Page 1

Data Sheet

Programmable DC Electronic Loads

8600 Series

The 8600 Series programmable DC electronic

loads provide the performance of modular system

DC electronic loads in a compact benchtop form

factor. With fast transient operation speeds and

high 16-bit measurement resolution, these

standalone DC loads can be used for testing and

areas for quick system recall. All load parameters

such as voltage, current, slew rate, and width

can be set via the front panel or programmed

remotely. The 8600 Series provides standard

USB (USBTMC-compliant), GPIB, or RS-232

serial interfaces for remote communication.

evaluating a variety of DC sources such as DC

power supplies, DC-DC converters, batteries,

battery chargers, and photovoltaic arrays.

To ensure the reliability of your testing, the 8600

Series provides a power-on system self-test and

numerous protection features: overtemperature

The DC loads can operate in constant current

(CC), constant voltage (CV), constant resistance

(CR), or constant power (CW) mode and be

(OTP), overvoltage (OVP), overcurrent (OCP),

overpower (OPP), and local/remote reverse

voltage (LRV/RRV) protection.

configured to provide a dynamically changing load

to the DC source with fast load switching times.

Versatile internal, external, and remote triggering

options allow the dynamic load behavior to be

synchronized with other events.

Special Applications

The 8600 Series provides a built-in battery test

mode to measure the ampere-hour (Ah)

characteristic of a battery and a unique CR-LED

Increase productivity by saving your test

parameters into any one of the 100 memory

Model 8600 8601 8602 8610 8612 8614 8616

Power 150 W 250 W 200 W 750 W 750 W 1500 W 1200 W

Operating

Voltage

Rated Current 0 – 30 A 0 – 60 A 0 – 15 A 0 – 120 A 0 – 30 A 0 – 240 A 0 – 60 A

0 – 120 V 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V

mode to simulate the loading behavior of a

typical LED.

Features

■ Voltage range up to 500 V

■ Current range up to 240 A

■ CC/CV/CR/CW operating modes

■ 16-bit voltage and current measurement

system providing 1 mV / 0.1 mA resolution

■ Transient mode up to 25 kHz in CC mode

■ List mode function

■ Store and recall up to 100 setups

■ Adjustable slew rate in CC mode

■ Flexible triggering options via front panel,

external input, timer, or bus

■ Built-in battery test function with voltage level,

capacity level, and timer stop conditions

■ Test modes to validate the OCP/OPP

protection functions of a power supply

■ CR-LED mode to simulate the loading behavior

of typical LEDs

■ Remote sense

■ Analog current control and monitoring

■ Thermostatically controlled fan

■ Standard USB (USBTMC-compliant), RS232,

and GPIB interfaces supporting SCPI

commands for remote control

■ OVP/OCP/OPP/OTP including local and

remote reverse voltage (LRV/RRV) protection

■ Compact 19” half-rack form factor allows for

side-by-side rack mounting of two units

(models 8600, 8601 and 8602)

Technical data subject to change

© B&K Precision Corp. 2015

www.bkprecision.com

Page 2

Programmable DC Electronic Loads

8600 Series

Models 8600, 8601 & 8602

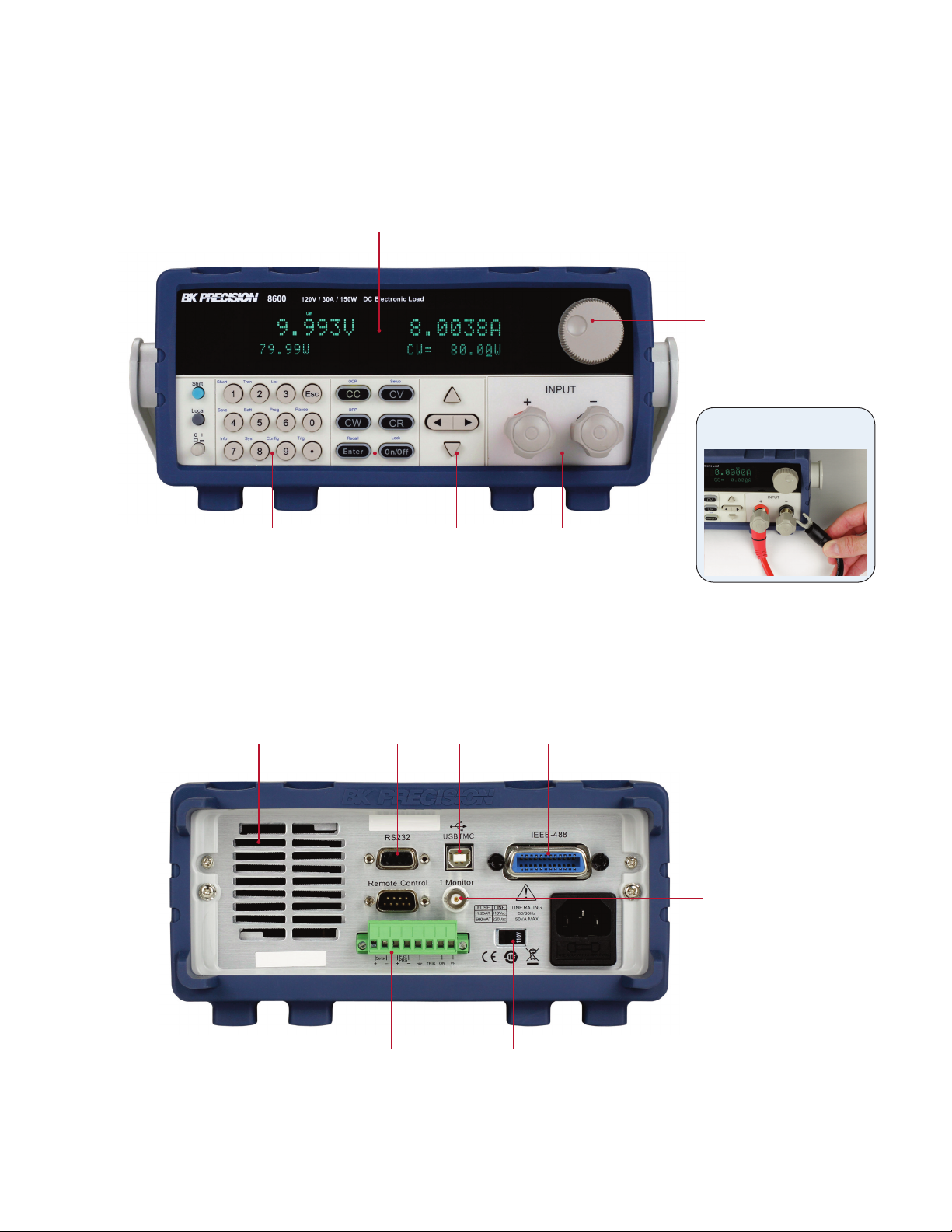

right dual-line display

Front panel

B

The 8600 Series display shows both measured input

values and set parameters simultaneously.

otary control

R

knob

High current test lead accessory

model TLPWR1

Numeric keypad Function keys Cursor keys Load input terminal

Intuitive user interface

The numeric keys and rotary knob provide a convenient interface for setting the operating mode and desired current, voltage, and resistance levels quickly

and precisely.

Rear panel

Cooling fan

RS-232

interface

USB

interface

GPIB interface

Current monitor BNC output

Outputs a 0-10 V signal that follows

0-full range of the input current.

I/O terminal block

External trigger, external analog programming,

external input On/Off control, voltage fault pin,

and remote sense terminals

2

Line voltage selector

www.bkprecision.com

Page 3

Programmable DC Electronic Loads

8600 Series

Models 8610, 8612, 8614 & 8616

Front panel

right dual-line display

B

Power

witch

s

The 8600 Series display shows both measured

input values and set parameters simultaneously.

Operating

ode keys

m

Cursor

eys

k

unction

F

eys

k

Numeric

eypad

k

Rear panel

Input

terminals

Current monitor BNC output

Outputs a 0-10 V signal that follows

0-full range of the input current.

Cooling fan I/O terminal block

RS-232

interface

External trigger, external analog programming, external input

On/Off control, voltage fault pin, and remote sense terminals

USB

interface

GPIB

interface

Line voltage

selector

Input fuse holder

AC line

input

3

www.bkprecision.com

Page 4

Programmable DC Electronic Loads

8600 Series

Flexible operation

Transient operation

A

A level

B level

Slew Rate

t

Transient operation enables the load to periodically

switch between two load levels (A/B). A power

supply’s regulation and transient characteristic can

be evaluated by monitoring the supply’s output

voltage under varying combinations of load levels,

duty cycle, and slew rate. The 8600 Series can

simulate these conditions in CC, CV, CW, and CR

mode.

List mode

A

Trigger

012345678

teps

S

Not limited to just switching between two levels,

list mode lets you generate more complex

sequences of input changes with several different

levels. Up to 7 groups of list files can be saved

and executed in CC mode via internal or external

trigger. Each list can contain up to 84 steps with

varying slew rates and a minimum width time of

20 μs per step.

Low voltage operation

The 8600 Series can operate at low voltages for applications such as fuel cell and solar cell testing.

I

Automatic test mode

CV 3 V

ail

f

CC 1 A

pass

t

1 s 0.5 s 1.5 s 2.5 s

CW 0.5 W

pass

CR 2 Ω

ass

p

The 8600 Series can execute multiple test

sequences in automatic test mode. Up to 100

different sequences can be linked to run steps of

various operating modes and loading conditions.

Each sequence can also be programmed with

upper and lower limit Pass/Fail criteria. When

applied in production testing, you can easily

judge whether the test parameters of your

devices are within the specification limits and

adjust your process according to the Pass/Fail

verdict.

CR-LED mode

240

≈

120

Current (A)

60

30

0

12345

Voltage (V)

Typical minimum operating voltage at full scale current

8600 8601 8602 8610 8612 8614 8616

1.1 V 1.1 V 4.5 V 1.2 V 3.6 V 1.5 V 3.6 V

8601

8600

8612

8614

8

6

1

8616

8602

I

Io

0

Vd Vo

LED I-V Curve

Rd

V

Vd = Forward voltage of the LED

Rd = LED operating resistance

Vo = LED operating voltage

Io = LED operating current

Use the load’s unique CR-LED operating mode

to test LED drivers. This function allows users to

configure the LED’s operating resistance and

V

forward voltage to simulate the loading behavior

of typical LEDs.

4

www.bkprecision.com

Page 5

Programmable DC Electronic Loads

8600 Series

Remote control and programming

Powerful communication interfaces

he 8600 Series provides standard GPIB, USB,

T

and RS232 interfaces for remote communication.

These interfaces offer SCPI and USBTMC

tandard communication protocols to control

s

your electronic load from a PC.

.8

1

1.6

.4

1

1.2

1.0

Volts

0.8

0.6

.4

0

Typical battery discharge curve

0 0.5 1.0 1.5 2.0 2.5

Hours

The built-in battery test function uses CC mode

to calculate the battery capacity using a fixed

current load discharge. Users can specify cut-off

voltage level, capacity level, and time stop

conditions.

Built-in rise and fall time measurement

External analog programming and

monitoring interface

In addition to front panel and remote interface

control, current values can also be programmed

with an analog control signal. The electronic

loads can be externally controlled from zero to

full scale with a 0-10 V input signal. A BNC

output is available on the rear for monitoring

the current with a 0-10 V output signal.

Voltage-on (Von) latch operationBattery test function

V

Von

evel

L

t

A

Load Sink

Current

ise Rate

R

A/µs

t

Control the input turn on state for the DC

electronic load by configuring the Von latch

function. This can be used to start and stop

discharging of a battery or other power source

at a specified voltage level.

Application software

PC software is provided for front panel emulation,

generating and executing test sequences, or

logging measurement data without the need to

write source code. Additionally, this application

software integrates with NI Data Dashboard for

LabVIEW apps, which allows users to create a

custom dashboard on a tablet computer or

smartphone to remotely monitor 8600 Series

DC loads via this PC software.

■ Remote monitoring on iOS, Android or

Windows 8 compatible tablets or

smartphones via NI Data Dashboard for

LabVIEW apps

■ Log voltage, current, and power values with

timestamp

■ Run transient operation and list mode

programs remotely

■ Create an unlimited number of external list

files to be executed from PC memory

8600 Series display

Oscilloscope display

The 8600 Series can measure the rise or fall time from a specified start and stop voltage level of

the measured input without the need for an oscilloscope. This function can also be used as an

internal timer to count how long the input has been enabled.

5

Adjustable slew rate

A

Slew Rate

t

In CC mode, users can control the rate or slope

of the change in current in a transient response

test. Set the slew rate to as slow as 0.001 A/ms

or as fast as 2.5 A/µs depending on the model

and selected current range.

www.bkprecision.com

Page 6

Programmable DC Electronic Loads

8600 Series

Specifications

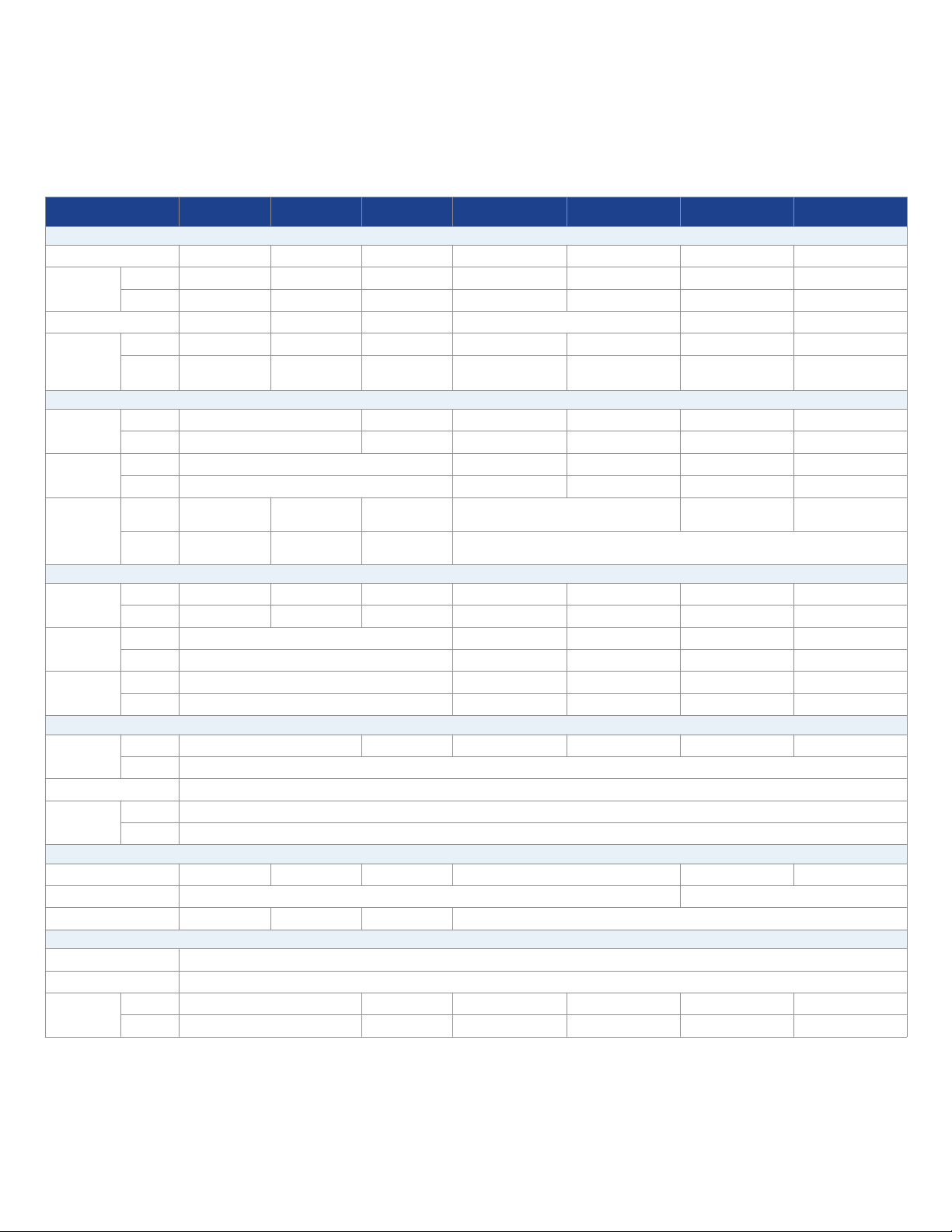

Model 8600 8601 8602 8610 8612 8614 8616

nput ratings

I

Input voltage 0 – 120 V 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V

Input

current

Input power 150 W 250 W 200 W 750 W 1500 W 1200 W

Minimum

operating

voltage

V mode

C

Range

Resolution

Accuracy

CC mode

Range

Resolution

Accuracy

CR mode

Range

Resolution 16 bit

Accuracy

CW mode

Resolution 10 mW 100 mW

Accuracy 0.1% + 0.1% FS 0.2% + 0.2% FS 0.1% + 0.1% FS 0.2% + 0.2% FS

Transient mode (CC mode)

T1 & T2

Accuracy 5 µs + 100 ppm

Slew Rate

(1)

Fast pulse trains with large transitions may not be achievable.

(2)

The slew rate specifications are not warranted, but are descriptions of typical performance. The actual transition time is defined as the time for the input to change from 10% to 90%, or vice versa, of the

programmed current values. In case of very large load changes, e.g. from no load to full load, the actual transition time will be larger than the expected time. The load will automatically adjust the slew rate to fit within the range

(high or low) that is closest to the programmed value.

Low 0 – 3 A 0 – 6 A 0 – 3 A 0 – 12 A 0 – 3 A 0 – 24 A 0 –6 A

High 0 – 30 A 0 – 60 A 0 – 15 A 0 – 120 A 0 – 30 A 0 – 240 A 0 –60 A

Low 0.11 V at 3 A 0.18 V at 6 A 1 V at 3 A 0.12 V at 12 A 0.36 V at 3 A 0.15 V at 24 A 0.36 V at 6 A

High 1.1 V at 30 A 1.1 V at 60 A 4.5 V at 15 A 1.2 V at 120 A 3.6 V at 30 A 1.5 V at 240 A 3.6 V at 60 A

Low 0 – 18 V 0 – 50 V 0 – 18 V 0 – 50 V 0 – 18 V 0 – 50 V

High 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V 0 – 120 V 0 – 500 V

Low 1 mV 0.1 mV 1 mV 0.1 mV 1 mV

High 10 mV 1 mV 10 mV 1 mV 10 mV

Low

High

±(0.05%+

0.02% FS)

±(0.05%+

0.025% FS)

±(0.025%+

0.05% FS)

±(0.025%+

0.05% FS)

±(0.05%+

0.025% FS)

±(0.05%+

0.025% FS)

±(0.025%+0.05% FS)

±(0.025%+

0.025% FS)

±(0.025%+0.05% FS)

±(0.025%+

0.05% FS)

Low 0 – 3 A 0 – 6 A 0 – 3 A 0 – 12 A 0 – 3 A 0 – 24 A 0 – 6 A

High 0 – 30 A 0 – 60 A 0 – 15 A 0 – 120 A 0 – 30 A 0 – 240 A 0 – 60 A

Low 0.1 mA 1 mA 0.1 mA 1 mA 0.1 mA

High 1 mA 10 mA 1 mA 10 mA 1 mA

Low ±(0.05%+0.05% FS) ±(0.05%+0.1% FS) ±(0.05%+0.05% FS) ±(0.05%+0.1% FS) ±(0.05%+0.05% FS)

High ±(0.05%+0.05% FS) ±(0.05%+0.1% FS) ±(0.05%+0.05% FS) ±(0.05%+0.1% FS) ±(0.05%+0.05% FS)

Low 0.05 Ω – 10 Ω 0.3 Ω – 10 Ω 0.02 Ω – 10 Ω 0.15 Ω – 10 Ω 0.01 Ω – 10 Ω 0.01 Ω – 10 Ω

High 10 Ω - 7.5 kΩ

Low 0.01%+0.08

High 0.01%+0.0008

S

S

Range 150 W 250 W 200 W 750 W 1500 W 1200 W

(1)

Low 0.001-2.5 A/ms 0.001-1 A/ms 0.001-0.25 A/µs 0.0001-0.1 A/µs 0.001-0.25 A/µs 0.0001-0.1 A/µs

(2)

20 µs – 3600 s / Resolution: 10 µs

High 0.001-2.5 A/µs 0.001-1 A/µs 0.01-2.5 A/µs 0.001-1 A/µs 0.01-2.5 A/µs 0.001-1 A/µs

6

www.bkprecision.com

Page 7

Programmable DC Electronic Loads

8600 Series

0

0

6

l

ode

M

ge

a

t

ol

v

ck

dba

a

e

R

w

o

o

e

n

c

cur

n

c

Ra

s

c

r

u

c

ur

c

ng

ut

ol

ur

c

ange (

Lo

g

i

H

w

Lo

g

i

H

y

c

a

nt

e

r

w

Lo

g

i

H

w

Lo

g

i

H

y

c

a

er

e

on

i

y

c

a

ypi

t

e

ng

Ra

i

t

u

l

o

s

e

R

A

ck

dba

a

e

R

e

ng

Ra

i

t

u

l

o

s

e

R

A

Readback pow

R

A

on r

i

ect

ot

Pr

OPP

OCP

Low

Hi

g

OVP

OTP

)

cal

ypi

t

(

al

ener

G

t

ui

c

r

i

c

t

hor

S

Low

CC)

(

nt

e

r

Cur

a

t

Vol

a

t

s

i

s

e

R

g

Hi

CV)

(

e

g

)

CR

(

e

nc

Input terminal impedance

ut

inp

AC

rature

pe

tem

perating

O

erature

p

m

Storage te

umidity

H

ety

Saf

h

h

h 0

h

cal

h

h

8

V

8

1

–

0

V

0

2

1

–

0

A

3

–

0

A

0

3

–

A

m

1

0

.

0

A

m

1

.

0

+

05%

0.

(

±

1%

(

±

)

)

FS

05%

0.

150 W 250 W

)

FS

1%

0.

+

150 W

3 A

3.

33 A

120 V

3 A

30 A 60 A

Ω

35 m

Ω

150 k

1 8

0

6

8

V

8

1

–

0

0

2

1

–

0

m

1

.

0

V

m

1

A

6

–

0

A

0

6

–

0

A

m

1

.

0

A

m

1

05%

0.

(

±

FS

1%

0.

0.

+

2%

0.

(

±

250 W

6 A

6.

66 A

120 V

6 A

Ω

m

30

kΩ

300

2

0

6

V

0

5

–

0

V

0

0

5

–

V

0

0

V 0

2

0

.

0

(

±

A

3

–

0

A

5

1

–

0

A

m

1

0

.

0

A

m

1

.

0

+

05%

0.

(

+

)

±

)

FS

05%

0.

0

±

200 W

W

10 m

)

FS

1%

0.

+

1%

0.

(

±

)

FS

2%

200 W

3 A

3.

5 A

16.

500 V

185 ºF

3 A

15 A

Ω 10 m

300 m

Ω

M

1

110 V/220 V ±10%, 50/60 Hz

32 ºF to 104 ºF (0 °C to 40 °C)

14 ºF to 140 ºF (-10 °C to 60 °C)

Indoor use,

EN61010-1:2001, EU Low Voltage Directive 2006/95/EC

0 8

1

6

8

FS

0

–

0

)

0

0

0

(

±

0.

V

8

1

–

0

V

0

2

1

–

V

m

1

.

V

m

1

%

5

2

0

.

0

+

%

5

A

2

1

–

0

A

0

2

1

–

A

m

1

A

m

0

1

+

05%

0.

(

)

FS

1%

0.

750 W

760 W

2 A 3.

13.

132 A

130 V

C)

85 °

(

12 A

120 A 30 A

0 V

120 m

300

kΩ

Ω

≤

95%

1

6

5

–

5

m

1

m

0

1

3

–

3

–

m

1

.

m

1

05%

0.

05%

3 A

33 A

530 V

3 A

M

1

6

1

W

6

–

0

5

–

0

1

0

1

–

0

–

0

1

.

0

1

0.

(

±

05%

0.

1200 W

1250 W

6.

66 A

530 V

6 A

60 A

60 m

1

5

m

m

6

6

m

m

05%

6 A

M

V

0

V

0

0

V

V

A

A

0

A

A

+

)

FS

Ω

Ω

4 8

1

6

2

V

0

V

0

0

V

V

A

A

0

A

A

+

)

FS

8

V

8

1

–

0

V

0

2

1

–

0

V

m

1

.

0

V

m

1

A

4

2

–

0

A

0

4

2

–

0

A

m

1

A

m

0

1

+

05%

0.

(

±

)

FS

1%

0.

1500 W

100 m

)

FS

2%

0.

+

2%

0.

(

±

1550 W

4 A

26.

264 A

130 V

24 A

240 A

Ω

Ω

Ω

6 m

300

Ω

k

Electromagnetic

compatibility

ions (W x H x D)

Dimens

Weight

Standard accessories

Optional accessories

7

v081215

Directive 2004/108/EC, EN 61000-3-2:2006, EN 61000-3-3:1995+A1:2001+A2:2005

eets EMC

M

8.5” x 3.5” x 15.2” (218 x

9.9 lbs (4.5 kg)

TLPWR1 high current test leads, IT-E151 rackmount kit (models 8600, 8601, and 8602 only)

EN 61000-4-2/-3/-4/-5/-6/-11, EN 61326-1:2006

90 x 387 mm)

19” x 5.8” x 24.5” (485 x 147 x 621 mm)

User manual, power cord, certificate of calibration & test report

54 lbs (24.6 kg)

Three-Year Warranty

www.bkprecision.com

Loading...

Loading...