Page 1

3-3/8 INCH (86 MM)

TRIMSAW ATTACHMENT

INSTRUCTION MANUAL

Catalog Number

BDCMTTS

Thank you for choosing Black & Decker!

Go to www.BlackandDecker.com/NewOwner

to register your new product.

PLEASE READ BEFORE RETURNING THIS

PRODUCT FOR ANY REASON:

If you have a question or experience a problem with your Black & Decker purchase, go to

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

If you can’t find the answer or do not have access to the Internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri. to speak with an agent.

Please have the catalog number available when you call.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPANOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 2

WARNING:

Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

WARNING: Read all safety warnings and all instructions provided with

your Power Unit (BDCDMT112, BDCDMT120, or BDEDMT) before using

this attachment. Failure to follow the warnings and instructions may result in

electric shock, re and/or serious injury.

SPECIFIC SAFETY RULES

a)

DANGER: Keep hands away from cutting area and the blade. Keep your second hand

on auxiliary handle or motor housing. If both hands are holding the saw, they cannot be cut

by the blade.

b) Do not reach underneath the workpiece. The guard cannot protect you from the blade

below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the

blade teeth should be visible below the workpiece.

d) Never hold piece being cut in your hands or across your leg. Secure the workpiece to

a stable platform. It is important to support the work properly to minimize body exposure,

blade binding, or loss of control.

e) Hold power tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

also make exposed metal parts of the power tool “live” and shock the operator.

f) When ripping always use a rip fence or straight edge guide. This improves the accuracy

of cut and reduces the chance of blade binding.

g) Always use blades with correct size and shape (diamond versus round) of arbour holes. Blades

that do not match the mounting hardware of the saw will run eccentrically, causing loss of control.

h) Never use damaged or incorrect blade washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing the blade to climb out of the kerf and jump

back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below:

a) Maintain a rm grip with both hands on the saw and position your arms to resist

kickback forces. Position your body to either side of the blade, but not in line with

the blade. Kickback could cause the saw to jump backwards, but kickback forces can be

controlled by the operator, if proper precautions are taken.

b) When blade is binding, or when interrupting a cut for any reason, release the trigger

and hold the saw motionless in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work or pull the saw backward while

the blade is in motion or kickback may occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, center the saw blade in the kerf and check

that saw teeth are not engaged into the material. If saw blade is binding, it may walk up

or kickback from the workpiece as the saw is restarted.

d) Support large panels to minimize the risk of blade pinching and kickback. Large

panels tend to sag under their own weight. Supports must be placed under the panel on

both sides, near the line of cut and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be tight and secure before

making cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

2

Page 3

g) Use extra caution when sawing into existing walls or other blind areas. The protruding

blade may cut objects that can cause kickback.

LOWER GUARD SAFETY INSTRUCTIONS

a) Check lower guard for proper closing before each use. Do not operate the saw if lower

guard does not move freely and close instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and make sure it moves freely and does not touch

the blade or any other part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the guard and the spring are not

operating properly, they must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

c) Lower guard should be retracted manually only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard by retracting handle and as soon as blade

enters the material, the lower guard must be released. For all other sawing, the lower guard

should operate automatically.

d) Always observe that the lower guard is covering the blade before placing saw down

on bench or oor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch

is released.

ADDITIONAL SAFETY INSTRUCTIONS

• Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to loss

of control.

• Keep your body positioned to either side of the blade, but not in line with the saw

blade. KICKBACK could cause the saw to jump backwards (see Causes and Operator

Prevention of Kickback and KICKBACK).

• Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

• Always make sure nothing interferes with the movement of the lower blade guard.

• Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over rated speed can y apart and cause

injury. Accessory ratings must always be above tool speed as shown on tool nameplate.

• Always make sure the saw is clean before using.

• Stop using this saw and have it properly serviced if any unusual noise or abnormal operation

occurs.

• Always be sure all components are mounted properly and securely before using tool.

• Always handle the saw blade with care when mounting or removing it or when removing the

diamond knockout.

• Always wait until the motor has reached full speed before starting a cut.

• Always keep handles dry, clean and free of oil and grease. Hold the tool rmly with both

hands when in use.

• Always be alert at all times, especially during repetitive, monotonous operations. Always be

sure of position of your hands relative to the blade.

• Stay clear of end pieces that may fall after cutting off. They may be hot, sharp and/or heavy.

Serious personal injury may result.

• Replace or repair damaged cords. Make sure your extension cord is in good condition. Use

only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles

that accept the tool’s plug.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

CAUTION: Blades coast after turn off. Serious personal injury may result.

3

Page 4

WARNING: ALWAYS wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

WARNING: ALWAYS use proper eye protection. All users and bystanders must wear

proper eye protection that conforms to ANSI Z87.1.

WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certied safety

equipment:

• ANSI Z87.1 eye protection (CAN/CPA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NOSH/OSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known in the state of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints, crystalline silica from bricks and cement and other masonry

products, and arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to lter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body. Always

operate tool in well-ventilated area and provide for proper dust removal. Use dust collection

system wherever possible.

SYMBOLS

The label on your tool may include the following symbols. The symbols and their definitions are as follows:

V .................. volts A ...................amperes

Hz ................ hertz W ..................watts

min .............. minutes ................alternating current

............ direct current

................ Class I Construction ..................earthing terminal

(grounded) ................safety alert symbol

................ Class II Construction .../min or rpm...revolutions or

(double insulated) reciprocation per minute

............ Read instruction manual before use ............... Use proper respiratory protection

................ Use proper eye protection ..................Use proper hearing protection

When using an extension cord, be

sure to use one heavy enough to carry

the current your product will draw. An

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. The following table shows

the correct size to use depending on

cord length and nameplate ampere

rating. If in doubt, use the next heavier

gauge. The smaller the gauge number,

the heavier the cord.

n

o ..................no load speed

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Minimum Gauge for Cord Sets

4

Page 5

TO REDUCE THE RISK OF KICKBACK

• Keep a firm grip on saw with both hands at all times.

• Stay alert – exercise control.

• Support long overhanging materials. As the material is cut and weakens, it will sag, causing a

pinched blade.

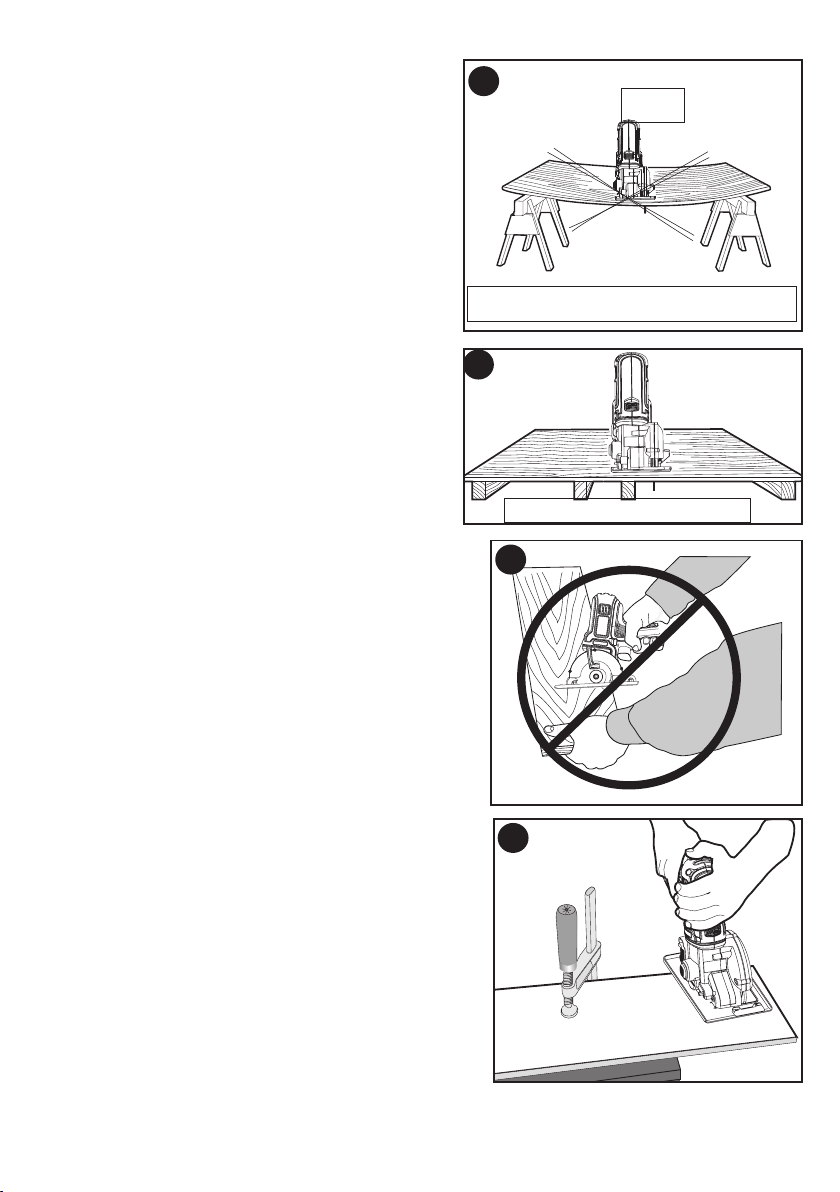

• Support large panels as shown (FigureC). Material supported only at the ends (Figure B) will

lead to blade pinching.

• Avoid sawing overhead. Material can sag and will pinch blade.

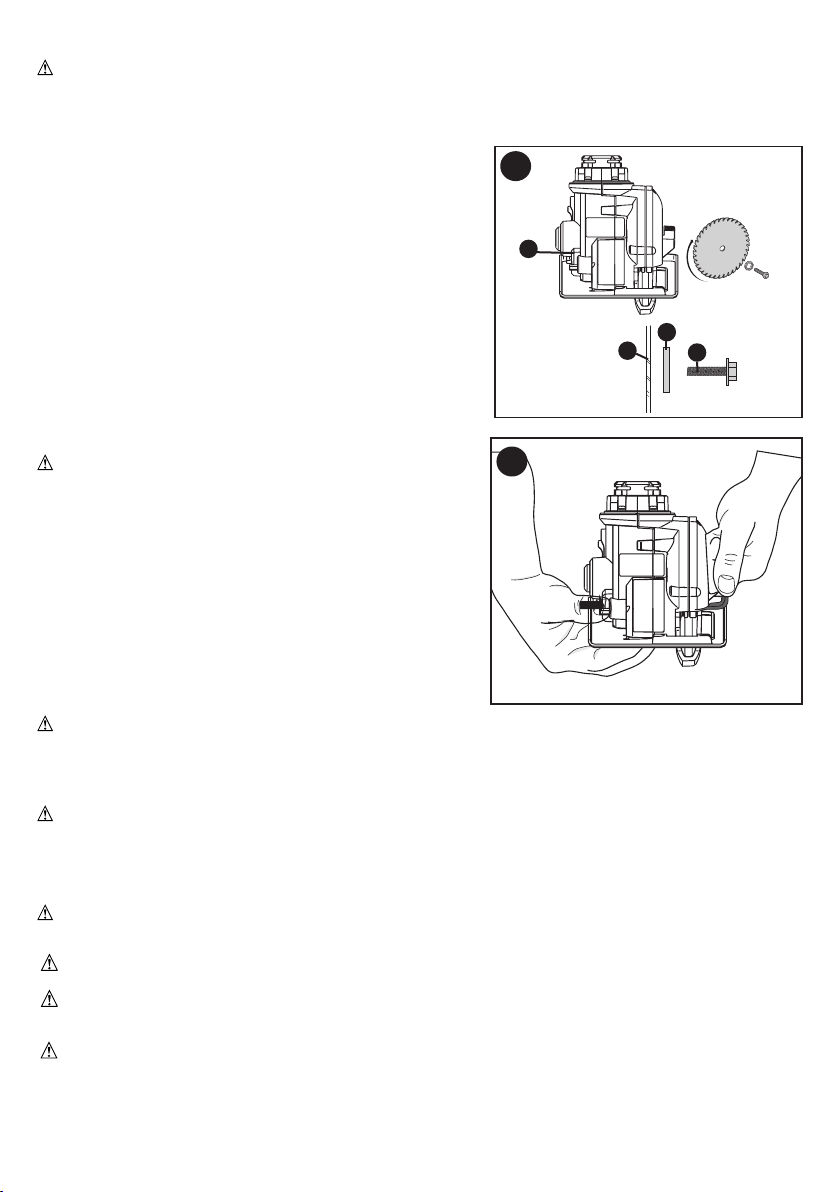

• Insure that the material to be cut is clamped (Figure E) and solidly supported and balanced on a

strong, stable and level work surface. Support the work so that the wide portion of the saw shoe

is on the portion of the material that doesn’t fall after the cut is made. Never hold cut off piece by

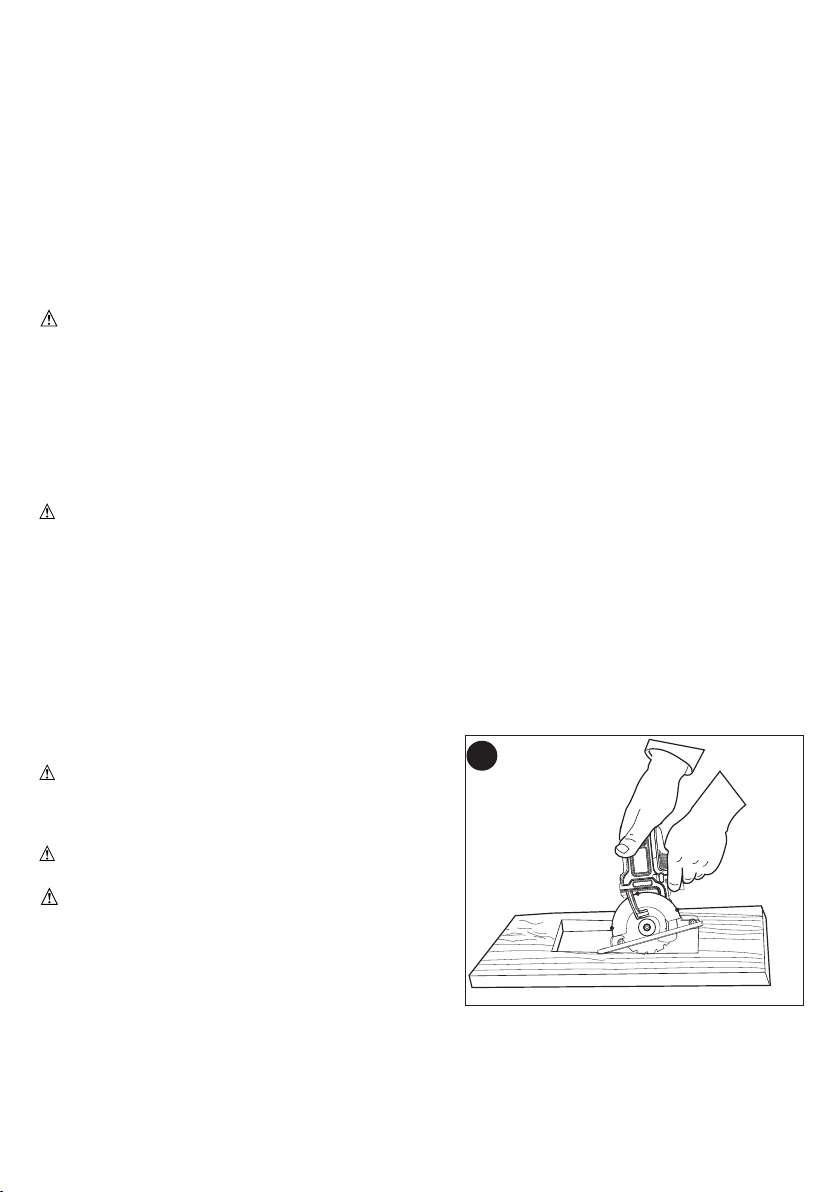

hand (Figure D).

• Keep blades sharp and clean.

• Use fence or straight edge guide when ripping. Be careful as the cut off strip can sag or twist,

closing the cut and pinching the blade, leading to KICKBACK.

• Don’t force tool. Wood variables such as knots, hardness, toughness, wetness, pressure

treated and freshly cut green lumber can heavily load the saw which can lead to stalling. Push

the saw slower when this occurs.

• Don’t remove saw from work during a cut while the blade is moving.

• Allow saw to reach full speed before blade contacts material to be cut. Starting the saw with

the blade against the work or pushed forward into cut can lead to stalling or sudden backward

movement of saw.

• Never attempt to lift saw when making a bevel cut. This leads to blade binding and stalling.

• Always secure work to prevent workpiece movement during cut.

• Do not try to force saw back on line if your cut begins to go off line. This can cause KICKBACK.

Stop saw and allow blade to coast down to a stop. Withdraw from cut and start a new cut on

the line.

• Do not back up a rotating blade in the cut. Twisting the saw can cause the back edge of the

blade to dig into the material, climb out of the work and run back toward the operator.

• Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

1

2

3

4

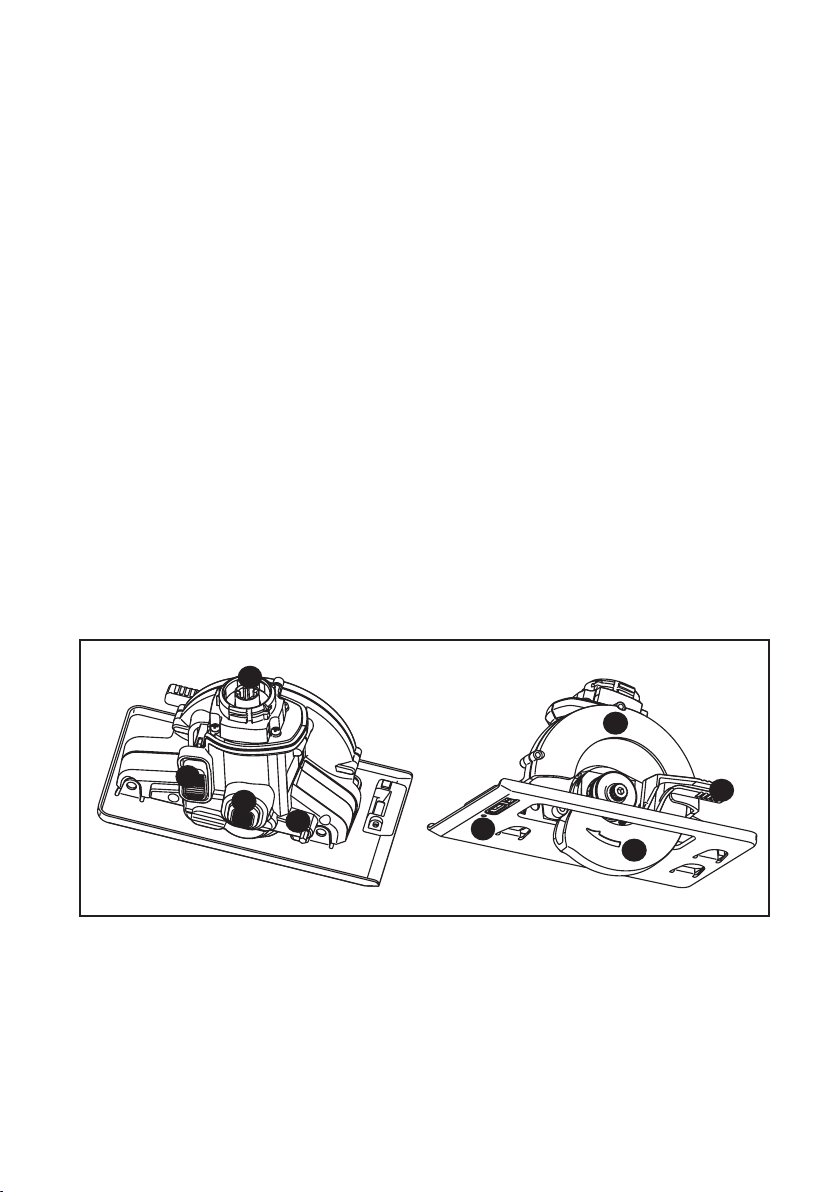

FUNCTIONAL DESCRIPTION

Figure A

1. BDCMTTS trimsaw attachment

2. Lock-off button

3. Spindle lock

4. Wrench

6

8

5

7

5. Shoe

6. Upper guard

7. Lower saw blade guard

8. Retracting lever

5

Page 6

SUPPORTING LARGE PANELS / SECURING WORKPIECE

Support large panels to minimize the risk of blade

pinching and kickback. Large panels tend to sag

under their own weight as shown in Figure A.

A

Material bends on blade causing

heavy loads or kickback

Wrong

Supports must be placed under the panel on both

sides, near the line of cut and near the edge of the

panel (Figure B).

Never hold piece being cut in your hands or across your

leg (Figure C).

Secure the workpiece to a stable platform as shown in

Figure D. It is important to support the work properly to

minimize body exposure, blade binding, or loss of control.

B

Support work near cut

C

D

6

Page 7

ASSEMBLY/ADJUSTMENT SET-UP

WARNING: To reduce the risk of injury, always remove battery from saw before any of

the following adjustment operations.

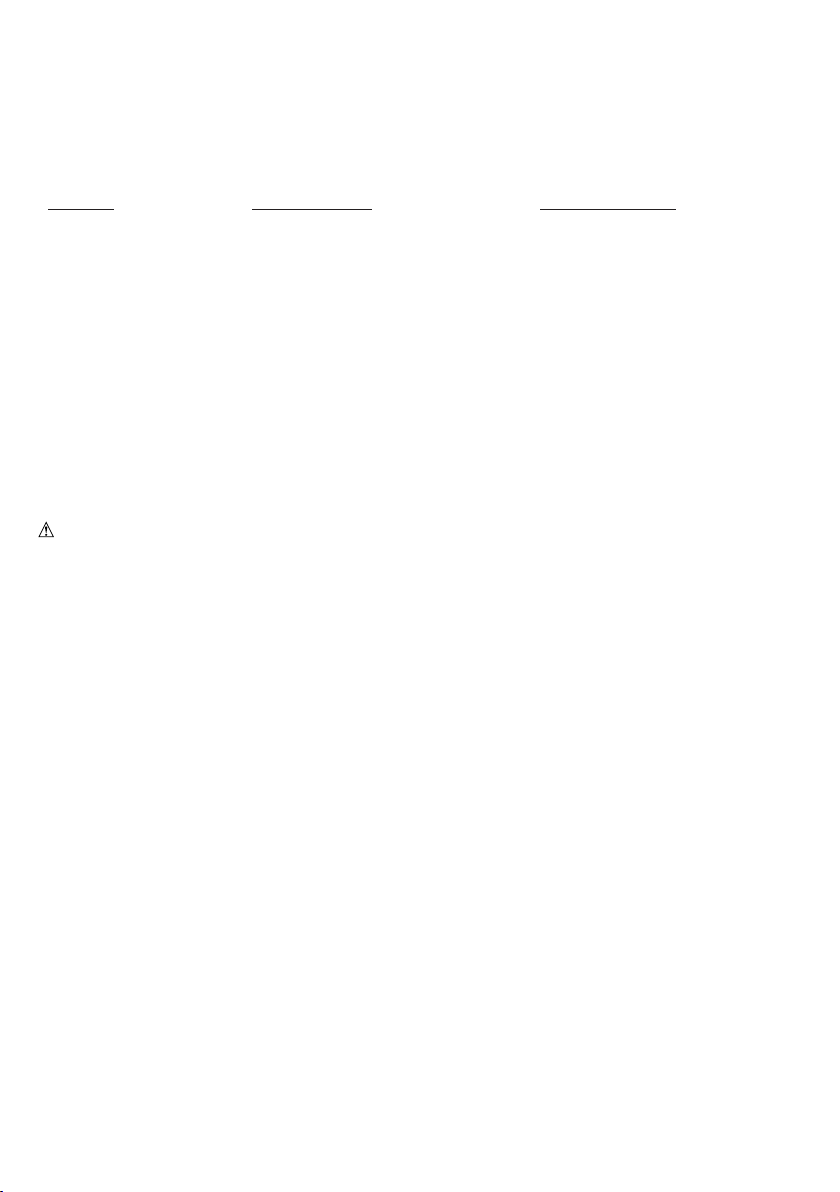

ATTACHING AND REMOVING THE BLADE: FIGURE E & F

• Retract lower guard and assemble blade (7) and clamp

washer (9) as shown in Figure E.

• Depress the spindle lock (3) while turning the saw

spindle with the blade wrench (4) until the blade lock

engages and the blade stops rotating as shown in

Figure F.

NOTE: Blade wrench is stored on the saw as shown in

Parts and Features.

• Tighten the blade clamping screw (10) securely with the

blade wrench.

NOTE: Never engage the spindle lock while the saw is

running, or engage in an effort to stop the tool. Never

turn the tool on while the spindle lock is engaged.

Serious damage to your saw will result.

E

3

9

7

10

LOWER BLADE GUARD

WARNING

guard is a safety feature which reduces the risk of

serious personal injury. Never use the saw if the lower

guard is missing, damaged, mis-assembled or not

working properly. Do not rely on the lower blade guard

to protect you under all circumstances. Your safety

depends on following all warnings and precautions as

well as proper operation of the saw. Check lower guard

for proper closing before each use as outlined in

Additional Safety Rules for Circular Saws. If the lower

blade guard is missing or not working properly,

immediately discontinue use of the saw, and take it to

a qualied service dealer for possible repair.

: Laceration Hazard. The lower blade

F

WARNING: To minimize the risk of eye injury, always use eye protection. Carbide is a hard

but brittle material. Foreign objects in the work piece such as wire or nails can cause tips to crack

or break. Only operate saw when proper saw blade guard is in place. Mount blade securely in

proper rotation before using, and always use a clean, sharp blade.

WARNING: Do not cut ferrous metals (steel), masonry, glass or tile with this saw.

A dull blade will cause slow, inefficient cutting overload on the saw motor, excessive splintering,

and could increase the possibility of kickback.

OPERATING INSTRUCTIONS

WARNING: To reduce the risk of serious personal injury, read, understand and follow

all important safety warnings and instructions prior to using tool.

WARNING:

Shock hazard. Under no circumstances should this product be used near water.

WARNING: To reduce the risk of injury, turn off and remove battery from the tool before

making any adjustments or removing or installing attachments or accessories.

WARNING: Risk of lacerations or burns. Do not touch work piece or blade immediately

after operating the tool. They can become very hot. Handle carefully. Always allow accessories

and workpiece to cool before handling.

IMPORTANT: Refer to Power Unit instruction manual before operating this tool for all safety

warnings and details on installing and removing attachments.

7

Page 8

OPERATION

• To switch the tool on, press and hold the active lock-off button (2), then fully press the variable speed

switch on the power unit. Once the bit begins to operate, release the active lock-off button (2).

• To switch the tool off, release the variable speed switch.

NOTE: This tool attachment only operates in the forward direction; the forward/reverse slider

of the Power Unit should not be able to be switch to reverse.

BLADE SELECTION

Your circular saw is designed for use with 3-3/8 inch (86 mm) diameter blades that have a

15 mm diameter bore. Blades must be rated for 3000 RPM operation (or higher).

NOTE: This saw is designed to cut wood and plastic. Do not use masonry or metal

cutting blades. DO NOT use any abrasive wheels.

GENERAL CUTS

WARNING: To reduce the risk of injury, remove the battery, and follow all assembly,

adjustment and set up instructions.

Make sure lower guard operates. Select the proper blade for the material to be cut.

• Measure and mark work for cutting.

• Support and secure work properly (See Safety Rules and Instructions).

• Use appropriate and required safety equipment (See Safety Rules).

• Secure and maintain work area (See Safety Rules).

• With battery inserted, make sure switch turns saw on and off.

SAWING

WARNING: To reduce the risk of serious personal injury, always hold the tool with both

hands as illustrated in Figure G below.

• Let the blade run freely for a few seconds before starting the cut.

• Apply only a gentle pressure to the tool while performing the cut.

• Work with the shoe (5) pressed against the workpiece.

HINTS FOR OPTIMUM USE

• For best results use a blade with 20-24 cutting teeth.

• As some splintering along the line of cut on the top side of the workpiece cannot be avoided,

cut on the side where splintering is acceptable.

• Where splintering is to be minimized, e.g. when cutting laminates, clamp a piece of plywood

onto the top of the workpiece.

POCKET CUTTING (FIGURE G)

G

WARNING: Never tie the blade guard in a raised

position. Never move the saw backwards when

pocket cutting. This may cause the unit to raise up off

the work surface which could cause injury.

WARNING

injury, always hold the tool with both hands.

: To reduce the risk of serious personal

WARNING: Laceration Hazard. As blade starts

cutting the material, release the retracting lever

immediately.

A pocket cut is one that is made in a floor, wall, or

other flat surface.

• Tilt the saw forward and rest front of the shoe on

material to be cut.

• Using the retracting lever (8), retract lower blade guard (7) to an upward position. Lower rear of

shoe until blade teeth almost touch cutting line.

• Release the blade guard (its contact with the work will keep it in position to open freely as you

start the cut). Remove hand from retracting lever and firmly grip the top of the power unit, as

shown in Figure G. Position your body and arm to allow you to resist kickback if it occurs.

• Make sure blade is not in contact with cutting surface before starting saw.

8

Page 9

• Start the motor and gradually lower the saw until its shoe rests flat on the material to be cut.

Advance saw along the cutting line until cut is completed.

• Release trigger and allow blade to stop completely before withdrawing the blade from the material.

• When starting each new cut, repeat as above.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Attachment is not secured. • Make certain the attachment is fully

pushed into the Power Unit.

For assistance with your product, visit our website www.blackanddecker.com for the location

of the service center nearest you or call the BLACK & DECKER help line at 1-800-544-6986.

NOTE: Refer to Power Unit instruction manual for troubleshooting solutions regarding opera-

tion of the Power Unit.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

ACCESSORIES

WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

Recommended accessories for use with your tool are available from your local dealer or authorized

service center. If you need assistance regarding accessories, please call: 1-800-544-6986.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment. This Class B digital

apparatus complies with Canadian ICES-003.

SERVICE INFORMATION

All Black & Decker Service Centers are staffed with trained personnel to provide customers with

efficient and reliable power tool service. Whether you need technical advice, repair, or genuine

factory replacement parts, contact the Black & Decker location nearest you. To find your local

service location, refer to the yellow page directory under “Tools—Electric” or call: 1-800-544-6986

or visit www.blackanddecker.com

9

Page 10

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or

workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale).

Proof of purchase may be required. Please check with the retailer for their specific return policy

regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required.Black & Decker owned and authorized Service Centers are listed under

“Tools-Electric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state or province to province. Should you

have any questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, check country specific warranty information contained in the packaging,

call the local company or see the website for warranty information.

Imported by:

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

10

Page 11

MODULE

D’ÉBOUTEUSE

MODE D’EMPLOI

N° de catalogue

BDCMTTS

Merci d’avoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/

NewOwner pour enregistrer votre nouveau produit.

ÀLIRE AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après l’achat d’un produit Black & Decker,

consulter le site Web

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

Si la réponse est introuvable ou en l’absence d’accès à Internet, composer le

1-800-544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière d’avoir le numéro de catalogue sous la main lors de l’appel.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

11

Page 12

AVERTISSEMENT : Lire tous les avertissements de sécurité et toutes les

directives. Le non-respect des avertissements et des directives pourrait se solder par

un choc électrique, un incendie et/ou une blessure grave.

Conserver tous les avertissements et toutes les directives pour un usage ultérieur.

AVERTISSEMENT : Lire tous les avertissements de sécurité et toutes les

directives fournies avec le bloc d’alimentation (BDCDMT112, BDCDMT120 ou

BDEDMT) avant d’utiliser l’accessoire. Le non-respect des avertissements et des

directives peut entraîner des risques de décharge électrique, d’incendie ou de

blessures graves.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES

a) AVERTISSEMENT

lame. Gardez une de vos mains sur la poignée auxiliaire ou sur le carter du moteur. Si

vous tenez la scie de vos deux mains, elles ne peuvent pas être coupées par la lame.

b) N’essayez pas de tenir le dessous de l’ouvrage. Le protège-lame ne peut pas vous

protéger de la lame en dessous de l’ouvrage.

c) Ajustez la profondeur de coupe à l’épaisseur de l’ouvrage. Moins d’une dent entière de

lame devrait être visible en dessous de l’ouvrage.

d) Ne tenez jamais dans vos mains ou sur vos genoux un ouvrage qui est en cours

de coupe. Fixez votre ouvrage sur une plateforme stable. Il est important de soutenir

correctement l’ouvrage afin de minimiser l’exposition du corps à la lame, le risque de

coincement de la lame ou la perte de contrôle de l’outil.

e) Tenez l’outil électrique par ses surfaces de préhension isolantes quand vous réalisez

une opération au cours de laquelle l’outil de coupe pourrait entrer en contact avec

des câbles dissimulés ou avec son propre cordon électrique. Le contact avec un fil

sous tension mettra également sous tension toutes les pièces métalliques exposées et

donnera un choc électrique à l’utilisateur de l’outil.

f) Pendant les coupes de refente, utilisez toujours un guide de refente ou un guide

à bord droit. Ceci augmente toujours l’exactitude de la coupe et diminue la possibilité de

coincement de la lame.

g) Utilisez toujours des lames dont l’alésage central est de la taille et de la forme

appropriées (soit en forme de diamant, soit en forme de rond). Les lames qui ne

correspondent pas aux pièces de montage de la cie tourneront de façon excentrique, ce qui

causera une perte de contrôle de l’outil.

h) Ne vous servez jamais de rondelles ou de boulons de lames qui sont

endommagés ou inappropriés. Les rondelles et le boulon de lame ont été conçus

spécifiquement pour votre scie dans le but d’assurer une performance optimale et un

fonctionnement sans danger.

:

Gardez les mains à distance de la zone de coupe et de la

CAUSES DES REBONDS ET MÉTHODES DE PRÉVENTION POUVANT

ÊTRE UTILISÉES PAR L’UTILISATEUR :

• Le rebond est une réaction subite (causée par une lame de scie pincée, coincée ou mal

alignée) qui peut entraîner le soulèvement d’une scie non contrôlée, sa sortie de l’ouvrage et

sa projection en direction de l’utilisateur.

• Si la lame est pincée ou coincée fortement pendant l’abaissement de la scie, la lame se cale et

le moteur réagit en entraînant rapidement l’outil vers l’arrière dans la direction de l’opérateur.

• Si la lame se tord ou perd son alignement correct au cours de la coupe, les dents sur le bord

arrière de la lame peuvent entamer la surface supérieure du bois, forçant ainsi la lame à sortir

du trait de scie et à « sauter » vers l’arrière en direction de l’opérateur.

Le rebond est la conséquence d’une mauvaise utilisation de la scie et/ou de procédures ou

de conditions incorrectes, et il peut être évité en prenant les précautions qui sont décrites

ci-dessous :

a) Maintenez fermement la scie avec vos deux mains et positionnez vos bras de

façon à résister aux forces de rebond. Les forces de rebond peuvent être contrôlées par

l’utilisateur quand les précautions appropriées sont prises.

b) En cas de coincement de la lame ou d’interruption d’une coupe pour une raison

quelconque, relâchez la gâchette et tenez la scie immobile dans l’ouvrage

12

Page 13

jusqu’à ce que la lame se soit immobilisée complètement. Ne

tentez jamais de retirer la scie de l’ouvrage ou de la

tirer vers l’arrière pendant que la lame est en mouvement, car

un rebond risquerait de se produire. Évaluez la situation et prenez les mesures

correctives nécessaires pour éliminer la cause du coincement de la lame.

c) Lorsque vous remettez une scie en marche quand l’ouvrage est présent, centrez

la lame de scie dans le trait de scie et vériez que les dents de la lame ne sont pas

engagées dans le matériau de l’ouvrage. Si la lame de scie se coince, elle peut grimper

hors de l’ouvrage ou rebondir sur celui-ci quand la scie est remise en marche.

d) Soutenez les panneaux de grande taille de façon à minimiser le risque de pincement

et de rebond de la lame. Les panneaux de grande taille ont tendance à s’affaisser sous

leur propre poids. Des supports doivent être placés des deux côtés sous le panneau, à

proximité de la ligne de coupe et à proximité du rebord du panneau.

e) N’utilisez pas de lame émoussée ou endommagée. Des lames non aiguisées ou mal

installées produisent un trait de scie étroit qui cause une friction excessive, le coincement

de la lame et un effet de rebond.

f) Les leviers de réglage de la profondeur et de l’angle de coupe de la lame doivent être

bien serrés et assujettis avant de réaliser une coupe. Une modification du réglage de la

lame pendant la coupe risque d’entraîner un coincement et un rebondissement de la lame.

g) Procédez avec une prudence supplémentaire quand vous réalisez une coupe « en

plongée » dans des murs déjà en place ou dans des pièces sans issue. La lame

saillante peut couper des objets, et ceci peut entraîner un rebond.

CONSIGNES DE SÉCURITÉ RELATIVES AU PROTÈGE-LAME INFÉRIEUR

a) Inspectez le protège-lame inférieur avant chaque utilisation pour vous assurer qu’il

se ferme correctement. Ne faites pas fonctionner la scie si le protège-lame inférieur

ne se déplace pas librement et ne se ferme pas instantanément. Ne forcez jamais

le protège-lame inférieur dans la position ouverte à l’aide d’un collier de serrage ou d’une

attache. Il est possible que le protègelame inférieur se torde en cas de chute accidentelle

de la scie. Soulevez le protège-lame inférieur à l’aide de la poignée rétractable et assurez vous qu’il se déplace sans problème et qu’il ne touche pas la lame ou une autre pièce, quel

que soit l’angle ou la profondeur de la coupe.

b) Vériez le fonctionnement du ressort du protège-lame inférieur. Si le protège-lame

inférieur et le ressort ne fonctionnent pas correctement, ils doivent être réparés

avant l’emploi. Le protège-lame inférieur peut parfois mal fonctionner à cause de pièces

endommagées, d’accumulation de résine ou de débris.

c) Le protège-lame inférieur doit être rétracté à la main uniquement à l’occasion de

coupes spéciales telles que les « coupes en plongée » ou les « coupes composées».

Soulevez le protège-lame inférieur à l’aide la poignée rétractable et relâchez-le dès

que la lame pénètre dans le matériau de l’ouvrage. Pour toute autre opération de

sciage, le protège-lame inférieur doit fonctionner automatiquement.

d) Vériez toujours que le protège-lame inférieur couvre la lame avant de placez la

scie sur un banc ou sur le sol. Une lame non protégée qui tourne librement entraînera le

mouvement de la scie en marche arrière, ce qui provoquera la coupe de tout se qui se

trouve sur sa trajectoire. Soyez conscient du temps nécessaire à la lame pour s’arrêter une

fois que la gâchette est relâchée.

CONSIGNES DE SÉCURITÉ SUPPLÉMENTAIRES

• Utiliser des pinces ou tout autre moyen pratique de soutenir et de xer solidement la

pièce sur une plate-forme stable. Tenir la pièce avec la main ou contre son corps n’est pas

suffisamment stable et risque de provoquer une perte de maîtrise de l’outil.

• Il faut se tenir de l’un ou l’autre côté de la lame de la scie et non dans sans trajectoire.

L’EFFET DE REBOND risque de faire rebondir la scie vers l’arrière (consulter les rubriques «

Causes de l’effet de rebond et prévention par l’opérateur » et « EFFET DE REBOND »).

• Éviter de couper des clous. Inspecter le bois et retirer tous les clous qui s’y trouvent

avant d’entamer la découpe.

• Toujours s’assurer que rien ne nuit au mouvement du pare-main inférieur.

• Le régime nominal (vitesse) des accessoires doit au minimum égaler la vitesse

recommandée sur l’étiquette d’avertissement de l’outil. Les meules et autres

accessoires allant plus vite que le régime nominal peuvent être projetés et provoquer

des blessures. Le régime nominal des accessoires doit toujours se situer au-dessus de la

13

Page 14

vitesse de l’outil, tel que l’indique la plaque signalétique de l’outil.

• Toujours être certain que tous les composants sont montés adéquatement et

solidement avant d’utiliser l’outil.

• Toujours manipuler soigneusement la lame de la scie au moment de la pose ou de la dépose.

• Toujours attendre le plein régime du moteur avant d’amorcer une coupe.

• Toujours maintenir les poignées sèches, propres et exemptes d’huile et de graisse.

Tenir fermement l’outil à deux mains au moment de l’utiliser.

• Toujours être vigilant, surtout durant les opérations répétitives et monotones. Toujours

être certain de la position de ses mains par rapport à la lame.

• Se tenir à l’écart des extrémités de la pièce, car des morceaux pourraient tomber après

la coupe. Les morceaux peuvent être chauds, tranchants et/ou lourds. Il peut en résulter

des blessures corporelles graves.

• Remplacer ou réparer les cordons endommagés. S’assurer que la rallonge est en

bon état. Utiliser uniquement une rallonge à 3 fils pourvue d’une fiche de mise à la terre à 3

broches et d’une prise à 3 fentes correspondant à la fiche de l’outil.

• Pour la sécurité de l’utilisateur, utiliser une rallonge de calibre adéquat (AWG ou American

Wire Gauge [calibrage américain normalisé des fils]). Plus le numéro de calibre de fil est petit

et plus sa capacité est grande, par exemple un calibre 16 a plus de capacité qu’un calibre 18.

Une rallonge de calibre inférieur causera une chute de tension de ligne et donc une perte de

puissance et une surchauffe. Si plus d’une rallonge est utilisée pour obtenir la longueur totale,

s’assurer que chaque rallonge présente au moins le calibre de fil minimum. Le tableau suivant

indique le calibre approprié à utiliser selon la longueur de la rallonge et l’intensité nominale de

la plaque signalétique. En cas de doute, utiliser le calibre suivant le plus gros. Plus le numéro

de calibre est petit, plus le cordon est lourd.

AVERTISSEMENT : porter une protection auditive personnelle appropriée pour

utiliser cet appareil. Dans certaines conditions et selon la durée d’utilisation, le bruit

provoqué par ce produit pourrait contribuer à une perte auditive.

AVERTISSEMENT : certaines poussières produites par les activités de ponçage,

sciage, meulage, perçage et autres activités de construction peuvent contenir des produits

chimiques pouvant causer le cancer, des anomalies congénitales ou d’autres problèmes

liés aux fonctions reproductrices. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline provenant de la brique, du ciment et d’autres produits de maçonnerie;

• l’arsenic et le chrome provenant du bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient selon la fréquence à laquelle l’utilisateur

travaille avec ce type de matériaux. Pour réduire l’exposition à ces produits chimiques, travailler

dans un endroit bien ventilé et porter un équipement de sécurité approuvé comme un masque

antipoussières conçu spécialement pour filtrer les particules microscopiques.

AVERTISSEMENT : TOUJOURS porter des lunettes de sécurité. Les lunettes de

vue ne constituent PAS des lunettes de sécurité. Utiliser également un masque facial ou

anti-poussière si l’opération de découpe génère de la poussière. TOUJOURS PORTER

UN ÉQUIPEMENT DE PROTECTION HOMOLOGUÉ :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/CSA Z94.3);

• protection auditive ANSI S12.6 (S3.19);

• protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

• Éviter le contact prolongé avec les poussières produites par les activités de ponçage,

sciage, meulage, perçage et autres activités de construction. Porter des vêtements de

protection et laver les parties du corps exposées avec une solution d’eau et de savon.

Le fait de laisser la poussière pénétrer dans la bouche et les yeux ou de la laisser reposer sur la

peau, peut promouvoir l’absorption de produits chimiques nocifs.

AVERTISSEMENT : l’utilisation de cet outil peut produire et/ou propulser des poussières

qui pourraient causer des problèmes respiratoires graves et permanents, ou d’autres problèmes

médicaux. Toujours porter un appareil respiratoire approuvé par la NIOSH/OSHA pour se protéger

de la poussière. Diriger les particules loin du visage et du corps.

14

Page 15

SYMBOLES

• L’étiquette apposée sur votre outil pourrait comprendre les symboles suivants. Les symboles et

leurs dénitions sont indiqués ci-après :

V ................. volts A ...............ampères

Hz ............... hertz W .............. watts

min ..............minutes ............ courant alternatif

............ courant continu

................Construction de classe I

n

o ............. sous vide

.............. borne de mise à la minute

(mis à la terre)

...............

Construction de classe II ............ symbole d´avertissement

.../min ..........tours à la minute

.............. Lire le mode d’emploi avant l’utilisation

............Utiliser une protection respiratoire adéquate.

...........Utiliser une protection oculaire adéquate.

............Utiliser une protection auditive adéquate.

• En cas d’utilisation d’une rallonge,

s’assurer que les valeurs nominales

de la rallonge utilisée correspondent

bien à celles de l’outil alimenté.

L’usage d’une rallonge de calibre

insuffisant causera une chute

de tension entraînant perte de

puissance et surchauffe. Le tableau

ci-dessous illustre les calibres à

utiliser selon la longueur de rallonge

et l’intensité nominale indiquée sur

la plaque signalétique. En cas de

doutes, utiliser le calibre suivant.

Tension Longueur totale du cordon en pieds

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Calibre minimal des cordons de rallonge

Plus le calibre est petit, plus la

rallonge peut supporter de courant.

POUR RÉDUIRE LE RISQUE D’EFFET DE REBOND

• Saisir fermement la scie avec les deux mains à tout moment.

• Rester attentif – conserver la maîtrise.

• Soutenir les longs matériaux qui dépassent. Lorsque le matériau est découpé et qu’il s’affaiblit,

il s’affaissera et entraînera un pincement de lame.

• Soutenir les grands panneaux comme dans l’illustration (figure C). Les pièces soutenues

uniquement aux extrémités (figure B) provoqueront un pincement de lame.

• Éviter de scier au-dessus de la tête. Les matériaux peuvent fléchir et pincer la lame.

• S’assurer que le matériau à découper est serré (figure E), solidement soutenu et en équilibre

sur une surface de travail solide, stable et mise de niveau. Soutenir la pièce de sorte que la

plus large partie de la semelle de la scie soit sur la partie de la pièce qui ne tombe pas après

réalisation de la coupe. Ne jamais tenir à la main la portion de la pièce qui sera coupée (figure D).

• Conserver les lames aiguisées et propres.

• Utiliser un guide longitudinal ou à bord droit lors de sciage en long. Faire attention, car la

bande découpée peut s’affaisser ou se tordre, fermant ainsi le trait de scie, pinçant la lame et

provoquant un EFFET DE REBOND.

• Ne pas forcer l’outil. Des paramètres du bois tels que nœuds, dureté, solidité, humidité, bois

traité par pression et fraîchement coupé peuvent fortement charger la scie et provoquer un

blocage. Pousser la scie plus lentement lorsque cela se produit.

• Ne pas retirer la scie de la pièce pendant une opération de découpe lorsque la lame se déplace.

• Laisser la scie atteindre son plein régime avant de placer la lame en contact avec le matériau à

découper. Un démarrage de la scie lorsque la lame est en contact avec la pièce ou dans le trait

de coupe peut provoquer des blocages ou un mouvement soudain de la scie vers l’arrière.

• Ne jamais essayer de soulever la scie lors d’une opération de découpe biseautée. Cela

provoque le grippage et le blocage de la lame.

15

Page 16

• Fixer toujours votre ouvrage pour éviter tout mouvement durant la découpe.

• Ne pas forcer la scie sur sa ligne si la découpe commence à dériver. Cela peut provoquer des

EFFETS DE REBOND. Arrêter la scie et laisser la lame ralentir et s’immobiliser. La retirer du

trait de coupe et entamer une nouvelle coupe sur la ligne.

• Ne pas reculer une lame en rotation dans le trait de coupe. Suite à une torsion de la scie,

l’arête postérieure de la lame peut mordre dans le matériau, sortir de la pièce et se déplacer

rapidement en direction de l’opérateur.

• Éviter de couper des clous. Inspecter le bois et retirer tous les clous qui s’y trouvent avant

1

6

2

3

4

DESCRIPTION FONCTIONNELLE

1. Module d’ébouteuse BDCMTTS

2. Bouton de verrouillage actif

3. Dispositif de verrouillage de la broche

4. Clé

d’entamer la découpe.

SOUTIEN DE GRANDS PANNEAUX/FIXATION DE

LA PIÈCE

Soutenir les grands panneaux pour réduire le risque

de pincement et d’effet de rebond de la lame. Les

grands panneaux s’affaissent sous leur propre poids,

comme montré à la

gure A.

5

7

5. Semelle

6. Pare-main supérieur

7. Pare-main inférieur de la scie

8. Retracción de la palanca

A

Le matériel se plie sur la lame causant les

charges lourdes ou le contrecoup

Mal

8

Installer des pièces d’appui sous le panneau, des

deux cotés, près de la ligne de coupe et du bord du

panneau (gure B).

16

B

Le travail de soutien près a coupé

Page 17

Ne jamais tenir la pièce dans ses mains ou la placer de

travers sur ses jambes pour la couper (gure C).

C

Fixer solidement la pièce à une plateforme stable, comme

montré à la figure D. Il est important de soutenir la pièce

correctement afin de minimiser l’exposition des parties

du corps à la lame, de coincer celle-ci ou de perdre la

maîtrise de l’outil.

PRÉPARATION POUR L’ASSEMBLAGE

ET LE RÉGLAGE

AVERTISSEMENT

blessures, toujours retirer le bloc-piles de la scie

avant n’importe lequel des réglages qui suivent.

FIXATION ET RETRAIT DE LA LAME –

FIGURES E ET F

• Dégager le pare-main inférieur et assembler la lame (7)

et la rondelle de serrage (9), comme l’illustre la gure E.

• Enfoncer le dispositif de verrouillage de la broche (3)

tout en tournant la broche de la scie avec la clé de lame

(4) jusqu’à ce que le verrou de la lame s’engage et que

la lame s’immobilise, comme l’illustre la gure F.

REMARQUE : La clé de lame se range sur la scie,

comme l’illustre la figure A.

• Serrer solidement la vis de serrage de la lame (10)

avec la clé de lame.

REMARQUE : Ne jamais enclencher le dispositif

de verrouillage de la broche pendant que la scie

fonctionne ou l’utiliser pour immobiliser l’outil. Ne

jamais mettre la scie en marche avec le dispositif de

verrouillage de la broche engagé. Ces actions pourront

se solder par de graves dommages à la scie.

:

pour réduire le risque de

D

E

3

9

7

10

PROTÈGE-LAME INFÉRIEUR

AVERTISSEMENT

protège-lame inférieur est un dispositif de sécurité

qui réduit le risque de blessures corporelles graves.

Ne jamais utiliser la scie lorsque le protège-lame

inférieur est manquant, endommagé, mal assemblé

ou en mauvais état de fonctionnement. Ne pas se

er sur le protège-lame inférieur pour se protéger

en toutes circonstances. Pour assurer sa propre

sécurité, respecter tous les avertissements et les

mesures de précaution et utiliser correctement la

scie. Vérier le protège-lame inférieur avant chaque

utilisation an de s’assurer qu’il se ferme

correctement tel que décrit sous la rubrique

:

risque de lacération. Le

17

F

Page 18

« Règles de sécurité supplémentaires pour les scies circulaires ». En cas d’absence

ou d’un mauvais fonctionnement du protège-lame, veuillez faire réparer la scie avant

son utilisation. Pour garantir la sécurité et la abilité du produit, coner les réparations,

l’entretien et le réglage à un centre de réparation autorisé ou tout autre centre de

réparation professionnel. On ne doit utiliser que des pièces de rechange identiques.

AVERTISSEMENT : pour réduire le risque de blessure aux yeux, toujours porter une

protection oculaire. Le carbure est un matériel dur mais fragile et les matières étrangères présentes

dans la pièce, comme des fils ou des clous, peuvent fendre ou briser les pointes. Utiliser la scie

uniquement avec le protège-lame en place. Bien assembler et fixer la lame dans la bonne position

de rotation avant son utilisation. Toujours utiliser une lame propre et bien affûtée.

AVERTISSEMENT : ne pas utiliser la scie pour couper les métaux ferreux (acier), la

maçonnerie, le verre ou des carreaux. Une lame émoussée produira des coupes lentes et inefficaces,

surchargera le moteur, engendrera davantage d’éclats de bois et augmenterait le risque de rebond.

FONCTIONNEMENT

MISE EN GARDE : Risque de choc électrique. L’outil ne doit être utilisé près de l’eau

en aucun temps.

AVERTISSEMENT

la lame immédiatement après avoir utilisé l’outil. En effet, elles peuvent devenir très chaudes. À

manipuler avec précaution. Toujours laisser refroidir les accessoires et la pièce avant de les manipuler.

AVERTISSEMENT

bloc-piles ou débrancher la fiche de l’alimentation avant d’effectuer tout réglage ou de retirer ou

d’installer tout module ou accessoire. Retirer tout accessoire du module avant le retrait ou

l’installation du module.

REMARQUE : Consulter le mode d’emploi du bloc d’alimentation avant d’utiliser l’outil pour

connaître tous les avertissements de sécurité et les détails au sujet de l’installation et du

retrait des modules.

FONCTIONNEMENT

• Pour passer de l’outil, appuyez sur et maintenez le verrou actif off (2), puis appuyez sur

l’interrupteur pleinement à vitesse variable sur l’unité de puissance. Une fois que le foret

commence à fonctionner, relâchez le verrou actif-off (2).

• Pour éteindre l’outil, relâcher la détente à vitesse variable.

REMARQUE : Ce module ne fonctionne que vers l’avant. Le commutateur coulissant avant/

arrière du bloc d’alimentation ne devrait pas être capable de commuter vers l’arrière.

: Risque de lacérations ou de brûlures. Ne pas toucher à la pièce ou à

:

Pour réduire le risque de blessures, éteindre l’outil et en retirer le

SÉLECTION DE LA LAME

La scie circulaire est conçue pour les lames d’un diamètre de 86 mm (3 3/8 po) avec un

alésage d’un diamètre de 15 mm. Les lames doivent fonctionner à un régime de 3 000 tr/

min (ou plus).

REMARQUE : Cette scie est conçue pour couper le bois et le plastique. Ne pas utiliser

les lames à maçonnerie ou à métaux. NE PAS utiliser de meules abrasives.

COUPES GÉNÉRALES

AVERTISSEMENT : Pour réduire le risque de blessure, retirer le bloc-piles et suivre

toutes les consignes d’assemblage, de réglage et de conguration.

S’assurer que le pare-main inférieur fonctionne. Sélectionner la lame appropriée au matériau à découper.

• Mesurer et marquer le bois à découper.

• Soutenir et fixer solidement la pièce (voir Règles de sécurité et instructions).

• Utiliser le matériel de sécurité approprié et requis (voir Règles de sécurité).

• Protéger et entretenir la zone de travail (voir Règles de sécurité).

• Insérer le bloc-piles et s’assurer que la détente de la scie fonctionne.

SCIAGE

AVERTISSEMENT : Pour réduire le risque de blessure corporelle grave, toujours tenir

l’outil des deux mains.

• Laisser la lame fonctionner librement quelques secondes avant de commencer la coupe.

• Appuyer légèrement sur l’outil tout en effectuant la coupe.

• Travailler en appuyant la semelle sur la pièce.

18

Page 19

CONSEILS POUR UNE UTILISATION OPTIMALE

• Pour obtenir de meilleurs résultats, utiliser une lame à 20 à 24 dents.

• Comme il est impossible d’éviter des éclats le long de la ligne de coupe sur la partie

supérieure de l’ouvrage, couper sur le côté où les éclats sont tolérés.

• Lorsque les éclats doivent être limités, par exemple lors de la coupe de stratifiés, fixer une

planche de contreplaqué sur la partie supérieure de l’ouvrage.

DÉCOUPE EN POCHE (FIGURE G)

AVERTISSEMENT

main en position élevée. Ne jamais déplacer la scie

vers l’arrière lors de la coupe en poche, car elle peut

alors se soulever de la pièce, ce qui risque de

provoquer une blessure.

AVERTISSEMENT

blessure corporelle grave, toujours tenir l’outil des

deux mains.

AVERTISSEMENT

Lorsque la lame commence à couper le matériau,

relâchez immédiatement le levier de rétraction.

Une coupe en poche est une coupe effectuée dans

un plancher, un mur ou toute autre surface plane.

• Incliner la scie vers l’avant et faire reposer la partie avant de la plaque d’assise sur la pièce à couper.

• Au moyen du levier d’escamotage, relever le pare-main inférieur. Abaisser l’arrière de la

plaque d’assise jusqu’à ce que les dents de la lame touchent presque le trait de coupe.

• Relâcher le pare-main (son contact avec la pièce permettra de le maintenir en place et de

l’ouvrir librement au moment d’amorcer la coupe). Cesser de tenir le levier du pare-main et

saisir fermement le haut du bloc d’alimentation. Positionner le corps et les bras pour résister

à l’effet de rebond le cas échéant.

• S’assurer que la lame ne touche pas la surface à couper avant le démarrage de la scie.

• Démarrer le moteur et abaisser lentement la scie jusqu’à ce que la plaque d’assise repose à

plat contre la pièce à couper. Avancer la scie le long de la ligne de coupe jusqu’à ce que la

coupe soit terminée.

• Relâcher la détente et attendre que la lame s’immobilise puis retirer la lame de la pièce.

• Lors de l’amorce d’une nouvelle coupe, répéter les étapes précédentes.

:

Ne jamais fixer le pare-

:

Pour réduire le risque de

:

Risque de lacération.

G

DÉPANNAGE

Problème Cause possible Solution possible

• L’appareil refuse de

démarrer

• Le module n’est • S’assurer que le module est poussé

pas solidement fixé. entièrement dans le bloc d’alimentation.

Pour de l’aide avec l’outil, consulter notre site Web www.blackanddecker.com pour

l’emplacement du centre de réparation le plus près ou communiquer avec l’assistance BLACK &

DECKER au 1-800-544-6986.

REMARQUE : Consulter le mode d’emploi du bloc d’alimentation pour trouver des solutions de

dépannage en cas de défaut de fonctionnement.

ENTRETIEN

Nettoyer l’outil seulement à l’aide d’un savon doux et d’un linge humide. Ne laisser aucun liquide

s’infiltrer dans l’outil et ne jamais immerger l’outil.

IMPORTANT : Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en confier la

réparation, l’entretien et les rajustements qu’à un centre de service ou à un atelier d’entretien

autorisé n’utilisant que des pièces de rechange identiques.

ACCESSOIRES

AVERTISSEMENT: L’utilisation de tout accessoire non recommandé pour l’outil peut

être dangereuse.

Les détaillants et le centre de service de la région vendent les accessoires recommandés pour

l’outil. Pour trouver un accessoire, composer le 1 800 544-6986.

19

Page 20

Cet appareil est conforme aux dispositions du paragraphe 15 des règlements de la FCC.

Son fonctionnement est régi par les deux conditions suivantes : (1) Cet appareil ne peut pas

causer d’interférence nuisible et (2) cet appareil doit accepter toutes les interférences reçues, y

compris celles qui risquent d’en gêner le fonctionnement.

REMARQUE : ce matériel a été testé et a été déclaré conforme aux limites en vigueur

concernant les dispositifs numériques de classe B, en vertu de la partie 15 de la réglementation

FCC. Ces limites visent à assurer une protection raisonnable contre tout brouillage nuisible

dans une installation résidentielle. Ce matériel produit, consomme et peut émettre une

énergie de radiofréquence et, s’il n’est pas installé et utilisé conformément aux directives qui

l’accompagnent, il peut entraîner un brouillage nuisible des communications radio. Cependant,

nous ne garantissons pas l’absence de brouillage dans tous les types d’environnement. Si,

après avoir effectué une vérification en mettant l’appareil hors tension puis sous tension,

l’utilisateur s’aperçoit que ce matériel provoque un brouillage nuisible à la réception des

signaux de radio ou de télévision, il lui faudra essayer de corriger ce brouillage en prenant une

ou plusieurs des mesures ci-dessous :

• Réorienter ou repositionner l’antenne de réception.

• Éloigner le plus possible le matériel du récepteur.

• Brancher le matériel dans une prise électrique située sur un circuit différent de celui du récepteur.

• Consulter le distributeur ou un technicien radio/télévision expérimenté pour obtenir de l’aide.

Tout changement ou toute modification à cet appareil qui nʼest pas expressément approuvé par

lʼinstitution responsable de la conformité peut faire annuler le droit de lʼutilisateur dʼutiliser ce

matériel. Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

INFORMATION SUR LES RÉPARATIONS

Tous les centres de réparation Black & Decker sont dotés de personnel qualifié en matière

d’outillage électrique; ils sont donc en mesure d’offrir à leur clientèle un service efficace et fiable.

Que ce soit pour un avis technique, une réparation ou des pièces de rechange authentiques

installées en usine, communiquer avec l’établissement Black & Decker le plus près de chez vous.

Pour trouver l’établissement de réparation de votre région, consulter le répertoire des Pages

jaunes à la rubrique « Outils électriques » ou composer le numéro suivant : 1-800-544-6986 ou

consulter le site www.blackanddecker.com

GARANTIE COMPLÈTE DE DEUX ANS POUR UNE UTILISATION DOMESTIQUE

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout défaut

de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé sans frais de

l’une des deux façons suivantes :

La première façon consiste en un simple échange chez le détaillant qui l’a vendu (pourvu qu’il

s’agisse d’un détaillant participant). Tout retour doit se faire durant la période correspondant à

la politique d’échange du détaillant (habituellement, de 30 à 90 jours après l’achat). Une preuve

d’achat peut être requise. Vérifier auprès du détaillant pour connaître sa politique concernant

les retours hors de la période définie pour les échanges.

La deuxième option est d’apporter ou d’envoyer le produit (transport payé d’avance) à un

centre de réparation autorisé ou à un centre de réparation de Black & Decker pour faire réparer

ou échanger le produit, à notre discrétion. Une preuve d’achat peut être requise. Les centres

Black & Decker et les centres de service autorisés sont répertoriés dans les pages jaunes,

sous la rubrique « Outils électriques ».

Cette garantie ne s’applique pas aux accessoires. Cette garantie vous accorde des droits

légaux spécifiques et vous pourriez avoir d’autres droits qui varient d’un État ou d’une province

à l’autre. Pour toute question, communiquer avec le directeur du centre de réparation Black &

Decker le plus près de chez vous. Ce produit n’est pas destiné à un usage commercial.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1-800-544-6986 pour

en obtenir le remplacement gratuit.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits vendus en Amérique

latine. Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique

présente dans l’emballage, appeler l’entreprise locale ou consulter le site Web pour les

informations relatives à cette garantie.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique

“Outils électriques”

des Pages Jaunes

pour le service et les ventes.

20

Page 21

ADITAMENTO DE

SIERRA DE RECORTE

MANUAL DE INSTRUCCIONES

Catálogo N°

BDCMTTS

Gracias por elegir Black & Decker!

Visite www.BlackandDecker.com/NewOwner

para registrar su nuevo producto.

LEA EL MANUAL ANTES DE DEVOLVER

ESTE PRODUCTO POR CUALQUIER MOTIVO:

Si tiene una consulta o algún inconveniente con su producto Black & Decker, visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

Si no encuentra la respuesta o no tiene acceso a Internet, llame al 1-800-544-6986 de

lunes a viernes de 8 a.m. a 5 p.m. hora del Este para hablar con un agente.

Cuando llame, tenga a mano el número de catálogo.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

21

Page 22

ADVERTENCIA: Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

Conserve todas las advertencias e instrucciones para futuras consultas.

ADVERTENCIA: Lea todas las advertencias de seguridad y todas las

instrucciones que vienen con la unidad motriz (BDCDMT112, BDCDMT120 o

BDEDMT) antes de utilizar este accesorio. El incumplimiento de las advertencias e

instrucciones puede provocar una descarga eléctrica, un incendio y/o lesiones graves.

Normas especícas de seguridad

a) ADVERTENCIA: Mantenga las manos alejadas del área de corte y de la hoja.

Mantenga la segunda mano en el mango auxiliar o en la carcasa del motor. Si las dos

manos están sujetando la sierra, no pueden ser cortadas por la hoja.

b) No ponga las manos debajo de la pieza de trabajo. El protector no puede protegerle de

la hoja debajo de la pieza de trabajo.

c) Ajuste la profundidad de corte al grosor de la pieza de trabajo. Menos de un diente

completo de los dientes de la hoja debe ser visible debajo de la pieza de trabajo.

d) No sujete nunca la pieza que esté cortando en las manos o atravesada sobre una

pierna. Sujete rmemente la pieza de trabajo a una plataforma estable.

e) Sujete la herramienta mecánica por las supercies de agarre con aislamiento cuando

realice una operación en la que la herramienta de corte podría entrar en contacto

con cables ocultos o con su propio cable de alimentación. El contacto con un cable

“con corriente” hará que las partes metálicas de la herramienta mecánica que estén al

descubierto también “lleven corriente”, lo cual causará descargas al operador.

f) Cuando corte al hilo, utilice siempre un tope-guía para cortar al hilo o una guía de

borde recto. Esto mejora la precisión del corte y reduce las probabilidades de que la hoja

se atasque.

g) Utilice siempre hojas que tengan el tamaño correcto y la forma correcta (de diamante

frente a redonda) de agujeros para el eje portaherramienta. Las hojas que no coincidan

con los herrajes de montaje de la sierra funcionarán excéntricamente, causando pérdida de control.

h) No use nunca arandelas de hoja o un perno de hoja que estén dañados o sean

incorrectos. Las arandelas y el perno de la hoja se diseñaron especialmente para su sierra,

con el fin de lograr un rendimiento óptimo y una seguridad óptima de funcionamiento.

CAUSAS DEL RETROCESO Y SU PREVENCIÓN POR PARTE DEL OPERADOR

• El retroceso es una reacción repentina a una hoja de sierra pellizcada, atascada o

desalineada, que hace que una sierra descontrolada se levante y se salga de la pieza de

trabajo, hacia el operador.

• Cuando la hoja se pellizca o se atasca fuertemente al cerrarse la sección de corte, la hoja se

para y la reacción del motor impulsa la unidad rápidamente hacia atrás, hacia el operador.

• Si la hoja se tuerce o se desalinea en el corte, los dientes ubicados en el borde trasero de la

hoja pueden penetrar en la superficie superior de la madera, haciendo que la hoja trepe, se

salga de la sección de corte y salte hacia atrás, hacia el operador.

El retroceso es el resultado de un uso inapropiado de la sierra y/o de procedimientos o

situaciones de utilización incorrectos y se puede evitar tomando las precauciones apropiadas

que se indican a continuación:

a) Mantenga un agarre rme con las dos manos en la sierra y posicione los brazos

de modo que puedan resistir las fuerzas de retroceso. Las fuerzas de retroceso pueden

ser controladas por el operador, si se toman las precauciones adecuadas.

b) Cuando la hoja se esté atascando o cuando se interrumpa un corte por cualquier

motivo, suelte el gatillo y sujete la sierra de modo que esté inmóvil en el material

hasta que la hoja se detenga por completo. No intente nunca retirar la sierra de la

pieza de trabajo ni tirar de la sierra hacia atrás mientras la hoja esté en movimiento

o se podría producir retroceso. Investigue y tome medidas correctivas para eliminar la

causa de atasco de la hoja.

22

Page 23

c) Cuando rearranque una sierra en la pieza de trabajo, centre la hoja de sierra en

la sección de corte y asegúrese de que los dientes de la hoja de sierra no estén

acoplados en el material. Si la hoja de sierra se está atascando, podría desplazarse o

experimentar retroceso respecto a la pieza de trabajo cuando se arranque la sierra.

d) Soporte los paneles grandes para minimizar el riesgo de que la hoja se pellizque y se

produzca retroceso. Los paneles grandes tienden a combarse bajo su propio peso. Se

deben colocar soportes debajo del panel a ambos lados, cerca de la línea de corte y cerca

del borde del panel.

e) No use hojas desaladas o dañadas. Las hojas desafiladas o con triscado inapropiado

producen una sección de corte estrecha que causa fricción excesiva, atasco de la hoja y

retroceso.

f) Las palancas de jación de ajuste de la profundidad y del bisel de la hoja deben estar

apretadas y sujetas rmemente antes de realizar el corte. Si el ajuste de la hoja cambia

mientras se realiza el corte, dicho cambio podría causar atasco y retroceso.

g) Tenga precaución adicional cuando haga un “corte por penetración” en paredes

existentes u otras áreas ciegas. La hoja que sobresale podría cortar objetos que pueden

causar retroceso.

INSTRUCCIONES DE SEGURIDAD PARA EL PROTECTOR INFERIOR

a) Compruebe el protector inferior para vericar si se cierra apropiadamente antes

de cada uso. No utilice la sierra si el protector inferior no se mueve libremente

y no se cierra instantáneamente. No sujete nunca con abrazaderas ni amarre el

protector inferior en la posición abierta. Si la sierra se cae accidentalmente, el protector

inferior se podría doblar. Suba el protector inferior con el mango retráctil y asegúrese de

que se mueve libremente y no toca la hoja ni ninguna otra pieza, en todos los ángulos y

profundidades de corte.

b) Compruebe el funcionamiento del resorte del protector inferior. Si el protector y el

resorte no están funcionando correctamente, se les debe hacer servicio de ajustes

y reparaciones antes de la utilización. El protector inferior podría funcionar con dificultad

debido a que haya piezas dañadas, depósitos gomosos o una acumulación de residuos.

c) El protector inferior se debe retraer manualmente sólo para realizar cortes

especiales, tales como “cortes por penetración” y “cortes compuestos”. Suba

el protector inferior por el mango retráctil y, en cuanto la hoja entre en el material,

se debe soltar el protector inferior. Para todas las demás operaciones de aserrado, el

protector inferior debe funcionar automáticamente.

d) Asegúrese siempre de que el protector inferior esté cubriendo la hoja antes de

dejar la sierra en un banco de trabajo o en el piso. Una hoja que se esté moviendo

por inercia hasta detenerse y no esté protegida hará que la sierra se desplace hacia atrás,

cortando todo aquello que esté en su camino. Tenga en cuenta el tiempo que se requiere

para que la hoja se detenga después de soltar el interruptor.

INSTRUCCIONES DE SEGURIDAD ADICIONALES

• Utilice abrazaderas u otra forma práctica para asegurar y soportar la pieza de trabajo en

una plataforma estable. Sostener la pieza de trabajo con la mano o contra el cuerpo no brinda la

estabilidad requerida y puede llevar a la pérdida del control.

• Mantenga el cuerpo a un u otro lado de la hoja de la sierra, nunca en línea con la misma. El

RETROCESO podría despedir la sierra hacia atrás (vea Causas del retroceso y prevención por

parte del operador y RETROCESO).

• Evite cortar clavos. Inspeccione si hay clavos. Retire todos los clavos de la madera antes

de cortar.

•

Siempre asegúrese de que nada interera con el movimiento del protector inferior de la hoja.

• Los accesorios deben estar clasicados para la velocidad recomendada en la etiqueta de

advertencia de la herramienta, como mínimo. Los discos y otros accesorios que funcionen

por encima de su velocidad nominal pueden desarmarse y provocar lesiones. La capacidad

nominal de los accesorios siempre debe ser superior a la velocidad de la herramienta, indicada en

la placa de la misma.

• Siempre asegúrese de que todos los componentes estén montados correcta y rmemente

antes de utilizar la herramienta.

• Siempre manipule la hoja de la sierra con cuidado al montarla o retirarla.

23

Page 24

•

Siempre espere hasta que el motor haya alcanzado la velocidad máxima antes de

iniciar un corte.

• Siempre mantenga los mangos secos, limpios y libres de aceite y grasa. Sostenga la

herramienta rmemente con ambas manos cuando esté en uso.

• Siempre esté alerta en todo momento, especialmente durante operaciones repetitivas y

monótonas. Siempre asegúrese de la posición de sus manos con respecto a la hoja.

• Manténgase alejado de los pedazos de los extremos que pueden caer después de

cortarlos. Estos pueden estar calientes, filosos y/o ser pesados. Pueden producirse graves

lesiones personales.

• Reemplace o repare los cables dañados. Asegúrese de que el cable prolongador esté en

buenas condiciones. Utilice solamente cables prolongadores de 3 conductores que tengan

enchufes a tierra de 3 patas y receptáculos tripolares que se adapten al enchufe de la herramienta.

• Para garantizar la seguridad, un cable prolongador debe tener un tamaño de cable

adecuado (AWG o Calibre de conductor de Estados Unidos). Cuanto más pequeño sea el

número de calibre del conductor, mayor será la capacidad del cable; es decir, un calibre 16 tiene

más capacidad que un calibre 18. Un cable de menor capacidad provocará una disminución en

el voltaje de la línea, lo cual producirá una pérdida de potencia y sobrecalentamiento. Cuando se

utiliza más de una prolongación para lograr la longitud total, asegúrese de que cada prolongación

tenga la medida mínima del conductor. La siguiente tabla muestra la medida correcta que debe

usar según la longitud del cable y la capacidad nominal en amperios indicada en la placa. En

caso de duda, utilice el calibre inmediatamente superior. Cuanto menor sea el número de calibre,

más grueso será el cable.

ADVERTENCIA: Durante el uso, utilice siempre protección auditiva adecuada que

cumpla con la norma ANSI S12.6 (S3.19). En ciertas circunstancias y según el período de uso,

el ruido de este producto puede contribuir a la pérdida de audición.

ADVERTENCIA: USE SIEMPRE LENTES DE SEGURIDAD. Los anteojos de uso diario

NO son lentes de seguridad. Utilice también máscaras faciales o para polvo si el corte produce

polvillo. UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• Protección para los ojos según la norma ANSI Z87.1 (CAN/CSA Z94.3)

• Protección auditiva según la norma ANSI S12.6 (S3.19)

• Protección respiratoria según las normas NIOSH/OSHA/MSHA

ADVERTENCIA

esmerilar, taladrar y realizar otras actividades de la construcción, contiene productos químicos

reconocidos por el Estado de California como causantes de cáncer, defectos de nacimiento u

otros problemas reproductivos. Algunos de estos productos químicos son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, el cemento y otros productos de mampostería, y

• el arsénico y el cromo de la madera con tratamiento químico.

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este tipo

de trabajo. Para reducir la exposición a estos productos químicos: trabaje en áreas bien ventiladas

y trabaje con equipos de seguridad aprobados, como las máscaras para polvo especialmente

diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado, esmerilado y taladrado

eléctricos, así como de otras actividades del sector de la construcción. Lleve ropa protectora y

lave con agua y jabón las zonas expuestas. Si permite que el polvo se introduzca en la boca u ojos

o quede sobre la piel, puede favorecer la absorción de productos químicos peligrosos.

: parte del polvo producido por las herramientas eléctricas al lijar, aserrar,

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo lo cual

puede causar lesiones respiratorias serias y permanentes y otros tipos de lesión. Siempre use

protección respiratoria aprobada por NIOSH/OSHA para la exposición al polvo. Dirija las partículas

en dirección opuesta a su cara y cuerpo.

24

Page 25

SÍMBOLOS

• La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y