Page 1

1

Model: 4007B, 4013B

DDS Function Generator

USER MANUAL

Page 2

2

Do not alter the ground connection. Without the protective ground connection, all accessible

conductive parts (including control knobs) can render an electric shock. The power jack and mating

plug of the power cable meet IEC safety standards.

To avoid electrical shock hazard, disconnect power cord before removing covers. Refer servicing to

qualified personnel.

Before connecting the line cord to the AC mains, check the rear panel AC line voltage indicator.

Applying a line voltage other than the indicated voltage can destroy the AC line fuses. For continued

fire protection, replace fuses only with those of the specified voltage and current ratings.

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be

observed during all phases of operation, service, and repair of this instrument. Before applying

power, follow the installation instructions and become familiar with the operating instructions for this

instrument.

If this device is damaged or something is missing, contact the place of purchase immediately.

This manual contains information and warnings that must be followed to ensure safe operation as

well as maintain the meter in a safe condition.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. This instrument is grounded through the ground conductor of the supplied, three-conductor

ac power cable. The power cable must be plugged into an approved three-conductor electrical

outlet. Do not alter the ground connection. Without the protective ground connection, all accessible

conductive parts (including control knobs) can render an electric shock. The power jack and mating

plug of the power cable must meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component replacement and

internal adjustments must be made by qualified maintenance personnel. Disconnect the power

cord before removing the instrument covers and replacing components. Under certain conditions,

even with the power cable removed, dangerous voltages may exist. To avoid injuries, always

disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person, capable of rendering first

aid and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications to this instrument. Return

the instrument to B&K Precision for service and repair to ensure that safety features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples, denote a hazard and

appear throughout this manual. Follow all instructions contained in these statements.

A WARNING statement calls attention to an operating procedure, practice, or condition, which, if

not followed correctly, could result in injury or death to personnel.

A CAUTION statement calls attention to an operating procedure, practice, or condition, which, if not

followed correctly, could result in damage to or destruction of part or all of the product.

WARNING:

WARNING:

CAUTION:

Page 3

3

This product uses components which can be damaged by electro-static discharge (ESD). To avoid

damage, be sure to follow proper procedures for handling, storing and transporting parts and

subassemblies which contain ESD

This product is subject to Directive 2002/96/EC of the

Refer to the user manual for warning information to

damage to instrument.

On (Supply). This is the AC mains

instrument.

Off (Supply). This is the AC mains

CAUTION:

-sensitive components.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the Europea n

Union and other European countries with separate collection syst ems)

European

Parliament and the Council of the European Union on

waste

electrical and electronic equipment (WEEE) , and in

jurisdictions

adopting that Directive, is marked as being put on the

market after August 13, 2005, and shou ld no t be

disposed of as unsorted

municipal waste. Please utilize your local WEEE

collection

facilities in the disposition of this product and

otherwise observe all applicable requirements.

Safety Symbols

avoid hazard or personal injury and prevent

Chassis (earth ground) symbol.

On (Power). This is the In position of the power

switch when instrument is ON.

Off (Power). This is the Out position of the power

switch when instrument is OFF.

connect/disconnect switch at the back of the

connect/disconnect switch at the back of the

instrument.

Page 4

4

CE Declaration of Conformity

The model 4007B and 4013B meet the requirements of 2006/95/EC Low Voltage

Directive and 2004/108/EC Electromagnet Compatibility Directive with the following

standards.

Low Voltage Directive

- EN61010

Safety requirements for electrical equipment for measurement, control,

and laboratory use.

EMC Directive

- EN55011

For radiated and conducted emissions.

- EN55082

Electrical discharge immunity

Page 5

1 INTRODUCTION .................................................................. 6

1.1 Introduction ............................................................................................. 6

1.2 Description ............................................................................................. 6

1.3 Specifications ......................................................................................... 6

2 INSTALLATION ................................................................... 8

2.1 Introduction ............................................................................................. 8

2.2 Package Contents .................................................................................. 8

2.4 Instrument Mounting ............................................................................... 8

2.5 Power Requirements .............................................................................. 8

2.6 Fuse Replacement.................................................................................. 9

2.7 Grounding Requirements ........................................................................ 9

2.8 Signal Connections ................................................................................. 9

3 OPERATING INSTRUCTIONS .......................................... 10

3.1 General Description .............................................................................. 10

3.2 Display Window .................................................................................... 11

3.3 Front Panel Controls ............................................................................. 11

3.4 Connectors ........................................................................................... 11

3.5 Output Connections .............................................................................. 11

3.6 MENU Keys .......................................................................................... 12

3.6.1 WAVEFORM Keys ................................................................................. 12

3.6.2 UTILITY Key ............................................................................................ 13

3.6.3 SWEEP Key ........................................................................................... 14

3.7 ON Key ................................................................................................. 14

3.8 Cursor Keys .......................................................................................... 14

3.9 Rotary Input Knob ................................................................................. 14

3.10 Power-On Settings .............................................................................. 15

3.11 Memory .............................................................................................. 15

3.12 Displaying Errors ................................................................................ 15

3.13 Quick Start .......................................................................................... 15

3.13.1 Selecting a Standard Waveform .......................................................... 16

3.13.2 Setting the Output ................................................................................ 16

3.13.3 Using Voltage Offset ........................................................................... 16

3.13.4 Storing and Recalling a Waveform Generator Setup ........................... 16

5

Page 6

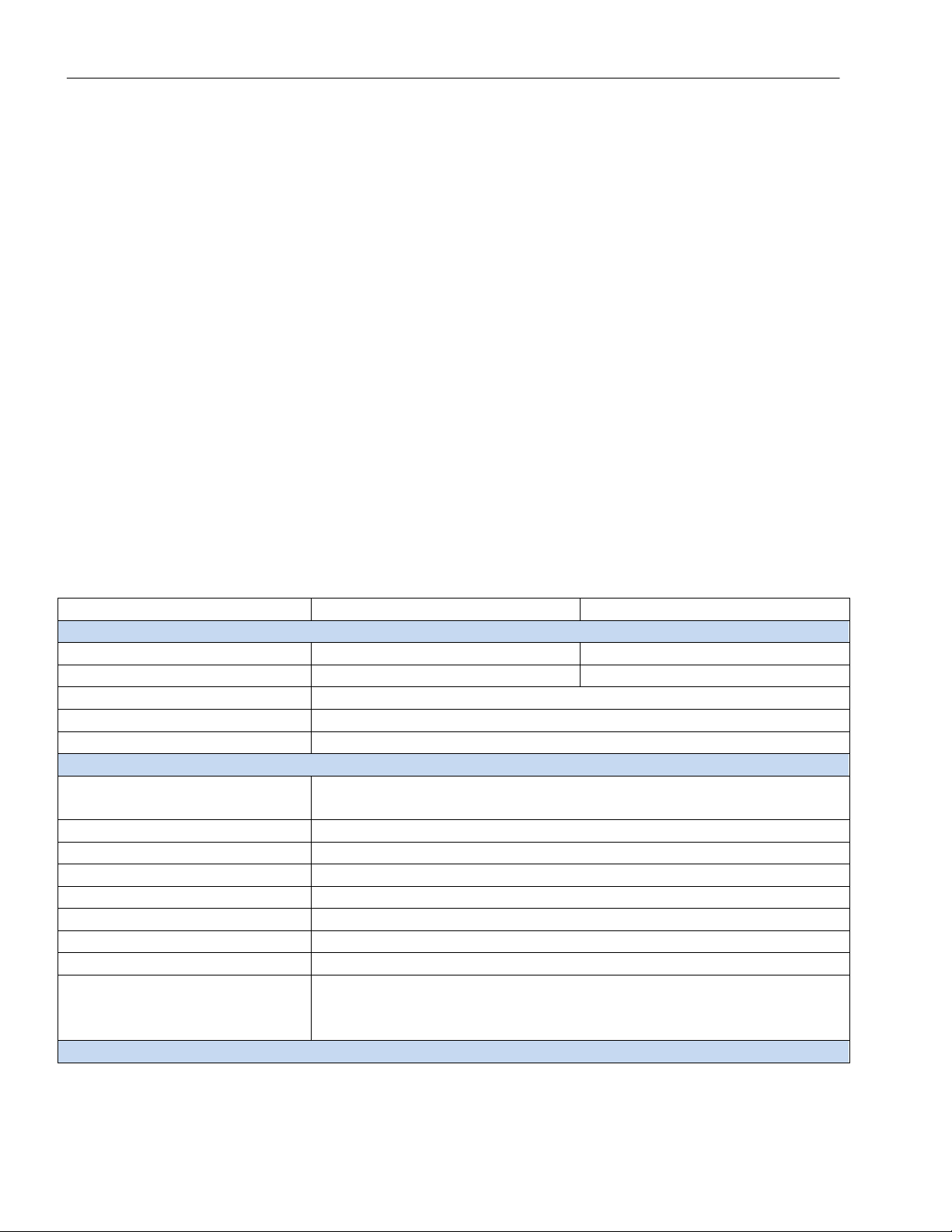

4007B/4013B – Operating Manual

Model

4007B

4013B

Frequency Characteristics

Sine

0.1 Hz – 7 MHz

0.1 Hz – 12 MHz

Square

0.1 Hz – 7 MHz

0.1 Hz – 12 MHz

Triangle

0.1 Hz – 1 MHz

Accuracy

0.01% ± 0.186 Hz

Resolution

5 digits or 100 mHz

Output Characteristics

Amplitude Range

10 mV to 10 Vp-p (into 50 Ω)

20 mV to 20 Vp-p (open circuit)

Resolution

3 digits (1000 counts)

Amplitude Accuracy

± 2 % ± 20 mV of programmed output from 1.01 V – 10 V

Flatness

± 1 dB to 12 MHz

Offset Range

± 4.5 V (into 50 Ω)*

Offset Resolution

10 mV, 3 digits

Offset Accuracy

± 2 % ± 10 mV (into 50 Ω)

Output Impedance

50 Ω

Output Protection

Protected against short circuit or accidental voltage practically

connector

Waveform Characteristics

1 Introduction

1.1 Introduction

This manual contains information required to operate the B&K Precision model 4007B and

4013B DDS Function Generators. This section covers the instrument’s general description,

specifications and characteristics.

1.2 Description

The 4007B and 4013B are versatile high performance function generators. Implemented

using a DDS (direct digital synthesis) architecture, these instruments generate stable and

precise sine, square, and triangle waveforms. Both models also provide linear and logarithmic

sweep for users needing sweep capability. An auxiliary TTL output at the generator’s

frequency is available to synchronize external devices. Up to 9 fr ont panel settings can be

saved to memory storage.

1.3 Specifications

available in electronic laboratories, applied to the main output

6

Page 7

Harmonic Distortion

DC – 100 kHz, -55 dBc

1MHz – 7 MHz, -30 dBc

DC – 100 kHz, -55 dBc

1MHz – 12 MHz, -30 dBc

Square Rise/Fall Time

< 20 ns (10% to 90% at full amplitude into 50 Ω)

Variable Duty Cycle

20% to 80 %, up to 1 MHz for Square waveform

Symmetry Accuracy at 50%

< 1 %

Sweep Characteristics

Sweep Shape

Linear or Logarithmic, up or down

Sweep Time

20 ms to 100 s

Input and Output

Sync Out

TTL pulse at programmed freq uency; 50 Ω source impedance

General

Memory Storage

Store up to 9 instrument settings

Power Requirements

100 V – 240 V AC ± 10% (90 V – 264 VAC)

Max. Power Consumption

25 VA

Operating Temperature

0 °C – 50 °C

Storage Temperature

-10 °C – 70 °C

Humidity

95% RH, 0 °C – 30 °C

Dimensions

213 mm x 88 mm x 210 mm (WxHxD)

Weight

Approx. 2 kg

Safety Standards

EN55011 for radiated and conducted emissions

EN61010

100 kHz – 1 MHz, -45 dBc

EN55082

100 kHz – 1 MHz, -45 dBc

*Depends on amplitude setting.

Note: All specifications apply to the unit after a temperature stabilization time of 15 minutes

over an ambient temperature range of 23 °C ± 5 °C. Specifications are subject to change

without notice.

To ensure the most current version of this manual, please download the latest version here:

http://www.bkprecision.com/search/4013B

For current up-to-date product in for mation, please visit www.bkprecision.com

7

Page 8

4007B/4013B – Operating Manual

2 Installation

2.1 Introduction

This section contains installation information, power requirements, initial inspection and signal

connections for the 4007B and 4013B signal generators.

2.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items

from the shipping carton, and check for any obvious signs of physical damage that may have

occurred during transportation. Report any damage to the shipping agent immediately. Save

the original packing car t on for possi bl e fut ur e res hi pm ent. Every generator is shipped with the

following contents:

• 4007B / 4013B DDS function generator

• AC Power Cord

• Manual contained on CD

• Certificate of Calibration

Verify that all items above are included in the shipping container. If anything is missing,

please contact B&K Precis ion.

2.4 Instrument Mounting

The 4007B and 4013B Function Generators are intended for bench use. The instrument

includes a front feet tilt mechanism for optimum panel viewing angle. The instrument does not

require special cooling when operated within conventional temperature limits. It may be

installed in a closed rack or test station if proper air flow can assure removing about 15 W of

power dissipation.

2.5 Power Requirements

The 4007B and 4013B can be operated from any source of 90V to 264V AC, frequency from

48Hz to 66Hz. The maximum power consumption is 25 VA. Use a slow blow fuse of 1A,

UL/CSA approved as indicated on the rear panel of the instrument.

The instrument power fuse is located in the AC input plug. To access the fuse, first

disconnect the power cord and then remove the fuse cartridge.

8

Page 9

Fuse box slit

Fuse box

Check/Remove Fuse

2.6 Fuse Replacement

There is a 1A, 250V rated slow blow fuse at the AC input. Should the fuse ever get blown,

follow the steps below to replace:

1. Locate the fuse box next to the AC input connector in the rear panel.

2. With a small flat blade screwdriver, insert into the fuse box slit to pull and slide out the fuse box

as indicated below.

3. Check and replace fuse if necessary.

2.7 Grounding Require me nts

For the safety of operating personnel, the instrument must be grounded. The central pin on

the AC plug grounds the instrument when properly connected to the ground wire and plugged

into proper receptacle.

WARNING

TO AVOID PERSONAL INJURY DUE TO SHOCK, THE THIRD WIRE EARTH

GROUND MUST BE CONTINUOUS TO THE POWER OUTLET. BEF ORE

CONNECTION TO THE POWER OUTLET, EXAMINE ALL CABLES AND

CONNECTIONS BETWEEN THE UNIT AND THE FACILITY POWER FOR A

CONTINUOUS EARTH GROUND PATH.

THE POWER CABLE MUST MEET IEC SAFETY STANDARDS.

2.8 Signal Connections

Use RG58U 50Ω or equivalent coaxial cables for all input and output signals to and from the

instrument.

9

Page 10

4007B/4013B – Operating Manual

3 Operating Instructions

3.1 General Description

This section describes the displays, controls and connectors of the function generator.

All controls for the instrument local operation are located on the front panel.

1 Power Button Power ON/OFF

2 LCD Display

3 Function Keys F1 – F4 function keys

4 Waveform Buttons Select Sine, Ramp/Triangle, Square waveform shape

5 Rotary Knob

6 Cursor Keys

7 Output ON/OFF Enable/Disable Output

8 SWEEP Button Selects Sweep functio n menu

9 UTIL Button Utility menu

10 Units Keys

11 Numeric Keypad

10

Page 11

3.2 Display Window

The function generator has a graphic LCD display that can display up to 124 x 32 dots. When you poweron the unit sine waveform is selected and current settings appear in the display. The bottom displays a

menu (selectable with function keys) that corresponds to the function, parameter or mode display selected.

3.3 Front Panel Controls

The front-panel controls select, display, and change parameter, function, and mode settings.

Use the numerical keypad, rotary input knob and the cursor movement keys to enter data into the

waveform generator.

To change a setting:

1. Press the key that leads to the item to change.

2. Move cursor using cursor keys to the appropriate position in the numeric field (if applicable).

3. Use the rotary input or the numerical keyboard to change the value of the displayed item. Changes take

effect immediately.

3.4 Connectors

The function generator has two BNC connectors on the front panel where you can connect coaxial cables.

These coaxial cables serve as carrier lines for output signals delivered from the function generator.

Output

Use this connector to transfer the main output signal from the function generator.

Sync Out

Use this connector to output a positive TTL sync pulse generated at each waveform cycle.

3.5 Output Connections

The waveform generator output circuits operate as a 50 Ω voltage source working into a 50 Ω

load. At higher frequencies, non terminated or improperly terminated output causes

aberrations on the output waveform. In addition, loads less than 50 Ω reduce the waveform

amplitude, while loads more than 50 Ω increa s e w av eform am pl it ud e.

Excessive distortion or aberrations caused by improper termination are less noticeable at

lower frequencies, especially with sine and triangle waveforms. To ensure waveform integrity,

follow these precautions:

1. Use good quality 50 Ω coaxial cable and connectors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators if it is necessary to reduce waveform amplitudes applied to

sensitive circuits.

11

Page 12

4007B/4013B – Operating Manual

4. Use termination or impedance-matching devices to avoid reflections.

5. Ensure that attenuators and terminations have adequate power handling capabilities.

If there is a DC voltage across the output load, use a coupling capacitor in series with the

load. The time constant of the coupling capacitor and load must be long enough to maintain

pulse flatness.

Impedance Matching

If the waveform generator is driving a high impedance, such as a 1 MΩ input impedance

(paralleled by a stated capacitance) of an oscilloscope vertical input, connect the transmission

line to a 50 Ω attenuator, a 50 Ω termination and t o the osc i ll os cop e input. The attenuator

isolates the input capacitance of the device and terminates the waveform generator properly.

3.6 MENU Keys

These keys select the main menus for displaying or changing a parameter, function or mode.

3.6.1 WAVEFORM Keys

The keys select the waveform output and displays the waveform parameter menu (frequency,

amplitude and offset).

Sine Menu

F1: FREQ – (Frequency) Selects and displays the frequency. Change the frequency setting

using the cursor keys, rotary knob or numerical keys.

F2 : AMPL – (Amplitude) Selects and displays the Amplitude. Change the amplitude setting

using the cursor keys, rotary knob or numerical keys.

F3:OFST – (Offset) Selects and displays the Offset parameter. Change the offset by using

the cursor keys, rotary dial or numerical keys. If a certain setting cannot be produced, the

waveform generator will display a “Setting Conflict” message.

Amplitude and Offset Interaction:

Amplitude and offset settings interact and are bound by hardware restrictions. In order to

obtain the desired waveform, the following amplitude and of fset hardware limitations must be

considered:

12

Page 13

Output Voltage

Range

Constraints of Amplitude +

Offset

(Vp-p)/2 + |offset| <= 5 volts

(Vp-p)/2 + |offset| <= 0.5 volts

(Vp-p)/2 + |offset| <= 0.05 volts

The offset voltage has three ranges as follows:

1.01 volt to 10.00 volts

0.101 volt to 1 volt

0.010 volt to 0.100 volt

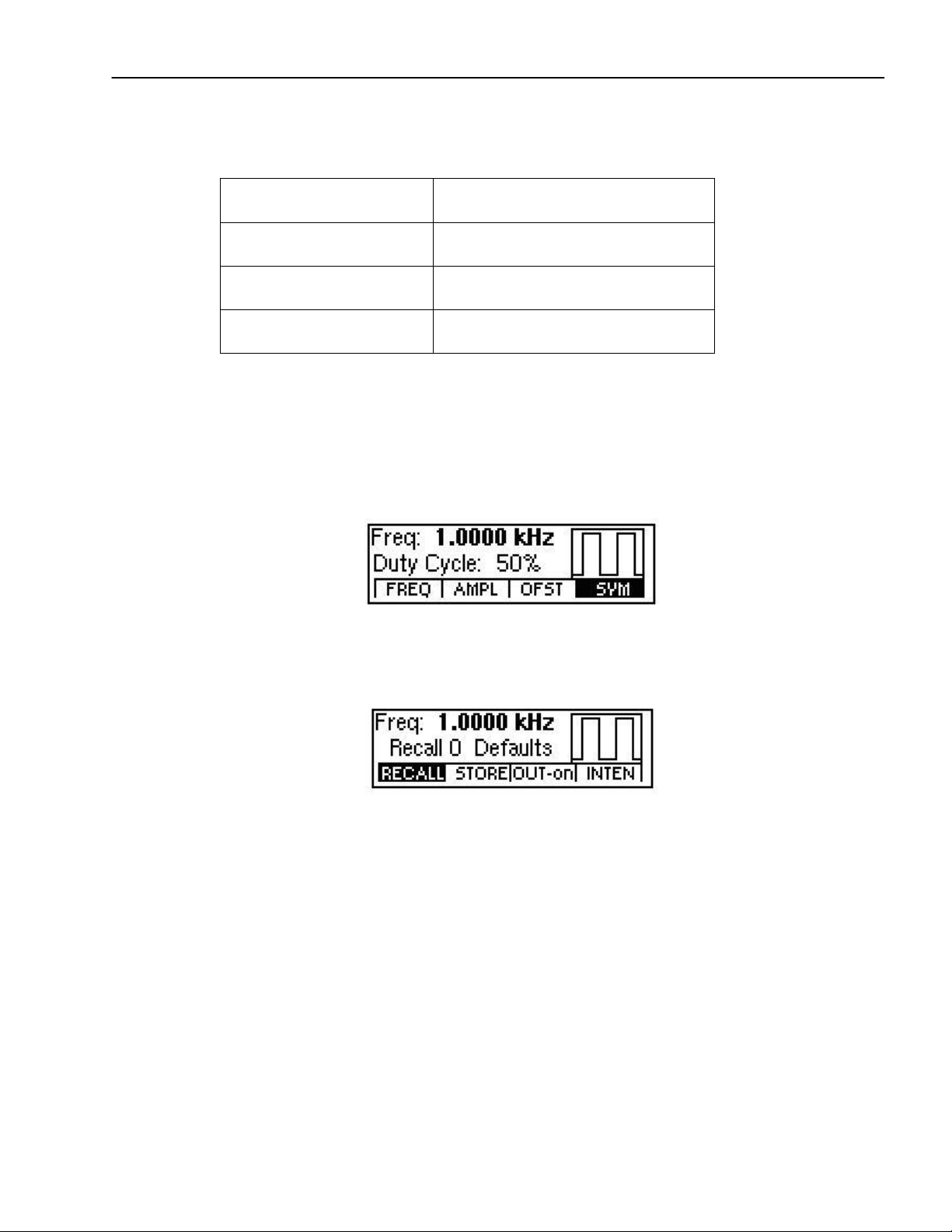

F4:SYM – (Symmetry) When the Square or Triangle waveforms are selected, the

SYMMETRY(Duty cycle) parameter is available. Change the symmetry(Triangle) or duty

cycle(square) by using the cursor keys, rotary dial or numerical keys. If a certain setting

cannot be produced, the waveform generator will display a warning message.

Square Menu

3.6.2 UTILITY Key

Utility Menu

F1: RECALL – Recalls a previously stored front-panel setup from the selected buffer. Change

the buffer number by using the rotary input knob. Valid storage buffer numbers are from 1 to

9.

Buffer 0 is the factory default setup.

F2:STORE – Stores the current front-panel setup to the specified storage buffer. Change the

buffer number by using the data keys or the rotary input knob. Valid storage buffer numbers

range from 1 to 9.

F3: OUT-ON – Selects the OUTPUT state from a power-up. Select ON to enable or OFF to

disable the output from a pow er-up.

13

Page 14

4007B/4013B – Operating Manual

F4: INTENSITY – Adjusts the intensity of the LCD screen. Valid range is 1 – 9; 9 giving th e

highest intensity and contrast.

3.6.3 SWEEP Key

Selects the Sweep Mode and allows entering sweep parameters Sweep Start, Sweep Stop

and Sweep Rate.

To select the sweep mode, press SWEEP, then press the function key that corresponds to

the desired Sweep menu option , as show n:

Sweep Menu

F1: ON/OFF – Enables/disables the sweep function. Select between Sweep ON or OFF.

F2: LIN – Selects the Linear sweep shape.

F3: LOG – Selects the Logarithmic sweep shape.

F4: SET – Defines the Sweep Start and Stop frequencies.

Set Sweep Menu

3.7 ON Key

Use this key to control the main output signal. When the output is active, the key will lit. By

default, this will be ON (enabled) from a power-up. This can be changed by changing the

OUT-ON settings from the utility menu.

3.8 Cursor Keys

Use these keys to move the cursor (when visible) either left or right. They are used in

conjunction with the rotary input knob to set the step size of the rotary input knob.

3.9 Rotary Input Knob

14

Page 15

Use this knob to increase and decrease numeric values. The cursor indicates the low-order

Key Function

Value

Description

Function

Sine

Output Waveform

Frequency

1.0000 kHz

Waveform Frequency

Amplitude

5.00 V

Peak-to-peak output amplitude

Offset

0.00 V

Zero DC offset

Output

OFF

Output disabled

Sweep

OFF

Sweep function disabled

Message Text

Description

Out of range

The set value is out of the instrument’s limits

Setting Conflict

Settings conflict with another parameter setting or value.

Empty location

Attempt to recall settings from an empty storage location.

position of the displayed value which changes when you rotate the knob (for straight numeric

entries only). For other types of data, the whole value changes when you rotate the knob.

3.10 Power-On Settings

Table 3-2 lists the factory default settings or selected after RECALL 0.

Table 1 – Power-on Default Settings

3.11 Memory

The waveform generator uses non-volatile flash memory for storing the front panel settings.

Up to 9 front panel settings can be stored (not including default settings).

3.12 Displaying Errors

The waveform generator displays error messages when front-panel setti ng s are either inv alid

or may produce unexpected results.

Table 2 – Error Messages

3.13 Quick Start

This section explains how to generate various waveforms and modify the output waveform.

* Generating a waveform output

* Modifying waveform output

* Storing and recalling a waveform generator setup

15

Page 16

4007B/4013B – Operating Manual

3.13.1 Selecting a Standard Waveform

You can select several standard waveforms as: sine, triangle, square. Creating a standard

waveform requires selecting the waveform type, parameters and their settings that define the

waveform.

Generating a standard waveform requires the following:

* Selecting the waveform

* Setting the output frequency

* Setting the output amplitude and offset

3.13.2 Setting the Output

To set the output channel, press the Output ON key. The key will lit indicating the output is

enabled.

3.13.3 Using Voltage Offset

Through the offset parameter you can add a positive or negative DC level to the output

waveform.

To set voltage offset:

1. Select a waveform to displ ay its menu.

2. Press F3 :OFST to display the offset setting.

3. Use the rotary input knob or the numerical keys to set the voltage offset.

To turn the voltage offset OFF, repeat the steps above, but set the offset voltage level to 0.

3.13.4 Storing and Recalling a Waveform Generator Setup

You can store up to 9 front-panel setups inside the internal non-volatile flas h me mory. When

you recall a stored setup, the front-panel settings change to match the settings in the stored

setup.

Storing Setups

To store the front-panel setup:

1. Press UTILITY to display the menu.

2. Press F2:STORE to select the Store mode.

3. Use the rotary input knob to select a buffer number. Vali d buffer numbers r ange from 1 to 9.

Buffer 0 is a read-only buffer that contains the default setup/power-on settings.

The function generator will overwrite and store settings into a buffer that had settings

previously stored inside without a warning.

16

Page 17

Recalling Setups

To recall stored fro nt-panel setup:

1. Press UTILITY to display the menu.

2. Press F1:RECALL to select the Recall mode.

3. Use the rotary input knob to select a buffer number. Valid buffers numbers range from 0 to 9.

Buffer 0 is a read-only buffer that contains the default power-on setup.

17

Page 18

SERVICE INFORMATION

Warranty Service: Please go the support and service section on our website www.bkprecision.com to obtain a RMA #. Return the product

in the original packaging with proof of purchase to the address below. Clearly state on the RMA the performance problem and return any

leads, probes, conn ectors and accessories that you are using with the device.

Non-Warranty Service: Please go the support and service s ection on our website www.bkprecision.com to obtain a RMA #. Return the

product in the original packaging to the address below. Clearly state on the RMA the performance problem and return any leads, probes,

connectors and accessories that you are using with the device. Customers not on an open account must include payment in the form of a

money order or credit card. For the most current repair charges please refer to the service and support section on our website.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty Service

does not include return shipping. Return shipping to locations in North America is included for Warranty Service. For overnight

shipments and non-North American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number and

description of problem.

LIMITED THREE-YEAR WARRANTY

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be free from

defects in workmanship and materials for a period of three years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts. Returned

product must be accompanied by proof of the purchase date in the form of a sales receipt.

To help us better serve you, please complete the warranty registration for your new instrument via our website

www.bkprecision.com

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of

unauthorized alterations or repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting from

loss of use. Some states do not allow limitations of incidental or consequential damages. So the above limitation or exclusion

may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Page 19

Index

Amplitude, 6, 12, 13, 15

cursor, 14

duty cycle, 13

Errors, 15

factory default, 15

frequency, 12

Impedance Matching, 12

intensity, 14

LCD, 11

Linear, 14

Offset, 12

recall, 17

safety, 2

Specifications, 6

store, 16

Symmetry, 13

Sync Out, 11

Page 20

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

© 2012 B&K Precision Corp.

v030713

Loading...

Loading...