Bosch BSS250E-2, BSS250-21-2, BSS250-26-2, BSS300E-2, BSS300-21-2 Installation And User Manual

...

19/07/2011 Version 19 Solar Wizard

MODELS

BSS250E-2 / BSS250-21-2 / BSS250-26-2

BSS300E-2 / BSS300-21-2 / BSS300-26-2

BSS400E-2 / BSS400-21-2 / BSS400-26-2

Australia & New Zealand

INSTALLATION AND USER

HANDBOOK

System Installation

Controller & Pump

Solar Panels

Gas solar booster

Solar Tank

This solar hot water system must be installed in accordance with the manufacturer’s installation

instructions, AS5601, AS3500.4. AS3000 wiring regulations (in New Zealand NZBC G12) and all Local

Building, Water and Gas fitting regulations.

To be installed and serviced only by an authorised person

This appliance is not suitable for use as a pool heater

Please see important note regarding tank on Page 15

The “authorised installing person” is responsible for:

1. Correct commissioning of this system.

2. Ensure units perform to the specifications stated on the rating label.

3.. Demonstrate operation of the system to the customer before leaving.

4. Hand these instructions to customer.

Failure to install this system in accordance with these installation instructions may void warranty

Note: These instructions are subject to change, due to continuous product improvement.

2

INDEX

Page Number

Basic Solar Hot Water Layout 3 - 4

Introduction 5

Basic Installation steps 5 - 6

Contents 7

Solar Collectors 8- 14

Solar Tank and Components 15-21

Electric Boosting 22-23

Solar Tank Specifications 24

Gas Boosting 25-32

Controller & Pump 32-42

Commissioning 42

Home Owners Guide & Safety Instructions 43-50

Warranty Details 51-52

3

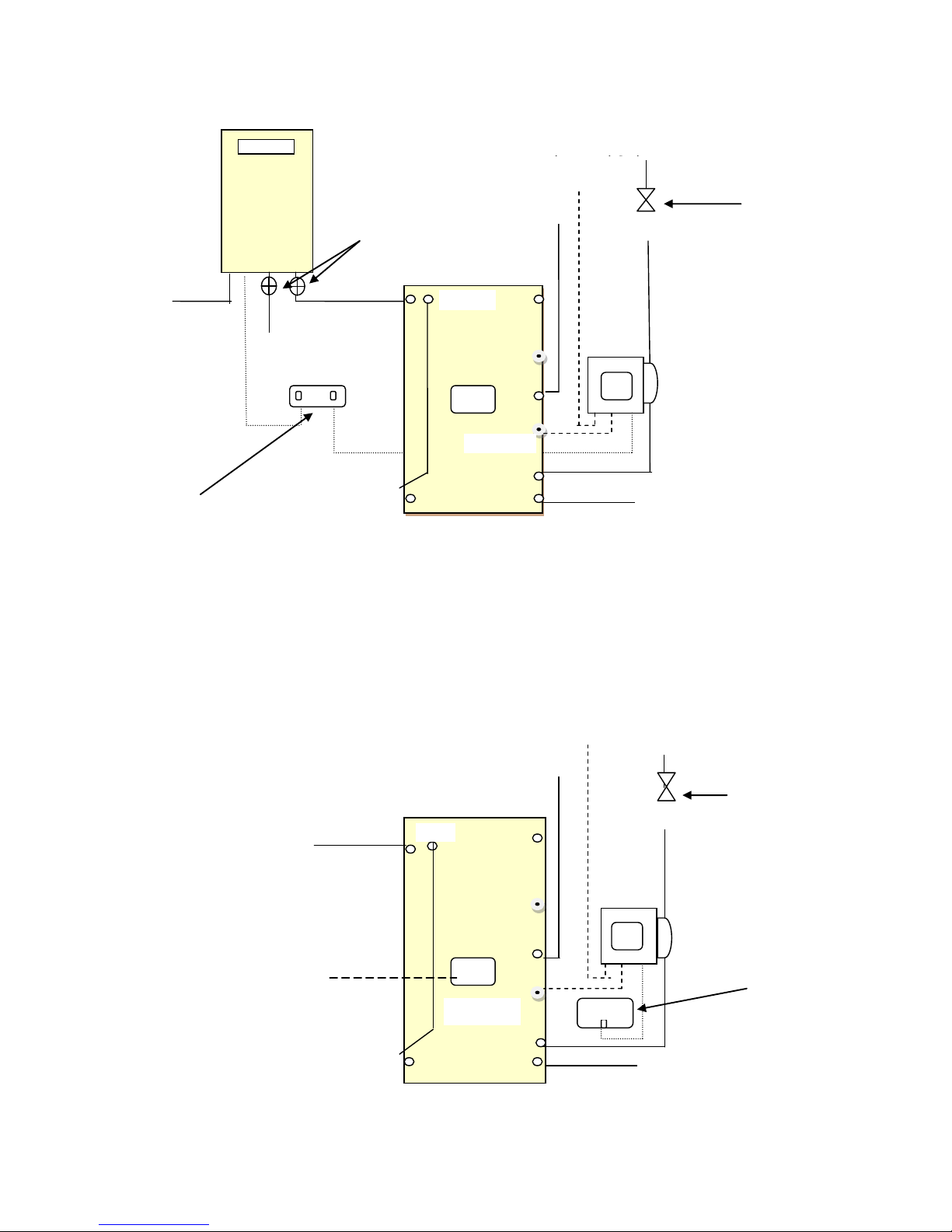

BASIC SOLAR TANK AND COMPONENT LAYOUT

I

250L, 300L & 400L Gas

Solar Booster

Set to 75°c

Hot water supply to fixtures

(Temperature control valve Must be

fitted)

Gas

piping

Dual GPO

Power supply to

solar pump &

controller

Solar storage tank

Cold water inlet valve train isolation valve, non-

return valve PLV (600Kpa & cold water expansion

(Where required)

Solar circulation

pump and controller

Tank outlet

Tank sensor

Solar return

from panel

Solar panel sensor

Flow to panels

250L, 300L & 400L Electric boosted solar

PTR

*NOTE For ease of installation, the tank has

cold inlet and hot outlet ports on both the left

and right hand sides

Cold water inlet valve train isolation valve, nonreturn valve PLV (600Kpa & cold water

expansion (Where required)

Hot water supply to fixtures

(Temperature control valve

Must be fitted)

Power supply from

switchboard to

booster

GPO

Solar circulation

pump and controller

Flow to panels

Solar panel sensor

Solar return from

panel

PTR

Tank sensor

Solar storage tank

*NOTE For ease of installation, the tank has

cold inlet and hot outlet ports on both the left

and right hand sides

Continuous

supply

Continuous supply

Non-Return valve

Non-Return valve

Isolating

valves

4

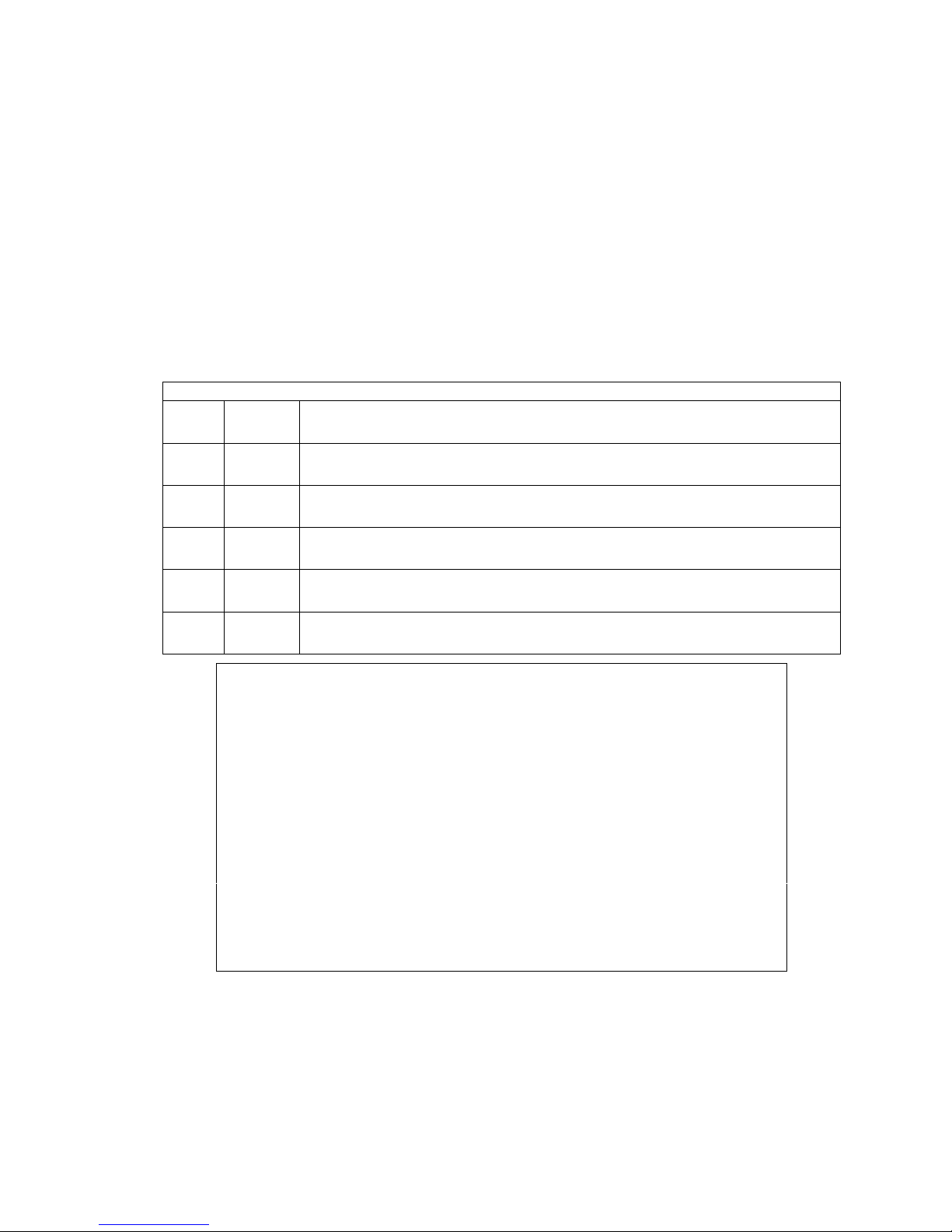

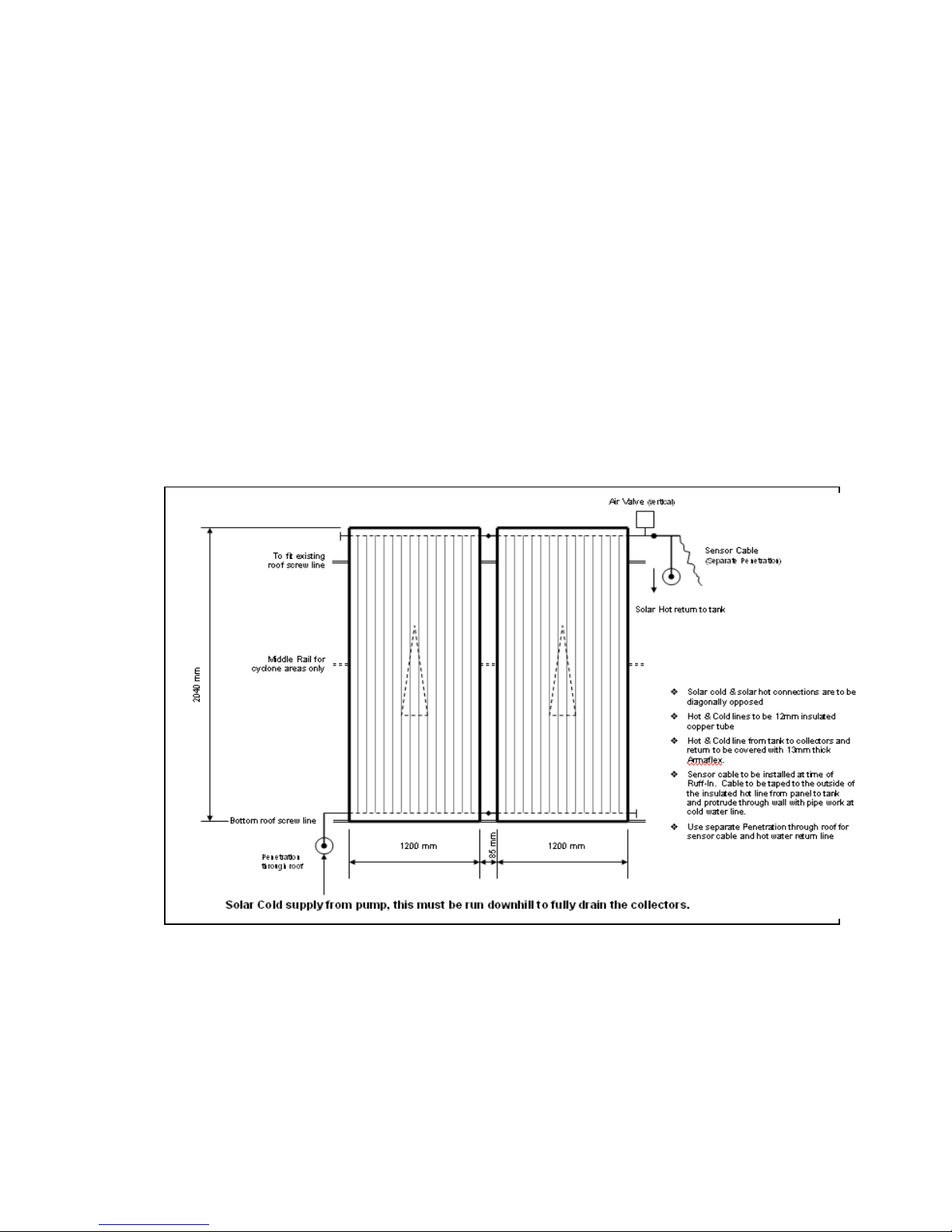

BASIC PANEL LAYOUT 1,2 & 3 PANEL

Solar Panel

2040 x 1200

Auto Air vent

Must be upright and

ensure vent cap is

open

Custom fitting to suit top left of

collector with inbuilt sensor socket

and connection for Air Relief Valve

Frost valve

¾ x ½ nipple

Cold water flow

from pump

¾ Barrel union

with pipe insulation

*NOTE: All pipes and fittings must be

lagged with pipe insulation to prevent

heat loss.

Brass plug

Return to tank

Custom

fitting for

inlet

connection

5

INTRODUCTION

The following instructions are for the installation of a Split solar hot water system/s, being the

panels are mounted on the roof of the dwelling and the solar tank is located either internally or

externally at ground level. Where a gas solar booster is to be used, it should be mounted

adjacent (In an external location) to the solar tank.

BASIC INSTALLATION STEPS

Check packaging and product for damage (If the product is damaged, do not install and

contact your supplier immediately)

Check and ensure that you have all components as listed on page 7

Panel installation (See page 7 – 14 for more detail)

Select Panel location

Facing north (Not unduly shaded during the day and to the pitch requirements)

Roof structure can support filled weight of panels (44Kg each)

Panels can fit on available space on the roof (Panels are 1200mm x 2040 plus pipe

and fittings)

At and before installation, cover panels to prevent excessive heat building up in the

panels that may cause damage to the panels and personal injury.

Fix panels securely with brackets provided (in Cyclonic areas, cyclone kits are

required)

Tank location (See page 15- 22 for more detail)

As close as possible to the most frequently used fixture

As close as possible to the solar panels (Max 8m)

Ensure the tank is mounted on a solid base

Power, water is accessible to be connected to the tank and system

PTR drain is discharged in a safe manner and conforms to AS 3500.4

Note There are inlets and outlets on both sides of the tank, so ensure the unused

points are plugged with brass plugs prior to filling the tank.(Plastic plugs must be

discarded)

Tank is fitted in accordance with the manufacturer‟s installation instructions,

AS3500.4. AS3000 wiring regulations (in New Zealand NZBC G12) and all Local

Building, Water regulations.

The piping between the panels and tank is copper and is well insulated.

6

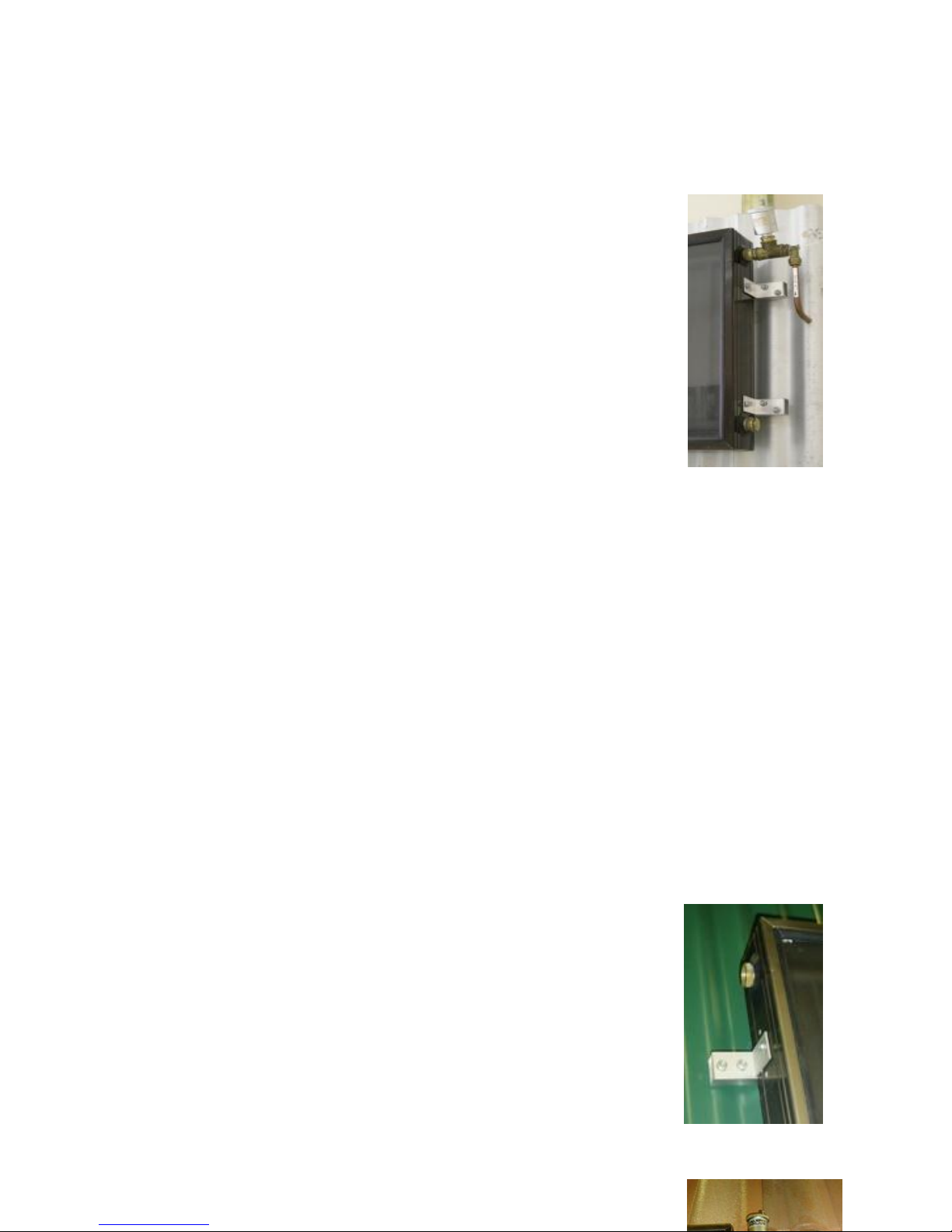

Pump & Controller (See page 30 - 39 for more detail)

Pump and controller is securely mounted on a wall to the side of the tank (within

500mm of the tank.) The power supply lead to the pump and controller is 1500mm in

length.

A continuous supply power point is within 1.5 metres of the controller.

Run sensor leads to the tank and panels (it is recommend that the sensor leads are

protected from the elements and mechanical damage)

Gas Booster (See page 23 - 29 for more detail)

Booster is mounted on either the left or right hand side of the tank

The 75c bridge is fitted to the booster. (See page 29 for more detail)

A continuous supply power point is within 1 metre of the booster.

Booster is fitted in accordance with the manufacturer‟s installation instructions,

AS3500.4. AS3000 wiring regulations (in New Zealand NZBC G12), AS 5601 & NZS

5261 and all Local Building, Water regulations.

Commissioning the system

Once the installation is complete the system will need to be filled with water and

commissioned.

First flush all piping of debris.

Turn the water isolation valve on at the tank.

Check pipework for leaks.

Open household taps individually and purge out any air.

Open vent on auto vent cap (At panels).

For electric boost turn power supply onto tank.

Turn power supply onto Controller/Pump station

For gas boost turn on isolation valves at booster.

Plug in three pin plug to power supply and turn on

Commission booster (See page 29 for more detail)

Check and adjust temperature control valve

7

Clean up site

Hand the customer the operating instructions

Explain the system operation

Answer any customer queries.

CONTENTS

Your „Solar Wizard‟ Solar hot water system is supplied with the following components:

Parts List

Item

No.

Qty

Description

1

1

storage tank

2

1 or 2

solar collector

3

2

2610mm (L) x 38mm (W) x 25mm (H) x 1.6mm (T) Upper mounting rail

– 3 units required for Cyclone areas or Standard bracket kit

4

1

Solar PK1 – Panel Installation Kit (See contents below)

5

1

Pump station & Controller

*Optional tank installation kit available as an accessory.

Please check to make sure all these components are included with the kit.

Solar-PK1

Panel Installation Kit

20mm Barrel Unions (MI x MI)

2

Custom Connection for top left of collector include

Sensor Pocket

1

Custom Connection for bottom right of collector

1

20mm x 15mm Hex Nipple

15mm Hex Nipple

1

15mm MI x C Unions

1

20mm Brass Plugs

5

NVHT-15F-15C

15mm High Temperature Non-Return Valve

1

AEHT-10

Air Eliminator

1

FPV15

Anti-Frost Valve

2

PTR15/1000

15mm 1000kPa TPR Valve

1

Note

Insulation kits for most valves & Fittings

8

SOLAR COLLECTORS

The solar panels absorber material is Black painted copper fins, the outer casing is

constructed from corrosion resistant brown anodized aluminum and the glass is low-ironed

prismatic glass.

Width (mm)

Length (mm)

Weight empty (Kg)

Weight Full (Kg)

1200

2040

42

44

SOLAR COLLECTOR LOCATION

The solar collectors must be installed in a shade free position.

The solar collectors are to be installed facing toward the equator (i.e. north facing in the

southern hemisphere and south facing in the northern hemisphere). Where this orientation is

not practical, a system facing up to 45° from the equator will have its efficiency reduced by

approximately 4%.

Inclination of the solar collectors should be approximately equal to 90% of the local latitude

angle.

Solar collectors may be installed at the roof angle for simplicity of installation and appearance,

but must never be flat. If the roof angle varies by 15° from the correct angle, efficiency will be

reduced by 10%.

The installer must ensure the structural integrity of the building is not compromised by the

solar water heater installation and the roof structure is suitable to carry the full weight of the

solar collector(s). If in doubt the roof structure should be suitably strengthened.

Each solar collector and its fittings weighs approximately 44 kg when full of water.

INSTALLATION – SOLAR COLLECTORS

PREFACE:

Approximate roof area required:

2 Collectors are 2.8m wide x 2.4m high. (88kgs total, filled with water)

3 Collectors are 4m wide x 2.4m high. (132kgs total, filled with water)

NOTE: Ensure the mounting surface is strong enough to support the collectors. Most roofs can

support the panels, but if unsure consult a structural engineer.

ONLY QUALIFIED TRADESPERSONS SHOULD INSTALL THESE COLLECTORS.

GLAZING CANNOT BE REPLACED ONSITE.

FRAME INSTALLATION Tiled roof (Non Cyclone Area)

9

Conduct an inspection of the intendant installation position and ensure that the

panels can be fitted in this position prior to commencing any work.

1. Position the lower bracket on the roof ensuring there is sufficient room to fit the panels.

2. Remove the row of tiles above the bracket position.

3. Loop bracket support strap through the bracket and fix bracket support to the roof

rafters, Ensure the bracket is level.

4. Flatten out return of bracket strap

5. Bend all bracket straps to fit over tiles.

6. Replace tiles above the bracket

7. Unpack panels (where fitted remove protective plastic from the panels)

8. Place panels into position and fit against lower bracket

9. Join the panels together using the brass barrel unions supplied in the panel installation

kit.

10. Centre the panels onto the lower bracket and secure the panels onto the bracket 20mm

above the bottom of the bracket using the hex screws supplied. Warning: Do not drill

above 20mm from the bottom of the bracket, as this may cause damage to the internal

workings of the panel and this will void the warranty.

11. Remove the row of tiles above the panels to enable the upper bracket to be fitted.

12. Loop bracket support strap through the bracket, Flatten out return of bracket strap

13. Secure bracket to panels 20mm above the bottom of the bracket using hex self-drilling

screws. Warning: Do not drill above 20mm from the bottom of the bracket as this may

cause damage to the internal workings of the panel and this will void the warranty.

14. Fix bracket support strap to the roof rafters.

15. Bend all bracket straps to fit through and over tiles.

10

16. Replace tiles

17. Make all water connections, fit all valves and components as per the solar layout

diagram contained in these instructions.

18. Note: The panels should be covered fully to prevent the panels heating up to

temperatures that have potential to cause damage or injury during system fill or

commissioning.

FRAME INSTALLATION metal roof (Non Cyclone Area)

Conduct an inspection of the intendant installation position and ensure that the

panels can be fitted in this position prior to commencing any work.

1. Position the lower bracket on the roof ensuring there is sufficient room to fit the panels.

2. Level the panel bracket and fix to the steel roof using roofing screws or rivets, one

fastener per rib is recommended.

3. Weather proof screw heads and rivets with silicone sealant.

4. Unpack panels (where fitted remove protective plastic from the panels)

5. Place panels into position and fit against lower bracket

6. Join the panels together using the brass barrel unions supplied in the panel installation

kit.

7. Slide the upper panel support bracket under the top of the panels then press it flush

against the top of the panels. Mark its position on the roof.

11

8. Remove the panels, align the upper bracket with the marked line and fix the panel to

the steel roof using roofing screws or rivets.

9. Weather proof screw heads and rivets with silicone sealant.

10. Refit the panels between the brackets.

11. Centre the panels onto the brackets and secure the panels onto the brackets 20mm

above the bottom of the bracket using the hex screws supplied. Warning: Do not drill

above 20mm from the bottom of the bracket, as this may cause damage to the internal

workings of the panel and this will void the warranty.

12. Make all water connections, fit all valves and components as per the solar layout

diagram contained in these instructions.

13. Note: The panels should be covered fully to prevent the panels heating up to

temperatures that have potential to cause damage or injury during system fill or

commissioning.

FRAME INSTALLATION (Cyclone areas):

1. Select a suitable place to install the lower mounting rail on the

roof, align panel location as high as possible on the roof.

2. Locate lower rail and mark 4 bolt positions on the rail. The

bolts are positioned to line up with the peaks of the tin or tile

profile. DO NOT drill in the troughs of the roofing material.

Ensure the holes are a minimum of 120mm from the end of

the rail.

3. Drill the 4 bolt positons on the top of the rail using a 16-20mm

metal cutting hole saw, leaving a 5mm pilot hole through the

bottom of the rail.

4. Using the drilled rail as a guide mark and drill the roof material

with a 5mm pilot hole. This may not be needed for tin roofs, as

the screws supplied are self tapping.

5. For tile roofs drill the tiles using a 12-14mm concrete drill bit,

paying careful attention for any cracking in the tiles. Replace

any cracked tiles with a new tile before continuing.

6. Once the holes have been drilled fill the hole with silicone

sealant, and apply a 6mm bead around hole.

7. Apply silicone into the drilled hole then insert the Aluminium spacer tube into the

hole. This is not required for a tin roof.

12

8. Position the mounting rail and insert the screws through the rail and into the roof

batten, place a rubber washer as a seal between the roof surface and the mounting

rail, then evenly tighten the screws. Do not over tighten and break a tile.

NOTE: ensure a rubber sealing washer is placed between the

rail and the roof surface for each screw hole, to provide

adequate sealing of the screw hole from water ingress. Use

adequate amounts of silicone sealant into the holes before

placing the screws in the holes.

9. Also ensure that the fixing screws are of sufficent length to

adequately secure the brackets to the roof.

10. Measure and where possible evenly space the three rails to

fit under the panels.

11. Fit the middle and top rails as per steps 3 thrhough to 9.

12. After the three mounting rails have been fixed to the roof, fix a

set of side brackets on the lefthand edge of each of the rails.

Then lift the first panel into place and fix that panel to the rail

bracket. Once this has been done you can then lift the 2nd

panel into place and using the two barrell unions supplied in

the panel fixing kit, join the 2nd panel to the first panel.

13. Then fix the second panel to the rail brackets. The panels are

now secure.

14. A total of 3 rails are required for cyclone rated areas.

15. Connect them as shown in the diagram, remembering to use

Teflon tape or approved liquid sealant on all plumbing joints.

16. Always use two spanners to tighten panel fittings, and do

not exert any torque on the panels.

17. NOTE: WATER FLOW THROUGH PANELS - the water inlet

from the pump must be connected to the lower header pipe of

the array. Ensure that the water exits the panels from the top

13

header pipe, diagonally opposite from the inlet and returns to

the “Solar Return” on the tank.

18. Install the air bleed valve onto the outlet of the panels at the top

Left hand corner of the panels.

19. NOTE: The air bleed valve needs to be commissioned and checked to ensure the

valve top is opened and that when the pump operates the valve seals properly. This

can be done by listening to the valve to ensure air is not entering the pipe work. Let

the pump run for 3-5 minutes if air is still bubbling into the tank at this stage the

valve is not sealing.

20. Mount the panel temperature sensor to the Air bleed T piece

and the tank sensor into the top (Middle of tank) sensor

drywell.

21. Drill a 10mm hole in the roof near the sensor and run the

sensor leads through the hole drilled in the roof, once this is

done seal the hole with silicone.

22. NOTE: Do not use the same hole as the pipe work as movement of

the pipes will case the cable to break or short circuit.

23. Install the Solar Hot Pipe and Solar Cold Pipe to run between the storage tank and

the collectors. Both pipes should be DN15 (1/2”) copper pipe, with 13mm or thicker

synthetic rubber insulation (Armaflex, Bradflex). All insulation should be protected

from UV degradation by two thick coats of paint, or by covering with ductwork. Prelagged pipe (often green PVC or plastic insulation) is not suitable for thermal

insulation purposes – only use foamed synthetic rubber insulation.

24. Connect the Solar Hot Pipe and Solar Cold Pipe to the heater and to the panels.

NOTE: Ensure that the water inlet from the system pump flow is to the lower right edge of

the array, and that the water exits the panels diagonally opposite and through the sensor

outlet fitting, and returns to the solar return on the tank.

14

Upon completion of the water heater installation, check the panels and associated

plumbing for leaks while the pump is operating.

COLLECTOR INSTALLATION IN CYCLONE AREAS

The solar panels are SUITABLE for installation in cyclonic locations when installed with an

additional rail mounting and brackets to provide the required additional fixing to the roof frame.

This ensures conformance with AS1170.2. Three mounting rails meet the requirement for a C3

rated area.

Note: Drawing for illustration purposes only, connection points may vary from product to

product.

15

SOLAR TANK

Important Note: Please ensure you remove plastic transit plugs from tank and replace with

brass plugs supplied with panel fitting kit (These plastic plugs will not withstand solar water

temperature and will melt causing leakage from tank).

Solar tanks are available in 250 Litre, 300 & 400 Litres capacities. All three tanks have cold

water inlet and hot water outlets on both the left and right hand sides of the tanks for

convenience. The connection points not used must be sealed off with the brass plugs

supplied.

The Solar tanks have incorporated a single element electric solar booster, or the system can

be boosted via a gas booster separate to the solar tank.

The inner tank is manufactured from mild steel sheet coated with a special porcelain enamel.

The tank is protected from corrosion by two magnesium anode rods, which softens the water

and lengthens the service life of inner vessel.

The inner vessel is insulated by a thickened high-density, environment friendly polyurethane

thermal insulation layer.

The external casing is a high quality galvanized sheet shell, with outdoor coating technology,

anticorrosive and rust-resistant, makes for a longer service life.

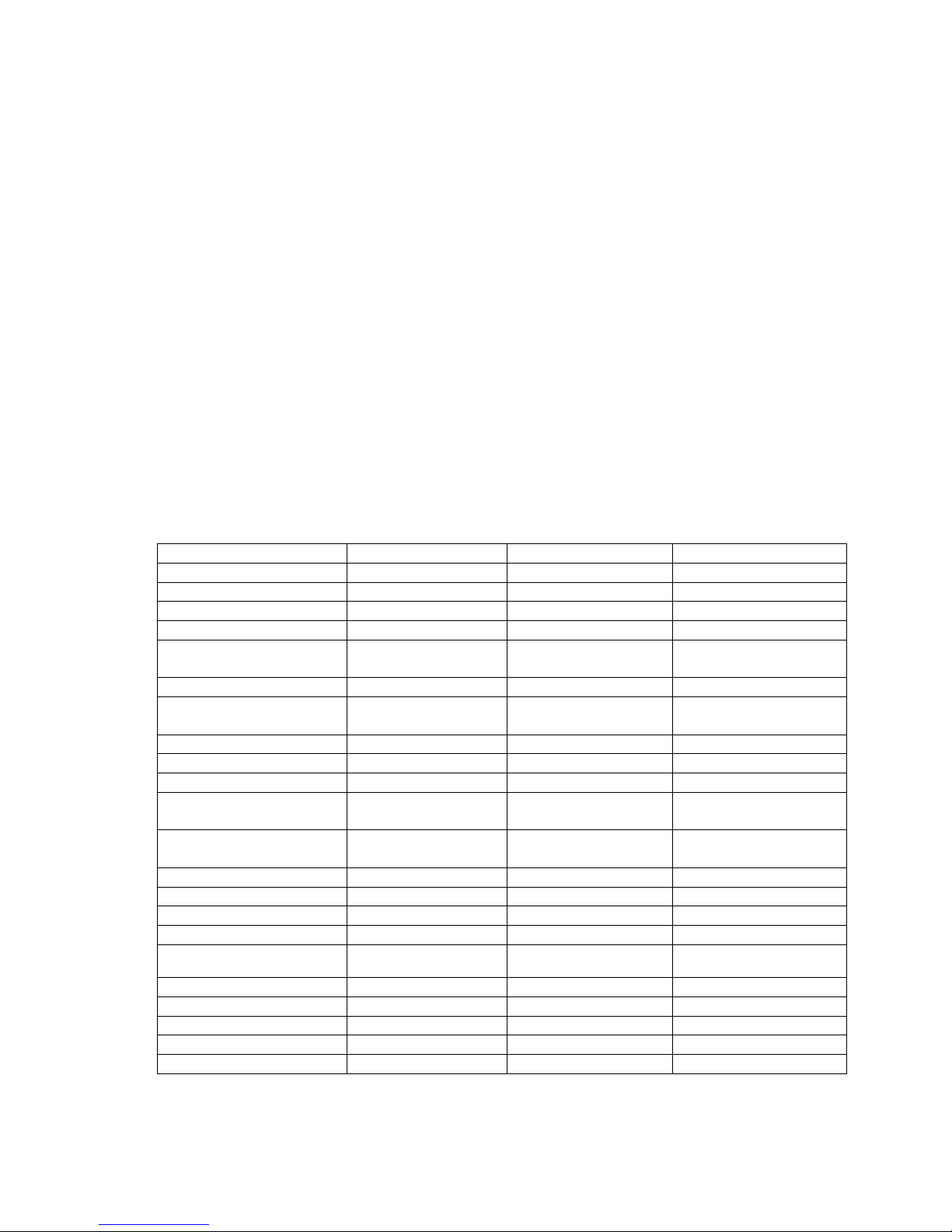

250 Litre

300 Litre

400 Litre

DIMENSIONS (mm)

Height

1325

1545

1600

Diameter

620

620

710

Material & thickness of

inner vessel

BTC340

R-2.0mm

BTC340

R-2.0mm

BTC340

R-2.0mm

Material and thickness

of shell

Galvanised sheet

0.5mm

Galvanised sheet

0.5mm

Galvanised sheet

0.5mm

Insulation thickness

40mm

40mm

40mm

Minimum inlet Water

Pressure

200 kPa

200 kPa

200 kPa

Maximum inlet Water

Pressure

750 kPa

750 kPa

750 kPa

Connection Cold

20mm

20mm

20mm

Connection Hot

20mm

20mm

20mm

Connection solar

15mm

15mm

15mm

ELECTRICAL

(Not applicable for gas boosting)

Power

240v/50Hz

240v/50Hz

240v/50Hz

amps

15

15

15

Elements

3.6kW

3.6kW

3.6kW

Weight

75Kg

95Kg

112Kg

16

INSTALLATION – STORAGE TANK

COMPLIANCE WITH STANDARDS

The installation must be performed by an Authorised Persons and comply with the

requirements of AS/NZS 3500.4, AS/NZS 3000 in New Zealand NZBC G12 and all local codes

and regulatory authority requirements. It is recommended the solar storage tank be installed

at ground or floor level. The water heater must stand vertically upright.

SUITABILITY FOR INSTALLATION IN FROST AREAS

The system is suitable for installation in areas that experience sub-zero temperatures; it has

an air bleed valve freeze protection system integrated into the system to prevent damage in

the event of a light frost. Areas of known heavy frost or altitudes higher than 600 m above sea

level are not suitable for this system. The minimum temperature these systems are suitable for

in no lower than -5°C.

NOTE: THIS WATER HEATER IS NOT SUITABLE FOR POOL HEATING.

LOCATION

Whether located outdoor or indoor, the solar water storage tank should be installed close to

the most frequently used hot water outlet (typically the shower) and its position chosen with

safety and service in mind. The panels should be located as close as possible to the storage

tank.

CLEARANCES

Allow adequate room to work with tools. A minimum of 250mm clearance around the water

heater is required. An additional 300mm is required for relief valve removal, 800mm for access

cover removal and 400mm for element removal. You should be able to read the information on

the rating plate and all informative labelling.

Loading...

Loading...