Page 1

DFGĆ100 AND DFGĆ200 SERIES

CONVECTION OVEN

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN 33082 Rev F (7/10)

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

E 2010 - G.S. Blodgett Corporation All rights reserved.

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

Oven Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. OPERATION

Manual Controls with ElectroĆMechanical Thermostat 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Cook Only 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Cook & Hold 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Delay with Pulse Plus 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidaire 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intelliplus with Chain Event Control 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch II 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CALIBRATION AND ADJUSTMENT

Doors 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Blower Switch 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burners 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Manual 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch Control Second Level Programming 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital Second Level Programming 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch II Second Level Programming 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intelliplus Second Level Programming 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. PARTS REPLACEMENT

Access Panels and Doors 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combustion Compartment Cover 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Cover 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perimeter Door Gasket 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Center Door Gasket 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oven Door 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Assembly for ovens with 50/50 Doors 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Assembly for Ovens with 60/40 Doors 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Door Hinge and Sprocket Assembly 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Chain Assembly 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor and Blower Assembly 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Wheel 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burner and Deflector Assemblies 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manifold and Burner Orifices 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burners 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compartment Liner Bottom 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

TABLE OF CONTENTS

Deflector Assembly 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Igniter (Glow Coil) and Plumbing Components 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Igniter 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Delay Relay Assembly 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Pressure Regulator 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid Valve 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Stack Assembly 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

combination Dual Gas Valve 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intermittent Ignition Device (IID) and Plumbing Components 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pilot Burner and Spark Ignition 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control and

Transformer 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Stack Assembly 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combination Dual Gas Valve 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulb and Capillary Thermostat 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components Located in the Control Module 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Switch 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. TROUBLESHOOTING

Heat HSI System 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Diagram 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Error Codes 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe resistance vs temperature 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 4

CHAPTER 1

INTRODUCTION

Page 5

DFGĆ100 and DFGĆ200

OVEN SPECIFICATIONS

VENTILATION REQUIREMENTS

Canopy Type Exhaust Hood

The preferred method of ventilation is the use of a

mechanically driven, canopy type exhaust hood.

The hood should completely cover the unit with an

overhang of at least 6" (15 cm) on all sides not adjaĆ

cent to a wall. The distance from the floor to the lowĆ

er edge of the hood should not exceed 7' (2.1 m).

The ventilation system should replace 80% of the

exhaust volume with fresh make up air.

Direct Flue

NOTE: U.S. and Canadian installations only.

The minimum recommended clearance of the oven

from any combustible, or nonĆcombustible material

should be 6" (15 cm). The height of the flue should

rise 6Ć8' (2Ć2.5 m) above the roof of the building, or

any proximate structure. The flue should be capped

with a UL listed vent cap to isolate the unit from exterĆ

nal environmental conditions.

The direct vent does not have the capability of reĆ

placing air consumed and vented by the oven. It is

important that provisions be made to supply the

room with sufficient makeĆup air. Total makeĆup air

requirements for each oven section should be

about 19 CFM.

ELECTRICAL SPECIFICATIONS

NOTE: Three Phase hookup is not permitted on

gas models.

WARNING: DO NOT INSTALL A HIGH LEG" TO

ANY CONVECTION OVEN!

The DFGĆ100 and DFGĆ200 ovens are supplied for

connection to 115 VAC grounded circuits with the

6' (1.8 m) power cord supplied. All ovens, when

installed must be electrically grounded in accorĆ

dance with National Electric or local codes.

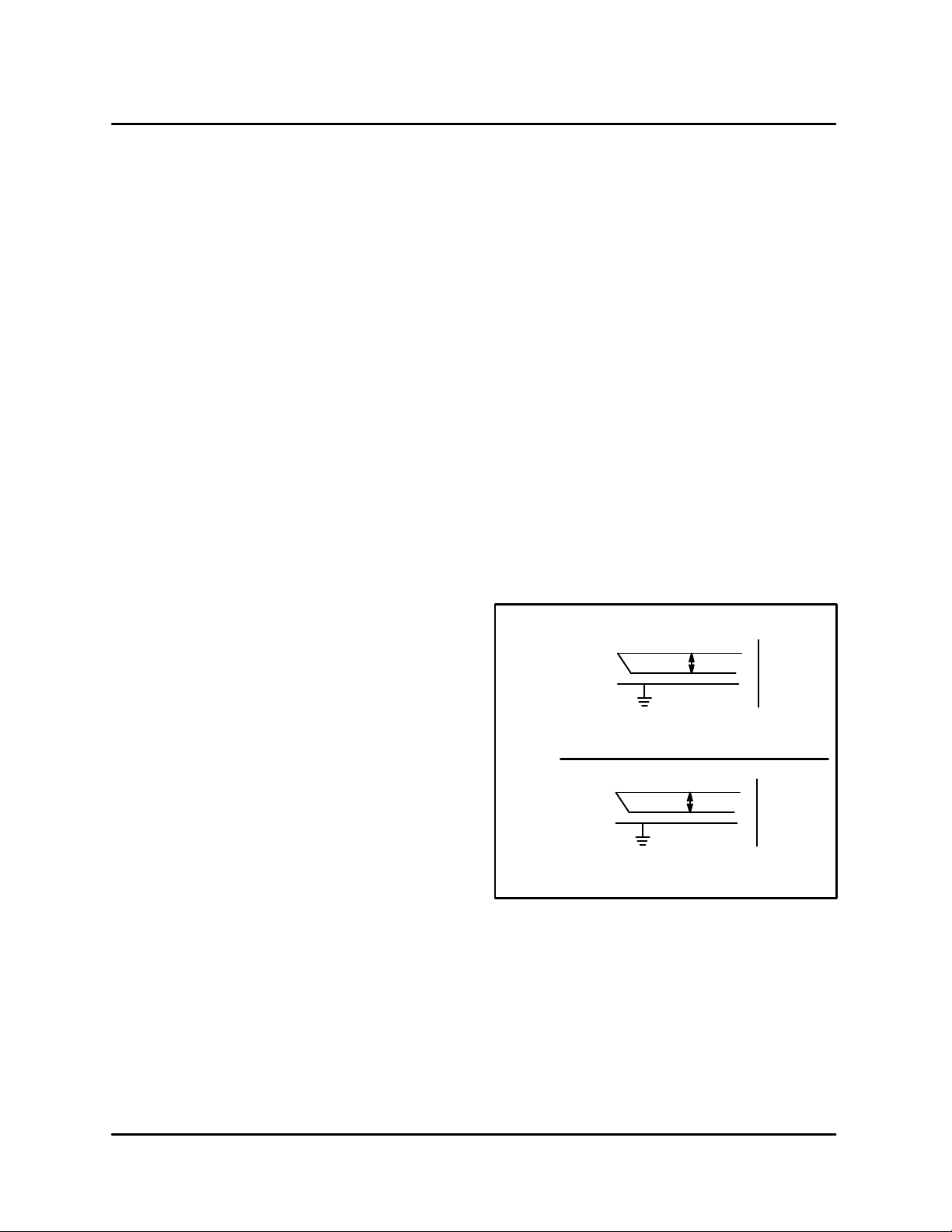

CE approved installations

Connect the oven to a separate group 230V, 50 hz

with rigid connection and operating switch. Use

90_C wire and size according to local codes.

NOTE: The burner control unit is phase sensitive.

If the phase and neutral are switched the

control locks out.

Connect phase + neutral + ground.

L1

N

115

OvenSupply

1-1

U.S. Installations

L1

N

230

CE Approved Installations

FIGURE 1

OvenSupply

Page 6

GAS SPECIFICATIONS

INTRODUCTION

GAS CONNECTIONS

Domestic and General Export installations

The gas line should be large enough to accommoĆ

date the peak demand of all the gas appliances.

TABLE 1 reflects a straight line, 50 foot run with no

coupling restrictions and no other appliances

drawing service. Gas line installations MUST conĆ

form to National Fuel Gas Code NFPA 54/ANSI

Z223.1 Sec. 1.4 (Latest Edition). TABLE 1 should

be used as a guideline only.

NOTE: For any pipe runs over 50 feet (15 m), conĆ

sult the factory.

CE approved installations

1. Connect the oven to the gas line with the propĆ

er type of gas according to Local and National

Installation Standards. See TABLE 1.

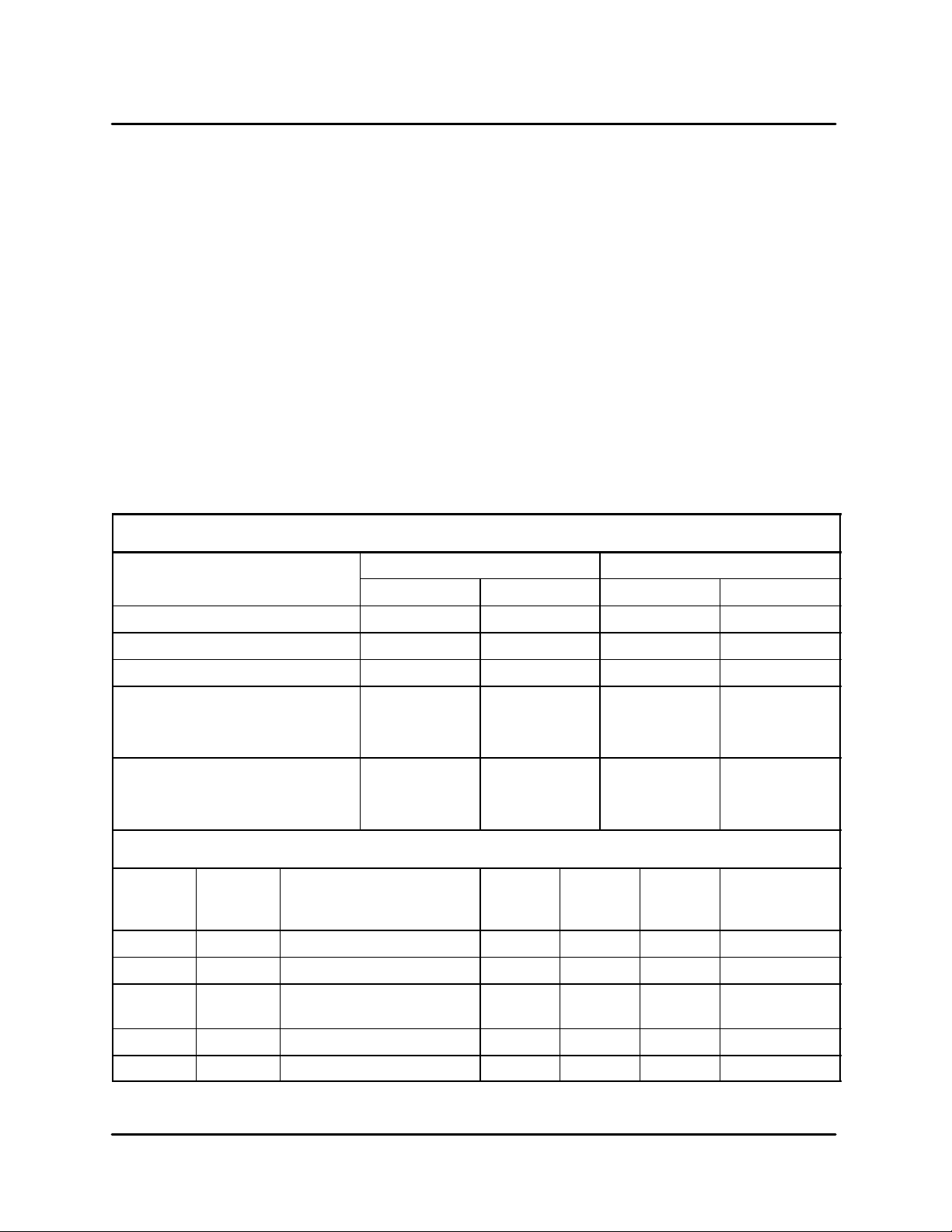

DOMESTIC AND GENERAL EXPORT

Natural Gas Propane Gas

US units SI units US units SI units

Heating Value 1000 BTU/hr 37.3 MJ/m

GAS REQUIREMENTS

NOTE: For natural gas meter sizing, consult your

Installations within the U.S.

1. Add the total BTU's/hr of all the gas appliances.

2. Convert BTU's to cubic ft/hr using the formula

Cu Ft/Hr = 1000 BTU/Hr for natural gas.

3. Size the meter accordingly.

Installations outside the U.S.

1. Add the total M3/min of all the appliances.

2. Size the meter accordingly.

local gas company to ensure that your meĆ

ter will provide the proper supply.

3

2550 BTU/hr 95.0 MJ/m

3

Specific Gravity (air = 1.0) 0.63 0.63 1.53 1.53

Gas Manifold Pressure 3.5" W.C. 0.87 kPa 10" W.C. 2.49 kPa

Oven Input

DFGĆ100Ć3

DFGĆ200ĆL

Main Burner Orifice Size

DFGĆ100Ć3

DFGĆ200ĆL

CE APPROVED UNITS

Type of

Gas

G25 25 12 2,60 18 0,53 16,2 Nat. Gas

G20 20 8 2,60 18 0,53 16,2 Nat. Gas

G20/G25 20/25 Totally Inscrewed

G30 30/50 17 1,60 10 0,28 16,2 Butane

G31 30/37/50 24 1,60 10 0,28 16,2 Propane

Inlet

Pressure

mbars

Burner Pressure

Pressure Regulator

55,000 BTU/hr

60,000 BTU/hr

40 MTD

38 MTD

mbars

16.2 kW/Hr.

17.6 kW/Hr.

2.5 mm

2.6 mm

Injector

Diameter

mm

2,10 18 0,53 16,2 Nat. Gas

55,000 BTU/hr

60,000 BTU/hr

Air

Opening

mm

53 MTD

1/16 dia.

Pilot

Injector

mm

16.2 kW/Hr.

17.6 kW/Hr.

1.5 mm

1.55 mm

Standard

Delivery

Value kW (HS)

TABLE 1

1-2

Page 7

DFGĆ100 and DFGĆ200

VENTILATION

CANOPY TYPE EXHAUST HOOD

Ovens that are ordered for underĆhood venting are

supplied with a draft diverter. When supplied with

a draft diverter, the oven must be installed under a

mechanically driven exhaust hood.

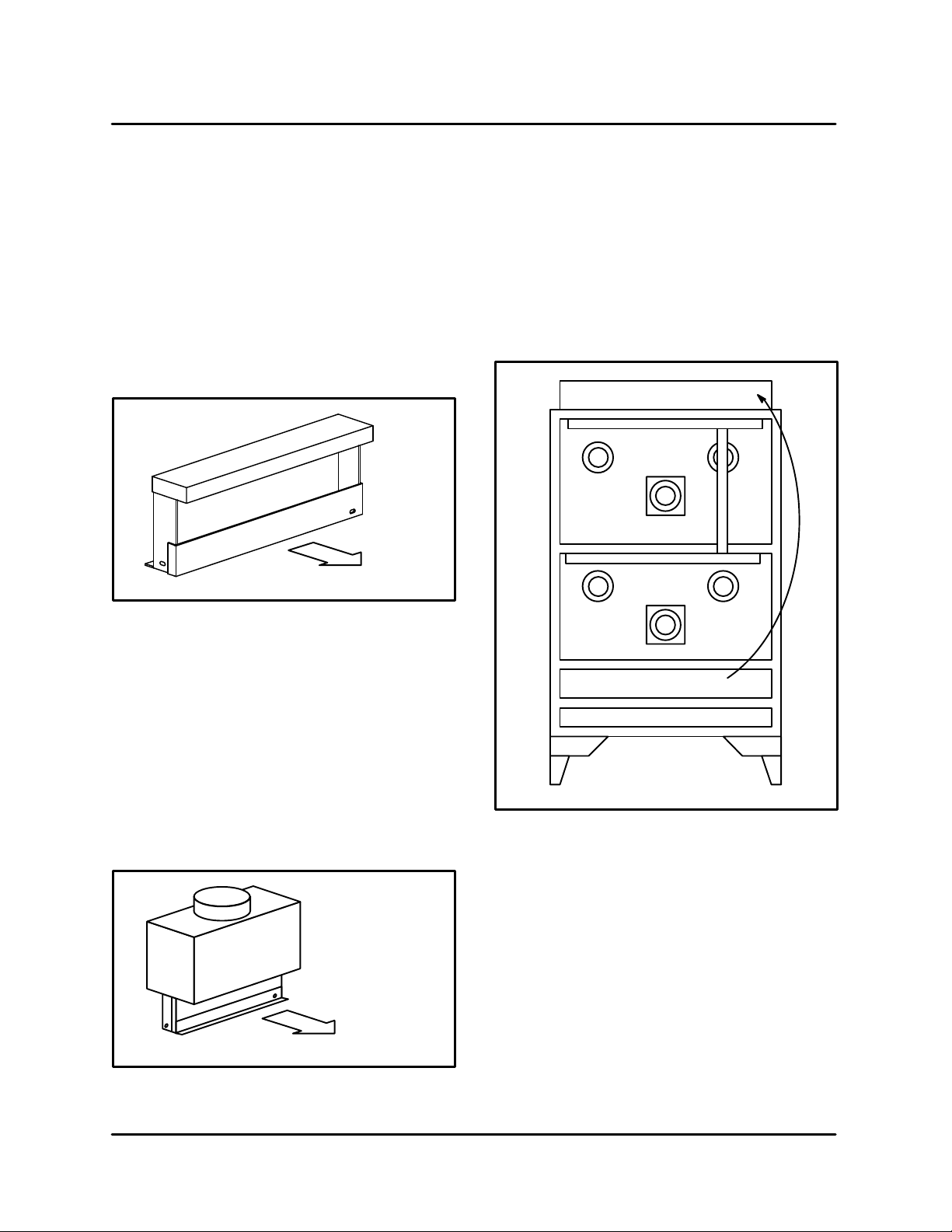

1. To install, place the diverter with the open area

toward the rear of the oven.

2. Secure both ends with the sheet metal screws

provided.

Front of

Oven

FIGURE 2

TRIM COLLAR

1. Remove the trim collar from its shipping posiĆ

tion at the rear of the oven.

2. Remove the protective coating from the stainĆ

less steel portion of the collar.

3. Install the collar in the proper position at the top

of the oven.

Trim Collar

DIRECT FLUE ARRANGEMENT

NOTE: Not available for CE approved installations.

Ovens that are ordered for direct venting are

supplied with a direct vent.

1. To install, place the direct vent with the angle on

the bottom facing toward the front of the oven

2. Secure both ends with the sheet metal screws

provided.

Front of

Oven

FIGURE 3

Trim Collar

FIGURE 4

1-3

Page 8

CHAPTER 2

OPERATION

Page 9

DFGĆ100 and DFGĆ200

MANUAL CONTROLS WITH ELECTROĆMECHANICAL THERMOSTAT

NOTE: The following instructions represent the most common controllers. For questions regarding other

options call the Blodgett Service Department at (800)331Ć5842.

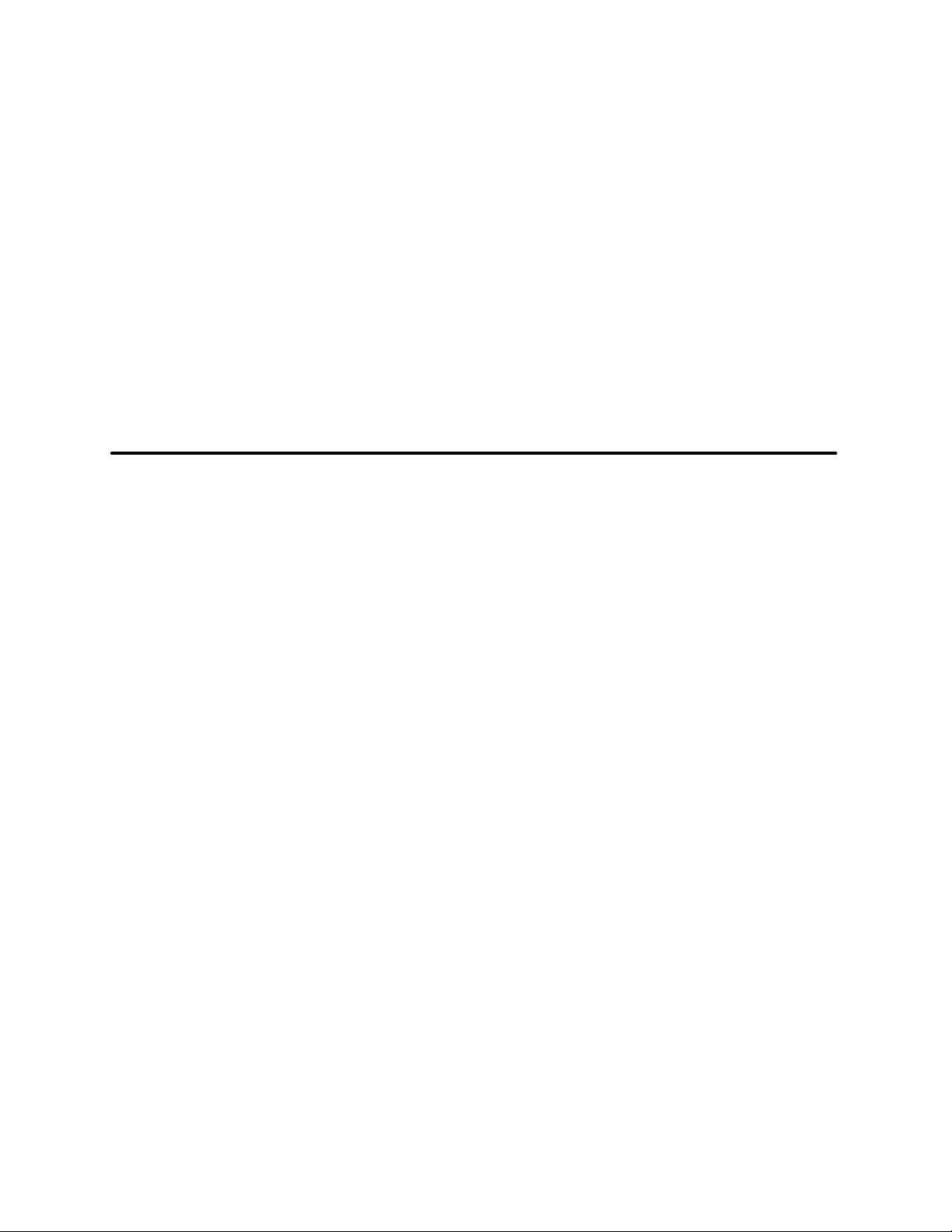

SEQUENCE OF OPERATION - DIAGRAM P/N 17794 REV A

Component Reference

NOTE: Refer to FIGURE 5 page 2-2 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK THERMOSTAT

3. COOK TIMER

4. GAS SOLENOID

5. DOOR SWITCH

6. CONVECTION MOTOR

7. CENTRIFUGAL SWITCH

8. THERMAL DELAY RELAY

9. HOT SURFACE IGNITER

10. COOK LIGHT

11. BUZZER

12. LIGHT BULBS

13. LIGHT SWITCH

Operation

1. Power is applied to the appliance by a 110VAC

power cord attached to the rear of the oven.

2. Power is at terminal L1 and N of the mode seĆ

lector switch (1).

3. If the mode switch is turned on then a circuit is

made between L1 and Terminal 1 allowing curĆ

rent flow to one side of the cook thermostat (2),

cook timer (3), pilot valve portion of the gas soĆ

lenoid valve (4) and one side of a SPST door

switch (5).

4. If the door switch is closed, power goes to terĆ

minal #4 of the mode selector switch and to

the L1 side of the convection motor (6) allowing

the motor to start.

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam that is mounted to the right

hand hinge pin.

5. On a call for heat, the cook thermostat closes

sending power to one side of a centrifugal

switch (7). If the motor is operating at full

speed, this switch should be closed sending

power to terminals 8 and 6 of a thermal delay

relay (8).

NOTE: The centrifugal switch is an integral

part of the convection motor and is not

field repairable.

NOTE: The thermostat is a fluid filled bulb and

capillary style. The bulb is located in

the upper right hand corner of the bake

chamber.

6. The area connecting terminals 6 and 1 of the

thermal delay relay is called a heater strip.

NOTE: The thermal delay relay contains both

the heater strip and the set of contacts

that operate the gas valve in what looks

like an old TV tube. This tube is

plugged into a socket, so removal of

the tube is simple.

NOTE: This strip warms up as voltage is apĆ

plied to the HSI.

7. As the hot surface igniter (9) gets hotter so

does the heater strip. The heat from the strip

causes two strips of metal to come together

and touch allowing current to flow from termiĆ

nal 8 to terminal 3 of the TDR to the main porĆ

tion of the gas solenoid valve and an indicator

light (10). This light goes on and off every time

the main gas valve is powered up.

8. Gas flows to the burners and is ignited by the

high temperature of the HSI.

9. The timer is a mechanical count down timer. It

closes a set of contacts within the timer to powĆ

er up a buzzer (11) at the expiration of whatevĆ

er time the operator dials in.

10. The lights (12) are operated by a STDP rocker

switch (13).

2-1

Page 10

12

OPERATION

1

11

4

10

9

4

13

6

2

8b

8a

7

5

3

1

FIGURE 5

2-2

Page 11

DFGĆ100 and DFGĆ200

SOLID STATE COOK ONLY

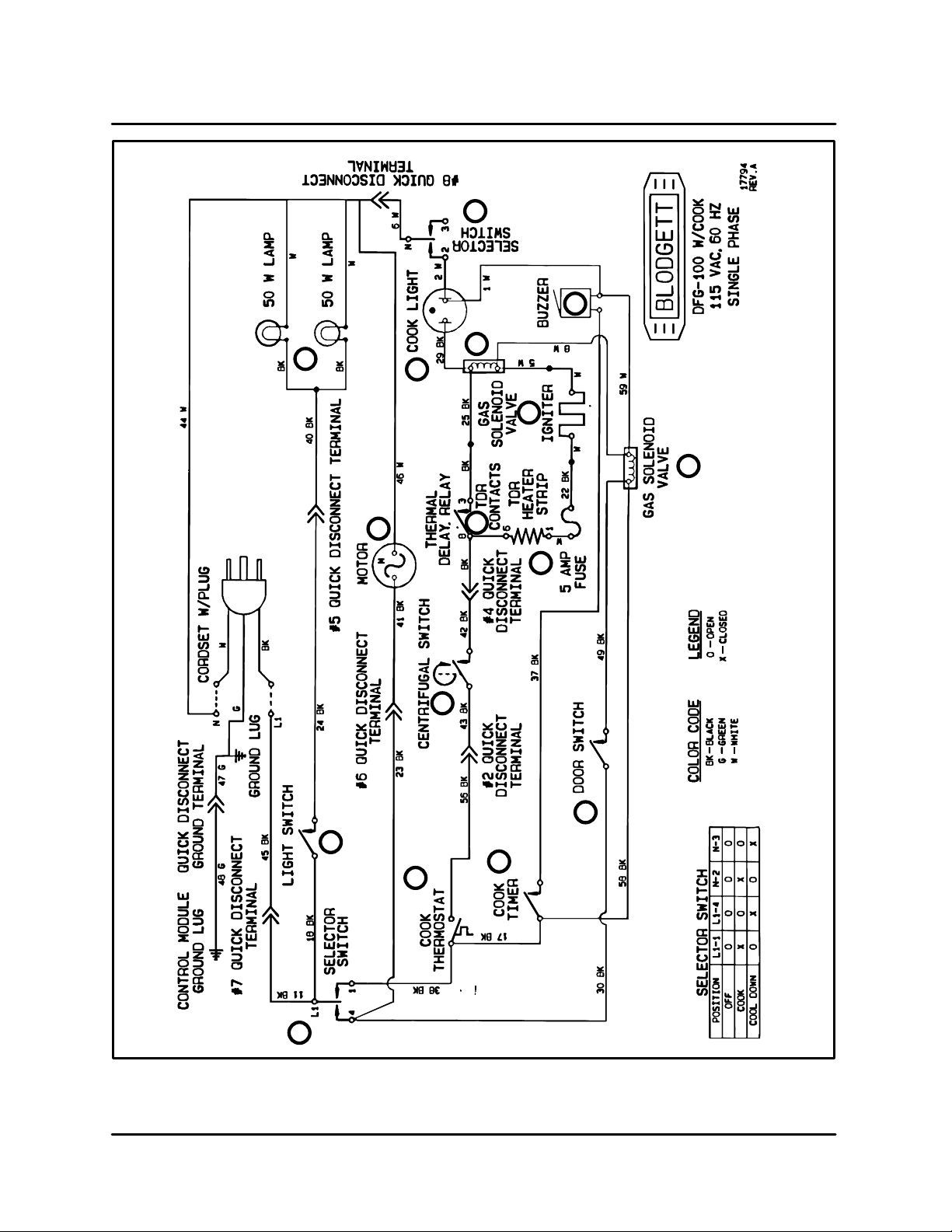

SEQUENCE OF OPERATION - DIAGRAM P/N 20027 REV A

Component Reference

NOTE: Refer to FIGURE 6 page 2-4 for compoĆ

nent locations.

1. MODE SWITCH

2. DOOR MICROSWITCH

3. TEMPERATURE CONTROL BOARD

4. AXIAL FAN

5. 60 MINUTE TIMER

6. 110/24 VOLT TRANSFORMER

7. TEMPERATURE PROBE

8. IGNITION CONTROL MODULE

9. TWO SPEED MOTOR

10. CENTRIFUGAL SWITCH

11. PILOT VALVE

12. PILOT BURNER

13. MAIN VALVE

14. LIGHT BULBS

15. LIGHT SWITCH

16. BUZZER

Operation

1. Power is applied to the appliance by a 110VAC

power cord attached to the rear of the oven.

2. Power is at terminal L1 and N of the mode seĆ

lector switch (1).

ture control board (3) and the ignition control

module (8).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam that is mounted on the right

hand hinge pin.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

5. On a call for heat from the thermostat as

sensed by an RTD probe (7), a set of contacts

on the temperature control board (3) close

completing a circuit to terminal 2 of the ignition

control module (8).

NOTE: The thermostat consists of three comĆ

ponents (RTD probe, solid state temĆ

perature control board and 1000 ohm

potentiometer)

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

6. After the ignition control module (8) completes

a diagnostics and all functions check out,

24VAC is sent to the pilot valve (11) and a high

energy spark jumps a gap at the pilot burner

(12). Once the pilot is lit and the pilot flame is

proven, the ignition control module (8) sends

24VAC to the main valve (13).

3. If the mode switch (1) is turned on a circuit is

made between L1 and 1, N and 2 allowing curĆ

rent to flow to one side of a SPST door switch

(2), terminal #8 of the solid state temperature

control board (3), axial fan (4), terminal 1 of the

cook timer (5) and to the primary side of a 110

volt to 24 volt transformer (6).

4. If the doors are closed, the door switch (2)

should be closed sending power to the conĆ

vection blower (9). When this motor reaches

full speed a centrifugal switch (10) closes

sending 24VAC to terminal 6 of the temperaĆ

NOTE: A 24VAC indicator light is wired in parĆ

allel with the main valve to inform the

operator that the main gas valve is beĆ

ing powered up. When the light goes

out the thermostat is satisfied.

7. The lights (14) are controlled by a SPST rocker

switch (15).

8. The buzzer (16) is controlled by a switch in the

cook timer.

NOTE: The timer's only function is to count

down and activate a buzzer. This will

not shut down the oven.

2-3

Page 12

OPERATION

4

9

3

16

6

11

13

15

14

7

5

2

1

12

8

10

FIGURE 6

2-4

Page 13

DFGĆ100 and DFGĆ200

SOLID STATE COOK & HOLD

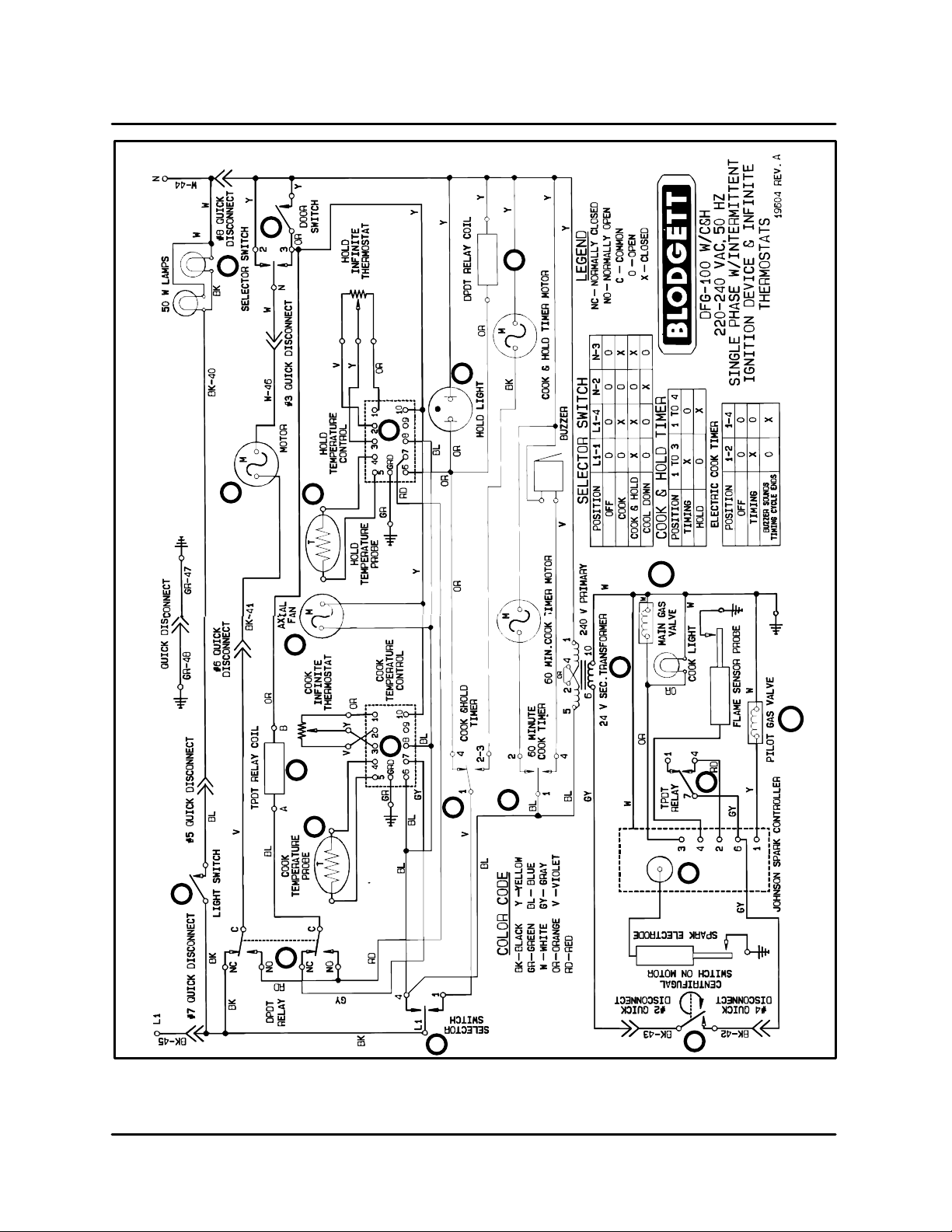

SEQUENCE OF OPERATION - DIAGRAM P/N 19604 REV A

Component Reference

NOTE: Refer to FIGURE 7 page 2-7 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DPDT RELAY

3. LIGHT SWITCH

4. 60 MINUTE TIMER

5. 110/24 VOLT TRANSFORMER

6. TEMPERATURE CONTROL BOARD

7. AXIAL FAN

8. HOLD TEMPERATURE CONTROL BOARD

9. DOOR MICROSWITCH

10. CONVECTION BLOWER MOTOR

11. CENTRIFUGAL SWITCH

12. IGNITION CONTROL MODULE

13. TPDT RELAY

14. COOK TEMPERATURE PROBE

15. A & B DUAL SOLENOID GAS VALVE

16. COOK & HOLD TIMER

17. HOLD INDICATOR LIGHT

18. HOLD TEMPERATURE PROBE

Operation

1. Power is applied to the appliance by a 110VAC

power cord attached to the rear of the oven.

2. Power is at terminal L1 and N of the mode seĆ

lector switch (1), one of the NC terminals of a

DPDT relay (2) and one terminal of SPST light

switch (3).

3. If the mode selector switch (1) is turned to the

cook position a circuit is made between L1 and

terminal 4. 110VAC flows to terminal 1 of the 60

minute timer (4), the primary side of a 110 to 24

volt transformer (5), terminals 6 and 8 of the

temperature control board (6), axial cooling

fan (7) and terminal 8 of the hold temperature

board (8).

tion control module (12) and terminal 7 of a

TPDT relay (13).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam mounted on the right hand

hinge pin.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

5. On a call for heat from the thermostat as

sensed by an RTD probe (14), a set of contacts

on the temperature control board (6) closes

completing a circuit between terminals 6 and

7 allowing 110 volts AC to go to one of the norĆ

mally closed contacts on the DPDT relay (2).

The relay sends 110 volts AC to the coil of the

TPDT relay (13) allowing the circuit to be made

between terminals 7 and 4 of the same relay.

This completes the circuit to the ignition conĆ

trol module (12).

NOTE: The thermostat consists of three comĆ

ponents (RTD probe, solid state temĆ

perature control board and a 1000

ohm potentiometer.)

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

6. After the ignition control module (12) has comĆ

pleted a diagnostics and all functions check

out, 24VAC is sent to the pilot valve (15a) and

a high energy spark jumps a gap at the pilot

burner. Once the pilot is lit and the pilot flame

is proven, the ignition control (12) sends

24VAC to the main valve (15b).

NOTE: A 24VAC indicator light is wired in parĆ

allel with the main valve to inform the

operator that the main gas valve is beĆ

ing powered up. When the light goes

out the thermostat is satisfied.

4. If the doors are closed, the door switch (9)

should be closed sending power to the conĆ

vection blower (10). This switch interrupts the

neutral going to the motor. Once this motor

reaches full speed a centrifugal switch (11)

closes sending 24VAC to terminal 6 of the igniĆ

2-5

Page 14

OPERATION

7. If the mode selector switch (1) is set to the

Cook & Hold position a circuit is made in the

switch between L1, 1 and 4. All of the previousĆ

ly mentioned circuitry is active as well as the

cook and hold circuit.

8. At the expiration of time on the cook and hold

timer (16) a circuit is made between terminals

1 and 4 allowing power to go to a hold indicator

light (17), terminal 6 of the hold temperature

board and the coil of the DPDT relay (2) allowĆ

ing the relay (8) to toggle between C-NC to

C-NO terminals.

9. When there is a demand for heat from the hold

temperature board (8) as sensed by the temĆ

perature probe (18) a set of contacts on the

temperature control board closes completing

a circuit between terminals 6 and 7 allowing

110VAC to go to one of the normally open conĆ

tacts on the DPDT relay (2) which in turns

sends 110VAC to the coil of the TPDT relay (13)

allowing the circuit to be made between termiĆ

nals 7 and 4 of the same relay. This completes

the circuit to the ignition control module (12).

This toggling effect also allows 110VAC to go

to the convection blower (10). This cycles the

blower on and off every time there is a call from

heat from the hold board (8).

NOTE: The thermostat consists of three comĆ

ponents (RTD probe, solid state temĆ

perature control board and a 1000

ohm potentiometer).

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

NOTE: The two temperature probes and poĆ

tentiometers used in this oven configuĆ

ration are identical. The solid state

temperature control boards appear

identical, however, they are significantĆ

ly different. The hold board will not allow

for temperatures over 200_F (93_C).

NOTE: The timer's only function is to count

down and activate a buzzer. This will

not shut down the oven.

2-6

Page 15

DFGĆ100 and DFGĆ200

9

1

17

8

10

18

7

2

15b

5

15a

6

13

16

14

3

2

1

4

13

12

11

FIGURE 7

2-7

Page 16

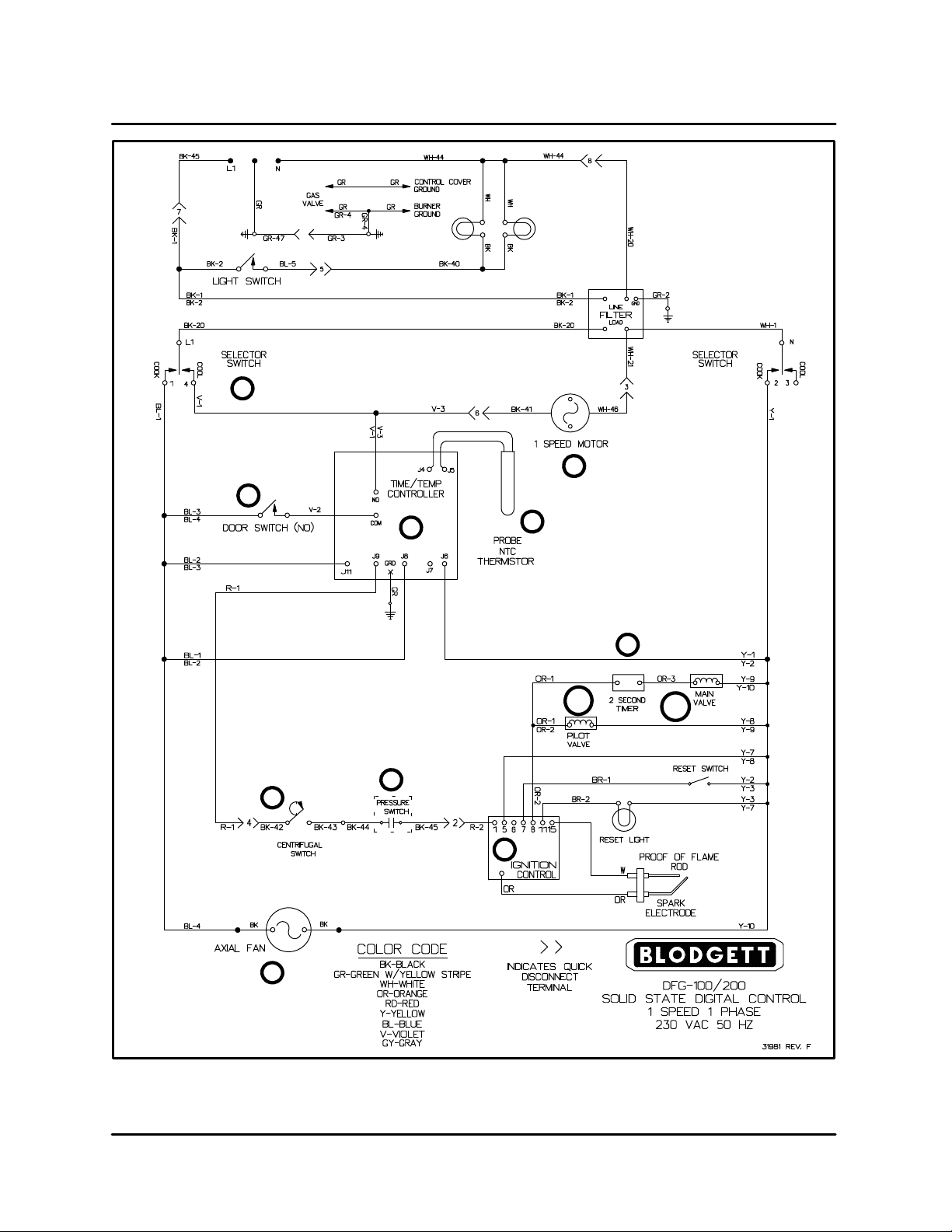

SOLID STATE DIGITAL

SEQUENCE OF OPERATION - DIAGRAM P/N 31981 REV F

OPERATION

NOTE: Refer to FIGURE 8 page 2-9 for compoĆ

nent locations.

Component Reference

1. MODE SWITCH

2. DOOR SWITCH

3. TIME AND TEMPERATURE CONTROL

4. AXIAL FAN

5. SINGLE SPEED MOTOR

6. CENTRIFUGAL SWITCH

7. PRESSURE SWITCH

8. LANDIS & GYR IGNITION CONTROL

9. 2 SECOND TIMER

10. A & B DUAL SOLENOID GAS VALVE

11. TEMPERATURE PROBE

Operation

1. Power is applied to terminals L1 and N of the

mode selector switch (1).

2. If the mode selector switch is set to cook,

230VAC is sent to one side of a SPST door

switch (2), terminals J11 and J8 of the time and

temperature control (3) and the axial cooling

fan (4).

3. If the doors are closed the door switch (2)

should be closed sending 230VAC to the conĆ

vection fan motor (5).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam mounted on the right hand

hinge pin.

NOTE: The motor only operates continuously

if the control is not set for pulse. If there

is a time programmed into the control

for pulse the control opens and closes

a set of contacts on the control to cycle

the fan on and off.

4. If there is a temperature programmed into the

time and temperature control (3) and the control

is calling for heat as sensed by the RTD probe

(11), 230VAC is applied to one side of a centrifuĆ

gal switch (6) in the convection motor (5).

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

5. If the motor (5) is up to full speed the centrifugal

switch (6) should be closed sending power to

the pressure switch (7). If the pressure switch

is closed, 230VAC is applied to the Landis &

Gyr ignition module (8).

6. This ignition module is used for direct spark

application. This appliance utilizes a two secĆ

ond timer (9) wired in parallel with the pilot

valve (10a) to keep power from going to the

main valve (10b) for two seconds after the pilot

is lit.

2-8

Page 17

DFGĆ100 and DFGĆ200

1

2

5

3

11

9

10A

7

6

8

4

10B

FIGURE 8

2-9

Page 18

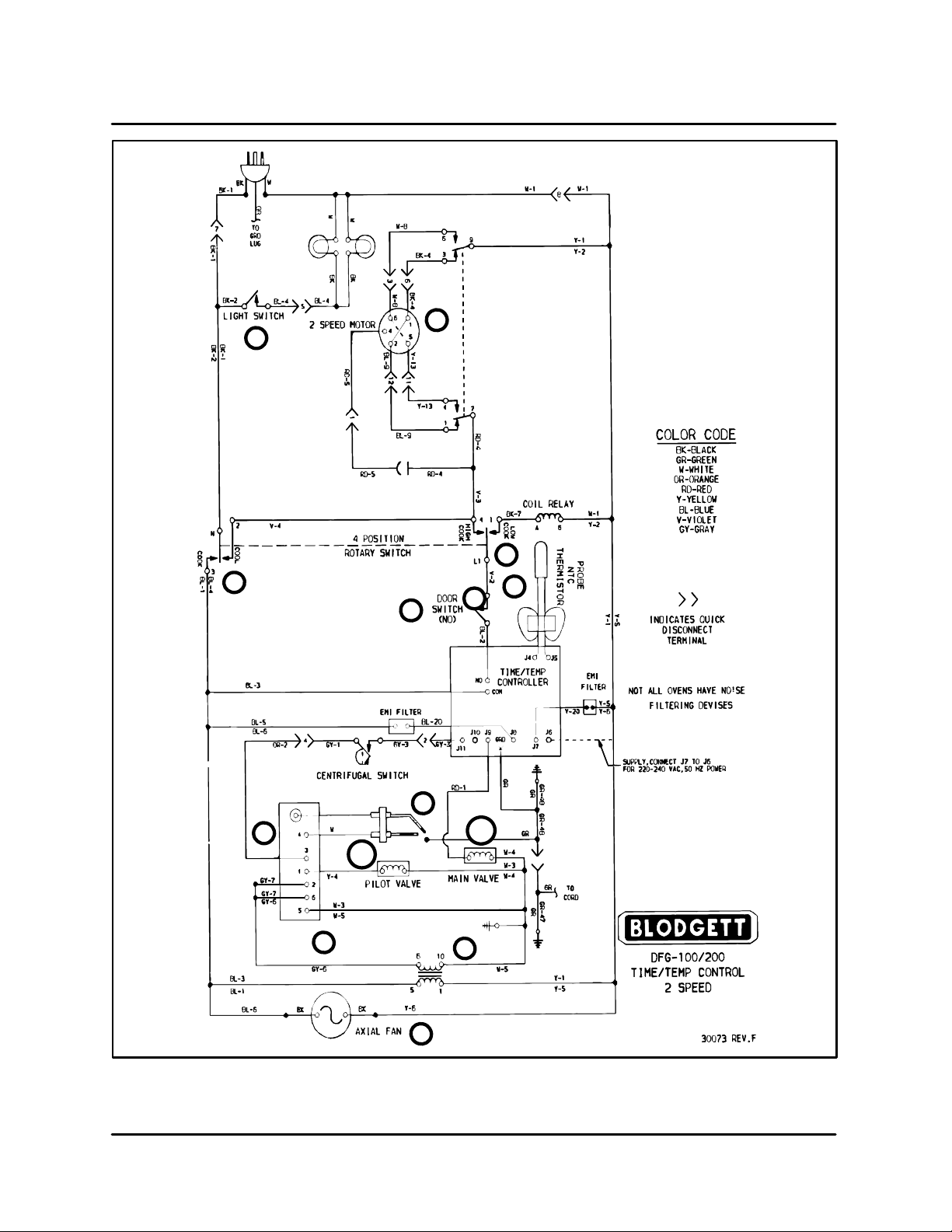

SEQUENCE OF OPERATION - DIAGRAM P/N 30073 REV F

OPERATION

NOTE: Refer to FIGURE 9 page 2-11 for compoĆ

nent locations.

Component Reference

1. MODE SWITCH

2. LIGHT SWITCH

3. TIME AND TEMPERATURE CONTROL

4. TRANSFORMER

5. AXIAL FAN

6. TWO SPEED MOTOR

7. TEMPERATURE PROBE

8. CENTRIFUGAL SWITCH

9. IGNITION CONTROL MODULE

10. A & B DUAL SOLENOID GAS VALVE

11. PILOT BURNER

12. DOOR SWITCH

Operation

1. Power is applied to the appliance by a 110 volt

power cord attached to the rear of the oven.

2. Power is at L1 and N of the mode selector

switch (1).

3. Power is also applied to one side of a SPST

light switch (2).

6. If the doors are closed, the door switch (12)

should be closed sending 110VAC to the conĆ

vection fan motor (6).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam that is mounted on the right

hand hinge pin.

NOTE: The motor will only operate continuĆ

ously if the control is not set for pulse.

If there is a time programmed into the

control for pulse the control opens and

closes a set of contacts on the the conĆ

trol to cycle the fan on and off.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

7. If the motor (6) is up to full speed, the centrifuĆ

gal switch (8) closes sending 24VAC to termiĆ

nal J11 of the temperature control (3).

8. If there is a temperature programmed into the

time and temperature control (3) and the conĆ

trol is calling for heat as sensed by an RTD

probe (7), a circuit is completed between J9

and J11 of the time and temperature control (3)

allowing 24VAC to go to the main valve (10b).

4. When the mode selector switch (1) is set to the

cook position a circuit is made between N and

terminal 3 as well as L1 and terminal 4 or 1 deĆ

pending on which motor operation is selected.

NOTE: The mode selector switch in this apĆ

plication is a four position selector

switch and allows for hi and low speed

fan operation.

5. Power is delivered to the common terminal and

terminal J8 of the time and temperature conĆ

troller (3), the primary side of a 110 to 24 volt

transformer (4) and to an axial cooling fan (5).

When the transformer is powered up 24VAC is

delivered to terminals 6 and 2 of the ignition

control module (9). After the ignition control

module has completed a diagnostic and all

functions check out, 24VAC is sent to the pilot

valve (10a) and a high energy spark jumps a

gap at the pilot burner (11). Once the pilot is lit

and the pilot flame is proven the ignition control

module (9) sends 24VAC to the centrifugal

switch (8) in the convection fan (6).

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

2-10

Page 19

DFGĆ100 and DFGĆ200

2

6

1

1

12

11

9

10a

8

4

3

10b

7

5

FIGURE 9

2-11

Page 20

FAN DELAY WITH PULSE PLUS

SEQUENCE OF OPERATION - DRAWING P/N 20029 REV A

OPERATION

Component Reference

NOTE: Refer to FIGURE 10 page 2-14 for compoĆ

nent locations.

1. MODE SELECTOR

2. TEN MINUTE FAN DELAY TIMER

3. TEMPERATURE CONTROL BOARD

4. AXIAL FAN

5. PULSE TIMER

6. TRANSFORMER

7. DOOR SWITCH

8. TWO SPEED MOTOR

9. CENTRIFUGAL SWITCH

10. IGNITION CONTROL

11. TEMPERATURE PROBE

12. A & B DUAL SOLENOID GAS VALVE

13. COOK TIMER

14. TPDT RELAY

15. TPDT SWITCH

16. LIGHT BULBS

17. LIGHT SWITCH

18. BUZZER

Operation

5. If the doors are closed the door switch (7)

should be closed sending power to the conĆ

vection blower (8). When this motor reaches

full speed, a centrifugal switch (9) closes sendĆ

ing 24VAC to terminal 6 of the temperature

control board (3) and the ignition control modĆ

ule (10).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam that is mounted on the right

hand hinge pin.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

6. On a call for heat from the thermostat as

sensed by an RTD probe (11) a set of contacts

on the temperature control board (3) close

completing a circuit to terminal 2 of the ignition

control module (10).

NOTE: The thermostat consists of three comĆ

ponents (RTD probe, solid state temĆ

perature control board and a 1000

ohm potentiometer).

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

1. Power is applied to the appliance by a 110 volt

power cord attached to the rear of the oven.

2. Power is at L1 and N of the mode selector

switch (1).

3. If the mode switch (1) is turned on, a circuit is

made between L1-1 and N-2, allowing curĆ

rent to flow to terminal 1 of the fan delay timer

(2), terminal #8 of the solid state temperature

control board (3) and the axial fan (4).

4. If the fan delay timer (2) is not counting down,

a circuit is made between terminals 1 and 4 alĆ

lowing voltage to go to terminal 3 of the pulse

timer (5), one side of a SPST door switch (7),

terminal 1 of the cook timer (13) and the primaĆ

ry side of a 110 to 24 volt transformer (6).

7. After the ignition control module (10) has comĆ

pleted a diagnostics and all functions check

out, 24VAC is sent to the pilot valve (12a) and

a high energy spark jumps a gap at the pilot

burner. When the pilot is lit and the pilot flame

is proven, the ignition control module (10)

sends 24VAC to the main valve (12b).

NOTE: A 24VAC indicator light is wired in parĆ

allel with the main valve to inform the

operator that the main gas valve is beĆ

ing powered up. The light goes out

when the thermostat is satisfied.

2-12

Page 21

DFGĆ100 and DFGĆ200

8. If time has been set on the fan delay timer (2),

a circuit is made between terminals 1 and 2 alĆ

lowing voltage to go to terminal 2 of the pulse

timer. This sends voltage to the coil of a TPDT

relay (14).

NOTE: The sole purpose of this relay is to

eliminate power to the cook timer moĆ

tor during pulse operation.

NOTE: The pulse timer is a solid state device

which pulses the convection fan on

and off for approximately 30 second inĆ

tervals.

9. The fan delay timer (2) can be set for no more

than 10 minutes. The solid state pulse timer (5)

will make and break the circuit between termiĆ

nals 2 and 3 allowing voltage to go to the door

switch (7) and the primary side of the step

down transformer (6).

10. If the door switch (7) is closed a circuit is comĆ

pleted to a TPDT blower switch (15).

NOTE: This blower switch will operate motor

speed based on the switch position.

NOTE: When the convection fan cycles on and

off, the ignition control system also

cycles on and off.

11. The lights (16) are controlled by a SPST rocker

switch (17).

12. The buzzer (18) is controlled by a switch in the

cook timer (13).

NOTE: The timer's only function is to count

down and activate a buzzer. This will

not shut down the oven.

2-13

Page 22

OPERATION

1

14

13

15

8

5

3

11

2

7

1

6

12B

4

10

12A

9

FIGURE 10

2-14

Page 23

DFGĆ100 and DFGĆ200

HUMIDAIRE

SEQUENCE OF OPERATION - DRAWING P/N 18486 REV H

Component Reference

NOTE: Refer to FIGURE 11 page 2-17 for compoĆ

nent locations.

1. MODE SWITCH

2. 60 MINUTE COOK TIMER

3. TEMPERATURE CONTROL BOARD

4. TRANSFORMER

5. AXIAL FAN

6. DOOR SWITCH

7. SINGLE SPEED MOTOR

8. CENTRIFUGAL SWITCH

9. IGNITION CONTROL

10. TEMPERATURE PROBE

11. A & B DUAL SOLENOID VALVE

12. PILOT BURNER

13. STEAM POTENTIOMETER

14. SINGLE SHOT TIMER

15. THERMAL DISC

16. STEAM SWITCH

17. WATER SOLENOID

18. LIGHT BULBS

19. LIGHT SWITCH

20. BUZZER

Operation

1. Power is applied to the appliance by a 110 volt

power cord attached to the rear of the oven.

2. Power is at L1 and N of the mode selector

switch (1).

3. If the mode switch (1) is turned on, a circuit is

made between L1and 1, N and 2 allowing curĆ

rent to flow to terminal 1 of the cook timer (2), terĆ

minal #8 of the solid state temperature control

board (3), the axial fan (5) and the primary side

of a 110 to 24 volt step down transformer (4).

4. If the doors are closed, the door switch (6)

should be closed sending power to the convecĆ

tion blower (7). When the motor reaches full

speed a centrifugal switch (8) closes sending

24VAC to terminal 6 of the temperature control

board (3) and the ignition control module (9).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam mounted on the right hand

hinge pin.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

5. On a call for heat from the thermostat as

sensed by an RTD probe (10) a set of contacts

on the temperature control board (3) close

completing a circuit to terminal 2 of the ignition

control module (9).

2-15

NOTE: The thermostat consists of three comĆ

ponents (RTD probe, solid state temĆ

perature control board and a 1000

ohm potentiometer).

NOTE: The temperature probe has a deĆ

scending temperature coefficient.

Page 24

6. After the ignition control module (9) has comĆ

pleted a diagnostics and all functions check

out, 24VAC is sent to the pilot valve (11a) and

a high energy spark jumps a gap at the pilot

burner (12). When the pilot is lit and the pilot

flame is proven, the ignition control module (9)

sends 24VAC to the main valve (11b).

NOTE: A 24VAC indicator light is wired in parĆ

allel with the main valve to inform the

operator that the main gas valve is beĆ

ing powered up. When the light goes

out, the thermostat is satisfied.

7. If there is a time set on the steam potentiomeĆ

ter (13), a solid state single shot timer (14) actiĆ

vates, only if the temperature on the oven cavĆ

ity is above 212_F (100_C) as sensed by a

thermal disc (15). When the steam cycle

switch (16) is pressed atomized water is inĆ

jected into the oven cavity through a water soĆ

lenoid valve (17) onto the blower wheel.

NOTE: The thermal disc is located in the back

of the oven attached to the oven liner.

OPERATION

NOTE: The steam start switch is a momentary

switch located on the front control panel.

8. The lights (18) are controlled by a SPST rocker

switch (19).

9. The buzzer (20) is controlled by a switch in the

cook timer (2).

NOTE: The timer's only function is to count

down and activate a buzzer. This will

not shut down the oven.

2-16

Page 25

DFGĆ100 and DFGĆ200

18

1

17

13

19

7

4

20

3

10

6

2

15

14

16

5

11b

9

12

11a

1

8

FIGURE 11

2-17

Page 26

INTELLIPLUS WITH CHAIN EVENT CONTROL

SEQUENCE OF OPERATION - DRAWING P/N 21846 REV D

OPERATION

Component Reference

NOTE: Refer to FIGURE 12 page 2-19 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. CONTROLLER

4. AXIAL FAN

5. TRANSFORMER

6. TWO SPEED MOTOR

7. CENTRIFUGAL SWITCH

8. IGNITION CONTROL

9. RTD PROBE

10. A & B GAS VALVES

11. PILOT BURNER

12. A & B DPDT RELAY

13. LIGHT BULBS

14. LIGHT SWITCH

Operation

1. Power is applied to the appliance by a 110 volt

power cord attached to the rear of the oven.

2. Power is at L1 and N of the mode selector

switch (1).

3. If the mode switch (1) is turned on then a circuit

is made between L1 and 1, N and 2, allowing

current to flow to a terminal on a SPST door

switch (2), to terminal E3 of the Intelliplus control

board (3), an axial fan (4) and the primary side

of a 110 to 24 volt step down transformer (5).

4. If the doors are closed the door switch (2)

should be closed sending 110VAC to K2 and

K3 of the Intelliplus controller (3) and the conĆ

tacts of a DPDT relay (12a). If there is a time,

temperature and motor function either dialed

or programmed into the controller (3), K2 or K3

should close sending power to the convection

blower motor.

NOTE: If K3 is energized, the coil of the DPDT

relay powers up allowing its contacts

to toggle.

NOTE: The motor only operates continuously

if the control is not set for pulse. If a

time is programmed for pulse, the conĆ

trol opens and closes a set of contacts

to cycle the fan on and off.

NOTE: Every time the convection fan cycles

on and off the ignition control system

also cycles on and off.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

5. If the motor (6) is up to full speed the centrifugal

switch (7) should be closed sending 24VAC to

terminal 6 of the ignition control (8) and E6 of

K1 on the Intelliplus control (3).

6. If there is a temperature programmed into the

Intelliplus control (3) and the control is calling

for heat as sensed by the RTD probe (9), a cirĆ

cuit is completed between E6 and E7 of the InĆ

telliplus control (3) allowing 24 volts to go to

terminal 2 of the ignition control (8).

NOTE: The temperature probe has an ascendĆ

ing temperature coefficient.

7. After the ignition control module (8) has comĆ

pleted a diagnostic and all functions check

out, 24VAC is sent to the pilot valve (10a) and

a high energy spark jumps a gap at the pilot

burner (11). When the pilot is lit and the pilot

flame is proven, the ignition control module

sends 24VAC to the main valve (10b).

NOTE: A 24VAC indicator light is wired in parĆ

allel with the main valve to inform the

operator that the main gas valve is beĆ

ing powered up. When the light goes

out the thermostat is satisfied.

NOTE: The time and temperature indicators

built into the control flash until the oven

has reached set point.

8. The lights (13) are controlled by a SPST rocker

switch (14).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam mounted on the right hand

hinge pin.

2-18

Page 27

DFGĆ100 and DFGĆ200

1

12a

5

10a

12b

6

13

14

1

3

2

9

4

10b

18

11

7

FIGURE 12

2-19

Page 28

INTELLITOUCH

SEQUENCE OF OPERATION - DRAWING P/N 19465 REV B

OPERATION

Component Reference

NOTE: Refer to FIGURE 13 page 2-21 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. TRANSFORMER

4. CONVECTION BLOWER

5. CENTRIFUGAL SWITCH

6. IGNITION CONTROL MODULE

7. SPDT RELAY

8. TEMPERATURE CONTROLLER

9. RTD PROBE

10. PILOT VALVE

11. PILOT BURNER

12. MAIN VALVE

Operation

1. Power is applied to the appliance by a 110VAC

power cord delivering power to the mode seĆ

lector switch (1).

2. If the mode selector switch (1) is in the cook

position a circuit is made between L1 and terĆ

minal 1 and N and terminal 2 allowing voltage

to go to one side of a SPST door switch (2) and

the primary side of a 110 to 24 volt step down

transformer (3).

4. On a call for heat from the temperature controlĆ

ler (8) as sensed by an RTD probe (9) a set of

contacts in the temperature control (8) closes

allowing 24VAC to go to the coil of a SPDT relay

(7). When this relay is energized a switch within

the relay toggles allowing a circuit to be made

between terminals 7 and 5 (7). This completes

the circuit to the ignition control module (6) at

terminal 2.

5. After the igntion control module (6) has comĆ

pleted a diagnostics and all functions check

out, 24VAC is sent to the pilot valve (10) and a

hight energy spark jumps a gap at the pilot

burner (11). When the pilot is lit and the pilot

flame is proven, the ignition control module (6)

sends 24VAC to the main valve (12)

NOTE: The cooling fan in this oven runs all of

the time when the unit is turned on.

NOTE: The lights are activated by a SPST

switch and can be turned on even if the

oven is off.

3. If the doors are closed, the door switch (2)

should be closed sending power to the conĆ

vection blower (4). When this motor reaches

full speed a centrifugal switch (5) closes sendĆ

ing 24VAC to terminal 6 of the ignition control

module (6) and terminal 7 of a SPDT relay (7).

NOTE: The door switch is located behind the

combustion cover and is operated by

the cam that is mounted on the right

hand hinge pin.

NOTE: The centrifugal switch is an integral

part of the convection blower and is

not field repairable.

2-20

Page 29

DFGĆ100 and DFGĆ200

1

4

8

9

12

7

7a

10

3

11

2

1

5

FIGURE 13

2-21

Page 30

INTELLITOUCH II

SEQUENCE OF OPERATION - DRAWING P/N 31173 REV C

OPERATION

Component Reference

NOTE: Refer to FIGURE 14 page 2-23 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. TPDT RELAY

3. TPDT RELAY

4. AXIAL FAN

5. DOOR SWITCH

6. CONTROL

7. TRANSFORMER

8. TWO SPEED MOTOR

9. IGINTION CONTROL

10. A & B GAS VALVE

11. TEMPERATURE PROBE

Operation

1. Power is applied to the appliance by a 110VAC

power cord. Power is delivered to the mode seĆ

lector switch (1).

2. If the switch (1) is turned on, power goes to a

set of contacts on relay 1 (2), a set of contacts

on relay 2 (3), an axial fan (4), one side of a

SPST door switch (5), terminals J20, J25 and

J47 of the Intellitouch temperature control (6)

and the primary side of a 110 to 24 volt step

down transformer (7).

3. If the control (6) is programmed to cook a prodĆ

uct and the door switch (5) is closed, the relays

within the control close depending on the funcĆ

tion chosen. When the operator chooses a

particular program, the high or low fan switch

closes allowing the coils of either relay 1 (2a)

or relay 2 (3a) to power up closing their respecĆ

tive contacts.

NOTE: These relays interrupt both the hot and

neutral wires to the convection fan.

4. If the temperature control (6) is calling for heat

as sensed by a temperature probe (11) and the

convection motor (8) has reached full speed,

a centrifugal switch cloes sending 24VAC to

terminal 2 of the ignition control (9). After the

ignition control (9) has completed a diagnosĆ

tics the pilot valve (10a) powers up. After proof

of flame, the main valve (10b) powers up.

NOTE: The centrifugal switch is an integral

part of the convection motor and is not

considered field repairable.

NOTE: The lights get power from a momentary

switch. Lights go out every time the

switch is released.

NOTE: The temperature control is a chain

event control that allows the operator

to program various motor, timing and

temperature functions for different

food product. At the expiration of proĆ

grammed time another event takes

place. If no time is put into the control,

the control cannot count down and the

chain is broken.

NOTE: The control is backed up with several

different support items such as a meĆ

chanical thermostat and switch to take

the control out of the heat circuit.

NOTE: The temperature probe ascends as

temperature increases.

2-22

Page 31

DFGĆ100 and DFGĆ200

1

2

3

5

8

4

6

3a

2a

1

11

9

10b

7

10a

FIGURE 14

2-23

Page 32

CHAPTER 3

CALIBRATION AND

ADJUSTMENT

Page 33

DFGĆ100 and DFGĆ200

DOORS

The DFGĆ100 and DFGĆ200 ovens feature double

side mounted doors which operate simultaneously

by means of a chain and turnbuckle linkage asĆ

sembly. Should field adjustment be necessary, the

two turnbuckles are located immediately behind

the combustion compartment cover. CAUTION:

the turnbuckles are located in a heat zone.

For units manufactured prior to August 1984.

1. Adjust one turnbuckle, then the other until the

doors are properly synchronized.

NOTE: The doors are properly adjusted if the

right door is fully closed when the left

door (the door with the handle) has beĆ

tween 1/2 and 1 inch of travel remaining.

Both turnbuckles must be adjusted to prevent

strain on the door operating mechanism.

2. Tighten the turnbuckle lock nuts.

Turnbuckle

(not shown)

For units manufactured after August 1984

Be sure the doors are in line with each other when

viewed from the top and front. If the doors are misaĆ

ligned adjust as follows:

1. Remove the bottom trim.

2. Loosen the five (5) bolts in the UĆshaped lower

door hinge and sprocket assembly.

3. Slide the assembly until the doors are aligned.

4. Tighten the bolts.

5. Replace the bottom trim.

Door Hinge

Sprocket

Assembly

Turnbuckle

Turnbuckle

FIGURE 1

To adjust the ball plunger catch:

1. Insert a spanner key in the notches on both

sides of the ball plunger. Loosen the lock nut

with a wrench.

2. Adjust the ball plunger by turning left or right

with the spanner key until the plunger engages

in the striker plate on the door.

3. With the spanner key still inserted in the ball

plunger notches, tighten the lock nut.

FIGURE 2

To adjust the doors for proper operation, open the

doors until the right hand door back flange is even

with the front line of the oven as viewed from above.

The left hand door should be positioned so the

door pressure lock touches the right hand door. If

the doors need adjustment proceed as follows:

1. Loosen the chain drive.

2. Adjust for proper location.

3. Tighten the chain drive.

Front of Oven

Left

Door

Right Door

Pressure Lock

FIGURE 3

3-1

Page 34

CALIBRATION AND ADJUSTMENT

DOOR BLOWER SWITCH

The door activated blower switch should be adĆ

justed so the doors are about 1Ć1/2" (4 cm) from

the liner when the switch shuts the blower off. If

field adjustment is necessary, the switch can be

reached by removing the combustion compartĆ

ment cover.

1. Open the right hand door until it is approxiĆ

mately 2" (5 cm) from the liner.

2. Place the arm of the cam assembly, located on

the door sprocket, against the push button.

3. Tighten the set screw.

When the doors are fully closed, the cam arm deĆ

presses the push button enough to allow blower

operation. An audible click will determine if the

switches are operating correctly.

The switch may be moved forward or backward in

the mounting bracket as necessary for alignment.

Door Arm

Sprockets

THERMOSTAT

DFG BULB AND CAPILLARY THERMOSTAT

For units with rocker style switches

1. Turn the mode selector/power switch to COOK

ONLY.

2. Toggle the blower switch to ON.

3. Toggle the cool down switch to MANUAL.

4. Place a pyrometer thermocouple or reliable

mercury thermometer on the middle shelf 6"

from the front edge and in the center of the

shelf.

5. Turn the thermostat dial to 350_F (177_C).

6. When the red indicator light on the control panĆ

el goes out, check the thermometer or pyromĆ

eter to determine oven temperature.

If this reading is within 10_F (6_C) of the therĆ

mostat setting, do not change the thermostat.

If this reading differs more than 10_F (6_C) from

the thermostat setting recalibrate the thermostat.

For units with rotary mode selector switch

Door

Chain

Door Switch

Cam Assembly

Hinge Pin

FIGURE 4

Micro

Switch

1. Turn the selector switch to COOK.

2. Place a pyrometer thermocouple or reliable

mercury thermometer on the middle shelf 6"

from the front edge and in the center of the

shelf.

3. Turn the thermostat dial to 350_F (177_C). Let

the oven heat for at least 1/2 hour.

4. When the red indicator light on the control panĆ

el goes out, check the thermometer or pyromĆ

eter to determine oven temperature.

If this reading is within 10_F (6_C) of the therĆ

mostat setting, do not change the thermostat.

If this reading differs more than 10_F (6_C) from

the thermostat setting recalibrate the thermostat.

Refer to page 3-3.

3-2

Page 35

DFGĆ100 and DFGĆ200

CALIBRATING THE THERMOSTAT

Bulb and Capillary Style Thermostat

1. Loosen the set screws in the thermostat knob.

Pull the knob forward.

2. With a screwdriver, turn the small screw loĆ

cated in the center of the thermostat stem eiĆ

ther clockwise to lower the temperature or

counterĆclockwise to raise the temperature.

NOTE: Do not allow the main stem of the therĆ

mostat to turn when adjusting the calĆ

ibration screw.

Solid State Analog Thermostat

1. Place a pyrometer thermocouple or reliable

mercury thermometer on the middle shelf 6"

from the front edge and in the center of the

shelf.

2. Turn the thermostat dial to 350_F (177_C).

3. When the red indicator light on the control panĆ

el goes out, check the thermometer or pyromĆ

eter to determine oven temperature.

NOTE: If adjustments are need locate the adjustĆ

ment pot on the solid state temperature

control board. Turn the pot to raise or lower

the temperature.

Calibration

Screw

3-3

FIGURE 5

Page 36

BURNERS

CALIBRATION AND ADJUSTMENT

Check the rating plate for proper orifice size and

correct pressure regulator for the type of gas

supplied. If different, the oven must be converted

to the correct type of gas before operation. Do not

attempt to operate the oven until corrected for

the gas supplied.

Check the gas pressure at the manifold with a maĆ

nometer or pressure gauge. Make certain that othĆ

er equipment on the gas line is ON.

1. Gas pressure at the manifold should be 3.5"

W.C. (0.87 kPa) for natural gas, and 10" W.C.

(2.50 kPa) for propane with burners operating

at full demand.

2. Adjust primary air shutters at the front of the

burner to obtain a stable and quiet flame.

Too little primary air will create yellow tipping or all

yellow flames. This indicates incomplete combusĆ

tion and may produce carbon sooting on metal

parts near the flame.

When a flame raises off the burner it is important to

determine if it is a lifting flame or a floating flame.

Lifting flames:

Lifting flames rise and burn some distance above

the ports. In some cases these flames will drop

back to the port and lift again intermittently. They

are well defined, hard, and may make a blowing

noise. They are caused by too much primary air.

Decrease the shutter opening to correct the condiĆ

tion.

Floating flames:

Floating flames are long, lazy, poorly defined, quiet

flames which roll around the combustion chamber

sometimes completely off the ports. Floating

flames result from too little secondary or makeĆup

air. Lack of secondary air can be caused by incorĆ

rect venting, blocked flue ways, blocked secondĆ

ary air inlet openings or lack of natural room makeĆ

up air to the oven.

Both of these conditions are unacceptable and reĆ

quire prompt corrective action.

Steel Tube Burners

Manifold

Locknut for

Air Shutters

Air

Shutters

Attach manometer here

FIGURE 6

3-4

Page 37

DFGĆ100 and DFGĆ200

SOLID STATE MANUAL

1. Place a pyrometer in the center of the oven.

2. Turn the mode selector switch to cook.

3. Turn the thermostat to 350_F (177_ C).

4. When the red indicator light goes out, check

the pyrometer to determine oven temperature.

5. If this reading is within 10_ (6_C) of the thermoĆ

stat setting no adjustment is needed.

If the reading is greater than 10_ (6_C) adjust

as follows:

A.) Locate the trim pot on the solid state temĆ

perature board.

B.) Turn the adjustment screw to raise or lower

the setting.

LIGHT OFF

OVEN READY

THERMOSTAT

TIMER

3-5

FIGURE 7

Page 38

SELECTOR SWITCH CALIBRATION

CALIBRATION AND ADJUSTMENT

1. Place a pyrometer in the center of the oven.

2. Turn the mode selector switch to cook.

3. Set 8 position selector switch to one of the

eight positions.

NOTE: The 8 individual positions are each set

for a temperature of the customer's

choosing. For example, if position 1 is

set for 350_F (177_ C) the red indicator

light should go out when it gets to withĆ

in 10 degrees of setpoint.

4. If the light goes out within 10 degrees, no adĆ

justment is required. If the light does not go out

within 10 degrees of setpoint calibrate the

switch as follows:

A.) Locate the potentiometer on the 8 position

selector switch labeled R1.

NOTE: There are 8 trim pots on this device.

They are labeled R1, R2, R3, etc.

B.) Turn the brass screw on top of the potenĆ

tiometer clockwise to increase the temperaĆ

ture. Turn the brass screw on top of the poĆ

tentiometer counterĆclockwise to decrease

the temperature.

5. Repeat steps 3-4 for all 8 positions.

NOTE: It is possible for all 8 positions to be out

of calibration but highly unlikely.

FIGURE 8

3-6

Page 39

DFGĆ100 and DFGĆ200

INTELLITOUCH CONTROL SECOND LEVEL PROGRAMMING

To access 2nd level programming

1. Turn the oven off.

2. Locate the 3 pin header on the bottom right

side of the control. Move the jumper from the

middle and bottom pins to the middle and top

pins exposing the bottom pin.

3. Turn the oven on. The program LED (1) lights.

Programming the 2nd level parameters

1. The #1 LED illuminates.

NOTE: The LED's (3) are located next to the

product and load keys. The LED identiĆ

fication numbers (2) are located to the

left of the product and load keys. See

FIGURE 9.

INTELLITOUCH

HEAT PROGRAM

DISPLAY

PROD

1

PROD

2

PROD

3

PROD

4

PROD

5

PROD

6

PROD

7

READY

8

LOAD

9

ENTER

TEMP

CNCL

TEMP

TIME

LOAD

0

LOAD

LOAD

R

LOAD

R

FIGURE 9

1

2

3

4

5

2

1

3

2

3

4

5

6

7

1

2

3

5. Repeat steps 1Ć3 for each parameter. When

the final parameter setting is entered and

saved the #1 LED illuminates.

LED(s) Parameter Setting

1 Offset 0

2 Hrs/Min timer 0F

1,2 Fahrenheit (0=_F, <1=_C) 0F

3 Proportional 0F

1,3 Integration 1F

2,3 Dead band 3F

1,2,3 Cycle time 12F

4 Minimum on time 3F

1,4 Hi temp alarm 550F

2,4 Ready temp differential 15F

1,2,4 Minimum setpoint 150F

3,4 Maximum setpoint cook 500F

1,3,4 Minimum setpoint hold 0F

2,3,4 Maximum setpoint hold 0F

1,2,3,4 Fan 2 speed 0F

5 Fan rev. 0F

TABLE 2

To exit the 2nd level programming

1. Turn the oven off.

2. Move the jumper from the middle and top pins

to the middle and bottom pins exposing the

top pin.

3. Turn the oven on.

2. Use the product and load keys to enter numeriĆ

cal data. See TABLE 2 for correct parameter

settings.

NOTE: Use product keys 1Ć7 for numerals 1Ć7.

Use load keys 1Ć3 for numerals 8,9 and

0 respectively.

3. Press the enter key to save the parameter setĆ

ting.

4. The #2 LED illuminates

Error codes

HELP the temperature setting exceeds the maxiĆ

mum setting of 550_F. This will be shown as

an alternating HELP and PROB display.

PROB 1. Defective temperature probe.

2. Stripped insulation on probe wires.

3. Poor connection of probe terminals.

4. Probe sensing temperatures above or

below the probe sensing range.

8888 an Intellitouch computer failure.

3-7

Page 40

CALIBRATION AND ADJUSTMENT

SOLID STATE DIGITAL SECOND LEVEL PROGRAMMING

NOTE: Refer to page NO TAG for illustration of

control.

To Initiate Programming

1. Set the time to 1 minute.

2. Set the temperature to 151_F (66_C).

To Access Second Level Programming

1. Press and hold the TEMPERATURE key and

the START/STOP key simultaneously.

2. The control beeps and displays the software

version for a few seconds.

3. The control then displays . The control has

entered the second level program.

To Change the Temperature Offset

1. Press the TEMPERATURE key.

2. The control displays or offset for a few secĆ

onds. It then displays the current offset which

should be 0_ F or .

3. Rotate the DIAL to enter a 50_F (28_C) offĆ

set. Use this to calibrate the oven if necessary.

To Set the Display Scales

1. Press the TEMPERATURE key.

2. The control displays the current setting from

the menu to the right. This menu controls 3

separate parameters:

C.) The desired temperature scale (ie Celsius

or Fahrenheit)

D.) Electric or Gas oven

E.) The desired time display (ie hrs/min or

min/sec)

3. To adjust the setting turn the DIAL 1 click at a

time.

0:01 01:00

SETTING THE DISPLAY SCALES

DIGITS

ST

1

H = Hrs/Min Display (Factory Setting)

_Ă = Min/Sec Display

To Return to Normal Operating Mode

1. Press the TEMPERATURE key.

2. The control goes through self check then disĆ

plays the set temperature 151_F (66_C).

3. The oven can now be controlled as normal.

ND

2

E = Electric Oven

_ = Gas Oven

RD

3

_C or _F

Temperature Display

FIGURE 10

4

TH

3-8

Page 41

DFGĆ100 and DFGĆ200

INTELLITOUCH II SECOND LEVEL PROGRAMMING

COMPUTERS WITH ON/OFF KEY IN CONTROL

1. Place the control in OFF mode.

2. Press the CLEAR key.

3. Press the B, A, K, and E keys followed by the

PROG/ENTER key.

4. The display reads ACCES S.

5. Input the relevant code from TABLE 3.

6. Press the PROG/ENTER key.

7. Press CLEAR CLEAR CLEAR to exit.

COMPUTERS WITHOUT ON/OFF KEY

1. Place the control in SELECT mode.

2. Press the 1, 2, 3, 4, 5, 6 keys follows by the

PROG/ENTER key.

3. The display reads ACCES S.

4. Input the relevant code from TABLE 3.

5. Press the PROG/ENTER key.

6. Press CLEAR CLEAR CLEAR to exit.

ALL CONTROLS

Temperature display scale

1. The display flashes _ F/_C then MODE-?

2. Press any key to toggle the scale from _F to _C.

3. Press the PROG/ENTER key to lock in new

scale.

4. The display flashes T'_F ( or T'_C).

Ready Band

1. The display flashes READY, BAND and POS.

2. Use the numeric keys to enter a value between

1 and 25. Press the PROG/ENTER key.

3. The display flashes READY, BAND and NEG.

4. Use the numeric keys to enter a value between

1 and 25. Press the PROG/ENTER key.

To exit oven calibration

1. The display flashes ACCESS, DONE and EXIT.

2. Press CLEAR, CLEAR, CLEAR.

3. The display flashes REBOOT and SELECT.

Access Codes

123 Display model, version, date and checksum of firmware

000 STD unit test

CLEAR, TEMP, TEMP, TEMP, PROG/ENTER Temperature offset (+/-)

Ready band offset (+/-)

TABLE 3

3-9

Page 42

CALIBRATION AND ADJUSTMENT

INTELLIPLUS SECOND LEVEL PROGRAMMING

NOTE: Time must be zeroed out in order to perĆ

form the following functions.

SETTING A TEMPERATURE OFFSET

1. Set the temperature dial to 210_.

2. Push and hold the CANCEL and START TIMER

keys until the display reads 000.UPO

3. Enter the desired offset.

4. Push the ACTUAL TEMP key.

FAHRENHEIT TO CENTIGRADE CONVERSION

1. Set the temperature dial 220_.

2. Push and hold the START TIMER until the disĆ

play reads CCC_.

3. Enter the desired temperature.

4. Push the ACTUAL TEMP key.

CHANGING MINUTES TO SECONDS OR

HOURS TO MINUTES

1. Set the temperature dial to 230_.

2. Push and hold the START TIMER until the disĆ

play changes from MIN to HR.

3. Push the ACTUAL TEMP key.

3-10

Page 43

DFGĆ100 and DFGĆ200

BLODGETT IQ2T CONTROL FACTORY LEVEL PROGRAMMING

Entering the programming mode

1. Press the program key. The top display reads

CodE.

2. Use the product keys to enter the factory proĆ

gramming accss code: 4 5 2 3. Press the enter

key. The top dislay reads Fact.

Programming the oven configuration

1. Press the SCAN KEY. The display rads Appl.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween electric oven and gas oven. Set the

choice for the oven type. Press the SCAN KEY

to enter the choice.

3. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween half sized or full sized oven. Set the

choice for the oven type. Press the SCAN KEY

to enter the choice.

NOTE: Mark V and DFGĆ100 are full sized

ovens. CTB and DFGĆ50 are half sized

ovens.

Programming the temperature offset

1. The top display reads oFF. The bottom display

reads SEt.

2. Press the SCAN KEY. The top display reads oFST.

The bottom display reads either xxF or -xxF.

3. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween positive and negative. Use the product

keys to the enter the desired temperature offset.

4. Press the SCAN KEY to enter the new temperaĆ

ture offset.

Enabling/Disabling the fan error detection circuit

1. The top display reads FanC. The bottom disĆ

play reads YES or NO.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween choices.

3. Press scan to move to next operating parameĆ

ter.

Programming fan speed option

1. The top display reads FanS. The bottom disĆ

play reads 1 or 2.

2. Press the TOGGLE/CLEAR KEY to toggle beĆ

tween choices: 1 for a single speed motor or 2

for a two speed motor.

3. Press SCAN to move to the next operating paĆ

rameter.

Programming the maximum temperature setpoint

1. The top display reads tELt (temperature limit)

and the bottom display reads either 500 or 550.

2. Press the TOGGLE/CLEAR key to toggle beĆ

tween choices 500_F or 550_F maximum temĆ

perature setting.

3. Press scan to enter the maximum setpoint

temperature.

NOTE: Use 500_F for the DFGĆ100, DFGĆ200,

Mark V, CTB and DFGĆ50. Use 550_F

for the DFGĆ100 XCEL and Mark V

XCEL.

Exiting the factory programming mode

1. The top display reads Fact. Press the PROG

KEY. The control returns to the operating

mode.

3-11

Page 44

CHAPTER 4

PARTS REPLACEMENT

Page 45

REMOVAL AND REPLACEMENT OF PARTS

ACCESS PANELS AND DOORS

WARNING

Before performing any maintenance or

replacing any component on this unit,

disconnect the oven from its electrical

source and shut off the gas supply.

If it is necessary to replace a defective

component, use only genuine Blodgett

OEM replacement parts.

COMBUSTION COMPARTMENT COVER

1. Open the doors.

2. Remove the two (2) screws in the top edge of

the panel.

3. Lift the panel up and outward.

4. Replace by reversing the above procedure.

CONTROL COVER

1. Remove combustion compartment cover.

2. Remove the screw in the top of the control cover.

3. Pull the bottom of the control cover forward,

down and off.

4. Replace by reversing the above procedure.

To p

Screw

Control Cover

Combustion

Cover

FIGURE 2

FIGURE 1

4-1

Page 46

DFGĆ100/DFGĆ200

PERIMETER DOOR GASKET

1. Remove gasket screws.

2. Remove all door gaskets and top and bottom

trim pieces.

NOTE: Side trim pieces remain in place.

3. Position the top gasket over the upper trim

piece. Replace the screws.

4. Position side gaskets 1/8" from the end of the

top gasket. Replace the screws.

5. Position the bottom gasket over the trim piece.

Top Perimeter

Gasket

CENTER DOOR GASKET

For ovens with 50/50 doors

1. Remove screws securing gaskets to the leadĆ

ing edge right and left doors. Remove the gasĆ

kets.

2. Place rigid stainless strip which has been

formed at a 90_ angle between the front and

back halves of the right hand door. Position

properly.

3. Align a 1/8" drill bit in the existing holes along

the edge of the door. Drill through the stainless

strip with formed sections to the outside.

4. Place the two (2) pieces of flexible gasket maĆ

terial sideĆbyĆside.

NOTE: The right door gasket has holes

punched in the center of the strip. The

left door gasket has holes punched

slightly to the left of center of the strip.

5. Place the right side gasket flush with the leadĆ

ing edge of the right door. Secure with four (4)

screws.

FIGURE 3

6. Place the left side gasket flush with the leading

edge of the left door assembly and secure.

7. Readjust the chain and turnbuckle assembly

to ensure that the doors operate properly.

NOTE: Refer to page 3-1 in the Calibration

and Adjustment section for door adĆ

justment.

Bottom Perimeter

Gasket

4-2

Page 47

REMOVAL AND REPLACEMENT OF PARTS

OVEN DOOR

1. Open the door. Remove the handle from the

left hand door.

2. Remove three (3) machine screws located

along the bottom edge of the door.

3. Lift the door slightly. Pull forward until it clears

the support.

4. Pull the door down to remove from the oven.

5. Replace by reversing the above procedure.

NOTE: For doors with wooden handle, the

handle is attached and is removed with

the door.

8. Position the glass in the frame with the black

border facing upward.

9. Replace the front frame assembly. Press firmly

until the screw holes around the edge of the

door are aligned.

10. Replace the screws, the center door gasket

and the door handle.

11. Reinstall the door on the oven.

WINDOW ASSEMBLY FOR OVENS

WITH 60/40 DOORS

1. Remove the door as described. Place the door

on a flat surface with the front facing up.

2. Remove the outer door skin. Turn the door

onto its back.

3. Use the window insertion tool to pry up the corĆ

ners of the window assembly in the following

order:

A.) Bottom right (farthest from the hinge pin)

B.) Bottom left

FIGURE 4

WINDOW ASSEMBLY FOR OVENS

WITH 50/50 DOORS

1. Remove the door from the oven.

2. Remove the door handle and center door gasket.

3. Place the door on a flat, clean surface. Remove

the screws around the edge of the door.

4. Remove the outer (front) door frame.

5. Remove the old glass assembly.

6. Clean the frame thoroughly.

7. Place the glass retainer bracket in each corner

of the back frame.

C.) Top right

D.) Top left (closest to the hinge pin)

NOTE: The window insertion tool is provided

with the window assembly.

4. Use the window insertion tool to pry up the corĆ

ners of the window assembly.

5. Reverse steps 1-4 to replace.

NOTE: To install the door front start at the corĆ

ner closest to the hinge pin.

Hinge Pin

Window

Insertion Tool

FIGURE 1

4-3

Page 48

DFGĆ100/DFGĆ200

LOWER DOOR HINGE AND SPROCKET

ASSEMBLY

For models manufactured prior to May 1986:

1. Remove the door from the oven.

2. Remove the rollĆpin securing the sprocket to

the hinge pin assembly.

3. Loosen the set screw. Lift the hinge pin assembly

upward to allow the removal of the sprocket.

4. Replace by reversing the above procedure.

For models manufactured after May 1986:

1. Remove the door from the oven.

2. Remove the rollĆpin securing the door arm to

the hinge pin assembly.

3. Remove the door switch activating the cam

from the right hand door.

4. Loosen the set screw. Lift the hinge pin assembly

upward to allow the removal of the sprocket.

5. Replace by reversing the above procedure.

DOOR CHAIN ASSEMBLY

If the replacement of the sprocket as well as the

chain is necessary, use the removal instructions for

Door Glass Removal. If only the door chain needs

to be replaced, remove as follows:

For units manufactured prior to August 1984.