Page 1

Service Manual

SRP-F310/312

Front Exit Thermal Printer

Rev. 1.00

http://www.bixolon.com

Page 2

SRP-F310/312

■ Table of Contents

1. Precaution Segment...................................................................................................................................4

1-1 Safety Precautions..................................................................................................................................4

1-2 Servicing Precaution...............................................................................................................................5

1-3 Precaution for Electrostatically Sensitive Devices (ESDs) .....................................................................6

1-4 Operational Precautions .........................................................................................................................6

2. Installation and Operation .........................................................................................................................7

2-1 Installation...............................................................................................................................................7

2-1-1 AC Adapter Installation ....................................................................................................................7

2-1-2 Interface Cable Installation ..............................................................................................................7

2-1-3 USB Cable Installation .....................................................................................................................7

2-1-4 Cash Drawer Cable Installation .......................................................................................................7

2-1-5 ETHERNET Cable Installation.........................................................................................................8

2-1-6 Dongle(Usb A-Type) Cable Installation ...........................................................................................8

2-1-7 Cover Open Installation ...................................................................................................................8

2-1-8 Paper Roll Installation ......................................................................................................................8

2-2 Operation ................................................................................................................................................9

2-2-1 Setting the DIP switches..................................................................................................................9

2-2-2 Setting the DIP switch (RS-232C Serial Interface) .......................................................................... 9

2-2-3 Setting the DIP switch (IEEE1284 Parallel, USB Interface) ............................................................9

2-2-4 Hexadecimal Dumping...................................................................................................................10

2-2-5 The self Test Mode ........................................................................................................................10

2-2-6 Setting the Memory Switches ........................................................................................................12

3. Product Specifications.............................................................................................................................15

3-1 Appearance...........................................................................................................................................15

3-1-1 Printer Dimensions (mm) ...............................................................................................................15

3-1-2 AC Adapter Dimensions (mm) .......................................................................................................15

3-1-3 Feature Locations-SRP-F310/312 .................................................................................................16

3-2 General Specifications..........................................................................................................................17

3-3 Thermal Printer Specifications..............................................................................................................18

3-3-1 Printer Specification .......................................................................................................................18

3-3-2 Character Specification..................................................................................................................18

3-3-3 Paper Specification ........................................................................................................................19

3-3-4 Reliability and Environment Specification......................................................................................19

3-3-5 Printable Area ................................................................................................................................20

3-3-6 TPH (Thermal Printer Head) Specification ....................................................................................20

3-3-7 Other Component Specification.....................................................................................................21

3-4 SMPS Specifications ............................................................................................................................22

3-4-1 SMPS (Switching Mode Power Supply) Specification ...................................................................22

3-4-2 SMPS Output Connector ...............................................................................................................22

3-5 Interface Specifications.........................................................................................................................23

3-5-1 RS-232C Serial Interface...............................................................................................................23

3-5-2 IEEE1284 Parallel Interface...........................................................................................................25

3-5-3 USB2.0 Interface............................................................................................................................27

3-6 Cash Drawer Specifications..................................................................................................................30

3-6-1 Drawer Cable .................................................................................................................................30

3-6-2 Cable Connection ..........................................................................................................................30

3-7 ETHERNET Specifications ...................................................................................................................31

3-7-1 Ethernet..........................................................................................................................................31

3-7-2 WLAN.............................................................................................................................................32

Rev. 1.00

- 2 -

Page 3

SRP-F310/312

4. Hardware ...................................................................................................................................................33

4-1 Wiring Diagram .....................................................................................................................................33

4-2 Block Diagram.......................................................................................................................................34

4-3 Special Circuit Descriptions..................................................................................................................39

4-3-1 Power Circuit..................................................................................................................................39

4-3-2 RESET Circuit................................................................................................................................40

4-3-3 Buzzer and Cash Drawer Circuits..................................................................................................41

4-3-4 I/F PBA Detect Block Diagram.......................................................................................................42

4-3-5 RS-232C Communication Block Diagram......................................................................................42

4-3-6 Parallel Communication Block Diagram ........................................................................................43

4-3-7 USB Communication Block Diagram ............................................................................................. 43

4-3-8 DIP Switch Circuit ..........................................................................................................................43

4-3-9 Thermal Printer Head Circuit .........................................................................................................44

5. Disassembly and Assembly ....................................................................................................................45

5-1 Case lower block ..................................................................................................................................45

5-2 Case Upper block .................................................................................................................................48

5-3 Frame block ..........................................................................................................................................51

6. Adjustments and Maintenance................................................................................................................53

6-1 Adjustment............................................................................................................................................53

6-1-1 Remaining Roll Paper Adjustment.................................................................................................53

6-2 Maintenance .........................................................................................................................................54

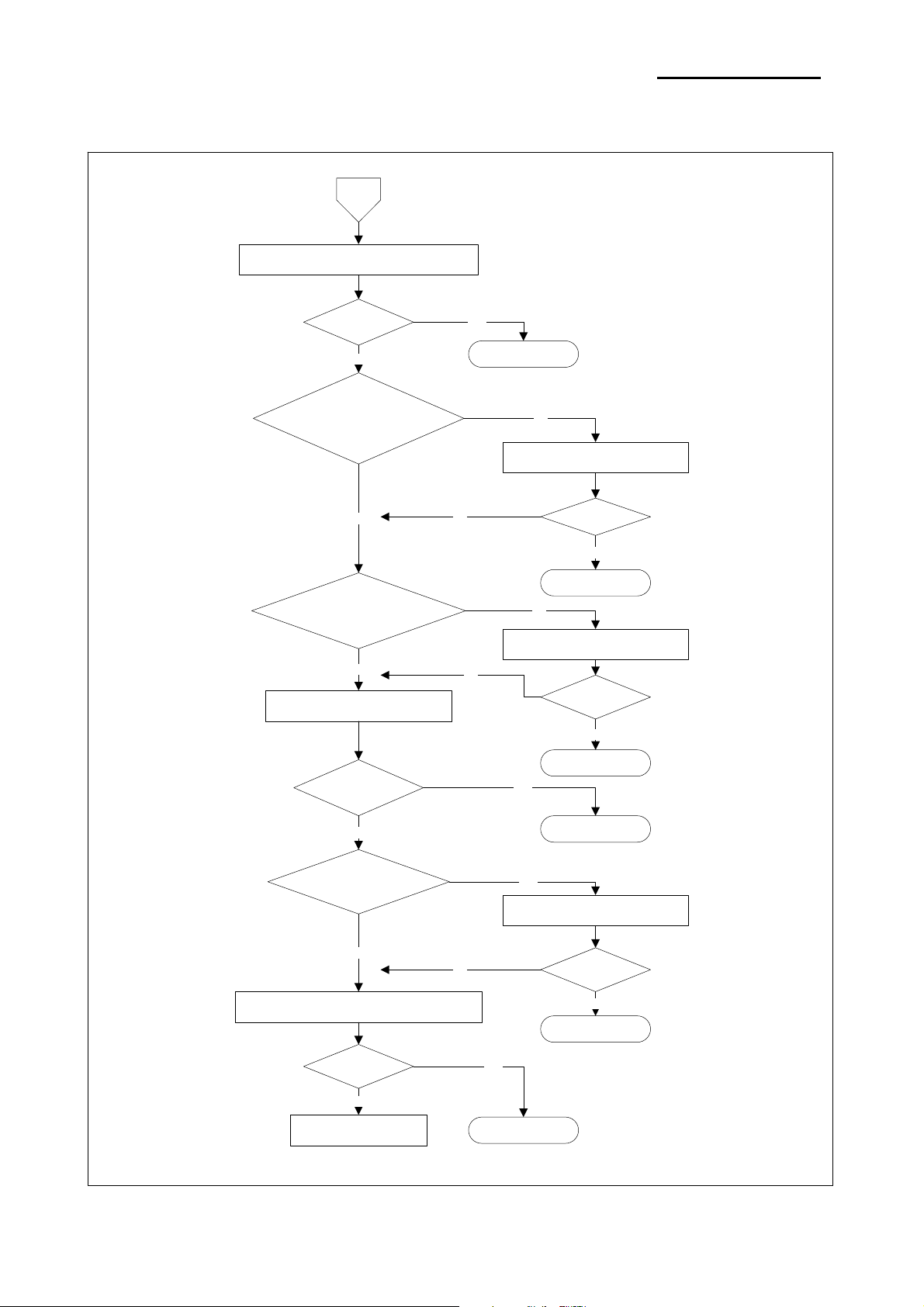

7. Troubleshooting .......................................................................................................................................55

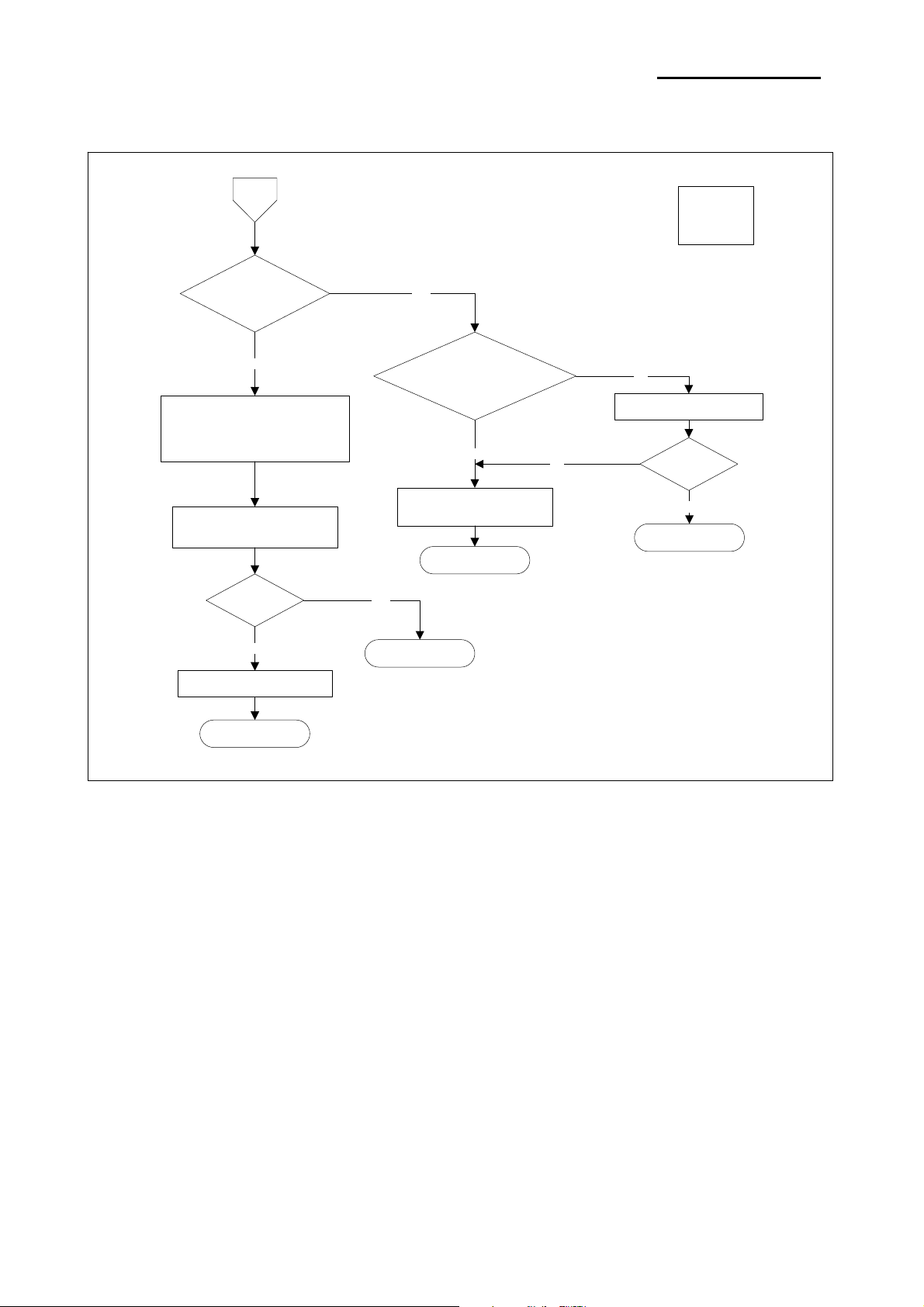

7-1 Troubleshooting flow chart....................................................................................................................55

7-1-1 POWER LED does not light...........................................................................................................56

7-1-2 Paper and Error led blink ...............................................................................................................57

7-1-3 Paper and Error led lit ....................................................................................................................58

7-1-4 Paper led lit ....................................................................................................................................59

7-1-5 Error led blink.................................................................................................................................60

7-1-6 Error led lit......................................................................................................................................61

7-1-7 Self test is not normal ....................................................................................................................62

7-1-8 Data from host is not printed normally ...........................................................................................63

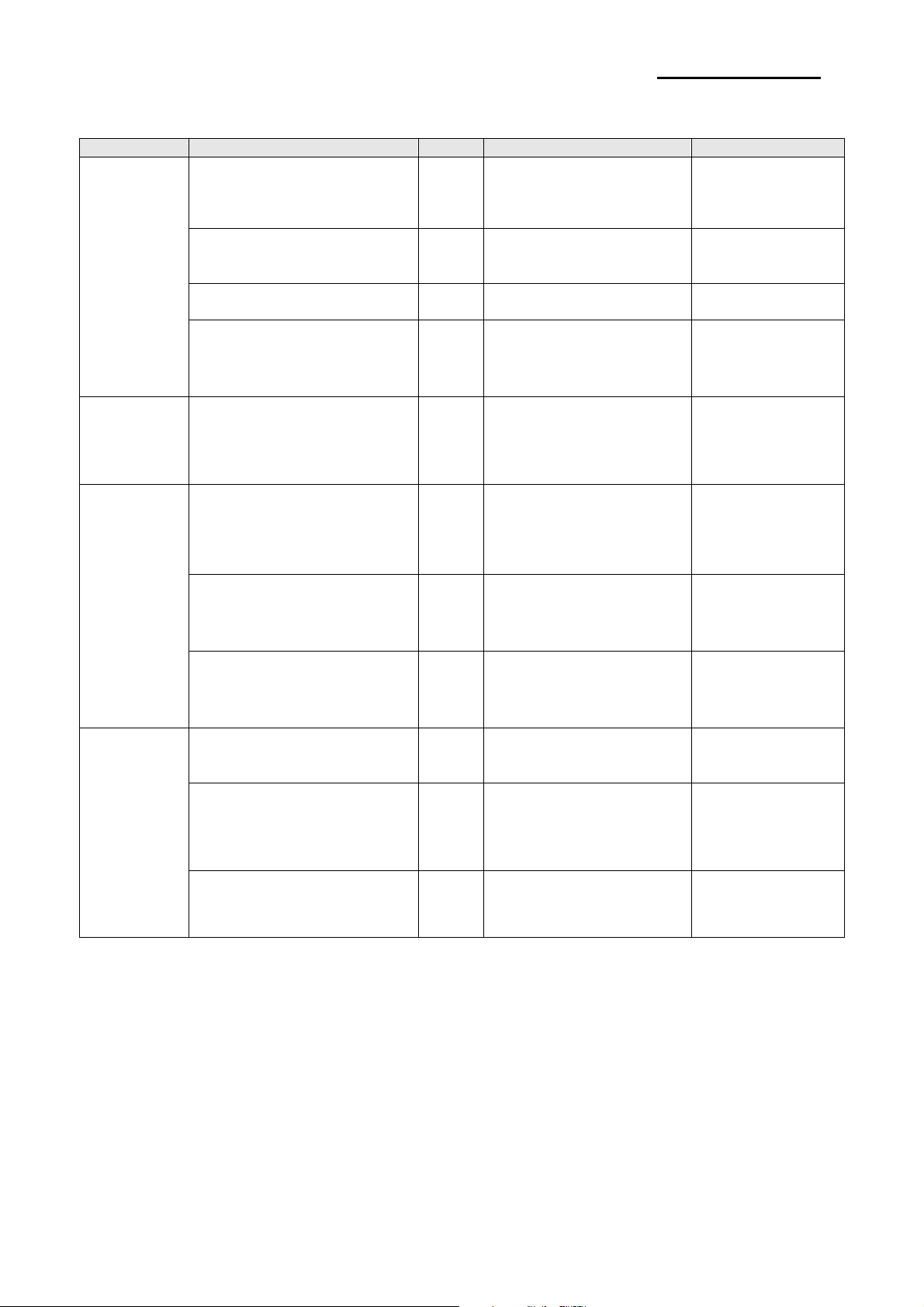

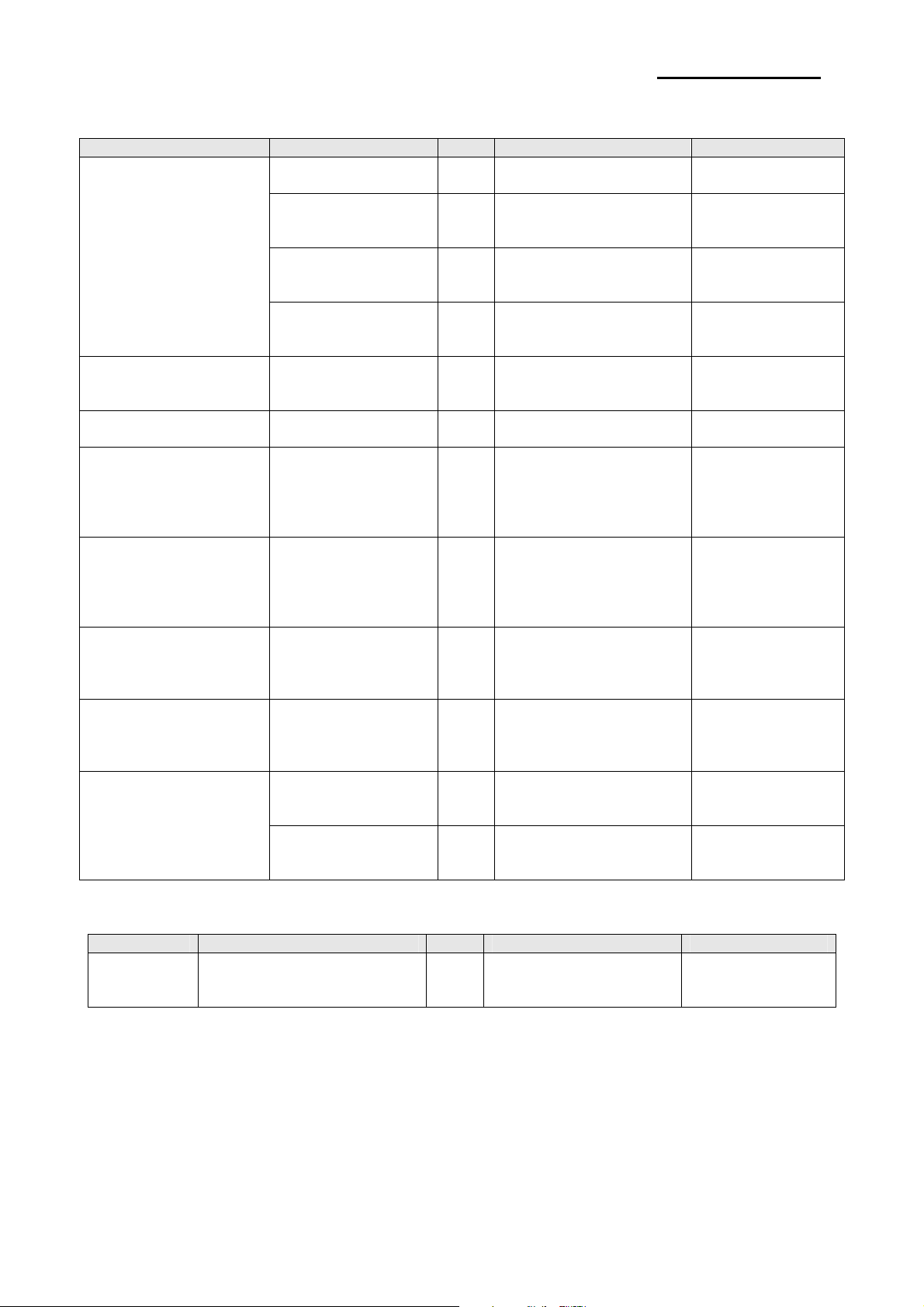

7-2 Power Problem .....................................................................................................................................64

7-2-1 Printing Quality Problems ..............................................................................................................65

7-2-2 Printer Mechanism Problems......................................................................................................... 66

7-2-3 Auto Cut Mechanism Problems .....................................................................................................66

Rev. 1.00

- 3 -

Page 4

SRP-F310/312

1. Precaution Segment

1-1 Safety Precautions

1. Be sure that all of the built-in protective devices are replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices including:

nonmetallic control knobs and compartment covers.

3. Make sure that there are no cabinet openings through which people – particularly children - might

insert fingers and contact dangerous voltages. Such openings include excessively wide cabinet

ventilation slots and improperly fitted covers and drawers.

4. Leakage Current Hot Check:

WARING: Do not use an isolation transformer during this test.

Use a leakage-current tester or a metering system that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for Applications), and Underwriters Laboratories (UL Publications

UL1410, 59.7).

With the unit completely reassembled, plug the AC line cord directly into a 100VAC or 240VAC outlet of the

Adaptor.

With the unit’s AC switch first in the ON position and then OFF, measure the current between a

known Earth ground (metal water pipe, conduit, etc.) and all exposed metal part, including: metal cabinet,

frame, and screw-heads and printer. The current measure should not exceed 0.1 milliamp. Reverse the

power-plug prong in the AC outlet and repeat the test.

5. Design Alteration Warning:

Never alter or add to the mechanical or electrical design of the ECR. Unauthorized alterations might create

a safety hazard. Also any design changes or additions will void the manufacture’s warranty.

6. Components, parts and wiring that appear to have overhead or that are otherwise damaged should be

replaced with parts that meet the original specifications. Always determine the cause of damaged or

overheating and correct any potential hazards.

7. Observe the original lead dress, especially near the following areas: sharp edges, and especially the AC

and high voltage supplies. Always inspect for pinched, out-of-place, or frayed wiring.

Do not change the spacing between components and the printed circuit board. Check the AC power cord

for damage. Make sure that leads and components do not touch thermally hot parts.

8. Product Safety Notice:

Some electrical and mechanical parts have special safety-related characteristics, which might not be

obvious from visual inspection. These safety features and the protection they give might be lost if the

replacement component differs from the original-even if the replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are indicated in the circuit diagram by shading, ( )or ( ).

Use replacement components that have the same ratings, especially for flame resistance and dielectric

strength specifications. A replacement part that does not have the same safety characteristics as the

original might create shock, fire or other hazards.

Rev. 1.00

- 4 -

Page 5

SRP-F310/312

1-2 Servicing Precaution

WARNING 1: First read the Safety Precaution section of this manual. If some unforeseen

circumstance creates a conflict between the servicing and safety precautions,

always follow the safety precaution.

WARNING 2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Always unplug the unit’s AC power cord from the AC power source or the Power Switch off before

attempting to:

(a) Remove or reinstall any component or assembly,

(b) Disconnect an electrical plug or connector,

(c) Connect a test component in parallel with an electrolytic capacitor.

2. Some components are raised above the printed circuit board for safety.

An insulation tube or tape is

sometime used. The internal wiring is sometimes clamped to prevent contact with thermally hot

components. Reinstall all such elements to their original position.

3. After servicing, always check that the screws, components and wiring have been

correctly reinstalled.

Make sure that the portion around the serviced part has not been damaged.

4. Check the insulation between the blades of the AC plug and accessible conductive parts

(example: metal panels and input terminals).

5. Insulation Checking Procedure: Disconnect the power cord from the AC source and

turn the power switch

ON. Connect an insulation resistance meter (500V) to the blades of the AC plug.

The insulation resistance

between each blade of the AC plug and accessible conductive parts (see above) should be

greater than 1 mega-ohm.

6. Never defeat any of the B+ voltage interlock. Do not apply AC power to the unit

(or any of its assemblies)

unless all solid-state heat sinks are correctly installed.

7. Always connect an instrument’s ground lead to the instrument chassis ground before

connecting the positive lead; always remove the instrument’s ground lead last.

Rev. 1.00

- 5 -

Page 6

SRP-F310/312

1-3 Precaution for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor (solid state) devices are easily damaged by static electricity. Such components are

called Electrostatically Sensitive Devices (ESDs); examples include integrated circuits and some field-effect

transistors. The following techniques will reduce the occurrence of component damaged caused by static

electricity.

2. Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge

from your body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device.

(Be sure to remove it prior to applying power-this is an Electric shock precaution.)

3. After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to

prevent accumulation of electrostatic charge.

4. Do not use freon-propelled chemical. These can generate electrical charges that damage ESDs.

5. Use only a grounded-tip soldering iron when soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device. Many solder removal devices are not rated as anti-static;

these can accumulate sufficient electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its protective package until you are ready to install it.

Most replacement ESDs are packaged with leads that are electrically shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective material from the leads of a replacement ESD, touch the

protective material to the device will be installed.

9. Minimize body motions when handling unpacked replacement ESDs. Motions such as brushing clothes

together, or lifting a foot from a carpeted floor can generate enough static electricity to damaged an ESD.

1-4 Operational Precautions

1. The heating element of the printer mechanism’s thermal head and the driver IC are easily damaged.

Never allow these components to come into contact with metal or other hard objects.

2. Never touch the printer mechanism’s heating element with your hand. Doing so can damage the heating

element and affect proper operation.

3. The head and motor areas are very hot during and immediately after printing. Do not touch components

in these areas directly with your hand.

4. Do not use any paper other than these specified in this manual otherwise print head reliability and print

quality are affected adversely.

5. Thermal paper starts to color at around 70ºC. Take care to protect unused and printed thermal paper

against the affects of heat, light and characters on the paper to feed.

6. Take the roll paper out of the printer when you will not use the printer for a long time in a high

temperature and humidity environment.

Rev. 1.00

- 6 -

Page 7

SRP-F310/312

2. Installation and Operation

2-1 Installation

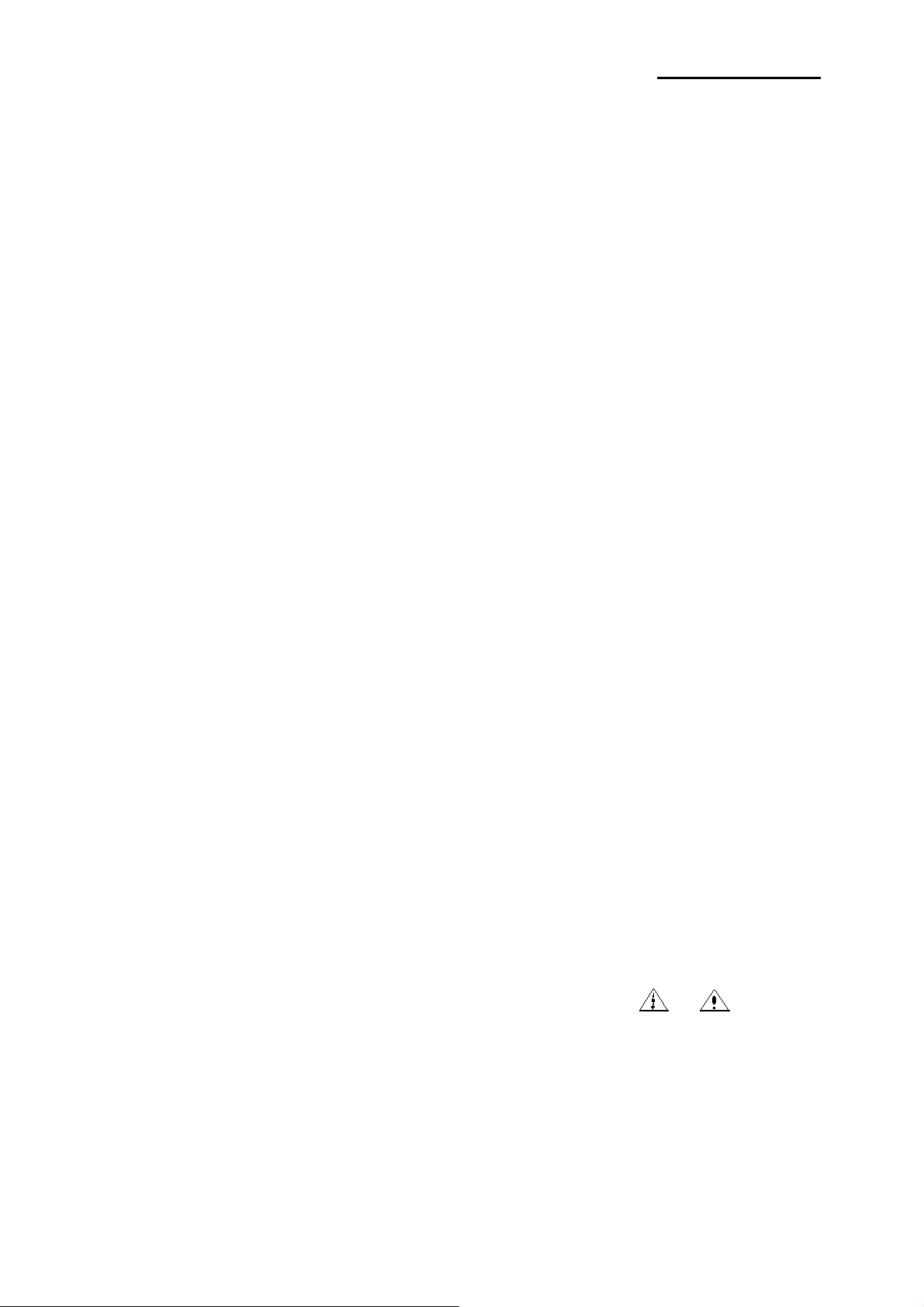

2-1-1 AC Adapter Installation

Figure 2-1 AC Adapter Installation

1. Make sure the printer is turned off with the

side of the switch.

2. Plug the power cord into the SMPS

on the printer.

3. Plug the AC Adapter power cord into the wall outlet.

2-1-3 USB Cable Installation

2-1-2 Interface Cable Installation

1. Turn off the printer, host ECR and Computer.

2. Plug RS-232, USB or Parallel Cable connector

into the I/F connector on the printer.

3. Tighten the screws on both sides of the connector.

4. Turn on the printer, host ECR and Computer.

2-1-4 Cash Drawer Cable Installation

Interface Cable

Figure 2-2 I/F Cable Installation

Interface connector

USB Connector

UAB-B Cable

Figure 2-3 USB B-TYPE Cable Installation

1. Turn the printer off.

2. Plug USB cable connector into

the connector on the printer.

Figure 2-4 Cash Drawer Cable Installation

1. Turn the printer off.

2. Plug the cash drawer cable connector into

the connector on the printer.

(To remove the cash drawer cable, press

the clip on the connector, grasp the connector

and pull it out.)

Rev. 1.00

- 7 -

Page 8

SRP-F310/312

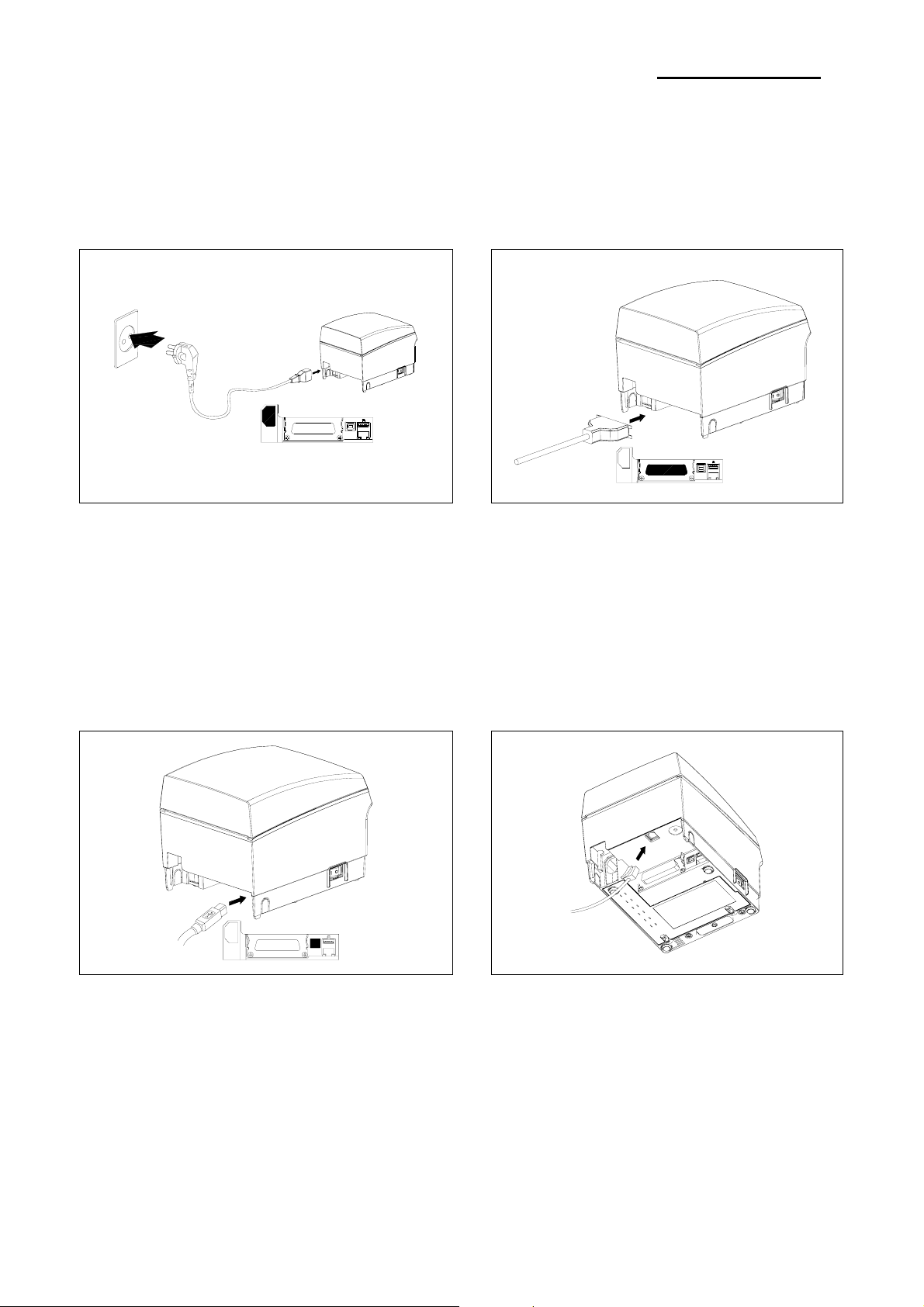

2-1-5 ETHERNET Cable Installation

Interface Connector

Figure 2-5 ETHERNET Cable Installation

1. Turn the printer off..

2. Plug the ETHERNET Cable into

the connector on the printer.

2-1-7 Cover Open Installation

2-1-6 Dongle(Usb A-Type) Cable Installation

Dongle Cable

Figure 2-6 Dongle Cable Installation

1. Turn the printer off..

2. Plug the Dongle Cable into

the connector on the printer.

2-1-8 Paper Roll Installation

Figure 2-7 Cover Open Installation

1. Turn the printer off.

2. Push the Cover-open Button

Figure 2-8 Paper Roll Installation

1. Open the cover printer and remove the used

paper roll core if there is one.

2. Load the paper roll on the paper holder as

shown.

3. Close the cover printer.

Rev. 1.00

- 8 -

Page 9

SRP-F310/312

2-2 Operation

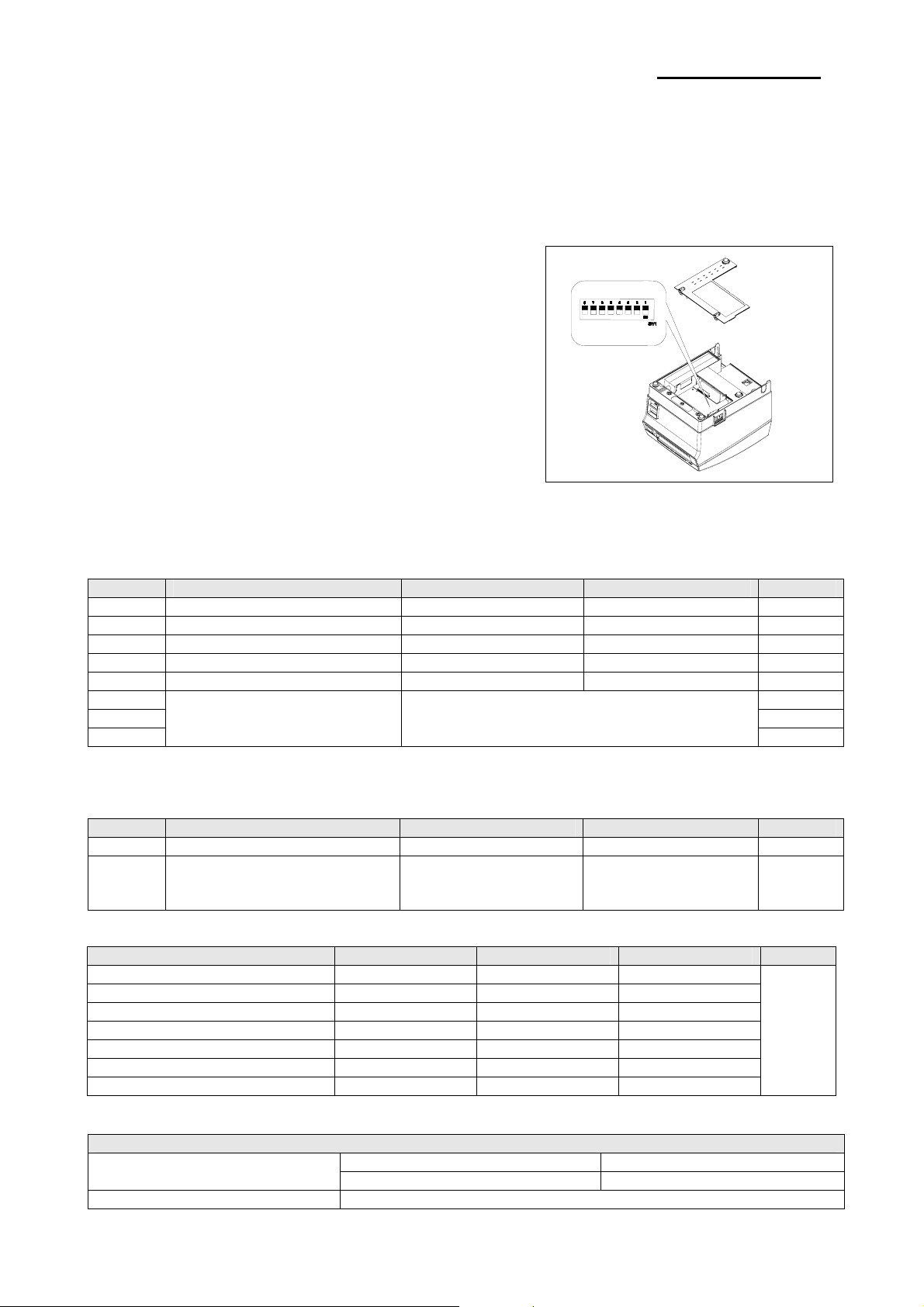

2-2-1 Setting the DIP switches

The DIP switches are located on the bottom of the printer. The DIP switches are used to set the printer to perform various

functions. Follow these when changing DIP switches setting:

1. Turn the printer power switch off.

Open the Cover .

2. Flip the DIP switches using tweezers or another marrow-ended

tool. Switches are in when up and off when off down in the

Figure 2-9.

3. The new setting takes effect when you turn on the printer.

Note: Always change DIP switch settings only when the

printer is turned off. Change made with the power on

have no effect and then on again.

Figure 2-9 Setting the DIP switches

2-2-2 Setting the DIP switch (RS-232C Serial Interface)

• DIP Switch

SW Function ON OFF Default

1-1 Auto-Cutter Selection Disable Enable OFF

1-2 Handshaking XON/XOFF DTR/DSR OFF

1-3 Data Length 7bits 8bits OFF

1-4 Parity Check Yes No OFF

1-5 Parity Selection EVEN ODD OFF

1-6 OFF

1-7 ON

Baud Rate Selection (bps) Refer to the following table

1-8

2-2-3 Setting the DIP switch (IEEE1284 Parallel, USB Interface)

• DIP Switch

SW Function ON OFF Default

1-1 Auto-Cutter Selection Disable Enable OFF

1-2

~

Reserved - - OFF

1-8

• Table – Baud rate (bps) Selection

Transmission Speed SW 1-6 SW 1-7 SW 1-8 Default

2400 ON OFF OFF

4800 ON OFF ON

9600 OFF ON OFF

19200 OFF OFF OFF

38400 OFF ON ON

57600 OFF OFF ON

115200 ON ON ON

※ Auto Cutter Enable / Disable selection

Dip Switch Set 1

SW 1-1

ON Auto Cutter Disabled

OFF Auto Cutter Enabled

Application Ignores Auto Cutter error for continuous printing.

OFF

9600

Rev. 1.00

- 9 -

Page 10

SRP-F310/312

2-2-4 Hexadecimal Dumping

This feature allows experienced users to see exactly what data is coming to the printer. This can be useful in

finding software problems. when you turn on the hexadecimal dump function, the printer prints all commands

and data in hexadecimal format along with a guide section to help you find specific commands.

To use the hexadecimal dump function, follow these steps:

1. After you make sure that the printer is off.

Open the cover.

2. Turn on the printer, while holding down the FEED button with beep.

3. close the cover, then the printer enters the hexadecimal dump mode.

Run any software program that sends data to the printer. The printer will print all the codes it

receives in a two-column format. The first column contains the hexadecimal codes and the second

column gives the ASCII characters that corresponds to the codes.

1B 21 00 1B 26 02 40 40 . ! . . & @ @

02 0D 1B 44 0A 14 1E 28 . . . D . . . . (

00 01 0A 41 0D 42 0A 43 . . . A . B . C

Note: A period(.) is printed for each code that no ASCII equivalent.

Note: During the hex dump all commands expect DLE EOT and DLE ENQ are disabled.

4. When the printing finishes, turn off the printer.

5. Turn on the printer and then the hexadecimal model is off.

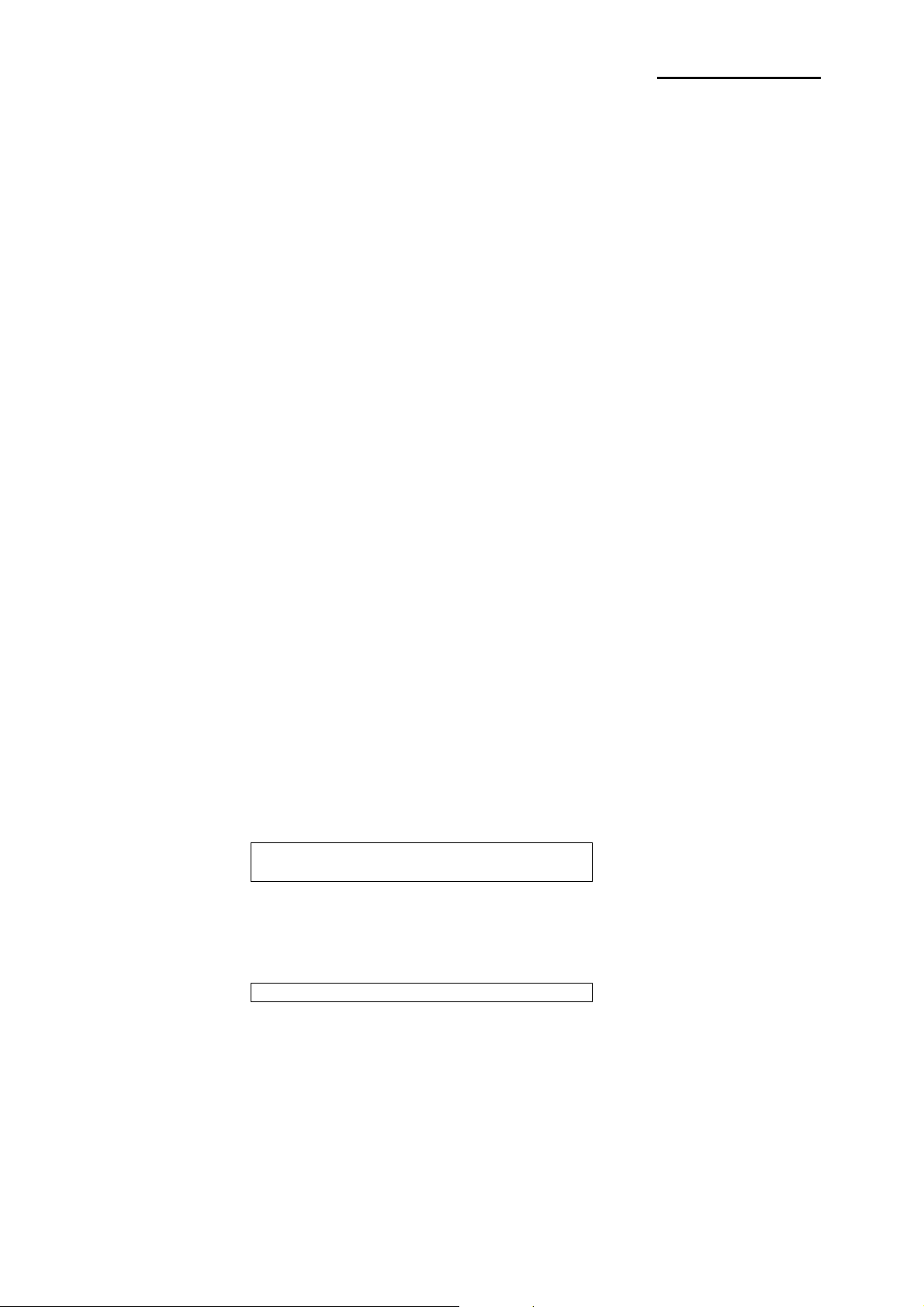

2-2-5 The self Test Mode

The self-test checks whether the printer has any problem. If the printer does not function properly, contact

your dealer The self-test checks the following:

1. Make sure paper roll ahs been installed properly.

2. Turn on the power while holding down the FEED button with beep. The self-test begins.

3. Tue self-test prints the current printer status, which provides the control ROM version and the DIP

witch setting.

4. After printing the current printer status, self-test printing will print the following and pause (The

PAPER LED light blinds).

SELF-TEST PRINTING.

PLEASE PRESS THE FEED BUTTON.

5. Press the FEED button to continue printing. The printer prints a pattern using the built-in character

set.

6. The self-test automatically ends and cuts the paper after printing the following.

*** COMPLETED ***

The printer is ready to receive data as soon as it completes the self-test.

Rev. 1.00

- 10 -

Page 11

SRP-F310/312

SRP-F310 V01.00 STD 010110

================================

FPGA INFORMATION

BOARD VER.: 0x3

PROGRAM VER. : 0x11

DIP SWITCH STATUS

12345678

ON: *

OFF: ****** *

MEMORY SWITCH STATUS

MSW1 12345678

MSW2 12345678

MSW3 12345678

MSW4 12345678

MSW5 12345678

MSW6 12345678

MSW11 12345678

MSW12 12345678

SERIAL SETTING

BAUD RATE : 115200 BPS

DATA BITS : 8 BITS

PARITY CHECK : NONE

STOP BITS : 1 BIT OR MORE

HANDSHAKING : DTR/DSR

ETHERNET SETTING

MAC ADDR: 00:11:22:33:44:55

LAN_DHCP disabled

IP ADDR : 192.168.192.123

NETMASK : 255.255.255.0

GATEWAY : 192.168.192.254

WLAN SETTING

NETWORK: adhoc

AUTH: open

ENCRYPT: none

ESSID: BIXOLON_adhoc

WLAN_DHCP disabled

IPADDR: 192.168.1.1

NETMASK: 255.255.255.0

GATEWAY: 192.168.1.2

BUFFER CAPACITY: 512KBYTES

PRINT DENSITY

LIGHT [ 1 2 3 4 ] DARK

*

SELF-TEST PRINTING

PLEASE PRESS THE FEED BUTTON

ASCII

!"#$%&'()*+,-./0123456789:;<=>?@

"#$%&'()*+,-./0123456789:;<=>?@A

#$%&'()*+,-./0123456789:;<=>?@AB

$%&'()*+,-./0123456789:;<=>?@ABC

%&'()*+,-./0123456789:;<=>?@ABCD

&'()*+,-./0123456789:;<=>?@ABCDE

'()*+,-./0123456789:;<=>?@ABCDEF

()*+,-./0123456789:;<=>?@ABCDEFG

)*+,-./0123456789:;<=>?@ABCDEFGH

*+,-./0123456789:;<=>?@ABCDEFGHI

+,-./0123456789:;<=>?@ABCDEFGHIJ

,-./0123456789:;<=>?@ABCDEFGHIJK

-./0123456789:;<=>?@ABCDEFGHIJKL

./0123456789:;<=>?@ABCDEFGHIJKLM

/0123456789:;<=>?@ABCDEFGHIJKLMN

0123456789:;<=>?@ABCDEFGHIJKLMNO

123456789:;<=>?@ABCDEFGHIJKLMNOP

23456789:;<=>?@ABCDEFGHIJKLMNOPQ

3456789:;<=>?@ABCDEFGHIJKLMNOPQR

456789:;<=>?@ABCDEFGHIJKLMNOPQRS

56789:;<=>?@ABCDEFGHIJKLMNOPQRST

6789:;<=>?@ABCDEFGHIJKLMNOPQRSTU

789:;<=>?@ABCDEFGHIJKLMNOPQRSTUV

89:;<=>?@ABCDEFGHIJKLMNOPQRSTUVW

9:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWX

PC437

ЗьйвдаезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒ

ьйвдаезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒб

йвдаезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒбн

вдаезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒбну

даезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒбнуъ

аезклипомДЕЙжЖфцтыщяЦЬ¢£¥Ptƒбнуъс

езклипомДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсС

зклипомДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСª

клипомДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº

липомДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿

ипомДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌

помДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐

омДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½

мДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼

ДЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡

ЕЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«

ЙжЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»

жЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓

ЖфцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓▒

фцтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓▒░

цтыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓▒░┃

тыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓▒░┃┤

ыщяЦЬ¢£¥PtƒбнуъсСªº¿┌ ┐½¼¡«»▓▒░┃┤╡

ùÿÖÜ¢£¥

яЦЬ¢£¥PtƒбнуъсСªº¿┌┐½¼¡«»▓▒░┃┤╡╢╖

Pt

ƒбнуъсѪº¿┌ ┐½¼¡«»▓▒░┃┤╡╢

Rev. 1.00

Figure 2-10 The Self-Test Sheet

- 11 -

Page 12

SRP-F310/312

2-2-6 Setting the Memory Switches

This printer has Memory Switch set which is software switches. Memory Switch set has MSW1,

MSW2,MSW3, MSW4, MSW5, MSW6, MSW11, MSW12, Customize value.

Memory Switch setting utility can change the Memory Switch set to ON or OFF as shown in the table below

(default: all OFF):

Settings of the Memory Switch are stored in the NV memory: therefore, even if the printer is turned off, the

settings are maintained.

※ Notes: The Memory Switch is available to be changed by three methods:

- Memory Switch setting utility.

- Control from BXL/POS command.

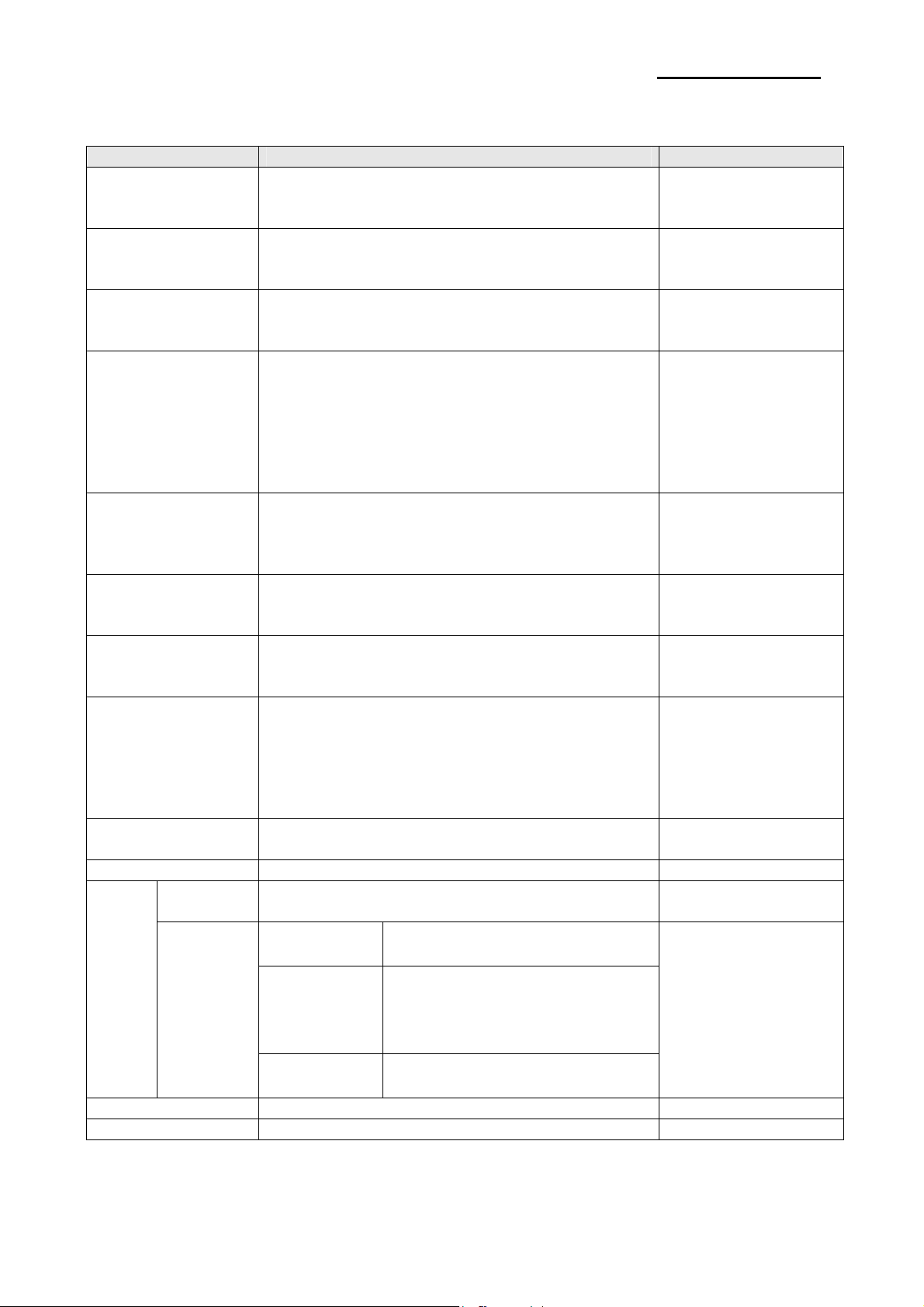

MSW1

Switch Function ON OFF

MSW 1-1

MSW 1-2

MSW 1-3

MSW 1-4~5 -- Fixed to OFF

MSW 1-6

MSW 1-7

MSW 1-8 -- Fixed to OFF

MSW1-1~MSW1-3

MSW 1-3 MSW 1-2 MSW 1-1 Print speed Remark

OFF OFF OFF Print speed level 4 270 mm/s

OFF OFF ON Print speed level 3 250 mm/s

OFF ON OFF Print speed level 2 230 mm/s

OFF ON ON Print speed level 1 200 mm/s

MSW1-6~MSW1-7

MSW 1-7 MSW 1-6 Print density Remark

ON OFF Density level 3 Dark

OFF ON Density level 2

OFF OFF Density level 1 Light(Default)

MSW2

Switch Function ON OFF

1 Specification for Destination Double byte Country Single byte Country

2 Reserved -- Fixed to OFF

3~8 Code Page Selection Refer to following Table

Select Print Speed Refer to following Table

Select Print Density Refer to following Table

Rev. 1.00

- 12 -

Page 13

SRP-F310/312

MSW2-3~MSW2-8

MSW2-8 MSW2-7 MSW2-6 MSW2-5 MSW2-4 MSW2-3 Character Table

OFF OFF OFF OFF OFF OFF Page 0 437

(USA, Standard Europe)

OFF OFF OFF OFF ON OFF Page 1 Katakana

OFF OFF OFF ON OFF OFF Page 2 850 (Multilingual)

OFF OFF OFF ON ON OFF Page 3 860 (Portuguese)

OFF OFF ON OFF OFF OFF Page 4 863 (Canadian-French)

OFF OFF ON OFF ON OFF Page 5 865 (Nordic)

OFF OFF ON ON OFF OFF Page 16 1252 (Latin I)

OFF OFF ON ON ON OFF Page 17 866 (Cyrillic #2)

OFF ON OFF OFF OFF OFF Page 18 852 (Latin 2)

OFF ON OFF OFF ON OFF Page 19 858 (Euro)

OFF ON OFF ON OFF OFF Page 21 862 (Hebrew DOS code)

OFF ON OFF ON ON OFF Page 22 864 (Arabic)

OFF ON ON OFF OFF OFF Page 23 Thai42

OFF ON ON OFF ON OFF Page 24 1253 (Greek)

OFF ON ON ON OFF OFF Page 25 1254 (Turkish)

OFF ON ON ON ON OFF Page 26 1257 (Baltic)

ON OFF OFF OFF OFF OFF Page 27 Farsi

ON OFF OFF OFF ON OFF Page 28 1251 (Cyrillic)

ON OFF OFF ON OFF OFF Page 29 737 (Greek)

ON OFF OFF ON ON OFF Page 30 775 (Baltic)

ON OFF ON OFF OFF OFF Page 31 Thai14

ON OFF ON OFF ON OFF Page 32 Hebrew Old code

ON OFF ON ON OFF OFF Page 33 1255

(Hebrew New code)

ON OFF ON ON ON OFF Page 34 Thai11

ON ON OFF OFF OFF OFF Page 35 Thai18

ON ON OFF OFF ON OFF Page 36 855 (Cyrillic)

ON ON OFF ON OFF OFF Page 37 857 (Turkish)

ON ON OFF ON ON OFF Page 38 928 (Greek)

ON ON ON OFF OFF OFF Page 39 Thai16

ON ON ON OFF ON OFF Page 40 1256 (Arabic)

ON ON ON ON OFF OFF Page 41 1258 (Vietnam)

ON ON ON ON ON OFF Page42 Khmer(Cambodia)

OFF OFF ON OFF OFF ON Page47 1250 (Czech)

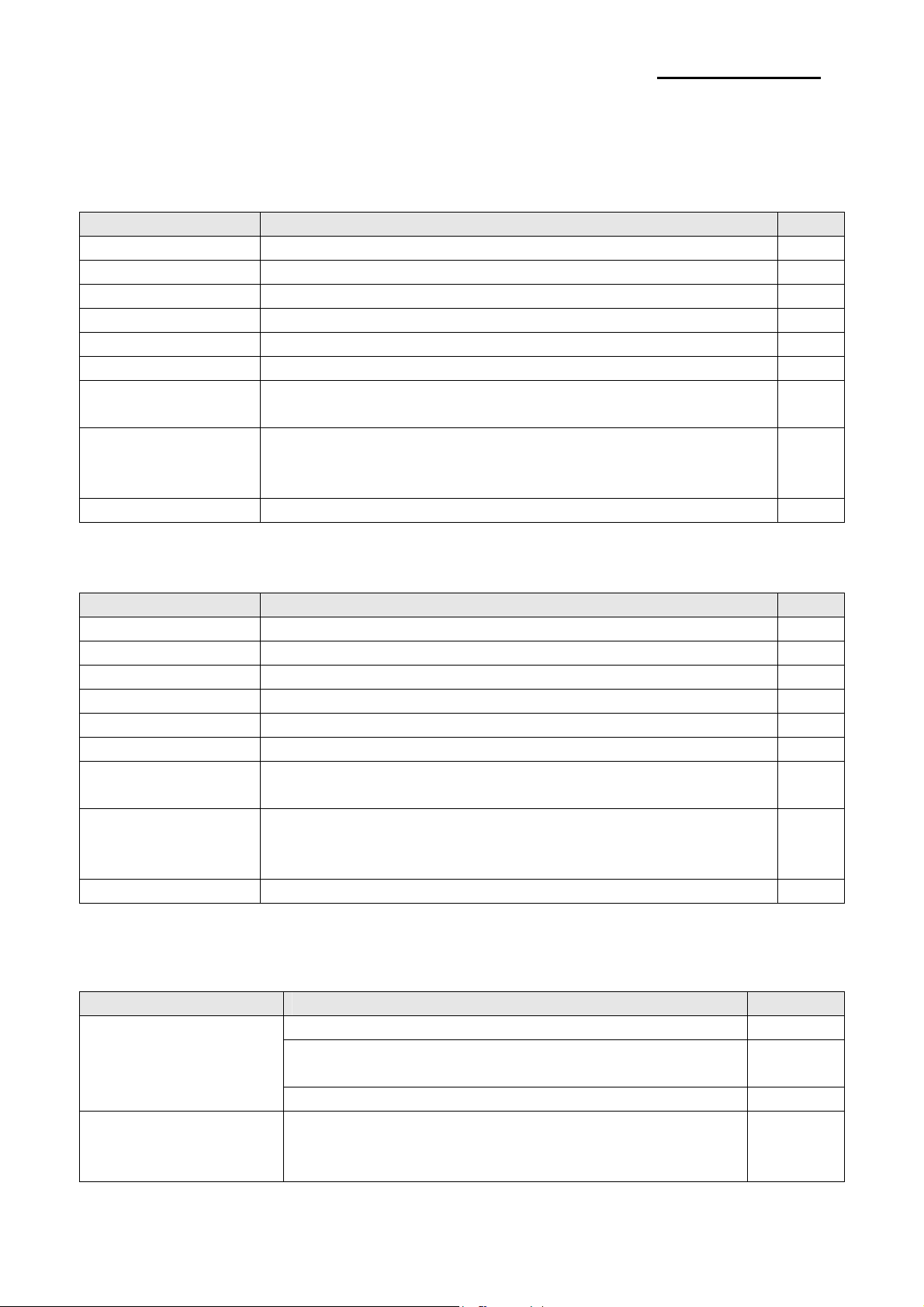

MSW3

Switch Function ON OFF

MSW 3-1

MSW 3-2

Select Emulation Refer to following Table

MSW 3-3

1~8 Reserved -- Fixed to OFF

MSW3-1~MSW3-3

MSW 3-3 MSW 3-2 MSW 3-1 Emulation Remark

OFF ON ON Emulation 4

OFF ON OFF Emulation 3

OFF OFF ON Emulation 2

OFF OFF OFF Emulation 1 BXL/POS

MSW4

Switch Function ON OFF

MSW 4-1 ASCII font selection Customized font Resident font

MSW 4-2 Extended font selection Customized font Resident font

MSW 4-3

MSW 4-4

Single byte Font Selection Refer to following Table

MSW 4-5

MSW 4-6

Double byte Font selection Refer to following Table

MSW 4-7

MSW 4-8 Reserved -- Fixed to OFF

Rev. 1.00

- 13 -

Page 14

SRP-F310/312

MSW\4-3~MSW4-4

MSW 3-4 MSW 3-3 Single byte Font Selection Remark

OFF OFF Font A 12x24

OFF ON Font B 9x17

ON OFF Font C 9x24

MSW\4-5~MSW4-7

MSW 4-7 MSW 4-6 MSW 4-5 Double byte font type Remark

OFF OFF OFF KS5601

OFF OFF ON SHIFT-JIS

OFF ON OFF BIG5

OFF ON ON GB2312

ON OFF OFF GB18030

MSW5

Switch Function ON OFF

MSW 5-1 Auto cutter function Full cutting Partial cutting

MSW 5-2 Reserved -- Fixed to OFF

MSW 5-3 2 color support Enable Disable

MSW 5-4 Auto Line Feed Enable Disable

MSW 5-5 Near-End Sensor Disable Enable

MSW 5-6 Reserved -- Fixed to OFF

MSW 5-7 Reserved -- Fixed to OFF

MSW 5-8 Reserved -- Fixed to OFF

MSW6

Switch Function ON OFF

MSW 6-1

MSW 6-2 Internal buzzer control Disable Enable

MSW 6-3

MSW 6-4 Reserved -- Fixed to OFF

MSW 6-5 Offline status condition Pulse mode Step mode

MSW 6-6 Select watermark printing function Enable Disable

MSW 6-7 Reserved -- Fixed to OFF

MSW 6-8 NearEnd sensor detect signal Enable Disable

MSW11

Switch Function ON OFF

11-1~8 Reserved -- Fixed to OFF

MSW12

Switch Function ON OFF

12-1~8 Reserved -- Fixed to OFF

Auto generate pulse to internal

buzzer

Internal buzzer with cash drawer

pulse

Enable Disable

Enable Disable

Rev. 1.00

- 14 -

Page 15

SRP-F310/312

3. Product Specifications

3-1 Appearance

3-1-1 Printer Dimensions (mm)

3-1-2 AC Adapter Dimensions (mm)

150mm

SRP-F310/312

Figure 3-1 Printer Dimension

120mm

Figure 3-2 Adapter Dimension

31mm

56mm

Rev. 1.00

- 15 -

Page 16

SRP-F310/312

3-1-3 Feature Locations-SRP-F310/312

1. cover-open

2. case-lower

3. function-led

4. feed-button

5. Push Button

6. Power Button

7. cover Dip Switch

8. SMPS

9. TPH

Rev. 1.00

10. Paper Sensor Control

11. Auto-Cutter

12A. Parallel interface(IEEE-1284)

12B. Serial interface(RS-232C)

12C. Default interface

13. USB B-TYPE 2.0

14. ETHERNET

15. Dongle

16. ETHERNET, WLAN Reset

17. DK(RJ11)

Figure 3-3 Feature Location

- 16 -

Page 17

SRP-F310/312

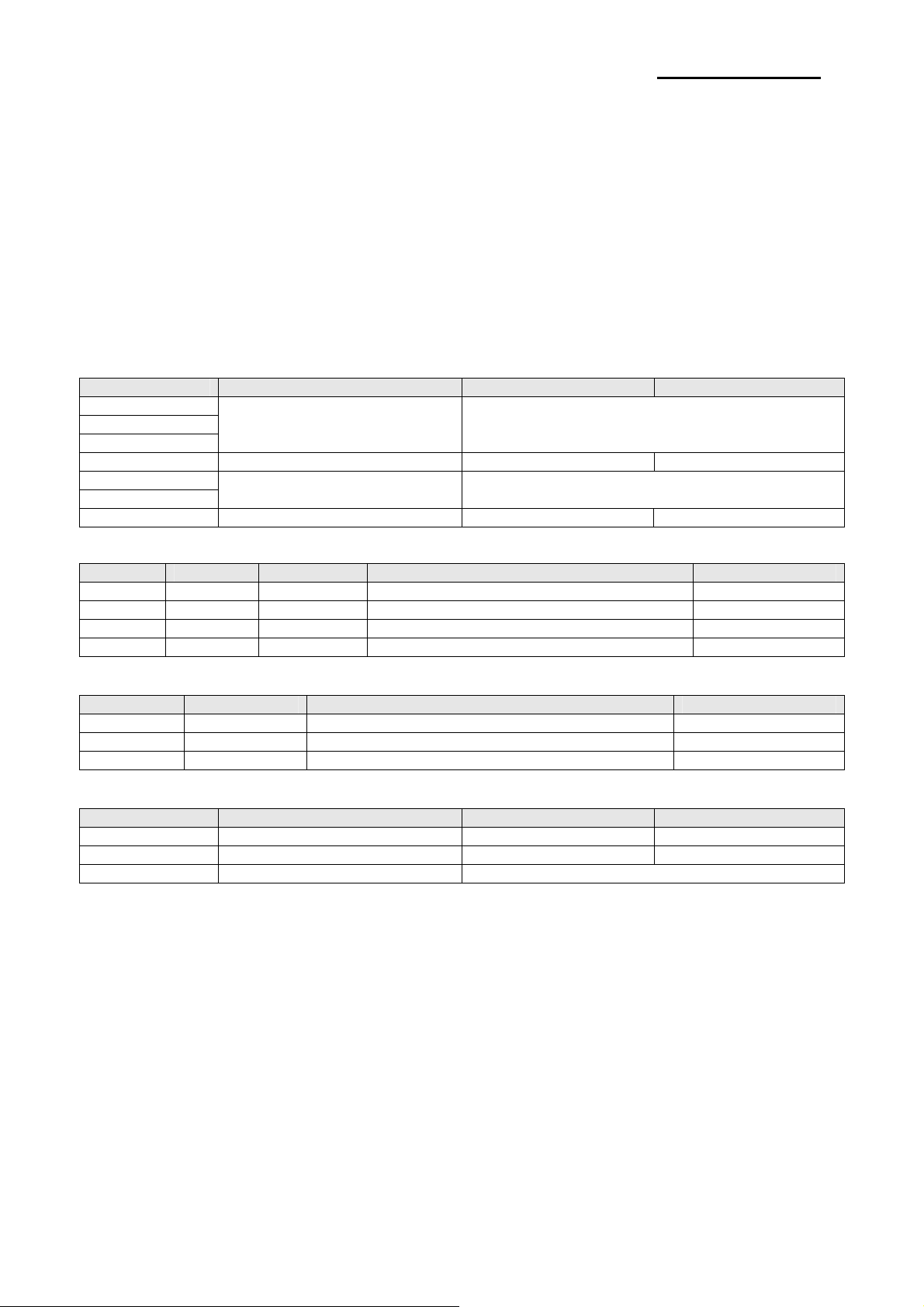

3-2 General Specifications

Item Description Remark

• SRP-F310/312: Default Communication

Product

Processor

Memory

Interface Serial

(RS-232C)

Interface Parallel

USB

USB2.0

Printer

Auto Cutter

Power Consumption • Approx. 27W (Peak)

Electrical

Condition

AC

Adapter

(SMPS)

Dimensions(mm) • 203(W) x 154(D) x 148(H)

Environmen

t Condition

Weight • 3.1 Kg (With Packing)

• SRP-F310/312P: IEEE1284 Parallel Communication

• SRP-F310/312S: RS-232C Serial Communication

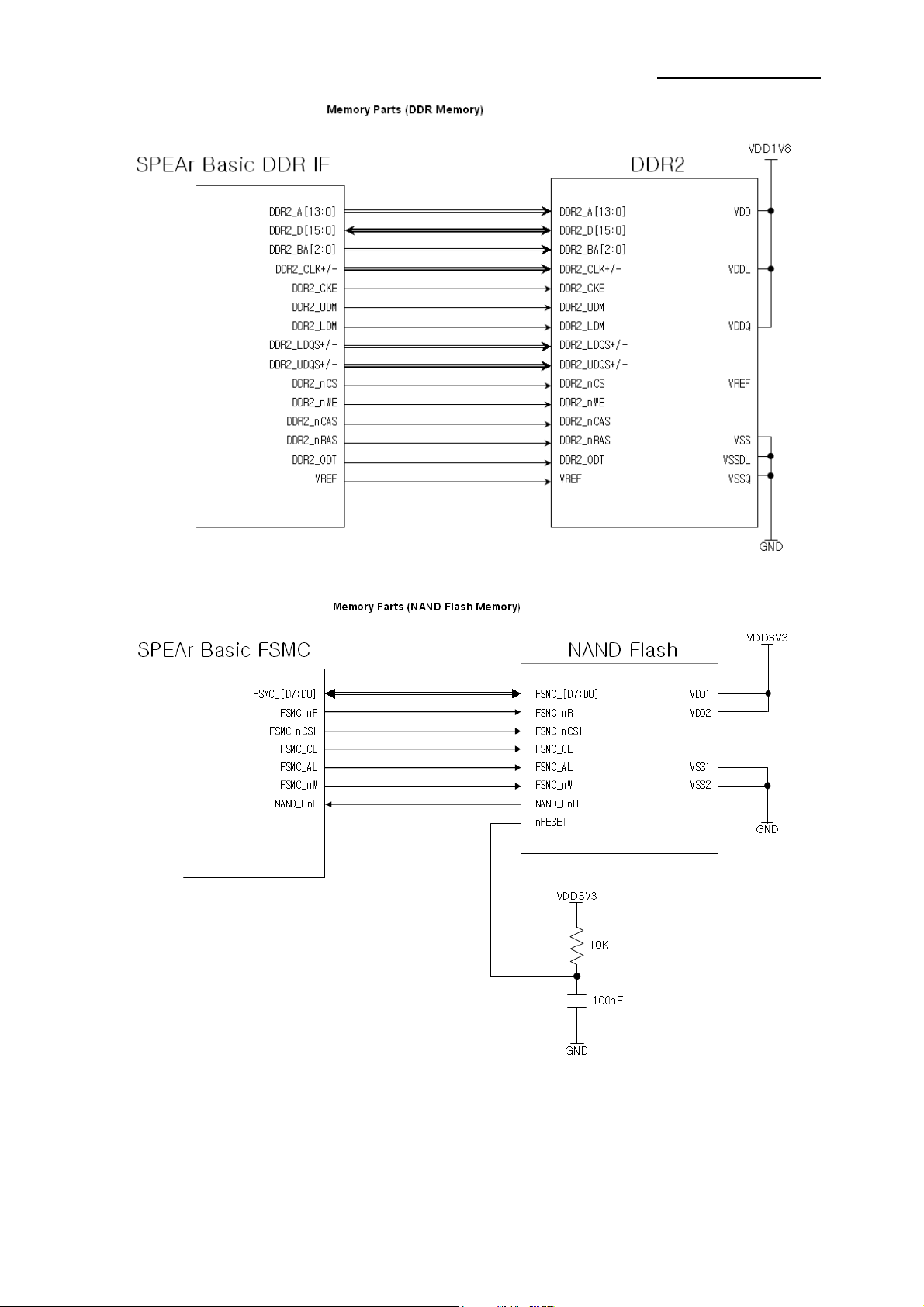

• ST SPEAR-09-B042(ARM926EJ-S core @ 333MHz)

Internal boot ROM Size: 32KBytes

Internal static RAM Size: 8KBytes

• RAM

DDR2 SDRAM: 256Mbits (MT47H16M16BG-3:G)

NAND FLASH: 128Mbits (NAND128W3A2CN6F)

• Flow Control:

1) DTR / DSR (H/W Flow Control)

2) XON / XOFF (S/W Flow Control)

• Baud Rate: 2400 / 4800 / 9600 / 19200 / 38400

/ 57600 / 115200 bps

• Receive Buffer: 4 Kbytes

• Connector: DB25P Female (I/F PBA Side)

• Mode:

1) Forward Mode: Compatibility Mode

2) Reverse Mode: Nibble / Byte Mode

• Connector: 36 Pin Centronics (Ribbon Type)

• Transfer Type: BULK

• Speed: 12 Mbps (Full-Speed)

• Power: Self-Powered

• Transfer Type: BULK

• Speed: 480 Mbps (High-Speed)

• Power: Self-Powered

• Printing Method: Thermal Line Printing

• Printing Speed

1) SRP-F310: Mono 270mm/Sec, 63.82 Line/Sec

2Color 130mm/Sec, 30.73Line/sec

2) SRP-F312: Mono 270mm/Sec, 72 Line/Sec

2Color 130mm/Sec, 34.6Line/sec

• Type: Guillotine

• Cutting Method: 1 Point Partial Cutting

• Input: AC 100V ~ 240V, 50Hz/60Hz

• Output: DC 24V±5%, 2.5A

Temperature

Humidity

Altitude

• Operating: 0°C ~ +45°C

• Storage: -20°C ~ +60°C

• Operating: 10% to 80%

non-condensing

• Storage: 10% to 90%

non-condensing

• Operating: 10,000ft(Max)

• Storage: 10,000ft(Max)

Table 3-1 General Specification

The Flow Control, Baud

Rate, Stop Bit and

Parity Are determined

by DIP S/W position.

Rev. 1.00

- 17 -

Page 18

SRP-F310/312

3-3 Thermal Printer Specifications

3-3-1 Printer Specification

1) 180dpi

Item Description Remark

Model • SRP-F310 (TPH: KRB-72-7TA02-BIX2,KYOCERA CORPORATION)

Print Method • Thermal Line Printing

Dot Density • 0.141 mm(7 Dots/mm)

Printing Direction • Unidirection with friction feed

Printing Width • 72.2mm, 512 dot Position

Character / Line • 42 (Font A: 12x24) • 56 (Font B: 9x17 )

Character Spacing

Printing Speed

Paper feeding Speed • Approx. 270mm/sec

2) 203 dpi

Item Description Remark

Model • SRP-F312 (TPH: KRC-80-8TA02-BIX2,KYOCERA CORPORATION)

Print Method • Thermal Line Printing

Dot Density • 0.125mm(8 Dots/mm)

Printing Direction • Uni-direction with friction feed

Printing Width •80.0mm, 640 dot Position

Character / Line • 48 (Font A: 12x24) • 64 (Font B: 9x17 )

Character Spacing

Printing Speed

Paper feeding Speed • Approx. 270mm/sec

3-3-2 Character Specification

Item Description Remark

Number of Character

Character Structure

• 0.28mm (0.01) (2 dots) (Font A)

• 0.28mm (0.01) (2 dots) (Font B)

• Mono Max. 270mm (63.82 Lines/sec, 1/6inch feed)

• 2color Max. 130mm (30.73 Lines/sec, 1/6inch feed)

• Ladder Barcode: Mono 270mm/sec, 2Color 130mm/sec

Table 3-2 Thermal Printer Specification

• 0.25mm (0.01) (2 dots) (Font A)

• 0.25mm (0.01) (2 dots) (Font B)

• Mono Max. 270mm (72 Lines/sec, 1/7inch feed)

• 2color Max. 130mm (34.6 Lines/sec, 1/7inch feed)

• Ladder Barcode: Mono 270mm/sec, 2Color 130mm/sec

Table 3-3 Thermal Printer Specification

• Alphanumeric Characters: 95

• Extended Characters: 128 x 34 Page

(Including one space page)

• International Characters: 32

• 12 x 24 (Font A) (Including 2-dot spacing in horizontal)

• 9 x 17 (Font B) (Including 2-dot spacing in horizontal)

Font A is selected as the default

Table 3-4 Thermal Printer Character Specification

Rev. 1.00

- 18 -

Page 19

SRP-F310/312

3-3-3 Paper Specification

Item Description Remark

Paper Type

Paper Form • Paper Roll

Paper Width • 80mm / 83mm

Paper Roll Size • Max 105mm(3.26”)

Spool Inside Dia. • 12mm (0.47)

Spool Outside Dia. • 18mm (0.71)

※ Note

* Mono: The Following paper can be used instead of the specified paper above.

TF50KS-E(Paper thickness: 65μm): Nippon Paper industries Co., Ltd.

PD 160R ( “ : 75μm): New Oji Paper Mfg, Co., Ltd.

P350 ( “ : 62μm): Kansaki Specialty Paper, Inc. (USA)

* 2Color: PB-670 ( “ : 75μm): Mitsubishi

PD750R ( “ : 75μm): Oji paper Mfg. Co.,Ltd.

• Mono:TF50KS-E(Nippon paper)

• 2Color: PB-70(Mitsubishi)

Table 3-5 Thermal Printer Paper Specification

3-3-4 Reliability and Environment Specification

Item Description Remark

• Mechanism: Monochrome: 20,000,000 Lines

2Color : 10,000,000 Lines

Life

MCBF • Monochrome:70,000,000Lines, 2Color:35,000,000Lines

Environmental

Temperature

Humidity

The reliability values above are assumed When a 15-Line feed

and a 10-Line print repeat alternately

• Head: 1x10

• Auto Cutter: 1,800,000 Cut,

• Operating: 0°C ~ +45°C

• Storage: -20°C ~ +60°C (Except for Paper)

• Operating: 10% ~ 80% RH(non-condensing)

• Storage: 10% ~ 90% RH(non-condensing)

Table 3-6 Thermal Printer Reliability Specification

8

Pulses, Monochrome: 150Km, 2Color: 75Km

Rev. 1.00

- 19 -

Page 20

SRP-F310/312

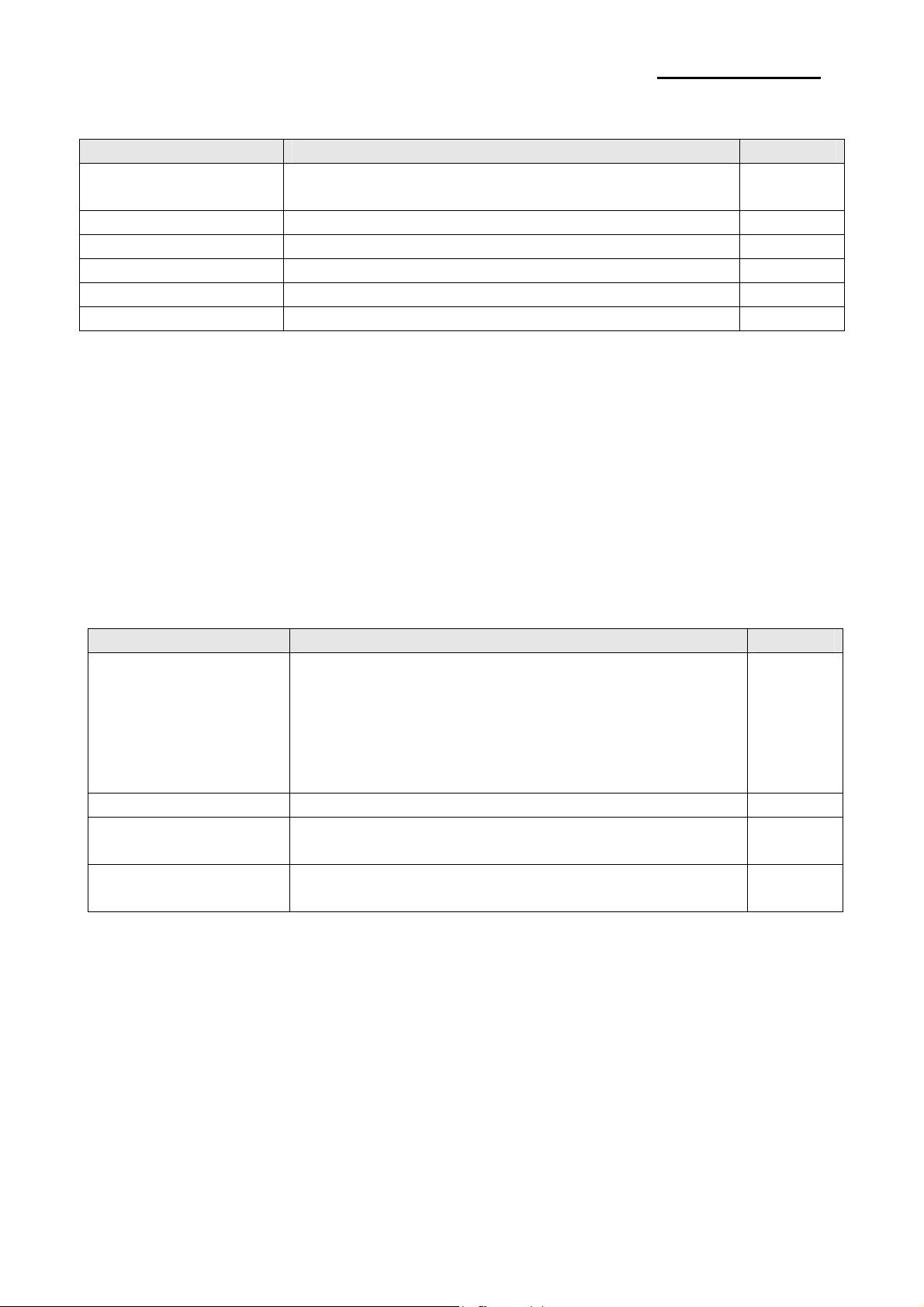

a

3-3-5 Printable Area

1) 180dpi

Item Description Remark

a 80±0.5mm(3.15 ±0.0197)

b 0.141 (0.0056 )

c 72.2±0.2mm(2.83 ±0.0079)

d 2.75mm~4.25mm

e 2.75mm~4.25mm

Dots 512

Font 9X17 56 Character

Font 12X24 42 Character

* ‘d’ & ‘e’ position can be shifted while printing according to the paper position.

2) 203dpi

Item Description Remark

A 80±0.5mm(3.15 ±0.0197)

B 0.125 (0.0049 )

C 80mm±0.2mm (2.83±0.0079)

D 2.75mm~4.25mm

E 2.75mm~4.25mm

Dots 640

Font 9X17 64 Character

Font 12X24 48 Character

* ‘d’ & ‘e’ position can be shifted while printing according to the paper position.

d c e

b

Figure 3-4 Printable Area

3-3-6 TPH (Thermal Printer Head) Specification

1) 180dpi

Item Description Remark

Heat Element Structure 2 Heaters / Dot

Number of Heat Element 512 Dots

Heat Element Pitch 0.141mm/dot, 7Dot/mm (180DPI)

Print Width 72.2±0.2mm

Average Resistance 800Ω ± 3%

Thermister

1) Resistance R25: 30kΩ ± 5% (At 25℃)

2) B Value: 3950K ± 2%

3) Temperature: - 40℃ ~ +80℃

Table 3-7 TPH Specification

Rev. 1.00

- 20 -

Page 21

SRP-F310/312

Item Maximum Unit Conditions

Print Cycle (S.L.T.) 0.46 ms/Line

T=25℃

Supply Energy 0.20 mJ/Dot

Supply Voltage 24 V Voltage among the connector terminals

Substrate Temperature 70

℃

Temperature detected by Thermistor

Number of heating dots at same time 256 Dots

Logic Supply Voltage (VDD) 3.3 V

Logic Supply Current (IDD) 204 mA ALL-HIGH

Table 3-8 TPH Maximum Condition (At 25℃)

2) 203dpi

Item Description Remark

Heat Element Structure 2 Heaters / Dot

Number of Heat Element 640 Dots

Heat Element Pitch 0.125mm/dot, 8Dot/mm (203DPI)

Print Width 80±0.2mm

Average Resistance 800Ω ± 3%

Thermister

1) Resistance R25: 30kΩ ± 5% (At 25℃)

2) B Value: 3950K ± 2%

3) Temperature: - 40℃ ~ +80℃

Table 3-9 TPH Specification

Item Maximum Unit Conditions

Print Cycle (S.L.T.) 0.42 ml/Line

Supply Energy 0.09 mJ/Dot

T=25℃

Supply Voltage 24 V Voltage among the connector terminals

Substrate Temperature 70 ℃ Temperature detected by Thermistor

Number of heating dots at same time 320 Dots

Logic Supply Voltage (VDD) 3.3 V

Logic Supply Current (IDD) 255 mA ALL-HIGH

Table 3-10 TPH Maximum Condition (At 25℃)

3-3-7 Other Component Specification

Item Description Remark

• Model: ORC-RWB80 (OHYANE RIKI MFG, Co., Ltd)

• Type: Guillotine Type

Auto Cutter

• Motor: DC Brush Motor FK-180SH-12280 (Mabuchi Motor)

• Voltage: 24V DC ± 5%(Motor), 5V DC ± 5%(Switch)

• Current: 200mA (Average), 1.5A(Peak)

• Model: STH-39H0001 (SHINANO MOTOR CO, LTD.)

• Type: 2-Phase, Bi-Polar chopper dual,3.75 Step angle

Paper Feed Motor

• Voltage: 4.13V ± 10% DC

• Drive Current: 0.7A [PHASE]

• Winding Resistance: 5.9Ω ±10% @ 25℃

• Winding Inductance: 4.2mH ±20% @ 1KHz 1Vrms

Paper End Sensor • Reflection Type Photo Sensor

Paper Roll Near End Sensor • Reflection Type Photo Sensor

Table 3-11 Other Component Specification

Rev. 1.00

- 21 -

Page 22

3-4 SMPS Specifications

3-4-1 SMPS (Switching Mode Power Supply) Specification

Item Description Remark

• Typical: 100V ~ 240V AC

Input Voltage

Input Current • Max: 1.5A (When 120V)

Inrush Current Limiting

Load Regulation

Ripple Noise • ±200mV @ 24Vdc

Short-Circuit Protection

O.V.P

(Over Voltage Protection)

O.T.P

(Over-temperature Protection)

3-4-2 SMPS Output Connector

• Min: 90V AC

• Max: 264V ac

• Max: 30A at 115Vac input Voltage for a cold start at 25℃

ambient conditions

• +24V ±5% @ 0~2.5A Static

• +24V +5/-10% @ 2~6.5A Dynamic

• The power supply shall not be damaged from the condition that

between DC output and DC ground are shorted. An output short

circuit is defined as output impedance of less than 300mΩ for

greater than 1 second. The power supply will operate normally

when this condition is removed promptly within 2 seconds.

• 26Vdc~30Vdc

• The power supply will be shutdown at an over-temperature

condition. This shutdown shall be cleared by removal of this

abnormal condition and input power recycling.

Table 3-12 Power Adapter (SMPS) Specification

Pin Number Signal Name

1 +24 VDC

2 GND

3 N.C

Shield Frame GND

Table 3-13 Power Connector Pin Description

SRP-F310/312

Rev. 1.00

(a)

Figure 3-5 SMPS DC Output Connector(a) & Printer Power Connector(b)

(b)

- 22 -

Page 23

SRP-F310/312

3-5 Interface Specifications

3-5-1 RS-232C Serial Interface

3-5-1(a) Specification

Item Description Remark

Data Transmission • Serial

Synchronization • Asynchronous

HandShaking

(Flow Control)

Signal Level

Baud Rate • 2400/4800/9600/19200/38400/57600/115200 bps

Data Word Length • 8 bits

Parity • None

Connector • DB25P Female (I/F PBA)

※ Note: The HandShaking (Flow Control) / Data Word Length / Baud Rate / Parity functions depend on the

DIP Switch settings. Refer to the Operation Manual.

3-5-1(b) RS-232C I/F Cable

• H/W: DTR/DSR

• S/W: XON/XOFF

• Logic1 (MARK): -3V ~ -15V

• Logic0 (SPACE): +3V ~ +15V

Table 3-14 RS-232C Specification

XON: ASC Code 11h

XOFF:ASC Code 13h

Connector: User Spec.

In Case PC: D-SUB25P-Female or D-SUB9P-Female

Figure 3-6 RS-232C Cable

Printer Side: D-SUB25P-Male

Rev. 1.00

- 23 -

Page 24

3-5-1(c) Cable Connection

SRP-F310/312

PRINTER

SIDE (25P)

3-5-1(d) Signal Description

Pin No. Signal name Direction Function

1 FG - Frame Ground

2 TxD Output Transmit Data

3 RxD Input Receive Data

4 RTS Output Ready To Send

5 CTS Input Clear To Send

6 DSR Input

7 SG -

20 DTR Output

HOST

SIDE (25P)

Figure 3-7 RS-232C Cable Connection

This signal indicates whether the host computer can receive data.

(H/W flow control)

1) MARK(Logic1): The host can receive a data.

2) SPACE(Logic0): The host can not receive a data.

3) The printer transmits a data to the host, after confirming

this signal.

4) When XON/XOFF flow control is selected, the printer does

not check this signal.

Signal Ground

This signal indicates whether the printer is busy. (H/W flow control)

1) MARK(Logic1): The printer is busy.

2) SPACE(Logic0): The printer is not busy.

3) The host transmits a data to the printer, after confirming

this signal.

4) When XON/XOFF flow control is selected, the host does

not check this signal.

Table 3-15 RS-232C Pin Description

PRINTER

SIDE (25P)

HOST

SIDE (9P)

Rev. 1.00

- 24 -

Page 25

SRP-F310/312

3-5-1(e) H/W Flow Control

When DTR/DSR flow control is select, before transmitting a data, the Printer checks whether the host is

BUSY or not. If the host is BUSY, the Printer does not transmit a data to the host. If the host is not BUSY, the

Printer transmits a data to the Host. The host is the same. Refer to the Interface Part of Chapter 7 (Special

Circuit Diagrams).

3-5-1(f) S/W Flow Control

When XON/XOFF flow control is selected, the printer transmits XON(ACSII 11h) or XOFF(ASCII 13h) signal

through the TXD line.

If the Printer is BUSY, the Printer transmits XOFF(ASCII 13h) to host through the TXD line. Then the host

recognize that the Printer is BUSY. So, the host does not transmit a data to the Printer. If the Printer is

released from BUSY, the Printer transmits XON(ASCII 11h) to host through the TXD line. Then the host

recognize that the Printer is not BUSY. And the host transmit a data to the Printer.

※ Note: Refer to the Operation Manual about XON/XOFF flow control.

3-5-2 IEEE1284 Parallel Interface

Bidirectional parallel interface: in accordance with the IEEE1284 Nibble/Byte mode.

3-5-2(a) Forward Mode Specification (Compatibility mode)

Data transmission from host computer to printer: Centronics compatible

Item Description Remark

Data Transmission • 8-bits Parallel

Synchronization • External supplied nStrobe signals

HandShaking • nACK and Busy signals

Signal Level • TTL compatible

Connector • Centronics 36P

Table 3-16 IEEE1284 Specification

3-5-2(b) Reverse Mode Specification (Nibble / Byte mode)

Data transmission from the printer to the host computer.

The STATUS data transmission from the printer to the host computer is accomplished in the Nibble or Byte

mode. This mode allows data transmission from the asynchronous printer under the control of the host

computer. Data transmission in the Nibble mode are made via the existing control lines in units of for bits

(Nibble). In the Byte mode, data transmission in accomplished by making the 8-bit data lines bidirectional.

Neither mode can operate at the same time as the compatibility mode, so switching is always required.

Rev. 1.00

- 25 -

Page 26

SRP-F310/312

3-5-2(c) Signal Specification (Compatibility/Nibble/Byte mode)

Pin No. Source Compatibility Mode Nibble Mode Byte Mode

1 Host nStrobe HostClk HostClk

2 Host / Printer Data 0 (LSB) - Data 0 (LSB)

3 Host / Printer Data 1 - Data 1

4 Host / Printer Data 2 - Data 2

5 Host / Printer Data 3 - Data 3

6 Host / Printer Data 4 - Data 4

7 Host / Printer Data 5 - Data 5

8 Host / Printer Data 6 - Data 6

9 Host / Printer Data 7 (MSB) - Data 7 (MSB)

10 Printer nAck PtrClk PtrClk

11 Printer Busy PtrBusy/Data3,7 PtrBusy

12 Printer Perror AckDataReq /Data2,6 AckDataReq

13 Printer Select Xflag/Data1,5 Xflag

14 Host nAutoFeed HostBusy HostBusy

15 NC ND ND

16 GND GND GND

17 FG FG FG

18 Printer Logic-H Logic-H Logic-H

19~30 GND GND GND

31 Host nlnit nInit nlnit

32 Printer nFault nDataAvail /Data0,4 nDataAvail

33 GND ND ND

34 Printer DK_Status ND ND

35 Printer +5V ND ND

36 Host nSelectln 1284-Active 1284-Active

Table 3-17 IEEE1284 Pin Description

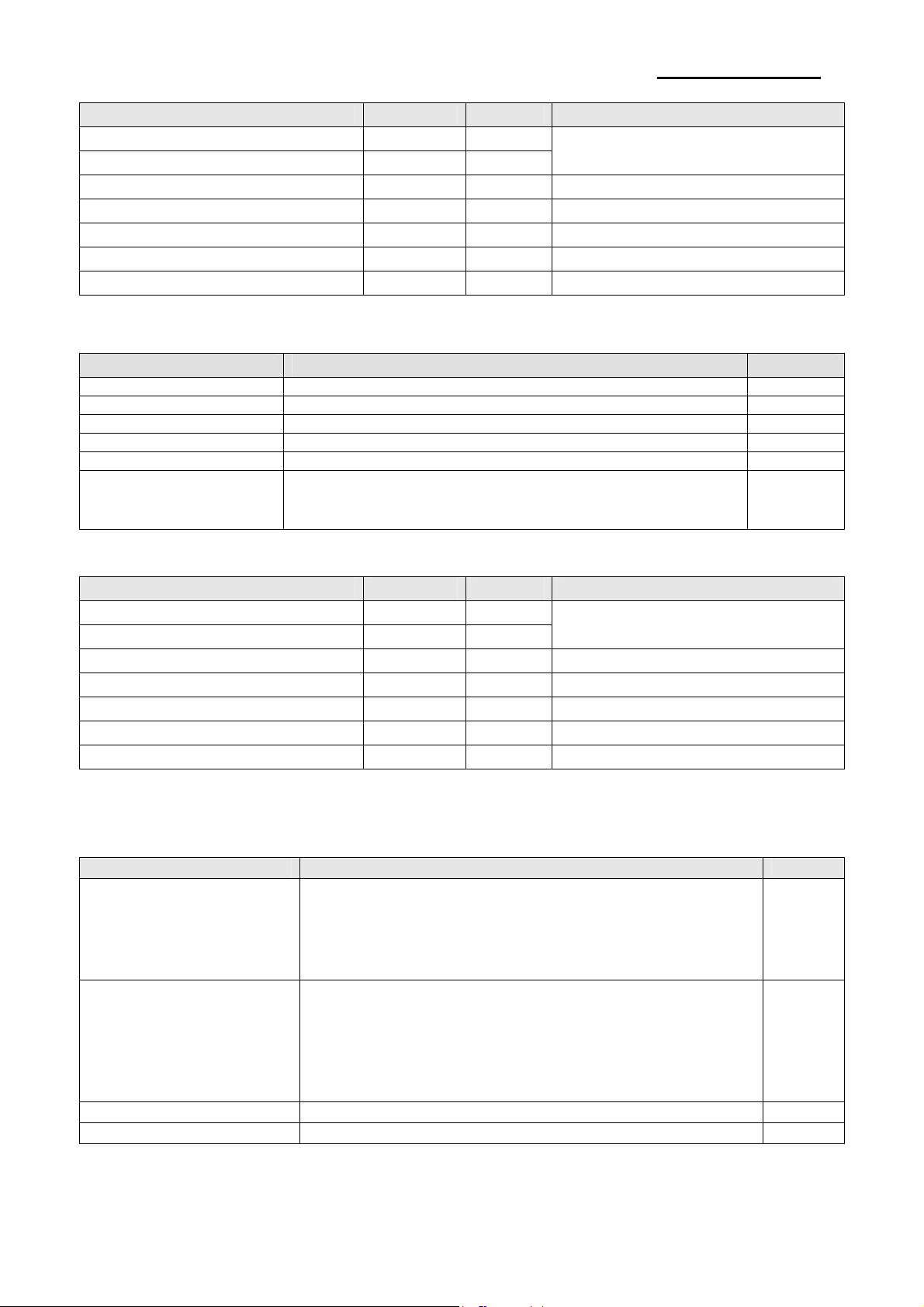

3-5-2(c) IEEE1284 I/F Cable

Rev. 1.00

Host Side: DB25M

Printer Side: CN36M

Figure 3-8 IEEE1284 Cable

- 26 -

Page 27

SRP-F310/312

3-5-3 USB2.0 Interface

SRP-F310/312 support the USB (Universal Serial Bus) Serial Communication.

3-5-3(a) Specification

Item Description Remark

Transfer Type • BULK

Data Signal

Data Format

Speed • 480 Mbps

Cable & Connector

Other

3-5-3(b) Signal Description

Pin No. Signal Name Assignment(Color) Function

Shell Shield Drain Wire Frame Ground

1 VBUS Red Host Power: DC5[V] / 500[mA]

2 D- White Differential Data Line

3 D+ Green Differential Data Line

4 GND Black Signal Ground

3-5-3(c) Cable

USB cable consists of four conductors, two power conductors, and two signal conductors.

High-/full-speed cable consists of a signaling twisted pair, VBUS, GND, and an overall shield. High-/full

speed cable must be marked to indicate suitability for USB usage. High-/full-speed cable may be used with

either low-speed, full-speed, or high-speed devices. When high-/full-speed cable used with low-speed

devices, the cable must meet all low-speed requirements.

Low-speed recommends, but does not require the use of a cable with twisted signaling conductors.

• Bi-direction, Half-Duplex

• Differential Signal Pair (D+ / D-)

• NRZI Format

• Zero Bit Stuffing after 6 ones

• Cable: 5m / 2m

• Connector: B Type(Device) / A Type(Host)

• Supports the 480 Mbps high-speed mode (HS) for

USB 2.0, as well as the 12 Mbps full-speed (FS) and

the low-speed (LS modes) for USB 1.1

Table 3-18 USB Specification

Table 3-19 USB Pin Description

Rev. 1.00

- 27 -

Page 28

SRP-F310/312

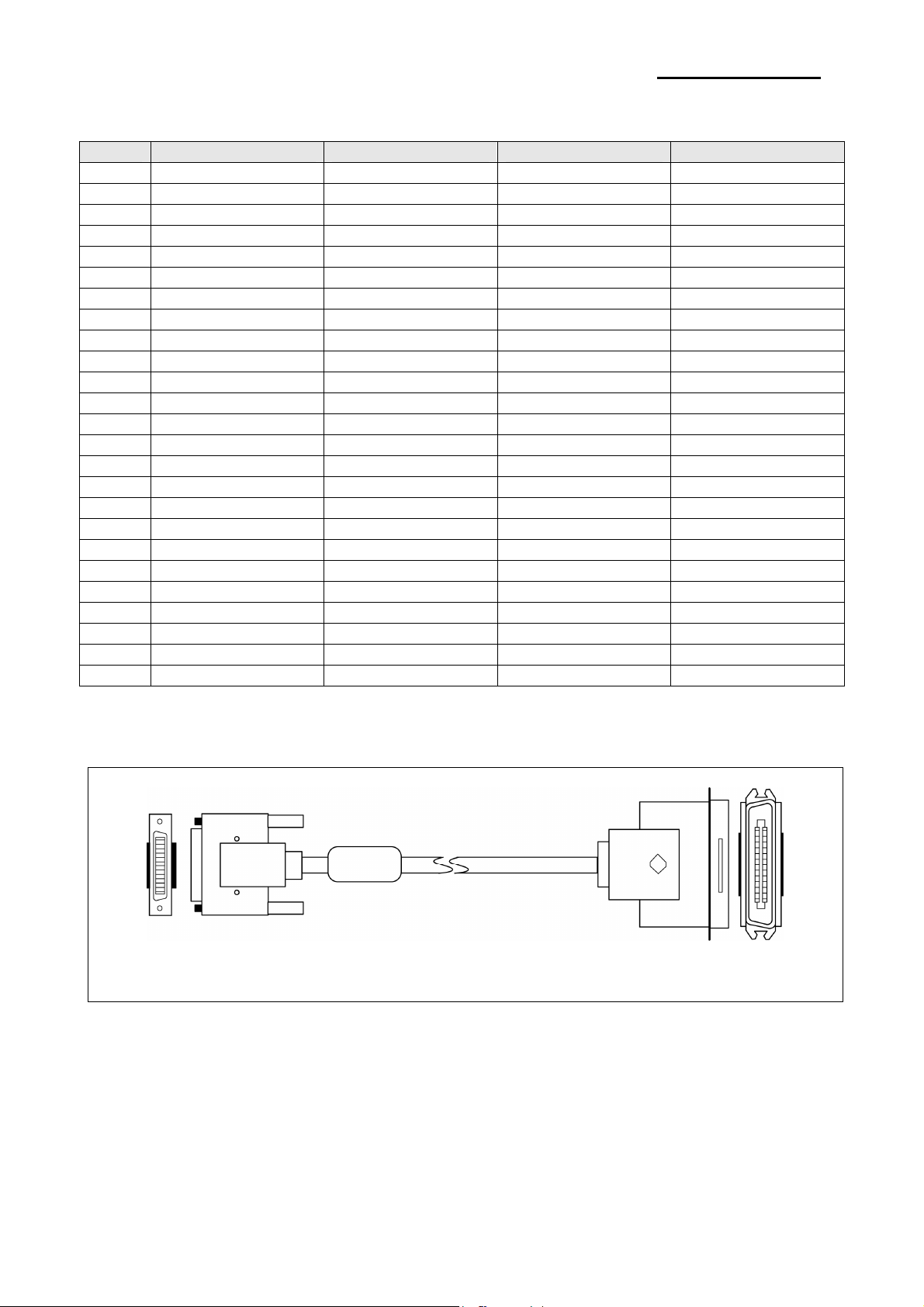

Figure 3-9 USB Cable

3-5-4(d) Construction

Raw materials used in the fabrication of this cable must be of such quality that the fabricated cable is

capable of meeting or exceeding the mechanical and electrical performance criteria of the most current USB

Specification revision and all applicable domestic and international safety/testing agency requirements; e.g.,

UL, CSA, BSA, NEC, etc., for electronic signaling and power distribution cables in its category.

American Wire

Gauge (AWG)

28

26

24

22

20

Nominal Conductor

Outer Diameter

0.381 mm (0.015)

0.406 mm (0.016)

0.483 mm (0.019)

0.508 mm (0.020)

0.610 mm (0.024)

0.610 mm (0.024)

0.762 mm (0.030)

0.787 mm (0.031)

0.890 mm (0.035)

0.931 mm (0.037)

Table 3-20 Power Pair

Stranded Tinned

Conductors

7 x 36

19 x 40

7 x 34

19 x 38

7 x 32

19 x 36

7 x 30

19 x 34

7 x 28

19 x 32

Rev. 1.00

- 28 -

Page 29

SRP-F310/312

※ Note: Minimum conductor construction must be stranded tinned copper.

To minimize end user termination problems, USB uses a keyed connector protocol. The physical difference

in the Series A and B connectors insures proper end user connectivity. The A connector is the principle

means of connecting USB devices directly to a host or to the downstream port of a hub. All USB devices

must have the standard Series A connector specified in this chapter. The B connector allows device vendors

to provide a standard detachable cable. This facilitates end user cable replacement.

Figure 2-10 illustrates the keyed connector protocol.

Series A Connectors

Series B Connectors

◆Series A plugs are

always oriented upstream

towards the Host System

A Plugs

(From the

USB Device)

A Receptacles

(Downstream Output

from the USB Host orHub)

Figure 3-10 Keyed Connector Protocol

The following list explains how the plugs and receptacles can be mated:

• Series “A” receptacle mates with a Series “A” plug. Electrically, Series “A” receptacles function as outputs

from host systems and/or hubs.

• Series “A” plug mates with a Series “A” receptacle. The Series “A” plug always is oriented towards the host

system.

• Series “B” receptacle mates with a Series “B” plug (male). Electrically, Series “B” receptacles function as

inputs to hubs or devices.

• Series “B” plug mates with a Series “B” receptacle. The Series “B” plug is always oriented towards the USB

hub or device.

◆Series B plugs are

always oriented downstream towards

the USB Device

B Plugs

(From the

Host System)

B Receptacles

(Upstream Input to the

USB Device or Hub)

Rev. 1.00

- 29 -

Page 30

SRP-F310/312

3-6 Cash Drawer Specifications

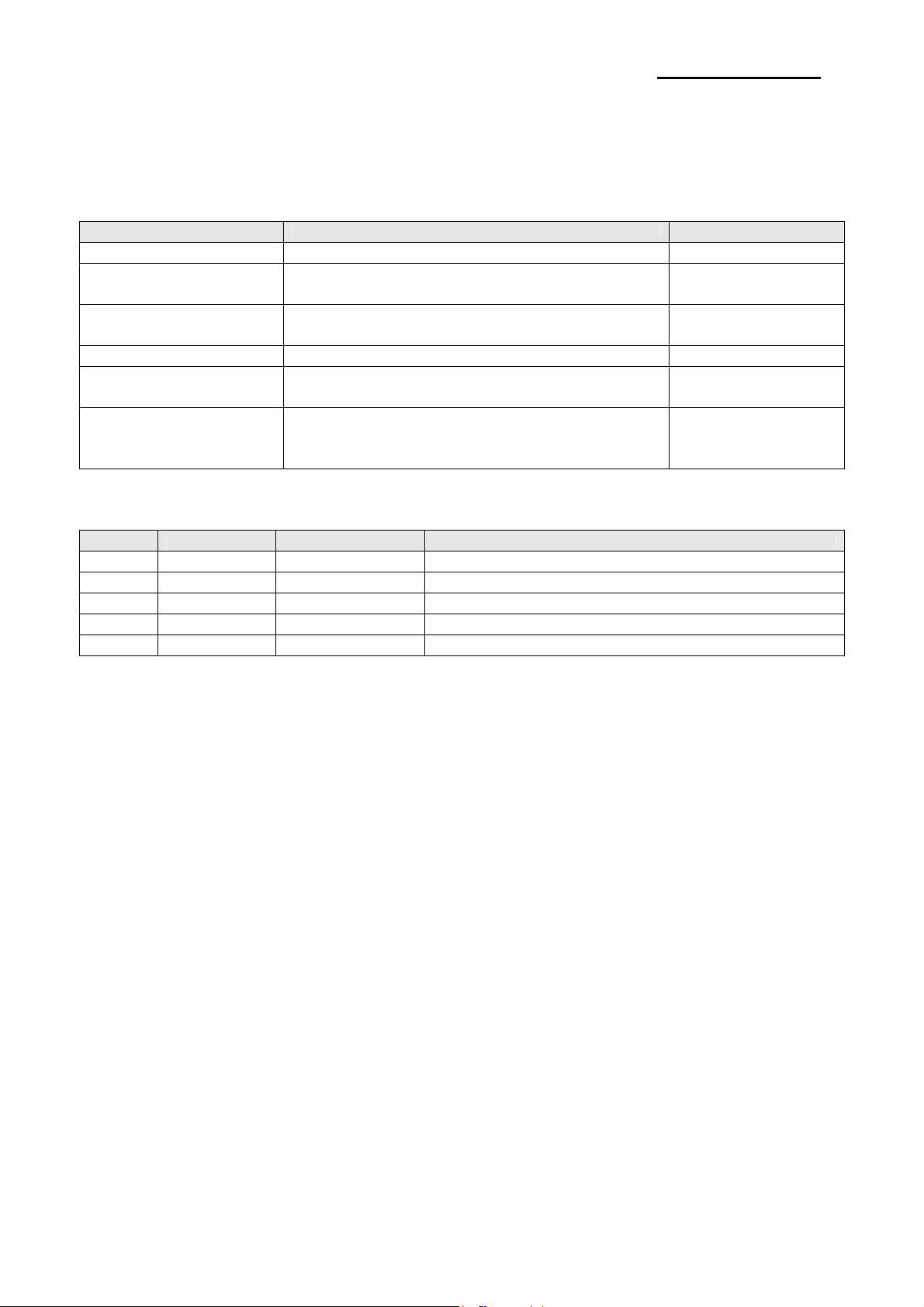

3-6-1 Drawer Cable

Ferrite Core: 1 turn (OP-18E: 18.2 x 12.5 x 25.5)

Figure 3-11 Drawer Cable

3-6-2 Cable Connection

Pin No. Description Direction

1 Frame GND 2 Drawer Kick-Out Driver Signal #1 Output

3 Drawer Open / Close Signal Input

4 +24V 5 Drawer Kick-Out Driver Signal #2 Output

6 Signal GND -

Table 3-21 Drawer Cable Connection

※ Note: +24V is always output through pin 4 during power on.

Rev. 1.00

- 30 -

Page 31

SRP-F310/312

3-7 ETHERNET Specifications

3-7-1 Ethernet

1) Ethernet specifications

Network Interface: 10/100 Base-T All in one type (Auto detection)

[Protocol]

Layer Protocol

Network Layers ARP, IP, ICMP

Transport Layers TCP, UDP

Application Layers

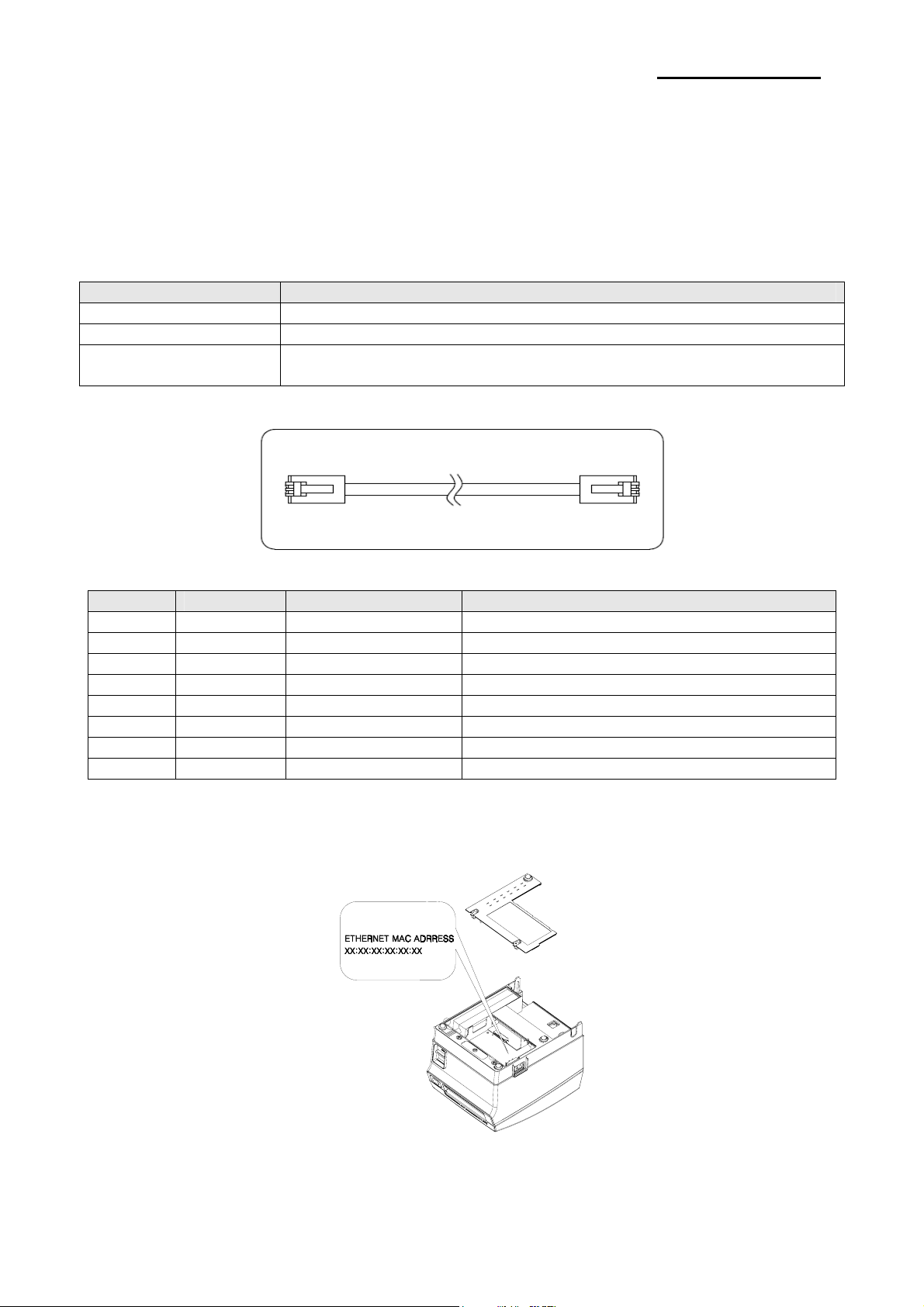

2) Ethernet cable

3) Ethernet signal descriptions

Pin No. Signal name Assignment (Color) Function

1 TD+ White Orange Transmit +

2 TD- Orange Transmit 3 TCT White Green Receive +

4 NC Blue

5 NC White Blue

6 RCT Green Receive 7 RD+ White Brown

8 RD- Brown

* For more information, refer to the Network User Manual in Bixolon Web Site.

4) Ethernet MAC address

When you open the cover, you can see the 'ethernet MAC address' on the board.

DHCP, DNS, Raw Print, SMTP(notify Printer status)

HTTP, HTTPS(setting), FTP (settings), TELNET (settings)

Rev. 1.00

- 31 -

Page 32

SRP-F310/312

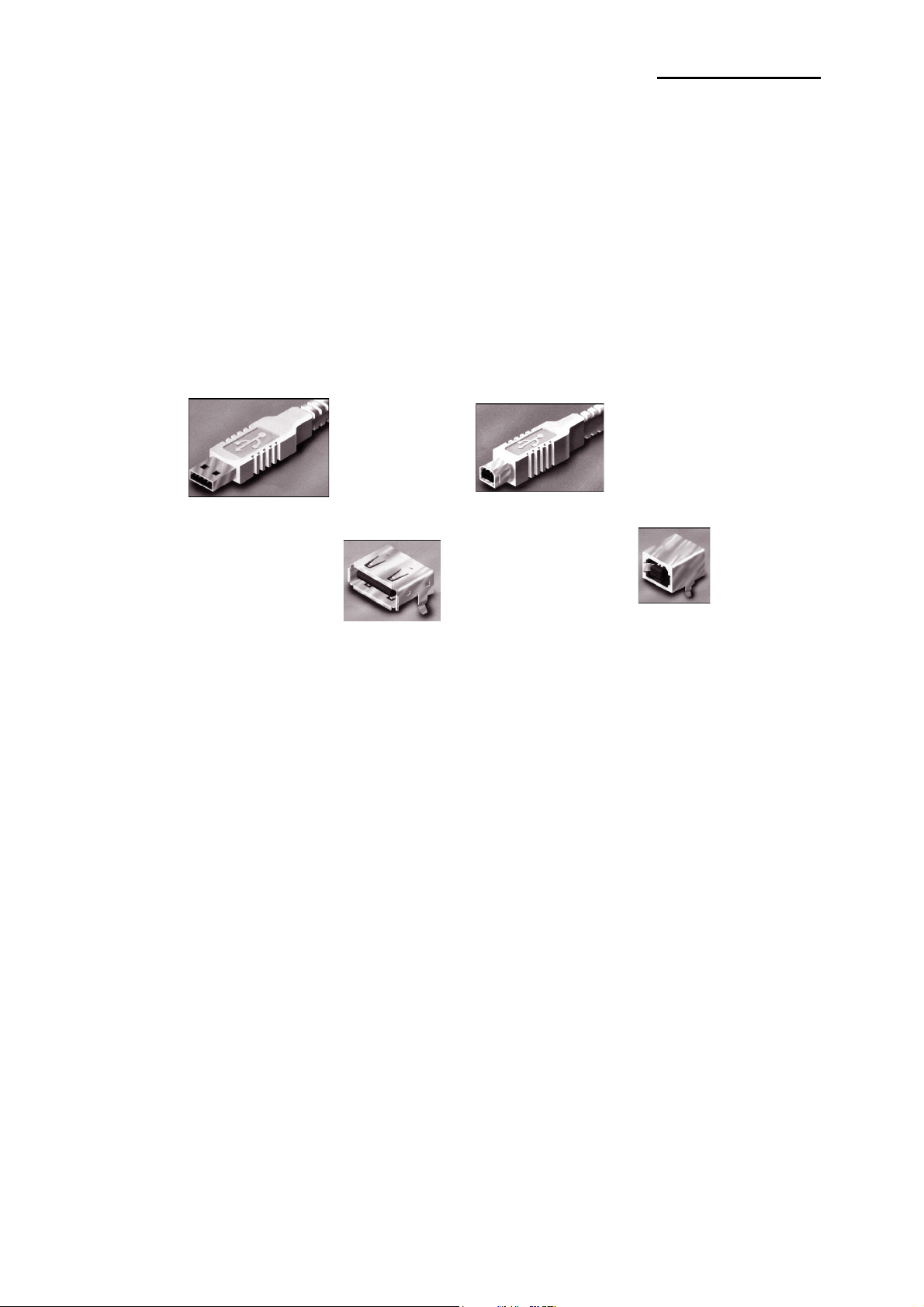

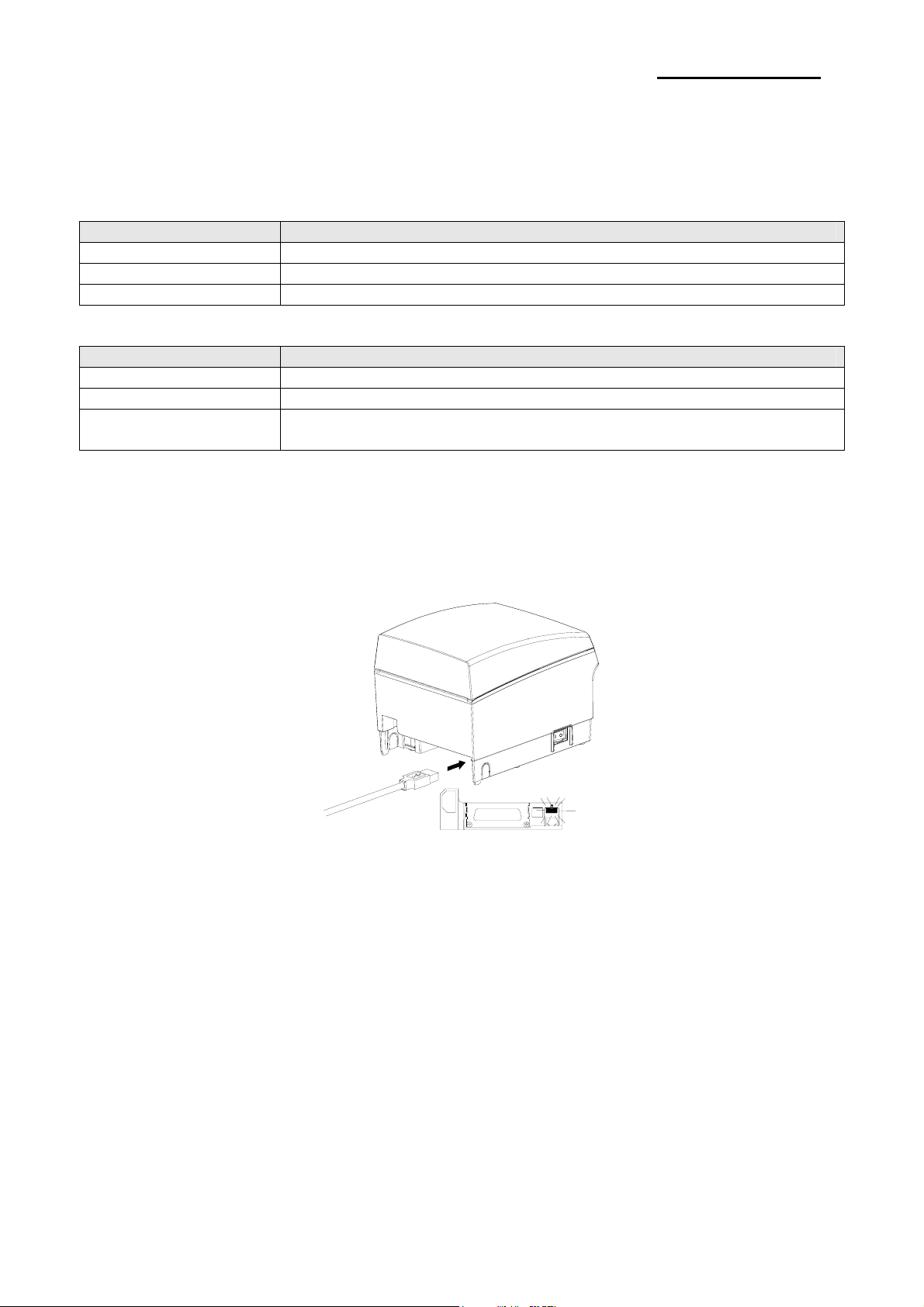

3-7-2 WLAN

1) WLAN specifications

Support IEEE 802.11b/g Infrastructure, Ad-hoc mode.

Frequency Band and Operating Channels]

Item Description

Frequency band 2.4000 – 2.497 GHz

Modulation OFDM with BPSK, QPSK, 16QAM, 64QAM (11g) BPSK, QPSK, CCK (11b)

Data rate : 54/48/36/24/18/12/11/9/6/5.5/2/1 Mbps auto fallback

[Protocol]

Layer Protocol

Network Layers ARP, IP, ICMP

Transport Layers TCP, UDP

Application Layers

[Security]

- WEP64/128

- WPA/WPA2(TKIP/AES-CCMP) PSK

- HTTPS(SSL2.0, SSL3.0, TLS1.0)

2) WLAN USB extension cable

DHCP, DNS, Raw Print, SMTP(notify Printer status)

HTTP, HTTPS(settings), FTP (settings), TELNET (settings)

3) Compatible WLAN USB adaptor list

SRP-F310/312 is compatible with WLAN USB adaptor using RT73(RT2571W/RT2573/RT2671) chipset.

You can use WLAN printer with WLAN USB adaptor offered by BIXOLON Co.,Ltd. or purchased by

personally.

Tested WLAN USB adaptor list is below.

- CNET CWD-854

- TP-Link TL-WN32G

- D-Link DWA-110

- Buffalo WLI-U2-SG54HP

We recommand using WLAN USB adaptor in a list.

* For more information, refer to the Network User Manual in BIXOLON Co.,Ltd. Web Site.

Rev. 1.00

- 32 -

Page 33

SRP-F310/312

4. Hardware

4-1 Wiring Diagram

Rev. 1.00

[Figure 4-1 Board Wiring Diagram]

- 33 -

Page 34

SRP-F310/312

4-2 Block Diagram

Rev. 1.00

- 34 -

Page 35

SRP-F310/312

Rev. 1.00

- 35 -

Page 36

SRP-F310/312

Rev. 1.00

- 36 -

Page 37

SRP-F310/312

Rev. 1.00

- 37 -

Page 38

SRP-F310/312

[Figure 4-2 Block Diagram]

Rev. 1.00

- 38 -

Page 39

SRP-F310/312

4-3 Special Circuit Descriptions

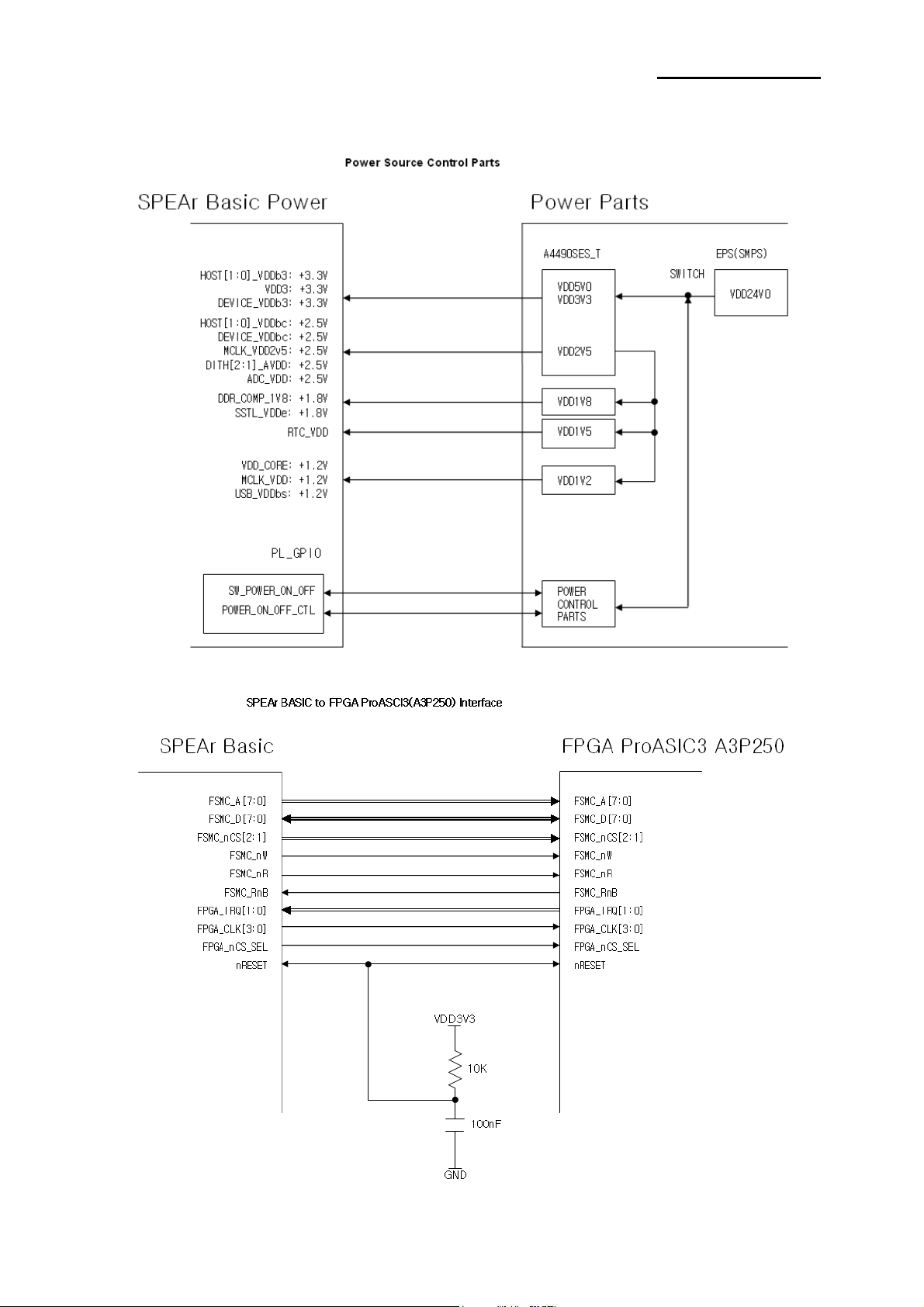

4-3-1 Power Circuit

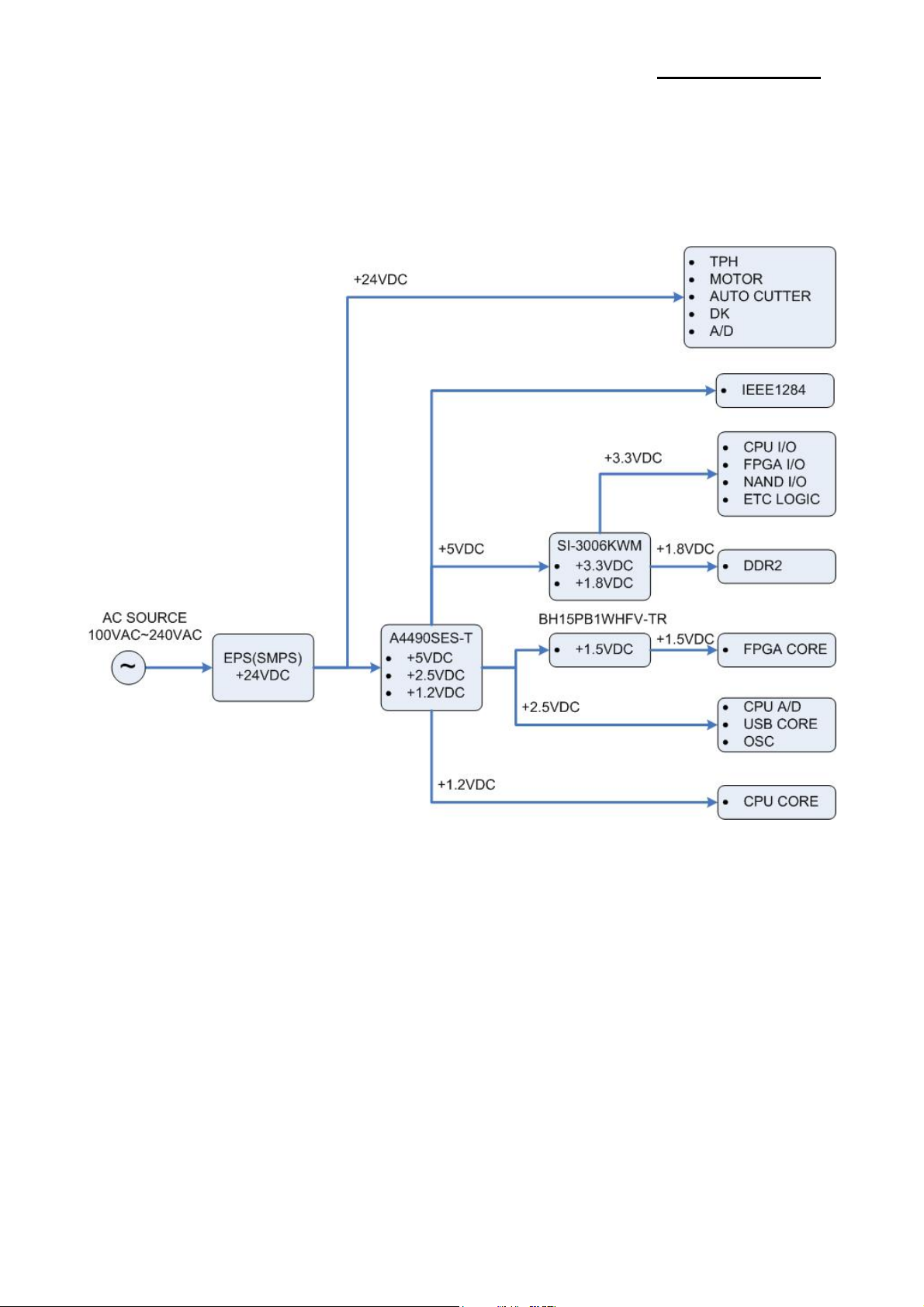

This system is operated under 100Vac or 240Vac. The power circuit supplies the three differential DC voltage

sources.

[Figure 4-3 Power Block Diagram]

1) Drawer Driving and Feed, Auto Cutter Motor Voltage and TPH Driving Voltage: +24VDC

+24VDC is supplied from SMPS. This Voltage is smoothed by capacitors (CE1).

This voltage is used as a Cash Drawer Solenoid Driving voltage, Step motor driving voltage and a source

voltage of the other voltage sources and TPH Driving Voltage.

2) IEEE1284 Logic IC Driving Voltage: +5VDC

Step down voltage the input +24VDC to +5VDC by a switching regulation U13(A4490SES-T)

3) CPU I/O, FPGA I/O, NAND Flash and etc. LOGIC Voltage: +3.3VDC

Step down voltage the input +5VDC to +3.3VDC by a regulation.U15(SI-3006KWM)

4) CPU A/D, USB core and OSC Voltage: +2.5VDC

Step down voltage the input +24VDC to +2.5VDC by a switching regulation.U13(A4490SES-T)

5) DDR2 Voltage: +1.8VDC

Step down voltage the input +5VDC to +1.8VDC by a regulation.U15(SI-3006KWM)

Rev. 1.00

- 39 -

Page 40

SRP-F310/312

6) FPGA core Voltage: +1.5VDC

Step down voltage the input +2.5VDC to +1.5VDC by a regulation.U16(BH15PB1WHFV-TR)

7) CPU core Voltage: +1.2VDC

Step down voltage the input +24VDC to +1.2VDC by a switching regulation.U13(A4490SES-T)

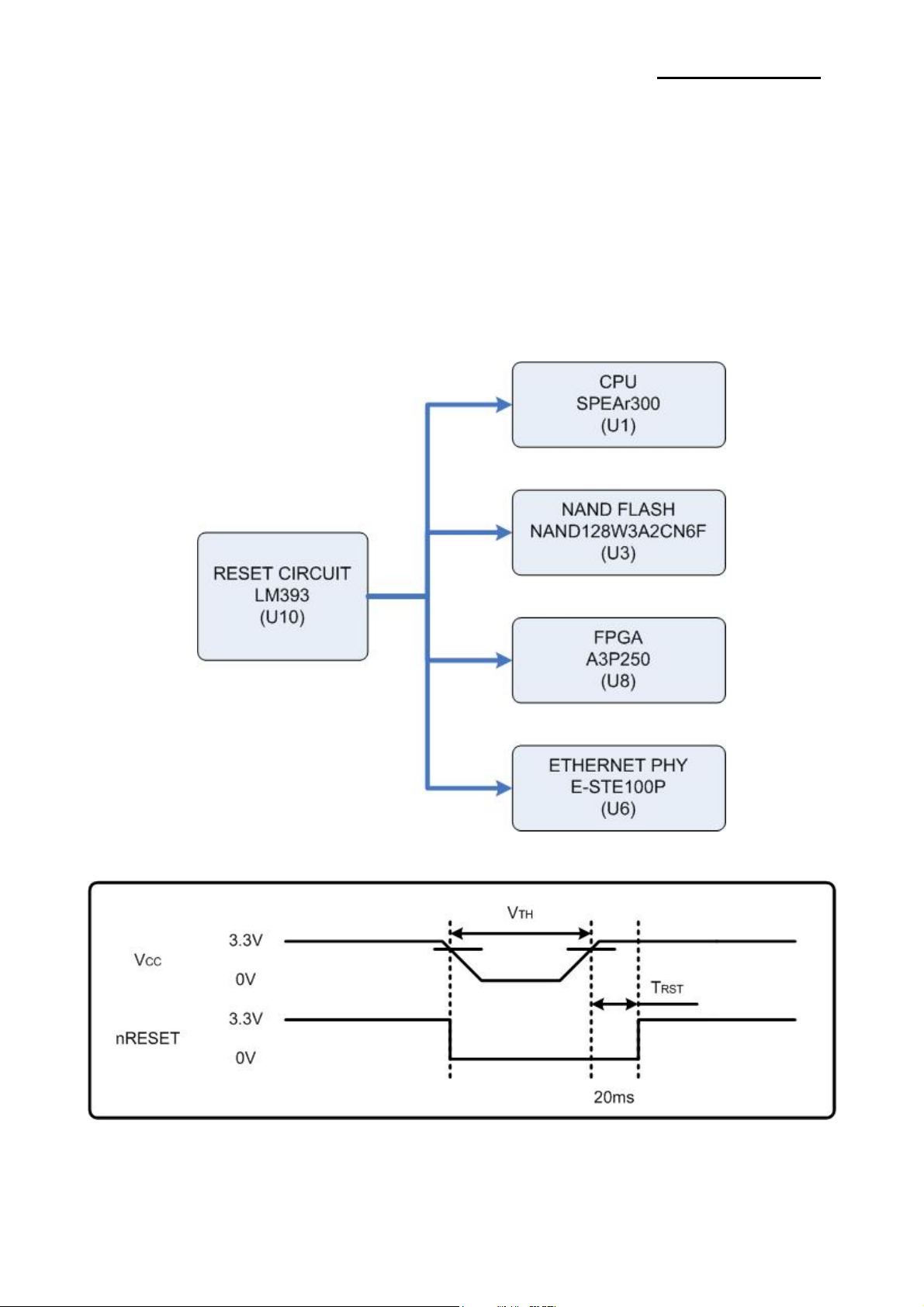

4-3-2 RESET Circuit

Reset signal is signal in order to start-up CPU under Power-on.

Reset circuit uses a reset ASM811REUSF-T(U8). When 3.3Vdc is fallen under 2.7Vdc by Power-off,

reset signal prohibits the system from miss-operating by lowering down to 0V.

Rev. 1.00

[Figure 4-4 Reset Block Diagram]

[Figure 4-5 Reset Waveform]

- 40 -

Page 41

SRP-F310/312

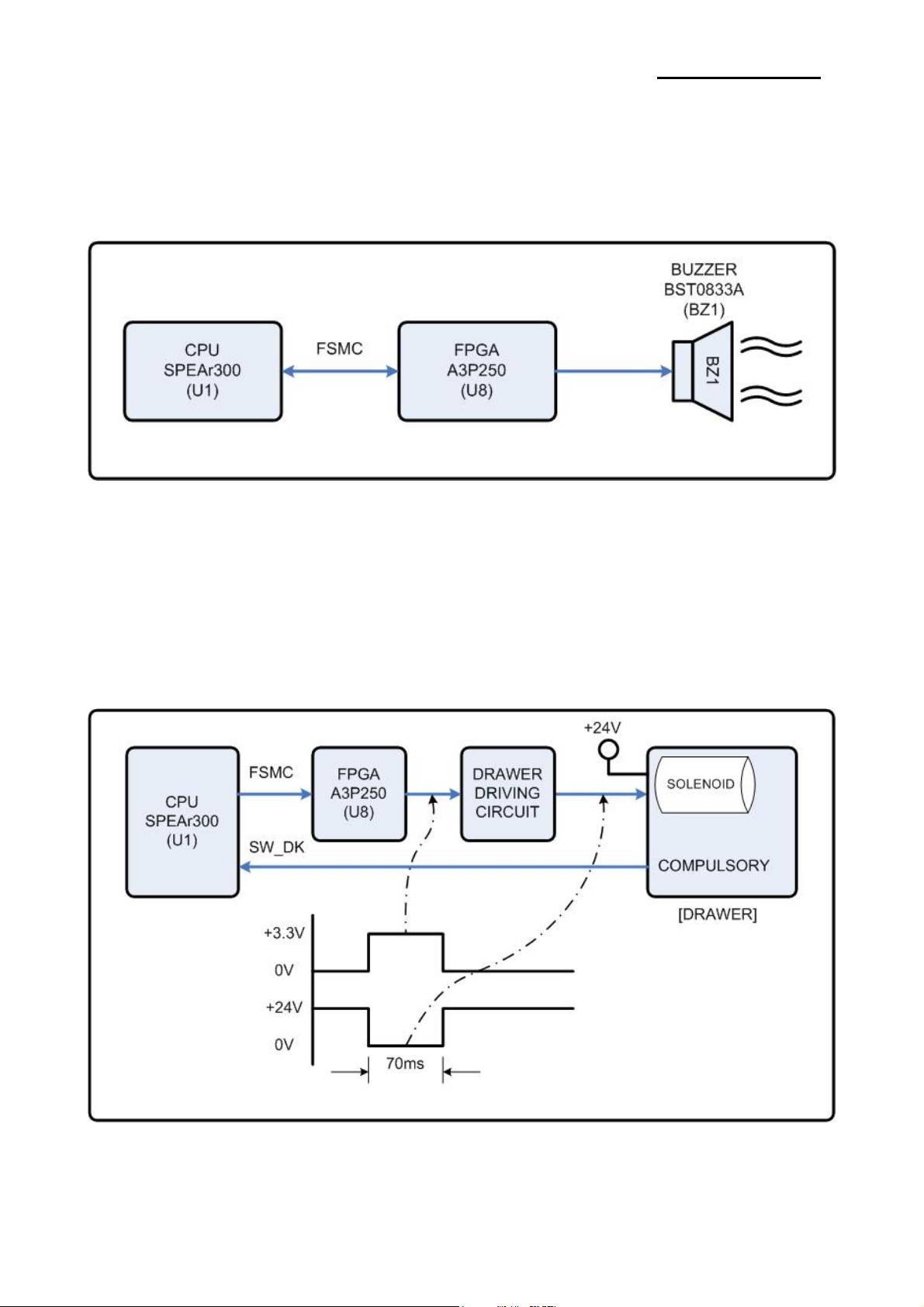

4-3-3 Buzzer and Cash Drawer Circuits

1) Buzzer Driving Circuit

The Buzzer is used to inform several kinds of states which occur under system operating and gives some

information to users by controlling the CPU (SPEAr300)

[Figure 4-6 Buzzer Block Diagram]

2) Cash Drawer Driving Circuit

The circuit is used for opening cash drawer and driven by the Q301, Q302(2SD2170). When its state is high

level signal, Q301 or Q302 (2SD2170) drive the solenoid to open the cash drawer. As an optional item, we

provide sensor switch (we call it a compulsory switch) which checks the drawer whether it is opened or not.

This sensor switch turns on for the drawer open condition, and turns off for the other.

※ Caution: Make sure that the Cash Drawer solenoid resistance is more than 20Ω.

Rev. 1.00

[Figure 4-7 Cash Drawer Block Diagram]

- 41 -

Page 42

SRP-F310/312

4-3-4 I/F PBA Detect Block Diagram

When the printer is ON, the printer checks what kind of the I/F PBA is installed. After detection, the CPU

specify the I/O port properly. The following is the method of I/F PBA detection.

The I/F PBA has the three return Signal (MD0~2).

The CPU recognize the I/F PBA by the value of the three return signal.

I/F PBA MD0 MD1 MD2

RS-232C L H L

IEEE1284 H L L

No Connection L L L

4-3-5 RS-232C Communication Block Diagram

The CPU is used for serial communication. And also RS-232C Driver (MAX232), is used to serial

communication. Show following block diagram.

[Figure 4-8 RS-232C Communication Block Diagram]

Rev. 1.00

[Figure 4-9 RS-232C Communication Waveform]

- 42 -

Page 43

SRP-F310/312

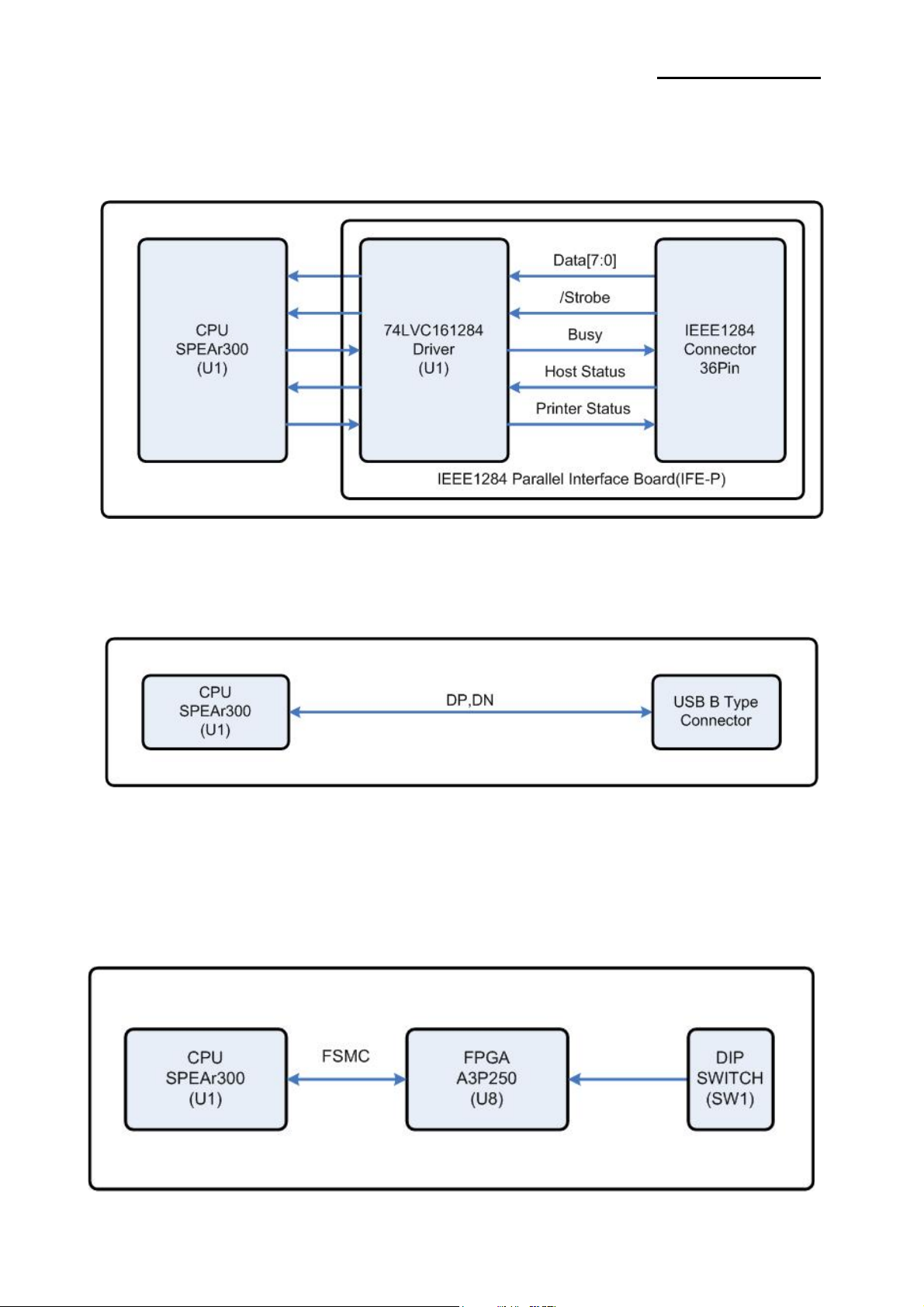

4-3-6 Parallel Communication Block Diagram

The printer support the bidirectional Parallel Interface with Centronics, Nibble, Byte Mode.

The Centronics is Forward and the Nibble, Byte are reverse Mode.

[Figure 4-10 IEEE1284 Communication Block Diagram]

4-3-7 USB Communication Block Diagram

The printer support the USB (Universal Serial Bus). The transfer type of the printer is the BULK.

[Figure 4-11 USB2.0 Communication Block Diagram]

4-3-8 DIP Switch Circuit

The key board circuit consist of the scan signal of 3 lines and the return signal of 2-line. The CPU sends

repeatedly and continuously the scan data DIP_A~DIP. The DIP S/W information input in the return signal if

the specific DIP S/W is ON status during the given time. The CPU reads the data through DIP IN1~IN2 and

analyzes what DIP S/W is ON and performs the selected function.

[Figure 4-12 USB Communication Block Diagram]

Rev. 1.00

- 43 -

Page 44

SRP-F310/312

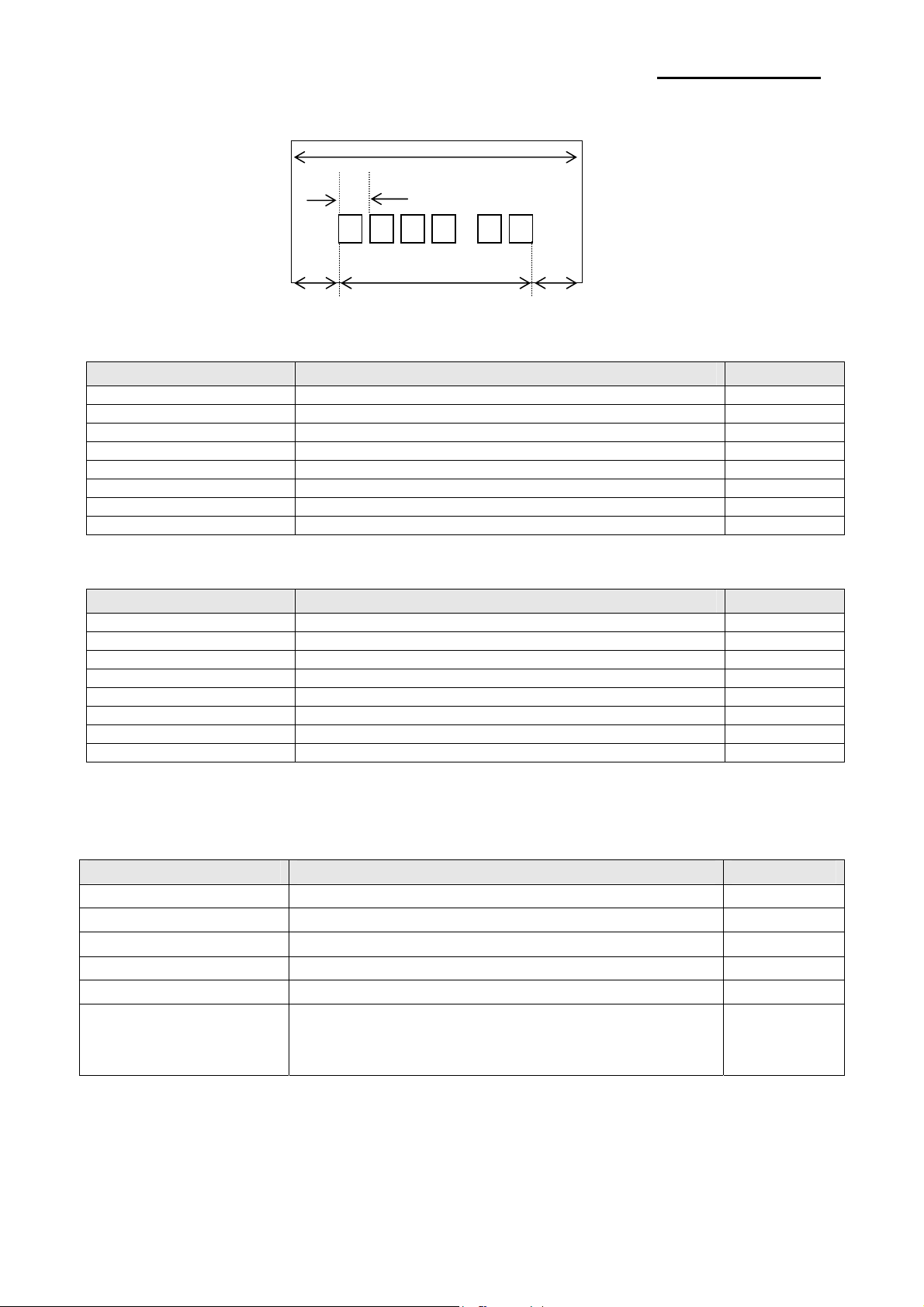

4-3-9 Thermal Printer Head Circuit

First, the CPU sends a Serial Clock and Serial Data 256bits(32Bytes) to the Shift Register of the Thermal

Printer. The Serial Data are stored to each Shift Register in the Thermal Printer. Because the Data#1 Pin and

the Data#2 pin are shorted on Main PCB, the Data(256bits) are stored in both Shift Register#1 and #2.

Second, the CPU send a Latch Signal to the Thermal Printer. Then, the Data of both Shift Register#1 and #2

(256*2=512bits) are moved to the Latch Register. After that, the CPU sends a Strobe Signal to the Thermal

Printer. Then, the Printer outputs the Serial Data. Each Strobe Signal manages the Printer Dot.

STB No. DOT No. DOTs/STB SRP-F310/312 Strobe Processing

STB1 1 ~ 256 256

STB2 257 ~ 512 256

The content of data is same.

CPU

SPEAr300

CLK

DATA#1,2

[Figure 4-13 Thermal Printer Block Diagram]

256 CLK

256bits 256bits 256bits

/LATCH

STROBE1

STROBE2

Rev. 1.00

Printing (1~256 ) P rinting(1~256)

Printing( 257~512)

[Figure 4-14 Thermal Printer Timing Waveform]

- 44 -

Page 45

5. Disassembly and Assembly

5-1 Case lower block

SRP-F310/312

1. Remove the ①two screws.

2. Separate the ②COVER DOWN-FRONT

1. Remove the ①two screws.

2. Separate the ②INTERFACE DEFAULT

Rev. 1.00

- 45 -

Page 46

SRP-F310/312

1. Separate the ①COVER DIP-SWITCH

form the SRP-F310/312

2. Remove the ②SMPS

1. Remove the ①two screws.

2. Separate the ②ASE LOWER

Rev. 1.00

- 46 -

Page 47

SRP-F310/312

1. Separate the ①FPC from MAIN PCB

2. Separate the ②FIVE CONNECTOR

from MAIN PCB

1. Remove the ①four screws.

2. Separate the ②MAIN PCB

from ④BRACKET PCB.

3. Remove the ③two screw.

4. Separate the ④BRACKET PCB

from SRP-F310/312.

Rev. 1.00

- 47 -

Page 48

SRP-F310/312

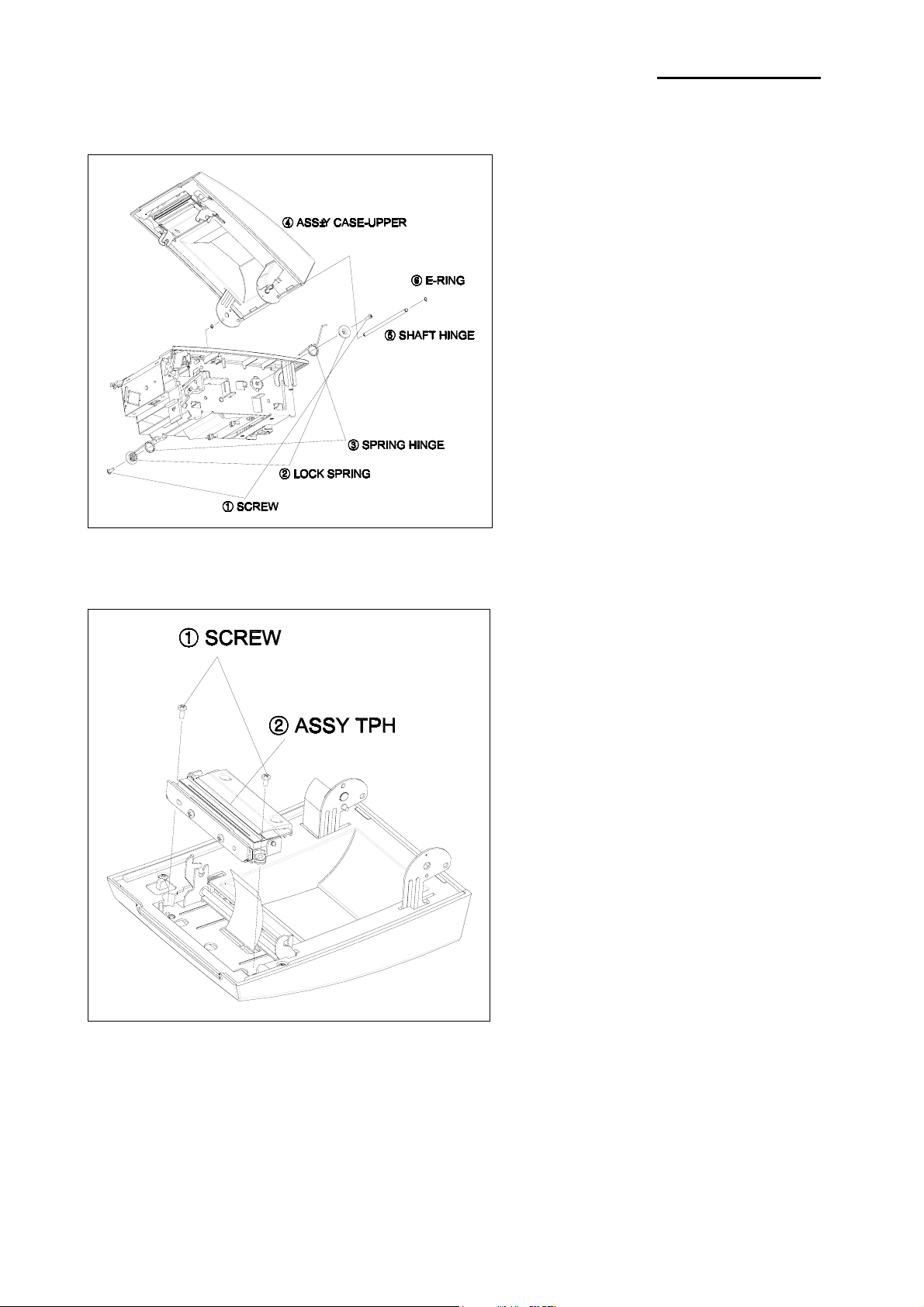

5-2 Case Upper block

1. Remove the ①screw

2. Separate the ②LOCK SPRING,

③SPRING HINGE

3. Remove the ⑥E-Ring.

4. Separate the ⑤SHAFT HINGE

From ④ASS`Y CASE-UPPER

1. Remove ①two screws.

2. Separate the ②ASS`Y TPH

From ASS`Y CASE-UPPER

Rev. 1.00

- 48 -

Page 49

SRP-F310/312

1. Remove the ①two screws.

2. Separate the ②CASE UPPER

from the ASSY HOUSING.

3. Separate the ③COVER UP-FRONT

from ②CASE UPPER

4. Remove the ④screw.

5. Separate the ⑤COVER HINGE

from the ASSY HOUSING.

1. Remove the ①four screws.

2. Separate the ②BRACKET HOUSING

from the ASSY HOUSING

3. Separate the ⑥two WASHER

from the ⑤SHAFT HINGE

4. Separate the ⑤SHAFT HINGE and

③BRACKET HOOK and ④SPRING

from the ②BRACKET HOUSING

5. Remove the ⑧screw.

6. Separate the ⑨PCB LED

from the ⑦COVER HOUSING

7. Remove the ⑫⑬FFC,FPC

from the ⑪PCB TPH

8. Remove the ⑩two screws.

9. Separate the ⑪PCB TPH

from the ⑦COVER HOUSING

Rev. 1.00

- 49 -

Page 50

SRP-F310/312

1. Remove the ①two screws.

2. Separate the ②GUIDE TPH

from the ASSY TPH

3. Remove the ⑥screw.

4. Separate the ASSY FIXED CUTTER

from the ASSY TPH

5. Remove the ③two screws.

6. Separate the ④CUTTER

from the ⑤GUIDE CUTTER

7. Remove the ⑫SPECIAL SCREW.

8. Separate the ⑪E-RING, ⑩SHAFT TPH

from the ⑦TPH

9. Remove the ⑧SPRING TPH, ⑦TPH

from the ⑨BRACKET TPH

Rev. 1.00

- 50 -

Page 51

5-3 Frame block

SRP-F310/312

1. Remove the ①two screws.

2. Separate the ASSY CUTTER

from the FRAME MAIN

3. Remove the ③four screws.

4. Separate the ④AUTO CUTTER

from the ②BRACKET CUTTER

1. Separate the ①PARTITION

from the FRAME MAIN

2. Remover the ③WASHER.

3. Separate the ②SHAFT FEED

from the FRAME MAIN

4. Remover the ④WASHER.

5. Separate the ⑤PUSH BUTTON

And ⑥SPRING LOCK-L

from the FRAME MAIN

Rev. 1.00

- 51 -

Page 52

SRP-F310/312

1. Remove the ①four screws.

2. Separate the ②BRACKET MAIN

From the FRAME MAIN

3. Remove the ③screw.

4. Separate the ④COVER OPEN S/W

From the FRAME MAIN

5. Remove the ⑤screw.

6. Separate the ⑥PCB FEED

From the FRAME MAIN

7. Remove the ⑦screw.

8. Separate the ⑧PCB PAPER-END

From the FRAME MAIN

Rev. 1.00

1. Remove the ①screw, And separate

the NEAR END SENSOR from

the BRACKET MAIN.\

2. Remover the ⑥SCREW.

3. Separate the ③KNOB P-END and

④HOUSING SENSOR from the

②HOUSING P-END

4. Separate the ⑤PCB SENSOR

from the ④HOUSING SENSOR

5. Remover the ⑧E-RING

6. Separate the ⑦two GEARS

from the BRACKET MAIN

7. Remove the ⑨two SCREWS

8. Separate the ⑩MOTOR

from the BRACKET MAIN

9. Remove the ⑪SCREW.

10. Separate the ⑫ PCB-DK

from the BRACKET MAIN

11. Remover the⑬ WASHER

12. Separate the ⑭SHAFT FIX

13. Remover the ⑮WASHER

14. Separate the ASSY ROLLER

PLATEN from the BRACKET MAIN

15. Remover the BUSHING

17. Remover the GEAR PLATEN

- 52 -

Page 53

SRP-F310/312

6. Adjustments and Maintenance

6-1 Adjustment

6-1-1 Remaining Roll Paper Adjustment

This sensor is set to the step4 position at the factory. If you find that there is not or too enough paper

remaining on the roll when the near-end sensor is triggered, you can change the setting to the upper or

Lower position as described below.

Note: The factory setting is based on a paper roll core with an outside diameter of 18mm. If you use a paper

roll with a core with an outside diameter of more than 18mm, it is better to change to the upper

position(Rotate the tab at front side) as described below.

1. Open the paper roll cover.

2. Rotate the tab at front or rear Position.

Rev. 1.00

- 53 -

Page 54

SRP-F310/312

6-2 Maintenance

Paper dust in the heating elements may lower the print quality.

In this case, clean the print head as follow;

Caution: ※ Turn off the printer power before cleaning.

Caution: ※ Note that the thermal head (Thermal element and Radiation plate) becomes very hot during

normal operation, creating the danger of burn injury. Be sure to wait for about 10 minutes after

turning printer power off before beginning the cleaning.

1. Open the cover-open.

2. Clean the thermal element (the area that looks like it is marked a thin black line) of the thermal head

with a cotton swab moistened with an alcohol solvent. (ethanol, methanol, or IPA)

3. After confirming that the alcohol solvent has been dried up completely, close the cover open.

Radiation plate

Head tip

Spring pin

Print circuit board

Connector

Note: ※ Never touch the thermal element with your hand.

Doing so can damage the thermal element.

Note: ※ Do not scratch the printer head.

Base

Heat sensitive

layer

Protective

layer

Electrode

Resistor

Board

Rev. 1.00

- 54 -

Page 55

SRP-F310/312

7. Troubleshooting

This chapter describes the methods for troubleshooting in this Receipt Printer.

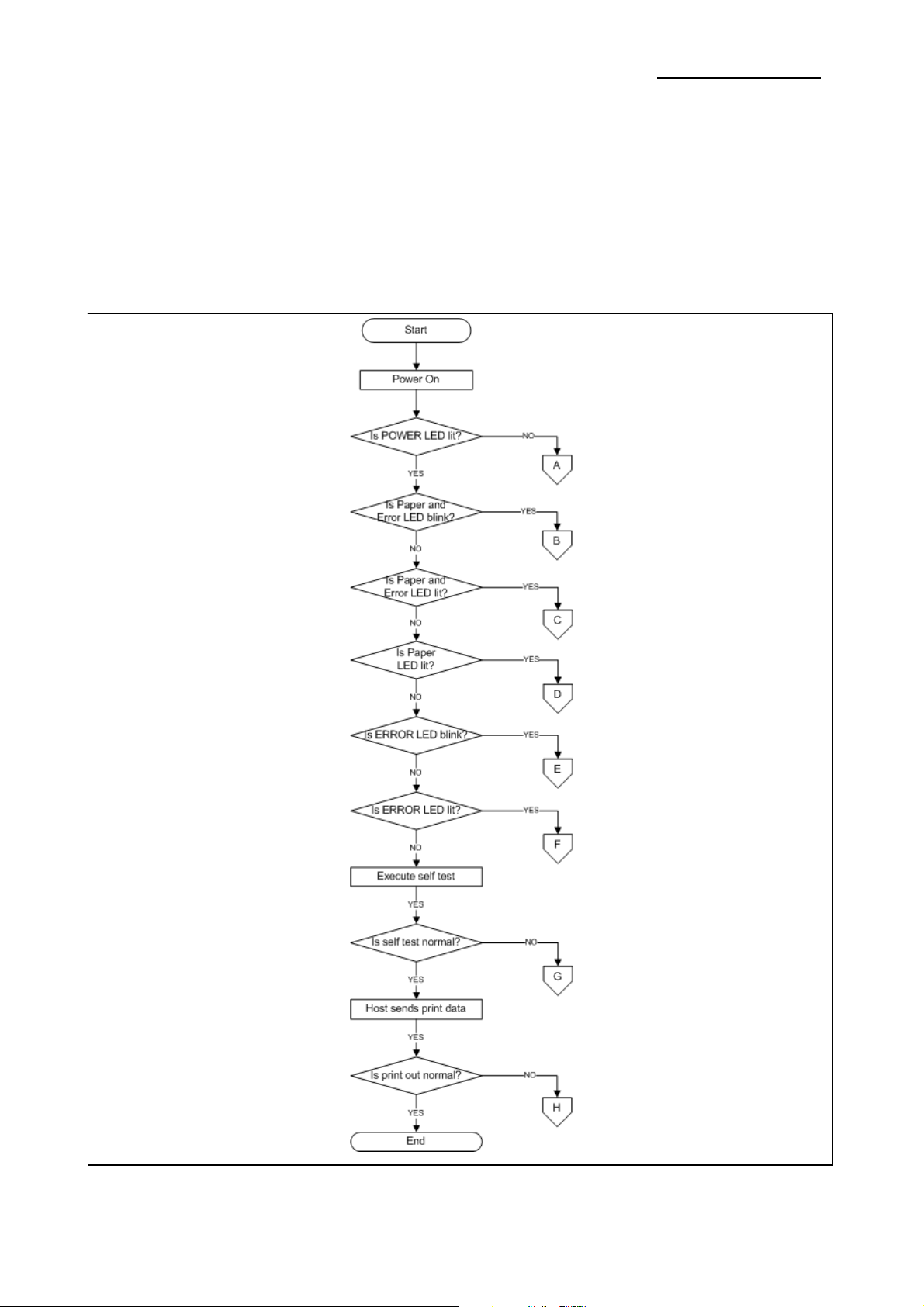

7-1 Troubleshooting flow chart

If the source of a problem is not clear, use the flowchart below to find and replace a defective component.

Normally, servicing should be performed by component replacement. Repairs of the PCBs and other

components should be performed only by technicians.

Rev. 1.00

- 55 -

Page 56

SRP-F310/312

7-1-1 POWER LED does not light

A

Is AC adaptor & power cord

connected properly?

YES

Does AC adaptor have

proper output voltage rating?

(approx. +24V)

NO

NO

Connect AC adaptor & power cord

properly.

OK?

YES

END

NO

Replace AC adaptor.

YES

Has fuse F1 on

main PCB blown?

NO

Is POWER LED

continuity normal?

YES

Replace PCB-main ass’y

END

NO

NO

NO

OK?

YES

END

YES

Replace fuse F1

OK?

YES

END

NO

Replace Operation panel ass’y

OK?

YES

END

Rev. 1.00

- 56 -

Page 57

SRP-F310/312

7-1-2 Paper and Error led blink

Rev. 1.00

- 57 -

Page 58

SRP-F310/312

7-1-3 Paper and Error led lit

Turn power off, then once again

Is paper roll not inserted?

C

OK?

NO

YES

Is paper-end sensor,

continuity normal?

NO

YES

END

NO

Replace or insert paper roll

OK?

YES

END

NO

Replace Sensor-paper-end ass’y

YES

Replace PCB-main ass’y

END

NO

OK?

YES

END

Rev. 1.00

- 58 -

Page 59

SRP-F310/312

7-1-4 Paper led lit

D

Turn power off, then once again

OK?

NO

Is paper roll in

paper near-end condition?

YES

Is paper near-end sensor

continuity normal?

NO

YES

END

NO

Replace or insert paper roll

NO

OK?

YES

END

YES

Replace PCB-main ass’y

END

Replace Sensor-paper-near end ass’y

NO

OK?

YES

END

Rev. 1.00

- 59 -

Page 60

SRP-F310/312

7-1-5 Error led blink

E

Turn power off, then once again

OK?

NO

Is correct I/F PBA inserted?

YES

Replace PCB-main ass’y

NO

YES

END

NO

Replace I/F PBA

OK?

YES

END

END

Rev. 1.00

- 60 -

Page 61

SRP-F310/312

7-1-6 Error led lit

Rev. 1.00

- 61 -

Page 62

SRP-F310/312

7-1-7 Self test is not normal

G

Does not printer

operate at all?

NO

Printing is carried out,

but print quality is deficient or

paper feeding is not normal

Replace printer

mechanism ass’y

YES

Is output voltage of

regulator on PCB-main

within SPEC?(*1)

YES

Replace printer

mechanism ass’y

END

NO

*1

VH : +24V

VCC : +5V

NO

Replace PCB-main ass’y

OK?

YES

END

OK?

NO

Replace PCB-main ass’y

END

YES

END

Rev. 1.00

- 62 -

Page 63

SRP-F310/312

7-1-8 Data from host is not printed normally

H

Send data from host to printer

OK?

NO

Are interface

parameters set to

identical values at host and

printer?

YES

NO

YES

END

NO

Make settings identical

OK?

Does interface cable

match specifications?

YES

Replace interface PCB ass’y

OK?

NO

Is the interface

wire broken?

NO

NO

YES

END

NO

Replace with a proper cable

NO

OK?

YES

END

YES

END

YES

Replace the interface cable

OK?

Rev. 1.00