Page 1

Page 2

Contents

1 General Information 5

1.1 Product Overview 5

1.2 Package Contents 5

1.3 Product Dimensions 6

1.4 Rackmount Installation 6

1.5 Front Panel Overview 6

1.5.1 Combination Keys 6

1.6 Rear Panel Overview 8

1.7 Display Overview 8

2 Getting Started 10

2.1 Input Power 10

2.2 Fuse Requirements 10

2.2.1 Fuse Replacement 10

2.3 Input Connections 11

2.4 Preliminary Check 11

2.4.1 Verify AC Input Voltage 11

2.4.2 Self-test Errors 11

2.4.3 Input Check 12

2.4.4 Check Model and Firmware Version 12

3 Front Panel Operation 13

3.1 Local Mode/Remote Mode 13

3.2 Constant Current (CC) Mode 13

3.2.1 Congure CC Parameters 13

3.3 Slew Rate Measurement and Actual Transition time 14

3.4 Constant Voltage (CV) Mode 14

3.4.1 Congure CV Parameters 14

3.5 Constant Power (CW) Mode 14

3.5.1 Congure CW Parameters 14

3.6 Constant Resistance (CR) Mode 15

3.6.1 Congure CR Parameters 15

4 Front Panel Operation 16

4.1 Local Mode/Remote Mode 16

4.2 Constant Current (CC) Mode 16

4.2.1 Congure CC Parameters 16

4.3 Slew Rate Measurement and Actual Transition time 17

4.4 Constant Voltage (CV) Mode 17

4.4.1 Congure CV Parameters 17

4.5 Constant Power (CW) Mode 17

4.5.1 Congure CW Parameters 17

4.6 Constant Resistance (CR) Mode 18

4.6.1 Congure CR Parameters 18

4.7 CR-LED Test Function 18

4.7.1 Setup 18

5 Rear Panel Functions 19

5.1 Remote Sensing 19

5.2 External Triggering 19

5.3 Current Monitoring (I Monitor) 20

2

Page 3

6 Advanced Functions 21

6.1 Short Operation 21

6.2 Short-circuit Analog Function 21

6.3 Transient Operation 21

6.3.1 CC Mode 22

6.3.2 CV, CW, and CR modes 22

6.4 LIST Operation 22

6.4.1 Congure List 23

6.4.2 Run List 23

6.4.3 Disable List Mode 24

6.5 Battery Test Function 24

6.5.1 Test Conguration 24

6.5.2 Enable Battery Test Mode 25

6.5.3 Recall Battery File 25

6.5.4 Start Battery Test 25

6.6 Program Mode 25

6.6.1 Example: Small AC/DC power supply test 25

6.6.2 Start Auto Test File 30

6.6.3 Recall Test File 30

6.7 Measurement of Voltage Rise Time 30

6.7.1 Set initial Voltage and Final Voltage 30

6.8 Ripple Function 31

7 Conguration Functions 32

7.1 VON Function 32

7.2 Menu Operation 32

7.3 System Menu 32

7.4 Menu Options 32

7.5 System Menu (System) 33

7.6 Cong Menu 34

8 System Settings 35

8.1 Run Recall Edit 35

8.2 To recall the settings 35

8.3 To run the OPP test 35

8.4 Key Lock 35

8.5 Restore Factory Default Settings 36

8.5.1 Congure Power-On State 36

8.5.2 Load On Knob 37

8.5.3 Congure Trigger Source 37

8.5.4 Save/Recall Instrument Settings 37

8.5.5 Select Storage Group 38

8.5.6 Save Settings 38

8.5.7 Recall Settings 38

8.5.8 Display Input On Timer 39

8.5.9 Remote Interface Setup 39

8.5.10 RS-232 39

8.5.11 CONFIG Menu 40

8.5.11.1 Von Operation 40

8.5.12 Congure Protection Settings 40

8.5.13 PROTECT MENU 40

8.5.14 Max-P A-Limit P-Limit Time 40

8.5.15 Overcurrent Protection (OCP) 41

8.5.16 Overpower Protection (OPP) 42

8.5.17 Recall OPP File 43

3

Page 4

8.5.18 Overvoltage Protection (OVP) 44

8.5.19 Overtemperature Protection (OTP) 44

8.5.20 Reverse Voltage Protection (LRV/RRV) 44

8.5.21 Congure Timed Input 44

8.5.22 Measurement Congurations 45

8.5.23 CR LED Function 46

8.5.24 Remote Sensing 46

8.5.25 External Triggering 47

8.5.26 Current Monitoring (I Monitor) 47

9 Protection Functions 48

9.1 OCP Test Function 48

9.2 OPP Test Function 49

9.3 OPP TEST 49

9.4 Over Voltage Protection (OVP) 49

9.5 Over Current Protection (OCP) 50

9.6 Over Power Protection (OPP) 50

9.7 Over Temperature Protection (OTP) 50

9.8 Reverse Voltage Protection (LRV) 51

10 Remote Operation 52

10.1 Interface Connection 52

10.2 Serial Interface 52

10.2.1 GPIB 52

10.2.2 USBTMC 52

10.2.3 Remote Commands 52

11 Troubleshooting Guide 53

11.1 General 53

11.2 Remote Control 53

11.3 Error Information References 53

11.4 Exception handling 53

12 Service Information 55

13 LIMITED THREE-YEAR WARRANTY 56

4

Page 5

General Information

1.1 Product Overview

The 8500B Series DC Electronic Loads are versatile instruments used for static and dynamic testing of DC power supplies,

batteries, DC-to-DC converters, battery chargers, and other applications including fuel-cell, and solar cell test. Primary

modes include constant voltage (CV), constant current (CC), constant resistance (CR), and constant power (CW). A

wide range of dynamic loading applications can also be simulated through user-programmable slew rates, load levels,

duration, and conducting voltage. Further, transient, list mode, battery mode, and LED modes further extend testing

capabilities. Versatile triggering options allow the dynamic load behavior to be synchronized with other events. The DC

load is remotely programmable via the TTL serial interface. This interface requires 0-5V signal levels and can connect

to typical serial ports via an adapter such as the IT-E132B.

Features:

• CC/CV/CR/CW operating modes

• List mode

• Transient mode

• Measurement speed up to 40 kHz

• Remote sense function

• Battery test function

• OCP and OPP automatic test

• CR-LED function

• Store/recall up to 100 setups

• Analog current monitoring

• Adjustable slew rate in CC mode

• OVP/OCP/OPP/OTP and reverse voltage protection

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from the shipping carton,

and check for any obvious signs of physical damage that may have occurred during transportation. Report any damage

to the shipping agent immediately. Save the original packing carton for possible future reshipment. Every instrument is

shipped with the following contents:

• 8500B series DC Electronic load

• IT-E132B USB to TTL adapter

• AC Power Cord

• Certicate of Calibration

• Test Report

5

Page 6

Verify that all items above are included. If anything is missing, please contact B&K Precision.

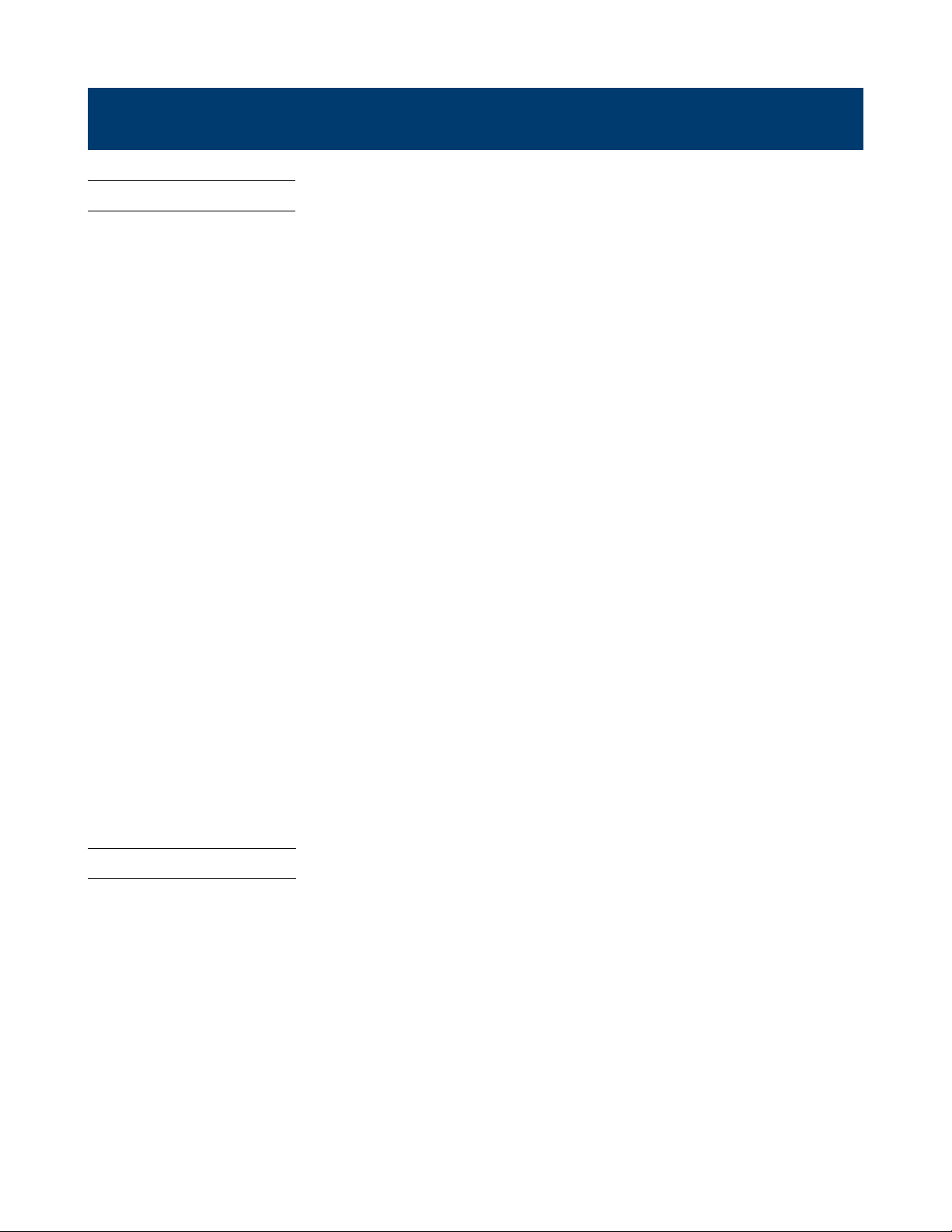

1.3 Product Dimensions

All models are designed to t in a standard 19-inch rackmount. The dimensions are shown in Figure 1.1.

Figure 1.1 External Dimensions - Half-rack models

1.4 Rackmount Installation

The instrument can be installed in a standard 19 inch rack. For half-rack models, the optional rackmount kit IT-E151 is

required. Figure 1.2 shows one of the half-rack sized units using the IT-E151 rackmount kit. This rackmount kit also

accomodates up to two half-rack models installed side by side.

Figure 1.2 Half-Rack sized Unit

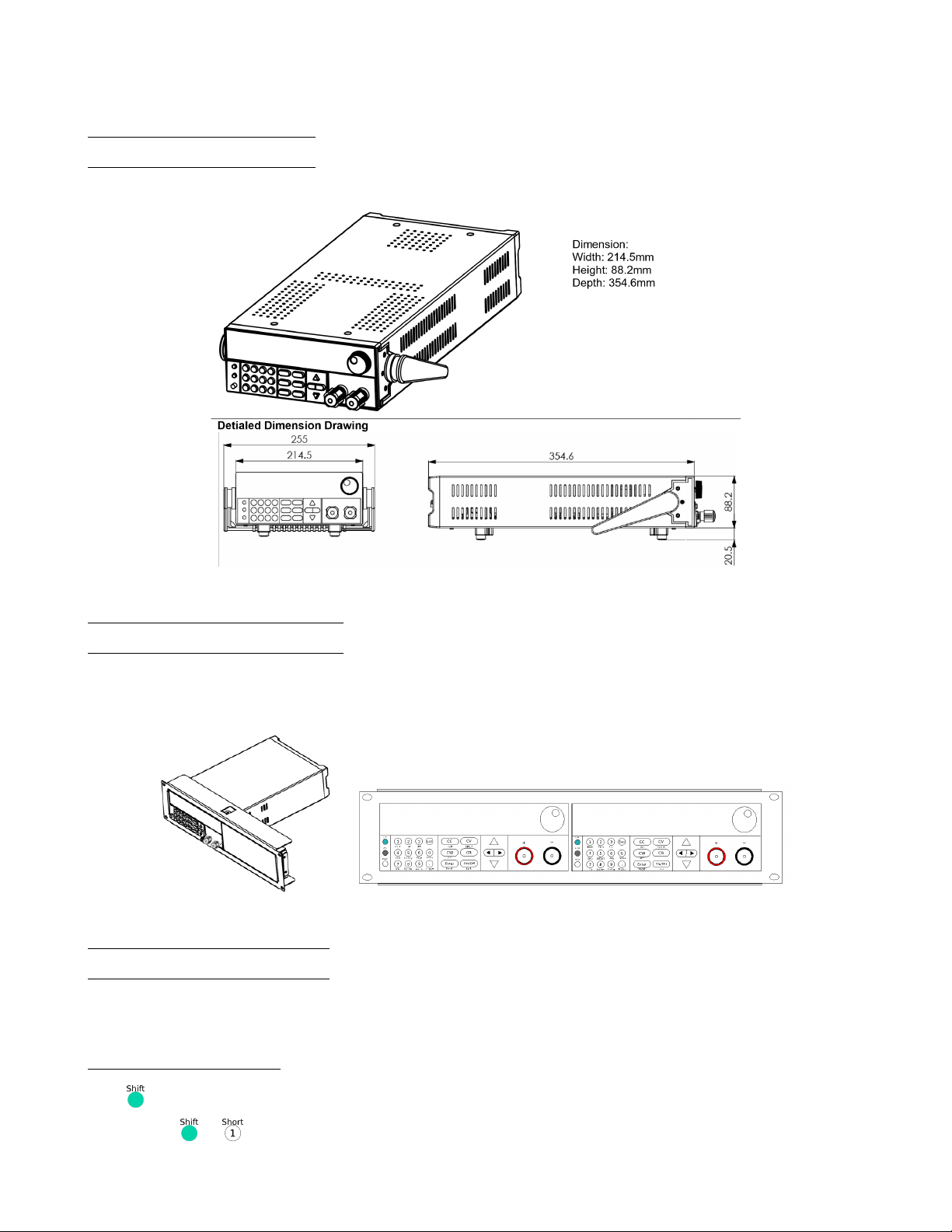

1.5 Front Panel Overview

See Figure 1.3.

1.5.1 Combination Keys

Press button rst and then other keys to activate the more advanced functions.

+ Turn short circuit on or off.

6

Page 7

Item Description

1 VFD Display

2 Power Switch and Function Keys

3 Numeric Input and Advanced Functions

4 Mode keys and Input Control

5 Navigation Keys

6 Input Terminals

7 Rotary Input Knob

Figure 1.3 Front Panel

+ Start or stop transient condition.

+ Set LIST operation parameters.

+ Store the DC Load state in non-volatile memory.

+ Turn on or off battery testing function.

+ Enter auto test function.

+ Display product’s Model/SN/Version.

+ System menu setting

+ Congure menu setting

+ Press this button if you need a pause when runing an auto test le.

+ Cause an immediate trigger.

+ Enter OCP test function.

+ Set detailed parameters in CC/CV/CW/CRmode.

+ Enter OPP test function.

+ Recall the DC Load state from non-volatile memory.

+ Key lock function

7

Page 8

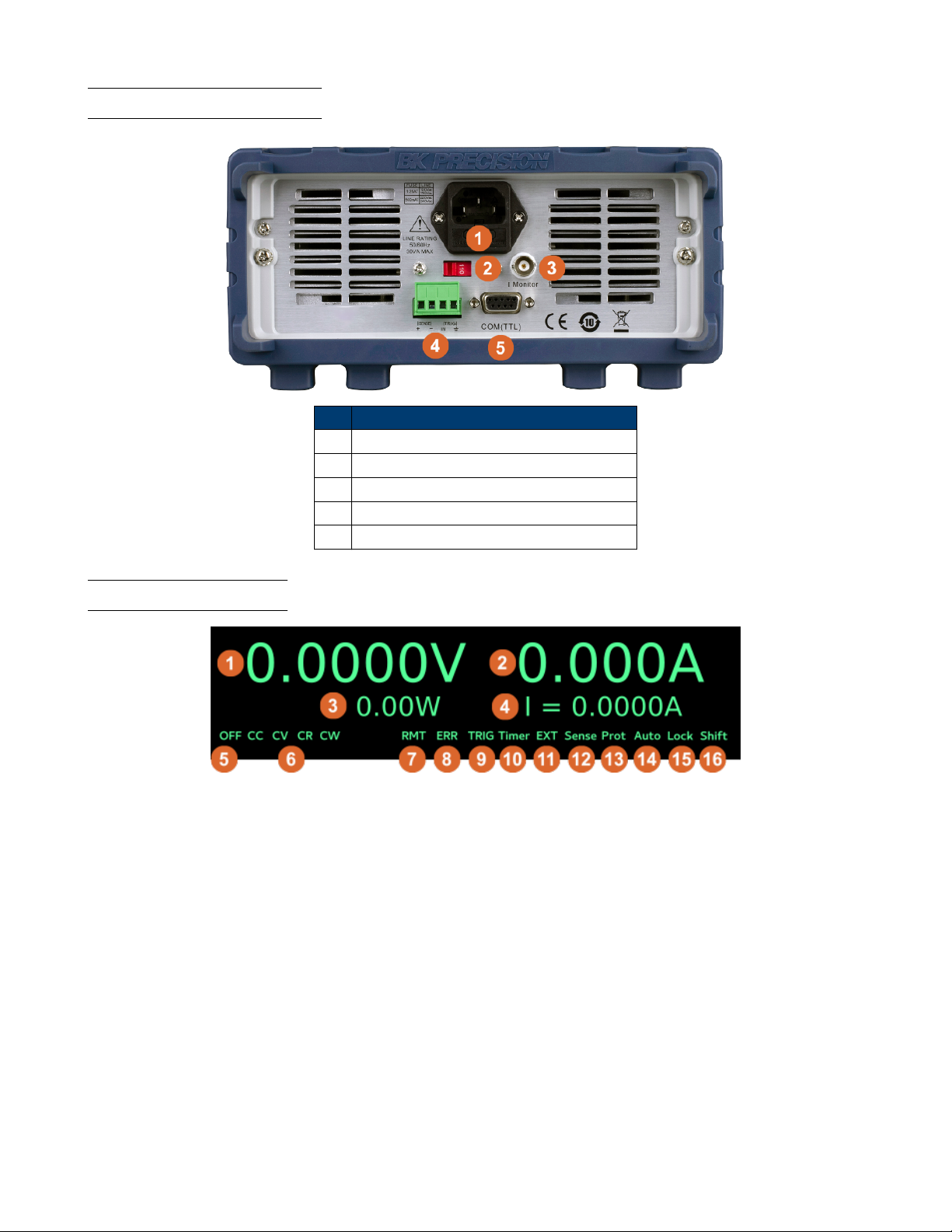

1.6 Rear Panel Overview

Item Description

1 Power Input and Fuse Holder

2 AC Voltage Switch

3 Current Monitor Output

4 Remote Sense and Trigger Input

5 TTL (5V) Communication DE-9 Connector

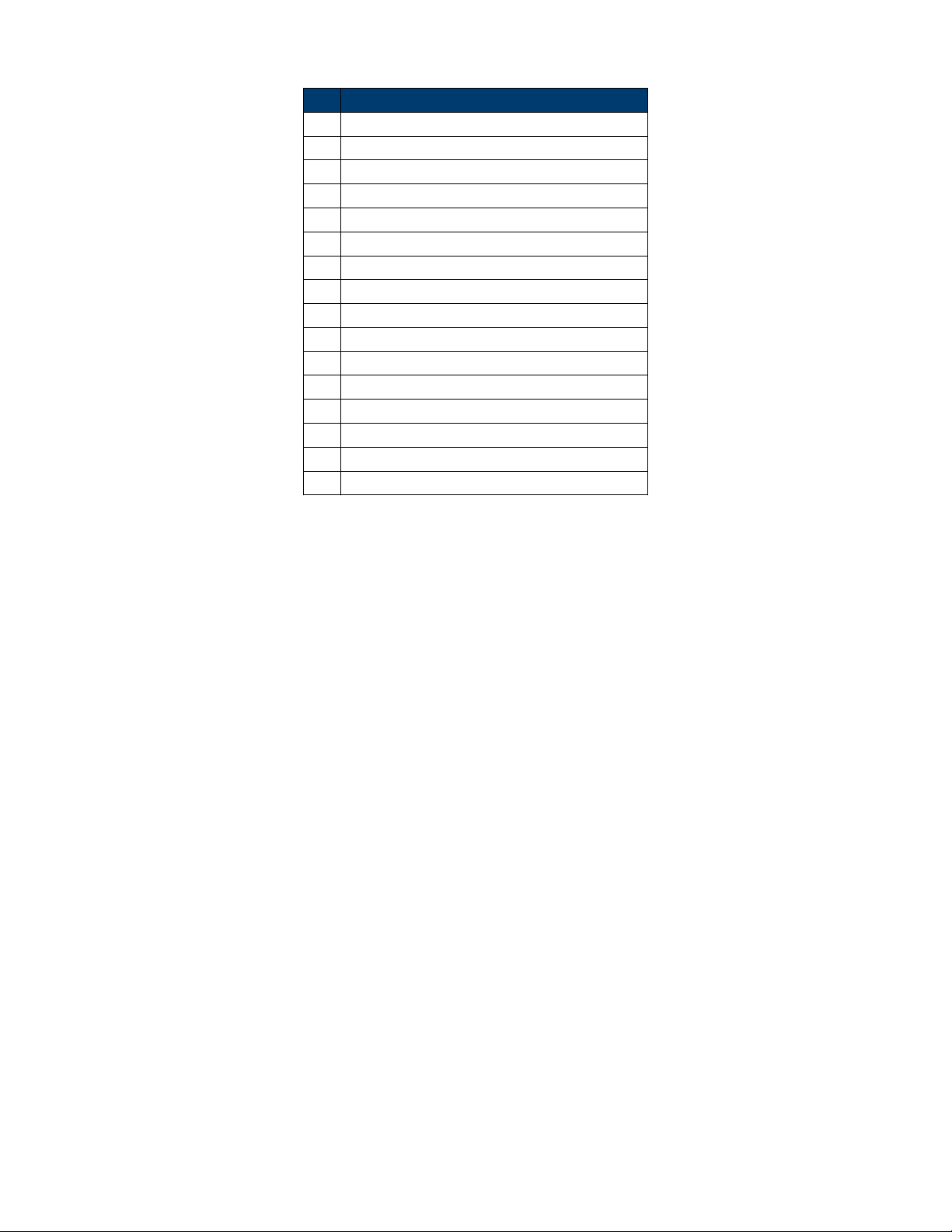

1.7 Display Overview

8

Page 9

Item Description

1 Measured Voltage

2 Measured Current

3 Measured Power

4 Set Value

5 Input Off indicator, lit when input is off

6 Operation mode indicators (CC, CV, CW, CR)

12 Remote control active indicator

13 Error indicator

14 Waiting for Trigger indicator

15 Timer indicator

16 External indicator

16 Remote Sense active indicator

17 Protection event indicator

18 Auto range

19 Key Lock indicator

20 Shift indicator

9

Page 10

Getting Started

Before connecting and powering up the instrument, please review and go through the instructions in this chapter.

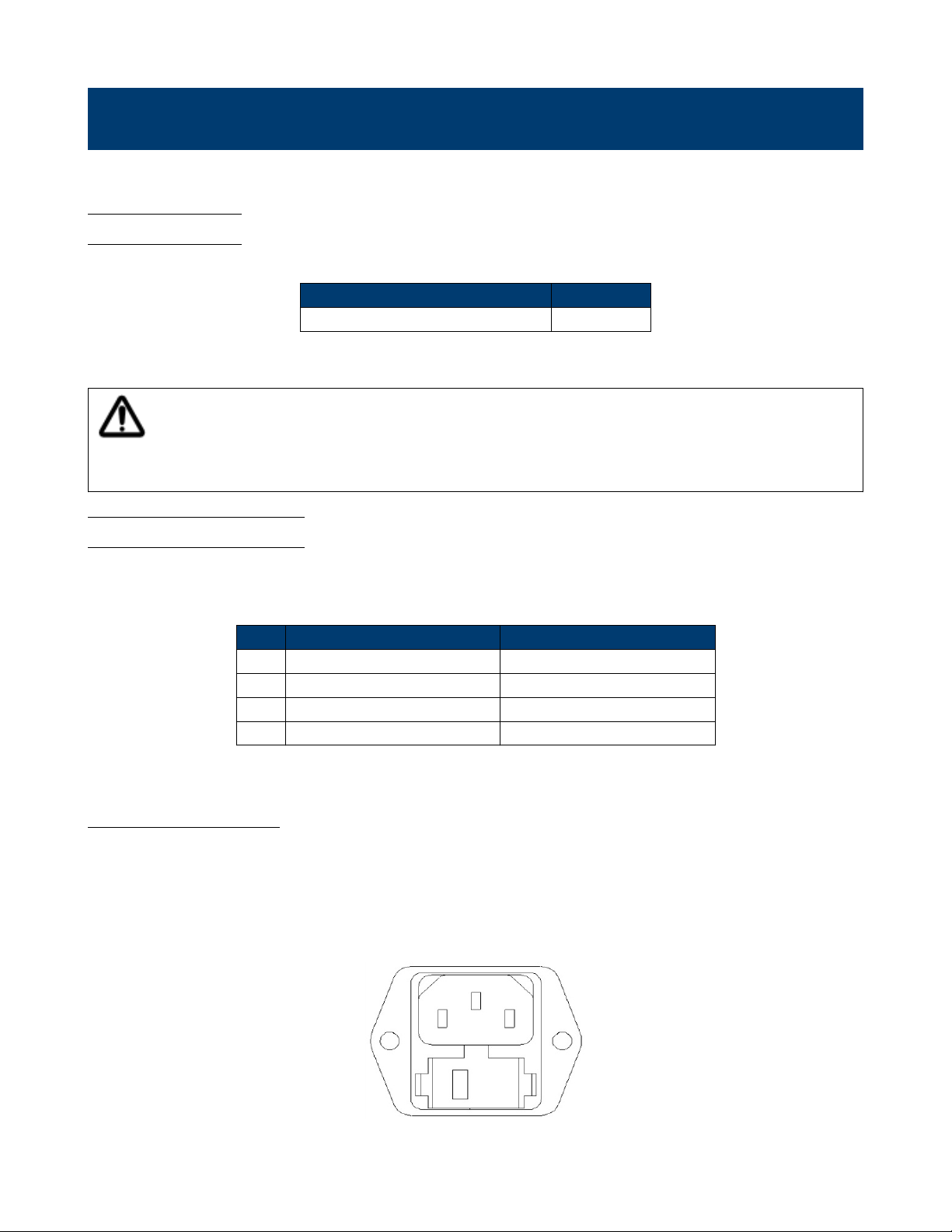

2.1 Input Power

The load has a selectable AC input that accepts line voltage input within:

Voltage Frequency

115 V (+/-10%) or 230 V (+/- 10%) 47 Hz – 63 Hz

Table 2.1 Input Power Requirements

Use the line voltage selector switch in the back to switch between 110 V and 220 V operation.

Disconnect all cables including the power cord from the instrument when changing the instrument’s line

voltage. After changing the line voltage setting, ensure the instrument has fuses of the proper ratings and types for

the selected line voltage before applying line power.

2.2 Fuse Requirements

An AC input fuse is necessary when powering the instrument. Below is a table of the fuse required for all models operating

with either 110 VAC or 220 VAC input. See Table ??. The fuses are 5mm x 20mm High Energy Slow Blow type

(ceramic casing with sand ll).

Model Fuse Specication (110 VAC) Fuse Specication (220 VAC)

8542B 1.25 A, 250 V 500 mA, 250 V

8500B 1.25 A, 250 V 500 mA, 250 V

8502B 1.25 A, 250 V 500 mA, 250 V

8510B 3.15 A, 250 V 1.6 A, 250 V

Table 2.2 Fuse Ratings

2.2.1 Fuse Replacement

Follow the steps below to replace to check the fuse:

1. Locate the fuse box next to the AC input connector in the rear panel, see Figure 2.1.

2. With a small at blade screwdriver, insert into the fuse box slit to pull and slide out the fuse box as indicated below.

3. Check and replace fuse (if necessary) for the desired line voltage operation.

Figure 2.1 Fuse Holder

10

Page 11

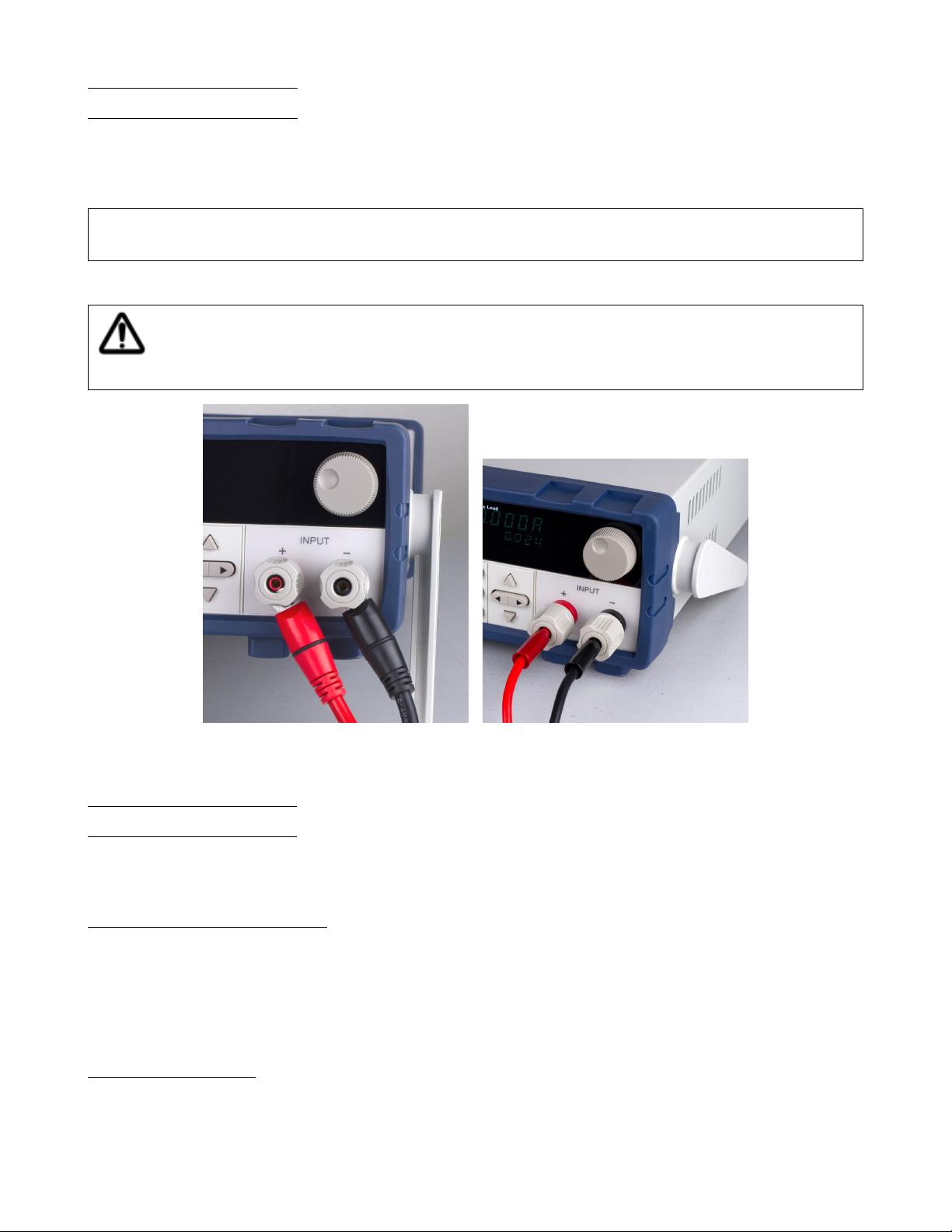

2.3 Input Connections

The main DC input terminal is a screw type binding post terminal located in the front panel, holes are included for

inserting wires, and the binding post also includes “banana jack” connections. Each connection allows for different

current levels. The “banana” input is capable of up to 10 A of current. Any more current is not recommended and could

lead to excessive connector heating, melting and worse.

Note: The screws on the terminals can be completely removed to allow for ring type adapters. The screw posts are

7mm in diameter.

Due to the high current rating of the DC load, proper wire sizes are necessary for safe connectivity and to prevent wires

from overheating.

Before connecting wires to the input terminals, turn OFF the load to avoid damage to the instrument and

the device under test (DUT).

High Current Connection Low (<10 A) Current Connection

Figure 2.2 Input Connections

2.4 Preliminary Check

Complete the steps in this section to verify that the load is ready for use.

2.4.1 Verify AC Input Voltage

Verify and check to make sure proper AC voltages are available to power the instrument. The AC voltage range must

meet the acceptable specication as explained in Section ??.

Connect AC power cord to the AC receptacle in the rear panel and press the power switch to the ON position to turn

ON the instrument. It will run through a self test procedure with the screen shown below:

2.4.2 Self-test Errors

Connect AC power cord to the AC receptacle in the rear panel and press the power switch to the ON position to turn

ON the instrument. Various elements of the system are checked during the power-on self test routine. If any occur, they

11

Page 12

are reported during the power-up procedure. See Section 11 for troubleshooting and error information details. During

self-test, the display displays “System Init”, and dots are displayed showing the test progress level.

2.4.3 Input Check

Follow the steps below to check that the load is operating correctly, and that the load elements (power transistors) are

not damaged. A DC power supply rated for at least 5V and 1 A is required for this check.

1. Connect the input terminal to a DC power supply and congure the supply to output 5 V and current limit to 1 A.

2. Power on the load. The display will show the “OFF” annunciator above the voltage display.

3. Turn on the DC power supply’s output. Observe the load’s measured voltage display, it should read approximately 5

V.

4. Press the “CC” button to enable the constant current load mode.

5. Use the keypad to enter 0.5 A. Press the Enter key to set the value.

6. The display should show CC = 0.500A on the bottom right.

7. Press “On/Off” to enable the load. The “On/Off” button should light up, and the “Off” indicator on screen should

disappear. The measured current should now display a value close to 0.5 A.

8. This setup veries that the load is drawing power correctly from the power supply.

If the load does not show 5 V, or shows signicant current draw from the connected power supply, the load may be

damaged and need service. If when the supply is connected, showing 5 V on the load’s display, and no current is drawn,

the load may be damaged and need service.

Note: If the load is not drawing power from the DC power supply, check all load protection limits and settings within

the menu to verify that the load is congured to allow drawing power at 5V, 0.500 A. Also, verify that the CC mode

parameters are setup to operate within the congured valid ranges by pressing +

If after checking all of the above, and verifying the power supply used for testing is not at fault, contact B&K for further

assistance.

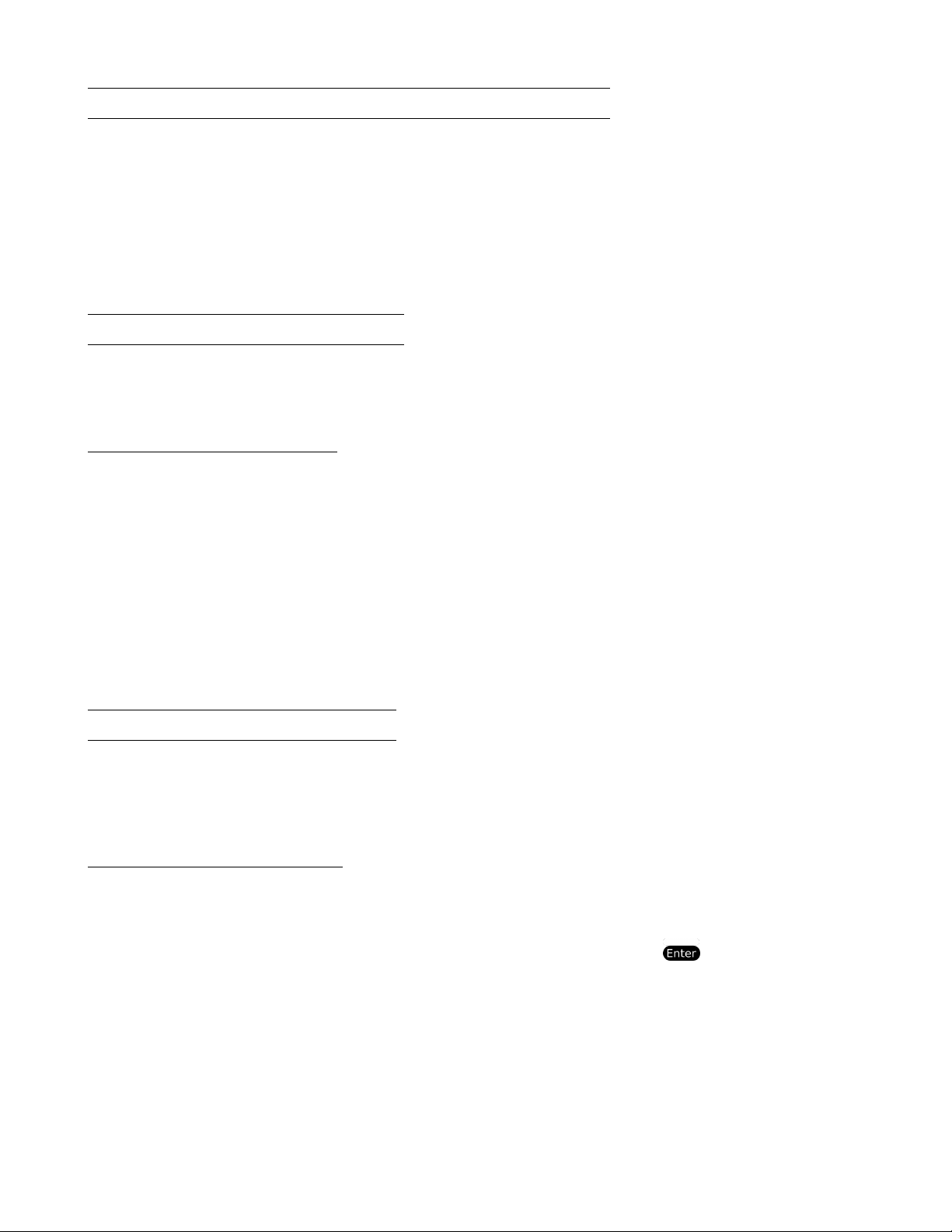

2.4.4 Check Model and Firmware Version

The model and rmware version can be veried by using the *IDN? query remote command. It can also be found from

the front panel:

1. Press and

2. The display will show the following:

3. This shows the model to be a BK8542B with Firmware: 1.45

4. Press (esc) to return to the normal display.

12

Page 13

Front Panel Operation

The electronic load provides the following modes:

• Constant current (CC) operation mode

• Constant voltage (CV) operation mode

• Constant resistance (CR) operation mode

• Constant power (CW) operation mode

3.1 Local Mode/Remote Mode

The 8500B series can either be operated locally or remotely. When in “Remote” mode, the RMT indicator will be lit.

When in this mode, the front panel of the load is disabled and all commands are issued via the serial interface. In order

to exit “Remote” mode and work in “Local” mode, press the “Local” button. This is the small grey button on the left

hand side of the numeric keypad.

3.2 Constant Current (CC) Mode

In this mode, the load will draw the specied current as long as the source is capable of delivering it. The load uses

transistors in parallel to implement the load circuit, and as such there are some limits. For example, the load has a nite

minimum resistance determined by the RdsOn of the transistors. Next, given the resistance limits, there is a limit to the

amount of current that may be drawn for a given voltage. The datasheet shows curves for this limit in the section called

“Low Voltage Operation”. Please refer to the datasheet for details for each model.

3.2.1 Congure CC Parameters

There are several parameters that should be setup prior to operating in CC mode. First, enable the “CC” mode of

operation by pressing the CC mode key. Next, enter the setup menu by pressing “Shift” and then the “CV” key. Above

the “CV” key, “Setup” is written. The following are the available menu items, scroll through them with the up/down

arrow keys or by entering a value and pressing enter.

Range This denes the maximum allowed current set value. Use this limit to protect against acciden-

tally entering excessive current values either from the keypad or dial.

High This is the voltage high limit for the automatic test mode, it does not apply otherwise. During

automatic test mode, the device under test (DUT) must be operating below the congured value

for the test to PASS upon completion. If the DUT operates above the congured value, the test

will FAIL upon completion.

Low This parameter refers to the voltage low limit for the automatic test mode. During automatic

test mode, the DUT must be operating above the congured value for the test to PASS upon

completion. If the DUT operates below the congured value, the test will FAIL upon completion.

Rise Up/ Fall Down These parameters dene the current slew rate of the load as it changes to a new programmed

value. The programmed slew rate takes effect immediately when set, so if the transient or triggered modes are active, it will apply immediately.

13

Page 14

3.3 Slew Rate Measurement and Actual Transition time

Current slew rate is dened as the change in current over time. A programmable slew rate allows a controlled transition

from one load setting to another. The actual transition time is dened as the time for the input to change from 10% to

90%, or 90% to 10% of the programmed current values. The graph below illustrates slew rate measurements.

Between the 10% and 90% region, the slew rate can be measured by observing the steepest slope portion. In case of very

large load changes, e.g. from no load to full load, the actual transition time will be larger than the expected (measured)

time. For this reason, the rmware allows the user to program slew rate values outside of the specied slew rate ranges.

The minimum transition time for all programmable slew rates is also limited in cases where the transition from one setting

to another is very small, due to bandwidth limitations of the load.

3.4 Constant Voltage (CV) Mode

In this mode, the electronic load will attempt to sink enough current to control the source voltage to the programmed

value.

3.4.1 Congure CV Parameters

There are several parameters that should be set up prior to operating in CV mode. Press so that it lights up, then press

) and to access Setup for CV mode. The setup menu will be shown:

Range This value will also act as a limit to how much voltage the load can be congured.

High This is the current upper limit for the automatic test mode. The system must be operating be-

low the congured value for the test to PASS upon completion. If the DUT operates above this

value, the test will FAIL.

Low This is the current lower limit for the automatic test mode. The system must be operating be-

low the congured value for the test to PASS upon completion. If the DUT operates below this

value, the test will FAIL.

3.5 Constant Power (CW) Mode

In this mode, the electronic load will consume a constant power. When input voltage increases, the input current will

decrease, while power (P = V*I) will remain the same. This is a sampled system, so the performance is not as fast as in

CC and CV modes.

3.5.1 Congure CW Parameters

There are several parameters that should be set up prior to operating in CW mode. Press

so that it lights up, then press )and to access “Setup” for CW mode. The setup menu will be shown:

The setup parameters are: Range, High (Voltage limit), and Low (Voltage limit). Use the

) keys to select each parameter, and use the numeric keypad to change the value. Press to conrm the change.

Range This value will also act as a limit the allowed power setting value.

High This parameter sets the upper voltage limit for the automatic test mode. If the voltage exceeds

this upper limit during the test, the test will fail.

High This parameter sets the lower voltage limit for the automatic test mode. If the voltage exceeds

this lower limit during the test, the test will fail.

14

Page 15

3.6 Constant Resistance (CR) Mode

In this mode, the electronic load approximates a resistor. The current draw is varied by the load according to the input

voltage. The performance of this mode is not as fast as in CC or CV mode. This is because it is a sampled system and

response to changing input takes a nite amount of time.

3.6.1 Congure CR Parameters

There are several parameters that should be set up prior to operating in CR mode. Press

so that it lights up, then press )and to access Setup for CR mode. The setup menu will be shown:

The setup parameters are: Range, High (Voltage limit), and Low (Voltage limit). Use the (arrow keys) key to select each

parameter, and use the numeric keypad to change the value. Press (enter) to conrm the change.

Range This value will also act as a limit the allowed resistance setting value.

High This parameter sets the upper voltage limit for the automatic test mode. If the voltage exceeds

this upper limit during the test, the test will fail.

High This parameter sets the lower voltage limit for the automatic test mode. If the voltage exceeds

this lower limit during the test, the test will fail.

15

Page 16

Front Panel Operation

The electronic load provides the following modes:

• Constant current (CC) operation mode

• Constant voltage (CV) operation mode

• Constant resistance (CR) operation mode

• Constant power (CW) operation mode

4.1 Local Mode/Remote Mode

The 8500B series can either be operated locally or remotely. When in “Remote” mode, the RMT indicator will be lit.

When in this mode, the front panel of the load is disabled and all commands are issued via the serial interface. In order

to exit “Remote” mode and work in “Local” mode, press the “Local” button. This is the small grey button on the left

hand side of the numeric keypad.

4.2 Constant Current (CC) Mode

In this mode, the load will draw the specied current as long as the source is capable of delivering it. The load uses

transistors in parallel to implement the load circuit, and as such there are some limits. For example, the load has a nite

minimum resistance determined by the RdsOn of the transistors. Next, given the resistance limits, there is a limit to the

amount of current that may be drawn for a given voltage. The datasheet shows curves for this limit in the section called

“Low Voltage Operation”. Please refer to the datasheet for details for each model.

4.2.1 Congure CC Parameters

There are several parameters that should be setup prior to operating in CC mode. First, enable the “CC” mode of

operation by pressing the CC mode key. Next, enter the setup menu by pressing “Shift” and then the “CV” key. Above

the “CV” key, “Setup” is written. The following are the available menu items, scroll through them with the up/down

arrow keys or by entering a value and pressing enter.

Range This denes the maximum allowed current set value. Use this limit to protect against acciden-

tally entering excessive current values either from the keypad or dial.

High This is the voltage high limit for the automatic test mode, it does not apply otherwise. During

automatic test mode, the device under test (DUT) must be operating below the congured value

for the test to PASS upon completion. If the DUT operates above the congured value, the test

will FAIL upon completion.

Low This parameter refers to the voltage low limit for the automatic test mode. During automatic

test mode, the DUT must be operating above the congured value for the test to PASS upon

completion. If the DUT operates below the congured value, the test will FAIL upon completion.

Rise Up/ Fall Down These parameters dene the current slew rate of the load as it changes to a new programmed

value. The programmed slew rate takes effect immediately when set, so if the transient or triggered modes are active, it will apply immediately.

16

Page 17

4.3 Slew Rate Measurement and Actual Transition time

Current slew rate is dened as the change in current over time. A programmable slew rate allows a controlled transition

from one load setting to another. The actual transition time is dened as the time for the input to change from 10% to

90%, or 90% to 10% of the programmed current values. The graph below illustrates slew rate measurements.

Between the 10% and 90% region, the slew rate can be measured by observing the steepest slope portion. In case of very

large load changes, e.g. from no load to full load, the actual transition time will be larger than the expected (measured)

time. For this reason, the rmware allows the user to program slew rate values outside of the specied slew rate ranges.

The minimum transition time for all programmable slew rates is also limited in cases where the transition from one setting

to another is very small, due to bandwidth limitations of the load.

4.4 Constant Voltage (CV) Mode

In this mode, the electronic load will attempt to sink enough current to control the source voltage to the programmed

value.

4.4.1 Congure CV Parameters

There are several parameters that should be set up prior to operating in CV mode. Press so that it lights up, then press

) and to access Setup for CV mode. The setup menu will be shown:

Range This value will also act as a limit to how much voltage the load can be congured.

High This is the current upper limit for the automatic test mode. The system must be operating be-

low the congured value for the test to PASS upon completion. If the DUT operates above this

value, the test will FAIL.

Low This is the current lower limit for the automatic test mode. The system must be operating be-

low the congured value for the test to PASS upon completion. If the DUT operates below this

value, the test will FAIL.

4.5 Constant Power (CW) Mode

In this mode, the electronic load will consume a constant power. When input voltage increases, the input current will

decrease, while power (P = V*I) will remain the same. This is a sampled system, so the performance is not as fast as in

CC and CV modes.

4.5.1 Congure CW Parameters

There are several parameters that should be set up prior to operating in CW mode. Press

so that it lights up, then press )and to access “Setup” for CW mode. The setup menu will be shown:

The setup parameters are: Range, High (Voltage limit), and Low (Voltage limit). Use the

) keys to select each parameter, and use the numeric keypad to change the value. Press to conrm the change.

Range This value will also act as a limit the allowed power setting value.

High This parameter sets the upper voltage limit for the automatic test mode. If the voltage exceeds

this upper limit during the test, the test will fail.

High This parameter sets the lower voltage limit for the automatic test mode. If the voltage exceeds

this lower limit during the test, the test will fail.

17

Page 18

4.6 Constant Resistance (CR) Mode

In this mode, the electronic load approximates a resistor. The current draw is varied by the load according to the input

voltage. The performance of this mode is not as fast as in CC or CV mode. This is because it is a sampled system and

response to changing input takes a nite amount of time.

4.6.1 Congure CR Parameters

There are several parameters that should be set up prior to operating in CR mode. Press

so that it lights up, then press )and to access Setup for CR mode. The setup menu will be shown:

The setup parameters are: Range, High (Voltage limit), and Low (Voltage limit). Use the (arrow keys) key to select each

parameter, and use the numeric keypad to change the value. Press (enter) to conrm the change.

Range This value will also act as a limit the allowed resistance setting value.

High This parameter sets the upper voltage limit for the automatic test mode. If the voltage exceeds

this upper limit during the test, the test will fail.

High This parameter sets the lower voltage limit for the automatic test mode. If the voltage exceeds

this lower limit during the test, the test will fail.

4.7 CR-LED Test Function

The Constant Resistance LED mode roughly simulates a diode characteristic. There are 2 main parameters that are set

to accomplish this, the overall resistance and diode threshold voltage (Vd). At input voltages above the threshold (Vd),

the resistance of the load decreases. For example, set the Vd to 1.6 V, R to 0.1 and connect a current limited power

supply. Set the power supply voltage limit to 5 V, and the current limit to 300 mA. When the input is enabled, the

voltage at the input will be approximately 1.6 V, and the current will be 300 mA. This is equivalent to a resistance of 16

Ohms, much larger than the set value of 0.1 Ohms. See Table 4.1.

Like in CR mode, a resistance value is also set. This value sets the slope of the diode characteristic. A 3 V VD, 0.1

Ohms, and 1.38 A results in 3𝑉 + 0.1Ω ∗ 1.38𝐴 = 3.18𝑉.

Voltage Current Equivalent Load Resistance

1.00 0 innite

1.58 15mA 105 Ohms

1.62 0.215 A 7.5 Ohms

1.63 0.3 5.4 Ohms

1.69 1 A (limit changed) 1.7 Ohms

Table 4.1 CR Mode example

4.7.1 Setup

Enable CR-LED mode via + . Use the arrow keys to move the ashing value “ON”. Press to conrm

and move on. The next screen shows the VD value. Enter the desired threshold voltage and press . CR LED mode

is now setup.

Note: As in CR mode, the control system speed can make loading switching power supplies problematic.

18

Page 19

Rear Panel Functions

Item Description

1 Power Input

2 Fuse Holder

3 AC Input Voltage Selection

4 Current Monitor Output

5 Remote Sense/Trigger Input

6 Remote Interface

Figure 5.1 Rear Panel

5.1 Remote Sensing

Remote sensing is used to counteract the effect of lead resistance. For example, if you connect a power supply to the DC

Load, the voltage at the power supply’s terminals will not be the same as the voltage at the DC Load’s terminals if there

is a current owing because of the nite resistance from the wires. Using remote sensing, you can sense the voltage at

the power supply’s terminals, effectively removing the effect of the voltage drop in the connection wire.

Connect the “+” and “-” terminals at the rear of the unit to the power source.

Note:To reduce interference, twist the sense lines together and run together with the wires connecting the load to

the source.

Note:When using remote sensing, the power displayed by the instrument includes both the power dissipated inside

the instrument and the power dissipated in the leads from the power supply to the DC Load’s input terminals.

1. Press + to enter the conguration menu.

2. Use the arrow keys to navigate to the “SENSE” menu item. Press to enter the menu.

3. Use the arrow keys to select the desired value “ON, or OFF” and press to conrm the setting.

4. When active, the “Sense” indicator will show on the display.

5.2 External Triggering

An external trigger is a TTL low signal applied to the Trigger connection on the back panel. This TTL signal must last

for more than 5 ms. A trigger applied to this input can be used to change settings (voltage, current ,resistance), toggle

between settings in transient-toggle mode, or generate a pulse in pulse mode.

1. Press + .

2. Use the arrow keys or the knob to navigate to the “TRIGGER” menu item.

3. Select “EXTERNAL” and press to conrm the setting.

19

Page 20

5.3 Current Monitoring (I Monitor)

The current monitor output, the bnc connector, outputs a scaled voltage relative to the current owing. The relationship

is 𝑉

𝑜𝑢𝑡

= 10𝑉 ∗

monitor output will be 10𝑉 ∗

𝑐𝑢𝑟𝑟

. For example, the 8542B maximum current is 30 A. When a current of 1 A is owing, the current

𝑚𝑎𝑥

1

= 333𝑚𝑉.

30

Note: The output accuracy is approximate. Verify the scaling relationship for each unit.

20

Page 21

Advanced Functions

In addition to the 4 general modes of operation, there are a number of other more application specic functions. These

functions enable more advanced testing.

6.1 Short Operation

The electronic load can simulate a short circuit at its input. During front panel operation, press + to switch the

short on/off state. Short operation will not affect the present setting. When turning off the short state, the load returns

to the original set state. The actual value of the electronic load in short operation depends on the mode and range that

is active when the short is turned on. In CC or CR mode, the maximum short current is typically 110% of the current

range. In CV mode, short means setting the load’s constant voltage to be 0 V. In short operation mode, you can measure

the maximum short current (Amax) or DC current (ADC) of the power source to be measured. You can set this function

via the Conguration menu.

6.2 Short-circuit Analog Function

Short circuit simulation and short circuit current measurement:you may press [ Shift ] + [ 1 ] botton to emulate a short

state.It can be used to check whether the tested instrument’s short protection is avaiable.

In short mode,the DC load will draw maximum current from the DC supply in any of the four operation modes(CC,CV,CW

or CR).In CC,CV,or CR mode,you may press [ Shift ] + [ 1 ] to stop short.The DC load will return to its previous

operation.However,in CW mode,the short current will continue to be drawn.To stop the short,you must press the [On/Off]

key after you press [ Shift ] + [ 1 ]. When emulating a Short in CC, CW or CR mode, the maximum allowable short

current is equal to the 110% of current range. Under CV mode, short circuit current is equivalent to that constant

voltage value of load is 0 V.

6.3 Transient Operation

Transient mode periodically switches between two load levels. There are three different transient modes:

Continuous Generates a respective pulse stream that toggles between two load levels.

Pulse Generates a load change that returns to its original state after some time period.

Toggle Generates a repetitive pulse stream that toggles between two load levels. It is similar to contin-

uous mode except that the transient points are controlled by explicit triggers instead of an internal transient generator.

Depending on the selected Trigger Source from within the “SYSTEM” menu, the operation may start immediately.

To run the transient operation, rst press to enable the input. Then, send a trigger to start the operation. If Trigger

Source is set to “Manual”, press and then (or press ) to send a trigger. Refer to “Congure Trigger Source” in section

“SYSTEM Menu” to congure the Trigger Source.

Note: The number next to “TRAN” on display will count each transition. It can only count up to 65535 transitions,

after which it will reset to 0 and start over.

To disable transient operation, rst press to disable the input. Then, press and (or press ). Select “Off” and press to

conrm.

21

Page 22

1. First, select the load’s mode of operation, which will determine which type of transient operation will be congured.

Press or to select between CC, CV, CW, or CR mode. Verify the selection by the backlight behind its corresponding

button, which will be lit when selected.

2. Enable transient mode from the “Tran” menu. This is accessed via “ + ”.

3. Select the transient mode “Continuous”, “Pulse”, or “Toggle”. Press .

6.3.1 CC Mode

In Constant Current mode, the congurable parameters are the following:

Mode Continuous, pulse, or toggle

Up The rising edge current slew rate in A/us.

Down The falling edge slew rate in A/us.

Level A, Level B The 2 current levels applied.

In Continuous mode, the following are also set:

Freq The transient cycle frequency.

Duty The duty cycle or percentage of time the load will be at either level (A/B). The percentage de-

nes the ratio of the B level to the cycle. So for 75% and 1 Hz, the B level will be on for 750

ms and the A level 250 ms.

In Pulse Mode, the following is also set:

Width The transient frequency

6.3.2 CV, CW, and CR modes

In Constant Voltage, Power and Resistance modes, the congurable parameters are the following:

Mode Continuous, pulse, or toggle

Level A, Level B The 2 levels.

In Continuous mode, the following are also set:

Freq The transient cycle frequency.

Duty The duty cycle or percentage of time the load will be at either level (A/B). The percentage de-

nes the ratio of the B level to the cycle. So for 75% and 1 Hz, the B level will be on for 750

ms and the A level 250 ms.

In Pulse Mode, the following is also set:

Width The transient frequency

6.4 LIST Operation

List mode allows you to generate a complex current sequence. Moreover, the mode change can be synchronized with an

internal or external signal to accomplish dynamic and precise test. A list le includes following parameters: le name,

step count (range 2-84), step width (0.00005 s - 3600 s), step value and slope. The list le is saved in memory for later

recall. There is storage for up to 7 list programs. In list mode, the load starts the list following a trigger signal. The list

will continue run to completion or until another trigger signal is received.

22

Page 23

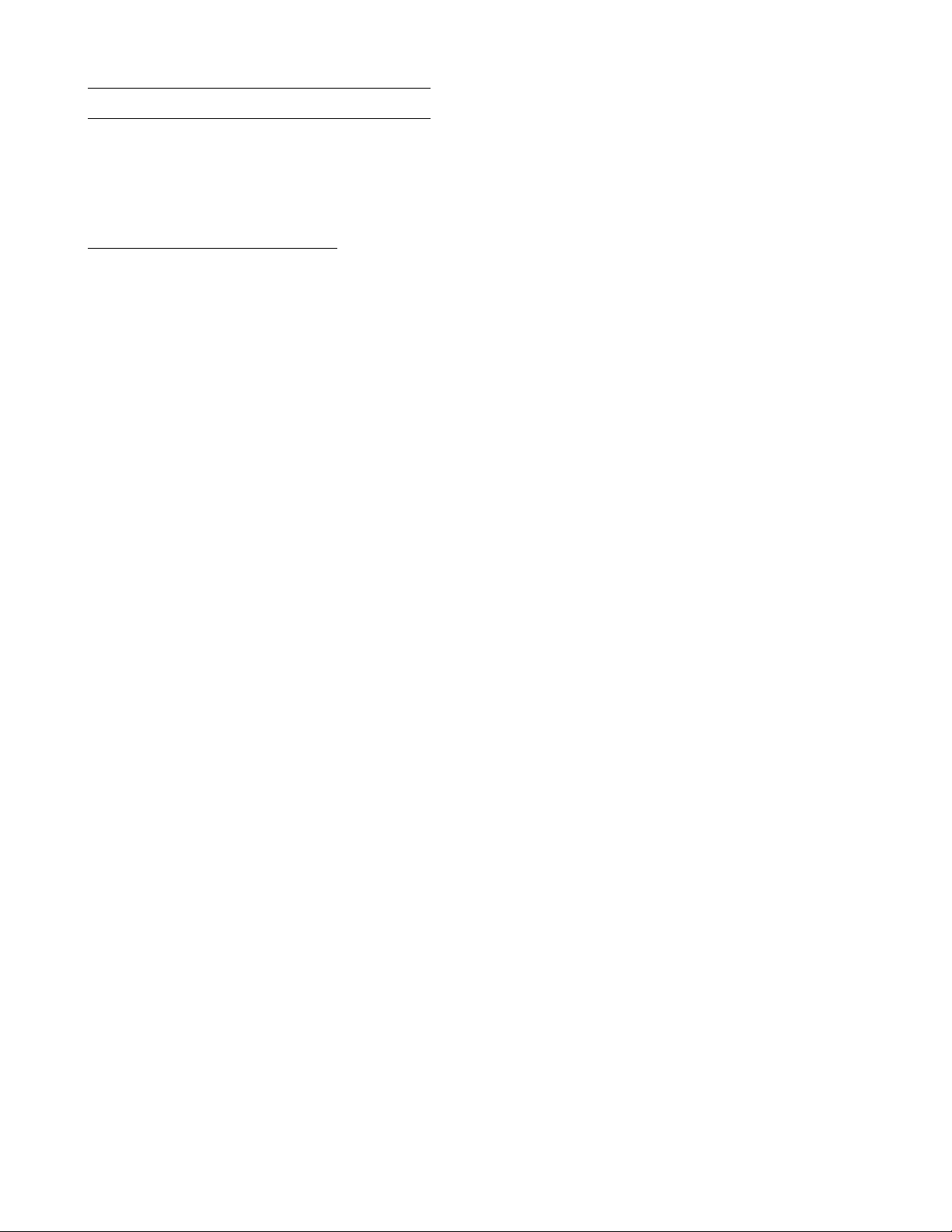

Figure 6.1 List Mode Current Waveform

6.4.1 Congure List

Lists are run exclusively from internal memory only. As in other menus, an active eld is denoted by an underline cursor

or ashing. To enter a list into memory, complete the following:

1. Press + .

2. Set the rst eld in the menu to “OFF”. If the eld is set to “ON”, press to change the value to “OFF”.

3. Move the selected eld via the buttons to the “EDIT” (shown as EDI) eld and press to start editing a

List. If nothing happens, ensure the rst eld is set to “OFF”.

4. Set the current range.

5. Set the number of steps in the list. This is a value between 2 and 84.

6. Set the rst step’s current, slew rate, and step time.

7. The next step in the list will prompt automatically. Enter the values for each step in the same way.

8. When each step is entered, the system prompts for the number of times to run the sequence. A 1 in this eld means

the sequence will run only once.

9. Enter the list le location to store the newly created list.

The list is now saved and may be recalled.

6.4.2 Run List

1. Select the list to run:

1. From the “List” menu, select “CALL” and press .

The load prompts for the list to recall (1 through 7).

2. Enter the list number and press to recall it.

2. Enable List mode by selecting the “Off” menu item and press .

The “OFF” changes to “ON” and the “Trig” indicator lights.

23

Page 24

3. Use the button to go back to the normal display. The load is now ready and waiting for a trigger.

4. Press to enable the input, and send a trigger to start the list program.

If Trigger Source is set to Manual, press + to send a trigger. See Section ?? for details about triggers.

Note: The number next to LIST on the display shows the current running step number. When the list ends, it will

change back to “0”.

Note: At the end of a list operation, the load’s input remains on the settings of the last step value.

6.4.3 Disable List Mode

1. Disable the input via the or remote command.

2. Press +

3. Select the “ON” item and press to change the value to conrm. The “Trig” indicator will disappear.

6.5 Battery Test Function

The 8500B series products include battery test capabilities. This function provides a constant current load. The test

records the time, and charge consumed in Amp-hours. Three independent conditions are available to customize the test.

These are voltage, charge (Ah), and time.

Stop conditions are not optional. If one of the conditions is not required for a test, then the value should be set so

that it will not trigger. For example, if the capacity is unimportant to the test, set the value to maximum (999.999

Ah).

The run the battery test function a conguration is loaded into memory, the battery test mode is then enabled, and

nally the mode is started by a trigger signal.

6.5.1 Test Conguration

To congure a battery test, the “RUNMODE” must be set to “NORMAL”. See Section ?? for details.

1. Press +

2. The battery test parameters menu will open.

3. Set the parameters of the test:

Range The maximum current allowed. Set to a value equal to or higher than the desired discharge

current.

Current The discharge current for the test.

Stop Voltage The lower limit voltage for the battery.

Stop Cap (Capacity) The maximum capacity to discharge. For example, 50% discharge of a 10 Ah battery, this

would be 5 Ah.

24

Page 25

Stop Timer The maximum test time.

4. When the settings are entered, the last step is to set the memory location. Set the value (1 - 10) and press to

complete the conguration entry.

6.5.2 Enable Battery Test Mode

1. Press + to enter the system menu.

2. Use the keys to navigate to the ‘RUNMODE’ setting.

3. Press to enter the setting menu.

4. Use the to scroll through the different settings and select “BATTERY”.

5. After setting the mode, exit the menu using the .

Battery test mode is now enabled.

6.5.3 Recall Battery File

Press + to select program le, the panel displays “RECALL BATTERY 1”. Enter the le name (1-10) and

press button.

6.5.4 Start Battery Test

With the battery mode enabled, the load will work in a limited CC mode. If the battery test conditions are met, the input

may be enabled, and the battery mode test current will be drawn. If the limits are not met, the input will automatically

turn off.

To start a battery test, send a trigger to the load. In manual trigger mode, press the . The battery test will automatically

terminate when the stop conditions are met.

6.6 Program Mode

Test les are a generalization of lists. They generate a sequence of tests using different modes, mode parameters, and

durations. They are useful for executing a set of tests on a device, then displaying pass/fail results. Up to 10 groups of

test les can be dened. Each le contains 10 steps.

6.6.1 Example: Small AC/DC power supply test

Suppose we have a small AC to DC power supply (a “wall-wart”) and we want to set up an acceptance test for a number

of these devices.

1. Set the DC load to constant current mode to draw the rated current of 1.2A from the device. The output voltage of

the device at the rated current must be between 4.4V and 4.6V.

2. Set the DC load to constant voltage 3V. The output current of the device is between 2A and 3A.

3. When the device operates into a short, the supplied current must be larger than 3.0 A.

Steps Operation VFD Display

25

Page 26

1. Press + (Prog).

ACTIVE =0987654321

2. Press , and press enter to conrm.

ACTIVE =0987654YYY

3. Select the step that should pause during the test. When paused, press [downarrow] continue the test.

PAUSE=NNNNNNN32Y

4. Step 3 short circuit testing, press , and press to conrm.

SHORT =NNNNNNNY21

5. Set Ton for the rst step if you want to load on for 2S, press , and then press to conrm. T-on range 0-60S.

SEQ01 ON =2S

6. Set Toff for the rst step, if you want to load off 2S, press , and then press to conrm.

SEQ01 OFF =2S

7. Set testing delay time, 0-60S e.g. 1S, press [1].

SEQ01 P/F =1S

8. Set Ton for the second step, if you want to load 2S, press , then press Enter to conrm

SEQ02 ON =2S

9. Set Toff of the second step, if you need 2S, press , and then press to conrm.

SEQ02 OFF =2S

10. Set testing delay time of the second step, e.g. 1S, press

SEQ02 P/F =1S

11. Set Ton for the third step, if you want to load on 3S, press , then press to conrm

SEQ03 ON =3S

12. Set Toff of the third step, if you need 2S, press , then press to conrm.

SEQ03 OFF =2S

13. Set testing delay time of the third step, e.g. 2S, press .

SEQ03 P/F =2S

14. set start voltage. Please refer to “function of auto start voltage”.

AUTO START=0.000V

15. Set stop condition

STOP COMP FAILURE

Function of Auto Start Voltage:

1. Auto start=0V.

Auto test le start to run when receive a trigger signal by pressing +

2. Auto start is not equal to 0V (Take 2V as an example)

In this conditionuser only need to connect the charger to input termianls of E-load. The unit can auto start to run

test le when detect a rising edge from 0-2V. Auto start voltage is not suggested to be a big value.2V is suitable.

name:

or providing a external trigger signal.

images/trigButton

file:

images/trigButton

state:

unknown

26

Page 27

Ton, Toff and Tpf (P/F) Relation:

Tpf the delay time for a step

15. Set stop conditions: COMP means stop test when all the steps are completed, FAILURE means stop test when the

testing fails. Press to conrm.

STOP COMP FAILURE

16. Select the test le to link if you’d like to. The linked le must be saved before. 0 stands for not linking to other les.

Press key to conrm.

CHAIN PROGRAM =0(0-10)

Program/Save

PROGRAM

Sequence 1

Save Group 1 2 3 4 5 6 7 8 9 10

PROGRAM

Sequence 2

Save Group 11 12 13 14 15 16 17 18 19 20

PROGRAM

Sequence 10

Save Group 91 92 93 94 95 96 97 98 99 100

17. Save the edited les in EEPROM, you can save up to 10 groups of les, e.g please press to save the edited le

in group 1, and then press to conrm.

SAVE PROGRAM =1(1-10)

18. Select a operation mode and then press +[CV] to set related parameters

10.0000V 0.0000A

0.00W CC=1.000A

Locations

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

19. Edit the three steps of the test le, details refer to below procedure. After all the steps are set , Press to exit

setup, and then press + to save.

You need to recall the test le before runing it

27

Page 28

Set the steps of a test le in the example

CC Mode, 1.2A, Voltage Range 4.4V-4.6V

1. Press [[Shift)+[CC] buttonand then [CV] (Setup) to enter the setting interface.

RANGE=30.000A

CC

2. Set the current rangepress to conrm.

RANGE =1.2A CC

3. set the upper limit of voltage, press to conrm.

HIGH=4.6V

CC

4. Set the lower limit of voltage, press to conrm.

LOW=4.4V

CC

5. Set the rise speed of current, press to conrm.

UP=1A/uS

CC

6. Set the fall speed of current, press to conrm.

DOWN=1A/uS

CC

7. Finish the setup

10.0000V 0.000A

0.00W CC=0.000A

CV Mode, 3V, Current Range 2A 3A

1. Press [CV] buttonpress to set related +[parameters]

RANGE=120.00V

2. Set the voltage rangepress to conrm.

RANGE=3.00V

3. set the upper limit of currentpress to conrm.

HIGH=3A

4. Set the lower limit of currentpress to conrm.

LOW=2A

5. Finish the setup

10.0000V 0.000A

0.00W CV=10V

The CW and CR is set as the same way:

CW Mode

Steps Operation VFD Display

28

Page 29

1. Press [CW] buttonpress to set related +[parameters]

RANGE=150.00W

CV

2. Set the power rangepress to conrm.

RANGE =1.00W

3. Set the upper limit of voltagepress to conrm.

HIGH=120.00V

4. Set the lower limit of voltagepress to conrm.

LOW=0.000V

5. Finish the setup

10.0000V 0.000A

0.00W CW=1.00W

CR Mode

1. Press [CR] button, press [ +[CV] (Setup) to set related paramters.

RANGE=7500.0Ω

2. Set the resistance rangepress to conrm.

RANGE=2Ω

3. set the upper limit of voltagepress to conrm.

HIGH=120.0V

4. Set the lower limit of voltagepress to conrm.

LOW=0.000V

5. Finish the setup.

10.0000V 0.000A

0.00W CR=2.000Ω

Go into Autotest Mode

Operation Display on Front Pannel

1. Press + (system) to enter the system menu.

0.0000V 0.000A

POWER-ON BUZZER

2. Press right key, select RUNMODE and conrm with button.

0.0000V 0.000A RUN <NORMAL>

3. Press direction key to select OCP_TESTPress Enter to conrm.

0.0000V 0.000A RUN <PROG_TEST>

4. Press [Esc] button to leave the menu.

0.0000V 0.000A

P01

29

Page 30

According to the following steps to escape OPP mode:

Press + (system)—“RUNMODE”— —-select “NORMAL” mode— .

6.6.2 Start Auto Test File

Press []

are reached.

name:

to provide a signal to start auto test le. The discharing process will be auto terminated when stop conditions

images/triggerButton

file:

images/triggerButton

6.6.3 Recall Test File

state:

unknown

Press + button to select programe le the panel displays “RECALL PROGRAM= 1” Enter the le name(1-

10)press button to conrm.

If you need a pause, press + (pause). Press can continue the test.

6.7 Measurement of Voltage Rise Time

The 8500B series electronic load is provided with special voltage rise/drop time measurement function. This function

gives a simple analog of voltage rise/drop speed of oscilloscope test power.

Operation methods:

1 Set initial Voltage and Final Voltage

1. Press + keys to enter conguration menu. Press Right key. Select “Measure” and press key.

2. Press to select “TimeV1”. Press key. Press numeric keys to set initial voltage value and press key.

3. Press to select “TimeV2”. Press key. Press numeric keys to set nal voltage value and press key.

4. Press to exit setting. Start timer function

5. Press + keys to enter system menu. Press Right key till “Displ” icks and press key.

6. Press key to select “On”. Start timer function and press key.

7. Press to exit setting.

8. VFD second line will display time 0.0000S between power value and set value.

OFF CC

v-0.0002a 0.0001V 0.0002A

0.00W 0.0000S CC=0.000A

Measurement of Rise Time

9. Connect DC power to be tested to the input terminal of the electronic load. The power is set with a value that is

higher than the set nal voltage value. Keep power output in OFF status.

10. Set a constant current value on the load and open the load input.

11. Open power output.

30

Page 31

12. The electronic load timer starts timing. After ending, time will keep stable, which is rise time of voltage.

13. Close the power output. The electronic load VFD will display voltage drop time.

6.8 Ripple Function

The 8500B series DC electronic loads have test ripple function. You can read ripple voltage and ripple current by sending

instructions. See the programming manual for more information.

31

Page 32

Conguration Functions

7.1 VON Function

The DC load can be set to only turn on if the voltage is above a set value (VON set) under congure menu by pressing

+ . There are two types of VON function: “Living” and “Latch”. The following will have detailed description for

the two types.

NOTE

VON set is used to ensure an electronic system under test will not have power applied unless the supply voltage is above

a certain value. If you have no such testing request, do not set this value arbitrarily. If your instrument can not work

normally, for example, set CC=1 A, after turn on the input while the current is still 0 A instead of setting value 1 A,

then you should check VON set rstly. If VON set is not 0 V, then please modify to 0 V.

VON LIVING MODE In Living mode, when power is applied to the DC load, the voltage must rise above VON set-

ting before the load draws current from the source. If the voltge below VON setting on the load’s

terminals, the load will turn off input.

VON LATCH MODE In Latch mode,as before,the load will turn on only when the voltage exceed VON setting,but once

on,it will now stay on,even if the voltage drops to zero.

7.2 Menu Operation

How to Navigate the Menu

Before using the instrument, it is important to be familiarized with its menu structure and learn how to view or change

settings and parameters. Follow the steps below to guide you in selecting menu options.

1. Follow the instructions above to access the System or Cong menu.

2. The selected item will be blinking. Use and ) keys to move through the menu selections.

3. When the desired menu section is blinking, press to access its menu settings.

4. Below is the display when SYSTEM is selected.

7.3 System Menu

Initialize Power-On:

1. The selected item will be blinking. Use ) keys to move through the menu items. When there is a on the right side of

the display, that means there are more menu items available to select from. Similarly, a will appear on the left side

of the display when there are menu items to the left

2. There may be parameters or options to select within each menu item. Follow the same instructions as described in

the previous steps to select them. Some settings can be changed by using ) arrow keys. To save changes to a setting,

press .

3. To exit the menu at any time, press .

7.4 Menu Options

Most settings and parameters can be congured from the built-in menu systems of the instrument. There are two main

menus: System and Cong.

32

Page 33

7.5 System Menu (System)

Press + to enter the system menu.

POWER-ON : POWER-ON Power on state of instrument

RST (default) Do not remember state in SAVE 0. Customer can save a often used data in SAVE 0 to

recall when power on the DC load next time.

SAV0 Remember state in SAVE 0

BUZZER : BUZZER

ON (default) Enable audible beep when key is pressed

OFF No sound when key is pressed

KNOB : KNOB

UPDATE (default) The value modied with knob during operation will be saved after load is off. For

example; the DC load is set to 1 A by press to turn on the input. Then

increase the setting value to 2 A with knob. When customer turn off load and trun on

again, the setting value changes to 2 A.

OLD As explained above, after the DC load is turned on again,the setting value is 1 A

instead of 2 A changed with knob.

TRIGGER : SOURCE Set trigger mode

MANUAL (Def)

EXTERNAL Triggered from a TTL high signal at the trigger connector on rear panel

BUS Triggered from a serial bus command 5 AH

HOLD Receving a command 9 DH

MEMORY : MEMORY Recall the prestored datas

GROUP=0 0: indicates1-10 group;“1”:indicates 11-20group, by parity of reasoning

DISPLAY : DISP-TIMER Timer function

ON Enable timer function

OFF (default) Disable timer function

RS-232 : RS-232

4800_8 N 1 Baudrate 4800, data bit 8, none parity, stop bit 1

9600_8 N 1 Baudrate 9600, data bit 8, none parity, stop bit 1

19200_8 N 1 Baudrate 19200, data bit 8, none parity, stop bit 1

38400_8 N 1 Baudrate 38400, data bit 8, none parity, stop bit 1

PROTOCOL : SCPI Select SCPI protocol

FRAME Select FRAME protocol

ADDRESS : ADDRESS= 0 Set the instrument’s address (0-31)

RUNMODE : RUN Runing mode at power on

NORMAL Normal mode

BATTERY Default in battery test mode at power on

PROG_TEST Default in autotest mode at power on

OCP_TEST Default in OCP test mode at power on

OPP_TEST Default in OPP test mode at power on

DEFAULT : DEFAULT

NO Do not return instrument to factory default settings.

YES Retrun instrument to factory default settings

Triggered from the + [] key

33

Page 34

7.6 Cong Menu

Press + to enter the menus.

PROTECT - Max-P Set hardware power protection

MAX POWER=150.00 W Set hardware OPP value

A-LIMIT Set software current protecting state

A-LIMIT

ON Enable software over current protection function

A-LIM POIN=30.00 0 A Set the software OCP level

A-LIM DELAY= 3 S Set the OCP delay time

OFF Disable the software OCP funtion

P- LIMIT Set software power protecting state.

P-LIM POIN=150.0 0 W Set the software OPP level.

P-LIM DELAY= 3 S Set the OPP delay time.

TIMER Set load on timer

LOAD-TIMER

ON Enable load-on timer

LOAD-TIMER=10.0 S Set the load on time (0.1 S-9999.9 S)

OFF Disable load on timer

MEASURE ::: V-RANGE Voltage auto-rangefuntion

V-RANGE

ON Enable voltage auto range function

OFF Disable voltage auto range function

FILTER Set the lter parameter

FILTER COUNT = 2^14 Filter count set, range 2-16

TIME-V1

TIME-VOLT1=0.000 V Set the start time, to measure the voltage rise/fall time.

TIME-V2

TIME-VOLT2=120.00 V Set the end time, to measure the voltage rise/fall time

CR-LED ::: CR-LED Imitate LED (in CR mode)

ON

OFF Disenable the function

SENSE ::: REM- SENSE Remote sense function

ON Enable remote sense function

OFF Disable remote sense function

VON ::: VON Set the load’s VON point

LIVING VON point living state

VON POINT = 0.10 V Set the VON value

LATCH VON point latch state, ON /OFF

VON POINT = 0.10 V Set the VON value

RESET ::: RESET Reset the cong menu

NO Do not reset

YES Reset

Open the function (in CR mode, press + to set Vd value)

34

Page 35

System Settings

8.1 Run Recall Edit

1. Select “Edit” and press . Enter a value using the numeric keypad or rotary knob for “Voltage On Level”. The value

must be within the maximum input limits of the load. Press to continue.

2. Enter a value for “Voltage On Delay”. This is set between 0.00s and 99.99s. Then press to continue.

1. Follow the same steps for “Current Range”. The value must be within the maximum input limits of the load. Press

to continue.

2. Set the “Start Power”. The value must be within the maximum input limits of the load. Press to continue.

3. Follow the same steps for “Step Power” and “End Power”. Press after each settings to continue.

4. Enter a value for “OPP Voltage” and press to continue.

5. Enter a value for “Max Trip Power”, and then “Min Trip Power”. Press after each settings to continue.

1. The load will prompt to “Save OPP File”. Select a number between 1 and 5. Then press to save all settings to the

selected location.

Note: At any time when conguring any parameters for the test, you can press the ) key to select the previous parameter

to edit.

8.2 To recall the settings

1. Press to enter the “OPP Test” menu.

2. Select “Recall” and press .

3. Use the keypad or knob to select the saved location number and press . All settings will be recalled when selecting

“Edit” from the “OPP Test” menu.

8.3 To run the OPP test

1. Recall the settings from memory by following the steps above.

2. From the “OPP Test” menu, select “Run” and press . The display will show the following:

OFF CC

v-0.000a 10.000V 0.000A

0.00W 0.00W Stop

3. Press ) to start the test. When the test is running, “Run” will be indicated in place of “Stop”. When the test ends,

either “Pass” or “Fault” will appear next to “Stop”.

4. To stop the test at any time, press ).

8.4 Key Lock

The front panel keys are locked to prevent unwanted changes to output settings and instrument congurations. Follow

the steps below to enable/disable key lock.

35

Page 36

1. Press ) and then ( ). A “*” indicator will light up on the display, indicating that the front panel keys are lock. At

this point, all keys are disabled except for the Lock function.

2. To unlock the keys again, press ) and then ( )again. The “*” indicator will disappear and all keys will be enabled.

8.5 Restore Factory Default Settings

All instrument settings are reset back to their factory default values by doing the following:

Note: Restoring the instrument to factory default will change all current instrument settings and parameters back to

their default values.

1. From the “SYSTEM” menu, select “Initialize” and press .

2. The following screen will display. Select “Yes” to restore default settings, or “No” to cancel.

Table 8.1 lists some of the factory default settings.

Item Default Setting

Communication RS232 (4800, 8, N, 1, NONE)

Display On Timer Off

Trigger Source Manual

Protocol SCPI

Von Latch

A-Limit Off

Memory Group 0

Power-On RST

Buzzer On

Load On Knob Update

On Timer Off

Voltage Auto Range On

Averaging Filter 2^14

Remote Sense Off

External Program Off

Table 8.1 Factory Default Settings

8.5.1 Congure Power-On State

The initial Power-On state of the load is congured by following the steps below:

1. From the “SYSTEM” menu, select “Power-On” and press .

2. There are two options:

Rst(Def) – Factory Default.

“Sav0” – Settings before last power up. Recalls the settings saved to “0” memory location.

1. Select the settings you want during power up, and press to save changes.

2. To exit the menu at any time, press twice.

36

Page 37

8.5.2 Load On Knob

This setting controls the behavior of the knob.

1. From the “SYSTEM” menu, select “Knob” and press .

2. There are two options:

Update(default) Real time update.

Old No update (when turning load ON/OFF, original value before use of rotary knob will be set)

3. Select the settings you want during power up and press to save changes.

4. To exit the menu at any time, press twice.

8.5.3 Congure Trigger Source

The trigger function is used to initiate the start of a program in list mode and also as a toggle for transient mode. The

trigger source is set so that users can send a trigger from the front panel, through a remote command via remote interface

or through the external trigger input in the rear panel. Follow the steps below to congure the trigger mode:

1. From the “SYSTEM” menu, browse and select “Trigger” and press .

Manual(Def) Manual trigger. Front panel trigger button is used to send a trigger (press and (or press

) to send trigger).

External External trigger. Trigger is sent by connecting the “Trig” input and the ground input together

in the rear panel. A TTL signal may also be used as a trigger signal when sent across these

terminals. If using a TTL signal, the unit triggers off of a falling edge.

Signal pulse width must be > 10 µs.

Hold Hold trigger. This behaves similarly to “Bus” trigger, however the “TRIG:IMM” command

is used instead.

Bus Bus trigger. Remote commands “*TRG” and “TRIG:IMM” can both be used to send a trig-

ger. With “Bus” trigger, multiple devices are triggered at the same time when communicating via GPIB interface.

Timer Timer trigger. A trigger will be sent periodically based on the set time. Time is set from 0.01

s to 9999.99 s.

2. Select one of the options. For timer trigger, use the numeric keypad or rotary knob to set the time.

3. To exit the menu at any time, press twice.

8.5.4 Save/Recall Instrument Settings

The instrument can save up to 100 instrument settings in non-volatile memory. Memory is allocated in 10 different

storage groups (group 0 to 9), and each group has 10 memory locations to store settings (0 to 9). These memory

locations are referenced by numbers 1 – 100. When saving an instrument setting, numbers 1 to 100 is selected. However,

when recalling an instrument setting, the group must be selected rst and then the numeric keypad buttons 1 through

9 and 0, which refers to the 10 locations of the selected storage group. Below is the table illustrating the storage group

and allocated memory locations.

37

Page 38

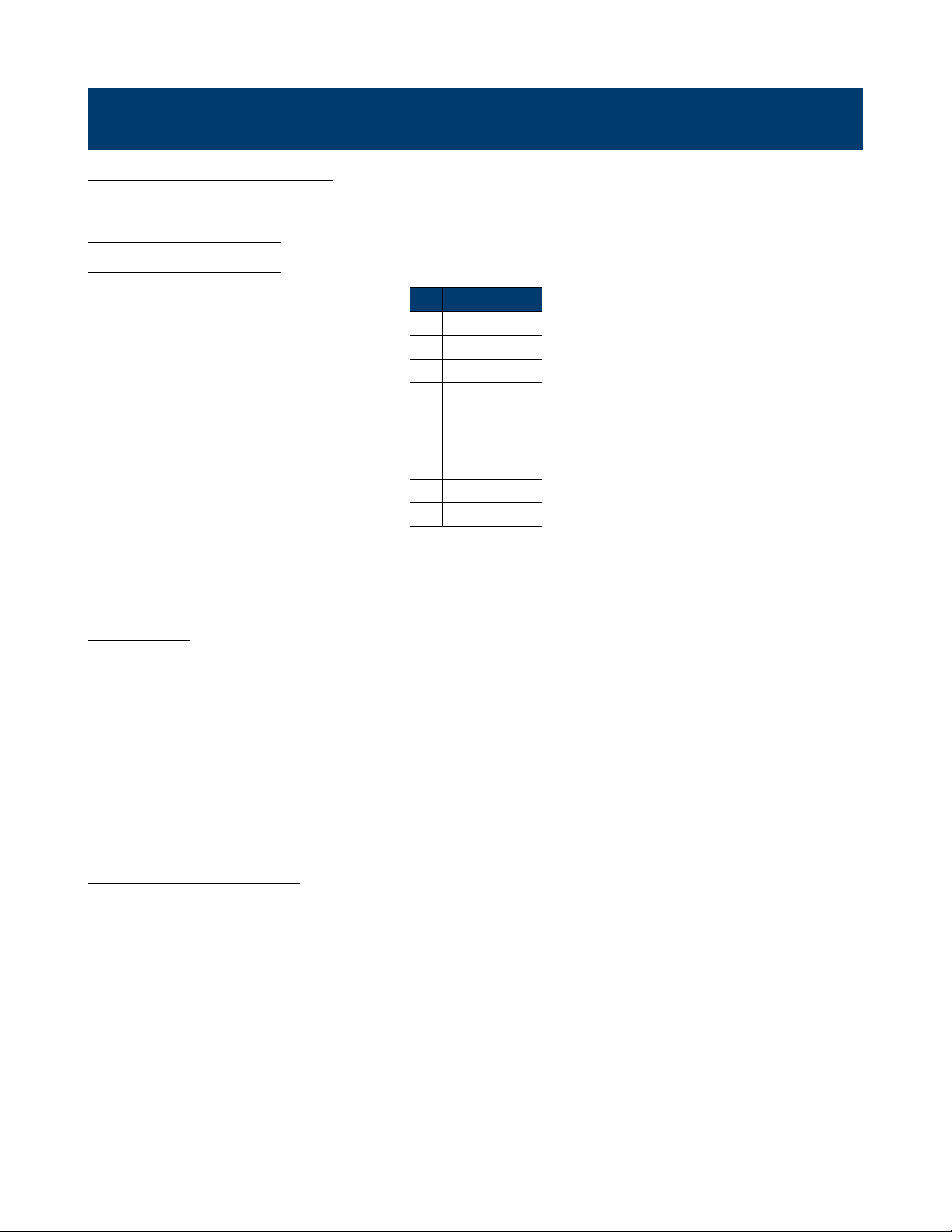

Storage Group Memory locations

0 1 – 10

1 11 – 20

2 21 – 30

3 31 – 40

4 41 – 50

5 51 – 60

6 61 – 70

7 71 – 80

8 81 – 90

9 91 - 100

When recalling settings, each of the numeric keypad numbers corresponds to the memory locations based on the storage

group selected according to the table above. For storage group 0, recalling memory location 1 is done by pressing ;

location 2 is done by pressing , and so on. Memory location 10 is recalled by pressing . For storage group 1, recalling

memory location 11 by pressing , location 12 by pressing , and so on.

Example:

Settings are saved to memory location 60. To recall those settings, set storage group to 5 from the menu, then press

recall and the number .

8.5.5 Select Storage Group

1. From the “SYSTEM” menu, browse and select “Memory” and press . The following screen will appear.

1. Use the current adjust knob or the numeric keypad to enter the storage group. Select between “0 – 9”. Press

to save selection.

2. To exit the menu at any time, press twice.

NOTE: The storage group setting also affects the automatic test function of the load. Refer to “Automatic Test

Function” for more details.

8.5.6 Save Settings

1. Set up all the instrument settings that you want to save.

2. Then, press ) and . The display will show the following:

3. Use the current adjust knob or the numeric keypad to enter the memory location in which to store current instrument

settings. Select between “0 – 100”. Press to save to the selection location.

NOTE: The “0” memory location is reserved for storing instrument settings last congured before power-off and is used

only for power-on state conguration only.

8.5.7 Recall Settings

38

Page 39

1. First, consider the memory locations you want to recall from. As they are grouped together, select the appropriate

storage group from the “SYSTEM” menu rst by following the instructions in previous section.

2. Once selected, press (b- ) and (or press (recall) ) and it will light up to indicate the instrument is in “Recall”

mode.

3. Use the keypad numbers to recall the settings from the corresponding memory location referenced by the storage

group selected in Step 1.

4. Once entered, the saved settings at the location will be immediately recalled.

Note: When in Recall mode, users can recall settings from different locations without having to press additional keys

each time. For example, you can press 1 to recall settings in location one, and then press 5 to recall settings in location

5 on the y.

1. To exit “Recall” mode, press .

8.5.8 Display Input On Timer

The instrument has an internal timer that counts how long the input has been enabled (ON). Follow the steps below to

enable the timer display.

1. From the “SYSTEM” menu, browse and select “Displ” and press . The following screen will appear.

1. Select “On” to enable the timer, and “Off (default)” to disable. Press to conrm.

2. Press twice to exit the menu. The timer will now be displayed like the following:

4. When input is enabled (ON), the timer will start counting the time. When input is disabled (OFF), the timer will

reset itself to a value close to 0 seconds.

8.5.9 Remote Interface Setup

The instrument has RS232, USBTMC, and GPIB remote interfaces available for remote communication. Follow the steps

below to select and congure each interface.

Note: The “RMT” indicator will appear on display when the instrument is successfully connected to a PC remotely

through any remote interface. Keys on the front panel will be locked until the instrument is in LOCAL mode. To

return to LOCAL mode from the front panel, press (and then ) . The “RMT” indicator will disappear when

the instrument is in LOCAL mode.

From the “SYSTEM” menu, browse and select “Communication” and press . The following screen will appear.

8.5.10 RS-232

Follow the steps below to congure the instrument for RS-232 operation:

1. Select “RS-232” and press to set to RS-232 for remote communication. The following display will be shown:

1. “” is the baud rate; “8” is the data bits; “N” is the parity; “1” is the stop bit; “Addr…” is for address.

2. Use the ) keys to select between each serial settings, and use

) keys to change the settings.

1. The following setting options that are used: Baudrate: 4800, 9600, 19200, 38400, 57600, 115200* Data bits: 8

39

Page 40

Parity: N (None), E (Even), O (Odd)

Stop bit: 1

Flow control: NONE, CTS/RTS, XON/XOFF

Note: The default is 4800, 8, N, 1, NONE.

*Setting the baud rate to 115200 may provide unstable results during remote communication. Select a lower baud rate

if communication errors occur.

1. All serial settings must match with the settings congured on the PC in order for communication to link successfully.

8.5.11 CONFIG Menu

All setup procedures and settings explained in this section are accessed from the CONFIG

menu. To access this menu, press ) and ( ). The following screen will show:

8.5.11.1 Von Operation

The Von voltage value is set to control the voltage turn on state for the electronic load. When the input voltage exceeds

the Von voltage value, the electronic load’s input state turns on.

This function can protect a DUT when its voltage goes below a specied level. For example, when testing a power

supply’s discharge characteristics, you can set the Von voltage level start and stop discharging of the power supply.

Note: Von Operation will have a short delay (< 1 s) from when a condition exceeds or goes below a specied level to

when the load’s input state changes.

When Von Latch is ON, the electronic load will begin sinking current if input voltage exceeds Von voltage. When the

input voltage drops below the Von voltage value, the electronic load will stop sinking current and the input will turn off.

Figure 15 - The Load’s Operating Range with Von Latch set to ON

When Von Latch is OFF, the electronic load will begin sinking current if the input voltage exceeds the Von voltage.

When the input voltage drops below the Von voltage value, the electronic load will still continue sinking current and the

input remains on.

Figure 16 - Von Latch OFF The Load’s Operating Range with Von Latch set to OFF

To set the Von modes, from the “CONFIG” menu, select “Von” and press . The following will be displayed:

Use the and (arrows) ) keys to select between “On” or “Off” and press conrm

selection. Afterwards, you will be prompted to enter the voltage point of “Von”. Use the numeric keypad or rotary knob

to change this value.

8.5.12 Congure Protection Settings

The electronic load has the following protection functions: Overvoltage protection (OVP), overcurrent protection (OCP),

overpower protection (OPP), overtemperature protection (OTP), and local and remote reverse voltage protection (LRV/RRV).

The instrument will act appropriately once any of the above protections are active. You can press any button on the front

panel to restore the protection function. For example, if the electronic load triggers the overtemperature protection, the

buzzer will alarm, the input will automatically turn off, and the mainframe VFD will display OTP.

Some OCP and OPP features are congured from within the “Protect” menu. To access this menu, go into “CONFIG”

menu and select “Protect”. The following display will show:

8.5.13 PROTECT MENU

8.5.14 Max-P A-Limit P-Limit Time

40

Page 41

8.5.15 Overcurrent Protection (OCP)

The electronic load includes both hardware and software overcurrent protection features.

“Hardware OCP” - The electronic load’s maximum input current will be limited to approximately 110% of the current

range. Once the hardware OCP is triggered, the status register’s OC bit will be set. When the hardware OCP is removed,

the status register’s OC bit will be reset. Hardware overcurrent protection will not affect the electronic load’s input on/off

state.

“Software OCP” - Users can set the electronic load’s software OCP value with the following steps.

1. Go to “CONFIG” menu and select “Protect”. Then press .

2. Select “A-limit” and press .

3. To enable software OCP, select “On” and press . The default is “Off”.

4. If enabled (ON), the load will prompt to enter a value for “Point”. Use the numeric keypad or rotary knob to enter

the OCP current limit value, then press . The valid range depends on the model of the load.

5. It will then prompt to enter a value for “Delay”. This is the protection trip delay, which is the amount of time to

delay from when the input has reached the limit before triggering

OCP. Use the numeric keypad or rotary knob to enter a value, then press to conrm change. The valid range is 0

– 60 seconds.

NOTE:

Software OCP will disable the input if the input current has reached or exceeded the protection limits.

Operations to Clear the OCP State

Check whether the input current is within the electronic load’s rated current or the programmed protection current ranges.

If it is outside the range, disconnect the device under test. Then press any key on the front panel or remotely send SCPI

command PROTection:CLEar. The OCP displayed on the front panel will turn off and the load exits OCP protection

state.

To start an OCP test,press “[ ]+ []”

Press “[ ]+ [ CC ]” (OCP) to enter OCP operation.

EDIT OCP TEST

1. VON LEVEL=0.000V: - Set Voltage thresholdd

2. VON DELAY=0.00S - After delay certain time,the DC load starts to draw current.

name:

.

images/triggerButton

file:

images/triggerButton

state:

unknown

3. RANGE=3.000A - Set current range

4. START=0.1000A - Set start current

5. STEP=0.1000A - Set step current

6. STEP DEL=0.20S - Set delay time of each step

7. END=2.0000A - Set end current

8. OCP VOLT=2.000V - Set OVP value

9. MAX TRIP =1.5000A - Upper limit of OCP value

10. MIN TRIP=0.9000A - Lower limit of OCP value

11. SAVE OCP FILE=1 - Save OCP test le (1-10)

Set the power on mode to be OCP test mode:

41

Page 42

Operation - Display on front pannel

1. Press “[ ]+ [ 8 ]” (system) enter into sysmtem menu - 0.0000V 0.000A POWER-ON BUZZER

2. Press right key,select RUNMODE and conrm - 0.0000V 0.000A RUN <NORMAL

with button -

3. Press direction key to select OCP_TEST,Press “ ” to conrm. - 0.0000V 0.000A RUN <OCP_TEST>

4,Press [ Esc ] button to quit the set. - 0.0000V 0.000A STOP 0.000A

After above steps,press [ ]

1. Press “[ ]+ ” button to select programe le,the panel displays “CALL OCP FILE= 1”. Enter the le

name(1-10),press “ ” button to conrm.

name:

button to run ocp test le. Recall OCP File:

images/triggerButton

file:

images/triggerButton

state:

unknown

2. According to the following steps to escape OCP mode:press “[ ]+ [ 8 ]” (system)——“RUNMODE” —– “[Enter]”

——-select “NORMAL” mode—-“ ”.

8.5.16 Overpower Protection (OPP)

The electronic load includes both hardware and software OPP features.

“Hardware OPP” – In the event that the electronic load’s input power exceeds the set power protection limit, the

hardware OPP will limit the power. Once the hardware OPP is triggered, the status register’s OP bit will be set. When

the hardware OPP is removed, the status register’s OP bit will be reset. Hardware overpower protection will not turn the

electronic load’s input off.

Follow the steps below to set the hardware OPP limit.

1. Go to “CONFIG” menu and select “Protect”. Then press .

2. Select “Max-P” and press .