B&M Dana 60, Dana 70 User Manual

Instructions

Cast Aluminum Cover for

DANA 60/70

(see www.bmracing.com for the latest vehicle fitment applications and model years)

Part Number 10314

© 2013 by B&M Racing and Performance Products

This B&M Cast Aluminum Cover

has been designed to work on most

vehicles equipped with a Dana 60 or

70 axle. The B&M Cast Aluminum

Cover provides several advantages

over stock factory covers. The extra

capacity provides increased oil

volume and added cooling, while the

thick aluminum construction

increases case rigidity. The

reinforced center bar, along with the

load bolts, prevents bearing cap

deflection under severe loads. The

magnetic drain plug feature allows

regular gear oil changes without the

usual mess, and limits ferrous debris

from circulating in the axle.

INTRODUCTION

This cover can be installed in about

an hour by carefully following the

instructions. It is suggested that the

vehicle be allowed to cool off for a

few hours to avoid burns from hot oil

and parts. The vehicle should be off

the ground for ease of installation jack stands, wheel ramps or a hoist

will work fine. MAKE SURE

VEHICLE IS FIRMLY SUPPORTED

- DO NOT WORK UNDER A

VEHICLE IF IT IS SUPPORTED BY

ONLY A JACK! Try to raise the

vehicle 1-2 feet so you will have

plenty of room to work. Also, have

a small box to put bolts in and a

drain pan to catch oil.

INSTALLATION

STEP 1. Clean axle housing cover

area from dirt and other debris.

NOTE: On some vehicles it

might be necessary to remove

some parts (e.g. sway bar,

panhard rod) to make the

installation of the cover easier.

STEP 2. Place a drain pan

underneath the axle housing.

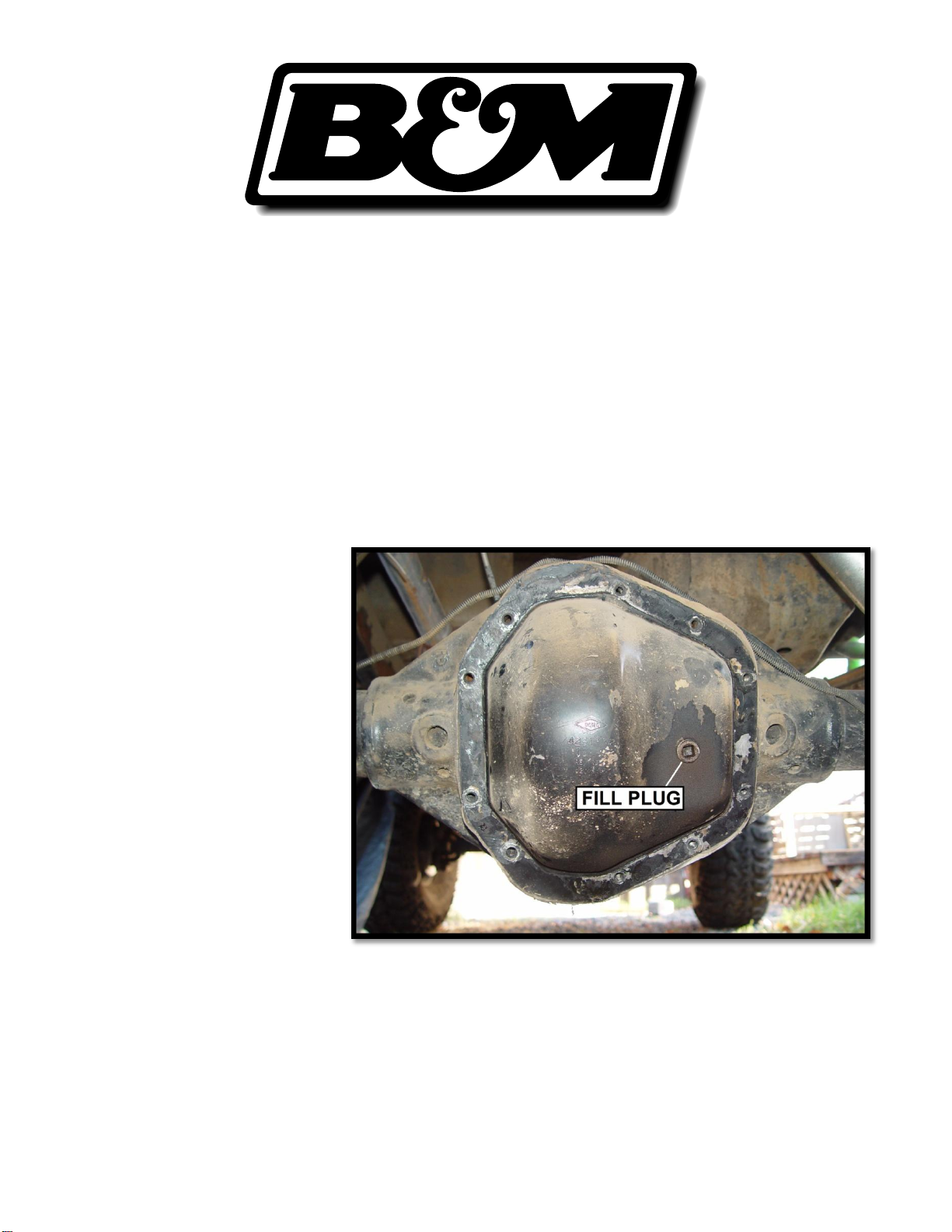

STEP 3 (OPTIONAL). Loosen the

fill plug with a 3/8” square ratchet

and extension. This is done as a

precaution; if stock cover needs to

Printed in the USA 9500893-00

be re-installed for any reason, there

will be no question whether the plug

is seized or cannot be removed.

STEP 4. Remove the 10 bolts

around the cover.

STEP 5. Carefully pry the cover

loose with a flat head screw driver,

being careful not to damage the

surface, and allow the oil to drain.

STEP 6. Using a dry lint free rag,

clean the accessible areas of the

axle housing and check internal

components for visible excessive

wear or other problems.

STEP 7. Clean all gasket material

from the axle housing surface.

STEP 8. We recommend running a

3/8”-16 tap through each threaded

cover hole on the axle housing to

ensure an accurate torque on all

bolts.

STEP 9. Install the supplied load

bolts in each boss from the inside

of the B&M Cast Aluminum

Cover until they bottom out.

STEP 10. Apply a bead of RTV

silicone gasket maker to the B&M

Cast Aluminum Cover. Run the

bead inside the bolt holes.

STEP 11. Install the B&M Cast

Aluminum Cover on the axle

housing using a supplied bolt and

washer at a bottom hole on the

cover so it can be used as a

guide.

STEP 12. Install the rest of the

supplied bolts and washers and

torque to 25 ft/lb in a crisscross

pattern.

STEP 13. Screw in the two load

bolts by hand until they touch the

bearing caps. Torque the load

bolts to 5 ft/lb max.

NOTE: Do not over torque the

load bolts as you run the risk of

distorting the bearing caps,

creating abnormal wear and

premature failure.

STEP 14. Apply a very small amount

of RTV on the threads of the load

bolts, and then install the two

supplied jam nuts onto the load

bolts. Torque the jam nuts to 5 ft/lb.

STEP 15. Install the supplied

magnetic 1/4” NPTF drain plug on

the B&M Cast Aluminum Cover

and tighten.

STEP 16. Fill with factory

recommended gear oil using the

B&M Cast Aluminum Cover fill

plug hole. Add ½ quart MORE

than factory specified.

STEP 17. Install the supplied 1/2”

NPT fill plug on the B&M Cast

Aluminum Cover and tighten.

STEP 18. Install and tighten any

other parts (e.g., sway bar,

panhard rod) if removed.

Owner’s Manual/Maintenance

Booklet recommends replacing

axle lubricant anytime axle is

submerged in water. (Refer to

Owner’s Manual/Maintenance

Booklet for details).

Loading...

Loading...