Page 1

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 9 Ver página 16

3814

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com.

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Page 2

Work Area

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work

area.

• KEEP WORK AREAS CLEAN. Cluttered areas and benches

invite accidents.

• MAKE WORKSHOP CHILDPROOF. with pad lock, master

switches, or by removing starter keys.

• AVOID DANGEROUS ENVIRONMENTS. Don’t use power

tools in damp or wet locations. Keep work area well lit. Do

not expose power tools to rain. Do not use the tool in the

presence of flammable liquids or gases.

Personal Safety

• KNOW YOUR POWER TOOL. Read and understand the

owner’s manual and labels affixed to the tool. Learn its

application and limitations as well as the specific potential

hazards peculiar to this tool.

• DON’T OVERREACH. Keep proper footing and balance at

all times.

• STAY ALERT. Watch what you are doing. Use common

sense. Do not operate tool when you are tired. Do not operate

while under medication or while using alcohol or other drugs.

• DRESS PROPERLY. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts. Roll long sleeves above elbows.

Rubber gloves and non skid footwear are recommended

when working outdoors.

• USE SAFETY EQUIPMENT. ALWAYS WEAR SAFETY

GOGGLES. Dust mask, safety shoes, hard hat or hearing

protection must be used for appropriate conditions. Everyday

eyeglasses only have impact resistant lenses. They are NOT

safety glasses

• GUARD AGAINST ELECTRIC SHOCK. Prevent body

contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures.

•

DISCONNECT TOOLS FROM POWER SOURCE.

When not in

use, before servicing, when changing blades, bits, cutters,

etc.

• KEEP GUARDS IN PLACE. In working order, and in proper

adjustment and alignment.

•

REMOVE ADJUSTING KEYS AND WRENCHES.

When not in

use, before servicing, when changing blades, bits, cutters,

etc.

• AVOID ACCIDENTAL STARTING. Make sure the switch is

in the “OFF” position before plugging in tool.

• NEVER STAND ON TOOL OR ITS STAND. Serious injury

could occur if the tool is tipped or if the cutting tool is

accidentally contacted. Do not store materials on or near the

tool such that it is necessary to stand on the tool or its stand

to reach them.

• CHECK DAMAGED PARTS.Before further use of the tool, a

guard or other part that is damaged should be carefully

checked to ensure that it will operate properly and perform its

intended function. Check for alignment of moving parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should be

properly replaced.

• All repairs, electrical or mechanical, should be attempted

only by trained repairmen. Contact the nearest Bosch Service

Center, Authorized Bosch Service Station or other competent

repair service.

• THE USE OF ANY OTHER ACCESSORIES NOT

SPECIFIED IN THIS MANUAL MAY CREATE A HAZARD.

Accessories that may be suitable for one type of tool, may

become hazardous when used on an inappropriate tool.

Tool Use

• DON’T FORCE TOOL. It will do the job better and safer at

the rate for which it was designed.

• USE THE RIGHT TOOL. Don’t force a small tool or

attachment to do the job of a heavy duty tool. Don’t used tool

for purpose not intended—for example, don’t use a circular

saw for cutting tree limbs or logs.

• SECURE WORK. Use clamps or a vise to hold work. It’s

safer than using your hand and it frees both hands to operate

the tool.

• DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotation of the blade or cutter only.

•

NEVER LEAVE TOOL RUNNING UNATTENDED.

Turn power

off. Don’t leave tool until it comes to a complete stop.

•

USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The table on page 4

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge.

number. The smaller the gauge

, the heavier the cord.

Tool Care

• DO NOT ALTER OR MISUSE TOOL. These tools are

precision built. Any alteration or modification not specified is

misuse and may result in dangerous conditions.

• AVOID GASEOUS AREAS. Do not operate electric tools in

a gaseous or explosive atmosphere. Motors in these tools

normally spark, and may result in a dangerous condition.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for better and safer performance. Follow instructions for

lubricating and changing accessories. Inspect tool cords

periodically and if damaged, have repaired by authorized

service facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free from oil

and grease.

•

Before connecting the tool to a power source (receptacle,

outlet, etc.), be sure voltage supplied is the same as that

specified on the nameplate of the tool. A power source with a

voltage greater than that specified for the tool can result in

serious injury to the user, as well as damage to the tool. If in

doubt, DO NOT PLUG IN THE TOOL. Using a power source

with a voltage less than the nameplate rating is harmful to the

motor

.

“SAVE THESE INSTRUCTIONS”

General Safety Rules — for all Power Tools

-2-

“READ ALL INSTRUCTIONS” Failure to follow the SAFETY RULES identified by BULLET (•)

symbol listed BELOW and other safety precautions, may result in serious personal injury.

WARNING

!

Page 3

-3-

• Keep the lower wheel guard attached and working

properly and the guard in the maximum wheel covering

position over the workpiece in operation. Keep your body

positioned to either side of the wheel, but not in line with the

wheel. It is important to position your body and the guard to

minimize body exposure from the possible fragments of a burst

wheel.

• Abrasive Cut Off Wheels must have a maximum safe

operating speed greater than the “no load RPM” marked on

the tool’s nameplate. Wheels running over the rated speed can

fly apart and cause injury.

• Keep hands away from cutting area and wheel. NEVER

place your hand behind the wheel. Do not attempt to

remove cut material when wheel is moving. Contact with the

spinning wheel may cause serious personal injury.

• Wear proper apparel while using an abrasive cut off

machine. Face shield or at least safety goggles, dust mask,

leather gloves and shop apron capable of stopping small wheel

or workpiece fragments.

• Use only Type 1 abrasive cut off wheels with the correct

size arbor hole. Never use damaged or incorrect wheel

flanges or round nut. Other types of wheels are not intended to

apply load on periphery and may shatter. Wheels with arbor

holes that do not match the mounting hardware of the tool will

run eccentrically, vibrate excessively and will cause loss of

control.

• Do not use a cut off wheel that is larger than the maximum

recommended size for your tool, or worn down damaged

wheels from larger abrasive cut off machines. Wheels

intended for larger tools are not suitable for the higher speed of a

smaller tool, these wheels may easily burst and the fragments

strike you or bystanders.

• Before each use inspect the cut off wheel for chips and

cracks. Do not use a wheel that may be damaged. Install a

new wheel if tool was dropped. When installing a new wheel

carefully handle individual cut off wheels to avoid chipping

or cracking. Run the tool at no load for one minute, holding

the tool’s cutting head down and in the direction away from

people. Wheels with flaws will normally break apart during

this time. Fragments from a wheel that bursts during operation

will fly away at great velocity possibly striking you or bystanders.

• Do not grind on the side of Type 1 abrasive cut off wheels.

Side forces applied to these wheels may cause them to shatter.

• Always use the vise to clamp the work and properly

support the over-hanging portion or the workpiece level with

the base of the machine. Proper support of workpiece is

important to keep the cut off and over-hanging pieces from

falling and striking the operator.

• Do not “jam” the abrasive wheel into the work or apply

excessive pressure while using this machine. Avoid

bouncing and snagging the wheel, especially when working

corners, sharp edges etc. If the wheel is damaged due to

misuse it may develop cracks and eventually burst or shatter

without warning.

• Keep the depth stop properly adjusted. If the depth stop is

improperly set it may cause the tool to flip over when releasing

the cutting head too quickly or if the depth is set too deep the

wheel may cut into the surface below the base.

• This machine is not intended to be used with Wet Diamond

Wheels. Using water or other liquid coolants with this machine

may result in electrocution or shock. Use of Dry Diamond

Wheels is acceptable.

• Do not use this tool with “Woodcarving” blade or standard

wood cutting toothed blades. These blades are not intended

for this machine and can create loss of control during use.

• This tool and abrasive wheel are not intended to cut wood

or wood products. Abrasive wheels cut by grinding or fretting

while in work piece with the embedded grit in the wheel, these

grits may grab wood and cause loss of control or could cause

the wood to burn due to friction heating.

• Do not set or mount the tool on a flammable surface or use

the abrasive cut off machine near flammable materials.

During operation the wheel ejects sparks and hot chips from

grinding on the workpiece, these sparks could ignite flammable

materials.

• Never cut or attempt to cut magnesium with this tool. The

dust generated when cutting magnesium is highly flammable

and may be explosive under certain conditions.

• Avoid overloading the motor and prevent burn-out

especially when cutting large cross sectional pieces, apply

light pressure on the handle during cutting. If any sign of

smoke is evident at the air vents, immediately discontinue

the use of the tool. Electric shock is possible if motor is

overloaded and burns out.

• Regularly clean the tool’s air vents by compressed air.

Excessive accumulation of powdered metal inside the motor

housing may cause electrical failures.

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry

products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

“READ ALL INSTRUCTIONS” Failure to follow the SAFETY RULES identified by BULLET (•) symbol

listed BELOW and other safety precautions, may result in serious personal injury.

WARNING

!

Bench Top Abrasive Cut-Off Machine Safety Rules

“SAVE THESE INSTRUCTIONS”

WARNING

!

Page 4

-4-

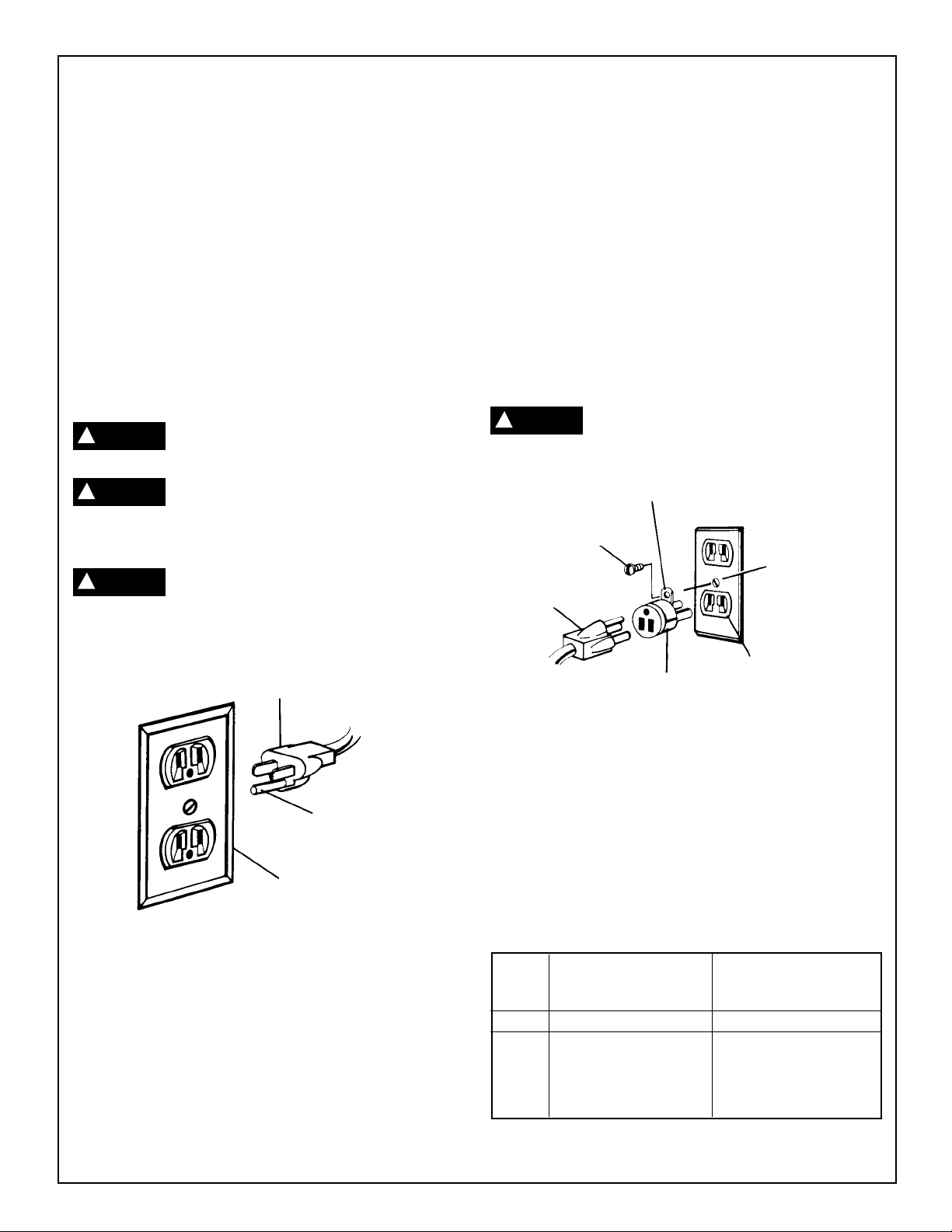

Grounding Instructions For Tools

With Three Prong Plugs

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of

electric shock.

Connection To A

Power Source

This machine must be grounded while in use to protect the

operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet

protected by a 15-amp dual element time delay fuse or circuit

breaker.

Not all outlets are properly grounded. If you are not sure that

your outlet, as pictured below, is properly grounded; have it

checked by a qualified electrician.

To avoid electric shock, do not touch the metal

prongs on the plug when installing or removing

the plug to or from the outlet.

Failure to properly ground this power tool can

cause electrocution or serious shock,

particularly when used near metal plumbing or other metal

objects. If shocked, your reaction could cause your hands to hit

the tool.

If power cord is worn, cut or damaged in any

way, have it replaced immediately to avoid

shock or fire hazard.

Your unit is for use on 120 volts; it has a plug that looks like the

one below.

This power tool is equipped with a 3-conductor cord and

grounding type plug, approved by Underwriters Laboratories

and the Canadian Standards Association. The ground conductor

has a green jacket and is attached to the tool housing at one end

and to the ground prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type outlet as

shown.

If the outlet you are planning to use for this power tool is of the

two-prong type, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Use an adapter as

shown and always connect the grounding lug to known ground.

Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

It is recommended that you have a qualified electrician replace

the TWO-prong outlet with a properly grounded THREE-prong

outlet.

An adapter as shown below is available for connecting plugs to

2-prong receptacles.

The green grounding lug extending from the

adapter must be connected to a permanent

ground such as a properly grounded outlet box.

NOTE: The adapter illustrated is for use only if you already have

a properly grounded 2-prong receptacle. Adapter is not allowed

in Canada by the Canadian Electrical Code.

The use of any extension cord will cause some loss of power. To

keep this to a minimum and to prevent overheating and motor

burn-out, use the table below to determine the minimum wire

size (A.W.G.) extension cord. Use only 3-wire extension cords

which have 3-prong grounding type plugs and 3-pole

receptacles which accept the tool’s plug.

Extension Cords

RECOMMENDED SIZES OF EXTENSION CORDS

DANGER

!

DANGER

!

WARNING

!

3-PRONG PLUG

GROUNDING PRONG

ALWAYS USE A

GROUNDED

OUTLET

3-PRONG

PLUG

SCREW

GROUNDING LUG

2-PRONG RECEPTACLE

ADAPTER

WARNING

!

MAKE SURE THIS

IS CONNECTED

TO A KNOWN

GROUND

Tool’s

Ampere

Rating

120 VOLT A.C. TOOLS

Cord Length in Feet

Cord Size in A.W.G.

240 VOLT A.C. TOOLS

Cord Length in Meters

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

“SAVE THESE INSTRUCTIONS”

Page 5

-5-

2

TRIGGER SWITCH

1

SPINDLE LOCK

4

WHEEL GUARD

3

ABRASIVE WHEEL

7

ADJUSTABLE

VISE STOP

8

QUICK RELEASE

LEVER

10

WRENCH AND

STORAGE

6

HOLD DOWN

CHAIN

11

BASE

9

LOCK NUT

9

DEPTH STOP

ADJUSTMENT

BOLT

AIR VENTS

CORD

5

HANDLE

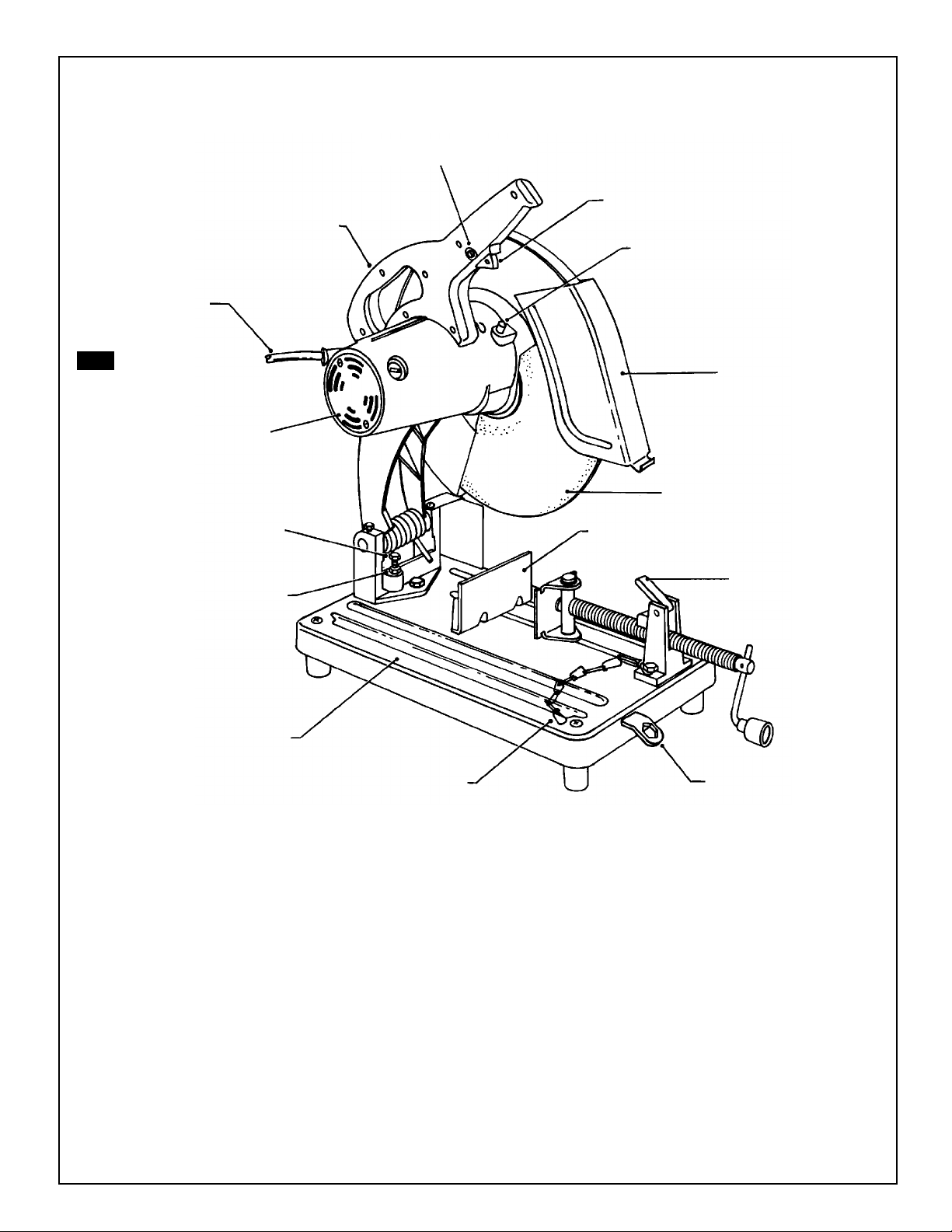

FIG. 1

Introduction

2

"LOCK-ON" BUTTON

Your new Abrasive Cutoff Machine is designed, engineered, and

built for heavy-duty cutting. It’s a high performance tool with all

the operating features that will allow you to easily complete your

cutting requirements.

1. SPINDLE LOCK . . .

For changing wheels easily.

2. LOCKING TRIGGER SWITCH . . .

For operators convenience.

3. 14" WHEEL . . .

Cuts bundles of standard steel drywall studs in one pass.

4. WHEEL GUARD . . .

For operators protection, should always be lowered in place and

working properly during cutting operation.

5. HANDLE . . .

Large handle for easy carrying.

6. HOLD DOWN CHAIN . . .

For easier carrying.

7. ADJUSTABLE VISE STOP . . .

Swivels 0º to 45º for angle cuts.

8. QUICK RELEASE LEVER . . .

For quick and easy clamping.

9. ADJUSTABLE DEPTH STOP . . .

For setting wheel to desired depths of cut.

10. WRENCH AND STORAGE AREA . . .

Your tool is equipped with a double ended wrench. The large

end of wrench is for the vise adjustment, or for removing or

installing wheels. The small end of wrench is used for the depth

stop adjustment bolt. The wrench also can be stored in a

convenient storage area in the base of your tool.

11. BASE . . .

Large base for more stability.

Page 6

-6-

Operating Instructions

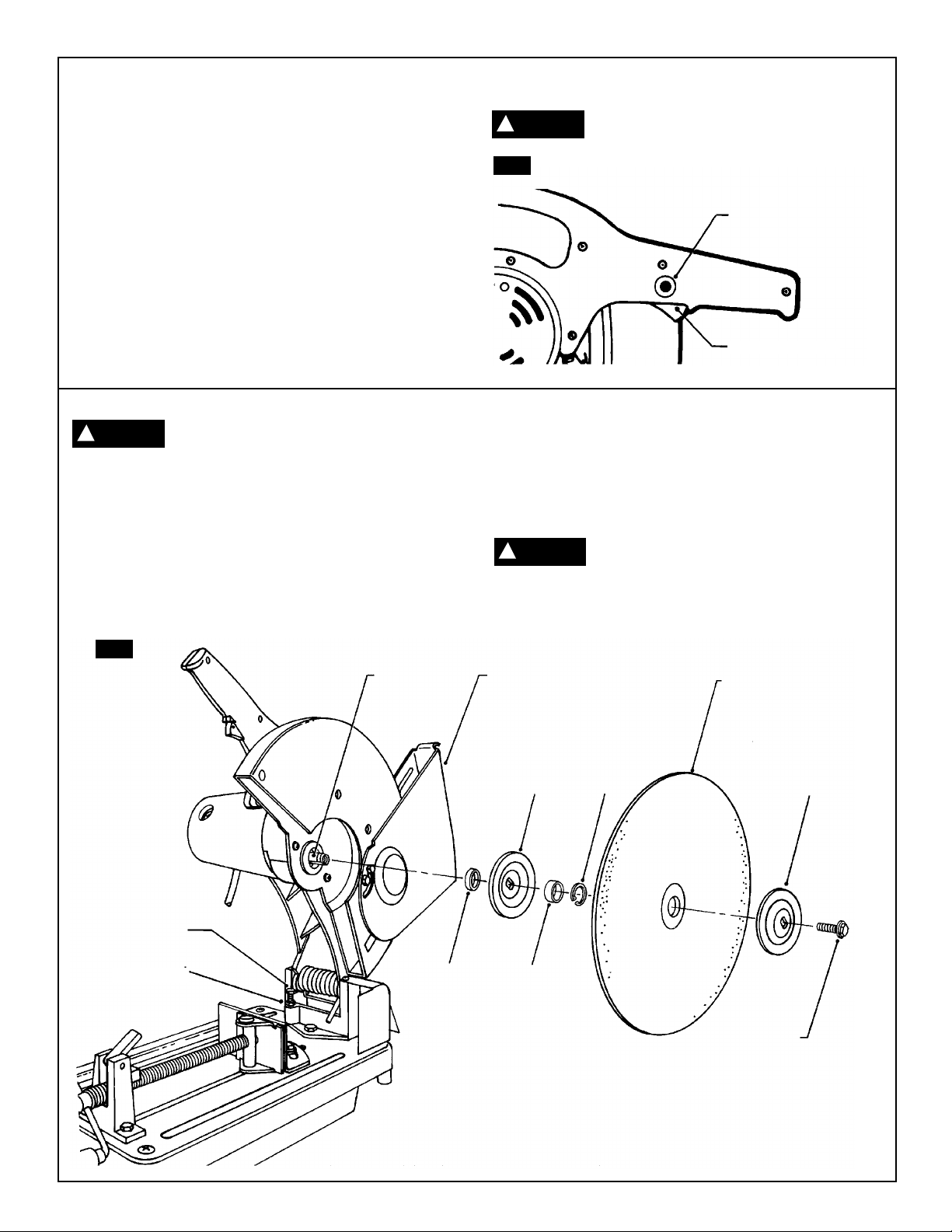

To prevent serious personal injury, always disconnect the plug for the power source before changing wheels, or

making any adjustments on the tool.

1. Raise wheel guard as shown in (Fig. 3), push in spindle lock

(Fig. 1), and loosen the hex head bolt in the center of abrasive

wheel by rotating counter-clockwise with the wrench provided.

2. Remove the hex head bolt, outside flange and abrasive wheel

(Fig. 3).

3. Carefully install the new abrasive wheel onto the spindle shaft

and replace outside flange and hex head bolt.

4. Press in spindle lock and tighten hex bolt with the wrench

provided (ATTENTION: DO NOT OVERTIGHTEN).

Whenever replacing a wheel, always adjust the

depth stop bolt to prevent the wheel from

cutting into the surface the tool is resting on. Failure to make this

adjustment may result in serious personal injury.

Removing and Installing Wheels

TRIGGER SWITCH WITH “LOCK-ON” BUTTON

Your tool can be turned “ON” or “OFF” by squeezing or

releasing the trigger. Your tool is also equipped with "Lock-ON"

button, located on the left side of the trigger handle, that allows

for continuous operation without holding the trigger. The “LockON” is a convenience for long cutting operations.

NOTE: Switch can accommodate a padlock with a shackle of

up to 3/16” in diameter (not provided with tool) to prevent

unauthorized use.

TO LOCK SWITCH ON: Squeeze trigger, depress button and

release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger and release it

without depressing the “Lock-ON” button.

If the “Lock-ON” button is continuously being

depressed, the trigger cannot be released.

WARNING

!

WARNING

!

WARNING

!

"LOCK-ON" BUTTON

TRIGGER SWITCH

SPINDLE

SHAFT

WHEEL

GUARD

INSIDE

FLANGE

RETAINING

RING

ABRASIVE

WHEEL

OUTSIDE

FLANGE

HEX HEAD

BOLT

ADAPTER

(THICKER)

SPACER

(THINNER)

DEPTH STOP

ADJUSTMENT BOLT

LOCK NUT

FIG. 2

FIG. 3

Page 7

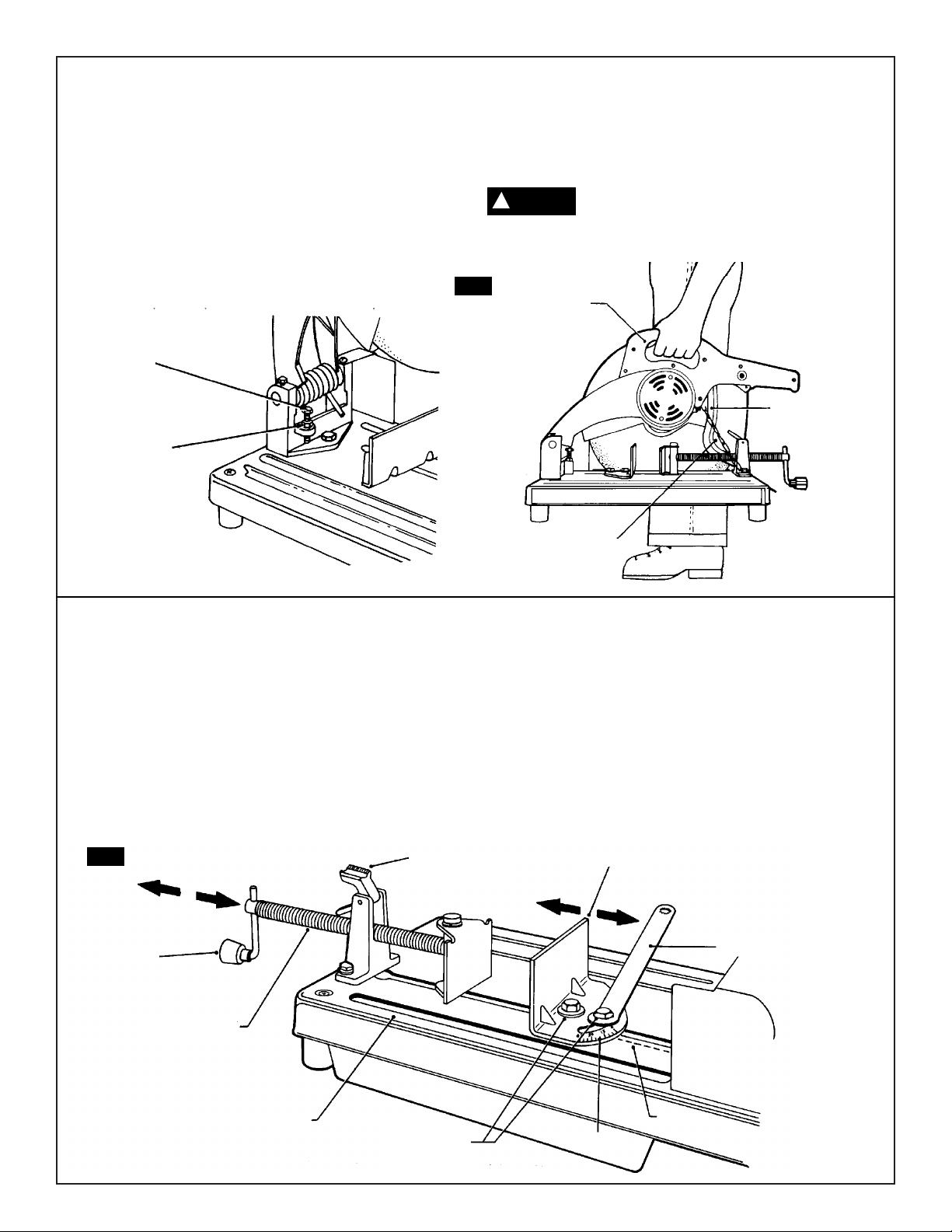

ADJUSTABLE DEPTH STOP BOLT

Your tool is equipped with a depth stop bolt. As the wheel

wears, or when replacing a wheel it will be necessary to make

this adjustment.

TO RAISE WHEEL, Loosen nut on depth stop bolt and rotate

bolt counter-clockwise with the wrench provided.

TO LOWER WHEEL, rotate depth stop bolt clockwise. Attention:

To maintain adjustment, securely tighten nut on the depth stop

bolt with the wrench provided.

CARRYING THE TOOL

1. Lower arm as far as it will go, and attach the hold down chain

to the hook provided and release tension on arm.

2. Raise the depth stop adjustment bolt until the bolt touches

the arm as shown in (Fig. 4) to prevent any movement or

bouncing of the arm.

Be certain that the hold down chain is tightly

secured to the base and arm for transporting. If

the abrasive cut off machine is carried in the open position the

depth stop may be damaged.

-7-

CHANGING CUTTING ANGLE

1. Loosen the vise stop adjustment bolts with the wrench

provided, (Fig. 5), DO NOT REMOVE.

2. Align desired angle on vise stop scale with index line in base,

and securely tighten bolts with the wrench provided.

OPENING ADJUSTMENT

1. Loosen vise stop adjustment bolts with the wrench provided

(Fig. 5), DO NOT REMOVE.

2. Slide vise stop forward or backward to desired location, and

securely tighten bolts with the wrench provided.

QUICK RELEASE LEVER

To release work, turn crank to loosen, lift quick release lever up

(Fig. 5), and pull screw shaft away from work.

To lock work, push screw shaft toward work, lower quick release

lever and turn crank clockwise to tighten.

MAXIMUM CUTTING DEPTH

To obtain maximum cutting depth, position vise stop so material

being cut is approximately centered under wheel, when wheel is

lowered all the way down.

Adjusting the Vise

DEPTH STOP

ADJUSTMENT

BOLT

LOCK NUT

HANDLE

HOOK

HOLD DOWN

CHAIN

CRANK

SCREW SHAFT

BASE

VISE STOP

ADJUSTMENT

BOLTS

SCALE

INDEX

LINE

WRENCH

VISE STOP

QUICK RELEASE

LEVER

FIG. 4

FIG. 5

CAUTION

!

Page 8

Maintenance

-8-

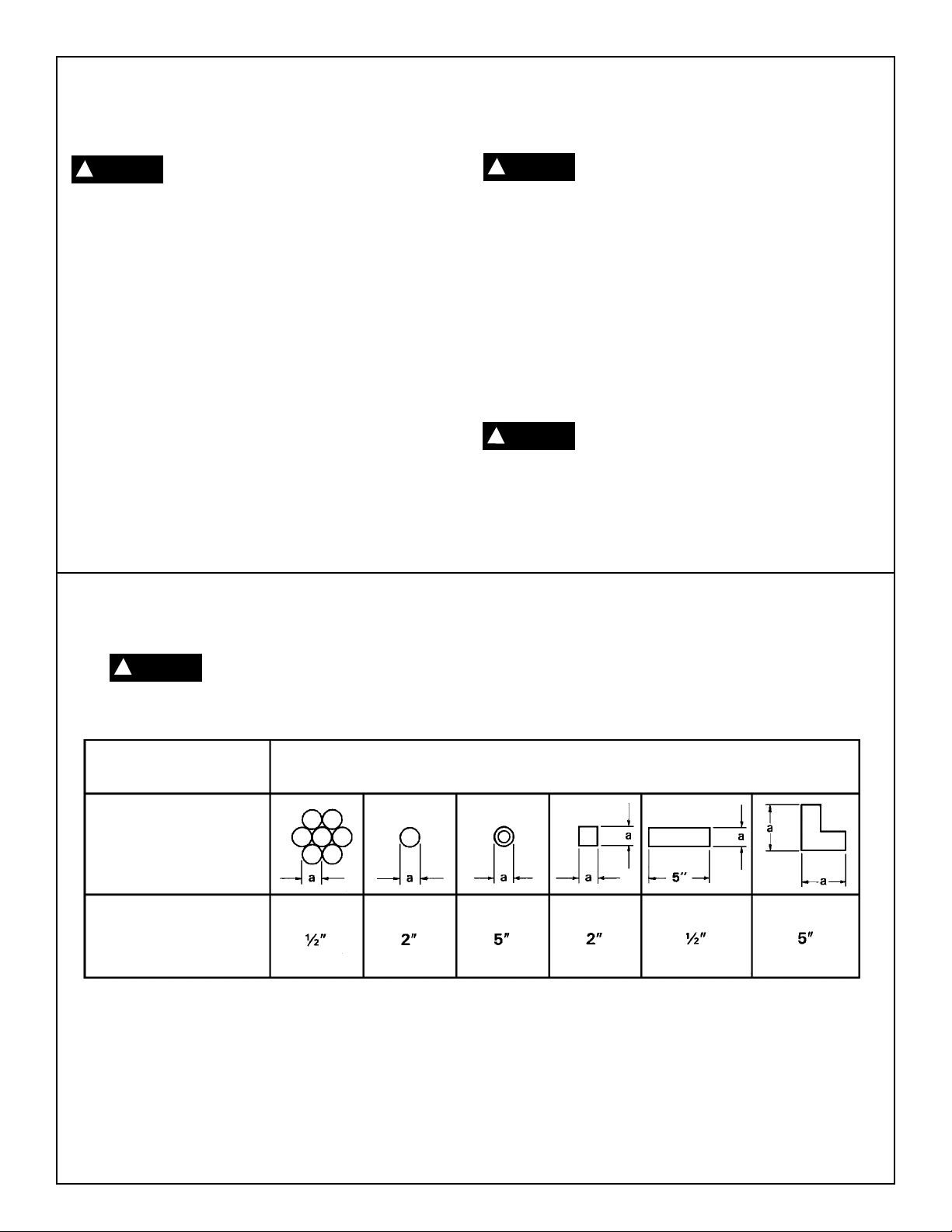

RECOMMENDED CUTTING CAPACITY:

Use of this tool beyond recommended capacities may lead to

motor burn-out and possible electric shock.

Service

Preventive maintenance performed by unautho-

rized personnel may result in misplacing of internal wires and components which could cause serious hazard.

We recommend that all tool service be performed by a Bosch

Factory Service Center or Authorized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use.

It is recommended that tools with gears be regreased with a

special gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered

for many hours of dependable service. To maintain peak

efficiency of the motor, we recommend every two to six months

the brushes be examined. Only genuine Bosch replacement

brushes specially designed for your tool should be used.

BEARINGS

After about 300-400 hours of operation, or at every second brush

change, the bearings should be replaced at a Bosch Factory

Service Center or Authorized Bosch Service Station. Bearings

which become noisy (due to heavy load or very abrasive material

cutting) should be replaced at once to avoid overheating or motor

failure.

Cleaning

To avoid accidents always disconnect the tool

from the power supply before cleaning or performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when

cleaning tools with compressed air.

After each use disconnect the plug from the power source,

remove the wheel and washers to wipe deposits of dust from

housing and wheel guards. The lower wheel guard should be

wiped occasionally with a clean cloth and mild soap to prevent

deterioration from oil and grease. After cleaning check operation

and condition of the lower wheel guard to make certain it is

functional for next use.

Ventilation openings and switch levers must be kept clean and

free of foreign matter. Do not attempt to clean by inserting pointed

objects through openings.

Certain cleaning agents and solvents damage

plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

Applicable Wheel

Dimensions

355 mm (14") outer diameter x less than 4.5 mm (3/16")

thickness x 25.4 mm (1") hole diameter

Workpiece

Configuration

(Cross-Section)

Maximum

Cutting

Capacity

(a)

Page 9

Zone de travail

• NE LAISSEZ PAS LES ENFANTS S’APPROCHER. Ne laissez aucune

personne entrer en contact avec l’outil ou le cordon de rallonge. Tout

visiteur doit se tenir à une distance suffisante de la zone de travail.

• ASSUREZ-VOUS QUE VOTRE ZONE DE TRAVAIL EST BIEN DÉGAGÉE.

Des lieux et des établis encombrés multiplient les risques d’accident.

• RENDEZ L'ATELIER À L'ÉPREUVE DES ENFANTS à l'aide de cadenas

ou d'interrupteurs principaux, ou en retirant les clés du démarreur.

• NE TRAVAILLEZ PAS DANS UN ENVIRONNEMENT DANGEREUX. Un

outil électrique ne doit jamais être employé dans un endroit humide ou

mouillé, ni être exposé à la pluie. Éclairez bien les lieux où vous travaillez.

N’utilisez pas l’outil en présence de liquides ou de gaz inflammables.

Sécurité de l’utilisateur

• FAMILIARISEZ-VOUS AVEC VOTRE OUTIL. Lisez attentivement le

manuel de l’utilisateur et les étiquettes collées sur l’outil, afin de bien les

comprendre. Vous devez connaître aussi bien les possibilités et les limites

de l’outil que les dangers éventuels précis qu’il présente.

• GARDEZ TOUJOURS VOTRE ÉQUILIBRE. Assurez-vous que vous ne

risquez pas de trébucher ou de perdre l’équilibre.

• RESTEZ SUR VOS GARDES. Gardez toujours les yeux sur votre travail.

Faites preuve de bon sens. N’utilisez pas l’outil quand vous êtes fatigué, ni

si vous êtes sous l’effet d’un médicament, de l’alcool ou d’une autre

drogue.

• PORTEZ DES VETEMENTS CONVENABLES. Ne portez pas de

vêtements amples ni de bijoux. Pour les cheveux longs, nous

conseillons le port d’un serre-tête. Tenez les cheveux, les vêtements et

les gants à l’écart des pièces mobiles. Les vêtements amples, les

bijoux ou les cheveux longs risquent de s’accrocher dans les pièces

mobiles. Roulez les manches longues au-dessus du coude. Le port de

gants en caoutchouc et de chaussures à semelle antidérapante est

recommandé si vous travaillez à l’extérieur.

• UTILISEZ L’ÉQUIPEMENT DE SÉCURITÉ. PORTEZ TOUJOURS DES

LUNETTES À COQUES LATÉRALES. Un masque anti-poussière, des

chaussures de sécurité, un casque dur ou des protège-oreilles doivent

être utilisés si la situation l’exige.Les lunettes de tous les jours

comportent uniquement des verres résistant aux chocs. Ce NE SONT

PAS des lunettes de sécurité.

• PROTÉGEZ-VOUS CONTRE LES CHOCS ÉLECTRIQUES. Évitez d’entrer

en contact avec les surfaces mises à la terre, telles que tuyaux, radiateurs,

cuisinières et réfrigérateurs, quand vous utilisez l’outil.

• DÉBRANCHEZ LES OUTILS. Quand ils ne servent pas ; avant l’entretien ;

avant de changer les lames, les forets, les couteaux, etc.

• LAISSEZ EN PLACE LES CARTERS DE PROTECTION. Ils doivent être en

bon état, bien réglés et bien alignés.

• ENLEVEZ LES CLÉS DE RÉGLAGE ET SERRAGE. Quand ils ne servent

pas ; avant l’entretien ; avant de changer les lames, les forets, les

couteaux, etc.

• ÉVITEZ LES MISES EN MARCHE ACCIDENTELLES. Assurez-vous que

l’interrupteur est en position « ARRÊT » quand vous branchez l’outil.

• NE MONTEZ JAMAIS SUR L’OUTIL NI SUR SON SOCLE. L’utilisateur

s’expose à de graves blessures s’il renverse l’outil ou s’il entre en contact

avec l’outil de coupe. Ne pas entreposer des objets quelconques, sur

l’outil ou près de celui-ci, de façon à ce qu’il faille monter sur l’outil ou sur

son socle pour les atteindre.

• EXAMINEZ LES PIÈCES ENDOMMAGÉES. Avant de poursuivre votre

travail, examinez soigneusement toute pièce endommagée afin de vérifier

si elle fonctionne toujours correctement et qu’elle remplit la fonction

voulue. Vérifiez que les pièces mobiles sont correctement alignées et bien

assujetties, et remédiez à tout autre problème qui risquerait d’affecter son

fonctionnement. Un carter de sécurité ou toute autre pièce qui serait en

mauvais état doivent être réparés.

• Les réparations électriques ou mécaniques ne doivent être enterprises

que par des techniciens qualifiés. Adressez-vous à votre Centre de service

Bosch le plus proche, à une Station-service Bosch agréée ou à un autre

service de réparation compétent.

• L’UTILISATION DE TOUT AUTRE ACCESSOIRE NON PRÉCISÉ DANS

CE MANUEL PEUT CRÉER UN DANGER. Les accessoires qui peuvent

être adéquats pour un type d’outil peuvent devenir dangereux

lorsqu’ils sont utilisés sur un outil inapproprié.

Utilisation de l’outil

• N’IMPOSEZ PAS DE CONTRAINTES EXCESSIVES À L’OUTIL. Il sera

plus efficace et plus sûr si vous le faites fonctionner au régime pour lequel

il a été conçu.

• EMPLOYEZ L’OUTIL QUI CONVIENT. N’employez pas un outil ou un

accessoire de capacité réduite pour faire un travail exigeant un outil de

grande puissance. N’utilisez pas l’outil pour des travaux autres que ceux

pour lesquels il a été conçu. Par exemple, n’utilisez pas une scie circulaire

pour couper des branches d’arbre ou des rondins.

• ASSUJETTISSEZ BIEN LA PIÈCE SUR LAQUELLE VOUS TRAVAILLEZ.

Maintenez-la en place avec des serre-joints ou un étau. Vous courrez

moins de risques qu’en la tenant à la main, et garderez ainsi les deux

mains libres pour actionner l’outil.

• DIRECTION DE COUPE. Faites avancer l’ouvrage contre une lame ou

autre outil de coupe uniquement dans la direction opposée au sens de

rotation de ces derniers.

• NE VOUS ÉLOIGNEZ JAMAIS DE L’OUTIL SANS L’ARRÊTER. Coupez le

contact et ne vous éloignez pas avant que l’outil ait complètement cessé

de fonctionner.

• UTILISEZ UN CORDON DE RALLONGE APPROPRIÉ. Assurez-vous que

votre cordon de rallonge est en bon état. Lorsque vous utilisez un cordon

de rallonge, assurez-vous d'en employer un de calibre suffisant pour

transporter le courant que votre produit consommera. Un cordon de

dimension insuffisante causera une chute de la tension secteur avec, pour

conséquences, une perte de puissance et une surchauffe. Le tableau de la

page 11 montre la dimension correcte à utiliser suivant la longueur du

cordon et l'intensité nominale indiquée sur la plaque signalétique. En cas

de doute, utilisez le cordon du calibre immédiatement plus élevé. Plus le

calibre est petit, plus le cordon est puissant.

Entretien de l’outil

• NE MODIFIEZ PAS L’OUTIL ET NE LE SOUMETTEZ PAS À UN USAGE

ABUSIF. Cet outil a été fabriqué selon des critères de haute précision.

Toute modification ou transformation non prévue constitue un usage

abusif et risque de présenter un danger.

• ÉVITEZ LES ENDROITS À L’ATMOSPHÈRE CONTAMINÉE PAR DES

GAZ. N’employez pas d’outils électriques dans une atmosphère gazeuse

ou explosive. Les moteurs de ces outils produisent normalement des

étincelles qui risqueraient de présenter un danger.

• PRENEZ SOIN DE VOS OUTILS ET ENTRETENEZ-LES BIEN. En les

gardant bien affûtés et propres, vous en obtiendrez le rendement

maximum dans des conditions optimales de sécurité. Suivez les

instructions pour le graissage ou la pose et le démontage des accessoires.

Inspectez les cordons d’alimentation à intervalles réguliers et, s’ils sont

endommagés, faites-les réparer à un centre de service après-vente

autorisé. Inspectez périodiquement les cordons de rallonge et remplacez

ceux qui ont été endommagés. Gardez les poignées des outils sèches,

propres et exemptes de toute trace d’huile ou de graisse.

• Avant de raccorder votre outil à une source de courant (prise de courant,

etc.), assurez-vous que la tension est bien la même que celle indiquée sur

la plaque d’identification de l’outil. Le branchement d’un outil sur une

source de courant ayant une tension supérieure à celle prescrite par le

fabricant présente des risques de dommages corporels graves pour

l’utilisateur et peut causer des dégâts à l’outil. En cas de doute, NE

BRANCHEZ PAS L’OUTIL SUR UNE PRISE DE COURANT. L’utilisation

d’une source de courant ayant une tension inférieure à celle indiquée sur

la plaque d’identification peut endommager le moteur.

« CONSERVEZ CES INSTRUCTIONS »

Règles générales de sécurité — pour tous les outils motorisés

-9-

« LISEZ ATTENTIVEMENT TOUTES LES INSTRUCTIONS ». Faute d’observer les RÈGLES DE SÉCURITÉ précédées d’un point noir (•) et les

autres consignes du présent manuel risque de vous exposer à de graves blessures.

AVERTISSEMENT

!

Page 10

-10-

« LISEZ ATTENTIVEMENT TOUTES LES INSTRUCTIONS ». Faute d’observer les RÈGLES DE SÉCURITÉ précédées d’un point noir (•) et les

autres consignes du présent manuel risque de vous exposer à de graves blessures.

AVERTISSEMENT

!

• Gardez le protecteur de meule inférieur fixé et en bon état de marche et

le protecteur en position de couverture maximale de meule par-dessus

l'ouvrage en cours d'utilisation. Gardez votre corps positionné d'un côté

ou de l'autre de la meule, mais non dans le prolongement de celle-ci. Il

importe de positionner votre corps et le protecteur de manière à minimiser

l'exposition du corps aux fragments éventuels d'une meule éclatée.

• Les meules de tronçonnage doivent avoir une vitesse sûre maximale

de fonctionnement supérieure à la vitesse à vide marquée sur la plaque

signalétique de l'outil. Les meules qui fonctionnent à une vitesse

supérieure à la vitesse prévue peuvent voler en éclats et causer des

blessures.

• Gardez les mains à l'écart de l'aire de coupe et de la meule. Ne placez

JAMAIS votre main derrière la meule. Ne tentez pas de retirer le

matériau coupé lorsque la meule se déplace. Le contact avec la meule en

rotation peut causer des blessures graves.

• Portez des vêtements appropriés lors de l'utilisation d'une machine

à tronçonner à meule. Un écran facial ou, à tout le moins, des lunettes

de sécurité, un masque antipoussières, des gants en cuir et un tablier

d'atelier pouvant arrêter les petits fragments de meule ou d'ouvrage.

• Utilisez uniquement des meules de tronçonnage de type 1 avec le

trou d'arbre de la dimension correcte. N'utilisez jamais des brides de

meule abîmées ou incorrectes ou un écrou rond. Les autres types de

meule ne sont pas destinés à appliquer la charge sur la périphérie et

peuvent voler en éclats. Les meules avec trous d'arbre qui ne

correspondent pas aux ferrures de montage de l'outil fonctionneront de

manière excentrique, vibreront excessivement et causeront une perte de

contrôle.

• N'utilisez pas une meule de tronçonnage de dimensions supérieures

aux dimensions maximales recommandées pour votre outil, ni des

meules abîmées et usées provenant de machines à tronçonner à

meule de dimensions supérieures. Les meules destinées aux outils plus

gros ne conviennent pas à la vitesse supérieure d'un outil plus petit ; ces

meules peuvent facilement éclater et les fragments peuvent vous frapper

ou frapper les personnes présentes.

• Avant chaque usage, inspectez la meule de tronçonnage pour y

relever tout éclat et fissure. N'utilisez pas une meule qui peut être

abîmée. Posez une nouvelle meule si l'outil est tombé. Lors de la pose

de la nouvelle meule, maniez soigneusement les meules de

tronçonnage individuelles en vue d'éviter les éclats ou les fissures.

Faites fonctionner l'outil à vide pendant une minute, en tenant la tête

de coupe de l'outil vers le bas et en sens opposé aux personnes

présentes. Les meules présentant des défaillances voleront

normalement en éclats durant cette période. Les fragments d'une

meule qui éclate durant le fonctionnement seront projetés à grande

vitesse et pourraient vous frapper ou frapper des personnes présentes.

Ne rectifiez pas sur le côté des meules de tronçonnage de type 1. Les

forces latérales appliquées sur ces meules peuvent les faire voler en

éclats.

• Utilisez toujours l'étau pour serrer l'ouvrage et supporter

adéquatement la partie en porte-à-faux de manière à maintenir

l'ensemble de l'ouvrage de niveau avec la base de la machine. Un

support approprié de l'ouvrage est important pour empêcher les pièces

tronçonnées et en porte-à-faux de tomber et de frapper l'opérateur.

• Ne coincez pas la meule dans l'ouvrage et n'exercez pas une

pression excessive en utilisant cette machine. Évitez de faire rebondir

et d'accrocher la meule, surtout lorsque vous travaillez des coins, des

arêtes vives, etc. Si la meule est abîmée en raison d'une utilisation

erronée, elle peut développer des fissures et finir par éclater ou se briser

sans avertissement.

• Gardez la butée de profondeur réglée adéquatement. Si la butée de

profondeur est mal réglée, elle peut faire renverser l'outil si la tête de

coupe est dégagée trop rapidement ou, si la profondeur est réglée trop

profondément, la meule peut couper dans la surface sous la base.

• Cette machine n'est pas destinée à être utilisée avec les meules à

diamant par voie humide. L'utilisation d'eau ou d'autres agents liquides

de refroidissement avec cette machine peut provoquer une électrocution

ou des chocs. L'utilisation de meules à diamant par voie sèche est

acceptable.

• N'utilisez pas cet outil avec une lame de cisèlement du bois ou des

lames à dents standard pour couper le bois. Ces lames ne sont pas

destinées à cette machine et peuvent provoquer une perte de contrôle en

cours d'utilisation.

• Cet outil et la meule ne sont pas destinés à couper le bois ni des

produits en bois. Les meules coupent en rectifiant ou en érodant pendant

qu'elles sont dans l'ouvrage avec l'abrasif logé dans la meule, ces

abrasifs peuvent saisir le bois et causer une perte de contrôle ou

pourraient provoquer la combustion du bois en raison du chauffage par

friction.

• Ne placez ou ne montez pas l'outil sur une surface inflammable et

n'utilisez pas la machine à tronçonner à meule à proximité de

matières inflammables. Durant le fonctionnement, la meule éjecte des

étincelles et des éclats chauds par suite de la rectification sur l'ouvrage,

ces étincelles pourraient enflammer des matières inflammables.

• Ne coupez ou ne tentez jamais de couper du magnésium à l'aide de

cet outil. La poussière produite durant la coupe de magnésium est très

inflammable et peut être explosive dans certaines conditions.

• Évitez de surcharger le moteur et prévenez le brûlage surtout en

coupant de grosses pièces en croix, exercez une légère pression sur la

poignée en coupant. En cas de signe de fumée aux prises d'air, cessez

immédiatement d'utiliser l'outil. Des chocs électriques peuvent être

causés si le moteur est surchargé et brûle.

• Nettoyez régulièrement les prises d'air de l'outil à l'aide d'air

comprimé. L'accumulation excessive de métal en poudre à l'intérieur du

carter du moteur peut causer des défaillances électriques.

Les travaux à la machine tel que ponçage,

sciage, meulage, perçage et autres travaux

du bâtiment peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer, de malformation

congénitale ou d’autres problèmes reproductifs. Ces produits

chimiques sont, par exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du ciment et d’autres

produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités chimiquement

Le niveau de risque dû à cette exposition varie avec la fréquence de ces

types de travaux. Pour réduire l’exposition à ces produits chimiques, il

faut travailler dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière conçus

Consignes de sécurité de la machine à tronçonner à meule d'établi

« CONSERVEZ CES INSTRUCTIONS »

AVERTISSEMENT

!

Page 11

-11-

Instructions de mise à la terre des outils

équipés de fiche trois broches

En cas mauvais fonctionnement ou de panne, la ligne de mise à la terre

fournit à l’électricité une voie de moindre résistance, de façon à réduire les

risques de choc électrique.

Alimentation électrique

Cette machine doit être reliée à la terre lorsqu’elle est en marche afin de

protéger l’utilisateur contre les risques de choc électrique.

Branchez le cordon d’alimentation dans une prise de 110-120 volts

correctement mise à la terre et protégée par un fusible ou coupe-circuit à

retard à double élément de 15 ampères.

Toutes les prises de courant ne sont pas correctement reliées à la terre. Si

vous n’êtes pas certain que la prise que vous voulez utiliser (voir

ilustration ci-dessous) soit correctement mise à la terre, faites-la vérifer

par un électricien.

Pour éviter les chocs électriques, ne touchez pas les

broches métalliques de la fiche lorsque vous

l’introduisez dans la prise de courant ou que vous l’en retirez.

Si cet outil électrique n’est pas correctement mis à la

terre, l’utilisateur risque d’être électrocuté ou de subir un

grave choc électrique, tout particulièrement si la meuleuse est installée à

proximité de tuyauteries ou d’autres objets métalliques. Sous l’effet d’un

choc électrique éventuel, vos mains pourraient entrer en contact avec la

meule.

Si le cordon d’alimentation est usé, entaillé ou

endommagé de quelque façon que ce soit,

faites-le remplacer immédiatement afin d’éliminer les dangers

d’électrocution et d’incendie.

Votre appareil est conçu pour fonctionner à une tension de 120 volts ; il est

doté d’une fiche d’aspect similaire à celle présentée dans l’illustration cidessous.

Cet outil électrique est doté d’un cordon à trois conducteurs et d’une fiche

de type terre approuvés par les Laboratoires des assureurs et l’Association

canadienne de normalisation. Le fil de terre est gainé de vert et est relié

d’un côté au boîtier de l’outil et de l’autre à la broche de mise à la terre de

la fiche du cordon.

Cette fiche ne peut être branchée qu’à une prise de courant à trois

conducteurs avec mise à la terre du type présenté dans l’illustration.

Si la prise que vous voulez utiliser est du type à deux broches, NE

RETIREZ PAS LA BROCHE DE MISE À LA TERRE DE LA FICHE ET NE LA

MODIFIEZ EN AUCUNE FAÇON. Utilisez un adaptateur (voir illustration) et

reliez toujours à la terre la borne de mise à la terre de cet adaptateur.

Un mauvais branchement du conducteur de mise à la terre de la machine

présente des risques de choc électrique. S’il est nécessaire de réparer ou

remplacer le cordon ou la fiche d’alimentation électrique, ne reliez pas le

conducteur de mise à la terre à une borne sous tension.

Si vous ne comprenez pas parfaitement les instructions de mise à la terre

ou si vous n’êtes pas certain que l’outil soit correctement mis à la terre,

consultez un électricien ou un réparateur qualifié.

Il est recommandé de faire remplacer par un électricien la prise à DEUX

broches par une prise à TROIS broches correctement reliée à la terre.

On peut se procurer dans le commerce un adaptateur permettant de

brancher la fiche de la meuleuse dans une prise à deux broches.

La borne de mise à la terre de couleur verte

dépassant de l’adaptateur doit être reliée à une

terre permanente telle qu’une prise de courant correctement mise à la

terre.

NOTA : L’adaptateur présenté dans l’illustration ne doit être utilisé que si

vous disposez d’une prise de courant à deux broches correctement mise à

la terre. Le Code canadien de l’électricité interdit l’utilisation de cet

adaptateur au Canada.

L’utilisation d’une rallonge entraîne une légère perte de puissance. Pour

réduire au minimum cette dernière tout en évitant que le moteur ne

surchauffe ou ne grille, servez-vous du tableau ci-dessous pour

déterminer le calibre minimum (A.W.G.) du câble de rallonge. N’utilisez

que des rallonges à trois conducteurs munies de fiches de type terre à

trois broches et des prises de courant à trois broches adaptées à la fiche

de l’outil.

Rallonges

DIMENSIONS DE RALLONGES RECOMMANDÉES

DANGER

!

DANGER

!

AVERTISSEMENT

!

FICHE À TROIS BROCHES

BROCHE DE MISE À LA TERRE

TOUJOURS UTILISEZ

UNE PRISE DE COURANT

AVEC PRISE DE TERRE

AVERTISSEMENT

!

VIS

BORNE DE MISE À LA TERRE

FICHE À TROIS

BROCHES

S’ASSURER QUE LE

LOGEMENT DE

LA VIS EST BIEN

RELIÉ À LA TERRE

PRISE DE COURANT À

DEUX BROCHES

ADAPTATEUR

« CONSERVEZ CES INSTRUCTIONS »

Intensité

nominale

de l’outil

OUTILS 120 VOLTS C.A.

Longueur en pieds

Calibre A.W.G.

OUTILS 240 VOLTS C.A.

Longueur en mètres

Calibre en mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Page 12

-12-

Votre nouvelle machine de découpage à meule est conçue et construite

à l'intention de gros travaux de coupe. C’est un outil haute performance

avec toutes les qualités de fonctionnement qui vous permettront

d’exécuter toute coupe en facilité.

1. BOUTON DE VERROUILLAGE DE L’ARBRE

Facilitant le remplacement des meules.

2. GÂCHETTE DE COMMANDE BLOCABLE

Pour l’agrément de l’utilisateur.

3. MEULE DE 14"

Coupe d’un seul coup un paquet de montants d’acier standard pour

placoplâtre.

4. GARDE INFÉRIEUR

Pour la protection de l’utilisateur pendant la coupe, le garde devrait

toujours être abaissé en place et fonctionner correctement.

5. POIGNÉE

Grande poignée facilitant le transport.

6. CHAÎNE DE RETENUE

Pour faciliter le transport.

7. MORS D’ÉTAU RÉGLABLE

Pivote de 0 à 45˚ en cas de coupes à angle.

8. DÉCLENCHE RAPIDE

Pour le desserrage rapide et facile.

9. BUTÉE DE RÉGLAGE EN PROFONDEUR

Pour régler la meule aux profondeurs de coupe désirées.

10. CLÉ ET LOGEMENT

Votre outil est doté d’une clé double. La grosse extrémité sert au réglage

de l’étau ou à la dépose et repose des meules alors que la petite sert à la

butée de réglage en profondeur. La clé peut également être rangée dans

son logement dans la table de l’outil.

11. TABLE

Grande table plus stable.

Introduction

2

GÂCHETTE DE COMMANDE

1

BOUTON DE VERROUILLAGE DE L’ARBRE

4

GARDE INFÉRIEUR

3

MEULE

7

MORS D’ÉTAU

RÉGLABLE

8

DÉCLENCHE

RAPIDE

10

CLÉ ET

LOGEMENT

6

CHAÎNE DE

RETENUE

11

TABLE

9

CONTRE-ÉCROU

9

BUTÉE DE RÉGLAGE EN

PROFONDEUR

PRISES D’AIR

CORDON

5

POIGNÉE

FIG. 1

2

BOUTON DE BLOCAGE EN MARCHE

Page 13

-13-

1. Levez le garde inférieur comme le montre la fig. 3, enfoncez le bouton

de verrouillage de l’arbre (fig. 1) et, au moyen de la clé fournie, desserrez

le boulon à tête hexagonale du centre de la meule en tournant dans le sens

contraire des aiguilles d’une montre.

2. Enlevez le boulon, le flasque extérieur et la meule (fig. 3).

3. Montez soigneusement la meule de rechange sur l’arbre et remettez le

flasque et le boulon en place.

4. Appuyez sur le bouton de verrouillage de l’arbre et serrez le boulon avec

la clé (ATTENTION : NE SERREZ PAS À L’EXCÈS).

Lors d’un remplacement de meule, prenez

toujours soin d’ajuster la butée de réglage en

profondeur de sorte que la meule ne coupe pas la surface sur laquelle

repose l’outil. Faute de le faire risque de causer de sérieuses blessures.

GÂCHETTE DE COMMANDE AVEC BOUTON DE BLOCAGE

EN MARCHE

Votre outil peut être mise en marche ou au repos à l’enfoncement ou

relâchement de la gâchette. Elle est aussi équipée, à la gauche de la

gâchette, d’un bouton de blocage en marche qui maintient l’interrupteur

sous tension sans avoir à appuyer sur la gâchette de commande. Le

blocage en marche est utile en cas de longs travaux.

REMARQUE : L’interrupteur peut recevoir un cadenas avec une tige d’un

diamètre allant jusqu’à 3/16 po (non fourni avec la outil) afin de prévenir

l’utilisation non autorisée.

BLOCAGE DE L’INTERRUPTEUR EN MARCHE : appuyez sur la gâchette,

enfoncez le bouton et relâchez la gâchette.

DÉBLOCAGE DE L’INTERRUPTEUR : appuyez sur la gâchette et relâchez-la

sans toucher au bouton de blocage en marche.

Le relâchement de la gâchette est impossible si

le bouton de blocage en marche est maintenu

enfoncé.

Mode d’emploi

Pour éviter le risque de blessure, débranchez toujours la fiche de la prise de courant avant de

changer de meule ou d’effectuer tout réglage quelconque.

Dépose et repose de la meule

AVERTISSEMENT

!

AVERTISSEMENT

!

BOUTON DE BLOCAGE

EN MARCHE

GÂCHETTE DE

COMMANDE

ARBRE

GARDE

INFÉRIEUR

FLASQUE

INTÉRIEUR

ANNEAU

ÉLASTIQUE

MEULE

FLASQUE

EXTÉRIEUR

BOULON À TÊTE

HEXAGONALE

ADAPTATEUR

(PLUS ÉPAIS)

ESPACEUR

(PLUS ÉTROIT)

BUTÉE DE RÉGLAGE

EN PROFONDEUR

CONTRE-ÉCROU

FIG. 2

FIG. 3

AVERTISSEMENT

!

Page 14

-14-

BUTÉE DE RÉGLAGE EN PROFONDEUR

Votre outil est doté d’une butée de réglage en profondeur. Au fur et à

mesure que la meule s’use ou à l’occasion d’un remplacement de meule, il

faudra effectuer ce réglage.

POUR LEVER LA MEULE, desserrez le contre-écrou et tournez la butée

dans le sens contraire des aiguilles d’une montre avec la clé fournie.

POUR BAISSER LA MEULE, tournez la butée dans le sens des aiguilles

d’une montre. ATTENTION : Pour maintenir ce réglage, serrez fermement

le contre-écrou avec la clé fournie.

TRANSPORT DE L’OUTIL

1. Baissez le bras à fond et attachez la chaîne de retenue au crochet, puis

laissez revenir le bras.

2. Pour éviter le battement ou le rebondissement du bras, levez la butée de

réglage en profondeur jusqu’à ce qu’elle touche au bras comme le montre

la fig. 4.

Assurez-vous que la chaîne de retenue est

fixée solidement à la base et au bras pour le

transport. Si la machine à tronçonner à meule est transportée en position

ouverte, la butée de profondeur peut être abîmée.

Réglage de l’étau

RÉGLAGE DE L’ANGLE DE COUPE

1. Desserrez (SANS ENLEVER) les boulons de réglage du mors arrière de

l’étau avec la clé fournie, (fig. 5).

2. Alignez le repère de l’angle désiré sur l’échelle graduée du mors avec

celui de la table et resserrez fermement les boulons avec la clé fournie.

RÉGLAGE DE L’OUVERTURE

1. Desserrez (SANS ENLEVER) les boulons de réglage du mors arrière de

l’étau avec la clé fournie, (fig. 5).

2. Avancez ou reculez le mors arrière à la position désirée et resserrez

fermement les boulons avec la clé fournie.

DÉCLENCHE RAPIDE

Pour libérer le matériau, desserrez la manivelle, soulevez la déclenche

rapide (fig. 5) et retirez la vis du mors avant.

Pour serrer le matériau dans l’étau, repoussez la vis vers la pièce, rabattez

la déclenche rapide sur la vis et tournez la manivelle dans le sens des

aiguilles d’une montre.

PROFONDEUR DE COUPE MAXIMALE

Pour obtenir la profondeur de coupe maximale, placez le mors arrière de

sorte que le matériau à couper soit centré sous la meule quand celle-ci est

totalement baissée.

BUTÉE DE

RÉGLAGE EN

PROFONDEUR

CONTRE-ÉCROU

POIGNÉE

CROCHET

CHAÎNE DE

RETENUE

FIG. 4

MANIVELLE

VIS

TABLE

BOULONS DE

RÉGLAGE DU MORS

ARRIÈRE

ÉCHELLE

GRADUÉE

REPÈRE

CLÉ

MORS ARRIÈRE

DÉCLENCHE

RAPIDE

FIG. 5

MISE EN GARDE

!

Page 15

-15-

DIMENSIONS DE COUPE RECOMMANDÉE

Les coupes aux profondeurs supérieures à celles recommandées peut causer le « brûlage » du

moteur et possiblement le choc électrique.

Entretien

L’entretien préventif par des personnes non

autorisées peut être dangereux. Il est recommandé que l’entretien et la réparation de nos outils soient confiés à un

centre de service-usine Bosch ou à un centre de service après-vente

Bosch agréé.

GRAISSAGE DE L’OUTIL

Votre outil Bosch a été convenablement graissé et est prêt à utiliser. Il est

recommandé que les outils à engrenages soient regraissés avec une

graisse spéciale à l’occasion de tout remplacement de balais.

BALAIS DE CHARBON

Les balais et le collecteur de votre outil ont été conçus pour donner

plusieurs heures de fonctionnement sans aléas. Pour maintenir le moteur

en forme, nous recommandons d’examiner les balais tous les deux à six

mois. Vous ne devriez utiliser que les balais de rechange d’origine Bosch

qui conviennent spécialement à votre outil.

ROULEMENTS

Après environ 300 à 400 heures d’utilisation, ou à tous les deux remplacements des balais, il faudrait confier le remplacement des roulements

à un centre de service-usine Bosch ou à un centre de service après-vente

Bosch agréé. Les roulements qui sont devenus bruyants (à cause de

sciage de matériaux très abrasifs ou de durs efforts) devraient être

remplacés à l’instant pour éviter la surchauffe et la défaillance du moteur.

Nettoyage

Pour éviter le risque d’accidents, débranchez

toujours l’outil de la prise de courant avant de

procéder au nettoyage ou à l’entretien. Vous pouvez très bien le nettoyer à

l’air comprimé. Dans ce cas, portez toujours des lunettes de sécurité.

Après chaque usage, débranchez la fiche de la prise de courant, retirez la

meule et les rondelles afin d'essuyer les dépôts de poussière sur le carter

et les protecteurs de meule. Le protecteur de meule inférieur doit être

essuyé à l'occasion à l'aide d'un chiffon propre et de savon doux afin de

prévenir la détérioration sous l'effet de l'huile et de la graisse. Après le

nettoyage, vérifiez le fonctionnement et l'état du protecteur de meule

inférieur pour vous assurer qu'il est fonctionnel pour l'usage suivant.

Gardez les prises d’air et les interrupteurs propres et libres de débris.

N’essayez pas de les nettoyer en introduisant des objets pointus dans

leurs ouvertures.

Certains produits de nettoyage et dissolvants

dont la gazoline, le tétrachlorure de carbone,

les nettoyeurs chlorés, l’ammoniaque et les détergents ménagers

contenant de l’ammoniaque peuvent abîmer les pièces en plastique.

AVERTISSEMENT

!

AVERTISSEMENT

!

Maintenance

AVERTISSEMENT

!

Dimensions de la

meule concernée

Diamètre extérieur de 355 mm (14") x épaisseur de moins

de 4,5 mm (3/16" avec ouverture centrale de 25,4 mm (1") de diamètre.

Configuration

de la pièce

(vue en coupe)

Capacité

de coupe

maximale

(a)

MISE EN GARDE

!

Page 16

-16-

“CONSERVE ESTAS INSTRUCCIONES”

Reglas generales de seguridad para todas las herramientas mecánicas

“LEA TODAS LAS INSTRUCCIONES”. El incumplimiento de las REGLAS DE SEGURIDAD identificadas por el símbolo del PUNTO NEGRO (•)

que se indican A CONTINUACION y otras precauciones de seguridad puede dar lugar a lesiones personales graves.

ADVERTENCIA

!

Area de trabajo

• MANTENGA ALEJADOS A LOS NIÑOS. No permita que los visitantes

toquen la herramienta o el cordón de extensión. Todos los visitantes deben

mantenerse alejados del área de trabajo.

• MANTENGA LIMPIAS LAS AREAS DE TRABAJO. Las áreas y mesas

desordenadas invitan a que se produzcan accidentes.

• HAGA EL TALLER A PRUEBA DE NIÑOS con candados, interruptores

maestros o quitando las llaves de arranque.

• EVITE LOS ENTORNOS PELIGROSOS. No utilice herramientas

mecánicas en lugares húmedos o mojados. Mantenga el área de trabajo

bien iluminada. No exponga las herramientas mecánicas a la lluvia. No

utilice la herramienta en presencia de líquidos o gases inflamables.

Seguridad personal

• CONOZCA SU HERRAMIENTA MECANICA. Lea y entienda el manual del

usuario y las etiquetas puestas en la herramienta. Aprenda las aplicaciones

y los límites, así como los peligros potenciales específicos que son propios

de esta herramienta.

• NO INTENTE ALCANZAR DEMASIADO LEJOS. Mantenga una posición y

un equilibrio adecuados en todo momento.

• MANTENGASE ALERTA. Fíjese en lo que está haciendo. Use el sentido

común. No utilice la herramienta cuando esté cansado. No la use cuando se

encuentre bajo la influencia de medicamentos o al tomar alcohol u otras

drogas.

• VISTASE ADECUADAMENTE. No se ponga ropa holgada ni joyas.

Sujétese el pelo largo. Mantenga el pelo, la ropa y los guantes alejados

de las piezas móviles. La ropa holgada, las joyas o el pelo largo pueden

quedar atrapados en las piezas móviles. Súbase las mangas largas por

encima de los codos. Se recomiendan guantes de caucho y calzado

antideslizante cuando se trabaja a la intemperie.

• UTILICE EQUIPO DE SEGURIDAD. USE SIEMPRE GAFAS DE SEGURIDAD. Se debe utilizar una máscara antipolvo, calzado de seguridad,

casco o protección en los oídos según lo requieran las condiciones. Los

lentes de uso diario sólo tienen lentes resistentes a los golpes. NO son

gafas de seguridad.

• PROTEJASE CONTRA LAS SACUDIDAS ELECTRICAS. Evite el contacto

del cuerpo con las superficies conectadas a tierra. Por ejemplo: tuberías,

radiadores, cocinas y refrigeradores.

• DESCONECTE LAS HERRAMIENTAS DE LA FUENTE DE ENERGIA.

Cuando no se estén utilizando, antes del servicio de ajustes y reparaciones,

al cambiar hojas, brocas, cortadores, etc.

• MANTENGA PUESTOS LOS PROTECTORES. En buenas condiciones de

funcionamiento y con el ajuste y la alineación adecuados.

• QUITE LAS LLAVES DE AJUSTE Y DE TUERCA. Cuando no se estén

utilizando, antes del servicio de ajustes y reparaciones, al cambiar hojas,

brocas, cortadores, etc.

• EVITE EL ARRANQUE ACCIDENTAL. Asegúrese de que el interruptor

está en la posición “OFF” (desconectado) antes de enchufar la herramienta.

• NUNCA SE SUBA A LA HERRAMIENTA NI A SU SOPORTE. Se podrían

producir lesiones graves si la herramienta se vuelca o si se toca

accidentalmente la herramienta de corte. No guarde materiales sobre la

herramienta ni cerca de ésta de tal manera que sea necesario subirse a la

herramienta o a su soporte para llegar a ellos.

• REVISE LAS PIEZAS DAÑADAS. Antes de volver a utilizar la herramienta,

una protección u otra pieza que esté dañada deberá revisarse

cuidadosamente para asegurarse de que funcionará adecuadamente y de

que realizará la función para la cual está diseñada. Verifique la alineación de

las piezas móviles, el montaje y cualquier otra situación que pueda afectar

su funcionamiento. Un protector o cualquier otra pieza que presenta daños

se debe sustituir adecuadamente.

• Todas las reparaciones, eléctricas o mecánicas, deben ser realizadas

únicamente por técnicos de reparación capacitados. Póngase en contacto

con el Centro de servicio Bosch más próximo, con la Estación de servicio

Bosch autorizada o con otro servicio de reparaciones competente.

• LA UTILIZACION DE CUALQUIER OTRO ACCESORIO NO

ESPECIFICADO EN ESTE MANUAL PUEDE CONSTITUIR UN PELIGRO.

Los accesorios que pueden ser adecuados para un tipo de herramienta

pueden resultar peligrosos cuando se utilizan en una herramienta

inadecuada.

Utilización de la herramienta

• NO FUERCE LA HERRAMIENTA. La herramienta hará el trabajo mejor y

con más seguridad a la capacidad para la cual fue diseñada.

• UTILICE LA HERRAMIENTA ADECUADA. No fuerce una herramienta

pequeña o un accesorio pequeño a realizar el trabajo de una herramienta

pesada. No utilice la herramienta para funciones para las cuales no fue

diseñada — por ejemplo, no use una sierra circular para cortar ramas o

troncos de árboles.

• FIJE LA PIEZA DE TRABAJO. Utilice abrazaderas o un tornillo de

carpintero para sujetar la pieza de trabajo cuando esto resulte práctico. Es

más seguro que utilizar la mano y deja libres ambas manos para manejar la

herramienta.

• DIRECCION DE AVANCE. Haga avanzar la pieza de trabajo por una hoja o

cortador en contra del sentido de rotación de la hoja o cortador

únicamente.

• NUNCA DEJE LA HERRAMIENTA FUNCIONANDO DESATENDIDA.

Apague la herramienta. No deje la herramienta hasta que ésta se haya

detenido por completo.

• UTILICE EL CORDON DE EXTENSION ADECUADO. Asegúrese de que el

cordón de extensión esté en buenas condiciones. Al utilizar un cordón de

extensión, asegúrese de usar uno suficientemente pesado para llevar la

corriente que su producto utiliza. Un cordón de tamaño insuficiente

causará una caída de la tensión de la línea, lo cual producirá una pérdida de

potencia y recalentamiento. La tabla que aparece en la página 18 muestra

el tamaño correcto que debe utilizarse según la longitud del cordón y la

capacidad nominal en amperios que figura en la placa del fabricante. En

caso de duda, utilice el siguiente número de calibre más pesado. Cuanto

más pequeño es el calibre, más pesado es el cordón.

Cuidado de la herramienta

• NO ALTERE NI HAGA USO INCORRECTO DE LA HERRAMIENTA. Estas

herramientas están fabricadas con precisión. Cualquier alteración o

modificación no especificada constituye un uso incorrecto y puede dar

lugar a situaciones peligrosas.

• EVITE LAS AREAS DE GASES. No utilice herramientas eléctricas en una

atmósfera gaseosa o explosiva. Los motores de estas herramientas

normalmente producen chispas y pueden dar lugar una situación peligrosa.

• MANTENGA LAS HERRAMIENTAS CON CUIDADO. Conserve las

herramientas afiladas y limpias para que funcionen mejor y con más

seguridad. Siga las instrucciones para lubricar la herramienta y cambiar los

accesorios. Inspeccione periódicamente los cordones de las herramientas y

si están dañados hágalos reparar por un centro de servicio autorizado.

Inspeccione periódicamente los cordones de extensión y sustitúyalos si

están dañados. Mantenga los mangos secos, limpios y libres de aceite y

grasa.

• Antes de conectar la herramienta a una fuente de energía (caja

tomacorriente, tomacorriente, etc.), asegúrese de que el voltaje

suministrado es el mismo que el que se indica en la placa del fabricante de

la herramienta. Una fuente de energía con un voltaje superior al

especificado para la herramienta puede ocasionar graves lesiones al

usuario, así como daños a la herramienta. En caso de duda, NO ENCHUFE

LA HERRAMIENTA. La utilización de una fuente de energía con un voltaje

inferior a la capacidad nominal indicada en la placa del fabricante es

perjudicial para el motor.

Page 17

-17-

“LEA TODAS LAS INSTRUCCIONES”. El incumplimiento de las REGLAS DE SEGURIDAD identificadas por el símbolo del PUNTO NEGRO (•)

que se indican A CONTINUACION y otras precauciones de seguridad puede dar lugar a lesiones personales graves.

ADVERTENCIA

!

• Mantenga el protector inferior de la rueda colocado, funcionando

adecuadamente y ubicado en la posición de máxima cobertura de la

rueda sobre la pieza de trabajo cuando la herramienta está

funcionando. Mantenga su cuerpo situado a uno de los lados de la

rueda, pero no en línea con la rueda. Es importante situar el cuerpo y

el protector de manera que se minimice la exposición del cuerpo a

posibles fragmentos de una rueda que reviente.

• Las ruedas abrasivas de corte deben tener una velocidad máxima de

funcionamiento con seguridad superior a las "RPM sin carga"

indicadas en la placa del fabricante de la herramienta. Las ruedas que

estén funcionando a una velocidad superior a la nominal pueden

romperse, salir despedidas y causar lesiones.

• Mantenga las manos alejadas del área de corte y de la rueda.

NUNCA ponga la mano detrás de la rueda. No intente retirar el

material cortado cuando la rueda se esté moviendo. El contacto con la

rueda que gira puede causar lesiones personales graves.

• Use indumentaria adecuada mientras utiliza una máquina de rueda

abrasiva. Careta protectora o al menos anteojos de seguridad, máscara

antipolvo, guantes de cuero y delantal de taller capaces de detener

pequeños fragmentos de la rueda o de la pieza de trabajo.

• Utilice únicamente ruedas abrasivas de corte de tipo 1 con el agujero

para eje portaherramienta de tamaño correcto. No utilice nunca

pestañas de rueda dañadas o incorrectas ni una tuerca redonda. Otros

tipos de ruedas no están diseñados para aplicar carga en la periferia y

pueden hacerse pedazos. Las ruedas con agujeros para eje

portaherramienta que no coincidan con la tornillería de montaje de la

herramienta funcionarán excéntricamente, vibrarán excesivamente y

causarán pérdida de control.

• No utilice una rueda de corte cuyo tamaño sea mayor que el tamaño

máximo recomendado para la herramienta, ni ruedas desgastadas o

dañadas provenientes de máquinas de rueda abrasiva más grandes.

Las ruedas diseñadas para herramientas más grandes no son adecuadas

para la velocidad más alta de una herramienta más pequeña. Estas

ruedas pueden reventar fácilmente y los fragmentos pueden golpearles a

usted o a las personas que se encuentren presentes.

• Antes de cada uso, inspeccione la rueda de corte para ver si tiene

astillas y grietas. No utilice ninguna rueda que pueda estar dañada.

Instale una rueda nueva si la herramienta se ha caído. Al instalar una

rueda nueva, maneje cuidadosamente las ruedas de corte individuales

para evitar que se astillen o se agrieten. Haga funcionar la

herramienta sin carga durante un minuto, sujetando su cabeza de

corte hacia abajo y orientada de manera que se aleje de las personas

que se encuentren presentes. Normalmente, las ruedas con defectos

se romperán durante este período. Los fragmentos de una rueda que

revienta durante el funcionamiento saldrán despedidos a gran velocidad,

posiblemente golpeándoles a usted o a las personas que se encuentren

presentes.

• No amuele en el lado de ruedas abrasivas de corte de tipo 1. Las

fuerzas laterales aplicadas a estas ruedas pueden hacer que salten en

pedazos.

• Utilice siempre el tornillo de carpintero para fijar la pieza de trabajo

y soportar adecuadamente la porción saliente de la pieza de trabajo

nivelada con la base de la máquina. El soporte adecuado de la pieza de

trabajo es importante para evitar que las piezas cortadas y que sobresalen

se caigan y golpeen al operador.

• No "trabe" la rueda abrasiva en la pieza de trabajo ni ejerza una

presión excesiva mientras utiliza esta máquina. Evite hacer rebotar y

enganchar la rueda, especialmente al trabajar en esquinas, bordes

afilados, etc. Si la rueda se daña debido a uso incorrecto, puede

agrietarse y finalmente reventar o hacerse pedazos inesperadamente.

• Mantenga el tope de profundidad ajustado adecuadamente. Si el

tope de profundidad está ajustado incorrectamente, puede hacer que la

herramienta vuelque al soltar la cabeza de corte demasiado rápidamente,

o si la profundidad se ajusta a un valor demasiado grande, la rueda puede

cortar la superficie que está debajo de la base.

• Esta máquina no está diseñada para utilizarse con ruedas

adiamantadas mojadas. La utilización de agua u otros refrigerantes

líquidos con esta máquina puede ocasionar electrocución o sacudidas

eléctricas. El uso de ruedas adiamantadas secas es aceptable.

• No utilice esta herramienta con una hoja para "tallar madera" ni con

hojas dentadas estándar para cortar madera. Estas hojas no están

diseñadas para esta máquina y pueden ocasionar pérdida de control

durante el uso.

• Esta herramienta y esta rueda abrasiva no están diseñadas para

cortar madera ni productos de madera. Las ruedas abrasivas cortan

mediante amolado o fricción con el grano incrustado en la rueda mientras

se encuentran en el interior de la pieza de trabajo. Estos granos pueden

engancharse en la madera y causar pérdida de control, o podrían hacer

que la madera se queme debido al calentamiento por fricción.

• No ponga ni monte la herramienta sobre una superficie inflamable ni

utilice la máquina de rueda abrasiva cerca de materiales inflamables.

Durante el funcionamiento, la rueda lanza chispas y virutas calientes

como consecuencia del amolado de la pieza de trabajo. Estas chispas

podrían incendiar los materiales inflamables.

• Nunca corte ni intente cortar magnesio con esta herramienta. El

polvo generado cuando se corta magnesio es altamente inflamable y

puede ser explosivo bajo ciertas condiciones.

• Evite sobrecargar y quemar el motor, especialmente al cortar piezas

de sección transversal grande; ejerza una ligera presión sobre el

mango durante la operación de corte. Si hay evidencia de señales de

humo en las aberturas de ventilación, interrumpa inmediatamente el

uso de la herramienta. Es posible que se produzcan sacudidas

eléctricas si el motor se sobrecarga y se quema.

• Limpie periódicamente las aberturas de ventilación de la

herramienta utilizando aire comprimido. La acumulación excesiva de

metal en polvo en el interior de la caja protectora del motor puede causar

fallos eléctricos.

Cierto polvo generado por el lijado, aserrado,

amolado y taladrado mecánicos, y por otras

actividades de construcción, contiene agentes químicos que se sabe

que causan cáncer, defectos de nacimiento u otros daños sobre la

reproducción. Algunos ejemplos de estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros productos de

mampostería, y

• Arsénico y cromo de madera tratada químicamente.

Su riesgo por causa de estas exposiciones varía, dependiendo de con

cuánta frecuencia realice este tipo de trabajo. Para reducir su exposición

a estos agentes químicos: trabaje en un área bien ventilada y trabaje con

equipo de seguridad aprobado, como por ejemplo máscaras antipolvo

que estén diseñadas especialmente para impedir mediante filtración el

paso de partículas microscópicas.

Normas de seguridad para máquinas de rueda abrasiva de banco

“CONSERVE ESTAS INSTRUCCIONES”

ADVERTENCIA

!

Page 18

En caso de mal funcionamiento o avería, la conexión a tierra proporciona

un camino de resistencia mínima para la corriente eléctrica a fin de reducir

el riesgo de sacudidas eléctricas.

Conexión a una fuente

de energía

Esta máquina debe estar conectada a tierra durante su utilización para

proteger al operador contra las sacudidas eléctricas.

Enchufe el cordón de energía en un tomacorriente de 110-120 V del tipo

conectado a tierra adecuadamente y protegido por un cortacircuito o

fusible de acción retardada de dos elementos de 15 amperios.

No todos los tomacorrientes están conectados a tierra adecuadamente. Si

usted no está seguro de que su tomacorriente, tal como se ilustra más

abajo, está conectado a tierra adecuadamente, haga que lo revise un

electricista competente.

Para evitar sacudidas eléctricas, no toque las terminales

de metal del enchufe al meter el enchufe en el

tomacorriente o al sacarlo de éste.

El no conectar a tierra adecuadamente esta herramienta

mecánica puede causar electrocución o “shock” grave,

especialmente cuando se utiliza cerca de tuberías de metal o de otros

objetos de metal. En caso de sacudida, la reacción de usted podría hacer

que las manos golpearan la herramienta.

Si el cordón de energía está desgastado o cortado o

dañado de cualquier manera, haga que lo

sustituyan inmediatamente para evitar sacudidas o peligro de incendio.

La unidad esta diseñada para ser utilizada a 120 voltios; tiene un enchufe

con un aspecto como el del que se muestra a continuación.

Esta herramienta mecánica está equipada con un cordón de 3 conductores

y un enchufe del tipo de conexión a tierra aprobados por Underwriters’

Laboratories y la Canadian Standards Association. El conductor de

conexión a tierra tiene una envuelta verde y está conectado a la caja de la

herramienta en un extremo y a la terminal de conexión a tierra del enchufe

de conexión en el otro extremo.

Este enchufe requiere un tomacorriente correspondiente del tipo

conectado a tierra de 3 conductores, tal como se muestra.

Si el tomacorriente que piensa utilizar para esta herramienta mecánica es

del tipo de dos terminales, NO QUITE NI ALTERE LA TERMINAL DE

CONEXION A TIERRA DE NINGUNA MANERA. Utilice un adaptador tal

como se muestra y conecte siempre la lengüeta de conexión a tierra a una

toma de tierra conocida.

La conexión incorrecta del conductor de conexión a tierra del equipo

puede dar lugar a riesgo de sacudidas eléctricas. En caso de que sea

necesario reparar o cambiar el cordón eléctrico o el enchufe, no conecte el

conductor de conexión a tierra del equipo a una terminal con corriente.

Consulte a un electricista competente o al personal de servicio si las

instrucciones de conexión a tierra no se entienden del todo o en caso de

duda respecto a si la herramienta está conectada a tierra adecuadamente.

Se recomienda que haga que un electricista competente quite el

tomacorriente para DOS terminales y ponga un tomacorriente para TRES

terminales conectado a tierra adecuadamente.

Un adaptador como el que se muestra más abajo está disponible para

conectar enchufes a tomacorrientes para 2 terminales.