Page 1

INSTRUCTION

MANUAL

MANUAL DE USUARIO

MODEL 4010A

MODELO 4010A

2 MHz

FUNCTION

GENERATOR

2MHz GENERADOR

DE FUNCIONES

1

Page 2

TEST INSTRUMENT SAFETY

WARNING

Normal use of test equipment exposes you to a certain amount of danger from electrical shock because testing must sometimes be

performed where exposed voltage is present. An electrical shock causing 10 milliamps of current to pass through the heart will stop most

human heartbeats. Voltage as low as 35 volts dc or ac rms should be considered dangerous and hazardous since it can produce a lethal

current under certain conditions. Higher voltages pose an even greater threat because such voltage can more easily produce a lethal

current. Your normal work habits should include all accepted practices to prevent contact with exposed high voltage, and to steer current

away from your heart in case of accidental contact with a high voltage. You will significantly reduce the risk factor if you know and

observe the following safety precautions:

1. Don't expose high voltage needlessly. Remove housings and covers only when necessary. Turn off equipment while making test

connections in high-voltage circuits. Discharge high-voltage capacitors after removing power.

2. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However, remember that

high voltage may appear at unexpected points in defective equipment.

3. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to place

equipment; and make certain such surfaces are not damp or wet.

4. Use the time proven "one hand in the pocket" technique while handling an instrument probe. Be particularly careful to avoid

contacting a nearby metal object that could provide a good ground return path.

5. When testing ac powered equipment, remember that ac line voltage is usually present on some power input circuits such as the on-

off switch, fuses, power transformer, etc. any time the equipment is connected to an ac outlet, even if the equipment is turned off.

(continued on inside back cover)

2

Page 3

Instruction Manual

for

MODEL 4010A

2 MHz

FUNCTION

GENERATOR

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

3

Page 4

TABLE OF CONTENTS

page

TEST INSTRUMENT SAFETY............... inside front cover

INTRODUCTION ............................................................ 5

SPECIFICATIONS...........................................................6

CONTROLS AND INDICATORS ....................................8

OPERATING INSTRUCTIONS..................................... 10

Frequency and Waveform Selection ............................10

Considerations ........................................................... 11

Duty Cycle Control .................................................... 12

TTL/CMOS Output .................................................... 13

Voltage Controlled Frequency Operation..................... 13

Output Protection Considerations ............................... 14

Function Generator Applications Guidebook ..............14

page

MAINTENANCE........................................................... 15

Fuse Replacement....................................................... 15

Function Generator Guidebook ................................... 15

CUSTOMER SUPPORT ................................................ 16

SERVICE INFORMATION............................................ 17

LIMITED TWO-YEAR WARRANTY............................ 18

SPANISH MANUAL ..................................................... 20

4

Page 5

INTRODUCTION

The B+K Precision Model 4010A Function Generator is a

versatile signal source which combines several functions into one

unit. A calibrated dial provides frequency accuracy within 5%.

High stability assures that the output frequency does not drift.

The heart of the function generator is a VCG (voltage-controlled

generator) that produces precision sine, square, or triangle waves

over the 0.2 Hz to 2 MHz range. This encompasses subaudible,

audio, ultrasonic, and RF applications. A continuously variable dc

offset allows the output to be injected directly into circuits at the

correct bias level.

Variable symmetry of the output waveform converts the

instrument to a pulse generator capable of generating

rectangular waves or pulses, ramp or sawtooth waves, and

slewed sine waves.

In addition to the above features, an external signal may

be used to sweep the output frequency or control operating

frequency. This is useful in situations where an externally

controlled frequency is desirable.

With this versatility, the unit has a vast number of

applications in both analog and digital electronics in the

engineering, manufacturing, servicing, educational, and

hobbyist fields.

5

Page 6

SPECIFICATIONS

FREQUENCY CHARACTERISTICS

Waveforms

Sine, Square, Triangle, ± Pulse, ± Ramp

Range

0.2 Hz to 2 MHz in 7 ranges

Dial Accuracy

± 5%

Tuning Range

10:1

Variable Duty Cycle

15:85:15 Continuously Variable

Operating Modes

Normal, VCG (Voltage Controlled Generator)

OUTPUT CHARACTERISTICS

Impedance

50 Ω ± 10%

Level

20 V p-p Open-circuit, 10 V p-p into 50Ω

Amplitude Control

Variable, 20 dB range typical

Attenuation

-20 dB ±1 dB

DC Offset

Preset: ±0.1 V typical

Variable: ±10V open-circuit, ±5V into 50 Ω

SINE WAVE

Distortion

4% typical at 1 kHz

Flatness

±5% (0.45 dB)

SQUARE WAVE

Symmetry

≤2% 0.2 Hz to 100 kHz

Rise Time

≤120 nS

TRIANGLE WAVE

Linearity

≥98% to 100 kHz

6

Page 7

SPECIFICATIONS

TTL OUTPUT

Level 0.8 V to 2.4 V

Rise Time ≤20 nS

Duty Cycle 50% typical

CMOS OUTPUT

Level 4 V to 14 V ±0.5V p-p,

Continuously Variable

Rise Time ≤50 nS

POWER SOURCE

DIMENSIONS (H x W x D)

WEIGHT

VCG (Voltage Controlled Generator) INPUT

Input Voltage

0 - 10 V ±1 V causes a 100:1 frequency change

Impedance

10 kΩ ±5%

NOTE: Specifications and information are subject to change without notice. Please visit

information.

ACCESSORIES

120 / 230 VAC ±10%, 50 / 60 Hz, internal jumper

selectable

4 1/2" x 10 1/2" x 12 1/4" (26.7cm x 11.4cm x 31.1cm)

4.1 lb. (1.845 kg.)

Instruction Manual

Output Cable, BNC to Alligator Clips

www.bkprecision.com for the most current product

7

Page 8

CONTROLS AND INDICATORS

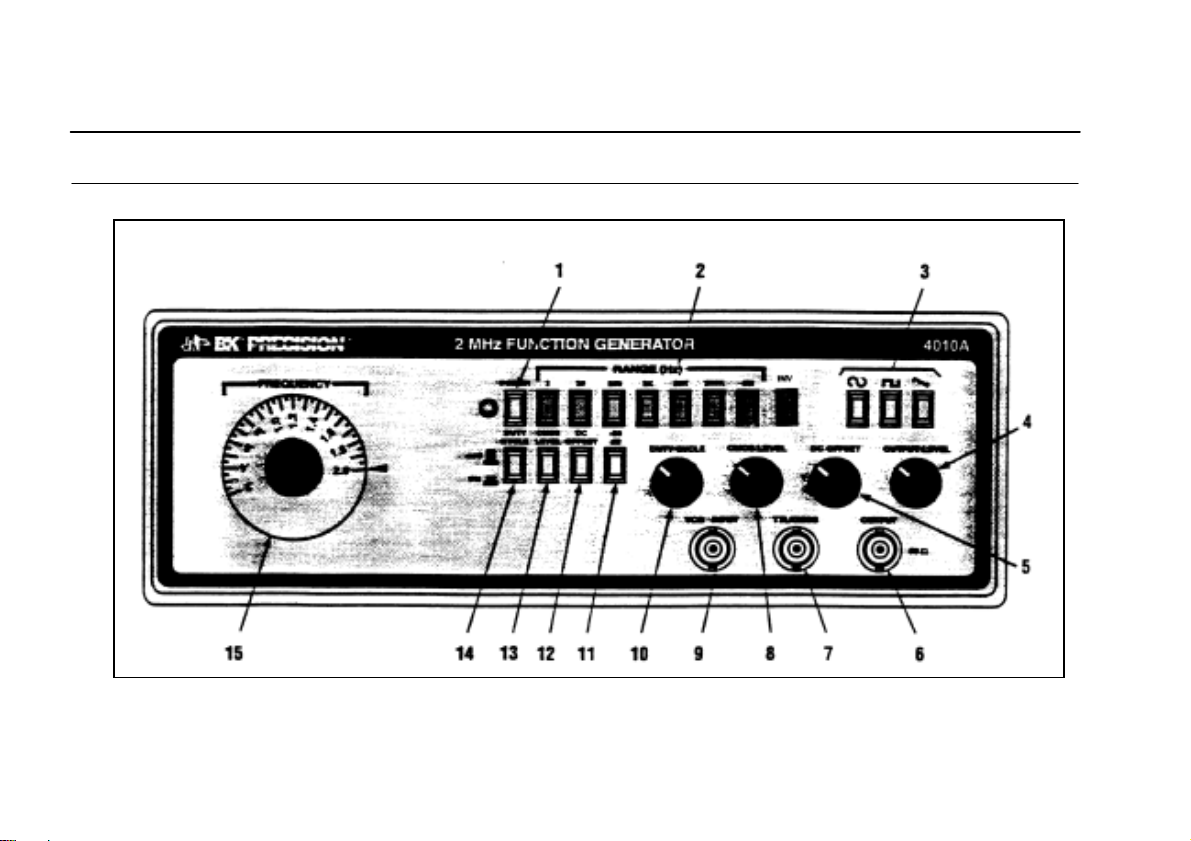

FRONT PANEL (Refer to Fig. 1)

1. POWER Switch. Turns power on and off.

2. RANGE Switch. Selects output frequency range. Seven

ranges from 2 Hz to 2 MHz. Switch indicates maximum

frequency of range and is adjusted with FREQUENCY

control to 0.1 times the maximum. For example, if the

200 kHz range is selected, the output frequency can be

adjusted from 20 kHz to 200 kHz.

3. FUNCTION Switch. Selects sine, square, or triangle

waveform at OUTPUT jack.

4. OUTPUT LEVEL Control. Controls the amplitude of

the signal at the OUTPUT jack. Output level can be

decreased by approximately 20 dB with this control.

5. DC OFFSET Control. Enabled by the DC OFFSET

Switch (12). Clockwise rotation from center changes the

DC offset in a positive direction while counterclockwise

rotation from center changes the DC offset in a negative

direction.

6. OUTPUT Jack. Waveform selected by FUNCTION

switch as well as the superimposed DC OFFSET voltage

is available at this jack.

7. TTL/CMOS Jack. TTL or CMOS square wave,

depending on the position of the CMOS LEVEL switch

(13) is output at this jack. This output is independent of

the OUTPUT LEVEL and DC OFFSET controls.

8. CMOS LEVEL Control. Rotating this control

clockwise increases the amplitude of the CMOS

square wave at the TTL/CMOS jack.

9. VCG Jack. Voltage Controlled Generator input.

Permits external control of generator output

frequency by a DC voltage input at this jack. A

positive voltage will decrease frequency.

10. DUTY CYCLE Control. Enabled by the DUTY

CYCLE Switch (14). Rotation from center position

adjusts the duty cycle of the main OUTPUT signal.

11. -20 dB Switch. When engaged, the signal at the

OUTPUT jack is attenuated by 20 dB.

12. DC OFFSET Switch. When engaged, enables

operation of the DC OFFSET control (5).

13. CMOS LEVEL Switch. When engaged, changes

the TTL signal to CMOS signal at the TTL/CMOS

jack.

14. DUTY CYCLE Switch. When engaged, enables

operation of DUTY CYCLE control (10).

15. FREQUENCY Control. Adjustment of the output

frequency from 0.1 to 1 times the selected range.

16. INV. Allows the user to invert the polarity of the

normal output signal.

8

Page 9

CONTROLS AND INDICATORS

Figure 1. Model 4010A Controls and Indicators.

9

Page 10

OPERATING INSTRUCTIONS

The B+K Precision Model 4010A Function Generator is a

versatile instrument, capable of producing a variety of output

waveforms over a broad range of frequencies. To gain a working

familiarity with the unit, it is recommended that it be connected

initially to an oscilloscope, so that the effects of the various

controls on the output waveforms can be observed. Use this

manual as required for reference until becoming accustomed to

the operating procedures.

FREQUENCY AND WAVEFORM SELECTION

l. Initially, verify that the DUTY CYCLE (14), CMOS

LEVEL (13), DC OFFSET (12), -20dB (11) switches are

in the OUT position (released). This will produce a

symmetrical waveform unaffected by the other controls.

2. Plug the unit into an appropriate power source and turn it on

by engaging the POWER switch (1).

3. Select the desired waveform (SINE, SQUARE, or

TRIANGLE) by engaging one of the FUNCTION switches

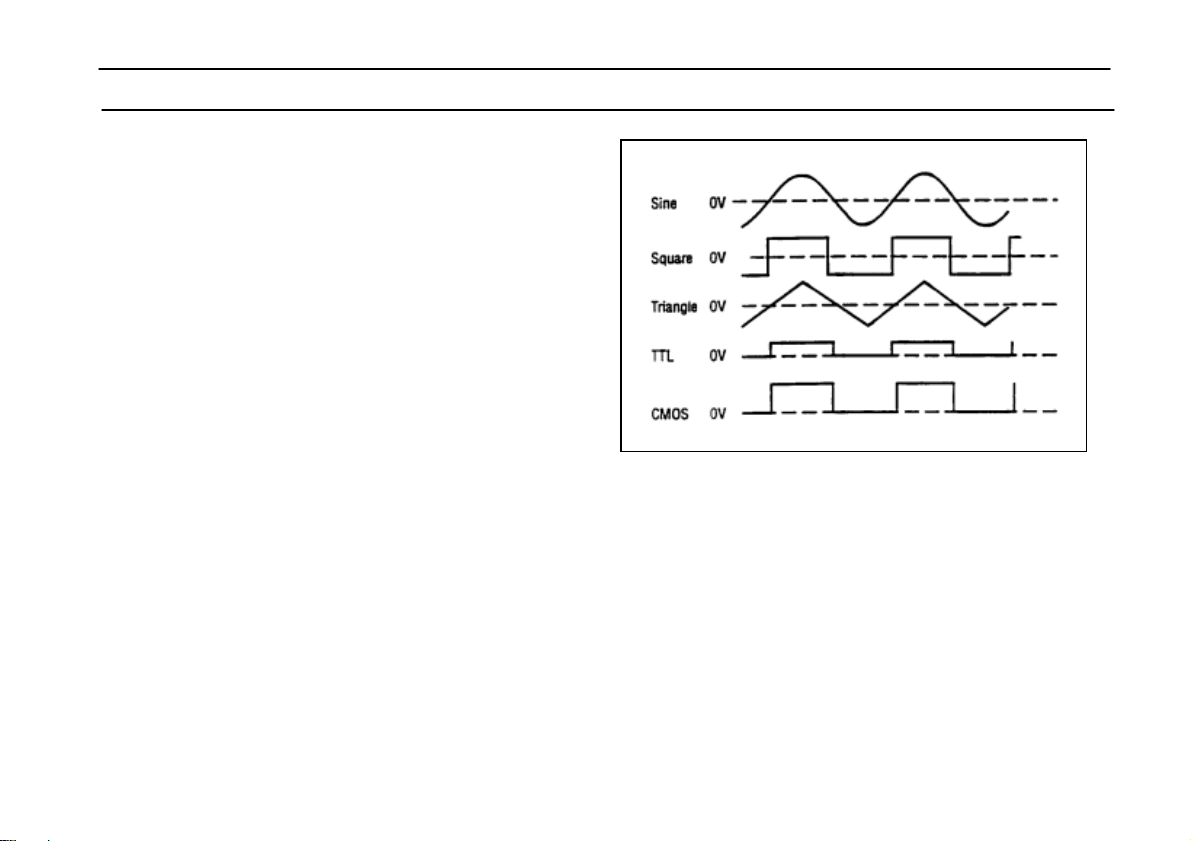

(3). Phase relationships of the waveforms are shown in Fig.

2.

4. Select the frequency of the waveform by engaging one of

the RANGE switches (2).

5. Rotate the FREQUENCY control (15) to set the output

frequency to the desired value. The frequency selected is

available at the OUTPUT jack (6). In addition, a digital

signal, either TTL or CMOS is available at the TTL/CMOS

jack (7) (refer to the “TTL/CMOS OUTPUT” section of this

manual).

10

Figure 2. Output Waveform and Phase

Relationship

6. Adjust the amplitude of the output as desired using the

OUTPUT LEVEL control (4). Rotation of this control

varies the amplitude from maximum to 20 dB below

maximum. An additional attenuation of -20 dB is

available by pushing in the -20dB switch (11). The

attenuation factors can be combined for a total of -40

dB. The maximum signal level is 10 V p-p (into 50 Ω).

Page 11

OPERATING INSTRUCTIONS

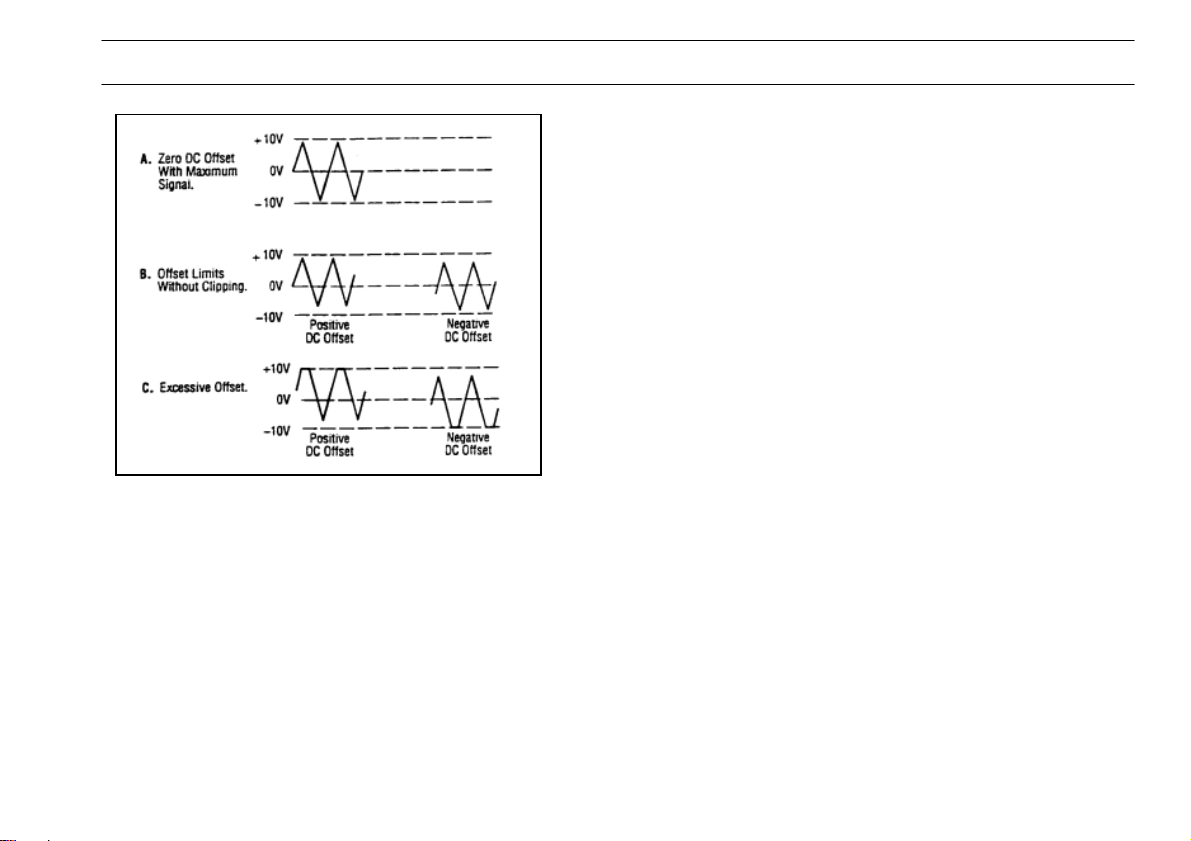

Figure 3. Use of DC OFFSET Control

6. Remember that the output signal swing of the generator

is limited to ±10 volts open circuited or ±5 volts into 50

Ω, and applies to the combined peak-to-peak signal and

DC offset. Clipping occurs slightly above these levels.

Fig. 3 illustrates the various operating conditions

encountered when using the DC offset. If the desired

output signal is large or if a large DC offset is required,

an oscilloscope should be used to make sure that the

desired signal is obtained without undesirable clipping.

7. A superimposed DC component can be added to the output

signal by engaging the DC OFFSET switch (12) to enable

operation of the DC OFFSET control (5). Rotation of this

control adds a positive or negative DC component to the

output signal. The DC component introduced is

independent of the OUTPUT LEVEL control and can be

varied by ±10 volts open circuited or ±5 volts into 50 Ω.

The DC Offset does not affect the TTL/CMOS output

jack. The effect of DC OFFSET is shown in Fig. 3.

CONSIDERATIONS

l. Counterclockwise rotation of the FREQUENCY control

decreases the output frequency to approximately one-tenth

of the maximum for the range selected (10:1). For

example, if the 20K range is selected and the

FREQUENCY control is set to full counterclockwise (dial

setting of .2), the output frequency is approximately 2 kHz.

2. Clockwise rotation of the FREQUENCY control increases

the output frequency. At the fully clockwise setting (dial

setting of 2.0), the output frequency will be equal to the

RANGE selection. That is, when the 20K range is selected

and the dial is set to 2.0, the output will be 20 kHz.

3. When the dial is set to 1.0, the output frequency is one half

of the maximum for the range selected. When the 20K

range is selected and the dial is set to 1.0, the output will

be 10 kHz.

4. A more precise frequency setting may be achieved by

connecting an external frequency counter to the TTL or

output jack.

5. When outputting square waves or when using the TTL

output, terminate the cable into 50 Ω to minimize ringing.

Also, keep cables as short as possible.

11

Page 12

OPERATING INSTRUCTIONS______________________________ _______________ _____________ ____________

DUTY CYCLE CONTROL

The DUTY CYCLE control can be used to alter the

symmetry of the output waveform, to produce waveshapes

such as those shown in Fig. 4. For a square wave, symmetry

variation amounts to changing the duty cycle (ratio of

"high" to "low" time), effectively converting the instrument

into a pulse generator. For a triangle wave, the result is a

ramp, and with a sine wave, a distorted waveshape called a

slewed sine is produced. The Model 4010A provides for

symmetry variation from 15% to 85%.

1. Select the waveform desired either SINE, SQUARE or

TRIANGLE.

2. Engage the DUTY CYCLE switch (14) and adjust the

DUTY CYCLE control (10) for the desired

waveshape. Clockwise rotation from center results in

an increase in square wave duty cycle, and changes the

sine and triangle waves as shown in the top waveform

of each pair of Fig. 4. Counter-clockwise rotation

results in the bottom waveform in each pair.

3. Varying the duty cycle setting results in a slight

change in frequency. Adjust the FREQUENCY

control as required.

Figure 4. Effects of Symmetry Variation.

12

Page 13

OPERATING INSTRUCTIONS

TTL/CMOS OUTPUT

The TTL/CMOS output jack provides a fast rise time square

wave output. Either a fixed TTL or a variable CMOS output

level is available. The output is positive with respect to ground

and can be used as an external sync pulse for oscilloscopes or

as a variable frequency signal source for exercising logic

circuits. Because of the fast rise time of this output, cable

length should be minimized to limit ringing and overshoot.

1. Select the desired frequency range and adjust the frequency

controls as required. The OUTPUT LEVEL and DC

OFFSET controls have no effect on the signal at the

TTL/CMOS jack.

2. When the CMOS LEV E L switch (13) is OFF, a TTL signal

is output at the TTL/CMOS jack. Select a CMOS signal by

engaging the CMOS LE V E L switch and adjust the level of

the signal by rotating the CMOS LEVE L control (8).

VOLTAGE CONTROLLED FREQUENCY OPERATION

The Model 4010A can be operated as a voltage-controlled generator

by using an external control voltage applied to the VCG INPUT

jack. The externally applied voltage will vary the frequency which is

preselected by the range switches and the frequency controls.

Applying approximately +l0 V with the FREQUENCY control at

full clockwise decreases the output frequency by about 100 times (a

100:1 ratio).

1. . Select the desired frequency range and waveform.

2. Set the starting frequency with the FREQUENCY control.

Apply a positive DC voltage to the VCG INPUT jack (9) to

decrease the frequency. A voltage from 0 to +10 V will

cause the frequency to decrease by a factor of 100 if the

FREQUENCY control is set at maximum CW rotation.

For example, if the starting frequency is 200 kHz, applying

+10 V will change the output frequency to 2 kHz.

3. To operate the function generator as a sweep generator,

apply a positive going ramp signal to the VCG INP UT

jack. As the ramp voltage increases, the frequency

decreases. The rate of sweep can be adjusted by varying

the frequency of the ramp signal.

4. Specific frequencies can be selected by applying a fixed

dc voltage to the VCG INPUT jack or the frequencies

can be stepped by applying a stepped dc voltage.

5. Do not apply more than ±15 volts (dc or dc + ac peak)

to the VCG INPUT jack. Inputs of more than 15 volts

will not cause any further shift in the frequency and

could cause damage to the generator.

OUTPUT PROTECTION C ONS IDE R ATI ONS

Use care when connecting the function generator output to a

signal injection point. Excessive voltage at the point of signal

injection of the function generator can cause internal damage.

Under normal operation, the generator output should never be

connected to an external voltage other than low dc values that

can be matched with the DC OFFSET control. The Model

4010A is overload protected so that shorting the output, even

continuously, will not cause damage. A fuse has been added in

series with the OUTPUT jack to help protect the instrument

from damage by connection to excessive external voltage.

Damage of this type usually occurs by accidentally

connecting the output of the function generator to a voltage in

the equipment under test. The following protective measures are

strongly recommended:

1. The user should understand the equipment under test well

enough to identify valid signal injection points (i.e.: the

base of a transistor, a logic input of a gate, etc.). The

voltage at valid signal injection points is rarely high

13

enough to damage the instrument.

Page 14

OPERATING INSTRUCTIONS___________________________________________________________________________

2. If in doubt about the safety of a signal injection

point, measure the voltage present at the intended

point of signal injection before connecting the

function generator output to that point.

3. When applying the main output of the function

generator to a circuit point containing a dc level,

adjust the DC OFFSET control so that the dc level

at the main output matches the circuit voltage.

4. Connect the TTL output only to TTL-level circuits.

Connect the CMOS output only to CMOS circuits.

Measure the Vcc of the circuit under test and adjust

the CMOS LEVEL control as instructed in the

manual.

5. When the function generator is used by students or

other inexperienced users, the circuit of Fig. 5 could

be added into your TTL output probe or test clip

set. It will protect the TTL output of the generator

against external voltages up to ±20 volts.

FUNCTION GENERATOR APPLICATIONS GUIDEBOOK

which describes numerous applications for this instrument,

including hook-up details. It also includes a glossary of

function generator terminology and an explanation of function

generator circuit operation. It maybe downloaded for free off

our website at www.bkprecision.com.

Figure 5. Circuit for Protection of TTL Output.

B+K Precision offers a “Guidebook to Function Generators”

14

Page 15

MAINTENANCE

WARNING

The following instructions are for use by qualified service

personnel only. To avoid electrical shock, do not perform

servicing other than contained in the operating instructions

unless you are qualified to do so.

Remember that ac line voltage is present on line voltage input

circuits any time the instrument is plugged into an ac outlet,

even if turned off. Always unplug the function generator before

performing service procedures.

FUSE REPLACEMENT

1. Locate the fuse holder on the input line receptacle.

2. Remove the fuse holder and replace the fuse with an

equal value fuse

INSTRUMENT REPAIR SERVICE

Because of the specialized skills and test

equipment required for instrument repair and

calibration, many customers prefer to rely upon

B+K PRECISION for this service. We maintain a

network of B+K PRECISION authorized service

agencies for this purpose. To use this service, even

if the instrument is no longer under warranty, follow

the instructions given in the WARRANTY

SERVICE INSTRUCTIONS portion of this manual.

There is a nominal charge for instruments out of

warranty.

15

Page 16

CUSTOMER SUPPORT

1-800-462-9832

B+K Precision offers courteous, professional technical support before and after the sale of their test instruments. The following services are

typical of those available from our toll-free telephone number:

Technical advice on the use of your instrument.

Technical advice on special applications of your instrument.

Technical advice on selecting the best instrument for a given task.

Information on optional accessories for your instrument.

Information on instrument repair and recalibration services.

Replacement parts ordering.

Availability of service publications.

Information on other B+K Precision instruments.

Requests for a new B+K Precision catalog.

The name of your nearest B+ K Precision distributor.

Call toll-free 1-800-462-9832

Monday through Thursday, 8:00 A.M. to 5:00 P.M, Friday 8:00 A.M. TO 11:30 A.M.

Pacific Standard Time

(Pacific Daylight Time summer)

16

Page 17

Service Information

Warranty Service: Please return the product in the original packaging with proof of purchase to the address below. Clearly state in writing

the performance problem and return any leads, probes, connectors and accessories that you are using with the device.

Non-Warranty Service: Return the product in the original packaging to the address below. Clearly state in writing the performance problem

and return any leads, probes, connectors and accessories that you are using with the device. Customers not on open account must include

payment in the form of a money order or credit card. For the most current repair charges please visit

“service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty Service does not include

return shipping. Return shipping to locations in North American is included for Warranty Service. For overnight shipments and non-North

American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number and description of

problem.

www.bkprecision.com and click on

17

Page 18

Limited Two-Year Warranty

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be free from defects in

workmanship and materials for a period of two years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts. Returned product must be

accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration form on

www.bkprecision.com within fifteen (15) days of purchase.

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of unauthorized alterations or

repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting from loss of use.

Some states do not allow limitations of incidental or consequential damages. So the above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

18

Page 19

TEST INSTRUMENT SAFETY

(continued from inside front cover)

6. Some equipment with a two-wire ac power cord, including some with polarized power plugs, is the “hot chassis” type. This

includes most recent television receivers and audio equipment. A plastic or wooden cabinet insulates the chassis to protect the

customer. When the cabinet is removed for servicing, a serious shock hazard exists if the chassis is touched. Not only does this

present a dangerous shock hazard, but damage to test instruments or the equipment under test may result from connecting the

ground lead of most test instruments to a “hot chassis”. To test “hot chassis” equipment, always connect an isolation transformer

between the ac outlet and the equipment under test. The B+K Precision Model TR-110 or 1604 Isolation Transformer, or Model

1653 or 1655 AC Power Supply is suitable for most applications. To be on the safe side, treat all two-wire ac equipment as “hotchassis” unless you are sure it has an isolated chassis or an earth ground chassis.

7. On test instruments or any equipment with a 3-wire ac power plug, use only a 3-wire outlet. This is a safety feature to keep the

housing or other exposed elements at earth ground.

8. Never work alone. Someone should be nearby to render aid if necessary. Training in CPR (cardio-pulmonary resuscitation) first

aid is highly recommended.

19

Page 20

SEGURIDAD DEL INSTRUMENTO DE PRUEBA

PRECAUCIONES

El Uso normal de equipo de prueba lo expone a cierto riesgo de choque eléctrico cuando efectúa pruebas donde hay alto voltaje descubierto. Un

choque eléctrico que cause una corriente de 10 mili amperes a través del corazón pararía la mayoría de los corazones humanos. Un voltaje tan bajo

como de 35 volts DC o AC rms podría considerarse de peligro porque puede producir una corriente letal bajo ciertas condiciones. Voltajes

mayores pueden ser aun más peligrosos. Sus hábitos normales de trabajo deben de incluir todas las prácticas aceptadas para prevenir descargas de

alto voltaje, y desviar la corriente lejos del corazón en caso de contacto accidental con un alto voltaje. Puede reducir el factor de riesgo

significativamente si observa las siguientes medidas de seguridad:

1. No se exponga a altos voltajes sin necesidad. Remueva la caja y tapas solo cuando sea necesario. Apague el equipo cuando haga conexiones de

prueba en circuitos de alto voltaje. Descargue los capacitores de alto voltaje después de apagar.

2. Si es posible, familiarícese usted mismo con el equipo por revisar y la localización de los puntos de alto voltaje. Considere, sin embargo, que

un voltaje alto puede aparecer en puntos inesperados en equipo defectuoso.

3. Use un piso de material aislante o un tapete aislante largo para situarse, y una superficie de trabajo aislante en la cual pueda poner el equipo;

asegúrese que las superficies no estén húmedas o mojadas.

4. Use la probada técnica de mantener “una mano en la bolsa” cuando este usando una sonda o punta de prueba del instrumento. Evite con

particular cuidado tocar un objeto metálico que pueda proveer un buen retorno a tierra.

5. Cuando revise un equipo conectado a voltaje de AC, recuerde que el voltaje está usualmente presente en algunos circuitos de entrada tal como el

switch de encendido y apagado, fusibles, transformadores de poder, etc. mientras el equipo esté enchufado a una toma de AC aun aún cuando

esté apagado.

(continuó la cubierta de espalda)

15

Page 21

MANUAL DE USUARIO

MODELO 4010A

2MHz GENERADOR DE FUNCIONES

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

16

Page 22

TABLA DE CONTENDIDO

SEGURIDAD DEL INSTRUMENTO DE PRUEBA ..... Segunda de forros

INTRODUCION ......................................................................................18

ESPECIFICACIONES .............................................................................19

CONTROLES E INDICADORES ...........................................................21

INSTRUCCIONES DE OPERACIÓN.....................................................23

Selección de frecuencia y forma de onda .............................................23

Consideraciones....................................................................................24

Control de ciclo de servicio..................................................................25

Salida para TTL/CMOS........................................................................26

Operación de la frecuencia controlada por voltaje................................26

Consideraciones de protección de salida .............................................. 27

Guía de aplicaciones del generador de funciones .................................27

Página

17

Página

MANTENIMIENTO.....................................................28

Desensamblado y reensamblado ...............................28

Reemplazo de fusible................................................28

Selección de línea de voltaje.....................................28

SOPORTE AL CLIENTE.................................... 29

INFORMACIÓN DE SERVICIO.................................30

GARANTIA LIMITADA DE DOS AÑOS ..................31

Page 23

INTRODUCCIÓN

El B & K Precision modelo 4010A generador de funciones es una

versátil fuente de señales que combina varias funciones en una

unidad. Un dial calibrado provee una precisión de frecuencia dentro

del 5% con alta estabilidad, para asegurar que la frecuencia no se

desplace.

El corazón del generador de funciones es un VCG (generador

controlado por voltaje) que produce ondas de seno, cuadradas y

triangulares precisas desde los 0.2Hz hasta 2 MHz, para

aplicaciones subaudibles, de audio, de ultrasonido y RF. Un

desplazamiento (offset) de DC de variación continua permite

inyectar la señal directamente en circuitos con la polarización

correcta.

La simetría variable de la forma de salida convierte al instrumento

en un generador de pulsos capaz de generar ondas rectangulares o

pulsos, ondas de rampa o diente de sierra y senoidales inclinadas.

Además de estas características, puede usar un voltaje externo para

controlar la frecuencia de operación.

18

Page 24

CARACTERÍSTICAS DE FRECUENCIA

Formas de onda

seno,cuadrada,triangular, ±pulso,±rampa

Rango

0.2Hz a 2MHz en 7 rangos

Precisión del dial

±5%

Rango de sintonía

10:1

Ciclo de servicio variable

15:85:15 continuamente variable

Modos de operación

normal, VCG

CARACTERÍSTICAS DE SALIDA

Impederica

50 OHM ± 10%

Nivel

20 V p-p circuito abierto,10Vp-p a 50

Control de amplitud

Variable, 20db rango tipico

Atenuación

-20db±1db

Compensación DC (offset)

Preestablecido: ±0.1 V típico

Variable: ±10V circuito abierto ,±5V a 50

ESPECIFICACIONES

ONDA SENOIDAL

Distorsión

3% a 1Khz típica

Aplanado

±5% (.45dB)

ONDA CUADRADA

Simetría

0.2Hz a 100KHz 2%

Tiempo de elevación

120Ns

ONDA TRIANGULAR

Linealidad

98% a 100KHz

19

Page 25

_______________________________________________________________________ESPECIFICACIONES

SALIDA TTL

Nivel 0.8V a 2.4V

Tiempo de elevación 20ns

Ciclo de servicio 50% típico

SALIDA CMOS

Nivel 4V a 14 V ±0.5V p-p

continuamente variable

Tiempo de elevación 50ns

ENTRADA DE VCG (generador controlado por voltaje)

Voltaje de entrada

0-10V ±1V causa un cambio de frecuencia 100:1

Impedancia

10K OHM ± 5%

FUENTE DE PODER

120/230 VAC ± 10% 50/60hz Selección por jumper interno

DIMENSIONES

(26.7 x 11.4 x 31.1 cm)

PESO

4 LB (1.845 kg)

ACCESORIOS

Cable de salida BNC a clips de cocodrilo, Manual de usuario

NOTA: Las especificaciones y la información están conforme a cambio sin el aviso de B&K Precision Corp. Por favor visite

www.bkprecision.com

para las especificaciones más corriente y información de nuestros productos.

20

Page 26

CONTROLES E INDICADORES

PANEL DELANTERO (Vea la Fig. 1)

10. INTERRUPTOR DE ENCENDIDO (POWER). Enciende y

apaga el instrumento.

11. SWITCH DE R ANGO (RANGE). Selecciona el rango de la

frecuencia de salida. 7 rangos de 2Hz a 2MHz. El switch

indica la máxima frecuenta del rango y se ajusta con el control

grueso de frecuencia a 0.1 veces el máximo. Por ejemplo, si el

rango de 200kHz es seleccionado, la salida de frecuencia

puede ser ajustada de 20kHz a 200kHz

12. SWITCH DE FUNCIONES (FUNCTION). Selecciona la

forma de onda del jack de salida : senoidal, cuadrada,

triangular en el jack OUTPUT de salida

13. CONTROL DE NIVEL DE SALIDA (OUTP UT LEVEL).

Controla la amplitud de la señal al jack de salida. El nivel de

salida puede ser disminuido por aproximadamente 20dB con

este control

14. CONTROL DE DC OFFSET. Activado por el switch de

OFFSET (12). La rotación en la dirección de las manecillas del

reloj desde el centro cambia el desplazamiento de DC en la

dirección positiva, en tanto que la rotación en contra de las

manecillas del reloj desde el centro cambia el desplazamiento

de DC en la dirección negativa.

15. JACK DE SALIDA (OUTPUT). La forma de onda

seleccionada por el switch de funciones así como el voltaje de

desplazamiento de DC sobre impuesto está disponible en este

jack.

16. Jack TTL/CMOS . Onda cuadrada TTL o CMOS,

dependiendo de la posición del switch (13) de nivel CMOS.

Esta salida es independiente del los controles de OUTPUT

LEVEL y OFFSET CD .

1. CONTROL DE NIVEL CMOS (LEVEL). Girando este

control en la dirección de las manecillas del reloj aumenta la

amplitud de la señal CMOS al jack TTL/CMOS.

2. Jack de entrada VCG. Permite el control externo de la

frecuencia de salida del generador por un voltaje de DC

aplicado a este jack. Un voltaje positivo disminuirá la

frecuencia.

3. CONTROL DEL CICLO DE SERVICIO (DUTY CYCLE).

Activado por el switch DUTY CYCLE(14). La rotación desde

la posición central ajusta el ciclo de servicio de la señal de la

salida principal OUTPUT.

4. –20 DB SWITCH. Al accionarse, la señal del jack de salida es

atenuada por –20 dB.

5. Switch DC OFFSET. Al accionarse se habilita la operación del

control DC OFFSET(5).

6.

Switch CMOS LEVEL. Accionado, cambia la señal TTL a

señal CMOS en el jack TTL/CMOS

7. Switch DUTY CYCLE. Su activación habilita la operación del

control DUTY CYCLE(10).

8. Control FREQUENCY. Ajusta la frecuencia de salida de 0.1 a 1

del rango seleccionado

9. INV. Permite invertir la polaridad de la señal normal de salida

21

Page 27

____________________________________________________________CONTROLES E INDICADORES

Figura 1. Panel frontal del modelo 4010A

22

Page 28

INSTRUCCIONES DE OPERACION

El Generador de funciones B&K Precison Modelo 4010A es un

instrumento versátil, capaz de producir una variedad de formas de

onda con un amplio rango de frecuencias. Para familiarizarse con

esta unidad, se recomienda conectarla inicialmente a un

osciloscopio, para observar los efectos de los controles en las

formas de onda generadas. Use este manual según requiera como

referencia hasta que domine los procedimientos de operación.

SELECCION DE FRECUENCIA Y FORMA DE ONDA

1. Inicialmente, verifique los switches DUTY CYCLE (14),

CMOS LEVEL(13), DC OFSSET(12),

y - 20dB (11) estén desactivados. Esto producirá una onda

simétrica no afectada por el generador de barrido y otros

controles.

2. Enchufe la unidad en una fuente de energía apropiada y

enciéndalo oprimiendo el switch POWER (1)

3. Seleccione la onda de forma deseada (SINE, SQUARE,

TRIANGLE) oprimiendo uno de los switches de FUNCTION

(3). Sus relaciones de fase se muestran en la figura 2.

4. Seleccione la frecuencia de la onda de forma oprimiendo uno de

los switches RANGE (2).

5. Gire el control FREQUENCY (15) para fijar la frecuencia de

salida rápidamente al valor deseado. La frecuencia

seleccionada estará disponible en el jack OUTPUT (6).

Además, una señal digital estará presente en el jack TTL/MOS

(7) (Refiérase a la señal TTL/CMOS OUTPUT de este

manual.

Figura 2. Formas de onda de salida y relación de frase

6. Ajuste la amplitud de la salida como desee usando el control

OUTPUT LEVEL (4) (Nivel de salida) La rotación de

este control varía la amplitud desde el máximo hasta 20

dB debajo del máximo. Una atenuación adicional de –

20dB esta disponible oprimiendo el –20dB switch (11).

Los factores de atenuación pueden ser combinados por un

total de –40dB. El máximo nivel de señal es de 10V p-p

(con carga de 50 Ohms)

23

Page 29

_________________________________________________________INSTRUCCIONES DE OPERACIÓN

7. Un componente de DC puede sumarse a la señal de salida

oprimiendo el switch DC OFFSET (12) para activar la

operación del control DC OFFSET (5). La rotación de este

control añade una componente de DC positiva o negativa a

la señal de salida. La componente de DC introducido es

independiente del control OUTPUT LEVEL y puede

variarse ± 10 voltios en circuito abierto o

± 5 voltios a través de 50 ohms. El desplazamiento de DC

no afecta al jack de salida TTL/CMOS. El efecto del

desplazamiento se muestra en la Fig. 3.

CONSIDERACIONES

1. La rotación contra el reloj del control FREQUENCY reduce la

frecuencia de salida por un factor aproximado de 10:1 del

rango seleccionado. Por ejemplo, en el rango de 20K, el giro

completo del dial en contra de las manecillas reduce la

frecuencia a 2KHz aproximadamente.

2. La rotación del control en sentido del reloj aumenta la

frecuencia hasta el valor tope del rango. Esto es, si

selecciona el rango de 20K y el dial se fija en 2.0, la

frecuencia será de 20KHz.

3. Con el dial en 1.0, la frecuencia de salida es aproximadamente

la mitad del rango seleccionado. Así, en el rango de 20K y el

dial en 1.0, la salida es de 10KHz.

4. Para mayor precisión, conecte un contador externo de

frecuencia a los jacks de salida TTL u OUTPUT

5. Cuando genere ondas cuadradas o utilice la salida de TTL,

termine el cable en 50 ohms para disminuir oscilaciones

transitorias. También, use cables tan cortos como sea

posible.

Figura 3. Uso del control DC OFFSET

6. Recuerde que la variación de la señal de salida de generador esta

limitada a ±10 volts en circuito abierto o ± 5 volts en 50 ohms, y

aplica a la señal combinada pico a pico con el desplazamiento

DC. El truncamiento ocurre ligeramente arriba de estos niveles.

La Fig. 3 ilustra diversas condiciones de operación posibles al

introducir el desplazamiento DC. Si la amplitud de la señal o el

desplazamiento DC son grandes, utilice un osciloscopio para

asegurar que la señal deseada no presenta un truncamiento

indeseable.

24

Page 30

INSTRUCCIONES DE OPERACIÓN_________________________________________________________

CONTROL DUTY CICLE (CICLO DE SERVICIO)

El control DUTY CYCLE puede usarse para alterar la simetría

de la forma de onda de salida, y generar ondas de forma tales como

las mostradas en la Fig. 4. Para una onda cuadrada, la variación de

simetría equivale a cambiar el ciclo servicio (razón del tiempo

“alto” al “bajo”), efectivamente convirtiendo al instrumento en un

generador de pulsos. Para una onda triangular, el resultado es una

rampa, y para una onda senoidal, obtenemos una onda distorsionada

llamada “seno inclinado”. El Modelo 4011A permite la variación

de simetría desde 15% hasta 85%.

1. Seleccione la onda de forma deseada sea SENOIDAL,

CUADRADA, o TRIANGULAR.

2. Active el switch DUTY CYCLE (14) y ajuste el control DUTY

CYCLE (10) para obtener la forma de onda deseada. La

rotación desde el centro en sentido de las manecillas del reloj

incrementa el ciclo de servicio en una onda cuadrada, y

modifica las ondas de seno y triángulo como se muestra en las

ondas superiores de cada par de la Fig.4. La rotación contraria

produce las formas de onda inferiores de cada par.

3. Las variaciones del ciclo de servicio producen cambios ligeros de

la frecuencia. Ajuste el control como se requiera.

Figura 4 Efectos de variación de simetría

25

Page 31

_________________________________________________________INSTRUCCIONES DE OPERACIÓN

SALIDA TTL/CMOS

El jack de salida TTL/CMOS presenta una señal cuadrada de

tiempo de levantamiento rápido, con un nivel fijo TTL o variable

CMOS. La salida es positiva respecto a tierra y puede usarse como

pulso externo de sincronización para osciloscopios o como fuente

de frecuencia variable para probar circuitos lógicos. Dado el rápido

tiempo de levantamiento, se recomienda usar cables cortos para

minimizar transitorios o sobre impulsos.

4. Seleccione el rango de frecuencia deseado y ajuste los controles

de frecuencia como requiera. Los controles OUTPUT LEVEL

y DC OFFSET no producen efecto alguno en la señal

TTL/CMOS.

5. Cuando el switch CMOS LEVEL (13) se desactiva, se produce

una señal TTL en el jack. Seleccione una señal CMOS

accionando el switch CMOS LEVEL y ajuste el nivel de la

señal girando el control CMOS LEVEL (8).

OPERACION DE LA FRECUENCIA CONTROLADA POR

VOLTAJE

El modelo 4010A puede ser operado como un generador

controlado por voltaje aplicando al jack VCG/SWEEP de entrada)

un voltaje externo de control. Dicho voltaje variará la frecuencia

preseleccionada por los switches de rango y los controles de

frequencia. Aplicando aproximadamente +10V con el control

COARSE a rotación completa en la dirección del reloj se

disminuye la frecuencia de salida por cerca de 100 veces (un factor

de100:1 ).

1. Seleccione el rango de frequencia deseado y la forma de onda

2. Ajuste la frecuencia de inicio con el control FREQUENCY.

Aplique un voltaje de DC positivo al jack VCG/SWEEP (9)

de entrada para disminuir la frecuencia. Un voltaje de 0 a

+10 V causa que la frecuencia disminuya por un factor

de100 si el control se rota a su máximo. Por ejemplo, si la

frecuencia de inicio es de 200 kHz, aplicando +10 V

cambiará la frecuencia de salida a 2kHz.

1. Para usar el generador de funciones como un generador de

barrido, aplique una señal de rampa al jack de entrada VCG

INPUT. Cuando el voltaje de rampa aumenta, la frecuencia

disminuye. La velocidad de barrido puede ajustarse

variando la frecuencia de la señal de rampa.

2. Puede seleccionar frecuencias específicas aplicando un voltaje

de DC fijo al jack VCG IMPUT o las frecuencias pueden ser

escalonadas aplicando un voltaje de DC escalonado.

3. No aplique mas de ± 15 volts (DC o DC + AC pico) al jack

VCG INPUT jack. Entradas de mÁs de 15 volts no varían

más la frecuencia y podrían ocasionar daños al generador.

26

Page 32

INSTRUCCIONES DE OPERACIÓN_________________________________________________________

CONSIDERACIONES DE PROTECCION DE SALIDA

Tenga cuidado al conectar la salida del generador de funciones a

un punto receptor de señales. Un voltaje excesivo del generador en

el punto de inyección puede causar daño interno. Bajo operación

normal, la salida del generador nunca debe conectarse a un voltaje

externo mayor que el que provee el control DC OFFSET. El

Modelo 4010A esta protegido contra sobrecargas, así que, aunque

se establezca un corto circuito continuo en la salida, no sufrirá

daños. Se incluye un fusible en serie con el jack OUTPUT de salida

para ayudar a proteger al instrumento contra daños al conectarlo a

un voltaje excesivo externo.

Daño de este tipo usualmente ocurre al conectar accidentalmente

la salida del generador de funciones a un voltaje en el equipo bajo

prueba. Se recomiendan enfáticamente las siguientes medidas de

protección:

1. El usuario debe conocer el equipo bajo prueba lo suficiente bien

para identificar los puntos correctos de inyección de señales

(e.g. la base de un transistor, una entrada lógica de una

compuerta, etc.) El voltaje en un punto de inyección de señales

válido rara vez es suficientemente elevado para dañar al

instrumento.

2. Si duda sobre la seguridad de un punto de inyección de señales,

mida el voltaje presente en dicho punto antes de conectarle la

salida del generador de funciones.

3. Cuando aplique la salida principal del generador de señales a un

punto de un circuito que contenga un nivel de DC, ajuste el

control DC OFFSET para que el voltaje se salida iguale al voltaje

del circuito.

4. Conecte la salida de TTL solo a circuitos de nivel TTL. Conecte

la salida de CMOS solo a circuitos CMOS. Mida el voltaje Vcc

del circuito bajo prueba y ajuste el control CMOS LEVEL como

se indica en el manual.

5. Cuando el generador de funciones es usado por estudiantes u

otros usuarios sin experiencia, el circuito mostrado en Fig. 5

puede ser añadido a su sonda de la salida TTL o al juego de clips

de prueba. Esto protegerá las salidas TTL del generador contra

voltajes externos hasta de ± 20 volts.

Figura 5. Circuito de protección para la salida TTL

LIBRO GUIA DE APLICACIONES DE EL GENERADOR DE

FUNCIONES

B &K Precision ofrece una “Guía del Generador de Funciones” que

describe numerosas aplicaciones de este instrumento, incluyendo

detalles de conexión. También incluye un glosario de la terminología

del generador de funciones y una explicación de la operación de su

circuito. Puede ser descargado gratis de nuestra Web site en

www.bkprecision

27

Page 33

MANTENIMIENTO

PRECAUCION

Las siguientes instrucciones son para uso solo por personal de

servido calificado. Para evitar choque eléctrico, no haga servicios

distintos al contenido en las instrucciones de operación a menos

que esté calificado para hacerlo.

Recuerde que la línea de voltaje de AC está presente en los

circuitos de entrada siempre que el instrumento esté conectado a un

enchufe de AC, aunque esté apagado. Siempre desenchufe el

generador de funciones antes de efectuar procedimientos de

servicio.

REEMPLAZO DE FUSIBLES

1. Localice el sostenedor de fusible en la linea de entrada.

2. Quite el sostenedor del fusible y dubstituya el fusible por

un fusible de valor egual.

SERVICIO DE REPARACION DEL INSTRUMENTO

Debido a las especializadas habilidades y equipo de prueba

requerido para la reparación y calibración del instrumento,

muchos clientes prefieren depender en B & K Precisión para

este servicio. Nosotros mantenemos una red de agencias de

servicio autorizadas para este propósito. Para usar este

servicio, aún si el instrumento ya no esta bajo garantía, siga

las instrucciones en la parte de INSTRUCCIONES DE

SERVICIO DE GARANTIA de este manual. Hay un cargo

nominal por instrumentos fuera de garantía.

28

Page 34

SOPORTE AL CLIENTE

1-800-462-9832

b+k Precision ofrece soporte técnico profesional y cortés antes y después de la venta de sus equipos de prueba. Los siguientes son servicios típicos

de los disponibles de nuestro teléfono sin carga:

• Asesoría técnica sobre el uso de su instrumento

• Asesoría técnica sobre aplicaciones especiales de su instrumento

• Asesoría técnica para escoger el mejor instrumento para una tarea específica

• Información sobre accesorios opcionales para su instrumento

• Información sobre servicios de reparación y recalibración

• Pedidos de partes de reemplazo

• Disponibilidad de publicaciones de servicio

• Información sobre otros instrumentos de B+K Precision

• Solicitudes de catálogos de B+K Precision

• El nombre de su distribuidor más cercano

Llame sin cargo 800-462-9832

29

Page 35

Información de Servicio

Servicio de Garantía: Por favor regrese el producto en el empaquetado original con prueba de la fecha de la compra a la dirección debajo. Indique

claramente el problema en escritura, incluya todos los accesorios que se estan usado con el equipo.

Servicio de No Garantía: Por favor regrese el producto en el empaquetado original con prueba de la fecha de la compra a la dirección debajo.

Indique claramente el problema en escritura, incluya todos los accesorios que se estan usado con el equipo. Clientes que no tienen cuentas deben

de incluir pago en forma de queque, orden de dinero, o numero de carta de crédito. Para los precisos mas corriente visite www.bkprecision.com

oprime “service/repair”.

Vuelva toda la mercancía a B&K Precision Corp. con el envío pagado por adelantado. La carga global de la reparación para el servicio de la NoGarantía no incluye el envío de vuelta. El envío de vuelta a las localizaciones en norte americano es incluido para el servicio de la garantía. Para

los envíos de noche y el envío del no-Norte los honorarios americanos satisfacen el contacto B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Incluya con el instrumento la dirección de vuelto para envío, nombre del contacto, número de teléfono y descripción del problema.

y

30

Page 36

Garantía Limitada de Un Ano

B&K Precision Corp. Autorizaciones al comprador original que su productos y componentes serán libre de defectos por el periodo de un ano desde

el día en que se compro.

B&K Precision Corp. sin carga, repararemos o sustituir, a nuestra opción, producto defectivo o componentes. Producto devuelto tiene que ser

acompañado con prueba de la fecha del la compra en la forma de un recibo de las ventas.

Para obtener cobertura en los EE.UU., este producto debe ser registrado por medio de la forma de registro en www.bkprecision.com dentro de

quince (15) días de la compra de este producto.

Exclusiones: Esta garantía no se aplica en el evento de uso en error o abuso de este producto o el resultado de alteraciones desautorizado o

reparaciones. La garantía es vacía si se altera, se desfigura o se quita el número de serie.

B&K Precision Corp. no será obligado a dar servicio por danos consecuente, incluyendo sin limitaciones a danos resultando en perdida de uso.

Algunos estados no permiten limitaciones de daños fortuitos o consecuentes. Tan la limitación o la exclusión antedicha puede no aplicarse a usted.

Esta garantía le da ciertos derechos y pueden tener otros derechos, cuales cambian estado por estado.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

31

Page 37

SEGURIDAD DEL INSTRUMENTO DE PRUEBA

(continuacion desde el )

6. Ciertos equipos con cable de poder de 2 puntas, incluyendo otros con cable polarizado, son del tipo de #chasis caliente”. Esto

incluye la mayoría de los más recientes receptores de televisión y equipos de sonido. Un gabinete de plástico o de madera aísla

el chasis para proteger al cliente. Cuando el gabinete es removido para servicio, un serio peligro de choque existe si se toca el

chasis. Además del peligro de choque eléctrico, tanto el instrumento de prueba como el aparato bajo prueba pueden dañarse al

conectar la punta de tierra del instrumento al “chasis caliente” Para probar equipos con “chasis caliente”, conecte siempre un

transformador de aislamiento entre el enchufe de AC y el equipo bajo prueba. El B & K Precision Modelo TR-110 o el

transformador de aislamiento 1604, o bien las fuentes de poder de AC modelos 1643 o 1655 son adecuados para la mayoría de

las aplicaciones. Para mayor seguridad, trate todos los equipos con cable de poder de 2 puntas como de “chasis caliente” a

menos que esté seguro que tiene un chasis aislado o un chasis a tierra.

7. En instrumentos de prueba o cualquier equipo con cables de AC de 3 puntas, conéctelos sólo a un enchufe que acepte las 3 puntas

. Esta es una característica de seguridad para mantener la caja u otros elementos expuestos ,a tierra.

8. Los productos B & K Precision no están autorizados para uso en cualquier aplicación que involucre el contacto directo con el

cuerpo humano, o para el uso como un componente critico en un dispositivo o sistema para el soporte de vida. Aquí, “contacto

directo” se refiere a cualquier conexión de o a nuestro equipo a través de cualquier cableado o interruptores. Un “componente

critico” es cualquier componente de un dispositivo de soporte de vida o sistema cuyo fallo pueda causar una falla del dispositiva

o sistema, o afecte su seguridad o efectividad.

9. Nunca trabaje solo. Alguien debe de estar cerca para prestar ayuda de ser necesario. Entrenamiento en primeros auxilios CPR

(resucitación cardiopulmonar) se recomienda ampliamente.

32

Page 38

Declaration of CE Conformity

according to EEC directives and NF EN 45014 norm

Responsible Party Alternate Manufacturing Site

Manufacturer’s Name: B&K Precision Corporation B&K Taiwan 0574

Manufacture’s Address: 22820 Savi Ranch Pkwy.

Yorba Linda, CA 92887-4610

USA

Declares that the below mentioned product

Product Name: Function Generator

Part Numbers: 4010A, 4011A, 4012A, 4040A, 4017A

complies with the essential requirements of the following applicable European Directives:

Low Voltage Directive 73/23/EEC (19.02.73) amended by 93/68/EEC (22.07.93)

Electromagnetic Compatibility (EMC) 89/336/EEC (03.05.88) amended by 92/68/EEC (22.07.93)

and conforms with the following product standards:

Safety EN 61010-1:2001

EMC EN 61326:1997 + A1:1998 + A2:2001

EN 50081-1

EN 50081-2

This Declaration of Conformity applies to above listed products place on the EU market after:

February 4, 2005

Date Victor Tolan

President

Page 39

22820 Savi Ranch Parkway • Yorba Linda, CA 92887

© 2005 B+K Precision

480-748-9-100 Printed in U.S.A.

20

Loading...

Loading...