Page 1

ENRUUA

www.blackanddecker.com

BDCHD12S1

Page 2

ENGLISH

(Original instructions)

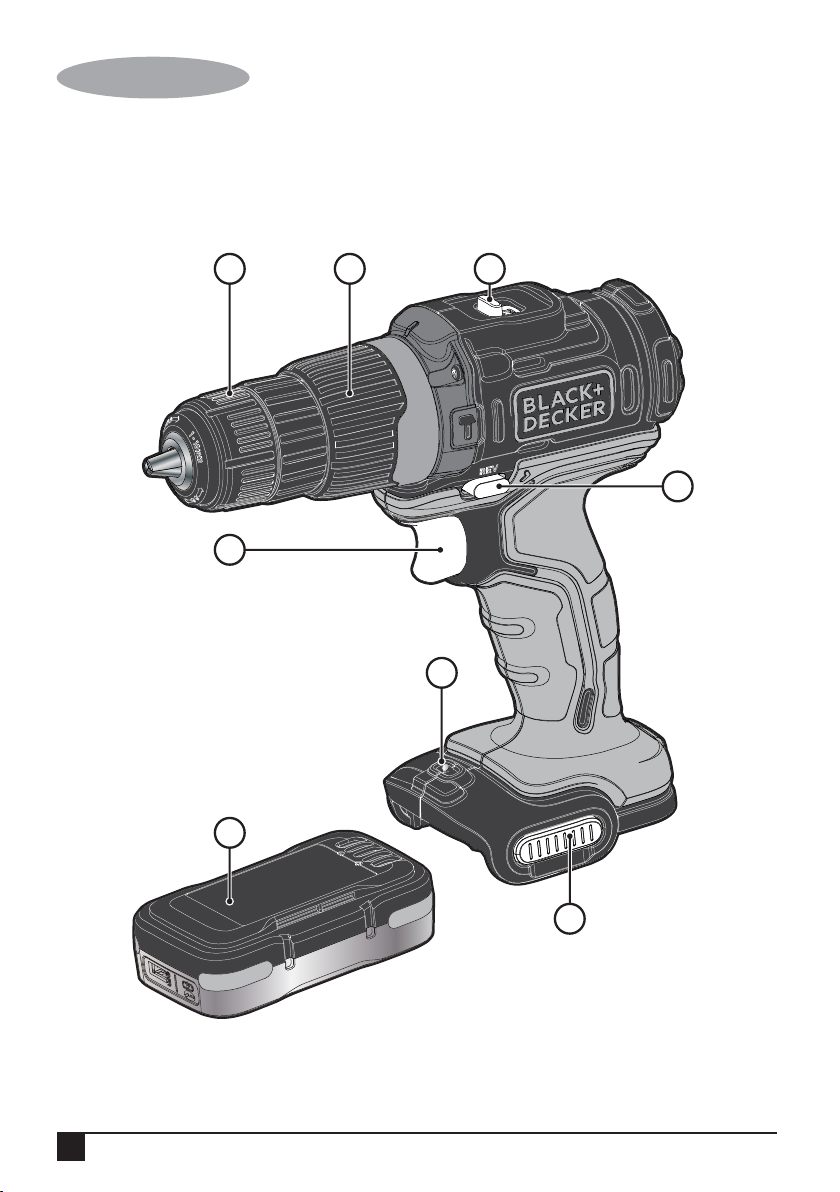

4

3 5

2

1

6

7

8

2

Page 3

(Original instructions)

ENGLISH

79

8

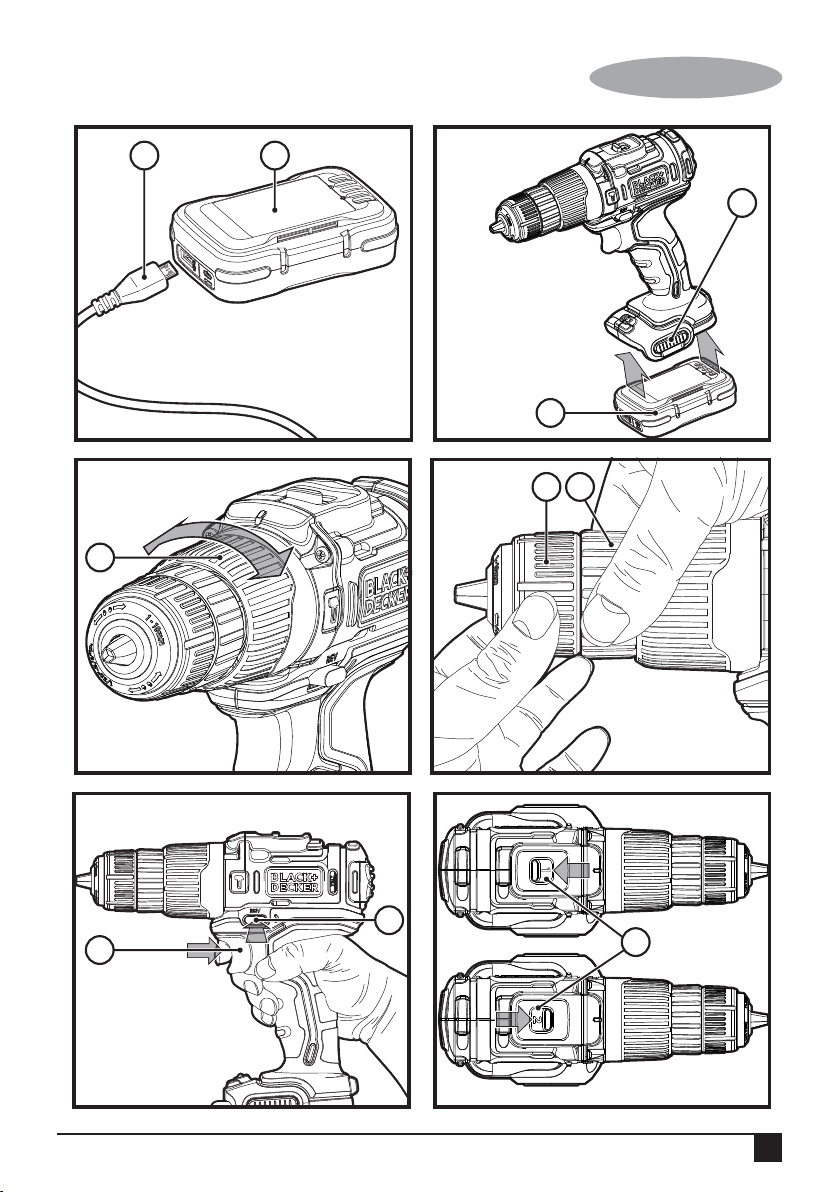

A

7

B

4 4a

3

C

D

2

1

5

E

F

3

Page 4

ENGLISH

(Original instructions)

Intended Use

Your BLACK+DECKER™ BDCHD12S1 Impact

Drill has been designed for screw driving

applications and for drilling in wood, metal

and plastics. This tool is intended for

consumer use only.

Do not return this product to the store,

first contact your local BLACK+DECKER

oce or nearest authorized service center.

Safety instructions

General power tool safety warnings.

Warning! Read all safety warnings,

instructions, illustrations and

specifications provided with this

power tool. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious injury..

Save all warnings and instructions for

future reference.

The term "power tool" in all of the warnings

listed below refers to your mains operated

(corded) power tool or battery operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well

it.Cluttered or dark areas invite

accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if

your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e. When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3. Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious personal

injury.

b. Use personal protective equipment.

Always wear eye protection. Protective

equipment such as a dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure

the switch is in the o-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

4

Page 5

(Original instructions)

ENGLISH

ENGLISH

e. Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair and

clothing away from moving parts. Loose

clothes, jewellery or long hair can be

caught in moving parts.

g. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

h Do not let familiarity gained from

frequent use of tools allow you to

become complacent and ignore tool

safety principles. A careless action can

cause severe injury within a fraction of a

second.

4. Power tool use and care

a. Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b. Do not use the power tool if the switch

does not turn it on and o. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c. Disconnect the plug from the power

source and/or remove the battery pack,

if detachable from the power tool

before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

d. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools and accessories.

Check for misalignment or binding of

moving parts, breakage of parts and any

other condition that may aect the

power tools operation. If damaged, have

the power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g. Use the power tool, accessories and tool

bits etc., in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations dierent from those intended

could result in a hazardous situation.

h. Keep handles and grasping surfaces dry,

clean and free from oil and grease.

Slippery handles and grasping surfaces

do not allow for safe handling and control

of the tool in unexpected situations.

5. Battery tool use and care

a. Recharge only with the charger specified

by the manufacturer. A charger that is

suitable for one type of battery pack may

create a risk of fire when used with

another battery pack.

b. Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of

injury and fire.

c. When battery pack is not in use, keep it

away from other metal objects, like

paper clips, coins, keys, nails, screws, or

other small metal objects, that can make

a connection from one terminal to

another. Shorting the battery terminals

together may cause burns or a fire.

d. Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

If contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from

the battery may cause irritation or burns.

e. Do not use a battery pack or tool that is

damaged or modified. Damaged or

modified batteries may exhibit

unpredictable behaviour resulting in fire,

explosion or risk of injury.

f. Do not expose a battery pack or tool to

fire or excessive temperature. Exposure

to fire or temperature above 130 °C may

cause explosion. NOTE The temperature

„130 °C“ can be replaced by the

temperature „265 °F“.

5

Page 6

ENGLISH

(Original instructions)

g. Follow all charging instructions and do

not charge the battery pack or tool

outside the temperature range specified

in the instructions. Charging improperly

or at temperatures outside the specified

range may damage the battery and

increase the risk of fire.

6. Service

a. Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool

is maintained.

b. Never service damaged battery packs.

Service of battery packs should only be

performed by the or authorized service

providers.

7. Drill safety warnings

1) Safety instructions for all operations

a. Wear ear protectors when impact

drilling. Exposure to noise can cause

hearing loss.

b. Use the auxiliary handle(s). Loss of

control can cause personal injury.

c. Brace the tool properly before use. This

tool produces a high output torque and

without properly bracing the tool during

operation, loss of control may occur

resulting in personal injury.

d. Hold the power tool by insulated

gripping surfaces, when performing an

operation where the cutting accessory

may contact hidden wiring or its own

cord. Cutting accessory contacting a

“live” wire may make exposed metal

parts of the power tool “live” and could

give the operator an electric shock.

2) Safety instructions when using long drill

bits

a. Never operate at higher speed than the

maximum speed rating of the drill bit. At

higher speeds, the bit is likely to bend if

allowed to rotate freely without

contacting the workpiece, resulting in

personal injury.

b. Always start drilling at low speed and

with the bit tip in contact with the

workpiece. At higher speeds, the bit is

likely to bend if allowed to rotate freely

without contacting the workpiece,

resulting in personal injury.

c. Apply pressure only in direct line with

the bit and do not apply excessive

pressure. Bits can bend causing breakage

or loss of control, resulting in personal

injury.

Additional power tool safety

warnings

Warning! Additional safety warnings for

drill/drivers.

• Use clamps or another practical way to

secure and support the workpiece to a

stable platform Holding the work by hand

or against your body leaves it unstable

and may lead to loss of control.

• Before drilling into walls, floors or ceilings

check for the location of wiring and

pipes.

• Avoid touching the tip of a drill bit just

after drilling, as it may be hot.

• This tool is not intended for use by

persons(including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instruction concerning use of the

appliance by a person responsible for

their safety. Children should be

supervised to ensure that they do not

play with the appliance.

• The intended use is described in this

instruction manual. The use of any

accessory or attachment or performance

of any operation with this tool other than

those recommended in this instruction

manual may present a risk of personal

injury and/or damage to property.

Safety of others

• This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instruction concerning use of the

appliance by a person responsible for

their safety.

6

Page 7

(Original instructions)

ENGLISH

• Children should be supervised to ensure

that they do not play with the appliance.

Residual risks

Additional residual risks may arise when

using the tool which may not be included in

the enclosed safety warnings. These risks

can arise from misuse, prolonged use etc.

Even with the application of the relevant

safety regulations and the implementation

of safety devices, certain residual risks

cannot be avoided. These include:

• Injuries caused by touching any

rotating/moving parts.

• Injuries caused when changing any parts,

blades or accessories.

• Injuries caused by prolonged use of a

tool. When using any tool for prolonged

periods ensure you take regular breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust

developed when using your tool

(example: working with wood, especially

oak, beech and MDF).

Labels on tool

The label on your tool may include the

following symbols:

Warning! To reduce the risk of injury,

the user must read the instruction

manual.

The charger is intended for indoor

use only.

Read this entire manual carefully

before using the appliance.

Position of date barcode

The Date Code, which also includes the year

of manufacture, is printed into the housing.

Example:

2017 XX JN

Year of manufacturing

Electrical safety

Your charger is double insulated;

therefore no earth wire is required.

Always check that the mains voltage

corresponds to the voltage on the rating

plate. Never attempt to replace the charger

unit with a regular mains plug.

• If the supply cord is damaged, it must be

replaced by the manufacturer or an

authorised BLACK+DECKER Service

Centre in order to avoid a hazard.

Batteries

• Never attempt to open for any reason.

• Do not expose the battery to water.

• Do not store in locations where the

temperature may exceed 40 °C.

• Charge only at ambient temperatures

between 10 °C and 40 °C.

• Charge only using the charger provided

with the tool.

• When disposing of batteries, follow the

instructions give in the section

"Protecting the environment".

Do not attempt to charge damaged

batteries

.

Chargers

• Use your BLACK+DECKER charger only

to charge the battery in the tool with

which it was supplied. Other batteries

could burst, causing personal injury and

damage.

• Never attempt to charge

non-rechargeable batteries.

• Have defective cords replaced

immediately.

• Do not expose the charger to water.

• Do not open the charger.

• Do not probe the charger.

The charger is intended for indoor

use only.

Read the instruction manual before

use.

7

Page 8

ENGLISH

(Original instructions)

Features

This tool includes some or all of the

following features.

1. Variable speed switch

2. Forward/reverse slider

3. Torque adjustment collar

4. Keyless chuck

5. Dual range gearing

6. LED work light

7. Battery

8. Battery release button

Assembly

Use

Warning! Let the tool work at its own pace.

Do not overload.

Charging the battery (fig.A)

The battery needs to be charged before first

use and whenever it fails to produce

sucient power on jobs that were easily

done before. The battery may become

warm while charging; this is normal and

does not indicate a problem.

Warning! Do not charge the battery at

ambient temperatures below 10 °C or above

40 °C. Recommended charging

temperature: approx. 24 °C.

Note: The charger will not charge a battery

if the cell temperature is below

approximately 10 °C or above 40 °C.

The battery should be left in the charger

and the charger will begin to charge

automatically when the cell temperature

warms up or cools down.

• To charge the battery, insert the USB

charger (9) into the Battery (7).

• Plug the charger (9) into a suitable

power source and switch on.

• Charge discharged batteries within 1

week. Battery life willn be greatly

diminished if stored in a discharged

state.

Warning! fire Hazard. When disconnecting

the charger from the tool, be sure to unplug

the charger from the outlet first, then

disconnect the charger cord from the tool.

Fitting and removing the battery

(fig.B)

• To fit the battery, line it up with the

receptacle on the tool. Slot the battery

into the receptacle and push up until the

battery snaps into place.

• To remove the battery, push the release

buttons (8) while at the same time pulling

the battery out of the receptacle.

Operating Instructions

Trigger switch & reversing button

(fig.

E)

• The drill is turned ON and OFF by pulling

and releasing the trigger switch (1). The

farther the trigger is depressed, the

higher the speed of the drill.

• A forward/reverse control button (2)

determines the direction of the tool.

• To select forward rotation, release the

trigger switch and depress the

forward/reverse control button to the left.

• To select reverse, depress the

forward/reverse control button the

opposite direction.

Torque control (fig.C)

This tool is fitted with a torque adjustment

collar (3) to select the operating mode and

to set the torque for tightening screws.

Large screws and hard workpiece materials

require a higher torque setting than small

screws and soft workpiece materials.

• For drilling in wood, metal and plastics,

set the collar to the drilling position

symbol

• For screwdriving, set the collar to the

desired setting. If you do not yet know

the appropriate setting, proceed as

follows:

• Set the collar to the lowest torque setting.

• Tighten the first screw.

8

Page 9

(Original instructions)

ENGLISH

• If the clutch ratchets before the desired

result is achieved, increase the collar

setting and continue tightening the

screw. Repeat until you reach the correct

setting. Use this setting for the remaining

screws.

Keyless chuck (fig. D)

To insert a drill bit or other accessory:

• Grasp the rear half of the chuck (4a) with

one hand and use your other hand to

rotate the front half (4) in the

counterclockwise direction, as viewed

from the chuck end.

• Insert the bit or other accessory fully into

the chuck, and tighten securely by

holding the rear half of the chuck and

rotating the front portion in the

clockwise direction as viewed from the

chuck end.

Warning! Do not attempt to tighten drill bits

(or any other accessory) by gripping the

front part of the chuck and turning the tool

on. Damage to the chuck and personal

injury may occur when changing

accessories.

Dual range gearing (Figure F)

The dual range feature of your drill allows

you to shift gears for greater versatility. To

select low speed, high torque setting

(position 1), turn tool off and permit to stop.

Slide gear shifter button (5) away from the

chuck. To select the high speed, low torque

setting (position 2), turn tool off and permit

to stop. Slide gear shifter button towards

the chuck.

Note: Do not change gears when tool is

running. If you are having trouble changing

gears, make sure that the dual range gear

button is either completely pushed forward

or completely pushed back.

Drilling/screwdriving

• Select forward or reverse rotation using

the forward/reverse slider (2).

• To switch the tool on, press the switch

(1). The tool speed depends on how far

you press the switch.

• To switch the tool off, release the switch.

Hints for optimum use

Drilling

• Use sharp drill bits only.

• Support and secure work properly, as

instructed in the Safety Instructions.

• Use appropriate and required safety

equipment, as instructed in the Safety

Instructions.

• Secure and maintain work area, as

instructed in the Safety Instructions.

• Run the drill very slowly, using light

pressure, until the hole is started enough

to keep the drill bit from slipping out of it.

• Apply pressure in a straight line with the

bit. Use enough pressure to keep the bit

biting but not so much as to stall the

motor or deflect the bit.

• Hold the drill firmly with two hands to

control its twisting action.

• DO NOT CLICK THE TRIGGER OF A

STALLED DRILL OFF AND ON IN AN

ATTEMPT TO START IT. DAMAGE TO THE

DRILL CAN RESULT.

• Minimize stalling on breakthrough by

reducing pressure and slowly drilling

through the last part of the hole.

• Keep the motor running while pulling the

bit out of a drilled hole. This will help

reduce jamming.

• Make sure switch turns drill on and off.

Drilling in wood

Holes in wood can be made with the same

twist drill bits used for metal or with spade

bits. These bits should be sharp and should

be pulled out frequently when drilling to

clear chips from the flutes.

Drilling in metal

Use a cutting lubricant when drilling metals.

The exceptions are cast iron and brass which

should be drilled dry. The cutting lubricants

that work best are sulfurized cutting oil or

lard oil.

9

Page 10

ENGLISH

(Original instructions)

Drilling in masonry

For drilling in masonry, set the collar (3) to

the hammer drilling position by aligning the

symbol with the marking. Slide the speed

selector (5) towards the front of the tool

(2nd gear).

Screwdriving

• Always use the correct type and size of

screwdriver bit.

• If screws are difficult to tighten, try

applying a small amount of washing

liquid or soap as a lubricant.

• Always hold the tool and screwdriver bit

in a straight line with the screw

Troubleshooting

Problem Possible cause Possible solution

Unit will not

start.

Battery pack

will not charge.

Unit shuts off

abruptly.

Battery pack not

charged.

Charger not plugged

in.

Surrounding air

temperature too hot

or too cold.

Battery pack has

reached its

maximum thermal

limit.

Out of charge.

(To maximize the life

of the battery pack

it is designed to

shut off abruptly

when the charge is

depleted.)

Check battery pack

charging requirements.

Plug charger into

a working outlet.

Move charger and

battery pack to a

surrounding

airtemperature of

above 40degrees F

(45ºC) or below105

degrees F (+40.5ºC)

Allow battery pack to

cool down.

Place on charger and

allow to charge.

Maintenance

Your BLACK+DECKER tool has been

designed to operate over a long period of

time with a minimum of maintenance.

Continuous satisfactory operation depends

upon proper tool care and regular cleaning.

Your charger does not require any

maintenance apart from regular cleaning.

Warning! Before performing any

maintenance on the tool, remove the

battery from the tool. Unplug the

charger before cleaning it.

• Regularly clean the ventilation slots in

your tool and charger using a soft brush

or dry cloth.

• Regularly clean the motor housing using

a damp cloth. Do not use any abrasive or

solvent-based cleaner.

• Regularly open the chuck and tap it to

remove any dust from the interior.

Important! To ensure product SAFETY and

RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this

manual) should be performed by authorized

service centers or other qualified

organizations, always using identical

replacement parts. Unit contains no user

service able parts inside.

Accessories

Recommended accessories for use with your

tool are available at extra cost from your

local dealer or authorized service center.

Warning! The use of any accessory

not recommended for use with this

tool could be hazardous.

Batteries

BLACK+DECKER batteries can be

recharged many times. At the end of

their useful life, discard batteries with

due care for our environment:

• Run the battery down completely, then

remove it from the tool.

• NiCd, NiMH and Li-Ion batteries are

recyclable. Take them to any authorized

repair agent or a local recycling station.

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you find one day that your

BLACK+DECKER product needs replacement, or if it is of no further use to you, do

not dispose of it with household waste. Make

this product available for separate collection.

10

Page 11

(Original instructions)

ENGLISH

Separate collection of used products

and packaging allows materials to be

recycled and used again. Reuse of

recycled materials helps prevent environmental pollution and reduces the demand for

raw materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by

the retailer when you purchase a new

product.

BLACK+DECKER provides a facility for the

collection and recycling of BLACK+DECKER

products once they have reached the end of

their working life. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER office at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair

agents and full details of our after-sales

service and contacts are available on the

Internet at: www.2helpU.com.

Technical data

Voltage

VDC 12

No-load speed min

0 -1350 RPM

Max. torque Nm 17.5 / 40

Chuck capacity mm 1 - 10

Max Drilling capacity

Steel/wood/Masonary mm 10 / 25/ 10

Weight kg 0.90

(with battery

1.15)

BDCHD12S1

-1

0 - 350 /

Battery

Voltage V

dc

12

Capacity Ah 1.5

Type Lithium-Ion

Guarantee

BLACK+DECKER is confident of the quality

of its products and offers an outstanding

guarantee. This guarantee statement is in

addition to and in no way prejudices your

statutory rights.

If a BLACK+DECKER product becomes

defective due to faulty materials,

workmanship or lack of conformity, within

24 months from the date of purchase,

BLACK+DECKER guarantees to replace

defective parts, repair products subjected to

fair wear and tear or replace such products

to make sure of the minimum inconvenience

to the customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to

misuse or neglect.

• The product has sustained damage

through foreign objects, substances or

accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

BLACK+DECKER service staff.

To claim on the guarantee, you will need to

submit proof of purchase to the seller or an

authorised repair agent. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER office at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair agents

and full details of our aftersales service and

contacts are available on the Internet at:

www.2helpU.com

11

Page 12

РУССКИЙ

(Перевод с оригинала инструкции)

Назначение

Ваша ударная дрель/шуруповёрт BDCHD12S1

BLACK+DECKER

отверстий и заворачивания саморезов в древесине,

металле и кирпичной кладке. Данный инструмент

предназначен только для бытового использования.

не возвращайте данный продукт в магазин.

Сначала обратитесь в ближайший авторизованный

сервисный центр BLACK+DECKER

™ предназначена для сверления

Инструкции По Технике Безопасности

ОБЩИЕ ПРАВИЛА БЕЗОПАСНОСТИ

Внимание! Внимательно прочтите все

инструкции по использованию, правила

безопасности, спецификации, а также

в руководство по эксплуатации данного

электроинструмента. Несоблюдение всех

перечисленных ниже инструкций может привести к

поражению электрическим током, возникновению

пожара и/или получению серьёзной травмы.

Сохраните все инструкции по безопасности и

руководство по эксплуатации для их дальнейшего

использования. Термин «Электроинструмент» во всех

приведённых ниже указаниях относится к вашему

сетевому (с кабелем) электроинструменту или

аккумуляторному (беспроводному)

электроинструменту.

1. Безопасность рабочего места

a. Содержите рабочее место в чистоте и

b. Не используйте электроинструменты, если есть

c. Во время работы с электроинструментом не

2. Электробезопасность

a. Вилка кабеля электроинструмента должна

рассмотрите все иллюстрации, входящие

обеспечьте хорошее освещение. Плохое

освещение рабочего места может привести к

несчастному случаю.

опасность возгорания или взрыва, например,

вблизи легко воспламеняющихся жидкостей,

газов или пыли. В процессе работы

электроинструменты создают искровые разряды,

которые могут воспламенить пыль или горючие

пары.

подпускайте близко детей или посторонних лиц.

Отвлечение внимания может вызвать у Вас потерю

контроля над рабочим процессом.

соответствовать штепсельной розетке. Ни в

коем случае не видоизменяйте вилку

электрического кабеля. Не используйте

соединительные штепсели-переходники, если в

силовом кабеле электроинструмента есть

провод заземления. Использование оригинальной

вилки кабеля и соответствующей ей штепсельной

розетки уменьшает риск поражения электрическим

током.

b. Во время работы с электроинструментом

избегайте физического контакта с

заземлёнными объектами, такими как

трубопроводы, радиаторы отопления,

электроплиты и холодильники. Риск поражения

электрическим током увеличивается, если Ваше тело

заземлено.

c. Не используйте электроинструмент под дождём

или во влажной среде. Попадание воды в

электроинструмент увеличивает риск поражения

электрическим током.

d. Бережно обращайтесь с электрическим кабелем.

Ни в коем случае не используйте кабель для

переноски электроинструмента или для

вытягивания его вилки из штепсельной розетки.

Не подвергайте электрический кабель

воздействию высоких температур и смазочных

веществ; держите его в стороне от острых

кромок и движущихся частей. Повреждённый или

запутанный кабель увеличивает риск поражения

электрическим током

e. При работе с электроинструментом на открытом

воздухе используйте удлинительный кабель,

предназначенный для наружных работ.

Использование кабеля, пригодного для работы на

открытом воздухе, снижает риск поражения

электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде

используйте источник питания, оборудованный

устройством защитного отключения (УЗО).

Использование УЗО снижает риск поражения

электрическим током. Примечание: Термин

«устройство защитного отключения (УЗО)» может

быть заменён на «аварийный прерыватель

заземления» или «автоматический выключатель тока

утечки».

3. Личная безопасность

a. При работе с электроинструментами будьте

внимательны, следите за тем, что Вы делаете, и

руководствуйтесь здравым смыслом. Не

используйте электроинструмент, если Вы устали,

а также находясь под действием алкоголя или

понижающих реакцию лекарственных

препаратов и других средств. Малейшая

неосторожность при работе с

электроинструментами может привести к серьёзной

травме.

b. При работе используйте средства

индивидуальной защиты. Всегда надевайте

защитные очки. Своевременное использование

защитного снаряжения, а именно: пылезащитной

маски, ботинок на нескользящей подошве,

12

Page 13

(Перевод с оригинала инструкции)

РУССКИЙ

защитного шлема или противошумовых наушников,

значительно снизит риск получения травмы.

c. Не допускайте непреднамеренного запуска.

Перед тем, как подключить электроинструмент

к сети и/или аккумулятору, поднять или

перенести его, убедитесь, что выключатель

находится в положении «выключено». Не

переносите электроинструмент, держа палец на

пусковом выключателе, и не подключайте к сетевой

розетке электроинструмент, выключатель которого

установлен в положение «включено», это может

привести к несчастному случаю.

d. Перед включением электроинструмента

снимите с него все регулировочные или гаечные

ключи. Регулировочный или гаечный ключ,

оставленный закреплённым на вращающейся части

электроинструмента, может стать причиной

получения тяжёлой травмы.

e. Работайте в устойчивой позе. Всегда твёрдо

стойте на ногах, сохраняя равновесие. Это

позволит Вам не потерять контроль при работе

электроинструментом в непредвиденной ситуации.

f. Одевайтесь соответствующим образом. Во

время работы не надевайте свободную одежду

или украшения. Следите за тем, чтобы Ваши

волосы или одежда находились в постоянном

отдалении от движущихся частей инструмента.

Свободная одежда, украшения или длинные волосы

могут попасть в движущиеся части инструмента.

g. Если электроинструмент снабжён устройством

сбора и удаления пыли, убедитесь, что данное

устройство подключено и используется

надлежащим образом. Использование устройства

пылеудаления значительно снижает риск

возникновения несчастного случая, связанного с

запыленностью рабочего пространства.

h. Даже если Вы являетесь опытным

пользователем и часто используете подобные

инструменты, не позволяйте себе расслабляться

и игнорировать правила безопасности при

использовании инструментов. Неосторожность и

невнимательность при работе могут привести к

тяжёлым травмам за доли секунды.

4. Использование электроинструментов и

технический уход

a. Не перегружайте электроинструмент.

Используйте Ваш инструмент по назначению.

Электроинструмент работает надёжно и безопасно

только при соблюдении параметров, указанных в

его технических характеристиках.

b. Не используйте электроинструмент, если его

выключатель не устанавливается в положение

включения или выключения. Электроинструмент с

неисправным выключателем представляет

опасность и подлежит ремонту.

c. Отключайте электроинструмент от сетевой

розетки и/или извлекайте аккумулятор (если

имеется) перед регулировкой, заменой

принадлежностей или при хранении

электроинструмента. Такие меры

предосторожности снижают риск случайного

включения электроинструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты

представляют опасность в руках неопытных

пользователей.

e. Регулярно проверяйте исправность

электроинструмента и дополнительных

принадлежностей. Проверяйте точность

совмещения и легкость перемещения

подвижных частей, целостность деталей и

любых других элементов электроинструмента,

воздействующих на его работу. Не используйте

неисправный электроинструмент, пока он не

будет полностью отремонтирован. Большинство

несчастных случаев являются следствием

недостаточного технического ухода за

электроинструментом.

f. Следите за остротой заточки и чистотой

режущих принадлежностей. Принадлежности с

острыми кромками позволяют избежать

заклинивания и делают работу менее утомительной.

g. Используйте электроинструмент, аксессуары и

насадки в соответствии с данным Руководством

по эксплуатации и с учётом рабочих условий и

характера будущей работы. Использование

электроинструмента не по назначению может

создать опасную ситуацию.

h. Следите, чтобы рукоятки и поверхности захвата

оставались сухими, чистыми и не содержали

следов масла и консистентной смазки. Скользкие

рукоятки и поверхности захвата не обеспечивают

безопасное обращение и управление инструментом

в неожиданных ситуациях.

5. Использование аккумуляторных инструментов и

технический уход

a. Заряжайте аккумулятор зарядным устройством

марки, указанной производителем. Зарядное

устройство, которое подходит к одному типу

аккумуляторов, может создать риск возгорания в

случае его использования с аккумуляторами другого

типа.

13

Page 14

РУССКИЙ

(Перевод с оригинала инструкции)

b. Используйте электроинструменты только с

разработанными специально для них

аккумуляторами. Использование аккумулятора

какой-либо другой марки может привести к

возникновению пожара и получению травмы.

c. Держите не используемый аккумулятор

подальше от металлических предметов, таких

как скрепки, монеты, ключи, гвозди, шурупы, и

других мелких металлических предметов,

которые могут замкнуть контакты

аккумулятора. Короткое замыкание контактов

аккумулятора может привести к получению ожогов

или возникновению пожара.

d. В критических ситуациях из аккумулятора

может вытечь жидкость (электролит); избегайте

контакта с кожей. Если жидкость попала на

кожу, смойте её водой. Если жидкость попала в

глаза, обращайтесь за медицинской помощью.

Жидкость, вытекшая из аккумулятора, может

вызвать раздражение или ожоги.

e. Не используйте повреждённые или

модифицированные аккумуляторы и

инструменты. Повреждённые или

модифицированные аккумуляторы нестабильны и

непредсказуемы и могут стать причиной пожара,

взрыва или получения травмы.

f. Не подвергайте аккумулятор или инструмент

воздействию огня или чрезвычайно высоких

температур. Воздействие огня или температуры

выше +130°C может привести к взрыву

аккумулятора.

g. Следуйте всем инструкциям по зарядке и не

заряжайте аккумулятор или инструмент, если

окружающая температура выходит за пределы,

обозначенные в инструкциях. Несоблюдение

процедуры зарядки или зарядка при окружающей

температуре, выходящей за оговоренные пределы,

может стать причиной повреждения аккумулятора

и увеличивает риск возникновения пожара.

6. Техническое обслуживание

a. Ремонт Вашего электроинструмента должен

производиться только квалифицированными

специалистами с использованием идентичных

запасных частей. Это обеспечит безопасность

Вашего электроинструмента в дальнейшей

эксплуатации.

b. Никогда не ремонтируйте самостоятельно

повреждённые аккумуляторы. Ремонт

аккумуляторов должен производиться только

производителем или в авторизованном сервисном

центре.

7. Правила безопасности при сверлении

1) Меры безопасности при выполнении всех

операций

a. При сверлении с ударом всегда надевайте

противошумовые наушники. Воздействие шума

может привести к потере слуха.

b. Используйте дополнительную рукоятку

(рукоятки). Потеря контроля над инструментом

может привести к получению тяжёлой травмы.

c. Перед использованием правильно захватите

инструмент. Данный инструмент производит

высокий выходной крутящий момент, и без

правильного захвата существует риск потери

контроля над инструментом и получения телесной

травмы.

d. Держите инструмент за изолированные ручки

при выполнении операций, во время которых

режущий инструмент может соприкасаться со

скрытой проводкой или собственным кабелем.

Контакт насадки с находящимся под напряжением

проводом делает не покрытые изоляцией

металлические части электроинструмента также

«живыми», что создаёт опасность поражения

оператора электрическим током.

2) Меры предосторожности при использовании

длинных свёрл

a. Никогда не работайте на скорости,

превышающей максимальную скорость

вращения сверла. На более высоких скоростях

сверло, скорее всего, согнётся, если будет свободно

вращаться, не соприкасаясь с заготовкой, что

приведёт к получению телесной травмы.

b. Всегда начинайте сверление на низкой скорости,

и прижав кончик сверла к поверхности

заготовки. На более высоких скоростях сверло,

скорее всего, согнётся, если будет свободно

вращаться, не соприкасаясь с заготовкой, что

приведёт к получению телесной травмы.

c. Оказывайте давление только на прямой линии с

насадкой, и никогда не оказывайте чрезмерного

давления. Насадка может согнуться, что станет

причиной её поломки или потери контроля над

инструментом, что приведёт к получению телесной

травмы.

Держите инструмент за изолированные ручки при

выполнении операций, во время которых

крепежная деталь может соприкасаться со скрытой

проводкой или собственным кабелем. Контакт

крепёжного элемента с находящимся под напряжением

проводом делает не покрытые изоляцией

металлические части электроинструмента также

«живыми», что создаёт опасность поражения оператора

электрическим током.

14

Page 15

(Перевод с оригинала инструкции)

РУССКИЙ

Дополнительные меры

безопасности при работе с

электроинструментами

Внимание! Дополнительные меры предосторожности

при использовании дрелей/шуруповёртов

• Используйте струбцины или другие

приспособления для фиксации обрабатываемой

детали, устанавливая их только на неподвижной

поверхности. Если держать обрабатываемую деталь

руками или с упором в собственное тело, то можно

потерять контроль над инструментом или

обрабатываемой деталью.

• Прежде чем сверлить отверстия в стенах, полах или

потолках, проверьте наличие электропроводки и

трубопроводов.

• Не дотрагивайтесь до наконечника сверла сразу же

после окончания сверления, так как он может быть

горячим.

• Данный инструмент не может использоваться

людьми (включая детей) со сниженными

физическими, сенсорными и умственными

способностями или при отсутствии необходимого

опыта или навыка, за исключением, если они

выполняют работу под присмотром или получили

инструкции относительно работы с этим

инструментом от лица, отвечающего за их

безопасность. Не позволяйте детям играть с

инструментом.

• Назначение инструмента описывается в данном

руководстве по эксплуатации. Использование

любых принадлежностей или приспособлений, а

также выполнение данным инструментом любых

видов работ, не рекомендованных данным

руководством по эксплуатации, может привести к

несчастному случаю и/или повреждению личного

имущества.

Безопасность посторонних лиц

• Данный инструмент не может использоваться

людьми (включая детей) со сниженными

физическими, сенсорными и умственными

способностями или при отсутствии необходимого

опыта или навыка, за исключением, если они

выполняют работу под присмотром или получили

инструкции относительно работы с этим

инструментом от лица, отвечающего за их

безопасность.

• Не позволяйте детям играть с инструментом.

Остаточные риски

При работе данным инструментом возможно

возникновение дополнительных остаточных рисков,

которые не вошли в описанные здесь правила техники

безопасности. Эти риски могут возникнуть при

неправильном или продолжительном использовании

изделия и т.п.

Несмотря на соблюдение соответствующих инструкций

по технике безопасности и использование

предохранительных устройств, некоторые остаточные

риски невозможно полностью исключить. К ним

относятся:

• Травмы в результате касания

вращающихся/двигающихся частей инструмента.

• Риск получения травмы во время смены деталей или

насадок.

• Риск получения травмы, связанный с

продолжительным использованием инструмента.

При использовании инструмента в течение

продолжительного периода времени делайте

регулярные перерывы в работе.

• Ухудшение слуха.

• Ущерб здоровью в результате вдыхания пыли в

процессе работы с инструментом (например, при

обработке древесины, в особенности, дуба, бука и

ДВП).

Маркировка инструмента

Наклейка на вашем инструменте вместе с кодом даты

может содержать следующие символы:

Внимание! Для снижения риска травмирования

оператор должен прочитать эту инструкцию по

эксплуатации.

Зарядное устройство предназначено только

для использования внутри помещения.

Внимательно прочитайте всю инструкцию перед

использованием электрического инструмента.

Местоположение кода даты

Код даты, который также включает в себя год

изготовления, отштампован на поверхности корпуса

инструмента.

Пример:

2017 XX JN

Год изготовления

15

Page 16

РУССКИЙ

(Перевод с оригинала инструкции)

Электрическая безопасность

Ваше зарядное устройство имеет двойную

изоляцию, и поэтому провод заземления ему не

нужен. Всегда проверяйте, чтобы сетевое

напряжение соответствовало значению, указанному в

табличке с паспортными данными. Никогда не

пытайтесь заменить вилку в блоке зарядного устройства

обычной сетевой вилкой.

• В случае повреждения шнура питания, чтобы

избежать возникновения опасных ситуаций, его

замену должен выполнить производитель

оборудования или уполномоченный сервисный

центр BLACK+DECKER.

Аккумуляторы

• Ни в коем случае не пытайтесь разобрать

аккумулятор.

• Не погружайте аккумулятор в воду.

• Не храните в местах, где температура может

превысить 40°С.

• Заряжайте аккумулятор только при температуре

окружающей среды в пределах 10°С - 40°С.

• Заряжайте только зарядными устройствами,

входящими в комплект поставки инструмента.

• Утилизируйте отработанные аккумуляторы, следуя

инстру

кциям раздела «Защита окружающей среды».

Ни в коем случае не пытайтесь заряжать

повреждённый аккумулятор!

Зарядные устройства

• Используйте ваше зарядное устройство

BLACK+DECKER только для зарядки аккумулятора

инструмента, в комплект поставки которого он

входит. Аккумуляторы других марок могут

взорваться, что приведёт к получению травмы или

повреждению инструмента.

• Ни в коем случае не пытайтесь зарядить

неперезаряжаемые аккумуляторы.

• Немедленно заменяйте повреждённый сетевой

кабель.

• Не погружайте зарядное устройство в воду.

• Не разбирайте зарядное устройство.

• Не используйте зарядное устройство в качестве

объекта для проведения испытаний.

Зарядное устройство предназначено только

для использования внутри помещений.

Перед началом работы внимательно прочтите

руководство по эксплуатации.

Составные части

Данный инструмент может содержать все или некоторые

из перечисленных ниже составных частей:

1. Курковый пусковой выключатель с регулировкой

скорости

2. Переключатель направления вращения (реверса)

3. Муфта установки крутящего момента

4. Быстрозажимной патрон

5. Переключатель скоростей

6. Светодиодная подсветка

7. Аккумулятор

8. Отпирающая кнопка аккумулятора

Сборка

Эксплуатация

Внимание! Не форсируйте рабочий процесс. Избегайте

перегрузки инструмента.

Зарядка аккумулятора (не входит в комплект

поставки) (Рис. А)

Аккумулятор нуждается в зарядке перед первым

использованием и если он не обеспечивает достаточную

мощность для работ, которые ранее выполнялись легко и

быстро. В процессе зарядки аккумулятор может слегка

гудеть и нагреваться. Это нормально и не указывает на

наличие какой-либо проблемы.

Внимание! Не заряжайте аккумулятор при температуре

окружающей среды ниже 10°C или выше 40°С.

Рекомендуемая температура зарядки: приблизительно

24°C.

Примечание: Зарядное устройство не будет заряжать

аккумулятор, если температура его элементов ниже 10°C

или выше 40°C. Аккумулятор должен быть оставлен в

зарядном устройстве. При уменьшении или увеличении

температуры элементов зарядка начнётся

автоматически.

• Чтобы зарядить аккумулятор (7), вставьте в него

USB-штекер зарядного устройства (9).

• Вставьте вилку зарядного устройства (9) в

подходящую электрическую розетку и включите его.

• Разряженные аккумуляторы заряжайте в течение 1

недели после разрядки. Срок службы аккумулятора,

хранившегося в разряженном состоянии, значительно

уменьшается.

16

Page 17

(Перевод с оригинала инструкции)

РУССКИЙ

Внимание! Опасность возникновения пожара. При

отсоединении зарядного устройства от инструмента

сначала извлеките вилку зарядного устройства из

розетки, затем отсоедините кабель зарядного

устройства от инструмента.

Установка и извлечение аккумулятора (не

входит в комплект поставки) (Рис. В)

• Чтобы установить аккумулятор, совместите его с

приёмным гнездом на инструменте. Вдвиньте

аккумулятор в приёмное гнездо и нажимайте на него,

пока он не зафиксируется на месте.

• Для извлечения аккумулятора нажмите на

отпирающую кнопку (8), одновременно вынимая

аккумулятор из приёмного гнезда.

Инструкции по эксплуатации

Курковый пусковой выключатель и

переключатель направления вращения (Рис. Е)

• Данная дрель включается и выключается путём

нажатия и отпускания куркового пускового

выключателя (1). Чем сильнее нажим на курковый

выключатель, тем выше скорость инструмента.

• Направление вращения устанавливается при

помощи переключателя направления вращения (2).

• Для установки вращения вперёд, отпустите курковый

выключатель и переведите переключатель

направления вращения влево.

• Для установки реверса сдвиньте переключатель

направления вращения в противоположном

направлении.

Установка крутящего момента (Рис. С)

Данный инструмент оборудован муфтой установки

крутящего момента (3) для выбора режима работы и

регулировки крутящего момента при заворачивании

саморезов. Крупные саморезы и заготовки из твёрдых

материалов нуждаются в более высоком крутящем

моменте, чем мелкие саморезы и заготовки из мягких

материалов.

• При сверлении в древесине, металле и пластике

установите муфту напротив символа режима

сверления

• При заворачивании установите муфту на цифре,

соответствующей необходимому для работы

крутящему моменту. Если вы не знаете, какая из

настроек в полной мере соответствует выполняемой

операции, поступите следующим образом:

• Установите муфту на позицию минимального

крутящего момента.

• Заверните первый саморез.

• Если до завершения операции муфта

пробуксовывает, увеличьте крутящий момент и

продолжите заворачивание. Повторяйте это

действие, пока не будет определена правильная

величина крутящего момента. Используйте эту

величину при заворачивании остальных саморезов.

Быстрозажимной патрон (Рис. D)

Чтобы вставить сверло или другую насадку:

• Развернув патрон задней стороной к себе, одной

рукой обхватите заднюю часть патрона (4а), другой

рукой поворачивайте переднюю часть патрона (4) в

направлении против часовой стрелки.

• Вставьте хвостовик сверла или другой насадки в

патрон до упора. Развернув патрон задней стороной к

себе, надёжно затяните патрон, одной рукой

удерживая заднюю часть патрона, другой рукой

поворачивая переднюю часть патрона в направлении

по часовой стрелке.

Внимание! Не пытайтесь закрепить сверло (или

какую-либо другую насадку), захватив переднюю часть

патрона и одновременно включив инструмент. Это может

привести к повреждению патрона и получению травмы

при смене насадок.

Переключатель скоростей (Рис. F)

2-х скоростной редуктор Вашего инструмента позволяет

легко переключаться с одной скорости на другую для

максимальной универсальности применения

инструмента. Для установки низкой скорости/высокого

крутящего момента (положение 1) выключите инструмент

и дождитесь его полной остановки. Переведите

переключатель скоростей (5) в направлении от патрона.

Для установки высокой скорости/низкого крутящего

момента (положение 2) выключите инструмент и

дождитесь его полной остановки. Переведите

переключатель скоростей в направлении патрона.

Примечание: Не переключайте скорость при

работающем инструменте. Если у вас возникли

проблемы при переключении скоростей, убедитесь, что

переключатель скоростей полностью переведён вперёд

или назад.

Сверление/заворачивание

• Выберите направление вращения при помощи

переключателя (2).

• Чтобы включить инструмент, нажмите на курковый

пусковой выключатель (1). Скорость инструмента

зависит от глубины нажатия на курковый

выключатель

.

17

Page 18

РУССКИЙ

(Перевод с оригинала инструкции)

• Чтобы выключить инструмент, отпустите курковый

пусковой выключатель.

Рекомендации по оптимальному

использованию

Сверление

• Всегда используйте только остро заточенные

насадки.

• Поддерживайте и закрепляйте заготовку

надлежащим образом, как описано в Инструкциях

по технике безопасности.

• Используйте надлежащее и соответствующее

защитное оборудование, как описано в

Инструкциях по технике безопасности

• Обеспечьте безопасность рабочего места, как

описано в Инструкциях по технике безопасности.

• Прилагая лёгкое давление на дрель, очень

медленно начните сверление, пока

высверливаемое отверстие не будет достаточного

размера, чтобы из него не выскользнуло сверло.

• Прилагайте давление по прямой линии со сверлом.

Давление должно быть достаточным для

равномерного врезания сверла, но не слишком

сильным, чтобы не вызвать останов двигателя или

отклонение сверла.

• Крепко держите инструмент обеими руками, чтобы

контролировать вращательное действие сверла.

• При внезапном останове не пытайтесь запустить

двигатель многократным нажатием на курковый

пусковой выключатель. Это может привести к

повреждению дрели.

• Для сведения к минимуму риск внезапного

останова ослабьте прилагаемое давление и

медленно закончите высверливание отверстия.

• Не выключайте двигатель при извлечении сверла

из высверленного отверстия. Это позволит снизить

риск заклинивания сверла.

• Убедитесь, что инструмент включается и

выключается при нажатии и отпускании пускового

выключателя.

Сверление в дереве

Для сверления в дереве можно также использовать

спиральные свёрла для металла или перьевые свёрла

для сверления древесины. Данные свёрла должны быть

остро заточенными, и во время сверления их следует

часто извлекать из отверстия для прочищения канавок

от опилок.

Сверление в металле

При сверлении металлов используйте

смазочно-охлаждающую жидкость. Исключение

составляют чугун и медь, которые нужно сверлить без

смазки. Наиболее эффективные смазочные материалы –

сульфированная СОЖ или лярдовое масло.

Заворачивание

• Всегда используйте отвёрточную насадку

соответствующего типа и размера.

• Если винты заворачиваются с трудом, попробуйте

нанести на них небольшое количество моющего

средства или мыла в качестве смазки.

• Всегда держите инструмент и отвёрточную насадку

на прямой линии с винтом.

Возможные неисправности и способы их

устранения

Проблема возможная причина возможное решение

Инструмент не

включается.

Аккумулятор не

заряжается.

Инструмент

внезапно

отключается.

Аккумулятор не

заряжен.

Вилка зарядного

устройства не

подключена к розетке.

Слишком высокая или

слишком низкая

температура

окружающей среды..

Аккумулятор достиг

своего максимального

теплового предела.

Аккумулятор разряжен.

(Чтобы максимально

продлить срок службы

аккумулятора, его

конструкция

предусматривает

автоматическое

отключение

при чрезмерном

истощении

заряда.)

Проверьте правильность

установки аккумулятора.

Вставьте вилку зарядного

устройства в рабочую

розетку..

Перенесите аккумулятор

и зарядное устройство в

место, где температура

окружающей среды не

ниже +4,5°C и не выше

+40,5°C.

Дайте аккумулятору

полностью остыть.

Установите аккумулятор

в зарядное устройство и

оставьте его заряжаться.

18

Page 19

(Перевод с оригинала инструкции)

РУССКИЙ

Техническое обслуживание

Ваш инструмент

работу в течение продолжительного времени при

минимальном техническом обслуживании. Срок

службы и надёжность инструмента увеличивается при

правильном уходе и регулярной чистке. Ваше зарядное

устройство не требует никакого дополнительного

технического обслуживания, кроме регулярной чистки.

• Регулярно очищайте вентиляционные отверстия

вашего инструмента и зарядного устройства мягкой

щёткой или сухой тканью.

• Регулярно очищайте корпус двигателя влажной

тканью. Не используйте абразивные чистящие

средства, а также чистящие средства на основе

растворителей.

• Регулярно раскрывайте патрон и вытряхивайте из

него всю накопившуюся пыль.

Важно! В целях обеспечения БЕЗОПАСНОСТИ и

ДОЛГОВЕЧНОСТИ в использовании продукта ремонт,

техническое обслуживание и регулировка (кроме

перечисленных в данном руководстве по эксплуатации)

должны производиться только в авторизованных

сервисных центрах или других квалифицированных

мастерских и только с использованием идентичных

запасных частей. Внутри инструмента нет

обслуживаемых пользователем деталей.

BLACK+DECKER

Внимание! Перед любыми видами работ по

техническому обслуживанию извлекайте из

инструмента аккумулятор. Перед чисткой

зарядного устройства отключите его от

источника питания.

рассчитан на

Дополнительные принадлежности

Рекомендованные дополнительные принадлежности,

используемые с Вашим инструментом, можно

приобрести за дополнительную плату у местного

дилера или в авторизованном сервисном центре.

Внимание! Использование любых

принадлежностей, не рекомендованных к

использованию с данным инструментом,

может быть опасным.

Аккумуляторы

Аккумуляторы

подзаряжать неограниченное количество раз.

По окончанию срока службы утилизируйте

отработанные аккумуляторы безопасным для

окружающей среды способом:

• Полностью разрядите аккумулятор, затем извлеките

его из инструмента.

BLACK+DECKER

можно

• Li-Ion, NiCd и NiMH аккумуляторы подлежат

переработке. Сдайте их в любой авторизованный

сервисный центр или в местный пункт переработки.

Защита окружающей среды

Раздельный сбор отходов. Запрещается

утилизировать этот продукт вместе с

обычными бытовыми отходами.

Если вы решите, что ваше изделие

BLACK+DECKER

вы не будете его больше использовать¬, не

утилизируйте его вместе с бытовыми отходами. Этот

продукт подлежит раздельному сбору отходов.

Раздельный сбор использованных

продуктов и упаковочных материалов

позволяет производить их вторичную

переработку с дальнейшим повторным

использованием. Повторное использование

материалов, прошедших вторичную переработку,

снижает загрязнение окружающей среды¬ и

уменьшает потребность в сырьевых материалах.

Нормативные акты местных органов власти могут

предусматривать сбор использованных

электрических изделий отдельно от бытовых

отходов, в муниципальных пунктах сбора отходов

или в магазине при покупке нового изделия.

BLACK+DECKER предоставляет возможность для

сбора и повторной переработки продуктов

BLACK+DECKER после окончания срока их

службы. Чтобы воспользоваться преимуществом

этого сервиса, пожалуйста, отправьте ваш

продукт любому уполномоченному

представителю по ремонту, который собирает

такие изделия от нашего имени.

Вы можете узнать адрес нашего ближайшего

уполномоченного представителя по ремонту,

позвонив в региональное представительство

BLACK+DECKER, указанное в этой инструкции.

Кроме того, список уполномоченных

представителей по ремонту BLACK+DECKER ,

подробная информация о послепродажном

обслуживании и контактные данные можно найти

на сайте www.2helpU.com.

необходимо заменить, или если

19

Page 20

РУССКИЙ

(Перевод с оригинала инструкции)

Технические характеристики

BDCHD12S1

Напряжение питани В пост. тока 12

Скорость без нагрузки об/мин. 0-350 / 0-1350

Макс. крутящий момент Нм 17,5 / 40

Патро мм 1-10

Максимальный диаметр сверления

Сталь/дерево/кирпич мм 10 / 25 / 10

Вес кг 0,90

(1,15 с аккумулятором)

Аккумулятор (входит в комплект поставки)

Напряжение питания В пост. тока 12

Ёмкость Ач 1,5

Тип аккумулятора Li-Ion

20

Page 21

(Перевод с оригинала инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия Black+Decker и выражаем признательность за

Ваш выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно

заполненного гарантийного талона мы будем вынуждены

отклонить Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство.

Гарантийный срок на данное изделие составляет 24

месяца и исчисляется со дня продажи. В случае

устранения недостатков изделия, гарантийный срок

продлевается на период его нахождения в ремонте.

Срок службы изделия - 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в процессе

эксплуатации изделия рекомендуем Вам обращаться

только в уполномоченные сервисные центры

BLACK+DECKER, адреса и телефоны которых Вы

сможете найти в гарантийном талоне, на сайте

www.2helpU.com или узнать в магазине. Наши сервисные

станции - это не только квалифицированный ремонт, но и

широкий ассортимент запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

РУССКИЙ

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение

гарантийного срока и вызванные дефектами производства

и \ или материалов.

7. Гарантийные обязательства не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и

разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого

электрического кабеля, вызванного внешним ударным или

любым иным воздействием.

7.3. Попадания в вентиляционные отверстия и проникновение

внутрь изделия посторонних предметов, материалов или

веществ, не являющихся отходами, сопровождающими

применение изделия по назначению, такими как: стружка,

опилки, песок, и пр.

7.4. Воздействие на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанным на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов

напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченной сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как: приводные ремни и колеса, угольные щетки,

смазка, подшипники, зубчатое зацепление редукторов,

резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы и т.п.

8.3. на сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора

и других узлов и деталей. К безусловным признакам

перегрузки изделия относятся, помимо прочих: появление

цветов побежалости, деформация или оплавление

деталей и узлов изделия, потемнение или обугливание

изоляции проводов электродвигателя под воздействием

высокой температуры.

21

Page 22

РУССКИЙ

(Перевод с оригинала инструкции)

Приложение к руководству по эксплуатации электроинструмента

Модели: BDCD12*-*, BDCD18*-*, BDCD8*-*, BDCDD186*-*, BDCDD18*-*, BDCDD12*-*, BDCHD12*-*, LD12*-*, EPC12CAKA*-*,

EPC12*-*, EPC182K2*-*, EPC182*-*, BDCH188*-*, BDCHD18*-*, BDH18K*-*, BDH18*-*, BDK188K*-*, BDK188*-*, EGBHP1881*-*,

BDK188*-*, EGBHP1881*-*, CS3651*-*, CS3652*-*, CS3653*-*, DCD700*-*, DCD731*-*, DCD791*-*, DCD792*-*, DCD932*-*, DCD990*-*,

DCD991*-*, DCD992*-*, DCD796*-*, DCD797*-*, DCD937*-*, DCD996*-*, DCD997*-*, DCF620*-*, DCF621*-*, DCF682*-*, DCF885*-*,

DCF888*-*, FMC010PR*-*, FMC011*-*, FMC011S*-*, FMC600M2*-*, FMC600*-*, FMC601*-*, FMC635*-*, FMC020S*-*, FMC020*-*,

FMC520LB*-*, FMC620PR*-*, FMC620*-*, FMC625*-*, FMCK625PR*-*, FMCK625*-*, FMCK626C2*-*, FMC040*-*, FMC041S*-*,

FMC041*-*, FMC640*-*, FMC645*-*, FMCK012*-*, FMCK621*-*, SCD12*-*, SCD20*-*, STCD1081*-*, STCD1200*-*, STCD12*-*,

STCD20*-*, STCD001*-*, STCD012*-*, STCD100*-*, STCD1081*-*, STCD108LD*-*, STCD108L*-*, STCD108*-*, STCD18LD*-*,

STCD18*-*, STPC001L*-*, SHC12S*-*, SCH12*-*, SCH20C*-*, SCH20*-*, STCH1200B2*-*, STCH12*-*, STCH20*-*, STDC18HBK*-*,

STDC18LHB*-*, SCI12*-*, STCI1081*-*, STCI1200*-*, STCI12*-*, STCI1440*-*, STDC041*-*, SCS12*-*, где *- не более 5 символов

(буква от «А» до «Z» и\или цифра от 0 до 9, знак дефис или их отсутствие)

СЕРТИФИКАТ СООТВЕТСТВИЯ № RU С-DE.АЯ46.В.84366

Действителен до: 11 марта 2021 г.

Выдан: Орган по сертификации "РОСТЕСТ- Москва" , Адрес: 119049,

г. Москва, улица Житная, д. 14, стр. 1; 117418, Москва, Нахимовский

просп., 31 (фактический), Телефон: (499) 1292311, (495) 6682893,

Факс: (495) 6682893, E-mail: office@rostest.ru

Изготовитель: Изготовитель: Блэк энд Деккер Холдингс ГмбХ,

Германия, 65510, Идштайн, ул. Блэк энд Деккер, 40, тел.

+496126212790.

Хранение.

Необходимо хранить в сухом месте, вдали от источников

повышенных температур и воздействия солнечных лучей. При

хранении необходимо избегать резкого перепада температур.

Хранение без упаковки не допускается

Срок службы.

Срок службы изделия составляет 5 лет. Не рекомендуется к

эксплуатации по истечении 5 лет хранения с даты изготовления без

предварительной проверки.

Дата изготовления (код даты) указана на корпусе инструмента.

Код даты, который также включает год изготовления, отштампован на

поверхности корпуса изделия.

Пример:

2014 46 XX, где 2014 –год изготовления, 46-неделя изготовления.

Определить месяц изготовления по указанной неделе изготовления

можно согласно приведенной ниже таблице.

Месяц Январь евраль Март Апрель Май юнь Июль Август Сентябрь Октябрь Ноябрь Декабрь Год производства

01 05 09 13 17 22 26 31 35 39 44 48

02 06 10 14 18 23 27 32 36 40 45 49

Неделя 03 07 11 15 19 24 28 33 37 41 46 50 2016

04 08 12 16 20 25 29 34 38 42 47 51

09 13 17 21 26 30 35 39 43 48 52

22 44

01 05 09 13 18 22 26 31 35 39 44 48

02 06 10 14 19 23 27 32 36 40 45 49

Неделя 03 07 11 15 20 24 28 33 37 41 46 50 2017

04 08 12 16 21 25 29 34 38 42 47 51

05 09 13 17 22 26 30 35 39 43 48 52

31 44

01 05 09 13 18 22 26 31 35 40 44 48

02 06 10 14 19 23 27 32 36 41 45 49

Неделя 03 07 11 15 20 24 28 33 37 42 46 50 2018

04 08 12 16 21 25 29 34 38 43 47 51

05 09 13 17 22 26 30 35 39 44 48 52

18 31

01 05 09 14 18 22 27 31 35 40 45 48

02 06 10 15 19 23 28 32 36 41 46 49

Неделя 03 07 11 16 20 24 29 33 37 42 47 50 2019

04 08 12 17 21 25 30 34 38 43 48 51

05 09 13 18 22 26 31 35 39 44 52

40

01 05 09 14 18 23 27 31 36 40 44 49

02 06 10 15 19 24 28 32 37 41 45 50

Неделя 03 07 11 16 20 25 29 33 38 42 46 51 2020

04 08 12 17 21 26 30 34 39 43 47 52

05 09 13 18 22 27 31 35 40 44 48 53

14 36 49

Дрели-шуруповерты

Уполномоченное изготовителем юр.лицо:

ООО "Стэнли Блэк энд Деккер", 117485, город Москва, улица

Обручева, дом 30/1, строение 2

Телефон: + 7 (495) 258-3981, факс: + 7 (495) 258-3984, E-mail:

inbox@dewalt.com

Сведения о импортере указаны в сопроводительной документации

и/или на упаковке

Транспортировка.

Категорически не допускается падение и любые механические

воздействия на упаковку при транспортировке.

При разгрузке/погрузке не допускается использование любого вида

техники, работающей по принципу зажима упаковки.

Перечень критических отказов, возможные ошибочные

действия персонала.

Не допускается эксплуатация изделия:

-При появлении дыма из корпуса изделия

-При поврежденном и/ или оголенном сетевом кабеле

-при повреждении корпуса изделия, защитного кожуха, рукоятки

-при попадании жидкости в корпус

-при возникновении сильной вибрации

-при возникновении сильного искрения внутри корпуса

Критерии предельных состояний.

-При поврежденном и/или оголенном сетевом кабеле

-при повреждении корпуса изделия

22

Page 23

РУССКИЙ

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

Призначення

Ударний дриль BLACK+DECKER™ BDCHD12S1

призначений для загвинчування шурупів та свердління

дерева, металів та пластмас. Цей інструмент

призначений тільки для побутового використання.

Перш ніж повернути цей виріб до магазину,

спочатку зв’яжіться з регіональним представництвом

BLACK+DECKER або зверніться до найближчого

авторизованого сервісного центру.

Інструкції з техніки безпеки

Загальні вказівки щодо безпечної роботи з

електричним інструментом.

Увага! Необхідно ретельно ознайомитись

із усіма попереджувальними знаками,

вказівками щодо безпечної роботи,

графічними матеріалами та технічними

електричного інструмента. Недотримання вказівок

щодо безпечної роботи може призвести до ураження

електричним струмом, пожежі та/або серйозних травм

персоналу.

Зберігайте усі застереження та вказівки з техніки

безпеки для подальшого використання.

Термін «електричний інструмент», що використовується

у всіх застережливих написах та вказівках щодо техніки

безпеки, наведених нижче, стосується електричного

інструменту, що працює від мережі (зі шнуром

живлення) або від акумуляторної батареї (без шнура

живлення).

1. Вказівки з техніки безпеки на робочому місці

a. Робоче місце має бути прибране та добре

b. Не працюйте з електроінструментом в місці

c. Забороняється перебування дітей та сторонніх

2. Електрична безпека

a. Вилка шнура живлення інструмента має

описами, що додаються до цього

освітлене. Безлад або погане освітлення на

робочому місці можуть призвести до нещасного

випадку.

зберігання вибухонебезпечних матеріалів,

наприклад, у присутності легкозаймистих рідин,

газів або пилу. Іскри, що виникають під час роботи

електричного інструмента, можуть призвести до

займання пилу чи випарів.

осіб поблизу електричного інструменту під час

роботи. Відволікання може призвести до втрати

контролю за роботою інструмента.

відповідати мережевій розетці. Забороняється

будь-яким чином змінювати конструкцію вилки

шнура живлення. Забороняється включати

заземлений (занулений) електричний інструмент до

джерела струму через адаптер. Зміна конструкції

вилок шнурів живлення та невідповідність е

лектричних вилок і розеток збільшує ризик

ураження електричним струмом.

b. Не торкайтеся поверхонь заземлених чи

занулених предметів, наприклад, труб,

радіаторів, електроплит або холодильників.

Заземлення чи занулення тіла підвищує ризик

ураження електричним струмом.

c. Необхідно берегти електричні інструменти від

дощу та впливу підвищеної вологості. Попадання

вологи всередину електричного інструмента

підвищує ризик ураження електричним струмом.

d. Поводитися зі шнуром живлення необхідно

уважно і обережно. Забороняється підіймати,

тягнути електричний інструмент та виймати його

вилку з розетки за шнур. Слід берегти електричний

шнур від впливу джерел тепла, оливи, гострих країв

та рухомих деталей. Пошкодження і заплутування

шнурів живлення підвищує ризик ураження

електричним струмом.

e. Під час роботи з електричним інструментом за

межами приміщень необхідно використовувати

відповідний подовжувач. Використання