Page 1

Operating Manual

Translation of the original operating manual

VDL (E3.1)

Vacuum Drying Oven

with microprocessor program controller MB2

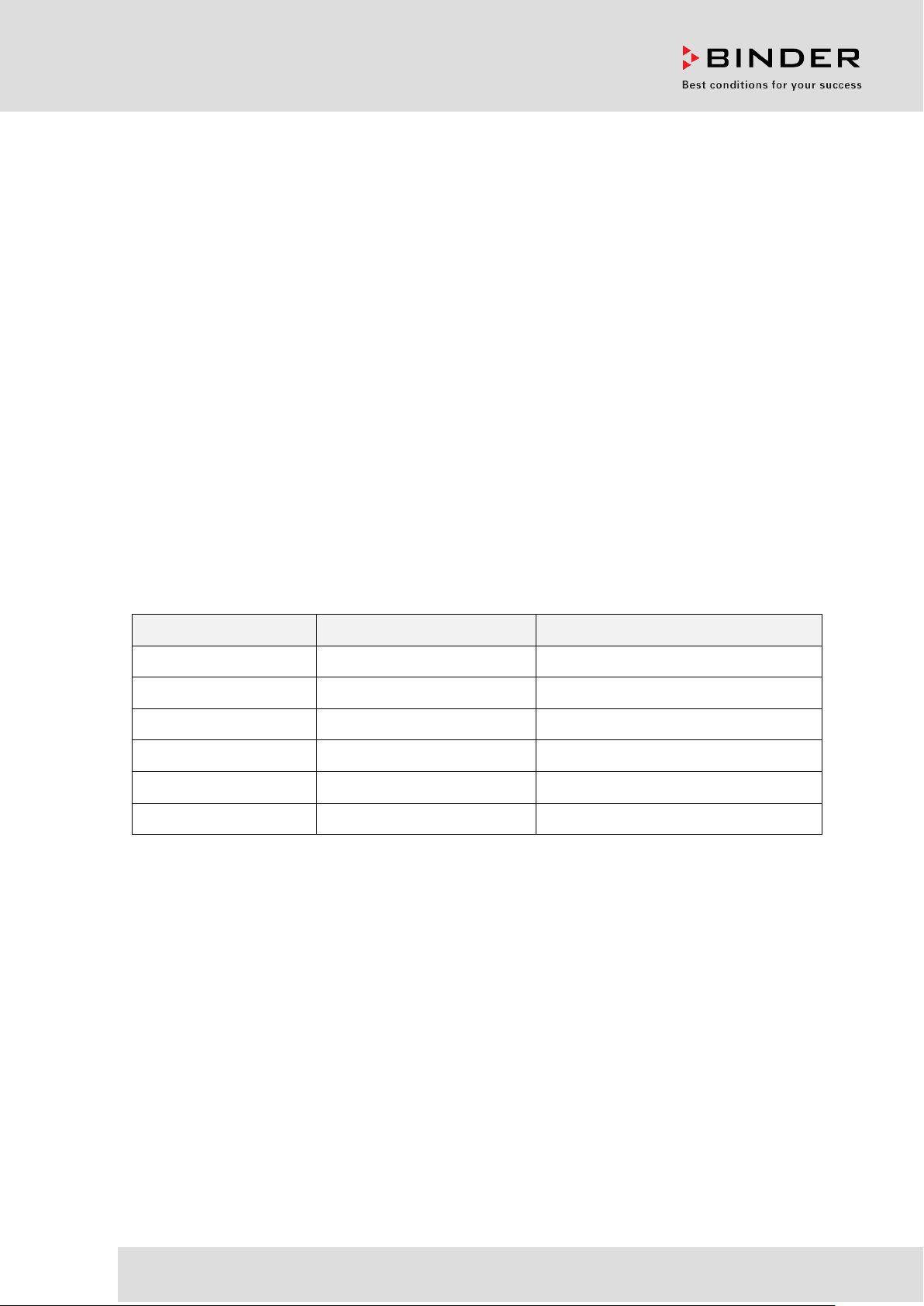

Model Model version Art. No.

VDL 23 VDL023-230V 9630-0009

VDL 23-UL VDL023UL-120V 9630-0013

VDL 56 VDL053-230V 9630-0010

VDL 56-UL VDL053UL-120V 9630-0014

VDL 115 VDL115-230V 9630-0011

VDL 115-UL VDL115UL-120V 9630-0015

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.b ind er -world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: customerservice@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacif ic: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 10/2020 Art. No. 7001-0384

Page 2

Contents

1. SAFETY .................................................................................................................. 8

1.1 Personnel Qualification ....................................................................................................................... 8

1.2 Operating manual ................................................................................................................................ 8

1.3 Legal considerations ........................................................................................................................... 9

1.4 Structure of the safety instructions .................................................................................................... 10

1.4.1 Signal word panel ................................................................................................................... 10

1.4.2 Safety alert symbol ................................................................................................................. 10

1.4.3 Explosion protection symbol ................................................................................................... 10

1.4.4 Pictograms in this manual ....................................................................................................... 11

1.4.5 Word message panel structure ............................................................................................... 12

1.5 Localization / position of safety labels on the chamber .................................................................... 12

1.6 Type plate.......................................................................................................................................... 13

1.7 Safety instructions on installing and operating the vacuum drying oven .......................................... 14

1.7.1 Safety instructions on installation and ambient conditions of the chamber ............................ 14

1.7.1.1 Aeration / ventilation of the insta lla tion sit e ....................................................................... 15

1.7.1.2 No installation in potentially explosive areas of Zone 1 or 0 ............................................. 15

1.7.1.3 Equipotential bonding according to the grounding concept............................................... 15

1.7.1.4 Accessibility to the disconnection from the power grid ...................................................... 16

1.7.1.5 Technical ventilation (extraction) ....................................................................................... 16

1.7.2 Safety instructions on compressed air supply ........................................................................ 16

1.7.3 Safety instructions on vacuum supply .................................................................................... 17

1.7.3.1 Selection and location of a suitable pump ......................................................................... 17

1.7.3.2 Observing the permissible gas inlet temperature .............................................................. 18

1.7.3.3 Technical Ventilation (extraction) ...................................................................................... 18

1.7.4 Safety instructions on the charging material ........................................................................... 19

1.7.5 Safety instructions on operating the vacuum drying oven ...................................................... 20

1.8 Ex classification of the chamber and immediate surroundings ......................................................... 23

1.9 Intended use ..................................................................................................................................... 25

1.10 Foreseeable Misuse .......................................................................................................................... 28

1.11 Residual Risks .................................................................................................................................. 30

2. OPERATOR RESPONSIBILITY, DOCUMENTATION, AND MEASURES .......... 32

2.1 Risk assessment / explosion protection document ........................................................................... 32

2.2 Employee training and protoc ols ....................................................................................................... 32

2.3 Operating instructions ....................................................................................................................... 33

2.4 Safety data sheets ............................................................................................................................ 33

2.5 Protective equipment ........................................................................................................................ 33

2.6 Standard Operating Procedures (SOPs) .......................................................................................... 34

2.7 Testing and maintenance .................................................................................................................. 35

2.8 Operation log ..................................................................................................................................... 35

3. DESCRIPTION OF THE EQUIPMENT ................................................................. 36

3.1 Manufacturer's safety plan: Protective measures and equipment .................................................... 37

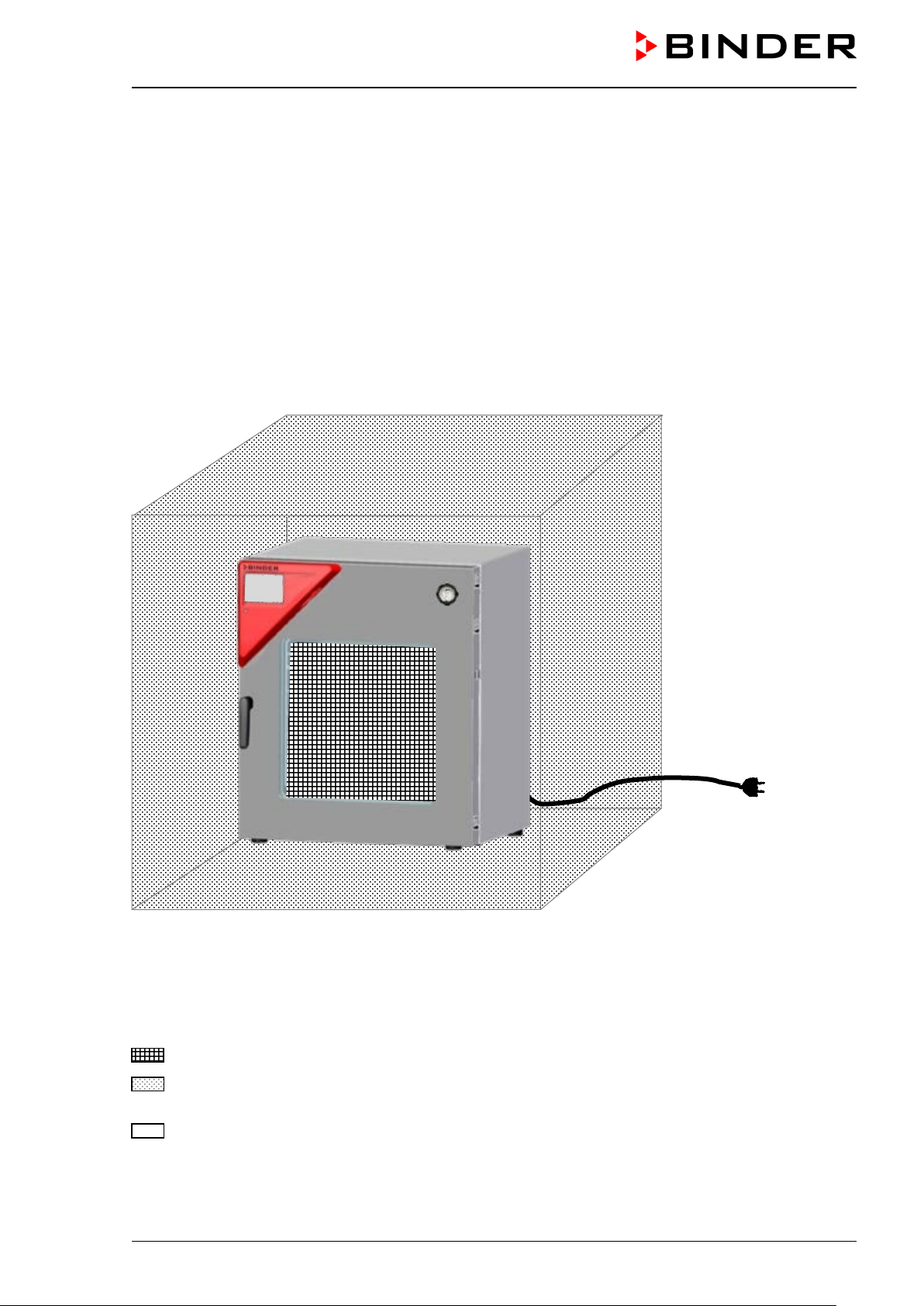

3.2 Chamber overview ............................................................................................................................ 41

3.3 Triangular instrument box with MB 2 contro l ler.................................................................................. 42

3.4 Connections on the rear of the chamber ........................................................................................... 42

3.5 Area classification, information for the zone classification ................................................................ 44

3.5.1 Area classification inside the chamber ................................................................................... 45

3.5.2 Area classification in the surroundings of the chamber .......................................................... 46

3.5.3 Area classification in the surroundings of the chamber: extraction lead to the pump, location

of the pump ........................................................................................................................ 47

4. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 48

4.1 Unpacking, and checking equipment and completeness of delivery ................................................ 48

4.2 Guidelines for safe lifting and transportation ..................................................................................... 49

4.3 Storage .............................................................................................................................................. 49

VDL (E3.1) 10/2020 Page 2/196

Page 3

5. LOCATION OF INSTALLATION AND AMBIENT CONDITIONS ......................... 49

5.1 General requirements for installation ................................................................................................ 49

5.2 Ventilation and extraction (technical ventilation) ............................................................................... 51

5.2.1 Ventilation for heat removal in normal operation .................................................................... 51

5.2.2 Technical ventilation during chamber operation and when emptying the condensate catchpot

of the pump ........................................................................................................................ 51

5.2.3 Air supply (breaking the vacuum) during operation with inert gas .......................................... 51

5.3 Equipotential bonding ........................................................................................................................ 52

5.4 Ambient conditions ............................................................................................................................ 52

5.5 Compressed air supply for sweeping the area for electrical equipment, the preheating chamber,

and the controller housing ................................................................................................................. 52

5.6 Fire extinguisher ................................................................................................................................ 52

5.7 Lightning protection device ............................................................................................................... 52

6. INSTALLATION AND CONNECTIONS ............................................................... 53

6.1 Vacuum expansion racks and rack holders ...................................................................................... 53

6.2 Mounting the pressure regulator ....................................................................................................... 54

6.3 Connecting compressed air supply for sweeping the area for electrical equipment, the preheating

chamber, and the controller housing ................................................................................................. 56

6.4 Pump module (option) ....................................................................................................................... 57

6.4.1 Mounting ................................................................................................................................. 58

6.4.2 Achieving equipotential bon din g acc. to the grou ndi ng pla n .................................................. 58

6.4.3 Connection of an extraction system at the pump module....................................................... 59

6.5 Vacuum connection ........................................................................................................................... 59

6.5.1 Instructions for using vacuum pumps ..................................................................................... 59

6.5.2 Vacuum pump VP4 (option) .................................................................................................... 61

6.5.3 Installation of the vacuum pump VP4 in the pump module (option) ....................................... 62

6.5.4 Note on the use of a flame arrester ........................................................................................ 64

6.5.5 ATEX connection kit for vacuum pump VP4 (option) ............................................................. 64

6.6 Connecting inert gas supply .............................................................................................................. 64

6.7 Mounting the tilt protection holders ................................................................................................... 65

6.8 Achieving equipotential bonding / Grounding concept ...................................................................... 66

6.9 Electrical connection ......................................................................................................................... 68

7. EXPLOSION SAFETY TESTS BEFORE COMMISSIONING ............................... 70

7.1 Scope of the functional test ............................................................................................................... 70

7.2 Explosion protection plan .................................................................................................................. 70

7.3 Objective of testing ............................................................................................................................ 71

7.4 Testing before initial commissioning ................................................................................................. 71

7.4.1 Scope of the test ..................................................................................................................... 71

7.4.1.1 Testing the plausibility of the explosion protection plan and measures ............................ 71

7.4.1.2 Verifying the implementation of measures ........................................................................ 71

7.4.1.3 Checking the deadlines for the recurring tests .................................................................. 72

7.4.1.4 Verifying the maintenance pla n ......................................................................................... 72

7.4.2 Tests of technical ventilation systems, gas warning devices, inerting devices, devices,

protective systems or safety, control or regulating devices, and other technical devices for

explosion protection ........................................................................................................... 73

7.5 Inspection after changes requiring review ........................................................................................ 73

7.6 Recurring tests for the explosive safety of the system ..................................................................... 73

8. FUNCTIONAL OVERVIEW AND MENU STRUCTURE O F THE CONTROLLER 74

8.1 Operating functions in normal display ............................................................................................... 75

8.2 Display views: Normal display, program display, chart-recorder display .......................................... 76

8.3 MB2 controller icons overview .......................................................................................................... 77

8.4 MB2 controller operating modes ....................................................................................................... 79

8.4.1 MB2 controller menu structure ................................................................................................ 79

8.4.2 Main menu .............................................................................................................................. 80

8.4.3 “Settings” submenu ................................................................................................................. 81

8.4.4 “Service” submenu .................................................................................................................. 81

8.5 Principle of controller entries ............................................................................................................. 82

8.6 Performance during and after power failures .................................................................................... 82

VDL (E3.1) 10/2020 Page 3/196

Page 4

9. START UP AND PERFORMING THE DRYING PROCESS ................................ 83

9.1 Requirements for safe commissioning .............................................................................................. 83

9.2 Overview of the drying process ......................................................................................................... 84

9.3 Sweeping the area for electrical equipment, the preheating chamber, and the controller housing

(triangular instrument box) with compressed air ............................................................................... 86

9.3.1 Setting the pressure regulator for sweeping with compressed air .......................................... 86

9.3.2 Sweeping before starting up / restarting the chamber ............................................................ 87

9.3.3 Sweeping during chamber operation ...................................................................................... 87

9.3.4 Sweeping after completion of chamber operation (recommended): ....................................... 88

9.4 Condition after establishing the power connection ........................................................................... 88

9.5 Standby mode Turning on and off the vacuum drying oven ............................................................. 89

9.6 Controller settings upon start up ....................................................................................................... 90

9.7 Loading.............................................................................................................................................. 91

9.8 Evacuation......................................................................................................................................... 93

9.9 Breaking the vacuum (flooding) ........................................................................................................ 93

9.9.1 Ventilation after completing the drying procedure (flooding with ambient air or inert gas) ..... 93

9.9.2 Operation with inert gas .......................................................................................................... 93

9.9.3 Ventilation / breaking the vacuum in case of a power failure ................................................. 94

9.9.4 Ventilation before completing the drying procedure (flooding with ambient air or inert gas) .. 94

9.10 Unloading the loading material ......................................................................................................... 95

9.11 Removing the full condensate catchpot of the pump ........................................................................ 96

9.12 Preparing a new drying process ....................................................................................................... 96

10. SET-POINT ENTRY .............................................................................................. 97

10.1 Set-point entry through the “Setpoints” menu ................................................................................... 97

10.2 Direct setpoint entry via Normal display ............................................................................................ 98

11. SETTING SPECIAL CONTROLLER FUNCTIONS .............................................. 99

11.1 Menu structure .................................................................................................................................. 99

11.1.1 “Functions on/off” menu .......................................................................................................... 99

11.1.2 “Control on/off” menu ............................................................................................................ 100

11.2 Using the optional universal connection “GAS/AIR 2” for ventilation .............................................. 100

11.3 Close all valves ............................................................................................................................... 101

11.4 Activating / deactivating temperature control .................................................................................. 101

11.5 Activating / deactivating pressure control ....................................................................................... 102

11.6 Drying monitoring ............................................................................................................................ 103

12. AUTHORIZATION LEVELS AND PASSWORD PROTECTION ........................ 105

12.1 User management, authorization levels and password protection ................................................. 105

12.2 Log in ............................................................................................................................................... 107

12.3 Log out ............................................................................................................................................ 108

12.4 User change .................................................................................................................................... 109

12.5 Password assignment and password change................................................................................. 109

12.5.1 Password change ................................................................................................................. 109

12.5.2 Deleting the password for an individual authorization level .................................................. 111

12.5.3 New password assignment for “service” or “admin” authorization level when the password

function was deactivated ................................................................................................. 112

12.6 Activation code ................................................................................................................................ 113

13. GENERAL CONTROLLER SETTINGS AND INFORMATION ........................... 114

13.1 Selecting the controller’s menu language ....................................................................................... 114

13.2 Setting date and time ...................................................................................................................... 114

13.3 Selecting the temperature unit ........................................................................................................ 116

13.4 Display configuration ....................................................................................................................... 116

13.4.1 Adapting the display parameters .......................................................................................... 116

13.4.2 Touchscreen calibration ........................................................................................................ 117

13.5 Event list .......................................................................................................................................... 118

13.6 Service contact page ....................................................................................................................... 118

13.7 Current operating parameters ......................................................................................................... 119

13.8 Technical chamber information ....................................................................................................... 119

VDL (E3.1) 10/2020 Page 4/196

Page 5

14. TEMPERATURE SAFETY DEVICES ................................................................. 120

14.1 Safety temperature limiter (TL) class 2 ........................................................................................... 120

14.2 Overtemperature safety controller class 2 ...................................................................................... 120

14.2.1 Safety controller mode .......................................................................................................... 120

14.2.2 Setting the safety controller .................................................................................................. 121

14.2.3 Message and measures in the state of alarm ....................................................................... 122

14.2.4 Function check ...................................................................................................................... 122

15. TOLERANCE RANGE SETTINGS ..................................................................... 122

15.1 Setting the alarm delay times and the tolerance ranges ................................................................. 122

15.1.1 Alarm condition ..................................................................................................................... 123

16. NOTIFICATION AND ALARM FUNCTIONS ...................................................... 123

16.1 Information messages ..................................................................................................................... 123

16.2 Alarm messages ............................................................................................................................. 125

16.3 Resetting an alarm .......................................................................................................................... 126

16.4 Activating / deactivating the audible alarm (buzzer) ....................................................................... 126

16.5 Test alarm of the safety temperature limiter (TL) ............................................................................ 127

17. TIMER PROGRAM (STOPWATCH FUNCTION) ............................................... 129

17.1 Starting a timer program ................................................................................................................. 129

17.1.1 Performance during program delay time .............................................................................. 130

17.2 Stopping a running timer program .................................................................................................. 130

17.2.1 Pausing a running timer program ......................................................................................... 130

17.2.2 Cancelling a running timer program ...................................................................................... 130

17.3 Performance after the end of the program ...................................................................................... 130

18. TIME PROGRAMS ............................................................................................. 131

18.1 Starting an existing time program ................................................................................................... 131

18.1.1 Performance during program delay time .............................................................................. 132

18.2 Stopping a running time program .................................................................................................... 132

18.2.1 Pausing a running time program ........................................................................................... 132

18.2.2 Cancelling a running time program ....................................................................................... 132

18.3 Performance after the end of the program ...................................................................................... 132

18.4 Creating a new time program .......................................................................................................... 133

18.5 Program editor: program management ........................................................................................... 133

18.5.1 Deleting a time program........................................................................................................ 134

18.6 Section editor: section management ............................................................................................... 135

18.6.1 Add a new program section .................................................................................................. 136

18.6.2 Copy and insert or replace a program section ...................................................................... 136

18.6.3 Deleting a program section ................................................................................................... 137

18.7 Value entry for a program section ................................................................................................... 138

18.7.1 Section duration .................................................................................................................... 138

18.7.2 Set-point ramp and set-point step ......................................................................................... 139

18.7.3 Special controller functions ................................................................................................... 140

18.7.4 Setpoint entry ........................................................................................................................ 141

18.7.5 Tolerance range .................................................................................................................... 141

18.7.6 Repeating one or several sections within a time program .................................................... 142

18.7.7 Saving the time program ....................................................................................................... 143

19. WEEK PROGRAMS ........................................................................................... 143

19.1 Starting an existing week program .................................................................................................. 144

19.2 Cancelling a running week program ............................................................................................... 144

19.3 Creating a new week program ........................................................................................................ 145

19.4 Program editor: program management ........................................................................................... 146

19.4.1 Deleting a week program ...................................................................................................... 147

19.5 Section editor: section management ............................................................................................... 147

19.5.1 Add a new program section .................................................................................................. 148

19.5.2 Copy and insert or replace a program section ...................................................................... 149

19.5.3 Deleting a program section ................................................................................................... 149

VDL (E3.1) 10/2020 Page 5/196

Page 6

19.6

Value entry for a program section in the Section view .................................................................... 149

19.6.1 Set-point ramp and set-point step modes ............................................................................. 150

19.6.2 Weekday ............................................................................................................................... 150

19.6.3 Start time ............................................................................................................................... 150

19.6.4 Setpoint entry ........................................................................................................................ 151

19.6.5 Special controller functions ................................................................................................... 151

20. NETWORK AND COMMUNICATION ................................................................ 152

20.1 Ethernet ........................................................................................................................................... 152

20.1.1 Configuration ......................................................................................................................... 152

20.1.2 Display of MAC addr es s ....................................................................................................... 153

20.2 Web server ...................................................................................................................................... 153

20.3 E-Mail .............................................................................................................................................. 154

21. USB MENU: DATA TRANSFER VIA USB INTERFACE ................................... 155

21.1 Using the USB connection during chamber operation .................................................................... 155

22. CHART RECORDER DISPLAY ......................................................................... 156

22.1 Views ............................................................................................................................................... 156

22.1.1 Show and hide legend .......................................................................................................... 156

22.1.2 History display ....................................................................................................................... 156

22.2 Setting the parameters .................................................................................................................... 158

23. REFERENCE MEASUREMENTS ...................................................................... 159

23.1 Checking the temperature in the inner chamber ............................................................................. 159

23.1.1 Checking the controller display ............................................................................................. 159

23.1.2 Checking the spatial temperature exactitude ....................................................................... 159

23.1.3 Checking the function of the manometer for compressed air sweeping ............................... 160

24. OPTIONS ............................................................................................................ 161

24.1 APT-COM™ 4 Multi Management software (option) ...................................................................... 161

24.2 Analog outputs for temperature and pressure (option) ................................................................... 161

24.3 Object temperature display with flexible Pt 100 temperature sensor (option) ................................ 162

24.3.1 Connection of the object temperature sensor ....................................................................... 162

24.3.2 Display on the MB2 controller ............................................................................................... 163

25. CLEANING AND DECONTAMINATION ............................................................ 163

25.1 Safety instructions on cleaning and decontamination ..................................................................... 163

25.2 Cleaning .......................................................................................................................................... 164

25.3 Decontamination / chemical disinfection ......................................................................................... 165

26. MAINTENANCE AND SERVICE, TROUBLESHOOTING, REPAIR, TESTING . 167

26.1 General information, personnel qualifications ................................................................................. 167

26.2 Simple troubleshooting .................................................................................................................... 168

26.3 Maintenance, Service ...................................................................................................................... 171

26.3.1 Safety instructions on maintenance work ............................................................................. 171

26.3.2 Maintenanc e int erv als ........................................................................................................... 172

26.4 Service Reminder ............................................................................................................................ 172

26.4.1 BINDER Service contact data ............................................................................................... 172

26.5 Sending the chamber back to BINDER GmbH ............................................................................... 173

27. DISPOSAL.......................................................................................................... 173

27.1 Disposal of the transport packing .................................................................................................... 173

27.2 Decommissioning ............................................................................................................................ 173

27.3 Disposal of the chamber in the Federal Republic of Germany ....................................................... 174

27.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany.......................................................................................................................................... 175

27.5 Disposal of the chamber in non-member states of the EU ............................................................. 176

28. TECHNICAL DESCRIPTION .............................................................................. 176

28.1 Factory calibration and adjustment ................................................................................................. 176

28.2 Over current protection ................................................................................................................... 177

VDL (E3.1) 10/2020 Page 6/196

Page 7

28.3 VDL / VDL-UL technical data .......................................................................................................... 177

28.4 Equipment and options (extract) ..................................................................................................... 179

28.5 Accessories and spare parts (extract) ............................................................................................ 180

28.6 Dimensions...................................................................................................................................... 182

28.6.1 VDL 23 .................................................................................................................................. 182

28.6.2 VDL 56 .................................................................................................................................. 183

28.6.3 VDL 115 ................................................................................................................................ 184

29. INDEX ................................................................................................................. 185

30. CERTIFICATES AND DECLARATIONS OF CONFORMITY ............................. 187

30.1 EU Declaration of Conformity.......................................................................................................... 187

31. PRODUCT REGISTRATION .............................................................................. 190

32. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 191

32.1 For chambers located outside USA and Canada ........................................................................... 191

32.2 For chambers located in USA and Canada .................................................................................... 194

List of figures

Figure 1: Position of labels on the chamber (example) ............................................................................... 12

Figure 2: Type plate (example of VDL 115) ................................................................................................ 13

Figure 3: VDL 115 with MB2 controller ....................................................................................................... 41

Figure 4: Triangular instrument box (controller housing) with MB2 program controller and USB interface 42

Figure 5: Chamber rear (example: VDL 115) .............................................................................................. 42

Figure 6: Rear connection panel VDL wit h optio ns ..................................................................................... 43

Figure 7: Area classification of the closed chamber (view without housing, insulation, heater and outer

chamber) ...................................................................................................................................... 45

Figure 8: Area classification in the surroundings of the chamber (schematic representation, standard

device) .......................................................................................................................................... 46

Figure 9: Area classification in the surroundings of the chamber during operation (example) ................... 47

Figure 10: Operating the expansion racks .................................................................................................. 53

Figure 11: Mounting the pressure regulator on the chamber rear .............................................................. 55

Figure 12: Compressed air connect ion on t he pressure regulator .............................................................. 56

Figure 13: VDL mounted on pump module ................................................................................................. 57

Figure 14: Pump module, rear view (example size 115) ............................................................................ 57

Figure 15: Position of the Vacuum connection (6) on the chamber rear (example size 56) ....................... 59

Figure 16: Vacuum pump VP 4 (MZ2C EX) ................................................................................................ 61

Figure 17: Variable length of the tilt protecti on ho lder depe nd ing on the ben d .......................................... 65

Figure 18: Possibilities of grounding (schematic representation) ............................................................... 66

Figure 19: Mounting the grounding cab le on the VDL ................................................................................. 67

Figure 20: Normal display of the MB2 program controller (sample values) ................................................ 74

Figure 21: Operating functions of the MB2 controller in normal display (example values) ......................... 75

Figure 22: Pressure regulator and sweeping plug for compressed air sweeping on the chamber rear ..... 86

Figure 23: analog pressure display (manometer) for compressed air sweeping on the chamber front ...... 86

Figure 22: Pressure regulator with defined setting at the upper stop ......................................................... 87

Figure 24: Schematic timing of the drying process and drying monitoring ............................................... 103

Figure 25: Pressure regulator and sweeping plug for compressed air sweeping on the chamber rear ... 160

Figure 26: Connection cable on the “Analog output” (3b) connection...................................................... 161

Figure 26: SUB-D socket for the analog outputs option ............................................................................ 161

Figure 29: Measuring connection (12) with measuring access port .......................................................... 162

Figure 29: Connection cable on the “Object temperature input” connection (3a) ..................................... 162

Figure 29: Plug connection between measuring access port and Lemo socket ....................................... 162

Figure 29: Cable connection of the option al Pt 100 sensor ...................................................................... 162

VDL (E3.1) 10/2020 Page 7/196

Page 8

Dear customer,

For the correct operation of the VDL vacuum drying oven, it is important that you read this operating manual

completely and caref ully and obser ve all instruc tions as ind icated. Failur e to read, understand an d follow

the instructions may result in personal injury. It can also lead to damage to the chamber and/or poor equipment performance.

1. Safety

1.1 Personnel Qualification

The chamber m ust only be installed, tested, and start ed up by personn el qualified for as sembly, startup,

and operation of the chamber with additional skills in explosion protection (ATEX). Qualified personnel are

persons whose professional education, knowledge, experience and knowledge of relevant standards allow

them to assess, carry out, and identify any potential hazards in the work assigned to them. They must have

been trained and ins truc ted , and be auth or ized , to w or k on the chamber. This incl udes a bas ic knowledge

of explosion protection ( ATEX training), instr uction based on the r isk assessment by the op erator (chap.

2.2) and knowledge of the Operating Instruction by the operator.

The device shall only be op erated b y laborator y personne l especiall y trained for this purpose and fam iliar

with all precautio nary measures required for working acc. to ATEX Directive 2014/37/EU . Observe the

national regulations on minimum age of laboratory personnel.

1.2 Operating manual

This operating m anual is part of the components of deliver y. Always keep it hand y for reference in the

vicinity of the chamber. If selling the unit, hand over the operating manual to the purchaser.

To avoid injuries a nd pr oper ty dam age obser ve t he saf et y instruct ions of the oper atin g m anual. Fa ilure t o

follow instructions and safety precautions can lead to significant risks and to the loss of explosion protection.

DANGER

Explosion hazard due to failure to observe the instructions and safety precautions.

Serious injuries and chamber damage. Risk of death.

Observe the safety instructions in this Operating Manual.

Follow the operating procedures in this Operating Manual.

Carefully read the complete operating instructions of the chamber prior to installing and

using the chamber.

Keep the operating manual for future reference.

Make sure that all persons who use the chamber and its associated work equipment have

read and understood the Operating Manual.

This Operating Manu al is supplemented a nd updated as needed. Alwa ys use the most recent version of

the Operating Manual. W hen in doub t, call the BIND ER Serv ice Hotline f or inform ation on the up-to-dateness and validity of this Operating Manual.

VDL (E3.1) 10/2020 Page 8/196

Page 9

1.3 Legal considerations

This operating m anual is for inform ational purposes only. It co ntains information f or correct and safe i nstalling, start-up, opera tion, decommissioning, cl eaning and maintenance of the product. The content of

this operating manual takes into account the applicable regulatory requirements and the latest technology.

Note: the contents and the product described are subject to change without notice.

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free use

and safety during operation and maintenance. Images are to provide basic understanding. They may deviate from the actual vers ion of the chamber. The actu al scope of delivery can, d ue to optional or special

design, or due to recent tec hnical chan ges, deviate f rom the information and illus trations i n these instruc tions this operating m anual. In no event shall BINDER be he ld liabl e for an y damages , direc t or inc identa l

arising out of or related to the use of this manual.

This operating manual can not cover all conce ivable applications. If you would lik e additional information,

or if special problem s arise that are not suff iciently addressed in th is manual, please ask your dealer or

contact us directly, e.g. by phone at the number located on page one of this manual.

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or existing

agreement, descriptio n, or l ega l rel ati ons h ip, nor d o they modify such a relati ons h ip. All o bl iga tio ns on t he

part of BINDER derive from the respective purchase contract, which also contains the entire and exclusively

valid statement of warranty administration and the general terms and conditions, as well as the legal regulations valid at the time the contract is concluded. T he statements in this manual neither augment nor

restrict the contractual warranty provisions.

Furthermore, relevan t national and international reg ulations on occupational saf ety apply. The operator

must know, compl y with, and implem ent these requir ements. In partic ular, this includ es the provisions of

ATEX Operational Directive 19 99/92/ EC (“ATEX 137”) (implem ented for Germ any in the In dustrial Safet y

Regulation (BetrSichV) and the Ordinance on Hazardous Substances (GefStoffV)). The operator is responsible for choosing suitabl e wor k equipm ent for t he are as c lassif ied as ex plos ion h azards and f or i nstalli ng

and operating equipment in accordance with respective requirements.

Limitation of liability

BINDER GmbH is not liable for any damage arising from the following causes:

• Non-observance of Instruction Manual

• Improper use

• Improper installation, setup, maintenance, repair

• Inspections not being performed (testing before ini tial commissioning, recurring tests, tes ting before

recommissioning

• Negligence or willf ul int ent

• Incorrect response to malfunctions

• Assignment of improperly or insufficiently trained personnel

• Technical changes and modifications made by the operator and not approved by the manufacturer

• Use of non-approved accessories and replacement parts

We reserve the right to technical changes as part of improvements to operating characteristics and further

development.

Have repairs performed only by experts authorized by BINDER. Repaired chambers must comply with the

quality standard sp ecified by BIND ER. In par ticular, carr y out an ins pectio n befor e recomm issioning after

maintenance or rep airs. Thes e can onl y be perf ormed by the manuf acturer or speciall y trained p ersonnel

(in Germany: Qualified Persons per BetrSichVO).

VDL (E3.1) 10/2020 Page 9/196

Page 10

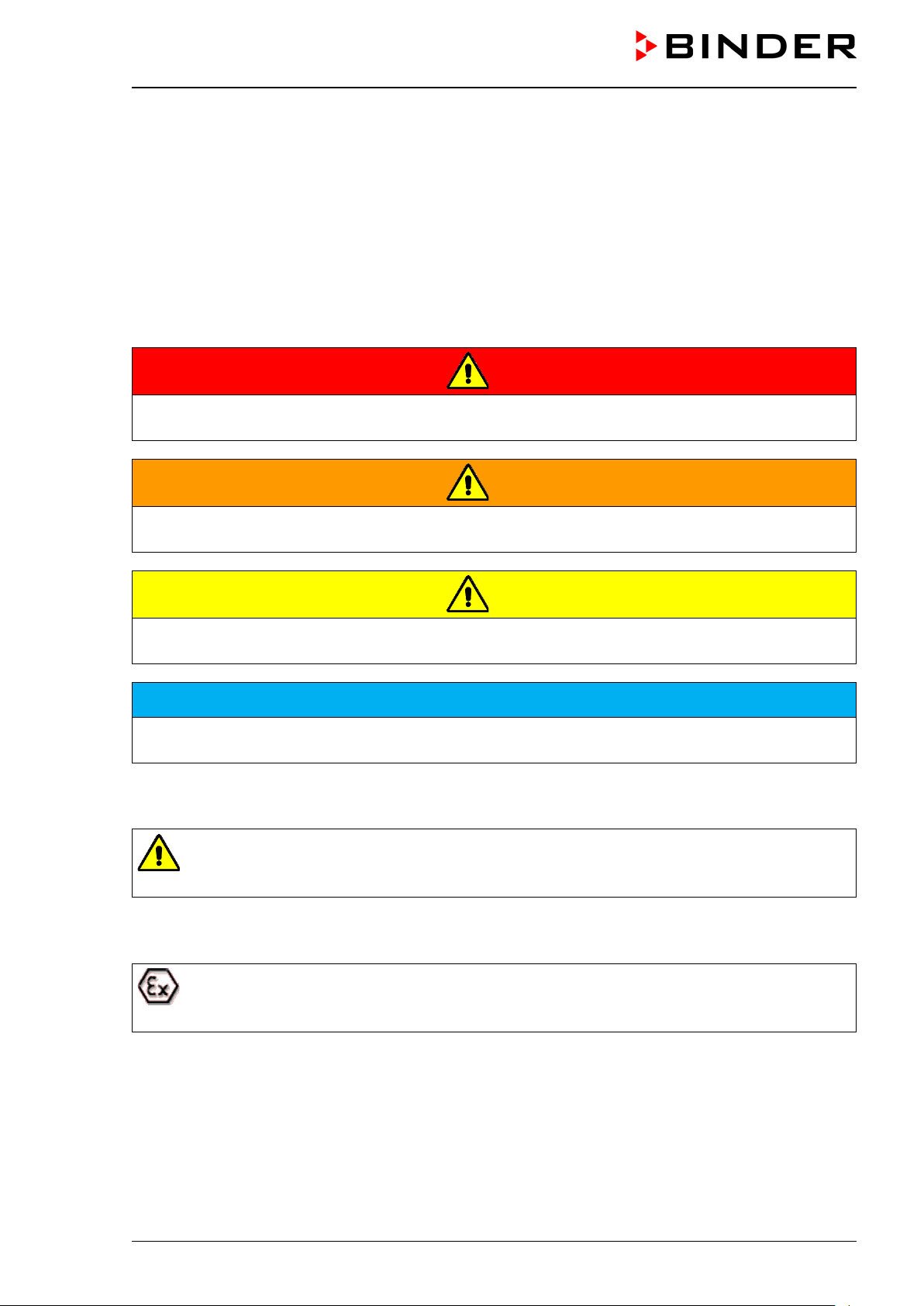

1.4 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations following the harmonization of ISO 3864-2 and ANSI Z535.6.

1.4.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal word,

the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious (irreversible) injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious (irreversible) injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor (reversible) injury.

NOTICE

Indicates a potentially hazardous situation, which, if not avoided, may result in damage to the product

and/or its functions or to property in its proximity.

1.4.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

1.4.3 Explosion protection symbol

Use of the explosion protection symbol warns against explosion hazards.

Observe all measures in this operating manual to avoid the formation of explosive atmosphere

as well as explosions.

VDL (E3.1) 10/2020 Page 10/196

Page 11

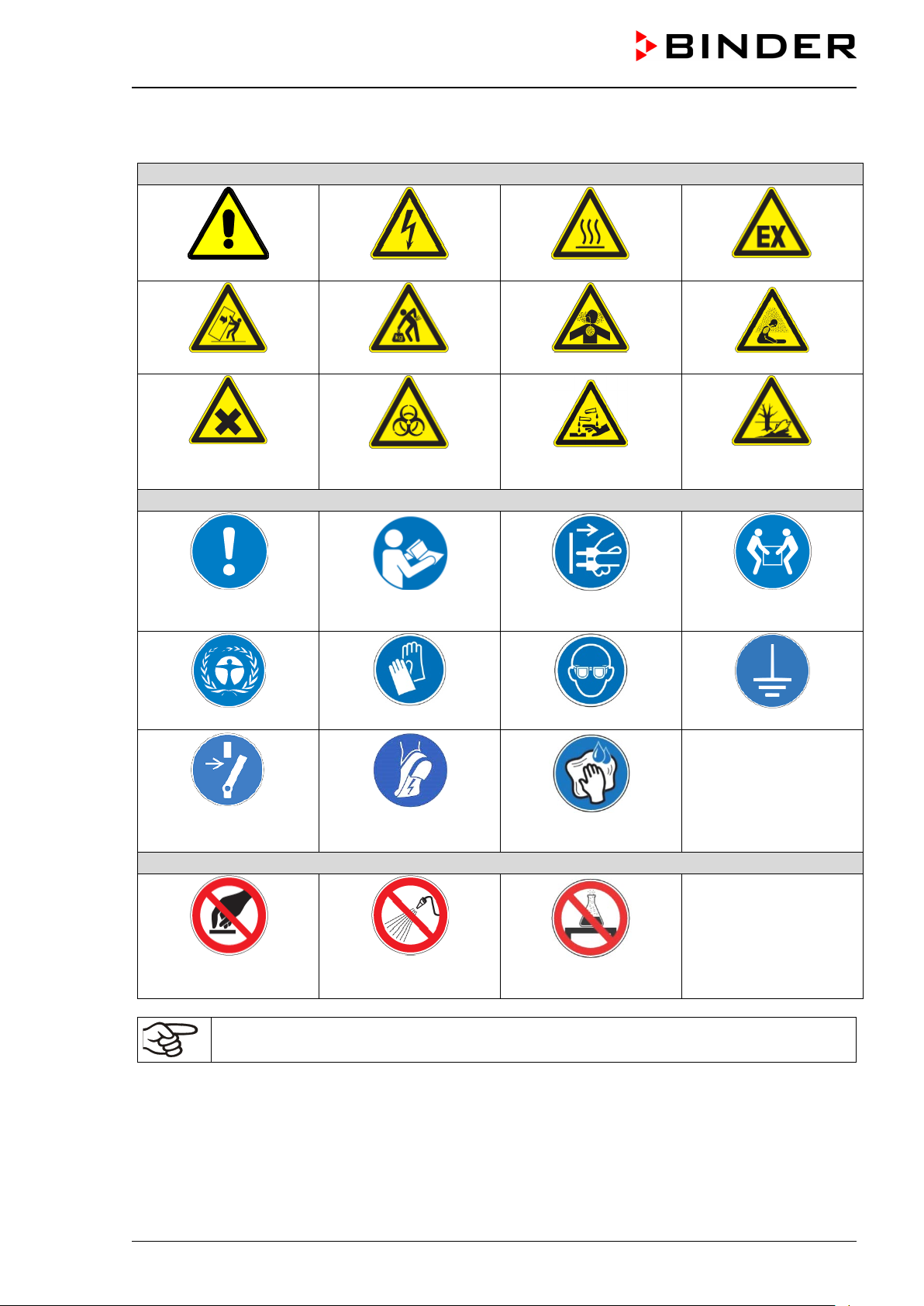

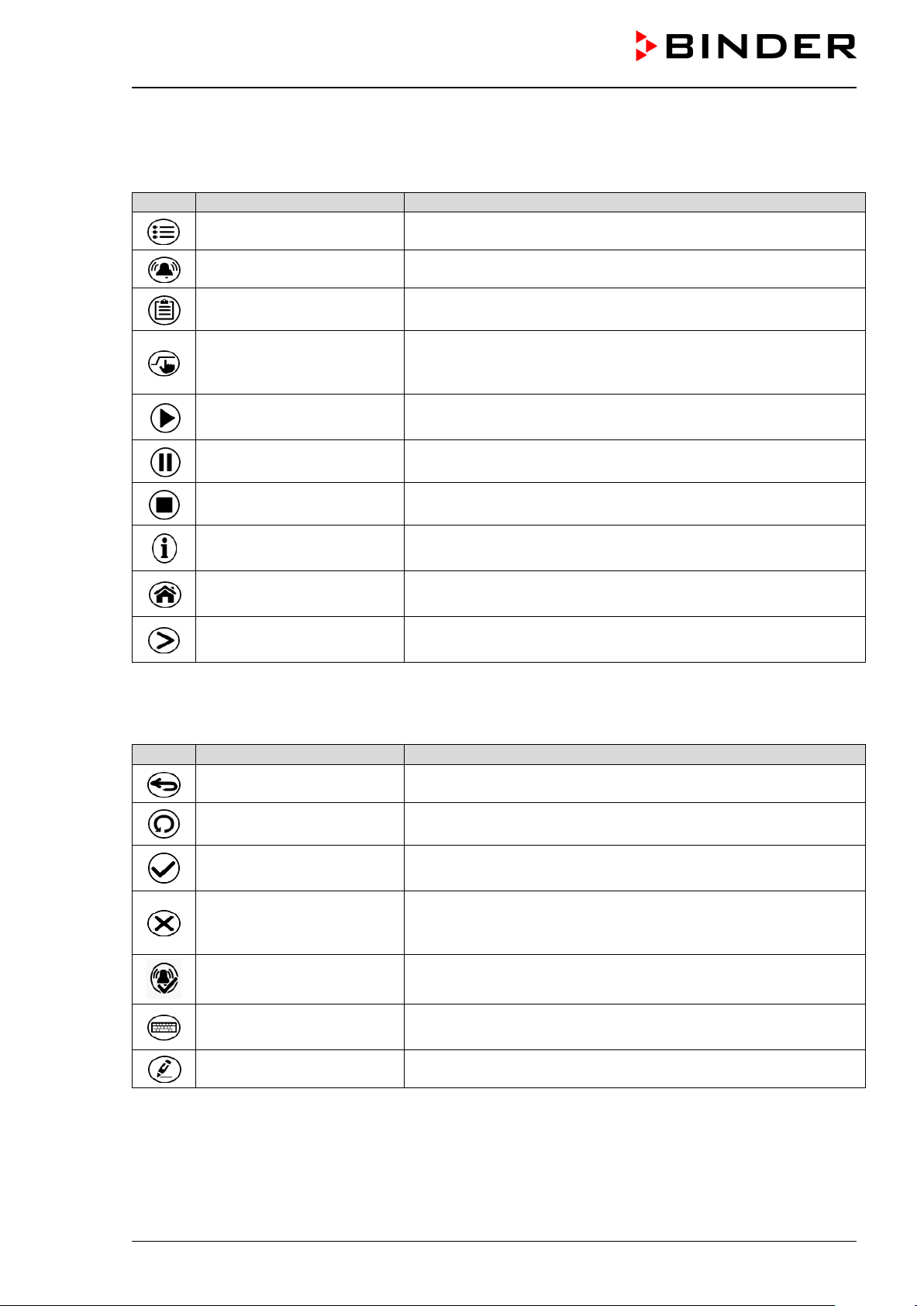

Warning signs

Danger of injury

Electrical hazard

Hot surface

Explosive atmosphere

Stability hazard

Lifting hazard

Inhalation hazard

Suffocation hazard

or chemical burns

Mandatory action signs

plug

Environment protection

Wear eye protectors

Ground before use

(antistatic shoes)

only

Prohibition signs

on the chamber

1.4.4 Pictograms in this manual

Harmful substances

Mandatory regulation

Biohazard

Read operating

instructions

Wear protective gloves

Risk of corrosion and /

Disconnect the power

Pollution Hazard

Lift with several persons

Release before mainte-

nance or repairs

Do NOT touch

Information to be observed in order to ensure optimum function of the product.

Wear ESD shoes

Do NOT spray with

water

Wipe with damp cloth

Do not place anything

VDL (E3.1) 10/2020 Page 11/196

Page 12

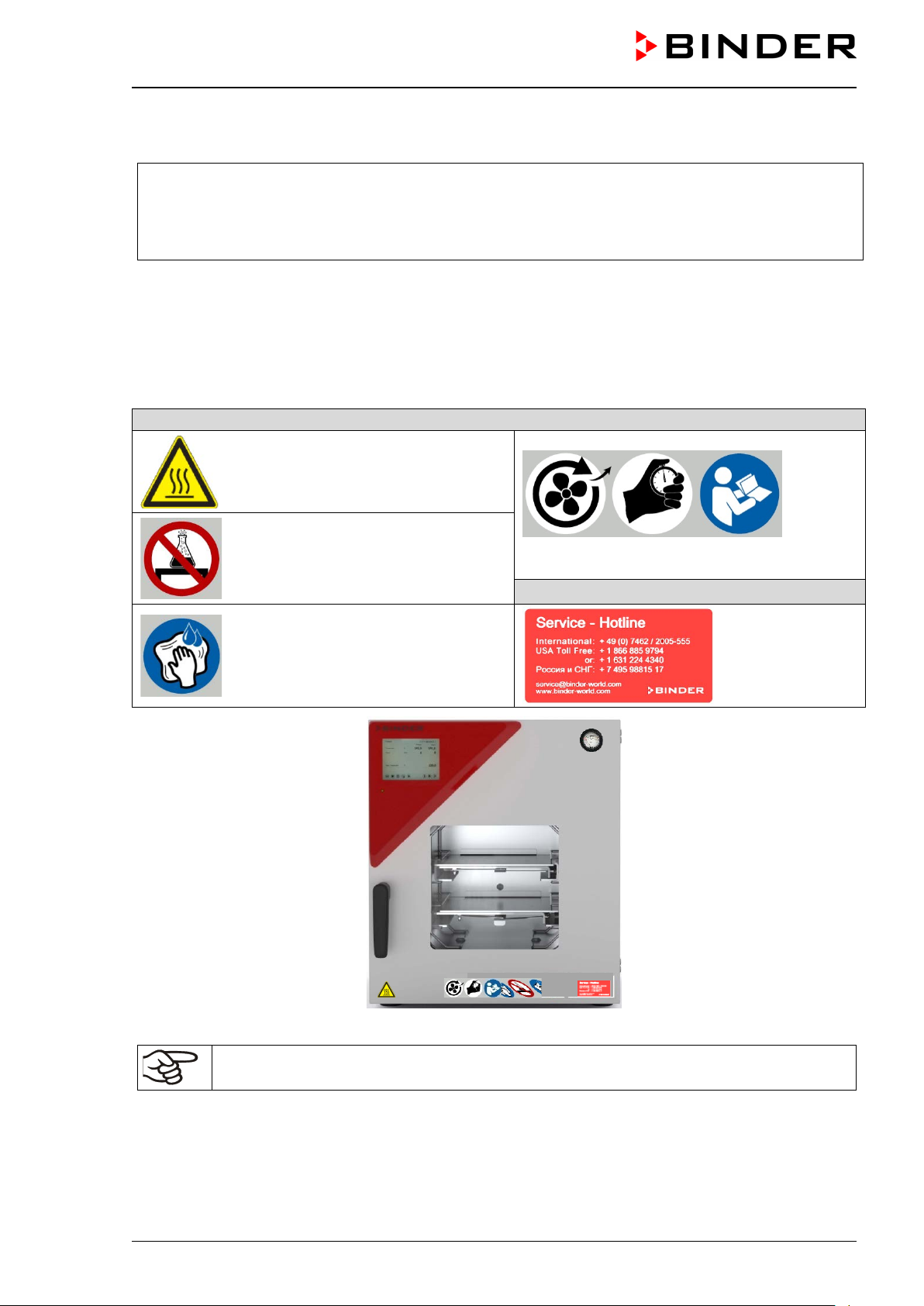

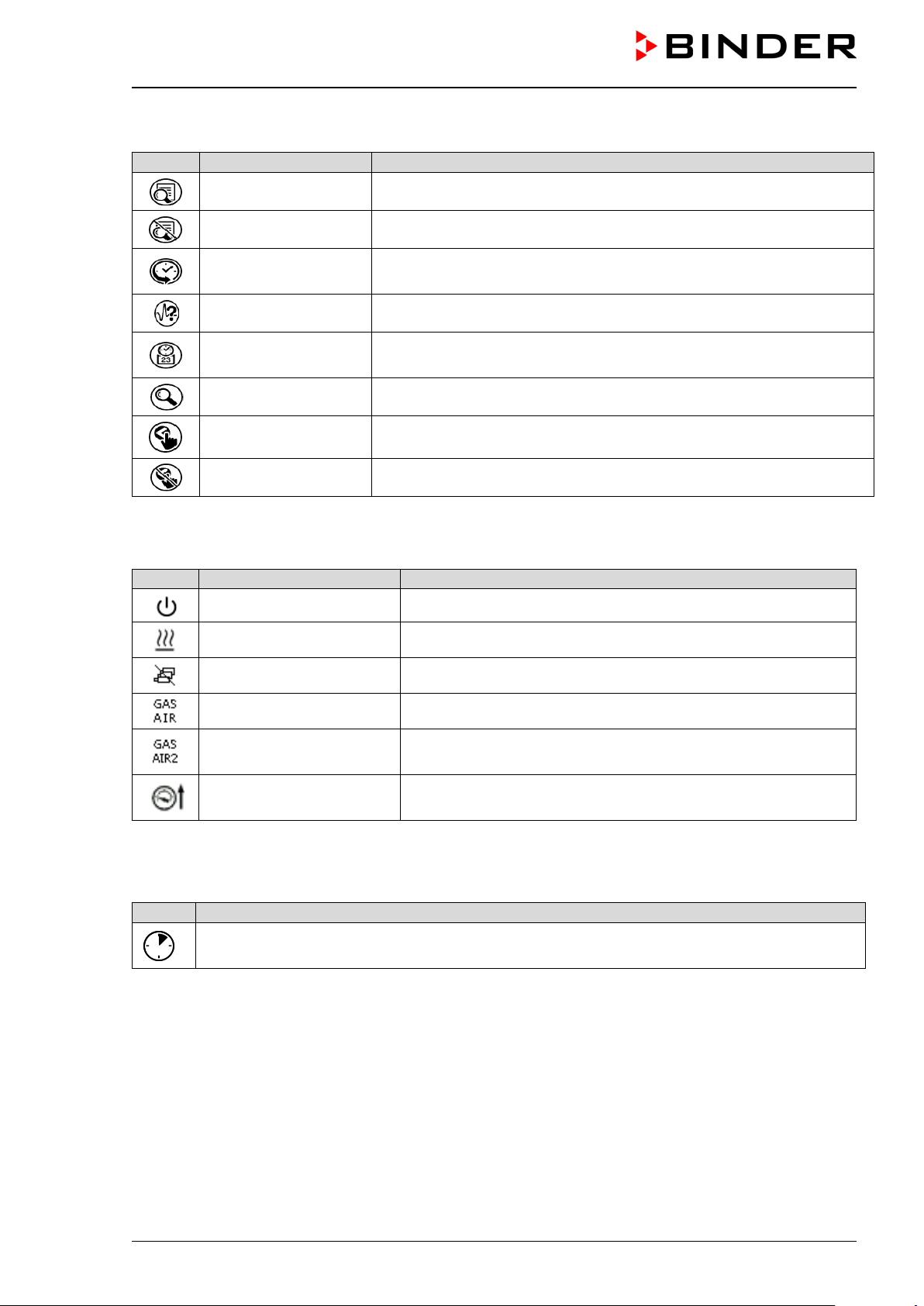

Safety labels

Service label

1.4.5 Word message panel structure

Type and cause of hazard.

Possible consequences.

∅ Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory action

Observe all other n otes and informat ion not necessarily em phasized in the sam e way, in order to a void

disruptions that could result in direct or indirect injury or property damage.

1.5 Localization / position of safety labels on the chamber

The following labels are located on the chamber door:

Hot surface

Do not place anything on the chamber

Wipe surfaces with damp cloth only

Observe sweeping time, read operating manual

Figure 1: Position of labels on the chamber (example)

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER Service for these replacements.

VDL (E3.1) 10/2020 Page 12/196

Page 13

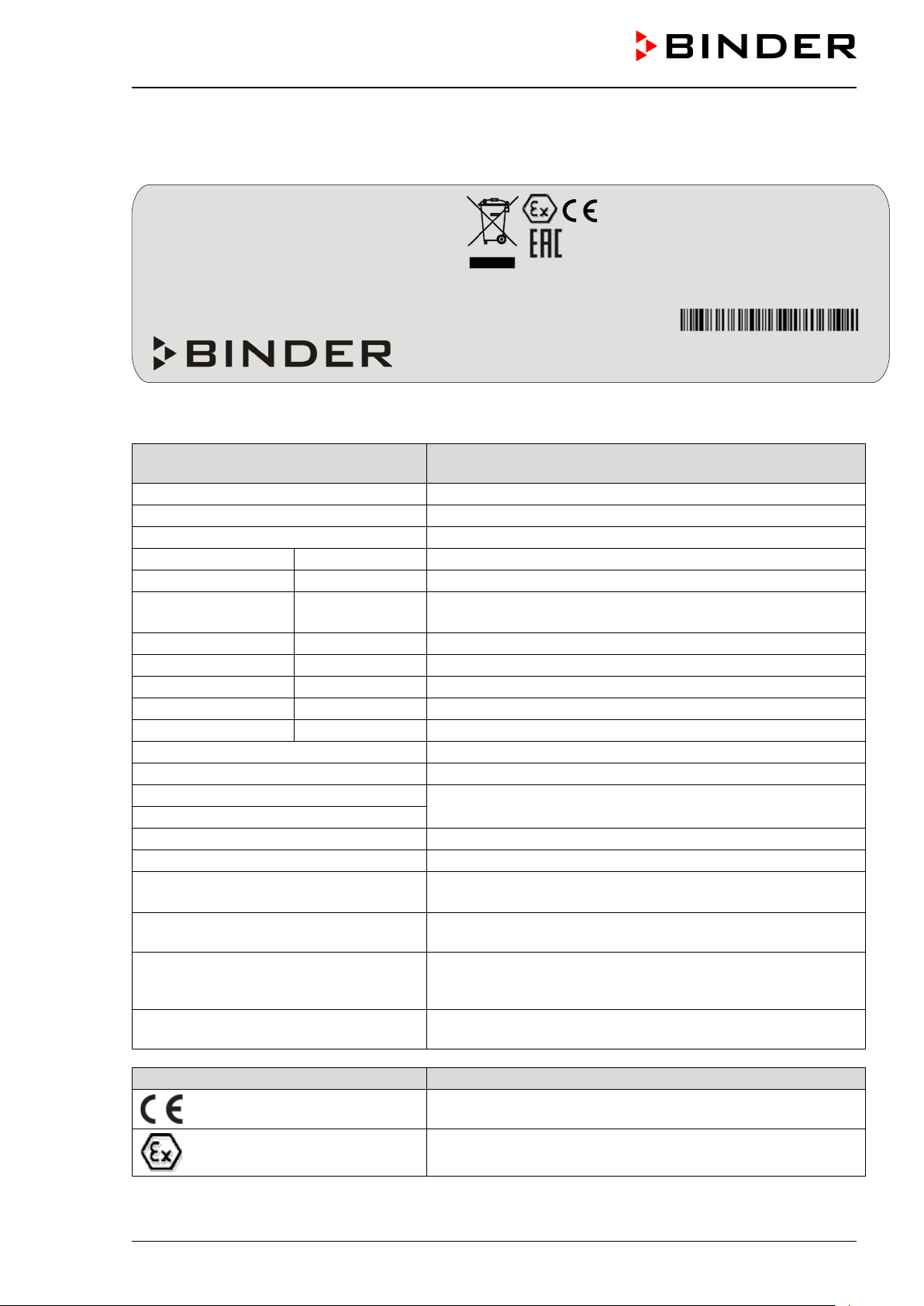

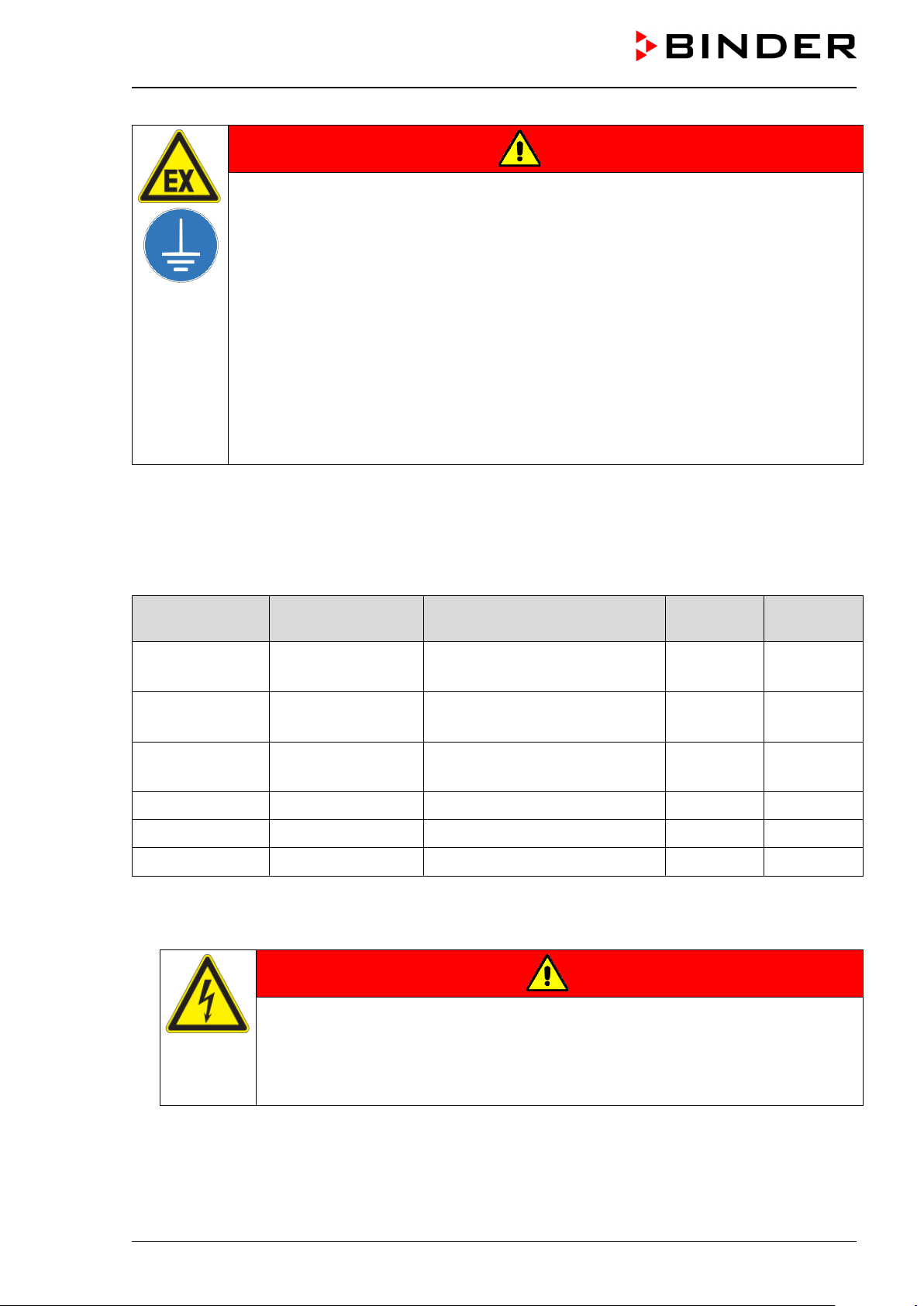

Indications of the type plate

(example)

Information

BINDER

Manufacturer: BINDER GmbH

VDL 115

Model designation

Vacuum Drying Oven

Chamber name: Vacuum drying oven

Serial No.

000000000000

Serial No. of the chamber

Built

2020

Year of construction

110 °C

230 °F

IP protection

20

Type of IP protection acc. to standard EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880:2007

Class

2.0

Class of temperature safety device

Art. No.

9630-0011

Art. No. of the chamber

Project No.

---

Optional: Special application acc. to project no.

1,60 kW

Nominal power

7,0 A

Nominal current

230 V / 50 Hz

230 V / 60 Hz

1 N ~

Current type

Explosion proof inner chamber

Explosion proof inner chamber

Ex classification acc. to 2014/34/EU

Ex II 2/3/- G IIB T3 Gb/Gc/- X

Ex classificatio n according to ATEX Directive 2014/34/EU

Max. temp. of inner chamber surface in

cat. 2: +160 °C

Maximum temperature of the inner chamber surfaces:

160 °C / 320 °F (Device category 2)

Maximum temperature of the outer surface of the preheating

3)

Temperature class acc. to IEC 60079-0 for the entire chamber

Symbol on the type plate

Information

Nominal temp.

110 °C

1,60 kW / 7,0 A

EXPLOSION PROOF INNER CHAMBER

TEMP. CLASS T3

230 V / 50 Hz

230 V / 60 Hz

1 N ~

VACUUM DRYING OVEN

BINDER GmbH

www.binder-world.com

VDL 115

1.6 Type plate

Position of type plate: left chamber side (seen from front), at the bottom right-hand.

IP protection

Safety device

Class

Art. No.

Project No.

Built

230 °F

20

DIN 12880

2.0

9630-0011

2020

Nominal temperature

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

E3.1

Figure 2: Type plate (example of VDL 115)

Nominal temperature

EX CLASSIF. ACC. TO 2014/34/EU

EX II 2/3/ - G IIB T3 GB/GC/- X

TEMP. OF INNER CHAMBER

MAX.

SURFACE IN CAT 2: +160 °C

MAX. TEMP. OF HEATING CHAMBER

SURFACE IN CAT 3: +195 °C

Serial No. 00000000000000

Made in Germany

Max. temp. of heating chamber

surface in cat. 3: +195 °C

Temp. class T3

VDL (E3.1) 10/2020 Page 13/196

Nominal voltage +/- 10% at the indicated power frequency

chamber (outer chamber): 185 °C / 365 °F (Device category

CE conformity marking

Explosion protection symbol. Ex classification acc. to ATEX

Directive 2014/34/EU

Page 14

Symbol on the type plate

Information

Electrical and electronic equipment manufactured / placed on

the market in the EU after 13 August 2005 and to be disposed of in a separate collection according to Directive

2012/19/EU on waste electrical and electronic equipment

(WEEE).

The chamber is certified according to Customs Union Technical Regulation (CU TR) for the Eurasian Economic Union

(Russia, Belarus, Armenia, Kazakhstan Kyrgyzstan).

1.7 Safety instructions on installing and operating the vacuum drying oven

With regard to o perating the vacuum dr ying o ven VDL an d to t he i nstal lation locat ion, p lease o bser ve t he

relevant national regulation s (for Germ any in partic ular: DGUV guidelines 213-850 o n safe work ing in laboratories, issued by the employers’ liability insurance association; Industrial Safety Regulation (BetrSichV); Ordinance on Hazardous Substances (GefStoffV); Technical Regulations on Industrial Safety and

Health (TRBS 1201 Part 1).

The central element of the Industrial Safet y Regulation is the risk ass essment performed by com petent

personnel which enables an employer to evaluate risks that may arise before using work equipment and to

derive necessary and suitable tests and measures.

Explosion protection plan

The explosion protection plan to be created by the operator r eprese nts the e ntiret y of the tech nica l and

organizational measures for explosion protection determined and specified on the basis of the risk assessment. In accordance with ATEX Operational Directive 1999/92/EC, these measures serve

• to prevent the formation of or to limit explosive atmospheres or to limit hazardous explosive mixtures

• to avoid the combustion of explosive atmospheres

• to limit the spread of an explosion and to minimize its effects on personnel in order to ensure the health

and safety of employees

The explosion pro tection d ocum ent serves t o docum ent the results of the r isk as sessm ent in accor dance

with § 6 Para. 9 GefStoffV (for Germany).

BINDER Gm bH is onl y responsible f or the safet y features of the cham ber provided s killed elec tricians or

qualified personnel authorized by BINDER perform all maintenance and repair, and if components relating

to chamber safety are replaced in the event of failure with original spare parts.

To operate the cham ber, use onl y original BIND ER acc essories or acc essories from third-part y suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

1.7.1 Safety instructions on installation and ambient conditions of the chamber

Familiarize yourself w ith the loca l conditions , particul arly alloca tion to a def ined potent ially exp losive area

(zones) and the according technical safety requirements. During installation, commissioning and operation

of the vacuum drying oven and the connected vacuum pump or in-house vacuum supply, always follow the

requirements defined by the classification of the installation site.

VDL (E3.1) 10/2020 Page 14/196

Page 15

1.7.1.1 Aeration / ventilation of the installation site

NOTICE

Danger of overheating due to lack of aeration.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of heat.

Observe the prescribed minimum distances when installing the chamber (chap. 5.1)

The vacuum drying ovens wer e construc ted in acc ordance with the applicab le VDE reg ulations a nd were

routinely tested in accorda n c e with VD E 041 1-1 (IEC 61010-1). The production underlies an internal monitoring according to ATEX Directive 2014/34/EU appendix VIII.

For the user there is no risk of temporary overvoltages in the sense of EN 61010-1:2010.

1.7.1.2 No installation in potentially explosive areas of Zone 1 or 0

Even when the equipment is used properly, there exists a residual risk of explosion that cannot be excluded,

particularly in relation to the environm ent of the chamber. T o minimize this risk , strictly observe the legal

regulations about how to select an appropriate location. Do not install and operate the vacuum drying oven

VDL in occasionally or continuously / for long periods / frequently potentiall y explo s ive areas .

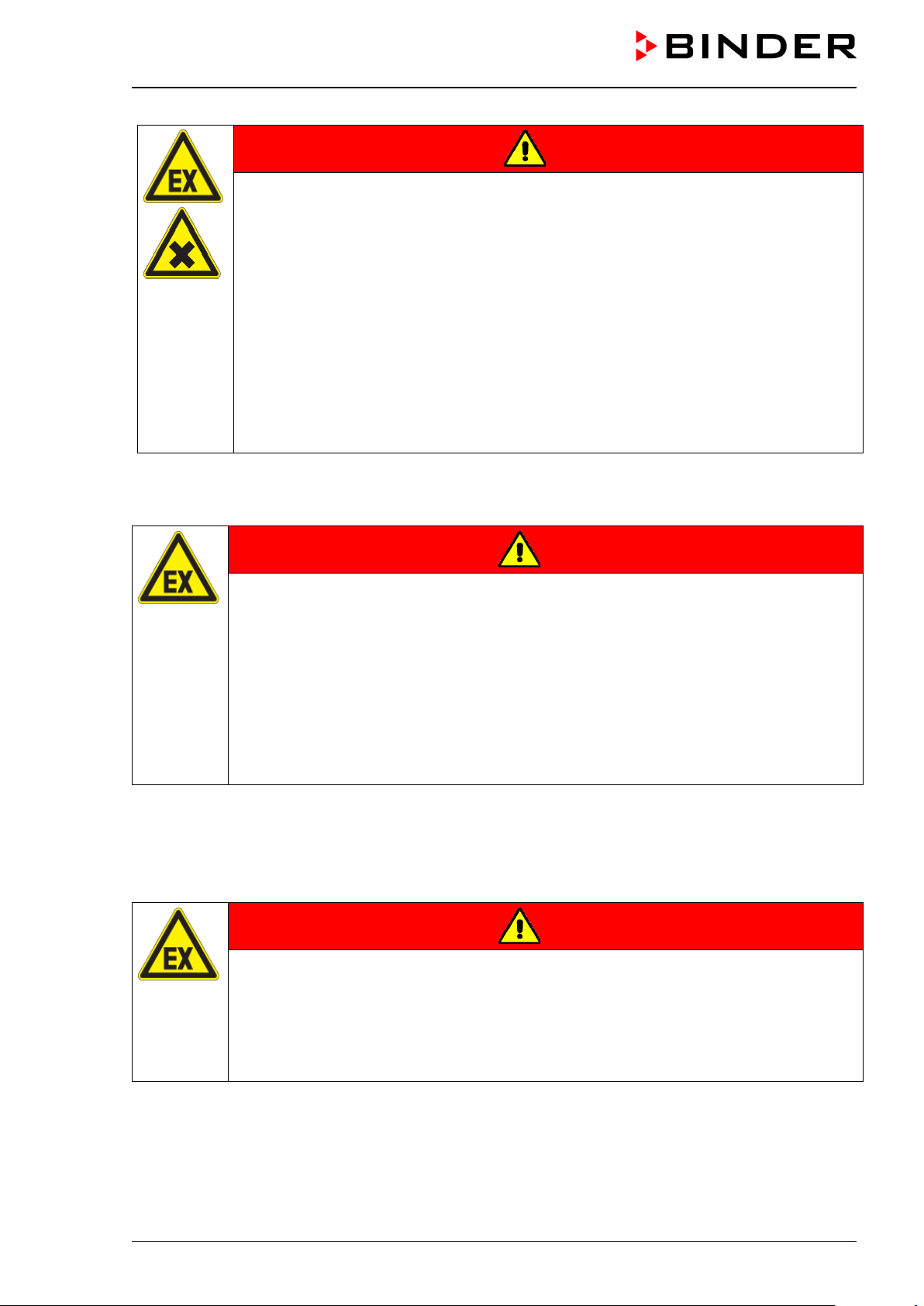

DANGER

Explosion hazard due to combustible dusts or explosive mixtures in the vicinity of

the equipment.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT operate the chamber in in occasionally or continuously / for long periods / fre-

quently potentially explosive areas. It is not intended for installation in a zone 1 or 0.

KEEP combustible dusts AWAY from the equipment

Make sure that air-solvent mixtures are NOT occasionally or continuously / for long pe-

riods / frequently in the vicinity of the equipment.

Reliably prevent spreading of an explosive atmosphere to unprotected areas (see chap.

3.5).

Strictly observe the relevant legal regulations about how to select an appropriate loca-

tion.

1.7.1.3 Equipotential bonding according to the grounding concept

The walkable install ation and o perating surf ace of the c hamber mus t be conductive. T his installat ion and

operating surface must be connected to the vacuum drying oven according to the grounding concept (chap.

6.8). Cyclic measurements of the equipotential bonding are required.

DANGER

Explosion hazard by electric sparking due to missing or improperly implemented

equipotential bonding.

Serious injury or death from burns and / or explo sion pressure.

Connect all equipment elements in the installation and operating area (VDL / pump

module / pump) with the conductive surface and/or with each other. Proceed according

to the grounding concept (Chap. 6.8).

Measure the equipotential bonding prior to commissioning the equipment.

Provide cyclic measurements of the equipotential bonding.

VDL (E3.1) 10/2020 Page 15/196

Page 16

1.7.1.4 Accessibility to the disconnection from the power grid

To completely separat e the cham ber from the power supp ly, you mus t disconnect the power plug. Install

the chamber in a way that the power plug is easily accessible and can be easily pulled in case of danger.

The chamber’s power plug is unprotected. The electrical connection must therefore be established outside

a zone.

1.7.1.5 Technical ventilation (extraction)

The operator shall provid e active ex tractio n (technic al venti lation ac c ord ing to c ou ntry-specific regulations

(TRBS 2152 Part 2 for Ger many) before comm issioning the chamber . Extraction must include t he entire

installation area of the vac uum drying oven and a vacuum pump. Observe the area classif ication in the

surroundings of the chamber (chap. 3.5.3). Extraction must be active during the entire chamber operation.

Operation, loading and unloading of t he load ing m ater ial an d rem oval of the f illed conde nsate catc hpot of

the pump must always take place under technical ventilation. If the technical ventilation fails, automatically

switch off power to the chamber.

This will prevent spreading of an explosive atmosphere to unprotected areas (see chap. 3.5).

DANGER

Explosion hazard due to the spread of an explosive atmosphere to unprotected areas and ignition due to electric sparking or hot surfaces.

Serious injury or death from burns and / or explo sion pressure.

Provide active suction (technical ventilation according to country-specific regulations

(TRBS 2152 Part 2 for Germany) prior to commissioning the chamber.

Extraction must include the entire installation area of the vacuum drying oven.

Make sure that the chamber is automatically turned off if the technical ventilation fails.

1.7.2 Safety instructions on compressed air supply

Before starting / restarting the chamber, the electrical installation room, preheating chamber, and controller

housing (triangular instr ument box) m us t be swept with c om press ed air with m axim um overpress ure for a

defined time (chap. 9.3).

Sweeping the area for electrical equipment, the preheating chamber and controller housing must take place

with an overpressure of at least 25 Pa (recommendation: >40 Pa) during the entire operation of the vacuum

drying oven. Also after termination or cancellation of the drying process, continued sweeping for at least 10

minutes is recommended.

An inlet pressure of 2 bar must be provided for compressed air sweeping. T he c ompressed air supply line

provided by the operator m ust be equipped with a monitoring device whic h clearly indicates a drop and

increase in the inlet pressure outside the permissible tolerance of ± 0.2 bar.

DANGER

Explosion hazard by solvent-containing air penetrating the electric al area of the

oven or the preheating chamber.

Serious injury or death from burns and / or explo sion pressure.

Make sure that sweeping the area for electrical equipment, preheating chamber, and

controller housing with compressed air for the defined time (chap. 9.3.2) at maximum

overpressure has been done before turning on the chamber.

Make sure that sweeping the area for electrical equipment, preheating chamber, and

controller housing with compressed air with an overpressure of at least 25 Pa (recommendation: >40 Pa) takes place during the entire operation.

Ensure that the operator compressed air supply line is equipped with active monitoring

of the defined inlet pressure.

VDL (E3.1) 10/2020 Page 16/196

Page 17

1.7.3 Safety instructions on vacuum supply

Prior to commissioning the cham ber m ake sure that all r elevant nation al and int ernational r egulations are

observed. Within the European Union, units that will be operated in potentially explosive areas have to meet

the requirements of ATEX Directive 2014/34/EU.

If combustible solvent is introduced i nto the dryin g cham ber, the vacuum pump must be constructed in a

suitable explosion-proof manner.

Observe the safety instructions of the pump manufacturer.

1.7.3.1 Selection and location of a suitable pump

The mixtures extrac ted f r om the inner chamber mus t be carr ie d a wa y m aking sure that there is no da nger

by ignition of these atmospheres. Sparking in t he p ump motor or the switchi ng elements, electrostatic discharges, as well as hot pump parts can ignite solvent vapors in the event of an error. To minimize this risk,

use an ATEX Directive 2014/34/EU com pliant vacuum pump suitable for s uction from Zone 0 or 1 and, if

appropriate, from the zone of its installation site.

Explosion hazard due to the spread of an explosive atmosphere to unprotected

pump parts and ignition due to electric sparking on the pump motor or switching elements, electrostatic discharges, or hot surfaces.

Serious injury or death from burns and / or explo sion pressure.

Use only suitable, explosion-proof pumps. See chap. 6.5.1.

Operate the pump in a stationary position and secure it so it is immobile.

Make sure that the suction line to the vacuum connection (6) of the VDL is fixed and

conductive.

Ensure sufficient solvent condensation, e.g., in an exhaust waste vapor condenser, to

avoid that ignitable solvent concentrations are conducted from the pump. Otherwise,

the exhaust pipe after the pump must be fixed and conductive and suction must be

done in an explosion-proof area.

Ensure equipotential bonding between the pump, the VDL vacuum drying oven and, if

appropriate, the pump module using the connections of the grounding conductors according to the grounding concept (Chap. 6.8).

Confirm that the vacuum pump is designed for a gas inlet temperature corresponding to

the used drying temperature, or take appropriate measures to cool down the extracted

vapor before it enters the vacuum pump.

Use ATEX compliant vacuum pumps providing an integral protective device for the

pump OR Install a current-dependent, delayed protective device for the pump (for the

triggering time of this protective device, see the manufacturer’s specifications). The protective and monitoring device must not be able to turn on independently again or be released.

Use ATEX compliant vacuum pumps providing an integral explosion proof switch OR

make sure that the switch gear box is either installed outside the hazardous area or that

it is explosion proof.

The ATEX compliant vacuum pump offered by BINDER provides an integral protective device

for the pump and an integral explosion proof switch.

DANGER

VDL (E3.1) 10/2020 Page 17/196

Page 18

1.7.3.2 Observing the permissible gas inlet temperature

Confirm that the vacuum pum p / vacuum s ystem is designe d for a gas inlet tem perature corresponding to

the used drying temperature, or take appropriate measures to cool down the extracted vapor before it enters

the vacuum pump / vacuum system. If the gas inlet temperature is too high and then becomes even warmer

by compression in th e p um p, th e r es ult ing temperature (of the gas-solvent mixture inside t he pump) could

exceed the solvent’s temperature class and auto-ignition temperature. The ATEX compliant vacuum

pumps offered by BINDER are designed for a gas inlet temperature of 40 °C / 104 °F max. Do NOT

exceed this temperature.

DANGER

Fire and explosion hazard by exceeding th e auto-ignition temperature of the solvent

due to excessive gas inlet temperature

Damage to the vacuum pump. Serious injury or death from burns and / or explosion

pressure.

∅ Do NOT exceed the maximum gas inlet temperature of the pump (ATEX compliant vac-

uum pumps from BINDER: 40 °C).

When operating with a higher set-point temperature take appropriate measures to cool

down the extracted vapor before it enters into to the vacuum pump.

1.7.3.3 Technical Ventilation (extraction)

When manipulating the vacuum pump (removing the filled condensate catchpot of the pump) or in the event

of an error (e.g. drop pi ng o r spil ling the filled condensate c atchpot) spreading of an ex p los ive atmosphere

to unprotected parts of the pump or the vacuum drying oven would be possible.

The operator must pr ovide ac tiv e extr ac tio n (technical ventilation acc ord ing t o c ou ntry-specific regulations

– TRBS 2152 P art 2 f or G e rmany) prior to comm is s ioning an d manipulating the vac uum pump. Extraction

must include the entire installation area of the vacuum drying oven, the pump and, if appropriate, the pump

module. Handling the pump always takes place under technical ventilation.

This will prevent spreading of an explosive atmosphere to unprotected chamber parts other than the defined

area (see Chap. 3.5).

DANGER

Explosion hazard due to the spread of an explosive atmosphere to unprotected

parts of the pump or the vacuum drying oven and ignition due to electric sparking

or hot surfaces.

Serious injury or death from burns and / or explo sion pressure.

Provide active suction (technical ventilation according to country-specific regulations

(TRBS 2152 Part 2 for Germany) prior to commissioning the vacuum pump.

Extraction must include the entire installation area of the vacuum drying oven, the pump

and, if appropriate, the pump module.

When using the pump module, connect an extraction system to the provided exhaust

port as described in the mounting instructions of the pump module (Art. no. 7001-0137).

VDL (E3.1) 10/2020 Page 18/196

Page 19

1.7.4 Safety instructions on the charging material

The temperature class of the inner chamber according to IEC 60079-0 can be T1, T2, or T3. Only introduce

substances with an auto-ignit ion temperature that is h igher than 200 °C / 392 °F. Yo u can use a sol vent

which would form an explosive mixture with air under normal conditions.

If the auto-ignition tem per ature of a solvent contained i n th e drying material is exceeded during the drying

process, there is an imm ediate risk of fire and explosion. This chamber is not sui table to dry substanc es

with an auto-ignition tem perature below 200 °C / 3 92 °F. Substances falling u nder explosion gro up / gas

group IIC are not permitted (e.g. carbon disulfide, hydrogen).

Combustible dusts are gener ally not permitted, neither in the vicinity nor as a load.

DANGER

Explosion hazard due to unsuitable drying material.

Serious injury or death from burns and / or explosion pressure.

∅ Do NOT introduce any substance with an auto-ignition temperaturebelow 200 °C / 392

°F into the chamber

∅ Do NOT introduce combustible dusts into the chamber.

∅ Do NOT introduce any substance which tends towards exothermal decomposition into

the chamber.

∅ Do NOT introduce any substance which comes under the explosive substance law into

the chamber.

∅ Do NOT introduce energy sources such as batteries or lithium-ion batteries into the

chamber.

∅ Do NOT introduce any substance which could lead to release of toxic gases into the

chamber.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the contained moisture co nstit uen t and its beh av ior wit h th e ad dit ion of he at ener gy and changes in pr es s ure. N o

dangerous chemical reactions must occur during the drying process.

DANGER

Fire and explosion hazard caused by chemical reactions with the addition of heat

energy and changes in pressure.

Serious injury or death from burns and / or explo sion pressure.

Make sure that no dangerous chemical reactions of the loading material can occur dur-

ing the drying process.

Familiarize yourself with any potential health risks caused by the charging material, the contained moisture constituent or by reaction products that may arise during the drying process.

Take adequate measures to exclude such risks prior to putting the VDL vacuum drying oven

into operation.

VDL (E3.1) 10/2020 Page 19/196

Page 20

1.7.5 Safety instructions on operating the vacuum drying oven

Note the following points before starting up the oven:

When loading the chamber and possibly at the moment of unloading, also in the context of

intended use, an explosive mixture may form in the working space. Define a safety area of

at least 1m from the chamber front and ensure active extraction (technica l vent ilat i on).

The walkable installation and operating surface of the chamber must be conductive. This

installation and operating surface must be connected to the vacuum drying oven according

to the grounding concept. Cyclic measurements of the equipotential bonding are required.

The operator must ensure an appropriate ventilation of the loading area in front of the

oven front prior to commissioning of the chamber.

Ensure that at no time any solvent vapors could enter in the area of the electrical installa-

tion room, preheating chamber, and controller housing (triangular instrument box).

Provide technical ventilation in the area of the vacuum pump stand, particularly in the areas

of the condensate catchpot (when emptying it) and the exhaust air of the vacuum pump.

The personal protective equipment (PPE) of the operating personnel must be ESD pro-

tected.

Only trained personnel with password authorization may work on the VDL vacuum drying

oven.

DANGER

Electrical hazard by water entering the chamber.

Deadly electric shock.

∅ The equipment must NOT become wet during operation, cleaning, or maintenance.

∅ Do NOT install the equipment in damp areas or in puddles.

Set up the equipment in a splash-proof manner.

DANGER

Electrical hazard due to damage to the equipment

Deadly electric shock.

∅ Do NOT insert any objects, particularly metallic objects, in louvers or other openings or