Black & Decker DW245 TYPE 3, DW222 TYPE 3, DW217 TYPE 3 Owner’s Manual

LULU

An

@

Zt--

.o z

<

>->o

t-

o-

_O

OEFr-

LUt--

COCO

Lu_Z

ALU

COt--

t- w

zCO

8,,I,

Z ,=

"O <

6

z

LIJ .

I-O

wo

<2

<o_

DZ m

"c <_ cr

-co%

_<CO

O

_ o

DEWALTIndustrialToolCo., 701 East Joppa Road, Baltimore, MD 21286

(SEP13) Part No. N343199 DW217, DW222, etc.

Copyright © 2002, 2004, 2006, 2007, 2013 DEWALT

Thefollowing are trademarks for one or more DEWALTpower tools: the yellow and black color scheme;

the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

F

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

i_,DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

_, WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

_,CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: Indicates apractice not related to personal injury which, if not avoided, may

_result in property damage.

\

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALTTOOL, CALL

US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}.

_ WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

_ ARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

0 If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury,

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

Q

u4

Q

Q

Q

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury,

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tooL Use the correct power tool for your application. The

correct power tool wll/ do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source andlor the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool's operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Rules

• Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury,

• Hold power tool by insulated gripping surfaces, when performing an operation where

the cutting accessory may contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the power tool "live" and could give

the operator an electric shock.

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

• Keep handles dry, clean, free from oil and grease. It is recommended to use rubber gloves.

This will enable better control.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

,_ WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use

face or dust mask if cutting operation is dusty, ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

_,WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Yourrisk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

_ WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury, Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body,

_WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions are

as follows:

V..................... volts

Hz................... hertz

min ................. minutes

.... or DC .....direct current

(_)................... Class I Construction

[] ................... Class IIConstruction

.../min ............ per minute

IPM ................. impacts per minute

SPM ............... strokes per minute

Not More

Than

6

10

12

16

(grounded)

(double insulated)

120 V 25 (7.6) 50 (15.2) 100 (30.5) I 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) I 300 (91.4)

AWG

18

18

16

14

A......................... amperes

W........................ watts

"_ or AC ............. alternating current

or AC/DC ......alternating or direct current

no ....................... no load speed

n......................... rated speed

....................... earthing terminal

........................ safety alert symbol

BPM ................... beats per minute

RPM ................... revolutions per minute

sfpm ................... surface feet per minute

16

16

16

12

16 14

14 12

14 12

Not Recommended

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating. DfiiiWALTtools are factory tested; if this tool does

not operate, check power supply.

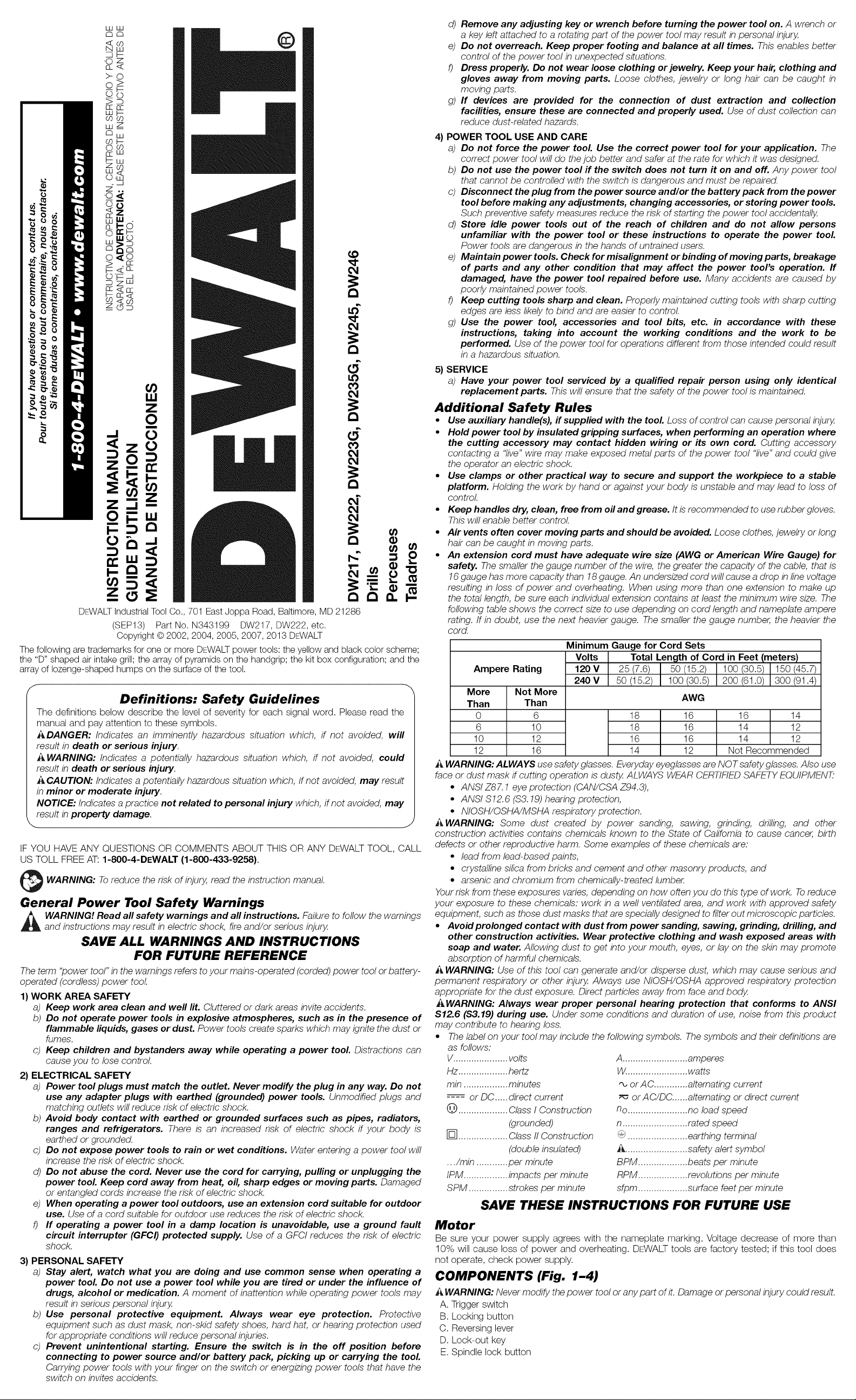

COMPONENTS (Fig. 1-4)

_ WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. Trigger switch

B. Locking button

C. Reversing lever

D. Lock-out key

E. Spindle lock button

INTENDED USE

These heavy-duty drills are designed for professional drilling applications. DO NOT use under wet

conditions or in presence of flammable liquids or gases.

These heavy-duty drills are professional power tools. DO NOT let children come into contact with

the tool. Supervision is required when inexperienced operators use this tool.

Motor Brushes

DEWALT uses an advanced brush system which automatically stops the drill when the brushes

wear out. This prevents serious damage to the motor.

Switch (Fig. 1)

Tostart drill, depress trigger switch; to stop the drill, release trigger. To lock trigger in the on position

for continuous operation, depress trigger and push up locking button (B), then gently release the

trigger. To release the locking mechanism, depress the trigger fully, then release it. Before using the

tool each time, be sure that the locking button release mechanism is working freely.

Do not lock the switch on when drilling by hand so that you can instantly release the trigger switch

if the bit binds in the hole.

The locking button is for use only when the drill is mounted in a drill press stand or otherwise held

stationary.

Be sure to release the locking button before disconnecting the plug from the power supply. Failure

to do so will cause the tool to start immediately the next time it is plugged in. Damage or injury

could result.

VARIABLE SPEED TRIGGER SWITCH

This switch permits speed control: the farther the trigger is depressed, the higher the speed of the

drill.

NOTE: Use lower speeds for starting holes without a center punch, drilling in metal or plastics,

driving screws or drilling ceramics. Higher speeds are better for drilling wood and composition

boards, and for using abrasive and polishing accessories.

REVERSING LEVER

The reversing lever changes the direction of rotation of the drill and is used when backing out

screws and jammed drill bits. To operate the tool in reverse, release the trigger switch and push

the lever to the left (when viewed from the chuck end) as shown in Figure 2. To operate the drill in

forward for drilling holes or driving screws (as well as when using other accessories) release the

trigger switch and push the lever to the right (when viewed from the chuck end).

Return the reversing lever to the forward position after all operations in reverse are completed.

SWITCH LOCK-ON

Your drill is equipped with a switch lock-on feature. Ifyou wish to disable this feature, take your tool

to any authorized service center. The service center can provide a lock-out key (D)to prevent the

unit from being locked inthe on position (Fig. 3).

OPERATION

A WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury,

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored

or clamped firmly, If drilling thin material, use a wood "back-up" block to prevent damage to the

material

Side Handle

J_WARNING: Toreduce the risk of personal injury,ALWAYS operate the tool with the side handle

properly installed and tightened. Failure to do so may result in the side handle slipping during tool

operation and subsequent loss of control Hold tool with both hands to maximize control

A side handle may be supplied with your drill. Side handles are included with these drills: DW235G,

DW245, DW246. The side handle clamps to the front of the gear case and can be rotated 360

degrees to permit right- or left-hand use.

Drilling

1. Use sharp drill bits only. For WOOD, use the low speed setting and twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use the low speed setting and steel twist drill bits

or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use carbide-tipped

bits rated for percussion drilling. Use low speed for bits greater than 3/8" (10 mm).

2. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the drill.

_ WARNING: Drillmay stall if overloaded causing a sudden twist. Always expect the stall. Grip the

drill firmly with both hands to control the twisting action and avoid injury,

4. IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE

TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO

NOT CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL --

THIS CAN DAMAGE THE DRILL.

5. To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit

through the last fractional part of the hole.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

7. With variable speed drills there is no need to center punch the point to be drilled. Use a slow

speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

DRILLING IN METAL

Start drilling with slow speed and increase to full power while applying firm pressure on the tool.

A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when

drilling metals. The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large [5/16" (8 mm) to 1/2" (13 mm)] holes in steel can be made easier if a pilot hole [5/32"

(4 mm) to 3/16" (5 mm)] is drilled first.

DRILLING IN WOOD

Start drilling with slow speed and increase to full power while applying firm pressure on the tool.

Holes in wood can be made with the same twist drills used for metal. These bits may overheat

unless pulled out frequently to clear chips from the flutes. Work that is apt to splinter should be

backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide-tipped bits rated for percussion drilling and be certain that

the bits are sharp. Use a constant and firm force on the tool to drill most effectively. A smooth,

even flow of dust indicates the proper drilling rate.

Keyed Chucks

Open chuck jaws by turning collar with fingers and insertshank of bit about 3/4" into chuck. Tighten

chuck collar by hand. Place chuck key in each of the three holes, and tighten in CLOCKWISE

direction. It's important to tighten chuck with all three holes to prevent slippage. To release bit, turn

chuck key COUNTERCLOCKWISE in just one hole, then loosen the chuck by hand. Any authorized

DEWALTservice center can install a keyless chuck in place of a keyed chuck.

Keyless Chucks

Open chuck jaws by turning plastic collar with fingers and insert shank of bit about 3/4" into chuck.

Tighten plastic collar CLOCKWISE while depressing spindle lock button (E) on the right side of the

tool housing (Fig. 4). To release bit, turn plastic collar COUNTERCLOCKWISE while depressing the

spindle lock button (Fig.4).

NOTE: DO NOT DEPRESS LOCK BUTTON WHILE OPERATING DRILL or while the chuck is

moving.

MAINTENANCE

i_ WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury,

Cleaning

i_ WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing

this.

i_ WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool,"never immerse

any part of the tool into a liquid.

Lubrica tion

Self-lubricating bearings are used inthe tool and periodic relubrication is not required. Inthe unlikely

event that service is ever needed, take your tool to an authorized service location.

FIG. 1

FIG. 3 SWITCH ASSEMBLY FIG. 4

INTERRUPTEUR

MONTAJE DEL INTERRUPTOR

FIG.2

shown in forward position

illustreen marche avant

ilustrada en posiciOn de

marcha hacia adelante

C

Accessories

i_ WARNING: Since accessories, other than those offered by DEWALT,have not been tested with

this product, use of such accessories with this tool could be hazardous. Toreduce the risk of injury,

only DEWALT recommended accessories should be used with this producL

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. If you need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-

9258) or visit our website: www.dewalt.com.

Repairs

To assure product SAFETYand RELIABILITY,repairs, maintenance and adjustment (including brush

inspection and replacement) should be performed by a DEWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always use identical replacement

parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you obtain more efficient warranty

service in case there is a problem with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft,

your registration of ownership will serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely event

a safety notification is required under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALTtools are covered by our:

1 YEAR FREE SERVICE

DFWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

Ifyou are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer

for any reason, you can return itwithin 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: Ifyour warning labels become illegible or are missing,

call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

SER,

3/8" (10mm)

VSR DRILL

DWXXX

_ AVERTISSEMENT

TO REDUCE THE RISK OF INJURY, USER MUST READ

INSTRUCTION MANUAL WHEN SERVICING, USE ONLY

IDENTICAL REPLACEMENT PARTS. ALWAYS USE

.PROPER EY_EAND RESPIRATORY PROTECTION,

A TITRE PREVENTIF, LIRE LEGUIDE.

OEWALT INDUSTRIAL TOOL DO,,8ALTIMODE, MD 21286 U,D,A,

FOD SERVICEINFODMATION, CALL 1-80_-4-D WALT www,O_WALT,co_

Ddfinitions : lignes directrices en

mati_re de sdcuritd

Les definitions ci-dessous decrivent le niveau de danger pour chaque

mot-indicateur employe. Lirele mode d'emploi et porter une attention particuliere

a.ces symboles.

A DANGER : indique une situation dangereuse imminente qui, si elle n'est pas

evitee, entra_nera la mort ou des blessures graves.

_AVERTISSEMENT : indique une situation potentiellement dangereuse qui,

si e//e n'est pas evitee, pourrait entra_ner/a mort ou des blessures graves.

i_ATTENTION : indique une situation potentiellement dangereuse qui, si elle

n'est pas evitee, pourrait entra_ner des blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de dommages corporels

mais qui par contre, si rien n' est fait pour I'eviter,pourraR poser des risques de

dommages materiels.

\

.J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE

OUTIL DEWALT,COMPOSEZ LE NUMFt:ROSANS FRAIS ' 1-800-4-DEWALT (1-800-433-9258}.

_ AVERTISSEMENT : afin de reduire le risque de blessures, life le mode d'emploi de I'outil.

Avertissements de sdcuritd gdndraux pour les outils

dlectriques

Le non-respect des avertissements et des directives pourrait se solder par un choc

_ AVERTISSEMENT ! Lire tousles avertissements de s_curit_ et toutes les directives.

dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES LES

DIRECTIVES POUR UN USAGE ULTERIEUR

Le terme <<outil dectrique _ cite dans les avertissements se rapporte a votre outil dectrique

alimentation sur secteur (avec ill) ou par piles (sans fll).

Loading...

Loading...