Page 1

Models E984,0984 and

K984-X8X Controllers

System Planning and

Installation Guide

GM-0984-EDK

Rev. R

I Modicon I Square D 8 Telemecanique

Page 2

Page 3

Modicon

System Planning and

Installation Guide for

984-X8X Controllers

Models E, D, and K

GM-0984-EDK Rev. B

August, 1995

MODICON, Inc.

One High Street

North Andover, Massachusetts 01845

Page 4

Page 5

Preface

This guide describes the ten different yet similar 984 slot mount Programmable

Logic Controllers and their available options, together with procedures for system

planning and installation.

The major differences are identified up front for easy reference in Chapter 1.

Throughout the manual a number of sections apply to all models, while others apply only to certain models as so noted.

The information in this document is subject to change without notice and should

not be construed as a commitment by Modicon, Inc., who assumes no responsibility for any errors that may appear in this document.

No part of this document may

be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without the express written permission of the publisher, Modicon,

Inc. All rights reserved.

0 Copyright 1995 Modicon, Inc.

The following are trademarks of Modicon, Inc.:

ModiconB

P190

984A

984-380

984-38 1

E984-381

984-385

E984-385

Micro 984

984

984B

984480

E984-480

984-485

E984-485

984-680

ModbusB

984X

984-685

E984485

984-780

984-785

984-785L

E984-785

984-l 20

984-l 30

984-l 45

984-351

984-455

Modsoft@

D984-385 K984-485 D984-785

K984-785 Modbus Plus

IBM8 is a registered trademark of International Business Machines, Inc.; IBM PC

is a trademark of International Business Machines, Inc.

Preface iii

Page 6

Objectives

This manual will help you plan, configure, mount, wire, connect, check out, and

troubleshoot your 984 slot-mount controller system, including 984/800 Series

Remote I/O. After reading this book:

o A Control Engineer will be able to identify and physically plan the location and

mounting of system components.

o A Plant Electrician/Installer will be able to install, power-up, and check out the

system.

o A Maintenance Technician will be able to recognize, locate, identify, and re-

solve or report system failures.

How To Use This Manual

Chapter 1 describes the various controllers and their functions.

Chapter 2 offers information for planning your installation.

Chapter 3 is an installation procedure for your controller with local I/O and

Remote I/O.

Appendix A gives system specifications.

Appendix B gives troubleshooting assistance.

iv Preface

Page 7

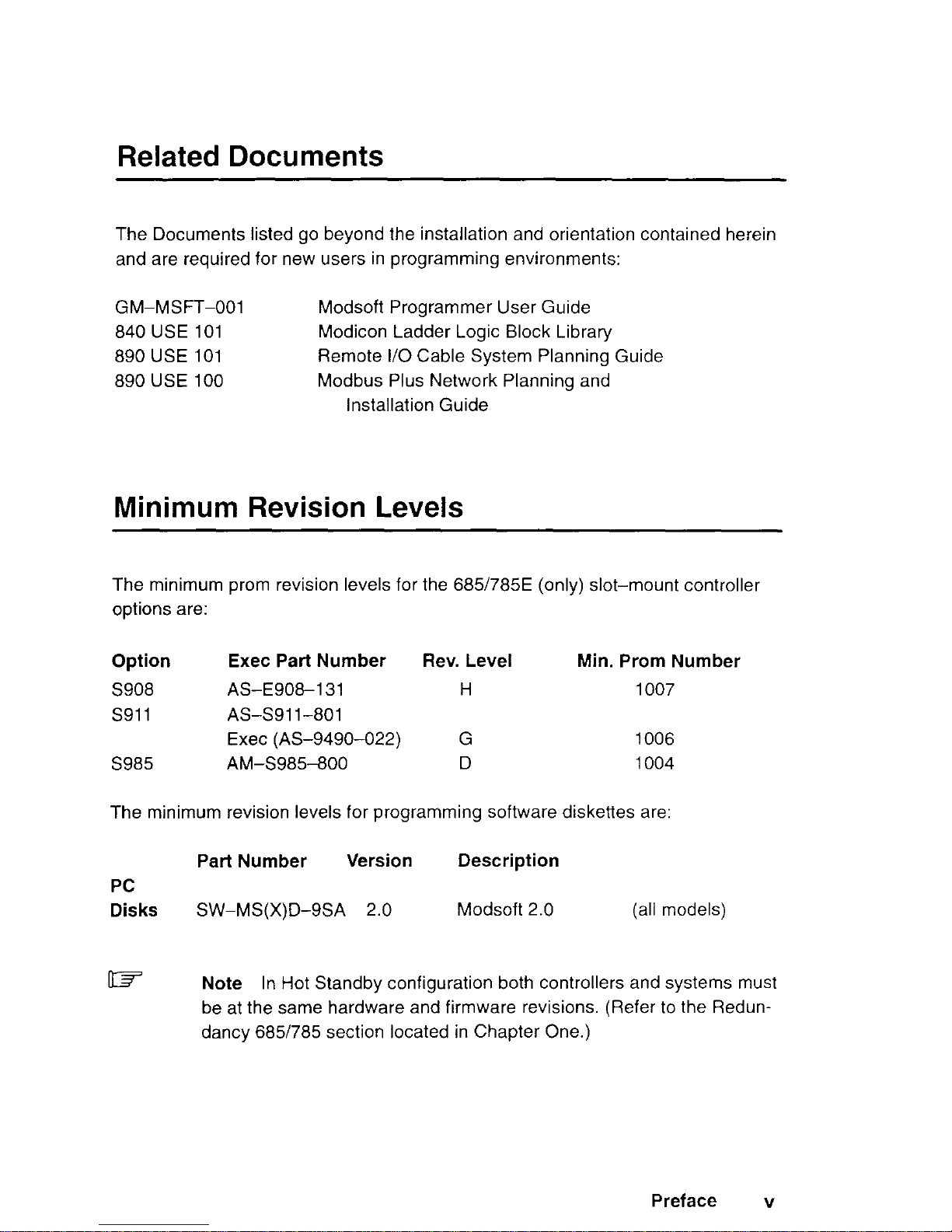

Related Documents

The Documents listed go beyond the installation and orientation contained herein

and are required for new users in programming environments:

GM-MSF--001

840 USE 101

890 USE 101

890 USE 100

Modsoft Programmer User Guide

Modicon Ladder Logic Block Library

Remote I/O Cable System Planning Guide

Modbus Plus Network Planning and

installation Guide

Minimum Revision Levels

The minimum prom revision levels for the 685/785E (only) slot-mount controller

options are:

Option

S908

s911

5985

Exec Part Number

Rev. Level Min. Prom Number

AS-E9081 31

H

1007

AS-S91 l-801

Exec (AS-9490-022)

G 1006

AM-S985800

D

1004

The minimum revision levels for programming software diskettes are:

PC

Disks

Part Number

Version

Description

SW-MS(X)D-9SA 2.0

Modsoft 2.0 (all models)

CR

Note

In Hot Standby configuration both controllers and systems must

be at the same hardware and firmware revisions. (Refer to the Redundancy 6851785 section located in Chapter One.)

Preface v

Page 8

Incoming Inspection Guidelines

Guidelines for Inspection

o Before you do anything, verify your shipment is complete and undamaged. If

the shipment is incomplete or damaged, notify the carrier and your distributor.

o Remove everything from its packing and check for physical defects or damage.

If the equipment is physically defective or damaged, notify your Modicon representative.

ID=

Note

Save shipping materials until installation is complete.

Sending Something Back?

o Whenever possible, use the original packing materials supplied by Modicon.

o All equipment should be firmly packed so that it cannot move around in its ship-

ping container.

o All equipment should be protected against impact during shipment.

IJ All equipment should be clearly marked with its Return Authorization Number

@A#).

vi Preface

Page 9

Table of Contents

Chapter 1 Introducing your Controller

. . . a

Programmable Logic Controllers (PLC) .

System Capacity . . . . . . . . . . . . .

. .

Optimize Mode (685E/785E ONLY) . . .

How Optimize Works . . . . . . . .

. .

Local

I/O

. . . . . . . . . . . . . . . . . . . . . . .

. .

Remote I/O . . . . . . . . . . . . . . . .

Executive NV FLASH Memory and RAM

. . .

Executive Functionality . . . . . . . .

. . .

Redundancy685785 . . . . . . . . . . . . .

Housings . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

Remote I/O Enclosures

. . . . . . .

. . .

Status Indicators . . . . . . . . . . .

. . . .

.........

.........

.........

.........

.........

.........

.........

.........

.........

.........

.........

1

2

6

7

8

9

9

11

11

12

13

14

15

Chapter 2 System Planning

. . . . . . . . . . . . L , _ . . . . . . . .

17

Planning . . . . . . . . . . . . . .

Overview . . . . . . . . . . .

Space Requirements . . . . . . .

Primary Power Lines . . . . . . . . .

Environmental Requirements . . . .

Mounting Hardware Requirements .

Housing Installation Options . . . . .

Panel or Bulkhead Mounting . .

Rack Mounting . . . . . . . . . . .

Grounding Your Installation . . . . . . . .

Power Supply Function (AC and DC) .

Primary Power Cable (AC/DC) . .

AC Power Cable . . . . . .

DC Power Cable . . . . . . . . . . .

Communications Processing Function .

381 E/385E/385D/480E/485E/485K

......

...... 18

......

......

18

......

......

18

......

...... 18

......

...... 19

......

...... 19

......

...... 20

......

...... 20

......

...... 22

......

...... 26

......

...... 26

......

...... 29

......

...... 29

......

...... 30

......

...... 30

......

...... 31

Comm Switch Configuration for MODBUS, Ports

........

31

Modbus Port Software Configuration

.................

31

Modbus Plus Node Address Setting (385/485 ONLY)

.... 33

Modbus Plus Bridge Mode (385/485 ONLY)

............

34

Table of Contents vii

GM-0984-EDK

Page 10

Using MSTR Block To Change Modbus Plus Address . . . 35

Modbus Plus Node Address Software Change (385/485 ) 35

MSTR Format . . . . . . . . . . . . . . . . . . . . . 35

Port Delay Timer . . . . . . . . . . . . 37

685El785El785DI785K . . . . . . . . . . . . . . . . . . . . . . . . . .

37

Comm Switch Configuration for MODBUS, Ports . 37

Modbus Port Software Configuration . . . . . . . . . . . . . . . .

38

Modbus Plus Node Address Setting (685i785 ONLY) . . .

41

Chapter 3 System Installation

.....................

43

Panel/Bulkhead Mounting ..............................

44

RackMounting ....................................

50

Procedure Rack Mounting Installation ..................

52

Procedure Connecting Your Field Wiring ................

55

I/O Module insertion

...................................

58

Procedure I/O Module Installation .....................

58

PowerSupply ........................................

60

Power Supply Installation and Wiring ...................

61

Verify Your Local I/O ...............................

64

Controller to IBM PC Programming Panel Software

..... 64

Getting PLC into RUN Mode .......................

64

I/OQuickCheck

................................. 65

RI/O Head/Receiver

...................................

68

RI/O Head Installation (685E/785E/785Di785K ONLY)

..... 68

Procedure Setup & Install. of S908 RI/OP in Prim. Housing 68

RI/O Receiver Install (480E/485E/485K & 685E/785E,D & K) 69

Procedure Set Drop Address/ASCII Ports for J89X & Install 70

Verify Your RIO Installation ..........................

74

. . .

VIII

Table of Contents

Page 11

Appendix A Specifications

. . . . . . . . . . . . . . . . . . . . . . .

75

Controller Specifications . . . .

Built-in Power Supply . . .

Output to I/O Service . . . .

External Power Requirements

Physical Characteristics . . .

Electrical Characteristics . . .

Circuit Characteristics . . . .

Environmental Characteristics

End User Part Numbers . . .

. . .

......

76

. . ......

76

. . .

......

77

. . . . .

......

77

. . . .

......

78

. . . .

......

78

. . .

......

78

. . . .

......

79

. . . .

......

80

Appendix B Troubleshooting

. . . . . . . . . . . . . . . . . . . . . .

83

Stopped Error Codes

. . . . . . . . . . . . .

........

. a4

Installation Verification Troubleshooting . .

........

. a7

Master Function Error Codes . . . . . . . . . . .

........

a9

Customer Service & Technical Assistance . .

........

. 90

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

GM-O984-EDK

Table of Contents ix

Page 12

Figures

Figure 1 381 EI385El385D Perspective Drawing ............. 3

Figure 2 480E/485E Perspective Drawing .................. 4

Figure 3 685E/785E Perspective Drawing .................. 5

Figure 4 RI/O Head (S908) Module (S908-110) ............. 10

Figure 5 Controller Location in Primary Housing AS-H81 9-209 . 14

Figure 6 H819 Housing Panel or Bulkhead Mounting Dimensions 21

Figure 7 H827 Housing Panel or Bulkhead Mounting Dimensions 22

Figure 8 H819 Housing Rack Mount Dimensions ............ 24

Figure 9 381 E/385E/480E/485E/485K Primary Power Input Conn. 27

Figure 10 685E/785E/785K Primary Power Input Connections . . 28

Figure 11 MEM/DEFAULT/MODEM DIP Switch .............. 32

Figure 12 Communication Port Selection Screen ............ 33

Figure 13 DIP Switch for Modbus Plus Node (385/485 ONLY) . 34

Figure 14 MSTR Block on Modsoft screen With I/O Labels ..... 36

Figure

15

MEM/DIP DIP Switch

.......................... 39

Figure 16 Comm. Port Selection Screen (485E Example) ...... 40

Figure 17 DIP Switch for Modbus Plus Node (685/785 ONLY) . . 41

Figure 18 Remote I/O H819 Panel/Bulkhead Mounting Dim. .... 45

Figure 19 H827 RI/O Housing Panel/Bulkhead Mounting Dim. .. 46

Figure 20 Attach Housing to Mounting Surface .............. 47

Figure 21 Connecting Cables within Each Drop

.............. 49

Figure 22 H819 Housing Rack Mount Dimensions ........... 51

Figure 23 Attaching Rack Mounting Flange to Housing ........ 52

Figure 24 Rack Mounting Your Housing .................... 54

Figure 25 Field Wiring to Terminal Strip (20 Pin Shown) ....... 56

Figure 26 800 Series RI/O Module Installation

............... 59

Figure 27 P810 Power Supply Insertion .................... 61

Figure 28 P810 Power Supply Terminal Strip ................ 62

Figure 29 P800 Power Supply Terminal Strip ................ 63

Figure 30 P884 Power Supply Terminal Strip ................ 63

Figure 31 A Configuration Overview Screen Initial Screen ..... 65

Figure 32 I/O Map Data ................................ 66

Figure 33 J89O/J892 Dip Switch Locations (Rear of Modules) 70

Figure 34 Drop Address Switch Characteristics .............. 71

Figure 35 ASCII Drop Port Assignment Switches ............ 73

Figure 36 Modbus Cable Pinouts ......................... 85

Figure 37 Modbus Cable Pinouts Cont. .................... 86

Figure 38 Modbus Cable Pinouts Cont. .................... 86

X

Table of Contents

GMa984-EDK

Page 13

Figure 39 Controller Installation Troubleshooting Chart . . . . . . 87

Figure 40 Controller Installation Troubleshooting Chart (Sheet 2)

88

Tables

Table 1 Memory Per Configuration

...........

Table 2 Memory Per Configuration Cont.

......

Table 3 Communication Options per PLC

......

Table 4 Port 1 Configuration

................

Table 5 Port 1 Configuration

................

Table 6 Partial Modbus Plus Address Examples

Table 7 J89O/J892 Drop Address Switch Settings

Table 8 J892 ASCII Port Address Settings

.....

Table 9 End User Part Numbers

.............

Table 10 Stopped Error Codes

...............

Table

11

MSTR Error Code Definitions

.........

. . .

. . . .

. . .

. . .

. .

. . .

. .

. 6

. 7

. 30

. 31

38

. 42

72

. 73

. 80

. 84

. 89

GM-0984-EDK

Table of Contents xi

Page 14

Page 15

Chapter

1

Introducing your Controller

~3 Programmable Logic Controllers (PLC)

0 System Capacity

o Executive NV FLASH Memory and RAM

o Housings

o Status Indicators

GM-0984-EDK

Introducing your Controller

1

Page 16

Programmable Logic Controllers (PLC)

The Modicon 984-381 ~t3a5~t385Dt480~~4a5~t485bu685~~785~~785~~785u

Controllers are mid-range Programmable Logic Controllers in a modular, expandable, architecture. They employ Modicon 800 series housings, interfaces and I/O

modules. These PLC’s are supported by the same instruction set as the other 984

models, and are programmed by Modsoft panel software. All of these units have a

built-in power supply. All of these units are fully compatible with the Modicon 984

PC instruction set, and solve user logic at a rate of from 1 ms to 2.5 ms per thousand nodes of user logic. The 785El785Dl785K are 24-bit CPU’s and the rest are

16-bit CPU’s.

These units have two, or three built-in Modbus ports for data transfer and remote

programming. Through these ports, communication processing on the CPU board

links the controller to multiple supervisory and programming devices such as a

host computer or Modicon’s programming panel. The two Modbus ports allow you

to connect more than one Modbus device to the controller. Some models have

both a single Modbus port and a second port for the Modbus Plus high speed Local Area Network. While others have two Modbus ports and one Modbus Plus

port. The DIP switch for setting the Modbus Plus port address can be accessed

through the bottom of the module’s case.

User memory is backed up by a lithium battery which has a conservatively rated

service life of one year. Once energized, the BATTERY LOW indicator will come

ON when the battery has 14 days left before it will be effectively drawn down. The

battery has a five-year shelf life.

w

Note

The 485K and 785K are the same has the 485E and 785E ex-

cept the K’s have a memory protect Key Switch on the front of the unit.

w

Note

The 385D and 785D are the same has the 385E and 785E ex-

cept the D’s operate on 125VDC rather than 115/23OVAC.

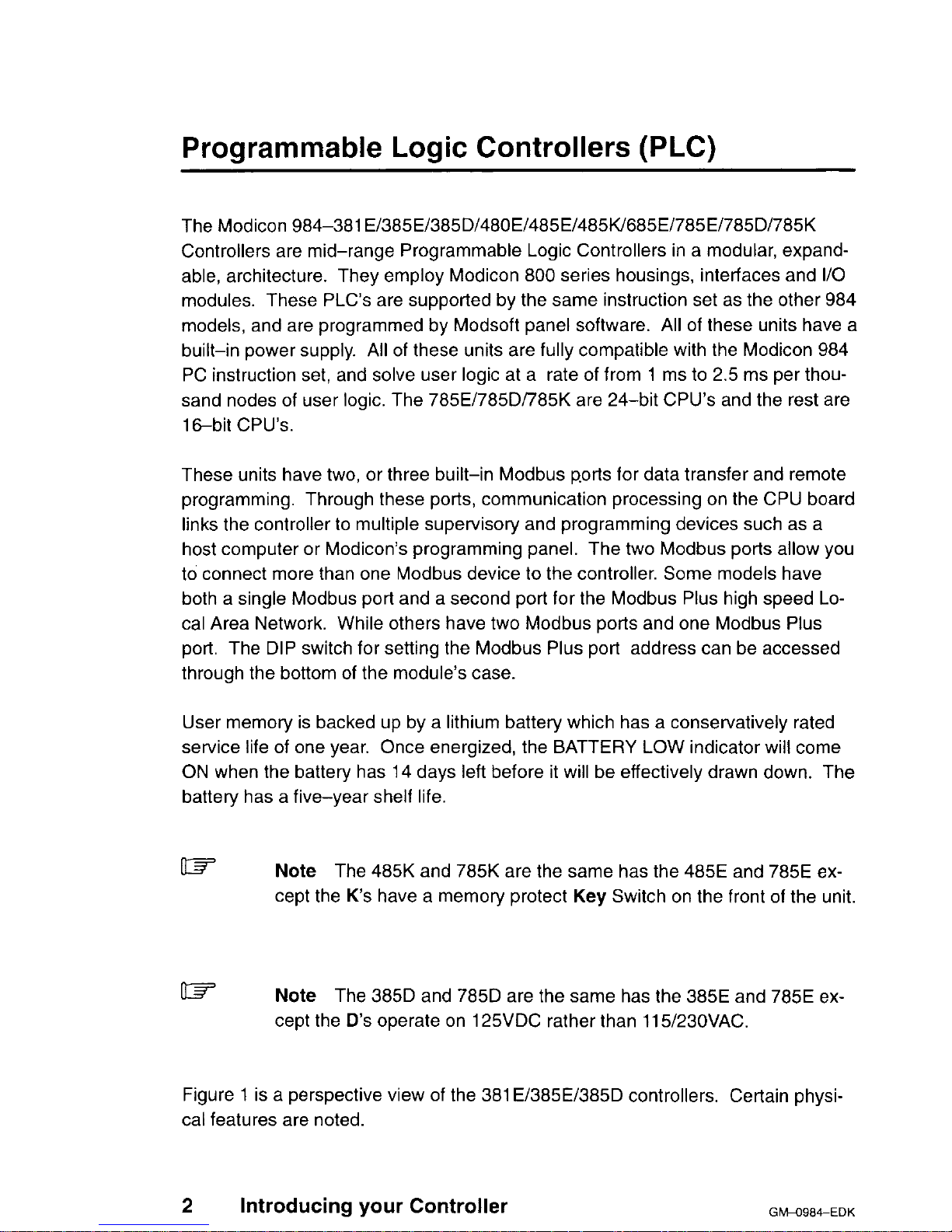

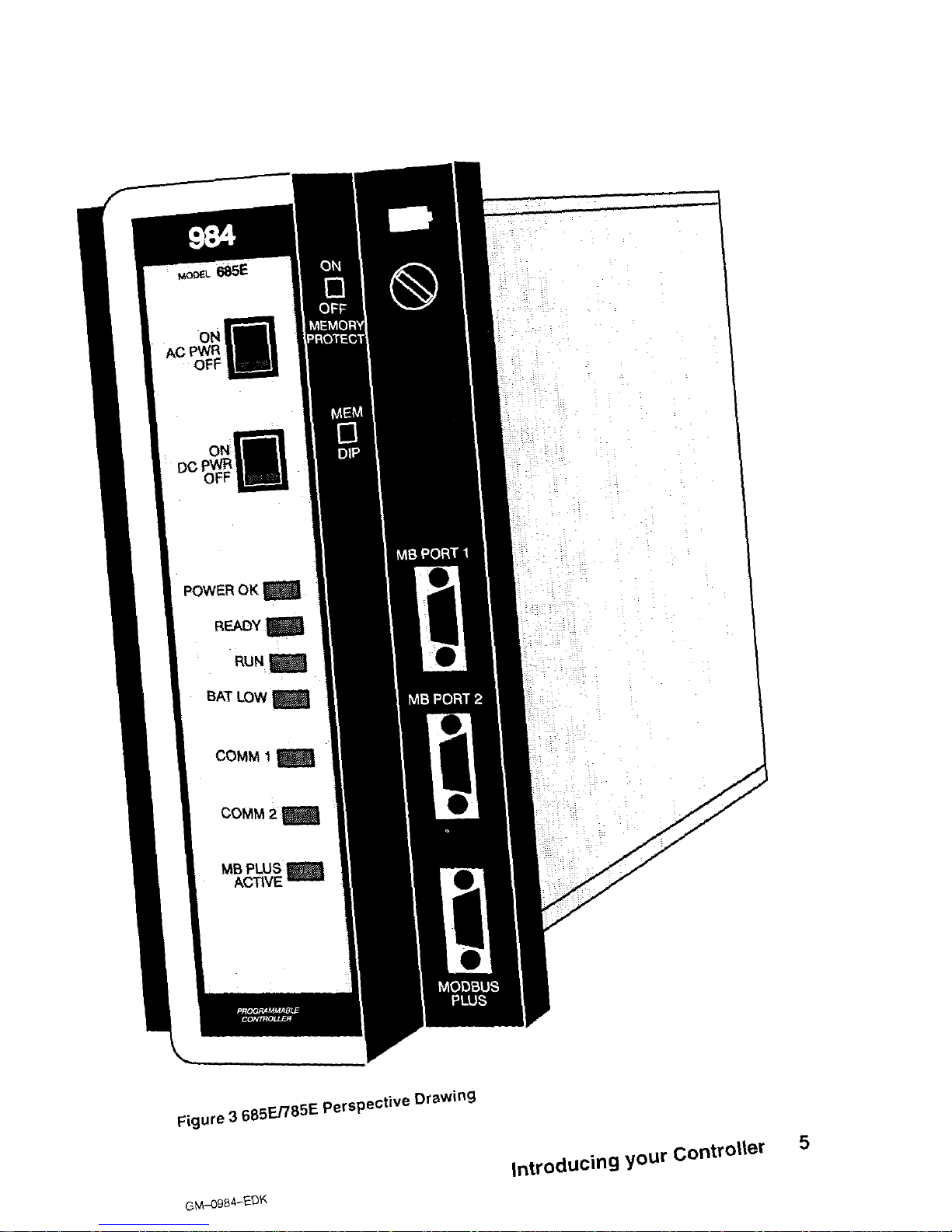

Figure 1 is a perspective view of the 381 E/385E/385D controllers. Certain physical features are noted.

2

Introducing your Controller

GWO984-EDK

Page 17

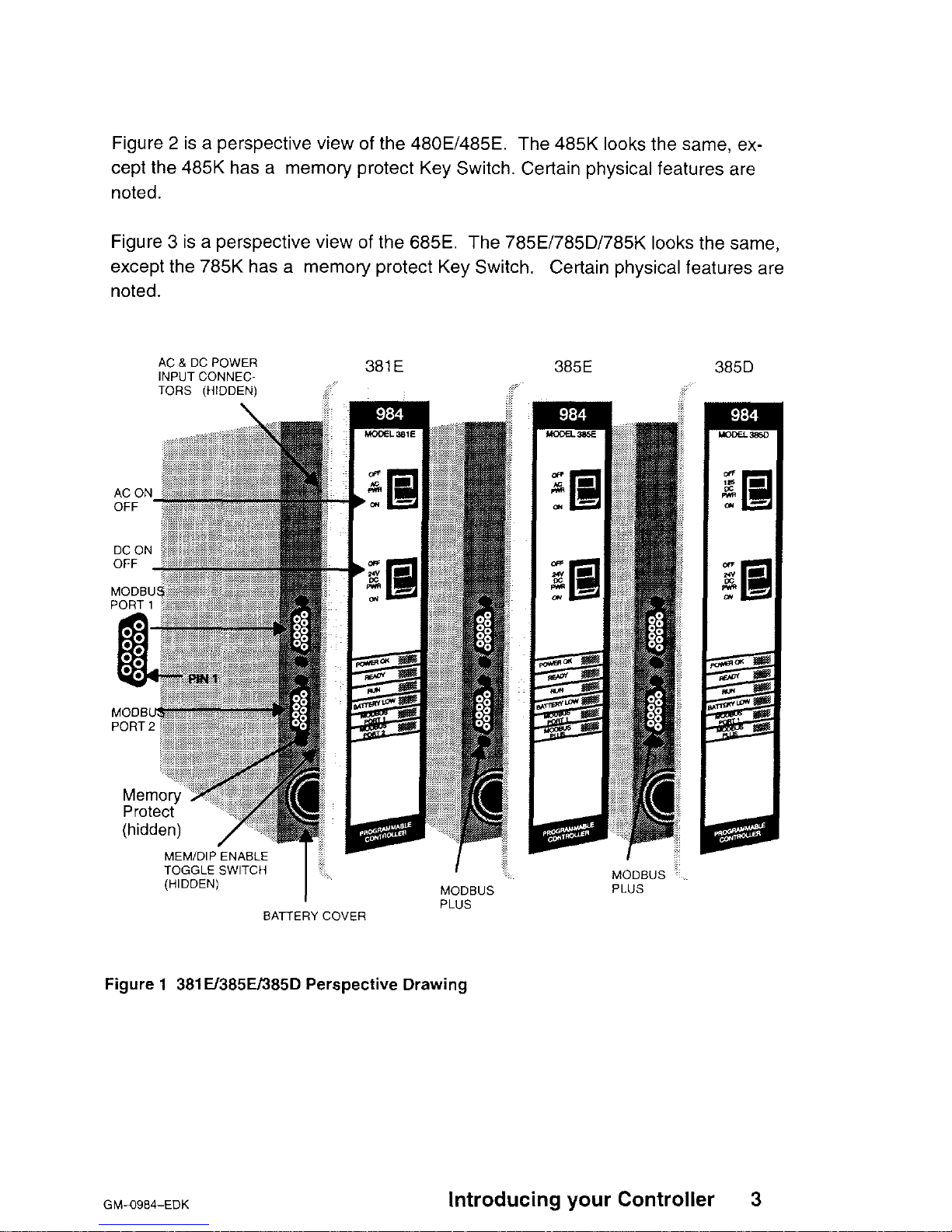

Figure 2 is a perspective view of the 480E/485E. The 485K looks the same, except the 485K has a memory protect Key Switch. Certain physical features are

noted.

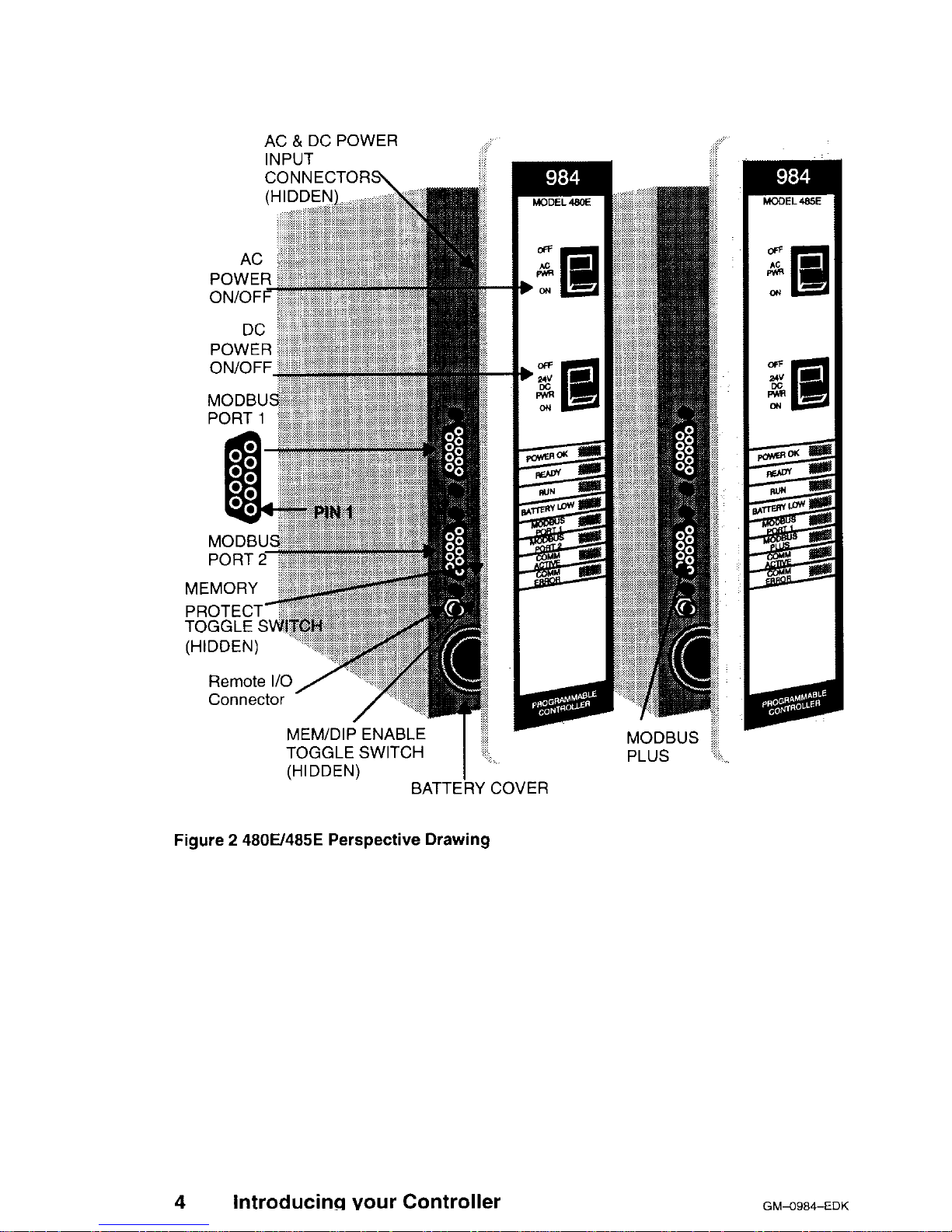

Figure 3 is a perspective view of the 685E. The 785E/785D/785K looks the same,

except the 785K has a memory protect Key Switch.

Certain physical features are

noted.

AC & DC POWER

INPUT CONNEC-

381 E 385E

TORS (HIDDEN)

TOGGLE SWITCH

I’

(HIDDEN)

BATTERY COVER

I

MODBUS

PLUS

Figure 1 381E/385E/385D Perspective Drawing

MODBUS

PLUS

GM-0984-EDK

Introducing your Controller

3

Page 18

AC 8, DC POWER

INPUT

CONNECTORS\

AC

POWER

ON/OFF

PORT 1

,“,LI.l_l . I

PROTECT-

TOGGI F .S\

Connects

MEM/DIP ENABLE ;

I

TOGGLE SWITCH ‘.

--

MODBUS

PLUS

(HIDDEN)

I

BATTERY COVER

Figure 2 4800485E Perspective Drawing

4 Introducing your Controller

GMXCF34-EDK

Page 19

AC P’%

OFF

POWER OK

READY

RUN

BAT LOW

COMM

1

COMM 2

Figure 3 685En85E Perspective Drawing

GM-0984-EDK

Introducing your Controller

5

Page 20

System Capacity

The system capacity for the various “E” controllers are described below.

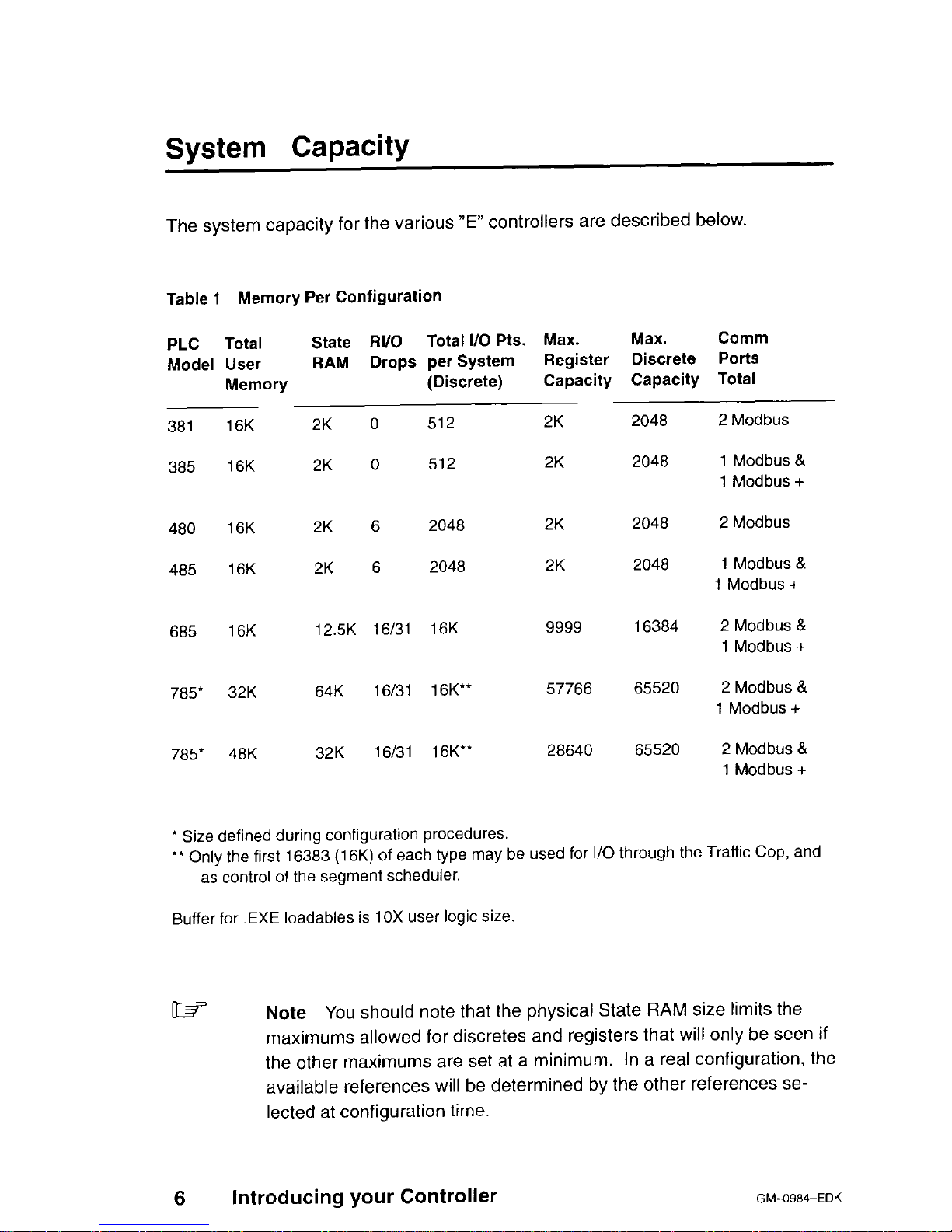

Table 1 Memory Per Configuration

PLC

Total

State RI/O Total I/O Pts. Max.

Max. Comm

Model User

RAM Drops per System

Register Discrete Ports

Memory

(Discrete)

Capacity Capacity Total

381 16K 2K 0 512

2K 2048 2 Modbus

385 16K 2K 0 512

2K 2048 1 Modbus &

1 Modbus +

480 16K 2K 6 2048

2K 2048 2 Modbus

485 16K 2K 6 2048

2K 2048 1 Modbus &

1 Modbus +

685 16K 12.5K 16/31 16K

9999 16384 2 Modbus &

1 Modbus +

785* 32K 64K 16/31 16K”

57766 65520 2 Modbus &

1 Modbus +

785* 48K 32K 16131 16K**

28640 65520 2 Modbus &

1 Modbus +

* Size defined during configuration procedures.

‘* Only the first 16383 (16K) of each type may be used for I/O through the Traffic Cop, and

as control of the segment scheduler.

Buffer for .EXE loadables is 10X user logic size.

6

Introducing your Controller

Note You

should note that the physical State RAM size limits the

maximums allowed for discretes and registers that will only be seen if

the other maximums are set at a minimum. In a real configuration, the

available references will be determined by the other references selected at configuration time.

GM-O984-EDK

Page 21

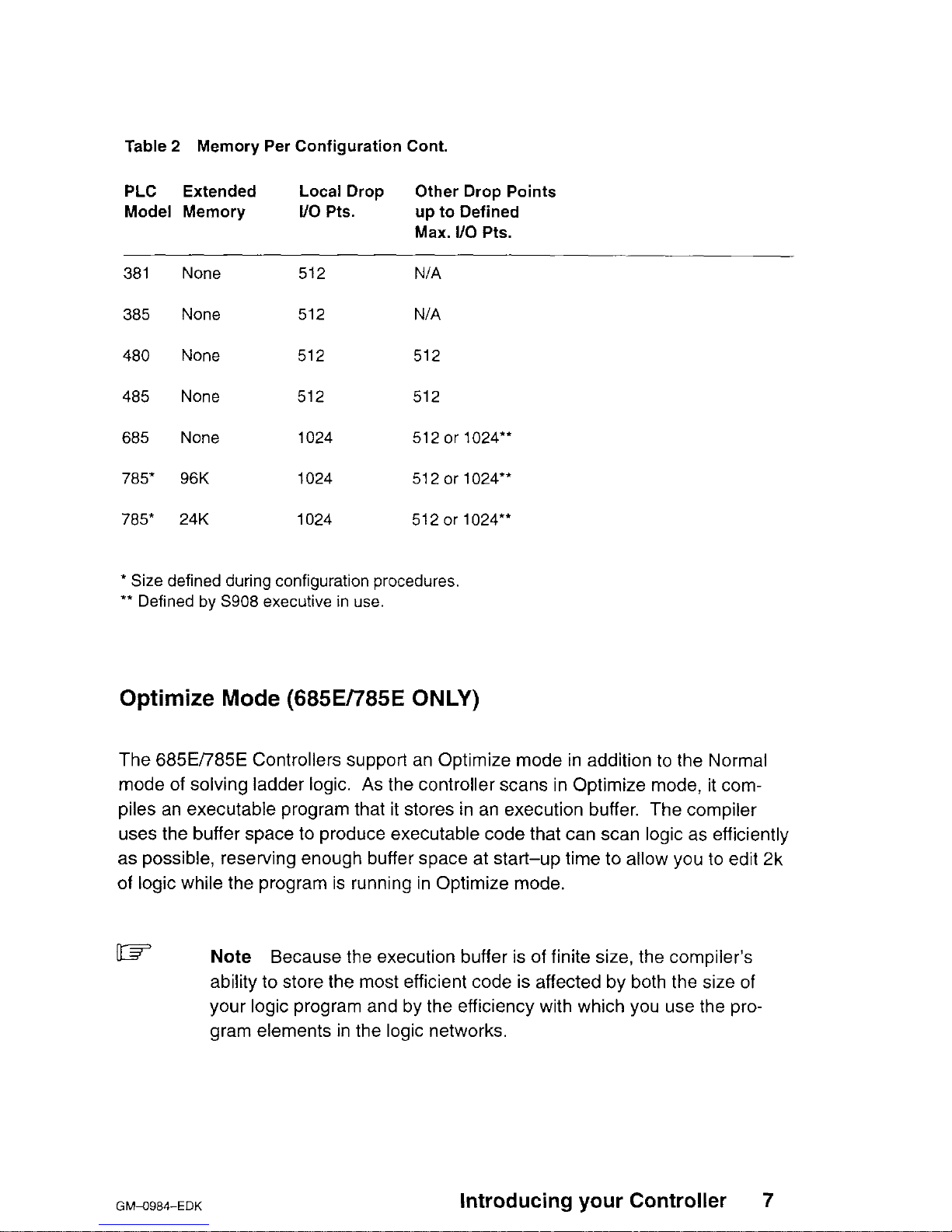

Table 2 Memory Per Configuration Cont.

PLC Extended

Model Memory

Local Drop Other Drop Points

l/o Pts. up to Defined

Max. l/O Pts.

381 None

512

N/A

385

None

512 N/A

480

None 512 512

485 None 512 512

685 None 1024 512 or 1024”

785* 96K

1024 512 or 1024”

785* 24K 1024 512 or 7024*’

* Size defined during configuration procedures.

** Defined by S908 executive in use.

Optimize Mode (685E/785E ONLY)

The 685EI785E Controllers support an Optimize mode in addition to the Normal

mode of solving ladder logic. As the controller scans in Optimize mode, it compiles an executable program that it stores in an execution buffer. The compiler

uses the buffer space to produce executable code that can scan logic as efficiently

as possible, reserving enough buffer space at start-up time to allow you to edit 2k

of logic while the program is running in Optimize mode.

w

Note

Because the execution buffer is of finite size, the compiler’s

ability to store the most efficient code is affected by both the size of

your logic program and by the efficiency with which you use the program elements in the logic networks.

GMa984-EDK

Introducing your Controller

7

Page 22

How Optimize Works

When you run the controller in Optimize mode, the compiler constructs inline code

in the execution buffer that executes more efficiently than Normal-mode operations. The controller uses an algorithm to automatically calculate a higher level of

optimization that does not exceed the execution buffer’s capacity and that always

reserves buffer space for 2k of logic editing while the controller is running in Optimize mode. Optimization is fully managed by the controller and is transparent to

you during scanning.

The compiler places related contacts and coils in each network into node groups

and then solves each group as an entity.

Each node group consists of a set of

connected contacts-with or without a coil-related to a common logic path that can

be solved simultaneously. The compiler:

1. Searches each network

2. Locates connected nodes and paths in each network and solves them as a

group

3. Skips the evaluation of nodes and paths that are known to be irrelevant

within each group. That is, if input power for a series of contacts is not on,

the executive will skip the logic solving of these contacts in a network.

By considering each node group as an entity, the compiler is able to reduce the

scan time in ladder logic programs.

When you start to run the controller in Optimize mode, the compiler automatically

reserves enough space in the execution buffer to support 2k of edits while the program is running. If your edits use up all the reserved buffer space, you may either

continue to run the program in Optimize mode with no further editing permitted or

stop and restart the controller with newly generated buffer space for another 2k

edits.

03

Note System performance may be slowed when the compiler adjusts

the buffer for on-line edits and creates the new buffer space for further

edits.

8

Introducing your Controller

GM0984-EDK

Page 23

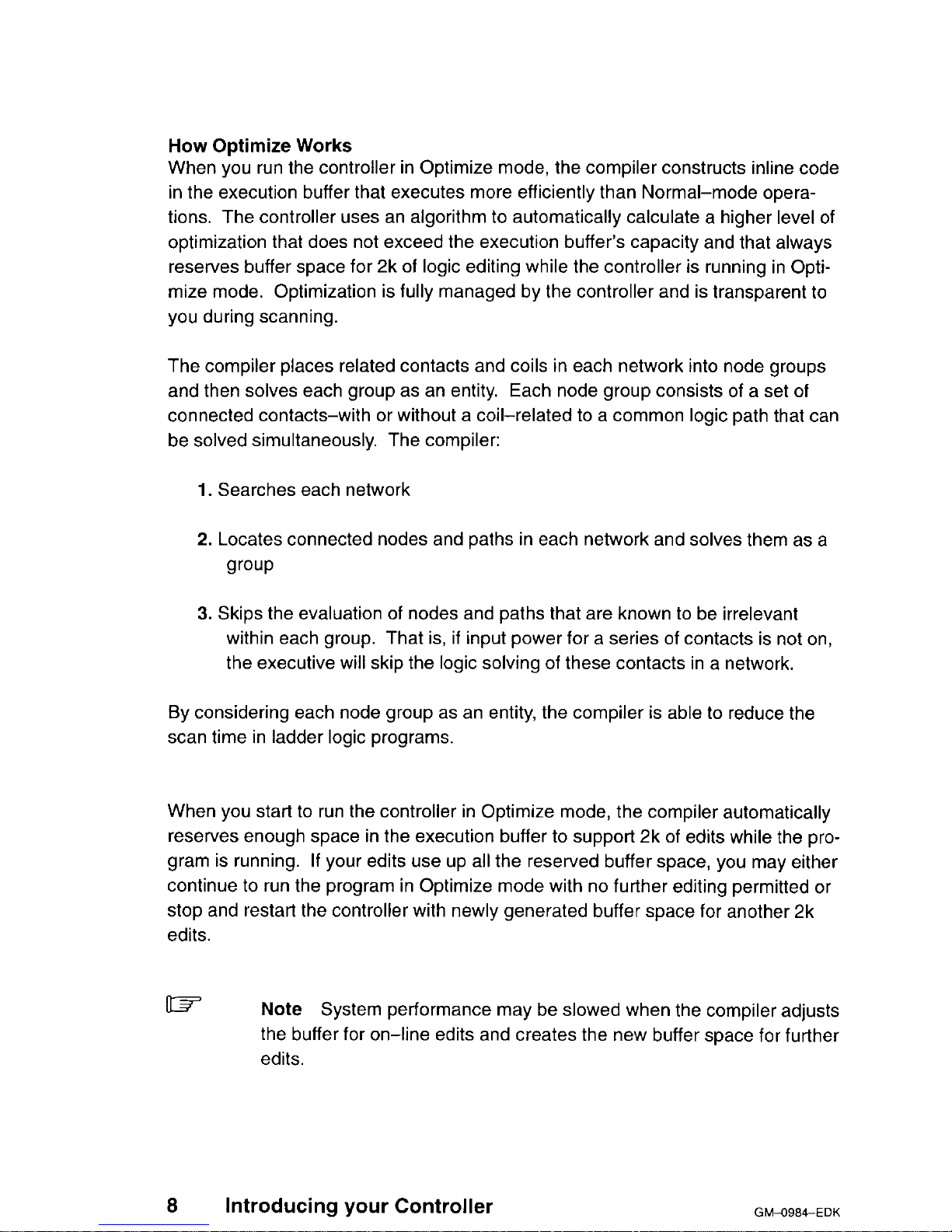

Local I/O

All of the Controllers support one local I/O drop in the form of Modicon 800 series

module housings. Local I/O processing is always Drop #I Total Local I/O pro-

vides for Discrete points configured in any mix and registers, refer to Table 1 for

memory configuration for each individual Controller.

Remote I/O

The 480E/485E/485K Controllers have up to 6 drops (one local and five remote)

for a total I/O support capacity of 1024 discrete I/O points (any mix). The

480E/485E/485K also support up to 5 RI/O drops (using the built-in S908 Remote

I/O Processor and optional J89O/P890 RI/O Adapters) with a maximum of 512

more discrete I/O points on one drop or spread over them all. Also, the

480E/485E/485K support a maximum of 2 ASCII ports per drop, up to a total maximum of 12 using optional J892YP892 RI/O ASCII Adapters. Please refer to

GM-0984RIO Modicon Remote l/O Cable System Planning Guide for more details.

The 685El785El785DI785K require a separate RI/O Head module with a plug-in

executive cartridge capable of supporting either 16/31 RI/O drops. The 16 RI/O

drops (using the Executive Cartridge AS-Ego&01 6 on the S908) have

1 Kin/l Kout (I/O bits). It can also support 31 RI/O drops (using the Executive Car-

tridge AS-E908-131 on the S908) with each drop having a maximum of

512in/512out (I/O bits). While the total I/O capacity is 65536 bits, only the first 16K

can be I/O mapped regardless of which S908 executive cartridge is used, (local Ii

0 bits maximum is 1 Kin/l Kout). The S908 Remote I/O Processor comes in two

versions: a single cable (AS-S908-ll O), or dual cable (AS-S908-120). Please

refer to GM-0984RIO Modicon Remote I/O Cable System Planning Guide.

These controllers also support a maximum of 2 ASCII ports per drop up to a total

maximum of 32 using optional J892/P892 RI/O ASCII Adapters. Please refer to

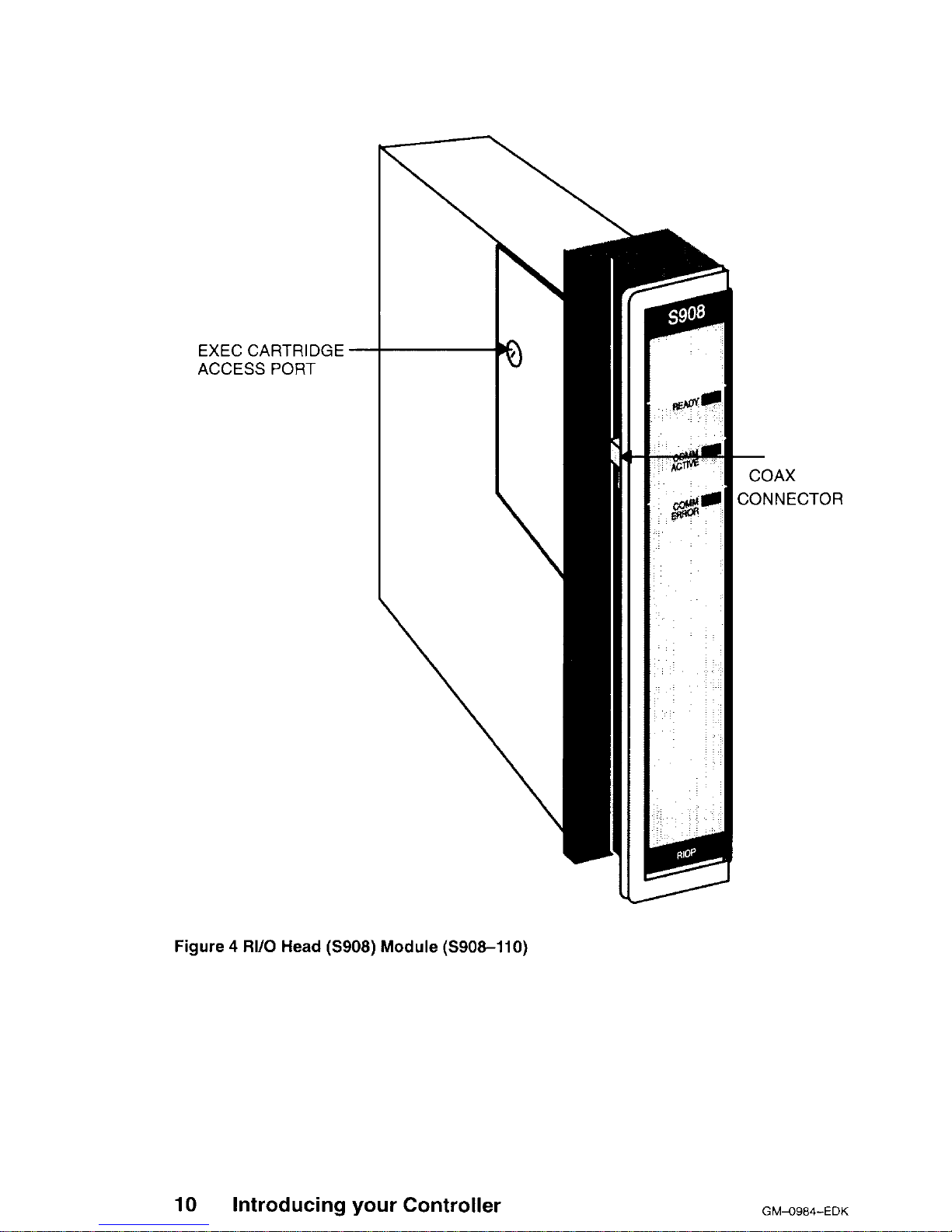

GM-0984-RIO Modicon Remote I/O Cable System Planning Guide for more details. Figure 4 is a perspective view of the RIOP module.

The RI/O interface will drive RI/O up to 5000 feet away (this distance can be increased depending upon the cable selection and certain other customer application considerations). Since the 5000 foot distance allows wide latitudes in system

layout and installation, substantial economies can be realized from carefully

planned layouts. Another planning requirement is to keep attenuation losses within

the system’s 35 dB dynamic range.

GM-0984-EDK

introducing your Controller 9

Page 24

EXEC CARTRIDGE -

ACCESS PORT

10

Introducing your Controller

COAX

CONNECTOR

Figure 4 RI/O Head (S908) Module (S908-110)

GM-O984-EDK

Page 25

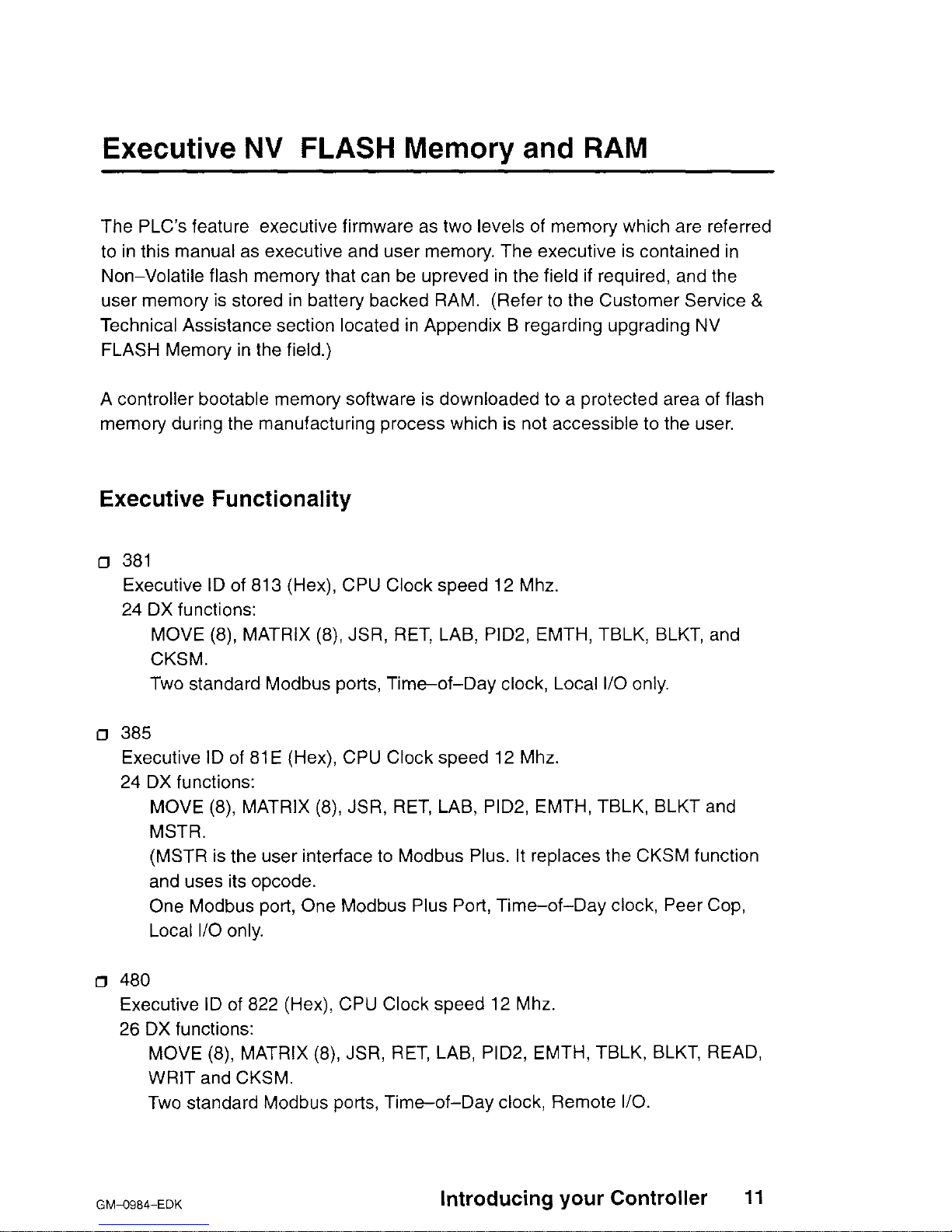

Executive NV FLASH Memory and RAM

The PLC’s feature executive firmware as two levels of memory which are referred

to in this manual as executive and user memory. The executive is contained in

Non-Volatile flash memory that can be upreved in the field if required, and the

user memory is stored in battery backed RAM. (Refer to the Customer Service &

Technical Assistance section located in Appendix B regarding upgrading NV

FLASH Memory in the field.)

A controller bootable memory software is downloaded to a protected area of flash

memory during the manufacturing process which is not accessible to the user.

Executive Functionality

381

Executive ID of 813 (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT, and

CKSM.

Two standard Modbus ports, Time-of-Day clock, Local l/O only.

385

Executive ID of 81 E (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT and

MSTR.

(MSTR is the user interface to Modbus Plus. It replaces the CKSM function

and uses its opcode.

One Modbus port, One Modbus Plus Port, Time-of-Day clock, Peer Cop,

Local I/O only.

480

Executive ID of 822 (Hex), CPU Clock speed 12 Mhz.

26 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT, READ,

WRIT and CKSM.

Two standard Modbus ports, Time-of-Day clock, Remote I/O.

GM-0984-EDK

Introducing your Controller

11

Page 26

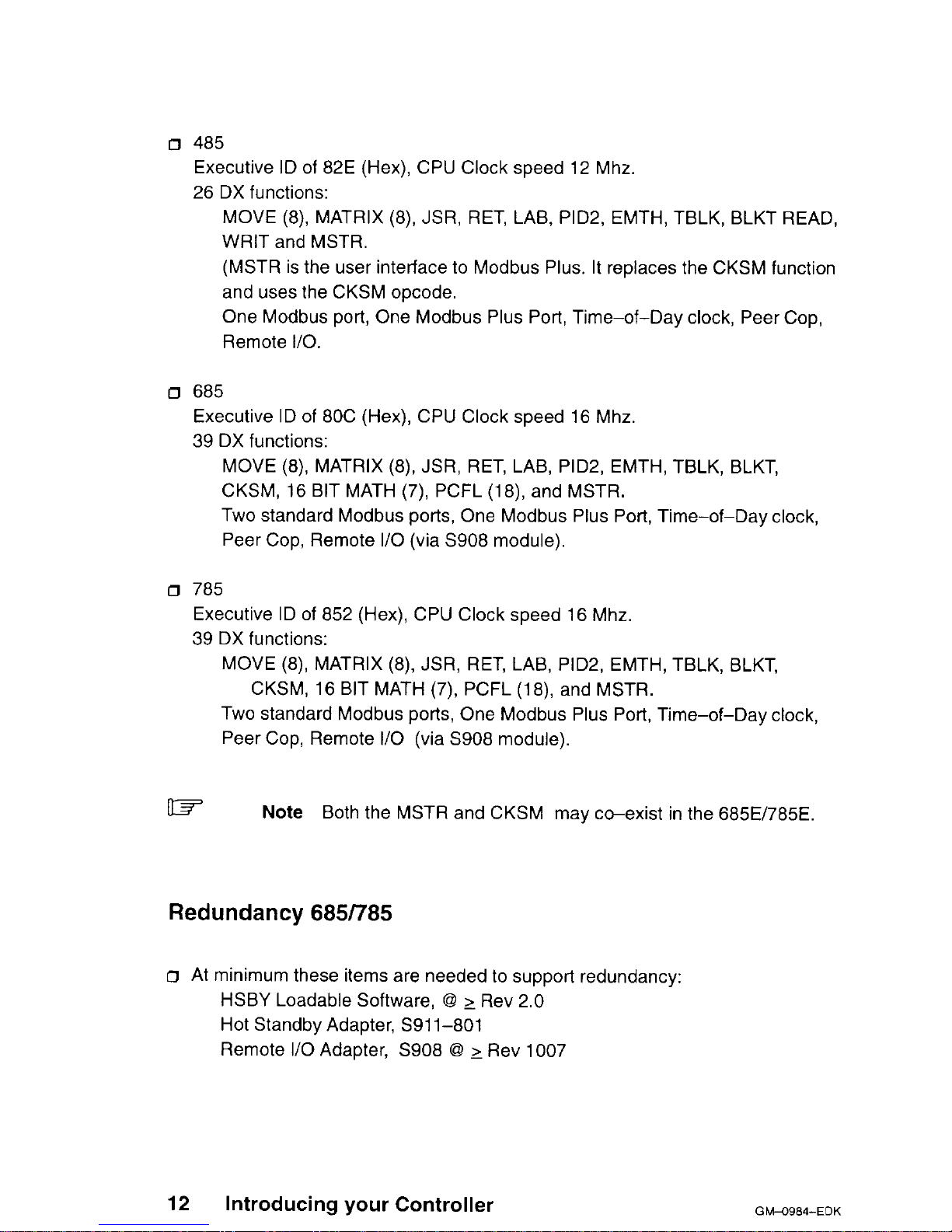

o 485

Executive ID of 82E (Hex), CPU Clock speed 12 Mhz.

26 DX functions:

MOVE (8) MATRIX (8) JSR, RET, LAB, PID2, EMTH, TBLK, BLKT READ,

WRIT and MSTR.

(MSTR is the user interface to Modbus Plus. It replaces the CKSM function

and uses the CKSM opcode.

One Modbus port, One Modbus Plus Port, Time-of-Day clock, Peer Cop,

Remote I/O.

IJ 685

Executive ID of 80C (Hex), CPU Clock speed 16 Mhz.

39 DX functions:

MOVE (8) MATRIX (8) JSR, RET, LAB, PID2, EMTH, TBLK, BLKT,

CKSM, 16 BIT MATH (7), PCFL (18), and MSTR.

Two standard Modbus ports, One Modbus Pius Port, Time-of-Day clock,

Peer Cop, Remote I/O (via S908 module).

o 785

Executive ID of 852 (Hex), CPU Clock speed 16 Mhz.

39 DX functions:

MOVE (8), MATRIX (8) JSR, RET, LAB, PID2, EMTH, TBLK, BLKT,

CKSM, 16 BIT MATH (7), PCFL (18) and MSTR.

Two standard Modbus ports, One Modbus Plus Port, Time-of-Day clock,

Peer Cop, Remote I/O (via S908 module).

UT

Note

Both the MSTR and CKSM may coexist in the

685E/785E.

Redundancy 685/785

o At minimum these items are needed to support redundancy:

HSBY Loadable Software, Q 2 Rev 2.0

Hot Standby Adapter, S91 I-801

Remote I/O Adapter, S908 8 1 Rev 1007

12

Introducing your Controller

GM+984-EDK

Page 27

IB

Note

For the 685E/785E only, the first 10K of registers, and the first

8192 inputs and 8192 coils, are transfered on a switchover.

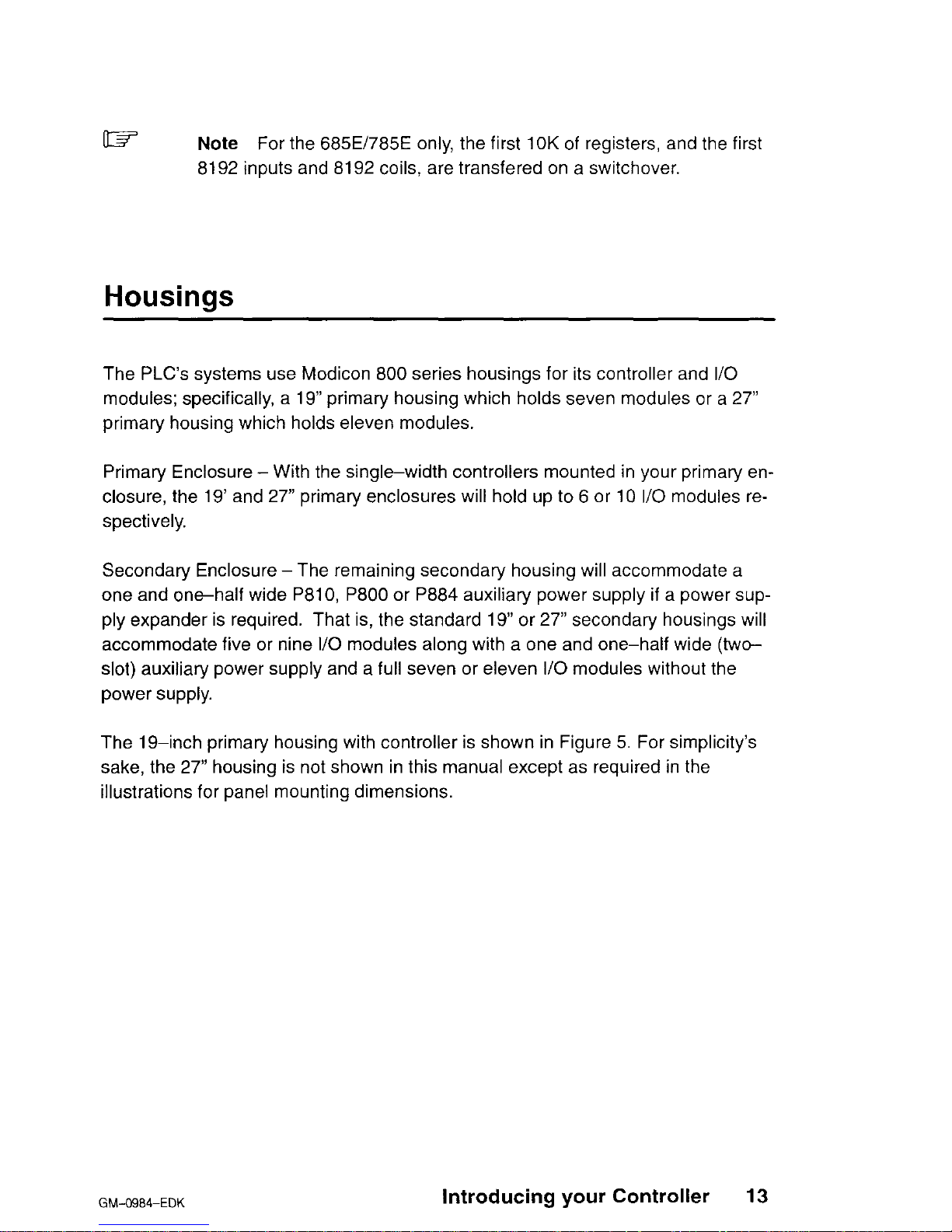

Housings

The PLC’s systems use Modicon 800 series housings for its controller and l/O

modules; specifically, a 19” primary housing which holds seven modules or a 27”

primary housing which holds eleven modules.

Primary Enclosure - With the single-width controllers mounted in your primary enclosure, the 19’ and 27” primary enclosures will hold up to 6 or 10 I/O modules respectively.

Secondary Enclosure-The remaining secondary housing will accommodate a

one and one-half wide P810, P800 or P884 auxiliary power supply if a power supply expander is required. That is, the standard 19” or 27” secondary housings will

accommodate five or nine I/O modules along with a one and one-half wide (twoslot) auxiliary power supply and a full seven or eleven I/O modules without the

power supply.

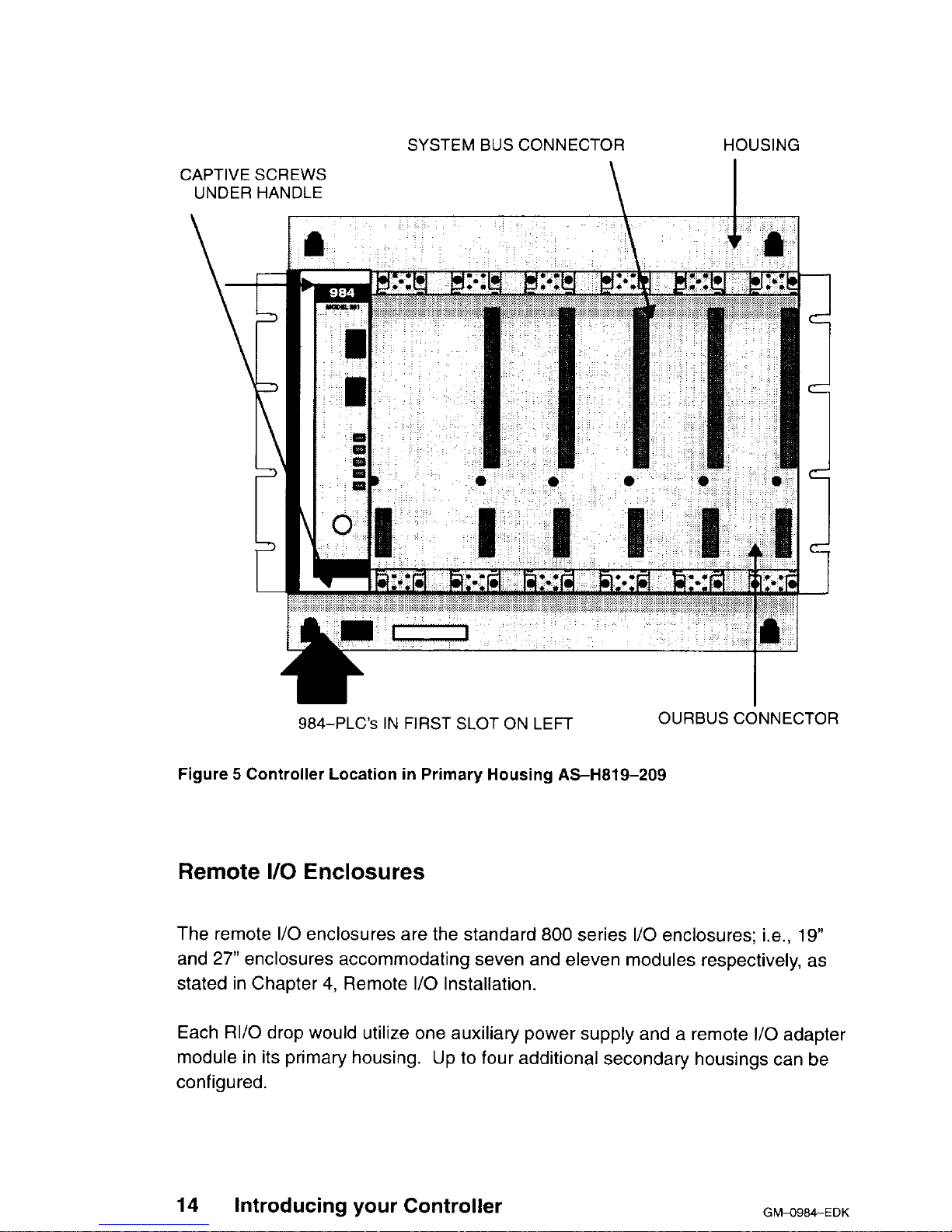

The 19-inch primary housing with controller is shown in Figure 5. For simplicity’s

sake, the 27” housing is not shown in this manual except as required in the

illustrations for panel mounting dimensions.

GM-O984-EDK

Introducing your Controller

13

Page 28

SYSTEM BUS CONNECTOR HOUSING

CAPTIVE SCREWS

UNDER HANDLE

\

I

984-PLC’s IN FIRST SLOT ON LEFT

OURBUS CONNECTOR

Figure 5 Controller Location in Primary Housing AS-H819-209

Remote I/O Enclosures

The remote I/O enclosures are the standard 800 series I/O enclosures; i.e., 19”

and 27” enclosures accommodating seven and eleven modules respectively, as

stated in Chapter 4, Remote I/O Installation.

Each RI/O drop would utilize one auxiliary power supply and a remote I/O adapter

module in its primary housing. Up to four additional secondary housings can be

configured.

14

Introducing

your Controller

GWO984-EDK

Page 29

Status Indicators

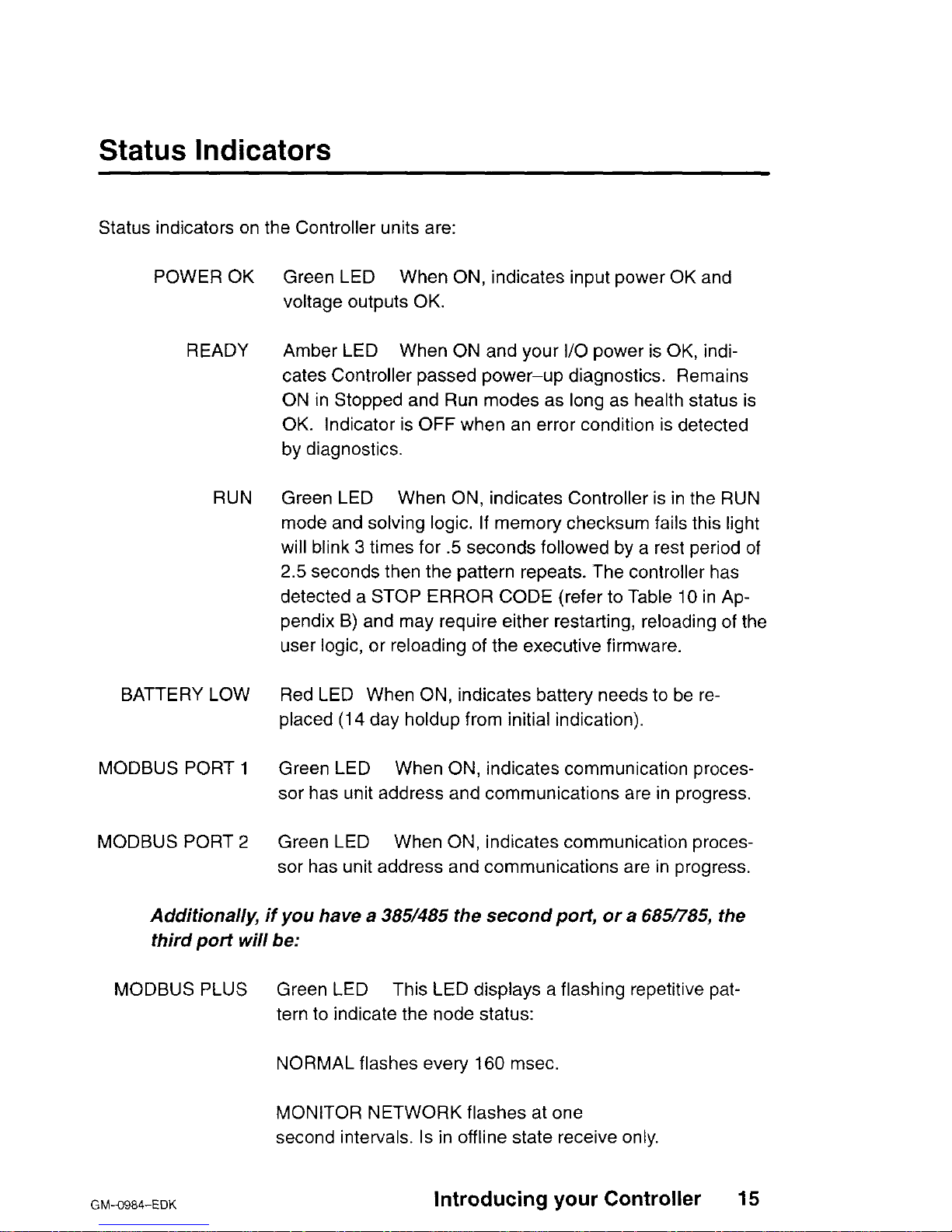

Status indicators on the Controller units are:

POWER OK

READY

RUN

BATTERY LOW

MODBUS PORT 1

MODBUS PORT 2

Green LED When ON, indicates input power OK and

voltage outputs OK.

Amber LED When ON and your I/O power is OK, indicates Controller passed power-up diagnostics. Remains

ON in Stopped and Run modes as long as health status is

OK. Indicator is OFF when an error condition is detected

by diagnostics.

Green LED When ON, indicates Controller is in the RUN

mode and solving logic. If memory checksum fails this light

will blink 3 times for .5 seconds followed by a rest period of

2.5 seconds then the pattern repeats. The controller has

detected a STOP ERROR CODE (refer to Table IO in Appendix B) and may require either restarting, reloading of the

user logic, or reloading of the executive firmware.

Red LED When ON, indicates battery needs to be re-

placed (14 day holdup from initial indication).

Green LED When ON, indicates communication processor has unit address and communications are in progress.

Green LED When ON, indicates communication processor has unit address and communications are in progress.

Additionally, if you have a 3851485 the second port, or a 6851785, the

third port will be:

MODBUS PLUS Green LED This LED displays a flashing repetitive pat-

tern to indicate the node status:

NORMAL flashes every 160 msec.

MONITOR NETWORK flashes at one

second intervals. Is in offline state receive only.

GM-0984-EDK

Introducing your Controller 15

Page 30

NOT RECEIVING TOKEN flashes two times then is off for

two seconds.

SOLE STATION flashes three times then is off for 1.7 seconds.

DUPLICATE NODE ADDRESS flashes four times then is

off for 1.4 seconds.

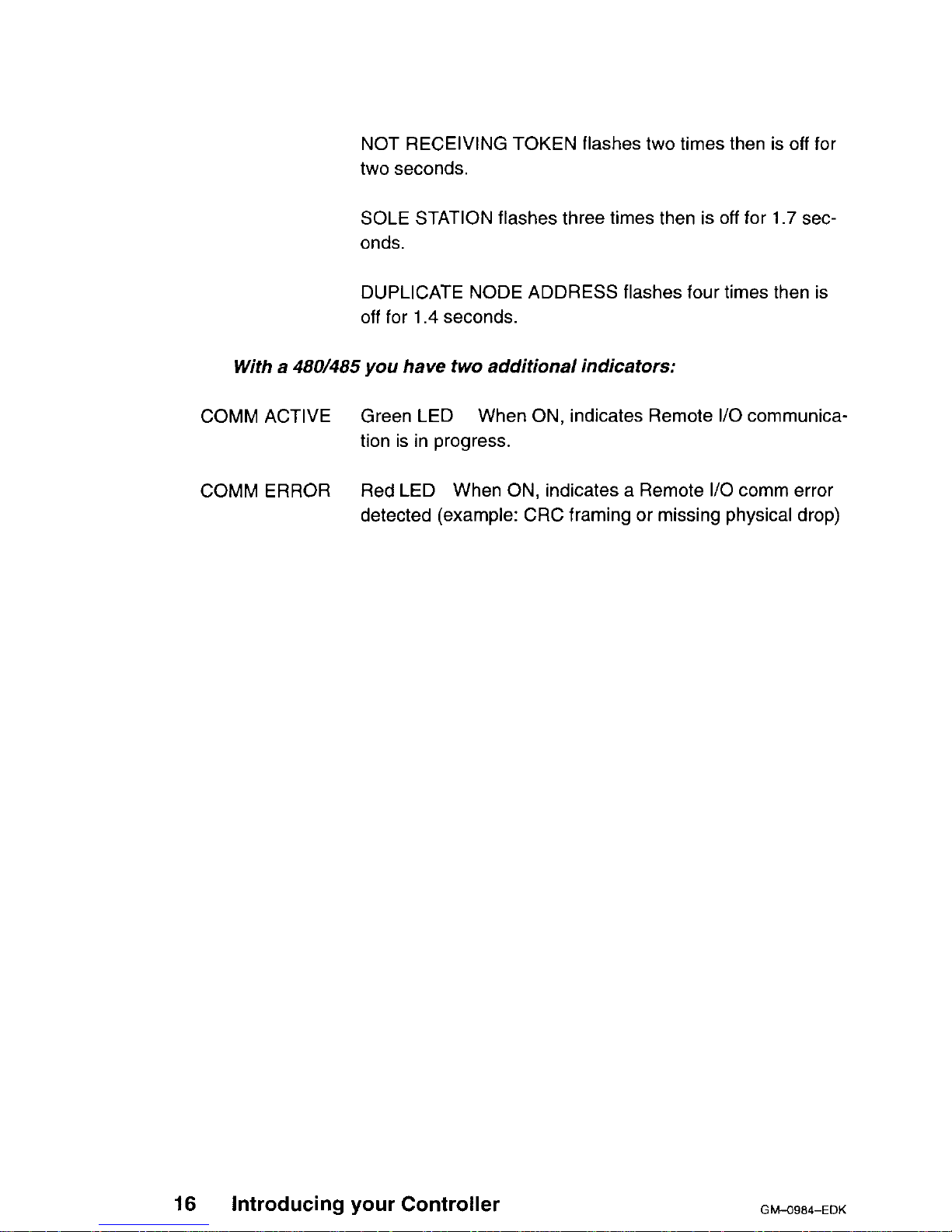

With a 480/485 you have two additional indicators:

COMM ACTIVE Green LED

When ON, indicates Remote I/O communica-

tion is in progress.

COMM ERROR

Red LED When ON, indicates a Remote I/O comm error

detected (example: CRC framing or missing physical drop)

16

Introducing your Controller

GM-O984-EDK

Page 31

Chapter 2

System Planning

0 Planning

o Housing Installation Options

o Grounding

o Power Supply Function (AC and DC)

o Communications Processing Function

GM-0984-EDK

System Planning

17

Page 32

Planning

Overview

The PLC’s are designed to work with your Modicon Programming panel software;

Modicon 800 series housings, interfaces and I/O modules.

The site planner must also consider the peripheral equipment (such as a Programmer, CRT monitor, or printer) when preparing an installation plan for the site. Refer to the appropriate Modicon publications for site preparation procedures for related equipment.

Space Requirements

For the primary housing, allow 12 inch clearance to the left so installer can see

power supply connectors. Allow 6 inches on the top and side of the housing for

convection cooling in vertical mounting situations. Allow 12 inch of clearance at

the bottom of the Controller for cable access.

For all other housings, allow 6 inches on the top and sides of each housing for unobstructed cooling airflow in vertical mounting situations.

Also consider installation and physical access for removal of the modules as well

as subsequent set-vice including the connection and detachment of signal and

power cables when required.

The primary housing may be separated up to 12 feet from the secondary housing.

Primary Power Lines

In addition to service access, distance to power sources has to be considered in

planning your controller installation. In addition to cable routing considerations,

good practices dictate that the power lines be dedicated to the Controller installation to minimize problems that sometimes arise when sharing AC power with electrically noisy equipment.

18 System Planning

GhMSS4-EDK

Page 33

Finally, plan to install a service loop and a cable restraint as the primary power

cable connector is not locked in place.

Environmental Requirements

In planning for the PI-C’s installation, consideration should be given to the environ-

ment around the controller. Although designed for a harsh industrial environment

and able to withstand factors that would harm other types of electronic equipment,

problems can be avoided by not placing the controller and its related equipment in

an operating area where there is high ambient temperature, acidic atmosphere, vibration, dust, and dirt if it can be avoided.

Mounting Hardware Requirements

After deciding on the final location of the Controller, its associated equipment and

cables, you should plan for related mounting hardware. This would include such

items as: nut and bolt combinations, flat and star washers, housings, mounting

surface, ground straps and system ground connections,

Mounting bolts are NOT provided. The recommended mounting bolts are

0.312-24 UNF-2B (insert or tapped) stainless steel (#8-13-SS).

GM-O984-EDK

System Planning 19

Page 34

Housing Installation Options

The PLC’s system housing can be panel/bulkhead mounted or rack mounted as

described in the following text.

Panel or Bulkhead Mounting

As shown in Figure 6 and Figure 7 below, the housing has keyholes at the top and

bottom of the housing for bulkhead mounting purposes. The keyholes are sized

for 5/l 6-inch bolts. The recommended ground point is also shown.

20

System Planning

Gb!-O984-EDK

Page 35

225.3

(8.87)

I

lndl’ T

342.9

(135)

7

f

ii!4

”

0

1

G-ROUND POINT

Figure 6 H819 Housing Panel or Bulkhead Mounting Dimensions

GM49846EDK

System Planning 21

Page 36

(“izz

(165iy

f

303.3

(11.941

1

687.7

(27.08)

645.2

(25.40) d

I

1

1 cl

-

-

-

-

-

I

GROUND POINT

Figure 7 Ha27 Housing Panel or Bulkhead Mounting Dimensions

T

225.3

(8.87)

10.4

(.41)

f

‘t

342.9

(13.50)

1

22

System Planning

GM-O984-EDK

Page 37

Rack Mounting

The H819 Module Housings can be mounted in a 1 C&inch standard (EIA) rack.

Optional hardware can be supplied for installing the “rack adaptor - mounting

flange kit”.

Figure 8 shows dimensions for rack mounting RI/O housing. The following hardware is required for rack mounting each housing:

o (1) 19-inch Standard (EIA) rack

CI (1) pair of rack mounting flanges

o (8) #lo-32, Pan Head Machine Screws to mount the housing to the NEMA rack

o (8) #I O-32 Flat Lock Nuts if mounting holes in rack’s side rails rails are not

threaded.

o (8) #8-32 Pan Head Machine Screws (supplied) to attach rack mount flanges to

ends of housing

o (8) l/4 bolts (supplied) to attach back of rack mount flanges back of housing

GM-O984-EDK

System Planning 23

Page 38

203

(7.99)

1!30.;~

(7.50)

+

234

(9.22)

381 E

S908 &ROUND POINT

Figure 8 H819 Housing Rack Mount Dimensions

Some planning considerations common to rack mounting for 800 series I/O

housings are:

24

System Planning

GM-O984-EDK

Page 39

1

Between housings, allow 12 inches below the primary

housing for cable breakout, physical inspection and ventila-

tion.

2 The cable length connecting the primary housing and sec-

ondary housing must not exceed 12 feet.

The modular chassis will fit in a 12-inch deep standard NEMA enclosure should

this be required (e.g., an acidic atmosphere in the factory).

07

Note

The only cooling available to the PLC’s is derived from natural

convection air flow. If the Controller is placed within a NEMA enclosure, some provision for added cooling may be required. The controllers should also be mounted vertically to ensure adequate convection

cooling of internal components.

GM4984-EDK

System Planning 25

Page 40

Grounding Your Installation

For grounding purposes, your PLC housing(s) should be mounted on a suitably

finished metal mounting plate capable of supporting its weight along with the other

modules in the installation. An aluminum mounting plate with a chromate finish

such as IRIDITE, ALODINE or OAKITE No.36 would provide a low frequency (AC)

safety ground path and a low impedance shield path for EMI/RFI.

If a metal mounting plate (the preferred method) is not feasible, all PLC housings

within each drop should be interconnected by a flat braided ground strap with a

minimum width of 1 inch. The ground strap should be short and installed without

loops and bends. Use stainless steel hardware including a flat washer to secure

the braid strap to the housing.

Regardless of the housing-to-housing method of ground interconnection, the entire installation should be grounded by a 1” wide (min) flat, braided cable installed

between the the primary housing ground connection point and a suitable factory

ground. This ground strap should also be short and installed without loops and

bends. The bulkhead and rack mounting illustrations show the housing’s recommended grounding point.

Power Supply Function (AC and DC)

The PLC’s come with a built-in power supply.

The 381 El385El480E/485E/485K

Controllers run on 97 through 276 VAC (47 to 63 Hertz) and 24Vdc. As shown on

Figure 9, Once connected, AC power is then switched ON/OFF with a front panel

rocker switch.

The PLC will also operate continuously on 24Vdc as its an alternate or exclusive

source. Figure 9 shows a primary power input connector for a customer supplied

24Vdc source. Once connected, DC power is then switched ON/OFF with a front

panel rocker switch.

26

System Planning

GM+3984-EDK

Page 41

r------

----

-‘-------1

AC POWER IN

1

I

AC

POWER 1

FWITCH

2

(BLACK) HOT

I

,

- (WHITE)

NEUT

,

- (GREEN) GND 1

I

DC POWER

I

SWITCH

AREA OF DETAlLj

_-_----

Figure 9 381 E/385E/480E/485E/485K Primary Power Input Conn.

As shown in Figure 10, the 685El785El785K runs on 115 or 230VAC (47 to 63H.z)

and/or 24VDC. The AC input, primary power variable is selected by means of a

customer installed jumper. The primary power input connector is located at the

front left side of the unit and shown on the drawing as “115V operation jumper”.

Once connected, AC or DC POWER is switched ON/OFF with a front panel rocker

switch.

GM-G984-EDK

System Planning

27

Page 42

I-

------------_-------___~

i

AC PQWER IN

AC POWER

SWITCH

/

(WHITE) NEUT

- (BLACK) HOT

- (GREEN) GND

7

11%

JUMPER

230V

OPERATIOF

+ WITHOUT

JUMPER

/

SWITCH

DC

POWER ,

--I-

I

DC POWER IN ,

-I

i

AREA OF DETAIL,

-----__

E984

CONTROLLER

Figure 10 685E/785E/785K Primary Power Input Connections

The 385D/785D input can range from 105 to 150 VDC with the nominal at 125

VDC controlled by a front panel rocker switch. The 24 VDC option is also available. The 385D I/O capacity is 18.75W maximum using 3.5Amps, while the 785D

I/O capacity is 60W maximum using 7 Amps.

28

System Planning

GM+3984-EDK

Page 43

Note

The primary power AC/DC input feature was not designed, nor

is it suitable as an automatic battery backup provision in the event of

an AC/DC outage. This is because the controller’s externally sourced

input joins with the, internally produced DC. At any given time, the

Controller is taking from the higher of the two voltage sources if there

is as little as a 1V differential. The consequence of this would be to

draw down the DC battery if there were an extended period(s) of reduced AC/DC voltage supply.

If you want a backup alternative, one could be configured from a user-supplied

DC power supply with its own backup battery and charger combination along with

appropriate monitoring provisions.

Primary Power Cable (AC/DC)

Ideally, the input AC/DC power lines should be dedicated to the PLC installation to

minimize problems that arise when sharing AC power with electrically “noisy’

equipment.

Provide for strain relief by installing a service loop and cable restraint on the primary power cable as its connector is not locked in place.

AC Power

Cable

The recommended AC power cable should consist of three insulated leads of

Number 14 AWG stranded copper. The cable leads insert in the plug-in power

cable connector shipped installed in the AC input connector jack from the factory.

The color code (standard) for the AC cable is white for AC neutral, black for AC

hot, and green for factory or earth ground. The European color code is light blue

instead of white for neutral, brown instead of black for the hot wire, and green/yellow instead of green for ground.

Your AC source cable must be suitable for supplying 115/230 Vat at 5A peak for

the turn-on surge and 0.4 continuous at worst-case, low voltage conditions at

60” c.

GMA3984-EDK

System Planning 29

Page 44

w

Note

Factory and earth grounds often have different potentials; e.g.,

building steel versus grounding rods.

DC

Power Cable

The recommended DC power cable should consist of three insulated leads of

Number 18 AWG stranded copper, The cable leads insert in the plug-in power

cable connector shipped installed in the DC input connector jack from the factory.

If you are planning DC backup, note the discussion under “Power Supply Function,“section 1.

Note also, that your external DC input should go directly to the

controller from the power source and not involve your I/O.

Communications Processing Function

Communications options vary from model to model. Modbus, Modbus and Bridge

mode, or Modbus Plus and Bridge mode, are available using a combination of

hardware DIP switches and software as discussed below.

Table 3

Communication Options per PLC

PLC

Comm Ports

381E

385E

385D

480E

485E

685E

785E

785D

785K

2 Modbus

1 Modbus & 1 Modbus

Plus

1 Modbus & 1 Modbus

Plus

2 Modbus & RI/O

1 Modbus & 1 Modbus Plus & RI/O

1 Modbus & 1 Modbus Plus & RI/O

2 Modbus & 1 Modbus

Plus

2 Modbus & 1 Modbus

Plus

2 Modbus & 1 Modbus

Plus

2 Modbus & 1 Modbus

Plus

30

System Planning

GM4984-EDK

Page 45

381 E/385Ef385D/480E/485E/485K

Comm Switch Configuration for MODBUS, Ports

MODBUS Port 1 is software configurable or will default to preset parameters de-

pending on the position of the three position toggle switch, located on the lower left

side panel behind the module handle. For software configuration, put the MEMDEFAULT-MODEM switch in the MEM position and use

your panel to select the

communications parameters required.

In the

“Default” or “Modem” positions you will power up with the following parame-

ters:

Table 4 Port 1 Configuration

381 E/385E/385D/480E/485E/485K 3851485 ONLY

MEM

DEFAULT

MODEM

Port 1 Communication Parameters Taken from

Configuration Table

Port 1 Communication Parameters are:

RTU, 9600 BAUD, Even Parity, 1 Stop Bit

Address is set on Dip Switch underneath

if 3851485 or is 1 if 3ai/480.

Port 1 Communication Parameters are:

ASCII, 2400 BAUD, Even Parity, 1 Stop Bit

Address is set on Dip switch underneath

if 3851485 or is 1 if 3811480

Bridge Mode capable only

if Panel programmed this

option (Default is NO Bridge

Modej

Bridge Mode capable

without panel intervention

(i.e. automatic)

Bridge Mode capable

without panel intervention

(i.e. automatic)

The second Modbus Port on the 3811480 is configurable only by using your programming panel.

Modbus

Port Software Configuration

You

can use Modicon Modsoft programming panel software to set an internal

memory variable for either Modbus

port 1

or

port

2 (when the MEM/DEFAULT/

MODEM slide switch is in MEM). Refer to Figure

11.

GMd?984-EDK

System Planning 31

Page 46

--

AREA OF DETAIL

--

J

CONTROLLER

Figure 11 MEMlDEFAULTlMODEM DIP Switch

For convenience, a summary of Modsoft screens showing the communications parameters available is presented here. From the Main menu you select the “Of-

fline” “Select

Program or

New

Program” entry and then select Config from the Status

screen, the results are illustrated in Figure 12. With the cursor on the Ports selection press the J key to display the port parameter screen.

32

System Planning

GM!J984-EDK

Page 47

Itllfty

0V8rV f W f/&+

Sagnnts Loadable Cfg Ext Quit

'1-z--

4-k

“7-L8V

G-f%-DFF--F"

CONFIGURRTlI

ze of Full Logic iwea 15396

PLC :

of I/O Map Words

88815

PLc T)ffl8

989 - #sE

Exec Pack

Meatory

i%K

Entttnded

Memory

II

Redundant

DCP Drop ID

8CiS1S :

Stt3Fy call

&____

Ranges :

P

her Register

+__-_

axxxx

G8BEif - 81536

Tim8 of Day Clack

+__--

1XXXX leeef -

18512

?KXXX 38891 -3G343

4xxxx 48881 - 41372

4xxxx far SFC blow

-I

Utility Default Brfdge

Quit

F1+2--W-6

7-Lev &%-OFF--F~

PORTS

Bridge Mode: N

Nunber Mode Data Bits Parity Stop Bits Baud Keyboard Address Delay

/I

MDDEUS

El

82

RTU 8

RTU 8

EVEN

EVEN

1

960E

1

9688

1 18 m

1

10 m

‘In

Figure

12 Communication

Port

Selection Screen

You can fill in the data fields as you require. Pressing the ? key while on a field

displays a parameter list for that field.

A

!

Caution Port 2 does not support the following parameters: 2

stop bits with RTU and parity; 1 stop bit with ASCII and no parity.

Modbus Plus Node Address Setting (385/485 ONLY)

These node address switches are the first 6 Dip’s shown in Figure 13, and viewed

from the bottom of the unit. Switches One through six can be set to the binary bit

pattern 000000 through 111111 which are the equivalent of decimal 0 through 63

GWO984-EDK

System Planning 33

Page 48

respectively. To derive the node address add “I” to the binary. The default shown

in Figure 13 is the binary 0 which is node address 1. To change to an address of 2,

place the LSB switch “Toward the number” (000001) etc. The 8 position DIP

switch for setting the Modbus Plus port address is located at the bottom of the unit

casing. Refer to Figure 13.

Lw

Note

The 381/480 models do not have an 8 position DIP Switch.

CONTROLLER MODULE BOTTOM VIEW

REAR

PCB

/

FACTORY SETTINGS:

DIP

SWITCH

UP (off\

FUNCTION

St

DOWN (On:

PCB

I

LSB

Node Addressing

MSB

I

I

Dl; SWITCH 7 & 8

(SW1-6, Modbus

ARE NOT USED

Plus Node Only)

Figure 13 DIP Switch for Modbus Plus Node (385/485

ONLY)

Modbus Pius Bridge Mode (3851485 ONLY)

A communications Bridge mode is a standard feature which allows access to the

Peer network in DIP mode. Using this mode you can program or monitor any individual node on the Modbus Plus Network using a program panel connected to

modbus port 1.

34 System Planning

GM-O984-EDK

Page 49

When

the Mem/DefaultiModem

DIP switch is in the MEM position the bridge mode

can also be enabled or disabled by using the panel software “Offline” ‘Configuration” “PORTS’ Bridge subfunction.

Using MSTR Block To Change Modbus Plus Address

You

setup the MSTR block by transitioning the enable input ON for one scan.

The MSTR function Done output passes power in the same scan (assuming no errors). There will be a delay of up to IO seconds in the availability of the newly addressed Controller due to the time required fully implement the change including

m-initializing the link.

If you hold the MSTR block enabled for more than one scan, the Change Address

Command is issued for each scan so enabled. This results in a race condition

locking the controller out of effective operation.

Part of the process of implementing the Change Address Command allows testing

for:

If the specified address equals 0

If the specified address is greater than 64

If the specified address is equal to the current address.

In each true case the PEER Processor ignores the Change Address Request but

remains available to the host processor.

Modbus Plus

Node

Address Software Change (385/485

ONLY)

The on board dip switches as shown in Figure 13 are read by the PEER PLC at

power-up to determine what the Node address is. This setting stays in effect until

a power-cycle with new settings or a software controlled “Change Address Com-

mand” is issued to the PEER PLC. The Ladder Logic implemented MSTR Block is

the mechanism by which you issue the proper command.

cl7

Note

The Controller in which you want to change the Node address

must be running.

MSTR

Format

You

can issue the “Change Address Command” using the ladder logic MSTR DX

block. Figure 14 is an example of a Modsoft screen with MSTR block.

GM-0984~EDK

System Planning 35

Page 50

Elements Edit

Go/Srch Network

F3-F4-F5-F6-

Figure 14 MSTR Block on Modsoft screen With Input/Output Labels

a The top node (40100 in the example) defines the first of a nine register block

that contains:

4-m-r Operation Type

4-m-T+1 Error Status

4TTTT+2

Pattern

1

4ll-l-r+3 Pattern 2

4-m-l-+4 Pattern 3

FFFF Hex Change Address Command

See Appendix C for Error Codes

1234 Hex

5678 Hex

XXAA Hex where xx = 00 for builtin

01 for 5985 #I

02 for S985 #2

4TTTT+5 Pattern 4

4lll-T+6

Pattern 5

4TTTT+7 Pattern 6

4l-TTT+8

Pattern 7

XXBB Hex

XXCC Hex

XXDD Hex

XXEE Hex

When the Error output passes power, the content of the Error Status register contains an error code to help you determine the cause of the error.

These registers provide a margin of safety against inadvertent change of address.

The values in these seven registers MUST contain exactly the above data or an

error will result.

o The middle node (40200 in the example Figure 14) contains the new address.

The new address can be a value between 1 and 64.

36

System Planning

GhWB84-EDK

Page 51

o The bottom node (a value of 1 in the example) may be set to any value from 1

to 100 but only one address is involved from the middle node.

Port Delay Timer

Each Modbus port (one or two) can be assigned a time delay value from IO

milliseconds to 200 milliseconds in duration. You use the Modsoft configurator

PORTS menu to do this.

685El785El785Dl785K

Comm Switch Configuration for MODBUS, Ports

MODBUS Ports 1 and 2 are software configurable, but through-thechassis, user

accessible DIP switch has been provided to manually configure Modbus Port 1 on

the 984 CPU. The second port is software configurable only. The MEM (software)

DIP switch (default) is enabled (even while operational) using a toggle switch lo-

cated on the controller side panel.

rw

Note

The switch used for Modbus Port 1 fixed defaults is selected by

opening (off) or closing (on)

DIP switch 8.

In the “Default” or “Mem” positions you will power up with the following parameters

in Table 5:

GM-O984-EDK

System Planning 37

Page 52

Table 5

Port 1 Configuration

685El785El785Dl785K

685l785 ONLY

MEM

DIP

DIP/

DIPSW8

Port 1 Communication Parameters Taken from

Configuration Table

Port 1 Communication Parameters are:

RTU, 9600 BAUD, Even Parity, 1 Stop Bit

Address is set on Dip Switch underneath

if 6&X%5.

Port

1 Communication Parameters are:

RTU, 2400 BAUD, Even Parity, 1 Stop Bit

Address is set on Dip Switch underneath

if 68W85.

Bridge Mode capable only

if Panel programmed this

option (Default is NO Bridge

Mode)

Bridge Mode capable

without panel intervention

(i.e. automatic)

Bridge Mode capable

without panel intervention

(i.e. automatic)

The second Modbus Port on the 68.51785 is configurable only by using your programming panel.

Modbus Port Software Configuration

You

can use Modicon Modsoft programming panel software to set an internal

memory variable for either Modbus port 1 or port 2 (when the MEM/DIP slide

switch is in MEM). Refer to Figure 11. The two settings available are:

RTU, 9600 baud, Even Parity, 1 Stop bit, (switch 8 in the position shown in

Figure 17) or, ASCII, 2400 baud, Even Parity, 1 Stop bit, (switch 8 position

“down”).

w

Note

When the MEM/DIP enable slide is returned to MEM position,

Port 1 comm parameters and link address return to original memory

configured values after a power cycle.

38

System Planning

Gh4-0984-EDK

Page 53

r

--

MM

I

I

DIP

AREA OF DETAIL

--

J

CONTROLLER

Figure 15 MEM/DIP DIP Switch

For convenience, a summary of Modsoft screens showing the communications parameters available is presented here. From the Main menu you select the “Offline” “Select Program or New Program”

entry and then select Contig from the Status

screen, the results are illustrated in Figure 12. With the cursor on the Ports selection press the J key to display the port parameter screen.

GM-0984-EDK

System Planning 39

Page 54

:ility

Segmnts Loadable Cfg Ext Quit

1+2+3+4

F6+7-Lev 8-F&OFF-F9-

ize of Full Logic Area 15396

PLC

:

.

of I/O Map Words

00015

PLC Type

Exec Pack

800

Memory

unber of Segments

32

Extended Memory

0 Drops / Channel Pairs 1

Redundant

1

DCP Drop ID

ISpecials

:

Battery Coil

0_----

Ranges

Timer Register

4__---

BXXKX BE001 - 01536 Time of Day Clock

4____-

lxxxx

lE001 - 10512

3xxxx

30001 - 30048

4xxxx

48001 - 41872 ASCII:

4xxxx for SFC None

Number of Messages

0

Message Area Size

0

Number of ASCII Ports 0

Bxxxx for SFC None

Simple ASCII Output

I

Simble ASCII Inpbt

I/O Map is the traffic cop which links the I/O modules to program logic.

w

Utility

Default Bridge

Fl-F2-F3-F4-FS-F6-

F7-Lev 8-F8-OFF-!;it

PORTS

Bridge Mode: N

Number Mode

Data Bits Parity Stop Bits Baud Keyboard Address Delay

MODBUS

/I

1

02 01 RTU RTU 8 8

EVEN EVEN 1 1 3600 3600 1 1 10 10 m m

I

Figure 16 Comm. Port Selection

Screen

(485E Example)

You can fill in the data fields as you require. Pressing the ? key while on a field displays a parameter list for that field.

A

I

Caution Unsupported Parameters are: 2 stop bits with RTU and

parity; 1 stop bit with ASCII and no parity.

40

System Planning

GM-O984-EDK

Page 55

Modbus Plus Node Address Setting (685R85 ONLY)

These node address switches are the first 6 Dip’s seen below, and viewed from

the bottom of the unit. Switch 7 is not used, switch 8 is the Modbus default select

switch. Switches one through six can be set to the binary bit pattern 000000

through 111111 which are the equivalent of decimal 0 through 63 respectively. To

derive the node address add “1” to the binary. The default shown in Figure 13 is

the binary 0 which is node address 1. To change to an address of 2, place the LSB

switch “Toward the number” (000001) etc,. The 8 position DIP switch for setting

the Modbus Plus port address is located at the bottom of the unit casing. Refer to

Figure 13.

CONTROLLER MODULE BOTTOM VIEW

FRONT

/

FACTORY SETTINGS: \

DIP

UP (off)

SWITCH

t-

FUNCTIONS DoWN ton)

PC6

I

LSB

Node Addressing

MSB

(SWl-6, Modbus

I

Plus Node Only)

Figure 17 DIP Switch for Modbus Plus Node (685/785 ONLY)

To familiarize you with the switch settings, Table 6 provides you with the first 16

addresses. Only the UP is shown all others are down.

GM4984-EDK

System Planning

41

Page 56

Table 6 Partial Modbus Plus Address

Examples

1

2

_

UP

UP

_

UP

_

UP

_

UP

_

UP

_

UP

UP

_

-

UP

UP

UP

UP

UP

_

_

UP

UP

_

UP

UP

3

_

_

_

UP

_

UP

UP

-

_

_

UP

UP

UP

UP

4 5 6 Address

_ _

_ 1

_ 2

_ 3

4

_ 5

6

7

_ 8

UP 9

UP

10

UP

11

UP

12

UP

13

UP

14

UP

15

UP

16

42

System Planning

GMa984-EDK

Page 57

Chapter

3

System Installation

o Panel/Bulkhead Mounting

o Rack Mounting

o Field Wiring

o I/O Module

0 Power Supply

o RI/O Head/Receiver

GM-0984-EDK

System Installation 43

Page 58

Panel/Bulkhead Mounting

As shown in Figure 18 and Figure 19 below, the housing has keyholes at the top

and bottom of the housing for bulkhead mounting purposes. The keyholes are

sized for 5/l 6-inch bolts. The recommended ground point is also shown.

Procedure

Step 1

Step

2

Step

3

Panel/Bulkhead Mounting Installation

Install and ground your bulkhead mounting surface for

Drop 2.

Layout your drop based on your RI/O configuration diagram

and installation plan.

Install l/4 inch inserts into the panel or metal mounting sur-

face for your primary housing as shown in Figure 18 and

Figure 19.

44

System Installation

GMa984-EDK

Page 59

5.5 --I

C.22)

+

T

303.3

(11.94)

1

15.7

(.62)

-

0”

1

c

--A

c

10.4

(.41)

f

3

342.9

(13.5)

Power RIO Adapter

I

SUPPlY

GROUND POINT

Figure 18 Remote l/O H819 Panel/Bulkhead Mounting Dimensions

GMa984-EDK

System Installation 45

Page 60

225.3

(8.87)

687.7

POWER

R I/O

GROUND POINT

SUPPLY

Figure 19 H827 RI/O Housing Panel/Bulkhead Mounting Dimensions

Step

4

As shown in Figure 20 below, attach the primary housing to

its mounting surface by inserting the required number of

l/4-inch bolts. (H819 requires four bolts in the housing’s

mounting flange.) Also install cable troughs for your RI/O

module slots.

46

System Installation

GMa984-EDK

Page 61

DETAILED VIEW

MOUNTING SURFACE

HOUSING

MOUNTING SURFACE

Figure 20 Attach Housing to Mounting Surface

Step

5

Repeat

Steps

(3) and (4)

above for each housing

in Drop 2.

GM-O984-EDK

System Installation

47

Page 62

Step

6

Using appropriate lengths, connect your W801 signal cable

and W802 power cable (use W804 auxiliary power cable

when required) between the signal and power connector

ports at the top and bottom of each housing as shown in

Figure 21. Make sure the cable ground lug is attached to

Housing Ground Point.

48

System Installation

GMA3984-EDK

Page 63

UPPER

FLANGE

PRIMARY

HOUSING

FEMAL

POR

I llltlllllllll

POWER CABLE GROUND POllvT

_ UPPER

FLANGE

W802 OR

W8

+-W801 SIGNAL CABLE

SECONDA

HOUSING

FEMALE- _

PORT

LOWER

t ] FLANGE

I-

f f

POWER CABLE GROUND POINT

W802 OR WE08

W801 SIGNAL CABLE

POWER CABLE

IRY

Figure 21 Connecting Cables within Each Drop

GM-O984-EDK

System installation 49

Page 64

Step 7

Ground all W802 power cables to each housing’s ground

point in the drop as shown in Figure 5-1 preceding. The

grounding lug requires a #lO machine screw.

Step

8

Repeat Steps (1) thru (7) above for all remaining RI/O

drops.

Rack Mounting

The H819 Module Housings can be mounted in a 1 g-inch standard (EIA) rack.

This requires installing a rack adaptor mounting flange kit. Figure 22 shows the

housing’s rack mounting dimensions.

The following hardware is required for rack mounting each housing:

o (1) Rack mounting adaptor kit which includes: a pair of rack mounting flanges;

(8) #8-32 Pan Head Machine Screws (supplied) to attach rack mount flanges to

ends of housing; (8) l/4 bolts (supplied) to attach flange kit to back of housing.

o (8) #lo-32, Pan Head Machine Screws to mount the housing with flange adap-

tor to NEMA rack.

o (8) #lo-32 Flat Lock Nuts if mounting holes in rack’s side rails rails are not

threaded.

Other special mounting hardware may be required depending upon the installation site.

50

System Installation

GM-O984-EDK

Page 65

203

(7.99)

4

76.6

(3.02)

57.’

II;

(2$

1 3.3

( .25)

190.5

(7.50)

12.7

(.50)

BOTH SIDES

-

234

(9.22)

3

P810 J890

dROUND POINT

Figure 22 H819 Housing Rack Mount Dimensions

GM-O984-EDK

System Installation 51

Page 66

Procedure Rack Mounting Installation

Step 1

At Drop 2, using #8-32 mounting hardware shown in

Figure 23, replace the primary housing’s two end plates

with rack mounting flanges.

Step

2

Use l/4-inch bolts (supplied) attach each flange to the

housing’s back panel.

Step

3

When the rack mount flange is installed, ensure that contact with the back plate of the housing makes a good

ground.

LEFT FLANGE

Figure 23 Attaching Rack Mounting Flange to Housing

52

System Installation

GMq984-EDK

Page 67

GhM984-EDK

Step 4

To attach the module housing to the rack as shown in

Figure 24, lift the empty module housing to its mount position in the rack and insert the mounting screws. Use

#l O-32 pan head screws to attach the module housing to

the rack. Install cable troughs for all Remote I/O modules.

System Installation

53

Page 68

MOUNTING SCREWS

TYPICAL ON BOTH SIDES

Figure 24 Rack Mounting Your Housing

Step 5

Repeat Steps (1) thru (4) above for all remaining housings

within Drop 2.

54

System installation

GMa984-EDK

Page 69

Step 6

Step 7

Step 6

Step 9

Using appropriate lengths, connect your W801 signal cable

and W802 power cable (use W808 auxiliary power cable

when required) between the signal and power connector

ports at the top and bottom of each housing within the drop

as shown in Figure 21.

Ground each W802 power cable to the housing’s ground

point shown earlier in Figure 18. The grounding lug re-

quires a #I 0 machine screw.

Ground your rack for Drop 2 to the best possible ground following good practices.

Repeat Steps (1) thru (8) above for all remaining drops ac-

cording to plan.

Procedure Connecting Your Field Wiring

Field wiring should be in place before the I/O modules are inserted into the racks.

During installation, the slot to the left of the slot being wired must be empty.

As shown in Figure 25, field wiring is routed through the wire trough to the terminal

block. There are field wiring terminal screws on each terminal block. User field

wiring crosses from the left side into the wire connectors. Each terminal can ac-

cept as many as four #22 AWG wires, as many as two #14 AWG wires, or a single

#I 2 AWG wire. The wires can be solid or stranded.

GMG984-EDK

System Installation

55

Page 70

Figure 25 Field Wiring to Terminal Strip (20 Pin Shown)

56 System Installation

GM-0984-EDK

Page 71

GM-O984-EDK

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

If you already have a Power Supply installed, ensure it’s

OFF and will remain OFF.

Bring field wiring to last housing in the Drop.

Fan-out your cable breakout and lay it in the cable trough

for rightmost I/O module slot on housing.

Open the wire connectors by turning the recessed terminal

screws CCW.

Insert the field wires into the wire connectors and tighten

the terminal screws.

Repeat Steps (3) thru (5) for each slot in last housing.

Repeat Steps (1) thru (6) above for each housing in the

Drop.

Repeat Steps (1) thru (7) above for each remaining Drop

System Installation

57

Page 72

I/O Module Insertion

The I/O modules insert into designated slots. They connect to each other within

the housing by way of the backplane connectors. The I/O connectors mounted on

the I/O modules mate with the terminal block connectors mounted on the housing.

Each module has two captive screws which secure it to the housing. Figure 26

shows the I/O module insertion.

Procedure l/O Module Installation

Step 1

At Drop, insert key pins in last housing according to plan.

Step

2

insert last I/O Module jn rightmost slot of last housing in

Drop.

Step

3

Secure I/O module with captive screws.

Step

4

Working right to left, repeat Steps (2) and (3) above for all

remaining I/O slots in last housing.

Step 5

Repeat Steps (1) thru (4) above for all housings in Drop.

Step

6

Repeat Steps (1) thru (5) above for all remaining drops.

w

Note

Initial module, auxiliary Power Supply or Remote I/O adapter installation, may be difficult, as the bullpin ground spring has to be expanded over the housing bullpin. If difficulty in seen, carefully rock the

module in the housing, until seated over the bullpin.

58

System Installation

GMa984-EDK

Page 73

HOUSING

CAP7

‘IVE SCREWS

(UND

SYSTEM BUS

CONNECTOR

OURBtiS

CONNECTOR

BULLPIN

Figure 26 800 Series RI/O Module Installation

Warning

800 SERIES i/O MODULES MUST NOT BE REMOVED

AND REPLACED (HOT-SWAPPED) WHILE THE POWER SUPPLY

MODULE IS ENERGIZED (ON).

GMa984-EDK

System Installation 59

Page 74

Power Supply

Your PLC and 800 remote I/O power supply (P810) module goes in the first slot of

the primary housing in each drop. The power supply passes power to the I/O

modules within its housing via backplane connectors and from housing to housing

within the drop via a W802 power cable(s) The W804 Auxiliary power cable is

used to send switching signals (IOPCH) into a housing that has its own auxiliary

power supply.

The power supply module shown in Figure 27 is secured to the housing by two

captive screws located behind the handle.

60

System Installation

GMa984-EDK

Page 75

HOUSING

CAPTIVE SCREWS

(UNDER HANDLE)

SYSTEM BUS

CONNECTOR

I

OURBUS

CONNECTOR

Figure 27 P810 Power Supply Insertion

Power Supply Installation and Wiring

Warning

ENSURE THE MAIN POWER TO THE INSTALLATION

IS OFF AND WILL REMAIN OFF BEFORE WIRING POWER SUPPLY.

Step 1

Install your P810 in a Drop.

GM-O984-EDK

System Installation 61

Page 76

Step 2

Remove protective cover plate over power supply’s input

power terminal strip.

Step 3

Wire AC input connector as shown in Figure 28.

Step 4

The P810 is shipped from the factory wired for

115

Vat

operation; i.e., 1 & 2 jumpered. Ensure this is the case.

To wire for 230 Vat operation, remove the jumper.

w

Note To wire a P800, see Figure 29. To wire a P884, see Figure 30.

Step 5

Reinstall protective cover.

Step 6

Repeat Steps (1) thru (5) above for each remaining drop.

P810

115v

230V

0

0

(WHITE) NEUTRAL@ (WHITE) NEUTRAL@

(BLACK) AC HOT@

(BLACK) AC HOT@

(GREEN) GROUNt@ (GREEN)

GROUNG

Figure 28 P810 Power Supply Terminal Strip

62 System Installation

GM-O984-EDK

Page 77

P800

115V

230V

c

0

E

c

@

0

(WHITE) NEUTRAL@

@ (WHITE) NEUTRAL

(BLACK) AC HOT 0

0 (BLACK) AC HOT

(GREEN) GROUND@

@ (GREEN) GROUND

Figure 29 P800 Power

Supply Terminal Strip

P884

11%

230V

c

0

c

c

8

(WHITE) NEUTRAL 0

@ (WHITE) NEUTRAL

(BLACK) AC HOT @

@ (BLACK) AC HOT

(GREEN) GROUND 0

0 (GREEN) GROUND

Figure 30 P884 Power Supply Terminal Strip

GMAl984-EDK

System Installation

63

Page 78

Verify Your Local I/O

Finish your installation verification by configuring and I/O mapping your PLC and

then communicating with local I/O.

ET

Note

Record Executive ID and version number from the panel soft-

ware status screen.

Step 1

Set your controller’s input power to OFF. Shut off auxiliary

power.

Step

2

Install a simple I/O module in Slot 2 of primary housing (a

8805 for example) and secure with captive screws.

Step

3

Re-power

Controller to

IBM

PC Programming Panel Software

Step 4

Connect PLC to panel via either Modbus Port 1 or Modbus

Plus.

Step 5

At your DOS prompt type CD\Modsoft then at the Modsoft

directory prompt (typically C:\MODSOFT>)type MODSOFT’

to execute the panel software.

Expert

Step 5 assumes your panel software is available in your com-

puter. If it is not refer to the Modsoft Programmer User Manual GM-

MSFT-001 for the load procedure.

Getting PLC into RUN Mode

A new controller can not be RUN without providing some data about the configuration in which it is to operate. Steps 6 through 11 provide a quick method to assure

that your new controller will RUN.

64

Step 6

Press the panel “Enter” key ( J ) to display the main menu.

System

Installation

GM-O984-EDK

Page 79

Step 7

You

can either download pre-existing configuration data

using the

“Transfer”

function or initialize a configuration by

selecting an Offline program function from the &Menu, then

overview PLC type and other Jparameters.

Step

8

You will see the configuration

“Overview”

screen illustrated

for example in Figure 31. Select the information that defines your PLC configuration.

Step 9

Return to the main menu and select

“File to PLC”

from the

“Transfer”

Menu.

Step 10

When the Transfer is complete, you are prompted to “Start

Controller”,

follow that up with a “Y”. The controller will start

and the Green RUN LED is lighted.

tllitv Overview I/OMau ports

Seqmnts Loadahle Cfq Ext Quit

lzF2-F3-F4-F5-F6- F7-Lev &FB:OFF-F9-

CONFIGURATION OVERVIEW

Size of Full Logic Area 15396

PLC :

No. of I/O Map Words 00015

PLC Type

984 -

485E

Exec Pack

904 I/O

:

I/O Type

800

Memory

16.0K

Number of Segments 32

Extended Memory

K IO Drops / Channel Pairs 1

Redundant

I/O Modules 1

DCP Drop ID

Specials

:

Battery Coil

0__--_

Ranges

:

Timer Register

4-----

0XXXX 00001

- 01536

Time of Day Clock

4 _-....

IXXXX 100!31

- 10512

3xxxx 30001

- 30048

4xxxx 40001

- 41872 ASCII:

4xxxx for SFC

None

Number of Messages 0

Message Area Size

0

Number of ASCII Ports

0

0xxxx for SFC

NOi%

Simple ASCII Output