Page 1

Model: 9171, 9172, 9173, 9174, 9181, 9182,

9183, 9184, 9185

Programmable DC Power

Supplies

USER MANUAL

Page 2

Page 3

Safety Summary

The following safety precautions apply to both operating and

maintenance personnel and must be observed during all phases of

operation, service, and repair of this instrument. Before applying

power, follow the installation instructions and become familiar with

the operating instructions for this instrument.

If this device is damaged or something is missing, contact the place

of purchase immediately.

This manual contains information and warnings that must be

followed to ensure safe operation as well as maintain the meter in

a safe condition.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet

must be connected to an electrical ground. This instrument is

grounded through the ground conductor of the supplied, threeconductor ac power cable. The power cable must be plugged into

an approved three-co nduc t or electr ical out let. Do not alter the

ground connection. Without the protective ground connection, all

accessible conductive parts (including control knobs) can render an

electric shock. The power jack and mating plug of the power cable

must meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases

or fumes. Operation of any electrical instrument in such an

environment constitutes a definite safety hazard.

Page 4

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel.

Component replacement and internal adjustments must be made

by qualified maintenance personnel. Disconnect the power cord

before removing the instrument covers and replacing components.

Under certain conditions, even with the power cable removed,

dangerous voltages may exist. To avoid injuries, always

disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJ UST ALONE

Do not attempt any internal service or adjustment unless another

person, capable of rendering first aid and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized

modifications to this instrument. Return the instrument to B&K

Precision for service and repair to ensure that safety features are

maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following

examples, denote a hazard and appear throughout this manual.

Follow all instructions contained in these statements.

A WARNING statement calls attention to an operating procedure,

practice, or condition, which, if not followed correctly, could result in

injury or death to personnel.

Page 5

Do not alter the ground connection. Without the protective

ground connection, all accessible conductive parts (including

control knobs) can render an electric shock. The power jack and

mating plug of the power cable meet IEC safety standards.

To avoid electrical shock hazard, disconnect power cord before

removing covers. Refer servicing to qualified personnel.

Before connecting the line cord to the AC mains, check the rear

panel AC line voltage indicator. Applying a line voltage other than

the indicated voltage can destroy the AC line fuses. For

continued fire protection, replace fuses only with those of the

specified voltage and current ratings.

This product uses components which can be damaged by electrostatic discharge (ESD). To avoid damage, be sure to follow proper

procedures for handling, storing and transporting parts and

subassemblies which contain ESD

A CAUTION statement calls attention to an operating procedure,

practice, or condition, which, if not followed correctly, could result in

damage to or destruction of part or all of the product.

WARNING:

WARNING:

CAUTION:

CAUTION:

-sensitive components.

Page 6

This product is subject to Directive

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable

in the European

Union and other European countries with separate collection

systems)

2002/96/EC of the European

Parliament and the Council of the

European Union on waste

electrical and electronic equipment

(WEEE) , and in jurisdictions

adopting that Directive, is marked

as being put on the market after

August 13, 2005, and should not be

disposed of as unsorted

municipal waste. Please utilize your

local WEEE collection

facilities in the disposition of this

product and otherwise observe all

applicable requirements.

Page 7

CE Declaration of Conformity

The power supplies models 9171, 9172, 9173, 9174, 9181, 9182,

9183, 9184, 9185 meet the requirements of 2006/95/EC Low

Voltage Directive and 2004/108/EC Electromagnet Compat ibility

Directive with the following standards.

Low Voltage Directive

- EN61010-1: 2001

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Part 1: General requirements

EMC Directive

- EN 61000-3-2: 2006

- EN 61000-3-3: 1995+A1: 2001+A2: 2005

- EN 61000-4-2: 1995+A1: 1998+A2: 2001

- EN61000-4-3: 2006+A1: 2008

- EN61000-4-4: 2004

- EN61000-4-5: 2006

- EN61000-4-6: 2007

- EN61000-4-11: 2004

- EN 61326-1: 2006

Electrical equipment for measurement, control,

and laboratory use.

Page 8

instrument.

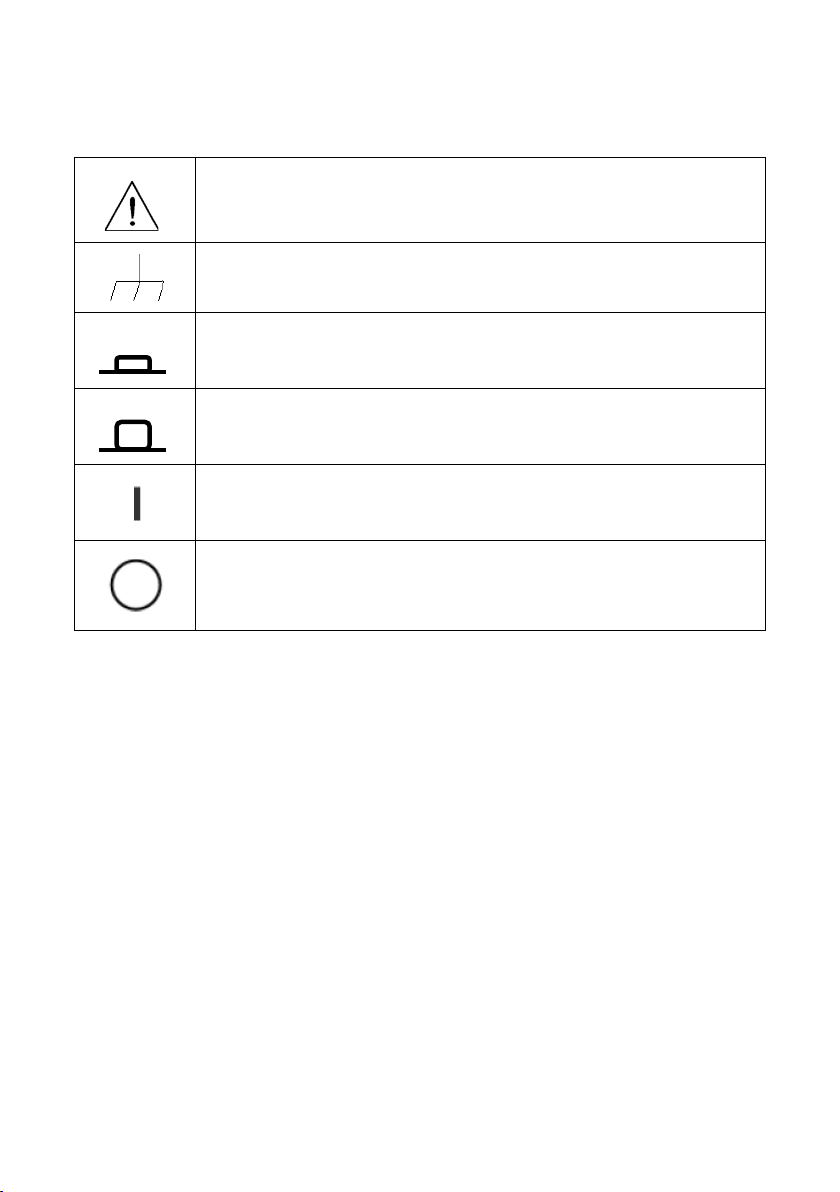

Safety Symbols

Refer to the user manual for warning information to

avoid hazard or personal injury and prevent damage to

Chassis (earth ground) symbol.

On (Power). This is the In position of the power switch

when instrument is ON.

Off (Power). This is the Out position of the power switch

when instrument is OFF.

On (Supply). This is the AC mains connect/disconnect

switch at the back of the instrument.

Off (Supply). This is the AC mains connect/disconnect

switch at the back of the instrument.

Page 9

Table of Contents

1 General Information ........................................................... 1

1.1 Product Overview ................................................................ 1

1.2 Package Contents ................................................................. 2

1.3 Front Panel Overview........................................................... 3

Front Panel Description ................................................................. 5

1.4 Rear Panel Overview ............................................................ 6

Rear Panel Description .................................................................. 8

1.5 Optional Accessories ............................................................ 8

Interface Card Options .................................................................. 8

Rack mount Options...................................................................... 9

1.6 Display Overview ................................................................. 9

Display Description ..................................................................... 10

1.7 Installing Optional Interface Cards .................................... 10

How to Install Interface Cards ..................................................... 11

Removing Interface Cards ........................................................... 12

1.8 Rackmount Installation ...................................................... 13

2 Getting Started .................................................................... 18

2.1 Input Power and Fuse Requirements ................................ 18

Input Power ................................................................................. 18

Fuse Requirements ...................................................................... 18

2.2 Line Voltage Selection ........................................................ 19

2.3 Output Connections ........................................................... 21

2.4 Preliminary Check .............................................................. 23

Output Check .............................................................................. 25

Check Model and Firmware Version ........................................... 27

3 Front Panel Operation ...................................................... 28

Page 10

3.1 Menu Options .................................................................... 28

How to Access the Menu ............................................................. 29

3.2 Remote Interface Setup ..................................................... 32

USB Interface (virtual COM) ........................................................ 32

GPIB Interface ............................................................................. 34

Ethernet (LAN) Interface ............................................................. 34

RS-232 and RS-485 Interface (Optional) ..................................... 35

3.3 Adjusting LCD Display, Key Lock, Key Sound ...................... 39

LCD Backlight Timer .................................................................... 39

Key Lock ...................................................................................... 39

Disabling Key Sound .................................................................... 40

3.4 Restore to Factory Default ................................................. 41

3.5 Configure Voltage and Current Output .............................. 43

Voltage and Current Limit Settings ............................................. 43

Configure Voltage and Current Output ....................................... 45

Slew Rate Configuration ............................................................. 51

Output Timer Function ................................................................ 53

Measurement Average Setting ................................................... 55

3.6 Dual Channel Configurations ............................................. 55

Multi/Single Output Control ....................................................... 55

Series/Parallel Tracking Mode .................................................... 56

3.7 Remote Sense .................................................................... 57

3.8 LED and Low Current Test Modes ...................................... 62

LED Mode .................................................................................... 62

Low Current Mode ...................................................................... 64

3.9 Output Protection .............................................................. 66

Configure OVP ............................................................................. 66

Configure OCP ............................................................................. 67

Page 11

3.10 Save/Recall Output Settings .............................................. 68

3.11 Sequence Program Mode .................................................. 71

3.12 External Analog Control ..................................................... 72

3.13 Digital I/O ........................................................................... 77

INPUT .......................................................................................... 79

OUTPUT ...................................................................................... 80

3.14 Display Errors ..................................................................... 81

3.15 Connecting in Series and Parallel ....................................... 82

4 Remote Operation .............................................................. 83

4.1 Interface Connection ......................................................... 83

USB (Virtual COM) & RS-232 ....................................................... 83

GPIB ............................................................................................ 84

Ethernet (LAN) ............................................................................ 85

4.2 Remote Commands ........................................................... 90

Parameter Definitions ................................................................. 91

Remote Commands ..................................................................... 91

4.3 Sequence Programming ................................................... 134

Examples ................................................................................... 134

4.4 Multi Unit Programming .................................................. 138

Remote Commands via USB ...................................................... 139

5 Troubleshooting Guide ................................................. 150

General ..................................................................................... 150

Remote Control ......................................................................... 152

6 Specifications ................................................................... 153

7 Calibration ......................................................................... 158

Access Calibration Menu ........................................................... 158

Requirements ............................................................................ 159

Current Calibration ................................................................... 159

Page 12

Voltage Calibration ................................................................... 163

External Analog Input Calibration............................................. 165

Index ........................................................................................... 170

SERVICE INFORMATION ........................................................ 171

LIMITED THREE-YEAR WARRANTY ................................. 172

Page 13

1 General Information

1.1 Product Overview

The 917x and 918x series are high-performance dual range linear

DC power supplies that provide clean and reliable power with high

resolution and accuracy. All models are programmable via standard

USB interface or optional RS232, GPIB and LAN interface.

Interface cards and I/O cards come in a modular form factor.

Selected models feature high voltage outputs or dual channels to

provide series/parallel tracking functionality. All models include front

and rear panel outputs for flexibility, and feature programmable list

mode for storing and running customized test sequences.

Additionally, a unique LED test mode function can be enabled for

LED test applications requiring minimal inrush current out put. These

power supplies are suitable for bench or rack mount operation with

the available rack mount kit option.

Features

• Single and dual output models with up to 210W output power

• High accuracy and low noise output

• Dual range output with automatic range selection (except of

high voltage models 9184 and 9185)

• Fast transient response of < 50 μs of most models

• Very low ripple and noise

• LED test mode for low inrush current output

• Programmable list mode for creating test sequences

• Front and rear remote sense terminals for single output

models (except of high voltage models 9184 and 9185)

• OVP, OCP, and OTP protection

• Two interchangeable interface slots accepting any of the

following optional interface cards: LAN/GPIB, Digital I/O and

Analog control, RS485, RS232

• Standard USB interface (virtual COM)

• Programmable voltage and current slew rates

1

Page 14

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon

receiving it. Unpack all items from the shipping carton, and check for

any obvious signs of physical damage that may have occurred

during transportation. Report any damage to the shipping agent

immediately. Save the original packing carton for possible future

reshipment. Every power supply is shipped with the following

contents:

• 917x/918x Power supply

• User Manual

• AC Power Cord

• USB Type A to Type B Cable

• Line fuse (for 115V or 230V operation)

• Certificate of Calibration

• Test Report

Verify that all items above are included in the shipping container. If

anything is missing, please contact B&K Precision.

2

Page 15

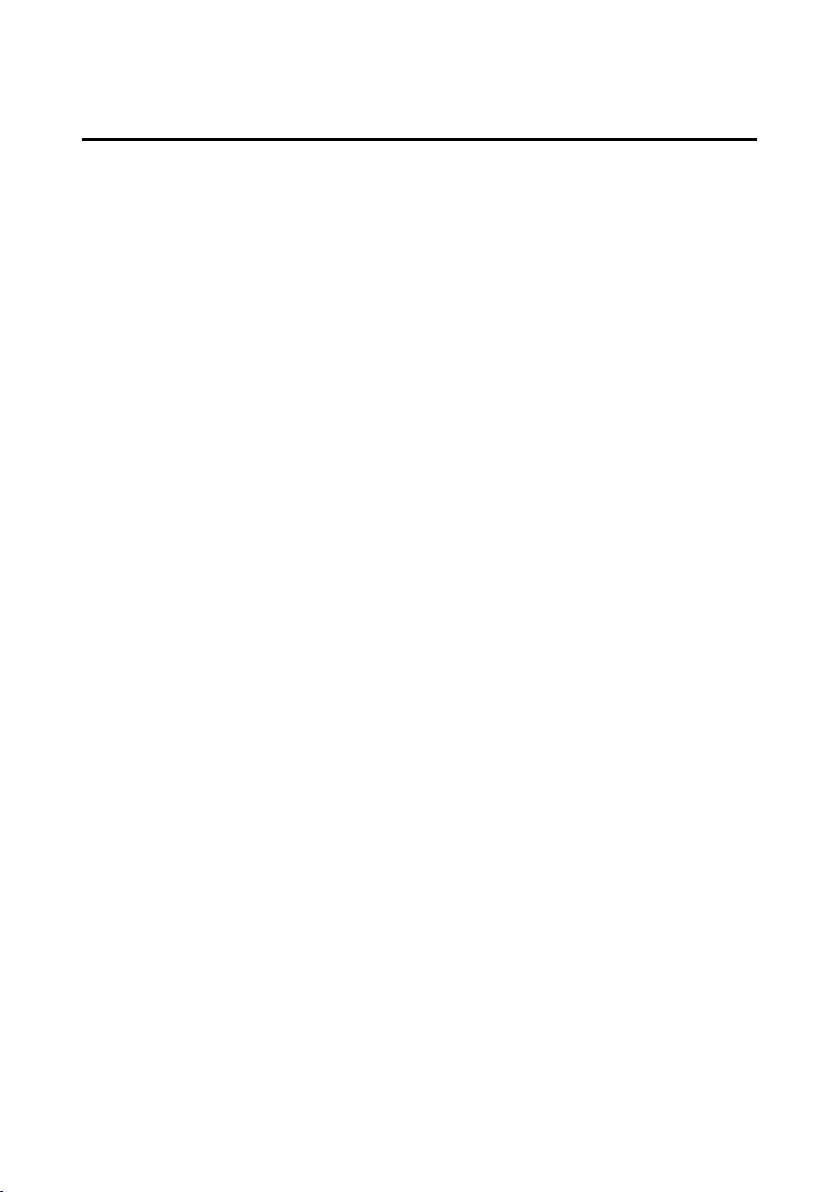

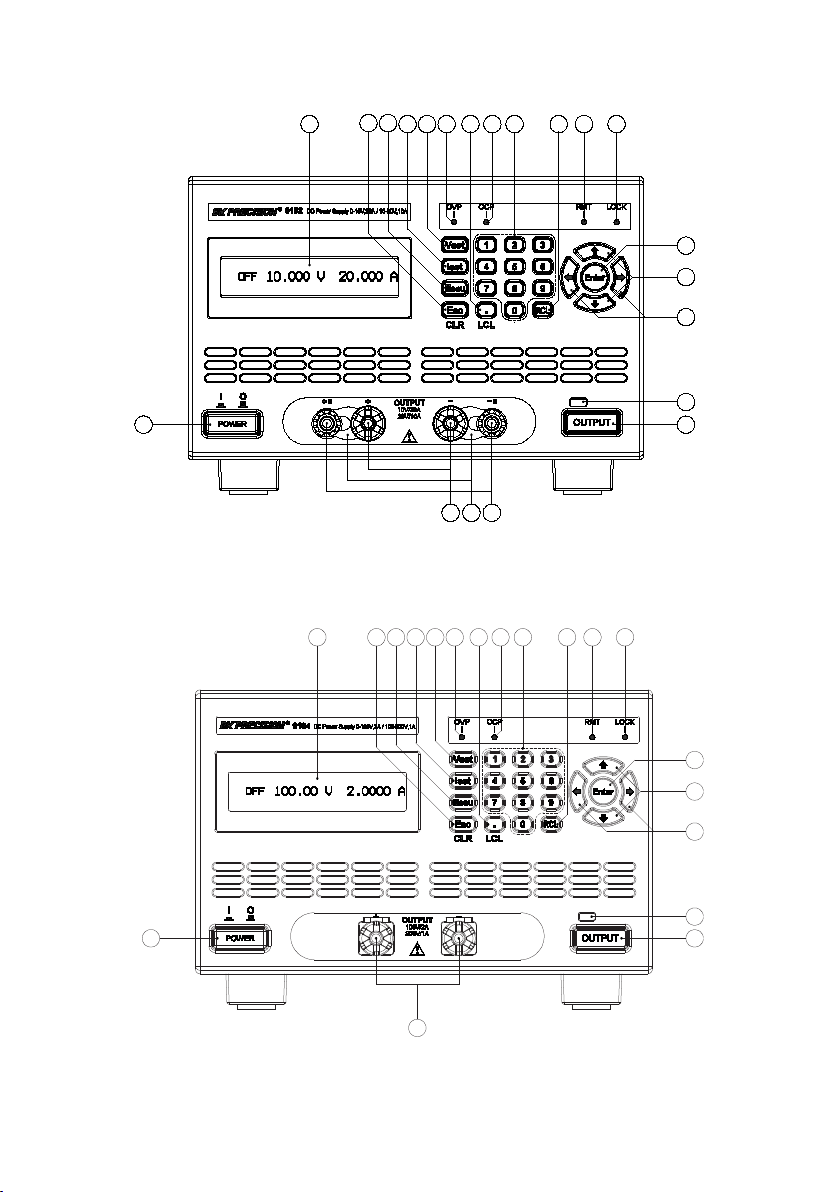

19

1

2 5 6

16

2120 18

17

10 11 8 12 13

14

3 4 97

15

1

19

2 517106 7 11 8 129 133 4

16

14

15

18

1.3 Front Panel Overview

Figure 1 - Front Panel for 9171/91 72/9 181

Figure 2 - Front Panel for 9173/91 74

3

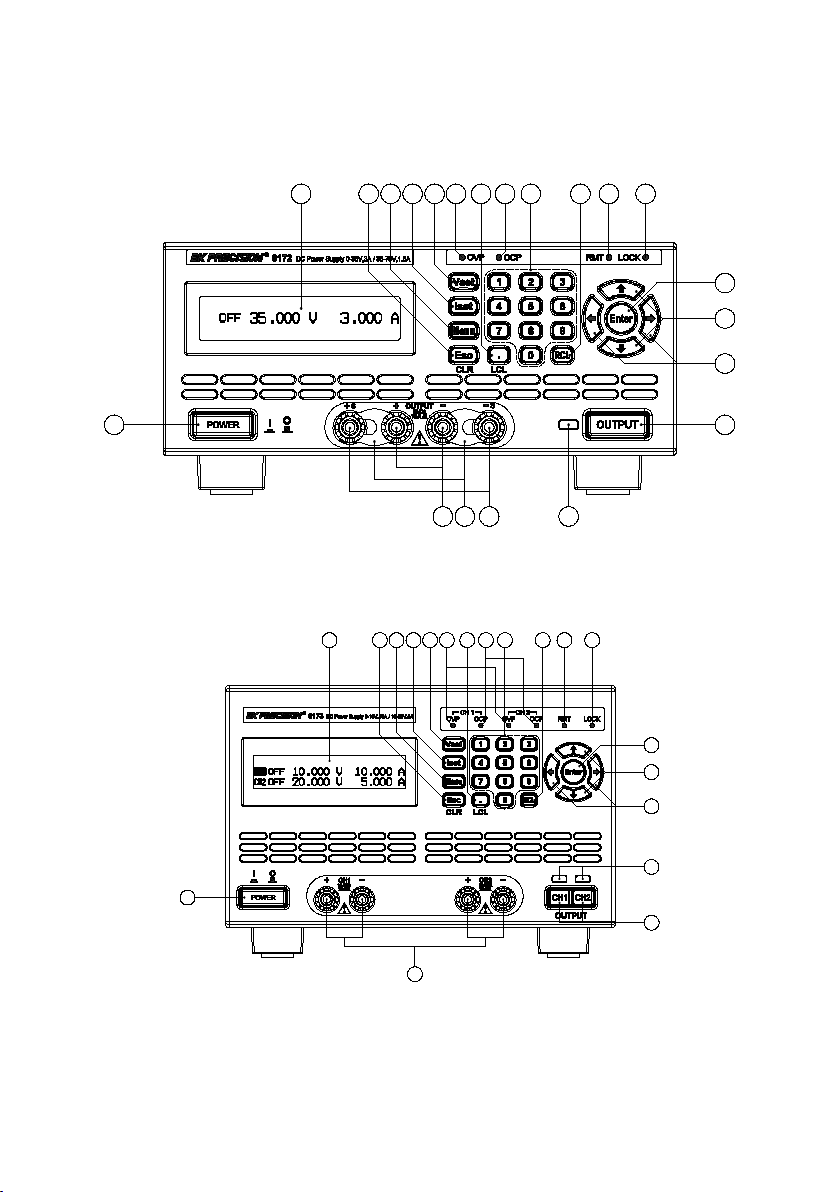

Page 16

1

2 5

17

10

6

7 11

8 12

9

13

3

4

16

14

15

18

20

19 21

1

2 517106 7 11 8 129 133 4

16

14

15

18

19

Figure 3 - Front Panel for 9182/91 83

4

Figure 4 - Front Panel for 9184/9185

Page 17

Output button (Dual channel models have CH1 and CH2 output

buttons)

Main output terminals (Models 9182,9184,9185 have larger binding

post terminals for high current/voltage outputs)

Front panel +S/-S sense terminals (Not available with models 9173,

9174, 9184, 9185)

1

2

3

4

5 6 7

8

9

10

11

14

15

16

17

18

19

20

21

12

13

Front Panel Description

Power ON/OFF button

LCD display

Esc / CLR button

Menu button

ISET button

VSET button

Decimal/LCL(Local) button

Numeric keypad

RCL (Recall) button

OVP indicator

OCP indicator

RMT (Remote mode) indicator

LOCK (Key lock) indicator

Enter button

Up, Down arrow keys

Left, Right arrow keys

Output ON/OFF indicator light

Front terminal shorting bars

5

Page 18

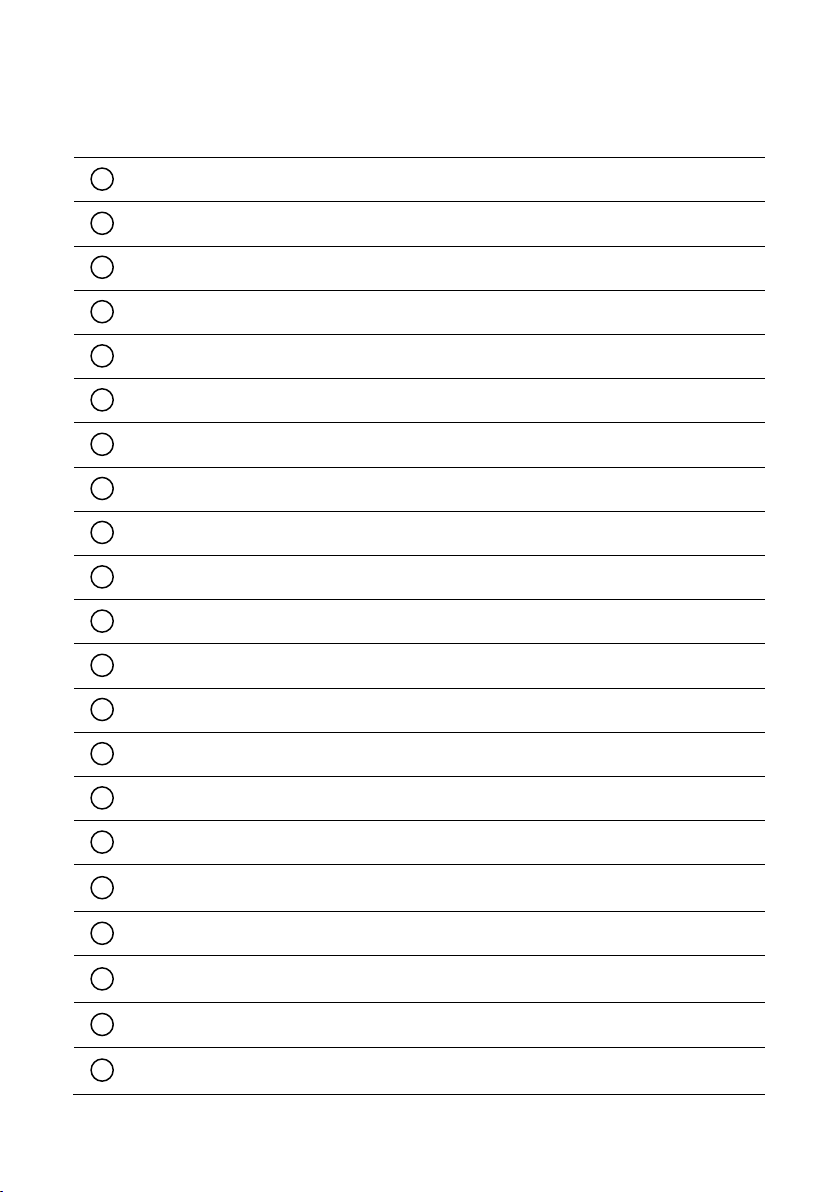

22

23

24

31

29

30

28

25 26 27

29

28

22

25

24

23

30

29

28

31

25

26 27

1.4 Rear Panel Overview

Figure 5- Rear View for 9171/9172/9181

Figure 6- Rear View for 9173/9174

6

Page 19

29

28

22

25 24

23

30

3125 26 27

29

28

22 23

30

3124 26 27

Figure 7- Rear View for 9182/9183

Figure 8- Rear View for 9184/9185

7

Line voltage selection switch (bottom of power supply) See “2.2Line

Voltage Selection” for details.

Page 20

Model

Description

DRGL

GPIB/LAN interface card

DR1DIO

Single channel digital I/O and analog control card

DR2DIO

Dual channel digital I/O and analog control card

DRRS485

RS485 interface card

DRRS232

RS232 interface card

24

25

26

27

28

29

30

31

22

23

Rear Panel Description

S1 interface slot (shown with optional LAN/GPIB interface card)

S2 interface slot (shown with optional DIO/Analog interface card)

USB interface

Temperature controlled cooling fan(s)

AC input fuse box

Line input receptacle

Rear panel outputs (++/--) and sense (+S/-S) terminals

Shorting pins

Chassis ground

1.5 Optional Accessories

The following lists all optional accessories supported by the

917x/918x series power supplies.

Interface Card Options

8

Page 21

Model

Description

Rackmount kit for two 2U power supplies mounted

side by side

DRRM3U1

Rackmount kit for single 3U power supply

Rackmount kit for two l 3U power supplies mounted

side by side

2 3 1

Rack mount Options

Rackmount kits are available for all 9 models. Refer to the following

to determine your power supply rack mount size.

2U size: Models 9171, 9172, 9181

3U size: Models 9173, 9174, 9182, 9183, 9184, 9185

DRRM2U1 Rackmount kit for single 2U power supply

DRRM2U2

DRRM3U2

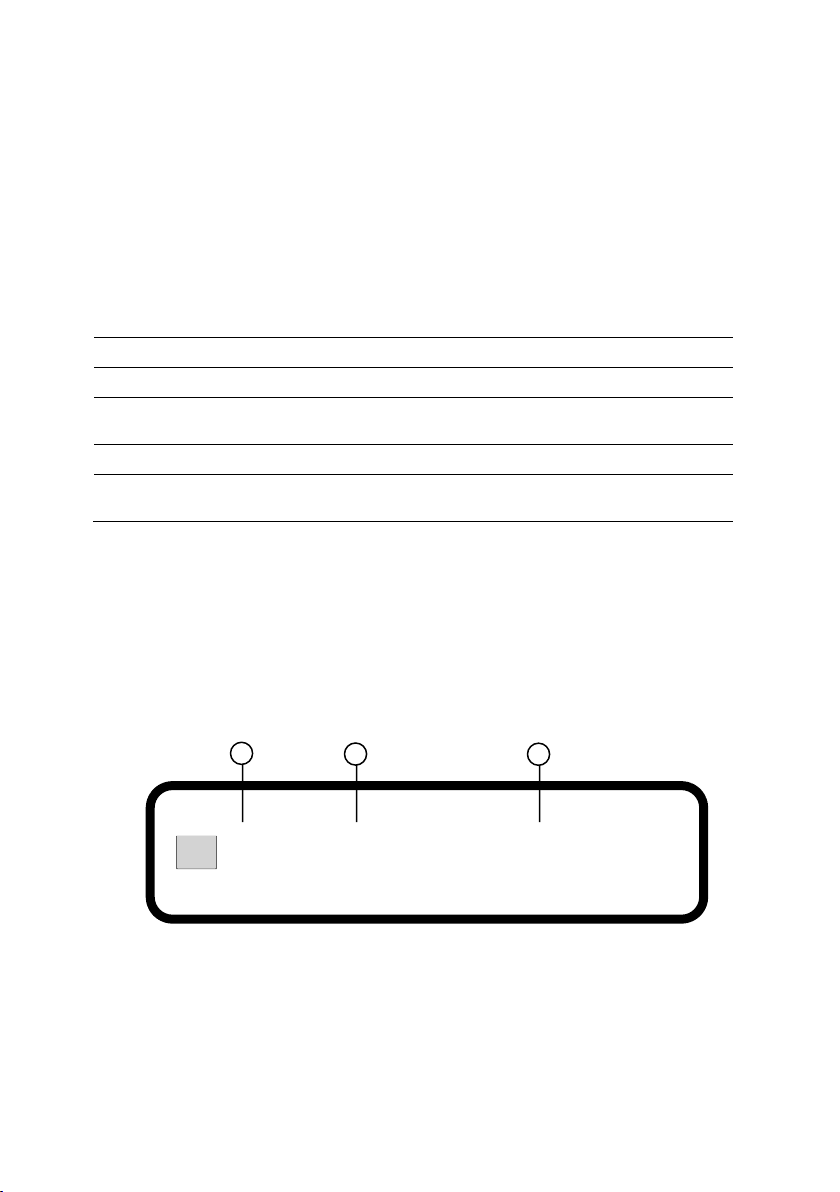

1.6 Display Overview

The main displays for single and dual channel models are shown

below.

CV5 . 000 V1 . 000 A

Figure 9- Main Display

9

Voltage display (When output is OFF, it shows VSET voltage. When

output is ON, it shows measured voltage)

Page 22

Current display (When output is OFF, it shows ISET current. When

output is ON, it shows measured current)

CH2CV5 . 000 V1 . 000 A

2 3 1

4

1 2 3

4

CH1CV

5 . 000 V1 . 000 A

Figure 10- Dual Channel Main Display

Display Description

Output Mode (CV, CC, OFF)

Selected channel indicators

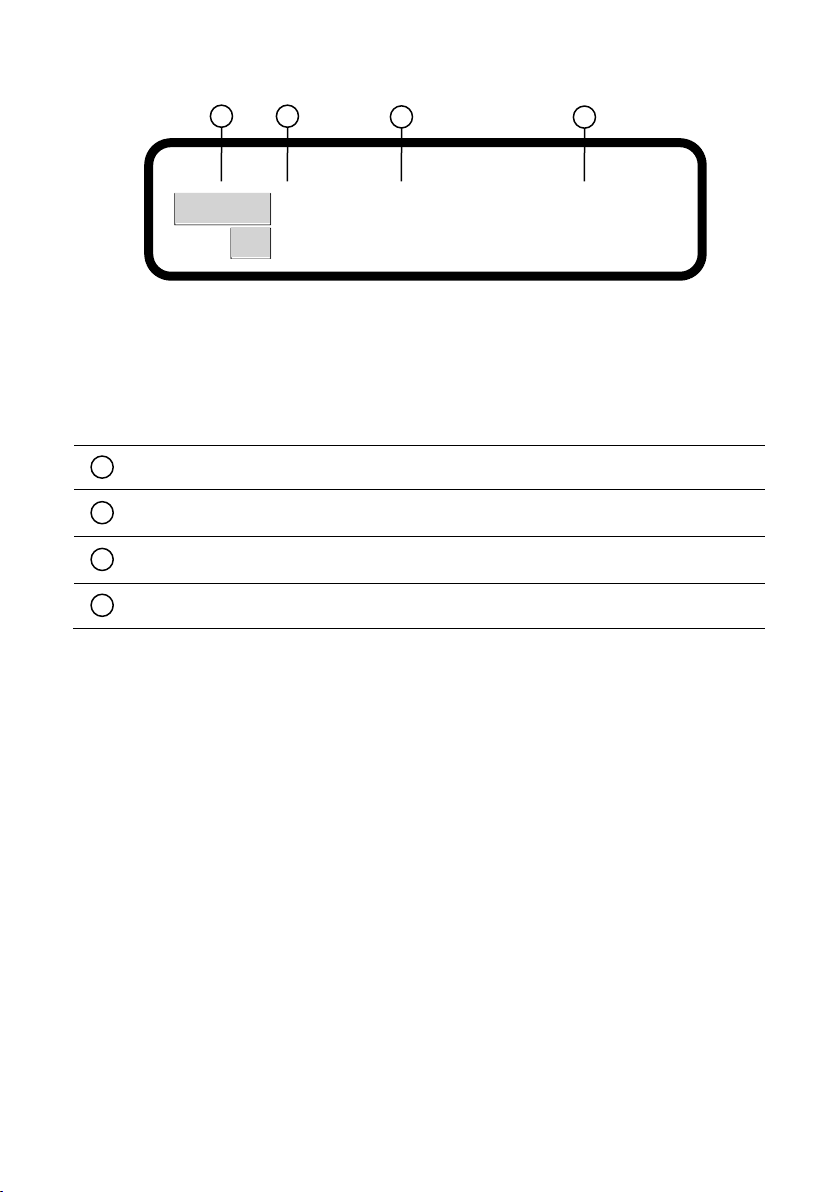

1.7 Installing Optional Interface Cards

Five optional interface cards are available and can be installed in

either the S1 or S2 slots. They are:

Option 1: GPIB/LAN Card

Adds GPIB and LAN interface

Option2: DIO/Analog Card (Single channel)

Adds digital I/O and External Analog Cont rol

Option 3: DIO/Analog Card (Dual channel)

Adds dual channel digital I/O and External Analog Control

Option 4: RS485 Card

10

Page 23

S1

S1

: : : : : : : : : : : : : : : : : : : : : :

Metal

notch

Card

rail

48-pin female connector

Adds RS-485 interface for multi power supply control

Option 5: RS232 Card

Adds RS-232 interface

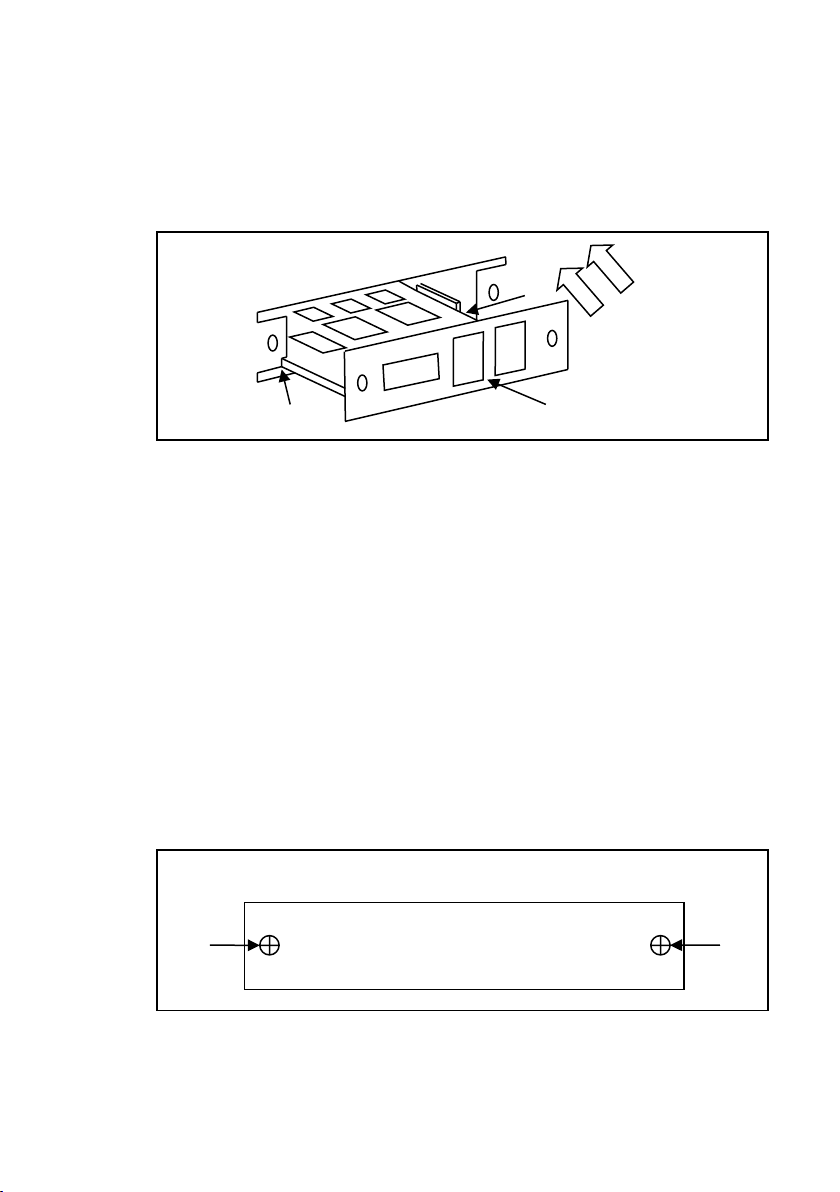

How to Install Interface Cards

1. Power off the instrument and disconnect the AC power cord

in the rear panel. Remove the back faceplate covering the

S1 or S2 slot in the rear panel by removing the two screws

on each side.

2. Make note of the metal notches that indicate where the card

should slide into. Inside the slot, there are two rails (left and

right side) where the card should slide smoothly into. The

very back of the slot is a 48-pin female connector that should

connect with the 48-pins on the back of the interface card.

3. The interface card should go right below the metal notches

on both sides and fit in between the inner card rails, also on

11

Page 24

Interface card

S1

both sides. Slide the card down carefully. When it touches

the 48-pin connector, slowly push the card all the way in until

the panel of the interface card aligns with the rear panel of

the power supply.

4. Place the two screws to tighten and secure the installed card.

5. Connect the power cord and turn on the power supply. The

newly installed card will be detected during boot up, indicated

next to S1: or S2: (depending on which slot the card is

installed into).

Removing Interface Cards

1. Power off the instrument and disconnect the AC power cord

2. Use a flat blade screwdriver to gently pry the left and right

in the rear panel. Remove the two screws on each side of

the installed interface card.

side of the interface card plate. When there is enough room,

12

Page 25

use the screwdriver to pry the top part of the card until the

card has slid out with enough room to pull out the card by

hand.

3. Be sure to ground yourself before pulling out or touching any

parts of the printed board on the interface card.

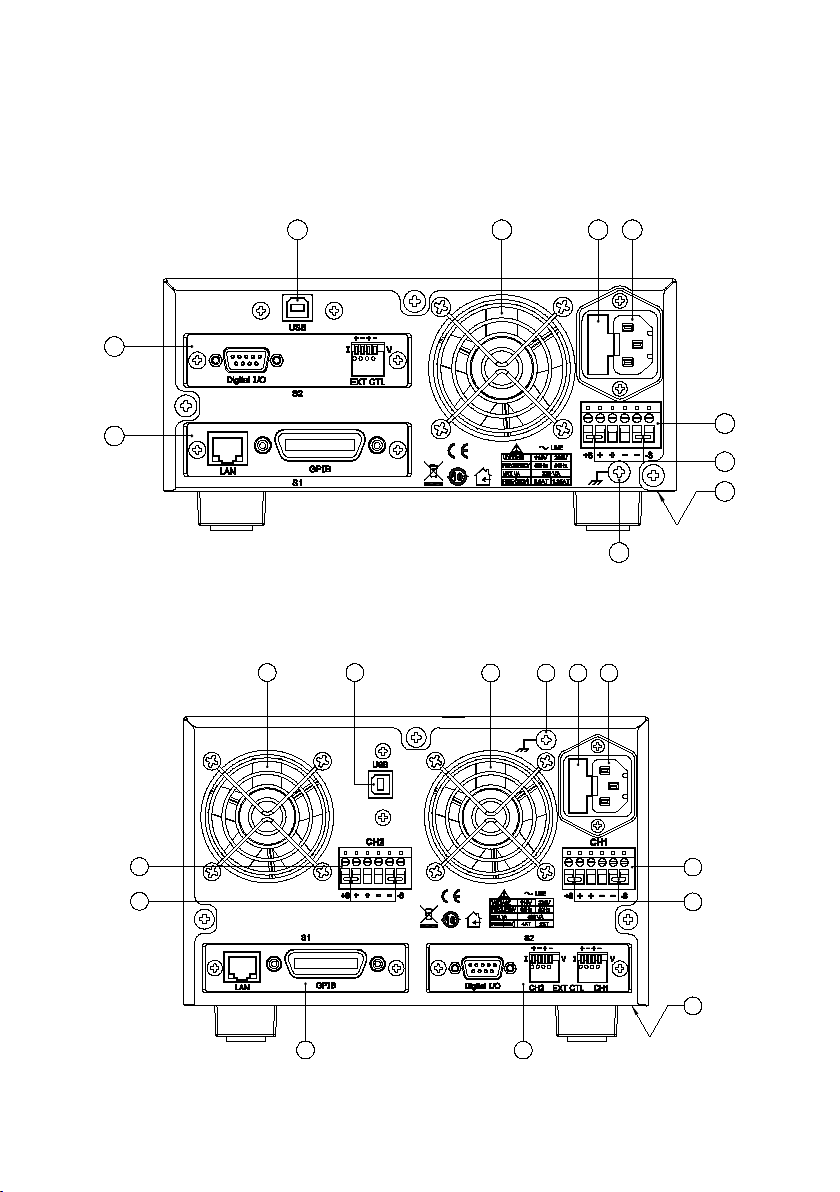

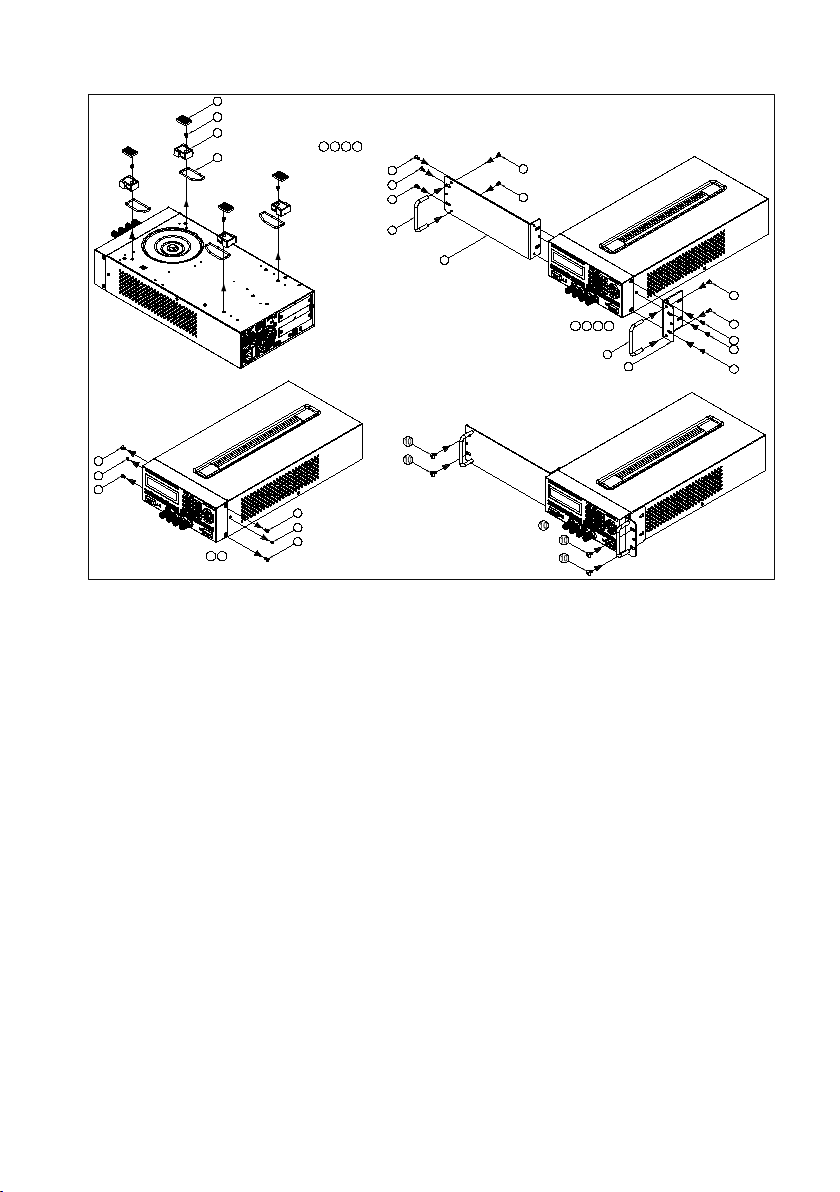

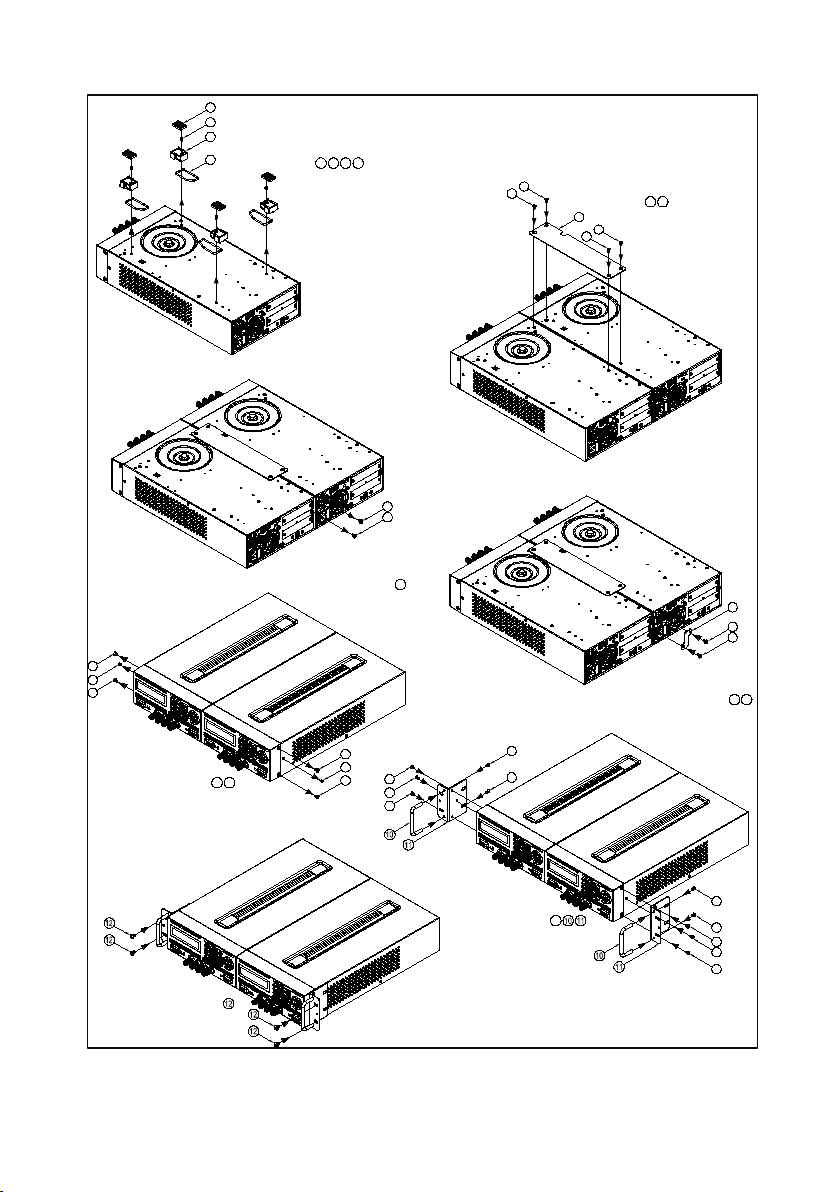

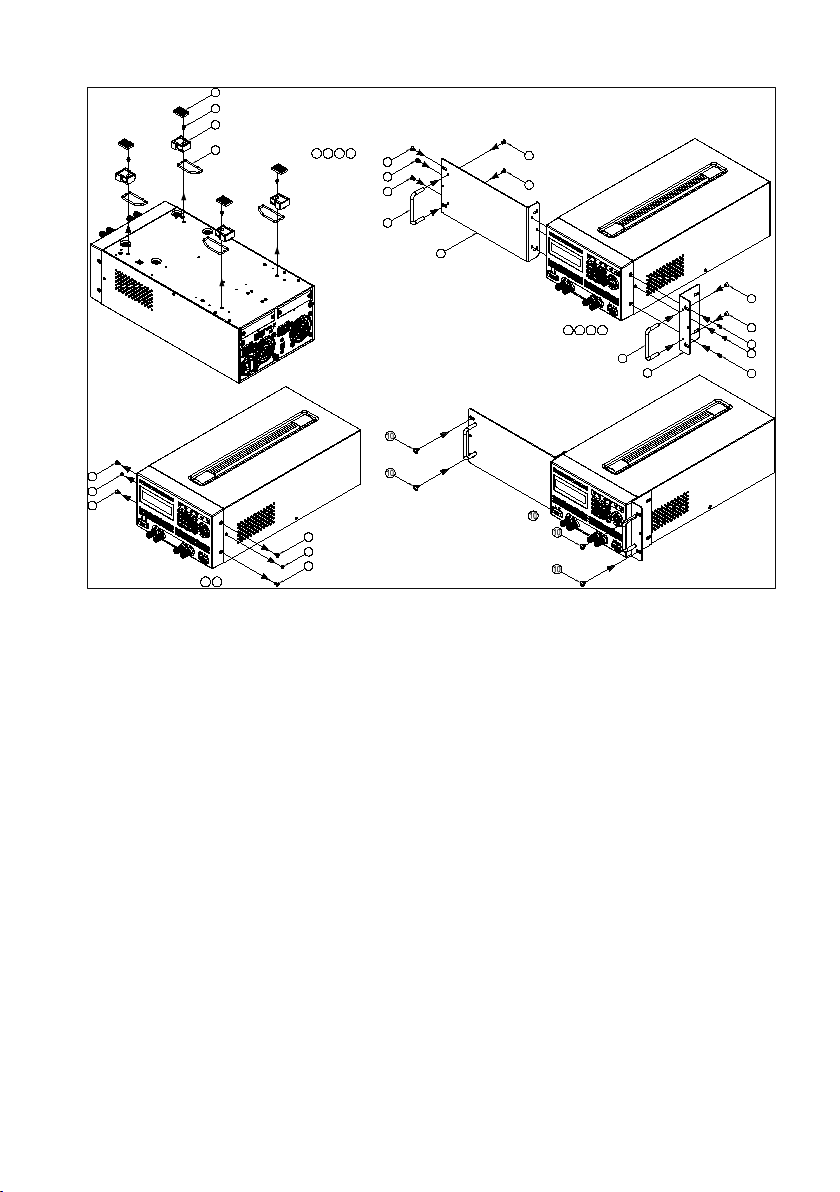

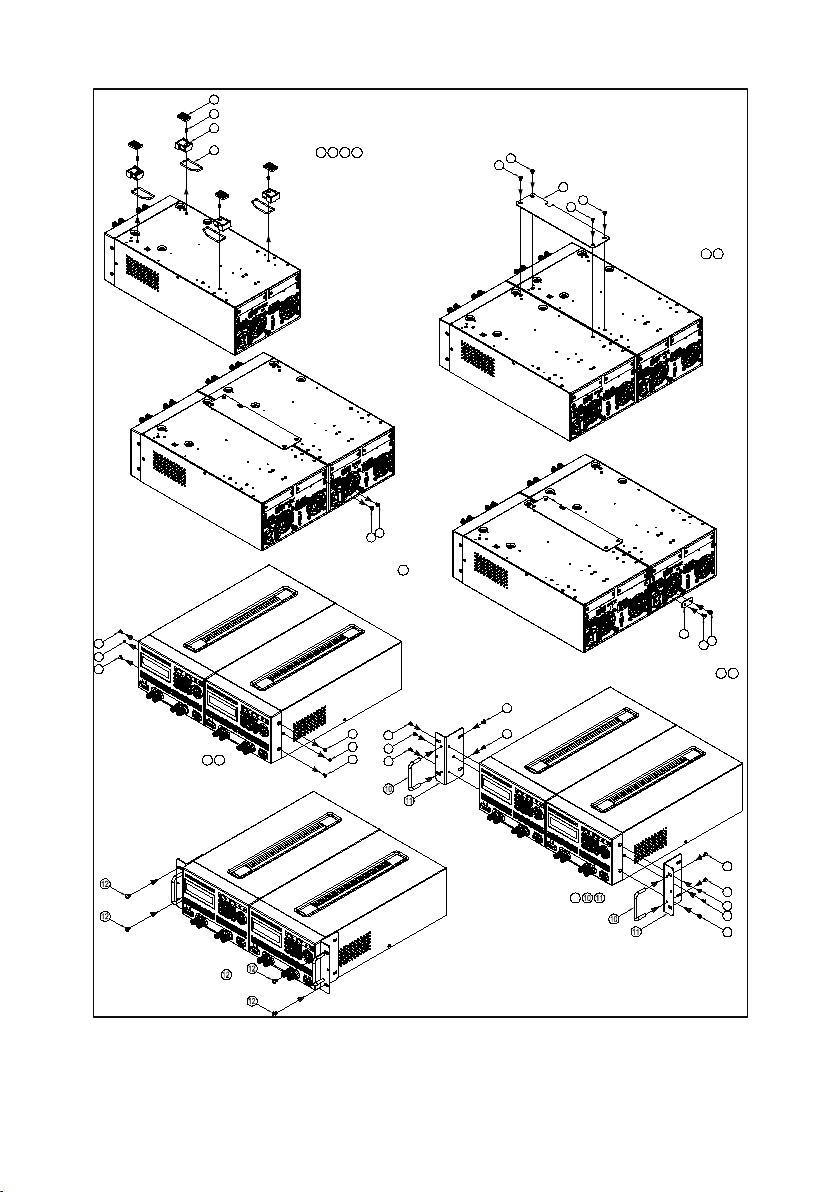

1.8 Rackmount Installation

There are four rackmount kit options available for this series of

power supplies: 2U size for single power supply, 2U size for two

power supplies mounted side by side, 3U size for single power

supply, 3U s ize f or two power supplies mounted side by side. The

following step by step instructions will guide you in installing these

optional rackmount kits onto the power supply for a standard 19-inch

rack fitting.

Models 9171, 9172, 9181: Follow instructions for 2U rackmount

installation.

Models 9173, 9174, 9182, 9183, 9184, 9185: Follow instructions for

3U rackmount installation.

13

Page 26

5

R

emo

ve t

he p

arts

S

tep

2:

5

6

5

6

6

5

5

Step 2

Step 1

7

5

5

1

1

Re

m

ov

e t

h

e p

ar

t

s

S

te

p 1

:

4

2

3

2 3 4

5

Step 4

Fas

ten

the

par

ts

S

tep

4:

7

9

5

5

5

Step 3

Fas

ten

the p

art

s

S

tep

3:

8

5

5

7 9

8

5

5

5

Figure 11- 2U Single Supply Rackmount Installation

14

Page 27

Step 1

Step1:

3

1

2

Remove the parts

4

21 3 4

6

9

6

7

Step 3

7

Step3:

Removethe parts

Step 5

7

Fastenthe parts

6

6

6

Step2:

5

6

65

Step 2

Step 4

8

Fastenthe parts

Step4:

7

7

7

8

Fastenthe parts

Remove the parts

Step5:

Step7:

Step 7

6

9

6

6

6

9

6

6

Step 6

6

6

Step6:

Fastenthe parts

6

6

6

6

6

6

Figure 12- 2U Dual Supplies Rackmount Installation

15

Page 28

Remove the parts

Step 2:

5

5

6

65

5

5

6

Step 2

5

Step 1

7

5

Remove the parts

2

3

4

Step 1:

1

21 43

5

Fasten the parts

Step 4:

7

Step 4

9 5

5

5

Step 3

Faste

n t

h

e p

arts

8

Step 3

:

5

97 8

5

5

5

5

Figure 13- 3U Single Supply Rackmount Installation

16

Page 29

Step 1

3

Step1:

1

2

Removetheparts

4

21 43

6

9

6

Step 3

Step3:

Removethe parts

Step 5

7

7

7

Step 2

Step2:

Fastenthe parts

6

6

5

6

6

5

6

Step4:

Fastenthe parts

Step 4

8

8

7

7

7

Fastenthe parts

Removethe parts

Step5:

Step7:

Step 7

96

6

6

9

6

6

6

Step 6

Step6:

6

6

Fastenthe parts

6

6

6

6

6

6

Figure 14–3U Dual Supplies Rackmount Installation

17

Page 30

2 Getting Started

2.1 Input Power and Fuse Requirements

Input Power

The rated AC input power source for powering the supplies must be

within:

115V Operation:103.5V-126.5V

230V Operation: 207V - 253V

Frequency:47 Hz – 63 Hz

Before connecting to an AC outlet or external power source, be sure

that the power switch is in the OFF position and verify that the AC

power cord, including the extension line, is compatible with t he r ated

voltage/current and that there is sufficient circuit capacity for the

power supply. Once verified, connect the cable firmly.

WARNING:

The included AC power cord is safety certified for

this instrument operating in rated range. To change

a cable or add an extension cable, be sure that it

can meet the required power ratings for this

instrument. Any misuse with wrong or unsafe

cables will void the warranty.

Fuse Requirements

An AC input fuse is necessary when powering the instrument.

Below is a table showing the required fuses for AC line input 115V

and 230V operation for all models.

18

Page 31

Model

115 V AC

230 V AC

9171

2.5 A

1.25 A

9172

2.5 A

1.25 A

9173

4 A

2 A

9174

4 A

2 A

9181

3.15 A

1.6 A

9182

5 A

2.5 A

9183

4 A

2 A

9184

4 A

2 A

9185

4 A

2 A

Table 1- Input Fuse Table

Note: All fuses listed have the specifications: T250V, slow

blow (slow acting), 5 x 20mm.

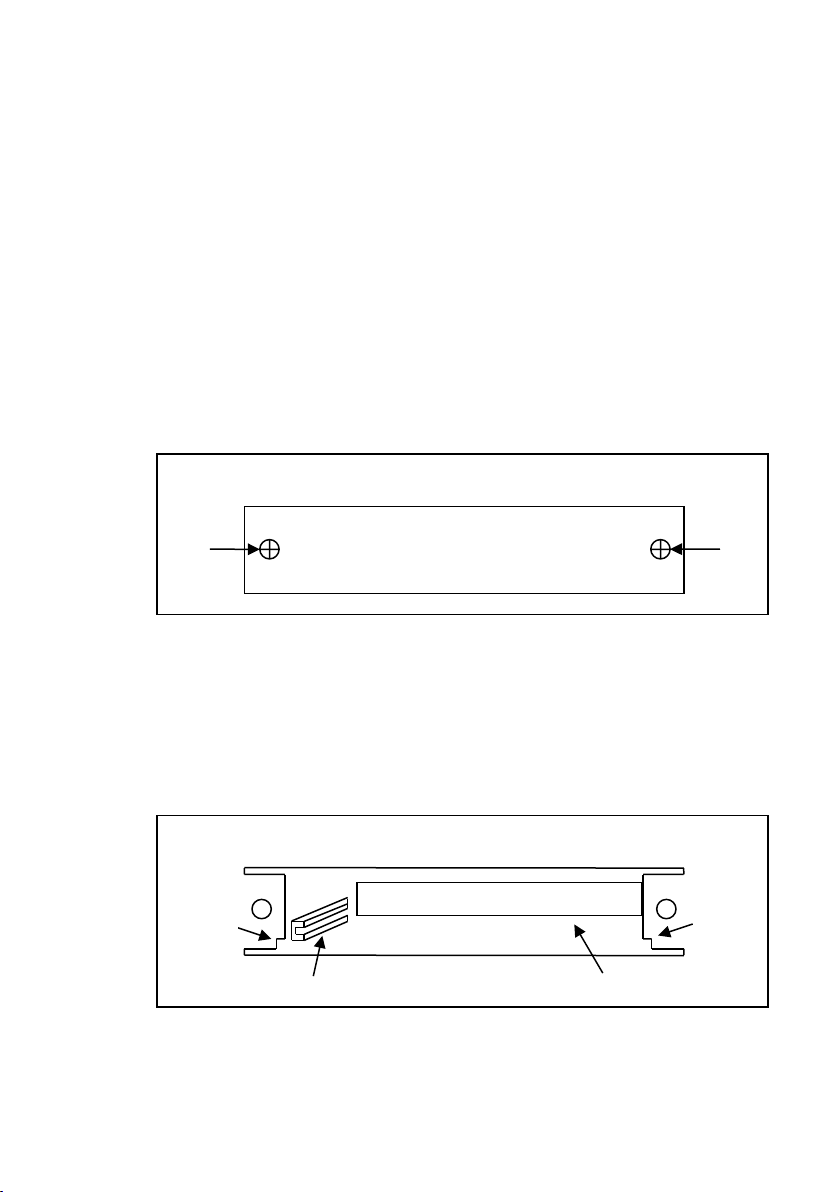

2.2 Line Voltage Selection

The power supplies can be selected to operate with 115V input or

230 V input. To ensure that your instrument is properly configured to

operate at the desired AC line voltage, please follow the steps

below:

CAUTION:

For safety, no power should be applied to the

instrument while changing line voltage operation.

Disconnect all cables connected to the instrument

before proceeding.

19

Page 32

Fuse box sli

Fuse box

Check/Remove Fuse

Step 1 - Check and/or Change Fuse

- Locate the fuse box next to the AC input connector in the rear

panel.

- With a small flat blade screwdriver, insert into the fuse box slit to

pull and slide out the fuse box as indicated below.

- Check and replace fuse (if necessary) for the desired line

voltage operation (see Table 1).

t

Step 2 - Check and/or Change Line Voltage Switch

- Carefully lift and turn the instrument upside down.

- Locate the red Line Voltage Switch, which has markings that

indicate “115” for 115V or “230” for 230V line operation. Set the

switch to the desired line voltage operation.

20

Page 33

instrument and void all warranty.

Line Voltage Switch

Rear P

Front Panel

(Bottom View)

Front Feet

Rear Feet

anel

WARNING:

Do not connect power to the instrument until the

line voltage selection is setup correctly. Applying

an incorrect line voltage or configuring the line

voltage selection improperly may damage the

2.3 Output Connections

These power supplies have both front panel binding posts and rear

panel terminals for output connections, and they are paralleled

together. The two (+) and two (-) (per channel for dual channel

models) rear output terminals can accept wire sizes AWG 24 to

AWG 12 (See Table 2

current output is between 5 to 10 A. For current output above 10 A,

remove the shorting barsfrom the front panel, but do not remove the

). However, we recommend using 12 AWG if

shorting pins on the rear panel.Use two separate wires/leads to

connect both (+) terminals and (-) terminals as shown below:

21

Page 34

WARNING:

damage the power supply.

AWG

10

12

14

16

18

20

22

24

26

28

Imax(A)

40

25

20

13

10 7 5

3.5

2.5

1.7

mΩ/meter

3.3

5.2

8.3

13.2

21

33.5

52.8

84.3

133.9

212.9

Rear Panel Output

+S

+

+

- - -

S

+ -

+S + - -S

Remove shorting bars

Front Panel Output

For 10 A or higher current output

DUT

DO NOT output 10 A or more with only one pair of

(+) and (-) terminals. Both (+) and (-) terminals

must all be connected for applications requiring

more than 10 A output. Each terminal can only

accept a maxi mum of 10 A. Exceeding this may

Table 2- Wire Gauge Rating

22

Page 35

WARNING:

wires.

Before connecting wires to the front or rear panel

output terminals, turn OFF the power supply to

avoid damage to the instrument and the device

under test (DUT). For safety, load wires must have

a wire gauge size large enough to prevent

overheating when the power supply operates at

maximum short circuit output current. It will also

prevent large voltage drops from resistances in the

2.4 Preliminary Check

Complete the following steps to verify that the power supply is ready

for use.

1. Verify Line Voltage Selection

Complete the steps as described in “2.2 Line Voltage

2. Connect Power and Self Test

Selection” to make sure the supply is correctly setup to

operate with the line voltage source to be used.

Connect AC power cord to the AC receptacle in the rear

panel and press to turn on the instrument. It will

run through a self test procedure, as well as check for

installed interface cards. The following scr ee n s will display

before it’s ready for use (Display will vary based on the model

and installed interface cards)

POWER

23

Page 36

S2 : RS485

VER : 2 . 00

SRAM TEST . . . . . . . . . . . . . . . . . . . OK

MAIN TEST . . . . . . . . . . . . . . . . . . .OK

CHECKING FOR EEPROM DATA

CHECKING FOR OPTION CARD . .

S1 : GPIB/LAN CARD

B&K PRECISION

9181

24

Page 37

Vset

Enter

CH1

Output Check

Voltage Check

Follow the steps below to check basic voltage output with no load

connected.

1. Turn on the power supply. The display will show the OFF

annunciator next to the setting voltage on the left side of the

display.

2. Enable the output by pressing (or and for

OUTPUT

CH2

dual channel models). The output indicator light will be lit

and display will show the measured output voltage. The

OFF annunciator will change to CV.

3. Using the numeric keypad, press and enter a voltage

value. Then press the key. For dual channel models,

select the channel first before setting the voltage. The

selected channel is indicated by a flashing CH1 or CH2

annunciator on the display. Press or to select

the channel.

4. Th e measured output voltage should change to a value close

to or exactly what you entered (For example, if voltage value

is 30.000 V, it may show 29.998 V).

5. (Optional) You may also verify the output voltage by

connecting either the (+) and (-) term ina ls on the front panel

or the rear panel to an external voltmeter. The measured

value should match or be close to the entered voltage value.

25

Page 38

Enter

Iset

Current Check

Follow the steps below to check basic current output of the power

supply.

1. Turn on the power supply. The display will show the OFF

annunciator next to the setting voltage on the left side of the

display.

2. Short the (+) and (-) output terminals with test leads, shorting

bar, or cl ip. (Ref er t o Table 2 to select appropriate test leads)

3. Enable the output by pressing (or and for

OUTPUT

CH1

CH2

dual channel models). The output indicator light will be lit

and display will showthe measured output voltage. The OFF

annunciator will change to CC.

4. Using the numeric keypad, press and enter a current

value. Then press the key. For dual channel models,

select the channel first before setting the voltage. The

selected channel is indicated by a flashing CH1 or CH2

annunciator on the display. Press or to select

the channel.

5. The measured output current should change to a value close

to or exactly what you entered (For example, if current value

is 5.0000 A, it may show 4.9998 A).

6. (Optional) You may also verify the output current by

connecting either the (+) and (-) term ina ls on the front panel

or the rear panel to an external current meter capable of

measuring the current that you set. The measured value

should match or be close to the entered current value.

26

Page 39

Menu

8

Esc

7. Press to turn off the power supply and remove the

POWER

short on the output terminals.

Check Model and Firmware Version

The model and firmware version can be verified from one of the boot

up screens, or from using the *IDN? query remote command,

described in “4.2 Remote Commands”. Additionally, ot her system

version and information can be found by following the steps below:

1. Press , then to enter INFORMATION. The

following screen will be displayed.

LCD VER = 2.00 / WEB VER = 1.04

MODULE VER = 1.10 / 1.10

2. There are multiple version numbers shown. However, the

firmware version is displayed under MODULE VER. In the

example screen above, firmware version is shown as 1.10.

3. Press twice to exit the menu.

27

Page 40

Menu

3 Front Panel Operation

3.1 Menu Options

All settings and parameters can be configured from the built-in menu

system of the power supply. To access the menu, press .

The menu system is divided into 8 categories and organized as

follows:

1. SYSTEM SETTING

• REMOTE(USB,ETHERNET,GPIB,RS232 (optional))

• GPIB ADDR(1-30)

• KEY LOCK(ON,OFF)

• IP CONFIG(STATIC)

• IP AD DRE SS(xxx.xxx.xxx.xxx, where x = 0-9)

• BEEP(ON,OFF)

• LCD BACKLIT(ALWAYS ON, 1,5,10,30 MINS OFF)

• RECALL DEFAULT(NO,YES)

• POWER ON STATE (OFF,LAST)

• OUTPUT MODE (MULTI,SINGLE)*

• TRACKING MODE (ON,OFF)*

• EXTERN CONTROL (VOLT,RES,OFF) (optional)

• EXTERN LEVEL (5V,10V) (optional)

• EXTERN TRIG (ON,OFF) (optional)

2. OUTPUT SET TING

1. VOLT LIMIT SETTING

• VOLT LIMIT MAX (0 – Max. Voltage)

• VOLT LIMIT MIN (0 – Max. Voltage)

2. CURR LIMIT SETTING

• CURR LIMIT MAX (0 – Max. Current)

• CURR LIMIT MIN (0 – Max. Current)

3. VOLT SLEWRATE SETTING

• V SLEWRATE

4. CURR SLEWRATE SETTING

• I SLEWRATE

5. M EASU R E AV E RAG E (1-10)

6. LED MODE SETTING

• LED MODE (ON,OFF)

28

Page 41

Note: All optional menu items appear only when their respective optional

Note: The menu cannot be accessed when the output(s) is turned ON or

• Low Current Mode (ON,OFF)**

3. PROTECTION

1. OVP SET TING

• OVP (ON,OFF)

• SET (0 – Max. Voltage)

2. OCP SETTING

• OCP (ON,OFF)

• SET (0 – Max. Current)

4. MEMORY SETTING(0-9)

5. PROGRAM MODE

6. TIMER FUNCTION

• TIMER (ON,OFF)

• TIME (hr:min:sec)

7. CALIBRATION

8. INFORMATION

9. CHAIN SETTING (optional)

• CHAIN ON/OFF (ON,OFF)

• CHAIN ADDRESS(1-31)

*Dual channel models 9173 and 9174 only.

**Models 9184 and 9185 only.

interface cards are installed inside the power supply.

How to Access the Menu

Before using the instrument, it is important to be familiarized with its

menu structure and how to view or change settings and parameters.

Follow the steps below to guide you in selecting menu options.

when it is in remote mode (indicated by RMT light).

29

Page 42

Menu

1

1. From the front panel, press to enter the main menu

and the below screen will display. The on the bottom right

indicates that there are more categories below that can be

displayed.

1 . SYSTEM SETTING

2 . OUTPU T S ETTING

2. Press t o display those categories. T he on the

upper right indicates that there are categories above the

current displayed categories shown. Press and the

screen will display the previous menu categories.

4 . MEMORY SETTING

5 . PROGRAM MODE

3. Each main category, as well as some submenu items within

the category, has a number next to their respective category

heading. Whenever you see a number next to a menu item

(i.e. 1. SYSTEM SETTING, 4. MEMORY SETTING), use the

numeric keypad to enter that number to access that

category’s menu or submenus. For example, press to

access the SYSTEM SETTING menu.

4. Within the category menus or submenus, adjustable settings

and parameters will have a cursor (indicated by an underline

of a digit or character) to indicate the current selection. Use

30

Page 43

Enter

Enter

Enter

the and keys to select the setting you want to

change. Below is an example of the Remote settings being

selected. Note the underline below the first characte r of the

setting “USB”.

REMOTE = USB

GPIB ADDR = 1

KEY LOCK = OFF

5. Settings have selectable options that are not numeric (i.e.

REMOTE settings shown above). To change them, press

or . To save the changes, press the key.

6. Parameters have numerical set values (i.e. GPIB ADDR

parameter shown above). To change them, use the numeric

keypad to enter the value you want to change to. To save

the changes, press the key.

Note: Changes to settings and parameters appl y only when the

key is pressed to confirm the changes. Otherwise, they will

default to previous set option or value.

31

Page 44

Menu

1

.

Enter

3.2 Remote Interface Setup

The standard remote interface available on all models in the series

is the USB (virtual COM) interface. Other optional supported

interfaces such as GPIB, Ethernet (LAN), RS-232, and RS-485are

available, but dependent on the interface card(s) installed on the

instrument. This section will describe how to setup all the supported

interfaces.

Note: The RMT LED will automatically light up when the power

supply is successfully connected to a PC remotely through any

remot e interface. Keys on the front panel will be locked until

(LCL) is pressed to set the instrument back to LOCAL mode.

USB Interface (virtual COM)

The USB interface comes standard on every power supply in the

series. A USB Type A to Type B cable (i.e. USB printer cable) is

required to connect the USB port ( ) in the rear panel to a PC.

Follow the steps below to setup the power supply for USB (virtual

COM) remote communication.

1. Press , then to enter SYSTEM SETTING. Select

REMOTE and verify that it shows USB, which is the default

option. If not, press or until “USB” is displayed.

Press to save changes.

32

Page 45

2. Insta ll the USB driver. Visit www.bkprecision.com to

download the driver. Run the setup executable after

unzipping the downloaded file.

Note: Do this before connecting the USB cable from the

power supply to the PC.

3. Once the installation is successful, connect the USB cable

between the power supply and the PC. Drivers should be

automatically recognized. To verify, go to “Device Manager”

in Windows, and under “Ports (COM & LPT)”, a new device

listed as “210x USB to UART Bridge (COM#)” will be listed.

The “#” is the COM port number assigned by your computer

to interface with the instrument via USB virtual COM.

4. The serial (virtual COM) sett ings to use are:

BAUDRATE: 57600

PARITY: NONE

DATA BITS: 8

STOP BI T: 1

FLOW CONTROL: NONE

33

Page 46

STATIC

Allows you to configure a static IP address for

the power supply.

Menu

1

Enter

Enter

Menu

1

Enter

Enter

GPIB Interface

GPIB interface is available when the LAN/GPIB card is installed in

the “S1” or “S2” slots in the rear panel. To setup the power supply

for GPIB interface, follow the steps below:

1. Press , then to enter SYSTEM SETTING. Select

REMOTE and press or until “GPIB” is displayed.

Press to save changes.

2. Select GPIB ADDR and use the numeric keypad to enter the

GPIB address (1 – 30). Press to save changes.

Ethernet (LAN) Interface

LAN interface is available when the LAN/GPIB card is installed in the

“S1” or “S2” slots in the rear panel. To setup the power supply for

LAN interface, follow the steps below:

1. Press , then to enter SYSTEM SETTING. Select

REMOTE and press or until “ETHERNET” is

displayed. Press to save changes.

2. Select IP CONFIG and choose STATIC. Press to

save changes.

34

Page 47

Enter

Menu

1

Enter

Enter

3. If STATIC is selected, then select IP ADDRESS and use the

numerical keypad to enter the static IP. After entering each

group of 3 digits, press to go to the next group. The

cursor will automatically move to the next group. Do this until

all 12 digits are entered. Be sure to press one more

time after entering the last 3 digits for the complete IP

address entry to be saved.

RS-232 and RS-485 Interface (Optional)

Both RS-232 and RS-485 interface are supported by the power

supply through an optional RS-232 or RS-485 interface card. Both

of these card options must be properly installed before they can be

used. See “1.7 Installing Optional Interface Cards” for details.

RS-232 Interface

The setup for remote control via RS-232 interface is very similar to

the same for USB virtual COM interface. To setup the power supply

for RS-232 operation:

1. Press , then to enter SYSTEM SETTING. Select

REMOTE and press or until “RS232” is displayed.

Press to save changes.

2. The settings used for RS232 communication are:

35

Page 48

BAUDRATE: 57600

PARITY: NONE

DATA BITS: 8

STOP BI T: 1

FLOW CONTROL: NONE

RS-485 Interface

Multiple power supplies (up to 31) can be connected together in

series and be controlled via USB (virtual COM) interface. Here is an

illustration of how the setup will look like:

Figure 15- RS-485 Setup to Control Multiple Supplies (USB)

To setup and configure the power supplies, follow these steps:

Requirements:

- Optional RS485 cards must be installed on each power supply

- For N number of power supplies, you will need N-1 number of

Ethernet CAT5 straight (pin-to-pin) cables. (Example: To connect

5 power supplies, 4 cables are required)

36

Page 49

Note:The cables are used to link the power supplies together.

possiblebetween each unit.

Note: The terminator switch should only be set to “On” for the

should have the terminator switch set to “Off”.

It is recommended to keep the cables as short as

Communicate via USB

1. Take one Ethernet CAT5 cable and connect one end to

labeled “OUT” on the RS485 interface card of the first power

supply (the one that will be connected to the PC via USB

cable).

2. Connect the other end to labeled “IN” on the RS485

interface card of the second power supply.

3. To connect a third power supply, use another Ethernet CAT5

cable and connect one end to labeled “OUT” on the

second power supply. Connect the other end to labeled

“IN” on the interface card of the third power supply.

4. Repeat steps 2 and 3 for each subsequent power supplies

added to the multi connection, making sure the connections

follow the “IN” and “OUT” scheme as described.

5. After connecting to the “IN” port of the last power supply in

the connection, if there are more than 10 units connected,

set the physical switch labeled “Terminator” on the RS485

interface card of this last unit to “On”.

last power supply in the chain. All other power supplies

6. With a USB Type A to Type B cable, connect one end to the

USB interface of the first power supply. Connect the other

end to a PC to be used to control all the supplies. Refer to

Figure 15 to verify your connections.

37

Page 50

Menu

1

Enter

Esc

9

Enter

Enter

Esc

7. With the connections setup properly, on the first power

supply, press , then to enter SYSTEM SETTING.

Select REMOTE and verify that “USB” is selected. Press

to save changes.

8. Press once to go back to the main menu and press

to enter CHAIN SETTING.

9. Select CHAIN ON/OF F and press or to set it to “ON”.

Press to save changes.

10. Select CHAIN ADDRESS and set it to “1”. Press to

save changes and then press twice to exit the

menu.

11. Repeat steps 7 thru 10 for each of the power supplies in the

chain. However in step 10, set the CHAIN ADDRESS of

each power supply to a different number. (i.e. Set to 1 for

power supply #1, 2 for power supply #2, 3 for power supply

#3, …etc.) The address is used to reference the power

supply during remote operation.

12. Refer to “4.2 Remote Commands” for the list of remote

commands specific for RS485 communication.

38

Page 51

Options

Description

ALWAYS ON

Default – Display never dims.

1 MINS OFF

Display dims after 1 minute

5 MINS OFF

Display dims after 5 minutes

10 MINS OFF

Display dims after 10 minutes

30 MINS OFF

Display dims after 30 minutes

Menu

1

Enter

Menu

1

3.3 Adjusting LCD Display, Key Lock, Key

Sound

LCD Backlight Timer

The LCD backlight has a timer that can be set to dim its brightness

within a set time from when the instrument is idle. To set this:

1. Press , then to enter SYSTEM SETTING. Select

LCD BACKLIT. Press or to change the backlight

timer setting. Selectable options are:

2. Press to save changes.

Key Lock

Users can manually lock the front panel keypad. To set this:

1. Press , then to enter SYSTEM SETTING. Select

KEY LOCK. Press or to change it. Selectable

options are:

39

Page 52

Options

Description

OFF

Default

ON

Lock keypad

Options

Description

ON

Default

OFF

Disable key beep

Enter

.

Esc

.

Menu

1

Enter

2. Press to save changes. Press twice to exit the

menu.

3. If ON is selected, all keys from the front panel, except

for , will be locked. The Lock LED indicator will be lit.

4. To unlock, press and the Lock LED indicator will turn off.

The KEY LOCK option under SYSTEM SETTING category

will automatically default back to OFF.

Disabling Key Sound

To disable the beep from key presses:

1. Press , then to enter SYSTEM SETTING. Select

2. Change it to OFF, and press to save changes. All key

3. To enable it again, set BEEP to ON.

BEEP. Press or to change it. Selectable options are:

presses will no longer beep.

40

Page 53

Options

Description

OFF

Default

ON

Resets instrument with factory

default settings and parameters

Menu

1

Enter

3.4 Restore to Factory Default

All instrument settings can be reset back to their factory default

values by doing the following:

WARNING:

Restoring the instrument to factory default will

change all current instrument settings and

parameters back to their default values.

1. Press , then to enter SYSTEM SETTING. Select

RECALL DEFAULT. Press or to change it.

Selectable options are:

2. Change it to ON, and press . The following prompt will

display:

ARE YOU SURE TO RECALL DEFAULT?

(YES/NO) NO

41

Page 54

REMOTE

USB

GPIB ADDR

1

KEY LOCK

OFF

IP CONFIG

STATIC

IP A DDRE SS

255.255.255.255

BEEP

ON

LCD BACKLIT

ALWAYS ON

VOLT LIMIT MAX

Max. rated voltage of model

VOLT LIMIT MIN

0.000V

CURR LIMIT MAX

Max. rated current of model

CURR LIMIT MIN

0.0005A

V SLEWRATE

7.000 V/ms

I SLEWRATE

0.6000 A/ms

MEASURE AVERAGE TIME

2

LED MODE

OFF

OVP SETTING

OFF, SET = Max. rated voltage

of model

OCP SETTING

OFF, SET = Max. rated current

of model

TIMER FUNCTION

OFF

Enter

Enter

3. To cancel this action, press with NO marked by the

cursor. To confirm resetting the instrument to factory default,

press to select YES and press .

4. After approximately 5 seconds, the inst rument wi ll

automatically jump back to the normal display. All settings

are now set back to their factory default values.

Table 3 Factory Default Settings

42

Page 55

Menu

2

1

Enter

Enter

Esc

3.5 Configure Voltage and Current Output

Voltage and Current Limit Settings

The power supply has software voltage and current limit protection

settings that can be configured to limit the settable range for output

from front panel or remote operation. Follow the steps in this section

to adjust these settings.

Voltage Limit Set

1. Press , then to enter OUTPUT SETTING. Press

to select VOLT LIMIT SETTING.

2. VOLT LIMIT MAX should be selected. Use the keypad to

enter the maximum voltage set limit and press to save

changes. The maximum voltage that can be set depends on

the power supply’s maximum output voltage.

3. VOLT LIMIT MIN is now selected. Again, use the keypad to

enter the minimum voltage set limit and press to save

changes.

4. Press once to return to previous menu items, or press

three times to exit the menu when finished.

Dual Channel Models

For models with dual channels, the display will look different, with

CH1 and CH2 indicators on the left side of the display to indicate

their respective VOLT LIMIT MAX/MIN parameters.

43

Page 56

CH2 VOLT LIMIT MAX = _20.400 V

Menu

2

2

Enter

Enter

Esc

CH1 VOLT LIMIT MAX = _20.400 V

CH1 VOLT LIMIT MIN = 0 V

CH2 VOLT LIMIT MIN = _ 0.000 V

Current Limit Set

1. Press , then to enter OUTPUT SETTING. Press

to select CURR LIMIT SETTING.

2. CURR LIMIT MAX should be selected. Use the keypad to

enter the maximum current set limit and press to save

changes. The maximum current that can be set depends on

the power supply’s maximum output current.

3. CURR LIMIT MIN is now selected. Again, use the keypad to

enter the minimum current set limitand press to save

changes.

4. Press once to return to previous menu items, or press

three times to exit the menu when finished.

Dual Channel Models

For models with dual channels, the display will look different, with

CH1 and CH2 indicators on the left side of the display to indicate

their respective CURR LIMIT M AX/MIN parameters.

44

Page 57

CH2 CURR LIMIT MAX = _10.200 A

Vset

Enter

CH1 CURR LIMIT MAX = _10.200 A

CH1 CURR LIMIT MIN= 0.000 A

CH2 CURR LIMIT MIN = _ 0.000 A

Configure Voltage and Current Output

Voltage and current can be set and output from the front panel and

the rear panel terminals. Refer to “3.7 Remote Sense” for setup

instructions if remote sense will be used for voltage compensation at

the output.

Setting Voltage

Follow the steps below to set the output voltage:

1. For single channel models, skip to step 2 below. For dual

channel models, from the main display press or

to select the channel for setting voltage. The channel

indicators CH1 or CH2 will flash to indicate the selected

channel.

2. With the main display shown, press and use the

numeric keypad to enter your set voltage. Then press .

Below is an example screen for setting 5 V.

45

Page 58

SET = 5.000 V

SET = 5.000 V

CH2 OFF 5 . 000 V 1 . 000 A

VOLT R ANGE = HIGH ( : H / : L )

OFF 5 . 000 V 1 . 000 A

For Dual Channel models:

CH1 OFF 5 . 000 V 1 . 000 A

3. Models 9184 and 9185 do not have auto ranging available.

The range must be selected manually and can be set as

HIGH or LOW range.

9184: HIGH range – 200 V / 1 A

LOW range – 100 V / 2 A

9185: HIGH range – 600 V / 0.35 A

LOW range – 400 V / 0.5 A

To select HIGH range, press from the normal display

where VOLT RANGE is indicated.

OFF 200 . 00 V 1 . 000 A

To select LOW range, press instead.

46

Page 59

Note:The voltage setting range is dependent on the unit’s

power supply.

VOLT RANGE = LOW ( : H / : L )

SET = 2.000 A

Iset

Enter

OFF100 . 00 V 2 . 000 A

maximum voltage output specification as well as the

voltage limits set from the system menu. Verify VOLT

LIMIT MAX and VOLT LIMIT MIN settings if you are

unable to set a voltage within the specifications of the

Setting Current

Follow the steps below to set the output current:

1. For single channel models, skip to step 2 below. For dual

channel models, from the main display press or

to select the channel for setting current. The channel

indicators CH1 or CH2 will flash to indicate the selected

channel.

2. With the main display shown, press and use the

numeric keypad to enter your set current. Then press .

Below is an example screen for setting 2 A.

OFF 5 . 000 V 2 . 000 A

47

Page 60

Note: The current setting range is dependent on the unit’s

power supply.

SET = 2.000 A

CH2 OFF 5 . 000 V 2 . 000 A

For Dual Channel models:

CH1 OFF 5 . 000 V 2 . 000 A

3. Models 9184 and 9185 do not have auto ranging available.

The range must be selected manually and can be set as

HIGH or LOW range.

9184: HIGH range – 200 V / 1 A

LOW range – 100 V / 2 A

9185: HIGH range – 600 V / 0.35 A

LOW range – 400 V / 0.5 A

To select HIGH range, press from the normal display

To select LOW range, press instead.

maximum current output specification as well as the

current limits set from the system menu. Verify CURR

LIMI T MAX and CURR LIMIT MIN settings if you are

unable to set a current within the specifications of the

48

Page 61

WARNING:

wires.

Enable/Disable Output

Before connecting wires to the front or rear panel

output terminals, output should remain OFF to

avoid shocks and damage to the device under test

The button is used to enable or disable the supply output

from both the front panel and the rear panel output terminals. A

green LED light next to the button will be lit when is

(DUT), especially when setting the supply for high

voltage output. For safety, load wires must have a

wire gauge size large enough to prevent

overheating when the power supply operates at

maximum short circuit output current. It will also

prevent large voltage drops from resistances in the

OUTPUT

OUTPUT

pressed to turn ON (enable), and the OFF annunciator will

disappear from the display. This will reappear when output is OFF

(disable) upon pressing again, and the green LED light

will disappear. For dual channel models, and are used

in place of as output ON/OFF for CH1 and CH2

respectively. Dual channel models can also be configured so that

both channels’ output states (ON or OFF) can be synchronized. See

“

3.6Dual Channel Configurations” under “Multi/Single Output

Control” for setup instructions.

OUTPUT

OUTPUT

49

CH1

CH2

Page 62

Note:The voltage setting range is dependent on the unit’s

voltage limits set from the system menu. Verify VOLT

CH2CV5 . 000 V1 . 000 A

Enter

Controlling Voltage/Current Output with Keys

When the output is ON (enabled), the voltage (CV mode) or current

(CC mode) output can be controlled incrementally by key presses.

To do this, press or and a cursor will appear, highlighting the

last digit of the measured voltage or current display. Use or

to change and select the digit you want to change, and press

or to increase or decrease that digit. The output voltage or

current will change immediately as you change the digits. Press

at any time or allow the supply to idle for 10 seconds (without any

key presses) to go back to the normal display.

CV

5 . 000 V1 . 000 A

For Dual Channel models:

CH1CV5 . 000 V1 . 000 A

maximum voltage output specification as well as the

50

Page 63

LIMI T MAX and VOLT LIMIT MIN settings if you are

power supply.

Menu

2

3

Enter

Esc

4

unable to set a voltage within the specific ations of the

Slew Rate Configuration

Voltage and current slew rate of the output can be configured by

doing the following:

1. Press , then to enter OUTPUT SETTING. Press

to select VOLT SLEWRATE SETTING. The following will be

displayed:

V SLEWRATE = _ 7.000 V / ms

For Dual Channel models:

CH1 V SLEWRATE = _ 7.000 V / ms

CH2 V SLEWRATE = _ 7.000 V / ms

2. Use the keypad to enter the voltage slew rate. (Refe r to

Table 4) Then press the save the changes.

3. Press once to return to the previous menu items, and

press to select CURR SLEWRATE SETTING. The

following will be displayed:

51

Page 64

Model

V Slew Rate (V/ms)

I Slew Rate (A/ms)

9171

0.001 – 2.500

0.001 – 1.250

9172

0.001 – 7.000

0.001 – 0.300

9173

0.001 – 2.500

0.001 – 1.250

9174

0.001 – 7.000

0.001 – 0.300

9181

0.001 – 4.500

0.001 – 1.000

9182

0.001 – 2.500

0.001 – 2.500

9183

0.001 – 7.000

0.001 – 0.600

9184

0.001 – 6.666

0.001 – 0.066

9185

0.001 – 15.00

0.001 – 0.0125

Enter

Esc

I SLEWRATE = _ 0.600 A / ms

For Dual Channel models:

CH1 I SLEWRATE = _ 0.600 A / ms

CH2 I SLEWRATE = _ 0.600 A / ms

4. Use the keypad to enter the current slew rate, then press

to save changes.

5. Press once to return to previous menu items, or press

three times to exit the menu when finished.

Table 4- Voltage and Current Slew Rate Ranges

52

Page 65

Menu

6

Enter

Enter

Enter

Esc

Output Timer Function

The power supply has a built-in output timer function that can be

enabled to allow setting a time in which output is remained ON.

Follow the steps below to setup this function:

1. Press , then to select TIMER FUNCTION. The

following screen will be displayed:

TIMER = OFF

TIME = 0 Hr 0 Min 0 Sec

2. While the cursor is selecting TIMER, press so that ON is

selected, then press to set and selectTIME. This will be

the time for which the output will remain ON.

3. Use the numeric keypad to enter the Hr (hour) for the output

to remain ON. Press to select Min (minute). Enter a

value and press again t o select Sec (second).

4. The acceptable ranges are:

Hr: 0 – 999, Min: 0 – 59, Sec: 0 – 59

5. Press once to return to previous menu items, or press

three times to exit the menu when finished.

6. Upon returning to the main display, it will show the following:

53

Page 66

Note:For dual channel models, the timer function will work only

by both channels.

TIMER = 000 : 00 : 00 Sec

TIMER = 000 : 00 : 00 Sec

10 . 000 V1 . 000 A

OFF10 . 000 V1 . 000 A

For Dual Channel models:

CH1OFF10 . 000 V1 . 000 A

CH2OFF

7. Press ( or for dual channel models) to

OUTPUT CH1

turn the output ON, and the TIMER on the display will start

running. The ON annunciator will display, and the output will

remain ON until the configured time period (from step 3)

CH2

ends.

with both channels ON (enabled) simultaneously

regardless of the OUTPUT MODE setting configured in

SYSTEM SETTING menu. The internal timer is shared

54

Page 67

Menu

2

5

Enter

Esc

Measurement Average Setting

The averaging measurements used to display a reading can be

adjusted by following the stepsbelow:

1. Press , then to enter OUTPUT SETTING. Press

to select MEASURE AVERAGE. The following will display:

AVERAGE TIME = _ 2

2. Use the numeric keypad to enter the number of

measurements the instrument will average out prior to

displaying the value. Valid numbers are from 1 to 10.

3. Press to save changes, then press three times

to exit the menu.

3.6 Dual Channel Configurations

Features described in this section pertain to dual channel models

9173 and 9174 only. They are not available for all other models.

Multi/Single Output Control

Dual channel outputs can be configured so that pressing the output

buttons can turn ON (enable) or OFF (disable) both channels’

outputs simultaneously.

55

Page 68

Enter

Esc

Menu

1

Enter

Esc

Menu

1

Note: When multiple output control is setup, there will be a maximum of 3

ms delay between channel 1 and channel 2 when both channels change

output from OFF (disable) state to ON (enable) state.

Follow the steps below to configure this setting:

1. Press , then to enter SYSTEM SETTING. Go

down the list of settings and select OUTPUT MODE.

2. Press to select MULTI. Press to confirm the

changes, and press twice to exit the menu. If SINGLE

is selected, output control of the two channels will not be

simultaneous; their output states can be controlled

independently.

Series/Parallel Tracking Mode

Tracking mode can be enabled so that both channels can be

synchronized, especially when connected together in series or

parallel. To tur n on tracking mode, follow the steps here:

1. Press , then to enter SYSTEM SETTING. Go

down the list of settings and select TRACKING MODE.

2. Press to select ON. Press to confirm the changes,

and press twice to exit the menu. To disable it, select

OFF.

56

Page 69

TRK

10 . 000 V 1 . 000 A

3. The TRK annunciator will appear on the display to indicate

tracking mode is enabled. Both channels are now

synchronized.

CH1OFF 10 . 000 V 1 . 000 A

CH2OFF

3.7 Remote Sense

Single channel models 9171, 9172, 9181, 9182, and 9183 have both

front and rear panel remote sense terminals. Dual channel models

9173 and 9174, and high voltage single channel models 9184 and

9185 have rear panel remote sense terminals only. Remote sense

can be used to compensate for voltage drops due to resistance from

test leads connected to your device under test (DUT), thus providing

more accurate output voltage. The power supply is initially setup to

local sense mode by default. Refer to the following sections for

details of local and remote sense setup.

Local Sense

All power supplies are setup with local sense by default. In local

sense mode, shorting bars between the sense terminals and output

terminals are connected on the front panel (if available) and rear

panel outputs. Refer to Figure 16 below (Note: Some models do not

have front panel sense terminals, indicated by +S and -S):

57

Page 70

+S

+

+

- - -

S

+S + - -S

Front Panel Shorting Bar

Rear Panel Shorting Bar

Figure 16-Local Sense with Shorting Bar

For front panel, +S and + terminals are shorted together, and –S

and – terminals are shorted together with shorting bars. For rear

panel, +S and + (next to +S) are shorted together, and –S and –

(next to –S) are shorted together with small metal shorting bars.

Note:For calibration, local sense should be used.

Remote Sense

To setup and use remote sense from the front panel (if available),

both the front panel and rear panel shorting bars must be removed.

The front +S and –S sense ports are then connected directly to the

DUT, like Figure 17 below:

58

Page 71

WARNING:

internally and cause damage to the supply.

Figure 17- Front Panel Remote Sense Setup

To use remote sense from the rear panel, both front panel (if

available) and rear panel shorting bars must also be removed. The

rear +S and –S ports are connected directly to the DUT, like Figure

18 below:

Figure 18- Rear Panel Remote Sense Setup

In remote sense where both the front and/or rear

panel shorting bars are removed, never connect a

device directly to the front (if applicable) and/or

back +S and –S terminals only. Always connect the

+ and – terminals first, then connect the +S and – S

terminals. Otherwise, the sense lines will burn out

59

Page 72

DO NOT CONNECT LIKE BELOW:

For operating with output current higher than 10 A, the connection is

the same as Figure 18 above, with the addition of connecting the

second pair of (+) and (-) terminals in the rear panel, like below:

60

Page 73

WARNING:

power supply.

+S

+

+

-

- - S

Rear Panel Output

Remove Shorting bars

+S

+

+

-

-

-

S

+ -

+S + - -S

Remove shorting bars

Front Panel Output

Rear Panel Output

DUT

Figure 19- Remote Sense Setup for 10A or Higher Current Output Operation

DO NOT output 10A or more with only one pair of

(+) and (-) terminals in the rear panel. Both (+)

terminals and both (-) terminals must all be

connected for applications requiring more than

10A output. Each terminal can only accept

maximum of 10A. Exceeding this may damage the

61

Page 74

LED MODE = ON

Enter

Esc

Menu

2

6

3.8 LED and Low Current Test Modes

LED Mode

All of these power supplies have LED mode, which enables them to

function specifically for LED test applications. When this mode is

ON (enabled), the power supply can operate in such a way as to

minimize or almost eliminate the inrush current drawn by the LED

load, which normally exists when the output switches from an OFF

state to an ON state.

To enable LED mode, follow these steps:

1. Press , then to enter OUTPUT SETTING. Press

to select LED MODE SETTING.

2. Press to select ON, then press to confirm the

changes. Press twice to exit the menu. For dual

channel models, both channels will have LED mode enabled.

Consider the following example for 9184 with setup in Figure 22:

62

Page 75

Inrush current

LED Mode OFF (disabled)

LED Mode ON (enabled)

Output ON

Output ON

Figure 20- LED Testing Example

The 9184 supply output is initially OFF (disabled). The LED light bar

is rated for 170 V. A 10 Ω resistor is placed in series with the LED

light bar. The power supply current setting (ISET) is 20 mA.

Using an oscilloscope to probe between the resistor to measure

current, the power supply’s output is then turned ON. The measured

results are shown in Figure 21, which compares the measured

results with and without LED mode ON (enabled):

Figure 21 - Inrush Current With and Without LED Mode Enabled

63

Page 76

Menu

2

6

With LED mode ON (enabled), the power supply can minimize or

eliminate any inrush current from turning the output ON, which in

turn will minimize damage or life of the LEDs under test.

Note: For LED mode to function correctly, the output must be turned

OFF when connecting between the power supply and the LEDs

under test. Turn ON the output after LED mode is enabled and

all other settings are configured.

WARNING:

For models 9184 and 9185, Low Current MODE

must be set to OFF when using LED mode. If both

are ON, the supply may produce inrush current.

Low Current Mode

Available on models 9184 and 9185 onl y.

Low current mode is a unique function that enables the power

supply to minimize voltage rise times when operating with low

current (< 1 A) output with a high voltage change.

To enable Low current mode, follow these steps:

1. Press , then to enter OUTPUT SETTING. Press

to select Low Current MODE.

64

Page 77

LED MODE = OFF

Low Current Mode

Low Current Mode ON

5

Enter

Esc

2. Press to select ON, then press to confirm the

changes. Press twice to exit the menu.

Low Current MODE = ON

Consider the following example screenshots measuring a voltage

chance from 0 V to 60 V with a load of 100 m A connected to the

output.

20 ms

Figure 22 - Inrush Current With and Without LED Mode Enabled

When operating with low current output, enabling Low Current mode

can reduce the voltage rise time upon a change in the voltage

output.

OFF

ms

65

Page 78

OVP = ON SET = 70.000 V

CH1 OVP = ON SET = 70.000 V

Menu

3

1

3.9 Output Protection

Configure OVP

Overvoltage protection (OVP) is available to limit the voltage output

and to protect a connected DUT from an overvoltage condition.

When the power supply trips the OVP, a short beep will sound and

the OVP (OVP1/OVP2 for dual channel models) LED indicator on

the front panel will be lit. The green output light will also disappear

and output will turn OFF (disable) immediately. To clear the OVP

trip, press any key and the OVP (OVP1/OVP2 for dual channel

models) LED indicator will turn OFF. To activate OVP, follow the

steps below:

1. Press , then to enter PROTECTION, and press

to select OVP SETTING.

For Dual Channel models:

CH2 OVP = OFF SET = 70.000 V

66

Page 79

OCP = ON SET = 10.000 A

Enter

Esc

Enter

Menu

3

2

2. Press to select ON. Press to confirm the changes,

and use the numeric keypad to set the voltage limit for the

protection to trip. Press again to save changes. When

the power supply voltage output reaches this limit, the OVP

will trip.

3. Press twice to exit the menu. To disable it, select

OFF.

Configure OCP

Overcurrent protection (OCP) is available to limit the current output

and to protect a connected DUT from an overcurrent condition.

When the power supply trips the OCP, a short beep will sound and

the OCP (OCP1/OCP2 for dual channel models) LED indicator on

the front panel will be lit. The green output light will also disappear

and output will turn OFF (disable) immediately. To clear the OCP

trip, press any key and the OCP (OCP1/ OC P2 for dual channel

models) LED indicator will turn OFF. To activate OCP, follow the

steps below:

1. Press , then to enter PROTECTION, and press

to select OCP SETTING.

67

Page 80

CH1 OCP = ON SET = 10.000 A

Enter

Esc

Enter

Menu

4

For Dual Channel models:

CH2 OCP = OFF SET = 10.000 A

2. Press to select ON. Press to confirm the changes,

and use the numeric keypad to set the current limit for the

protection to trip. Press again to save changes. When

the power supply current output reaches this limit, the OCP

will trip.

3. Press twice to exit the menu. To disable it, select

OFF.

3.10 Save/Recall Output Settings

The power supply has internal memory to store up to 10 settings,

and each setting includes the set voltage (VSET) and set current

(ISET) values.

Save Output Settings

Follow these steps to save settings:

1. Press , then to enter MEMO RY SETTING. The

following screen will bedisplayed:

68

Page 81

MEM = 0

MEM = 0

Enter

Enter

Enter

V = 0.000 V I = 0.000 A

For Dual Channel models:

CH1 V = 0.000 V I = 0.000 A

CH2 V = 0.000 V I = 0.000 A