HVĆ100E and HVĆ100G

INSTALLATION - OPERATION - MAINTENANCE

HVĆ100E et HVĆ100G

MANUEL D'INSTALLATION - FONCTIONNEMENT - ENTRETIEN

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN 52424 Rev H (6/11)

E 2011- G.S. Blodgett Corporation

THE REPUTATION YOU CAN COUNT ON

UNE RÉPUTATION SUR LAQUELLE VOUS POUVEZ COMPTER

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We've set the industry's quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, fullĆsize, halfĆsize, countertop and deck, conĆ

vection, Cook'n Hold, CombiĆOvens and the industry's highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Cela fait maintenant dessus un siècle et demi que Blodgett se spécialise dans

la fabrication de fours. Nous avons établi les normes de qualité qui s'appliĆ

quent dans l'industrie à tous les types de fours utilisés dans les services aliĆ

mentaires, quel qu'en soit la taille, l'exploitation ou le budget. En fait, ni n'offre

plus de modèles, de tailles et d'applications de fours que Blodgett. À gaz et

électriques. De tailles différentes, sur plan de travail et superposables. Qu'il

s'agisse de fours à convection, des modèles Cook'n Hold et CombiĆOven, ou

de la gamme de fours à pizzas de la plus haute qualité offerte sur le marché.

Pour de plus amples informations sur la gamme complète de fours Blodgett,

veuillez contacter votre représentant Blodgett.

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGES À LA PROPRIÉTE, DES BLESSURES OU LA MORT. LISEZ ATTENTIVEĆ

MENT LES DIRECTIVES D'INSTALLATION, D'OPÉRATION ET D'ENTRETIEN AVANT

DE FAIRE L'INSTALLATION OU L'ENTRETIEN DE CET ÉQUIPEMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflamĆ

mables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instrucĆ

tions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procéĆ

dures permettra d'obtenir de bons résultats de cuisson et une longue durée de serĆ

vice sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l'avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. SpecificaĆ

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d'illustration font l'objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Your Service Agency's Address:

Adresse de votre agence de service:

Model/Modèl:

Serial Number/Numéro de série:

Your appliance was installed by/

Installateur de votre four:

Your oven's installation was checked by/

Contrôleur de l'installation de votre four:

Table of Contents/Table des Matières

Introduction

Oven Description & Specifications 2. . . . . .

Installation

Agency Approvals 4. . . . . . . . . . . . . . . . . . . .

Oven Location and Ventilation 5. . . . . . . . . .

Leg Attachment 6. . . . . . . . . . . . . . . . . . . . . .

Caster Attachment 7. . . . . . . . . . . . . . . . . . . .

Stacking 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plumbing Connections 9. . . . . . . . . . . . . . . .

Electrical Connections 10. . . . . . . . . . . . . . . .

Gas Connections 11. . . . . . . . . . . . . . . . . . . . .

Gas Hose Restraint 13. . . . . . . . . . . . . . . . . . .

Operation

Safety Information for Gas Units 14. . . . . . . .

Standard Control 15. . . . . . . . . . . . . . . . . . . . .

MenuSelectt Control 17. . . . . . . . . . . . . . . . .

Touchscreen Control 23. . . . . . . . . . . . . . . . . .

Maintenance

Spray Bottle Operating Procedure 33. . . . . .

Cleaning and Preventive Maintenance 34. . .

Introduction

Description du four et Spécifications 36. . . .

Installation

Certifications 38. . . . . . . . . . . . . . . . . . . . . . . . .

Emplacement du four et mise de

niveau et Ventilation 39. . . . . . . . . . . . . . . . . . .

Montage des pieds 40. . . . . . . . . . . . . . . . . . .

Accessoire des roulettes 41. . . . . . . . . . . . . .

Superposition 42. . . . . . . . . . . . . . . . . . . . . . . .

Raccordement de la plomberie 43. . . . . . . . .

Raccordement à l'électricité 44. . . . . . . . . . . .

Raccordement au gaz 45. . . . . . . . . . . . . . . . .

Câble d'immobilisation du tuyau à gaz 47. .

Fonctionnement

Renseignements sur la sécurité des

appareils au gaz 48. . . . . . . . . . . . . . . . . . . . . .

Commandes standard 49. . . . . . . . . . . . . . . .

Commande MenuSelectt 51. . . . . . . . . . . . .

Touchscreen Control 59. . . . . . . . . . . . . . . . . .

Entretien

Procédure de fonctionnement du

pulvérisateur 69. . . . . . . . . . . . . . . . . . . . . . . . .

Nettoyage et entretien préventif 70. . . . . . . .

Introduction

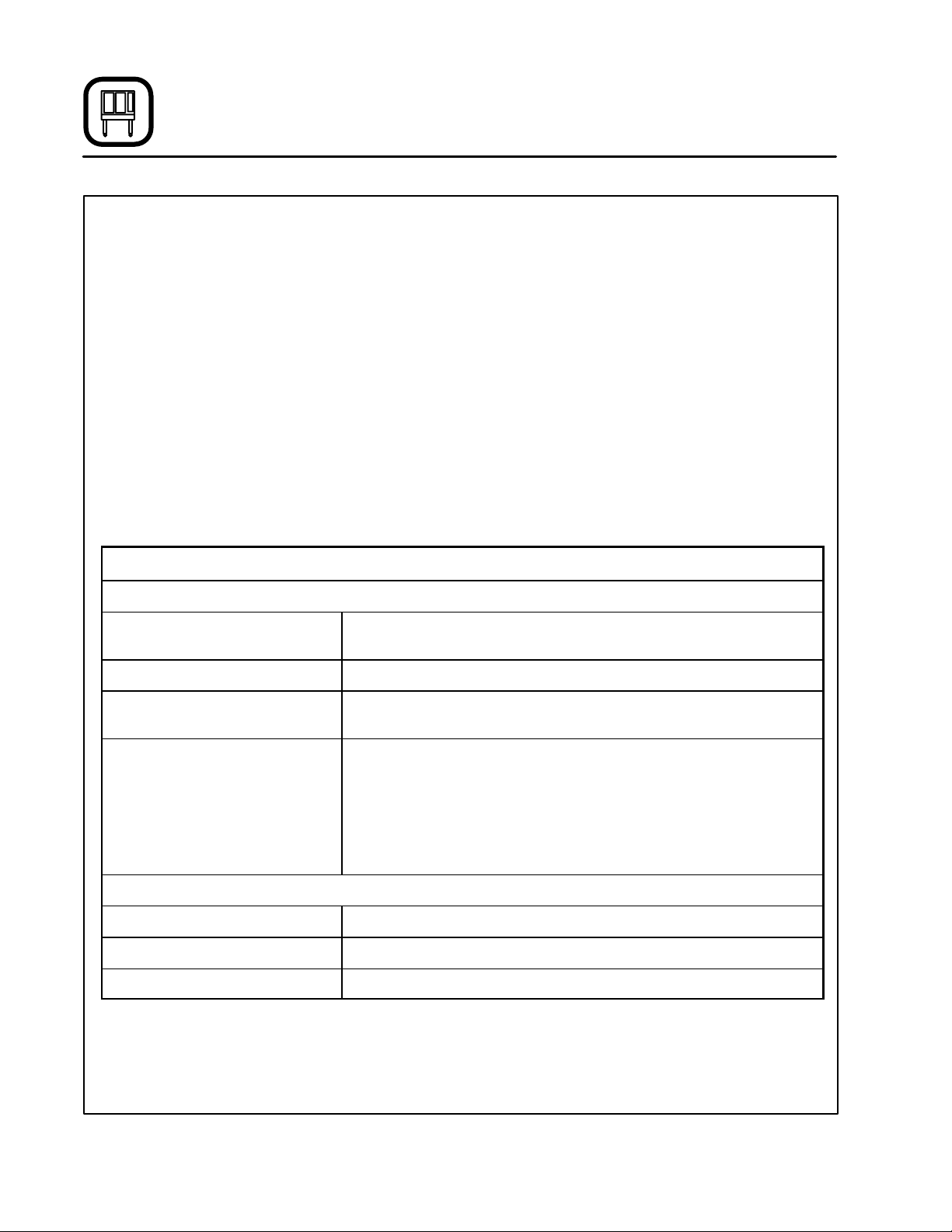

Oven Description & Specifications

ABOUT THE HYDROVECTION

Blodgett Hydrovection ovens are quality proĆ

duced using highĆgrade stainless steel with first

class workmanship.

The multiple speed fan, which is guarded against

accidental finger contact, is driven by a quiet and

powerful motor. The condenser draws out excess

moisture from the appliance. Condensation and

waste water, which result during hydro cooking

and cleaning, are continuously drained.

The use of high quality insulation impedes excesĆ

sive heat radiation and saves energy.

The Hydrovection has optional adjustable legs

which adapt easily to slightly uneven surfaces and

optional floor stands which are designed for use

with all of the table models.

PLUMBING SPECIFICATIONS

WATER

Water Pressure 30 PSI (207 kPa) minimum

50 PSI (345 kPa) maximum

Water Connection 3/4" garden hose - Cold water only

The practical oven doors, with viewing windows,

have a wide swing radius and handle which can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simĆ

ple arrangement of the controls. Graphic symbols

make the appliance easy for even inexperienced

kitchen staff to operate. A third function, the Cool

Down mode, allows the oven cavity to cool down

rapidly with the door opened.

Cleaning is kept to a minimum. The interior is

sprayed with a selfĆacting cleaning solution which

interacts with humidity to easily remove crusts and

stains. The oven is designed for easy care and is

welded water tight so that the internal cooking

cavity may be rinsed with a hose after the cleaning

process.

Water Pressure

Regulator Setting

Minimum Requirements TDS - less than 100 parts per million

DRAINAGE

Drain Type Atmospheric Vented Drain

Drain Connection 1" NPT Male

Avg Water Drain Temp. Approximately 140_F (60_C)

Preset to 30 PSI (207 kPa)

Total Hardness - 80Ć120 parts per million

Chlorides - less than 30 parts per million

Chlorine - 0 parts per million

pH Factor - 7.0Ć8.0

2

Introduction

Oven Description & Specifications

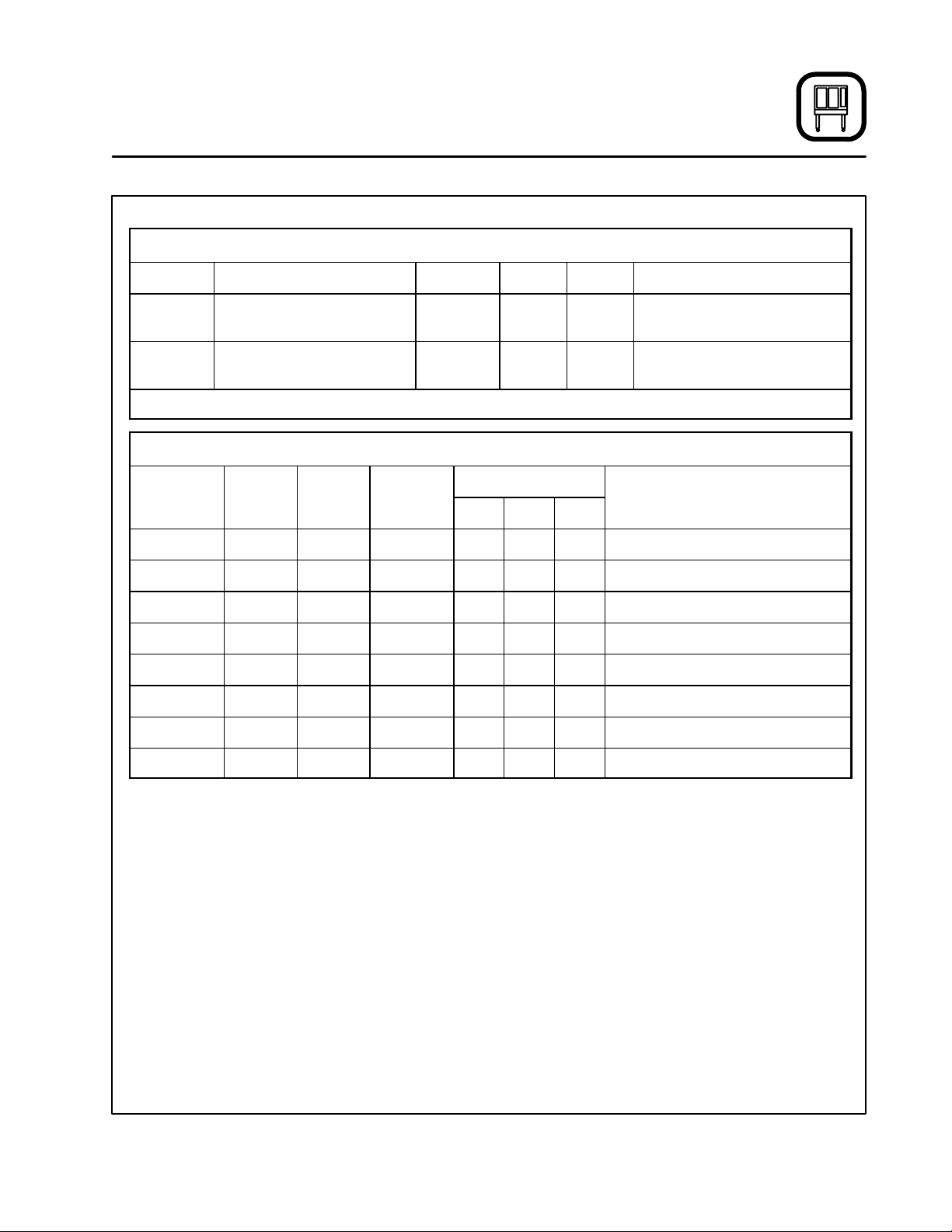

RATINGS - HVĆ100G

Gas Type Gas Input Voltage Phase Amps Motor

Natural 60,000 BTU/Hr 120 1 20 1/2 HP 208Ć240VAC, 3 phase,

50/60 Hz

Propane 60,000 BTU/Hr 120 1 20 1/2 HP 208Ć240VAC, 3 phase,

50/60 Hz

3/4" NPT connector for all U.S. and Canadian installations

RATINGS - HVĆ100E

Voltage Hz kW Phase

208 60 15 3 38 38 38 1/2 HP 208Ć240VAC, 50/60 Hz

240 60 15 3 36 34 34 1/2 HP 208Ć240VAC, 50/60 Hz

440 60 15 3 20 18 18 1/2 HP 208Ć240VAC, 50/60 Hz

480 60 15 3 18 17 17 1/2 HP 208Ć240VAC, 50/60 Hz

208 60 13 3 33 33 36 1/2 HP 208Ć240VAC, 50/60 Hz

240 60 13 3 31 29 29 1/2 HP 208Ć240VAC, 50/60 Hz

440 60 13 3 16 16 17 1/2 HP 208Ć240VAC, 50/60 Hz

480 60 13 3 15 15 16 1/2 HP 208Ć240VAC, 50/60 Hz

Max Load (amps)

L1 L2 L3

Motor

3

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONĆ

TAINED HEREIN ARE FOR THE USE OF QUALIĆ

FIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D The installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, be familiar with all precauĆ

tions required and have complied with all requireĆ

ments of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70-Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code of the Building OffiĆ

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration (FDA).

Appliance is to be installed with backflow prevenĆ

tion in accordance with applicable federal, provĆ

ince and local codes.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett at 0011Ć802Ć658Ć6600.

4

Installation

Oven Location and Ventilation

OWNER'S RESPONSIBILITIES

Installation responsibilities prior to service

startup inspection

You are entitled to a free startĆup inspection serĆ

vice by our factory ASAP. Before a factory repreĆ

sentative arrives to perform a startup procedure,

the owner must already have satisfied the followĆ

ing requirements.

1. Oven(s) are uncrated, stacked (if applies) and

put in place.

NOTE: Please refer to Leg Attachment and

Stacking.

Maximum shelf loading - 60 lbs (27.3 Kg)

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

Certain minimum clearances must be maintained

between the oven and any combustible or nonĆ

combustible construction. See the table below.

In addition, the following clearances are recomĆ

mended for servicing.

D Oven body sides - 12" (30cm)

D Oven body back - 12" (30cm)

MINIMUM REQUIRED

Oven

Model

Right

Side

HVĆ100E 0"

(0mm)

HVĆ100G 0"

(0mm)

CLEARANCES

Left

Side

0"

(0mm)6"(152.4mm)

0"

(0mm)6"(152.4mm)

Back

VENTILATION

The necessity for a properly designed and inĆ

stalled ventilation system cannot be over emphaĆ

sized. The ventilation system will allow the unit to

function properly while removing unwanted vaĆ

pors and products of combustion from the operatĆ

ing area.

The appliance must be vented with a properly deĆ

signed mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipment plus an overhang of at least 6" (15 cm)

on all sides not adjacent to a wall. The capacity of

the hood should be sized appropriately and proviĆ

sions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be

hazardous to the health of the operator;

and will result in operational problems,

unsatisfactory baking, and possible damĆ

age to the equipment. Damage sustained

as a direct result of improper ventilation

will not be covered by the Manufacturer's

warranty.

When installed in the Commonwealth of MassaĆ

chusetts, this appliance must be interlocked with

the hood exhaust system so that the appliance

may be operated only when the hood exhaust sysĆ

tem is running.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the abĆ

sence of local codes, refer to the National ventilaĆ

tion code titled, Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking EquipĆ

ment", NFPAĆ96Ć Latest Edition.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett at 0011Ć802Ć860Ć3700.

5

Installation

Leg Attachment

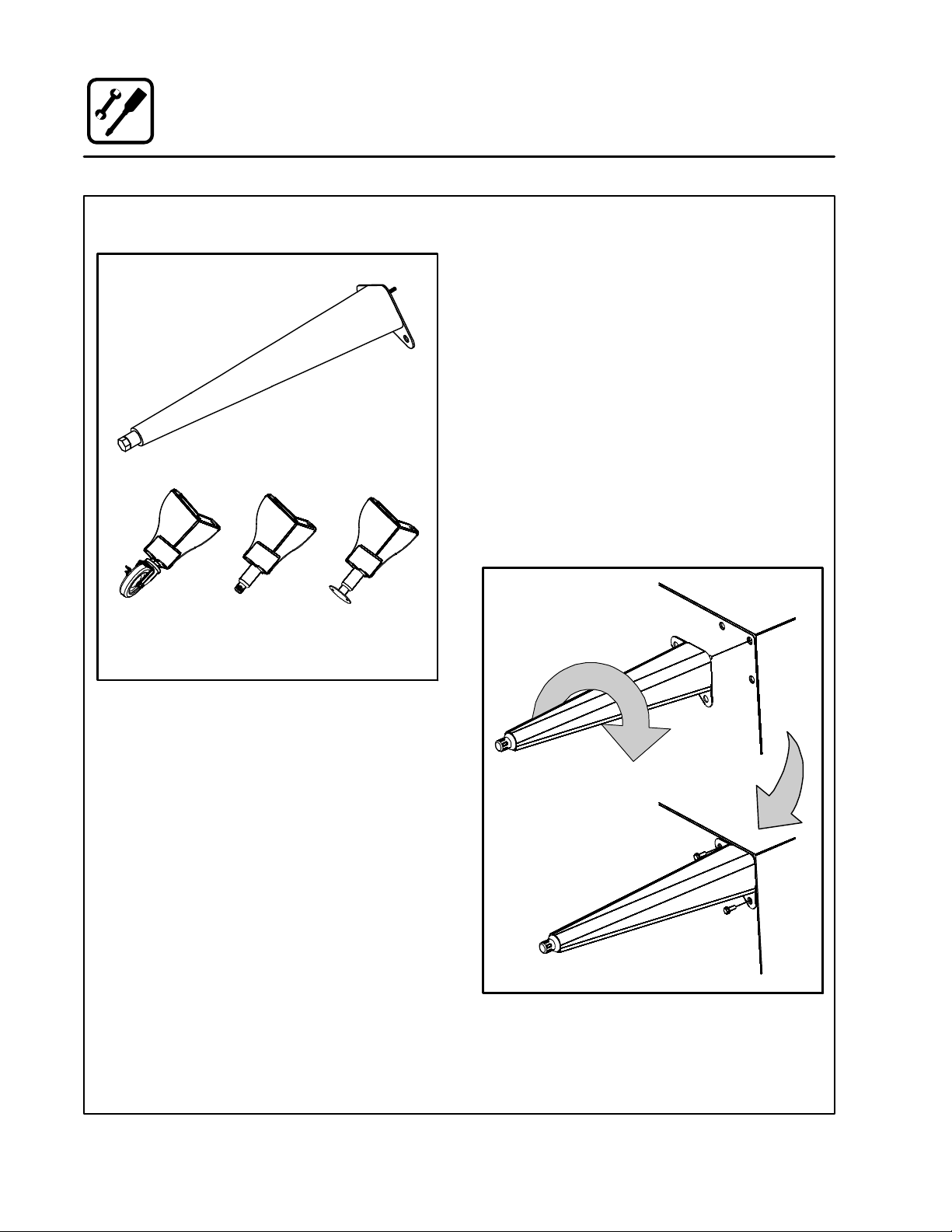

LEG OPTIONS

25" (635mm) Adjustable Leg

Casters, Adjustable Feet, or Seismic Feet

ATTACHMENT

1. Align the threaded stud on one of the front

legs to the bolt āholeā locatedāāā ināā ātheāā bottom ācorĆ

ner of the appliance. Turn the leg clockwise

and tighten to the nearest full turn.

2. Align the leg plate holes with the bolt holes.

Secure with the two 1/2" bolts provided.

3. Repeat the above steps with the other front

leg. If casters are used, install them with the

locking casters in the front of the oven. The rear

casters do not lock. Ensure that the locks are

set on the front casters.

4. Tip the oven up on the newly installed front

legs. If ācastersā are āused, checkā thatā the locksā

areā setā on ātheā front casters. āRepeat āthe above

steps for the rear legs.

5. Level the oven by screwing the adjustable feet

in or out as necessary.

8Ć1/2" (216mm) Leg with

Figure 1

Figure 2

6

Installation

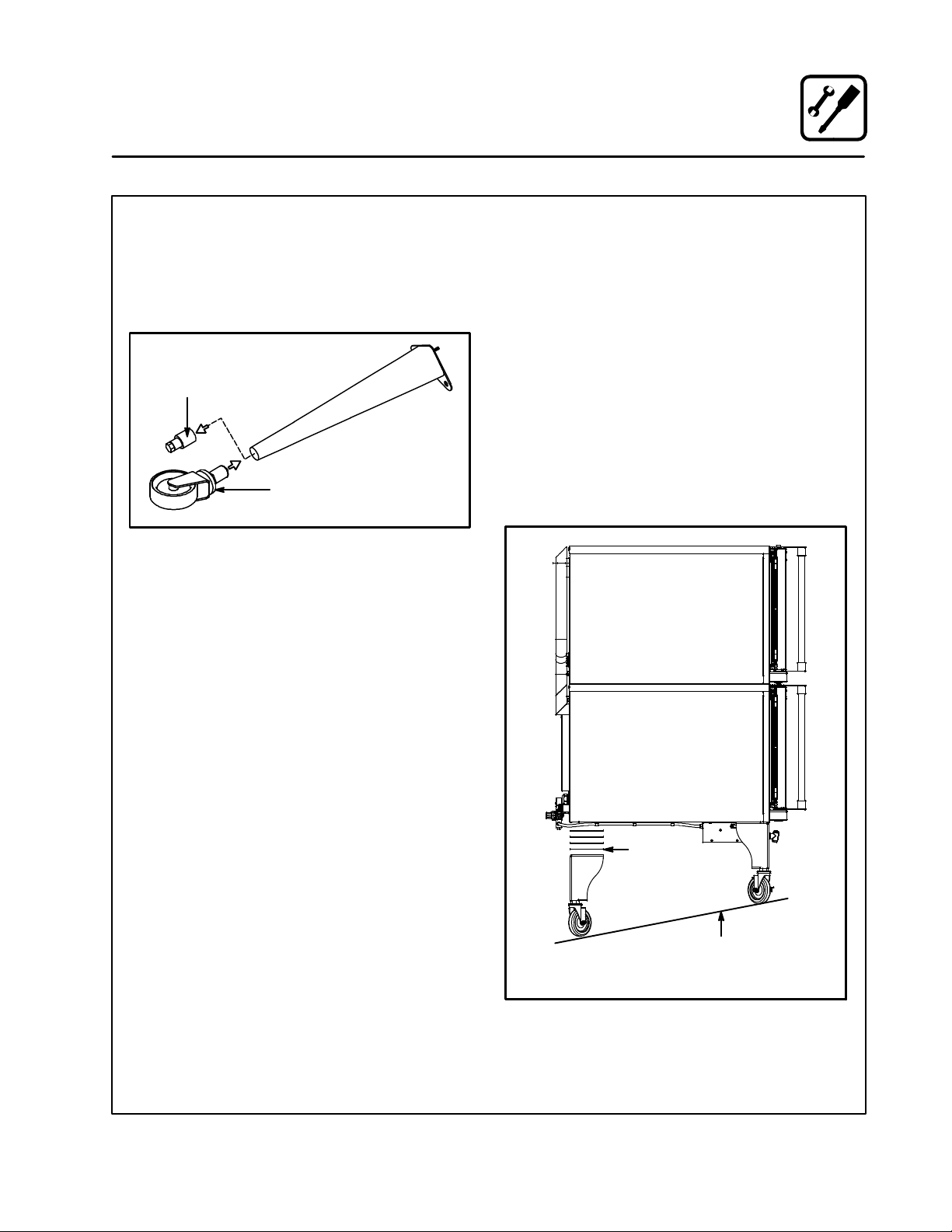

Caster Attachment

CASTERS FOR SINGLE OVENS

1. Attach the legs as described.

2. Pry the adjustable feet out of the legs.

3. Insert one caster into each leg as shown.

Tighten the lock nuts to secure the casters.

Adjustable

Leg Foot

Caster Assembly

Figure 3

PROFILE CASTERS FOR DOUBLE STACK

OVENS

1. Place a level on the floor where the casters are

to rest.

2. Place shims under the low side until it is level.

3. Mount the shims between the casters and the

oven as follows:

a.) Align the shims and caster holes with the

bolt holes.

b.) Secure with the 1/2" bolts provided.

NOTE: Install them with the locking casters in

the front of the oven. The rear casters

do not lock. Ensure that the locks are

set on the front casters.

4. Tip the oven up on the newly installed casters.

Add shims

as necessary

Floor

Exaggerated for clarity

Figure 4

7

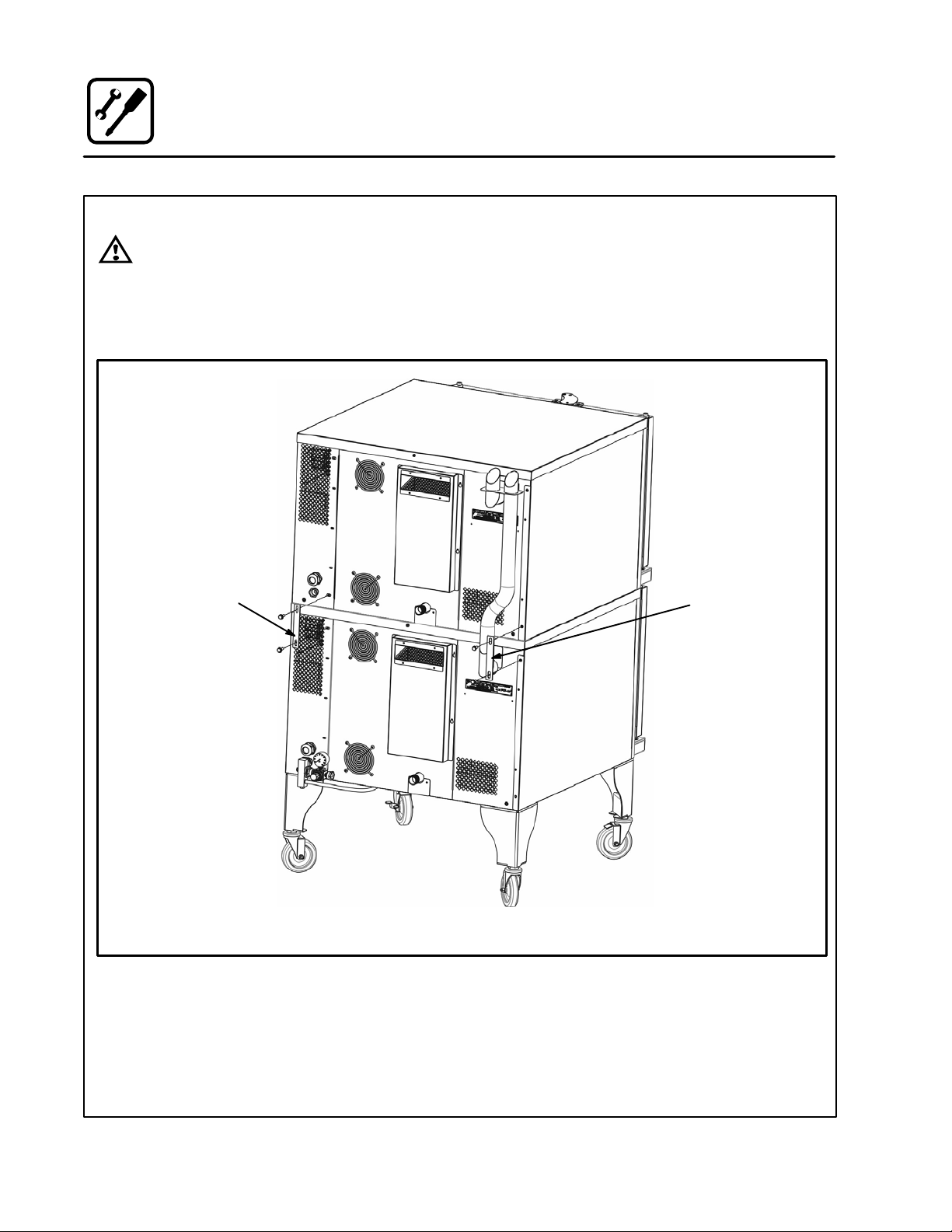

Stacking

WARNING!!

Stacking should be performed by qualiĆ

fied installation personnel only. The

ovens are heavy. Take care to use proper

tools and techniques when lifting and

stacking units.

Installation

1. Attach the legs or casters to the bottom oven.

See page 6 or 7.

2. Place the top oven on the bottom oven. Be

sure all four sides are flush.

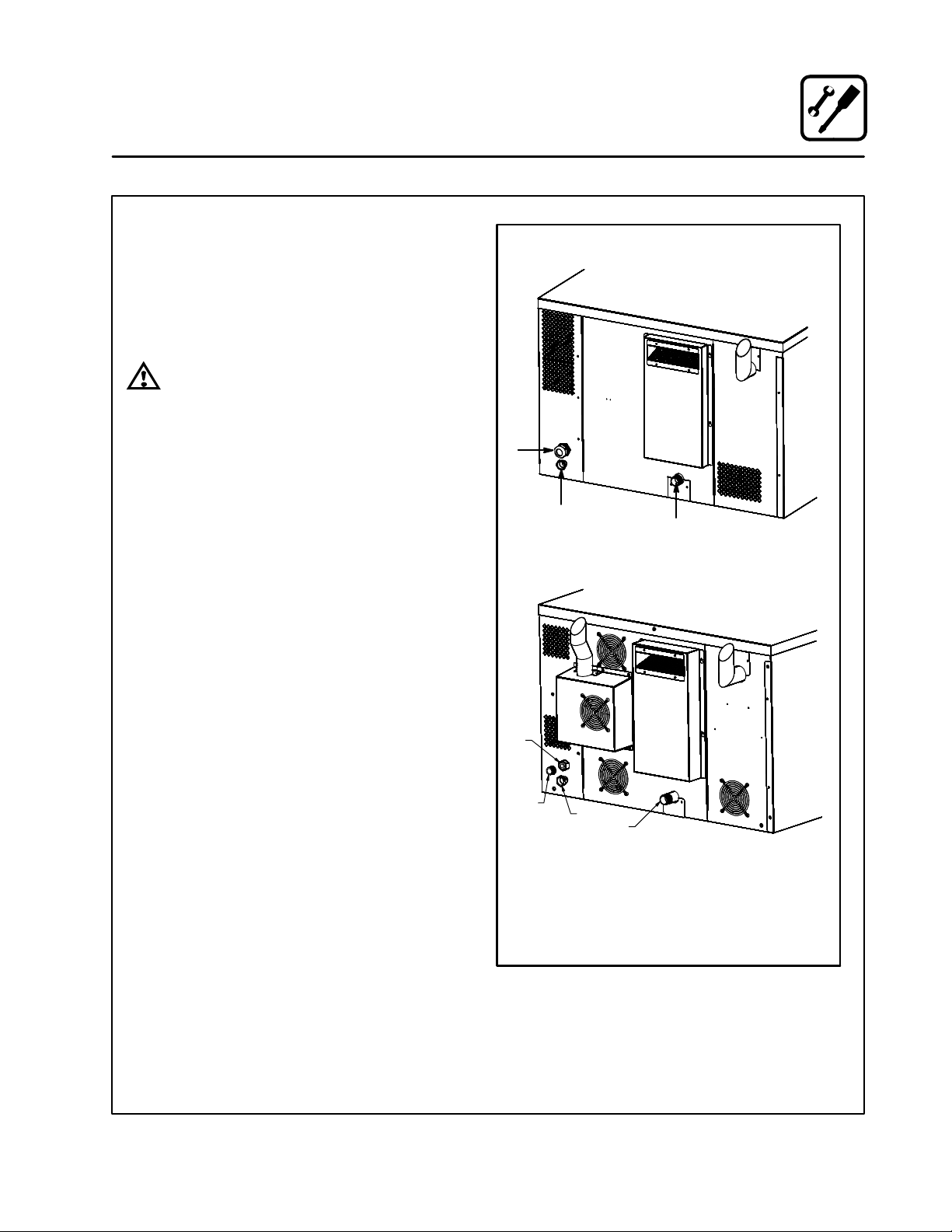

3. Bolt the two ovens together from behind using

the stacking brackets.

Stacking

Bracket

Stacking

Bracket

Rear View HVĆ100E

Figure 5

8

WATER CONNECTION

NOTE: Must use COLD WATER ONLY.

Connect the appliance to quality water via a presĆ

sure hose with 3/4" GHT (19mm) couplings. See

Figure 6 for connections. A shut off valve is to be

provided adjacent to the oven.

WARNING!!

Operating the appliance without a water

pressure regulator installed will invalidate

your warranty.

This product must be installed by a licensed

Plumber or Gas Fitter when installed within the

Commonwealth of Massachusetts.

DRAIN CONNECTION

The drain should be run to an open floor drain

avoiding flexible hose that could sag and allow

trapped water to accumulate. The customer must

supply the piping from the oven to the drain.

Specific water/drain connection for City of Los

Angeles

1. Each drain line from the appliance shall be

routed without dips or sags to terminate above

the flood level rim of an approved indirect waste

receptor.

2. The appliance shall be installed in accordance

with the manufacturer's printed instructions

and the LAPC and LAMC, 1999 editions.

3. A backflow protection device may be required

by local codes. If so, install on the potable water

system directly ahead of the appliance. The

backflow protection device shall be any of the

following: an approved pressure type vacuum

breaker installed at least 12" above the highest

point of use, a double check valve backflow preĆ

venter or a reduced pressure principal backflow

preventer.

Installation

Plumbing Connections

A

C

A

B

C

D

A = Electrical Connection

B = Gas Connection

C = Water Connection

Filtered Water highly recommended

D = Drain Connection

HVĆ100E

D

HVĆ100G

Figure 6

9

Installation

Electrical Connections

All Models

NOTE: Electrical connections must be performed

by a qualified installer only.

Before making any electrical connections to these

appliances, check that the power supply is adeĆ

quate for the voltage, amperage, and phase reĆ

quirements stated on the rating name plate

mounted on the appliance.

The circuit breaker that is used to provide power

to this appliance must have a minimum of .076"

(3mm) contact spacing. The circuit breaker must

meet all Local and National installation standards.

All appliances must be installed in accordance

with Local or National Electrical codes.

A wiring schematic is located on the inside of the

removeable side panel.

NOTE: Disconnect the power supply to the apĆ

pliance before servicing.

WARNING!!

Improper installation may invalidate your

warranty.

Electric Models

A strain relief for the power supply cord is provided.

The installer must supply a cord that meets all Local

and National installation standards.

Gas Models

U.S. and Canadian Installations

A power cord (115V units only) is supplied with a

plug attached. Plug the power cord into the deĆ

sired receptacle.

WARNING!!

If the supply cord is damaged, it must be

replaced by a special cord or assembly

available from the manufacturer or its serĆ

vice agent.

10

Installation

L

th

pg

Gas Connections

GAS PIPING

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a BCXĆ14G to add to your existing

cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the toĆ

tal.

Previous Total 230,000 BTU

HVĆ100G 60,000 BTU

New Total 290,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let's say

the pipe length is 30' (9 m) and the pipe size

is 1" (2.54 cm).

4. Use the appropriate table to determine the toĆ

tal capacity of your current gas piping.

The total capacity for this example is 375,000

BTU. Since the total required gas pressure,

290,000 BTU is less than 375,000 BTU, the

current gas piping will not have to be inĆ

creased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capaciĆ

ties. For example: a schedule 40 1Ć1/2" ell

fitting has an equivalent capacity of 4.2"

(10.2 cm) of straight pipe. Contact your loĆ

cal gas supplier if you have any questions.

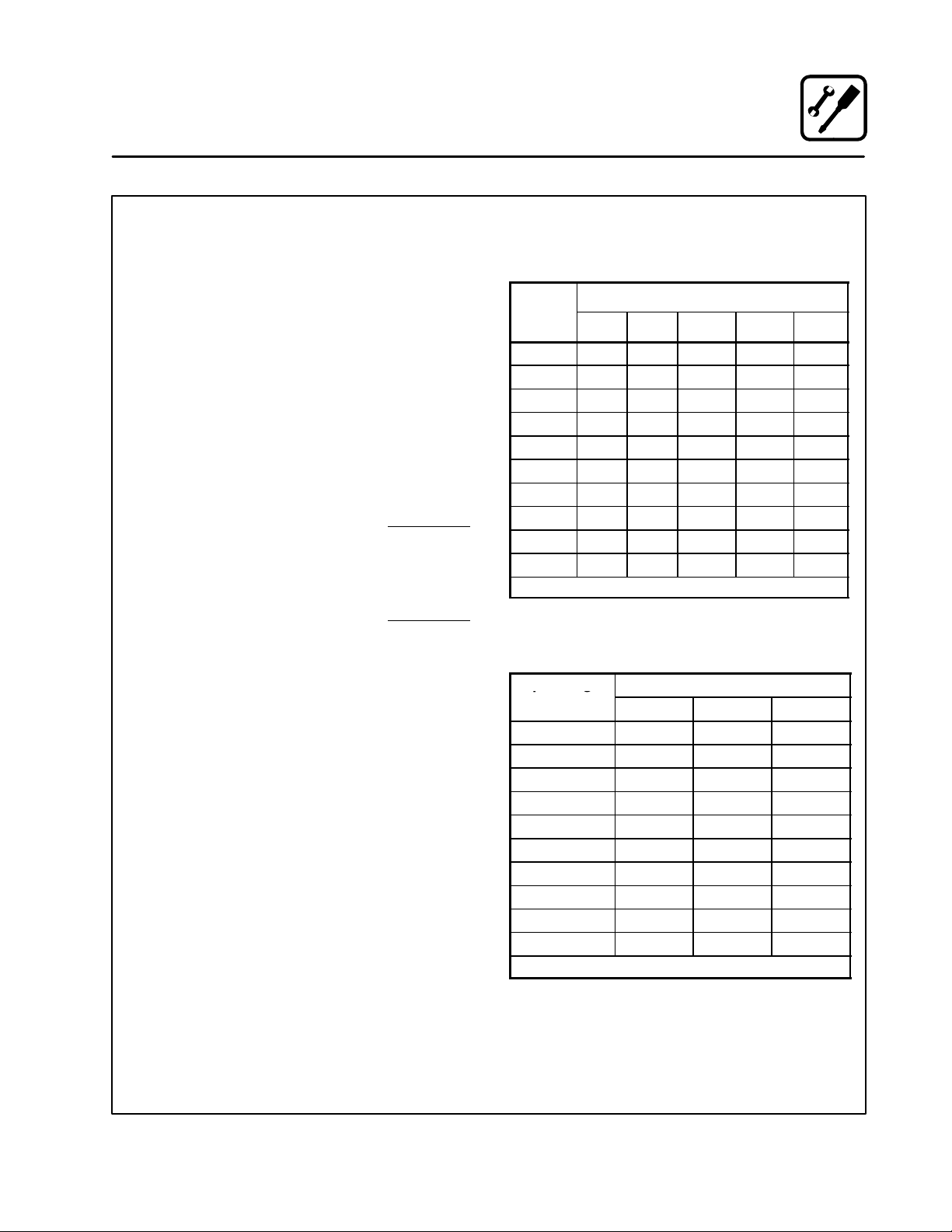

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10Ć2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11" W.C.

Pipe Length

From the National Fuel Gas Code Part 10 Table 10Ć15

3/4" 1" 1Ć1/4" 1Ć1/2" 2"

(Pressure drop of 0.5 Inch W.C.)

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Nominal Size, Inches

Inside Diameter, Inches

3/4" 1" 1Ć1/2"

11

Installation

Gas Connections

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated

for each appliance while the burners are on. A sufĆ

ficient gas pressure must be present at the inlet to

satisfy these conditions. Refer to the table below

for correct gas pressure.

Each appliance has been adjusted at the factory

to operate with the type of gas specified on the ratĆ

ing plate.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is essenĆ

tial to the proper operation of the oven and

should not be removed.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE UNIT CONNECTS TO THE GAS

SUPPLY UNLESS THE INLET PRESSURE IS

GREATER THAN 14" W.C. (1/2 PSI) (37mbar).

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Prior to connecting the appliance, gas lines

should be thoroughly purged of all metal filings,

shavings, pipe dope, and other debris. After conĆ

nection, the appliance must be checked for corĆ

rect gas pressure.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011Ć802Ć860Ć3700.

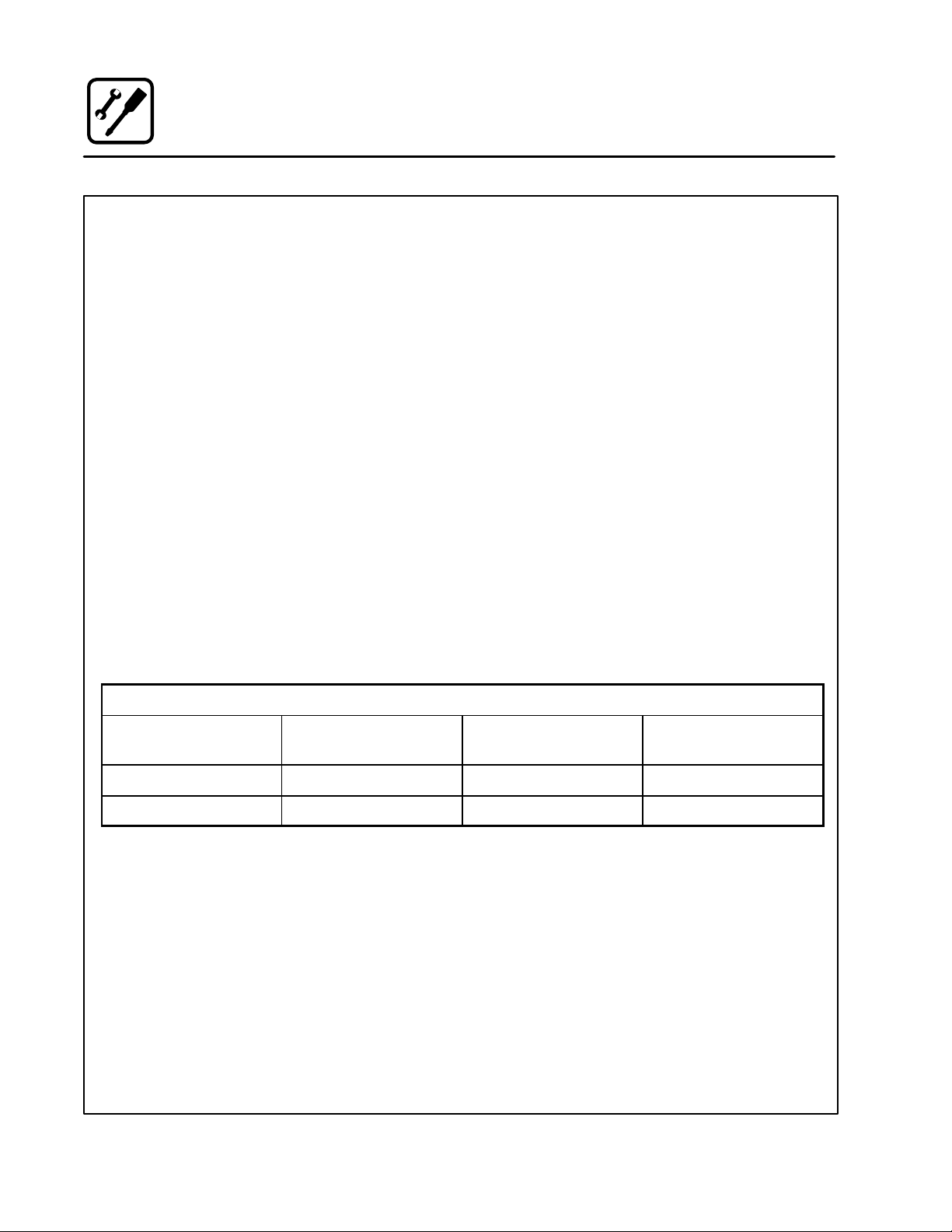

GAS PRESSURE - HVĆ100G

Gas

Type

Natural 7" W.C. .085" dia 3.5" W.C.

Propane 14" W.C. .063" dia 10" W.C.

Inlet

Pressure

Orifice Size at Sea

Level

Manifold Pressure

12

Installation

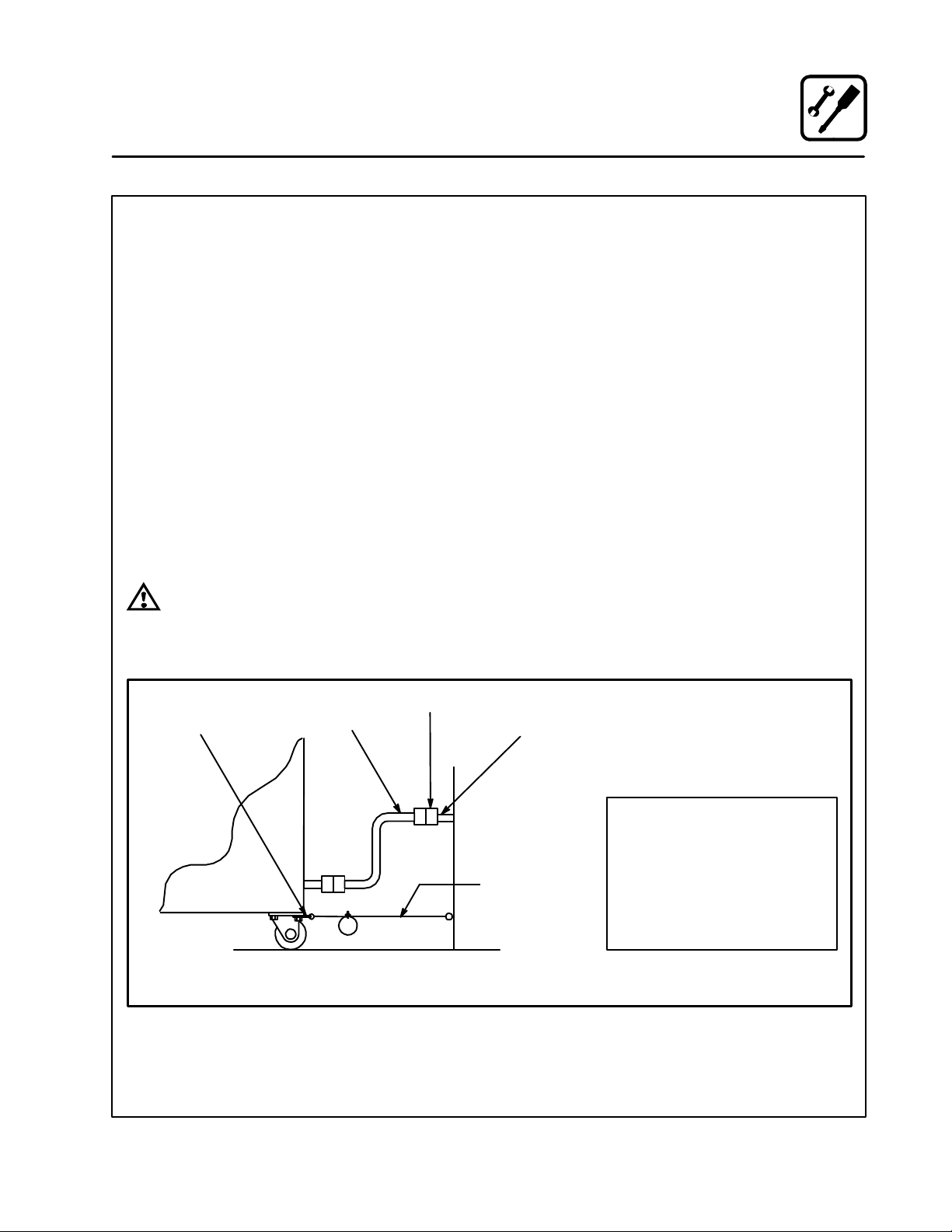

Gas Hose Restraint

If the appliance is mounted on casters, a commerĆ

cial flexible connector with a minimum of 3/4" (1.9

cm) inside diameter must be used along with a

quick connect device.

A restraint must be used to limit the movement of

the appliance so that no strain is placed upon the

flexible connector. The restraint should be fasĆ

tened to the base frame of the oven as close to the

flexible connector as possible. It should be short

enough to prevent any strain on the connector.

With the restraint fully stretched the connector

should be easy to install and quick connect.

The restraint (ie: heavy gauge cable) should be atĆ

tached without damaging the building. DO NOT

use the gas piping or electrical conduit for the atĆ

tachment of the permanent end of the restraint!

Use anchor bolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

WARNING!!

If the restraint is disconnected for any reaĆ

son it must be reconnected when the apĆ

pliance is returned to its original position.

U.S. and Canadian installations

The connector must comply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas ApĆ

pliances CAN/CGAĆ6.16 and a quick disconnect

device that complies with the Standard for QuickĆ

Disconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1Ć6.9. Adequate means must be provided to

limit the movement of the appliance without deĆ

pending on the connection and the quick disconĆ

nect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 Ć Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011Ć802Ć860Ć3700.

Attachment Plate

(secure with leg mount bolt)

Gas Hose

Quick Connect

Gas Supply Line

Restraint

Installation of Gas Hose and Restraint

(Single Section Shown)

Figure 7

IMPORTANT: Cable restraint should

be fastened as close as possible to the

flexible connector and short enough to

prevent any strain on the flexible conĆ

nector.

At maximum stretch of shortened reĆ

straint, the flexible connector should

be easy to install and quick to connect.

13

Operation

Safety Information for Gas Units

THE INFORMATION CONTAINED IN THIS SECĆ

TION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATĆ

ING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONĆ

TAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPĆ

ERATION OF THE EQUIPMENT DESCRIBED. ADĆ

HERENCE TO THE PROCEDURES RECOMĆ

MENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLEĆFREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett Combi apĆ

pliance.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D DO NOT try to light any appliance.

D DO NOT touch any electrical switches.

D Use an exterior phone to call your gas supplier

immediately.

D If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D Turn all switches to off.

D DO NOT attempt to operate the appliance until

the power is restored.

NOTE: In the event of a shutĆdown of any kind, alĆ

low a five (5) minute shut off period before

attempting to restart the oven.

General safety tips:

D DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

from the appliance before removing the reĆ

straint cable. Reconnect the restraint after the

oven has been returned to its original location.

D DO NOT remove the control panel cover unless

the oven is unplugged.

14

Operation

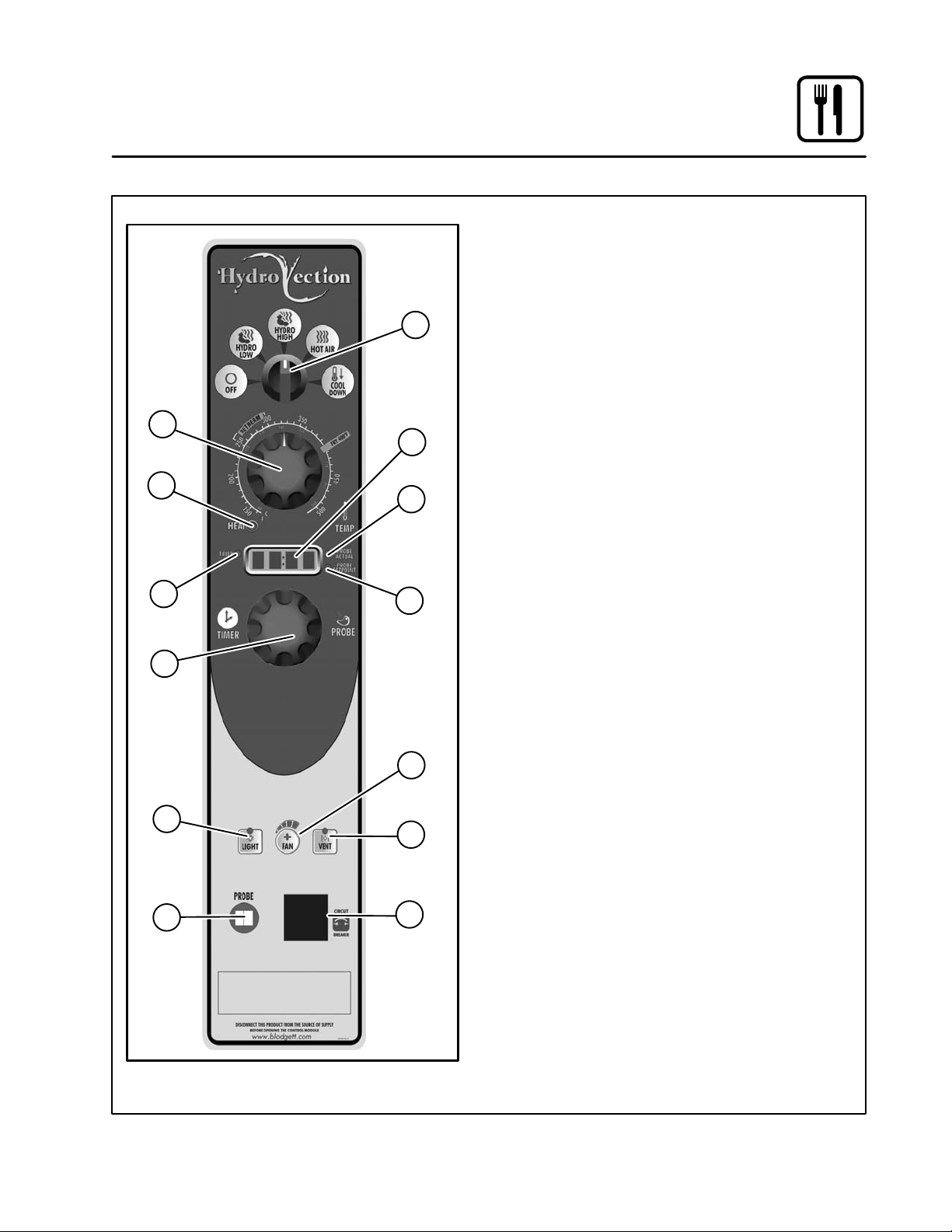

Standard Control

CONTROLS IDENTIFICATION

1. MODE SELECTOR SWITCH - turns power

to the oven on or off. Allows selection of Hydro

Low, Hydro High, Hot Air, or Cool Down

Modes.

1

3

2

4

5

8

6

7

11

2. DISPLAY - displays time and temperature inĆ

formation.

3. TEMPERATURE DIAL - used to set desired

cooking temperature.

4. HEAT LAMP - lights when the oven is calling

for heat

5. TIMER LED - lights when the cook time is

displayed

6. PROBE ACTUAL LED - lights when the actuĆ

al probe temperature is displayed

7. PROBE SETPOINT LED - lights when the

core setpoint temperature is displayed

8. TIMER/PROBE KNOB - use to select and

set either cook time or probe temperature

9. LIGHTS KEY - press to turn the oven lights

on and off

10. FAN SPEED KEY - used to select fan speed.

11. CAVITY VENT KEY - used to open or close

vent to release humidity from cavity.

12. PROBE CONNECTION - used to connect

the core temperature probe to the control.

13. CIRCUIT BREAKER - Used to turn power to

the unit on or off.

9

12

11

13

Figure 8

15

Operation

Standard Control

TIMER COOKING

1. Press the TIMER/PROBE KNOB (8) to select

the timer mode. The TIMER LED lights.

2. Turn the MODE SELECTOR Switch (1) to the

desired function.

3. Set the TEMPERATURE DIAL (3) to the deĆ

sired cook temperature.

4. When the oven has reached the cook temperĆ

ature, load the product.

5. Rotate knob to enter the desired cook time in

the display. You can clear the display by rotatĆ

ing counter clockwise. The timer begins on its

own.

6. The temperature, time, and mode can be alĆ

tered at any time during the cooking process.

7. When the timer reaches 00:00, the buzzer

sounds. Press or rotate the TIMER/PROBE

KNOB (8) counter clockwise to silence the

buzzer. Remove the product.

PROBE COOKING

1. Press the TIMER/PROBE knob (8) to select

the probe setpoint mode. The PROBE SETĆ

POINT LED (7) lights.

2. Rotate the knob to enter the desired final cook

temperature in the display.

3. Insert the core probe into the product. Load

product into the oven and close the door. Be

sure that the terminal end of the core probe is

outside of the oven and clear of the door.

4. Connect the core probe to the PROBE CONĆ

NECTION (12) at the bottom of the control.

5. The display gives the actual core probe temĆ

perature by pressing the TIMER/PROBE knob

(8) again.

6. When the product reaches the final cook temĆ

perature the buzzer sounds.

COOL DOWN

NOTE: The unit can be cooled down rapidly.

1. To cool down the oven cavity, open the door

and select Cool Down on the MODE SELECĆ

TOR Switch (1).

16

10

11

13

14

17

19

20

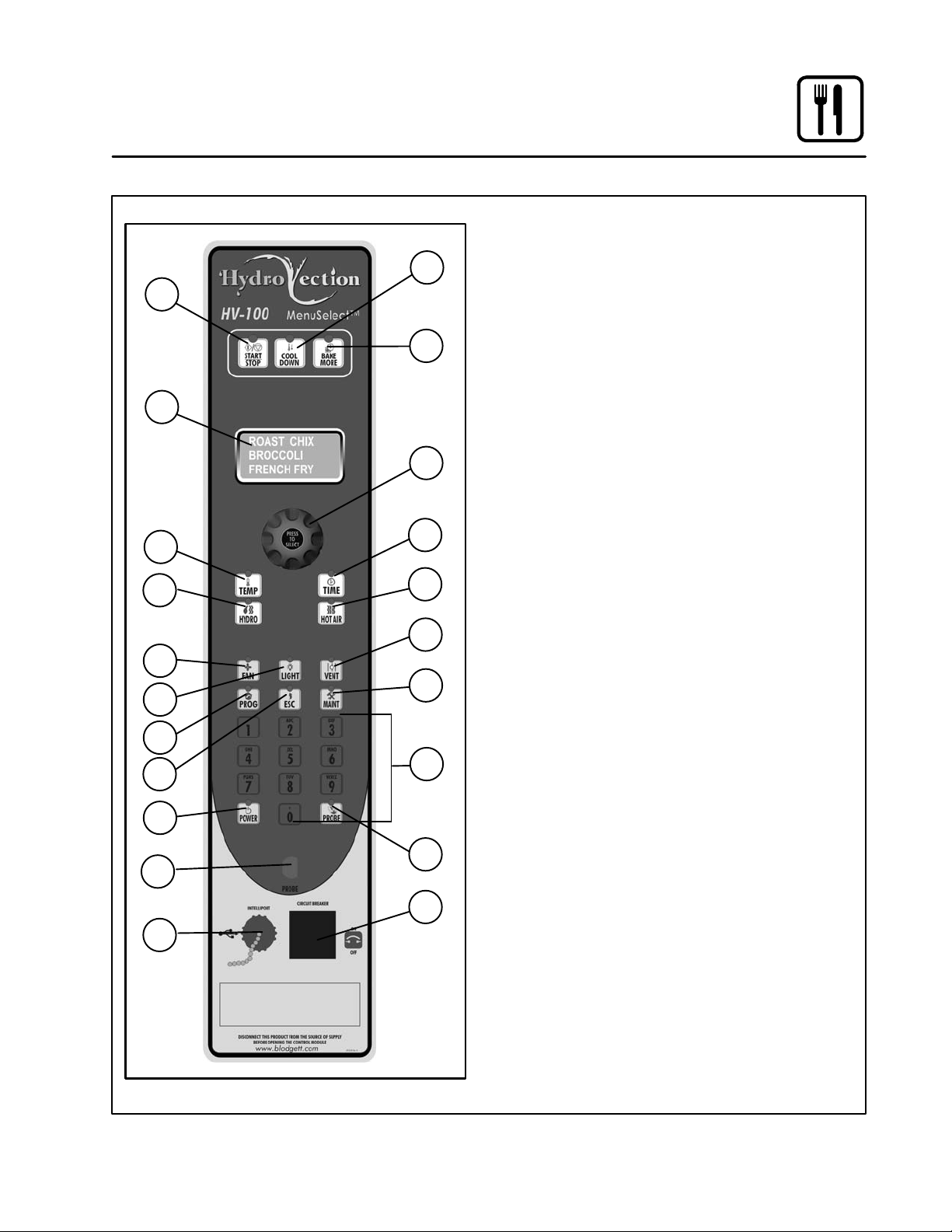

Operation

MenuSelectt Control

CONTROL DESCRIPTION

2

1

3

4

5

6

8

7

9

12

15

16

18

21

1. START/STOP KEY Ć press to start, cancel or

pause the bake

2. COOL DOWN KEY Ć initiates oven cool down

cycle

3. BAKE MORE KEY Ć press at the end of a bake

cycle to add additional bake time in one minĆ

ute increments.

4. DISPLAY Ć displays time or temperature and

other information related to oven function and/

or programming.

5. DIAL Ć used to enter set points, time, and proĆ

grammable settings. Also used to select the

programmed product.

6. TEMP KEY Ć used to set or change the bake

temperature

7. TIME KEY Ć used to set or change the bake

time.

8. HYDRO KEY Ć press to enter hydro mode

9. HOT AIR KEY Ć press to enter hot air mode

10. FAN KEY Ć press to select the fan speed

11. LIGHT KEY Ć press to turn the lights on and off.

12. VENT KEY Ć press to manually open and close

the oven vent

13. PROGRAM KEY Ć press to enter product proĆ

gramming and save programmed settings.

14. ESCAPE KEY Ć press to back up one step durĆ

ing programming

15. MAINTENANCE KEY Ć press to enter managĆ

er programming and save programmed setĆ

tings

16. ALPHA/NUMERIC KEYPAD Ć used to proĆ

gram recipes.

17. POWER KEY Ć used to place control in and out

of standby mode.

18. PROBE KEY Ć press to use core probe cookĆ

ing

19. CORE PROBE CONNECTION Ć plug core

temperature probe in here when using probe

cooking

20. USB Port and COVER - Use to transfer

recipes and data to/from the control

21. CIRCUIT BREAKER - Used to turn power to

the unit on or off.

Figure 9

17

Operation

MenuSelectt Control

OVEN STARTUP

1. Be sure the shutoff switch and/or circuit

breaker switch below the control panel are in

the on position. The display flashes OFF

PRESS POWER KEY TO START.

NOTE: If the real time clock and auto wake up

functions are enabled the display

reads PRESS POWER KEY TO START

AUTO START.

2. Press the POWER KEY (17). The display reads

PREHEAT and the oven heats to the last manuĆ

al set temperature in the hot air mode. The disĆ

play flashes READY / IDLE and the alarm beeps

5 times when the oven is at temperature and

ready to bake.

MANUAL COOKING

1. Turn the DIAL (5) until the display reads

MANUAL.

2. Press the TIME KEY (7). Rotate the dial, or use

the alpha/numeric keypad to enter the desired

bake time. Press the center of the dial to set

the bake time.

NOTE: Time is set in one minute increments

using the dial. To set time in less than

one minute increments use the alpha/

numeric keypad.

3. Press the TEMP KEY (6). Rotate the dial, or

use the alpha/numeric keypad to enter the deĆ

sired bake temperature. Press the center of

the dial to set the bake temperature. The oven

preheats to the new temperature.

NOTE: Temperature is set in 5 degree increĆ

ments using the dial. To set time in less

than 5 degree increments use the alĆ

pha/numeric keypad.

4. Press the desired mode key, Hydro or Hot Air.

If Hydro is selected, rotate the dial, or use the

alpha/numeric keypad to enter the desired

percentage of moisture.

5. When the display flashes READY / IDLE, open

the doors. Load the product.

6. Press the START/STOP KEY (1) to begin the

bake cycle. The timer counts down and the

display alternates between the cooking mode

and the name of the product.

PROGRAMMED COOKING

1. Turn the DIAL (1) until the name of the product

is highlighted. Press the center of the dial to

select. The oven preheats to the programmed

temperature in the correct cooking mode. The

display flashes READY / IDLE and the alarm

beeps 5 times when the oven is at temperaĆ

ture and ready to bake.

2. Open the doors. Load the product.

3. Press the START/STOP KEY (1) to begin the

bake cycle. The timer counts down and the

display alternates between the cooking mode

and the name of the product.

PROBE COOKING

1. Press the PROBE key (18) to select the probe

mode. The display reads CORE PROBE

COOK & HOLD. Turn the dial to select either

YES or NO. Press the center of the dial to seĆ

lect.

If YES is selected, Cook & Hold has been enĆ

abled. In the Cook & Hold mode, the oven cavĆ

ity lowers to the product pull temperature as

the product cooks.

If NO is selected, Cook & Hold has not been

enabled the cavity maintains the cook temperĆ

ature.

2. Turn the DIAL to enter the desired product pull

temperature in the display. Press the center of

the dial to save the pull temperature.

3. Press the TEMP KEY (6). Rotate the dial, or

use the alpha/numeric keypad to enter the deĆ

sired bake temperature. Press the center of

the dial to set the bake temperature. The oven

preheats to the new temperature.

NOTE: Temperature is set in 5 degree increĆ

ments using the dial. To set time in less

than 5 degree increments use the alĆ

pha/numeric keypad.

18

Operation

MenuSelectt Control

4. Press the desired mode key, Hydro or Hot Air.

If Hydro is selected, rotate the dial, or use the

alpha/numeric keypad to enter the desired

percentage of moisture.

5. Insert the core probe into the product. Load

product into the oven and close the door. Be

sure that the terminal end of the core probe is

outside of the oven and clear of the door.

6. Connect the core probe to the PROBE CONĆ

NECTION (19) at the bottom of the control.

NOTE: Do not connect the probe before the

cook mode has been selected.

7. The display gives the actual core probe temĆ

perature as well as the oven set temperature.

8. When the product reaches the pull temperaĆ

ture the buzzer sounds.

9. Press the START/STOP KEY (1) to silence the

buzzer.

If using Cook & Hold - The cavity temperaĆ

ture continues to drop to the product pull temĆ

perature and the display counts up, telling the

operator how long the product has been held.

Disconnect the core probe and remove the

product when ready.

If not using Cook & Hold - The cavity reĆ

mains at the cook temperature. The display

does not count up. Disconnect the core probe

and remove the product when the buzzer

sounds.

AT THE END OF ANY COOK CYCLE

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE

MORE KEY (3). This will add an additional one

minute of time for each press of the key.

3. When you are satisfied with the bake, press

the START/STOP KEY (1) to silence the alarm.

Open the door to remove the product.

OVEN SHUTDOWN

1. Press the COOL DOWN KEY (2). The display

reads AUTO COOL DOWN ACTUAL TEMP. To

speed up the cool down process, open the

doors and press the VENT KEY (12) to open

the vent.

2. When the oven has cooled down, the display

reads OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent closes

automatically at the end of the cool

down cycle.

DURING ANY COOK CYCLE

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (12). This manually

opens the vent until the key is pressed again

to close it.

Pause a Bake Cycle

1. To pause a cook cycle, press the START/

STOP KEY (1). The LED on the start/stop key

flashes. The bake cycle will pause until the key

is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold the

START/STOP KEY (1).

19

Operation

MenuSelectt Control

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (13). If the control

is password protected, the display reads ENĆ

TER CODE. Use the alpha/numeric keypad to

enter the manager passcode 3124, then press

the center of the dial to enter the program

mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a

new product or edit the name of an existing

product.

1. For a new recipe, turn the dial to the first open

product. Press the center of the dial to select.

To edit an existing name, rotate the dial to the

name to be changed. Press the center of the

dial to select.

2. Use the dial to scroll down to Edit Name. Press

the center of the dial to enter the edit name

menu.

3. Turn the dial or use the alpha/numeric keypad

to select the first character. Press the center of

the dial to advance to the next character. ReĆ

peat for all remaining characters.

NOTE: Product names may be up to 10 charĆ

acters long and can contain spaces.

Use the #1 key to insert spaces in a

recipe name.

NOTE: To select letters using the keypad,

press the appropriate key once if you

need the first letter on the key, twice for

the second and three times for the

third. For example to enter the letter L

press the #5 key three times.

4. Press the PROG KEY (13). With SAVE highĆ

lighted, press the dial to save the product

name.

Programming a Product Recipe

NOTE: The control can hold 99 recipes. Each recĆ

ipe may have up to 6 cooking stages.

1. Turn the dial to highlight the name of the prodĆ

uct to be programmed. Press the center of the

dial to select the product.

2. The display reads PRODUCT NAME: STAGE 1.

Press the center of the dial to select the stage.

3. Rotate the dial, or use the alpha/numeric keyĆ

pad to enter the desired bake time. Press the

center of the dial to set the bake time.

NOTE: Time is set in one minute increments

using the dial. To set time in less than

one minute increments use the alpha/

numeric keypad.

4. Rotate the dial to select the desired cooking

mode. Choose from Hydro or Hot Air. Press

the center of the dial to set the cook mode.

If Hydro is selected, rotate the dial, or use the

alpha/numeric keypad to enter the desired

percentage of moisture.

5. Rotate the dial, or use the alpha/numeric keyĆ

pad to enter the desired cook temperature.

Press the center of the dial to set the bake temĆ

perature.

NOTE: Temperature is set in 5 degree increĆ

ments using the dial. To set time in less

than 5 degree increments use the alĆ

pha/numeric keypad.

6. Rotate the dial to select the desired fan speed.

Choose from gentle, low, high or turbo. Press

the center of the dial to set the fan speed.

20

Operation

MenuSelectt Control

7. Rotate the dial to select the fan rotation cycle.

Choose between manual or auto.

NOTE: This is the length of time the fan will roĆ

tate in one direction before reversing.

If manual is selected, rotate the dial or use the

alpha/numeric keypad to enter the desired fan

cycle. Press the dial to set the fan cycle.

If auto is selected, the program will use the deĆ

fault fan cycle setting. The default is set

through the Manager Programming. See

page 22.

8. Rotate the dial to set the vent position. Choose

between OPEN or CLOSE. Press the center of

the dial to set the vent position.

9. Use the dial to scroll down to PRODUCT

NAME: STAGE 2. Press the center of the dial to

select stage 2.

10. Repeat steps 2Ć9 for all remaining stages.

11. When all stages have been programmed,

press the PROGRAM KEY (13). To save the

programming, use the dial to scroll to YES.

Press the center of the dial. The control exits

the program mode.

USING THE USB PORT

1. With the power on, remove the cover of the

USB port (20) and insert the USB drive.

2. Press the MAINTENANCE KEY (15).

3. Turn the dial to highlight MANAGER PROĆ

GRAM. Press the center of the dial to select.

4. Turn the dial to highlight either COPY RECIPE

FROM USB or COPY RECIPE TO USB, then

press the center of the dial to select.

5. When the transfer is complete, press any key

to return to the menu.

6. Turn the dial to highlight EXIT. Press the center

of the dial to select. The display returns to the

previous menu.

7. Turn the dial to highlight EXIT. Press the center

of the dial to select.

21

Operation

MenuSelectt Control

MANAGER PROGRAMMING

Entering the Manager Program Mode

1. Press the MAINTENANCE KEY (15). If the conĆ

trol is password protected, the display reads

ENTER CODE. Use the alpha/numeric keypad

to enter the manager passcode 3124, then

press the center of the dial to enter the proĆ

gram mode.

2. Turn the dial to highlight OVEN SETUP. Press

the center of the dial to select the product.

Programming Auto Start

NOTE: The Auto Start function enables the oven to

turn on at a programmed time of day and

preheat to a programmed temperature.

1. Turn the dial to highlight AUTO START. Press

the center of the dial to select.

2. Turn the dial to select either ON or OFF. Press

the center of the dial to select.

If ON is selected, the display reads AUTO

START 24 HOUR TIME 00:00. Turn the dial to

enter the time you would like the oven to begin

preheating. Press the center of the dial to seĆ

lect.

The display reads AUTO START TEMP XXX.

Turn the dial to enter the desired preheat temĆ

perature. Press the center of the dial to select.

Programming Oven Setup

These menus allow the manager to set up basic

oven functions

1. Turn the dial to highlight OVEN SETUP. Press

the center of the dial to select.

2. Turn the dial to highlight MANAGER PROĆ

GRAM. Press the center of the dial to select.

3. Turn the dial to highlight the oven function you

wish to change. Press the center of the dial to

select. Choose from the following functions:

Recipe Password - Select YES or NO to enĆ

able password protection on recipe programĆ

ming. If YES is selected the passcode 3124

must be entered to change recipe programĆ

ming.

Temp Unit - Select either degrees F or C.

Cool Down Temp - Select the set temperaĆ

ture for the oven to achieve in Cool Down

mode

Temp Disp Rate - Set the rate, in seconds,

at which the display switches between actual

and setpoint temperature

Input Rsp Time - Set the length of time alĆ

lowed to input each variable when programĆ

ming recipes before control automatically exĆ

its out

Setback Time - When not used for a period

of time, the oven temperature will automaticalĆ

ly reduce to conserve energy. This variable

sets the length of time the oven remains at the

idle temperature before being lowered.

Ready Beep - Select either ON or OFF. This

is the audible alarm that sounds when the

oven has reached the set temperature.

Cook Cool Fan - Select either YES or NO.

This function allows the control to display

OPEN OVEN DOOR when you are attempting

to lower the set temperature of the oven.

Restore Manual - Select either YES or NO.

This variable enables the oven to remember

the last settings used for manual cooking.

4. After editing a function, press the center of the

dial to save.

5. When all desired functions have been edited,

turn the dial to highlight EXIT. Press the center

of the dial to exit the manager programming

mode.

22

MANUAL MODE COOKING

1. Select the POWER button to turn on the oven

and proceed to the mode screen.

Operation

Touchscreen Control

2. Select MANUAL to cook using basic time and

temperature controls.

Figure 10

Figure 11

23

Operation

Touchscreen Control

3. Set the desired cooking parameters.

Temperature - Press the temperature text

and enter the desired oven temperature on

the keypad provided. Press SAVE and EXIT to

return to this screen.

Cook Time - Press the time text and enter the

desired bake time on the keypad provided.

Press SAVE and EXIT to return to this screen.

Core Probe Cooking - To use the probe

cooking feature, insert a product probe in the

probe outlet on the control panel. Press the

PROBE COOK icon. Press the temperature

text that appears and enter the desired prodĆ

uct core temperature on the keypad provided.

Press SAVE and EXIT to return to this screen.

Cavity Moisture - Press the HOT AIR icon to

reduce the cavity moisture content in 10% inĆ

crements. At 0% the oven is in the Hot Air

mode. Press the HYDRO icon to increase the

cavity moisture content in 10% increments. At

100% the oven is in the Hydro mode.

Temperature

Fan Speed - With the FAN icon highlighted,

press the fan speed text (75% in Figure 12) to

increase the fan speed in 25% increments.

When 100% is displayed, press the text again

to reduce the fans speed to 25%.

Fan Reversal Interval - To adjust the fan reĆ

versal time, press the FAN icon. Then press

the time text and enter the desired reversal inĆ

terval on the keypad provided. Press SAVE

and EXIT to return to this screen.

Vent Position - At any time the vent can be

opened or closed by toggling the VENT icon.

When the icon is highlighted the vent is open.

Lights - At any time the lights can be turned

on or off by toggling the LIGHT icon.

4. Press START Icon to begin cooking. Press

Cancel to stop cooking. Press +1 MIN to add

1 minute to the cook time.

Time

Hot Air Mode

Fan Speed

Lights

Probe cooking

Hydro Mode

Fan Reversal

Increment

Vent position

Figure 12

24

Operation

Touchscreen Control

MENU MODE COOKING

1. Select the MENU icon to cook using the pre

programmed menu items.

2. Select the desired food category for your

product.

Figure 13

Figure 14

25

Operation

Touchscreen Control

3. Within the food category, select the desired

product you wish to cook.

4. Select which shelves you intend to place the

food on. Press the ADD ITEM icon to return to

step #2 and add different items that share the

same set point parameters but may have difĆ

ferent cook times.

When the START HEATUP icon is pressed, the

oven will automatically heat up to the product

set temperature.

Once preheated, the START HEATUP icon will

change to START. At this point, load the prodĆ

uct, close the doors, and press START.

Figure 15

Figure 16

26

Operation

Touchscreen Control

5. During the cook cycle, individual shelf cook

timers will count down as the product is

cooked. If you wish to cancel the bake, you

can press the ESC button at any time.

Once the bake is complete the beeper will

sound and the ADD 1 MINUTE icon will appear

next to each complete product.

EDITING A MENU

1. Select the MENU/EDIT icon to edit the recipes

in the menu mode.

Figure 17

Figure 18

27

Operation

Touchscreen Control

2. Select the EDIT ITEMS icon to edit the menu

items.

To delete an Item, select the item while the DEĆ

LETE key is highlighted.

To create a new item, select the NEW ? icon

while the EDIT key is highlighted.

Figure 19

3. Select which mode you would like to be in,

Edit or Delete.

To edit an existing item, select the item while

the EDIT key is highlighted.

Figure 20

28

Operation

Touchscreen Control

4. Each recipe is made up of steps. A new step

is needed each time a parameter within a

stage changes.

To edit a parameter within a particular step,

press the text of that parameter. A keypad will

appear for you to input your desired value for

that parameter.

To add a step, press the ADD STEP icon on the

lower left of the screen.

To delete a step, use the arrows in the lower

left corner of the screen to highlight the step

you wish to delete. Press DELETE STEP to deĆ

lete the highlighted step.

Once you are finished, press SAVE and EXIT

to confirm your changes and return to the preĆ

vious screen.

EDITING A CATEGORY

1. Select the MENU/EDIT icon to edit the recipes

in the menu mode.

Figure 21

Figure 22

29

Operation

Touchscreen Control

2. Select the EDIT CATEGORIES icon to select

which items are in each category.

3. Select what you would like to edit about the

category.

To edit the name, press the EDIT NAME icon.

A keyboard will appear, enter the desired

name and press SAVE and EXIT to return to

this menu.

To edit the category icon, press EDIT ICON

and go to step #5.

To edit the items contained within a category,

press SELECT ITEMS and go to step #4.

If you are done, Press SAVE and EXIT to return

to the previous screen.

Figure 23

Figure 24

30

Operation

Touchscreen Control

4. Select which items you would like to appear

under the category. When complete, press

ESC to save and return to the previous menu.

5. After pressing EDIT ICON in step #3, the folĆ

lowing screen will appear. Select the desired

icon or press the arrow icon to view more icon

options. Once you select an icon, you will be

sent back to Step #3.

Figure 25

Figure 26

31

Operation

Touchscreen Control

COOL DOWN

1. To cool down the unit, press the COOL DOWN

icon.

2. The oven will display COOLING in yellow until

the oven is cool. Once cool, the oven will go to

standby.

Figure 27

Figure 28

32

Maintenance

Spray Bottle Operating Procedure

NOTE: Only use a commercial oven cleaner/deĆ

greaser with the spray bottle. DO NOT use

chemicals that are not intended as oven

cleaners. See chemical manufacturer's inĆ

formation for intended use.

1. Unscrewāā ātheā āāsprayerāāā āhead āāāāandāāā āfillā āāāthe containĆ

er to the MAX mark. Screw the head assembly

āon āfirmlyā toā āensureā āan āāairtight seal. The liquid

must be clean and free from foreign matter. Do

not overfill Ć space must be left for compressĆ

ing air.

2. To build up pressure, pump approximately 20

full strokes when the container is filled with liqĆ

uid. The higher the pressure, the finer the

spray. If the container is only partially filled,ā

then āmoreā pumping āāis āārequired āto compress

the additional air space.

3. To spray, depress the trigger with your thumb.

4. Adjust spray nozzle for a wide spray pattern.

5. After a period of spraying, the pressure will

drop. Restore the pressure by operating the

air pump.

6. Release pressure after use by inverting the

spray head and depressing the trigger or byā

slowly āunscrewing ā theā spray āhead assembly

āwhichā willā allow āairā toā escape āfrom around āāāthe

filling aperture.

7. Afterā use,ā rinse āthe āsprayā bottleā withā clean waĆ

ter and check that the hole in the nozzle is āperĆ

fectly āclean āand clear. Warm water (notā hot)ā

usedā withā aā household ādetergent is a useful

cleaning agent for this purpose.

NOTE: Further information can be found in the inĆ

struction leaflet supplied with your spray

bottle.

WARNING!!

Protective clothing and eyewear should

be worn while using cleaning agents.

Spray

Head

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Pressure Pump

Pump

MAX

Spray Trigger

Figure 29

Complete Spray Bottle - P/N R0006

Spray Head Repair Kit - P/N R6332

33

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily Cleaning

Daily cleaning of the appliance is essential for sanitaĆ

tion, and to ensure against operational difficulties.

The stainless steel cavity may corrode with improper

cleaning of the oven. Use an oven cleaning deterĆ

gent in conjunction with the supplied spray bottle.

For difficult cleaning, allow the sprayĆon oven

cleaner to work longer before rinsing.

1. Cool āāthe āappliance down to 140_F (60_C) or,

if the āāovenāā has āābeenā āidle, āāturnā the Hydro modeā

onā foār 3 āto ā4ā minutesā inā order āāāto warm the cavĆ

ity surfaces.

2. Fill āāāāātheāāā āsprayāāā ābottleā āāandāāā pump āāāairā āāintoāā āthe conĆ

tainer with the pressure pump.

3. Spray āāthe āinteriorā of āātheāā ovenā with a cleaning

solution. Be certain to spray cleaner through

the fan guard to cover all surfaces.

NOTE: Never spray water into the appliance

when the temperature is above 212_F

(100_C).

4. Let āthe ācleanerā āworkāā the time recommended by

the cleaning solution manufacturer. āForā āādifficult,

baked on grease, etc. allow to work over night.

5. Set the timer for 15 to 20 minutes.

6. Run āātheā āoven at 225_F (107_C) in the Hydro

mode with 100% humidity. This will soften all

burned on residue.

7. Rinseāā āātheāāā āapplianceāāāāā interiorā āāāwithāāāāā waterāā (a hose

is supplied,āā ābut āāātakeāā careā thatā only āātheā interior

cavity is sprayed with water). Wipe the interior

dry after rinsing.

8. The door should be kept slightly open after

cleaning. This will allow the oven to vent and

increase the life of the door gasket.

On stainless interiors, deposits of baked on splatĆ

ter, oil, grease or light discoloration āmay ābe āreĆ

moved āwith āa good non toxic industrial stainless

steel cleaner. Apply cleaners when the oven is

cold and always rub with the grain of the metal.

The racks, rack supports and the blower wheel

may be cleaned in the oven or by removing them

from the āoven āand āsoaking āthem in a solution of

ammonia and water.

NOTE: DO NOT use corrosive cleaners not inĆ

tended for oven cleaning on your HyĆ

drovection oven.

Recommended cleaners:

a.) ECOLAB Greasecutter Plus

b.) CELLO EZ Clean

c.) DiverseyĆLever Advance Oven Cleaner

WARNING!!

Be sure to read and follow the MSDS or

safety instructions on the bottle for your

oven cleaner.

34

Maintenance

Cleaning and Preventive Maintenance

Oven Weekly Cleaning

In addition to the daily cleaning, it is necessasry to

clean behind the fan guard of this oven on a weekĆ

ly basis. This is necessary for proper functioning

of the oven. Scale will build up on the fan and heat

source leading to a less efficient oven.

1. Turn off the oven. Make sure that the oven is

cooled down to under 140_F (60_C).

2. Remove the rack guides.

3. Rotate the two screws on the left side of the fan

guard.

Figure 30

4. Remove the fan guard.

5. Thoroughly spray cleaner onto the fan and

heat source. Close the door to allow the cleanĆ

er to work.

6. After ten minutes, rinse the cleaner off. Return

the fan guard to the closed position. Rotate

the two screws to secure the fan guard.

Remove and clean the blower wheel every 6

months.

CLEANING THE EXTERIOR

The exterior of the appliance may be cleaned and

kept in good condition with a light oil. Saturate a

cloth and wipe the appliance when it is cold; wipe

dry with a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. CleanĆ

ing with a water jet can impregnate chloĆ

rides into the stainless steel, causing the

onset of corrosion.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

āāāthe āāāproper āāinitial āāinstallation āāof āāthe equipment and

a program for cleaning the appliance routinely.

The Hydrovection requires no lubrication. Contact

the factory, the factory representative or a local

Blodgett service company to perform mainteĆ

nance and repairs should they be required.

Figure 31

35

Introduction

Description du four et Spécifications

Les fours Hydrovection de Blodgett sont des apĆ

pareils haut de gamme fabriqués en acier inoxyĆ

dable de première qualité en faisant appel à des

procédés supérieurs.

Le ventilateur à deux vitesses est doté d'un dispoĆ

sitif de protection pour les doigts et alimenté par

un puissant moteur silencieux. Le condenseur asĆ

pire l'excès de vapeur de l'appareil. La condensaĆ

tion et les eaux usées sont continuellement évaĆ

cuées.

L'isolant de haute qualité empêche un rayonneĆ

ment thermique excessif et aide à conserver

l'énergie.

En option, des pieds réglables et des supports

permettent d'adapter le four aux surfaces inégales

et à tous les modèles de table.

Les portes pratique du four est dotée d'un hublot

et possède un grand rayon d'ouverture. La poiĆ

SPÉCIFICATIONS DE PLOMBERI

EAU

Pression d'eau 30 lb/po2 (207 kPa) minimum

50 lb/po2 (345 kPa) maximum

gnée de la porte est facile à saisir, même avec des

mains mouillées ou grasses.

La disposition simple des commandes facilite l'utiliĆ

sation de l'appareil. Même un cuisinier inexpérimenĆ

té peut facilement utiliser l'appareil grâce à un systèĆ

me de pictogrammes explicites. La troisième

fonction du sélecteur, le mode Cool Down (refroidisĆ

sement), permet de refroidir rapidement la cavité du

four lorsque la porte est ouverte.

L'appareil exige un nettoyage minime. L'intérieur

est vaporisé d'une solution nettoyante à action inĆ

stantanée qui réagit avec avec l'humidité pour éliĆ

miner les croûtes et les taches. La conception du

fourĆétuveur Combi assure un entretien facile. Les

soudures sont étanches à l'eau, ce qui permet de

rincer la cavité du four après le nettoyage à la vaĆ

peur.

Raccordement d'eau Boyau d'eau froide 3/4 po

Réglage du régulateur

d'eau

Conditions requises

minimum

DRAINAGE

Type de drain Drain de mise à l'air libre

Raccordement du drain 1" NPT Mâle

Température moyenne

de l'eau au drainage

Prérégler à 30 lb/po2 (207 kPa)

Total des solides en suspension (TDS) - doit être moins que

100 parties par million

Dureté totale de l'eau - 80Ć120 parties par million

Chlorides - doit être moins que 30 parties par million

Chlorine - 0 parties par million

Le pH de l'eau - 7.0Ć8.0

Environ 60_C (140_F)

36

Introduction

Description du four et Spécifications

CARACTÉRISTIQUES TECHNIQUES - HVĆ100G

Type de

gaz

Naturel 60 000 BTU/h 120 1 20 1/2 HP 208Ć240 V c.a., 3 fase,

Propane 60 000 BTU/h 120 1 20 1/2 HP 208Ć240 V c.a., 3 fase,

Connecteur de 3/4 po FNPT pour toutes les installations canadiennes et américaines

Entrée Tension Phase Intensité Moteur

50/60 Hz

50/60 Hz

CARACTÉRISTIQUES TECHNIQUES - HVĆ100E

Tension Fréquence kW Phase

208 60 15 3 38 38 38 1/2 HP 208Ć240 V c.a., 50/60 Hz

240 60 15 3 36 34 34 1/2 HP 208Ć240 V c.a., 50/60 Hz

440 60 15 3 20 18 18 1/2 HP 208Ć240 V c.a., 50/60 Hz

480 60 15 3 18 17 17 1/2 HP 208Ć240 V c.a., 50/60 Hz

208 60 13 3 33 33 36 1/2 HP 208Ć240 V c.a., 50/60 Hz

Charge maximale

(ampères)

L1 L2 L3

Moteur

240 60 13 3 31 29 29 1/2 HP 208Ć240 V c.a., 50/60 Hz

440 60 13 3 16 16 17 1/2 HP 208Ć240 V c.a., 50/60 Hz

480 60 13 3 15 15 16 1/2 HP 208Ć240 V c.a., 50/60 Hz

37

Installation

Certifications

LES PRÉSENTES CONSIGNES D'INSTALLATION

SONT DESTINÉES AU PERSONNEL D'INSTALĆ

LATION ET D'ENTRETIEN QUALIFIÉ SEULEĆ

MENT. TOUTE INSTALLATION OU TOUT ENTREĆ

TIEN EFFECTUÉ PAR DES PERSONNES NON

COMPÉTENTES POURRAIENT ENDOMMAGER

LE FOUR OU CAUSER DES BLESSURES.

Le terme personnel d'installation qualifié désigne

une personne, une entreprise, une société ou une

organisation assumant, elleĆmême ou par l'entreĆ

mise d'un représentant, les responsabilités suiĆ

vantes :

D la pose ou le remplacement des tuyaux de gaz.

Le raccordement, la mise en service, la réparaĆ

tion ou l'entretien du matériel.

D La pose du câblage électrique à partir du compĆ

teur, de la boîte de distribution principale ou de

la prise jusqu'à l'appareil.

Le personnel qualifié doit détenir de l'expérience

dans ces domaines, connaître toutes les mesures

de sécurité pertinentes et respecter les normes de

la province ou des autorités locales.

Mises en service américaines et canadiennes

La mise en service doit respecter les normes locaĆ

les ou, en l'absence de tels normes, les règleĆ

ments suivants : National Fuel Gas Code,

NFPA54/ANSI Z223.1 - dernière édition, le Code

d'installation du gaz naturel CAN/CGAĆB149.1 ou

le Code d'installation du propane, CAN/CGAĆ

B149.2, selon le cas.

Référence : National Electrical Code, ANSI/NFPA

70 - dernière édition ou le Code canadien de

l'électricité CSA C22.1, selon le cas.

La mise en service de ce matériel doit respecter

les normes suivantes : Basic Plumbing Code of the

Building Officials and Code Administrators InterĆ

national Inc. (BOCA) et Food Service Sanitation

Manual du Food and Drug Administration (FDA).

L'appariel doit etre installe avec l'empechement

de refoulement selon les codes federale,

provincial et locaux.

Mise en service dans les autres pays

L'installation doit respecter les normes nationales

et locales, qui varient selon le pays. Si vous avez

des questions sur les méthodes d'installation acĆ

ceptables ou sur le fonctionnement de votre appaĆ

reil, veuillez communiquer avec votre détaillant.

S'il n'y a aucun détaillant dans votre région, veuilĆ

lez communiquer avec Blodgett au

0011Ć802Ć658Ć6600.

38

Installation

Emplacement du four et mise de niveau et Ventilation

RESPONSABILITÉS DU PROPRIÉTAIRE

Responsabilités de l'installation avant l'inspecĆ

tion de mise en service

Vous avez droit à une inspection de mise en serviĆ

ce gratuite effectuée dès que possible par notre

représentant. Avant que cette personne se préĆ

sente pour effectuer la mise en service, vous deĆ

vez vous assurer de satisfaire déjà aux exigences

suivantes :

1. Le four est déballé, empilé (s'il y a lieu) et mis

en place.

REMARQUE:Veuillez consulter la section MontaĆ

ge des pieds et Superposition.

Charges maximales sure une tablette - 27.3 kg

(60lb)

EMPLACEMENT DU FOUR

Il est important de bien choisir l'emplacement de voĆ

tre four afin d'en augmenter les performances et

l'utilité.

Vous devez conserver un dégagement minimal enĆ

tre le four et toute construction combustible ou non

combustible. Consultez le tableau ciĆdessous.

De plus, il est recommandé de respecter les dégaĆ

gements suivants pour l'entretien.

D Parois latérales du four - 30 cm (12 po)

D Paroi arrière du four - 30 cm (12 po)

DÉGAGEMENT ACCEPTABLE

Modèle

du four

HVĆ100E 0 mm

HVĆ100G 0 mm

VENTILATION

On ne saurait trop insister sur la nécessité de préĆ

voir un système d'aération bien conçu. Un tel

système permettra au four de bien fonctionner,

Côté

droit

(0 po)

(0 po)

Côté

gauche

0 mm

(0 po)

0 mm

(0 po)

Arrière

152,4 mm

(6 po)

152,4 mm

(6 po)

tout en évacuant les vapeurs et produits de comĆ

bustion gênants de la zone d'utilisation.

L'extraction des fumées de combustion de l'appareil

doit se faire au moyen d'un groupe d'aspiration à

commande mécanique. CeluiĆci doit être dimenĆ

sionné de façon à ce qu'il recouvre entièrement l'apĆ

pareil, tout en dépassant d'au moins 15 cm de tous

les côtés qui ne sont pas contigüs à un mur. Le

groupe doit avoir la capacité qui convient et un apĆ

point d'air adéquat doit être prévu.

AVERTISSEMENT!!

Une mauvaise extraction des fumées de

combustion du four peut mettre en danĆ

ger la santé de l'opérateur. Elle aura

également pour résultats des problèmes

de fonctionnement, une cuisson laissant

à désirer et de possibles dégâts subis par

le matériel. Les dégâts résultant directeĆ

ment d'une aération inadéquate ne seront

pas couverts par la garantie offerte par le

fabricant.

Si cet appareil est installé dans le Commonwealth

du Massachusetts, il doit s'emboîter avec le

système de sortie de la hotte, de sorte que l'appaĆ

reil puisse fonctionner seulement quand le

système de sortie de la hotte est en marche.

Mises en service américaines et canadiennes

Se reporter aux codes locaux de la ventilation. En

l'absence de codes locaux, se reporter au code

national de la ventilation intitulé Normes pour

l'installation d'équipements pour l'enlèvement des

fumées et vapeurs grasses provenant d'équipeĆ

ments commerciaux pour la cuisine", NFPA-96Édition la plus récente.

Mise en service dans les autres pays

L'installation doit respecter les normes nationales

et locales, qui varient selon le pays. Si vous avez

des questions sur les méthodes d'installation acĆ

ceptables ou sur le fonctionnement de votre appaĆ

reil, veuillez communiquer avec votre détaillant.

S'il n'y a aucun détaillant dans votre région, veuilĆ

lez communiquer avec Blodgett Combi au

0011Ć802Ć860Ć3700.

39

Installation

Montage des pieds

OPTIONS

Pied réglable de 635 mm (25 po)

216mm (8Ć1/2 po) avec

Les Roulettes, Pieds réglable ou Pieds Séismiques

MONTAGE

1. Alignez le goujon fileté situé sur l'un des pieds

avant avec le trou de boulon situé au coin inféĆ

rieur de l'appareil. Tournez le pied dans le

sens horaire et serrez jusqu'au tour complet

le plus proche.

2. Alignez les trous de la plaque de montage du

pied avec les trous de boulon. Fixez solideĆ

ment au moyen des deux boulons de 1/2 po

fournis.

3. Répétez les étapes précédentes pour l'autre

pied avant. Si vous utilisez des roulettes, inĆ

stallez les roulettes à frein à l'avant du four. Les

roulettes arrière ne se bloquent pas. AssurezĆ

vous que les roulettes avant sont bloquées.

4. Penchez le four vers l'avant sur les pieds avant

que vous venez d'installer. Si vous venez d'inĆ

staller des roulettes, assurezĆvous que les rouĆ

lettes avant sont bien bloquées. Répétez les

étapes précédentes pour les pieds arrière.

5. Pour mettre le four de niveau (sauf pour les

modèles dotés de roulettes), vissez ou dévisĆ

sez les pieds réglables selon le cas.

Figure 32

Figure 33

40

Installation

Accessoire des roulettes

ROULETTES POUR FOUR SIMPLE

1. Placer les pieds comme décrit.

2. Desserrer l'écrou de blocage des embouts au

bas de chaque pied réglable. Retirer les embouts.

3. Insérer une roulette dans chaque pied, comĆ

me illustré. Serrer les écrous de blocage pour

fixer les roulettes.

Embouts de

pied ajustables

Ensemble de roulette

Figure 34

ROULETTES POUR DEUX FOURS SUPERPOĆ

SÉS

1. Placez un niveau sur le plancher où les rouletĆ

tes seront installées.

2. Placez des cales sous le côté bas jusqu'à ce

qu'il soit de niveau.

3. Montez les cales entre les roulettes et le four

comme suit :

a.) Alignez les cales et les trous des roulettes

avec les trous des boulons.

b.) Attachez avec les boulons de 13 mm (1/2

pouce) fournis.

REMARQUE:Il faut les installer avec les rouletĆ

tes bloquantes à l'avant du four.

Les roulettes arrière ne se verĆ

rouillent pas. AssurezĆvous que

les verrous des roulettes avant

sont enclenchés.

4. Basculez le four vers le haut sur les roulettes

nouvellement installées.

41

Ajoutez des

ales selon

les besoins

Plancher

Echelle surdimensionnée pour raison de clarté

Figure 35

Installation

Superposition

ATTENTION !!

Seul un installateur qualifié peut effectuer

la superposition des appareils. Les appaĆ

reils sont lourds. AssurezĆvous d'utiliser

des outils et des méthodes appropriés

pour soulever et superposer les appareils.

1. Posez les pieds ou les roulettes sur l'appareil

du bas. Consultez la page 40 ou 41.

2. Placez le four du haut sur le four du bas. AssuĆ

rezĆvous que les quatre côtés sont bien

alignés.

3. Boulonnez les deux fours ensemble par derĆ

rière utilisant les agrafes d'empilage.

les agrafes

d'empilage

les agrafes

d'empilage

Vue arrière HVĆ100E

42

les agrafes

d'empilage

Installation

les agrafes

d'empilage

Vue arrière HVĆ100E

Figure 36

43

Installation

RACCORDEMENT À L'EAU

REMARQUE:Doit employer l'EAU FROIDE SEULEĆ

MENT.

Raccordez l'appareil à une source d'eau propre

au moyen d'un boyau de pression muni de racĆ

cords de 19 mm GHT (3/4 po). Consultez la

Figure 37 pour le raccordement. Prévoyez l'instalĆ

lation d'un robinet d'arrêt à proximité du four.

ATTENTION !!

L'utilisation de l'appareil non équipé du

régulateur d'eau annule votre garantie.

Ce produit doit être installé par un plombier ou un

monteur d'installations au gaz accrédité, si installé

dans le Commonwealth du Massachusetts.

RACCORDEMENT DU DRAIN

Raccordement de la plomberie

HVĆ100E

A