Black & Decker PM3000B Instruction Manual

• Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or main-

tenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min ........................minutes ......................alternating current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................

earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

Minimum Gage for Extension Cords

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 16 1614

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC means your tool

will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of

120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC power. This

information is printed on the nameplate. Lower voltage will cause loss of power and can

result in over-heating. All Black & Decker tools are factory-tested; if this tool does not

operate, check the power supply. This tool is AC only.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

CATALOG NUMBER PM3000B

INSTRUCTION MANUAL

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

insulation eliminates the need for the three wire grounded power cord and grounded

power supply system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from

an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W.” These cords are rated for outdoor use and reduce the risk of electric

shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts. Air vents cover moving parts and should be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools

with your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key

that is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce

the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

project

mate

TM

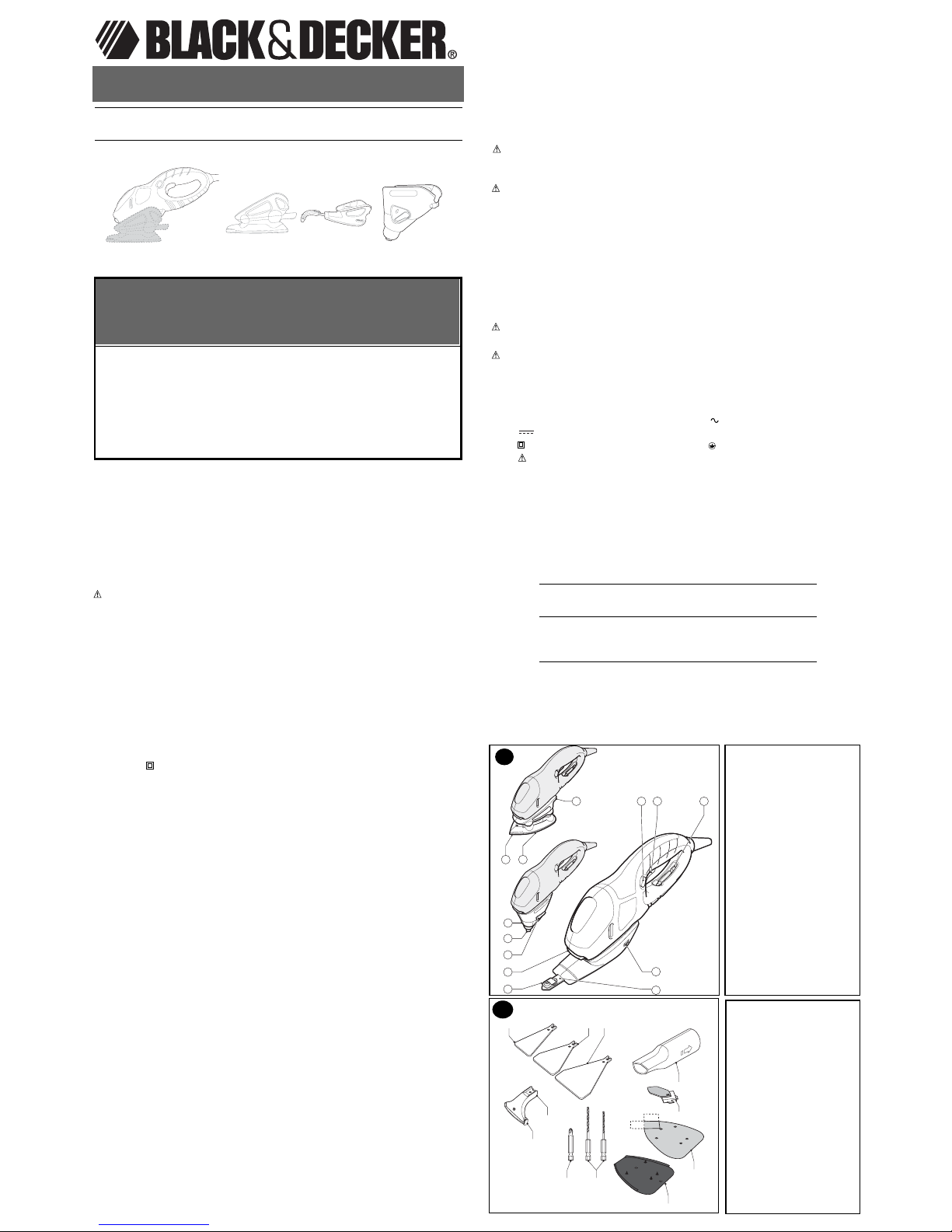

8 7

129 4

5

3

10

6

12

11

5a

FEATURES - Fig. A

POWER UNIT

1.) On/off trigger

2.) Lock-on button

3.) Head release button

4.) Bit storage

SCREWDRIVER HEAD

5.) Forward/reverse slider

5a.) Forward/reverse release button

6.) 1/4” hex shank bit holder

SANDER HEAD

7.) Sanding base

8.) Sanding base tip

9.) Dust extraction outlet

SCRAPER HEAD

10.) Mounting shaft

11.) Clamp plate

12.) Allen key storage

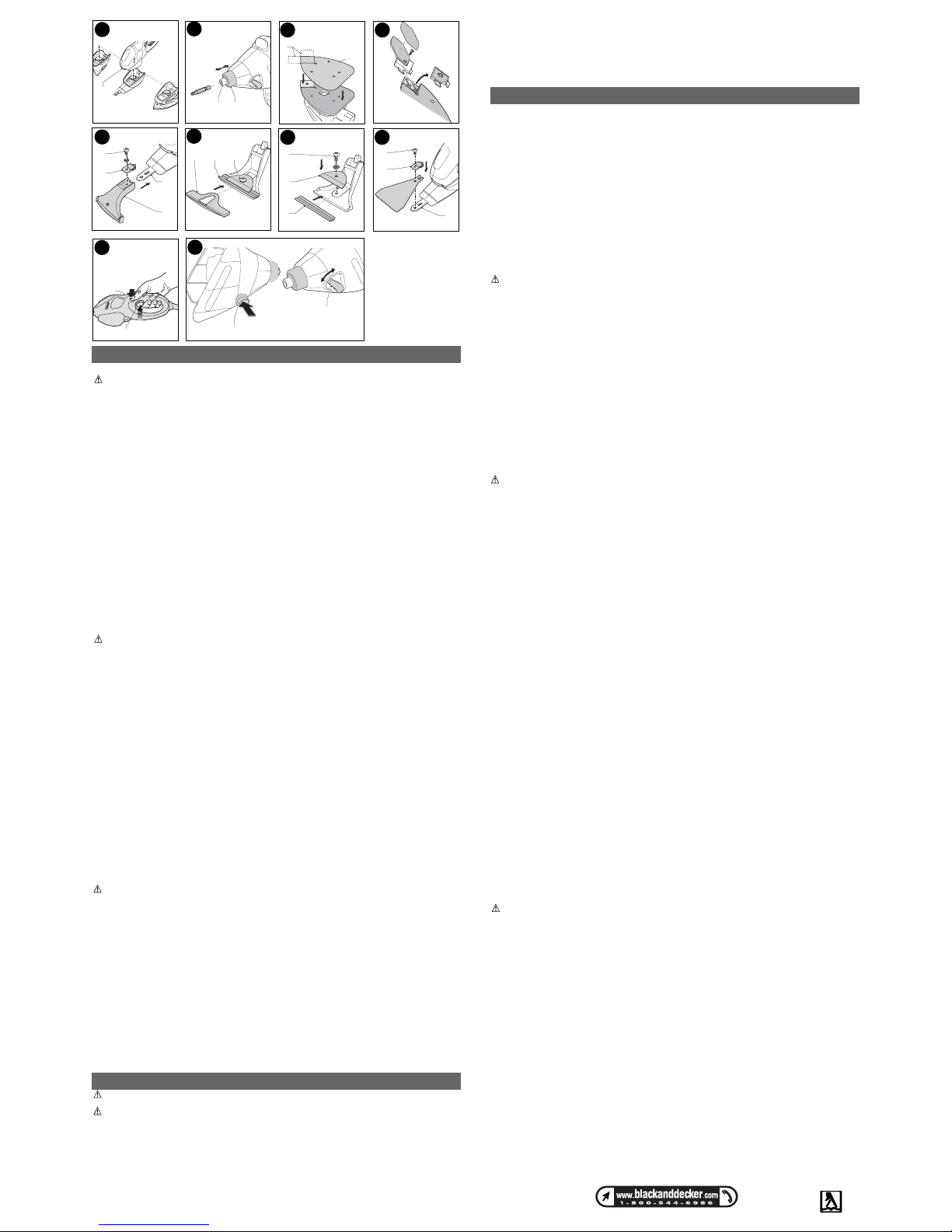

13

18

17

20

21

19

14

15 16

22

23

ACCESSORIES - Fig. A1

13. Claw blade

14. Blade cover

15. Rigid parallel blade

16. Small flexible parallel blade

17. Large flexible blade

18. Screw driver bit

19. Drill bits

20. Sanding sheet

21. Dust extraction adaptor

22. Paper punch

23. Detail Finger Attachment

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE APROBLEM

WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-54-HOW-TO (544-6986)

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No., TYPE

No., AND DATE CODE. IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE A SUGGESTION OR

COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

CAT. NO. PM3000B FORM NO. 478250-00

Copyright © 2005 Black & Decker JUNE ‘05 Printed in China

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

FIG.A

FIG.A1

ASSEMBLY

ATTACHING AND REMOVING TOOL HEADS (FIG. B)

WARNING: To prevent accidental operation, turn off and unplug power unit before

performing the following operations. Remove all accessories from tool heads before

removing or attaching. Failure to do this could result in serious personal injury.

- To attach a tool head, line it up with the power unit as shown and push it onto the tool until it

snaps into place.

- To remove a tool head, depress the head release button (3) and take the tool head off the

tool.

INSERTING AND REMOVING A 1/4” SHANK SCREWDRIVER BIT OR DRILLBIT (FIG. C)

- Pull the sleeve (21) backward.

- Insert the bit shaft into the bit holder (6) as far as it will go.

- Release the sleeve to secure the bit.

- To remove the bit, pull sleeve backward and pull the bit out firmly.

This tool is supplied with on board screwdriver bit storage (4).

- To remove the screwdriver bit from the bit storage press the bit down into the bit holder

recess then lift the bit out.

- To store the screwdriver bit, firmly push it into the recess.

ATTACHING SANDING SHEETS (FIG. D)

- Detach the two diamond-shaped tips (23) from the sanding sheet (20).

- Hold the tool with the sanding base facing upwards.

- Place the sanding sheet (20) onto the sanding base, making sure that the holes in the sheet

line up with the holes in the base.

The diamond-shaped tip (23) can be reversed and replaced when worn.

- When the front part of the tip is worn, detach it from the sheet, reverse it and press it onto

the sanding base again.

- When the whole tip is worn, remove it from the sanding base and fit a new tip.

CAUTION: Never use the sanding head without a sanding sheet or accessory in place.

TIP OF THE SANDING BASE ( FIG. E)

When the sanding base tip is worn, it can be reversed or replaced.

• Remove the screw.

• Reverse or replace the worn part.

• Fit and tighten the screw.

FINGER ATTACHMENT ( FIG. E)

The finger attachment is used for fine detail sanding.

• Remove the screw.

• Remove the diamond-shaped tip holder from the sanding base.

• Fit the finger attachment onto the sanding base.

• Fit and tighten the screw.

ATTACHING AND REMOVING THE CLAW BLADE (FIG. F)

- Slide the claw blade (13) onto the shaft (10).

- Align the tab on the clamp plate (11) with the slot in the shaft.

- Fit the clamp plate to the shaft by tightening the screw (24).

- To remove the head, remove the screw (24) and the clamp plate, and pull the head from the

shaft.

ATTACHING AND REMOVING THE BLADE COVER (FIG. G)

- Hold the blade cover (13) at the ends.

- Lift the blade cover slightly to release it from the screw (24) and pull the cover off. Take care

not to contact the edges of the blade (25).

- To fit the blade cover, hold the cover at the ends and place it over the claw blade. Push the

cover until it snaps into place.

CAUTION: Always keep the blade cover in place when the scraper head is not being

used.

REPLACING THE CUTTING BLADE (FIG. H)

The cutting blade provided with this tool is reversible. Replacement parts are available from

your local dealer or Black & Decker service center.

- Loosen the screw (24) and remove it.

- Remove the cutter clamp plate (25).

- Reverse the blade (26) so that the unused side comes in position. If both sides are worn, the

blade must be replaced.

- Re-install the cutter clamp plate.

- Re-fit the screw and tighten it.

ATTACHING AND REMOVING A PARALLELBLADE (FIG. I)

- Select the required parallel blade.

- Align the slot on the mounting end of the blade with the slot in the shaft (10).

- Align the tab on the clamp plate (11) with the slot in the shaft (10) and the blade.

- Fit the clamp plate to the shaft by tightening the screw (24).

- To remove the blade, remove the screw (24) and the clamp plate, and take the blade from

the shaft.

OPERATION

CAUTION: Let the tool work at its own pace. Do not overload.

CAUTION: Do not cover the ventilation slots when using the tool to avoid overheating.

SWITCHING THE TOOL ON AND OFF (FIG.J)

- Hold tool as shown. To switch the tool on, press the on/off trigger (1).

- For continuous operation, press the lock-on button (2) and release the on/off trigger.

- To switch the tool off, release the on/off trigger.

- To switch the tool off when in continuous operation, press the on/off trigger once more and

release it.

SELECTING THE DIRECTION OF ROTATION (FIG. K)

For tightening screws, use forward (clockwise) rotation. For loosening screws, use reverse

(counterclockwise) rotation.

- To select forward rotation, depress the forward/reverse release button (5a) then push the

forward/reverse slider (5) to the left.

- To select reverse rotation, depress the forward/reverse release button (5a) then push the

forward/reverse slider to the right.

HINTS FOR OPTIMUM USE

SCREWDRIVING AND DRILLING ( 1/4” HEX SHANK BITS ONLY)

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the Safety Instructions.

• Secure and maintain work area, as instructed in Safety Instructions.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting

but not so much as to stall the motor or deflect the bit.

• Hold the drill firmly to control its twisting action.

• DO NOT CLICK THE TRIGGER OF ASTALLED DRILL OFF AND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE DRILL CAN RESULT.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns tool on and off.

• Always use the correct type and size of screwdriver bit.

• If screws are difficult to tighten, try applying a small amount of washing liquid or soap as a

lubricant.

• Always hold tool and screwdriver bit in a straight line with the screw.

WARNING: It is important to support the work properly and to hold the tool firmly to

prevent loss of control which could cause personal injury.

SCRAPING

• Do not exert too much pressure on the tool.

• Choose the correct blade type for the application. Use the claw blade for loose or flaking

paint. Use the flexible blade for soft adhesives. Use the rigid blade for hard adhesives.

• Push or pull the claw blade steadily over the surface of the material. Note that the blade

will not move until it is pressed against the material.

• Do not exert too much pressure on the tool.

SANDING-GENERAL

• Use paper punch (22) to put holes in sandpaper to aid in dust collection when using a

vacuum.

• Do not exert too much pressure on the tool.

• Regularly check the condition of the sanding sheet. Replace when necessary.

• When sanding new layers of paint before applying another layer, use extra fine grit.

• On very uneven surfaces, or when removing layers of paint, start with a coarse grit. On

other surfaces, start with a medium grit. In both cases, gradually change to a fine grit for

a smooth finish.

• Consult your retailer for more information on available accessories for sanding,

polishing, stripping and scrubbing.

WARNING: SANDING / SCRAPING LEAD BASED PAINT

Sanding/scraping of lead based paint is NOT RECOMMENDED due to the difficulty of

controlling the contaminated dust. The greatest danger of lead poisoning is to children and

pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical

analysis, we recommend the following precautions when sanding/scraping any paint:

PERSONAL SAFETY

• No children or pregnant women should enter the work area where the paint

sanding/scraping is being done until all cleanup is completed.

• A dust mask or respirator should be worn by all persons entering the work area. The

filter should be replaced daily or whenever the wearer has difficulty breathing.

• Note: Only those dust masks suitable for working with lead paint dust and fumes should

be used. Ordinary painting masks do not offer this protection. See your local hardware

dealer for the proper (NIOSH approved) mask.

• NO EATING, DRINKING or SMOKING should be done in the work area to prevent

ingesting contaminated paint particles. Workers should wash and clean up BEFORE

eating, drinking or smoking. Articles of food, drink, or smoking should not be left in the

work area where dust would settle on them.

ENVIRONMENTAL SAFETY

• Paint should be removed in such a manner as to minimize the amount of dust

generated.

• Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

• Sanding/scraping should be done in a manner to reduce tracking of paint dust outside the

work area.

CLEANING AND DISPOSAL

• All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the

duration of the sanding/scraping project. Vacuum filter bags should be changed frequently.

• Plastic drop cloths should be gathered up and disposed of along with any dust chips or

other removal debris. They should be placed in sealed refuse receptacles and disposed

of through regular trash pick-up procedures. During cleanup, children and pregnant

women should be kept away from the immediate work area.

• All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-54-HOW-TO. (800-544-6986)

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact

the Black & Decker location nearest you. To find your local service location, refer to the

yellow page directory under "Tools—Electric" or call: 1-800-54-HOW TO (544-6986).

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may

be required. Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

Free warning label replacement: If your warning labels become illegible or are missing,

call 1-800-544-6986 for a free replacement.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

3

B

216

20

23

C

D E

13

10

11

24

F

242514

10

11

24

G

24

25

26

IH

5

5a

K

1

2

J

Loading...

Loading...