Page 1

Reliable diagnosis.

Time-saving repairs.

Bosch Diagnostics and service parts.

Everything from one single source

Bosch has a full range of products available to increase

efficiency and quality in the workshop’s everyday routine.

The globally operating developer and leading manufacturer

of automotive system technology provides service parts

in familiar original equipment quality.

Bosch Diagnostics offers workshops perfectly matched

hardware and software, technical training courses, a technical hotline and a knowledge database. All with a practical

focus and covering all brands.

Spare parts and accessories

Engine management | Gasoline injection

Expertise and quality – for the future of your workshop

1 987 721 090/200709

AA/MKV3 – 09.2007 – En

© 2007 Robert Bosch GmbH

Automotive Aftermarket

Postfach 41 09 60

76225 Karlsruhe

Token fee: € 10,00

www.bosch.de/aa

Editorial closing: 31. 07. 2007

Subject to change without

notice. Please direct questions

and comments to our

Authorized Representative in

your country. This edition

supersedes all previous

editions.

2008 | 2009

Engine

management

Gasoline injection

2008 | 2009

4 047023 038968

Page 2

Just right!

Lambda sensors from Bosch

Explanation of symbols

Part number

Date / Production period

The right sensor!

The right cable!

The right connector!

Electric fuel pump (in-line/in-tank)

Universal electric fuel pump

EKP non-return valve

Search number

Passenger cars

Original equipment number / Return number

Passenger cars / Small vans

Core deposit values

Quantity per pack

O-rings - Quantity per injector

pcs

Fuel inje ctor

O-ring on top

O-ring below

Parts kit

Export market

Special case

Convincing reasons for choosing Bosch lambda sensors

Bosch invented the lambda sensor.

Bosch has the most know-how in terms of development and

production. Since then Bosch has made more than 400 million

lambda sensors.

Bosch lambda sensors are all available in OEM quality.

Bosch has patented this convincing technology.

Most automobile manufacturers around the world use

Bosch lambda sensors as original equipment.

As market leader in the OEM and aftermarket sector, Bosch has

the ideal replacement sensor for more than 80 % of all vehicles.

Bosch has a comprehensive range of multipurpose lambda

sensors.

The multipurpose lambda sensors won awards at the Auto-

mechanika 2004 and the “Equip Auto 03” exhibition in Paris.

All your advantages at a glance:

Bosch lambda sensors…

… always right

through exact application data.

… save up to 15 % fuel

… avoid expensive consequential damage

as, e.g. a faulty catalytic converter.

… minimize emissions

The most stringent emission levels can be complied with.

… optimize engine performance

… are resistant

to splash water and contamination through the use of a stainless,

laser-welded steel casing.

… have a long service life

through continuous innovations such as, e.g. optimized protective

electrode layers and suitable protective tube devices.

… undergo 100 % functional testing in the manufacturing plant

… come with a pre-greased thread

Page 3

Technology, program

Content

A 2 Counterfeit and imitation products

A 3 More than 100 years of Bosch ignition systems

A 4 Ignition and gasoline-injection systems from Bosch

A 6 Gasoline injection systems

A 14 Electric fuel pumps

A 20 Sensors

A 21 Gasoline injectors

A 22 Ignition coils

A 24 eXchange – Back in Box

Applications

Cross-reference

A 26 eXchange – conditions for component return

A 30 Gasoline injection components

A 46 Central injection unit (ZEE)

A 50 Parts-assortment case

A 54 List of applications for O-rings

A 72 Low-way plug-in connections

B 1 Vehicle-specific equipment

B 2 Overview contents

B 9 Passenger cars, vans

C 2 Non-Bosch Bosch

C 92 Bosch-original parts (new) Bosch Exchange (BX)

C 99 Bosch (OE) Bosch Aftermarket (IAM)

2008 | 2009 Bosch Automotive Aftermarket

Page 4

A2 |

A2 | Counterfeit and imitation products

Counterfeit and imitation products

Important information

Warning about Lambda sensors

Be wary of using universal sensors which do not meet the standards

of vehicle manufacturers. There is a risk of premature damage and

thus failure of the Lambda sensor. In the interests of your customers please therefore make exclusive use of genuine Lambda sensors or universal Lambda sensors from Bosch.

Warning about electric fuel pumps

Certain rival companies make use of inferior imitation products instead of high-performance Bosch pumps. This can lead to problems

when driving and to a loss of engine power due to an inadequate

fuel supply. In the interests of your customers please therefore

make exclusive use of genuine fuel pumps from Bosch.

Warning about the use of non-Bosch air-mass meters

Only genuine air-mass meters from Bosch can ensure compliance

with the legally prescribed emission values. The vehicle homologation will be invalidated if use is made of air-mass meters from other

manufacturers. In addition, this can result in a considerable loss of

engine power and thus higher fuel consumption.

Warning about ignition coils

Bosch ignition coils always provide the engine with sufficient energy

for the ignition spark. This prevents cold-starting difficulties and

exhaust-emission test problems. The high-grade plastic or asphalt

insulation materials used by Bosch ensure a high breakdown voltage

and guard against the risk of fire, in contrast to the oil-based products of certain low-cost suppliers. High-precision, corrosion-proof

connections form the basis for a long product service life.

Bosch products guarantee Bosch quality

This means:

High performance, optimum operation

Long service life

Maximum reliability

Compliance with all legal requirements and

safety standards

Excellent workmanship

environmental compatibility

Bosch Automotive Aftermarket 2008 | 2009Bosch Automotive Aftermarket 2008 | 2009

Page 5

More than 100 years of Bosch ignition systems | A3

More than 100 years of Bosch ignition systems

1

2

7

Bosch started supplying high-voltage magnetos and spark plugs

as far back as 1902.

After 1910 the ignition distributors were separated from the

high-voltage source.

When Robert Bosch AG presented the battery-ignition system

in 1925, magneto ignition was predominant in the automotive

industry. This was considered to be the most reliable form of

ignition system.

At the same time, vehicle manufacturers were demanding a less

costly system and in the light of constant progress battery ignition

quickly became established in the automobile and motorcycle

industry throughout Europe.

8

6

5

3

4

In 2001, Bosch celebrated 50 years of gasoline injection.

The first experiments with injection systems for gasoline engines

took place in 1921. Following extensive trials between 1923 and

1928, gasoline injection was initially restricted to aircraft engines.

Whereas reliability and increased performance were the crucial

aspects with regard to aircraft engines, the economy aspect was

the main motivation in the development of automobile gasoline injection systems.

The Bosch gasoline-injection system presented at the Frankfurt

Motor Show in 1951 for the Gutbrod Superior two-stroke engine

achieved fuel savings of around 20 percent and raised the vehicle

power from 23 to 28 hp.

Nowadays, more advanced versions of this type of ignition are

standard equipment in virtually every gasoline-engine motor vehicle.

Spark plugs

H.T. cables

Distributor cap

Distributor rotor

Ignition distributors

Ignition coil

From battery

To contact breaker

2008 | 2009 Bosch Automotive Aftermarket2008 | 2009 Bosch Automotive Aftermarket

The power-enhancement aspect was however the major factor in

the first mass-produced four-stroke vehicle with gasoline injection

(Mercedes 300 SL). The advantages offered by fuel injection ousted

the carburetor.

In 1967, in the light of stringent US emission legislation,

VW launched the 1600 TL with Bosch-Jetronic, thus marking the

introduction of electronic injection control. By 1972 the Jetronic

system was the choice of 18 manufacturers and well on its way

to success.

Page 6

A4 | Ignition and gasoline-injection systems from Bosch

Ignition and gasoline-injection systems from Bosch

More than a century of system expertise

Renowned vehicle manufacturers rely on Bosch as original equipment supplier and thus form the basis for a fruitful replacement

parts business.

In addition to the full range of more than 10,000 items for gasolineinjection systems, Bosch also supplies the aftermarket and workshop sector with the appropriate replacement and wear parts.

1902 Delivery of the first high-voltage magneto and the first spark

plug

1910 Separation of ignition distributor and high-voltage source

1925 Presentation of battery-ignition system by Robert Bosch

GmbH

L-Jetronic components

KE-Jetronic components

1951 Presentation of Bosch gasoline-injection system at the

Frankfurt Motor Show

1967 First emission legislation in the USA

Introduction of the first electronic injection system:

The D-Jetronic controlled by intake-manifold pressure.

1973 Energy crisis – fuel consumption becomes the focus of

development efforts

Market launch of the L-Jetronic with air-flow sensor and the

K-Jetronic with mechanical-hydraulic control – this was also

an air-flow sensing system.

1976 Bosch invents the Lambda sensor, thus paving the way for the

closed-loop-controlled catalytic converter.

1979 Motronic market launch

The unique feature of this system was the digital processing

of a wide range of engine functions. It combines the

L-Jetronic principle with electronic map-controlled ignition.

The first microprocessor to be fitted in a motor vehicle.

1981 LH-Jetronic market launch

Instead of a flap-type air-flow sensor, the basic L-Jetronic

system was equipped with a hot-wire air-mass meter and

marketed for the first time as LH-Jetronic.

Motronic components

Bosch Automotive Aftermarket 2008 | 2009

Page 7

1982 KE-Jetronic market launch

The K-Jetronic was extended to include an electronic

control loop and the Lambda sensor and was employed

for the first time in a mass-produced vehicle in the

form of the KE-Jetronic.

1987 Mono-Jetronic market launch

The Mono-Jetronic is a particularly inexpensive single-point

injection system, making it feasible to equip even smaller

vehicles with Jetronic.

1989 Mono-Motronic market launch

The Mono-Motronic is a more advanced form of the MonoJetronic and has been extended to incorporate an electronic

map-controlled ignition and a microprocessor.

Ignition and gasoline-injection systems from Bosch | A5

1989 Electronic throttle control (ETC)

With ETC systems, the driver input is detected by a sensor

at the accelerator pedal. The Motronic control unit evaluates

the sensor signal and adjusts the electric motor-driven

throttle valve, taking into account other vehicle and engine

data.

1997 Increasing use of intake modules

Intake modules are pre-assembled units comprising the

intake manifold with injectors, throttle-valve unit, pressure

regulator etc.

2000 Market launch of Motronic gasoline direct injection

The Motronic MED 7 system with torque-based control makes

it possible to combine extremely economical fuel consumption and highly dynamic performance.

Mono-Jetronic components

Intake module

Gasoline direct injection

2008 | 2009 Bosch Automotive Aftermarket

Page 8

A6 | Gasoline injection systems

Gasoline injection systems

K-Jetronic

7

6

5

9

Further technical information can be found

in the “K-Jetronic” booklet.

Part number 1 987 722 159.

The booklets are available from franchized

Bosch wholesalers.

10

2

The K-Jetronic is a mechanical system in

which the fuel is constantly metered on the

basis of the volume of air drawn in by the

engine.

The K-Jetronic was used as original equipment in mass-produced vehicles between

1973 and 1995. Since then, the K-Jetronic

has only been of relevance in terms of

service and maintenance work.

8

4

3

1

Electric fuel pump

Fuel accumulator

Fuel filter

Warm-up regulator

Injector

Electric start valve

Fuel distributor

Air-flow sensor

Thermo-time switch

N Auxiliary-air device

Bosch Automotive Aftermarket 2008 | 2009

Page 9

KE-Jetronic

Gasoline injection systems | A7

12

5

6

7

Further technical information can be found

in the “KE-Jetronic” booklet.

Part number 1 987 722 101.

The booklets are available from franchized

Bosch wholesalers.

13

9

11

The KE-Jetronic is a mechanical/electronic

injection system based on the K-Jetronic.

Additional electronics record a variety of

measurement quantities at the engine, thus

permitting optimization of fuel requirements

and emission quality.

10

8

3

14

2

1

4

Electric fuel pump

Fuel accumulator

Fuel filter

Primary-pressure regulator

Injector

Cold-start valve

Fuel distributor

Air-flow sensor

Thermo-time switch

N Auxiliary-air device

O Engine-temperature sensor

Q Throttle-valve switch

M Lambda Sensor

K Electronic control unit

2008 | 2009 Bosch Automotive Aftermarket

Page 10

A8 | Gasoline injection systems

L-Jetronic

3

4

8

5

Further technical information can be found

in the “L-Jetronic” booklet.

Part number 1 987 722 160.

The booklets are available from franchized

Bosch wholesalers.

9

6

The L-Jetronic is an electronically controlled injection system featuring air-flow

measurement based on the sensor-plate

principle and electromagnetically controlled

fuel injection into the intake manifold. All

engine-related changes are recorded by

a variety of sensors and processed in the

electronic control unit. This ensures constant good emission quality in combination

with low fuel consumption.

7

2

10

1

Electric fuel pump

Fuel filter

Fuel-pressure regulator

Injector

Air-flow sensor

Thermo-time switch

Auxiliary-air device

Throttle-valve switch

Lambda Sensor

N Electronic control unit

Bosch Automotive Aftermarket 2008 | 2009

Page 11

LH-Jetronic

Gasoline injection systems | A9

3

4

8

5

Further technical information can be found

in the “L-Jetronic” booklet.

Part number 1 987 722 160.

The booklets are available from franchized

Bosch wholesalers.

9

6

The LH-Jetronic is closely related to the

L-Jetronic. It differs in terms of the recording of the volume of air drawn in by the

engine, which in this case is performed by

a hot-wire air-mass meter. This measures

the air mass drawn in by the engine.

The measurement result is thus independent of temperature and pressure.

7

2

10

1

Electric fuel pump

Fuel filter

Fuel-pressure regulator

Injector

Hot-wire air-mass meter

Engine-temperature sensor

Rotary idle actuator

Throttle-valve switch

Lambda Sensor

N Electronic control unit

2008 | 2009 Bosch Automotive Aftermarket

Page 12

A10 | Gasoline injection systems

Mono-Jetronic

6

5

4

7

3

2

8

9

Further technical information can be found

in the “Mono-Jetronic” booklet.

Part number 1 987 722 105.

The booklets are available from franchized

Bosch wholesalers.

The Mono-Jetronic is an electronically

controlled single-point injection system in

which a solenoid injector injects the fuel

for all cylinders at a central location above

the throttle valve. The operating data are

recorded by way of sensors and converted

into injection pulses in an electronic control

unit.

10

1

Electric fuel pump

Fuel filter

Throttle-valve potentiometer

Pressure regulator

Injector

Connector with intake-air temperature

sensor

Throttle-valve actuator

Engine-temperature sensor

Lambda Sensor

N Electronic control unit

Bosch Automotive Aftermarket 2008 | 2009

Page 13

Motronic manifold injection

Gasoline injection systems | A11

Further technical information can be found

in the “Motronic” booklet.

Part number 1 987 722 161.

The booklets are available from franchized

Bosch wholesalers.

12

10

6

9

3

4

11

The Motronic combines the injection and

ignition systems to form an engine-management system. Fuel metering and ignition are

optimally matched. Other electronic functions can also be incorporated. Digital data

processing and the use of microprocessors

make it possible to convert a wide range of

operating data into map-controlled injection

and ignition data.

8

5

7

2

1

Electric fuel pump

Fuel filter

Fuel-pressure regulator

Injector

Air-flow sensor

Engine-temperature sensor

Rotary idle actuator

Throttle-valve switch

Engine-speed/reference-mark sensor

N Lambda Sensor

O Electronic control unit

Q High-voltage distributor

2008 | 2009 Bosch Automotive Aftermarket

Page 14

A12 | Gasoline injection systems

ME-Motronic with ETC

1

5

2

9

3

4

6

7

8

The principal function of the engine-management system is to set the driver’s torque

input whilst at the same time achieving

optimum fuel consumption and the lowest

possible emission level. The ME-Motronic

engine-management system combines

all the sub-systems required for this: The

electronic throttle control (EGAS) sets

the amount of air needed to generate this

torque. The corresponding fuel mass is controlled in the gasoline injection sub-system

and the ignition sub-system sets the appropriate ignition point as well as the necessary ignition energy.

In combination with other electronic systems in the vehicle, the ME-Motronic also

enhances ride comfort and user safety. If,

for example, an ABS or ESP system requires

a specific engine torque to provide vehicle

traction, the ME-Motronic sets the necessary torque.

The sub-systems have become more closely

integrated in order to deal with this wide

range of engine-management tasks.

10

20

18

21

22

23

24

Carbon canister

Canister-purge valve

Intake-manifold pressure sensor*

Fuel rail/injector

Camshaft adjuster*

Ignition coil/spark plug

Phase sensor

Lambda Sensor

Air-mass meter

N Throttle device (ETC)

O EGR valve*

Q Speed sensor

M Knock sensor

K Temperature sensor

, Primary catalytic converter

- Lambda Sensor

I Main catalytic converter

H Accelerator-pedal module

J In-tank unit

N Electronic control unit

O CAN

Q Diagnosis lamp

M Diagnostics interface

K Immobilizer

15

11

13

12

19

ETC = Electronic throttle control

EOBD = European On-Board Diagnosis

14

16

17

System

RLFS = Non-return fuel supply system

Inlet and/or exhaust adjustment

* = optional

"

Bosch components

Bosch Automotive Aftermarket 2008 | 2009

Page 15

Motronic – gasoline direct injection

Gasoline injection systems | A13

Engines with gasoline direct injection form

the air/fuel mixture directly in the combustion chamber. Only fresh air flows through

the open intake valve on the induction

stroke. Special injectors inject the fuel

directly into the combustion chamber at

high pressure. Exact metering, conditioning and distribution of the air and fuel for

each individual combustion stroke permit

economical fuel consumption and a low

level of emissions. With its torque-based

electronic control function, the DI-Motronic

from Bosch sets new standards in the field

of gasoline direct injection. The intelligent

system adapts all the relevant quantities to

the corresponding driving situation with a

high degree of accuracy. In part-load mode

it generates a lean stratified air/fuel mixture

and at full load a homogeneous mixture.

Operation: With gasoline direct injection,

the high-pressure pump supplies the

high-pressure circuit with fuel at the high

pressure required for the fuel rail. The highpressure injector attached to the fuel rail

very quickly meters and atomizes the fuel

at high pressure, thus ensuring the bestpossible formation of the air/fuel mixture

directly in the combustion chamber.

Air-mass meter with temperature sensor

Carbon canister

Canister-purge valve

High-pressure pump

Pressure-control valve

Fuel rail

Ignition coil

Accelerator-pedal module

Throttle device (ETC)

N EGR valve

O Intake-manifold pressure sensor

Q High-pressure sensor

M High-pressure injector

K Knock sensor

, Engine-temperature sensor

- Lambda sensor (LSU)

I Lambda sensor (LSF)

H NO

Catalytic converter

x

J Electronic control unit

N Diagnosis interface

O Diagnosis lamp

Q Immobilizer

M CAN

K Delivery module with presupply pump

, Speed sensor

2008 | 2009 Bosch Automotive Aftermarket

Page 16

A14 | Electric fuel pumps

Electric fuel pumps

Replacement parts range and “in-tank” units

Cutting-edge technology sets new standards

The winning features of Bosch fuel pumps and delivery units:

Maximum pulsation-free performance (pressure/delivery)

for constant injection pressure

Longer service life thanks to extensive filter area

Improved ride comfort due to lower noise level

Extremely compact dimensions and low weight simplify

installation

Outstanding reliability even for “in-tank” applications

Capacitor and interference suppression cap provide excellent

protection against signal interference

Comprehensive market coverage with fuel pumps and in-tank

units from Bosch

Broadest possible market coverage with series-production

pumps and modules

New “present value” repair options for fuel-supply modules for

10 million vehicles in Europe

Top quality level – all products supplied by Bosch are of original-

equipment standard

Universal range with only 7 types for 72 original-equipment

pumps

Aftermarket range also includes fuel pumps for modern diesel-

injection systems such as common rail and unit injector

Long-term availability of all products – at competitive prices

Bosch Automotive Aftermarket 2008 | 2009

Page 17

The universal range “7 instead of 72”

Electric fuel pumps | A15

One type for a variety of applications: The universal electricfuel-pump range from Bosch

The 72 pumps used in the past can now be replaced by just

7 universal electric fuel pumps from Bosch. The key to this is

a parts set. Each of the 7 electric fuel pumps is supplied with

a parts set and easy-to-follow installation instructions. These

pumps form the Bosch universal range.

Bosch quality

Crucial criteria for electric fuel pumps:

Maximum operational reliability

Compliance with all original-equipment demands

Long service life

Low noise level

Optimum fuel delivery

Maximum possible safety for hot-fuel delivery

Excellent interference-suppression level

Warning about imitation pumps

Certain rival companies make use of inferior imitation products

instead of high-performance Bosch pumps. This can lead to

fuel-delivery problems and to a loss of engine power due to an

inadequate fuel supply. In the interests of your customers please

therefore make exclusive use of genuine fuel pumps from Bosch.

2008 | 2009 Bosch Automotive Aftermarket

Page 18

A16 | Electric fuel pumps

Electric fuel pumps

Universal range – technical data

12

7

8

1 2 3 4 5 6

0580...

... 254 053

... 254 909

... 254 910

... 254 911

... 464 069

... 464 070

... 464 085

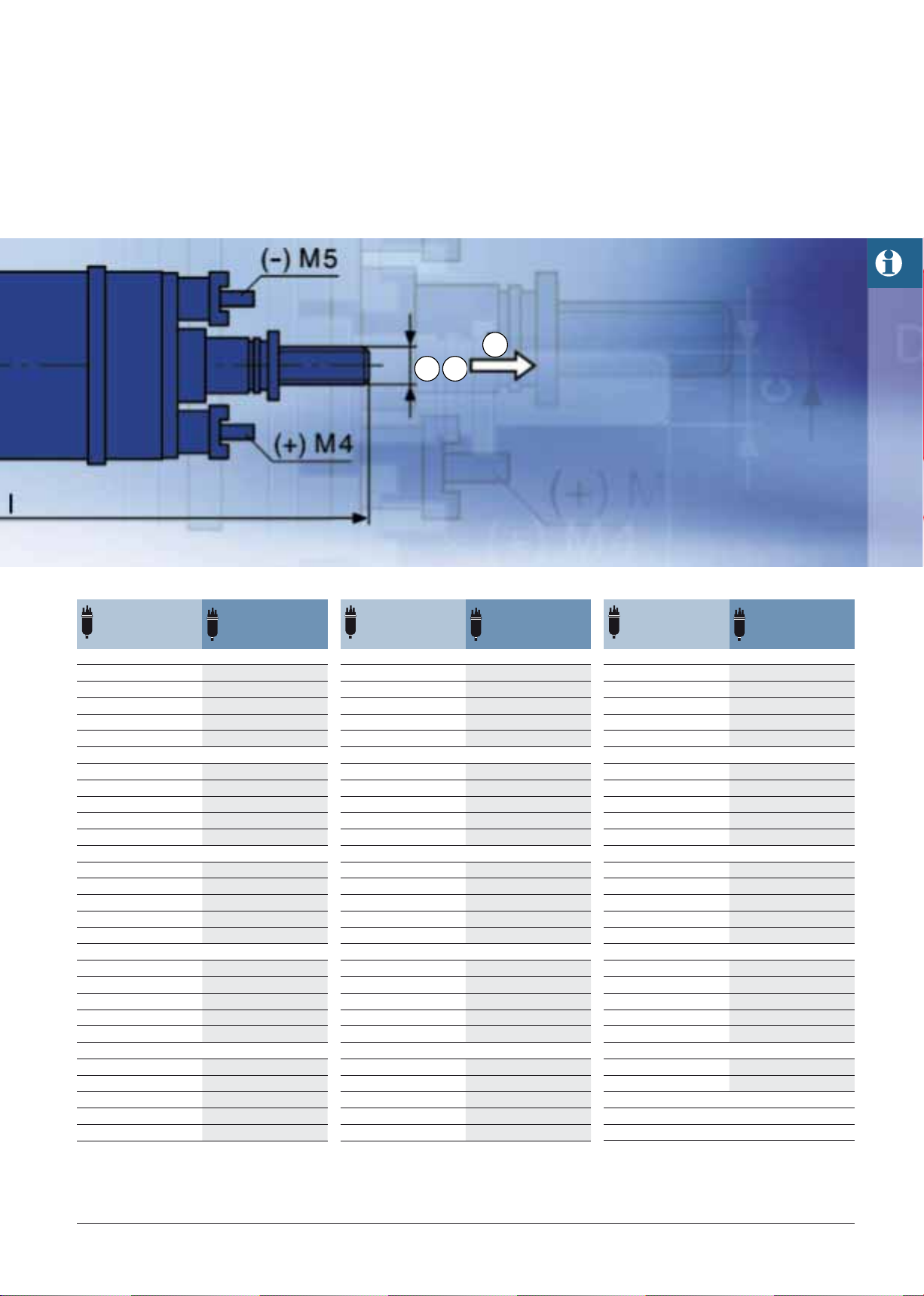

Electrical connections:

Cable lug: M 4/M 5

Temperature range: –40 °C ... +60 °C

Fuel grade as per DIN: 51 600, 51 607

Note:

All universal electric fuel pumps are of the “in-line” type.

They are only suitable for installation outside the fuel tank.

175...228 500 13 < 11.4 800...1450 180 60 12 M 12 x 1.5 – –

148...198 500 13 < 8.7 800...1450 180 60 12 M 12 x 1.5 – –

130...200 500 13 < 9.8 800...1450 203 60 15 M 12 x 1.5 – –

95...135 400 12 < 5.2 650...850 199 52 15 M 12 x 1.5 – M 10 x 1

98...148 400 12 < 7.0 480...850 186 52 12 M 12 x 1.5 – M 14 x 1.5

130...195 300 12 < 6.5 450...800 175 52 12 – 8 –

95...145 250 12 < 4.5 480...850 175 52 12 – 8 –

7

Scope of delivery:

Universal electric fuel pump with parts set (1 cable lug M4/M5

each with the corresponding washers and nuts).

8 9

10 11

6

Delivery at rated voltage l/h

Primary pressure kPa

Rated voltage V

Current input A

Pressure limitation kPa

Total length mm

Pump dia. mm

Intake connection nom. dia. mm

Pressure-connection thread

N

Pressure-connection nom. dia. mm

O

Additional threaded socket

Q

Suction end

M

Delivery end

Bosch Automotive Aftermarket 2008 | 2009

Page 19

Universal range – reference table

Electric fuel pumps | A17

| A17

13

9

10

0 580 254 921

0 580 254 922

0 580 254 927

0 580 254 928

0 580 254 931

0 580 254 932

0 580 254 934

0 580 254 942

0 580 254 943

0 580 254 945

0 580 254 946

0 580 254 949

0 580 254 950

0 580 254 951

0 580 254 952

0 580 254 956

0 580 254 957

0 580 254 958

0 580 254 959

0 580 254 960

0 580 254 961

0 580 254 962

0 580 254 964

0 580 254 965

0 580 254 966

U

N

I

0 580 254 910

0 580 254 910

0 580 254 910

0 580 254 910

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 910

0 580 254 910

0 580 254 911

0 580 254 911

0 580 254 909

0 580 254 911

0 580 254 911

0 580 254 910

0 580 254 910

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 967

0 580 254 968

0 580 254 969

0 580 254 970

0 580 254 971

0 580 254 972

0 580 254 973

0 580 254 974

0 580 254 980

0 580 254 981

0 580 463 010

0 580 463 011

0 580 463 012

0 580 463 013

0 580 463 014

0 580 463 015

0 580 463 016

0 580 463 017

0 580 464 008

0 580 464 013

0 580 464 014

0 580 464 015

0 580 464 016

0 580 464 019

0 580 464 020

U

N

I

0 580 254 053

0 580 254 053

0 580 254 053

0 580 254 909

0 580 254 909

0 580 254 909

0 580 254 910

0 580 254 910

0 580 254 909

0 580 254 909

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 085

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 021

0 580 464 022

0 580 464 023

0 580 464 024

0 580 464 025

0 580 464 027

0 580 464 028

0 580 464 030

0 580 464 032

0 580 464 033

0 580 464 034

0 580 464 037

0 580 464 038

0 580 464 040

0 580 464 041

0 580 464 042

0 580 464 044

0 580 464 048

0 580 464 050

0 580 464 051

0 580 464 056

9 580 810 046

U

N

I

0 580 464 069

0 580 464 069

0 580 464 070

0 580 464 069

0 580 464 069

0 580 464 069

0 580 464 069

0 580 254 911

0 580 464 070

0 580 464 070

0 580 254 911

0 580 464 069

0 580 464 070

0 580 254 911

0 580 254 911

0 580 464 069

0 580 464 069

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

0 580 464 070

2008 | 2009 Bosch Automotive Aftermarket

Page 20

A18 | Electric fuel pumps

Electric fuel pumps

The full range

Fuel-supply module

Pump Included

Fuel reservoir Optional

Fuel-level sensor Included

Pressure regulator Optional

Strainer Included

Electric fuel pump

Pump Included

Fuel reservoir –

Fuel-level sensor –

Pressure regulator –

Strainer Optional

Electric-fuel-pump parts sets and repair kits

Pump Included

Fuel reservoir Optional

Fuel-level sensor Optional

Pressure regulator –

Strainer Optional

Intake module

Pump –

Fuel reservoir Optional

Fuel-level sensor Included

Pressure regulator –

Strainer Optional

Bosch Automotive Aftermarket 2008 | 2009

Page 21

Non-return valves

On certain electric fuel pumps the nonreturn valve integrated into the threaded

socket on the delivery end can be replaced.

Each of the parts sets listed comprises the

genuine threaded socket with non-return

valve and a corresponding sealing ring.

0 580 254 001

0 580 254 002

0 580 254 003

0 580 254 005

0 580 254 010

0 580 254 011

0 580 254 012

0 580 254 013

0 580 254 018

0 580 254 019

0 580 254 020

0 580 254 021

0 580 254 023

0 580 254 033

0 580 254 035

0 580 254 039

0 580 254 040

0 580 254 044

0 580 254 049

0 580 254 050

0 580 254 052

0 580 254 914

0 580 254 916

0 580 254 918

0 580 254 919

0 580 254 920

0 580 254 921

0 580 254 922

0 580 254 927

0 580 254 928

0 580 254 929

0 580 254 930

0 580 254 933

0 580 254 934

0 580 254 935

0 580 254 936

0 580 254 937

0 580 254 938

0 580 254 941

0 580 254 942

0 580 254 943

0 580 254 945

0 580 254 947

0 580 254 948

0 580 254 949

1 587 010 533

1 587 010 533

1 587 010 531

1 587 010 531

1 587 010 536

1 587 010 532

1 587 010 532

1 587 010 536

1 587 010 532

1 587 010 531

1 587 010 531

1 587 010 532

1 587 010 531

1 587 010 532

1 587 010 531

1 587 010 531

1 587 010 531

1 587 010 532

1 587 010 536

1 587 010 536

1 587 010 532

1 587 010 004

1 587 010 004

1 587 010 533

1 587 010 536

1 587 010 536

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 535

1 587 010 532

1 587 010 534

1 587 010 533

1 587 010 537

1 587 010 533

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 538

1 587 010 532

1 587 010 534

1 587 010 532

0 580 254 950

0 580 254 951

0 580 254 952

0 580 254 953

0 580 254 956

0 580 254 957

0 580 254 958

0 580 254 959

0 580 254 967

0 580 254 968

0 580 254 975

0 580 254 979

0 580 254 982

0 580 254 984

0 580 254 992

0 580 463 998

0 580 464 017

0 580 464 021

0 580 464 022

0 580 464 024

0 580 464 025

0 580 464 027

0 580 464 028

0 580 464 029

0 580 464 031

0 580 464 037

0 580 464 039

0 580 464 040

0 580 464 041

0 580 464 042

0 580 464 044

0 580 464 045

0 580 464 047

0 580 464 057

0 580 464 058

0 580 464 068

0 580 464 990

0 580 464 995

0 580 464 997

Electric fuel pumps | A19

1 587 010 536

1 587 010 538

1 587 010 532

1 587 010 535

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 010 532

1 587 410 901

1 587 410 901

1 587 410 901

1 587 410 901

1 587 010 001

1 587 010 540

1 587 010 532

1 587 010 536

1 587 010 539

1 587 010 536

1 587 010 539

1 587 010 536

1 587 010 536

1 587 010 539

1 587 010 534

1 587 010 536

1 587 010 539

1 587 010 536

1 587 010 538

1 587 010 536

1 587 010 536

1 587 010 532

1 587 010 537

1 587 010 532

1 587 010 532

1 587 010 539

1 587 010 536

1 587 010 538

1 587 010 536

2008 | 2009 Bosch Automotive Aftermarket

Page 22

A20 | Sensors

Sensors

Comprehensive range of sensors from Bosch

Increasing original-equipment figures – growing replacement

demand

Even compact vehicle models are currently fitted with more than

50 individual sensors. With the exception of the Lambda sensor the

majority are not subject to wear, but accidents or other influences

may cause damage.

As the leading supplier of original-equipment automobile sensors,

Bosch can also offer the most comprehensive aftermarket range in

this sector. Suitable replacement parts can be found for nearly all

repair applications. In addition, Bosch provides workshops with the

essential electronic diagnosis techniques for the identification of

defective sensors.

The Bosch sensor range comprises several hundred different types.

The types of sensor based on ultra-modern micro electromechanical systems (MEMS) span a field of applications including pressure,

acceleration and yaw-rate detection. The wide range of conventional

measuring elements available extends from speed sensors and

hot-film air-mass meters or Lambda sensors right through to sensors

for automatic air-conditioning systems.

Bosch Automotive Aftermarket 2008 | 2009

Page 23

Gasoline injectors

Bosch is the worldwide market leader

Gasoline injectors | A21

A Bosch milestone: 40 years of manufacturing expertise

Bosch manufactures 80 million gasoline injectors every year at

seven production plants distributed around the world. With particularly high market shares in Western Europe, the NAFTA area,

and China, Bosch is way out in front as the world-market leader.

Bosch has the innovative answers for optimized gasoline-injection

systems and natural-gas injectors:

2001: EV14 for manifold injection – an optimized injection

orifice plate and finer atomization permit a reduction of up to

15 percent in hydrocarbon emissions.

2005: Injectors for environmentally compatible, inexpensive

natural gas – as compared to conventional gasoline, carbon dioxide emissions can be reduced by up to 30 %.

Refinement of the DI-Motronic gasoline direct-injection system

to obtain a jet-directed combustion process: Consumption can be

reduced by up to 15 % in comparison with manifold injection.

Parallel development of solenoid-controlled high-pressure

injectors with multihole nozzle suitable for all gasoline direct injection combustion processes.

2008 | 2009 Bosch Automotive Aftermarket

Page 24

A22 | Ignition coils

Ignition coils

Innovative plastic ignition coils of original-equipment standard

Bosch ignition systems set new standards

in engine management

Thanks to the expertise obtained from the

development of injection systems, Bosch

ignition systems are always ideally adapted

to the engine concerned and ensure low

fuel consumption and high power in combination with good emission values. This

means that compliance with ever more

stringent emission legislation can always

be guaranteed.

100 years of Bosch ignition

Bosch’s unrivalled wealth of experience in

the field of ignition technology makes all

the difference when it comes to developing

original equipment. Bosch ignition systems

offer the safety and reliability of established

system technology whilst at the same time

incorporating the latest research findings.

Market coverage and range expansion

At Bosch, technological development is a

constantly ongoing process. Keeping a close

eye on the market, technical innovations are

incorporated into engine production in close

cooperation with the automotive industry.

As a result, the range and thus also market

coverage are constantly being expanded.

Bosch is also a worldwide supplier of

plastic ignition coils for the automotive

industry

The use of Bosch plastic ignition coils

guarantees all the benefits of original

equipment:

Demand-oriented ignition voltage

Long spark duration

Improved engine performance

Lower fuel consumption

Reduced pollutant emissions

Primary coil body

Primary winding

Yoke

Silicone casing

Connectors

Spark-plug contact

Core

Shrink-down tubing

Secondary coil body

N Secondary winding

Bosch Automotive Aftermarket 2008 | 2009

Page 25

New additions to range

0 986 221 034

0 986 221 035

0 986 221 036

0 986 221 037

0 986 221 038

0 221 504 470

0 221 504 471

CITROËN

PEUGEOT

CITROËN

PEUGEOT

RENAULT 82 00 025 256

AUTOBIANCHI

FIAT

INNOCENTI

LANCIA

AUTOBIANCHI

FIAT

LANCIA

BMW

MINI

BMW 12 13 7 571 644 320i

O.E .

5970 72 / 74 Berlingo, Saxo, Xsara, 106, 206, 306, Partner, Ranch

5970 78 / 79,

9635864980

82 00 084 401

82 00 051 128

7746151 Croma, Delta, Elba, Fiorino 88, Tempra, Tipo, Uno 75, Y10

4439396 126, Panda

12 13 7 571 643

12 13 7 562 744

V7 571 64380

V7 562 744

C2, C3, Berlingo, Saxo, Xsara, 206, 306, Partner, Ranch

Clio II, Kangoo, Twingo

335i, Cooper, One

Ignition coils | A23

2008 | 2009 Bosch Automotive Aftermarket

Page 26

A24 | eXchange – Back in Box

eXchange – Back in Box

Outstanding quality, comprehensive range, top-class service

1. Delivery of genuine Bosch exchange product. 2. Replace the corresponding old part with the exchange product.

Note:

Gasoline-injection engine management

Deposits can only be redeemed if the old item is returned in the

Hot-film air-mass meter 5

Hot-wire air-mass meter 20

Air-flow sensor 10

Fuel distributor 20

Electronic control units 20

Central injection unit (ZEE) - top section 10

Central injection unit (ZEE) - bottom section 10

Ignition distributors 10

packaging of the exchange product supplied.

Advantages:

Protection of old items on return shipment

Faster processing of old items as old part is easier to identify

Disposal of packaging no longer necessary

No soiling by the old item

Bosch Automotive Aftermarket 2008 | 2009Bosch Automotive Aftermarket 2008 | 2009

Page 27

eXchange – Back in Box | A25

3. Place the old part in the packaging of the exchange product. 4. Return the old part to Bosch in the sealed packaging.

The comprehensive, intelligent exchange range

Currently a total of 21 product groups from the starter/alternator,

diesel/gasoline-injection and brake-caliper sectors

High degree of market coverage for all the major motor-vehicle

manufacturers

Constant updating of range

Top class service in the form of product information and technical

Outstanding quality at attractive prices

Quality standards comparable to original equipment

100 % replacement of all critical components

Consistent use of genuine Bosch replacement parts

Same warranty as for new products

media such as ESI[tronic] from the diagnostic sector

Quick and easy processing of old items

2008 | 2009 Bosch Automotive Aftermarket2008 | 2009 Bosch Automotive Aftermarket

Page 28

A26 | eXchange – conditions for component return

eXchange – conditions for component return

Hot-film air-mass meter Hot-wire air-mass meter

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Damage to bolts, bolts

screwed out and projecting, incorrect bolts

Damage to plug-in sensor and plug connection

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Damage to temperature

sensor

Damage to cylinder

housing

Damage to cylinder

housing or strainer

element

Damage to electronics

housing (no cover) or

plug connection

Bosch Automotive Aftermarket 2008 | 2009

Page 29

eXchange – conditions for component return | A27

Air-flow sensor Control unit

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Damage to plastic

housing

Damage to aluminum

housing

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Damage to housing,

screw connection and

flange

Damage to connector

or terminal strip

Severe corrosion

Water damage or

housing opened

2008 | 2009 Bosch Automotive Aftermarket

Page 30

A28 | eXchange – conditions for component return

Ignition distributor Central injection unit

(top/bottom section)

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Damage to vacuum unit,

mounting plate

Damage to ignition

module, distributor shaft

or cap

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Attention: Complete ZEE cannot be returned

Damage to housing

Damage to sealing

surfaces, thread,

throttle valve, control

lever

Distributor cap missing,

connector missing

Pressure regulator or

throttle-valve potentiometer missing

Bosch Automotive Aftermarket 2008 | 2009

Page 31

Fuel distributor

eXchange – conditions for component return | A29

Returned item not accepted if:

Not a genuine Bosch assembly

Severe corrosion

Assembly incomplete or dismantled

Assembly manipulated

Mechanical damage

Severe damage to

housing (e.g. deformation

or cracks)

2008 | 2009 Bosch Automotive Aftermarket

Page 32

A30 | Gasoline injection components

A30 | Gasoline injection components

Gasoline injection components

A to Z guide

Acceleration sensor

System:

Motronic

Purpose:

Compliance with OBDII requirements (engine management on-board diagnostics) demands

the detection of misfiring at individual cylinders as well as misfiring distributed randomly over

all the cylinders. This is achieved by recording the fluctuations in crankshaft speed. Speed

fluctuations also occur as a result of driving on particularly rough roads and frequent road

surface irregularities. Such road surface irregularities additionally give rise to extreme body

acceleration, which is measured by way of an acceleration sensor. This signal is used to block

the misfiring detection function.

Part number:

0 273 101 02.

Air-flow sensor

Systems:

L-Jetronic, Motronic

Purpose:

The air flowing into the engine deflects a sensor plate in opposition to the restoring force of

a spring. A potentiometer converts the deflection of the sensor plate into a voltage.

The electronic control unit uses this signal to calculate the quantity of fuel required.

Part number:

0 280 200 ..., 0 280 201 ..., 0 280 202 ..., 0 280 203 ...,

BX: 0 986 280 0..

Air-flow sensor (mechanical)

Systems:

K, KE-Jetronic, KE-Motronic

Purpose:

The air-flow sensor and the fuel distributor together form the mixture-control unit. The two

components are available separately and must be replaced separately. The air flowing through

the air funnel deflects the sensor plate by a certain distance. The sensor-plate deflection is

transmitted to the fuel distributor by way of a lever system.

Part number:

0 438 120 ..., 0 438 121 ..., F 026 TX2 ...,

BX: 0 986 439 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 33

Gasoline injection components | A31

Air-mass meter

System:

LH-Jetronic, Motronic

Purpose:

The air-mass meter is installed between the air filter and the throttle valve and measures

the intake-air mass. Use is made in practice of hot-wire and hot-film air-mass meters. Both

sensors operate on the same principle: An electrically heated thin platinum wire or platinum

film resistor is positioned in the intake-air flow together with a temperature sensor in the form

of a temperature-sensitive resistor. The electronic control unit is supplied with a voltage signal

proportional to the air mass flow and uses this signal to calculate the quantity of fuel required.

Part number:

0 280 21. ...,

BX: 0 986 280 1.. (HLM), 0 986 280 2.. (HFM)

Auxiliary-air device

Systems:

D, L, K-Jetronic, Motronic (some)

Purpose:

The auxiliary-air device is installed in a bypass around the throttle valve. In the warm-up phase,

the engine is supplied with additional air/fuel mixture to ensure stable idling. The auxiliary-air

device is electrically heated and closes the bypass with increasing engine temperature. The

bypass is completely closed off when the engine reaches operating temperature.

Part number:

0 280 140 001 – 0 280 140 299

Camshaft speed sensor

Systems:

Motronic

Purpose:

The camshaft position indicates whether an engine piston moving towards top dead center is

in the compression or exhaust stroke. The speed sensor at the camshaft (also referred to as

phase sensor) passes this information to the electronic control unit. Such sensors are used

where high accuracy is required. Further advantages include a comparatively large air-gap range

and good temperature compensation.

Part number:

0 232 10. ...

2008 | 2009 Bosch Automotive Aftermarket

Page 34

A32 | Gasoline injection components

System:

Canister-purge valve

Motronic

Purpose:

Vapors are produced in the fuel tank due to external heat radiation or surplus fuel having

warmed-up in the engine compartment while flowing back from the fuel circuit. These vapors

are purged by way of an activated charcoal filter. This filter retains the fuel vapor and only

allows the air to escape into the open. This also ensures pressure equalization. For regular

regeneration of the activated charcoal, a further pipe containing the canister-purge valve is

routed from the carbon canister to the intake manifold. The canister-purge valve (regeneration

valve) is actuated such that the activated carbon canister is adequately purged with minimal

Lambda deviations.

Part number:

0 280 142 150 – 0 280 142 499

Central injection unit (Mono-Jetronic)

Systems:

Mono-Jetronic, Mono-Motronic

Purpose:

The main component of Mono systems is the central injection unit. This contains the injector,

the pressure regulator, the throttle valve, the throttle-valve actuator and sensors for intake-air

temperature and throttle-valve position. Bosch supplies the appropriate workshop parts sets

for repair work. The replacement parts range can be found as of Page A 46. The parts sets for

the top and bottom sections of the central injection unit are also listed in the vehicle applications (B Section).

Part number:

0 438 201 ...,

BX: 0 986 438 5.., 0 986 438 6..

Cold-start valves

Systems:

D, L, LH, K, KE-Jetronic, Motronic (some)

Purpose:

The cold-start valve injects additional fuel into the intake manifold during the starting phase.

In this process, the fuel is highly atomized by a swirl nozzle. The cold-start valve is attached to

the intake manifold so as to provide a uniform supply for all cylinders. The injection time of the

cold-start valve is limited by the thermo-time switch or the electronic control unit.

Part number:

0 280 170 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 35

Gasoline injection components | A33

Coolant-temperature sensor

Systems:

D, L, LH-Jetronic, K-Jetronic (with Lambda sensor), KE-Jetronic, KE-Motronic, Motronic

Purpose:

The coolant-temperature sensor measures the temperature in the coolant circuit and

provides the electronic control unit with an electric signal. The sensor comprises an NTC

thermistor embedded in a threaded sleeve or a plastic casing. The “coolant temperature”

signal is particularly important for the starting and warm-up phase.

Part number:

0 261 220 ..., 0 280 130 ...

Crankshaft speed sensor

System:

Motronic

Purpose:

A ferromagnetic gear wheel with reference mark (tooth gap) is attached to the crankshaft.

The speed sensor scans the tooth sequence. The electronic control unit uses the signal to

calculate the crankshaft position and speed. Some systems are fitted with two sensors.

Crankshaft position and speed are then measured separately.

Part number:

0 261 210 ...

Electric fuel pumps/in-tank units

Systems:

All systems

Purpose:

The electric fuel pump (EKP) must supply the engine with sufficient fuel at the pressure

required for injection under all operating conditions. The EKP is also increasingly assuming

the function of a pre-supply pump for modern direct-injection systems in both gasoline and

diesel engines. Principal requirements: Delivery rate between 60 and 200 l/h at rated voltage,

pressure in fuel system between 300 and 450 kPa (3...4.5 bar), build-up of primary pressure

as of 50 % to 60 % of rated voltage; cold-starting operation is definitive for this.

Part number:

0 580 254 ..., 0 580 303 ..., 0 580 305 ..., 0 580 309 ..., 0 580 310 ..., 0 580 313 ..., 0 580 314 ...,

0 580 453 ..., 0 580 464 ..., 0 582 980 ..., 0 587 010 ..., 0 986 580 ..., etc.

2008 | 2009 Bosch Automotive Aftermarket

Page 36

A34 | Gasoline injection components

Systems:

Electronic control units

Jetronic and Motronic

Purpose:

The electronic control unit determines the quantity of fuel required in each case and regulates

all the connected actuators and injectors. This is implemented on the basis of the signals from

the temperature, pressure and load-detection sensors. Electronic control units for Motronic

systems also control the ignition point. In modern systems, the ECU also assumes diagnosis

functions. Faults occurring are stored in the fault memory and can be read out using self diagnosis testers.

Note:

Electronic control units in vehicles with immobilizer sometimes have to be “taught”. This work

can only be performed in specially equipped workshops.

Part number:

0 261 20. ... (Motronic), 0 280 00. ... (L/LH-Jetronic), 0 280 800 ... (KE-Jetronic/Motronic)

Fuel accumulator

Systems:

K, KE-Jetronic, KE-Motronic

Purpose:

The fuel accumulator keeps the fuel-supply system pressurized after shutting off the engine.

This considerably enhances starting performance, particularly with a hot engine. The accumulator also has a sound-absorbing effect.

Part number:

0 438 170 ...

Fuel distributor

Systems:

K, KE-Jetronic, KE-Motronic

Purpose:

The fuel distributor and the air-flow sensor together form the mixture-control unit. The two

components are available separately and must be replaced separately. The fuel distributor’s

control plunger is deflected by the air-flow sensor’s lever system. The fuel distributor meters

the quantity of fuel to be injected to each cylinder.

Note:

Note: The fuel distributor can only be replaced as a complete unit. It cannot be assembled

using workshop equipment after removing individual components.

Part number:

0 438 100 ..., 0 438 101 ..., T 026 TX2 ...,

BX: 0 986 438 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 37

Gasoline injection components | A35

Fuel rail

Systems:

L, LH-Jetronic, Motronic

Purpose:

Along with the electric fuel pump, fuel filter, injectors and pressure regulator, the fuel rail forms

part of the fuel-supply system which always supplies the engine with the necessary amount

of fuel under all operating conditions. The pressure generated by the fuel pump is applied to

all injectors by way of the fuel rail. The unused fuel flows back to the fuel tank via a pressure

regulator. In most cases, the pressure regulator (fuel rail – conventional design with pressure

regulator) uses the intake-manifold pressure as a reference. The use of this typical pressure

and the flow through the fuel rail (fuel cooling) prevent the formation of any unwanted vapor

bubbles in the fuel.

Part number:

0 280 151 ..., 0 280 152 ...

High-pressure injector HDEV-1 + HDEV-5

Purpose:

The high-pressure injector (HDEV), one of the key components of a gasoline direct-injection

system, is linked by way of hydraulic connections to the fuel rail (KVS-HD) and is actuated via a

current-controlled output stage. The solenoid swirl valve injects a precisely metered quantity of

fuel with a defined spray pattern directly into the combustion chamber in finely atomized form.

The injected fuel quantity is determined by pressure, flow rate and the actuation time of the

injector. The spray geometry is matched to the requirements of the corresponding engine and

the combustion process.

Part number:

0 261 500 ...

High-pressure injector HDEV-4

System:

Motronic gasoline direct injection

Purpose:

The HDEV-4 is a high-speed piezo injector for gasoline with variable needle lift. The nozzle

opens outwards and ensures outstanding spray stability whilst at the same time being

extremely resistant to coking. The injector covers a wide metering range in which the quantity

characteristic curve is distinguished by a high degree of linearity.

The HDEV-4 can be employed for various combustion methods and injection concepts. Its rapid

and accurate multiple injection action opens up new potential for configuring the injection

process.

Part number:

0 261 500 ...

2008 | 2009 Bosch Automotive Aftermarket

Page 38

A36 | Gasoline injection components

Purpose:

High-pressure pump HDP-1

The 3-barrel radial-piston high-pressure pump is driven by the camshaft via a coupling.

It compresses the fuel provided by the electric fuel pump up to 12 MPa and delivers it to the

high-pressure fuel rail (KVS-HD). The fuel cools and lubricates the high-pressure pump.

Part number:

0 261 520 ...

High-pressure pump HDP-2

System:

Motronic gasoline direct injection

Purpose:

In contrast to the HDP-1, the high-pressure pump HDP-2 is a unit pump. It is a demand regulated, intermittent-delivery 1-barrel piston pump with a maximum pressure range up to

120 bar. It features an integral pressure damper and the integrated fuel-quantity control valve.

The pump is of modular design for flexible adaptation to different customer requirements. The

HDP-2 is driven via the bucket tappet which is actuated by the camshaft. It is attached directly

to the cylinder head or to an adapter housing.

Part number:

0 261 520 ...

High-pressure pump HDP-5

System:

Motronic gasoline direct injection

Purpose:

The HDP-5 is a quantity-controlled single-barrel high-pressure pump for 4 to 8-cylinder engines.

In new engine projects it supersedes all the previous 1st-generation Bosch high-pressure

pumps (HDP-1 and HDP-2).

Part number:

0 261 520 ...

High-pressure sensor

Purpose:

The sensor installed in the high-pressure fuel rail is designed to detect the fuel-pressure level

in the rail. The pressure measured is used as actual quantity for rail-pressure regulation.

Part number:

0 261 545 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 39

Gasoline injection components | A37

Idle actuator

Systems:

LH, KE-Jetronic, KE-Motronic, Motronic

Purpose:

The idle actuator is installed in a bypass around the throttle valve and keeps the idling speed

steady under all conditions. Electrical actuation is effected by way of the engine control unit or

the idle controller on vehicles with idle-speed control. Extensive use is made of idle actuators

with hose connection. Add-on idle actuators are also employed in Motronic systems.

Part number:

0 280 140 5 ..

Idle controller (electronic control unit)

Systems:

All systems with idle-speed control

Purpose:

The idle controller regulates the rotary idle actuator and keeps the engine idling speed

absolutely steady. This avoids speed fluctuations when such loads as power steering,

air conditioner or automatic-transmission gearshift are activated.

Part number:

0 280 220 ...

Ignition coil

Purpose:

The operating principle of an ignition coil is based on Faraday’s law. Modern ignition coils

consist of iron cores made up of individual laminations and a plastic casing. To provide better

insulation of the windings, the casing is cast in epoxy resin or asphalt.

The pencil coil shown is one of the plastic ignition coils. It provides high spark energy (> 60 mJ)

and a long spark duration (≥ 1.8 ms) and thus ensures reliable, optimum combustion of the air/

fuel mixture under all engine operating conditions.

Part number:

0 221 ... ..., F 000 ZS0 ..., 1 227 030 ..., 0 986 221 ...

2008 | 2009 Bosch Automotive Aftermarket

Page 40

A38 | Gasoline injection components

Purpose:

Ignition distributors

The ignition distributor, which runs at half the engine speed, assigns the high voltage (ignition

sparks) to the particular engine cylinder (firing order). A basic distinction is made between

three types:

Type 1:

Contact-type ignition distributor (ZV-K). This is used with conventional coil ignition and

breaker-triggered transistorized ignition (TZ-K). The ignition point is modified by way of speeddependent centrifugal or vacuum advance.

Part number:

0 231 ... ...

Type 2:

Ignition distributor with non-contacting sensor. This is used for transistorized ignition with

inductive or Hall sensor. The ignition point is modified by way of speed-dependent centrifugal

or vacuum advance. Also double-acting. Also with add-on trigger box.

Part number:

0 237 ... ...

Type 3:

Ignition distributor for electronic ignition. The ignition distributor contains only the high-voltage

section (cap, rotor).

Part number:

0 237 5.. ...,

BX: 0 986 237 ...

Injectors (electromagnetic)

Systems:

D, L, LH-Jetronic, Motronic

Purpose:

Each cylinder is assigned an injector. This is triggered electronically and injects the fuel upstream of the engine intake valves. In this process, the nozzle needle is lifted off its seat by

approx. 0.1 mm, allowing the fuel to emerge through a precision annular orifice. Even the

slightest contamination of the fuel or deposits can impair operation. The injectors are installed

by way of special holders in rubber mouldings. The thermal insulation thus achieved prevents

the formation of vapor bubbles and thus ensures good hot starting performance. To avoid

unmetered air and leakage, the O-rings are always to be replaced prior to renewed installation.

Part number:

0 280 150 ..., 0 280 155 ..., 0 280 156 ..., 0 280 157 ..., 0 280 158 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 41

Gasoline injection components | A39

Injectors (mechanical)

Systems:

K, KE-Jetronic, KE-Motronic

Purpose:

K-Jetronic valves open at a precisely defined fuel pressure (usually between 3.5 and 4.1 bar). In

this process the valve needle oscillates at a high frequency and the fuel is thoroughly atomized

even in the case of very small injected quantities. Each cylinder is assigned an injector, which

injects the fuel directly upstream of the engine intake valves. Atomization, opening pressure

and freedom from leaks have a major influence on emission characteristics, fuel consumption

and starting performance. To avoid unmetered air and leakage, the O-rings are always to be

replaced prior to installation.

Part number:

0 437 502 ...

Injectors EV10 (electromagnetic)

Systems:

Mono-Jetronic, Mono-Motronic

Purpose:

The injector EV10 is installed in the top section of the central injection unit. In this case

one injector supplies all the cylinders with fuel. The fuel is injected into the intake manifold

upstream of the throttle valve. As each ignition pulse also triggers an injection pulse, the EV10

is designed for very short switching times. During injection, the valve needle is lifted off its

seat by approx. 0.06 mm. Even the slightest fuel contamination can impair operation. Injectors

to suit each central injection unit can be found in the replacement parts range as of Page A 46.

Part number:

0 280 150 051 – 0 280 150 099, 0 280 150 651 – 0 280 150 699

Knock sensors

System:

Motronic

Purpose:

The knock sensor converts vibration into electric signals. This enables the electronic control

unit to detect knocking combustion and to retard the ignition point to prevent engine damage.

In some cases several sensors are attached to the engine block for knock-control purposes.

Part number:

0 261 231 ...

2008 | 2009 Bosch Automotive Aftermarket

Page 42

A40 | Gasoline injection components

Systems:

Lambda sensors

All

Purpose:

With older systems, the Lambda sensor is installed upstream of the catalytic converter. The

sensor measures the oxygen content of the exhaust gas and supplies the electronic control unit

with a voltage of approx. 800 mV for a rich mixture (λ 1). Modern systems require two Lambda

sensors – one upstream of the catalytic converter (= Lambda control sensor) and one downstream (= Lambda diagnosis sensor). Increasing use is being made of planar sensors. These

attain the necessary operating temperature after just a few seconds. To permit lean operation

of the engine, the sensor upstream of the catalytic converter must be capable of detecting a

lean mixture composition. Use is made of the latest broadband sensors for this purpose. These

play a crucial part in reducing emissions in the critical warm-up phase and thus ensure compliance with the EURO IV and ULEV (Ultra Low Emission Vehicle) emission specifications.

Note:

Recommended torque: 40 – 60 Nm

Part number:

Unheated: 0 258 001 ..., 0 258 002 ...

Heated: 0 258 003 , 0 258 005 ...

Planar: 0 258 006 ..., 0 258 007 ..., 0 258 010 ... and 0 258 017 ...

Pedal-travel sensor/accelerator-pedal module

Systems:

Motronic with ETC

Purpose:

In contrast to conventional engine-management systems, with the EGAS Motronic the driver’s

acceleration input is no longer relayed to the throttle valve via a cable. Instead, the input is

detected using a pedal-travel sensor (also referred to as “electronic throttle control”) and

transmitted to the electronic control unit. The accelerator-pedal module is a pre-assembled unit

containing a vehicle-specific foot plate and the pedal-travel sensor. The Motronic ECU evaluates

the sensor signal and adjusts the electric motor-driven throttle valve (throttle device or EMS

positioner) taking into account other vehicle and engine data.

Part number:

0 205 001 ..., 0 280 752 ..., 0 280 755 ...

Pressure damper

Systems:

D, L, LH, K, KE-Jetronic, Motronic

Purpose:

The opening and closing of the injectors and the cyclic delivery action of fuel pumps cause

fluctuations in fuel pressure. These may be transmitted to other components and the body and

result in noise. The pressure damper smoothes the pressure peaks and is primarily designed

to reduce noise.

Part number:

0 280 161 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 43

Gasoline injection components | A41

Pressure regulator

Systems:

D, L, LH-Jetronic, Mono-Jetronic, Motronic, Mono-Motronic

Purpose:

The pressure regulator is designed to maintain the system-specific difference in pressure between the fuel-supply line and the intake manifold at a constant level. The regulator is located

at the end of the fuel rail (in the top section of the central injection unit on Mono systems).

If the set pressure is exceeded, a diaphragm-actuated valve opens up the return pipe and the

depressurized surplus fuel flows back to the tank.

Note:

The pressure regulator at the central injection unit cannot be replaced separately. Bosch

supplies top sections with pre-assembled pressure regulator for this purpose (as of Page A 46).

Part number:

0 280 160 0.., 0 280 160 2.., 0 280 160 5.., 0 280 160 7..,

0 438 161 ... Primary-pressure regulator for KE-Jetronic/Motronic

Pressure sensors (Motronic)

System:

Motronic

Purpose:

Pressure sensors can be used for a variety of applications. Intake-manifold pressure sensors

measure the absolute pressure in the intake manifold. These sensors are either integrated into

the electronic control unit or fitted in the vicinity of the intake manifold in the form of externally

mounted sensors. Modern systems featuring on-board diagnosis are additionally fitted with

tank-pressure sensors. Modern DUO sensors combine pressure and temperature measurement.

Part number:

0 261 230 ...

Pressure sensors (altitude sensors)

Systems:

L, K, KE-Jetronic, Motronic

Purpose:

Pressure sensors detect the atmospheric pressure and relay this to the electronic control

unit in the form of a voltage signal. This prevents the over-enrichment and increased fuel

consumption normally associated with decreasing atmospheric pressure at high altitudes.

Part number:

0 280 101 ...

Pressure-control valve (DSV)

Purpose:

The pressure-control valve is positioned between the fuel rail (KVS-HD) and the low-pressure

end of the high-pressure pump (HDP-1). The pressure in the rail is set by varying the flow

cross-section. The surplus fuel conveyed is returned to the tank.

Part number: 0 261 540 ...

2008 | 2009 Bosch Automotive Aftermarket

Page 44

A42 | Gasoline injection components

System:

Pulse valves

K-Jetronic (with Lambda control)

Purpose:

The pulse valve is installed in the connecting line between the fuel distributor’s lower chambers

and the fuel return. It is actuated by the Lambda controller and opened and closed in a defined

cycle. This enables the pressure in the lower chambers to be varied and the air/fuel mixture

regulated to λ = 1.

Part number:

0 280 150 300 – 0 280 150 349

Secondary-air pump (electrical)

System:

Motronic

Purpose:

Use is made of the electric secondary-air pump to comply with the stringent emission legislation

in the post-start phase. Fresh air injected directly downstream of the combustion chamber

causes afterburning of the hot exhaust gases and ensures more rapid warm-up of the catalytic

converter.

Part number:

0 580 000 ...

Shutoff valve

System:

Motronic

Purpose:

The shutoff valve is used in turbo engines to protect the turbocharger. The turbocharger

remains in operation on switching from turbo to overrun mode. Without a shutoff valve, the air

would impact against the closed throttle valve and flow back into the turbocharger. This return

flow of air could damage the turbocharger. To guard against this, the seat of the shutoff valve

is opened by the vacuum applied in the intake manifold in overrun mode with the throttle valve

closed. This enables the air conveyed by the continued operation of the turbocharger to be

routed via a bypass around the turbocharger and back into the intake manifold.

Part number:

0 280 142 100 – 0 280 142 150

Bosch Automotive Aftermarket 2008 | 2009

Page 45

Gasoline injection components | A43

Thermo-time switch

Systems:

D, L, LH, K, KE-Jetronic, Motronic

Purpose:

The thermo-time switch limits the injection period of the cold-start valve as a function of time

and temperature. The switch consists of an electrically heated bimetallic element, which breaks

or makes a contact. Actuation is implemented by way of the ignition/starter switch.

Part number:

0 280 130 2..

Throttle-valve assembly (EMS positioner)

Systems:

Motronic with ETC

Purpose:

In engine management systems with ETC, the throttle valve is no longer adjusted directly

by way of a cable. The acceleration input is detected via a pedal-travel sensor and the sensor

signal is relayed to the electronic control unit. The signal received by the control unit is

converted into a control signal incorporating other vehicle and engine data. This control signal

opens or closes the throttle valve (driven by an electric motor) in line with the driver input

and driving situation.

Part number:

0 205 003 0.., 0 280 750 ...

Throttle-valve potentiometer, throttle-valve sensor

Systems:

Mono-Jetronic, Motronic, Mono-Motronic

Purpose:

Throttle-valve sensors are attached to the throttle-valve assembly or the central injection unit.

These sensors detect the position of the throttle valve and the angular velocity on opening and

closing. The angular velocity is an important signal for the electronic control unit to provide

compensation for load-change reactions and to prevent part-load bucking. Note: Throttle-valve

sensors at central injection units cannot be replaced. The entire bottom section of the injection

unit has to be renewed. The appropriate bottom section can be found in the replacement parts

range as of Page A 46.

Part number:

0 261 211 ..., 0 280 122 ...

2008 | 2009 Bosch Automotive Aftermarket

Page 46

A44 | Gasoline injection components

Systems:

Throttle-valve switch

D, L, LH, KE-Jetronic, Motronic

Purpose:

The throttle-valve switch is attached to the throttle-valve assembly. The switch is actuated by

the throttle-valve shaft. One contact is made in each case in the “idle” and “full load” positions.

These signals enable the electronic control unit to activate the idle-increase function with a

cold engine and enrichment at full load.

Part number:

0 280 120 000 – 0 280 120 499

Vacuum limiter

Systems:

L, LH, K, KE-Jetronic, Motronic

Purpose:

The vacuum limiter restricts the difference in pressures upstream and downstream of the

throttle valve. Additional air flows into the intake manifold if the set pressure difference is

exceeded.

Part number:

0 280 160 1.., 0 280 160 3..

Warm-up regulator

System:

K-Jetronic

Purpose:

Warm-up regulators comprise a spring-controlled diaphragm valve and an electrically heated

bimetallic spring. As a function of engine temperature and time, the control pressure in the fuel

distributor is reduced and more fuel is injected into the engine.

Part number:

0 438 140 ...

Bosch Automotive Aftermarket 2008 | 2009

Page 47

A45

2008 | 2009 Bosch Automotive Aftermarket

Page 48

A46 | Central injection unit (ZEE)

Central injection unit (ZEE)

Mono-Jetronic replacement-parts range

Top-section parts set

Top section with pre-assembled pressure regulator

Note:

The pressure regulator cannot be replaced separately.

Bottom-section parts set

Bottom section with throttle valve and throttle-valve potentiometer

Note:

The throttle-valve potentiometer cannot be replaced separately.

Injector EV10

Injector complete with O-ring

1

2

3

Throttle-valve actuator

Idle actuator

Seal

Seal between top and bottom section

Connector

Connector for injector with integrated intake-air temperature sensor

4

5

6

Bosch Automotive Aftermarket 2008 | 2009

Page 49

Central injection unit (ZEE) | A47

ZEE

0 438 201 024 FD166

0 438 201 024 FD167

0 438 201 028

0 438 201 029

0 438 201 038

0 438 201 039 FD164

0 438 201 039 FD165

0 438 201 041 FD166

0 438 201 041 FD167

0 438 201 052

0 438 201 053

0 438 201 061

0 438 201 062

0 438 201 063

0 438 201 065

0 438 201 067

0 438 201 073

0 438 201 075

0 438 201 077

0 438 201 079

0 438 201 081

0 438 201 085

0 438 201 087

0 438 201 088

0 438 201 089

0 438 201 091

0 438 201 092

0 438 201 094

0 438 201 096

0 438 201 098

0 438 201 100

0 438 201 103

0 438 201 105

0 438 201 109

0 438 201 115

0 438 201 125

0 438 201 127

0 438 201 129

0 438 201 131

0 438 201 132

0 438 201 135

0 438 201 137

0 438 201 138

0 438 201 142

0 438 201 143

1

3 437 020 510 3 437 020 597 0 280 150 625 3 437 010 524 3 431 038 502 3 437 010 523