Page 1

User's Manual

SRP-275III

Impact Printer

Rev. 1.02

http://www.bixolon.com

Page 2

Rev. 1.02

- 2 -

SRP-275III

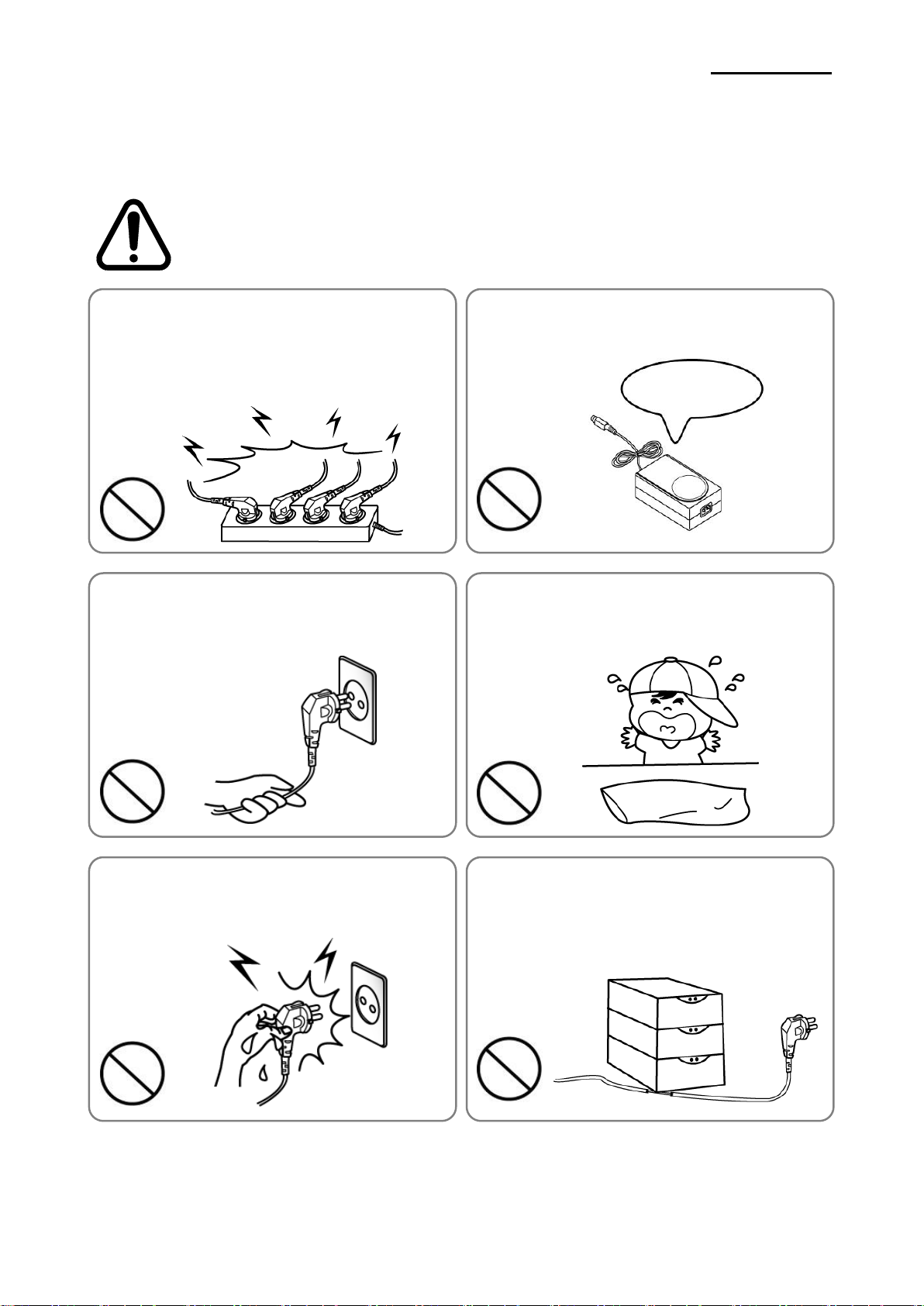

■ Safety Precautions

In using the present appliance, please keep the following safety regulations in order to

prevent any hazard or material damage.

WARNING

Violating following instructions can cause serious injury or death.

Do not bend the cable by force or leave it under any

heavy object.

• A damaged cable can cause a fire.

Do not plug in or unplug with your hands wet.

• You can be electrocuted.

Keep the plastic bag out of children’s reach.

• If not, a child may put the bag on his head.

Do not pull the cable to unplug.

• This can damage the cable, which is the origin of a fire or a

breakdown of the printer.

You must use only the supplied adapter.

• It is dangerous to use other adapters.

Do not plug several products in one multi-outlet.

• This can provoke over-heating and a fire.

• If the plug is wet or dirty, dry or wipe it before usage.

• If the plug does not fit perfectly with the outlet, do not plug in.

• Be sure to use only standardized multi-outlets.

PROHIBIT

PROHIBIT

PROHIBIT

PROHIBIT

PROHIBIT

ONLY SUPPLIED ADAPTER

PROHIBIT

Page 3

Rev. 1.02

- 3 -

SRP-275III

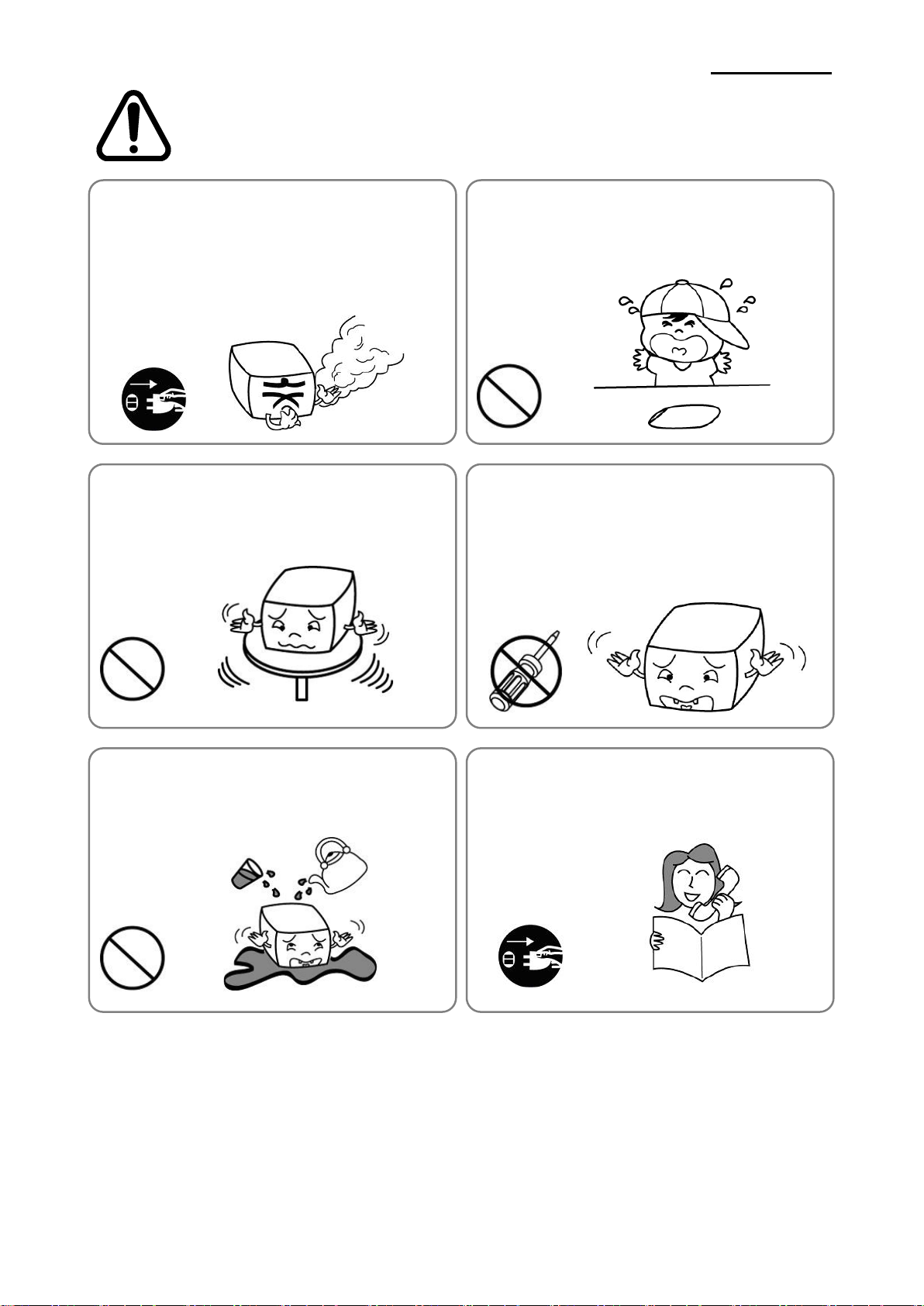

CAUTION

Violating following instructions can cause slight wound or damage the appliance

.

Do not use the printer when it is out of order. This

can cause a fire or an electrocution.

• Switch off and unplug the printer before calling your dealer.

Do not let water or other foreign objects in the

printer.

• If this happened, switch off and unplug the printer before

calling your dealer.

Use only approved accessories and do not try to

disassemble, repair or remodel it for yourself.

• Call your dealer when you need these services.

• Do not touch the blade of auto cutter.

Install the printer on the stable surface.

• If the printer falls down, it can be broken and you can hurt

yourself.

Keep the desiccant out of children’s reach.

• If not, they may eat it.

If you observe a strange smoke, odor or noise from

the printer, unplug it before taking following

measures.

• Switch off the printer and unplug the set from the mains.

• After the disappearance of the smoke, call your dealer to

repair it.

TO UNPLUG

PROHIBIT

DISASSEMBLING

PROHIBITED

PROHIBIT

PROHIBIT

TO UNPLUG

PRINTER

PRINTER

PRINTER

PRINTER

DEALER

PRINTER

Page 4

Rev. 1.02

- 4 -

SRP-275III

All rights reserved. No part of this publication may reproduced, stored in a retrieval, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of BIXOLON.

No patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, BIXOLON assumed

no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained herein.

Neither BIXOLON nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a

result of : accident, misuse, or abuse of this product or unauthorized modifications, repairs, or

alterations to this product, or failure to strictly comply with BIXOLON s operating and

maintenance instructions.

BIXOLON shall not be liable against any damages or problems arising from the use of any

options or ant consumable products other than those designated as Original BIXOLON

products.

■ Notice

We at BIXOLON maintain ongoing efforts to enhance and upgrade the functions and quality

of all our products. In following, product specifications and/or user manual content may be

changed without prior notice.

Page 5

Rev. 1.02

- 5 -

SRP-275III

■ WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the EMC

standards of this device. You are cautioned that changes or modifications not expressly

approved by the party responsible for compliance could void your authority to operate the

equipment.

■ Waste Electrical and Electric Equipment (WEEE)

This marking shown on the product or its literature, indicates that is should not be

disposed with other household wastes at the end of its working life, To prevent

possible harm to the environment or human health from uncontrolled waste

disposal, please separate this from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources. Household

users should contact either the retailer where they purchased this product, or their local

government office, for details of where and how they can take this item for environmentally

safe recycling. Business users should contact their supplier and check the terms and

conditions of the purchase contract. This product should not be mixed with other commercial

wastes for disposal.

■ Rating Label Symbol Information

DC (Direct current)

■ Label Material

* Control Label: PC

* Other Labels: PET

Page 6

Rev. 1.02

- 6 -

SRP-275III

■ Introduction

The SRP-275III is a high-quality impact printer.

This one-station printer has the following features.

• Compact design and light-weight.

• High-speed printing using logic-seeking (5.1LPS).

• Easy to use : Easy paper loading.

• High reliability and long life due to the use of stepping motors for head carriage return and

paper feeding.

• Two color printing (red/black) available.

• The head can be driven due to the internal drawer interface.

• Character font (7ⅹ9, 9ⅹ9) is selectable.

• The auto cutter uses a circular method with a high-quality blade and a long life

(Approximately 1,500,000 cuts).

• Default application of paper out sensor (not included with wall mount option).

• Black mark sensor function (front or rear option).

• A internal AC adaptor.

NOTES

Please be sure to read the instructions in this manual carefully before using your new printer.

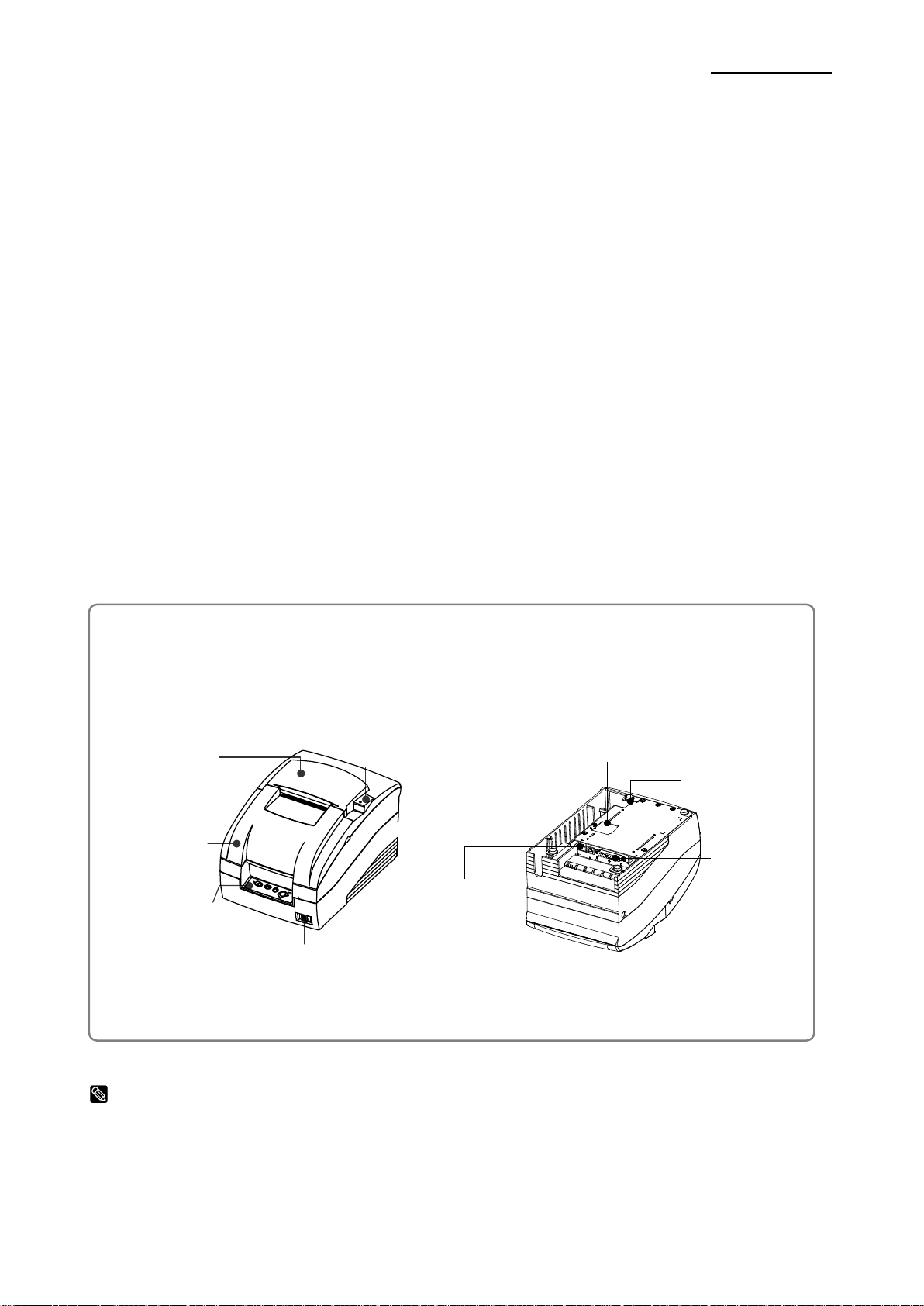

• Front view • Rear view

Rear cover

Front cover

Control panel

Power switch

Open button

Drawer kick-out

connect

Interface

connector

Power connect

DIP Switch cover

Page 7

Rev. 1.02

- 7 -

SRP-275III

■ Table of Contents

1. Setting Up the Printer ····················································································· 8

1-1 Unpacking ···························································································· 8

1-2 Choosing a place for the printer ································································ 8

1-3 Using the operation panel ········································································ 9

2. Connecting the cables·················································································· 10

2-1 Connecting the AC Adaptor···································································· 10

2-2 Connecting the Interface cable and Drawer kick-out cable ··························· 10

2-2-1 Serial Interface (RS-232C) + Ethernet + USB : OES Model ····················· 11

2-2-2 Parallel Interface (IEEE1284) + USB : OP Model ·································· 12

2-2-3 Serial Interface (RS-232C) + USB : OS Model ······································ 13

2-2-4 Drawer kick-out ·············································································· 14

3. Setting the Switches ···················································································· 15

3-1 Setting the DIP Switch ·········································································· 15

3-1-1 DIP Switch setting for Citizen(iDP 3550) mode ····································· 16

3-1-2 DIP Switch setting for Star(SP500) mode ············································· 17

3-1-3 Changing the DIP Switch setting ························································ 18

3-2 Setting the Memory Switches ································································· 19

3-2-1 Memory Switch setting for Star mode ·················································· 21

4. Ribbon Cassette Installation ········································································· 27

5. Roll Paper Installation ·················································································· 28

6. Installing the wall mount (Option) ·································································· 29

7. Self Test ····································································································· 30

8. Hexadecimal Dumping ················································································· 31

9. Specification ······························································································· 32

9-1 Printing specification ············································································· 32

9-2 Paper specifications ············································································· 32

9-3 Ribbon cassette specification ································································· 32

9-4 Electrical characteristics ········································································ 33

9-5 Reliability ··························································································· 33

9-6 Environment conditions ········································································· 33

9-7 Dimensions & weight ············································································ 34

9-8 Optional features ················································································· 35

10. Appendix - Troubleshooting ········································································ 36

10-1 ERROR LED blinking pattern ································································ 36

10-2 The printer does not start printing ·························································· 37

10-3 The printer stops printing ····································································· 38

10-4 You want to check the operation of the printer by itself ······························ 38

10-5 Printing is poor··················································································· 38

Page 8

Rev. 1.02

- 8 -

SRP-275III

1. Setting Up the Printer

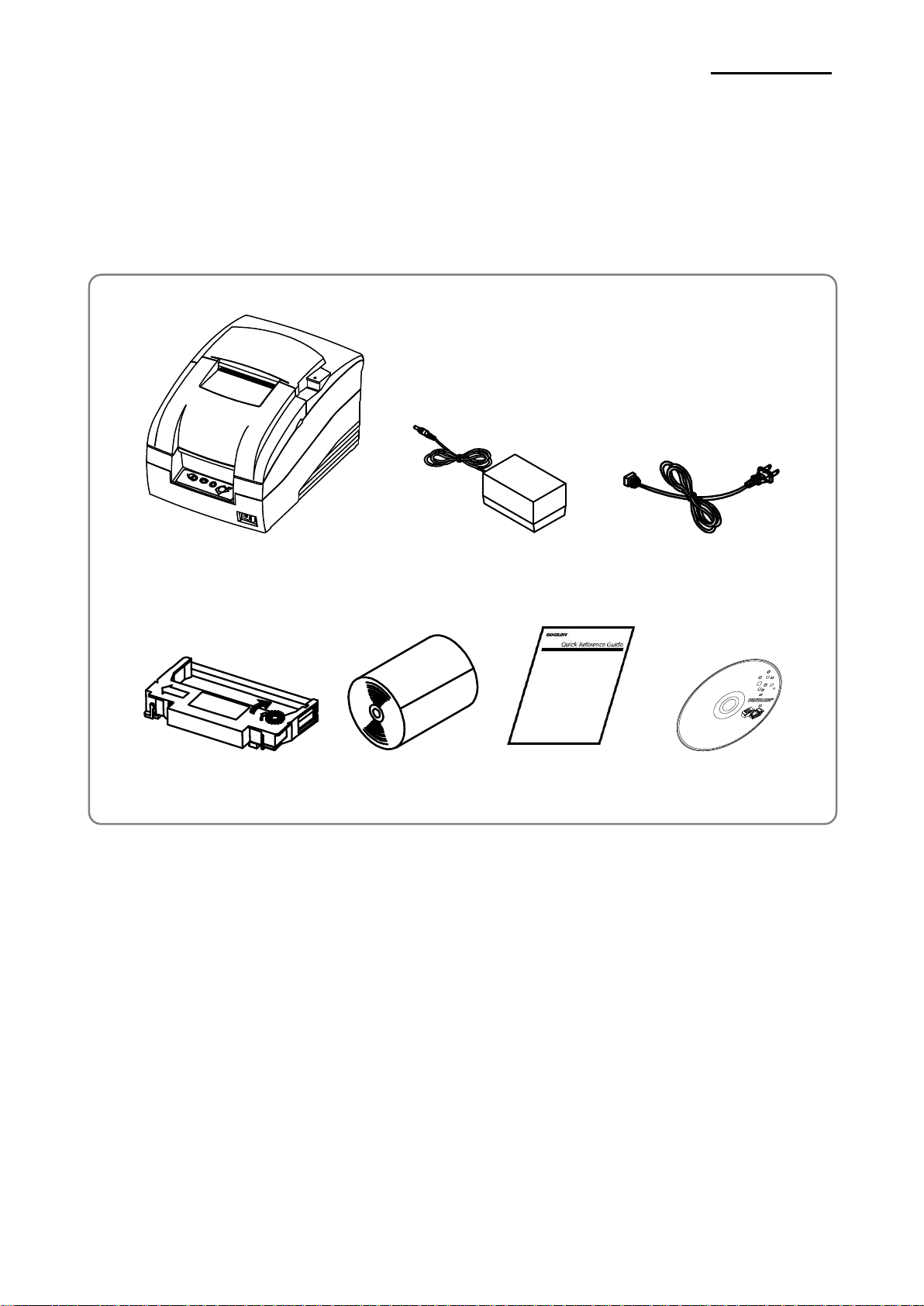

1-1 Unpacking

Your printer box should include the items shown in the illustration below.

If any items are damaged or missing, please contact your dealer.

1-2 Choosing a place for the printer

• Avoid locations that are subject to direct sunlight or excessive heat.

• Avoid using or storing the printer in a place subject to excessive temperature or moisture.

• Do not use or store the printer in a dirty location.

• When setting up the printer, choose a stable, horizontal location.

• Intense vibration or shock may damage the printer.

• Ensure the printer has enough space to be used easily.

SRP-275IIIA, C AC adaptor Power cord

Ribbon cassette Paper roll Manual CD

Page 9

Rev. 1.02

- 9 -

SRP-275III

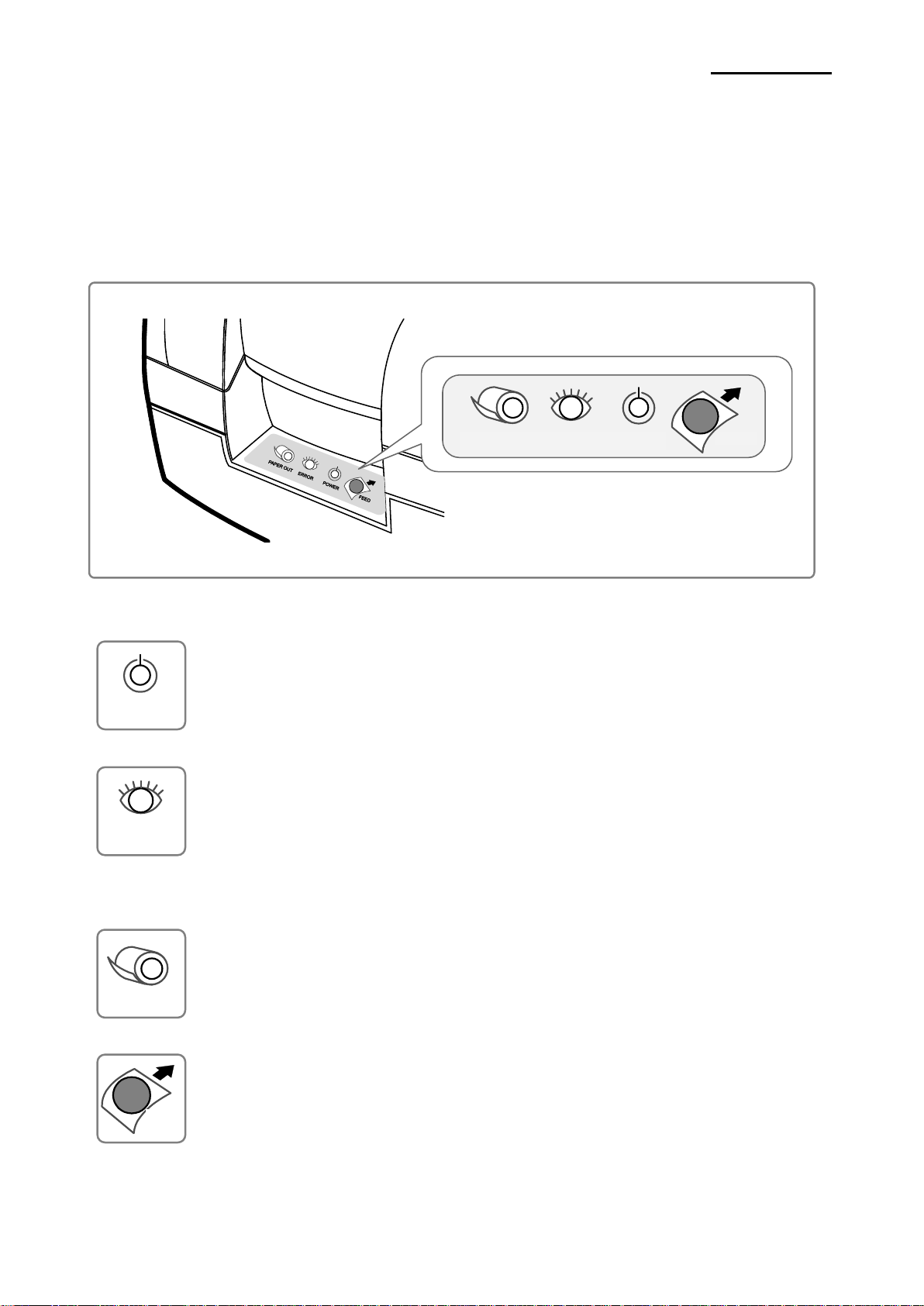

1-3 Using the operation panel

Most of the functions of this printer are governed by software, but you can monitor the printer

s status by

looking at the lights on the control panel and for some procedures you will use the buttons.

• Control panel

- POWER LED (Green Color)

This indicator light is on when the power is turned on.

- ERROR LED (Red Color)

When this indicator light is on (but not blinking), it means that the printer is

out of paper or almost out of paper or the printer covers are open. When

this light blinking, there is an error. (See "ERROR LED blinking pattern" in

Chapter 11.) If you see this light blinking, turn off the printer for a few

seconds and then turn it back on. If the light is still blinking, call your

supervisor or a service person.

- PAPER OUT LED (Red Color, not included with wall mount option)

When this indicator light is on, it means that the paper near end. Replace

the new paper roll. When ERROR and PAPER OUT indicator lights are on it

means paper end. Install the paper roll.(See "Installing paper roll" in

Chapter 5.)

- FEED button

Use this button to feed paper or to start self test and for hexadecimal dump

mode.(See the instructions "Self test" (8) in this chapter for self test.)

(See the instructions "Hexadecimal dump" in Chapter 9 for hexadecimal

dump mode.)

PAPER OUT ERROR POWER

FEED

POWER

ERROR

PAPER OUT

FEED

Page 10

Rev. 1.02

- 10 -

SRP-275III

2. Connecting the cables

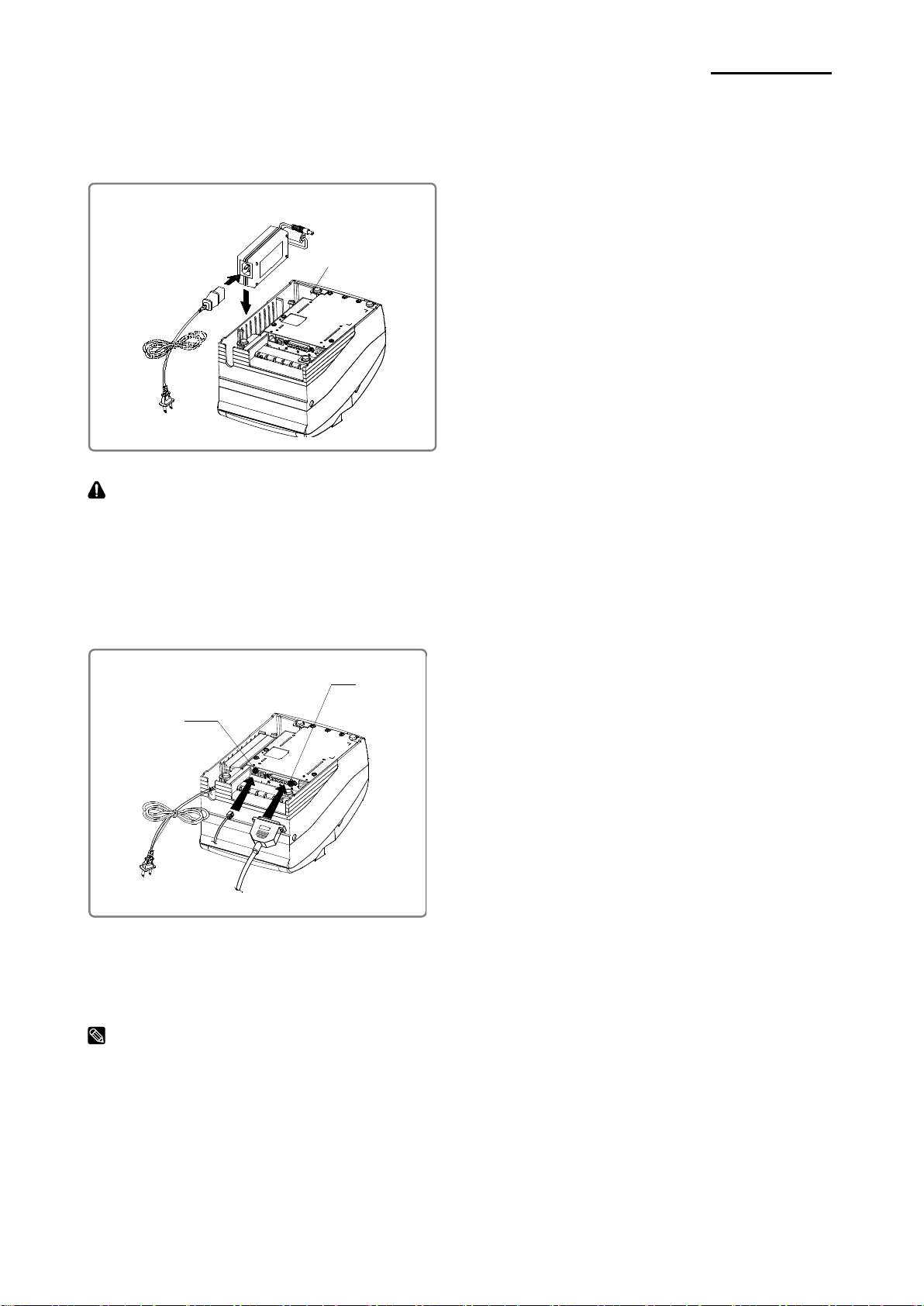

2-1 Connecting the AC Adaptor

CAUTION

Before connecting the printer to the power supply, make sure that the voltage and power

specifications match the printer’s requirements. Using an incorrect power supply can cause

serious damage to the printer.

2-2 Connecting the Interface cable and Drawer kick-out cable

NOTES

Connect the printer to the host ECR (host computer) though an interface cable matching the

specification of the printer and the host ECR (host computer). Be sure to use a drawer that

matches the printer’s specification.

Depending on the interface your system uses, either connect the serial, parallel, USB or

Ethernet communication cable to the appropriate connector on the back of the printer.

Cables are provided by your dealer or system installer.

• Connect the AC adapter according to

the following procedure.

1) Make sure the printer is turned off.

2) Before inserting the AC adaptor, connect

the power cord.

3) Insert the AC adaptor as shown.

4) Plug the AC adapter cable into the

printer’s power connector.

5) Plug the power cord into the outlet, and

turn on the power.

AC adaptor

Power connector

Power cord

Drawer kickout connector

Interface

connector

Serial/ Parallel/ USB/ Ethernet

Interface cable

Drawer kick-out

cable

• Connect the cables according to the

following procedure.

1) Turn off printer and the host ECR

(host computer).

2) Plug the interface cable into the interface

connector on the printer then fasten the

screw on both sides of the connector.

3) Plug the drawer kick-out cable into the

drawer kick-out connector on the printer.

(When removing the drawer kick-out cable,

press on the connector’s clip while pulling

out.)

Page 11

Rev. 1.02

- 11 -

SRP-275III

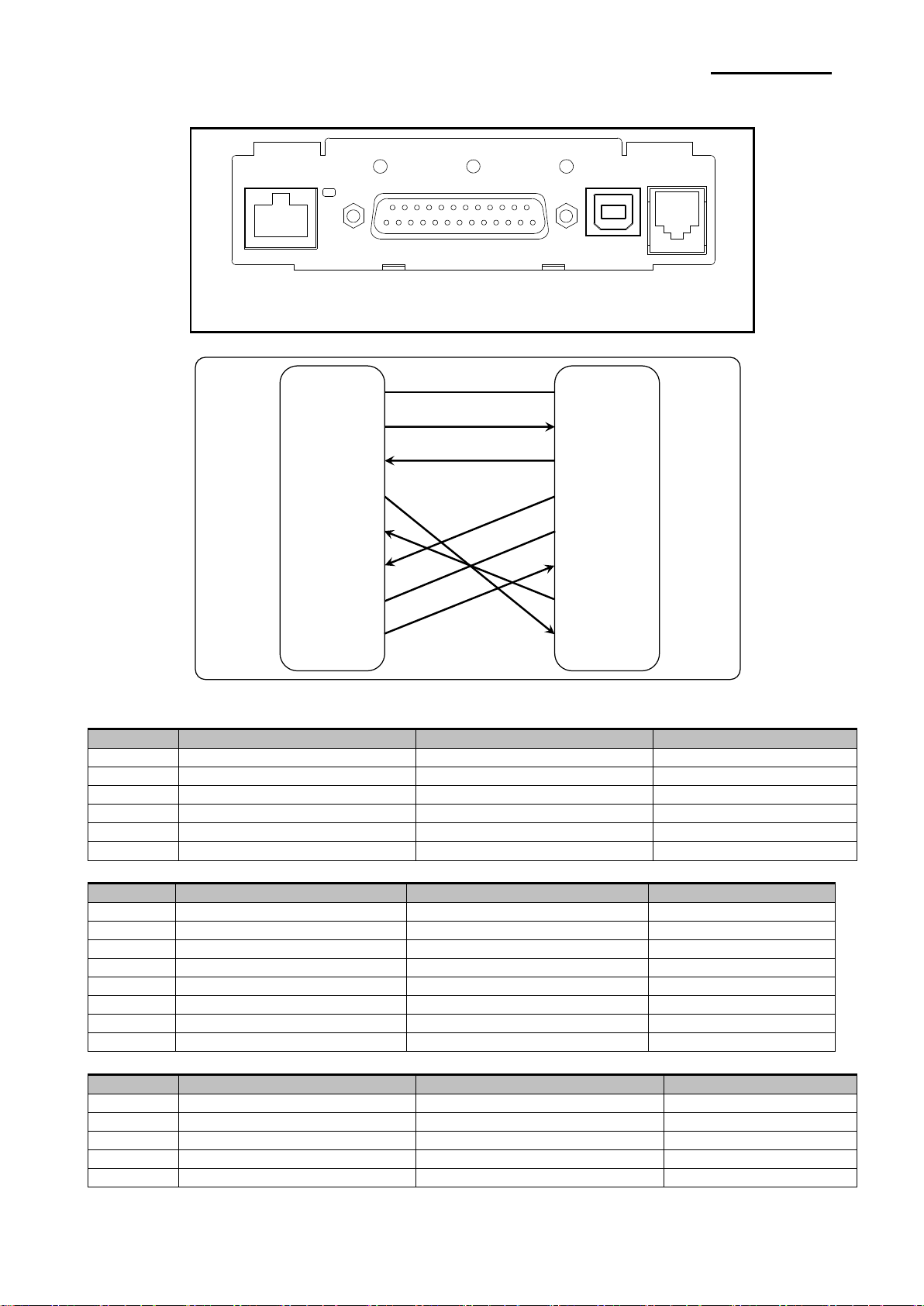

2-2-1 Serial Interface (RS-232C) + Ethernet + USB : OES Model

Ethernet

Interface connector

USB

Drawer kickout

Connector

(F.G) 1

(TXD) 2

(RXD) 3

(RTS) 4

(CTS) 5

(DSR) 6

(S.G) 7

(DTR) 20

1 (F.G)

2 (RXD)

3 (TXD)

4 (DTR)

5 (S.G)

6 (DSR)

7 (RTS)

8 (CTS)

PRINTER

SIDE

(25Pin)

HOST

SIDE

(9Pin)

• Serial

Pin No.

Signal name

Direction

Function 1 FG

-

Frame Ground

2

TxD

Output

Transmit Data

3

RxD

Input

Receive Data

6

DSR

Input

Data Set Ready

7

SG

-

Signal Ground

20

DTR

Output

Data Terminal Ready

• Ethernet

Pin No.

Signal name

Assignment (Color)

Function

1

TxD+

White with orange stripe

Transmit +

2

TxD-

Solid orange

Transmit -

3

RxD+

White with green stripe

Receive + 4 NC

Solid blue

- 5 NC

White with blue stripe

- 6 RxD-

Solid green

Receive - 7 NC

White with brown stripe

- 8 NC

Solid brown

-

• USB

Pin No.

Signal name

Assignment (Color)

Function

Shell

Shield

Drain wire

Frame ground

1

VBUS

Red

NC 2 D-

White

Differential data line

3

D+

Green

Differential data line

4

GND

Black

Signal ground

Page 12

Rev. 1.02

- 12 -

SRP-275III

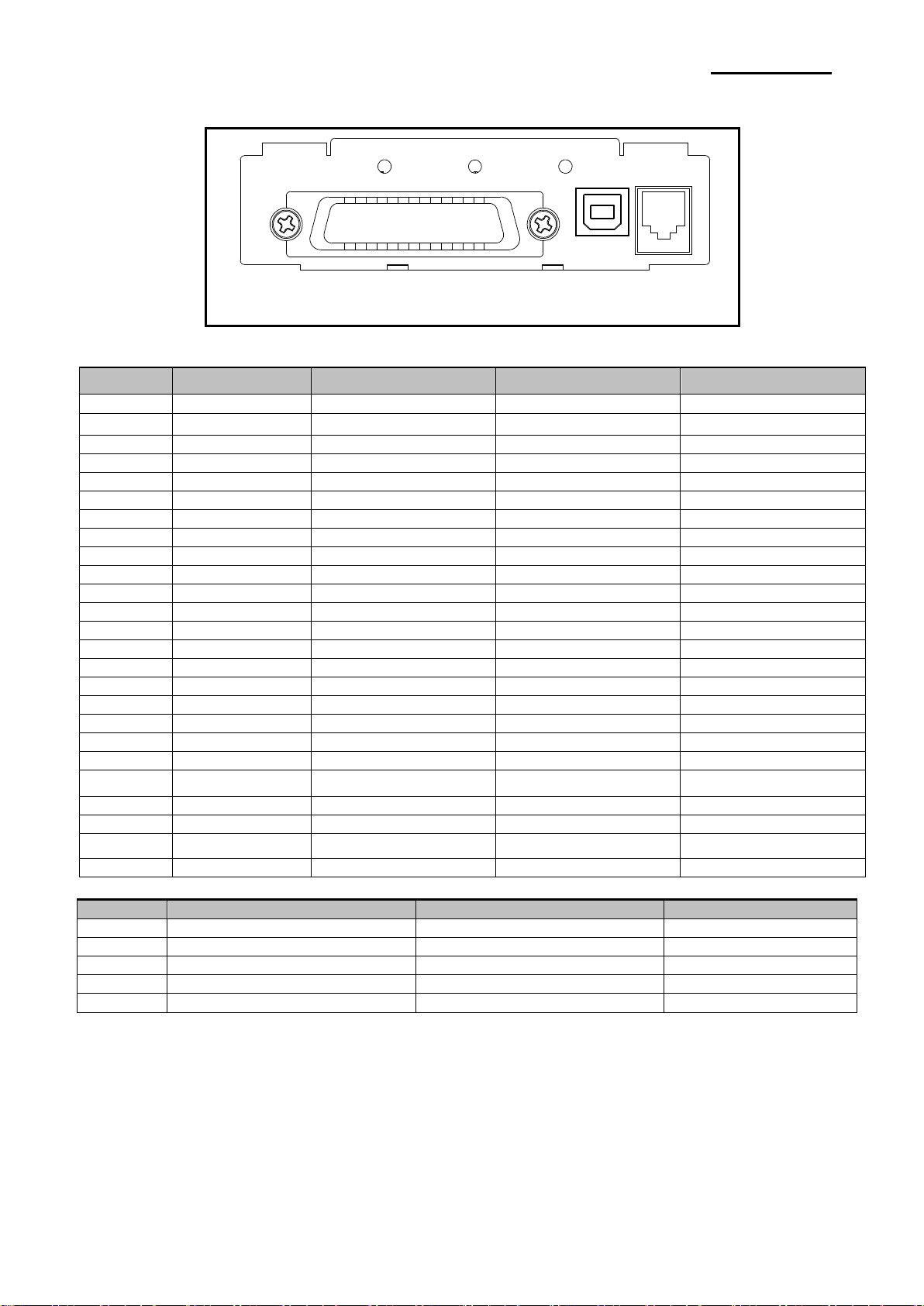

2-2-2 Parallel Interface (IEEE1284) + USB : OP Model

Interface connector

USB

Drawer kickout

Connector

• Parallel

Pin no.

Source

Compatibility mode

Nibble mode

Byte mode

1

Host

nStrobe

HostClk

HostClk

2

Host / Printer

Data 0 (LSB)

-

Data 0 (LSB)

3

Host / Printer

Data 1

-

Data 1

4

Host / Printer

Data 2

-

Data 2

5

Host / Printer

Data 3

-

Data 3

6

Host / Printer

Data 4

-

Data 4

7

Host / Printer

Data 5

-

Data 5

8

Host / Printer

Data 6

-

Data 6

9

Host / Printer

Data 7 (MSB)

-

Data 7 (MSB)

10

Printer

nAck

PtrClk

PtrClk

11

Printer

Busy

PtrBusy / Data3,7

PtrBusy

12

Printer

Perror

AckDataReq / Data2,6

AckDataReq

13

Printer

Select

Xflag / Data1,5

Xflag

14

Host

nAutoFd

HostBusy

HostBusy

15

-

NC

ND

ND

16

-

GND

GND

GND

17

-

GND

FG

FG

18

Printer

Logic-H

Logic-H

Logic-H

19~30

-

GND

GND

GND

31

Host

nInit

nInit

nInit

32

Printer

nFault

nDataAbail /

nDataAvail

33

-

NC

ND

ND

34

Printer

NC

ND

ND

35

Printer

NC

ND

ND

36

Host

nSelectln

1284-Active

1284-Active

• USB

Pin No.

Signal name

Assignment (Color)

Function

Shell

Shield

Drain wire

Frame ground

1

VBUS

Red

NC 2 D-

White

Differential data line

3

D+

Green

Differential data line

4

GND

Black

Signal ground

Page 13

Rev. 1.02

- 13 -

SRP-275III

2-2-3 Serial Interface (RS-232C) + USB : OS Model

Interface connector

USB

Drawer kickout

Connector

(F.G) 1

(TXD) 2

(RXD) 3

(RTS) 4

(CTS) 5

(DSR) 6

(S.G) 7

(DTR) 20

1 (F.G)

2 (RXD)

3 (TXD)

4 (DTR)

5 (S.G)

6 (DSR)

7 (RTS)

8 (CTS)

PRINTER

SIDE

(25Pin)

HOST

SIDE

(9Pin)

• Serial

Pin No.

Signal name

Direction

Function 1 FG

-

Frame Ground

2

TxD

Output

Transmit Data

3

RxD

Input

Receive Data

6

DSR

Input

Data Set Ready

7

SG

-

Signal Ground

20

DTR

Output

Data Terminal Ready

• USB

Pin No.

Signal name

Assignment (Color)

Function

Shell

Shield

Drain wire

Frame ground

1

VBUS

Red

NC 2 D-

White

Differential data line

3

D+

Green

Differential data line

4

GND

Black

Signal ground

Page 14

Rev. 1.02

- 14 -

SRP-275III

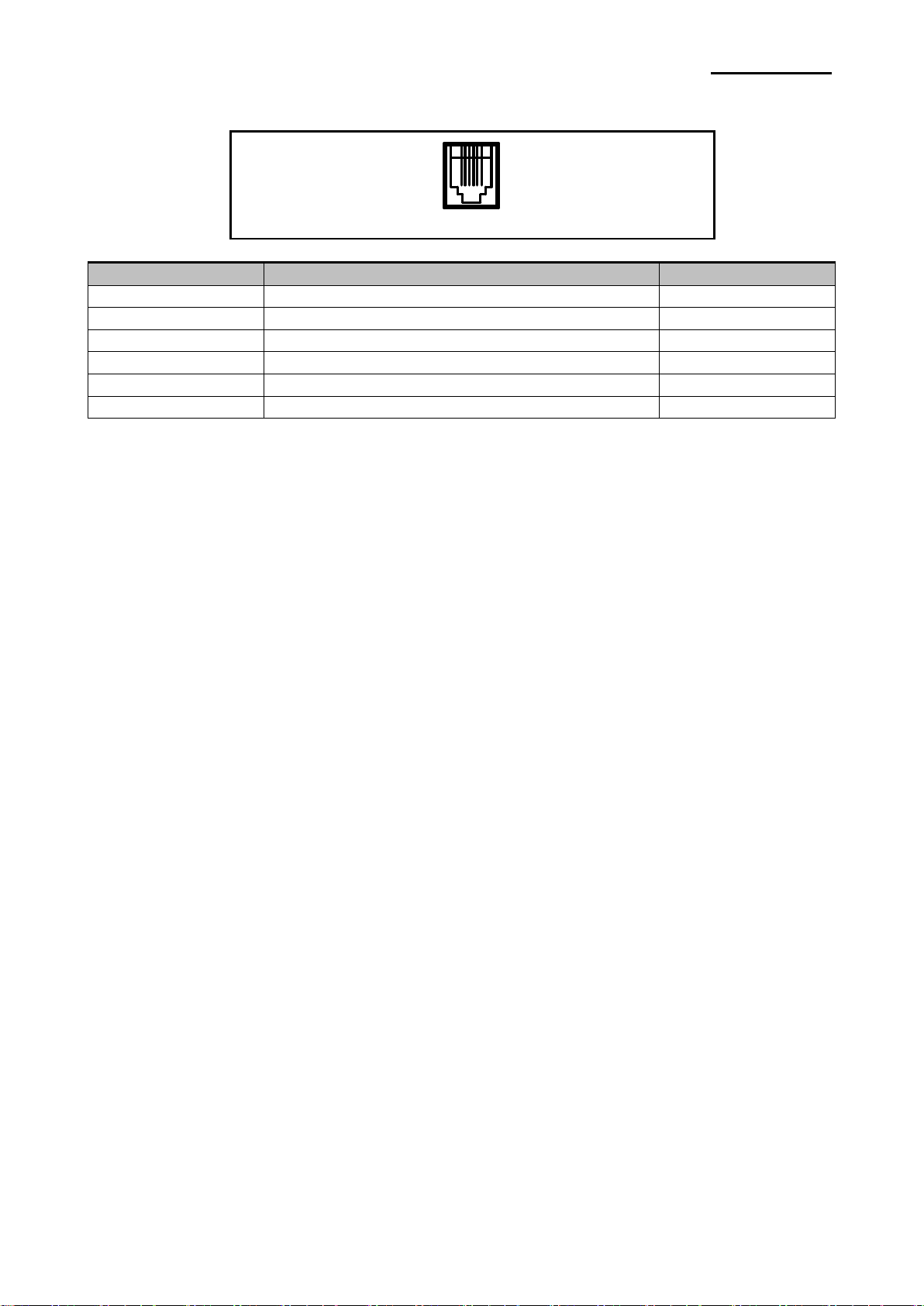

2-2-4 Drawer kick-out

1

6 Pin No.

Description

Direction

1

Signal GND - 2

Drawer kick-out driver signal #1

Output

3

Drawer Open / Close signal

Input

4

+24V - 5

Drawer kick-out driver signal #2

Output

6

Signal GND

-

Page 15

Rev. 1.02

- 15 -

SRP-275III

3. Setting the Switches

3-1 Setting the DIP Switch

Although the factory settings are best for almost all users, if you have special requirements,

you can change the DIP Switch. Your printer has two sets of DIP Switches. The functions of

the switches are shown in the following table.

• DIP Switch 1

Switch

Function

ON

OFF

Default

1-1

Emulation Selection (*1)

Refer to the following table

OFF

1-2

1-3

Auto cutter

Enable

Disable

ON

1-4

Compatible with SRP-275

Enable

Disable

OFF

1-5

Serial interface selection

Memory Switch

DIP Switch

OFF

1-6

Print NV bit image #1 after

cutting

Enable

Disable

OFF

1-7

Near end switch

Enable

Disable

ON

1-8

Printing column

42

40

OFF

• DIP Switch 2 (RS232C serial interface model)

Switch

Function

ON

OFF

Default

2-1

Data receive error

Ignore

Print “?”

OFF

2-2

Black Mark Sensor

Enable

Disable

OFF

2-3

Hand shaking

XON/XOFF

DTR/DSR

OFF

2-4

Word length

7 bits

8 bits

OFF

2-5

Parity check

Enable

Disable

OFF

2-6

Parity selection

EVEN

ODD

OFF

2-7

Baud rate selection (*2)

Refer to the following table

OFF

2-8

OFF

• DIP Switch 2 (Parallel interface model)

Switch

Function

ON

OFF

Default

2-1

Auto Line Feed

Enable

Disable

OFF

2-2

Black Mark Sensor

Enable

Disable

OFF

2-3~8

Undefined

OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation

1-1

1-2

BXL/POS

OFF

OFF

BXL/POS-KP

ON

ON

STAR

OFF

ON

CITIZEN

ON

OFF

- BXL/POS-KP(Kitchen Printer mode) : A alarm is generated by printer after auto cutting and

in paper end error.

(*2) Baud rate selection (Transmission speed)

Transmission

2-7

2-8

2400 baud

ON

ON

4800 baud

OFF

ON

9600 baud

OFF

OFF

19200 baud

ON

OFF

Page 16

Rev. 1.02

- 16 -

SRP-275III

3-1-1 DIP Switch setting for Citizen(iDP 3550) mode

• DIP Switch 1

Switch

Function

ON

OFF

Default

1-1

Emulation Selection (*1)

Refer to the following table

OFF

1-2

1-3

Auto cutter

Enable

Disable

OFF

1-4

CBM command

CBM2 mode

(iDP3530 system)

CBM1 mode

(iDP3540 system)

OFF

1-5

International characters (*2)

Refer to the following table

ON

1-6

1-7

1-8

CR mode

CR

CR+LF

OFF

• DIP Switch 2 (RS232C serial interface model)

Switch

Function

ON

OFF

Default

2-1

Word length

8 bits

7 bits

ON

2-2

Parity check

Disable

Enable

ON

2-3

Parity selection

ODD

EVEN

ON

2-4

Hand shaking

DTR/DSR

XON/XOFF

ON

2-5

Baud rate selection (*3)

Refer to the following table

OFF

2-6

2-7

Near end switch

Enable

Disable

OFF

2-8

Mechanism type

Graphic

Character

OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation

1-1

1-2

BXL/POS

OFF

OFF

BXL/POS-KP

ON

ON

STAR

OFF

ON

CITIZEN

ON

OFF

- BXL/POS-KP(Kitchen Printer mode) : A alarm is generated by printer after auto cutting and

in paper end error.

(*2) International Character Selection

No.

Country

DSW 1-5

DSW 1-6

DSW 1-7

Code page

U.S.A.

ON

ON

ON

Page 0 (PC437 : U.S.A.)

France

OFF

ON

ON

Page 2 (PC850 : Multilingual)

Germany

ON

OFF

ON

U.K.

OFF

OFF

ON

Denmark

ON

ON

OFF

Page 5 (PC865 : Nordic)

Sweden

OFF

ON

OFF

Italy

ON

OFF

OFF

Page 2 (PC850 : Multilingual)

Windows Code

OFF

OFF

OFF

Windows Code

(*3) Baud rate selection (Transmission speed)

Transmission

2-5

2-6

2400 baud

ON

ON

4800 baud

OFF

ON

9600 baud

OFF

OFF

19200 baud

ON

OFF

Page 17

Rev. 1.02

- 17 -

SRP-275III

3-1-2 DIP Switch setting for Star(SP500) mode

• DIP Switch 1

Switch

Function

ON

OFF

Default

1-1

Emulation Selection (*1)

Refer to the following table

OFF

1-2

1-3

Auto cutter

Enable

Disable

OFF

1-4

Black/Red Printing

Enable

Disable

OFF

1-5

Reserved

OFF

1-6

1-7

1-8

• DIP Switch 2 (RS232C serial interface model)

Switch

Function

ON

OFF

Default

2-1

Reserved

OFF

2-2

2-3

Hand shaking

XON/XOFF

DTR/DSR

OFF

2-4

Word length

7 bits

8 bits

OFF

2-5

Parity check

Enable

Disable

OFF

2-6

Parity selection

EVEN

ODD

OFF

2-7

Baud rate selection (*2)

Refer to the following table

OFF

2-8

OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation

1-1

1-2

BXL/POS

OFF

OFF

BXL/POS-KP

ON

ON

STAR

OFF

ON

CITIZEN

ON

OFF

- BXL/POS-KP(Kitchen Printer mode) : A alarm is generated by printer after auto cutting and

in paper end error.

(*2) Baud rate selection (Transmission speed)

Transmission

2-7

2-8

2400 baud

ON

ON

4800 baud

OFF

ON

9600 baud

OFF

OFF

19200 baud

ON

OFF

NOTICE

Change in DIP Switch settings are recognized only when the printer power is turned on or

when the printer is reset by using the interface. If the DIP Switch setting is changed after the

printer power is turned on, the change does not take effect until the printer is turned on

again or is reset.

Page 18

Rev. 1.02

- 18 -

SRP-275III

3-1-3 Changing the DIP Switch setting If you need to change settings, follow the steps below to make your changes.

CAUTION

Turn off the printer before removing the DIP Switch cover to prevent an electric short, which

can damage the printer.

1) Make sure the printer is turned off.

2) Remove the screw from the DIP Switch cover.

Then take off the DIP Switch cover, which is shown in the illustration below.

3) Set the switches using a pointed tool, such as tweezers or a small.

4) Replace the DIP Switch cover. Then secure it with the screw.

NOTES

The new settings take effect when you turn on the printer.

Page 19

Rev. 1.02

- 19 -

SRP-275III

3-2 Setting the Memory Switches

This printer has “Memory Switch” set which is software switches. Memory Switch set has

“MSW 2”, “MSW 8”, “Customize value”, “Serial communication condition”. “Memory Switch

setting utility” can change the Memory Switch set to ON or OFF as shown in the table below

(default: all OFF):

NOTES

The Memory Switch is available to be changed by two methods:

- Memory Switch setting utility

- Control from command

Settings of the Memory Switch are stored in the NV memory; therefore, even if the printer is

turned off, the settings are maintained.

• Memory Switch 2

Switch

Function

On

Off

1

Internal Buzzer Enable / Disable

Disable

Enable

2

External Buzzer Enable / Disable

Enable

Disable

3

Reserved

-

Fixed to Off

4~8

Code page selection (*1)

Refer to the following table

NOTES

Desired code page can be selected using Memory Switch 2-4~8 by setting as following.

(*1) Code page selection

MSW

2-8

MSW

2-7

MSW

2-6

MSW

2-5

MSW

2-4

Character Table

0 0 0 0 0

Page 0 (PC437 : U.S.A.)

0 0 0 0 1

Page 1 (Katakana)

0 0 0 1 0

Page 2 (PC850 : Multilingual)

0 0 0 1 1

Page 3 (PC860 : Portuguese)

0 0 1 0 0

Page 4 (PC863 : Canadian-French)

0 0 1 0 1

Page 5 (PC865 : Nordic)

0 0 1 1 0

Page 16 (WPC1252 : Latin1)

0 0 1 1 1

Page 17 (PC866 : Russian)

0 1 0 0 0

Page 18 (PC852 : Latin2)

0 1 0 0 1

Page 19 (PC858 : Euro)

0 1 0 1 0

Page 21 (PC862 : Israel)

0 1 0 1 1

Page 22 (PC864 : Arabic)

0 1 1 0 0

Page 23 (Thai character code 42)

0 1 1 0 1

Page 24 (WPC1253 : Greek)

0 1 1 1 0

Page 25 (WPC1254 : Turkish)

0 1 1 1 1

Page 26 (WPC1257 : Baltic)

1 0 0 0 0

Page 27 (Farsi) (*2)

1 0 0 0 1

Page 28 (WPC1251 : Russian) (*2)

1 0 0 1 0

Page 29 (PC737 : Greek) (*2)

1 0 0 1 1

Page 30 (PC775 : Baltic) (*2)

1 0 1 0 0

Page 31 (Thai character code 14)

1 0 1 0 1

Page 32 (OldCode : Israel)

1 0 1 1 0

Page 33 (WPC1255 : Israel)

1 0 1 1 1

Page 34 (Thai character code 11)

1 1 0 0 0

Page 35 (Thai character code 18)

1 1 0 1 0

Page 37 (PC857 : Turkish)

1 1 0 1 1

Page 38 (PC928 : Greek)

1 1 1 1 0

Page 41 (WPC1258 : Vietnam)

(*2) Only Font B available.

Page 20

Rev. 1.02

- 20 -

SRP-275III

• Memory Switch 8

Switch

Function

On

Off

1

Upside down

On

Off

2

Font Selection

Font B

Font A

3

Selection Paper End Buzzer

Off

On

4~5

Reserved

Fixed to Off

• Serial communication

Function

Selectable value

Modulation

rate

2400 bps, 4800 bps, 9600 bps, 19200 bps

Parity

None, Odd, Even, -

Handshake

DSR/DTR, XON/XOFF

Data length

7 bit, 8 bit

NOTES

There are two methods, DIP Switch and Memory Switch, to adjust the serial communication

conditions.

DIP Switch 1-5 selects which is effective, DIP Switch or Memory Switch.

To enable the “Serial communication“ setting, you have to adjust the “Serial interface

selection“ function of DIP Switch 1-5 to “Memory Switch”.

Page 21

Rev. 1.02

- 21 -

SRP-275III

3-2-1 Memory Switch setting for Star mode

• Settings

Memory Switches are from MSW 0 to MSW 8. They are stored in non-volatile memory (flash

memory). To change the settings, send the following commands from the host.

[Name] Set Memory Switch

[Code] ASCII ESC GS # m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}

8

LF NUL

Hexadecimal 1B 1D 23 m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8 0A 00

Decimal 27 29 35 m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8 10 0

[Defined Region] m = "W", "T", ",", "+", "-", "@"

"0" ≤ n1,n2,n3,n4 ≤ "9",

"A" ≤ n1,n2,n3,n4 ≤ "F"

[Function] Sends command to write after defining Memory Switch using the definition command specified by

the following classes to set the Memory Switch. The printer is automatically reset after writing the

setting defined by that command to the non-volatile memory.

Do not turn off the power to the printer while sending commands to the non volatile memory. Doing

so will destroy the Memory Switch setting. It is also possible for all Memory Switch settings to

become offset to their initial, default settings.

Consider the life of the non-volatile memory and avoid over-use of this command.

Function

Class

m

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data Definition (Data Specification)

Definition

","

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data definition (set specified bit)

Definition

"+"

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data definition (clear specified bit)

Definition

"-"

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data Definition (clear all data)

Definition

"@"

Fixed at "0000"

Definition data write and reset

Write

"W"

Fixed at "0000"

Definition data write and reset and test

print

Write

"T"

Fixed at "0000"

(Ex) Memory Switch 1-8 = 0; Memory Switch 2-7 = 1: Memory Switch 2-A =1 for a test print:

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2D); ' <ESC><GS> # -

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H31);CHR$(&H30);CHR$(&H30); ' 0100

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H0A);CHR$(0); ' 0000

<LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2B); ' <ESC><GS> # +

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H34);CHR$(&H38);CHR$(&H30); ' 0480

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); CHR$(&H0A);CHR$(0); '

0000<LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H54); ' <ESC><GS> # T

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H0A);CHR$(&H0); ' 0000

<LF><NUL>

Page 22

Rev. 1.02

- 22 -

SRP-275III

• Default Settings

The default settings for Memory Switch 0 to Memory Switch 8 are shown below.

Settings vary for single byte character countries (standard specifications (SBCS)) and for

double-byte character countries (Chinese character specifications (DBCS)).

- Standard Specifications (SBCS)

Memory Switch Number

Ex-factory Settings (n1, n2, n3, n4)

MSW 0

"0000"

MSW 1

"0000"

MSW 2

"0000"

MSW 3

"0000"

MSW 4

"0000"

MSW 5

"0000"

MSW 6

"0000"

MSW 7

"0000"

MSW 8

"0000"

- Chinese character specifications (DBCS) (For China)

Memory Switch Number

Ex-factory Settings (n1, n2, n3, n4)

MSW 0

"0010"

MSW 1

"0000"

MSW 2

"0000"

MSW 3

"0000"

MSW 4

"0000"

MSW 5

"0000"

MSW 6

"0000"

MSW 7

"0000"

MSW 8

"0000"

Page 23

Rev. 1.02

- 23 -

SRP-275III

• Function

- Memory Switch 0

Bit

Function

0

1

F~C

Reserved

Fixed to Off

B~A

Red and Black

(inverted black and white) Commands (*3)

Refer to the following table

9~5

Reserved

4

Country Specifications (*1)

SBCS

(Single Byte countries)

DBCS

(Double Byte countries)

3~2

<FF> Command (*2)

Refer to the following table

1~0

Reserved

Fixed to Off

NOTES

(*1) Country Specifications

Country

MSW 0-4 = 0

MSW 0-4 = 1

Overseas

Standard Specifications

Chinese Characters

(*2) <FF> Command Function Selection

MSW 0-3

MSW 0-2

<FF> Command Function

<FF> Command Function

Auto cutter model

Tear Bar Model (SRP-275IIIA type)

0

0

Executes a form feed.

Executes a form feed.

0

1

After paper fed to cutting position

executes partial cut (*3)

Paper fed to the tear-bar position

1

0

Executes a form feed.

Executes a form feed.

1

1

After paper fed to cutting position

executes partial cut (*3)

Paper fed to the tear-bar position

(*3) Red and Black (inverted black and white) Commands

MSW 0-B

MSW 0-A

<ESC> 4 / <ESC> 5 Command Functions

0

0

White/black inverted printing (1 Pass)

0

1

<Option 1> White/black inversion (7 × 9 font print) + enhancing (2 passes)

1

0

<Option 2> Upper line + Underline + enhancing (2 passes)

1

1

<Option 3> Upper line + Underline + double tall expanded + enhancing (4 passes)

This setting functions to specify adornments when the subsequent red (white/black inversion)

print command is set. It is a substitute function for the conventional red/black (white/black

inversion) printing.

<ESC> “4”: Red (white/black inversion) printing

<ESC> “5”: Red (white/black inversion) printing cancelled.

When using <ESC> 5 to cancel adornments, it returns to the previously set adornments.

(Adornments such as underline, upper line, double-tall expanded and enhancing are

cancelled if there is no command to set them (for example the <ESC> “-” 1 specification for

underlines).)

This setting is enabled only for ANK characters and block characters. It is disabled for IBM

block characters and Chinese characters composed of 12 dot vertical characters (IBM block

characters and Chinese characters do not have adornment with this command).

Page 24

Rev. 1.02

- 24 -

SRP-275III

- Memory Switch 1

Bit

Function

0

1

F~5

Reserved

Fixed to Off

E~5

4 Zero style

Normal

Slash zero

3~0

International Characters (*1)

Refer to the following table

NOTES

(*1) International Characters Default Value Settings

MSW1-3

MSW1-2

MSW1-1

MSW1-0

International Characters

0 0 0

0

U.S.A

0 0 0

1

France

0 0 1

0

Germany

0 0 1

1

U.K.

0 1 0

0

Denmark1

0 1 0

1

Sweden

0 1 1

0

Italy

0 1 1

1

Spain1

1 0 0

0

Japan

1 0 0

1

Norway

1 0 1

0

Denmark2

1 0 1

1

PC-999

- Memory Switch 2

Bit

Function

0

1

F

Reserved

Fixed to Off

E

How to recover to print ready after inserting paper

Press FEED.

Auto-recovery

D~4

Reserved

Fixed to Off

3

Contextual auto-cut function (*1)

Disabled

Enabled

2

1~0

Near end switch function (*2)

Refer to the following table

NOTES

(*1) Contextual Auto-cut Function

This function auto-cuts paper when a paper feed command that feeds continuously over 7/6

inch.

Hosts that cannot send an escape sequence, such as <ESC> “d” 0 can cut paper if a 1/6 inch

line feed code <LF> is sent seven times.

(*2) Near end switch Function

When an near end switch is mounted, settings should abide by those shown in the table

below.

MSW 2-1

MSW 2-0

Near end switch Function

0

0

Disabled

0

1

Disabled

1

0

Reflects the near end switch state to the status.

Printing does not stop for near end, and the printer does not go offline.

1

1

Reflects the near end switch state to the status.

Printing does stop for near end, and the printer goes offline.

Page 25

Rev. 1.02

- 25 -

SRP-275III

- Memory Switch 3

Bit

Function

0

1

F~D

Reserved

Fixed to Off

C~8

Character Table (*2)

Refer to the following table

7~2

Reserved

Fixed to Off

1~0

<CR> Command Functions (*1)

Refer to the following table

NOTES

(*1) <CR> Command Functions

MSW3-1

MSW3-0 <CR>

Functions

0

0 Ignored

0

1 Ignored

1

0

Prints and performs a line feed (same as <LF>.)

1

1

Prints (No line feed)

(*2) Character Table Settings

These settings are enabled only on standard specification printers.

MSW3-C

MSW3-B

MSW3-A

MSW3-9

MSW3-8

Character Table

0 0 0 0 0

Page 0 (PC437 : U.S.A.)

0 0 0 0 1

Page 1 (Katakana)

0 0 0 1 0

Page 2 (PC850 : Multilingual)

0 0 0 1 1

Page 3 (PC860 : Portuguese)

0 0 1 0 0

Page 4 (PC863 : Canadian-French)

0 0 1 0 1

Page 5 (PC865 : Nordic)

0 0 1 1 0

Page 16 (WPC1252 : Latin1)

0 0 1 1 1

Page 17 (PC866 : Russian)

0 1 0 0 0

Page 18 (PC852 : Latin2)

0 1 0 0 1

Page 19 (PC858 : Euro)

0 1 0 1 0

Page 21 (PC862 : Israel)

0 1 0 1 1

Page 22 (PC864 : Arabic)

0 1 1 0 0

Page 23 (Thai character code 42)

0 1 1 0 1

Page 24 (WPC1253 : Greek)

0 1 1 1 0

Page 25 (WPC1254 : Turkish)

0 1 1 1 1

Page 26 (WPC1257 : Baltic)

1 0 0 0 0

Page 27 (Farsi) (*3)

1 0 0 0 1

Page 28 (WPC1251 : Russian) (*3)

1 0 0 1 0

Page 29 (PC737 : Greek) (*3)

0 0 0 1 1

Page 30 (PC775 : Baltic) (*3)

1 0 1 0 0

Page 31 (Thai character code 16)

1 0 1 0 1

Page 32 (OldCode : Israel)

1 0 1 1 0

Page 33 (WPC1255 : Israel)

1 0 1 1 1

Page 34 (Thai character code 11)

1 1 0 0 0

Page 35 (Thai character code 18)

1 1 1 0 0

Page 37 (PC857 : Tukish)

1 1 1 0 1

Page 38 (PC928 : Greek)

1 1 1 1 0

Page 41 (WPC1258 : Vietnam)

(*3) Only Font B available.

Page 26

Rev. 1.02

- 26 -

SRP-275III

- Memory Switch 4

Bit

Function

0

1

F~1

Reserved

Fixed to Off

0

Data reception error (serial)

Prints “?”

Ignored

- Memory Switch 5

Bit

Function

0

1

F~0

Reserved

Fixed to Off

- Memory Switch 6

Bit

Function

0

1

F~0

Reserved

Fixed to Off

- Memory Switch 7

Bit

Function

0

1

F~0

Reserved

Fixed to Off

Page 27

Rev. 1.02

- 27 -

SRP-275III

4. Ribbon Cassette Installation

NOTES

Using unauthorized ribbon cartridges may result in poor printing quality or malfunction and

will void the warranty.

Refer to page 9-3 of the User Manual for the specifications of the supported ribbon cartridges.

1) Before inserting the ribbon cassette,

turn the knob clockwise to prevent

twisting the ribbon.

2) Open the front cover of printer.

3) Take out the old ribbon cassette if there

is one.

4) Insert the new ribbon cassette as

shown and pay particular attention to

the placement of the ribbon behind the

Printer Head.

5) During inserting the ribbon cassette,

turn the knob clockwise again to make

sure the ribbon moves freely in the

cassette.

Page 28

Rev. 1.02

- 28 -

SRP-275III

5. Roll Paper Installation

CAUTION

Do not touch the auto cutter blade when you open rear cover.

1) Open the rear cover by pushing the

open button.

2) Remove the used paper roll core if

there is one.

3) Insert the paper roll as shown.

4) Be sure to note the correct direction

that the paper should come off the

paper roll.

5) Pull out small amount of paper as

shown. Then close the cover and tear

off the extra paper by pulling it toward

the front of the printer.

Page 29

Rev. 1.02

- 29 -

SRP-275III

6. Installing the wall mount (Option)

NOTES

Wall mount is an optional item. DIP switch 1-7 should be set to OFF because wall mount

installation does not support Paper Out sensor. Contact seller or store you purchased the

product from for detailed information on wall mount installation.

Bracket hanger

Screw(3x5)

(4pieces)

Bracket mount

Screw(4x10)

(8pieces)

1) Turn the Set over and attach the

Bracket hanger to the Frame base then

tighten four screws.

2) Attach the Bracket mount to the wall

firmly with the eight screws. Be sure

that the Bracket attached properly to

match the direction of arrow as shown.

And the Bracket mount should be

always fixed vertically.

3) Insert the Bracket hanger of Set to the

Bracket mount as shown.

Page 30

Rev. 1.02

- 30 -

SRP-275III

7. Self Test

The self test let you know if your printer is operating properly. It checks the printing quality,

ROM version, DIP Switch settings, memory switch settings and statistic data.

The test is independent of any other equipment or software, so it is a good idea to run it

when you first set up the printer or if you have any trouble. If the self test works correctly, the

problem is in the other equipment or the software, not the printer.

• Running the self test

1) Make sure the printer is turned off and the printer cover is closed properly.

2) Turn on the power while pressing the Feed button and release the button, then the paper

will feed. Self diagnostics will begin and printer settings will be printed. Paper will be cut

upon completion of the test and printing will stop. (ERROR lamp will be on.)

3) Press the FEED button to continue printing the statistic data.

4) Press the FEED button to continue printing the rolling ASCII pattern.

5) The self test mode terminates after printing the rolling ASCII pattern automatically.

Page 31

Rev. 1.02

- 31 -

SRP-275III

8. Hexadecimal Dumping

• Hexadecimal dump

This feature allows experienced users to see exactly what data is coming to the printer.

This can be useful in finding software problems. When you turn on the hexadecimal dump

function, the printer prints all commands and other data in hexadecimal format along with a

guide section to help you find specific commands.

• To use the hexadecimal dump feature, follow these steps:

1) After you make sure that the printer is off, open the rear cover of the printer.

2) Hold down the FEED button while you turn on the printer.

3) Close the rear cover.

4) Run any software program that sends data to the printer. The printer prints "Hexadecimal

dump" and then all the codes are received in a two column format. The first column

contains the hexadecimal codes and the second column gives the ASCII characters that

correspond to the codes.

Hexadecimal Dump

To terminate hexadecimal dump

Press FEED button three times

1B 21 00 1B 26 02 40 40 . ! . . & . @ @

1B 25 01 1B 63 34 00 1B . % . . c 4 . .

41 42 43 44 45 46 47 48 A B C D E F G H

<Online Hex Dump Completed>

(A period(.) is printed for each code that has no ASCII equivalent.)

5) When the printing finishes, turn off the printer.

Page 32

Rev. 1.02

- 32 -

SRP-275III

9. Specification

9-1 Printing specification

Item

Description

Remark

Printing method

Serial impact method

Head wire

9 pin serial type

Dot pitch

0.352mm (1/72”)

Dot wire diameter

0.28mm (0.01”)

Printing direction

Bidirectional (logic seeking) with friction feed

Characters per line

Max. 42 (characters)

Printing speed

5.1 LPS (Line Per Second)

Printing width

63.5 mm

Line interval

4.233 mm (1/6”)

Paper feed method

Friction feed

Paper feed speed

Approximately 158 mm (6.2”)

Character font

7 x 9 / 9 x 9

Character sets

Alphanumeric characters : 95

International characters : 48

Extended graphics : 128 x 27 pages

9-2 Paper specifications

Item

Description

Remark

Paper type

Paper roll

Paper roll width

76±0.5 mm

Paper roll diameter

Max. ø83 mm (3.27")

Normal paper

Thickness : 1 sheet 0.06~0.085 mm (0.0024~0.0034")

Weight : 52.3~64g/m2 (0.115~0.1411 lb)

Paper core outside diameter

Max. ø19mm (0.75")

9-3 Ribbon cassette specification

Item

Description

Remark

Standard

GRC-201BR

Color

Black & Red

Size

13 mm (W)

Life

GRC-201BR : 1,500,000 characters (Black)

750,000 characters (Red)

Continuous printing 7x9 font

ASCII

25℃

NOTES

Using unauthorized ribbon cartridges may result in poor printing quality or malfunction and

will void the warranty.

Page 33

Rev. 1.02

- 33 -

SRP-275III

9-4 Electrical characteristics

Item

Description

Remark

SMPS Supply voltage

24VDC

Current consumption

(at 24V, except for drawer

kick-out driving)

Operating

Mean : Approximately 0.5A

Peak : Approximately 1.5A

Standby

Mean: Approximately 0.3A

NOTES

Maximum 1A for drawer kick-out driving.

9-5 Reliability

Item

Description

Remark

Life firing frequency

Mechanism : Approx. 18 million lines

Auto cutter : Approx. 1.5 million cuts

(End of life is defined as the point at which the printer reaches

the beginning of the Wear out Period.)

Head

Approx. 300 million dots/wire

9-6 Environment conditions

Item

Description

Remark

Temperature

Operating : 0~40℃ (32~104℉)

Storage : -20~60℃ (-4~140℉)

Relative humidity

Operating : 10~80% RH (Non-condensing)

Storage : 10~90% RH (Non-condensing)

NOTES

This equipment is indooruse and all the communication hiring are limited to inside of the

building.

Page 34

Rev. 1.02

- 34 -

SRP-275III

9-7 Dimensions & weight

• Dimensions

• Weight

Approx. Wt. : 2.5 kg

Shipping Wt. : 4.0 kg

157239160Dimension (mm)

HDWItem

Page 35

Rev. 1.02

- 35 -

SRP-275III

9-8 Optional features

The optional features either replace a standard feature or enhance the operation of the

printer.

All optional features are installed at the factory and must be selected when the printer is

ordered.

------------------------------------------------------------------------------------------------------------------------

• Auto cutter (SRP-275IIIA : Exclude auto cutter, SRP-275IIIC : Including auto cutter)

------------------------------------------------------------------------------------------------------------------------

• Interface (OES : USB+Serial+Ethernet / OS : USB+Serial / OP : USB+Parallel)

------------------------------------------------------------------------------------------------------------------------

• Cabinet color (Ivory / Dark gray)

------------------------------------------------------------------------------------------------------------------------

• Black mark sensor (front /rear)

The specifications of print density for the black mark.(DensiEye 700 used)

Density print of the black mark: 1.0 or more

Density of the non-black mark: 0.1 or less

------------------------------------------------------------------------------------------------------------------------

Page 36

Rev. 1.02

- 36 -

SRP-275III

10. Appendix - Troubleshooting

This chapter gives solutions to some printer problems you may have.

10-1 ERROR LED blinking pattern

The printer stops all printer operations for the selected paper section, goes off line, and the

ERROR LED blinks when an error is detected.

• Errors that automatically recover

Error

Description

ERROR LED blinking pattern

Recovery

Rear cover open error

(When recoverable

Error is selected)(*1)

The rear cover is opened

when printing

200ms

Recovers automatically

when the rear cover is

closed.

Print head

temperature error(*2)

The temperature of the

print head is extremely

high.

Recovers automatically

when the print head

cools.

NOTES

(*1) These conditions are selected by MSW8-5, 8-8. When MSW8-5 (mapping of the cover

open status) is off, the error hasn’t occurred but there is a “paper end error” instead. If

MSW8-8 is off, this error is handled as an automatically recoverable error.

(*2) Print head temperature error is not abnormal.

• Recoverable errors

When a recoverable error occurs, after the cause of the error is removed, the printer can

recover from the error by receiving an error recovery command without turning off the power.

Error

Description

ERROR LED blinking pattern

Recovery

Rear cover open error

(*1)

The rear cover is opened

when printing.

200ms

Recovers automatically

when the rear cover is

closed.

Auto cutter error

(Type C only)

The auto cutter does not

work correctly.

Recovers by error

recovery command.

Home position

detection error (This

is “Mechanical error”)

The home position

cannot be detected due

to a paper jam.

Recovers by error

recovery command.

NOTES

(*1) These conditions are selected by MSW8-5, 8-8. When MSW8-5 (mapping of the cover

open status) is off, the error hasn’t occurred but there is a “paper end error” instead. If

MSW8-8 is off, this error is handled as an automatically recoverable error.

Page 37

Rev. 1.02

- 37 -

SRP-275III

• Errors that are impossible to recover

Error

Description

ERROR LED blinking pattern

Recovery

R/W error in memory

or gate array

After R/W checking, the

printer does not work

correctly.

Writing to, reading out, or

erasing the NV memory for

image scanning results

does not work correctly.

200ms

Recovers automatically

when the rear cover is

closed.

High voltage error

The power supply voltage

is extremely high.

Impossible to recover.

Low voltage error

The power supply voltage

is extremely low.

Impossible to recover.

CPU execution error

The CPU executes an

incorrect address or I/F

board is not connected.

Impossible to recover.

Print head temperature

detection circuit error.

There is an abnormality is

the print head temperature.

Impossible to recover.

NOTES

If you see this light blinking, turn off the printer for a few seconds and then turn it back on.

If the light is still blinking, call your supervisor or a service person.

10-2 The printer does not start printing

• Are any of the operation panel lights on, If no operation panel lights are on, check

the following:

- Make sure that the printer is turned on.

- Make sure that the power supply cable is correctly plugged into the printer and to the

power outlet.

• If any of the lights are on, please check the following:

- If the ERROR LED is on (but not blinking), the printer is off line. Check to see that the

covers are closed and check the paper state. See Chapter 5 for instructions on installing

or replacing the paper roll.

- If the ERROR LED is blinking, there is an error. In this case, turn off the printer for a few

seconds and then turn it back on. If the light is still blinking, call your supervisor or

service person.

- If the PAPER OUT LED is on, check the paper roll in the printer. See Chapter 5 for

instruction on installing the paper roll.

Page 38

Rev. 1.02

- 38 -

SRP-275III

10-3 The printer stops printing

• If the ERROR LED is on (but not blinking), the printer is off line. Check to see that the

covers are closed and check the paper state. See Chapter 5 for instructions on installing or

replacing the paper roll.

• If the ERROR LED is blinking, there is an error. In this case, turn off the printer for a few

seconds and then turn it back on. If the LED is still blinking, call your supervisor or a

service person.

• Turn off the printer and check for a paper jam. To clear paper jam, follow the steps below:

1) Turn off the printer and open the rear cover of the printer.

2) Remove the jammed paper and reload the paper roll as described in Chapter 5.

3) Close the rear cover.

4) Turn on the printer.

10-4 You want to check the operation of the printer by itself

• Self test

Try to run the self test to check that the printer works properly. See the self test

instructions in Chapter 8 to run the self test. If the self test does not work, contact your

supervisor or a service person.

If the self test works properly, check the following:

1) Check the connection at both ends of the interface cable between the printer and the

computer. Also make sure that this cable meets the specifications for both the printer

and the computer.

2) The data transmission settings may be different between the printer and computer.

Make sure that the printer’s DIP Switch settings for data transmission are the same as

the computer’s. You can see the printer’s interface settings on your self test printout.

NOTES

If the printer still does not print, contact your dealer or a qualified service person.

10-5 Printing is poor

Check the state of ribbon cassette. If the ribbon cassette life ends, replace the ribbon

cassette as described in Chapter 4.

NOTES

If the printer is still poor, contact your dealer or a qualified service person.

Loading...

Loading...