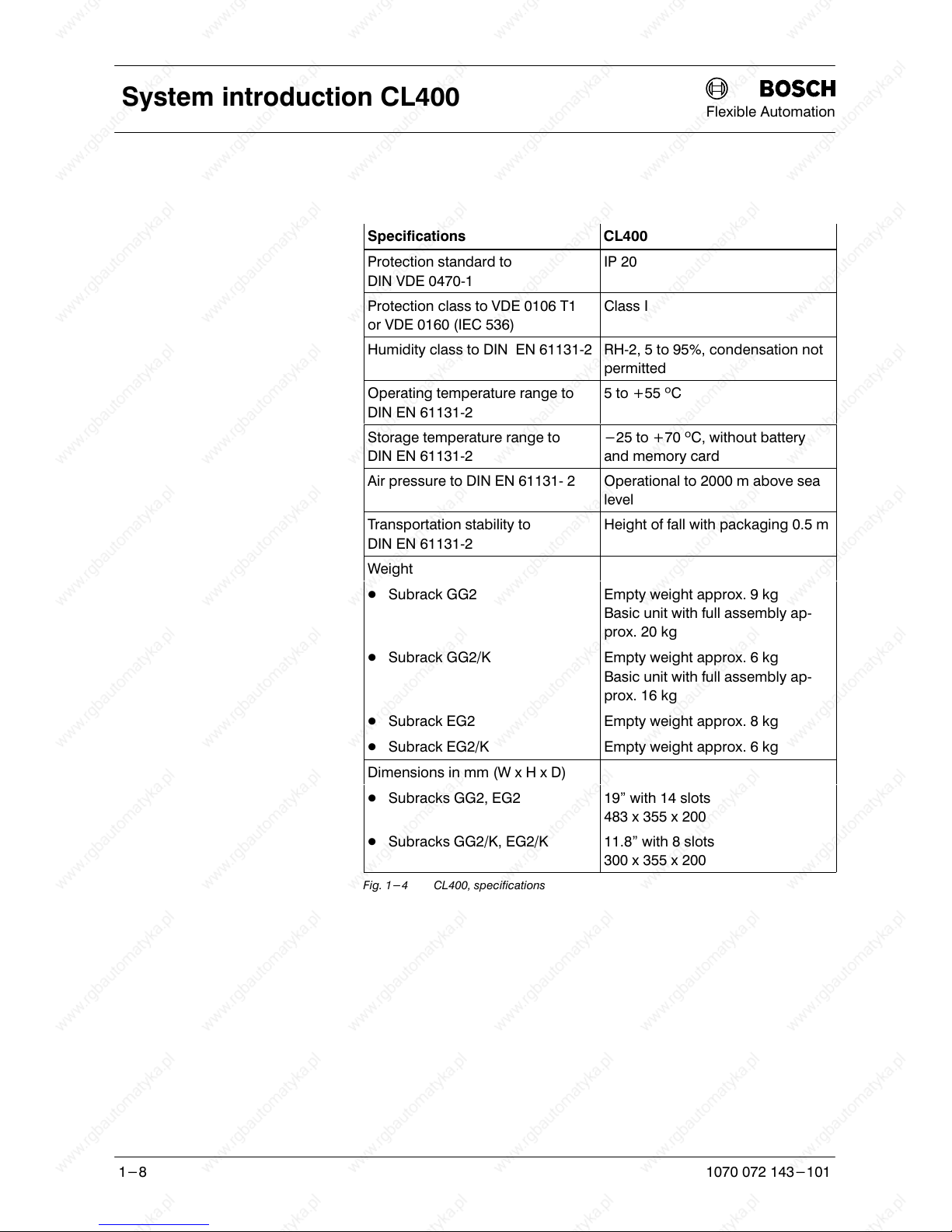

Specifications CL400

Protection standard to

DIN VDE 04701

IP 20

Protection class to VDE 0106 T1

or VDE 0160 (IEC 536)

Class Ι

Humidity class to DIN EN 611312 RH2, 5 to 95%, condensation not

permitted

Operating temperature range to

DIN EN 611312

5 to +55ºC

Storage temperature range to

DIN EN 611312

-25 to +70ºC, without battery

and memory card

Air pressure to DIN EN 61131 2 Operational to 2000 m above sea

level

Transportation stability to

DIN EN 611312

Height of fall with packaging 0.5 m

Weight

D Subrack GG2 Empty weight approx. 9 kg

Basic unit with full assembly ap

prox. 20 kg

D Subrack GG2/K Empty weight approx. 6 kg

Basic unit with full assembly ap

prox. 16 kg

D Subrack EG2 Empty weight approx. 8 kg

D Subrack EG2/K Empty weight approx. 6 kg

Dimensions in mm (W x H x D)

D Subracks GG2, EG2 19" with 14 slots

483 x 355 x 200

D Subracks GG2/K, EG2/K 11.8" with 8 slots

300 x 355 x 200

Fig. 1-4 CL400, specifications

Page 27

Flexible Automation

System introduction CL400

1-9

1070 072 143-101

1.5 Slots

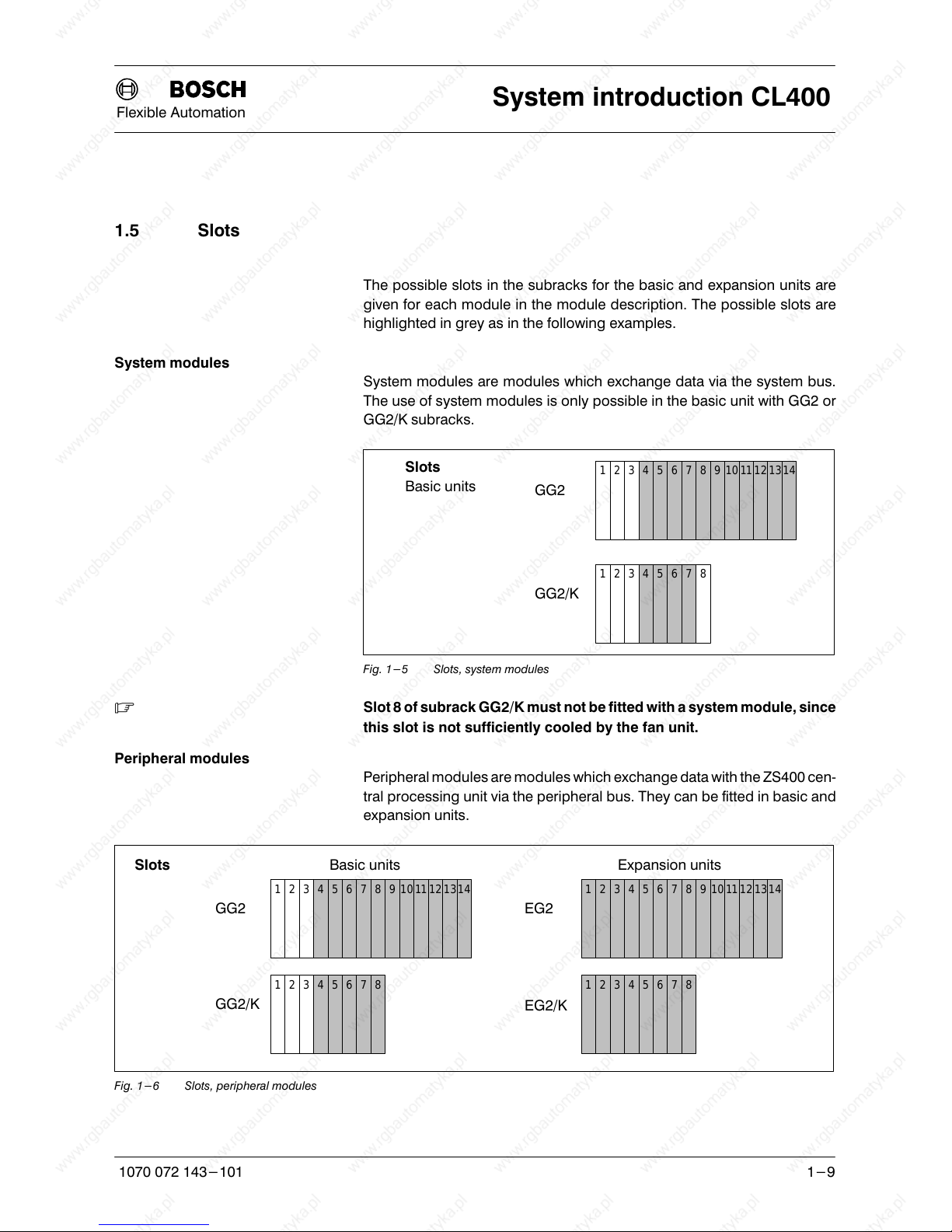

The possible slots in the subracks for the basic and expansion units are

given for each module in the module description. The possible slots are

highlighted in grey as in the following examples.

System modules

System modules are modules which exchange data via the system bus.

The use of system modules is only possible in the basic unit with GG2 or

GG2/K subracks.

GG2

1234567891011121314

Slots

Basic units

12345678

GG2/K

Fig. 1-5 Slots, system modules

. Slot 8 of subrack GG2/K must not be fitted with a system module, since

this slot is not sufficiently cooled by the fan unit.

Peripheral modules

Peripheral modules are modules which exchange data with the ZS400 cen

tral processing unit via the peripheral bus. They can be fitted in basic and

expansion units.

EG2GG2

12345678910111213141234567891011121314

Slots

EG2/K

12345678

GG2/K

12345678

Basic units Expansion units

Fig. 1-6 Slots, peripheral modules

Page 28

Flexible Automation

System introduction CL400

1-10

1070 072 143-101

Notes:

Page 29

Flexible Automation

Subracks

2-1

1070 072 143-101

2 Subracks

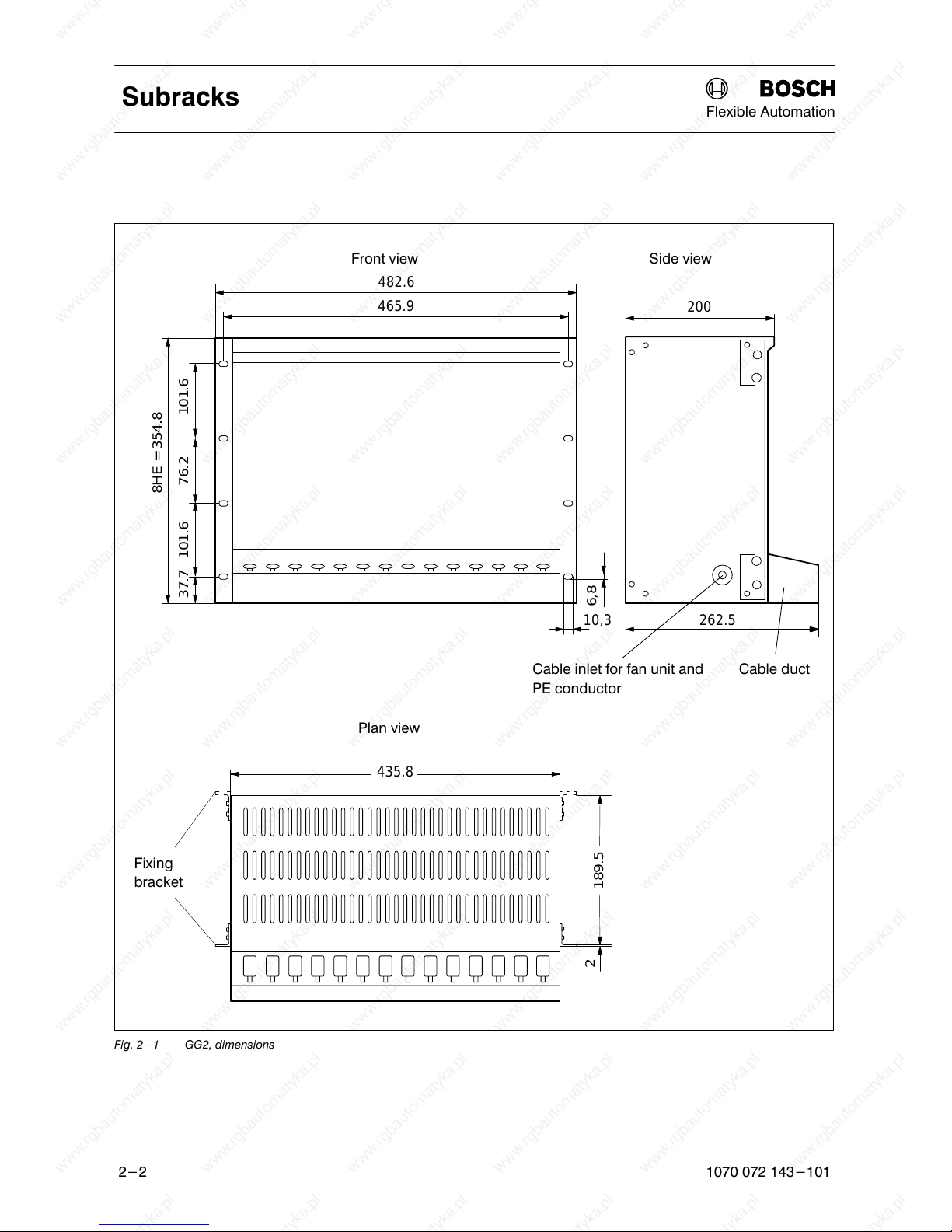

2.1 Subracks GG2 and GG2/K

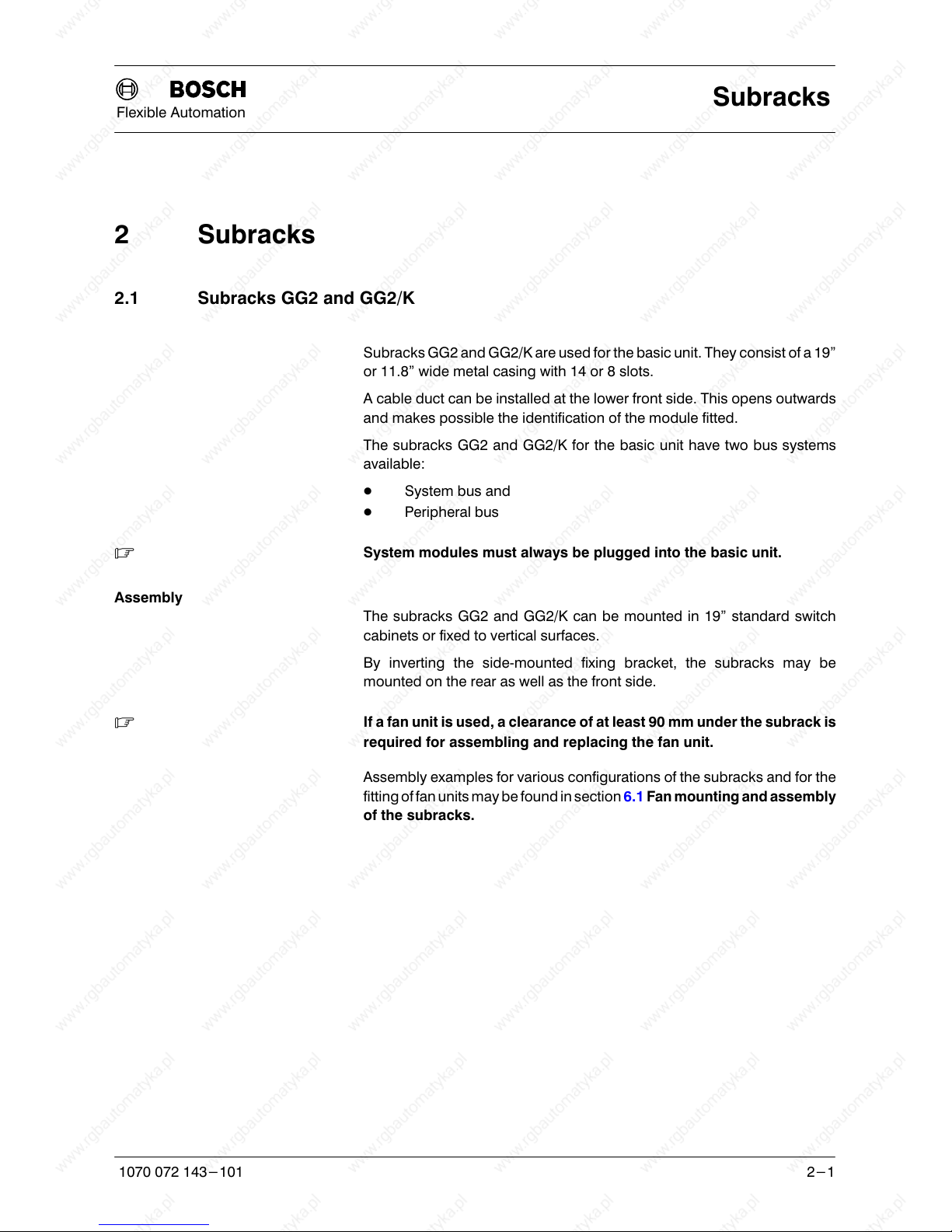

Subracks GG2 and GG2/K are used for the basic unit. They consist of a 19"

or 11.8" wide metal casing with 14 or 8 slots.

A cable duct can be installed at the lower front side. This opens outwards

and makes possible the identification of the module fitted.

The subracks GG2 and GG2/K for the basic unit have two bus systems

available:

D System bus and

D Peripheral bus

. System modules must always be plugged into the basic unit.

Assembly

The subracks GG2 and GG2/K can be mounted in 19" standard switch

cabinets or fixed to vertical surfaces.

By inverting the sidemounted fixing bracket, the subracks may be

mounted on the rear as well as the front side.

. If a fan unit is used, a clearance of at least 90 mm under the subrack is

required for assembling and replacing the fan unit.

Assembly examples for various configurations of the subracks and for the

fitting of fan units may be found in section 6.1 Fan mounting and assembly

of the subracks.

Page 30

Flexible Automation

Subracks

2-2

1070 072 143-101

482.6

465.9

8HE = 354.8

101.676.2101.637.7

10,3

6,8

262.5

200

435.8

189.5

2

Front view Side view

Cable inlet for fan unit and

PE conductor

Cable duct

Plan view

Fixing

bracket

Fig. 2-1 GG2, dimensions

Page 31

Flexible Automation

Subracks

2-3

1070 072 143-101

299.8

283.1

8HE = 354.8

101.676.2101.637.7

10.3

6.8

262.5

200

253

189.5

2

Front view Side view

Cable inlet for fan unit and

PE conductor

Cable duct

Plan view

Fixing

bracket

Fig. 2-2 GG2/K, dimensions

Page 32

Flexible Automation

Subracks

2-4

1070 072 143-101

2.2 Basic unit

Fig. 2-3 CL400, basic unit

The basic unit consists of at least

D one subrack GG2 or - GG2/K,

D one cable duct,

D one fan unit,

D one power supply module NT1, NT2, NT3 or NT24 and

D one central processing unit ZS400.

. If no system modules are fitted and the power supply module NT1 or

NT24 is fitted, operation without a fan unit is possible.

The remaining 11 or 5 slots can be used if desired for

D system modules:

ZAT1 and ZAT2

R500

R500P

DB500

D peripheral modules:

Input/output modules, bus master DESIDP, temperature controller

module RT6,

D max. 3 expansion modules AG/PS

Page 33

Flexible Automation

Subracks

2-5

1070 072 143-101

PE terminal

The basic unit must be equipped with adequate connection to a PE con

ductor.

. Slot 8 of subrack GG2/K must not be fitted with a system module, since

this slot is not sufficiently cooled by the fan unit.

. Dummy slots in a subrack must be sealed with dummy covers, be

cause otherwise the air circulation will be impaired.

. The following modules must not be plugged into the basic unit:

D Expansion module AG/ZS

D RM4DP

Ordering information

Designation Order no.

Subrack GG2 1070 062 324

Subrack GG2/K 1070 075 751

Fan unit with 3 fans 1070 062 325

Fan unit with 2 fans 1070 052 243

Fan unit K with 1 fan 1070 056 864

Power supply module NT1 1070 071 376

Power supply module NT2 1070 062 687

Power supply module NT3 1070 062 309

Power supply module NT24 1070 068 046

Central processing unit ZS400 1070 070 309

Buffer battery for NT1, NT2, NT3 and NT24 1070 914 447

Cable duct CL 1070 054 152

Dummy cover 1070 046 208

Fig. 2-4 Basic unit, ordering information

Page 34

Flexible Automation

Subracks

2-6

1070 072 143-101

2.3 Subracks EG2 and EG2/K

Subracks EG2 and EG2/K are used for the expansion unit. They consist of a

19" or 11.8" wide metal casing with 14 or 8 slots.

. Information on dimensions and assembly is contained in section 2.1

Subracks GG2 and GG2/K.

Assembly examples for various configurations of the subracks and for the

fitting of fan units may be found in section 6.1 Fan mounting and assembly

of the subracks.

A cable duct can be installed at the lower front side. This opens outwards

and makes possible the identification of the module fitted.

Page 35

Flexible Automation

Subracks

2-7

1070 072 143-101

2.4 Expansion unit

. The expansion unit is used only for the attachment of peripheral mod

ules.

The expansion unit consists of at least

D one subrack EG2 or EG2/K,

D one cable duct,

D one expansion module AG/ZS and

D one connection cable AG/ZS or AG/PS.

The 13 or 7 remaining slots in the expansion unit can be fitted with periph

eral modules.

Power supply

The internal power supply of the expansion units is supplied from the power

supply module of the basic unit; for this reason the current used must be

taken into account, see section 3.1 Selecting the power supply module.

PE terminal

All expansion units must be equipped pointtopoint with adequate con

nection to a PE conductor.

. Dummy slots in a subrack must be sealed with dummy covers, be

cause otherwise the air circulation will be impaired.

. Depending on the fitting and configuration of the control unit, the in

stallation of fan units must be assessed, see section 6.1 Fan mounting

and assembly of the subracks.

Expansion module AG/ZS

The expansion module AG/ZS is used to expand the CL400 and is plugged

into the expansion unit. It supplies the internal supply voltage to the expan

sion units and the peripheral bus.

The connection is established via both socket contacts on the front panel of

the module. The two socket contacts are connected in parallel so that the

connection can be made at the upper or lower socket contact as required.

The connection between two expansion units is always established via ex

pansion module AG/ZS.

. The expansion module AG/ZS must not be plugged into the basic unit

of the CL400.

Page 36

Flexible Automation

Subracks

2-8

1070 072 143-101

Specifications

Specifications AG/ZS

Power input from 12 V internal. 10 mA

max. cable length between

D two AG/ZS

D AG/PS and AG/ZS

0.55 m

1.8 m

Width 1 division

Fig. 2-5 AG/ZS, specifications

EG2

1234567891011121314

Slots

EG2/K

12345678

Expansion units

Fig. 2-6 AG/ZS, slots

Ordering information

Description Order no.

Subrack EG2 1070 052 004

Subrack EG2/K 1070 075 760

Cable duct CL 1070 054 152

Fan unit with 2 fans 1070 052 243

Fan unit K with 1 fan 1070 056 864

Expansion module AG/ZS 1070 064 719

Connection cable AG/Z-S (K13S) 1070 064 754

Dummy cover 1070 046 208

Fig. 2-7 Expansion unit, ordering information

Page 37

Flexible Automation

Subracks

2-9

1070 072 143-101

2.5 Expansion configuration

. The maximum address range of the control unit must always be ac

counted for when carrying out an expansion.

The expansion of a CL400 using the basic unit always begins with an Ex

pansion Module AG/PS in the basic unit.

Expansion Module AG/PS

The Expansion Module AG/PS contains drivers which permit a maximum

connection cable to the Expansion Module AG/ZS of 1.8 m.

A maximum of 3 Expansion Modules AG/PS in may be operated in the

basic unit of the CL400.

. The Expansion Module AG/PS must not be plugged into the expansion

unit.

. More detailed information may be found in the manual:

Parallel Expansion Module AG/P

Module description

Ordering information

Description Order no.

Expansion Module AG/PS 1070 064 905

Connection Cable AG/PS (K14S) 1070 064 753

Parallel Expansion Module AG/P, Module description 1070 072 110

Fig. 2-8 Expansion Module AG/PS, ordering information

Page 38

Flexible Automation

Subracks

2-10

1070 072 143-101

The following are necessary for the connection between the basic unit and

an expansion unit:

D Expansion module AG/PS in the basic unit,

D Connection cable AG/PS (K14S, length 1.8 m) or connection cable

AG/ZS (K13S, length 0.55 m) and

D Expansion module AG/ZS in the expansion unit.

Expansion unit

Basic unit

EG2

NT

GG2

AG/ZS

K13S

AG/PS

Fig. 2-9 CL400, expansion

. The maximum length of the connection cable will be:

D 1.8 m between the expansion module AG/PS in the basic unit

and the module AG/ZS in the expansion unit.

D 0.55 m between two modules AG/ZS in the expansion units.

Page 39

Flexible Automation

Subracks

2-11

1070 072 143-101

The connection between two expansion units is made up of:

D Expansion module AG/ZS in 1st expansion unit.

D Connection cable AG/ZS (K13S, length 0.55 m).

D Expansion module AG/ZS in 2nd expansion unit.

AG/ZS

AG/ZS

K13S

EG2

EG2

EG2

K14S

AG/PS

AG/ZS

NT

GG2

K13-S

Fig. 2-10 Expansion configuration, example

Page 40

Flexible Automation

Subracks

2-12

1070 072 143-101

2.6 Fan unit

To avoid heat accumulation and therefore the failure or destruction of mod

ules, fan units are installed in the subracks. Three fan units are available:

D Fan unit with 3 fans for the basic unit with 14 slots.

D Fan unit with 2 fans for basic or expansion units with 14 slots.

D Fan unit K with 1 fan for basic or expansion units with 8 slots.

. A clearance of at least 90 mm beneath the subrack is necessary for the

assembly and replacement of a fan unit.

. For each module, the special information in the respective module de

scription regarding operating conditions and installation of a fan unit

must be observed.

Basic unit

Basic units may be operated without a fan unit under the following condi

tions:

D Ambient temperature in switch cabinet V45 ºC,

D Power supply module NT1 or NT24,

D No system modules and

D No peripheral modules requiring a fan unit.

The basic unit must be equipped with a fan unit if one of these conditions is

not fulfilled.

Basic units may be operated with fan units with two fans under the following

conditions:

D Ambient temperature in switch cabinet V55 ºC,

D Power supply module NT1, NT2 or NT24,

D No system module at slots 7, 8, 9, 13 and 14.

The fan unit with three fans must be used at the maximum capacity of the

basic unit.

Page 41

Flexible Automation

Subracks

2-13

1070 072 143-101

Expansion unit

In the expansion unit, the use of a fan unit is dependent on the heat dissipa

tion of the modules installed there. Always assess whether a fan unit is re

quired in the expansion unit.

Examples for various configurations of the subracks and for the fitting of fan

units may be found in section 6.1 Fan mounting and assembly of the sub

racks.

Failure contact

The fan unit has a failure contact for purposes of fault recognition, which

can be evaluated on a systemspecific basis. The following faults can be

recognised and signalled via the failure contact:

D Standstill of one or several fans.

D Falling below the 24 V supply voltage.

CAUTION 2.1

Danger to the fan unit!

Observe the maximum switching voltage and capacity for the failure

contact, see fig. 2-11 Fan units, specifications!

. With regard to the degree of contamination of the ambient air, the filter

mat of the fan unit must be regularly inspected and replaced if necess

ary, see subsection 2.6.2 Replacing the filter mats.

Specifications

Specifications

Order no. 1070 ... ...

p

062 325 052 243 056 864

Number of fans 3 2 1

Power supply 24 V- to DIN 19 240

Power input from 24 V external 1.0 A 0.8 A 0.6 A

Reverse polarity protection Fuse

M 0.1 A

via diode

Failure contact

D Switching voltage

D Switching capacity

max. 250 V-

max. 100 W

max. 60 V-, 125 V

max. 30 W, 60 VA

Response time of failure contact

when fault arises

typ. 5 s, max. 8 s

Response time of failure contact

for fault removal

5 s

Fig. 2-11 Fan units, specifications

Page 42

Flexible Automation

Subracks

2-14

1070 072 143-101

Ordering information

Description Order no.

Fan unit with 3 fans 1070 062 325

Fan unit with 2 fans 1070 052 243

Fan unit K with 1 fan 1070 056 864

Fig. 2-12 Fan units, ordering information

Page 43

Flexible Automation

Subracks

2-15

1070 072 143-101

2.6.1 Installation into subracks and electrical connection

The fan unit is installed in the lower part of the subrack.

Cable inlet for fan unit and PE con

ductor

Cable duct

Fan unit

Fig. 2-13 Subracks, fan unit

. A clearance of at least 90 mm under the subrack is required for assem

bling and replacing a fan unit.

The connection cable is fed through a bore hole in the side wall of the sub

rack. The bore hole is fitted with a rubber grommet to protect the connec

tion cable. The cable can be fed from the left or the right.

The following cables are fed through the bore hole:

D PE conductor for subrack.

D PE conductor for fan unit.

D 24 V power supply for fan unit.

D Connecting lead for failure contact.

Page 44

Flexible Automation

Subracks

2-16

1070 072 143-101

Installation and connection

L Feed connection cables through the rubber grommet.

L Connect the PE conductor for the subrack via a cable lug to the designated

pin on the subrack.

L Connect the PE conductor for the fan unit via a cable lug to the designated

pin on the fan unit.

2 4

1 pin for PE terminal

2 Bore holes for connection cable retainers

3 Terminal

4 Retainers for connection cable

31

4

Fig. 2-14 Fan unit with 3 fans

2 4

1 Pin for PE terminal

2 Bore holes for connection cable retainers

3 Terminal

4 Retainers for connection cable

31

Fig. 2-15 Fan unit with 2 fans

Page 45

Flexible Automation

Subracks

2-17

1070 072 143-101

2

1 Pin for PE terminal

2 Retainers for connection cable

3 Terminal

31

Fig. 2-16 Fan unit with 1 fan

L Connect 24 V power supply and connecting lead for failure contact accord

ing to following diagram 2-17.

CAUTION 2.2

Danger to the fan unit!

Observe the maximum switching voltage and capacity for the failure

contact, see fig. 2-11 Fan units, specifications!

1234

0 V

+24 V

Fig. 2-17 Fan unit, terminal

L Install fan unit from the bottom of the subrack with fans facing up and the

filter mat grid facing down. Firstly fit the rear edge of the fan unit to the ap

propriate subrack face.

Page 46

Flexible Automation

Subracks

2-18

1070 072 143-101

Quickrelease lock Quickrelease lock

View from below

rear edge

Fig. 2-18 Fan unit, installation

L Raise the front side of the fan unit and engage the quickrelease locks by

pushing and turning simultaneously.

Page 47

Flexible Automation

Subracks

2-19

1070 072 143-101

2.6.2 Replacing the filter mats

. With regard to the degree of contamination of the ambient air, the filter

mat of the fan unit must be inspected regularly and replaced if necess

ary.

Ordering information

Description

Order no.

Filter mat for fan unit with three fans 129 mm x 396 mm 1070 062 899

Filter mat for fan unit with two fans, 127 mm x 366 mm 1070 052 245

Filter mat for fan unit with one fan, 127 mm x 179 mm 1070 056 916

Fig. 2-19 Filter mats, ordering information

L Loosen quickrelease lock for filter mat by turning and pulling simulta

neously.

Quickrelease lock

View from below

Rear edge

Fig. 2-20 Replacing filter mat

L Fold down grid and replace filter mat.

Page 48

Flexible Automation

Subracks

2-20

1070 072 143-101

Filter mat

Grid

Quickrelease lock

Front view

Fig. 2-21 Components of fan unit with two fans

L Close grid again and engage quickrelease lock by pushing and turning

simultaneously.

. Dispose of the contaminated filter mat in accordance with the waste

disposal law regardless of the degree of contamination by the ambient

air.

Page 49

Flexible Automation

Subracks

2-21

1070 072 143-101

2.7 Modules

CAUTION 2.3

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

CAUTION 2.4

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

A module is inserted along the rail in the subrack and fastened in place with

the two knurled screws on the front panel.

A good coupling of the module with the subrack guarantees high mechan

ical resistance and contact stability as well as increased insensitivity to ex

ternal electrical interference.

The knurled screws on the front panels must be fastened with max. 0.5 Nm.

. Dummy slots in a subrack must be covered with dummy covers, since

otherwise the air circulation will be impaired.

Page 50

Flexible Automation

Subracks

2-22

1070 072 143-101

Notes:

Page 51

Flexible Automation

Power supply modules

3-1

1070 072 143-101

3 Power supply modules

Fig. 3-1 Power supply modules NT1, NT2, NT3 and NT24

Page 52

Flexible Automation

Power supply modules

3-2

1070 072 143-101

3.1 Selecting the power supply module

The 4 power supply modules NT1, NT2, NT3 and NT24 are provided for the

internal power supply.

The selection of power supply module is made according to the configur

ation of the control. The power supply module in the basic unit is also re

sponsible for the internal power supply of all modules in the expansion

units.

To select the power supply module, some monitoring of the internal current

consumption of the modules used must be carried out.

The following table gives information on the maximum current values of the

power supply modules.

Supply voltage

Supply voltage [A]

pp y g

NT1 NT2 NT3 NT24

+5 V 4 8 26 11.2

+5 V buffer voltage 0.25 1 contained in 8 4 contained in 26 3 contained in 11.2

+12 V 1.8 3 6 4.4

+12 V ISO +0.5 +1 +4.5 +1.5

-12 V ISO -0.1 -0.5 -1.5 -1.0

Fig. 3-2 Current supply of the power supply modules

NT1

The NT1 power supply module is an inexpensive model and can be used

when no system modules can be used in the control. In this case, the basic

unit can also be operated without a fan unit; see also section 2.6 Fan units

NT2

The NT2 power supply module is an inexpensive model and can be used

when only very few modules can be used in the control.

Page 53

Flexible Automation

Power supply modules

3-3

1070 072 143-101

NT3

The NT3 power supply module is a powerful model for the maximum ca

pacity of the CL400.

The NT3 power supply module provides the 5 V and 12 V supply voltages

with a combined maximum power output of 153 W, i.e. the 5 V and 12 V sup

ply voltages may not both be loaded with their maximum current values of

26 and 6 A respectively.

NT24

The NT24 power supply module is desgined for a supply nominal voltage of

24 V-. It can be supplied via battery or rectifier.

The NT24 power supply module provides the 5 V and 12 V supply voltages

with a combined maximum power output of 99 W, i.e. the 5 V and 12 V sup

ply voltages may not both be loaded with their maximum current values of

11.2 and 4.4 A respectively.

Power input

The maximum power input of the control must be calculated when select

ing the suitable power supply module. The power inputs of the individual

modules must also be added for each supply voltage; see fig. 3-3.

Page 54

Flexible Automation

Power supply modules

3-4

1070 072 143-101

Module

max. power input in mA from

+5 V +5 V buffer volt

age

+12 V +12 V ISO -12 V ISO

ZS400

* +20 mA per active current loop

1400 150 25

70*

-10

ZAT1

* Power input of the supplementary

card

** +20 mA per active interface

2600*

150

450**

-60

ZAT2 2100 150 310 -40

R500

* +20 mA per active current loop

690 7 140* -40

R500P

* +20 mA per active current loop

1200 8 70* -20

DB500

* Colour monitor and V.24 interface

** Colour monitor and 20 mA interface

active, no control signal wiredup

1100 35

190*

250**

-20

digital input modules, per input set 0.5

E analog 150

E 10 ana 130

input module IE 24 V- 30

digital output modules, per output set 2

A analog 80

A 10 ana 100

AG/ZS 10

AG/P S 85

Bus master DESI 650

Bus master DESIDP 650

Counter module EI50 90

Positioning module CC10 120

Temperature controller module RT6 650

Peripheral buscoupling module PBK 150

Channel module MOBY ® I/F 70

Cycle time analysis module TZA 400

Fig. 3-3 Power input internal

Page 55

Flexible Automation

Power supply modules

3-5

1070 072 143-101

3.2 Tasks and functions

The power supply module takes on the following functions:

D Supply of the internal supply voltages +5V, +12V and 12V (insu

lated).

D Monitoring the input voltage for overvoltage and undervoltage.

D Monitoring the +5V and +12V for overvoltage and undervoltage.

D Monitoring the temperature of the power supply module at 60 _C

+10%.

If one of the 3 monitor functions mentioned above gives a response,

the power supply module will be switched off and all outputs will be

set to 0.

D If power failure occurs, the buffered memories of the control are sup

plied centrally from the power supply module via a buffer battery.

D Monitoring the buffer battery.

Buffer battery

The buffer battery serves the central fuse of the remanent areas for markers,

times, counters, data field and data buffer. The buffer battery takes over the

supply of the internal RAM memory of the ZS400 when the supply voltage

cuts out or the power supply module is switched off.

In connection with the Memorycard, the CL400 makes operation without

buffer battery possible.

module

max. Power input in MA at

25 _C 55 _C

NT1, NT2, NT3, NT24 60 60

ZS400 32 220

ZAT1 10 75

ZAT2 10 75

R500 10 75

R500P 15 110

DB500

D Program memory cards RAM

32 and 128 k words

D Program memory cards RAM

64 k words

10

10

20

75

75

150

Fig. 3-4 Buffer battery, power input of the modules

Page 56

Flexible Automation

Power supply modules

3-6

1070 072 143-101

The service life of the buffer battery depends

D on the fitting of the control with system modules; see fig. 3-4.

D on the ambient temperature.

D on the clearing time of the control.

. Change buffer battery after 1 year at the latest.

Monitoring the buffer battery

The monitor detects:

D absent buffer battery.

D undervoltage in the buffer battery.

Battery early warning

after

D switching on the power supply module or

D pressing the reset key on the front panel of the power supply module

a load test of the buffer battery is carried out. If an error is detected, the

special marker SM20.1 is set.

Battery failure

After a fault has been detected in the buffer battery, the ZS400 goes into op

erating status. Stop.

A battery failure is detected

D when the buffer battery monitor is switched on and the buffer battery

is absent.

D when the battery voltage is too low.

D when the ZS400 is absent or has already been withdrawn.

A detected battery failure is in addition reported on the 7segment display

of the ZS400; see fig. 4-7.

After the battery failure has been rectified, this must be acknowledged with

the reset key on the front panel of the power supply module.

Failure contact

The failure contact on the power supply module opens when:

D the internal 5 V supply voltage fails.

D ZS400 has operating status Stop

The failure contact is available to the user for systemspecific evaluation.

Page 57

Flexible Automation

Power supply modules

3-7

1070 072 143-101

Specifications NT1 NT2 NT3 NT24

Input voltage 220/230 V automatic switching 110/115 V,

-15 % to +10%, 47 to 63 Hz

24 V-,

-33% to +71%

Bonding from power inter

ruptions to the power sup

ply module

one full wave, repeat rate W 10 s to DIN EN 611312

class PS2 V10 ms,

repeat rate W 1 s

Input continuous current 1 A 1.9 A 6.9 A

Peak switching current typ. 25 A

max. 50 A

typ. 27 A

max. 50 A

typ. 23 A

max. 50 A

typ. 18 A

max. 30 A

Duration of increased cur

rent

5 ms 10 ms

Fuse M 1.6 A M 6.3 A T 6.3 A T 10 A

Supply voltages

D Buffer battery

D Logic

D Peripheral bus

D insulated for interfaces

3.6 V battery voltage

+5 V

+5 V buffer voltage

+12 V

12 V ISO

Current supply

D +5 V

D +5 V buffer voltage in

operation

D +12 V

D +12 V ISO

D -12 V ISO

4 A

0.25 A

1.8 A

+0.5 A

-0.1 A

8 A

1 A

contained in 8 A

3 A

+1 A

-0.5 A

26 A

4 A,

contained in 26 A

6 A

+4.5 A

-1.5 A

11.2 A

3 A,

contained in 11.2 A

4.4 A

1.5 A

-1 A

Buffer battery

D Capacity

D Battery voltage

D Buffer time

5.2 Ah

3.6 V

6 to 12 months

Failure contact

D Switching voltage

D Switching current

24 V-

V 2 A

Interference immunity to DIN EN 611312, VDE 0109,

VDE 0160, VDE 804, VDE 0871

IEC 8012/3/4,

DIN EN 61131-2,

VDE 0109, VDE 0160,

VDE 0871

IEC 8013/4,

DIN EN 611312,

VDE 0160

Width 2 divisions

Fig. 3-5 Power supply modules, specifications

Page 58

Flexible Automation

Power supply modules

3-8

1070 072 143-101

CAUTION 3.1

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

GG2

1234567891011121314

Slots

Basic units

12345678

GG2/K

Fig. 3-6 Power supply modules, slots

Ordering information

Designation Order no.

Power supply module NT1 1070 071 376

Power supply module NT2 1070 062 687

Power supply module NT3 1070 062 309

Power supply module NT24 1070 068 046

Buffer battery for NT1, NT2, NT3 and NT24 1070 914 447

Fig. 3-7 Power supply modules, ordering information

. The power supply modules in the basic unit do not supply the 24 V sup

ply voltage for the peripheral modules, transducers and actuators.

Power supplies for the 24 V supply voltage can be found in section 6.3

24 V load power supplies.

Page 59

Flexible Automation

Power supply modules

3-9

1070 072 143-101

3.3 NT1 and NT2

NT1

230/115 V

5/12 V

ISO 12 V

L1

N

230 / 115 V

M 1,6 A

Netz

I

O

Batterieausfall

Rücksetzen

Bereit

1 2 3 4 5

6 7 8 9

24V-/2A

LED green 5/12 V present

LED green ISO 12 V present

LED red Battery failure

Reset key, to confirm the battery failure

and for the load test of the buffer battery

Buffer battery

Failure contact

Strainrelief for the failure contact

Mains switch

Mains fuse

Mains connection

Strainrelief for the mains connection

NT2

230/115 V

5/12 V

ISO 12 V

L1

N

230 / 115 V

M6.3 A

Netz

I

O

Batterieausfall

Rücksetzen

Bereit

1 2 3 4 5

6 7 8 9

24V-/2A

Fig. 3-8 NT1 and NT2, front panel

Page 60

Flexible Automation

Power supply modules

3-10

1070 072 143-101

DANGER 3.2

Highly dangerous voltage!

Highly dangerous voltage is present at the input terminals of the power

supply modules NT1, NT2 and NT3!

Switch off the power to the terminals before working on the module!

CAUTION 3.3

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

CAUTION 3.4

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

Page 61

Flexible Automation

Power supply modules

3-11

1070 072 143-101

Failure contact

J1

J2

3

2

1

3

2

1

Back NT2

J1

J2

3

2

1

3

2

1

Back NT1

Fig. 3-9 NT1 and NT2, jumper setting

Jumper J1

D Setting 1-2

Failure contact opens due to ZS400 operating status Stop and

power interruption

D Setting 2-3

Failure contact opens only after voltage failure; not due to ZS400 op

erating status Stop

Buffer battery

Jumper J2

D Setting 1-2

No battery operation; monitoring of the buffer battery not active

D Setting 2-3

Battery operation; monitoring of the buffer battery is active

Page 62

Flexible Automation

Power supply modules

3-12

1070 072 143-101

Installation and replacement of the buffer battery

CAUTION 3.5

Data loss!

Removing the buffer battery when the power supply module is

switched off leads to the loss of all remanent data as well as the PLC

program in the RAM memory!

Only replace the buffer battery while the power supply module is

switched on!

L Unscrew the buffer battery seal.

Seal

Buffer battery

Reset key

Fig. 3-10 NT1 and NT2, buffer battery

L Remove old buffer battery.

L Gently knock the new buffer battery on solid undersurface so that the inner

layer of oxide is destroyed.

L Insert new battery, observing the correct polarity.

L Screw in the buffer battery seal again.

A battery failure is indicated by the 7segment display showing a

. The

battery failure must be acknowledged.

Page 63

Flexible Automation

Power supply modules

3-13

1070 072 143-101

L Acknowledge the battery failure with the reset key on the front panel of the

power supply module.

At the same time, a load test of the new battery is carried out. If the 7seg

ment display of the ZS400 then still shows a

, the new battery must be

faulty.

. The old buffer battery (Lithium battery) must be fed to a special waste

disposal unit under the waste key number 35 325. The conditions of

acceptance of the waste disposal depot must be observed.

Page 64

Flexible Automation

Power supply modules

3-14

1070 072 143-101

3.4 NT3 and NT24

230/115 V

NT3

220/115 V

5/12 V

ISO 12 V

L1

N

T 6,3 A

Netz

I

O

Batterieausfall

Rücksetzen

Bereit

Batterie

24 V-/2 A

+

-

107/914447

1 2 3 4 5

6 7 8 9

LED green 5/12 V present

LED green ISO 12 V present

LED red Battery failure

Reset key, for resetting the battery fail

ure and for the load test of the new

buffer battery

Buffer battery

Failure contact

Strainrelief for the failure contact

Mains switch

Mains fuse

Mains connection

Strainrelief for the mains connection

NT24

24 V-

5/12 V

ISO 12 V

24 V

0 V

T 10 A

Netz

I

O

Batterieausfall

Rücksetzen

Bereit

Batterie

24 V-/2 A

+

-

107/914447

1 2 3 4 5

6 7 8 9

Fig. 3-11 NT3 and NT24, front panel

Page 65

Flexible Automation

Power supply modules

3-15

1070 072 143-101

DANGER 3.6

Highly dangerous voltage!

Highly dangerous voltage is present at the input terminals of the power

supply modules NT1, NT2 and NT3!

Switch off the power to the terminals before working on the module!

CAUTION 3.7

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

CAUTION 3.8

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

NT3

The NT3 power supply module provides the 5 V and 12 V supply voltages

with a combined maximum power output of 153 W, i.e. the 5 V and 12 V sup

ply voltages may not both be loaded with their maximum current of 26 and

6 A respectively.

NT24

The NT24 power supply module provides the 5 V and 12 V supply voltages

with a combined maximum power output of 99 W, i.e. the 5 V and 12 V sup

ply voltages may not both be loaded with their maximum current of 11.2

and 4.4 A respectively.

Page 66

Flexible Automation

Power supply modules

3-16

1070 072 143-101

Failure contact

J1

J2

1

2

3

1

2

3

Back

Fig. 3-12 NT3 and NT24, jumper setting

Jumper J1

D Setting 1-2

Failure contact opens due to ZS400 operating status Stop and

power interruption

D Setting 2-3

Failure contact opens only after voltage failure; not due to ZS400 op

erating status Stop

Buffer battery

Jumper J2

D Setting 1-2

No battery operation; monitoring of the buffer battery not active

D Setting 2-3

Battery operation; monitoring of the buffer battery is active

Page 67

Flexible Automation

Power supply modules

3-17

1070 072 143-101

Installation and replacement of the buffer battery

CAUTION 3.9

Data loss!

Removing the buffer battery when the power supply module is

switched off leads to the loss of all remanent data as well as the PLC

program in the RAM memory!

Only replace the buffer battery while the power supply module is

switched on!

L Unscrew the fastening screw of the lid

Batterie

+

-

Fastening screw

Fig. 3-13 NT3 and NT24, buffer battery

L Remove lid.

L Remove buffer battery.

L Gently knock the new buffer battery on a solid undersurface so that the

inner layer of oxide is destroyed.

L Insert new battery, observing the correct polarity.

L Put the lid back on and tighten the fastening screw.

Page 68

Flexible Automation

Power supply modules

3-18

1070 072 143-101

A battery failure is indicated by the 7segment display ZS400 showing a

.

The battery failure must be acknowledged.

L Acknowledge the battery failure with the reset key on the front panel of the

power supply module.

At the same time, a load test of the new battery is carried out. If the 7seg

ment display then still shows a

, the new battery must be faulty.

. The old buffer battery (Lithium battery) must be fed to the special

waste disposal unit under the waste key number 35 325. The condi

tions of acceptance of the waste disposal depot must be observed.

Page 69

Flexible Automation

Central processing unit ZS400

4-1

1070 072 143-101

4 Central processing unit ZS400

Task

D Decoding and processing of commands in PLC program.

D Management of memory area for the data in the peripherals.

D Recognition and processing of interrupt signals.

D System monitoring

D Central system clock with calendar and alarm function

For the purposes of storing PLC programs, the central processing unit

ZS400 has an internal 256 kByte RAM memory. The PLC program is always

executed from the internal 256 kByte RAM memory.

Memory card

The central processing unit ZS400 has a plugin fixture for a memory card.

The memory card facilitates ZS400 operation without a buffer battery.

However, the PLC program being run is executed from the 256 kByte RAM

memory even when a memory card is in use and thus facilitates the use of

data modules as write/read memories. This is a major advantage of the

memory card in comparison with EPROM use up to now.

The ZS400 firmware can be loaded from a memory card.

The PLC program can be stored on a memory card or loaded from a mem

ory card.

Features

D Cyclic program execution with organisation module OM1

D Setting of system parameters in organisation module OM2

D Program startup controlled via organisation module OM5 or OM7

D Fault management in organisation module OM9

D 9 organisation modules for timers

D 8 organisation modules for interrupt inputs

D 16 organisation modules for system interrupts

D Definition of inputs/outputs

Fig. 4-1 ZS400

Page 70

Flexible Automation

Central processing unit ZS400

4-2

1070 072 143-101

D PLC program execution with monitor function

D Convenient floating point arithmetic by means of function module

D Block commands for Copy, Search and Compare

D Coordination flags

D Special marker management

D Mail boxes

D Variable cycle time monitoring

D Operations set concerning function and parameterisation compat

ible with ZS501

D Division of PLC program in two section possible, standard and sys

tem program modules

The system parameters of the ZS400 can be adapted to your requirements.

The file OB2.PCO is transferred to the directory INFO together with the PLC

service program. The system parameters can be amended in this file. This

file must be incorporated in the PLC program as organisation module OM2

in order that ZS400 recognises these amendments.

Specifications

Specifications ZS400

Program memory

D internal 256 kByte RAM buffered

D Pluggable 1 MByteMemory card, flash

EPROM or SRAM

Command execution time

D Bit command

D Word command

D Module command

<0.25 Ms

0.25 to 0.7 Ms

0.5 to 1.2 Ms

Register 4 16bit registers

Organisation modules OM 42

Program modules PM 1024

Nesting depth 62 modules

Nesting levels 7

Operand formats Bit, byte, word

Inputs

D with map

D without map

D addressable bit by bit

256 bytes, interface inputs II

256 bytes extended input EI

1024 I

Page 71

Flexible Automation

Central processing unit ZS400

4-3

1070 072 143-101

ZS400Specifications

Outputs

D with map

D without map

D addressable bit by bit

256 bytes, Interface outputs IO

256 bytes extended output EO

512 O

Marker M 2048

Timers T D 128, 10 ms time base

D 1, 1 ms time base

Counters C 128

Special markers SM 256

Data modules DM 512 per 512 bytes

Data buffer DB 512 bytes

Data field DF 24 kbyte

Mail boxes MB 8 within the data field

FIFO memory 4 x 512 byte

User stack AST 512 bytes

System range 512 bytes

Power input from

D buffer battery

D +5 V buffer voltage

D +5 V

D +12 V

D +12 V ISO

D -12 V ISO

32 MA at 25 ºC

220 MA to 55 ºC

max. 150 mA, typ. 130 mA

max. 1.4 A, typ. 0.8 A

max. 25 mA, typ. 15 mA

typ. 70 mA + 20 mA per active

current loop

typ. -10 mA

Interfaces D PCMCIA, version 2.0, type I

slot

D X31, serial V.24/20 mA inter

face, 25pin subD socket

Width 1 division

Fig. 4-2 ZS400, Specifications

Page 72

Flexible Automation

Central processing unit ZS400

4-4

1070 072 143-101

CAUTION 4.1

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage before

inserting or removing the module!

CAUTION 4.2

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

GG2

1234567891011121314

Slots

Basic units

12345678

GG2/K

Fig. 4-3 ZS400, slots

Ordering information

Description Order no.

Central processing unit ZS400 1070 070 309

1 MB memory card, flash EPROM 1070 917 668

Fig. 4-4 ZS400, ordering information

Page 73

Flexible Automation

Central processing unit ZS400

4-5

1070 072 143-101

4.1 Display and control elements

Eject lever

LED Stop

Eject lever

Retention switch

Reset key

Lock output states switch

Rolling LED

Rolling key

2figure 7segment

status display

Stop/run switch

Plugin memory card,

PCMCIA interface

Memory card eject key

Fix LED

Interface X31

Fig. 4-5 ZS400, front panel

Page 74

Flexible Automation

Central processing unit ZS400

4-6

1070 072 143-101

4.1.1 Status and rolling

Rolling LED

Rolling key

2figure 7segment

status display

Fig. 4-6 Status and rolling

The 2figure 7segment status display, the rolling key and the rolling LED

form a display and control panel.

The 2figure 7segment status display distinguishes two displays:

D Display for Power On

D Operational messages

Power On

With Power On, the continuing initialisation of the ZS400 is accompanied

with an ascending display from

to on the lower 7segment display. When

initialisation is complete, the display

of the lower 7segment display goes

out to indicate this.

An error of initialisation is indicated by the flashing or static display of a

character between

and .

With error displays

and you may attempt to remedy the fault by starting

the firmware from a memory card. For all other error displays, the ZS400

unit must be returned to out Customer Service department.

Page 75

Flexible Automation

Central processing unit ZS400

4-7

1070 072 143-101

Operational messages

All ZS400 operational messages are 2figure.

Display

Meaning

upper lower

Operational messages of the power supply module

Communication problem between power supply

module and ZS400

Fault remedy:

Replace power supply module

Cause:

D Incorrect setting of jumper J2 at power supply

module

D Failure of buffer battery

Fault remedy:

Replace buffer battery, acknowledge with Reset

key on the front panel of the power supply module

Battery early warning

Fault remedy:

Replace buffer battery, acknowledge with Reset

key on the front panel of the power supply module

ZS400 operational messages

Memory error

Cause:

D Incorrect setting of jumper J2 at power supply

module

D Failure of buffer battery

D Error when loading the memory card

Fault remedy:

Reload PLC program and delete retentive areas

Configuration error

Cause:

Difference between the fitting of the control unit with

system modules and the SK table

Page 76

Flexible Automation

Central processing unit ZS400

4-8

1070 072 143-101

Display Meaning

upper lower

System bus error

Cause:

A system module assigns the system bus for too

long

Fault remedy:

Switch control off and on again; generally the de

fective system module must be replaced

DESI bus master not ready

Cause:

PLC stop time of the DESI bus master not yet

elapsed

Configuration error system data fields/mail boxes

Cause:

The set start addresses and lengths cause overlap

ping

Reference list error

Cause:

The assignment at the ZS400 peripheral bus with

I/O modules does not correspond with the refer

ence list in OM2.