Page 1

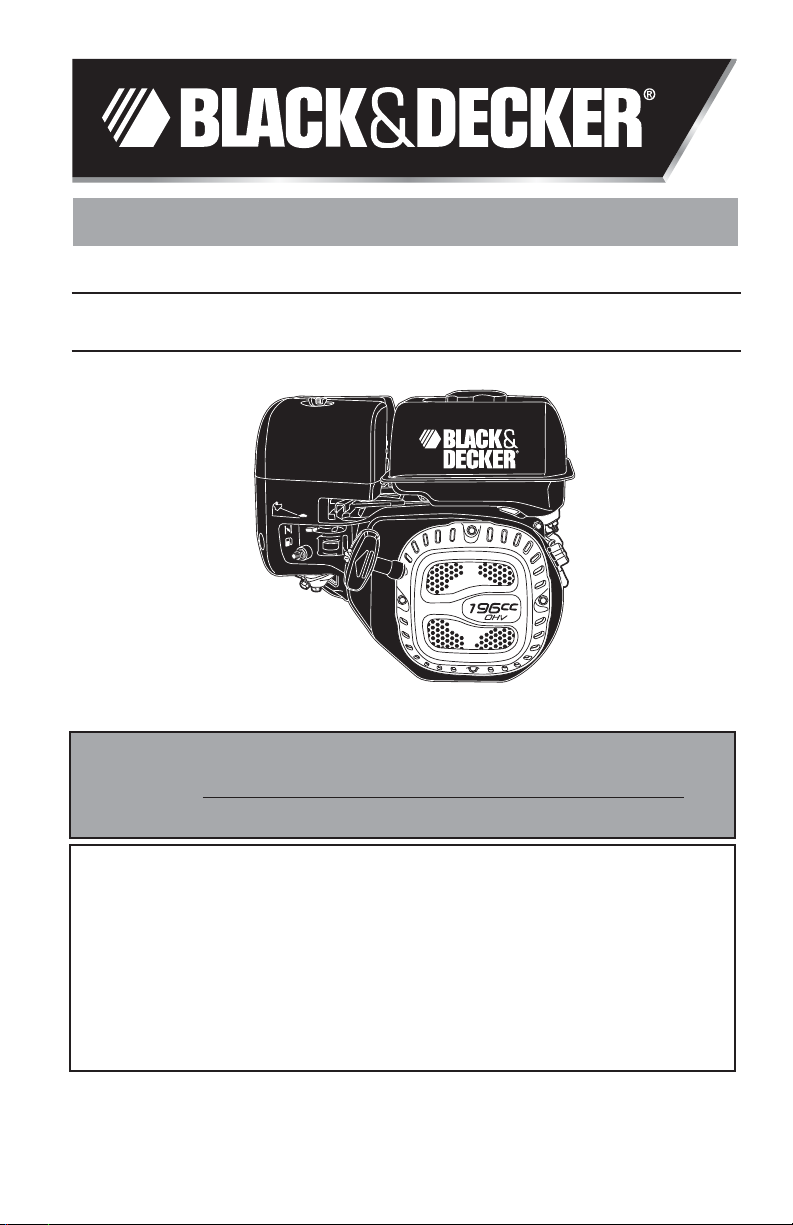

Engine

Engine

Catalog Number BD168F

INSTRUCTION MANUAL

THANK YOU FOR CHOOSING BLACK & DECKER!

G

O TO WWW.BLACKANDDECKER.COM/NEWOWNER

TO REGISTER YOUR NEW PRODUCT.

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

BEFORE YOU CALL, HAVE THE CATALOG No. AND DATE CODE AVAILABLE. IN MOST CASES, A

BLACK & DECKER REPRESENTATIVE CAN RESOLVE THE PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL TO BLAC K & DECKER.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 2

SAFETY GUIDELINES -

– This

manual contains important instructions

for model BD168F that should be followed during installation and maintenance of the engine.

DEFINITIONS

This manual contains information

that is important for you to know

and understand. This information

relates to protecting YOUR SAFETY

and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize

this information, we use the symbols

below. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

CAUTION: Used without the safety

alert symbol indicates a potentially

hazardous situation which, if not

avoided, may result in property

damage.

IMPORTANT SAFETY

SAVE THESE INSTRUCTIONS

manual contains important instructions

for model BD168F that should be followed during installation and maintenance of the engine.

DANGER: Carbon Monoxide.

Using an engine indoors will kill you

in minutes. Engine exhaust contains

high levels of carbon monoxide

(CO), a poisonous gas you cannot

see or smell. You may be breathing

CO even if you do not smell engine

exhaust.

– This

• NEVER use an engine inside

homes, garages, crawlspaces, or

other partly enclosed areas. Deadly

levels of carbon monoxide can build

up in these areas. Using a fan or

opening windows and doors does

NOT supply enough fresh air.

• Only use outdoors and far away

from open windows, doors

and vents. These openings

can pull in engine exhaust.

• Even when the engine is used

correctly, CO may leak into your

home. ALWAYS use a battery-

powered or battery backup CO

alarm (not supplied) in the home.

Read and follow all directions

for CO alarm before using. If you

start to feel sick, dizzy or weak at

anytime, move to fresh air immediately. See a doctor. You could

have carbon monoxide poisoning.

WARNING: Do not operate this

unit until you read and understand this

instruction manual and the tool instruction manual for safety, operation and

maintenance instructions.

WARNING: The engine exhaust

from this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm. Wash hands after

handling.

IMPORTANT: These products are

equipped with spark-arresting mufflers. It is legally required in the state of

California. It is a violation of California

statutes section 130050 and/or sections 4442 and 4443 of the California

Public Re sourc es Code, unless the

engine is equipped with a spark arrester, as defined in section 4442, and

maintained in ef fec tive work ing order.

Spark arresters are also required on

some U.S. For est Service land and may

also be legally required under other

statutes and or di nanc es.

N003333

SAVE THESE

INSTRUCTIONS

2- ENG

Page 3

READ AND SAVE THESE INSTRUCTIONS

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gas o line and it’s vapors

can be come ignited from sparks

from smoking products, electrical

arcing, exhaust, flame, gas es and

hot engine components such as

the muffler.

• Heat will ex pand fuel in the tank

which could result in spillage and

pos si ble fire explosion.

• Non-functioning or missing sparkarresting muffler may cause fire.

• Combustible materials which

come into contact with hot

engine parts can become

ignited.

• Improperly stored fuel could lead to

acciden tal ignition. Fuel im prop er ly

secured could get into the hands

of children or oth er un qual i fied

persons.

• Unattended operation of this

product could result in personal

injury or property damage. To

reduce the risk of fire, do not

allow the engine to operate

unattended.

• Shut off en gine and allow it to cool

before removing cap and adding fuel

to the tank.

• Use care in fill ing tank to avoid spilling fuel. Make sure the cap is secure

and move unit away from fueling

area before starting en gine.

• Keep maximum fuel level

shoulders on the debris screen

allow for expansion.

• Make sure spark-arresting muffler is

in place and not damaged.

• Replace spark-arresting muffler if

damaged or missing.

• Add fuel outdoors in a well

ventilated area. Make sure there

are no sources of ignition, such as

smoking products near refueling

location.

• Operate engine in a clean, dry, well

ventilated area a minimum of 48"

(1.2 m) from any building, object or

wall. Do not operate unit indoors

or in any confined area.

• Operate engine in an open area

away from dry brush, weeds or

other combustible materials

• Store fuel in an OSHA-ap proved

con tain er, in a se cure location away

from work area.

• Always remain in attendance with

the engine when it is operating.

below the

to

.

3 - ENG

N003333

Page 4

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Breathing ex haust fumes will cause

se ri ous injury or death!

Engine

exhaust contains high levels of

carbon monoxide (CO), a poisonous gas you cannot see or smell.

You may be breathing CO even if

you do not smell engine exhaust.

DANGER: RISK OF INJURY OR PROP ER TY DAMAGE

WHEN TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Oil and fuel can leak or spill and

could result in fire or breathing

hazard; serious injury or death can

result.

• Oil

and fuel leaks will damage

carpet, paint or other surfaces in

vehicles or trailers. Spilled oil and

fuel increases risk of injury.

• NEVER use an engine inside

homes, garages, crawlspaces or

other partly enclosed areas. Deadly

levels of carbon monoxide can

build up in these areas. Using a

fan or opening windows and doors

does NOT supply enough fresh air.

• Only use outdoors and far away

from open windows, doors and

vents. These openings can pull in

engine exhaust.

•

Keep children, pets and others away

from area of operation.

• Always keep the exhaust pipe free

of foreign object

• Never transport engine with fuel in

the fuel system, fuel valve open, or

while engine is in operation.

• Always place engine on a protective

mat when transporting to protect

against damage to vehicle from

leaks. Remove engine from vehicle

immediately upon arrival at your

destination. Always keep engine level

and never lie on its side.

• Transport fuel only in an OSHA

approved container.

N003333

4- ENG

Page 5

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Touching exposed metal (muffler

and other engine parts) can result in

serious burns.

WARNING:

RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• The engine can start accidentally

if the flywheel is turned by hand or

moved by pulling on the pull starter.

• Moving parts such as the pulley,

flywheel, and belt can cause serious

injury if they come into contact with

you or your clothing.

• Attempting to operate engine

with damaged or missing parts or

attempting to repair engine with

protective shrouds removed can

expose you to moving parts and

can result in serious injury.

• Never touch any exposed

metal parts on engine during or

immediately after operation. The

engine will remain hot for several

minutes after operation.

• Do not reach around protective

shrouds or attempt maintenance

until engine has been allowed to

cool.

• Always disconnect the spark plug

before performing maintenance.

• Never operate the

engine

with

guards or covers which are

damaged or removed.

• Keep your hair, clothing, and gloves

away from moving parts. Loose

clothes, jewelry, or long hair can be

caught in moving parts.

• Air vents may cover moving parts

and should be avoided as well.

• Any repairs required on this product

should be performed by a

Black &

Decker factory service center or a

Black & Decker authorized service

center.

5 - ENG

N003333

Page 6

WARNING: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

•

Unsafe op er a tion of your engine

could lead to se ri ous in ju ry or

death to you or others.

CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

•

Under some conditions, applications and duration of use, noise

from this product may contribute

to hearing loss.

READ AND SAVE THESE INSTRUCTIONS

•

Review and understand all

instructions and warnings in this

manual.

•

Be come fa mil iar with the opera tion

and con trols of the engine.

• Keep operating area clear of all

persons, pets, and obstacles.

• Keep chil dren away from the engine

at all times.

• Do not operate the engine when

fatigued or under the influence of

alcohol or drugs. Stay alert at all

times.

• Never defeat the safety features of

this prod uct.

• Equip area of operation with a fire

extinguisher.

• Do not op er ate engine with missing,

broken, or un au tho rized parts.

• Never stand on the engine.

•

ALWAYS

wear certified safety

equipment: ANSI S12.6 (S3.19)

hearing protection.

N003333

6- ENG

Page 7

1

A

N

S

R

Q

P

M

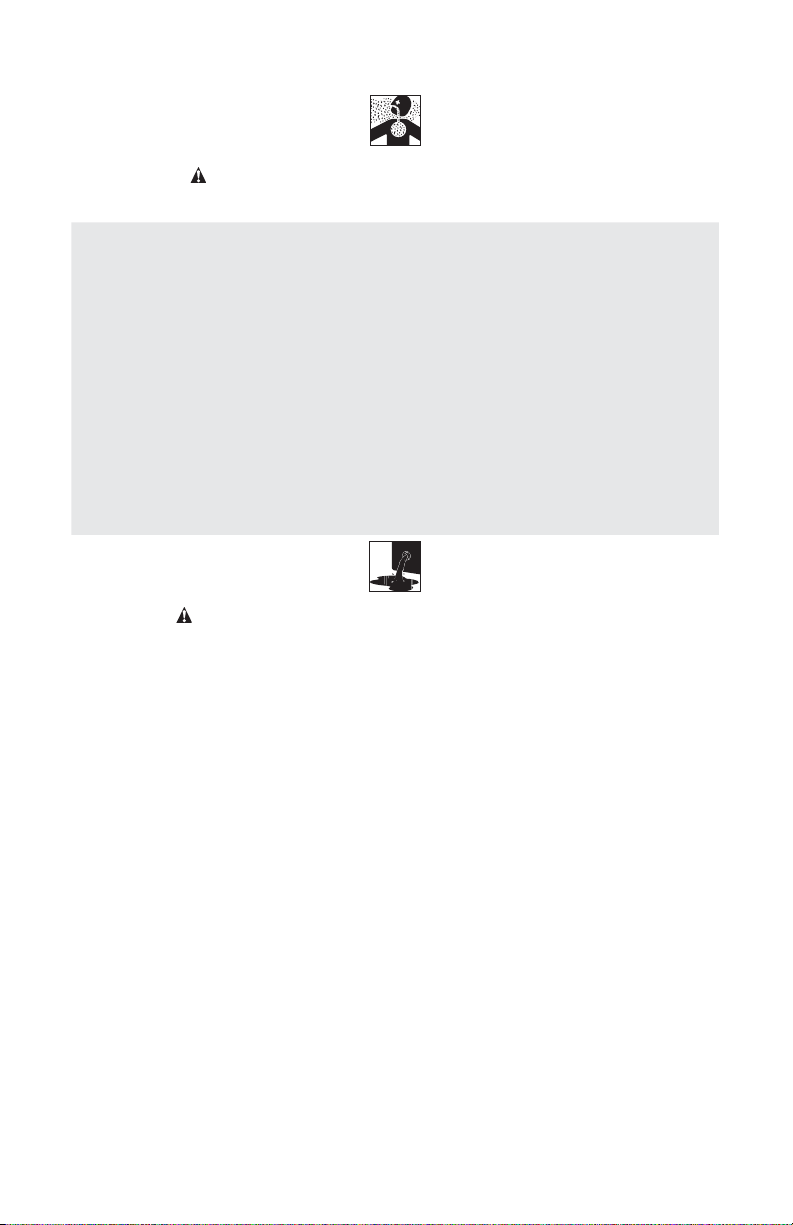

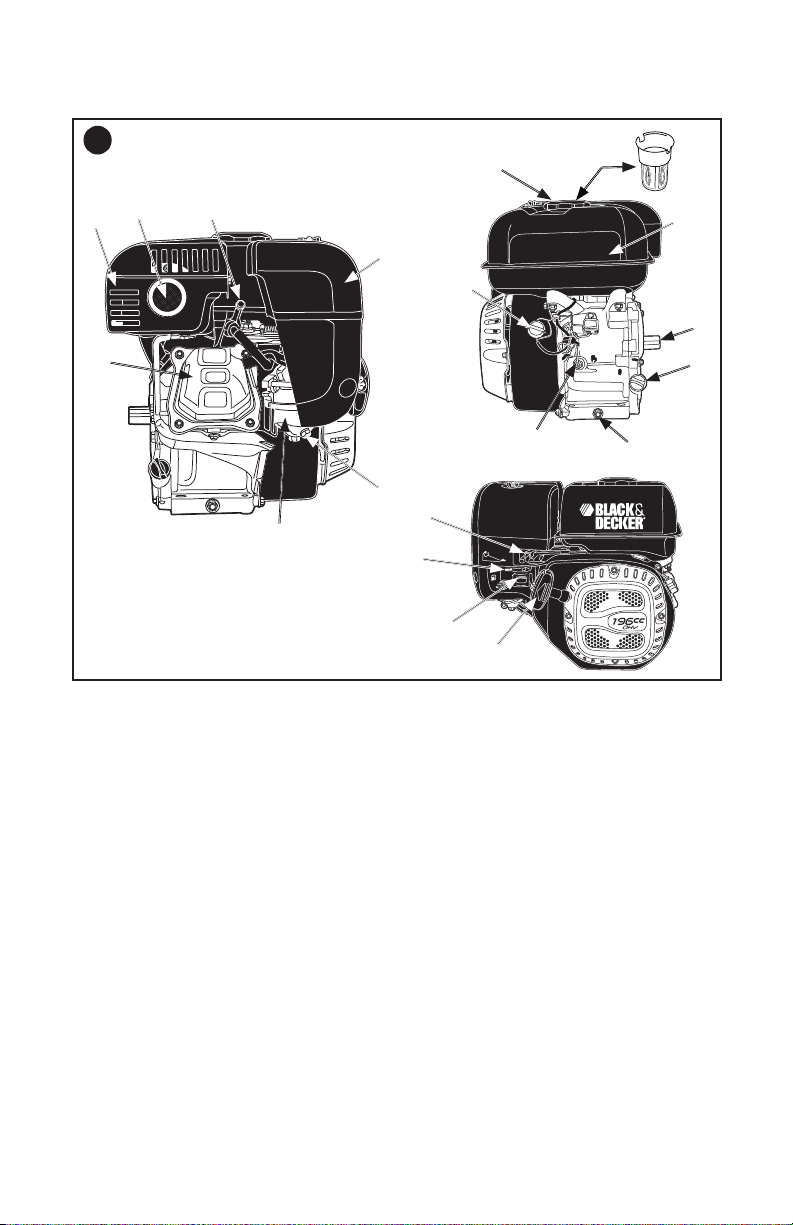

Components (Fig. 1)

A. Fuel cap

B. Fuel tank

C. Oil fill/dipstick

D. Oil drain

E. Crank shaft PTO

F. Air filter assembly

G. On/Off switch

H. Set throttle control

I. Choke lever

J. Fuel valve lever

K. Recoil pull starter

L. Carburetor bowl drain

M. Carburetor bowl

N. Debris Screen

O. Low oil shutdown sensor

F

G

L

H

I

J

K

Hot Surfaces (Fig. 1)

P. Spark plug

Q. Cylinder head

R. Muffler

S. Spark Arrestor

B

E

C

O

D

7 - ENG

N003333

Page 8

WARNING: Do not operate this

unit until you read and understand this

instruction manual as well as the product instruction manual for safety, operation and maintenance instructions.

This engine is only for use in Black &

Decker approved applications. If used

in unapproved applications, Black &

Decker is not responsible for repairs or

damage and the warranty is void. Call

Bl

ack & Decker 1-800-544-6986 for

more information.

To mount engine correctly, refer to

set-up instructions in shop manual.

CAUTION: The engine IS NOT filled

with oil from the factory. Oil must be

added to the engine before operating

or damage to engine may occur.

Oil Recommendations

SAE 10W-30 is recommended for

general use. Refer to the ViscosityAmbient Temperature Chart for

recommended oil within your

local area’s average temperature

range. NOTE: Synthetic oil is NOT

recommended.

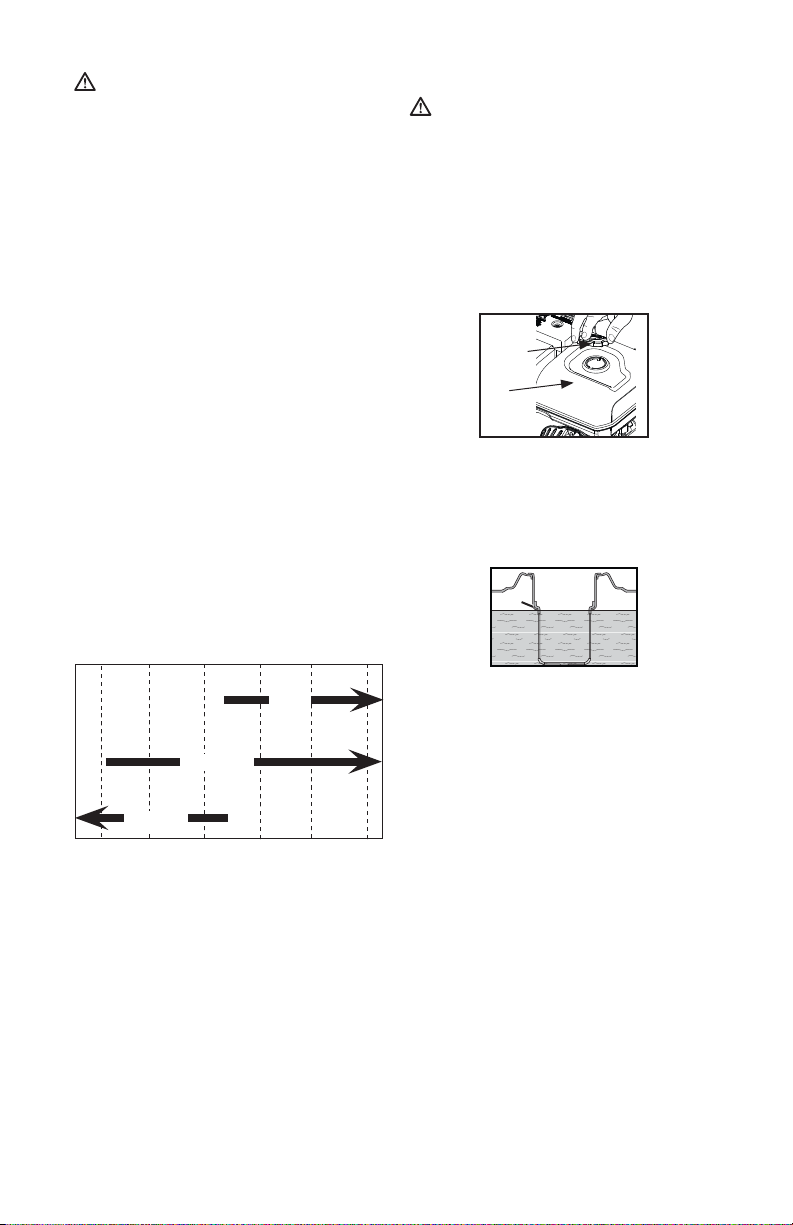

Viscosity-Ambient

Temperature Chart

30

10W-30

5W-30

˚F -20 0 20 40 60 80 100

˚C -28.8 -17.7 -6.6 4.4 15.5 26.6 37.7

To Add Oil (Fig. 1)

1. Refer to Viscosity-Ambient

Temperature Chart above for

correct viscosity.

2. Remove dipstick (C).

3. Slowly add recommended oil,

see specifications for oil capacity.

NOTE: If the oil is added too

quickly, it will overflow and appear

to be full.

See To Check Oil under Maintenance

for instructions.

N003333

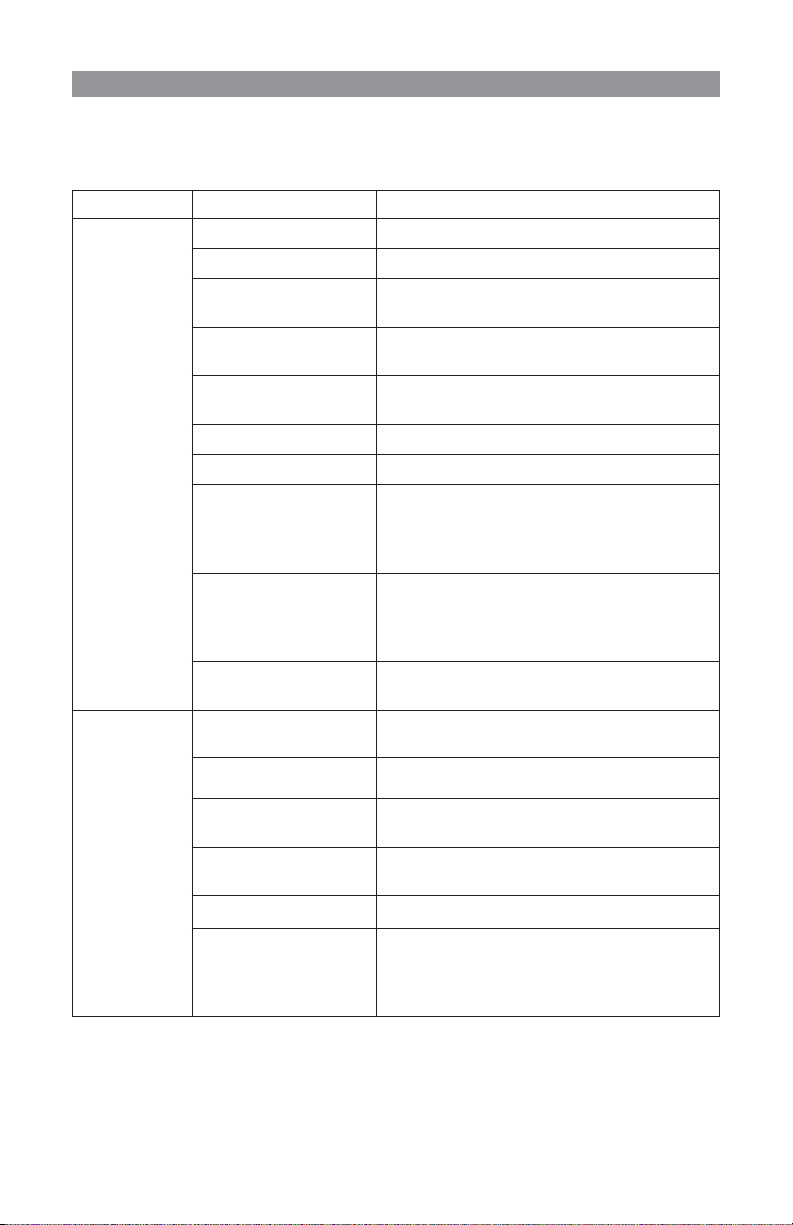

To Add Fuel

WARNING: Risk of explosion

or fire. Gasoline vapor is highly

flammable. Refuel outdoors only in

well-ventilated areas. Do not refuel or

check gasoline level while the engine

is running. Do not store, spill or use

gasoline near an open flame, a source

of sparks (such as welding) or near

operating electrical equipment.

1. Remove fuel cap (A).

A

B

2. Add fresh, clean, regular unleaded

gasoline with a minimum of 86

octane to the fuel tank (B). Do

not fill above the shoulders on the

debris screen (N) as shown.

N

NOTE: The debris screen protects

the engine from dirt and debris,

only remove screen when cleaning.

See Cleaning Debris Screen under

Maintenance for instructions.

NOTE: Do not mix oil with gasoline.

3. Replace the fuel cap on the tank.

Turn the cap clockwise until it

stops.

Oxygenated Fuels

Some conventional gasolines are

blended with alcohol or an ether

compound. These gasolines are

collectively referred to as oxygenated

fuels. To meet clean air standards,

some areas of the United States and

Canada use oxygenated fuels to help

reduce emissions.

If you use an oxygenated fuel, be

sure it is unleaded and meets the 86

minimum octane rating requirements.

Before using an oxygenated fuel,

try to confirm the fuel’s contents.

8- ENG

Page 9

Some states/provinces required this

information to be posted on the pump.

The following are the EPA approved

percentages of oxygenates:

Ethanol (ethyl or grain alcohol) 10%

by volume. You may use gasoline

containing up to 10% ethanol by

volume. Gasoline containing ethanol

may be marketed under the name

gasohol.

CAUTION: Risk of property damage.

DO NOT use E85 fuel.

MTBE (methyl tertiary butyl ether)

15% by volume. You may use gasoline

containing up to 15% MTBE by

volume.

Methanol (methyl or wood alcohol)

5% by volume. You may use gasoline

containing up to 5% methanol by

volume as long as it also contains

solvents and corrosion inhibitors to

protect the fuel system. Gasoline

containing more than 5% methanol

by volume may cause starting and/

or performance problems. It may also

damage metal, rubber and plastic

parts of the engine or your fuel system.

If you notice any undesirable operating

symptoms, try another service station

or switch to another brand of gasoline.

NOTE: Fuel system damage or

performance problems resulting

from the use of an oxygenated fuel

containing more than the percentages

of oxygenates mentioned above are

not covered under warranty.

Location

DANGER: Risk of breathing

(ASPHYXIATION)

. Exhaust from the

gasoline engine contains deadly carbon monoxide, which is odorless and

toxic. Operate engine only outside in

clean, dry, well-ventilated areas.

Noise Considerations

Consult local officials for information

regarding acceptable noise levels in

your area.

Preparation For Use

1. Place unit on level surface.

2. Check engine oil. See

Oil

under

Maintenance

To Check

.

CAUTION: Do not operate engine

without oil or with inadequate oil. Black

& Decker is not responsible for engine

failure caused by inadequate oil.

3. Check fuel level.

4. See product manual for specific

starting procedures.

NOTE: If any unusual noise or vibration

is noticed, stop the engine and refer to

the troubleshooting section as well as

the shop manual.

High Altitude Operating

At high altitude, the standard

carburetor air-fuel mixture will be too

rich. Performance will decrease and

fuel consumption will increase. A very

rich mixture will also foul the spark

plug and cause hard starting.

High altitude performance can be

improved by specific modifications

to the carburetor. If you always

operate your engine at altitudes above

1,524 meters (5,000 feet), have your

authorized service center perform a

carburetor modification.

Even with a carburetor modification,

engine horsepower will decrease

about 3.5% for each 300 meter (1,000

feet) increase in altitude. The effect of

altitude on horsepower will be greater

than this if no carburetor modification

is made. A decrease in engine

horsepower will decrease the power

output of the pressure washer.

NOTE: When the carburetor has been

modified for high altitude operation,

the air-fuel mixture will be too lean

for low altitude use. If the engine is

used at low altitudes after a carburetor

modification, the carburetor may cause

the engine to overheat and result in

serious engine damage. For use at low

altitudes, have your authorized service

center return the carburetor to original

factory specifications.

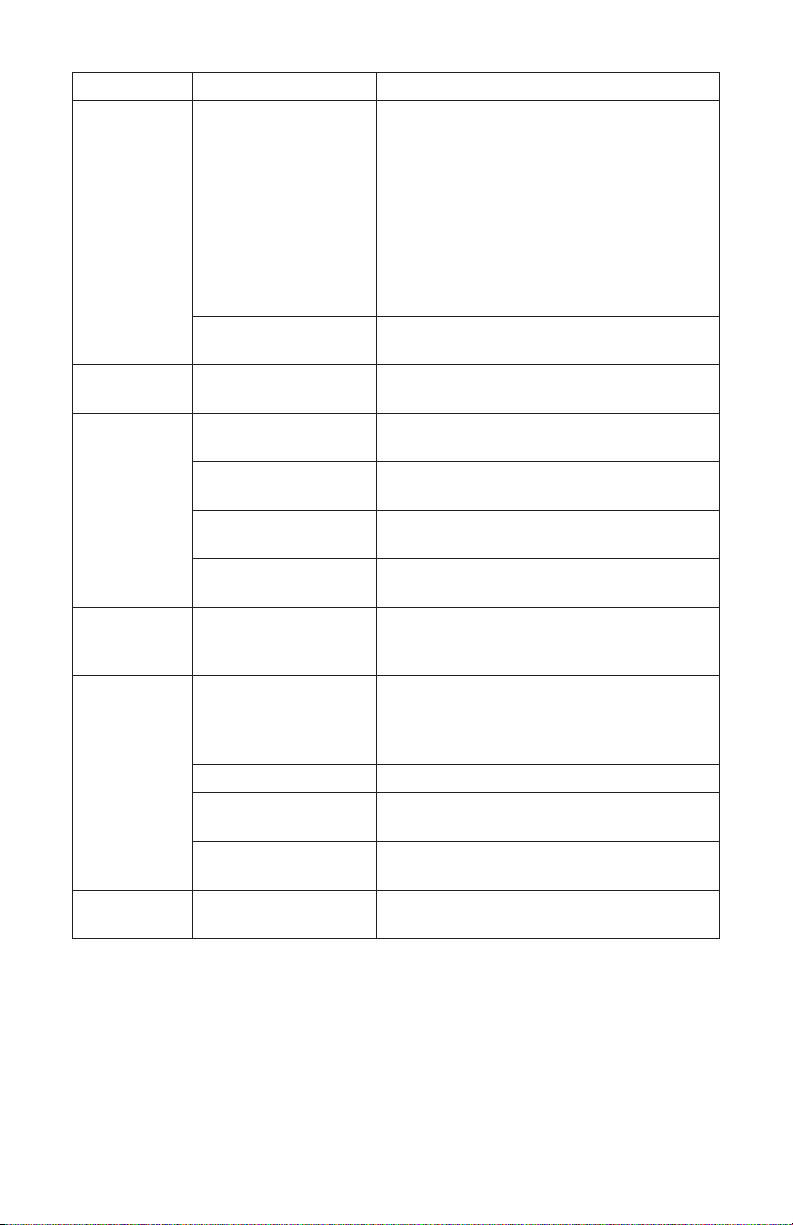

MAINTENANCE

CAUTION: When cleaning, use only

mild soap and a damp cloth on plastic parts. Many household cleaners

contain chemicals which could seriously damage plastic. Also, do not use

gasoline, turpentine, lacquer or paint

9 - ENG

N003333

Page 10

thinner, dry cleaning fluids or similar

products which may seriously damage plastic parts. Never let any liquid

get inside the engine; never immerse

engine into a liquid.

The following procedures must be followed when maintenance or service is

performed on the engine.

Any service operations not included in

this section should be performed by a

Black & Decker factory service center.

Contact Blacker & Decker Service

Represtentative at 1-800-544-6986.

This engine is only for use in Black &

Decker approved applications. If used

in unapproved applications, Black &

Decker is not responsible for repairs or

damage and the warranty if void. Call

1-800-544-6986 for more information.

Cleaning Air Filter (Fig. 1)

WARNING: Hot surfaces. Risk of

burn. Engine and surrounding parts

are very hot, do not touch (see the Hot

Surfaces identified in Figure 1). Allow

engine to cool prior to servicing.

A dirty air cleaner will restrict airflow

to the carburetor. To prevent carburetor mal func tion, service the air filter

regularly. Service more frequently

when operating the pressure washer in

extremely dusty areas.

WARNING: Using gasoline or flam-

mable solvent to clean the filter element can cause a fire or explosion.

WARNING: Risk of fire. Do not

operate without air filter.

150 hours or

comes first)

(whichever

monthly

Daily

100 hours

comes first)

(whichever

or weekly

50 hours

Procedure

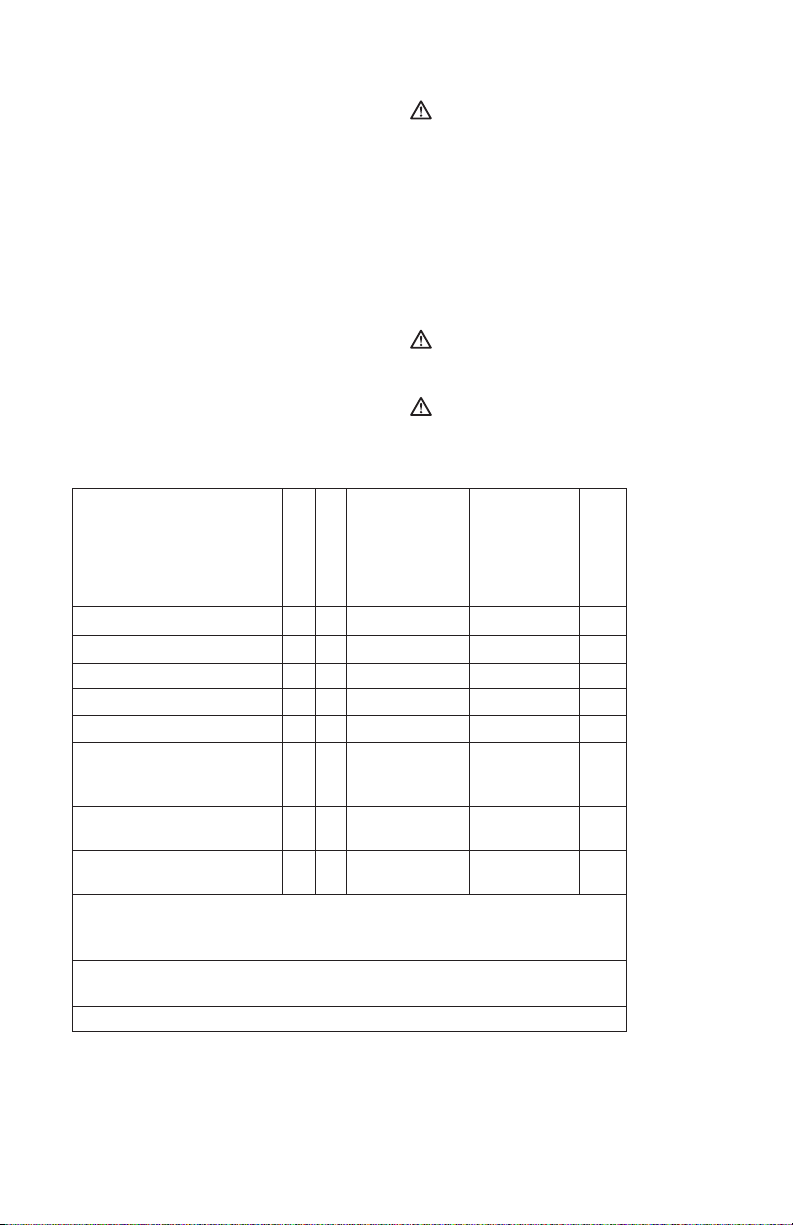

Maintenance Chart

Clean air filter (3)

Check oil level

Change oil (1,2,3)

Clean spark plug

Clean engine’s exterior

Check and adjust valve

clearance (.15 mm intake,

.2 mm exhaust) (2)

Clean spark

arrester (if equipped)

Clean debris screen (if

equipped)

X

X

X

X

X

X

X

1. The engine oil must be changed after the first 20 hours of

operation. Thereafter change oil every 150 hours of operation or

monthly, whichever comes first.

2. See Black & Decker shop manual for detail instructions. To order

a shop manual call

1-800-544-6986

.

3. Perform more frequently in dusty or humid conditions

500 hours

X

N003333

10- ENG

Page 11

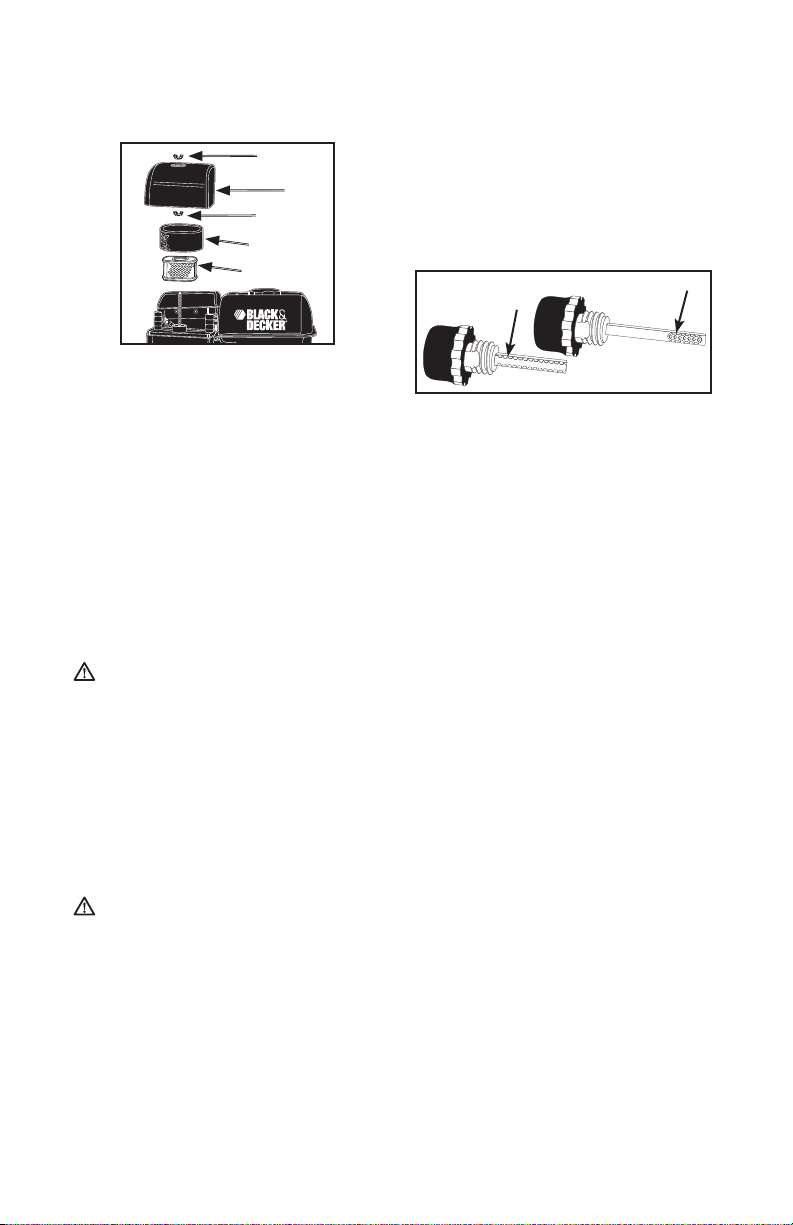

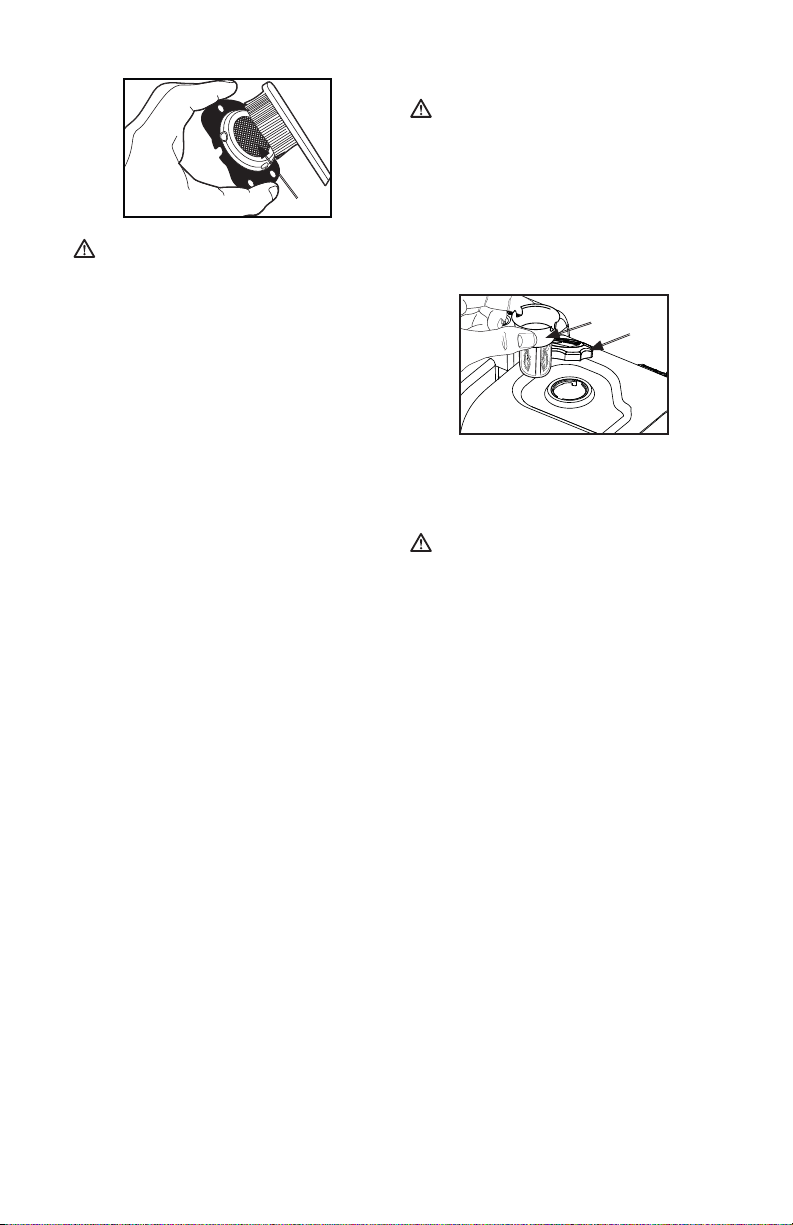

To Inspect the Elements

1. Remove the wing nut (Q) and the

air filter cover (R).

Q

R

Q

S

T

2. Remove the second wing nut (Q)

and remove the filter (T).

3. Remove the foam-type pre-filter

(S) from the filter (T).

4. Inspect foam and paper elements.

Replace them if damaged.

To Clean the Elements

Foam element: Wash element in

warm, soapy water. Then saturate it in

clean engine oil. Squeeze the element

to remove excess oil.

Paper element: Clean element by tapping gently to remove dust. Use compressed air to blow off dust.

WARNING: When using com-

pressed air, user always must wear

eye protection that conforms to ANSI

Z87.1. (CAN/CSA Z94.3).

Never use oil. Always blow the element

from the inside. If using compressed

air keep the air pressure less than 30

psi.

Place the foam pre-filter over the paper

element and reinstall it onto the engine.

Oil

WARNING: Hot surfaces. Risk of

burn. Engine and surrounding parts

are very hot, do not touch (see the Hot

Surfaces identified in Figure 1). Allow

engine to cool prior to servicing.

To Check Oil (Fig. 1)

1. Place unit on a flat level surface.

2. Remove oil fill/dipstick (C) and

wipe clean.

3. Reinsert oil fill/dipstick fully into

oil fill port and tighten. Allow oil to

collect on the dipstick for a few

seconds.

4. Remove oil fill/dipstick to read oil

level. If oil falls below top of pattern on dipstick, add oil. NOTE:

Patterns (CC) may differ according

to engine.

U

U

NOTE: When filling the crankcase,

allow the oil to flow very slowly. If

the oil is added too quickly, it will

overflow and appear to be full.

5. Replace dipstick and tighten

securely.

To Change Oil (Fig. 1)

NOTE: Engine oil contains substances

that are regulated and must be disposed of in accordance with local,

state, provincial and federal laws and

regulations.

1. Disconnect spark plug wire.

2. Locate a suitable container under

oil drain plug (D).

3. Remove the oil fill/dipstick (C)

from crank case.

4. Remove the oil drain plug (D).

5. Allow ample time for all oil to drain

out.

6. Install the oil drain plug.

7. Fill with recommended oil, refer

to Oil Recommendations under

Assembly.

8. Replace dipstick and tighten

securely.

9. Reconnect spark plug wire.

10. Dispose of oil according to

local, state and federal laws and

regulations.

11 - ENG

N003333

Page 12

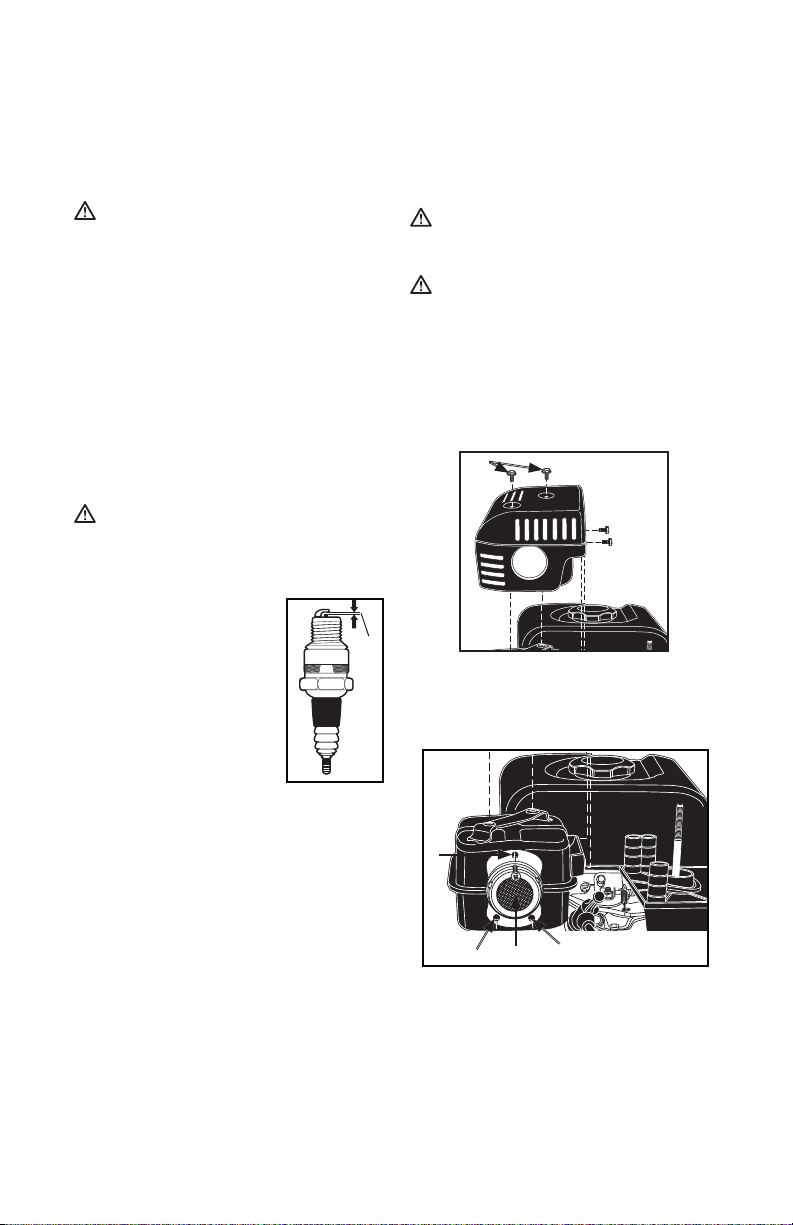

Spark Plug

Use recommended spark plugs, see

Specifications for correct spark plug.

To ensure proper engine operation, the

spark plug must be properly gapped

and free of deposits.

WARNING: If the engine has been

running, the muffler will be very hot. To

reduce the risk of injury, allow cooling

before proceeding.

1. Remove the spark plug cap.

2. Clean any dirt from around the

spark plug base.

3. Use a spark plug wrench (not supplied) to remove the spark plug.

4. Visually inspect the spark plug.

Replace it if the insulator is

cracked or chipped. Clean the

spark plug with a wire brush if it is

going to be reused.

WARNING: Always wear certified

safety equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3) with

side shields.

5. Measure the plug

gap with a feeler

gauge (V). Correct as

V

necessary by

carefully bending the

side electrode. The

gap should be:

0.70 –0.80 mm

(0.028 – 0.031 in).

6. Make sure the spark

plug washer is in good condition.

Thread the spark plug in by hand

to prevent cross threading.

7. After the spark plug is seated,

tighten with a spark plug wrench

to compress the washer. If installing a new spark plug, tighten the

spark plug 1/2 turn after it seats

to compress the washer. If reinstalling a used spark plug, tighten

1/8–1/4 turn after the spark plug

seats to compress the washer. Do

not overtighten.

8. Securely replace spark plug cap.

NOTE: The spark plug must be

securely tightened. An improperly

tightened spark plug can become very

hot and could damage the engine.

Never use spark plugs which have an

improper heat range. Use only the recommended spark plugs or equivalent.

Spark Arrester

WARNING: Risk of explosion or fire.

DO NOT operate engine without spark

arrestor (S).

WARNING: If the engine has been

running, the muffler will be very hot. To

reduce the risk of injury, allow engine

to cool before proceeding.

NOTE: The spark arrester must be serviced every 100 hours to maintain its

efficiency.

1. Remove muffler cover (W).

W

2. Remove the spark arrestor screws

(X) and remove the spark arrestor (S).

X

X

S

X

3. Use brush to remove carbon

deposits from the spark arrester

screen. Inspect the spark arrester

screen for holes or tears. Replace

the spark arrester if necessary.

N003333

12- ENG

Page 13

S

WARNING: Always wear certified

safety equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3) with

side shields when removing carbon

deposits.

Drain Carburetor Bowl (Fig. 1)

1. Place the fuel valve lever (J) in the

closed position.

2. Place an

OSHA-ap proved con tain er

suitable for fuel under the carburetor

NOTE:

bowl (M).

Using a funnel

will allow the fuel to flow into the

container with less spillage.

3. Remove the carburetor bowl drain

(L).

4. Fuel will drain from carburetor

bowl.

5. When drained, replace carburetor

bowl drain.

Cleaning Debris Screen (Fig. 1)

WARNING: Risk of explosion

or fire. Gasoline vapor is highly

flammable. Refuel outdoors only in

well-ventilated areas. Do not refuel or

check gasoline level while the engine

is running. Do not store, spill, or use

gasoline near an open flame, a source

of sparks (such as welding), or near

operating electrical equipment.

N

A

1. Remove fuel cap (A).

2. Remove debris screen (N).

3.

Clean debris screen.

Use

compressed air to blow off debris.

WARNING: When using

compressed air, user always must

wear eye protection that conforms

to ANSI Z87.1. (CAN/CSA Z94.3).

4. Replace debris screen and fuel

cap.

13 - ENG

N003333

Page 14

STORAGE

WARNING: If the engine has been

running, the muffler will be very hot. To

reduce the risk of injury, allow engine

to cool before proceeding.

If storing the unit for more than thirty

days drain all fuel out of fuel lines, tank

and carburetor bowl. Drain oil and refill

with fresh, clean oil. IMPORTANT: Fuel

will oxidize and deteriorate in storage.

If fuel is allowed to deteriorate during

storage the carburetor and fuel related

parts will need to be serviced. NOTE:

Fuel stabilizer can be used to lengthen

the fuel life, follow the fuel stabilizer’s

recommended instructions

SERVICE INFORMATION

Do not return this product to your

retailer. Black & Decker offers a

full network of company-owned and

authorized service locations throughout

North America. All Black & Decker

Service Centers are staffed with trained

personnel to provide cutomers with

efficient and reliable power tool service.

Whether you need technical advice,

repair, or genine factory replacement

parts, contact the Black & Decker

location nearest you.

To find your local service location,

refer to the yellow page directory

under “Tools—Electric” or call:

1-800-544-6986.

TWO-YEAR HOME USE

Black & Decker (U.S.) Inc. warrants

this product for two years against any

defects in material or workmanship.

The defective product will be replaced

or repaired at no charge. Do not

return this product to your retailer.

Take or send the product (prepaid)

to a Black & Decker owned or

authorized Service Center for repair

or replacement at our option. Proof

of purchase may be required. Black &

Decker owned and authorized Service

Centers are listed under “ToolsElectric” in the yellow pages of the

phone directory.

This warranty does not apply to

accessories. This warranty gives you

specific legal rights and you may have

other rights which vary from state to

state and province to province. Should

you have any questions, contact the

manager of your nearest Black &

Decker Service Center. This product is

not intended for commercial use.

Free Warning Label Replacement: If

your warning labels become illegible or

are missing, call 1-800-544-6986 for a

free replacement.

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

N003333

14- ENG

Page 15

TROUBLESHOOTING GUIDE

This section provides a list of the more frequently encountered malfunctions,

their causes and corrective actions. The operator or maintenance personnel can

perform some corrective actions, and others may require the assistance of a

qualified Black & Decker technician or your dealer.

Symptom Possible Cause Possible solution

Engine will

not start

Engine does

not continue

to run after

starting

Low or no fuel Add fuel

Low oil Add oil

On/Off switch is in

Place in ON position

the OFF position

Choke in the wrong

Adjust choke accordingly

position

Fuel valve in

Place in OPEN position

CLOSED position

Faulty spark plug Replace spark plug

Spark plug cap loose Attach spark plug cap securely

No or low

compression

Tighten spark plug. If problem is not

corrected, contact a B&D Customer

Service Representative at

1-800-544-6986.

No spark Check spark plug wire. If problem is

not corrected, contact a B&D Customer

Service Representative at

1-800-544-6986.

Dirty carburetor Contact a B&D Customer Service

Representative at 1-800-544-6986.

Low or no fuel Add fuel

Low oil Add oil

Choke in the wrong

Adjust choke accordingly

position

Fuel valve in

Place in OPEN position

CLOSED position

Spark plug cap loose Attach spark plug cap securely

No or low

compression

Tighten spark plug. If problem is not

corrected, contact a B&D Customer

Service Representative at

1-800-544-6986.

15 - ENG

N003333

Page 16

Symptom Possible Cause Possible solution

Engine does

not continue

to run after

starting

Spark plug fouling is

sooty or sticky black

a. Clean spark plug. See Spark Plug

under Maintenance.

b. Check spark plug gap, adjust if

needed. See Spark Plug under

Maintenance.

c. Replace spark plug. See

Specifications.

d. If engine still fails to start, con-

tact a B&D Customer Service

Representative at 1-800-544-6986.

Dirty carburetor Contact a B&D Customer Service

Representative at 1-800-544-6986.

Knocking

noise

Over speed

or low speed

Improper valve

clearances

Governor linkage

stuck or bent

Contact a B&D Customer Service

Representative at 1-800-544-6986.

Contact a B&D Customer Service

Representative at 1-800-544-6986.

Throttle shaft stuck Contact a B&D Customer Service

Representative at 1-800-544-6986.

Governor spring bent

or lost

Spark arrester

Contact a B&D Customer Service

Representative at 1-800-544-6986.

Clean and replace

clogged

Low power Bad fuel Drain fuel tank and replace with fresh,

clean, regular unleaded gasoline with a

minimum of 86 octane

No or low

compression

Tighten spark plug. If problem is not

corrected, contact a B&D Customer

Service Representative at 1-800-544-

6986.

Dirty air filter Clean or replace the air filter elements

Improper valve

clearances

Spark arrester

Contact a B&D Customer Service

Representative at 1-800-544-6986.

Clean and replace

clogged

Dirty Carburetor Contact a B&D Customer Service

Representative at 1-800-544-6986.

N003333

16- ENG

Page 17

THE FOLLOWING WARRANTY

APPLIES ONLY TO PRODUCTS

MANUFACTURED TO

MEET CALIFORNIA AND UNITED

STATES ENVIROMENTAL

PROTECTION AGENCY

SPECIFICATIONS, WHICH ARE

DISTRIBUTED AND SOLD IN THE

UNITED STATES.

I. EMISSION CONTROL WARRANTY

STATEMENT

Your warranty rights and obligations:

The California Air Resources Board,

the United States Environmental

Protection Agency and Black & Decker,

are pleased to explain the emission

control system warranty on your

model year small off-road engine. In the

United States and California, new small

off-road engines must be designed,

built and equipped to meet the State’s

stringent anti smog standards. Black

& Decker must warrant the emission

control system on your small off-road

engine for the periods of time listed

below provided there has been no

abuse, neglect or improper maintenance

of your small off-road engine.

Your emission control system may

include parts such as the carburetor

or fuel injection system, the ignition

system, and catalytic converter.

Also included may be hoses, belts,

connectors and other emission related

assemblies.

Where a warrantable condition exists,

Black & Decker will repair your small offroad engine at no cost to you including

diagnosis, parts and labor.

Manufacturer’s warranty coverage:

The 1995 and later small off-road

engines are warranted for two years. If

any emission related part on your engine

is defective, the part will be repaired or

replaced by Black & Decker.

Owner’s warranty responsibilities: As

the small off-road engine owner, you

are responsible for the performance

of the required maintenance listed in

your owner’s manual. Black & Decker

recommends that you retain all receipts

covering maintenance on your small

2008

off-road engine, but Black & Decker

cannot deny warranty solely for the

lack of receipts or for your failure to

ensure the performance of all scheduled

maintenance.

As the small off-road engine owner, you

should however be aware that Black

& Decker

coverage if your small off-road engine or

a part has failed due to abuse, neglect,

improper maintenance or unapproved

modifications.

You are responsible for presenting

your small off-road engine to a Black &

Decker distribution center as soon as a

problem exists. The

warranty repairs should be completed

in a reasonable amount of time, not to

exceed 30 days.

If you have any questions

regarding your warranty rights and

responsibilities, you should contact

Black & Decker Industrial Tool Co.,

Phone number (1-800-544-6986),

or visit Black & Decker website at

www.BlackandDecker.com for more

information and assistance.

II. EMISSION CONTROL SYSTEM

WARRANTY

Emission Control System Warranty

(ECS Warranty) for 1997 and later model

engines

(a) Applicability: This warranty shall

(b) General Emissions Warranty

(1) Designed, built and equipped so

(2) Free from defects in materials

. may deny you warranty

apply to 1997 and later model year

engines. The ECS Warranty Period

shall begin on the date the new

engine or equipment is purchased

by/delivered to its ultimate purchaser

and shall continue for 24 consecutive

months thereafter.

Coverage: Black & Decker

to the ultimate purchaser of the new

engine or equipments and each

subsequent purchaser for a two-year

period.

as to conform with all applicable

regulations adopted by the EPA and

CARB pursuant to their respective

authority, and

and workmanship, which, at any

time during the ECS Warranty

warrants

17 - ENG

N003333

Page 18

Period, may cause a warranted

emissions-related part to fail to be

identical in all material respects to

the part as described in the engine

manufacturer’s application for

certification.

The ECS Warranty only pertains

to emissions-related parts on your

engine, as follows:

(1) Any warranted, emissions-related

parts that are not scheduled

for replacement as required

maintenance in the Owner’s

Manual must be warranted for

the ECS Warranty Period. If any

such part fails during the ECS

Warranty Period, it shall be repaired

or replaced by Black & Decker

.

according to Subsection (4) below.

Any such part repaired or replaced

under the ECS Warranty shall be

warranted for the remainder of the

ECS Warranty Period.

(2) Any warranted, emissions-related

part that is scheduled only for

regular inspection as specified

in the Owner’s Manual must be

warranted for the ECS Warranty

Period. A statement in such written

instructions to the effect of “repair

or replace as necessary” shall not

reduce the ECS Warranty Period.

Any such part repaired or replaced

under the ECS Warranty shall be

warranted for the remainder of the

ECS Warranty Period.

(3) Any warranted, emissions-

related part that is scheduled

for replacement as required

maintenance in the Owner’s Manual

shall be warranted for the period

of time prior to the first scheduled

replacement point for that part.

If the part fails prior to the first

scheduled replacement, the part

shall be repaired or replaced by

Black & Decker according to

Subsection (4) below. Any such

emissions-related part repaired

or replaced under the ECS

Warranty shall be warranted for

the remainder of the ECS Warranty

Period prior to the first scheduled

replacement point for such

emissions-related part.

N003333

(4) Repair or replacement of any

warranted, emissions-related part

under this ECS Warranty shall

be performed at no charge to

the owner at a Black & Decker

Authorized Warranty Service

Facility. The warranty services or

repairs must be provided at all

manufacturer distribution centers

that are franchised to service the

subject engines.

(5) When the engine is inspected

by a Black & Decker

Authorized

Warranty Service Facility, the owner

shall not be held responsible for

diagnostic costs if the repair is

deemed warrantable.

(6) Black & Decker

shall be liable

for damages to other original

engine components or approved

modifications proximately caused

by a failure under warranty of any

emission-related part covered by

the ECS Warranty.

(7) Throughout the ECS Warranty

Period, Black & Decker shall

maintain a supply of warranted

emission-related parts sufficient

to meet the expected demand for

such emission-related parts.

(8) Any replacement part may be used

in the performance of any Warranty

maintenance or repairs and will

be provided without charge to the

ultimate purchaser. Such use shall

not reduce Black & Decker's ECS

warranty obligations.

(9) Add-on or modified parts that are

not exempted by the Air Resources

Board may not be used. Such use

will be grounds for disallowing a

warranty claim made in accordance

with this article. Black & Decker will

not be liable under this article to

warrant failures of warranted parts

caused by the use of such an addon or modified part.

EMISSION RELATED PARTS

INCLUDE THE FOLLOWING:

1) Fuel Metering System:

a) Gasoline carburetor assembly

and its internal components.

b) Fuel filter (if equipped)

c) Carburetor gaskets

18- ENG

.

Page 19

d) Fuel pump (if equipped)

2) Air Induction System including:

a) Intake pipe/manifold

b) Air cleaner

3) Ignition System including:

a) Spark plug

b) Ignition module/coil

4) Miscellaneous Items Used in Above

Systems

a) Vacuum, temperature, and

time sensitive valves and

switches.

b) Hoses, belts, connectors, and

assemblies.

5) Evaporate Emissions Control

a) Fuel Hose certificated for CARB

evaporative emission of 2008.

b) Fuel hose clamp

c) carbon canister (if equipped)

d) Roll over valve (if equipped)

e) Fuel tank

f) Fuel cap

6) Exhaust Emissions Control

a) catalytic converter (if equipped)

19 - ENG

N003333

Page 20

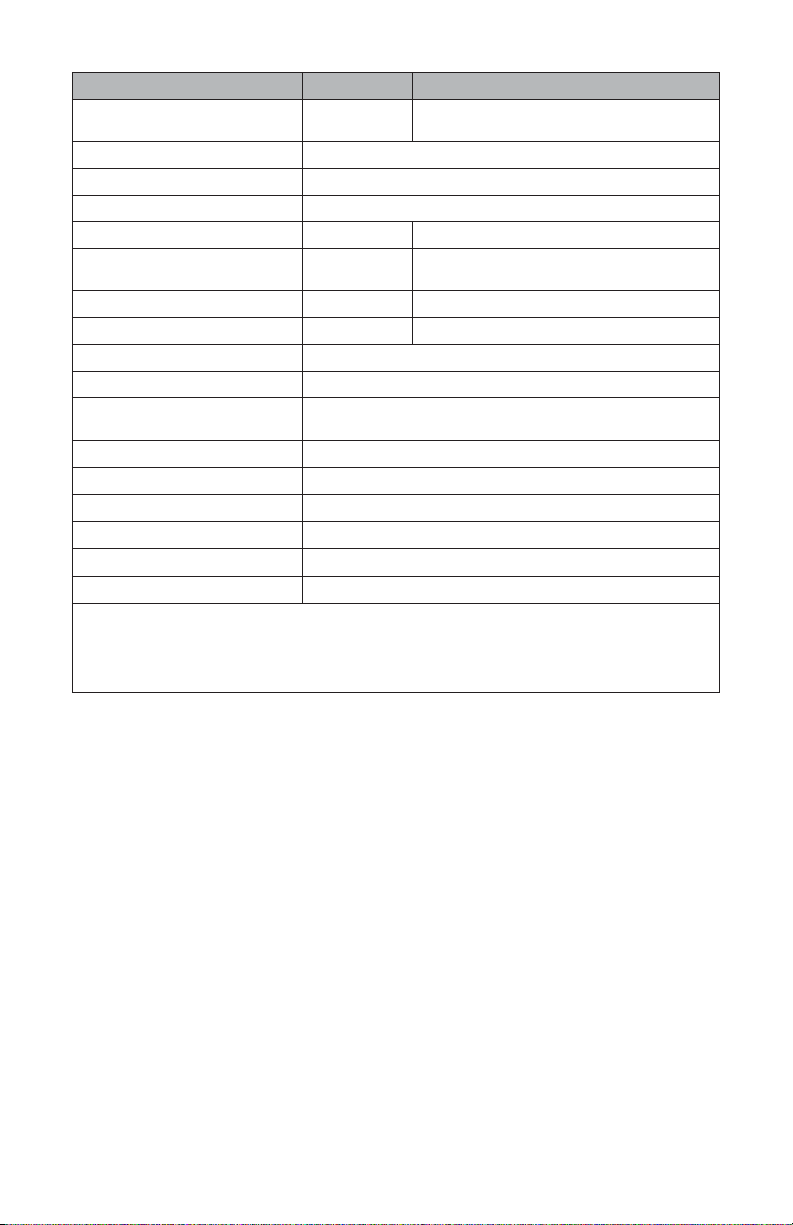

Engine Specifications BD168F-H BD168F-L

Dry weight (approximate) 38 lbs.

(17.38 kg)

38 lbs. (17.38 kg)

Dimensions (LxWxH) For dimensions, see shop manual installation drawings

Type

Fuel

Air cooled, 4 cycle single cylinder, spark ignited

Regular, unleaded gasoline (minimum 86 octane)

Displacement (cc) 163 196

Horsepower (*Gross HP)

(hp @ rpm)

*5.5 @3500 *6.5 @ 3600

Fuel tank capacity (gallons/liters) .95/3.6 .95/3.6

Oil capacity

Air cleaner type

Fuel filter

Spark plug type

Spark plug gap

Fuel shut off solenoid

Lamp coil

Idle control

Electric starter

Max. recommended tilt angle

* Gross horsepower (HP). This horsepower rating represents the maximum output under

laboratory conditions at 3600 RPM in accordance with SAE (Society of Automotive Engineers)

J1995 and should be used for comparison purposes only. Actual engine output will be lower

and will vary depending on the application, speed and other variables including altitude and

temperature.

.63 qt/.60 l .63 qt/.60 l

Foam element or paper

Equipped

NGK: BP6ES, BPR6ES/AUTOLITE: 63/AC DELCO: R41XL,

R42XLS, R43FS, R43XL, R43XLS, R44XLS, R45XLS or equivalent

0.028-0.031" (0.70-0.80 mm)

Without

Without

Without

Without

< 25 or 30°

N003333

20- ENG

Page 21

Moteur

Moteur

No de catalogue BD168F

MANUEL D'UTILISATION

MERCI D’AVOIR CHOISI BLACK & DECKER !

V

ISITEZ WWW.BLACKANDDECKER.COM/NEWOWNER

POUR ENREGISTRER VOTRE NOUVEAU PRODUIT.

AVANT DE RETOURNER CE PRODUIT POUR

QUELQUE RAISON QUE CE SOIT, COMPOSER LE

1-800-544-6986

AVANT D’APPELER, AYEZ EN MAIN LE N° DE CATALOGUE ET LE CODE DE DATE. DANS LA PLUPART

DES CAS, UN REPRÉSENTANT DE BLACK & DECKER PEUT RÉSOUDRE LE PROBLÈME PAR

TÉLÉPHONE. SI VOUS AVEZ UNE SUGGESTION OU UN COMMENTAIRE, APPELEZ-NOUS. VOS

IMPRESSIONS SONT CRUCIALES POUR BLACK & DECKER.

Page 22

MESURES DE SÉCURITÉ -

DÉFINITIONS

Ce guide contient des renseignements

importants que vous deviez bien saisir.

Cette information porte sur VOTRE

SÉCURITÉ et sur LA PRÉVENTION DE

PROBLÈMES D'ÉQUIPEMENT. Afin de

vous aider à identifier cette information, nous avons utilisé les symboles

ci-dessous. Veuillez lire attentivement

ce guide en portant une attention particulière à ces symboles.

DANGER: indique une situation

dangereuse imminente qui, si elle n’est

pas évitée, causera la mort ou des

blessures graves.

AVERTISSEMENT : indique une

situation potentiellement dangereuse

qui, si elle n’est pas évitée, pourrait

causer la mort ou des blessures

graves.

ATTENTION : indique une situa-

tion potentiellement dangereuse qui, si

elle n’est pas évitée, peut causer des

blessures mineures ou modérées.

ATTENTION : utilisé sans le symbole

d’alerte de sécurité, indique une situation potentiellement dangereuse qui,

si elle n’est pas évitée, peut se solder

par des dommages à la propriété.

MESURES DE SÉCURITÉ

IMPORTANTES

CONSERVER CES DIRECTIVES – Ce

manuel contient des directives importantes pour les modèles et BD168F

qui devraient être respectées lors de

l’installation et de l’entretien du moteur.

DANGER : Monoxyde de carbone. Le fonctionnement d’un

moteur à l’intérieur vous tuera en

quelques minutes. L’échappement

du moteur contient des niveaux

élevés de monoxyde de carbone

(CO), un gaz toxique, inodore et

invisible. Il est possible que vous

inhaliez du CO même en l’absence

de l’odeur de l’échappement du

moteur.

N003333

• NE JAMAIS utiliser un moteur à

l’intérieur d’une habitation, d’un

garage, d’un vide sanitaire ou de

tout espace partiellement clos.

Ces endroits peuvent accumuler

des niveaux mortels de monoxyde

de carbone. L’utilisation d’un

ventilateur ou l’ouverture des

fenêtres et portes NE FOUR-

NIT pas assez d’air frais.

• Utiliser UNIQUEMENT à l’exté-

rieur et loin de fenêtres, portes

et évents ouverts. En effets,

ces ouvertures peuvent aspirer l’échappement du moteur

à l’intérieur d’un espace.

• Même lors de l’utilisation correcte du moteur, le CO pourrait

pénétrer dans votre maison.

TOUJOURS utiliser un avertisseur de CO alimenté à pile ou un

avertisseur de CO de secours à

pile (non fourni) dans la maison.

Lire et respecter toutes les

directives de l’avertisseur de

CO avant son utilisation. En cas

de malaise, d’étourdissement ou

de faiblesse, à tout moment, se

déplacer à l’air frais immédiatement. Consulter un médecin. Ce

sont des signes d’intoxication

par le monoxyde de carbone.

AVERTISSEMENT: N'utilisez pas

cet appareil avant d'avoir lu et compris les instructions sur la sécurité,

l'utilisation et l'entretien de ce Guide

de l'utilisateur et du Guide du propriétaire du moteur.

AVERTISSEMENT :

L’échappement du moteur provenant

de ce produit contient des produits

chimiques reconnus par l’État de la

Californie comme pouvant causer le

cancer, des anomalies congénitales

et d’autres dangers pour la reproduction. Se laver les mains après

toute manipulation.

IMPORTANT : Ces produits sont dotés

de silencieux avec pare-étincelles. Ce

type de silencieux est requis par la loi

dans l’État de la Californie. L’absence

de pare-étincelles est en violation de

22- FR

Page 23

l’article 130050 et/ou des articles 4442

et 4443 du California Public Resources

Code, à moins que le moteur ne soit

muni d’un pare-étincelles comme il est

stipulé à l’article 4442 et tenu en bon

état de fonctionnement. Les pare-étince-

lles sont exigés sur certaines terres du

Service des forêts américain et peuvent

être également exigés par d’autres législations et règlements.

CONSERVER CES

DIRECTIVES

LISEZ ET CONSERVEZ CES INSTRUCTIONS

DANGER: RISQUE D'EXPLOSION OU D'INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

•

Les étincelles de produits du tabac,

des arcs électriques, des gaz

d’échappement, d’une flamme, des

gaz et des composants chauds du

moteur comme le silencieux peuvent enflammer l’essence renversée

et ses vapeurs.

• Éteindre le moteur et le laisser

refroidir avant de remplir le réservoir

d'essence

• Être attentif et éviter de déverser de

l'essence lors du remplissage du

réservoir. Éloigner la laveuse haute

pression de la zone de ravitaillement

avant de démarrer le moteur.

• Le combustible du réservoir se

dilate sous l’effet de la chaleur et

pourrait se solder par un déversement et un incendie ou une explosion.

• Un silencieux sans pare-étincelles

ou muni d’un pare-étincelles qui ne

fonctionne pas pourrait provoquer

un incendie.

• Les matériaux combustibles qui

touchent les pièces chaudes du

moteur risquent de s’enflammer.

•

Maintenir le niveau d’essence

maximal

à débris

de l’essence

sous l’épaulement du filtre

pour permettre l’expansion

.

• S’assurer que le silencieux muni

d’un pare-étincelles est en position

et en bon état.

• Remplacer le silencieux muni d’un

pare-étincelles s’il est endommagé

ou manquant.

• Faire le plein d’essence à

l’extérieur dans une zone bien

aérée. S’assurer de l’absence de

source d’inflammation près de la

zone de ravitaillement, comme des

produits du tabac.

• Se servir du moteur dans une zone

propre, sèche et bien aérée à une

distance minimale de 1,2 m (48 po)

de tout édifice, objet ou mur. Ne

pas utiliser l’appareil à l’intérieur

ou dans un endroit exigu.

• Utiliser le moteur uniquement

dans un endroit ouvert loin de

broussailles ou d’herbes sèches ou

de tout autre matière combustible

23 - FR

N003333

.

Page 24

• De l’essence mal entreposée pourrait provoquer un allumage (incendie) accidentel. Ranger l’essence de

façon sécuritaire pour en empêcher

l’accès aux enfants et à toutes

autres personnes non qualifiées.

• Le fonctionnement de ce produit

sans surveillance pourrait se solder par des blessures corporelles

ou des dommages matériels. Afin

de réduire le risque d’incendie, ne

pas laisser le moteur fonctionner

sans surveillance.

• Entreposer l’essence dans un

contenant homologué par l’OSHA

(Occupational Safety and Health

Administration - Sécurité et salubrité du travail) dans un emplacement sécuritaire loin de la zone de

travail.

• Être toujours présent lorsque le

moteur est en marche.

DANGER: RISQUE D'ASPHYXIE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• L’inhalation des fumées

d’échappement provoquera de

graves blessures, voire la mort!

L’échappement du moteur

contient des niveaux élevés de

monoxyde de carbone (CO), un

gaz toxique, inodore et invisible.

Il est possible que vous inhaliez

du CO même en l’absence de

l’odeur de l’échappement du

moteur.

• NE JAMAIS utiliser un moteur à

l’intérieur d’une habitation, d’un

garage, d’un vide sanitaire ou de

tout espace partiellement clos.

Ces endroits peuvent accumuler

des niveaux mortels de monoxyde

de carbone. L’utilisation d’un

ventilateur ou l’ouverture des

fenêtres et portes ne fournit PAS

assez d’air frais.

• Utiliser uniquement à l’extérieur

et loin de fenêtres, portes et

évents ouverts. En effets, ces

ouvertures peuvent aspirer

l’échappement du moteur à

l’intérieur d’un espace.

•

Éloigner les enfants, animaux et

toute autre personne de la zone de

travail.

• Toujours tenir le tuyau d’échappement exempt de corps étrangers.

N003333

24- FR

Page 25

DANGER: RISQUE DE BLESSURE OU DE DOMMAGE À LA PROPRIÉTÉ

LORS DU TRANSPORT OU DU RANGEMENT

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• L’huile et l’essence peuvent fuir ou

se déverser. Cela pourrait se

solder par un incendie ou un danger

d’inhalation; des blessures graves

ou un décès. Les fuites d’huile et

d’essence endommageront le tapis,

la peinture ou toutes autres surfaces de véhicules ou de remorques.

De l’huile et de l’essence déversés

accroissent le risque de blessures.

• Ne jamais transporter le moteur si

de l’essence se trouve dans le

système d’alimentation, si le robinet

à essence est ouvert ou si le moteur

est en marche.

• Toujours installer le moteur sur un

revêtement protecteur lors du

transport pour protéger le véhicule

de tous dommages associés aux

fuites. Retirer immédiatement le

moteur du véhicule dès votre

arrivée à destination. Toujours tenir

le moteur à niveau et ne jamais le

déposer sur son côté.

• Transporter l’essence uniquement

dans un contenant homologué par

l’OSHA.

AVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Un contact avec une surface

métallique exposée (silencieux et

autres pièces du moteur) peut se

solder par des brûlures graves.

• Ne jamais toucher à des pièces

métalliques exposées du moteur

pendant ou immédiatement après

son utilisation. Le moteur restera

chaud pendant plusieurs minutes

après son utilisation.

• Ne pas toucher aux coiffes

de protection ni effectuer des

réparations sur celles-ci avant que le

moteur n’ait refroidi.

AVERTISSEMENT : RISQUE ASSOCIÉ AUX PIÈCES MOBILES

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Le moteur peut démarrer accidentellement si le volant est tourné

• Toujours débrancher la bougie d’allumage avant tout entretien.

manuellement ou par l’action du

lanceur à rappel.

25 - FR

N003333

Page 26

• Les pièces mobiles comme une

poulie, un volant et une courroie

peuvent provoquer de graves blessures si elles entrent en contact

avec vous ou vos vêtements.

• Utiliser le moteur avec des pièces

endommagées ou manquantes ou

le réparer sans coiffes de protection

risque de vous exposer à des pièces mobiles et peut se solder par

de graves blessures.

• Ne jamais utiliser le

moteur

si les

protecteurs ou les couvercles sont

endommagés ou retirés.

• Tenir les cheveux, les vêtements et

les gants hors de portée des pièces

mobiles. Les vêtements amples,

bijoux ou cheveux longs peuvent

s’enchevêtrer dans les pièces mobiles.

• Se tenir éloigné des évents, car ces

derniers pourraient également

dissimuler des pièces mobiles.

•

Toutes les réparations requises pour

ce produit devraient être effectuées

par un

cEntre de réparation en

usine de Black & Decker ou un

centre de réparation agréé Black &

Decker.

AVERTISSEMENT: RISQUE DECHOC ÉLECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Un jet en direction de prises électriques ou d'interrupteurs ou tout

objet branché à un circuit électrique

pourrait se solder par un choc électrique.

• Débrancher tout produit fonctionnant

à l'électricité avant d'essayer de le

nettoyer. Éloigner le jet des prises

électriques et interrupteurs.

AVERTISSEMENT : RISQUE ASSOCIÉ À UNE

UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Une utilisation dangereuse de votre

moteur pourrait provoquer de graves blessures, voire votre décès ou

celui d’autres personnes.

•

Revoir et comprendre toutes les

directives et les avertissements

contenus dans le présent mode

d’emploi.

•

Se familiariser avec le fonctionnement et les commandes du moteur.

• Dégager la zone de travail de toutes

personnes, animaux et obstacles.

• Tenir les enfants hors de portée du

moteur en tout temps.

• Ne pas utiliser le moteur en cas de

fatigue ou sous l’emprise d’alcool

ou de drogues. Rester vigilant en

tout temps.

• Ne jamais rendre inopérant les

caractéristiques de sécurité de ce

produit.

N003333

26- FR

Page 27

• Installer un extincteur d’incendie

dans la zone de travail.

• Ne pas se servir du moteur lorsqu’il

manque des pièces ou que des

pièces sont brisées ou non autorisées.

• Ne jamais se tenir debout sur le

moteur.

AVERTISSEMENT : RISQUE ASSOCIÉ AU BRUIT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

•

Dans certaines conditions, applications et selon la durée d’utilisation, le bruit émis par ce produit

pourrait contribuer à une perte

•

TOUJOURS

utiliser un équipement

de sécurité homologué : protection

auditive conforme à la norme ANSI

S12.6 (S3.19).

auditive.

LISEZ ET CONSERVEZ CES INSTRUCTIONS

27 - FR

N003333

Page 28

1

A

N

S

R

Q

P

M

Composants (Fig. 1)

A. Bouchon du réservoir

d’essence

B. Réservoir d’essence

C. Jauge d’huile

D. Vidange d’huile

E. Carter de prise de force

F. Filtre à air assemblée

G. Commutateur marche/arrêt

H. Réglage de la comande des

gaz

I. Levier d’étrangleur

J. Robinet à essence

K. Lanceur à rappel

L. Purge de la cuve du

carburateur

M. Cuve du carburateur

N. Filtre à débris

O. Capteur de bas niveau d’huile

qui commande l’arrêt moteur

F

G

O

L

H

I

J

K

Surfaces Chaudes (Fig. 1)

P. Bougie d’allumage

Q. Culasse

R. Silencieux

S. Pare-étincelles

B

E

C

D

N003333

28- FR

Page 29

ASSEMBLGE

AVERTISSEMENT : Ne pas utiliser

cet appareil avant d’avoir lu et compris

le présent mode d’emploi et celui

de l’outil ainsi que l’intégralité des

directives de sécurité, d’utilisation et

d’entretien.

Ce moteur est conçu pour une

utilisation uniquement dans des

applications approuvées par Black &

Decker. En cas d’utilisation dans des

applications non approuvées, Black &

Decker ne peut être tenu responsable

des réparations ou dommages et

la garantie s’annule. Composer le

(1-800-544-6986) pour obtenir plus de

renseignements.

Pour assembler correctement le

moteur, se reporter aux directives de

montage du manuel de dépannage.

ATTENTION : Le moteur en

provenance de l’usine NE CONTIENT

PAS d’huile. Il faut ajouter de l’huile

au moteur avant de s’en servir pour

empêcher tout dommage.

Recommandations de type d’huile

Pour une utilisation générale, on

recommande l’huile SAE 10W-30.

Se reporter au tableau viscositétempérature ambiante pour l’huile

recommandée pour la température

moyenne de votre région.

REMARQUE : L’huile synthétique n’est

PAS recommandée.

Tableau Viscosité-

Température Ambiante

30

10W-30

2. Retirer la jauge d’huile (C).

3. Ajouter lentement l’huile

recommandée, consulter la

fiche technique pour connaître

le volume d’huile nécessaire.

REMARQUE : Si l’huile est

ajoutée trop rapidement, elle

débordera et le réservoir paraîtra

plein.

Consulter la rubrique Vérification

de l’huile à la section

Entretien pour

connaître les directives.

Ajout d’essence

AVERTISSEMENT : Risque

d’explosion ou d’incendie. Les

vapeurs d’essence sont hautement

inflammables. Faire le plein

uniquement à l’extérieur dans des

endroits bien aérés. Ne pas faire

le plein ou ne pas vérifier le niveau

d’essence avec le moteur en marche.

Ne pas ranger l’essence, ni la déverser

ni l’utiliser près d’une flamme nue,

d’une source d’étincelles (comme la

soudure) ou d’équipement électrique

en fonctionnement.

1. Retirer le bouchon du réservoir

d’essence (A).

A

B

2. Ajouter de l’essence sans plomb

propre et neuve dans le réservoir

d’essence (B) avec un indice

d’octane d’au moins 86. Ne pas

remplir au-dessus de l’épaulement

du filtre à débris (N) comme

indiqué.

5W-30

˚F -20 0 20 40 60 80 100

˚C -28.8 -17.7 -6.6 4.4 15.5 26.6 37.7

Ajout d’huile (Fig. 1)

1. Se reporter au tableau viscositétempérature ambiante pour

connaître la viscosité correcte.

N

REMARQUE : Le filtre à débris protège

le moteur de la saleté et des débris. Ne

le retirer qu’au moment du nettoyage.

Consulter la rubrique Nettoyage du

29 - FR

N003333

Page 30

filtre à débris à la section Entretien

pour connaître les directives.

REMARQUE : Ne pas mélanger l’huile

et l’essence.

3. Remettre le bouchon du réservoir

d’essence en position. Visser le

bouchon dans le sens horaire,

jusqu’à ce qu’il se bloque.

Carburants oxygénés

Certaines essences conventionnelles

sont mélangées avec de l’alcool ou

un composé éthéré. Ces essences

sont désignées collectivement sous le

nom de carburants oxygénés. Pour se

conformer aux normes de pureté de

l’air, certaines régions des États-Unis

et du Canada utilisent des carburants

oxygénés pour aider à la réduction des

émissions.

Dans le cas de l’utilisation de carburant

oxygéné, s’assurer qu’il soit sans

plomb et se conforme à l’exigence

de l’indice d’octane minimum de 86.

Avant l’utilisation d’un carburant

oxygéné, essayer de confirmer son

contenu. Certains États et provinces

exigent que cette information soit

apposée sur la pompe à essence. Les

composés ci-dessous sont approuvés

par l’EPA américaine en matière de

pourcentage de composés oxygénés :

Éthanol (alcool éthylique ou de vin)

à 10 % par volume. Il est possible

d’utiliser de l’essence qui contient

jusqu’à 10 % d’éthanol par volume.

L’essence qui contient de l’éthanol

peut être commercialisée sous le nom

de « gasohol » ou « alco-essence ».

MISE EN GARDE : risque de

dommages matériels. NE PAS utiliser

de carburant E85.

MTBE (éther de méthyle et de butyle

tertiaire) à 15 % par volume. Il est

possible d’utiliser de l’essence qui

contient jusqu’à 15 % de MTBE par

volume.

Méthanol (alcool méthylique ou de

bois) à 5 % par volume. Il est possible

d’utiliser de l’essence qui contient

jusqu’à 5 % de méthanol par volume

en autant qu’il comporte également

des solvants et des inhibiteurs de

N003333

corrosion pour protéger le système

d’alimentation. L’essence qui contient

plus de 5 % de méthanol par volume

pourrait démontrer des problèmes au

démarrage et/ou de rendement. Elle

pourrait également endommager les

pièces métalliques, de caoutchouc et

de plastique du moteur ou de votre

système d’alimentation.

Si vous remarquez un symptôme

indésirable au fonctionnement, essayer

une autre station d’essence ou changer

de marque d’essence.

REMARQUE : Les dommages ou

les problèmes liés au rendement du

système d’alimentation en fonction

de l’utilisation d’un carburant oxygéné

qui contient plus de composé que les

pourcentages de composés oxygénés

décrits ci-dessus ne sont pas couverts

par la garantie.

Emplacement

DANGER: Risque d'asphyxie.

L’échappement du moteur à essence

contient du monoxyde de carbone

mortel; gaz inodore et toxique. Faire

fonctionner le moteur uniquement à

l’extérieur dans des endroits propres,

secs et bien aérés.

Remarques à propos du bruit

Consulter les organismes de

règlementation locaux pour connaître

les niveaux de bruit tolérés dans votre

région.

Mode d’emploi

1. Déposer l’appareil sur une surface

à niveau.

2.

Vérifier l’huile du moteur. Consulter

la rubrique Vérification de l’huile

à

la section Entretien.

ATTENTION :

Ne pas utiliser le

moteur sans huile ou avec une huile

inappropriée. Black & Decker

ne peut

être tenu responsable pour toute

défaillance du moteur provoquée par

une huile inappropriée.

3. Vérifier le niveau d’essence.

4. Consulter le manuel du produit

pour les procédures particulières

de démarrage.

30- FR

Page 31

REMARQUE : Si on remarque un bruit

ou une vibration inhabituelle, arrêter

le moteur et se reporter à la rubrique

concernant le dépannage de même

que le manuel de dépannage.

Fonctionnement en altitude

En altitude, le mélange air-carburant

standard du carburateur sera trop

riche. Le rendement diminuera et la

consommation d’essence augmentera.

Un mélange très riche pourra également encrasser la bougie d’allumage

et rendre le démarrage plus difficile.

Il est possible d’améliorer le rendement

en altitude en modifiant de façon précise le carburateur. Si le moteur est toujours en fonctionnement à une altitude

de plus de 1 524 mètres (5 000 pi),

confier la modification du carburateur à

un centre de réparation agréé.

Même suite à une modification du carburateur, la puissance du moteur sera

plus réduite. Environ 35 % de moins

pour chaque tranche de 300 mètres

(1 000 pi) d’altitude supplémentaire.

L’effet de l’altitude sur la puissance du

générateur sera encore plus important

sans modification au carburateur. Une

réduction de la puissance du moteur

entraîne une réduction de la puissance

à la sortie.

REMARQUE : lorsque le carburateur

a été modifié pour un fonctionnement

en altitude, le mélange air-carburant

sera trop faible pour une utilisation en

basse altitude. Dans ce cas, le carburateur pourrait entraîner une surchauffe

du moteur et provoquer de graves

dommages à celui-ci. Pour une utilisation à basses altitudes, demander au

centre de réparation agréé de régler le

carburateur aux spécifications d’usine

d’origine.

ENTRETIEN

ATTENTION : Lors du nettoyage des

pièces de plastique, utiliser uniquement du savon doux et un chiffon

humide. Bon nombre de nettoyants

domestiques renferment des produits

chimiques pouvant grandement

endommager le plastique. En outre, ne

pas utiliser d’essence, de térébenthine,

de diluant à peinture ou à laque, de

liquides pour nettoyage à sec ou tout

autre produit semblable qui pourrait

endommager gravement les composants en plastique. Ne jamais laisser

de liquide pénétrer dans le moteur et

ne jamais immerger le moteur dans un

liquide.

Respecter les procédures suivantes

lors de l’entretien ou des réparations du

moteur.

Toute réparation non décrite dans cette

rubrique devrait être exécutée à un

centre de réparation en usine de Black

& Decker ou un centre de réparation

agréé Black & Decker.

Ce moteur est conçu uniquement pour

une utilisation dans des applications

approuvées par Black & Decker. En cas

d’utilisation dans des applications non

approuvées, Black & Decker ne peut

être tenu responsable des réparations

ou dommages et la garantie s’annule.

Composer le 1-800-544-6986 pour

obtenir plus de renseignements.

Nettoyage de l’élément du filtre à air

(Fig. 1)

AVERTISSEMENT : Surfaces

chaudes. Risque de brûlure. Le moteur

et les pièces contiguës sont très

chaudes, ne pas les toucher (consulter

la rubrique Surfaces chaudes des

figure 1). Laisser refroidir le moteur avant

d’y effectuer des réparations.

Un filtre à air sale restreindra le débit

d’air vers le carburateur. Pour empêcher

un mauvais fonctionnement du carburateur, faire l’entretien régulier du filtre à air.

Effectuer l’entretien plus fréquemment

lors de l’utilisation de l’alternateur dans

des endroits très poussiéreux.

AVERTISSEMENT : L’utilisation

d’essence ou de solvants inflammables

pour le nettoyage de l’élément du filtre

à air peut provoquer un incendie ou

une explosion.

AVERTISSEMENT : Risque

d’incendie. Ne pas utiliser sans le filtre

à air.

31 - FR

N003333

Page 32

Programme d’entretien

(selon la première éventualité)

(selon la première éventualité)

100 heures

hebdomadaire

Quotidienne

50 heures ou

mensuellement

150 heures ou

500 heures

Procédure

Nettoyage du filtre à air (3)

Vérification du niveau d’huile

Vidange d’huile (1, 2, 3)

Nettoyage de la bougie d’allumage

Nettoyage de la surface externe du moteur

Vérifier et régler le dégagement de la

soupape (0,15 mm admission, 0,2 mm

échappement) (2)

Nettoyage du pare-étincelles

(le cas échéant)

Nettoyage du filtre à débris (le cas échéant)

X

X

X

X

X

X

X

X

1. Vidanger l’huile du moteur après les 20 premières heures de

fonctionnement. Puis, à toutes les 150 heures de fonctionnement ou mensuellement, selon la première éventualité.

2. Consulter le manuel de dépannage de Black & Decker pour

obtenir des directives détaillées. Pour commander un manuel

de dépannage, composer le 1-800-544-6986.

3. Effectuer la vidange d’huile plus fréquemment dans des conditions poussiéreuse ou humides.

Nettoyage des éléments

1. Retirer l’écrou à oreilles (Q) et le

couvercle du filtre à air

(R)

.

Q

R

Q

S

T

2. Retirer le deuxième écrou à

oreilles (Q) et retirer le filtre (T).

3. Retirer le préfiltre de type mousse

(S) du filtre (T).

N003333

4. Examiner la mousse et les éléments en papier. Les remplacer si

endommagés.

Nettoyage des éléments (Fig. 1)

Pièce en mousse : Laver l’élément

dans une eau savonneuse tiède. Puis

le saturer d’huile à moteur propre.

Presser l’élément pour retirer l’excès

d’huile.

Pièce en papier :

Nettoyer l’élément

en le tapotant délicatement pour

dégager la poussière.

poussière à l’air comprimé.

Enlever la

AVERTISSEMENT : Lors de

l’utilisation de l’air comprimé,

l’utilisateur doit toujours porter une

protection oculaire conforme à la

norme ANSI Z87.1. (CAN/CSA Z94.3).

32- FR

Page 33

Ne jamais utiliser d’huile. Toujours

souffler l’élément de l’intérieur de la

pièce. Lors de l’utilisation d’air comprimé, maintenir la pression d’air à moins

de 2,07 bars (30 psi).

Placer le préfiltre de type mousse sur

l’élément en papier et le réinstaller

dans le moteur.

HUILE

AVERTISSEMENT : surfaces

chaudes. Risque de brûlure. Le moteur

et les pièces contiguës sont très

chaudes, ne pas les toucher (consulter

la rubrique Surfaces chaudes des

figure 1). Laisser refroidir le moteur

avant d’y effectuer des réparations.

Vérification de l’huile (Fig. 1)

1. Déposer l’appareil sur une surface

plane à niveau.

2. Retirer la jauge d’huile (C) et

l’essuyer.

3. Réinsérer la jauge d’huile complètement dans l’orifice de remplissage d’huile et serrer. Laisser

la jauge d’huile reposer quelques

secondes de façon à ce que l’huile

se dépose sur la jauge.

4. Retirer la jauge d’huile pour lire

le niveau de l’huile. Si le niveau

est sous le repère de la jauge

graduée, ajouter de l’huile.

REMARQUE : les repères (cc)

peuvent varier selon le moteur.

U

U

REMARQUE : Remplir le carter en

versant l’huile très lentement. Si

l’huile est ajoutée trop rapidement,

elle débordera et le réservoir

paraîtra plein.

5. Réinsérer la jauge graduée et bien

serrer.

Vidange d’huile (Fig. 1)

REMARQUE : L’huile du moteur

contient des substances réglementées

et doit être mise au rebut

conformément aux lois et règlements

municipaux, étatiques, provinciaux,

territoriaux et fédéraux.

1. Débrancher le fil de la bougie.

2. Déposer un récipient convenable

sous le bouchon de vidange (D).

3. Retirer la jauge d’huile (C) du

carter.

4. Retirer le bouchon de vidange

d’huile (D).

5. Laisser suffisamment de temps

pour que l’huile s’écoule complètement.

6. Remettre le bouchon de vidange

d’huile en place.

7. Remplir avec l’huile recommandée, se reporter à la rubrique

Recommandations de type

d’huile de la section Assemblage.

8. Réinsérer la jauge graduée et bien

serrer.

9. Rebrancher le fil de la bougie.

10. Éliminer l’huile conformément aux

lois et aux règlements municipaux,

étatiques, provinciaux, territoriaux

et fédéraux.

Bougie d’allumage

Utiliser les bougies d’allumage recommandées, consulter la fiche technique

pour connaître le bon type de bougie d’allumage. Pour garantir le bon

fonctionnement du moteur, la bougie

d’allumage doit être adéquatement

écartée et exempte de résidus.

AVERTISSEMENT : Si le moteur

était en marche, le silencieux sera très

chaud. Pour réduire le risque de blessures, laisser refroidir les pièces avant

de poursuivre.

1. Retirer le capuchon de la bougie

d’allumage.

2. Nettoyer toute trace de saleté à la

base de la bougie d’allumage.

3. Utiliser une clé à bougie (non

fournie) pour retirer la bougie

d’allumage.

4. Examiner visuellement la bougie d’allumage. La remplacer si

l’isolant est fissuré ou affiche un

éclat. La nettoyer avec une brosse

métallique si elle sera réutilisée.

33 - FR

N003333

Page 34

AVERTISSEMENT :

Toujours utiliser

de l’équipement de sécurité homologué :

protection oculaire conforme à la norme

ANSI Z87.1 (CAN/CSA Z94.3) munie

d’écrans latéraux.

5. Mesurer l’écartement

de la bougie avec

une jauge

V

d’épaisseur (V).

Corriger au besoin

en pliant avec soin

l’électrode latérale.

L’écart doit être de :

0,70 à 0,80 mm

(0,028 à 0,031 po).

6. S’assurer que la rondelle de la

bougie d’allumage est en bon état.

La visser à la main pour ne pas

fausser le filetage de la bougie.

7. Une fois la bougie d’allumage en

position, la serrer avec une clé à

bougie pour comprimer la rondelle. Lors de l’installation d’une

bougie d’allumage neuve, la serrer

d’un demi-tour supplémentaire

pour comprimer la rondelle. Lors

de la réinstallation de la bougie

d’allumage usée, la serrer d’un

quart à un huitième de tour supplémentaire pour comprimer la

rondelle. Ne pas trop serrer.

8. Replacer solidement le capuchon