Bosch C1210ES, C1210ESC, C1050ES, C950ES, 940ES Applications Manual

...

WARNING:

If the information in this manual is not followed

exactly, a re or explosion may result causing

property damage, personal injury or death.

Follow each appliance's instructions precisely.

Installation and service must be performed by a

trained and certi ed installer, service agency or the

gas supplier.

Application drawings in this manual are conceptual

only and do not purport to address all design,

installation, code, or safety considerations.

The diagrams in this manual are for reference use by

code of cials, designers and licensed installers. It is

expected that installers have adequate knowledge of

national and local codes, as well as accepted

industry practices, and are trained on equipment,

procedures, and applications involved. Drawings are

not to scale.

Refer to the appliance and accessory installation

manuals for additional detailed information!

GREENTHERM & THERM

Tankless Water Heaters

C1210ES/ESC, C1050ES, C950ES, 940ES, 940ESO, 830ES, 520HN, 520PN, 330PN

Applications Manual

|

2

THERM/GREENTHERM Tankless Water Heaters

Applications Manual

Bosch Thermotechnology Corp.Data subject to change

Applications Manual THERM/GREENTHERM Tankless Water Heaters | 3

Table of Contents

1 Explanation of symbols 4

2 Introduction 5

3 Model Certi cations 5

4 Tankless Water Heater Accessories 6

5 Pump sizing for circulation 7

5.1 Pressure drop curves 7

5.2 Domestic hot water circulation 8

5.3 Tank loading 9

6 Water Heater Sizing & Speci cations 10

6.1 Sizing tankless water heaters 10

6.2 Tankless Water Heater Speci cations 12

7 Water Quality 14

8 Applications Legend 15

9 Domestic Hot Water Applications 16

9.1 Low volume applications 17

9.2 Whole house applications 18

10 High Volume Potable Water Heating 22

10.1 Cascading unit applications 22

10.2 Parallel unit applications 25

11 Residential Solar Applications 26

11.1 Booster applications 27

12 Commercial Solar Applications 29

13 Commercial Water Heating Applications 30

13.1 Commercial Kitchen applications 31

13.2 Tank loading with domestic hot water

recirculation 32

13.3 Advanced tank loading commercial hot

water system 33

13.4 Common Venting 34

Bosch Thermotechnology Corp.

Data subject to change

|

4

THERM/GREENTHERM Tankless Water Heaters

1 Explanation of symbols

Warnings

Warnings in this document are identi ed by a

warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk if

measures to prevent the risk are not taken.

The following keywords are de ned and can be used in

this document:

f NOTICE indicates that damage to property may occur.

f CAUTION indicates that personal injury may occur.

f WARNING indicates that severe personal injury may

occur.

Applications Manual

f DANGER indicates that severe personal injury or

death may occur.

Important information

Important information in cases where there is no

risk of personal injury or material losses is identi-

ed by the symbol shown on the left. It is bordered

by horizontal lines above and below the text.

Bosch Thermotechnology Corp.Data subject to change

Applications Manual THERM/GREENTHERM Tankless Water Heaters | 5

2 Introduction

This Applications Manual is intended to present some

of the most common applications of the Bosch Therm

tankless water heaters. Application drawings are shown

with both piping and corresponding electrical schematics

where applicable. Auxiliary equipment depicted does not

necessarily represent any one manufacturer or speci c

model number. There are a wide variety of techniques,

practices and piping strategies possible when installing

water heating appliances. It is the responsibility of the

installing contractor to determine the best solution for the

application.

NOTICE: All drawings are conceptual in nature

and do not address all design, installation or

safety considerations. Additional safety and/or

auxiliary equipment may be needed. Drawings

are for reference use by of cials, designers and

licensed installers. It is expected that installers

have adequate knowledge of accepted industry

practices for the equipment, procedures, and

applications involved. It is the responsibiltiy of

the installer to ensure that the installation is in

accordance with local building codes.

3 Model Certi cations

The following are certi cation stamps and explanations

that are speci c to one or more Bosch tankless water

heaters. These certi cations bring the appliances in accordance with the requirements of the National Fuel Gas

Code ANSI Z223.1/NFPA 54.

appliances using gas or other petroleum fuel.

appliances using gas or other petroleum fuel.

Energy Star quali ed (models C 1050 ES,

C 950 ES, 940 ES, 940 ESO, 830 ES, 660 EF,

660 EFO).

Certi ed to applicable U.S. standards for

Certi ed to applicable Canadian standards for

Although this manual covers many common applications

for our products, system possibilities are virtually endless.

Should you encounter an application that is not covered

in this manual or have any questions regarding any of its

content, we encourage you to contact your local sales

representative or us directly at Bosch Thermotechnology

Corp.

This manual is not a substitute for any of the appliance

installation manuals. All speci cations are subject to

change.

NOTICE: Installation must conform with local

codes or, in the absence of local codes, the

National Fuel Gas Code ANSI Z223.1/NFPA 54.

In Canada: Installation must conform with CGA

B149.(1,2) INSTALLATION CODES and/or local

installation codes.

National Sanitation Foundation International

certi ed.

Energy ef ciency certi ed by AHRI -

Air-Conditioning, Heating, and

Refrigeration Institute.

R

For model C 1210 ESC only.

This model is built in accordance

with the requirements of the ASME

Boiler and Pressure Vessel Code and

received the Certi cate of

Authorization from the National

Board. The heat exchanger has the

NB and the HLW stamps.

Other certi cations:

f Meets California Energy Commission (CEC) standards.

Bosch Thermotechnology Corp.

f Approved by the Commonwealth of Massachusetts.

f South Coast Air Quality Management - 2012

For Models 830 ES, 940 ES, 940ESO, C 950 ES, C 1050 ES,

C 1210 ES and C 1210 ESC only

.

Data subject to change

|

6

THERM/GREENTHERM Tankless Water Heaters

Applications Manual

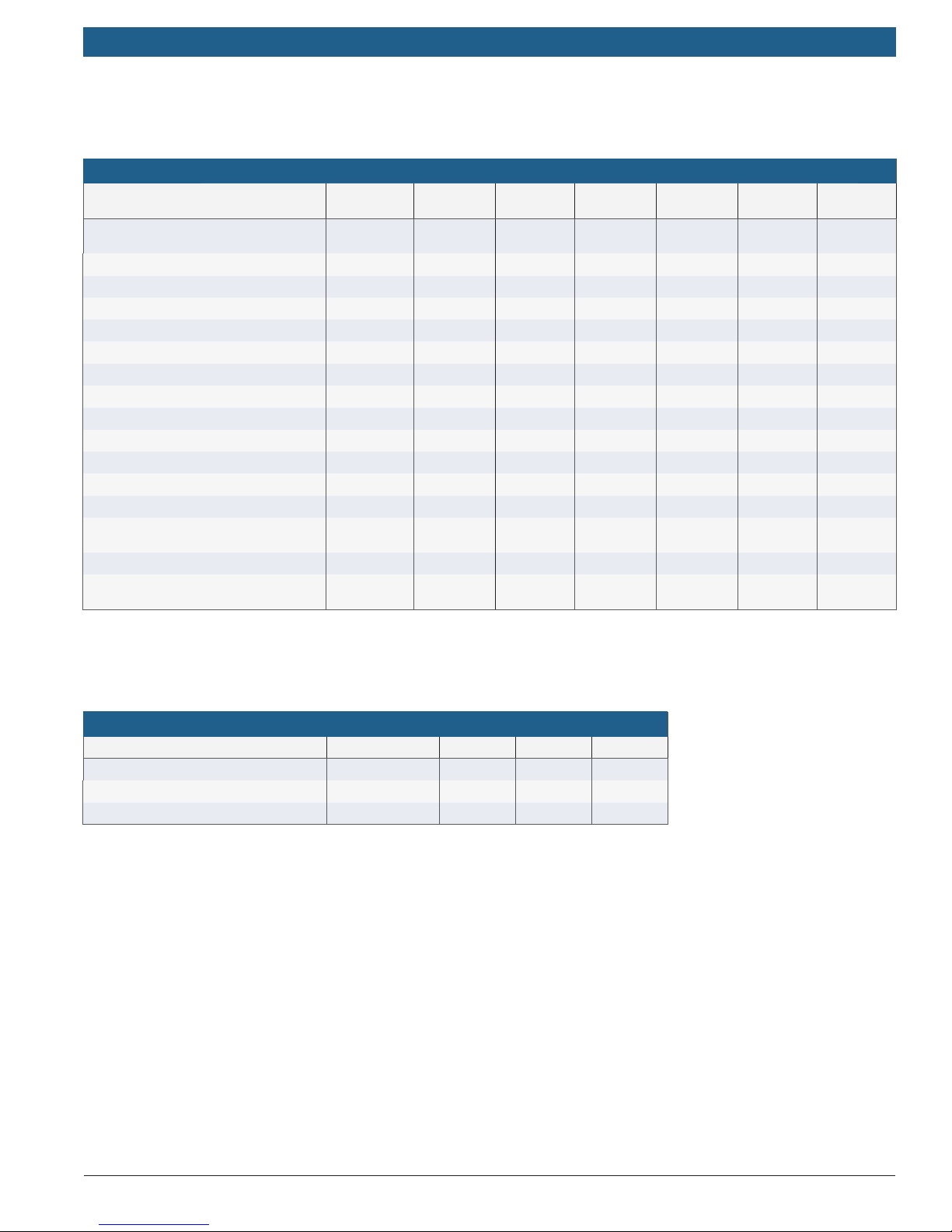

4 Tankless Water Heater Accessories

Available accessories

Part number

Concentric vent/air intake kit stainless

steel

Concentric termination kit - PVC* 196016

Exhaust/intake bird screen - PVC L2594

Vertical vent kit ES VVT

Horizontal vent kit 4TWHVK3SII

Outdoor kit for Therm 7709003913

Wireless remote control TSTAT2

Intelligent cascading kit 7709003962

High temperature kit 7736500074

PVC Condensing drain tee† 196061

Condensate neutralization cartridge kit¹ JM-2KIT

Isolation valve kit with PRV ES ISO KIT

Pipe Cover W2-3 Silver PTPCES

Recess Box for 830 ES to C 1210 ES

models

Polypropylene up and out venting kit 7738003210

Polypropylene common venting system

for up to 4 units

Meets ULC S636 Standard

*

Also included in the Concentric termination kit (196016)

†

¹ Condensate neutralization cartridge kit may be used for non-condensing product vent systems

ESHCK

7736500043

see vent

catalog

C 1210 ES /

C 1210 ESC

C 1050 ES C 950 ES 940 ES 940 ESO 830 ES

Available accessories

Part number 520 HN 520 PN 330 PN

Freeze prevention kit 7709003775

Isolation valve kit with PRV ES ISO KIT

Power vent w/back draft apper AQ4

Bosch Thermotechnology Corp.Data subject to change

Applications Manual THERM/GREENTHERM Tankless Water Heaters | 7

5 Pump sizing for circulation

For direct DHW recirculation and tank loading

The following section outlines pump sizing for domestic

hot water recirculation and tank loading. Only models

approved for such applications are listed in this section.

f Pump must be bronze or stainless steel and designed

for potable water systems.

f Size the pump according to the pressure drop curve of

your Therm model (fig. 1 below) and the loop pressure

drop tables.

f Maximum flow allowed for tank loading through the

pump loop is 5 GPM.

f Maximum flow recommended for direct DHW

recirculation is 3 GPM.

f Maximum flow allowed for mini-tank DHW recirculation

is 2 GPM.

applications:

Run the system for 30 minutes to remove debris

from the plumbing. Then remove the unit‘s inlet

water lter to decrease pressure drop through

the system. If the inlet water lter, when removed, contains debris, it is recommended to install

a 40 mesh Y-strainer (installer supplied) on the

cold water inlet.

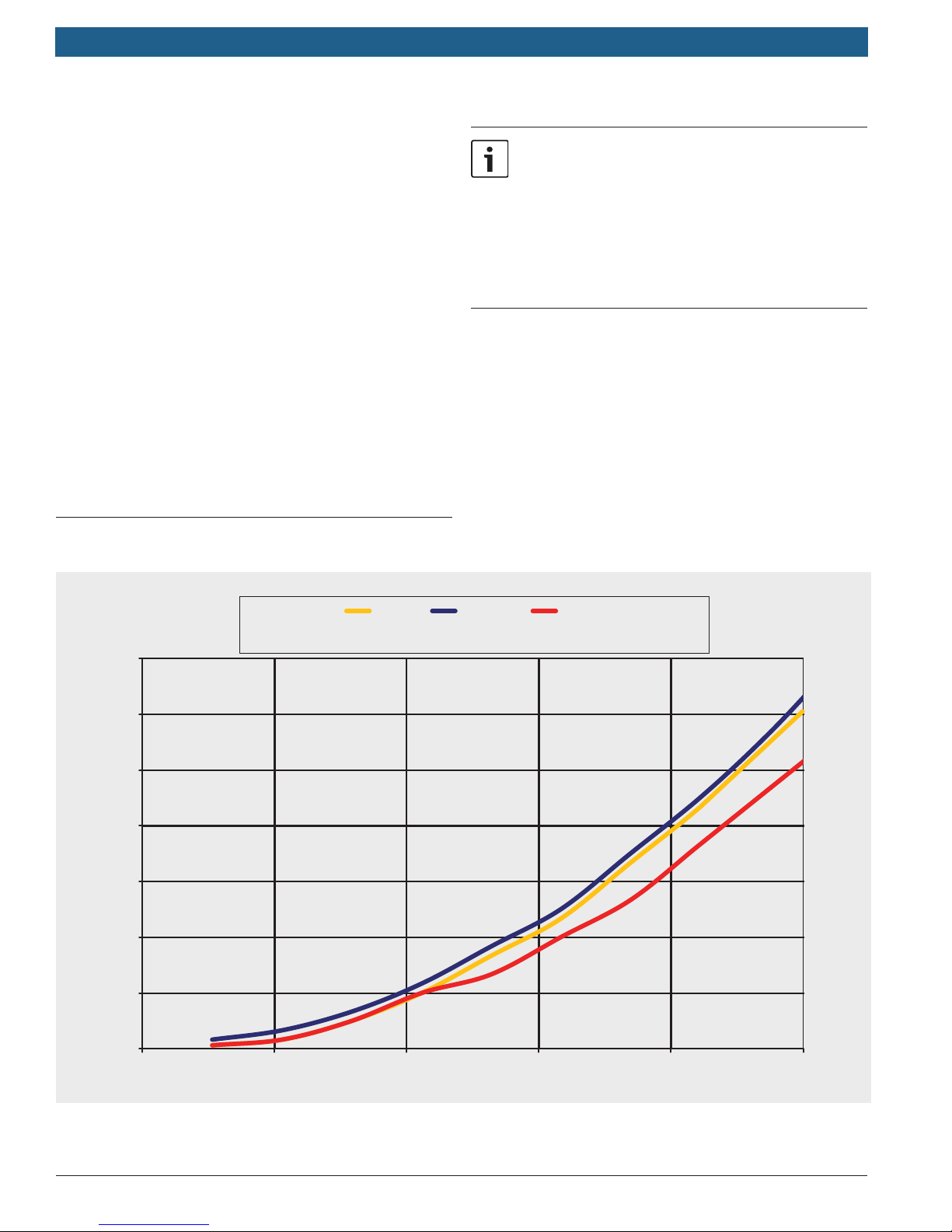

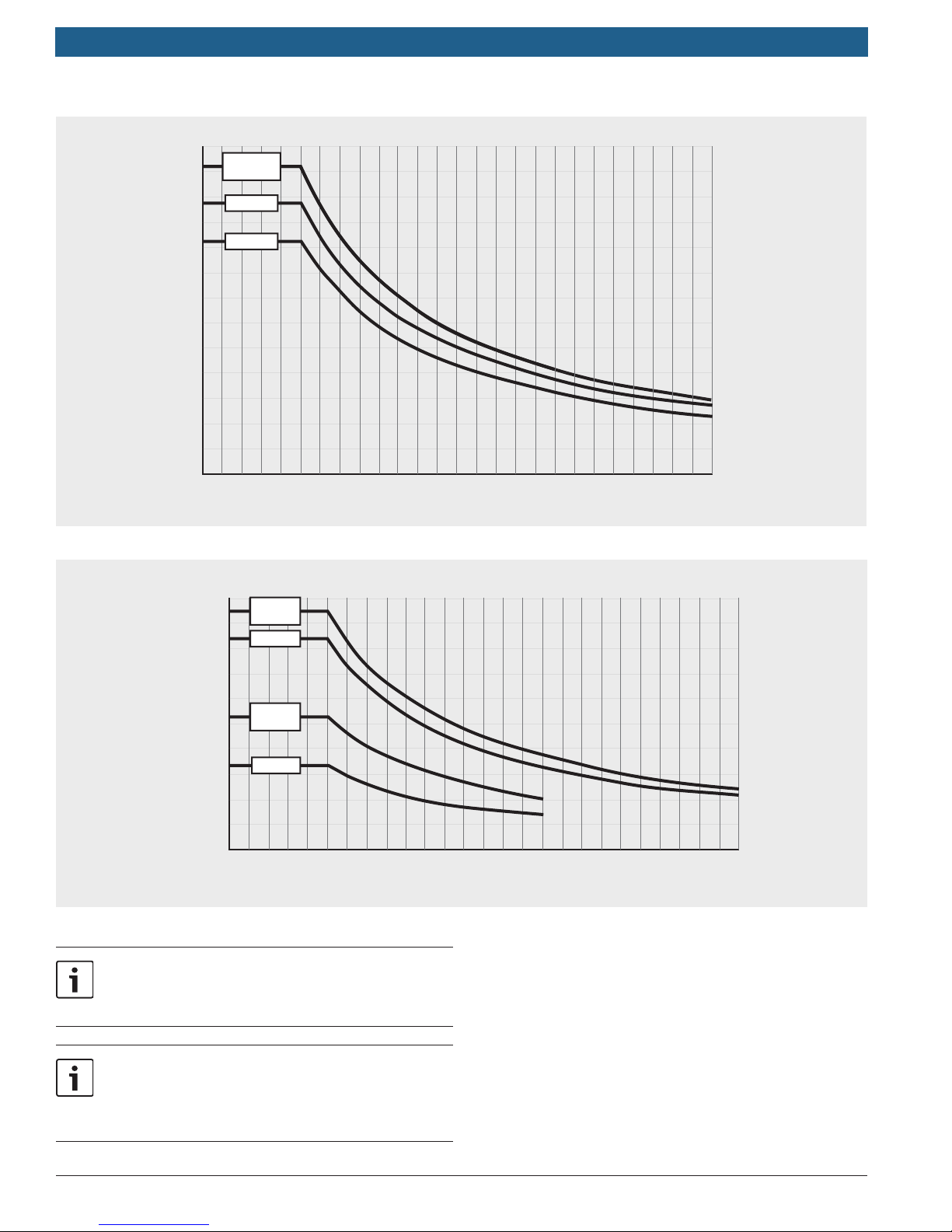

5.1 Pressure drop curves

70

60

50

40

30

Pressure (Feet of Head)

20

C 950 ES

C 1050 ES

C 1210 series

830 ES,

940 ES / ESO

10

0

F

igure 1 Pressure drop curves

Bosch Thermotechnology Corp.

0.50.40.30.20.10.0

Flow (GPM)

Data subject to change

|

8

THERM/GREENTHERM Tankless Water Heaters

Applications Manual

5.2 Domestic hot water circulation

5.2.1 Ariston mini-tank DHW recirculation

Reference drawing 9.2.3 on page 20.

If recirculating through an Ariston mini-tank only, use the

smallest pump that will overcome the pressure of the loop.

Recommended ow rate within the range of 1 to 2 GPM.

This method of recirculation maintains warranty.

f The tank and the Therm should be set at roughly the

same temperature.

f An aquastat is required to control the recirculation

pump operation. An aquastat temperature setting of

110° F with a 10° F differential is recommended.

f The recirculation flow must be <2 gpm. Higher flows

will waste energy and can erode the Ariston anode,

requiring frequent anode replacement to maintain its

warranty.

f To minimize energy costs:

1. Insulate all pipes in the recirculation loop.

2. Install a timer or sensor system that will shut the

pump off when hot water will not be used.

f Recirculation loops over 200 feet in total length will

require an electric tank with a larger heating capacity

than the Ariston 8 gallon model.

5.2.2 Direct DHW recirculation

Reference drawing 9.2.4 on page 21.

If the Bosch tankless water heater provides the

heat source for recirculated water , the heat

exchanger warranty is decreased. Please refer

to the installation manual for detailed warranty

period information.

f Direct recirculation flow through the tankless water

heater must be above 1.7 gpm for best performance.

Flow can be verified in the diagnostic menu, mode

P4-3d. Refer to the Diagnostic Menu section of your

Therm installation manual for details.

System conditions vary and each pump must be

sized by a professional to insure performance.

Use only bronze or stainless steel pumps. Do not

use pumps of iron construction as they will oxidize and clog the inlet lter on the appliance.

f When properly installed in a direct recirculation

application the Therm will regulate water temperature

in a recirculation loop within a 20° F range. A

thermostatic mixing valve is required after the water

heater if no other temperature control is used.

f Closer temperature control can also be accomplished

with a recirculation pump aquastat. The Therm

temperature setting must always be at least 14° F

higher than the aquastat cut-out setting.

EXAMPLE:

— Therm temperature setting: 122° F

— Aquastat cut-out temperature setting: 108° F

— To minimize energy costs:

1. Insulate all pipes in the recirculation loop.

2. Install a timer or sensor system that will shut

the pump off when hot water will not be used.

Recirculation Loop Pressure Drop at 2GPM (Feet of Head)

10 ft Pipe 90 Elbow 45 Elbow

½" Type L Copper

¾" Type L Copper

¾" Pex

" Pex

½" Pex

Source: 2009 International Plumbing Code

0.85 0.09 0.05 0.18

0.15 0.03 0.01 0.05

0.25 0.02 N/A 0.03

0.53 0.04 N/A 0.06

1.3 0.12 N/A 0.18

Tee

Branch

EXAMPLE:

Sizing a pump for a 2gpm direct DHW recirc system with a

THERM 940ES and have 150 ft total loop length.

Head Loss Loop Component

9.00 ft 940ES (See Fig.1, page 7)

1.20 ft 80 ft of ¾" copper

5.90 ft 70 ft of ½" copper return

0.24 ft 8 x ¾" 90 elbows

0.10 ft 2 x ¾" Tees (branch)

0.72 ft 8 x ½" 90 elbows

+ 0.18 ft 1 x ½" Tee (branch)

Refer to pump manufacturers ow vs pressure

speci cations to select a pump that can provide ow

between 1.7 gpm and 3 gpm while overcoming the

pressure loss through the Therm and the recirculation

loop. Refer to gure 1 and table... to determine pressure

loss.

17.34 ft Minimum Pump Head at 2.0 gpm

Once the loop head loss has been calculated, use the

pump manufacturer’s performance curves to select the

proper potable water circulator at the required ow rate.

Bosch Thermotechnology Corp.Data subject to change

Applications Manual THERM/GREENTHERM Tankless Water Heaters | 9

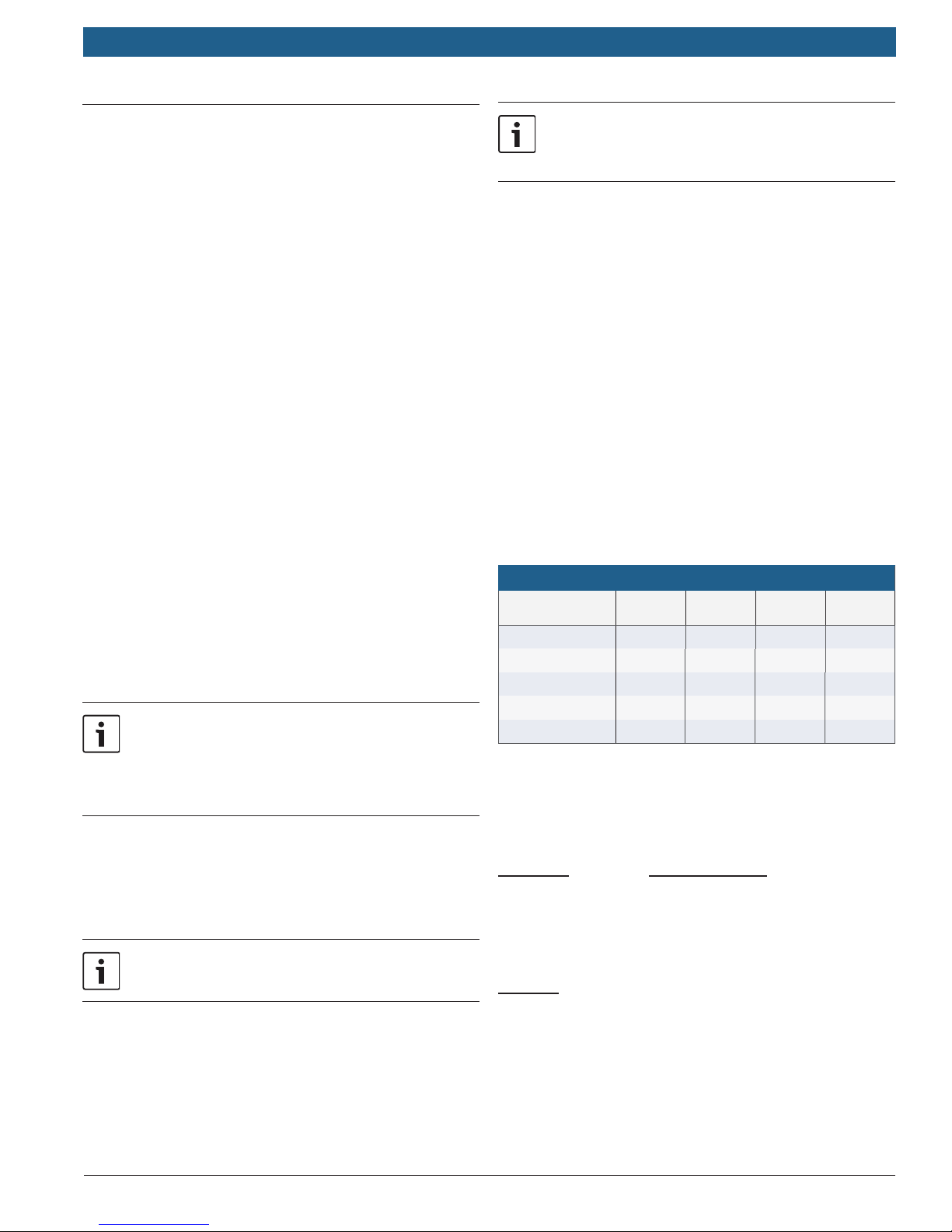

5.3 Tank loading

Refer to drawings 13.2 and 13.3 on pages 32 and 33.

Tank loading pairs tankless water heaters with storage

tanks to maximize peak ow for high demand applications.

A tank load system, because of the added storage, can

provide a high peak ow with fewer tankless units and

lower installed cost.

These guidelines should be followed to maximize system

output:

f Ensure flow through each water heater is between

3.5-5.0 gpm.

f Isolation valves or boiler drains should be installed to

facilitate descaling in applications with hard water.

f For best performance, plumb the system or configure

the tank to draw cold supply water into the water

heater during hot water use.

f Maintain a 20 degree temperature difference between

tankless set-point and desired tank temperature.

f Do not use a cascading kit in a tank loading

application.

f When multiple tankless water heaters are used, the

total equivalent length of piping to each unit should

be kept roughly equal. A reverse return piping scheme

is recommended to equalize flow through each water

heater.

f For tank temperature settings above 120° F, the Therm

C 1210 ESC is recommended. Other high capacity

Therms including the 830 ES, 940 ES/ESO, C 950 ES

and C 1050 ES can be used, but a high temperature

kit (part 7736500074) is required for each. In these

applications a thermostatic mixing valve is required.

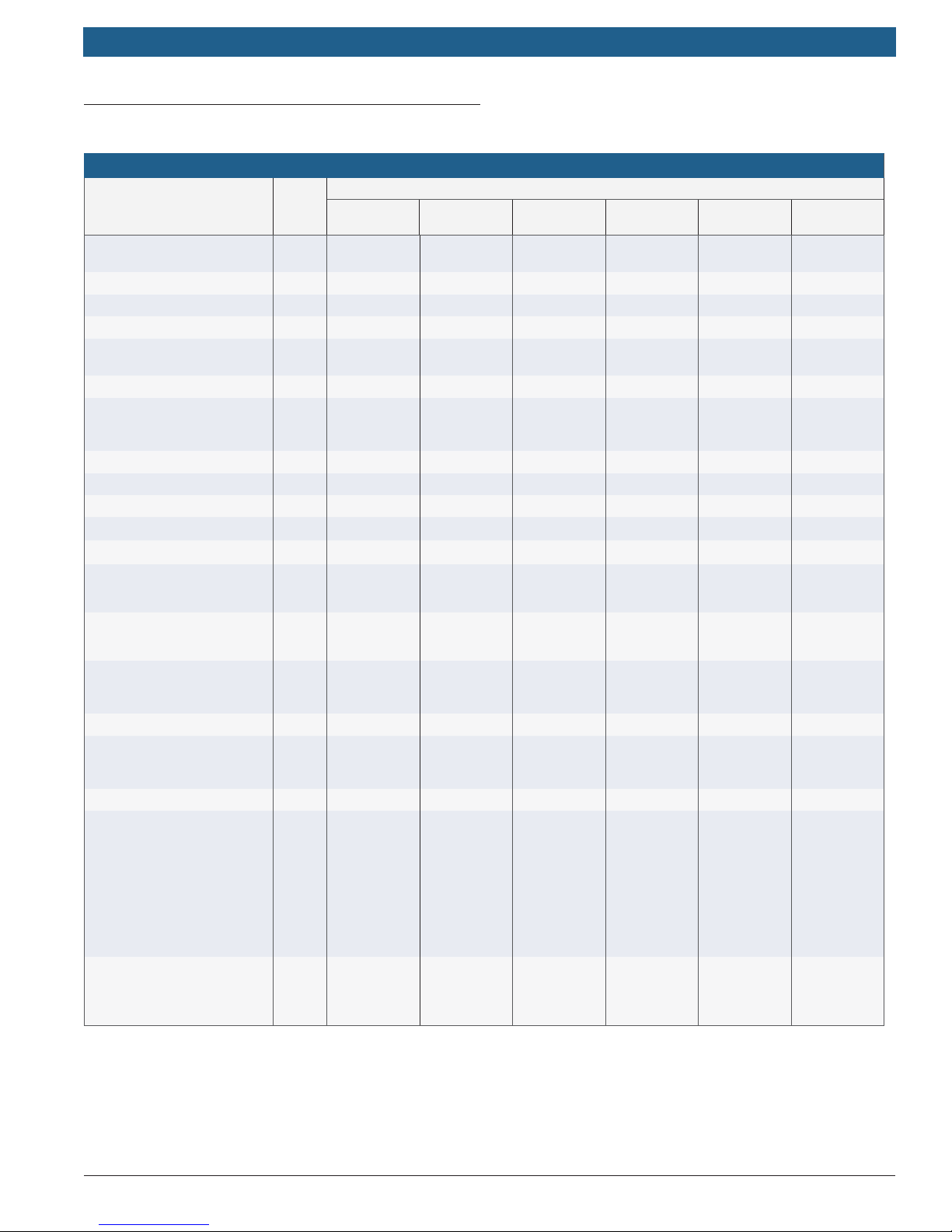

Pressure drop vs. ow*

# of

Units

1 40 feet of head @ 4gpm 32 feet of head @ 4gpm

2 40 feet of head @ 8gpm 32 feet of head @ 8gpm

3 40 feet of head @ 12gpm 32 feet of head @ 12gpm

4 40 feet of head @ 16gpm 32 feet of head @ 16gpm

5 40 feet of head @ 20gpm 32 feet of head @ 20gpm

6 40 feet of head @ 24gpm 32 feet of head @ 24gpm

7 40 feet of head @ 28gpm 32 feet of head @ 28gpm

8 40 feet of head @ 32gpm 32 feet of head @ 32gpm

9 40 feet of head @ 36gpm 32 feet of head @ 36gpm

10 40 feet of head @ 40gpm 32 feet of head @ 40gpm

11 40 feet of head @ 44gpm 32 feet of head @ 44gpm

12 40 feet of head @ 48gpm 32 feet of head @ 48gpm

13 40 feet of head @ 52gpm 32 feet of head @ 52gpm

14 40 feet of head @ 56gpm 32 feet of head @ 56gpm

15 40 feet of head @ 60gpm 32 feet of head @ 60gpm

16 40 feet of head @ 64gpm 32 feet of head @ 64gpm

17 40 feet of head @ 68gpm 32 feet of head @ 68gpm

18 40 feet of head @ 72gpm 32 feet of head @ 72gpm

19 40 feet of head @ 76gpm 32 feet of head @ 76gpm

20 40 feet of head @ 80gpm 32 feet of head @ 80gpm

21 40 feet of head @ 84gpm 32 feet of head @ 84gpm

22 40 feet of head @ 88gpm 32 feet of head @ 88gpm

23 40 feet of head @ 92gpm 32 feet of head @ 92gpm

24 40 feet of head @ 96gpm 32 feet of head @ 96gpm

C 1210 ES / ESC,

C 1050 ES, C 950 ES

940 ES, 940 ESO, 830 ES

EXAMPLE:

Sizing a pump for a 4GPM tank loading DHW system with a

1050ES and a 20 ft total loop length.

Tank Loading Loop Pressure Drop at 4GPM (Feet of Head)

10 ft

Pipe

¾" Type L Copper

1" Type L Copper 0.14 0.04 0.02 0.07

1.25" Type L Copper 0.06 0.02 0.01 0.04

1.5" Type L Copper 0.03 0.01 <0.01 0.02

2" Type L Copper 0.01 <0.01 <0.01 0.01

Source: 2009 International Plumbing Code

* Calculations based on 120°F Set-point temperature, 107°F shower temperature, 2.5 GPM showerhead ow rate, 1.5 GPM sink ow rate,

adequate water pressure and gas supply. Variation from these parameters may alter performance. GPM shown is the hot water ow rate

at

120°F Set-point temperature.

Bosch Thermotechnology Corp.

0.48 0.1 0.03 0.15

90

Elbow

45

Elbow

Tee

Branch

Head Loss Loop Component

39.00 ft 1050es (See Fig.1, page 7)

1.00 ft 20 ft of ¾ copper

0.80 ft 8 x ¾” 90 elbows

+ 0.30 ft 2 x ¾” Tees (branch)

41.10 ft Minimum Pump Head at 4.0 gpm

Once the loop head loss has been calculated, use the

pump manufacturer’s performance curves to select the

proper potable water circulator at the required ow rate.

Data subject to change

O

C

UT

CO

S

S

OKMO

O

S

G

SC

C

|

10

THERM/GREENTHERM Tankless Water Heaters

6 Water Heater Sizing &

Speci cations

This section describes the water heaters available from

Bosch Thermotechnology Corp. and provides a general

overview to the speci cations of each particular model.

More detailed information is contained in the installation

manuals. Download manuals at www.bosch-climate.us.

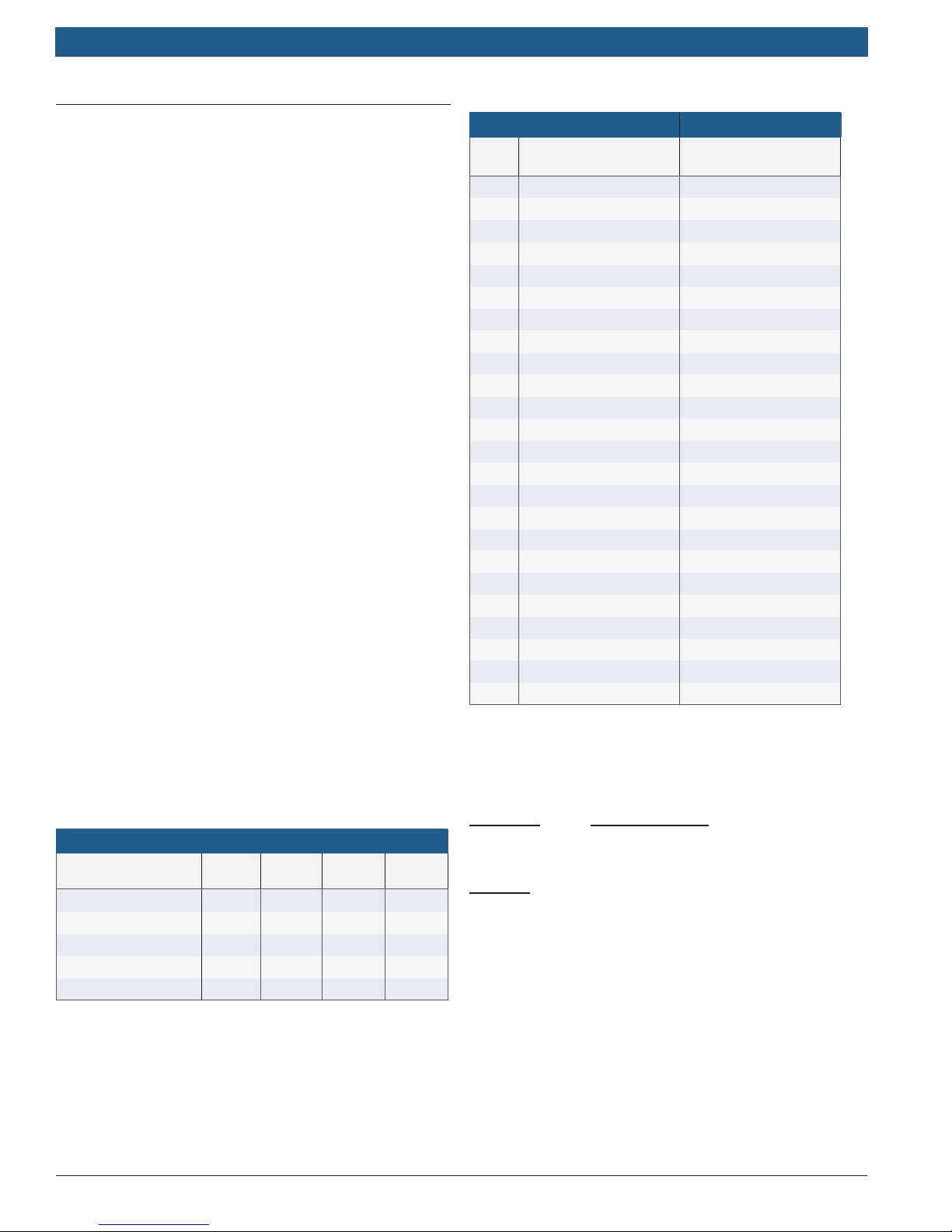

6.1 Sizing tankless water heaters

Rule of thumb sizing

The tables below provide a general rule of thumb when

sizing for most residential applications. For commercial

applications or for a more detailed sizing method, use the

Sizing by Chart instructions below in conjunction with the

charts on the next page.

Sizing by Chart

f Measure the flow rates at each fixture that will be

used simultaneously and add them together. If only

one application will be used at a time measure each

fixture and use the maximum flow rate observed.

Applications Manual

WA

R

OR

NV

CA

A

MT

ID

UT

AZ

ND

MN

D

SD

WY

CO

NM

IA

NE

K

KS

MO

OK

AR

TX

LA

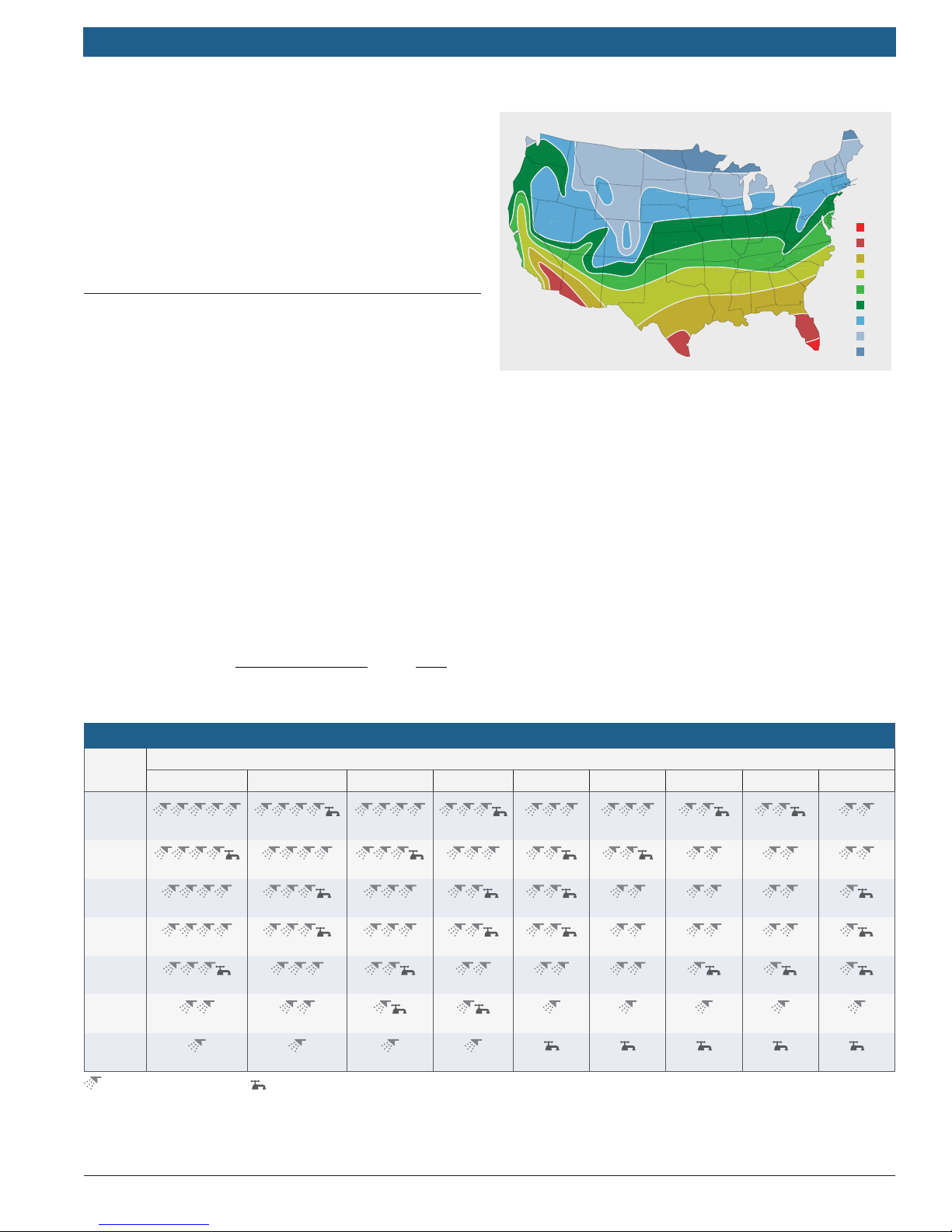

Figure 2 Average ground water temperatures

WI

MI

OH

H

IN

IL

KY

TN

GA

M

MS

AL

VT

NY

PA

VA

WV

N

NC

SC

A

FL

f Using a thermometer, measure the incoming water

temperature. For reference, see average ground water

temperature map. Subtract this temperature from

the desired hot water temperature to get the degree

rise. If the desired hot water temperature is 120F and

incoming temperature is 55F, the desired degree rise

is 65F.

ME

NH

RI

MA

CT

NJ

˚F

DE

77˚

MD

72˚

67˚

62˚

57˚

52˚

47˚

42˚

37˚

f Using a known volume container, record several fill

times. Perform the calculation below to determine the

flow rate (a one gallon fill time of 30 seconds is 2.0

gallons per minute (GPM):

Flow rate (GPM) =

Volume (gallons)

Fill time (sec)

Hot water ow rate at 120°F Set Point temperature

Model

C 1210

ES /

ESC

C 1050

ES

C 950

ES

940 ES

/ ESO

830 ES

520 HN

/ PN

77° 72° 67° 62° 57° 52° 47° 42° 37°

9.8 8.8 8.0 7.3 6.7 6.2 5.8 5.4 5.1

8.5 7.6 6.9 6.3 5.8 5.4 5.0 4.7 4.4

7.7 6.9 6.2 5.7 5.2 4.9 4.5 4.2 4.0

7.7 6.9 6.2 5.7 5.2 4.9 4.5 4.2 4.0

6.7 6.0 5.4 5.0 4.6 4.2 4.0 3.7 3.5

4.3 3.8 3.5 3.2 2.9 2.7 2.5 2.3 2.2

sec

x

60

min

EXAMPLE:

f Required flow rate of 2.0 GPM at a 65F rise.

f Refer to the graphs on page 10.

f Since the demand is above the 330 PN capacity, this

application would require a 520 HN/PN gas tankless

water heater.

Inlet temperature (°F)

330 PN

2.7 2.4 2.2 2.0

Simultaneous Showers Sink Faucet

1.9 1.7 1.6 1.5 1.4

Bosch Thermotechnology Corp.Data subject to change

Applications Manual THERM/GREENTHERM Tankless Water Heaters | 11

13

C 1210 ES/

12

C 1210 ESC

11

C 1050 ES

10

C 950 ES

9

8

Flow

7

Rate

(GPM)

6

5

4

3

2

1

0

10 20 30 40 50 60 70 80 90

Temperature rise (°F)

100 110 120 130 140

Figure 3 Flow rate vs. temperature rise - condensing models

11

10

Flow

Rate

(GPM)

940 ES/

940 ESO

9

830 ES

8

7

6

520 HN/

520 PN

5

4

330 PN

3

2

1

0

10 20 30 40 50 60 70 80 90

Figure 4 Flow rate vs. temperature rise - non-condensing models

Flows above 10 GPM require installation of a

mixing valve to help mitigate pressure drop in the

water heater and plumbing system

100 110 120 130 140

Temperature rise (°F)

Temperature rises above 110 °F or more,

or output temperatures above 140 °F require

either a commercial unit or optional accessories

such as a high temperature kit.

Bosch Thermotechnology Corp.

Data subject to change

|

12

THERM/GREENTHERM Tankless Water Heaters

Applications Manual

6.2 Tankless Water Heater Speci cations

Technical Speci cations

Models

Unit

Gas input BTU/hr

Minimum ow to activate GPM 0.5 0.5 0.5 0.5 0.5 0.5

Maximum ow rate at 35° rise GPM 12.1 10.5 9.2 9.4 9.4 8.3

Maximum ow rate at 90° rise GPM 4.6 3.9 3.6 3.6 3.6 3.6

Thermal ef ciency %

Energy factor N/A .94 .93 .83 .83 .83

Dimensions Inches

Weight LBS 88 74 74 67 67 67

Modulating gas valve Electronic Electronic Electronic Electronic Electronic Electronic

Ignition Electronic Electronic Electronic Electronic Electronic Electronic

Gas connection Inches

Water connections Inches

Inches

NG gas pressure

W.C.

Inches

LP gas pressure

W.C.

Water pressure- static PSI

Electrical supply VAC 120 120 120 120 120 120

Venting options

Venting diameter Inches 3 or 4 3 or 4 3 or 4 3 or 4 N/A 3 or 4

Vent material

Temperature range °F

C 1210 ES /

C 1210 ESC

Max: 225,000

Min: 25,000

NG: 94

LP: 94

H: 30½

W: 17

D: 11¼

C 1050 ES C 950 ES 940 ES 940 ESO 830 ES

Max: 199,000

Min: 19,900

NG: 94

LP: 94

H: 30½

W: 17

D: 11¼

Max: 175,000

Min: 19,900

NG: 93

LP: 93

H: 30½

W: 17

D: 11¼

Max: 199,000

Min: 19,900

NG: 82

LP: 82

H: 30½

W: 17

D: 11¼

Max: 199,000

Min: 19,900

NG: 82

LP: 82

H: 30½

W: 17

D: 11¼

¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT

¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT ¾ Male NPT

of

of

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 145

direct vent,

room-sealed,

combustion

PP common

vent, PP twin

pipe, PVC,

CPVC,

or ABS

(Schedule 40)

100-180°F

(ESC)

100-140°F

(ES)

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 150

direct vent,

room-sealed,

combustion

PP common

vent, PP

up and out

concentric

vent, PP twin

pipe, PVC,

CPVC,

or ABS

(Schedule 40)

100-140°F

100-184°F

(requires HT

kit)

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 150

direct vent,

room-sealed,

combustion

PP common

vent, PP

up and out

concentric

vent, PP twin

pipe, PVC,

CPVC,

or ABS

(Schedule 40)

100-140°F

100-184°F

(requires HT

kit)

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 150

direct vent,

room-sealed,

combustion

Stainless

steel

(AL29-4C)

100-140°F

100-184°F

(requires HT

kit)

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 150

outdoor

installation

only

Outdoor vent

cap supplied

100-140°F

100-184°F

(requires HT

kit)

Max: 175,000

Min: 19,900

NG: 82

LP: 82

H: 30½

W: 17

D: 11¼

Min: 3.5

Max: 10.5

Min: 8.0

Max: 13.0

Min: 30

Min (well): 40

Max: 150

direct vent,

room-sealed,

combustion

Stainless

steel

(AL29-4C)

100-140°F

100-184°F

(requires HT

kit)

Bosch Thermotechnology Corp.Data subject to change

Loading...

Loading...