Page 1

Operating Manual

CB-S / CB-S-UL (E7)

CO2 Incubator

with FPI-sensor system and RD4 controller

Model Model version Art. No.

CB-S 170 CBS170-230V 9040-0189, 9140-0189

CB-S 170-UL CBSUL170-120V 9040-0190, 9140-0190

CB-S 260 CBS260-230V 9040-0191, 9140-0191

CB-S 260-UL CBSUL260-120V 9040-0192, 9140-0192

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www .b ind er-world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacif ic: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 06/2020 Art. No. 7001-0402

Page 2

Contents

1. SAFETY .................................................................................................................. 6

1.1 Personnel Qualification ....................................................................................................................... 6

1.2 Operating manual ................................................................................................................................ 6

1.3 Legal considerations ........................................................................................................................... 6

1.4 Structure of the safety instructions ...................................................................................................... 7

1.4.1 Signal word panel ..................................................................................................................... 7

1.4.2 Safety alert symbol ................................................................................................................... 7

1.4.3 Pictograms ................................................................................................................................ 8

1.4.4 Word message panel structure ................................................................................................. 8

1.5 Localization / position of safety labels at the chamber ....................................................................... 9

1.6 Type plate.......................................................................................................................................... 10

1.7 General safety instructions on installing and operating the chamber ............................................... 11

1.8 Precautions when working with CO2 gas .......................................................................................... 13

1.9 Precautions when handling gas cylinders ......................................................................................... 13

1.10 Intended use ..................................................................................................................................... 14

1.11 Foreseeable Misuse .......................................................................................................................... 15

1.12 Residual Risks .................................................................................................................................. 16

1.13 Operating instructions ....................................................................................................................... 17

1.14 Measures to prevent accidents ......................................................................................................... 18

2. CHAMBER DESCRIPTION .................................................................................. 19

2.1 Chamber overview ............................................................................................................................ 20

2.2 Inner chamber ................................................................................................................................... 21

2.3 Connection panel on the rear of the chamber................................................................................... 22

2.4 Chamber doors ................................................................................................................................. 23

2.5 Instrument panel ............................................................................................................................... 23

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 24

3.1 Unpacking, and checking equipment and completeness of delivery ................................................ 24

3.2 Guidelines for safe lifting and transportation ..................................................................................... 25

3.3 Storage .............................................................................................................................................. 25

3.4 Location of installation and ambient conditions ................................................................................ 25

4. INSTALLATION AND CONNECTIONS ............................................................... 28

4.1 Shelves .............................................................................................................................................. 28

4.2 CO2 sensor ........................................................................................................................................ 28

4.2.1 Connecting the CO2 sensor .................................................................................................... 28

4.2.2 General notes ......................................................................................................................... 28

4.3 Water pan .......................................................................................................................................... 29

4.4 Gas connection ................................................................................................................................. 30

4.4.1 Connecting the CO2 gas cylinder ............................................................................................ 31

4.4.2 Connecting the gas hose to the chamber rear ....................................................................... 32

4.4.3 Gas cylinder connection kit (option) ........................................................................................ 33

4.5 Electrical connection ......................................................................................................................... 34

5. FUNCTIONAL OVERVIEW OF THE RD4 CHAMBER CONTROLLER ............... 35

5.1 Menu structure of the controller and access levels ........................................................................... 36

5.2 Performance during and after power failures and sh ut do wn ........................................................... 37

6. START UP ............................................................................................................ 37

6.1 Turning on the chamber .................................................................................................................... 37

6.2 Preset factory parameters ................................................................................................................. 38

6.3 Performance after turning on the chamber ....................................................................................... 38

6.4 Altitude of the installation site above sea level ................................................................................. 39

CB-S / CB-S-UL (E7) 06/2020 page 2/119

Page 3

7. TEMPERATURE AND CO2 SET-POINT ENTRY ................................................. 40

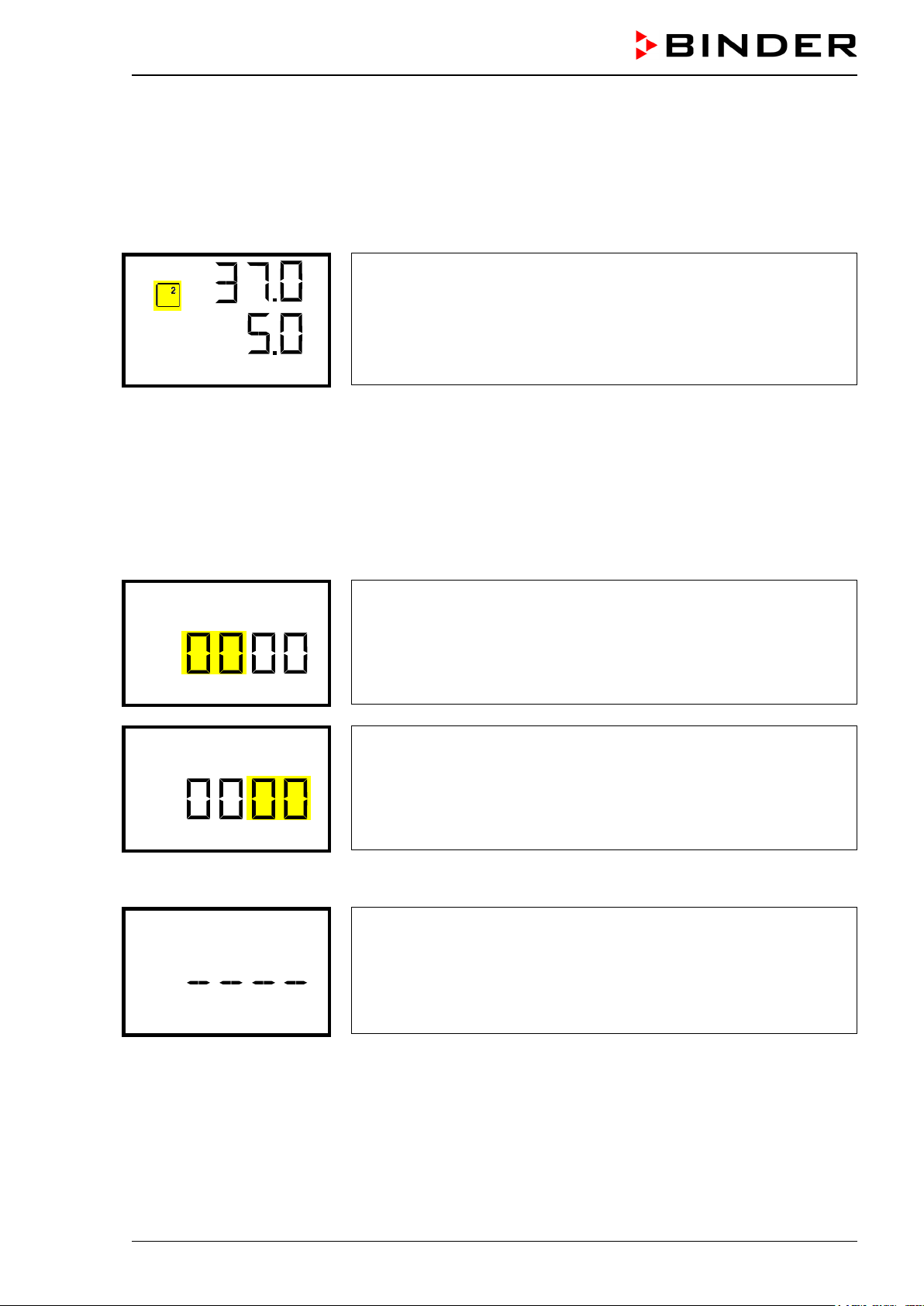

7.1 Temperature set-point entry .............................................................................................................. 40

7.2 CO2 set-point entry ............................................................................................................................ 40

8. PLACING SAMPLES IN THE INCUBATOR ........................................................ 41

9. SETTING SPECIAL CONTROLLER FUNCTIONS .............................................. 42

9.1 Idle mode........................................................................................................................................... 42

9.2 Deactivated CO2 control .................................................................................................................... 43

10. PASSWORD ......................................................................................................... 43

10.1 Password request ............................................................................................................................. 43

10.2 Assign and modify a password ......................................................................................................... 44

10.2.1 Assign and modify the User password ................................................................................... 44

10.2.2 Assign and modify the Admin password ................................................................................. 44

11. TEMPERATURE SAFETY DEVICES ................................................................... 45

11.1 Over temperature protective device (class 1) ................................................................................... 45

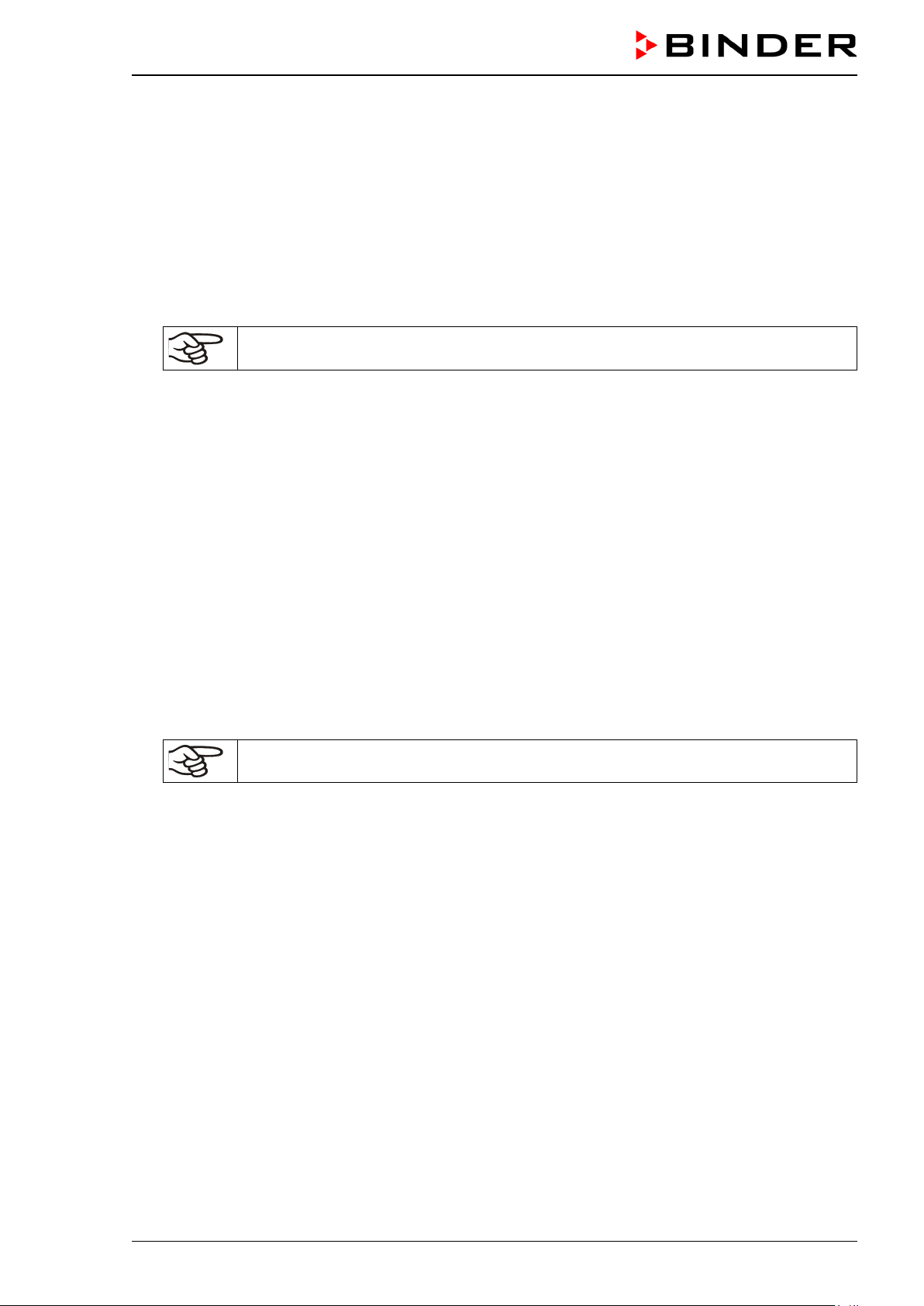

11.2 Overtemperature safety controller class 3.1 ..................................................................................... 45

11.2.1 Setting the safety controller mode .......................................................................................... 46

11.2.2 Setting the safety controller value ........................................................................................... 46

11.2.3 Message and measures in the state of alarm ......................................................................... 47

11.2.4 Function check ........................................................................................................................ 47

12. GENERAL CONTROLLER SETTINGS ................................................................ 48

12.1 Selecting the controller’s menu language ......................................................................................... 48

12.2 Selecting the temperature unit .......................................................................................................... 48

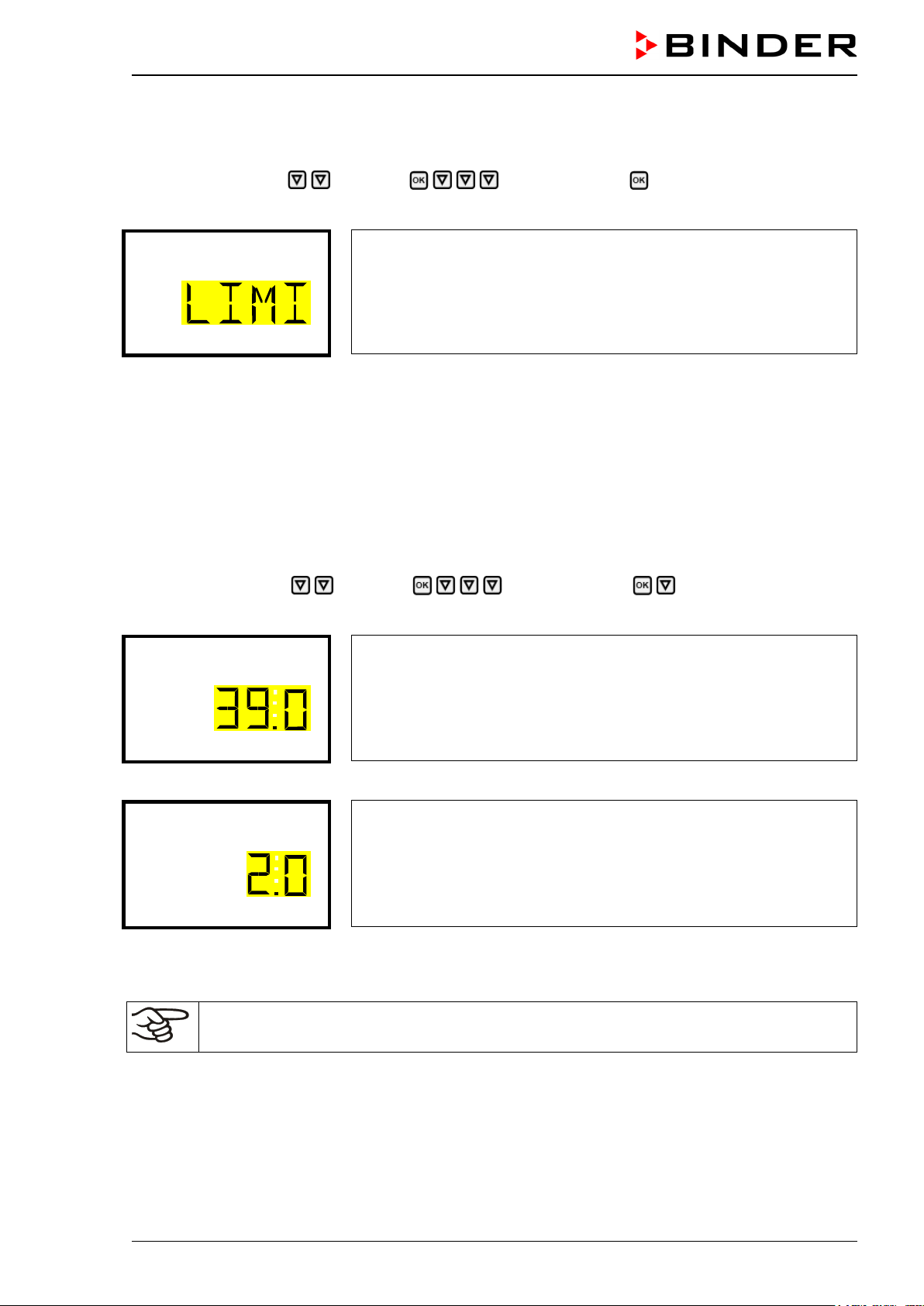

12.3 Setting the current date ..................................................................................................................... 49

12.4 Setting the current time ..................................................................................................................... 50

12.5 Function “Language selection at restart” .......................................................................................... 50

12.6 Setting the chamber address ............................................................................................................ 51

12.7 Display brightness ............................................................................................................................. 51

13. TOLERANCE RANGE SETTINGS ....................................................................... 52

13.1 Setting the delay time for tolerance range alarm .............................................................................. 52

13.2 Setting the temperature tolerance range .......................................................................................... 52

13.3 Setting the CO2 tolerance range ....................................................................................................... 53

13.4 Setting the delay time for door open alarm ....................................................................................... 53

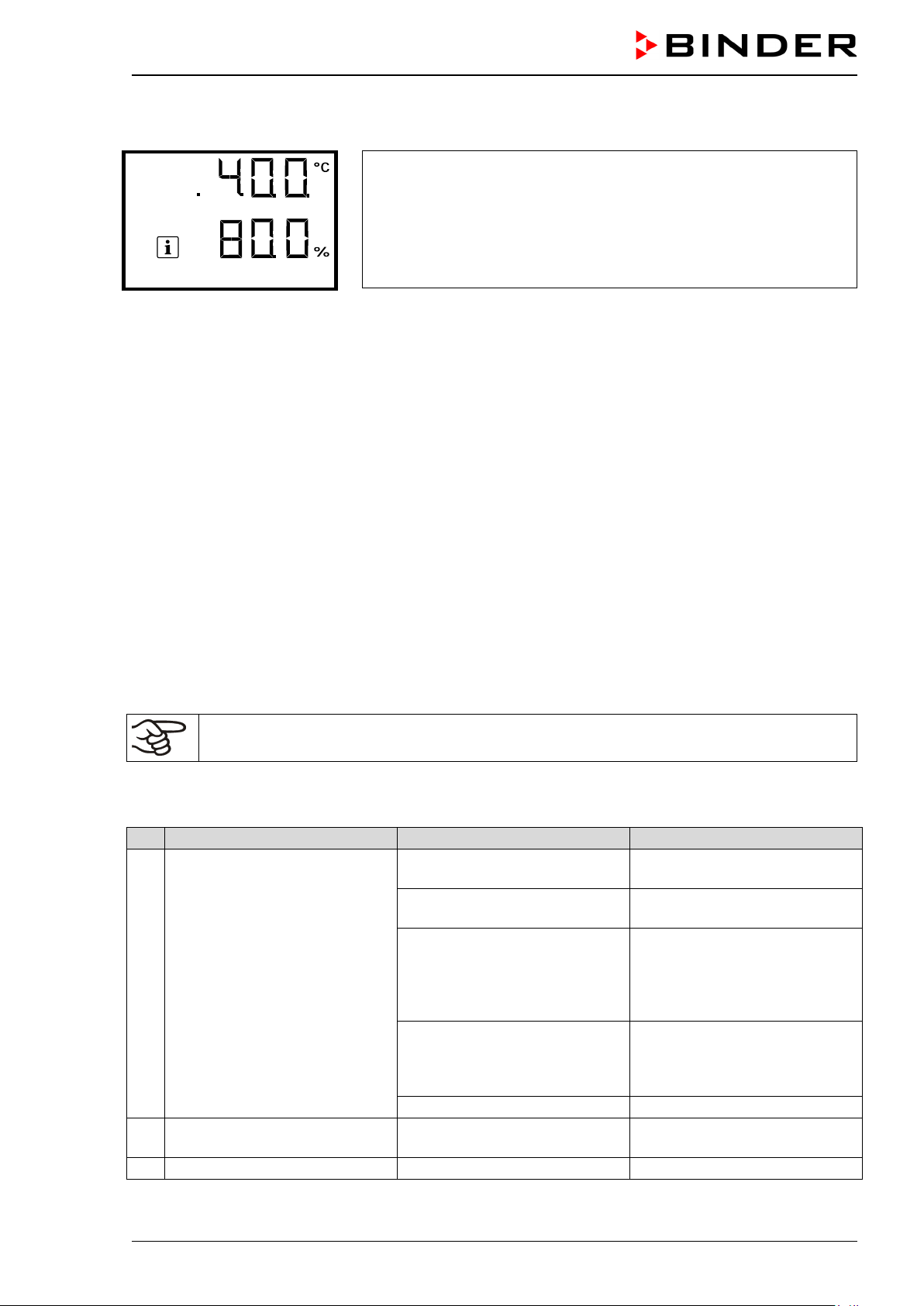

14. CHAMBER SETTINGS (FOR EXPERIENCED USERS ONLY) ........................... 54

14.1 Setting the humidity control ............................................................................................................... 54

14.2 Setting the door heating offset .......................................................................................................... 54

14.3 Adjusting the heating power – for BINDER Service only .................................................................. 55

15. NOTIFICATION AND ALARM FUNCTIONS ........................................................ 55

15.1 Alarm messages ............................................................................................................................... 55

15.2 Information messages ....................................................................................................................... 57

15.3 Activating / deactivating the audible alarm (alarm buzzer) ............................................................... 58

15.4 Measures in case of alarm ................................................................................................................ 58

15.4.1 Door open al arm ..................................................................................................................... 58

15.4.2 Safety controller temperature alarm ....................................................................................... 58

15.4.3 Temperature tolerance range alarm (overtemperature / too low temperature) ...................... 59

15.4.4 CO2 tolerance range alarm (CO2 over/under concentration) .................................................. 60

15.4.5 CO2 pressure alarm ................................................................................................................ 60

15.4.6 Power failure alarm ................................................................................................................. 61

15.4.7 Alarms referring to temperature sensor failures ..................................................................... 62

15.4.8 Alarms referring to CO2 sensor failure .................................................................................... 63

15.4.9 Alarm on ineffective sterilization ............................................................................................. 63

15.5 Zero-voltage relay alarm output ........................................................................................................ 64

CB-S / CB-S-UL (E7) 06/2020 page 3/119

Page 4

16. ETHERNET NETWORK SETTINGS .................................................................... 65

16.1 Showing the network settings ........................................................................................................... 65

16.1.1 Showing the chamber‘s MAC address .................................................................................... 65

16.1.2 Showing the IP address .......................................................................................................... 65

16.1.3 Showing the subnet mask ....................................................................................................... 66

16.1.4 Showing the standard gateway ............................................................................................... 66

16.1.5 Showing the DNS server address ........................................................................................... 66

16.1.6 Showing the DNS chamber name .......................................................................................... 67

16.2 Changing the configuration of the network settings .......................................................................... 67

16.2.1 Selecting the type of IP address assignment (automatic / manual) ....................................... 67

16.2.2 Selecting the type of assignment of the DNS server address (automatic / manual) .............. 68

16.2.3 Assigning the IP address ........................................................................................................ 68

16.2.4 Setting the subnet mask ......................................................................................................... 69

16.2.5 Setting the standard gateway ................................................................................................. 69

16.2.6 Assigning the DNS server address ......................................................................................... 70

17. DATA RECORDER .............................................................................................. 70

17.1 Recorded data ................................................................................................................................... 70

17.2 Storage capacity ............................................................................................................................... 71

17.3 Setting the storage rate for the “DL1” recorder data ......................................................................... 71

17.4 Deleting the data recorder................................................................................................................. 71

18. USB MENU: D ATA TR ANSFER VIA USB INTERFACE ..................................... 72

18.1 Connecting the USB stick ................................................................................................................. 72

18.2 Import function .................................................................................................................................. 73

18.3 Export functions ................................................................................................................................ 73

18.4 Ongoing data transfer ....................................................................................................................... 74

18.5 Error during data transmission .......................................................................................................... 74

18.6 Removing the USB stick ................................................................................................................... 74

19. REFERENCE MEASUREMENTS ........................................................................ 75

19.1 CO2 reference measuring ................................................................................................................. 75

19.1.1 Measuring the CO2 concentration indirectly via the pH of the cell medium ............................ 75

19.1.2 Measuring CO2 directly via chemical indicator tubes.............................................................. 76

19.1.3 Measuring CO2 directly with an electronic inf rar ed m eas uring de vice ................................... 77

19.2 Temperature reference measurement .............................................................................................. 77

20. OPTIONS .............................................................................................................. 77

20.1 Silicone access ports 30 mm / 1.18 in, closable with 2 silicone plugs (8012-0558 rear, 8012-0559

left, 8012-0560 right) (option) ............................................................................................................ 77

20.2 Base on castors (option) ................................................................................................................... 78

20.3 Flat stacking frame (option)............................................................................................................... 78

20.4 APT-COM™ 4 Multi Management Software (option) ........................................................................ 78

20.5 Data logger kit (option) ...................................................................................................................... 78

20.6 Analog outputs for temperature and CO2 (option) ............................................................................ 79

21. AVOIDING MICROBIAL CONTAMINATION........................................................ 79

21.1 Cells and media ................................................................................................................................ 79

21.2 Laboratory conditions / equipment around the CO2 incubator .......................................................... 79

21.3 Working and behavior in the lab ....................................................................................................... 80

21.4 Chamber design and equipment ....................................................................................................... 80

21.5 Handling the CO2 incubator .............................................................................................................. 81

22. CLEANING, DECONT AMI NATION / DISINFECTION, AND STERILIZATION .... 82

22.1 Cleaning ............................................................................................................................................ 83

22.2 Decontamination / chemical disinfection of the chamber .................................................................. 84

22.3 Disinfection of the CO2 sensor .......................................................................................................... 85

CB-S / CB-S-UL (E7) 06/2020 page 4/119

Page 5

23. HOT-AIR STERILIZATION AT 180 °C / 356 °F .................................................... 86

23.1 Overview ........................................................................................................................................... 86

23.2 Performing a hot-air sterilization ....................................................................................................... 87

23.2.1 Preparations for hot-air sterilization ........................................................................................ 87

23.3 Starting and running the hot-air sterilization cycle ............................................................................ 88

23.3.1 Starting sterilization ................................................................................................................. 88

23.3.2 Performance during sterilization ............................................................................................. 89

23.3.3 Completing the entire sterilization cycle ................................................................................. 89

23.4 Prematurely terminating the sterilization cycle – effects ................................................................... 90

23.4.1 Premature termination after less than 6 hours: Ineffective sterilization .................................. 90

23.4.2 Premature termination after more than 6 hours, i.e., during the cooling-do wn phas e:

successful sterilization ............................................................................................................ 91

23.5 Prematurely terminating the sterilization cycle – procedure ............................................................. 91

23.5.1 Cancelling sterilization via the controller menu ...................................................................... 91

23.5.2 Opening the outer door ........................................................................................................... 92

23.5.3 Turning off the chamber .......................................................................................................... 92

24. MAINTEN ANCE, AND SERVICE, TROUBLESHOOTING, REPAIR, TESTING .. 93

24.1 General information, personnel qualification..................................................................................... 93

24.2 Maintenance intervals, service .......................................................................................................... 94

24.3 Service Reminder .............................................................................................................................. 94

24.4 Gas inlet fine filter ............................................................................................................................. 95

24.5 Simple troubleshooting ...................................................................................................................... 95

24.5.1 General ................................................................................................................................... 95

24.5.2 Temperature ........................................................................................................................... 96

24.5.3 CO2 ......................................................................................................................................... 97

24.5.4 Humidity .................................................................................................................................. 98

24.5.5 Controller ................................................................................................................................ 98

24.5.6 Sterilization ............................................................................................................................. 98

24.6 Sending the chamber back to BINDER GmbH ................................................................................. 99

25. DISPOSAL.......................................................................................................... 100

25.1 Disposal of the transport packing .................................................................................................... 100

25.1.1 Outer chamber packing......................................................................................................... 100

25.1.2 Packing inside the chamber, equipment ............................................................................... 100

25.2 Decommissioning ............................................................................................................................ 101

25.3 Disposal of the chamber in the Federal Republic of Germany ....................................................... 101

25.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany................................................................

25.5 Disposal of the chamber in non-member states of the EU ............................................................. 103

.......................................................................... 102

26. TECHNICAL DESCRIPTION .............................................................................. 104

26.1 Factory calibration and adjustment ................................................................................................. 104

26.2 Over current protection ................................................................................................................... 104

26.3 Definition of usable volume ............................................................................................................. 104

26.4 CB-S / CB-S-UL technical data ....................................................................................................... 105

26.5 Important conversion data for non-SI units ..................................................................................... 106

26.6 Conversion table for gas inlet pressures, bar – psi ......................................................................... 107

26.7 Equipment and options (extract) ..................................................................................................... 107

26.8 Options, accessories, and spare parts (extract) ............................................................................. 108

26.9 Dimensions...................................................................................................................................... 109

27. CERTIFICATES AND DECLARATIONS OF CONFORMITY ............................. 111

27.1 EU Declaration of Conformity.......................................................................................................... 111

28. PRODUCT REGIS TRATION .............................................................................. 113

29. CONTAMIN ATION CLEARANCE CERTIFICATE ............................................. 114

29.1 For chambers located outside the USA and Canada ..................................................................... 114

29.2 For chambers in the USA and Canada ........................................................................................... 117

CB-S / CB-S-UL (E7) 06/2020 page 5/119

Page 6

Carefully read the com plete o perat ing i nstruc tions of t he cham ber prior t o inst alli ng and

Dear Customer,

For the correct operation of the C O

manual completely and carefully and observe all instructions as indicated. Failure to read, understand

and follow the instruc tions may result in personal inj ury. It c a n a ls o lead to damage to the chamber and/or

poor equipment performance.

incubator CB-S / CB-S-UL, it is important that you read this op erating

2

1. Safety

1.1 Personnel Qualification

The chamber m ust only be installed, tested, and start ed up by personn el qualified f or assembly, startup,

and operation of the chamber. Qualified personnel are persons whose professional education,

knowledge, experi ence and knowledge of rel e vant s ta n dar ds a llo w th em to assess, carr y out , and i den tify

any potential hazards i n the work assigned to them. T hey must hav e been tra ined and instructed, a nd be

authorized, to work on the chamber .

The chamber should only be operated by laboratory personnel especially trained for this purpose and

familiar with all prec aution ar y measures requir ed for work ing in a laboratory. Observe the nationa l reg ulations on minimum age of laboratory personnel.

1.2 Operating manual

This oper ating manual is part of t he components of deliver y. Always keep it hand y for reference in the

vicinity of the chamber. If selling the unit, hand over the operating manual to the purchaser.

To avoid injuries and damage observe th e safety instructions of the operating m anual. Failure to follow

instructions and safety precautions can lead to significant risks.

DANGER

Dangers due to failure to observe the ins truc tions and safety precautions.

Serious injuries and chamber damage. Risk of death.

Observe the safety instructions in this Operating Manual.

Follow the operating procedures in this Operating Manual.

using the chamber.

Keep the operating manual for future reference

Make sure that all persons who use the chamber and its associated work equipment have

read and understood the Operating Manual.

This Operating Manu al is supplem ented and updated as needed. Al ways use the m ost recent version of

the Operating Manual. When in doubt, call the BINDER Service Hotline for information on the up-todateness and validity of this Operating Manual.

1.3 Legal considerations

This operating m anual is for informationa l purposes only. It co ntains information f or correct and safe installing, start-up, operat ion, decommissioning, cleani ng and maintenance of the product. No te: the contents and the product described are subject to change without notice.

Understanding and obs erving the instructions in this operat ing manual are prerequisites for ha zard-free

use and safety dur ing oper ation and m ainten ance. Im ages are to pro vide basic under stan ding. The y ma y

deviate from the actual ver sion of the cham ber. The act ual scope of deliver y can, due to opt ional or special design, or due to recent technical changes, deviate from the information and illustrat ions in these

instructions this operating manual.

CB-S / CB-S-UL (E7) 06/2020 page 6/119

Page 7

In no event shall BINDER be held liable f or any damages , direct or incidental ar ising out of or related to

the use of this manual.

This operating manual ca nnot cover all conc eivable applicati ons. If you would like additional inf ormation,

or if special problem s arise that are not suff iciently addressed in th is manual, please ask your dealer or

contact us directly, e.g. by phone at the number located on page one of this manual

Furthermore, we emphas ize that the contents of this operating manual are not p art of an earlier or existing agreement, des c ripti on, or leg al rel ati ons h ip, nor d o t h e y m od ify such a relationship. All o bl ig ati ons on

the part of BINDER deriv e from the res pective purchase contr act, which also con tains the entire and exclusively valid stat ement of warrant y administration a nd the genera l terms and co nditions, as wel l as the

legal regulations va lid at the time the contr act is concluded. The s tatements in this m anual neither augment nor restrict the contractual warranty provisions.

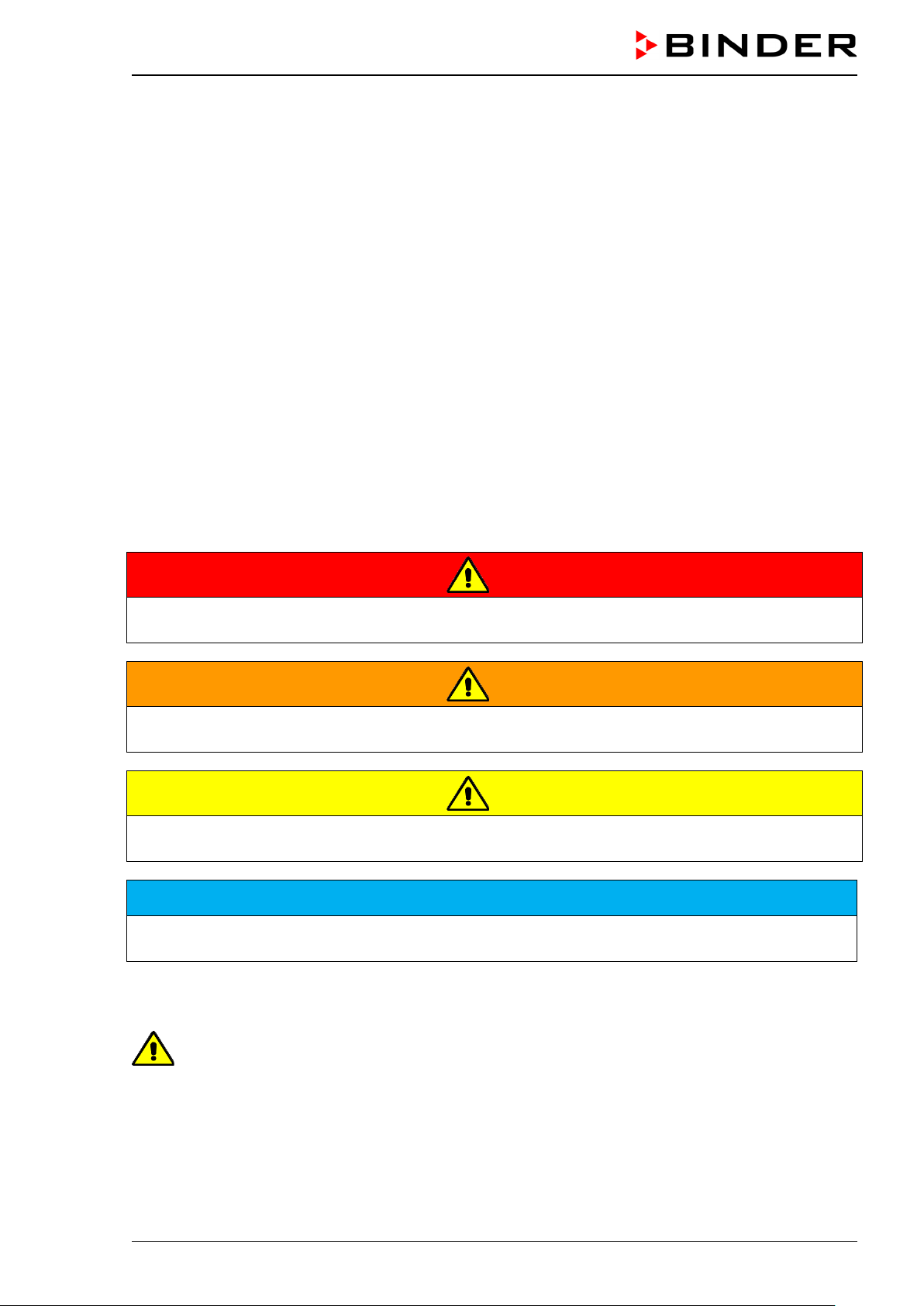

1.4 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations in

accordance with the standards ISO 3864-2 and ANSI Z535.6.

1.4.1 Signal word panel

Depending on the s eriousness and pro bability of serio us consequences, potential dangers are identified

with a signal word, the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

(irreversible) injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury

NOTICE

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its proximity.

1.4.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

CB-S / CB-S-UL (E7) 06/2020 page 7/119

Page 8

Warning signs

Electrical hazard

Hot surface

Explosive Atmosphere

poisoning hazard

or chemical burns

Mandatory action signs

instructions

Environment protection

Wear protective gloves

Wear safety goggles

Prohibition signs

water

1.4.3 Pictograms

Lifting hazard

Harmful substances

Mandatory regulation

Gas cylinders

Biohazard

Read operating

CO

suffocation and

2

Risk of corrosion and /

Disconnect the power

plug

Stability hazard

Pollution Hazard

Lift with several persons

Do NOT touch

Do NOT spray with

Do NOT climb

Information to be observed in order to ensure optimum function of the product.

1.4.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

∅ Instruction on how to avoid the hazard: prohibition

Instruction on how to avoid the hazard: mandatory action

Observe all other n otes and inform ation not necessarily em phasized in the sam e way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

CB-S / CB-S-UL (E7) 06/2020 page 8/119

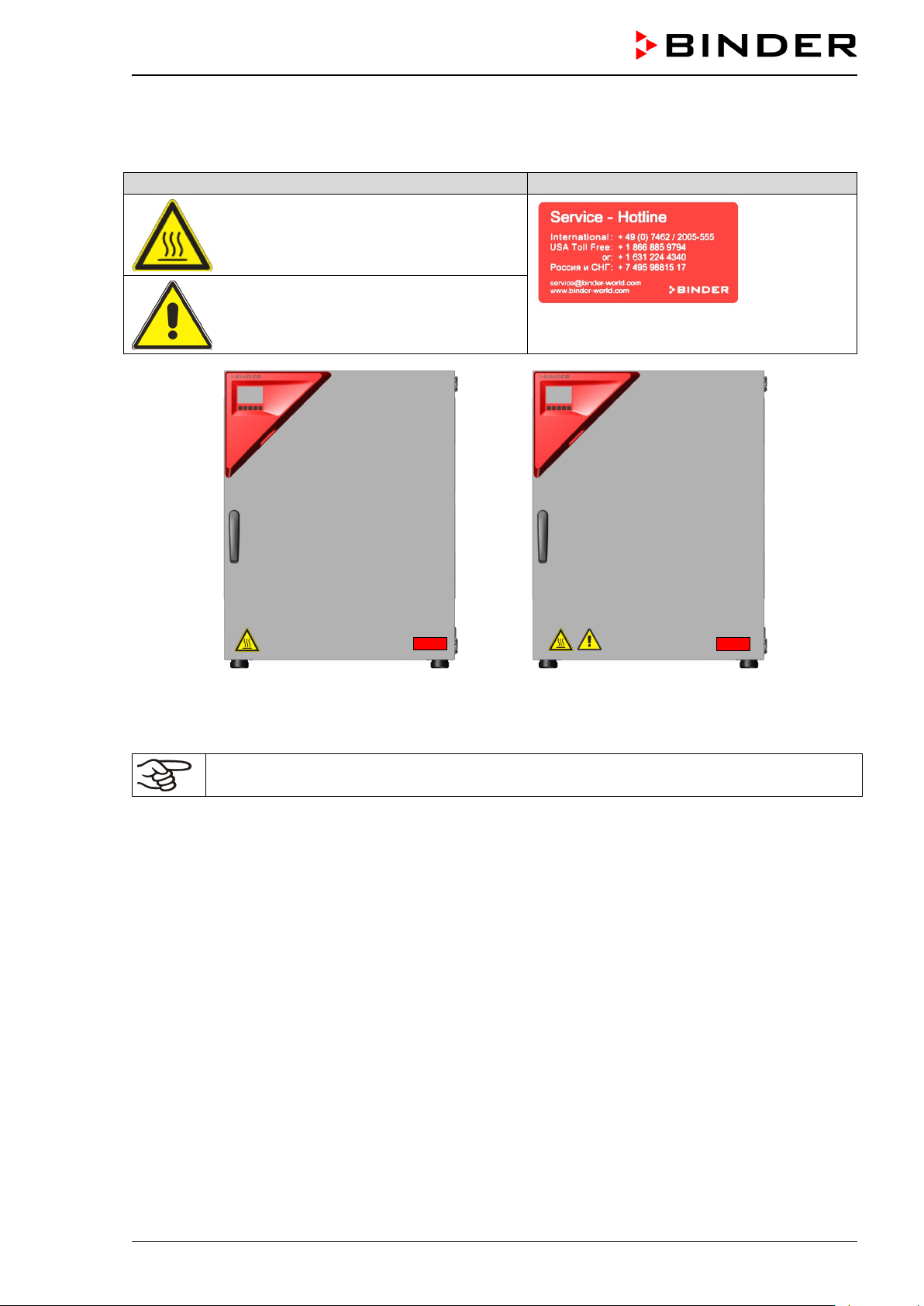

Page 9

Pictograms (Warning signs)

Service label

Figure 1: Position of labels

Figure 2: Position of labels

1.5 Localization / position of safety labels at the chamber

The following labels are located on the chamber:

Hot surface

Risk of injury (UL chambers only).

Observe the safety instructions in the

operating manual.

on the CO2 incubator CB-S

on the CO2 incubator CB-S-UL

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER Service for these replacements.

CB-S / CB-S-UL (E7) 06/2020 page 9/119

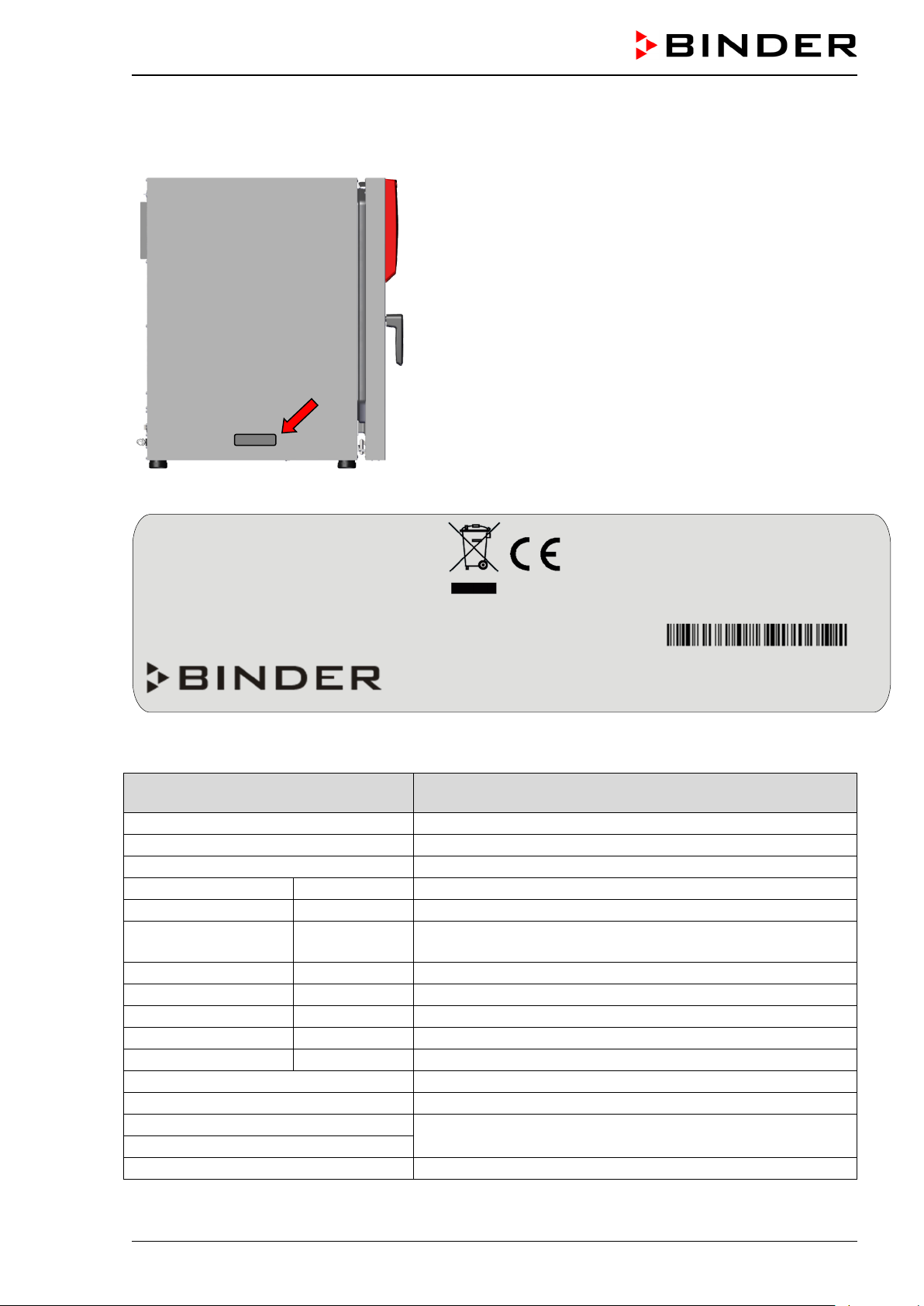

Page 10

Indications of the type plate

(example)

Information

BINDER

Manufacturer: BINDER GmbH

CB-S 170

Model designation

CO2 Incubator

Device name: CO2 Incubator

Serial No.

000000000000

Serial No. of the chamber

Built

2020

Year of construction

190 °C

374 °F

IP protection

20

Type of IP protection acc. to standard EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880:2007

Class

3.1

Class of temperature safety device

Art. No.

9040-0189

Art. No. of the chamber

Project No.

---

Optional: Special application acc. to project no.

1,30 kW

Nominal power

6,1 A

Nominal current

200-230 V / 50 Hz

200-230 V / 60 Hz

1 N ~

Current type

Nominal temp.

190 °C

1,30 kW / 6,1 A

374 °F

200-230 V / 50 Hz

IP protection

20

200-230 V / 60 Hz

Safety device

DIN 12880

1 N ~

Class

3.1

Art. No.

9040-0189

Project No.

Built

2020 CO2 Incubator

BINDER GmbH

www.binder-world.com

CB-S 170

E7

Serial No. 00000000000000

1.6 Type plate

Position of type plate: left chamber side (seen from front), at the bottom in the middle.

Figure 3: Position of type plate

Figure 4: Type plate (example CB-S 170 standard chamber, 9040-0189)

Nominal temperature

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

Nominal temperature

Made in Germany

CB-S / CB-S-UL (E7) 06/2020 page 10/119

Nominal voltage range +/- 10%

at the indicated power frequency

Page 11

Symbol on the type plate

Information

CE conformity marking

Electrical and electronic equipment manufactured / placed on

the market in the EU after 13 August 2005 and to be disposed of

in a separate collection according to Directive 2012/19/EU on

waste electrical and electronic equipment (WEEE).

1.7 General safety instructions on installing and operating the chamber

With regard to operat ing the chamber and to the installation location, please o bserve the local and national regulations rel evant for your country (for Germ any: DGUV guidelines 213-850 on saf e working in

laboratories, issued by the employers’ liability insurance association).

BINDER GmbH is only respons ible for the safety feat ures of the chamber provided s killed electricians or

qualified personnel authorized by BIND ER perform all m aintenance and rep air, and if com ponents relating to chamber safety are replaced in the event of failure with original spare parts.

To operate the chamber, use only origin al BINDER ac cessories or accessories from thir d-party suppli ers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

NOTICE

Danger of overheating due to lack of ventilation.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Observe the prescribed minimum distances when installing the chamber (chap.3.4).

Do not install or operate the chamber in ha zar dous lo c ations .

DANGER

Danger of explosion due to combustible du sts or explosive mixtures in the vicinity

of the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT operate the chamber in potentially explosive areas.

KEEP combustible dust or air-solvent mixtures AWAY from the chamber.

The chamber does not dispose of any measures of explosion protection.

DANGER

Danger of explosion due to introduction of flammable or explosive substances in

the chamber.

Serious injury or death from burns and / or explosion pressure.

∅ Do NOT introduce any substance into the chamber which is combustible or explosive at

working temperature.

∅ Do NOT introduce any combustible dust or air-solvent mixture in the inner chamber.

Any solvent contai ned in th e charging m aterial must not b e explosi ve or inflam mable. I.e., irrespecti ve of

the solvent concentrati on in the steam room, NO explos ive mixture with air m ust form. The temperature

inside the cham ber m ust lie belo w the f lash point or b elow the s ublim ation po int of the chargi ng m aterial.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy and humidity.

CB-S / CB-S-UL (E7) 06/2020 page 11/119

Page 12

Familiarize yourself with any potential health risk s caused by the ch arging material, the contained m oisture constituent or b y reaction products that m ay arise during the temperature process. Take adequate

measures to exclude such risks prior to putting the CO

incubator into operation.

2

DANGER

Electrical hazard by water entering the chamber.

Deadly electric shock.

∅ The chamber must NOT become wet during operation, cleaning, or maintenance.

∅ Do NOT install the chamber in damp areas or in puddles.

Set up the chamber in a splash-proof manner.

The chambers were produced in accord ance with VDE regulations and were routinely tested in acc ordance to VDE 0411-1 (IEC 61010-1).

During and after a sterilization the temperature of the inner surfaces almost equals the set-point. The

glass door, the glass door handle, and the inner chamber will become hot during a sterilization.

CAUTION

Danger of burning by touching hot chamber parts during or after a sterilization.

Burns.

∅ Do NOT touch the glass door, the glass door handle, the inner surfaces, and door gas-

kets during or after a sterilization.

Danger of injury and damages by the chamber tipping over.

Injuries and damage to the chamber and the charging material

∅ Do NOT load the chamber door with heavy objects while it is open.

WARNING

CB-S / CB-S-UL (E7) 06/2020 page 12/119

Page 13

Always close the valve ev e n with app ar ent l y empty cylinders; screw on the c ap when not in

1.8 Precautions when working with CO2 gas

Carbon dioxide (CO2) in high conce ntrations is hazardous to he alth. It is colorless and almost odorless

and therefore practica lly impercepti ble. Vent out an y CO

or a suitable connection to an exhaust system. We recommend installing a CO

gas that m ay escape via goo d room ventilat ion

2

warning system.

2

DANGER

Danger of suffocation and poisoning by high concentration of CO2 (> 4 Vol.-%).

Death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling CO

Close the CO

supply when decommissioning the chamber.

2

1.9 Precautions when handling gas cylinders

General information for safe handling of gas cylinders:

• Store and use gas cylinders only in well-ventilated locatio ns .

.

2

• Open the gas cylinder valve slowly to avoid pressure surges

• Secure gas cylinders during storage and use against falling (chaining).

• Transport gas cylinders with a cylinder cart, do not carry, roll, or throw them.

•

use. Return gas cylinders with the valve closed.

• Do not open gas cylinders by force. Mark them when dam aged

• Protect gas cylinders against fire, e.g. do not store together with flammable liquids

• Observe relevant regulations for dealing with gas cylinders.

Secure the gas cylinders against falling and other mechanical damage.

WARNING

Risk of injury through sudden release of the stored pressure energy when the valve

safety is torn off.

Injuries.

Secure gas cylinders against falling (chaining).

Transport gas cylinders with a cylinder cart.

The valve of the gas cylinder always must be closed before screwing on or unscrewing the gas hose.

WARNING

Risk of injury through sudden release of the stored pressure energy when opening

the cylinder valve of a not connected cylinder.

Injuries.

Close the gas cylinder valve before connecti ng or remov ing the gas hose.

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or

diluted soap solution).

CB-S / CB-S-UL (E7) 06/2020 page 13/119

Page 14

1.10 I nte nded use

Observing the instructions in this operating manual and conducting regular maintenance

work (chap. 24) is part of the intended use.

Any use of the chambers that does not comply with the requirements specified in this Operating

Manual shall be considered improper use.

Other applications than those described in this chapter are not approved.

Use

incubators CB-S / CB-S-UL are suitable f or the cultivation of m ammal cells under typical con ditions

CO

2

of approx. 37 °C / 98. 6 °F . The chambers permit s ettin g def ined pH con ditions b y comm on NaHC O

er systems of c ommercial cell media b y k eep in g a n exact CO

atmosphere i ns ide . T he c hambers guaran-

2

tee high humidity inside to avoid osmolarity increasing caused by the evaporation of the cell media.

The chambers are suitable for exact conditioning of harmless materials.

Requirements for the chamber load

Any solvent any solvent must not be explosive and flammable. Components of the charging material must

NOT form an explosive m ixture with air. The operat ing temperature m ust lie below the flash point or below the sublimation point of the c harging m aterial . An y component of the charging material m ust NO T be

able to release toxic gases.

buff-

3

The charging mater ial shall not conta in any corrosi ve ingredients that may damage th e machine com ponents made of stainless steel, aluminum, and copper. Such ingredients include in particular acids and

halides. Any corrosive damage caused by such ingredients is excluded from liability by BINDER GmbH.

The chamber does not dispose of any measures of explosion protection.

DANGER

Explosion or implosion hazard and danger of poisoning through the introduction of

unsuitable loading material.

Poisoning. Serious injury or death from burns and / or explosion pressure.

∅ Do NOT introduce any substance combustible or explosive at working temperature into

the chamber, in particular no energy sources such as batteries or lithium-ion batteries.

∅ NO explosive dust or air-solvent mixture in the inner chamber.

∅ Do NOT introduce any substance which could lead to release of toxic gases.

Contamination of the chamber by toxic, infectious or radioactive substances must be prevented

WARNING

Danger of intoxication and infection through contamination of the chamber with

toxic, infectious or radioactive substances.

Damages to health.

Protect the interior of the chamber from contamination by toxic, infectious or radioactive

substances.

Take suitable protective measures when introducing and removing toxic, infectious or

radioactive material

In case of foreseeable use of the device there is no risk for the user through the integrat ion of the cham ber into systems or by special environm ental or operating conditions in the sense of EN 61010-1:2010.

For this, the intended use of the chamber and all its connections must be observed.

CB-S / CB-S-UL (E7) 06/2020 page 14/119

Page 15

Medical devices

The chambers are not classified as medical devices as defined by the Medical Device Directive

93/42/EEC.

Due to the special demands of the Medical Device Directive (MDD), these chambers are not

qualified for sterilization of medical devices as defined by the directive 93/42/EWG.

Personnel Requirements

Only trained person nel with knowledge of the Oper ating Ma nual can s et up and install the c ham ber, start

it up, operate, clea n, and take it out of operat ion. Service and repairs call f or further technical requirements (e.g. electrical know-how), as well as knowledge of the service manual.

Installation site requirements

The chambers are designed for setting up inside a building (indoor use).

The requirements des cribed in the Operating Manu al for installation s ite and ambient conditions (C hap.

3.4) must be met.

WARNING: If customer should use a BINDER chamber running in non-supervised continuous operation, we strongly recommend in case of inclusion of irrecoverable specimen or

samples to split such specimen or samples and store them in at least two chambers, if this is

feasible.

Relevant regulations for dealing with CO2 and gas cylinders must be observed.

1.11 Foreseeable Misuse

Other applications than those described in chap. 1.10 are not approved.

This expressly incl udes the following misuses ( the list is not exhaustive), which pos e risks despite the

inherently safe construction and existing technical safety equipment:

• Non-observance of Operating Manual

• Non-observanc e of inf ormation and warnings on th e chamber (e.g. co ntro l uni t messages, safet y ide n-

tifiers, warning signals)

• Installation , startup, operation, maintenance and re pair by untrained, insufficiently qualified, or unau-

thorized personnel

• Missed or delayed maintenance and testing

• Non-observance of traces of wear and tear

• Insertion of materials excluded or not permitted by this Operating Manual.

• Non-compliance with the admissible parameters for processing the respective material.

• Failure to comply with the relevant regulations for handling gas cylinders

• Failure to comply with the relevant regulations for handling CO

2

• Operation of the chamber without ventilation measures

• Installation, testing, service or repair in the presence of solvents

• Installation of replacement parts and use of accessories and operating r esources not specified and

authorized by the manufac turer

• Installation , startup, operat ion, maintenance or repair of the c hamber in absence of operating instr uc-

tions

• Bypassing or c hang in g pr ot ec tive systems, operation of the c hamber without the designated prot ect iv e

systems

CB-S / CB-S-UL (E7) 06/2020 page 15/119

Page 16

• Non-observance of messages regarding cleaning and disinfection of the chamber.

• Spilling water or clean ing agent on the cham ber, water penetrating into the c hamber dur ing operat ion,

cleaning or maintenance.

• Cleaning activity while chamber is turned on.

• Operation of the chamber with a damaged housing or damaged power cord.

• Continued operation of the chamber during an obvious malfunction

• Insertion of objects, particularly metallic objects, in louvers or other openings or slots on the chamber

• Human error (e.g. insufficient experience, qualification, stress, exhaustion, laziness)

To prevent these and ot her r isk s from incorrect operation, it is rec om mended the operator issue o per at ing

instructions and standard operating procedures (SOPs).

1.12 Residual Risks

The unavoidable design f eatures of a chamber, as well as its proper f ield of application, can also pose

risks, even during corr ect operation. These residual risk s include hazards which, despite the in herently

safe design, existing technical protective equipment, safety precautions and supplementary protective

measures, cannot be ruled out.

Messages on the chamber and in the Operating Manual warn of residual risks. The consequences of

these residual risk s and the m easures required to prevent them ar e listed in th e Operati ng Manu al. Mor eover, the operator must take measures to minimize hazards from unavoidable residual risks. This includes, in particular, issuing oper ati ng instr uc tions .

The following list s ummarizes the hazar ds against which this Operating Manua l and the Service Manual

warn, and specifies protective measures at the appropriate spots:

Unpacking, Transport, Installati on

• Sliding or tilting the chamber

• Setup of the chamber in unauthorized areas

• Installation of a damaged chamber

• Installation of a chamber with damaged power cord

• Inappropriate site of installation

• Missing protective conductor connection

Normal operation

• Assem bly errors

• Contact with hot surfaces on the housing

• Contact with hot surfaces in the interior and inside of doors

• Emission of non-ionizing radiation from electrical operating resources

• Contact with live parts in normal state

Cleaning and Decontamination

• Penetration of water into the chamber

• Inappropriate cleaning and decontamination agents

• Enclosure of persons in the interior

CB-S / CB-S-UL (E7) 06/2020 page 16/119

Page 17

Malfunction and Damage

• Continued oper ation of the chamber during an obvio us malfunction or outage of the heating or gas

systems

• Contact with live parts during error status

• Operation of a unit with damaged power cord

Maintenance

• Maintenance work on live parts.

• Execution of maintenance work by untrained/insufficiently qualified personnel

• Electrical safety analysis during annual maintenance not performed

Trouble-shooting and Repairs

• Non-observance of warning messages in the Service Manual

• Trouble-shooting of live parts without specified safety measures

• Absence of a plausibility check to rule out erroneous inscription of electrical components

• Performance of repair work by untrained/insufficiently qualified personnel

• Inappropriate repairs which do not meet the quality standard specified by BINDER

• Use of replacement parts other than BINDER original replacement parts

• Electrical safety analysis not performed after repairs

1.13 O perating instructions

Depending on the appl ication and location of the chamber , it is recommended that the operator of the

chamber provides the re lev ant inf orm ation f or saf e op eratio n of the c ham ber in a s et of oper ating instr uctions.

Keep these operating instructions with the chamber at all times in a place where they are

clearly visible. They must be comprehensible and written in the language of the employees.

CB-S / CB-S-UL (E7) 06/2020 page 17/119

Page 18

1.14 Measures to prevent accidents

The manufacturer took the following measures to prevent dangers:

• Indications on the type plate

See operating manual chap. 1.6.

• Operating manual

An operating manual is available for each chamber.

• Overtemperature monitoring

The chamber is equipped with a temperature display, which can be read from outside.

The chamber is equipped with an additional saf et y controller (tem peratur e saf ety device c lass 3.1 ac c.

to DIN 12880:2007). Visual and audible (buzzer) signals indicate temperature exceeding.

• Safety, measurement, and control equipment

The safety, measuring, and control equipment is easily accessible.

• Electrostatic ch arg e

The interior parts are grounded.

• Non-ionizing radiation

Non-ionizing radiatio n is not intentionall y produced, but release d only for technical reas ons by electrical equipment (e.g. power cables). T he machine is equipped with no per manent magnets. If persons

with active implants ( e.g. pacemaker s, defibrillators) keep a safe distance (distan ce of field source to

implant) of 30 cm, an influence of these implants can be excluded with high probability.

• Protection against touchable surfaces

Tested according to EN ISO 13732-1:2008.

• Floors

See operating manual chap. 3.4 for correct installation

• Cleaning

See operating manual chap. 22.1.

CB-S / CB-S-UL (E7) 06/2020 page 18/119

Page 19

2. Chamber description

The CO2 incubators CB-S / CB-S-UL series were produc ed with great care using the latest tools for development and produc ti on. They can be oper at ed in a t emperature range from 6 °C / 10.8 °F ab ove ambient temperature up to +50 °C / 122°F and a CO

equipped with a m icroprocessor contr oller for tem perature and CO

to one-tenth of a degree resp. 0.1 vol.-%. T he y are availab le in dif f erent voltages .

Material: The inner cham ber, the pre-h eating cham ber and the ins ide of the d oors are all made of s tainless steel V2A (German materia l no. 1.4301, US equivalent AISI 304). The inner surfaces are smooth and

therefore easy to clean. T h e inner cham ber is deep-drawn from one p iece, p olis hed (s uitab le f or pharm aceutical applications) and has no welds or inaccessible corners. The hinges and the seal of the inner

glass door are glue d from the outside to aid cl eaning of the inner c ham ber. When op erating the cham ber

at high temperatures (sterilization), the im pact of the oxygen in the air may cause discoloration of the

metallic surfaces (yellowish-brown or blue) b y natural oxidation processes. T hese colorations are harmless and will in no way impair the function or quality of the chamber.

The perforated she lv es are also made of s ta in les s s te el (German mater ial no . 1.4016, US equ ival ent AISI

430). You can insert a maximum of 6 (CB-S / CB-S-UL 170) bzw. 8 (CB-S / CB-S-UL 260) shelves.

The housing is RAL 7 035 powder-coated. All corners and edges are also c ompletely coate d. The standard chamber door is hinged right. The chamber is optionally available with the door hinged left.

Sterilization: The heating system of the chamber permits hot-air auto-sterilization at 190 °C / 374 °F.

Thus, a temperature of at least 180 °C / 356 °F is maintained on al l inter na l s urf ac es , r esulti ng i n ster i lization of the entire inner chamber.

range of 0 vol.-% up t o 20 vol.-%. The chamber s are

2

levels and a dig ital display accurat e

2

Safety: T hanks to the standard s afety devic e (class 3.1 accord ing to DIN 12880:2007), the set t emperature is maintained in case of failure.

An error diagnost ics system monitors the c hamber functions and ge nerates audible and visual warning

and alarm messages. The door is monitored for being closed.

The controller provid es access control by com bining password pr otection with diff erent authorizati on levels.

system: A highly pre cise, drift-free CO2 infrared measuring s ystem in combination with the p erma-

CO

2

nent mixture of CO

precise and constant CO

gas through a special proprietary gas mixing head developed by BINDER allows

2

concentrations for long per iods. This creates optimum growth conditions for

2

cultures. The gas ent er s the c hamber via a fine filter (aseptic f ilt er ) with a h ig h f ilt r ation ef f iciency that also

filters the smallest particles.

The CO

sensor can be re m oved fr om the inner ch amber by hand and cleaned with s uita ble d etergent s if

2

needed.

Fast reaction times , maximum accurac y and selectivity charac terize the CO

chamber. The accurac y of the CO

measuring s ystem is based on an infrar ed measuring cell with NDIR

2

m easuring procedure of the

2

(non-dispersive inf rared) sensor, which continuously regul ates to a reference value. Therefore, distur bance variables an d aging phenom ena in th e meas uring s ystem are almost completel y elim inated, so that

this measuring system , in contrast to other measuring procedures , remains practic ally drift-free bet ween

calibrations and is entirely selective for CO

The CO

depends on the num ber of CO

measuring cell contains a measuring section inside, in which the absorption of infrared light

2

molecules in the be am path. This number of CO2 molecules changes with

2

.

2

the ambient press ure in relation t o a constant volume. The d istances between the molecules are consequently pressure-dependen t. T he collisio n frequenc y of the IR-beam with CO

molecules incr eases there-

2

fore by increasing pressure . For this reason, the am bient pr essure m ust be com pensate d in or der to cor rect the displa y readin g of t he CO

concentratio n i n vol .-%. This is achieved b y en tering the altitude of the

2

site above the sea (chap. 6.4).

Controller: T he efficient RD4 chamber controller is equipped with a m ultitude of operating functions, in

addition to recorder an d a la rm functions. Set-point entr y is easil y accom plished accurate to one-tenth of a

degree resp. 0.1 vol.-% directly via t he chamber contr oller and is also poss ible directly with a c omputer

via Intranet in connecti on with the APT-COM™ 4 Mu lti Management Software (option, chap. 20.4). The

controller provides password protection for the setting menus. An error diagnostics system generates

audible and visual alarm messages.

CB-S / CB-S-UL (E7) 06/2020 page 19/119

Page 20

(2)

(3)

(1)

Data monitoring and recording: The chamber is regularly equipped with a zero-voltage relay alarm

output (chap. 15.5) and optionally with analog outputs (chap. 20.6) for integration into customer systems.

The chamber is regularly equipped with an Ethernet interface for computer communication, enabling

monitoring via a netw ork. The BINDER APT-COM™ 4 Multi Managem ent Software (option, chap. 20.4)

permits network ing of up t o 100 ch am bers and con nection to a c om puter, as well as r ecordin g and re presenting temperature and CO

data.

2

A dat a logger independ ent from the cham ber controller (optio n, chap. 20.5) s erves to independentl y record the temperature values, data given out in compliance with FDA guideline 21 CFR part 11.

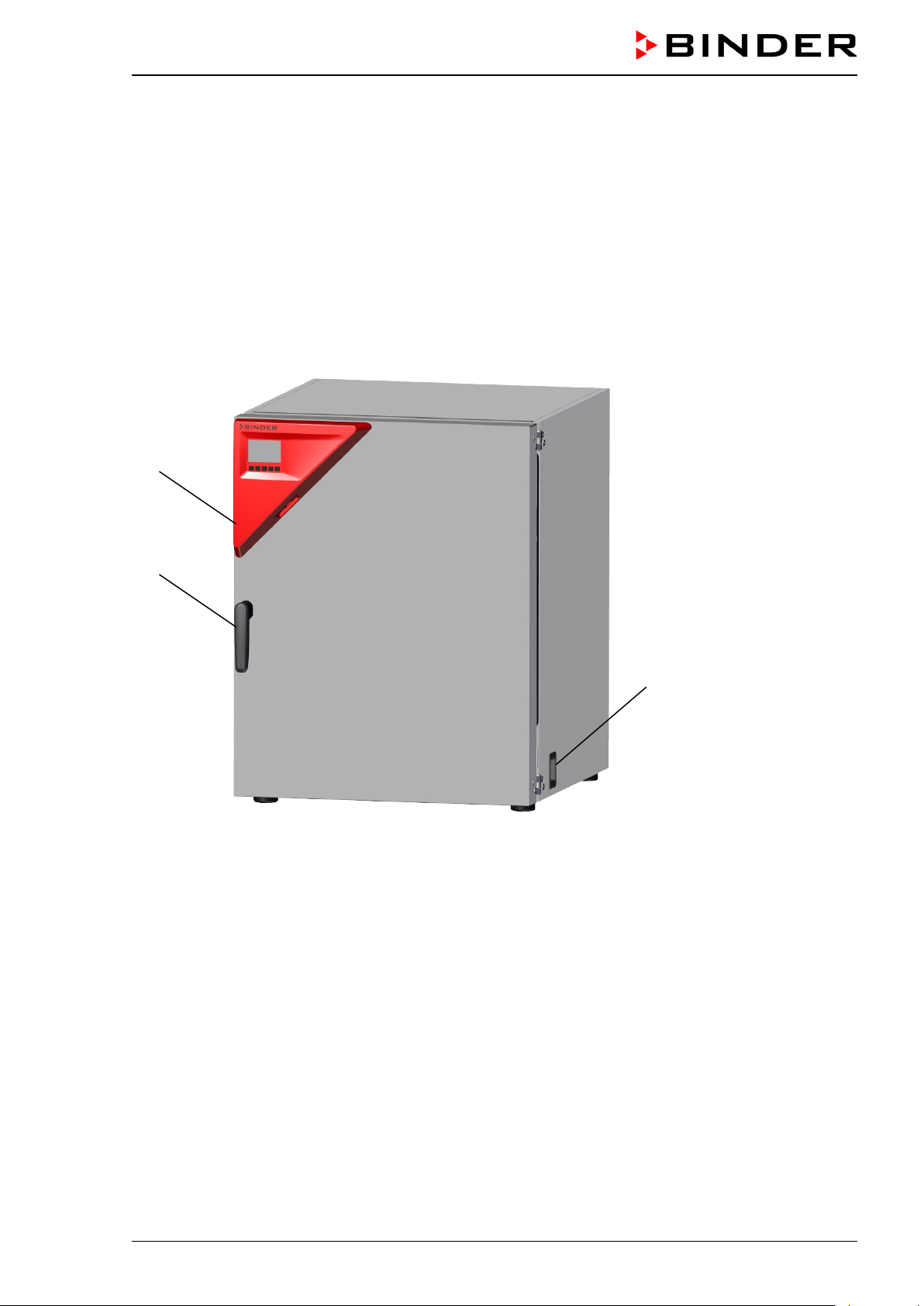

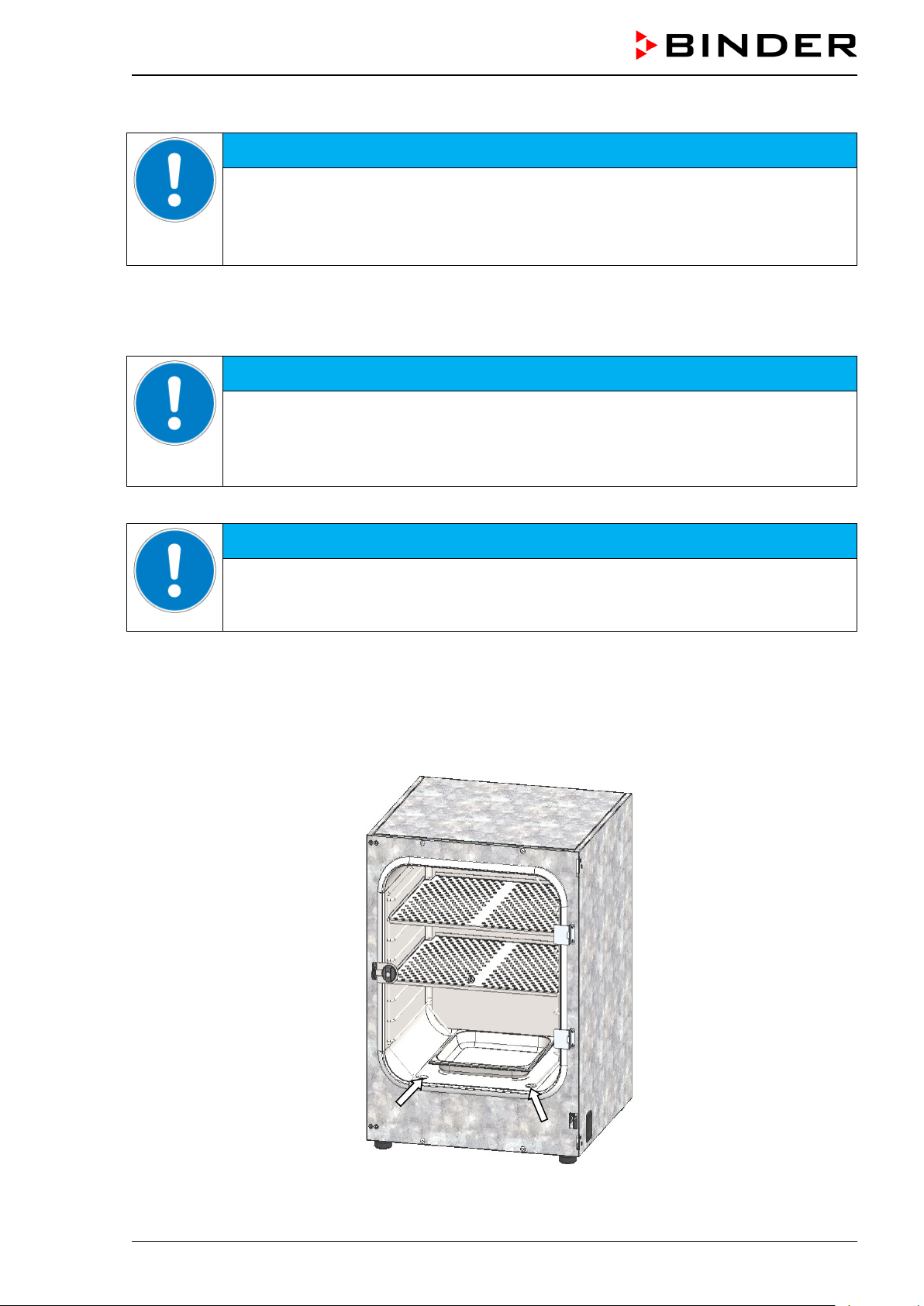

2.1 Chamber overview

Figure 5: CO

incubator CB-S / CB-S-UL (example CB-S 170), closed

2

(1) Triangle instrument panel w ith RD4 controller for temperature and CO

2

(2) Door handle

(3) Main power switch

CB-S / CB-S-UL (E7) 06/2020 page 20/119

Page 21

(11) (10) (9) (8) (1)

(4) (5) (6)

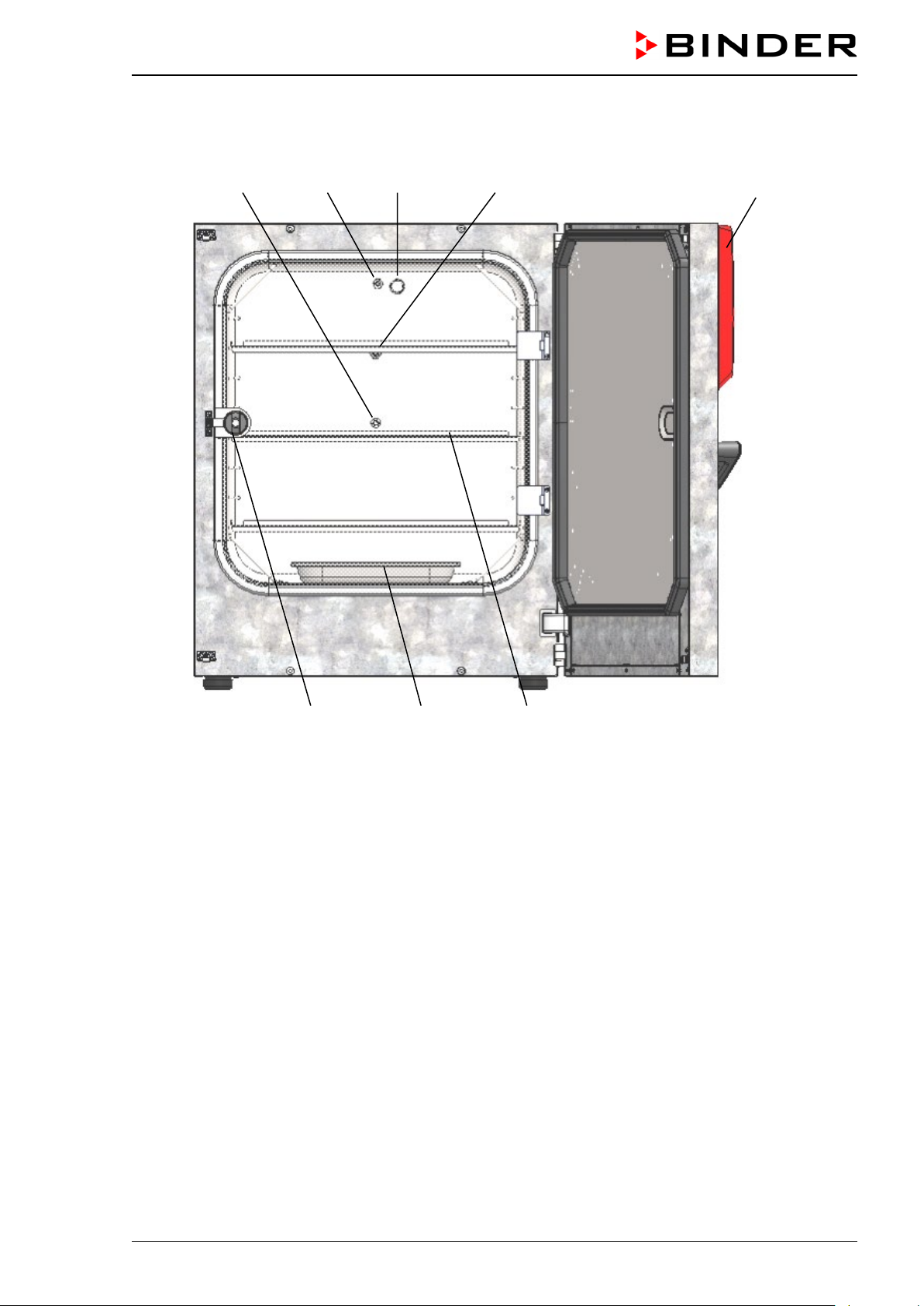

2.2 Inner chamber

Figure 6: CO

incubator CB-S / CB-S-UL (example CB-S 170), outer door open

2

(1) Triangle instrument panel with RD4 controller for temperature and CO

(4) Glass door handle

(5) Water pan

(6) Shelves

(7) (not used)

(8) Pt 100 temperature sensor

(9) CO

(10) Gas mixing head for CO

sensor

2

2

(11) Silicone measuring port in the glass door

2

CB-S / CB-S-UL (E7) 06/2020 page 21/119

Page 22

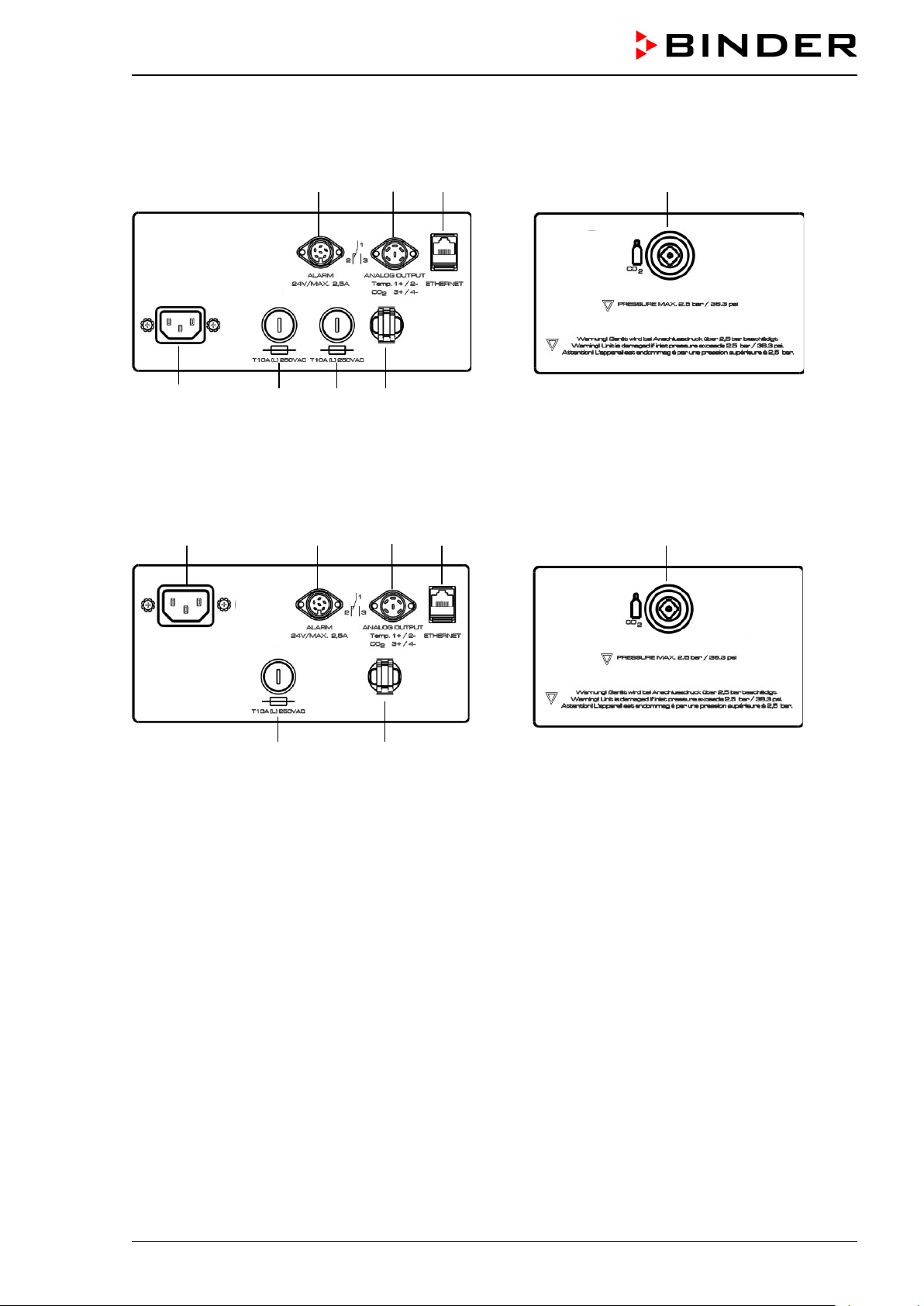

2.3 Connection panel on the rear of the chamber

(13) (14) (15) (18)

(12a) (16a) (16a) (17)

Figure 7: Rear control panel C with options

(12b) (13) (14) (15) (18)

(16b) (17)

Figure 8: Rear control panel C-UL with options

(12a) Socket for IEC connector plug / power cable 230 V AC for C

(12b) Socket for IEC connector plug / power cable 100-120 V AC for C-UL

(13) DIN-socket for zero-voltage relay alarm outputs

(14) DIN socket for analog outputs 4-20 mA (av ai lab le b y BINDER INDI VUD U AL Cus t omized Solutions)

(15) Ethernet interface for computer communication

(16a) Miniature fuse T10 A (L) 250 V AC for C

(16b) Miniature fuse T12,5 A (L) 250 V AV for C-UL

(17) Strain relief for power cable

(18) Quick acting closure socket for CO

2

CB-S / CB-S-UL (E7) 06/2020 page 22/119

Page 23

2.4 Chamber doors

The outer chamber door is equipped with a heater on its inner side. The do or must be closed while t he

chamber is operating normally in order to ensure stable climatic conditions in the inner chamber.

An additional glass door enables vi ewing of the s amples witho ut disturbi ng the tem peratur e in the interior

and contaminating the samples sealing the interior of the chamber.

When the outer door is open, the CO

Delay time for the temperature and CO

After closing the outer door, the tolerance range alarm is turned off for a programmable delay

time. This prevents alarms being constantly triggered during the unstable operating phase

after opening the outer door.

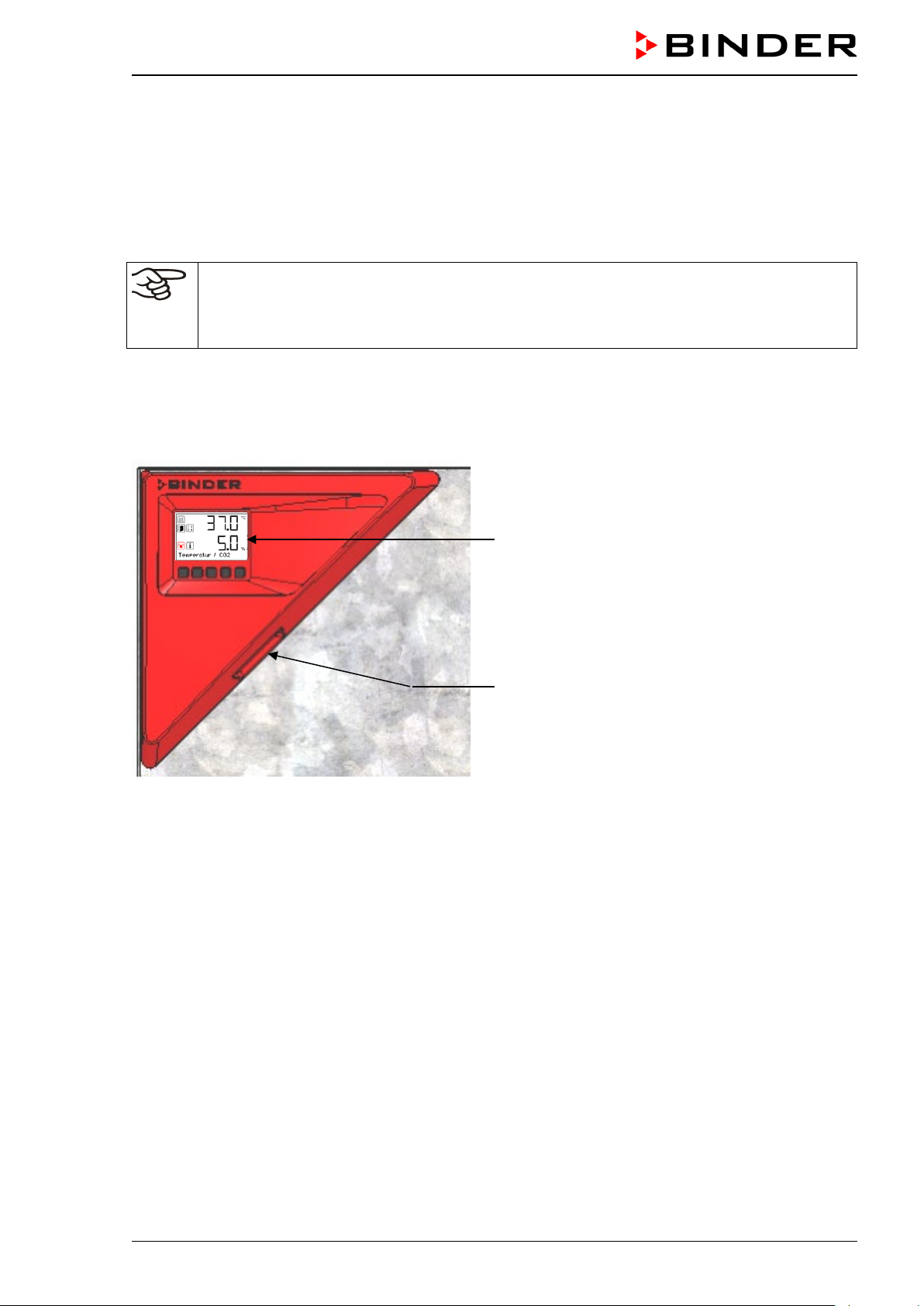

2.5 Ins trum ent panel

intake valve automatically closes.

2

tolerance range alarm :

2

RD4 controller display

USB interface

Figure 9: Instrument panel with RD4 controller and USB interface

CB-S / CB-S-UL (E7) 06/2020 page 23/119

Page 24

r corners with the aid of

3. Completeness of delivery, transportation, storage, and installa-

tion

3.1 Unpac king, and checking equipment and completeness of delivery

After unpacking, p lease check the chamber and its optiona l accessories, if any, based on t he delivery

receipt for completenes s and for transportation dam age. Inform the carrier immediate ly if transportation

damage has occurred.

The final tests of the manufacturer may have caused traces of the shelves on the inner surfaces. This has

no impact on the function and performance of the chamber.

Please remove an y transportati on protection devices and adh esives in/o n the chamber and o n the doors

and remove the operating manuals and accessory equipment.

For transport purpos e, a silica gel bag for dryin g purpose was added. Do not e at! Do not open the silica

gel bag and dispose of it with normal waste.

Remove any protective lamination sheet on the inner metal surfaces prior to commissioning.

CAUTION

If you need to return the chamber, please use the original packing and observe the guidelines for safe

lifting and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 25.1.

Note on second-hand chambers (Ex-Demo-Units):

Second-hand chambers are chambers that were used for a short tim e for tests or exhibitions. They are

thoroughly tested before resale. BINDER ensures that the chamber is technically sound and will work

flawlessly.

Second-hand chambers are marked with a sticker on the chamber door. Please remove the sticker before

commissioning the chamber.

Risk of injury and damages by lifting heavy loads and by sliding or

tilting of the chamber due to improper lifting.

Injuries, damage to the chamber.

∅ Do NOT lift or transport the chamber using the door handle or the door.

Lift the chamber from the pallet at the four lo we

four people.

CB-S / CB-S-UL (E7) 06/2020 page 24/119

Page 25

Lift the chamber at the four lower corners with the aid of 4 people and plac e it on a

ed location and lift it f rom the rolling pallet with the aid of

3.2 Guidelines for safe lifting and transportation

After operation, please observe the guidelines for temporarily decommissioning the chamber (chap. 25.2).

Empty the water pan befor e moving the incubator. In c ase of any spilling of the contents , shut down the

incubator and dry it out carefully and completely

CAUTION

Risk of injury and damages by lifting heavy loads and by sliding or tilting of the

chamber due to improper transportation.

Injuries, damage to the chamber.

Transport the chamber in its original packaging only.

For moving or shipping, secure the chamber with transport straps.

∅ Do NOT lift or transport the chamber using the door handle or the door.

rolling pallet.

Move the chamber to the d es ir

four people.

• Permissible ambient temperature range for transport: -10 °C / 14°F to +60 °C / 140°F.

You can order transport packing and rolling pallets for transportation purposes from BINDER Service.

3.3 Storage

Intermediate storage of the chamber is possible in a closed and dry room. Observe the guidelines for

temporary decommissioning (chap. 25.2).

• Permissible ambient temperature range for storage: -10 °C / 14°F to +60 °C / 140°F.

• Permissible ambient humidity: max. 70% r.h., non-condensing

When after storage in a co ld location you transf er the chamber to its warm er installation site, condensation may form in the inner chamber, on the hous ing or in the sensor com partment of the CO

ment. Before start-up, wait at least one hour until the CO

incubator h as attained ambient temperature

2

measure-

2

and is completely dry.

3.4 Location of installation and ambient conditions

Notes on the location of installation

Set up the chamber on a f lat, even surf ace, free f rom vibration and in a well-ventilated, dr y location. The

chambers are designed for setting up inside a building (indoor use).

Freestanding chambers are s uitable for installation on tables or on the optionally available st and. Note:

The site of installa tion must be capable of supportin g the chamber’s weight (see t echnical data, chap.

26.4).

Align the chamber using a spirit level to ensure even covering of the cell-cultures with the m edium. For

this purpose, manually adjust the four incubator feet.

In order to avoid contamination, never place the chamber directly on the floor.

CB-S / CB-S-UL (E7) 06/2020 page 25/119

Page 26

NOTICE

Danger of overheating due to lack of ventilation.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Observe the prescribed minimum distances when installing the chamber.

Do not install or operate the chamber in potentially explosive areas.

DANGER

Danger of explosion due to combustible du sts or explosive mixtures in the vicinity

of the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT operate the chamber in potentially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the vicinity of the chamber.

Ambient conditions

• Permiss ible ambient t em peratur e range f or oper ation: +18 °C / 64 .4 °F up to +30 °C / 86 °F. At elevat-

ed ambient temperature values, fluctuations in temperature can occur.

• Ideal ambien t temperature: by at l east 6 °C / 10.8 °F below the intended working temperature. E.g.,

working temperature 37 °C / 98.6 °F – resulting p ermitted ambient tem perature 31 °C / 87.8 °F and

lower

In the event of working t emperatures of less than 6 °C / 10. 8 °F above the ambient tem perature, the se t

point can be exceeded.

Do not place the chamber directly below the air outlet of an air conditioner.

The ambient temperature should not be substantially higher than the indicated ambient temperature of +22 °C +/- 3 °C / 71.6 °F ± 5.4 °F to which the specified technical data relate. For

other ambient conditions, deviations from the indicated data are possible.

Avoid direct solar radiation on the chamber.

Avoid strong drafts, e.g. by air conditioning.

• Permissible ambient humidity: 70% r.h. max., non-condensing.

• Installation he ight: max . 2000 m / 6562 ft. above sea level. After the incubator ha s been turned on f or

the first time, enter the altitude of the site above sea level into the RD4 controller (chap. 6.4).

• Wall distances: rear 100 mm / 3.94 in, sides 50 mm / 1.97 in.

To completely separate the chamber from the power supply, you must disconnect the power

plug. Install the chamber in a way that the power plug is easily accessible and can be easily

pulled in case of danger.

• Avoid any conduc tive dust in the ambiance according to the cham ber layout compl ying with pollution

degree 2 (IEC 61010-1).

CB-S / CB-S-UL (E7) 06/2020 page 26/119

Page 27

Notes on handling carbon dioxide (CO

Carbon dioxide (CO

) in high conce ntrations is hazardous to he alth. It is colorless and almost odorless

2

and therefore practica lly impercepti ble. Vent out an y CO

or a suitable connection to an exhaust system. We recommend installing a CO

)

2

gas that m ay escape via goo d room ventilat ion

2

warning system.

2

DANGER

Danger of suffocation and poisoning by high concentration of CO2 (> 4 Vol.-%).

Death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling CO

Observe the occupational exposure limit OEL for CO2 set b y the national authorities (formerl y maximum permitted work place concentration) . Check complianc e when operating a ll chambers located in the

room.

• OEL for Germany: 5000 ml/m3 (ppm) = 0,5 Vol.-%

• CO

lost with eac h door o pening: about 16.4 g , i.e. 0.0084 c ubic m eters / 0.29 6 cubic fee t (under nor-

2

mal pressure)

• CO

lost during 12h at 5 vol.-% without door opening: approx. < 2 g, i.e. 0. 001 cubic meters / 0.035

2

cubic feet (under normal pressure 1013 mbar / 14.7 psi)

An example of how to evaluate laboratory volume and air change rate:

.

2

Question: Is an air ch ange rate of 1/h suffic ient for a lab with a volum e of 100 cubic meters / 3,531.5

cubic feet with 10 CO

Calculation: CO

incubators, opened 4 times per hour?

2

concentration = CO2 lost by door opening, m ultiplied by 10 chambers, multiplied by 4

2

door openings per hour, divided by lab volume

0.0084 cubic meters x 10 x 4 div. 100 cubic meters = 0.00336, i.e. 0.336% or 3360 ppm.

0.296 cubic feet x 10 x 4 div. 3,531.5 cubic feet = 0.00336, i.e. 0.336% or 3360 ppm.

Result: The maximum permissible value of 5000 ppm is not exceeded under these operation conditions.

Even when CO

or systems operated with CO2 are handled caref ully and appropriately, a residual risk

2

remains, which can lead to life-threatening s ituations under certain circum stances . Therefore we str ongly

recommend continuo us monitoring of CO

be ensured permanently that the maximum permissible occupational exposure limit OEL for CO

% CO

for Germany) is not exceeded.

2

concentration in the am bient air of the CO2 incubator. It must

2

(0.5 vol -

2

CB-S / CB-S-UL (E7) 06/2020 page 27/119

Page 28

4. Installation and connections

4.1 Shelves

You can put the she lves in differ ent positions at the line of c hannel beads in th e inner c ham ber. Hold th e

shelf straight and then insert it so it will go smoothly inside the chamber.

Permitted shelf loads:

Maximum load on one single shelf: 10 kg / 22 lb

Maximum total load on all shelves: 40 kg / 88 lb

4.2 CO2 sensor

4.2.1 Connecting the CO2 sensor

Turn off the chamber. Open the door of the inner cham ber and plug the CO2 sensor (4) into the permanently installed holding tube located in the upper part of the rear of the inner chamber.

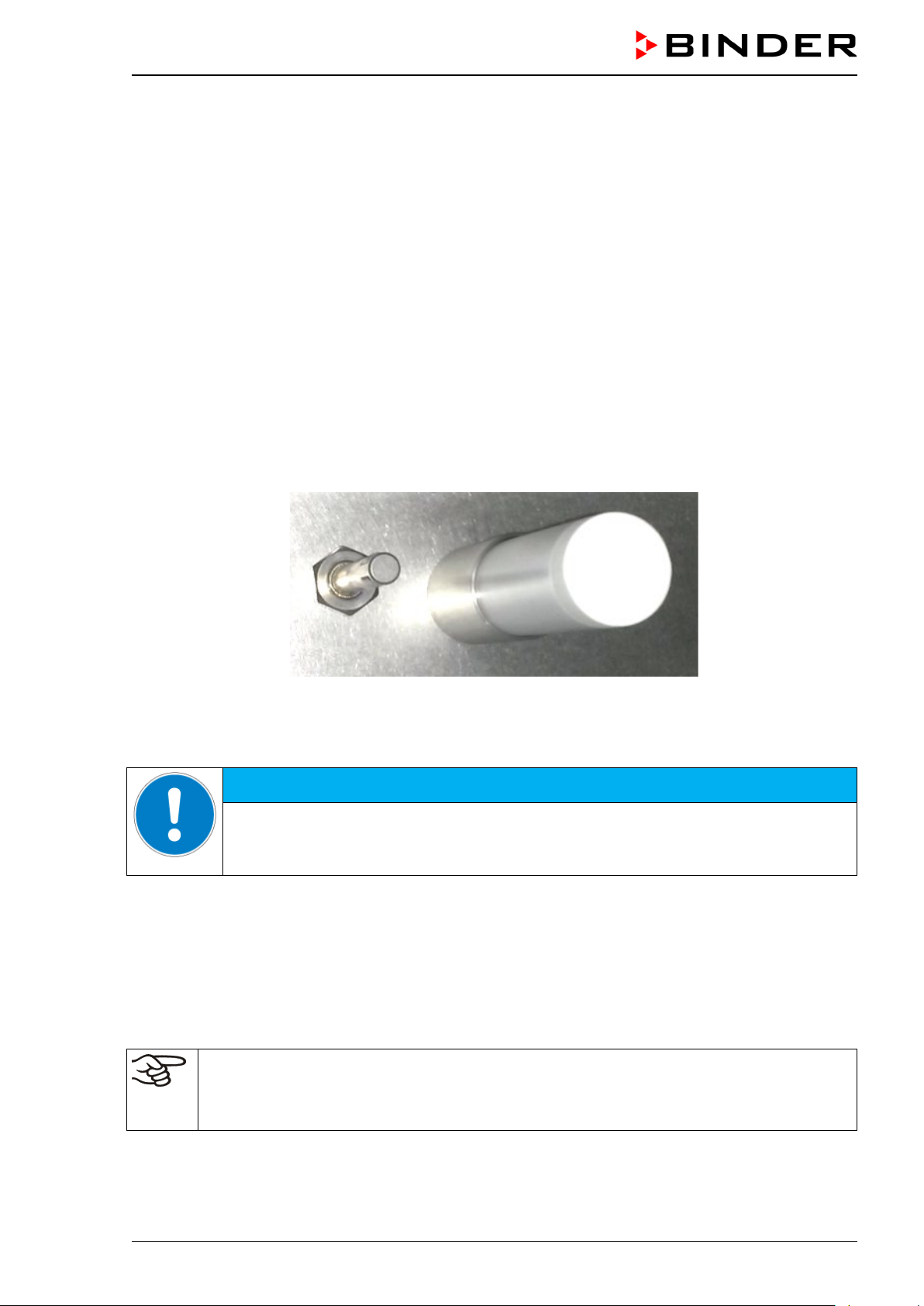

Figure 10: Plugged-in CO

sensor (right) and gas mixing head for CO2

2

The sensor must click in correctly and sit tightly in the connection socket.

NOTICE

Danger of damage to the CO2 sensor by connecting or removing it during operation.

Damage to the CO

Connect or remove the CO

4.2.2 General notes

Connect or remove t he CO2 sensor without rotati ng and only when the incubator is turned off. Remove

the CO

and humidity from intrudin g into the m easuring c ell. It is avai lable as a spare part. Re place it whene ver it

is damaged or soiled.

sensor before r emov ing or rep lacing its filter cap. T he PTF E filter of the CO2 sensor prevents dirt

2

The accuracy of the indicated values of CO

0.08 vol.-% per 10 mbar / 0.15 psi). In order to compensate this effect when measuring the

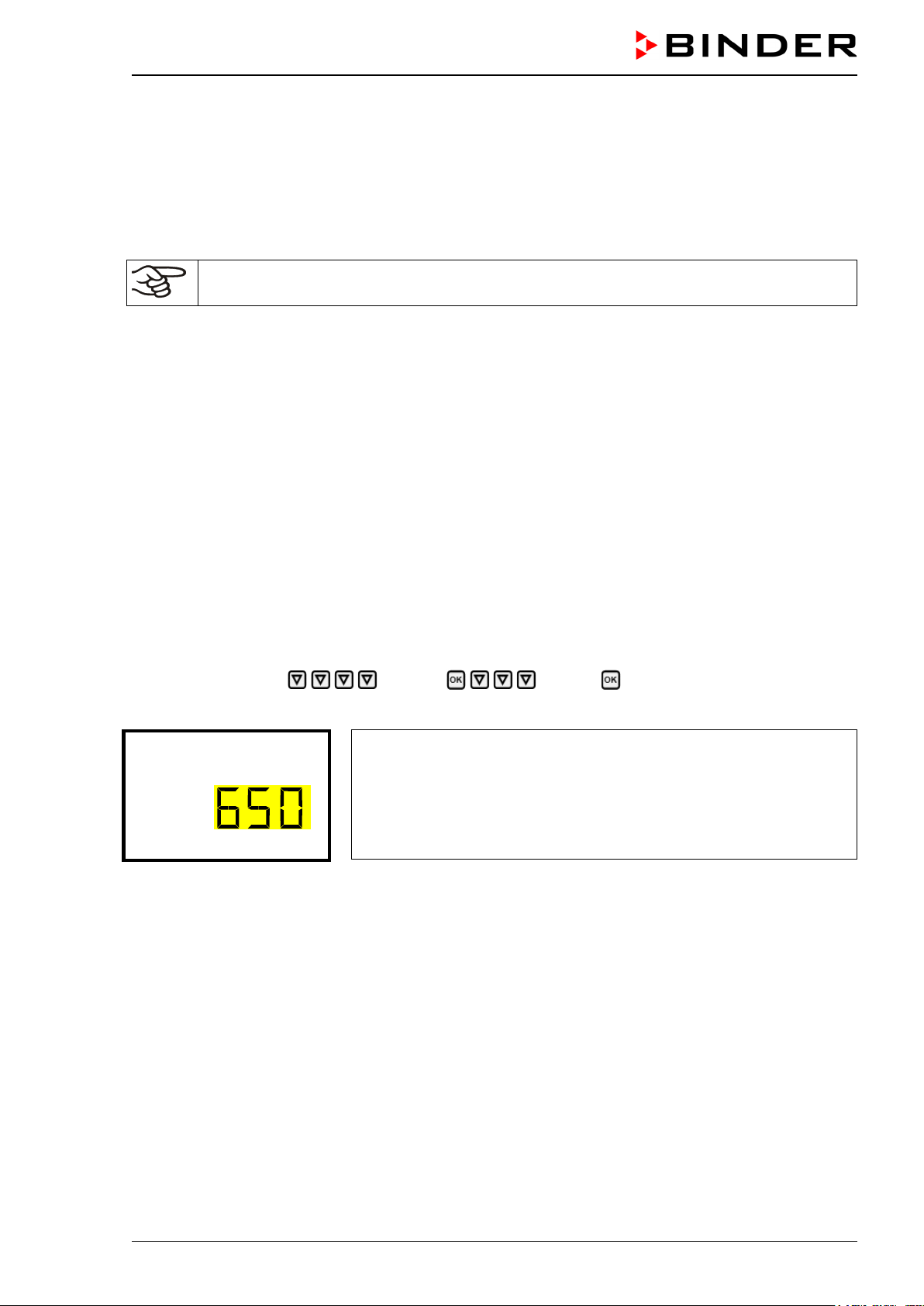

concentration, the altitude of the installation site above sea level can be entered into the

CO

2

controller (chap. 6.4).

sensor.

2

sensor only with the chamber turned off.

2

depends on the ambient air pressure (approx.

2

CB-S / CB-S-UL (E7) 06/2020 page 28/119

Page 29

NOTICE

NOTICE

NOTICE

The CO

sensor is temperature resistant up to a maxi m u m temperature of 60 °C / 140 °F.

2

Danger of damage to the CO2 sensor by excess temperature.

Damage to the CO

∅ Do NOT autoclave the CO

∅ Do NOT expose the CO

sensor.

2

Sensor.

2

sensor to hot-air sterilization..

2

The CO