Page 1

Instruction Manual

Fairlight Console

Assembly

June 2019

Page 2

English

Welcome

Thank you for purchasing a Blackmagic Fairlight console for your audio post production!

Fairlight has been the premiere audio post production suite in the film and television industries for

decades. It has a long history of innovative software and hardware engineering that’s led the way

for music and audio production. We are excited about the new Fairlight console and believe you

will enjoy your experience with it.

Your Fairlight console is customizable, letting you install just the Fairlight modules you want

depending on the number of bays in your console. Modules include the Fairlight Console Channel

Control, Fairlight Console Channel Fader, Fairlight Console Audio Editor and Fairlight Console LCD

Monitor. You can install the modules and build your system to suit your own needs.

All the fine controls in each module are designed for precision handling and finesse, featuring

illuminated buttons with easy to read LCDs that let you monitor your settings and know exactly

what is happening at all times. The faders are also servo assisted, so they are able to be saved

and recalled while maintaining sync with DaVinci Resolve. There is nothing like watching the

faders reacting to your adjustments in realtime while monitoring your audio mix!

With your Fairlight console and DaVinci Resolve’s Fairlight page, you have the tools you need to

shape your audio just the way you want it.

This instruction manual will guide you through assembling your Fairlight console, installing the

Fairlight console modules and getting started with DaVinci Resolve so you can quickly start using

your Fairlight console.

Also, please check the support page on our website at www.blackmagicdesign.com for the

latest version of this manual and for updates to DaVinci Resolve. Keeping your software up to

date will ensure you get all the latest features! We are continually working on new features and

improvements, so we would love to hear from you!

Grant Petty

CEO Blackmagic Design

Page 3

Contents

Fairlight Console Assembly

Fairlight Console Components 4

Unpacking and Assembling 5

Tools Required 6

Attaching the Legs to the Console Chassis 7

Alternative Assembly with Two or More People 9

Installing the Fairlight Panels 11

Attaching the Monitor Infill Module 13

Powering the Modules 14

Arranging Cables and Replacing the Leg Side Covers 14

Connecting the Fairlight Modules 15

Connecting the Fairlight Console to your Computer 15

Connecting the Computer’s HDMI or SDI Output 16

Reattaching the Chassis Back Panel 16

Configuring the Fairlight Modules 16

Fairlight Panel Setup 17

Changing Network Settings 19

Fairlight Studio Utility 20

Selecting your Fairlight Console in DaVinci Resolve 22

Technical Specifications 23

Fairlight Road Case Dimensions 23

Fairlight Console Dimensions and Weight 23

Fairlight Panels Dimensions and Weight 24

Power Consumption 24

Operating Temperature 24

Help 25

Regulatory Notices 26

Safety Information 27

Warranty 28

Page 4

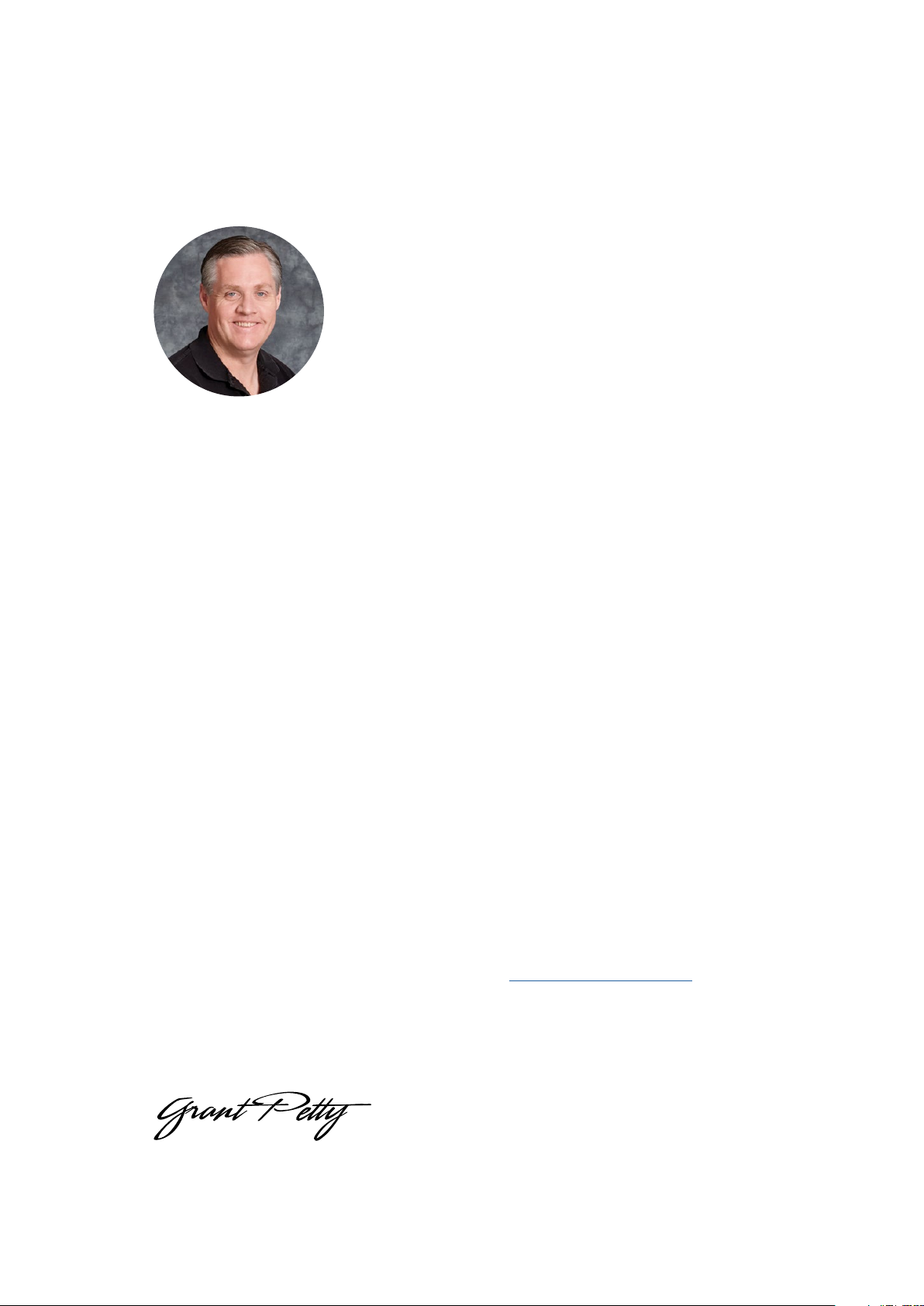

Fairlight Console Components

The Fairlight console is available in 4 configurations that let you build your console to suit

yourproduction requirements. Fairlight modules, for example the Fairlight Console Channel

Control, Fairlight Console Channel Fader, Fairlight Console Audio Editor, and the Fairlight

Console LCD Monitor, are installed into the module slots within the Fairlightconsole chassis.

Fairlight 3 Bay Console

1

2

3

4

1. Fairlight Console LCD Monitor 2. Fairlight Console Channel Control 3. Fairlight Console Channel Fader

4. Fairlight Console chassis, includes legs 5.Fairlight Console Audio Editor

6. Fairlight Console Channel Control Blank 7. Space for your mouse or notes

6

7

5

The illustration above shows a fully assembled Fairlight 3 Bay console. In a typical 3 bay

configuration, the Fairlight Console Channel Control and Fairlight Console Channel Fader

modules are installed on each side of the Fairlight Console Audio Editor. However you can

place modules in any position you prefer, as your Fairlight console is fully customizable.

On a 4 and 5 bay configuration, additional modules can be installed on each side.

Fairlight 5 Bay Console

4Fairlight Console Components

Page 5

Fairlight 2 Bay Console

The 2 bay configuration sets the Fairlight Console Channel Control module and Fairlight

Console Channel Fader module next to the Fairlight Console Audio Editor

NOTE You can arrange the Fairlight modules on either side of the audio editor and

change the position of the mouse area. For example you may be left handed and want to

have the mouse on the left side of the audio editor module. Fairlight modules are mounted

in a module bracket that can be lifted out and repositioned. Keep reading thismanual

for more information on how to install the Fairlight modules into the modulebrackets.

A Fairlight Console Channel Rack Kit is also available from Blackmagic Design resellers

if you need to install additional devices in your console. For example Blackmagic

HyperDeck recorders or SmartScope Duo monitors.

Additionally, you can install Fairlight Console LCD Monitor Blank, Fairlight Console

Channel Control Blank, or Fairlight Console Channel Fader Blank kits.

Unpacking and Assembling

Your Fairlight console is shipped in a large, strong and secure road case containing the

FairlightConsole chassis and legs. Each Fairlight module is shipped separately. Refer to the

‘technical specifications’ section of this manual for a complete list of size and weight

measurements foreach Fairlight configuration.

5Unpacking and Assembling

Page 6

After opening your Fairlight console's road case, carefully remove the console chassis and

place it gently onto a solid, stable surface strong enough to support the weight of the

chassis and legs.

NOTE Please note that an empty Fairlight 3 Bay Console weighs 90kg and up to

150kg for a 5 bay console. The console is built strong and is clearly too heavy to be

unpacked by one person. You will need to make sure that all lifting is performed by

4people using the correct lifting techniques, such as bending your knees, keeping a

straight back and lifting with careful, controlled movements.

The surface your Fairlight console will be placed onto for assembly needs to be high enough

from the ground to ensure the legs are elevated when attaching to the chassis. Allow for at

least550mm. A scissor lift trolley or similar utility is the perfect solution for assembly.

Alternatively, if assembling the console with two or more people, you can stand the chassis on

its rear panel while attaching the legs and feet. Refer to the next section named 'Alternative

Assembly with Two or More People' for more details.

Tools Required

For assembly you will need the following tools:

1 x Torque wrench with

19mm socket capable of 35 Nm.

1 x Pozidriv 2 torque driver capable

of 0.45 Nm for M3 and M4 screws.

We recommend using torque tools for tightening only, and using a regular wrench or driver

forremoving the screws.

6Unpacking and Assembling

Page 7

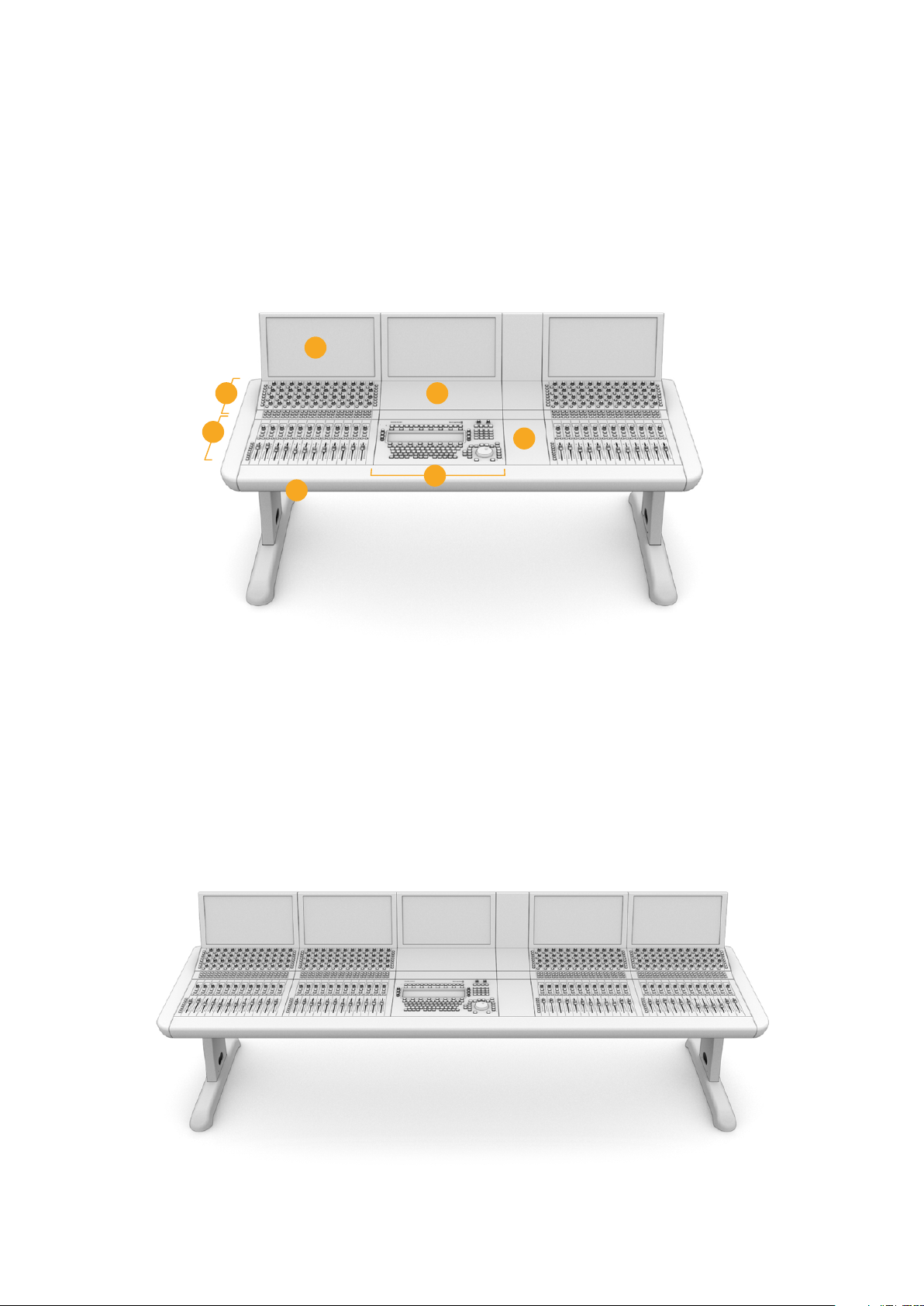

Attaching the Legs to the Console Chassis

The road case contains two legs that attach to each side of the console chassis. However,

before attaching to the chassis, you should first secure the feet to each leg. Each assembled

leg weighs 10 kilograms, so please take care when lifting.

The feet are attached to the console chassis with their length longer

atoneend. Ensure the longer end is facing the front of the console.

To attach the foot to each leg:

1 Lay the leg on its side with the cover panel facing upwards. Remove the two

M12screws fromthe end including the small brace plate.

2 Align the foot to the end of the leg and hold it in place. Make sure the rectangular

cutouts on the bottom of the leg and brace plate are completely aligned.

7Unpacking and Assembling

Page 8

3 Now place the support plate on the bottom of the foot and secure the

foot to the leg using the two M12 screws. Tighten to atorque of 35 Nm.

4 Repeat steps 1 to 3 for the second leg.

To attach the legs to the console chassis:

1 Remove the side cover from each leg by unscrewing the four M3 screws

from the opposite side of the leg using a Pozidriv 2 screwdriver.

2 Remove the four M12 leg fastening screws from each side of the console chassis.

3 Align each leg to the side of the console by mounting it against the

guide pins on the chassis.

8Unpacking and Assembling

Page 9

4 Secure the legs to the chassis with the leg fastening screws and tighten the screws to

atorque of 35 Nm.

The side cover for each leg can be reattached later. Leaving the cover off at this point

of assembly provides access to the inside of the leg for when you are wiring up the

panels inside the console.

5 Carefully lower the console from the support surface and place it on the floor.

Werecommend placing the assembled chassis as close to its intended position as

possible, as once Fairlight modules are installed, the overall weight of the unit will

increase substantially. Ensure there is enough space at the rear of the chassis to

replace the back panel before securing your console into position.

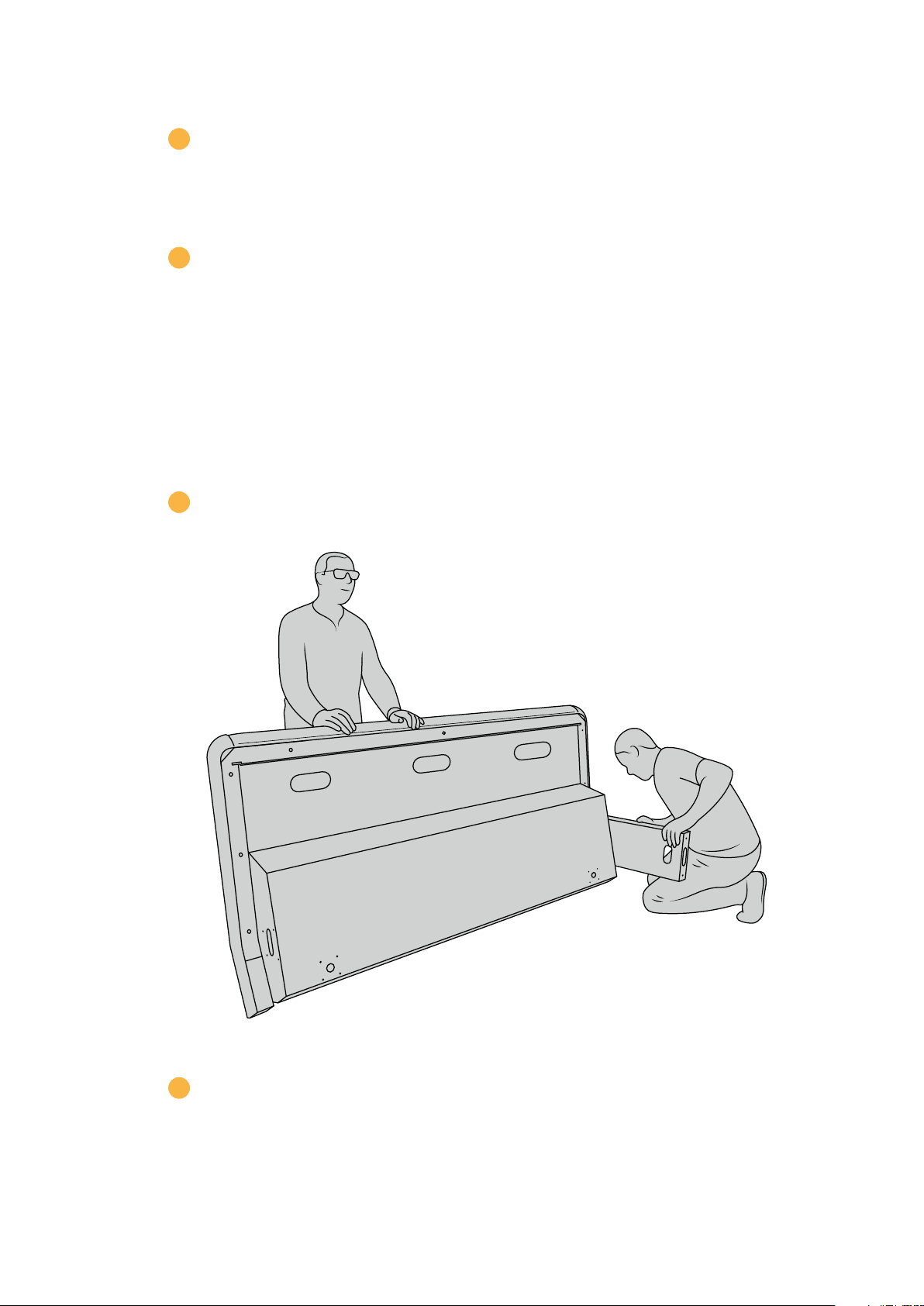

Alternative Assembly with Two or More People

If you don't have access to a scissor lift trolley or similar utility and have someone tohelp you,

you can stand the chassis on its rear panel and attach the legs and feet from this position.

To assemble the legs and feet:

1 After removing the console chassis from its road case, gently lean the chassis onto its

rear panel. Ensure a second person holds the chassis in place so it does not slip.

Lean the console chassis onto its rear panel so the front is facing upwards

2 With the console chassis securely held in place, attach the legs as shown in the

previous section.

9Unpacking and Assembling

Page 10

3 Attach the feet to each leg.

4 Once the legs and feet are attached, lean the chassis onto its feet into its

standing position.

Lean the Fairlight console onto its feet, ready to install the Fairlight panels

With the legs and feet attached to the console chassis, you can now install the

Fairlight panels.

10Unpacking and Assembling

Page 11

Installing the Fairlight Panels

The most common layout Fairlight audio engineers use for mounting the modules is to place the

Fairlight Console Audio Editor directly in front of the operator, the Fairlight Console Channel

Control and Channel Fader modules on each side, and the channel control modules above each

channel fader module. Their respective LCD monitors are installed along the top with the monitor

infill module. The small surface in between the Fairlight modules is for a mouse or trackball.

If you don't have all the modules for a full console, you can fill in the spaces with blank panels

until you are ready to add more modules later. You can add modules any time you like and as

you need them based on your production requirements.

To install the Fairlight modules into the console chassis:

1 Remove the back panel from the chassis by unscrewing the M3 screws using

aPozidriv2 screwdriver, and keep the panel and screws nearby in a safe place.

Removingthe back panel provides better access to the inside of the chassis

wheninstalling the Fairlight modules.

2 Each Fairlight module has its own module bracket you can easily lift and remove

fromthe chassis. This lets you install modules into their brackets on a bench where

thereismore space, then easily mount the assembled brackets into the chassis.

Hold each bracket arm and gently rotate the bracket up from the chassis. The bracket

hinges from the rear, allowing you tofree the bracket from the chassis by pulling it

awayfromthe hinge pin.

11Unpacking and Assembling

Page 12

3 With the module bracket removed from the chassis, place it on a stable surface, ready

forattaching the Fairlight modules. We recommend installing modules starting with the

LCD monitor at the top, the Fairlight Console Channel Control module in the middle,

then the Fairlight Console Channel Fader module closest to the audio operator.

4 Secure each module to the bracket usingthe M4 Pozidriv screws supplied with your

Fairlight module. Tighten to a torque of 1.5 Nm.

5 You can now place the assembled module bracket back into the chassis by

repositioning its rear latchesover the chassis hinge pins and gently lowering the

bracket into place.

NOTE When installing a bracket with Fairlight panel modules attached, we

recommend one person holding thefront edge of the bracket, with a second

supporting the bracket from underneath the chassis as it is lowered into place.

This lets you lower the bracket gently without dropping the edge at the

finalmoment.

After installation, the brackets can be lifted again by pushing from underneath

with one hand, and lifting the front of the bracket with the other. Each bracket

has a bay lift support brace you can swing out from underneath. This lets you

safely prop the bracket away from the chassis when you need to access the

interior for cabling.

12Unpacking and Assembling

Page 13

Lower the support brace by holding the brace handles and rotating

the brace down from the bracket. Allow the feet of the brace to rest

inside and against the front of the chassis so it cannot move.

Attaching the Monitor Infill Module

Inside the road case, you’ll find a small cardboard box. This box contains the LCD monitor infill

module that is installed next to the LCD monitors.

Remove the infill bracket from the chassis following the same procedure used for the other

module brackets.

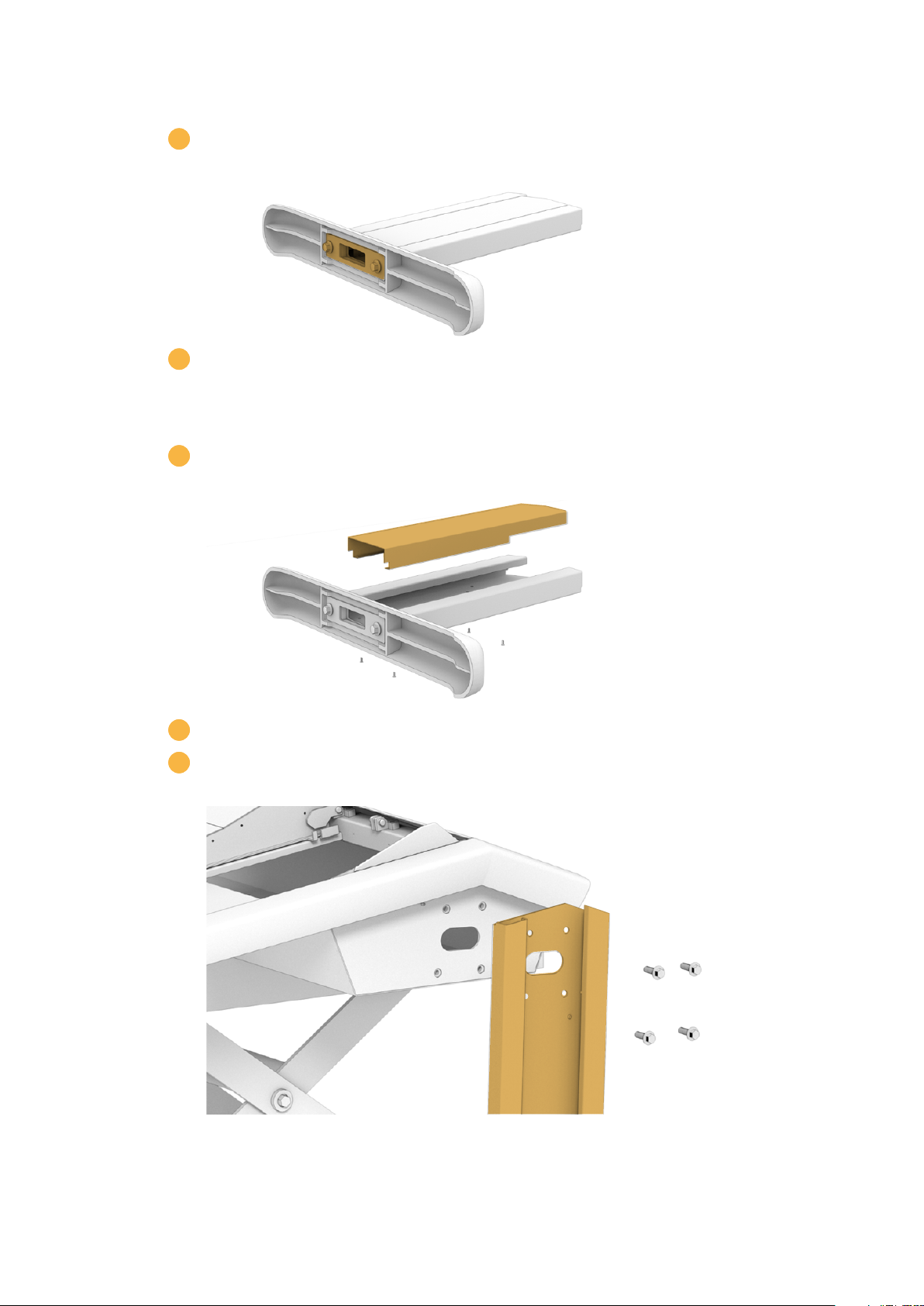

To attach the infill module:

1 Place the monitor infill module into the neck of the bracket.

2 Secure the inf ill module to the bracket using the supplied M4 Pozidriv screws.

Tighten to a torque of 0.45Nm.

3 Place the bracket back into the chassis.

13Unpacking and Assembling

Page 14

Powering the Modules

Each Fairlight module is powered independently via its own power input. Simply plug each

module into your mains power supply using a standard IEC power cable.

We recommend using five way power boards to distribute power to the Fairlight modules, with

each power board to supply up to five modules only. Ensure the power boards are not daisy

chained and are each independently connected to mains power.

Two chassis earth points are built into the inner sides of the chassis for securing to a building

earth point. After installation, ensure at least one of the chassis earth points is connected to the

building earth point via an appropriately sized and bonded earth wire. With the Fairlight console's

rear cover detached, you can easily access the earth points on each side of the chassis.

Connect power to each Fairlight module via its standard IEC power input

Arranging Cables and Replacing the Leg Side Covers

Your Fairlight console is designed to keep cables tidy. After connecting power cables, you can

bundle them together and guide them through the cable slots on each leg.

Once cables are in place, you can then re-install the leg side covers and tightentheir 4 x M3

Pozidriv screws to a torque of 0.35Nm.

14Unpacking and Assembling

Page 15

Connecting the Fairlight Modules

HDMI

After installing the Fairlight modules and plugging in power, connect each module to the other

using an Ethernet daisy chain. It doesn’t matter which particular unit is connected to the other,

as long asthey are all connected via their Ethernet ports.

If you would like to use an Ethernet switch to connect the modules, this is ok and just place the

Ethernet switch inside the console where there is lots of space. Then you can connect each

panel module to the switch directly.

Below is an example of how you could connect the Fairlight modules in a daisy chain.

Ethernet

CONTROL ROOM STUDIO

Computer

TIP We recommend using 1.2 meter Cat6 Ethernet cables. These will allow you to

liftthe panel brackets after installation without stretching the cables.

Connecting the Fairlight Console to your Computer

Once all the modules in the console are connected together via ethernet, connect one of them

to the computer that will run DaVinci Resolve.

15Unpacking and Assembling

Page 16

Connecting the Computer’s HDMI or SDI Output

The LCD monitor above the Fairlight Audio Editor connects to your computer’s HDMI monitor

output. This lets you monitor DaVinci Resolve’s Fairlight page.

This LCD monitor can also be connected to the SDI output from video playback equipment,

for example a Videohub router or Decklink video output.

You can also bundle the Ethernet and video cables together with the power cables that are

threaded through your console’s legs and feet. This keeps all cables neatly together to and

from your Fairlight console.

Reattaching the Chassis Back Panel

Now that all your Fairlight modules are installed, powered and connected, the final step to

complete the assembly of your console is to reattach the chassis’ back panel.

Secure in place using the M3 Pozidriv screws and tighten to a torque of 0.45 Nm.

This completes the assembly and connection setup for your Fairlight console. You are now

ready to confirm your console is working with DaVinci Resolve.

Configuring the Fairlight Modules

The next step is to configure your Fairlight console for your studio.

There are two Fairlight utilities that are included in the DaVinci Resolve installer. The utilities

arecalled Fairlight Panel Setup and Fairlight Studio Utility.

The full studio version of DaVinci Resolve can be installed from the SD card included

withyourFairlight Console, but we recommend downloading the latest version from the

Blackmagic Design Support Center at www.blackmagicdesign.com/support.

To install DaVinci Resolve, launch the DaVinci Resolve installer and follow the onscreen

prompts. Be sure to select the 'Fairlight Studio Utility' when installing DaVinci Resolve.

16Configuring the Fairlight Modules

Page 17

Fairlight Panel Setup

Fairlight Panel Setup can be connected to the Fairlight module via USB or Ethernet using DHCP.

If you are not using a DHCP server, you can set the network settings to a fixed IP address via

USB. More information for changing network settings is provided later in this manual.

When configuring the Fairlight console for your studio, the first step is to name each module

using the Fairlight Panel Setup utility. This lets you easily identifiy each panel module by clicking

on the 'identify me' checkbox.

To name each module:

1 Launch the Fairlight Panel Setup utility.

The currently selected module will be visible on the setup

utility home screen. Navigate to each installed unit by clicking

on the arrows on each side of the home screen

2 Select a module on the home screen and click on the settings icon. You can also click

on the module's image to open the settings window.

3 Click on the 'configure' tab. Under 'device name' you will see a 'label' text box.

Changethe name in the text box and click 'save'. You can visually identify each module

installed in your console by clicking on the 'identify' checkbox. This will illuminate

features on the module.

17Configuring the Fairlight Modules

Page 18

Assign a custom name for each Fairlight module using the

'configure' settings in the Fairlight Panel Setup utility

Studio Name

Name the studio this Fairlight module will be assigned to.

Network Settings

Refer to the ‘Changing Network Settings’ section for information on manually changing

these settings.

Brightness

Changes the brightness of the Fairlight module’s LCDs, or the brightness of the Fairlight

Console LCD Monitor. Drag the slider left or right to decrease or increase the brightness.

Display Source

Each Fairlight Console LCD Monitor can be set as a data display or video monitor. This means

the monitor can be set to display the Fairlight page connected via Ethernet, or a video image if

there is a signal connected to the monitor's HDMI or SDI video input.

Data display – Displays the Fairlight page.

Video monitor – Displays the SDI or HDMI video input.

If a video signal is connected to either the HDMI or SDI input, the monitor will automatically

detect which input is being used. However, if both inputs have a video signal connected, you

can manually set the desired input.

18Configuring the Fairlight Modules

Page 19

3D LUT

When monitoring a video input, you can load a 3D LUT. For example, a 3D LUT can be used to

change the color space of the input video from a flat look to Rec 709, or you may want to load a

preset 'look' designed during post production. You can also use this 3D LUT to fine tune the

display on each of your Fairlight console's LCD monitors if the color reproduction between them

is a little different.

To load a 3D LUT:

1 In the 'load LUT' setting, click on the 'load' button.

2 Navigate to the folder where your LUTs are stored and click on the desired

.cube LUT file.

3 Click 'open'.

The 3D LUT will now be applied to your video source. If you want to disable the LUT, click on

the 'clear' button.

Changing Network Settings

If you need to change the network settings for each module manually, you can change the

settings in the 'configure' tab of the Fairlight Panel Setup utility. When changing network

settings, you will need to connect the panel to your computer via USB.

To change network settings:

1 Open the Fairlight Panel Setup utility. Click on the settings icon, or the Fairlight module

displayed on the home page to open the settings for that module.

2 Click on the 'configure' tab.

3 Change the 'IP Setting' from DHCP to 'Static IP'.

4 In the 'network settings', type a new address into the IP address, subnet mask, and

gateway text boxes.

When the IP address is set correctly, the module will be accessible on your network.

Repeat the same process for each Fairlight panel via USB.

Updating your Fairlight Modules' Internal Software

It’s a good idea to regularly check our website for new software updates.

When a new version of DaVInci Resolve is installed, it may also install updates for your

Fairlight console. To check, open the Fairlight Panel Setup utility and if there are new

updates you will see an 'update' button on the home screen for each module. Simply

click on the 'update' button and follow the prompts to update each module.

With all the setup settings complete, you can now close the Fairlight Panel Setup utility.

19Configuring the Fairlight Modules

Page 20

Fairlight Studio Utility

After setting up your Fairlight modules in the setup utility, assign each module to your

FairlightConsole using the Fairlight Studio Utility. This configures your console as a studio,

telling DaVinci Resolve exactly where each panel is in your Fairlight console so the Fairlight

page can control them all properly and display their controls on the appropriate LCD monitors.

The Fairlight Desktop Audio Editor does not need to be added to a studio configuration to be

selected by DaVinci Resolve. If you have only a Desktop Audio Editor in your studio, go to the

next section, ‘Selecting your Fairlight Console in DaVinci Resolve’, and follow the instructions

there to select the editor in DaVinci Resolve.

To set up a Fairlight Console for each studio:

1 Launch the Fairlight Studio Utility.

2 Select the number of bays in your Fairlight console and click 'next'. This will open a

configuration screen where modules are assigned to the corresponding chassis slots

in each bay.

Select the number of bays in your Fairlight console

3 In the configuration screen, click on the top left slot to assign a Fairlight Console

LCDMonitor. From the list of modules, select the desired monitor for the corresponding

slot by clicking on its icon.

Click on the top left slot to assign the corresponding LCD monitor

20Configuring the Fairlight Modules

Page 21

Each module can be identified by the custom name you entered when labeling the

modules. You can also click on the light bulb icon for each module to visually identify it.

When clicking on the light bulb, features will illuminate on the relevant module.

Click on the light bulb icon to identify each module in your Fairlight console

4 Click 'add'.

The monitor will be assigned to the top left slot on your Fairlight console. You can now

follow the same procedure to assign all the other panels to the corresponding

positionsin the configuration utility. If you select the wrong module by mistake, all you

need to do is click on the module in the group to reveal its options and then click on

the 'X' icon to remove it.

As you configure each module, you can confirm it corresponds to the correct position

in the console by clicking on the module in the group to reveal its options and then

clicking on the light bulb icon.

Your Fairlight console is now conf igured as a studio and you can change the name of

the studio by clicking in the 'untitled studio' text box, typing a new name, and pressing

the 'return' key to confirm. This makes it easier to identify each studio if you have

multiple studios installed in your facility.

Rename the newly configured studio by clicking in the studio name,

typinganew one, then pressing the 'return' key to confirm the change

21Configuring the Fairlight Modules

Page 22

Selecting your Fairlight Console in DaVinci Resolve

The next step is to select your Fairlight console in DaVinci Resolve's preferences.

1 Launch DaVinci Resolve.

2 In the menu bar at the top of the screen, select DaVinci Resolve/Preferences.

3 In the ‘Control Panels’ menu, you’ll notice an option for ‘Audio Console’ and a drop

down menu where you can select your console for Fairlight. Click on the drop down

menu and select the studio name for your console. If you have a standalone Fairlight

Desktop Audio Editor, you can also select it here.

4 Click ‘Save’.

The preferences window will close and a new message will appear asking you to restart

DaVinci Resolve. Simply restart DaVinci Resolve and your console will now be selected for

control using the Fairlight page.

22Configuring the Fairlight Modules

Page 23

Technical Specifications

Fairlight Road Case Dimensions

All contents included

2 bay Console

Road Case

Width = 1353 mm

Height = 552 mm

Depth = 1101 mm

Weight = 180 kg

3 bay Console

Road Case

Width = 1844 mm

Height = 552 mm

Depth = 1101 mm

Weight = 205 kg

4 bay Console

Road Case

Width = 2825 mm

Height = 552 mm

Depth = 1101 mm

Weight = 280 kg

Fairlight Console Dimensions and Weight

5 bay Console

Road Case

Width = 2825 mm

Height = 552 mm

Depth = 1101 mm

Weight = 300 kg

2 bay Console

Width = 1295 mm

Height = 1047 mm

Depth = 982 mm

Weight

Empty chassis including

legs and monitor infill

panel = 90 kg

Fully assembled = 120 kg

3 bay Console

Width = 1788 mm

Height = 1047 mm

Depth = 982 mm

Weight

Empty chassis including

legs and monitor infill

panel = 110 kg

Fully assembled = 157 kg

4 bay Console

Width = 2277 mm

Height = 1047 mm

Depth = 982 mm

Weight

Empty chassis including

legs and monitor infill

panel = 130 kg

Fully assembled = 195 kg

5 bay Console

Width = 2769 mm

Height = 1047 mm

Depth = 982 mm

Weight

Empty chassis including

legs and monitor infill

panel = 150 kg

Fully assembled = 232 kg

23Technical Specifications

Page 24

Fairlight Panels Dimensions and Weight

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

SOLO

MUTE

CALL AUTO

10 •

5 •

0 •

5 •

10 •

15 •

20 •

30 •

40 •

50 •

70 •

100 •

• 10

• 5

• 0

• 5

• 10

• 15

• 20

• 30

• 40

• 50

• 70

• 100

BLUE

BANK

FLIP

1

POT

2

FDR

3

MAP

4

BUS

5

MSET

6

LOCK

MACRO1MACRO2MACRO3MACRO4MACRO5MACRO6MACRO7MACRO8MACRO9MACRO10MACRO11MACRO12MACRO13MACRO14MACRO

15

Audio

1

R S M

Audio

2

R S M

Audio

3

R S M

Audio

4

R S M

Audio

5

R S M

Audio

6

R S M

Audio

7

R S M

Audio

8

R S M

Audio

9

R S M

Audio

10

R S M

Audio

11

R S M

Audio

12

R S M

All

Tracks

Bank

Bank

LEFT

NUDGE

RIGHT

NUDGE

LEVEL

CUP

PAN EQ DYN AUX PLUGIN

SETUP REC MON

HEAD

TRIM

TAIL

TRIM

HEAD

CUT

TAIL

CUT

CLIP

CUT

CLIP

COPY

TAIL

COPY

IN

FADE

OUT

FADE

HEAD

COPY

EDITORMIXER MACRO

SPLIT DEL

SHTL

POSN

PLAY

JOG

JUMP

JUMP

UNDO

REDO

ENTER ZOOM

+ 0

GO

TO

–

1 2

3 :

4 5

6 BAR

7 8

9 CLEAR

DIM MUTE

TALK MUTE

CONTROL ROOM STUDIO

ESC

BLUE

CONTROL ROOM STUDIO

Fairlight Console LCD Monitor

Width = 489.6 mm

Height = 335.4 mm

Depth = 58.7 mm

Weight = 4.4 kg

BLUE

MSTR

U1

PLUG

U2

CHAN

U3

ENAB

COPY

CURVE

SPILL

ALT

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

INS

SHOW

PLUGS

IN

PLUGS

IN

PLUGS

IN

PLUGS

IN

PLUGS

IN

PLUGS

IN

PLUGS

AUTO

SOLO

AUTO

SOLO

AUTO

SOLO

AUTO

SAFE

SAFE

ARM SEL

SOLO

SAFE

SAFE

SAFE

SAFE

SAFE

SAFE

ARM SEL

ARM SEL

ARM SEL

IN

AUTO

SOLO

AUTO

SOLO

AUTO

SOLO

SAFE

SAFE

SAFE

SAFE

SAFE

SAFE

ARM SEL

ARM SEL

ARM SEL

INS

PLUGS

IN

PLUGS

IN

PLUGS

IN

AUTO

SOLO

AUTO

SOLO

AUTO

SOLO

SAFE

SAFE

SAFE

SAFE

SAFE

SAFE

ARM SEL

ARM SEL

ARM SEL

Fairlight Console Channel Control

Width = 489.6 mm

Height = 229.3 mm

Depth = 66.5 mm

Weight = 4.4 kg

BLUE

PAN

PATH

EQ

FLIT

AUX

AUX

COMP

U1

LIM

U2

EXP

U3

ALT

SHOW

INS

SHOW

INS

PLUGS

IN

PLUGS

IN

AUTO

SOLO

AUTO

SOLO

SAFE

SAFE

SAFE

SAFE

ARM SEL

ARM SEL

Fairlight Console Channel Fader

Width = 489.6 mm

Height = 329.9 mm

Depth = 66.6 mm

Weight = 8.45 kg

Power Consumption

Input Power

100-240VAC, 1.7A, 50-60Hz

Operating Temperature

Fairlight Console Audio Editor,

Fader and Channel Control panels

0 to 40°C or 40 to 104°F

Fairlight Console LCD Monitor

0 to 35°C or 40 to 95°F

Fairlight Console Audio Editor

Width = 489.6 mm

Height = 329.9 mm

Depth = 69 mm

Weight = 8.5 kg

24Technical Specifications

Page 25

Help

The fastest way to obtain help is to go to the Blackmagic Design online support pages and

check the latest support material available for your Fairlight Console.

Blackmagic Design Online Support Pages

The latest manual, software and support notes can be found at the Blackmagic Design support

center at www.blackmagicdesign.com/support.

Contacting Blackmagic Design Support

If you can’t find the help you need in our support material, please use the ‘Send us an email’

button on the support page to email a support request. Alternatively, click on the ‘Find your

local support team’ button on the support page and call your nearest Blackmagic Design

support office.

Checking the Software Version Currently Installed

To check which version of Fairlight Console software is installed on your computer, open the

Fairlight Console Components Setup utility and click on the ‘about’ tab. The current version

number will be displayed.

How to Get the Latest Software Updates

After checking the version of Blackmagic Fairlight software installed on your computer, please

visit the Blackmagic Design support center at www.blackmagicdesign.com/support to check for

the latest updates. While it is usually a good idea to run the latest updates, it is wise to avoid

updating any software if you are in the middle of an important project.

25Help

Page 26

Regulatory Notices

Disposal of waste of electrical and electronic equipment within the European union.

The symbol on the product indicates that this equipment must not be disposed of with

other waste materials. In order to dispose of your waste equipment, it must be handed

over to a designated collection point for recycling. The separate collection and recycling

of your waste equipment at the time of disposal will help conserve natural resources and

ensure that it is recycled in a manner that protects human health and the environment. For

more information about where you can drop off your waste equipment for recycling, please

contact your local city recycling office or the dealer from whom you purchased the product.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Operation of this product in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the

interference at personal expense.

Operation is subject to the following two conditions:

1 This device may not cause harmful interference.

2 This device must accept any interference received, including interference that may cause

undesired operation.

Connection to HDMI interfaces must be made with high quality shielded HDMI cables.

26Regulatory Notices

Page 27

Safety Information

Weight Warning

The Fairlight Console has considerable weight even when empty. For example, a three bay

console weighs up to 110 kg empty, and 157 kg fully assembled. You should always move a

Fairlight console with at least 4 people using safe lif ting procedures, such as keeping the

back straight, bending the knees and lifting with careful, controlled movements.

Electrical Warning Notice and Disclaimer

For installations involving the fitting of more than three Fairlight modules, additional

earthing requirements must be fitted before connecting the supply.

It is recommended that any metallic equipment enclosures are securely connected to

the metallic console frame. The metallic console frame must be earthed according to the

appropriate electrical standards that apply at the installation location. Earth posts are

welded internally at both ends of the console frame for connecting earth wires from the

console frame to the building earth point. Either of these posts can be used and they are

marked with the following label.

Fastening screws and associated washer par ts used to connect enclosures to the console

frame must ensure a reliable and low resistance electrical contact between the enclosures

and console frame.

The electrical mains wiring from the building supply point to the console and to all

equipment located inside the console is the customer’s responsibility.

Blackmagic Design recommends appointing a qualif ied and licenced electrician to install,

test and commission this wiring system. Safety requirements should be independently

assessed, certified and verified. For example, due consideration of the distribution cable

and wire types, sizes, ratings, insulation, armouring, screening, strain relief, protective

conduits and fixture methods would need to be addressed and calculations made to take

into account the maximum electrical load.

Blackmagic Design does not accept responsibility for the safety, reliability, damage or

personal injury caused to, or by, any third-party equipment fitted into the console.

From the building supply and earthing point, the correct wiring, electrical isolation,

switching, fusing and protective devices, such as earth leakage breakers, would need to

be located properly, labelled and regularly tested.

Earth continuity tests, that is earth resistance tests at high currents, would be necessary

during and regularly after installation to comply with the relevant electrical regulations. In

some cases, lightning protection and/or surge suppression may need to be installed.

To reduce the risk of electric shock, do not expose this equipment to dripping or splashing.

Ensure that adequate ventilation is provided around the product and is not restricted.

Use only at altitudes not more than 2000m above sea level.

No operator serviceable parts inside. Refer servicing to your local Blackmagic Design

service centre.

27Safety Information

Page 28

Warranty

12 Month Limited Warranty

Blackmagic Design warrants that this product will be free from defects in materials and workmanship

for a period of 12 months from the date of purchase. If a product proves to be defective during this

warranty period, Blackmagic Design, at its option, either will repair the defective product without

charge for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, you the Customer, must notify Blackmagic Design

of the defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. The Customer shall be responsible for packaging and shipping the

defective product to a designated service center nominated by Blackmagic Design, with shipping

charges pre paid. Customer shall be responsible for paying all shipping charges, insurance, duties,

taxes, and any other charges for products returned to us for any reason.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper

or inadequate maintenance and care. Blackmagic Design shall not be obliged under this warranty:

a) to repair damage resulting from attempts by personnel other than Blackmagic Design

representatives to install, repair or service the product, b) to repair damage resulting from improper

installation, use or connection to incompatible equipment, c) to repair any damage or malfunction

caused by the use of non Blackmagic Design parts or supplies, or d) to service a product that has

been modif ied or integrated with other products when the effect of such a modif ication or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY BLACKMAGIC DESIGN IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. BLACKMAGIC DESIGN AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. BLACKMAGIC

DESIGN’S RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS DURING THE

WARRANTY PERIOD IS THE WHOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER.

BLACKMAGIC DESIGN WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER BLACKMAGIC DESIGN OR THE

VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES. BLACKMAGIC

DESIGN IS NOT LIABLE FOR ANY ILLEGAL USE OF EQUIPMENT BY CUSTOMER. BLACKMAGIC

IS NOT LIABLE FOR ANY DAMAGES RESULTING FROM USE OF THIS PRODUCT. USER OPERATES

THIS PRODUCT AT OWN RISK.

© Copyright 2019 Blackmagic Design. All rights reserved. ‘Blackmagic Design’, ‘Cintel’, ‘DeckLink’, ‘DaVinci Resolve’ are registered

trademarks in the US and other countries. All other company and product names may be trademarks of the respective companies

with which they are associated.

28Warranty

Loading...

Loading...