Page 1

Operating Manual

Translation of the original operating manual

VD (E3.1)

Vacuum Drying Oven

Standard: with RD4 microprocessor program controller

Optional: with MB2 microprocessor program controller

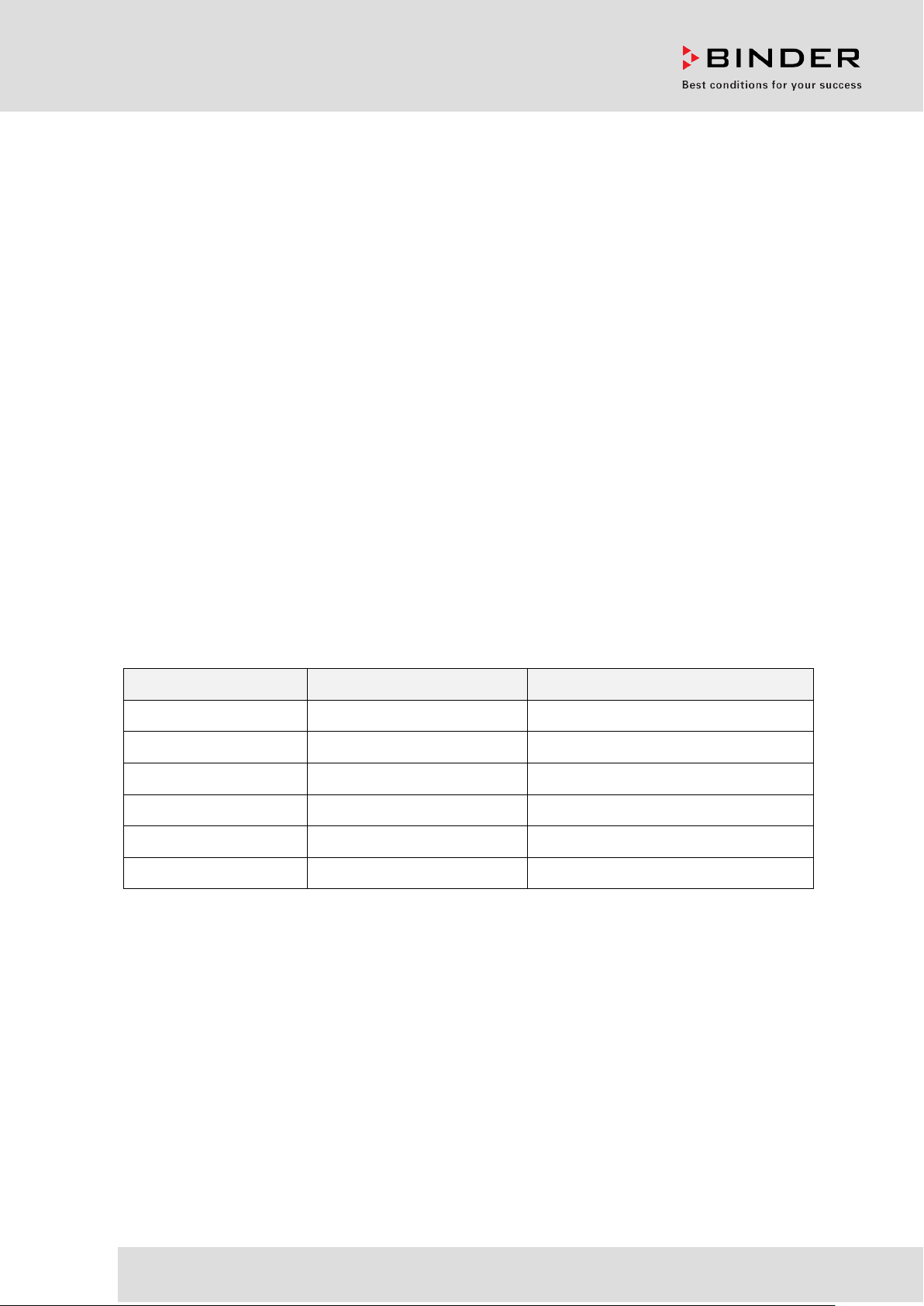

Model Model version Art. No.

VD 23 VD023-230V 9630-0001

VD 23-UL VD023UL-120V 9630-0005

VD 56 VD056-230V 9630-0002

VD 56-UL VD056UL-120V 9630-0006

VD 115 VD115-230V 9630-0003

VD 115-UL VD115UL-120V 9630-0007

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.b ind er -world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: customerservice@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacif ic: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 10/2020 Art. No. 7001-0383

Page 2

Contents

1. SAFETY .................................................................................................................. 8

1.1 Personnel Qualification ....................................................................................................................... 8

1.2 Operating manual ................................................................................................................................ 8

1.3 Legal considerations ........................................................................................................................... 8

1.4 Structure of the safety instructions ...................................................................................................... 9

1.4.1 Signal word panel ..................................................................................................................... 9

1.4.2 Safety alert symbol ................................................................................................................... 9

1.4.3 Pictograms .............................................................................................................................. 10

1.4.4 Word message panel structure ............................................................................................... 10

1.5 Localization / position of safety labels on the chamber .................................................................... 11

1.6 Type plate.......................................................................................................................................... 11

1.7 General safety instructions on installing and operating the chamber ............................................... 12

1.8 Intended use ..................................................................................................................................... 14

1.9 Foreseeable Misuse .......................................................................................................................... 16

1.10 Residual Risks .................................................................................................................................. 16

1.11 Operating instructions ....................................................................................................................... 18

1.12 Measures to prevent accidents ......................................................................................................... 18

2. DESCRIPTION OF THE EQUIPMENT ................................................................. 19

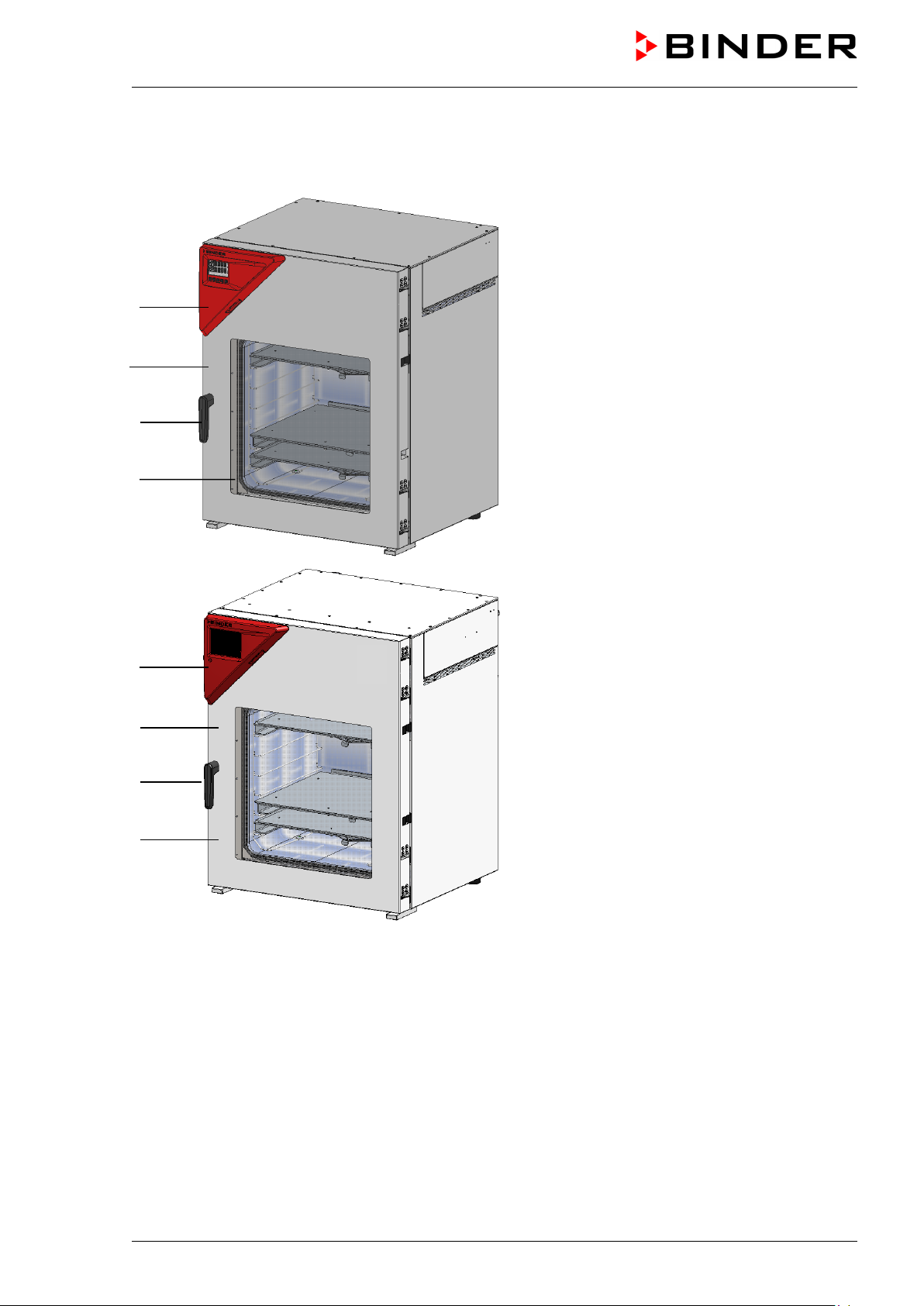

2.1 Chamber overview ............................................................................................................................ 20

2.2 Instrument panel with regular RD4 controller.................................................................................... 21

2.3 Instrument panel with optional MB 2 contr ol ler .................................................................................. 21

2.4 Connections on the rear of the chamber ........................................................................................... 21

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 23

3.1 Unpacking, and checking equipment and completeness of delivery ................................................ 23

3.2 Guidelines for safe lifting and transportation ..................................................................................... 24

3.3 Storage .............................................................................................................................................. 24

3.4 Location of installation and ambient conditions ................................................................................ 24

4. INSTALLATION AND CONNECTIONS ............................................................... 26

4.1 Vacuum expansion racks and rack holders ...................................................................................... 26

4.2 Mounting the tilt protection holders ................................................................................................... 27

4.3 Pump module (option) ....................................................................................................................... 28

4.3.1 Pump module without pump (option) ...................................................................................... 29

4.3.2 Pump module with pump stand (option) ................................................................................. 29

4.4 Vacuum connection ........................................................................................................................... 31

4.4.1 VD connection kit for VAP1-VAP2 (option) ............................................................................. 31

4.5 Connecting inert gas supply .............................................................................................................. 32

4.6 Electrical connection ......................................................................................................................... 33

5. FUNCTIONAL OVERVIEW AND MENU STRUCTURE O F THE CONTROLLER 34

5.1 RD4 controller ................................................................................................................................... 34

5.1.1 Menu structure of the controller and access levels ................................................................ 35

5.2 MB2 controller ................................................................................................................................... 36

5.2.1 Operating functions in normal display ..................................................................................... 37

5.2.2 Display views: Normal display, program display, chart-recorder display ............................... 38

5.2.3 MB2 controller icons overview ................................................................................................ 39

5.2.4 MB2 controller operating modes ............................................................................................. 41

5.2.5 MB2 controller menu structure ................................................................................................ 41

5.2.5.1 Main menu ....................................................................................................................... 42

5.2.5.2 “Settings” submenu ......................................................................................................... 43

5.2.5.3 “Service” submenu .......................................................................................................... 43

5.2.6 Principle of controller entries .................................................................................................. 44

VD (E3.1) 10/2020 page 2/179

Page 3

Performance during and after power failures .................................................................................... 44

5.3

5.3.1 RD4 controller ......................................................................................................................... 44

5.3.2 MB2 controller ......................................................................................................................... 45

6. START UP ............................................................................................................ 45

6.1 Condition after establishing the power connection ........................................................................... 45

6.2 Standby mode: Turning on and off the vacuum drying oven ............................................................ 46

6.2.1 RD4 controller ......................................................................................................................... 46

6.2.2 MB2 controller ......................................................................................................................... 47

6.3 Controller settings upon start up ....................................................................................................... 48

6.3.1 RD4 controller ......................................................................................................................... 48

6.3.2 MB2 controller ......................................................................................................................... 48

6.4 Vacuum system ................................................................................................................................. 49

6.4.1 Evacuation .............................................................................................................................. 49

6.4.2 Ventilation after completing the drying procedure (flooding with ambient air or inert gas) ..... 50

6.4.3 Ventilation / breaking the vacuum in case of a power failure ................................................. 50

6.4.4 Operation with inert gas .......................................................................................................... 50

7. SET-POINT ENTRY .............................................................................................. 51

7.1 RD4 controller ................................................................................................................................... 51

7.1.1 Temperature set-point entry ................................................................................................... 51

7.1.2 Pressure set-point entry .......................................................................................................... 52

7.2 MB2 controller ................................................................................................................................... 52

7.2.1 Set-point entry through the “Setpoints” menu ......................................................................... 52

7.2.2 Direct setpoint entry via Normal display ................................................................................. 53

8. SETTING SPECIAL CONTROLLER FUNCTIONS .............................................. 54

8.1 Menu structure .................................................................................................................................. 54

8.1.1 RD4 controller ......................................................................................................................... 54

8.1.1.1 “Functions on/off” menu................................................................................................... 54

8.1.1.2 Quick Access menu ......................................................................................................... 55

8.1.2 MB2 controller ......................................................................................................................... 55

8.1.2.1 “Functions on/off” menu................................................................................................... 55

8.1.2.2 “Control on/off” menu ....................................................................................................... 57

8.2 Turning off the vacuum pump via the socket on the pump module .................................................. 57

8.2.1 RD4 controller ......................................................................................................................... 57

8.2.2 MB2 controller ......................................................................................................................... 58

8.3 Using the optional universal connection “GAS/AIR 2” for ventilation ................................................ 58

8.3.1 RD4 controller ......................................................................................................................... 59

8.3.2 MB2 controller ......................................................................................................................... 59

8.4 Close all valves ................................................................................................................................. 60

8.4.1 RD4 controller ......................................................................................................................... 60

8.4.2 MB2 controller ......................................................................................................................... 60

8.5 Activating / deactivating temperature control .................................................................................... 61

8.5.1 RD4 controller ......................................................................................................................... 61

8.5.2 MB2 controller ......................................................................................................................... 61

8.6 Activating / deactivating pressure control ......................................................................................... 62

8.6.1 RD4 controller ......................................................................................................................... 62

8.6.2 MB2 controller ......................................................................................................................... 63

8.7 Drying monitoring .............................................................................................................................. 64

8.7.1 RD4 controller ......................................................................................................................... 65

8.7.2 MB2 controller ......................................................................................................................... 65

9. AUTHORIZATION LEVELS AND PASSWORD PROTECTION .......................... 66

9.1 RD4 controller ................................................................................................................................... 66

9.1.1 Password request ................................................................................................................... 66

9.1.2 Assign and modify a password ............................................................................................... 66

9.1.2.1 Assign and modify the User password ............................................................................ 66

9.1.2.2 Assign and modify the Admin password ......................................................................... 67

VD (E3.1) 10/2020 page 3/179

Page 4

MB2 controller ................................................................................................................................... 68

9.2

9.2.1 User management, authorization levels and password protection ......................................... 68

9.2.2 Log in ...................................................................................................................................... 71

9.2.3 Log out .................................................................................................................................... 72

9.2.4 User change ............................................................................................................................ 72

9.2.5 Password assignment and password change ........................................................................ 73

9.2.5.1 Password change ............................................................................................................ 73

9.2.5.2 Deleting the password for an individual authorization level ............................................ 75

9.2.5.3 New password assignment for “service” or “admin” authorization level when the

password function was deactiva ted .................................................................................................. 76

9.2.6 Activation code ........................................................................................................................ 77

10. GENERAL CONTROLLER SETTINGS AND INFORMATION ............................. 78

10.1 RD4 controller ................................................................................................................................... 78

10.1.1 Selecting the controller’s menu language ............................................................................... 78

10.1.2 Selecting the temperature unit ................................................................................................ 78

10.1.3 Setting the current date........................................................................................................... 79

10.1.4 Setting the current time ........................................................................................................... 80

10.1.5 Function “Language selection at restart” ................................................................................ 80

10.1.6 Setting the chamber address .................................................................................................. 81

10.1.7 Display bright n ess ................................................................................................................... 81

10.1.8 Display of the inner chamber temperature and the heating temperature ............................... 81

10.2 MB2 controller ................................................................................................................................... 82

10.2.1 Selecting the controller’s menu language ............................................................................... 82

10.2.2 Setting date and time .............................................................................................................. 82

10.2.3 Selecting the temperature unit ................................................................................................ 84

10.2.4 Display configuration............................................................................................................... 84

10.2.4.1 Adapting the display parameters ..................................................................................... 84

10.2.4.2 Touchscreen calibration .................................................................................................. 85

10.2.5 Event lis t ................................................................................................................................. 86

10.2.6 Service contact page .............................................................................................................. 86

10.2.7 Current operating parameters ................................................................................................. 87

10.2.8 Technical chamber information ............................................................................................... 87

11. TEMPERATURE SAFETY DEVICES ................................................................... 88

11.1 Over temperature protective device class 2 (thermal switch) ........................................................... 88

11.2 Overtemperature safety controller class 2 ........................................................................................ 88

11.2.1 Safety controller mode ............................................................................................................ 88

11.2.2 Setting the safety controller .................................................................................................... 89

11.2.2.1 RD4 controller: Setting the safety controller mode .......................................................... 89

11.2.2.2 RD4 controller: Setting the safety controller value .......................................................... 89

11.2.2.3 MB2 controller ................................................................................................................. 90

11.2.3 Message and measures in the state of alarm ......................................................................... 91

11.2.3.1 RD4 controller .................................................................................................................. 91

11.2.3.2 MB2 controller ................................................................................................................. 91

11.2.4 Function check ........................................................................................................................ 92

12. TOLERANCE RANGE SETTINGS ....................................................................... 92

12.1 RD4 controller ................................................................................................................................... 92

12.1.1 Setting the delay time for temperature tolerance range alarm ............................................... 92

12.1.2 Setting the temperature tolerance range ................................................................................ 92

12.1.3 Setting the delay time for pressure tolerance range alarm ..................................................... 93

12.1.4 Setting the pressure tolerance range ...................................................................................... 93

12.1.5 State of alarm .......................................................................................................................... 93

12.2 MB2 controller ................................................................................................................................... 94

12.2.1 Setting the alarm delay times and the tolerance ra ng e s ........................................................ 94

12.2.2 Alarm condition ....................................................................................................................... 94

VD (E3.1) 10/2020 page 4/179

Page 5

13. NOTIFICATION AND ALARM FUNCTIONS ........................................................ 95

13.1 Information messages ....................................................................................................................... 95

13.1.1 RD4 controller ......................................................................................................................... 95

13.1.2 MB2 controller ......................................................................................................................... 96

13.2 Alarm messages ............................................................................................................................... 97

13.2.1 RD4 controller ......................................................................................................................... 97

13.2.2 MB2 controller ......................................................................................................................... 98

13.3 Resetting an alarm ............................................................................................................................ 99

13.3.1 RD4 controller ......................................................................................................................... 99

13.3.2 MB2 controller ......................................................................................................................... 99

13.4 Activating / deactivating the audible alarm (buzzer) ....................................................................... 100

13.4.1 RD4 controller ....................................................................................................................... 100

13.4.2 MB2 controller ....................................................................................................................... 100

14. RD4 CONTROLLER: PROGRAM START / STOP FUNCTION ......................... 101

14.1 Start time program .......................................................................................................................... 101

14.2 Start week program ......................................................................................................................... 101

14.3 Stop program .................................................................................................................................. 102

15. MB2 CONTROLLER: TIMER PROGRAM (STOPWATCH FUNCTION) ............ 103

15.1 Starting a timer program ................................................................................................................. 103

15.1.1 Performance during program delay time .............................................................................. 103

15.2 Stopping a running timer program .................................................................................................. 104

15.2.1 Pausing a running timer program ......................................................................................... 104

15.2.2 Cancelling a running timer program ...................................................................................... 104

15.3 Performance after the end of the program ...................................................................................... 104

16. MB2 CONTROLLER: TIME PROGRAMS .......................................................... 105

16.1 Starting an existing time program ................................................................................................... 105

16.1.1 Performance during program delay time .............................................................................. 106

16.2 Stopping a running time program .................................................................................................... 106

16.2.1 Pausing a running time program ........................................................................................... 106

16.2.2 Cancelling a running time program ....................................................................................... 106

16.3 Performance after the end of the program ...................................................................................... 106

16.4 Creating a new time program .......................................................................................................... 107

16.5 Program editor: program management ........................................................................................... 107

16.5.1 Deleting a time program........................................................................................................ 108

16.6 Section editor: section management ............................................................................................... 109

16.6.1 Add a new program section .................................................................................................. 110

16.6.2 Copy and insert or replace a program section ...................................................................... 110

16.6.3 Deleting a program section ................................................................................................... 111

16.7 Value entry for a program section ................................................................................................... 112

16.7.1 Section duration .................................................................................................................... 112

16.7.2 Set-point ramp and set-point step ......................................................................................... 113

16.7.3 Special controller functions ................................................................................................... 114

16.7.4 Setpoint entry ........................................................................................................................ 115

16.7.5 Tolerance range .................................................................................................................... 115

16.7.6 Repeating one or several sections within a time program .................................................... 116

16.7.7 Saving the time program ....................................................................................................... 117

17. MB2 CONTROLLER: WEEK PROGRAMS........................................................ 118

17.1 Starting an existing week program .................................................................................................. 118

17.2 Cancelling a running week program ............................................................................................... 118

17.3 Creating a new week program ........................................................................................................ 119

17.4 Program editor: program management ........................................................................................... 120

17.4.1 Deleting a week program ...................................................................................................... 121

17.5 Section editor: section management ............................................................................................... 122

17.5.1 Add a new program section .................................................................................................. 123

17.5.2 Copy and insert or replace a program section ...................................................................... 123

17.5.3 Deleting a program section ................................................................................................... 124

VD (E3.1) 10/2020 page 5/179

Page 6

Value entry for a program section in the Section view .................................................................... 124

17.6

17.6.1 Set-point ramp and set-point step modes ............................................................................. 124

17.6.2 Weekday ............................................................................................................................... 125

17.6.3 Start time ............................................................................................................................... 125

17.6.4 Setpoint entry ........................................................................................................................ 125

17.6.5 Special controller functions ................................................................................................... 126

18. NETWORK AND COMMUNICATION ................................................................ 126

18.1 RD4 controller: Ethernet network settings ...................................................................................... 126

18.1.1 Showing the network settings ............................................................................................... 126

18.1.1.1 Showing the chamber’s MAC address .......................................................................... 126

18.1.1.2 Showing the IP address................................................................................................. 127

18.1.1.3 Showing the subnet mask ............................................................................................. 127

18.1.1.4 Showing the standard gateway ..................................................................................... 127

18.1.1.5 Showing the DNS server address ................................................................................. 128

18.1.1.6 Showing the DNS chamber name ................................................................................. 128

18.1.2 Changing the configuration of the network settings .............................................................. 128

18.1.2.1 Selecting the type of IP address assignment (automatic / manual) .............................. 129

18.1.2.2 Selecting the type of assignment of the DNS server address (automatic / manual) ..... 129

18.1.2.3 Assigning the IP address ............................................................................................... 129

18.1.2.4 Setting the subnet mask ................................................................................................ 130

18.1.2.5 Setting the standard gateway ........................................................................................ 131

18.1.2.6 Assigning the DNS server address ............................................................................... 131

18.2 MB2 controller ................................................................................................................................. 132

18.2.1 Ethernet ................................................................................................................................ 132

18.2.1.1 Configuration ................................................................................................................. 132

18.2.1.2 Display of MAC address ................................................................................................ 133

18.2.2 Web server ............................................................................................................................ 133

18.2.3 E-Mail .................................................................................................................................... 134

19. RD4 CONTROLLER: DATA RECORDER ......................................................... 135

19.1 Recorded data ................................................................................................................................. 135

19.2 Storage capacity ............................................................................................................................. 135

19.3 Setting the storage rate for the “DL1” recorder data ....................................................................... 136

19.4 Deleting the data recorder............................................................................................................... 136

20. USB MENU: DATA TRANSFER VIA USB INTERFACE ................................... 136

20.1 RD4 controller ................................................................................................................................. 136

20.1.1 Connecting the USB stick ..................................................................................................... 137

20.1.2 Import function ...................................................................................................................... 137

20.1.3 Export functions .................................................................................................................... 137

20.1.4 Ongoing data transfer ........................................................................................................... 138

20.1.5 Error during data transmission .............................................................................................. 138

20.1.6 Removing the US B stick ....................................................................................................... 138

20.2 MB2 controller ................................................................................................................................. 138

21. MB2 CONTROLLER: CHART RECORDER DISPLAY ...................................... 140

21.1 Views ............................................................................................................................................... 140

21.1.1 Show and hide legend .......................................................................................................... 140

21.1.2 History display ....................................................................................................................... 140

21.2 Setting the parameters .................................................................................................................... 143

22. REFERENCE MEASUREMENTS ...................................................................... 144

22.1 Checking the temperature in the inner chamber ............................................................................. 144

22.1.1 Checking the controller display ............................................................................................. 144

22.1.2 Checking the spatial temperature exactitude ....................................................................... 144

23. OPTIONS ............................................................................................................ 145

23.1 APT-COM™ 4 Multi Management software (Option) ..................................................................... 145

VD (E3.1) 10/2020 page 6/179

Page 7

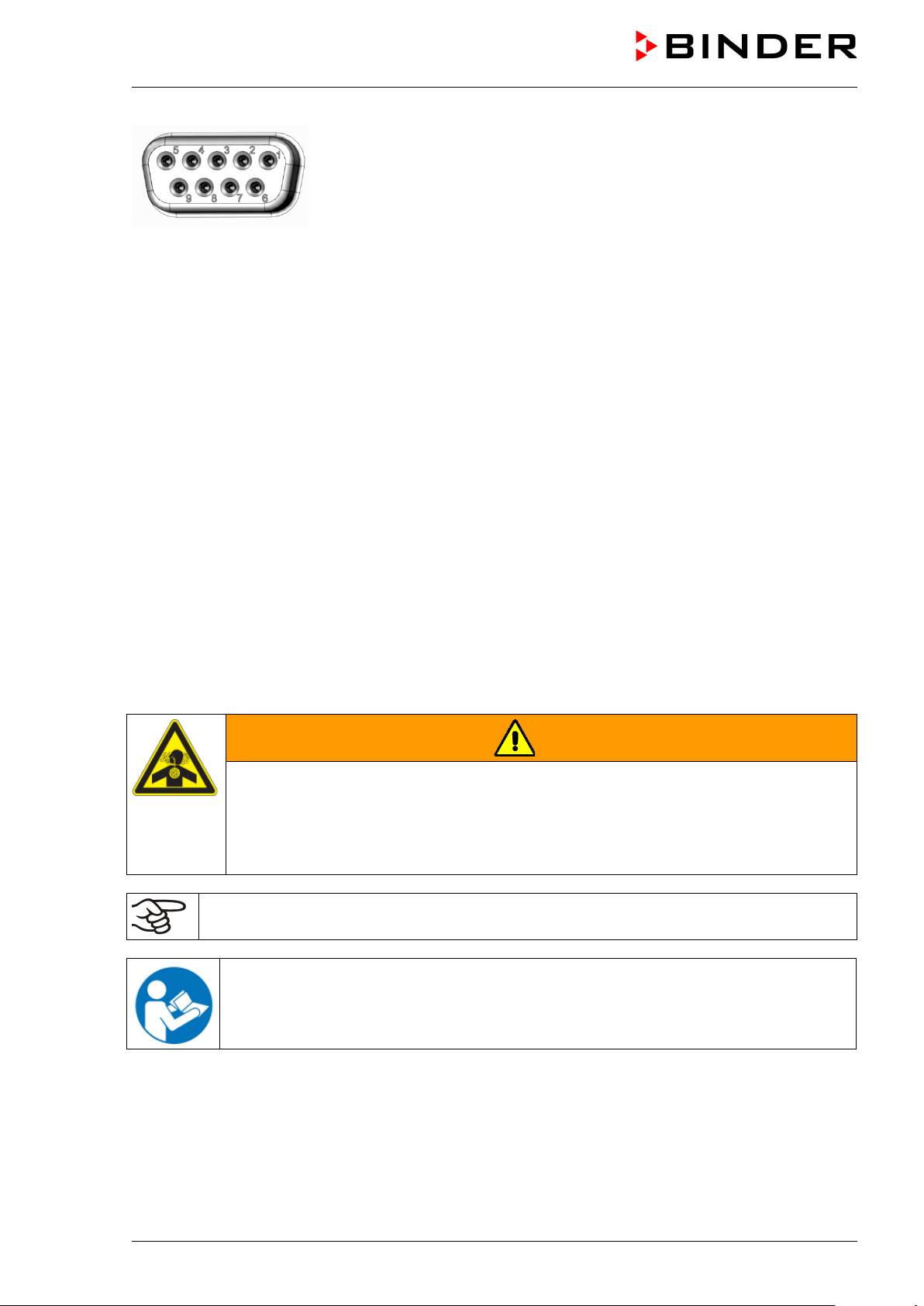

Analog outputs for temperature and pressure (option) ................................................................... 145

23.2

23.3 Measuring access port for vacuum, 9 poles (option) ...................................................................... 145

23.4 Object temperature display with flexible Pt 100 temperature sensor (option) ................................ 146

23.4.1 Connection of the object temperature sensor ....................................................................... 146

23.4.2 Display on the RD4 controller ............................................................................................... 147

23.4.3 Display on the MB2 controller ............................................................................................... 147

23.5 LED interior lighting ......................................................................................................................... 147

24. CLEANING AND DECONTAMINATION ............................................................ 148

24.1 Cleaning .......................................................................................................................................... 148

24.2 Decontamination / chemical disinfection ......................................................................................... 149

25. MAINTENANCE AND SERVICE, TROUBLESHOOTING, REPAIR, TESTING . 151

25.1 General information, personnel qualification................................................................................... 151

25.2 Simple troubleshooting .................................................................................................................... 151

25.3 Maintenance intervals, service ........................................................................................................ 154

25.4 Service Reminder ............................................................................................................................ 154

25.4.1 RD4 controller ....................................................................................................................... 154

25.4.2 MB2 controller ....................................................................................................................... 155

25.5 Sending the chamber back to BINDER GmbH ............................................................................... 155

26. DISPOSAL.......................................................................................................... 156

26.1 Disposal of the transport packing .................................................................................................... 156

26.2 Decommissioning ............................................................................................................................ 156

26.3 Disposal of the chamber in the Federal Republic of Germany ....................................................... 157

26.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany.......................................................................................................................................... 158

26.5 Disposal of the chamber in non-member states of the EU ............................................................. 159

27. TECHNICAL DESCRIPTION .............................................................................. 160

27.1 Factory calibration and adjustment ................................................................................................. 160

27.2 Over current protection ................................................................................................................... 160

27.3 VD / VD-UL technical data .............................................................................................................. 160

27.4 Equipment and options (extract) ..................................................................................................... 162

27.5 Accessories and spare parts (extract) ............................................................................................ 163

27.6 Dimensions...................................................................................................................................... 165

27.6.1 VD 23 .................................................................................................................................... 165

27.6.2 VD 56 .................................................................................................................................... 166

27.6.3 VD 115 .................................................................................................................................. 167

28. CERTIFICATES AND DECLARATIONS OF CONFORMITY ............................. 168

28.1 EU Declaration of Conformity.......................................................................................................... 168

28.2 Certificate for the GS mark of conformity of the “Deutsche Gesetzliche Unf al lver si c herung e.V .”

(German Social Accident Insurance) DGUV ................................................................................... 171

29. PRODUCT REGISTRATION .............................................................................. 173

30. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 174

30.1 For chambers located outside USA and Canada ........................................................................... 174

30.2 For chambers located in USA and Canada .................................................................................... 177

VD (E3.1) 10/2020 page 7/179

Page 8

Dear customer,

For the correct oper ation of the chamber, it is important that you read this operating manual completel y

and carefully and observe all instructions as indicated. Failure to read, understand and follow the

instructions may result in personal injury. It can also lead to damage to the chamber and/or poor

equipment performance.

1. Safety

1.1 Personnel Qualification

The chamber m ust only be installed, tested, and start ed up by personn el qualified f or assembl y, startup,

and operation of the chamber. Qualified personnel are persons whose professional education,

knowledge, experience an d k nowledge of rele vant stan dards allow th em to assess, car ry out, and ide ntif y

any potential hazards in the work assigned to them. T hey must hav e been tra ined and instructe d, and be

authorized, to work on the chamber .

The chamber should only be operated by laboratory personnel especially trained for this purpose and

familiar with all precautionary measures required for working in a laboratory. Observe the national

regulations on minimum age of laboratory personnel.

1.2 Operating manual

This operating m anual is part of the com ponents of delivery. Alwa ys keep it handy for refer ence in the

vicinity of the chamber. If selling the unit, hand over the operating manual to the purchaser.

To avoid injuries and damage obs erve the safety instructions of the opera ting manual. Failure to follow

instructions and safety precautions can lead to significant risks.

DANGER

Dangers due to failure to observe the ins truc tions and safety precautions.

Serious injuries and chamber damage. Risk of death.

Observe the safety instructions in this Operating Manual.

Follow the operating procedures in this Operating Manual.

Carefully read the complete operating instructions of the chamber prior to installing and

using the chamber.

Keep the operating manual for future reference

Make sure that all persons who use the chamber and its associated work equipment have

read and understood the Operating Manual.

This Operating Manu al is supplem ented and updated as needed. Al ways use the m ost recent version of

the Operating Manual. When in doubt, call the BINDER Service Hotline for information on the up-todateness and validity of this Operating Manual.

1.3 Legal considerations

This operating manual is for informational purposes only. It contains information for correct and safe

installing, start-up, operation, decommissioning, cleaning and maintenance of the product. Note: the

contents and the product descr ibed are subj ect to cha nge with out not ice.

Understanding and obs erving the instructions in this oper ating manual are prerequisites f or hazard-free

use and safety dur ing oper ation and m ainte nance. Im ages are to pro vide basic under stan ding. The y ma y

deviate from the actual version of the chamber. The actual scope of delivery can, due to optional or

special design, or due to re cent technical cha nges, devi ate from the inform ation and illustr ations in these

instructions this op erating manual. In no event shall BINDER be held liable for any dam ages, direct or

incidental arising out of or related to the use of this manual.

VD (E3.1) 10/2020 page 8/179

Page 9

This operating manual ca nnot cover all conc eivable applicat ions. If you would like additional inf ormation,

or if special problem s arise that are not suf ficiently addressed in th is manual, please ask your dealer or

contact us directly by phone at the number located on page one of this manual

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or

existing agreement, description, or legal relationship, nor do they modify such a relationship. All

obligations on the part of BINDER derive f rom the respective p urchase contract, which also contains the

entire and exclusively valid statement of warranty administr ati on and t he g en er al t erm s and c ond iti ons, as

well as the legal regulati ons valid at the time the contract is conc luded. The statements in this manual

neither augment nor restrict the contractual warranty provisions.

1.4 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations

following the harmonization of ISO 3864-2 and ANSI Z 535. 6.

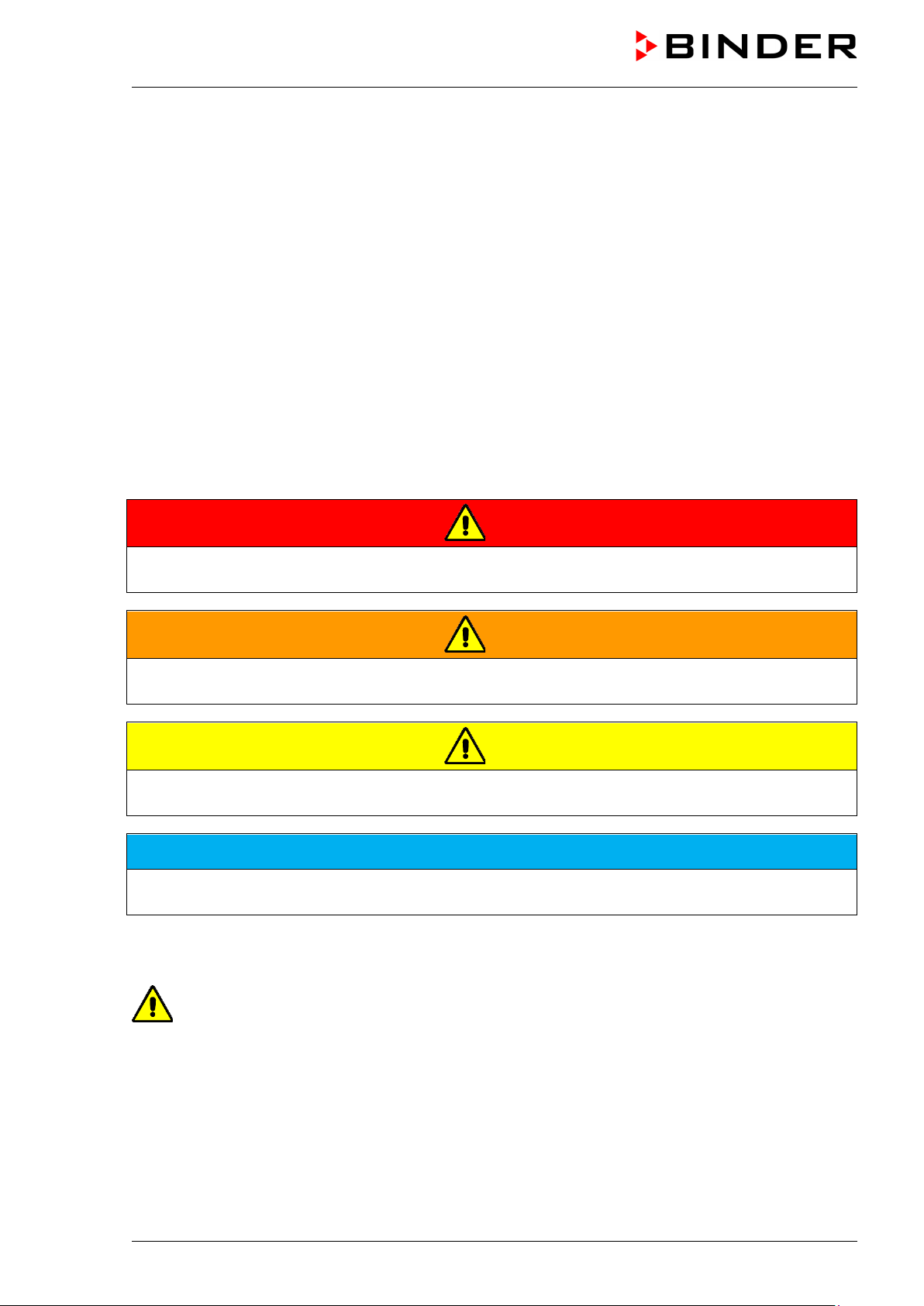

1.4.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal

word, the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

(irreversible) injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury.

NOTICE

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its proximity.

1.4.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

VD (E3.1) 10/2020 page 9/179

Page 10

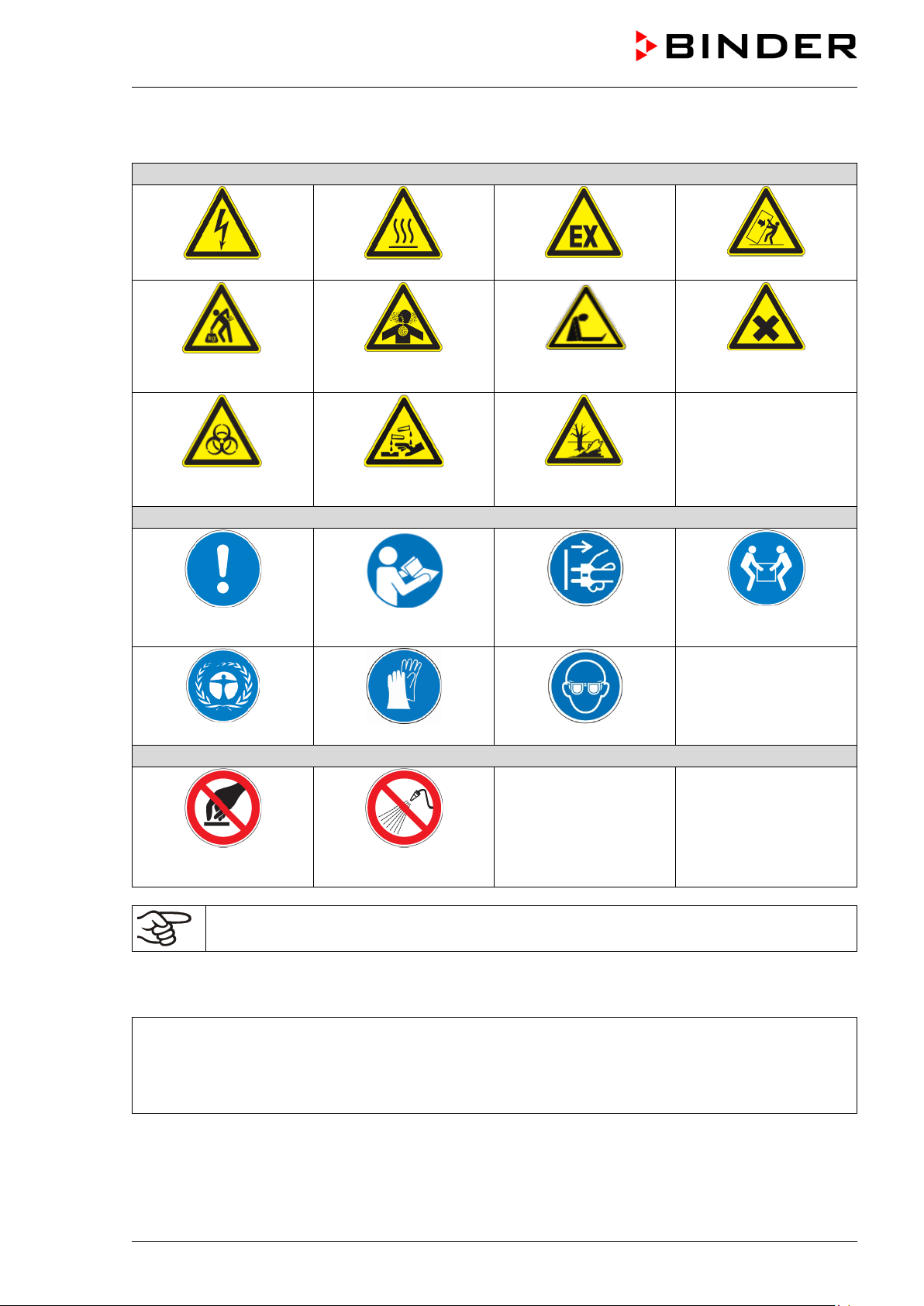

Warning signs

Electrical hazard

Hot surface

or chemical burns

Mandatory action signs

instructions

plug

Wear protective gloves

Wear safety goggles

Prohibition signs

water

1.4.3 Pictograms

Lifting hazard

Biohazard

Mandatory regulation

Inhalation hazard

Risk of corrosion and /

Read operating

Explosive atmosphere

Suffocation hazard

Pollution Hazard

Disconnect the power

Stability hazard

Harmful substances

Lift with several persons

Environment protection

Do NOT touch

Information to be observed in order to ensure optimum function of the product.

Do NOT spray with

1.4.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

∅ Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory action

Observe all other n otes and inform ation not necessarily em phasized in the s ame way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

VD (E3.1) 10/2020 page 10/179

Page 11

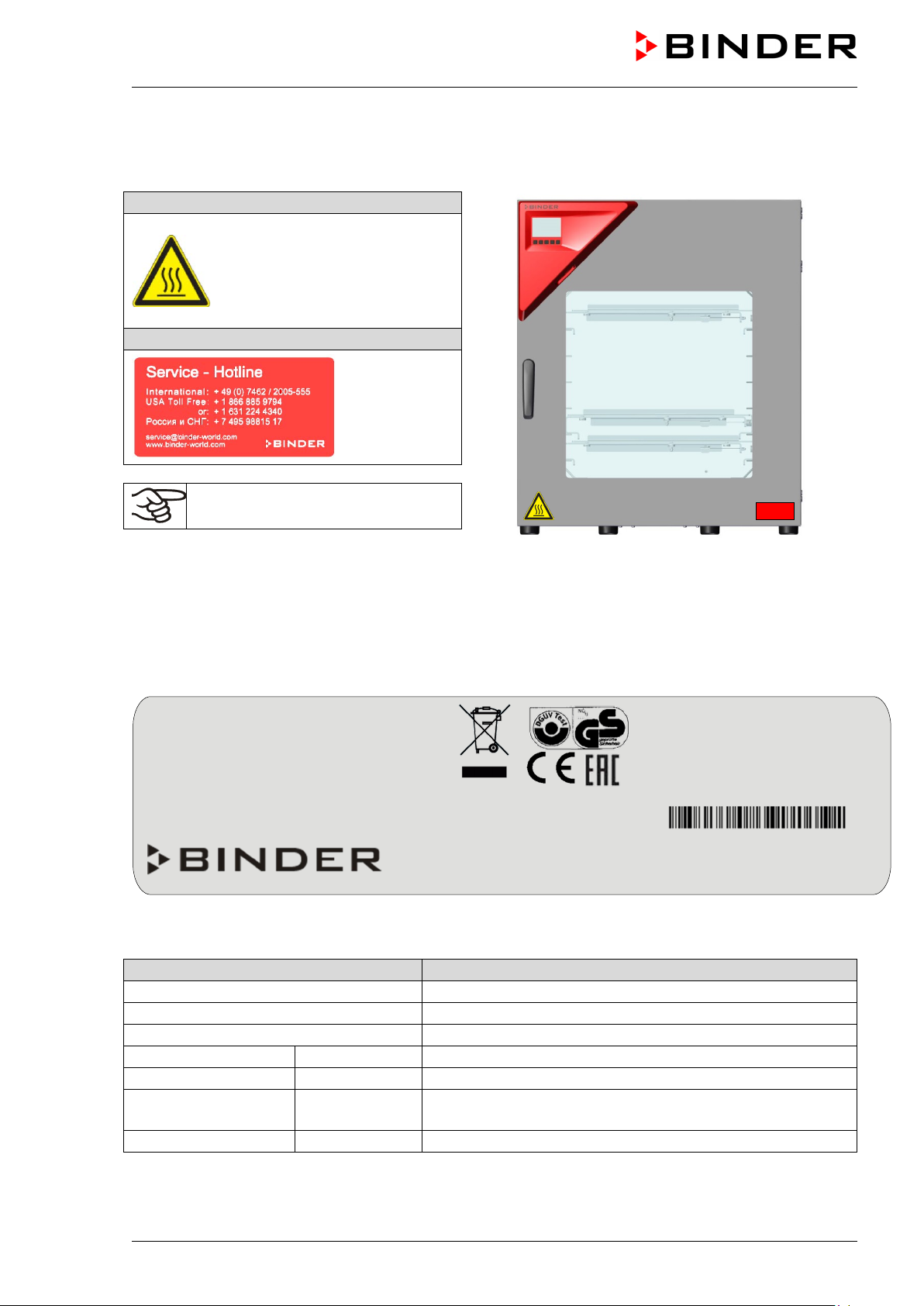

Pictograms (Warning signs)

Service label

safety labels that are no longer

legible. Contact BINDER Service for these

Indications of the type plate (example)

Information

BINDER

Manufacturer: BINDER GmbH

VD 115

Model designation

Vacuum Drying Oven

Device name

Serial No.

000000000000

Serial no. of the chamber

Built

2020

Year of construction

220 °C

428 °F

IP protection

20

IP type of protection acc. to standard EN 60529

Nominal temp.

220 °C

1,60 kW / 7,0 A

428 °F

230 V / 50 Hz

IP protection

20

230 V / 60 Hz

Safety device

DIN 12880

1 N ~

Class

2.0

Art. No.

9630-0003

Project No.

Built

2020

Vacuum Drying Oven

BINDER GmbH

www.binder-world.com

VD 115

Serial No. 00000000000000

1.5 Localization / position of safety labels on the chamber

The following labels are located on the chamber:

Hot surface

(on the outer chamber door)

Keep safety labels complete and

legible.

Replace

replacements.

Figure 1: Position of labels on the chamber (example:

regular chamber with RD4 controller)

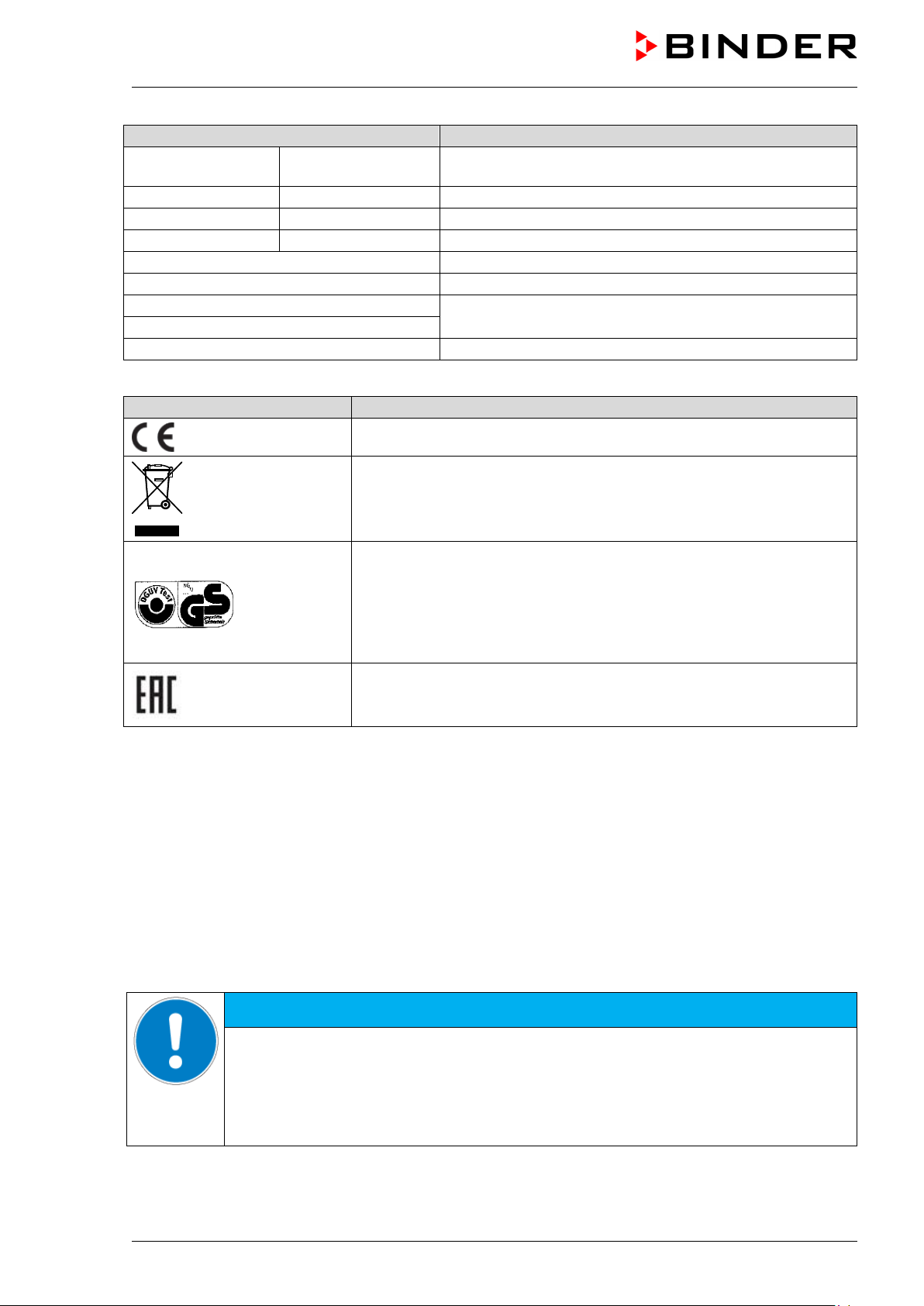

1.6 Type plate

The type plate sticks to the left side of the chamber, bottom right-hand.

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

Figure 2: Type plate (exam ple of VD 115)

E3.1

Made in Germany

Nominal temperature

VD (E3.1) 10/2020 page 11/179

Nominal temperature

Page 12

Indications of the type plate (example)

Information

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN

12880:2007

Class

2.0

Class of temperature safety device

Art. No.

9630-0003

Art. no. of the chamber

Project No.

---

Optional: Special application acc. to project no.

1,60 kW

Nominal power

7,0 A

Nominal current

230 V / 50 Hz

230 V / 60 Hz

1 N ~

Current type

Symbol on the type plate

Information

Nominal voltage +/- 10% at the indicated power frequency

CE conformity marking

Electrical and electronic equipment manufactured / placed on the

market in the EC after 13 August 2005 and to be disposed of in a

separate collection according to Directive 2012/19/EU on waste

electrical and electronic equipment (WEEE).

GS mark of conformity of the “Deutsche Gesetzliche

Unfallversicherung e.V. (DGUV), Prüf- und Zertifizierungsstelle

Nahrungsmittel und Verpackung im DGUV Test” (German Social

Accident Insurance (DGUV), Testing and Certification Body for

Foodstuffs and Packaging Industry in DGUV Test).

(Not valid for UL chambers)

The chamber is certified according to Customs Union Technical

Regulation (CU TR) for the Eurasian Economic Union (Russia,

Belarus, Armenia, Kazakhstan Kyrgyzstan).

1.7 General safety instructions on installing and operating the chamber

With regard to operating the chamber and to the installation location, please observe the DGUV

guidelines 213-850 on safe working in laboratories, issued by the employers’ liability insurance

association (for Germany).

BINDER GmbH is only respons ible for the safet y features of the chamber provided sk illed electricians or

qualified personnel authorized by BINDER perform all maintenance and repair, and if components

relating to chamber safety are replaced in the event of failure with original spare parts.

To operate the chamber, use only original BINDER ac cessories or ac cessories f rom third-party suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

Danger of overheating due to lack of ventilation.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Observe the prescribed minimum distances when installing the chamber (chap. 3.4)

VD (E3.1) 10/2020 page 12/179

NOTICE

Page 13

Do not install or operate the vacuum drying oven VD in potentially explosive areas.

DANGER

Danger of explosion due to combustible du sts or explosive mixtures in the vicinity

of the equipment.

Serious injury or death from burns and / or explo sion pressure.

Do NOT operate the equipment in potentially explosive areas.

KEEP combustible dust or air-solvent mixtures AWAY from the equipment.

The chamber does not dispose of any measures of explosion protection.

DANGER

Danger of explosion due to introduction of flammable or explosive substances in

the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT introduce any substance into the chamber which is combustible or explosive at

working temperature.

∅ Do NOT introduce any combustible dust or air-solvent mixture in the inner chamber.

∅ Do NOT use the vacuum drying oven for drying or heat treatments leading to release of

combustible vapors able to form an explosive mixture with air.

Any solvent contained in th e charging material m ust not be explosive or inflam mable. I.e., irres pective of

the solvent concentration in the steam room, NO explosive mixture with air must form. The drying

temperature must lie below the flash point or below the sublimation point of the charging material.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy and changes in pressure.

Familiarize yourself with any potential health risks caused by the charging material, the contained

moisture constituent or by reaction products that may arise during the drying process. T ake adequate

measures to exclude such risks prior to putting the chamber into operation.

DANGER

Electrical hazard by water entering the chamber.

Deadly electric shock.

∅ The chamber must NOT become wet during operation, cleaning, or maintenance.

∅ Do NOT install the chamber in damp areas or in puddles.

Set up the chamber in a splash-proof manner.

The chambers were produced in accordance with the relevant VDE re gulations and were routin ely tested

in accordance to VDE 0411-1 (IEC 61010-1).

During and shortl y after operation, t he tem perature of the i nner surf aces alm ost equals the set -point. The

inner chamber will become hot during operation.

CAUTION

Danger of burning when touching the inner surfaces during operation.

Burns.

∅ Do NOT touch the inner surfaces or the charging material during and after operation.

VD (E3.1) 10/2020 page 13/179

Page 14

In the case of operation with inert gas, the chamber is supplied with an oxygen-displ acing gas (e.g. N

The gas emerging fr om the system m ust therefore be rem oved from the install ation area by means of a

suitable extraction s ystem (see technical ventilation measures in the DGUV g uidelines 213-850 on safe

working in laboratories, issued b y the em plo yers’ liab il it y insuranc e ass oci ati on (f or Germany).

With use of a vacuum system or a vacuum pump, observe the permitted gas inlet

temperature. Observe the safety instructions of the pump manufacturer.

).

2

1.8 Intended use

Observing the instructions in this operating manual and conducting regular maintenance work

(chap. 24) is part of the intended use.

Any use of the chambers that does not comply with the requirements specified in this Operating

Manual shall be considered improper use.

Other applications than those described in this chapter are not approved.

Use

The VD vacuum dr ying ovens are suitable for drying and heat treatment of solid or pulverized chargi ng

material, as well as bulk material, using the supply of heat under vacuum.

Requirements for the chamber load

Any sol vent content must not be explos ive or flammabl e. A mixture of any component of the charging

material with air mus t NOT be explosive. The dr ying temperature m ust lie below the flas h point or below

the sublimation po int of the c har gi ng material. Any com ponent of the charging mater ia l must NOT be able

to release toxic gases.

The loading material shall not contain any corrosive ingredients that may damage the machine

components made of stainless steel and aluminum. Such ingredients include in particular acids and

halides. Any corrosive damage caused by such ingredients is excluded from liability by BINDER GmbH.

The chamber does not dispose of any measures of explosion protection.

DANGER

Explosion or implosion hazard and danger of poisoning through the introduction of

unsuitable loading material.

Poisoning. Serious injury or death from burns and / or explosion pressure.

∅ Do NOT introduce any substance combustible or explosive at working temperature into

the chamber, in particular no energy sources such as batteries or lithium-ion batteries.

∅ Do NOT introduce explosive dust or air-solvent mixture into the inner chamber.

∅ Do NOT introduce any substance which could lead to release of toxic gases.

VD (E3.1) 10/2020 page 14/179

Page 15

Contamination of the chamber by toxic, infectious or radioactive substances must be prevented

WARNING

Danger of intoxication and infection through contamination of the chamber with

toxic, infectious or radioactive substances.

Damages to health.

Protect the interior of the chamber from contamination by toxic, infectious or radioactive

substances.

Take suitable protective measures when introducing and removing toxic, infectious or

radioactive material

In case of foreseeable use of the chamber there is no risk for the user through the integration of the

chamber into systems or by special environm ental or operating conditions in the sense of EN 610101:2010. For this, the intended use of the chamber and all its connections must be observed.

Medical devices

The chambers are not classified as medical devices as defined by the Medical Device Directive

93/42/EEC.

Due to the special demands of the Medical Device Directive (MDD), these chambers are not

qualified for sterilization of medical devices as defined by the directive 93/42/EWG.

Personnel Requirements

Only trained person nel with knowledge of the Oper ating Ma nual can s et up and install the c ham ber, start

it up, operate, clean, and take it out of operation. Service and repairs call for further technical

requirements (e.g. electrical know-how), as well as knowledge of the service manual.

Installation site requirements

The chambers are designed for setting up inside a building (indoor use).

The requirements des cribed in the Operating M anual for installation site and ambient conditions (Chap .

3.4) must be met.

VD (E3.1) 10/2020 page 15/179

Page 16

1.9 Foreseeable Misuse

Other applications than those described in chap. 1.8 are not approved.

This expressly incl udes the following misuses ( the list is not exhaustive), which p ose risks despite the

inherently safe construction and existing technical safety equipment:

• Non-observance of Operating Manual

• Non-observance of information and warnings on the chamber (e.g. control unit messages, safety

identifiers, warning signals)

• Installation, startup, operation, maintenance and repair by untrained, insufficiently qualified, or

unauthorized personnel

• Missed or delayed maintenance and testing

• Non-observance of traces of wear and tear

• Insertion of materials excluded or not permitted by this Operating Manual.

• Non-compliance with the admissible parameters for processing the respective material.

• Installation, testing, service or repair in the presence of solvents

• Installation of replacement parts and use of accessories and operating resources not specified and

authorized by the manufac turer

• Installation, startup, operation, maintenance or repair of the chamber in absence of operating

instructions by the operator

• Bypassing or c han gin g pr ot ec tive systems, operation of the c hamber without the designated pr otec t ive

systems

• Non-observance of messages regarding cleaning and disinfection of the chamber.

• Spilling water or cleaning agent on the c ham ber, water penetrat ing into the c hamber dur ing operat ion,

cleaning or maintenance.

• Cleaning activity while the chamber is turned on.

• Operation of the chamber with a damaged housing or damaged power cord

• Continued operation of the chamber during an obvious malfunction

• Insertion of objects, particularly metallic objects, in louvers or other openings or slots on the chamber

• Human error (e.g. insufficient experience, qualification, stress, exhaustion, laziness)

To prevent these and other risks fr om incorrect operati on, the operator s hall issue operating instruc tions.

Standard operating procedures (SOPs) are recommended.

1.10 Residual Risks

The unavoidable design f eatures of a chamber, as well as its proper f ield of application, can also pose

risks, even during corr ect operation. These residual risk s include hazards which, despite the inher ently

safe design, existing technical protective equipment, safety precautions and supplementary protective

measures, cannot be ruled out.

Messages on the chamber and in the Operating Manual warn of residual risks. The consequences of

these residual risks and the measures required to prevent them are listed in the Operating Manual.

Moreover, the operator m ust take measures to minimize hazards from unavoidable residual risks. This

includes, in particular, issuing operating instructions.

The following list s ummarizes the hazar ds against which this Operating Manua l and the Service Manual

warn, and specifies protective measures at the appropriate spots:

VD (E3.1) 10/2020 page 16/179

Page 17

Unpacking, Transport, Installati on

• Sliding or tilting the chamber

• Setup of the chamber in unauthorized areas

• Installation of a damaged chamber

• Installation of a chamber with damaged power cord

• Inappropriate site of installation

• Missing protective conductor connection

Normal operation

• Assem bly errors

• Contact with hot surfaces on the housing

• Contact with hot surfaces in the interior and inside of doors

• Emission of non-ionizing radiation from electrical operating resources

• Contact with live parts in normal state

Cleaning and Decontamination

• Penetration of water into the chamber

• Inappropriate cleaning and decontamination agents

• Enclosure of persons in the interior

Malfunction and Damage

• Continued operation of the chamber during an obvious malfunction or outage of the heating or the

vacuum system

• Contact with live parts during error status

• Operation of a unit with damaged power cord

Maintenance

• Maintenance wor k on live parts.

• Execution of maintenance work by untrained/insufficiently qualified personnel

• Electrical safety analysis during annual maintenance not performed

Trouble-shooting and Repairs

• Non-observance of warning messages in the Service Manual

• Trouble-shooting of live parts without specified safety measures

• Absence of a plausibility check to rule out erroneous inscription of electrical components

• Performance of repair work by untrained/insufficiently qualified personnel

• Inappropriate repairs which do not meet the quality standard specified by BINDER

• Use of replacement parts other than BINDER original replacement parts

• Electrical safety analysis not performed after repairs

VD (E3.1) 10/2020 page 17/179

Page 18

1.11 O perating instructions

Depending on the applicati on and l ocation of the c ham ber, the operat or of th e cham ber mus t provide th e

relevant information for safe operation of the chamber in a set of operating instructions.

Keep these operating instructions with the chamber at all times in a place where they are

clearly visible. They must be comprehensible and written in the language of the employees.

1.12 Measures to prevent accidents

The manufacturer took the follo wing m eas ures to prevent ign iti on and ex plos io ns :

• Indications on the type plate

See operating manual chap. 1.6.

• Operating manual

An operating manual is available for each chamber.

• Overtemperature monitoring

The chamber is equipped with a temperature display, which can be read from outside.

The chamber is equipped with an additional safety controller (temperature safety device class 2 acc. to

DIN 12880:2007). Visual and audible (buzzer) signals indicate temperature exceeding.

• Safety, measurement, and control equipment

The safety, measuring, and control equipment is easily accessible.

• Electrostatic ch arg e

The interior parts are grounded.

• Non-ionizing radiation

Non-ionizing radiation is not intentionally produced, but released only for technical reasons by

electrical equipm ent (e.g. electric motors, po wer cables, solenoids) . The machine has no perm anent

magnets. If persons with active implants (e.g. pacemakers, defibrillators) keep a safe distance

(distance of field sour ce to i mplant) of 30 cm, an influenc e of thes e implants can be excluded with h ig h

probability.

• Protection against touchable surfaces

Tested according to EN ISO 13732-1:2008.

• Floors

See operating manual chap. 3.4 for correct installation

• Cleaning

See operating manual chap. 24.

• Examinations

The chamber has been inspected by the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV)

(German Social Accident Insurance (DGUV)” (German Social Accident Insurance (DGUV), Testing

and Certification Body for Foodstuffs and Packaging Industry i n DGUV Tes t) and bear s the GS m ark.

(Not valid for UL chambers)

VD (E3.1) 10/2020 page 18/179

Page 19

2. Description of the equipm e nt

Vacuum drying is used f or special dr ying problem s, for whic h conventio nal drying methods cannot off er a

solution due to physical limitations.

Controller

The chambers are equipped with a multifunctional microprocessor display controller with 2-channel

technology for tem perat ure and pr es sur e. Temperature is indicated accur ate to o n e-tenth of a degree, the

pressure inside the cham ber accur ate to on e 1 m bar. Pres sure is m easured b y a firmly installed pressure

sensor.

Standard RD4 controller: The chamber is regularly equipped with the RD4 controller. This efficient

chamber controller is equipped with a m ultitude of operatin g functions, in add ition to recorder and a larm

functions. Set-point entr y is easily accom plished directly via the chamber contr oller and is also pos sible

directly with a computer via Intranet in connection with the optional APT-COM™ 4 Multi Management

Software (option, chap. 23.1).

Option MB2 controller: T he chamber is optionally available with the MB2 display program controller.

This efficient program controller is equipped with a multitude of operating functions, in addition to recorder

and alarm functions. Programming of test cycles is easily accomplished via the modern MB2 touch

screen controller and is also possible directly with a computer via Intranet in connecti on with the APTCOM™ 4 Multi Management Software (option, chap. 23.1).

The chamber com es equipped with an Ethernet serial in terface for computer communication and with a

USB interface. In ad dition, the BINDER APT-COM™ 4 Multi Management Software permits networking

up to 100 chambers and c onnecting them to a PC for controlling an d programm ing, as well as recording

and representing temperature and pressure data. For further options, see chap. 23.

Material

The inner cham ber is made of especially corros ion resistant stainless steel V4A (German material no.

1.4404, US equivalent AISI 316L) micro-polished. The rack holder and all of the chamber's vacuum

connections and valves ar e made of especially corro sion resistant stainless steel V4A (German mater ial

no. 1.4571, US equiv alent AISI 316T i). The housing is RAL 703 5 powder-coated. All c orners and edges

are also completely coate d. W hen operating the chamber at tem peratures above 150 °C / 302 °F, the

impact of the oxygen in t he air m ay cause discol oratio n of the m etallic surfac es (yellowish-br own or b lue)

by natural oxidatio n processes. T hese colorations are harm less and will in n o way impair the function or

quality of the chamber.

The chambers are jacket-heated. The preheating chamber technique ensures a completely

homogeneous jack et temperature, ensuring uniform heat transfer into th e inner chamber. The low-loss

heat transfer to the material uses the aluminum vacuum expansion racks (or optionally available in

stainless steel). The elastic-mounted safety glass window reliably compensates any overpressure or

explosions that may occur. The additional laminated safety glass pane ensures proven and effective

splinter protection in the event of an implosion.

The chambers provide a universal connection for inert gas / ambient air and a measuring connection

serving to connect a measuring access port.

All installable items, such as racks and rack holders, can be easily removed. The completely smooth

inner chamber with its rounded corners and internally welded seams is easy to clean.

The minimum working temperature of the vacuum drying oven is approx. 10 °C / 18 °F above room

temperature. The maximum temperature is 220 °C / 428 °F.

3

Vacuum pumps with a suction capacity of 1 m

VD (E3.1) 10/2020 page 19/179

/h to 30 m3/h are suitable for the VD vacuum drying oven.

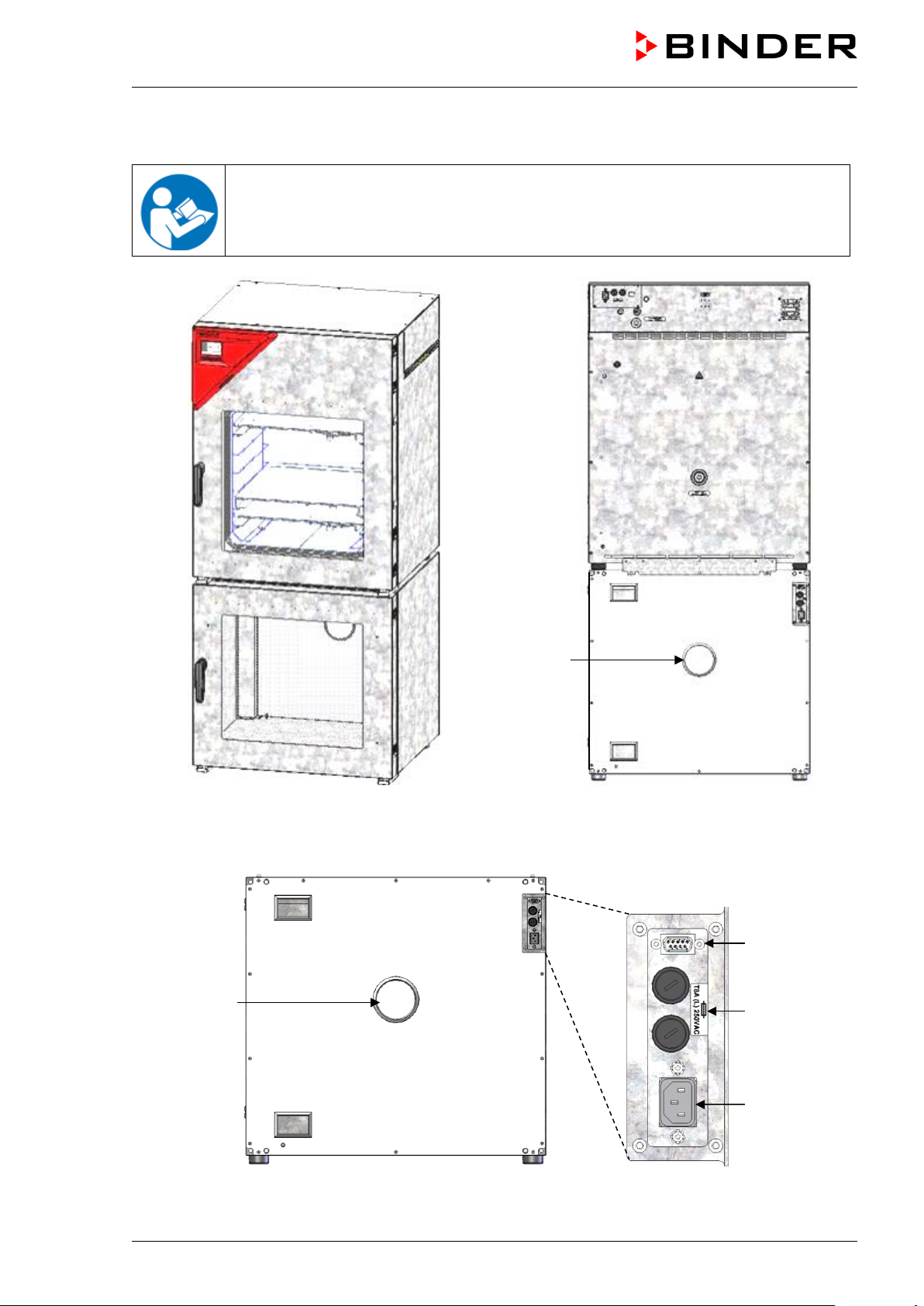

Page 20

(A)

(A)

2.1 Chamber overview

(B)

(C)

(D)

(B)

(C)

(D)

Figure 3: VD 115 with RD4 controller

Figure 4: VD 115 with optional MB2 controller

(A) Triangular instrument panel with chamber controller

(B) Chamber door

(C) Door handle

(D) Elastic-mounted safety glass window

VD (E3.1) 10/2020 page 20/179

Page 21

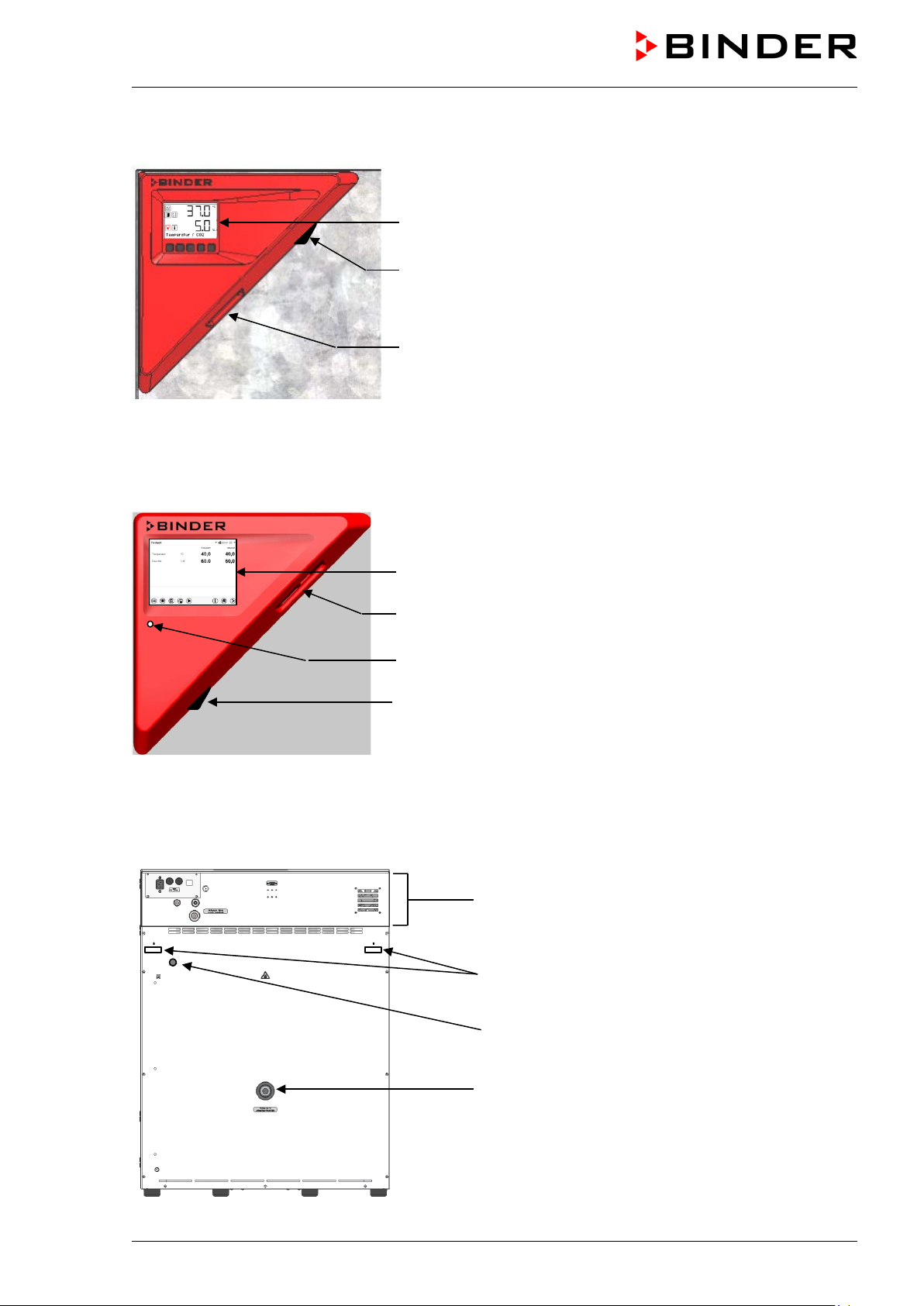

2.2 Instrument panel with regular RD4 controller

RD4 controller display

Switch for LED interior lighting (option)

USB interface

Figure 5: Instrument panel with RD4 controller and USB interface

2.3 Instrument panel with optional MB2 controller

5,7" controller display with touchscreen

USB interface

Pilot lamp

Switch for LED interior lighting (option)

Figure 6: Instrument panel with MB2 program controller and USB interface

2.4 Connections on the rear of the chamber

Rear control panel

Mounting holes for fixing the tilt protection holders

(1a) Strain relief for IEC connector plug

(12) Measuring connection with small flange DN16

Figure 7: Chamber rear (example: VD 115)

VD (E3.1) 10/2020 page 21/179

Page 22

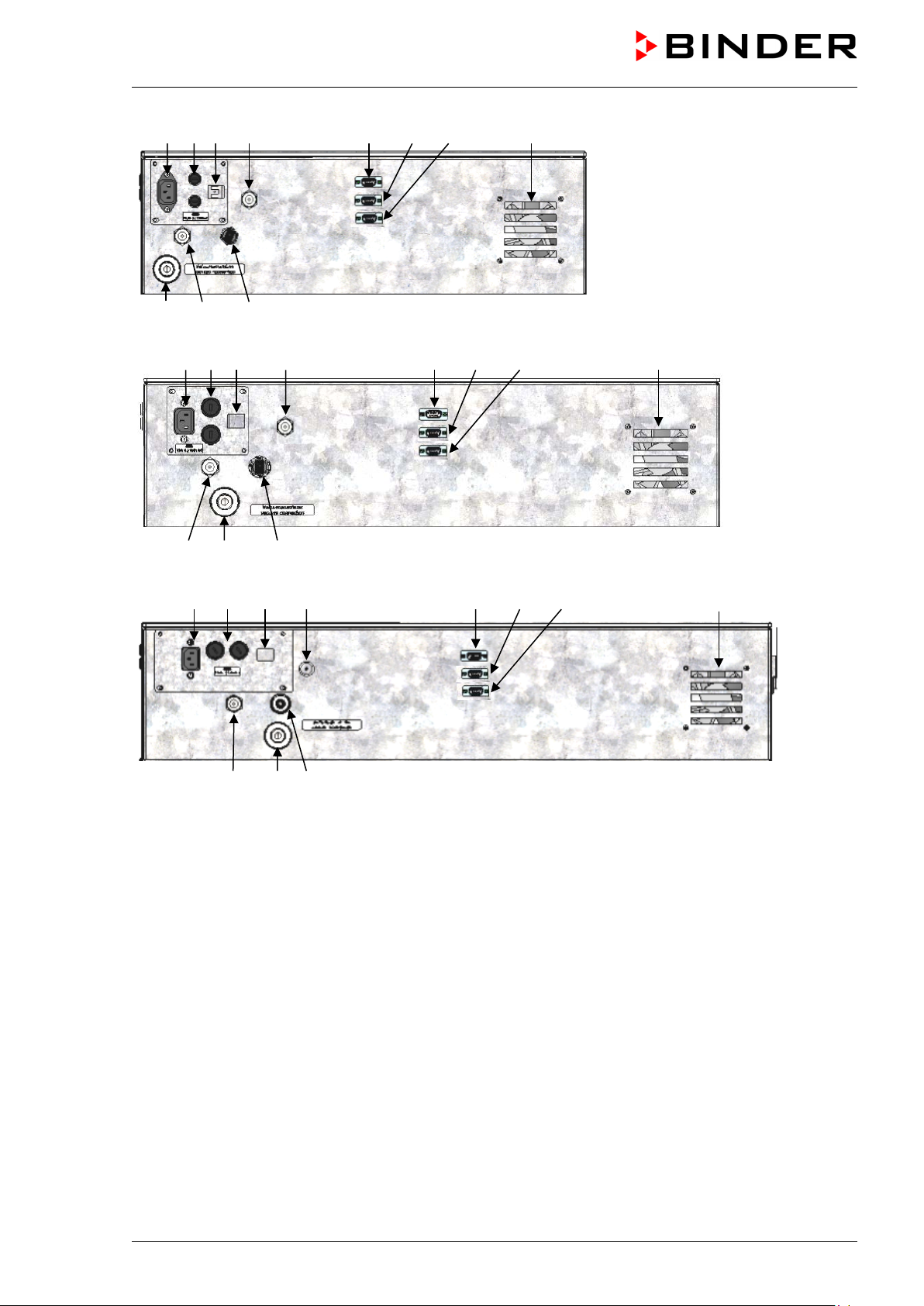

(1) (2) (3) (5) (8) (9) (10) (11)

VD 23

(6) (4) (7)

(1) (2) (3) (5) (8) (9) (10) (11)

VD 56

(4) (6) (7)

(1) (2) (3) (5) (8) (9) (10) (11)

VD 115

(4) (6) (7)

Figure 8: Rear control panel VD (230 V) with opt ions

(1) Connection for IEC connector plug 230 V AC for VD

Connection for IEC connector plug 100-120 V AC for VD -UL

(2) Miniature fuses 250 V AC (T): 2x 6,3 A for VD 23, 2x 8 A for VD 56, 2x 10 A for VD 115, 1x 10 A for

VD 23-UL, 2x 16 A for VD 56-UL, 2x 20 A for VD 115-UL

(3) Ethernet interface for computer communication

(4) Universal connection f or inert gas / ambient air “GAS/AIR” , adapter w ith hose ol ive ∅ 8 mm / 0.31

in

(5) Additional universal conne ction for inert gas / ambient air “ GAS/AIR 2” (op tion), adapter with hose

olive ∅ 8 mm / 0.31 in

(6) Vacuum connection with small flange DN16

(7) Plug “Manual ventilation” for emergency ventilation in case of power failure

(8) SUB-D socket “Pump module” for c ontro l line t o turn on/off the vacuum pum p via the sock et on th e

pump module

(9) SUB-D socket “Object temperature input” (option) for optional object temperature display

(10) SUB-D socket “Analog output” (option) for optional analog outputs for temperature and pressure

VD (E3.1) 10/2020 page 22/179

Page 23

3. Completeness of delivery, transportation, storage, and

installation

3.1 Unpacking, and checking equipment and completeness of delivery

After unpacking, p lease check the chamber and its optional acces sories, if any, based on the de livery

receipt for completenes s and for transportation dam age. Inform the carrier immediatel y if transportation

damage has occurred.

The final tests of the manufacturer may have caused traces of the shelves on the inner surfaces. This has

no impact on the function and performance of the chamber.

Please remove an y transportati on protection devices and adh esives in/o n the chamber and on th e doors

and remove the operating manuals and accessory equipment.

Due to different installat ion heights abo ve sea level, a s light negative press ure in the inner c hamber m ay

prevent the door from being opened. Therefore, af ter unpacking the cham ber, remove the plug “Manual

ventilation” (5) for emergency ventilation from the tube to ensure pressure equalization. After this,

thoroughly reinstall the plug.

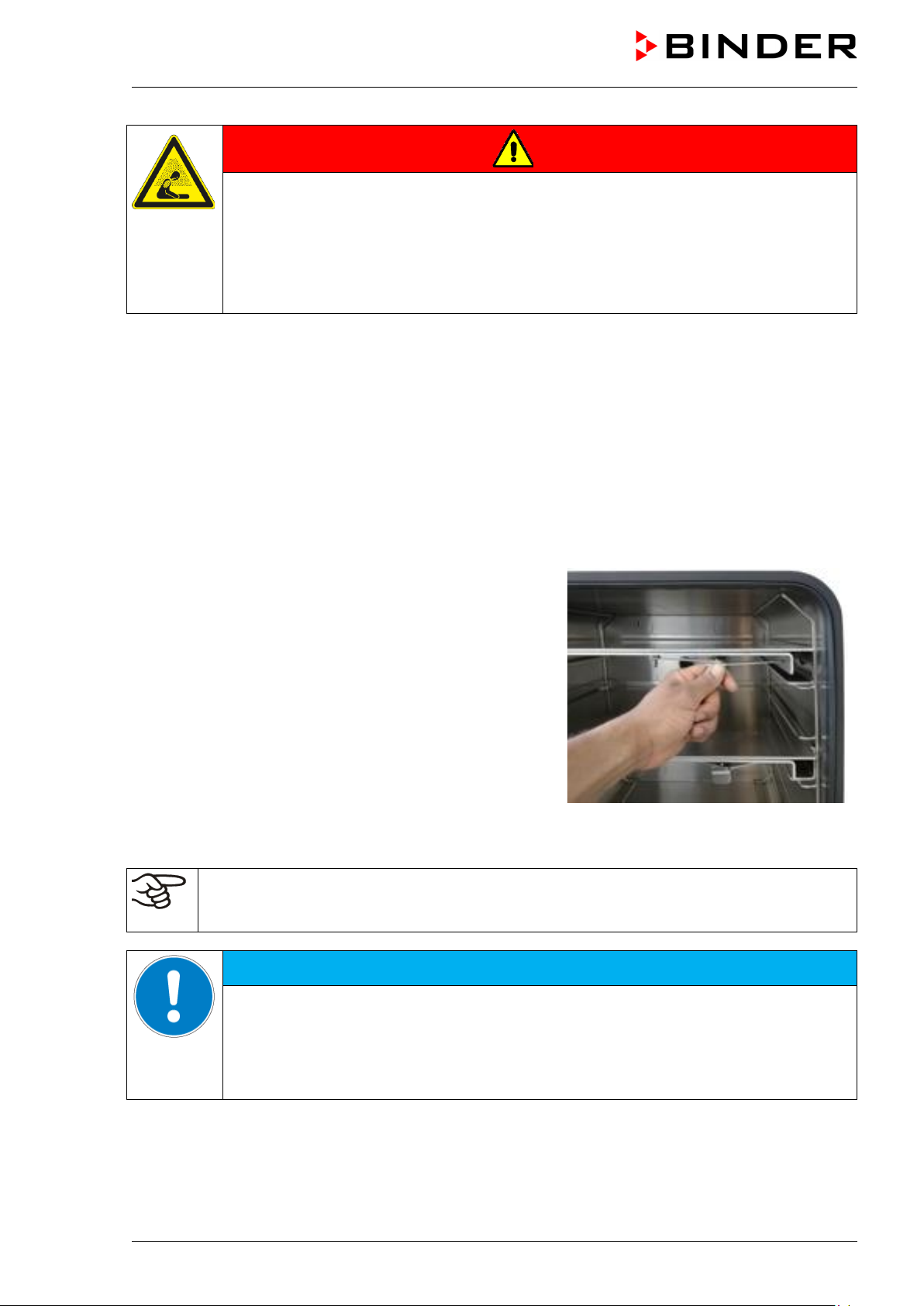

CAUTION

Risk of injury and damages by lifting heavy loads and by sliding or tilting of the

chamber due to improper lifting.

Injuries, damage to the chamber.

∅ Do NOT lift the chamber using the door handl e or the door.

Lift chambers size 23 and 56 from the pallet at the four lower corners with the aid of 4

people.

Lift chambers size 115 from the pallet with the aid of 6 people.

If you need to return the chamber, please use the original packing and obser ve the guidelines for saf e

lifting and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 26.1.

If you ordered th e option al pum p module with a chem ical m embrane pum p, the pum p will be de livered in

a separate box and must be fitted into the pump module and conn ected at the place of installatio n (see

chap. 4.3.2).

Note on second-hand chambers (Ex-Demo-Units):