Page 1

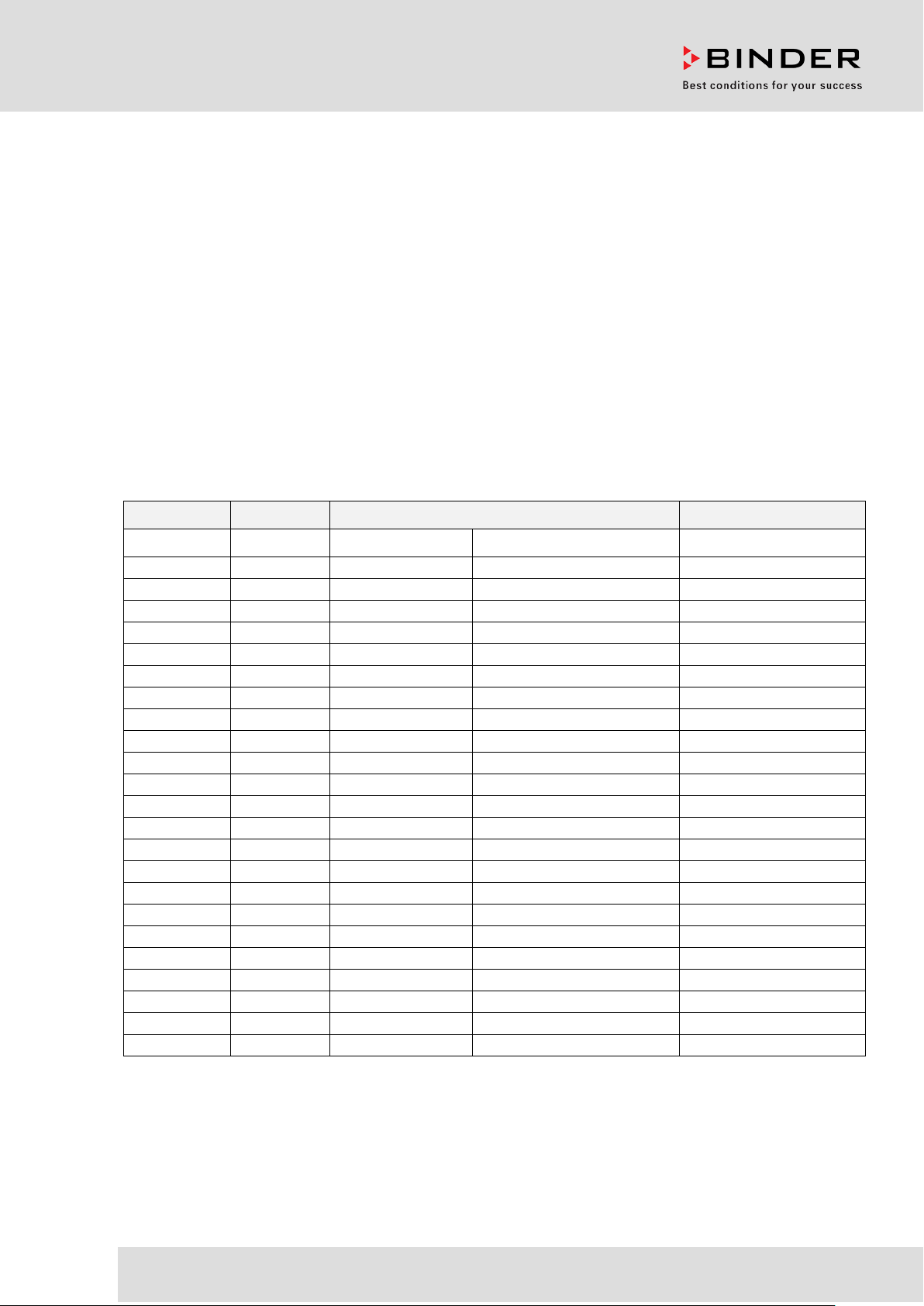

CB 60-UL

100-120V

9040-0089, 9140-0089

CB 60

230 V

O2 control

9040-0090, 9140-0090

CB 60-UL

100-120V

O2 control

9040-0091, 9140-0091

CB 60

230 V

Divided inner door

9040-0104, 9140-0104

CB 60-UL

100-120V

Divided inner door

9040-0105, 9140-0105

CB 60

230 V

O2 control

Divided inner door

9040-0106, 9140-0106

CB 60-UL

100-120V

O2 control

Divided inner door

9040-0107, 9140-0107

CB 160 (E6)

230 V

9040-0092, 9140-0092

CB 160-UL

100-120V

9040-0093, 9140-0093

CB 160 (E6)

230 V

O2 control

9040-0094, 9140-0094

CB 160-UL

100-120V

O2 control

9040-0095, 9140-0095

CB 160

230 V

Divided inner door

9040-0100, 9140-0100

CB 160-UL

100-120V

Divided inner door

9040-0101, 9140-0101

CB 160

230 V

O2 control

Divided inner door

9040-0102, 9140-0102

CB 160-UL

100-120V

O2 control

Divided inner door

9040-0103, 9140-0103

CB 220

230 V

9040-0096, 9140-0096

CB 220-UL

100-120V

9040-0097, 9140-0097

CB 220

230 V

O2 control

9040-0098, 9140-0098

CB 220-UL

100-120V

O2 control

9040-0099, 9140-0099

CB 220

230 V

Divided inner door

9040-0108, 9140-0108

CB 220-UL

100-120V

Divided inner door

9040-0109, 9140-0109

CB 220

230 V

O2 control

Divided inner door

9040-0110, 9140-0110

CB 220-UL

100-120V

O2 control

Divided inner door

9040-0111, 9140-0111

Operating Manual

CB (E6.1)

CO

CO

- Incubators

2

– Incubators with O2 control

2

with sterilizable NDIR sensor system for CO2

and microprocessor controller T4.12

Model Voltage Equipment Art. No.

CB 60

230 V 9040-0088, 9140-0088

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.binder-world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 2 24 4340 x3

Service Hotline Asia Pacific: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 07/2017 Art. No. 7001-0333

Page 2

Contents

1. SAFETY .................................................................................................................. 6

1.1 Legal considerations ........................................................................................................................... 6

1.2 Structure of the safety instructions ...................................................................................................... 6

1.2.1 Signal word panel ..................................................................................................................... 6

1.2.2 Safety alert symbol ................................................................................................................... 7

1.2.3 Pictograms ................................................................................................................................ 7

1.2.4 Word message panel structure ................................................................................................. 8

1.3 Localization / position of safety labels on the chamber ...................................................................... 8

1.4 Type plate ......................................................................................................................................... 10

1.5 General safety instructions on installing and operating the CO2 incubator ...................................... 11

1.6 Precautions when working with gases .............................................................................................. 12

1.7 Precautions when handling gas cylinders ......................................................................................... 14

1.8 Intended use ..................................................................................................................................... 15

2. CHAMBER DESCRIPTION .................................................................................. 16

2.1 Chamber overview ............................................................................................................................ 17

2.2 Instrument panel ............................................................................................................................... 17

2.3 Inner chamber ................................................................................................................................... 18

2.4 Control panel on the rear of the chamber ......................................................................................... 20

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 21

3.1 Unpacking, and checking equipment and complet eness of delivery ................................................ 21

3.2 Guidelines for safe lifting and transportation..................................................................................... 21

3.3 Storage .............................................................................................................................................. 22

3.4 Location of installation and ambient condi tions ................................................................................ 22

4. INSTALLATION AND CONNECTIONS ............................................................... 26

4.1 Shelves.............................................................................................................................................. 26

4.2 Permadry™ water pan ...................................................................................................................... 26

4.3 Connecting the O2 sensor (chamber with O2 control) ....................................................................... 27

4.4 Gas connections ............................................................................................................................... 28

4.4.1 Connection of the CO2 gas cylinder ........................................................................................ 29

4.4.2 Connection of the O2 gas cylinder (chamber with O2 control and optional alternative control

range 10 up to 95 vol.-% O

4.4.3 Connection of the N2 gas cylinder (chamber with O2 control)................................................. 31

4.4.4 Connecting the gas hose to the chamber rear (for CO2, O2, N2) ............................................ 32

4.4.5 Gas cylinder connection kits (option) ...................................................................................... 33

4.5 Electrical connection ......................................................................................................................... 34

4.6 Handling and aligning the divided inner door, gas proof (optional equipment) ................................. 35

) .................................................................................................. 30

2

5. START UP ............................................................................................................ 36

5.1 Equilibration time ............................................................................................................................... 36

5.2 Factory settings ................................................................................................................................. 36

6. FUNCTIONAL OVERVIEW OF THE T4.12 CHAMBER CONTROLLER ............. 37

6.1 Menu structure .................................................................................................................................. 38

6.1.1 General menu ......................................................................................................................... 38

6.1.2 Quick menu ............................................................................................................................. 39

6.1.3 User menu .............................................................................................................................. 40

6.2 Operating modes ............................................................................................................................... 41

6.2.1 Activating the “control off” mode or change to “f i xed value” operating mode ......................... 41

6.3 Deactivating the O2 control and O2/N2 pressure alarms (chamber with O2 control) ......................... 43

6.3.1 Required gas supply of the chamber with O2 control ............................................................. 43

6.3.2 Activating / deactivating the O2 control and O2 / N2 pressure alarms ..................................... 44

CB (E6.1) 07/2017 Page 2/145

Page 3

6.4

Humidity control of the Permadry™ system ...................................................................................... 45

6.5 Turning on / off the interior socket voltage (wit h optional interior socket) ......................................... 46

6.6 Performance during and after power failure ...................................................................................... 46

6.7 Information ........................................................................................................................................ 47

7. SETPOINT ENTRY ............................................................................................... 48

7.1 Setting ranges ................................................................................................................................... 48

7.2 Note when setting high gas concentrations ...................................................................................... 48

7.3 Entering the setpoints via “quick menu” ............................................................................................ 50

7.4 Entering the setpoints via general menu ........................................................................................... 52

8. KEY LOCK ........................................................................................................... 54

8.1 Directly activating the key lock .......................................................................................................... 55

8.2 Automatic key lock ............................................................................................................................ 55

8.3 Changing the password for unlocking the key lock ........................................................................... 57

9. GENERAL CONTROLLER SETTINGS ................................................................ 58

9.1 Setup wizard ..................................................................................................................................... 59

9.2 Date and time settings ...................................................................................................................... 59

9.3 Selecting the menu language of the T4.12 controller ....................................................................... 61

9.4 Setting display brightness ................................................................................................................. 61

9.5 Changing the temperature unit ......................................................................................................... 62

9.6 Defining the data recording rate ........................................................................................................ 62

9.7 Factory reset ..................................................................................................................................... 63

9.8 Network configuration ....................................................................................................................... 63

9.9 Display of the network configuration ................................................................................................. 67

9.10 RS 422 address (with optional RS 422 interface) ............................................................................. 68

9.11 Display and entry of the device configuration – for se rvice purpose ................................................ 68

10. DATA TRANSFER VIA USB INTERFACE .......................................................... 69

10.1 Exporting data to USB drive .............................................................................................................. 69

10.2 Importing data from USB drive .......................................................................................................... 70

11. NOTIFICATIONS AND ALARMS ......................................................................... 71

11.1 Notifications overview ....................................................................................................................... 71

11.2 Alarm messages overview ................................................................................................................ 71

11.3 Alarm status ...................................................................................................................................... 73

11.4 Confirming an active “set” alarm ....................................................................................................... 74

11.5 Alarm configuration and overview ..................................................................................................... 75

11.5.1 List of active alarms ................................................................................................................ 75

11.5.2 History – list of all alarms ........................................................................................................ 76

11.5.3 Activating, deactivating, and testing the alarm buzzer ........................................................... 77

11.5.4 Activating / deactivating all alarm functions ............................................................................ 77

11.5.5 Setting the delay time after opening the door ......................................................................... 78

11.5.6 Tolerance ranges and alarm delay times ............................................................................... 78

11.6 Zero-voltage relay alarm output ........................................................................................................ 82

12. EVENT LIST ......................................................................................................... 83

13. GRAPHICAL DISPLAY OF THE MEASURED VALUES ..................................... 84

13.1 Setting the sampling rate .................................................................................................................. 84

13.2 Defining the display range................................................................................................................. 85

13.3 Selecting the parameters .................................................................................................................. 86

14. TEMPERATURE SAFETY DEVICES ................................................................... 87

14.1 Overtemperature protective device (class 1) .................................................................................... 87

14.2 Overtemperature safety controller (temperature safety device class 3.1) ........................................ 87

14.2.1 Safety controller modes .......................................................................................................... 87

14.2.2 Setting the safety controller .................................................................................................... 88

CB (E6.1) 07/2017 Page 3/145

Page 4

15. OPTIONS .............................................................................................................. 91

15.1 Communication software APT-COM™ 3 DataControlSystem (option)............................................. 91

15.2 RS 422 interface (option) .................................................................................................................. 91

15.3 Silicone access ports 30 mm / 1.18 in, closable from both sides with silicon plugs (option) ............ 91

15.4 Interior socket 230V (option) ............................................................................................................. 92

15.5 Analog outputs for temperature and CO2 (option) ............................................................................ 94

15.6 Access port for extra-low voltage (option) ......................................................................................... 94

15.7 BINDER Gas Supply Service – External bottle cha nger for CO2, N2 or O2 (option) ......................... 95

15.8 Stands ............................................................................................................................................... 96

15.8.1 Stacking stand (option) ........................................................................................................... 96

15.8.2 Stacking adapter for direct thermal decoupled stac king (option) ........................................... 96

15.8.3 Base on castors (option) ......................................................................................................... 96

16. REFERENCE MEASUREMENTS ........................................................................ 97

16.1 CO2 reference measuring ................................................................................................................. 97

16.1.1 Measuring CO2 concentration indirectly via the pH of the cell m edium .................................. 97

16.1.2 Measuring CO2 directly via chemical indicator tubes ............................................................. 98

16.1.3 Measuring CO2 directly with an electronic infrared measuring device ................................... 99

16.2 Temperature reference measurement .............................................................................................. 99

17. AVOIDING MICROBIAL CONTAMINATION........................................................ 99

17.1 Cells and media ................................................................................................................................ 99

17.2 Laboratory conditions / equipment aroun d the incubator .................................................................. 99

17.3 Working and behavior in the lab ..................................................................................................... 100

17.4 Chamber design and equipment of the CO2 incubator ................................................................... 100

17.5 Handling the CO2 incubator ............................................................................................................ 101

18. CLEANING, DECONTAMINATION / DISINFECTION, AND STERILIZATION .. 103

18.1 Cleaning .......................................................................................................................................... 103

18.2 Decontamination / chemical disinfection of the chamber ................................................................ 105

18.3 Hot-air sterilization at 180 °C / 356 °F............................................................................................. 106

18.3.1 Overview ............................................................................................................................... 106

18.3.2 Performing a hot-air sterilization ........................................................................................... 107

18.3.3 Aborting the hot-air sterilization – general procedure ........................................................... 109

18.3.4 Aborting hot-air sterilization after less than 4 hours ............................................................. 110

18.3.5 Terminating successful sterilization during the cooling-down phase (abortion after more than

4 hours) ................................................................................................................................. 112

18.3.6 Terminating the completed sterilization cycle ....................................................................... 113

19. MAINTENANCE AND SERVICE ........................................................................ 115

19.1 Maintenance intervals, service ........................................................................................................ 115

19.2 Checking the air jacket heating fan ................................................................................................. 116

19.3 Checking the humidity system fan .................................................................................................. 116

19.4 Gas inlet fine filter ........................................................................................................................... 116

19.5 Sending the chamber back to BINDER GmbH ............................................................................... 116

20. DISPOSAL ......................................................................................................... 117

20.1 Disposal of the transport packing .................................................................................................... 117

20.1.1 Outer chamber packing ........................................................................................................ 117

20.1.2 Packing inside the chamber and equipment ......................................................................... 117

20.2 Decommissioning ............................................................................................................................ 118

20.3 Disposal of the chamber in the Federal Republic of Germany ....................................................... 118

20.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany.......................................................................................................................................... 119

20.5 Disposal of the chamber in non-member states of the EU ............................................................. 120

CB (E6.1) 07/2017 Page 4/145

Page 5

21. TROUBLESHOOTING ....................................................................................... 121

21.1 General............................................................................................................................................ 121

21.2 Heating ............................................................................................................................................ 121

21.3 Gas cylinder pressure too low ......................................................................................................... 123

21.4 Gas concentration ........................................................................................................................... 124

21.5 Sterilization ...................................................................................................................................... 126

21.6 Humidity .......................................................................................................................................... 126

21.7 Controller ......................................................................................................................................... 127

21.8 Open door ....................................................................................................................................... 127

22. TECHNICAL DESCRIPTION .............................................................................. 128

22.1 Factory calibration and adjustment ................................................................................................. 128

22.2 Over current protection ................................................................................................................... 128

22.3 Definition of usable volume ............................................................................................................. 128

22.4 CB technical data ............................................................................................................................ 129

22.5 Equipment and Options ................................................................................................................... 131

22.6 Accessories and spare parts (extract) ............................................................................................ 132

22.7 Important conversion data for non-SI units ..................................................................................... 133

22.8 Conversion table for gas inlet pressures, bar – psi ......................................................................... 133

22.9 Dimensions CB 60 .......................................................................................................................... 134

22.10 Dimensions CB 160 ........................................................................................................................ 135

22.11 Dimensions CB 220 ........................................................................................................................ 136

23. CERTIFICATES AND DECLARATIONS OF CONF ORMITY ............................. 137

23.1 EU Declaration of conformity .......................................................................................................... 137

24. PRODUCT REGISTRATION .............................................................................. 139

25. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 140

25.1 For chambers located outside the USA and Canada ..................................................................... 140

25.2 For chambers in the USA and Canada ........................................................................................... 143

CB (E6.1) 07/2017 Page 5/145

Page 6

Dear customer,

For the correct operation of the CO

completely and carefully and observe all instructions as indicated. Failure to read, understand and follow

the instructions may result in personal injury. It can also lead to damage to the chamber and/or poor

equipment performance

incubator CB, it is important that you read this operating manual

2

1. Safety

This operating manual is part of the components of delivery. Always keep it handy for reference. The

device should only be operated by laboratory personnel especially trained for this purpose and familiar

with all precautionary measures required for working in a laboratory. Observe the national regulations on

minimum age of laboratory personnel. To avoid injuries and damage observe the safety instructions of the

operating manual.

WARNING

Failure to observe the safety instructions.

Serious injuries and chamber damage.

Observe the safety instructions in this operating manual.

Carefully read the complete operating instructions of the chamber.

1.1 Legal considerations

This operating manual is for informational purposes only. It contains information for installing, start-up,

operation and maintenance of the product. Note: the contents and the product described are subject to

change without notice.

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free

use and safety during operation and maintenance. In no event shall BINDER be held liable for any

damages, direct or incidental arising out of or related to the use of this manual.

This operating manual cannot cover all conceivable applications. If you would like additional information,

or if special problems arise that are not sufficiently addressed in this manual, please ask your dealer or

contact us directly by phone at the number located on page one of this manual

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or

existing agreement, description, or legal relationship, nor do they modify such a relationship. All

obligations on the part of BINDER derive from the respective purchase contract, which also contains the

entire and exclusively valid statement of warranty administration. The statements in this manual neither

augment nor restrict the contractual warranty provisions.

1.2 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations

following the harmonization of ISO 3864-2 and ANSI Z535.6.

1.2.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal

word, the corresponding safety color, and i f appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

(irreversible) injury.

CB (E6.1) 07/2017 Page 6/145

Page 7

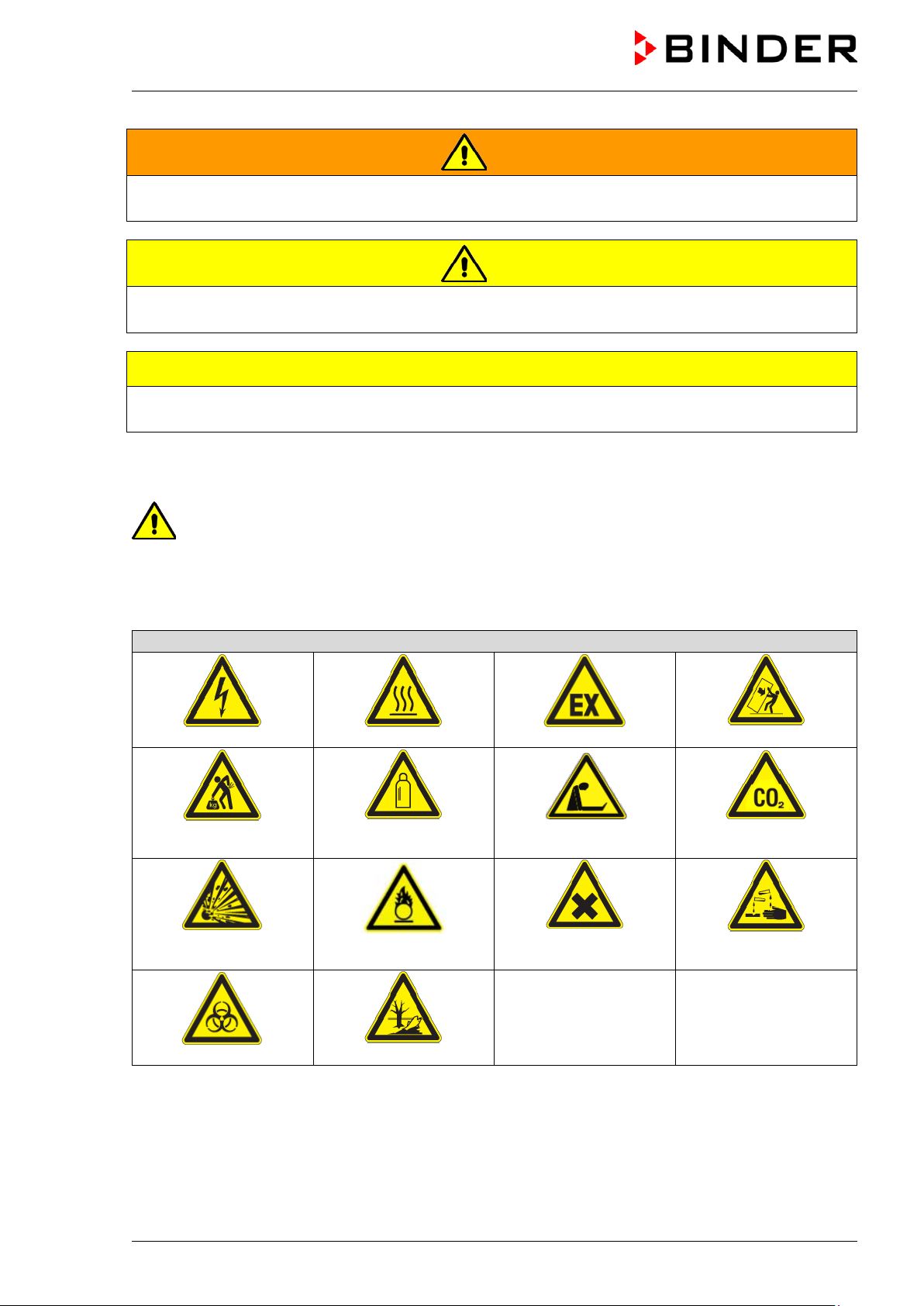

CAUTION

Warning signs

Electrical hazard

Hot surface

Explosive atmosphere

poisoning hazard

or chemical burns

Biohazard

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury.

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its prox i m i ty.

1.2.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the saf ety alert symbol in order to avoid death or

injury.

1.2.3 Pictograms

Lifting hazard

Explosive substances

Gas cylinders

Fire promoting agents

Suffocation hazard

Harmful substances

Stability hazard

suffocation and

CO

2

Risk of corrosion and /

CB (E6.1) 07/2017 Page 7/145

Pollution Hazard

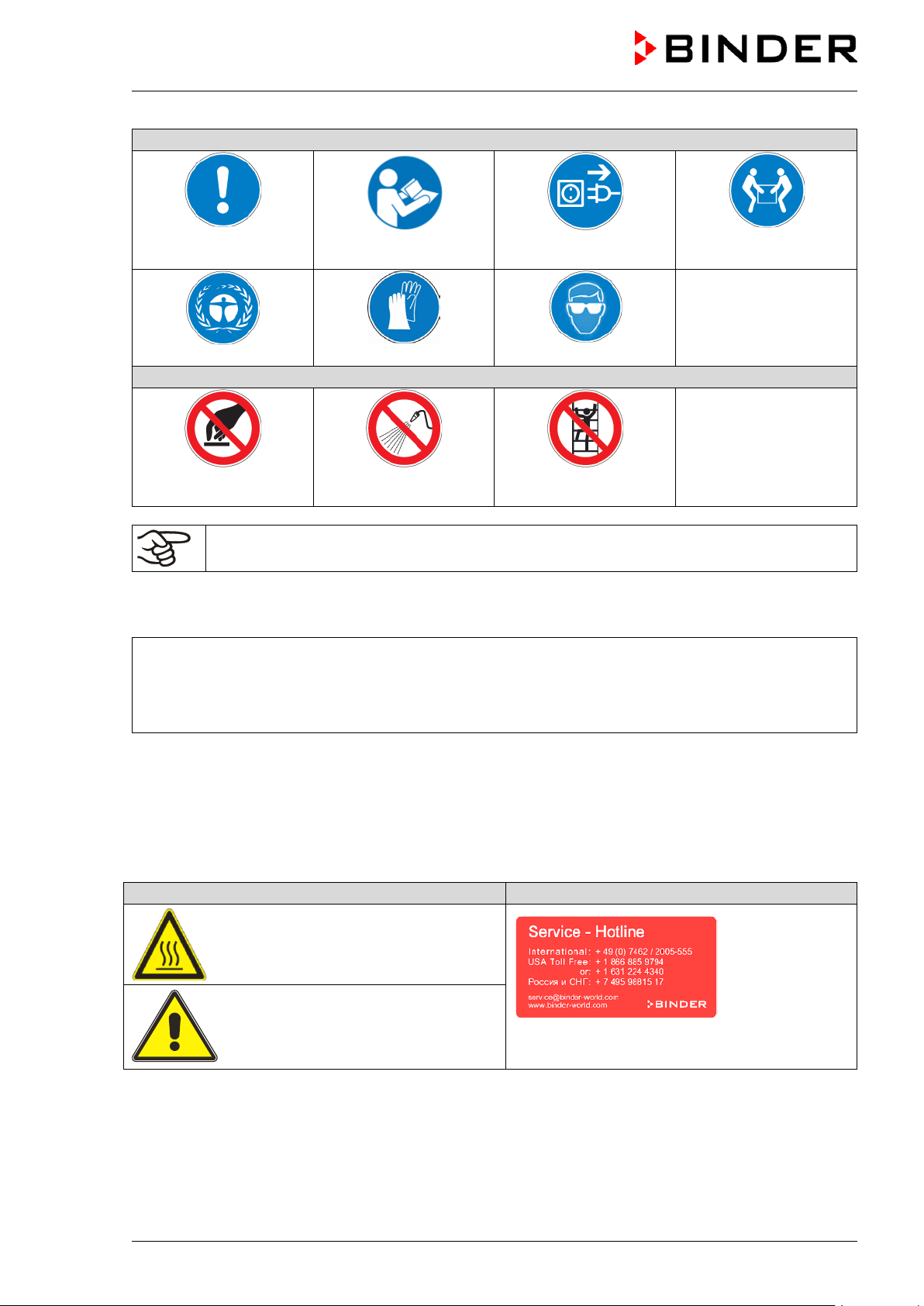

Page 8

Mandatory action signs

plug

Environment protection

Prohibition signs

water

Pictograms (Warning signs)

Service label

Mandatory regulation

Do NOT touch

Information to be observed in order to ensure optim um function of the product.

Read operating

instructions

Wear protective gloves

Do NOT spray with

1.2.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory a ct i on

Disconnect the power

Wear safety goggles

Do NOT climb

Lift with several persons

Observe all other notes and information not necessarily emphasized in the same way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

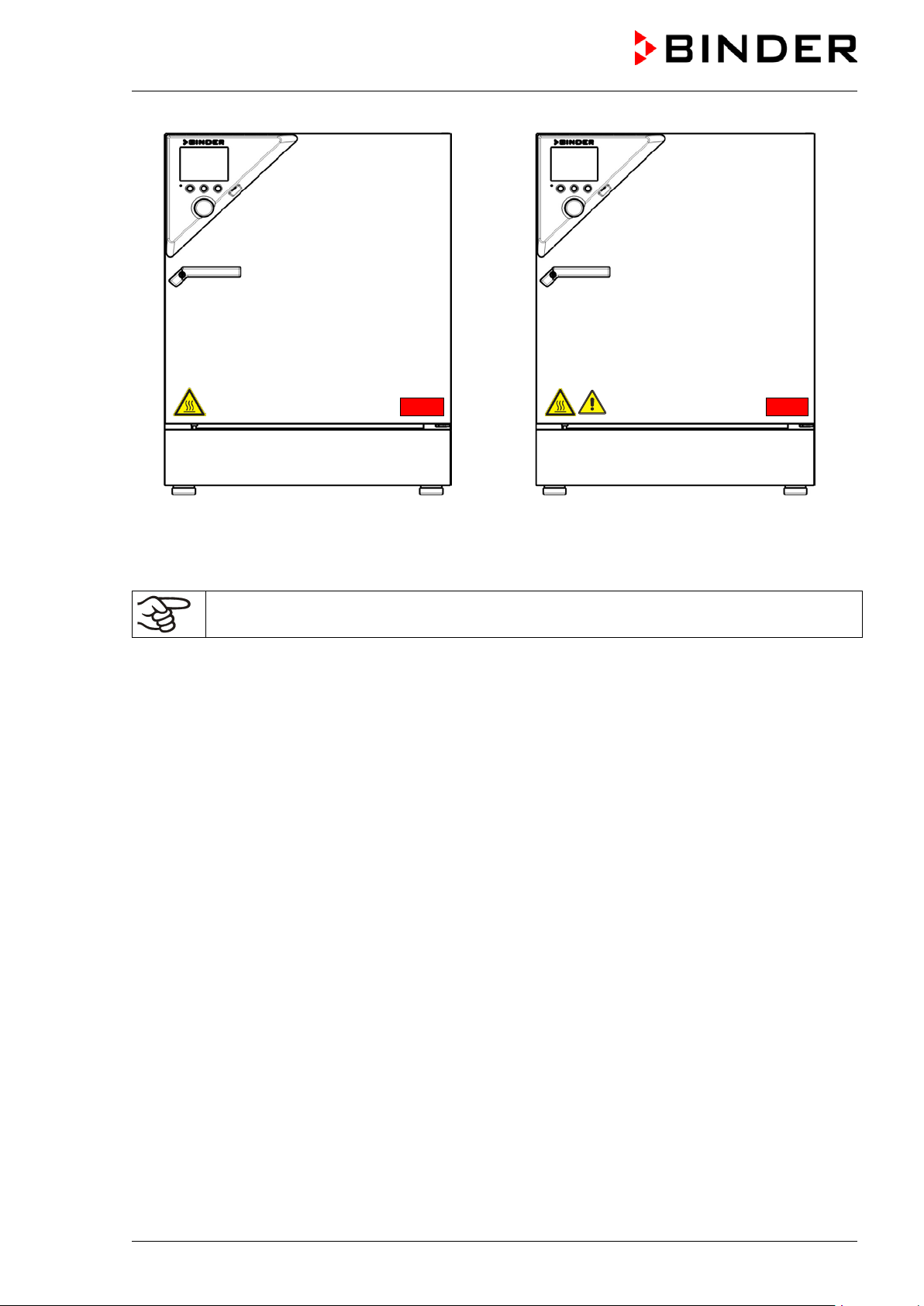

1.3 Localization / position of safety labels on t he chamber

The following labels are located on the chamber:

Hot surface

• on the outer chamber door

Risk of injury

• on the outer door: CB-UL only

• above the access ports (option)

CB (E6.1) 07/2017 Page 8/145

Page 9

CO2 -Incubator CB CO2 -Incubator CB-UL

Figure 1: Position of labels on the chamber

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER service for these replacements.

CB (E6.1) 07/2017 Page 9/145

Page 10

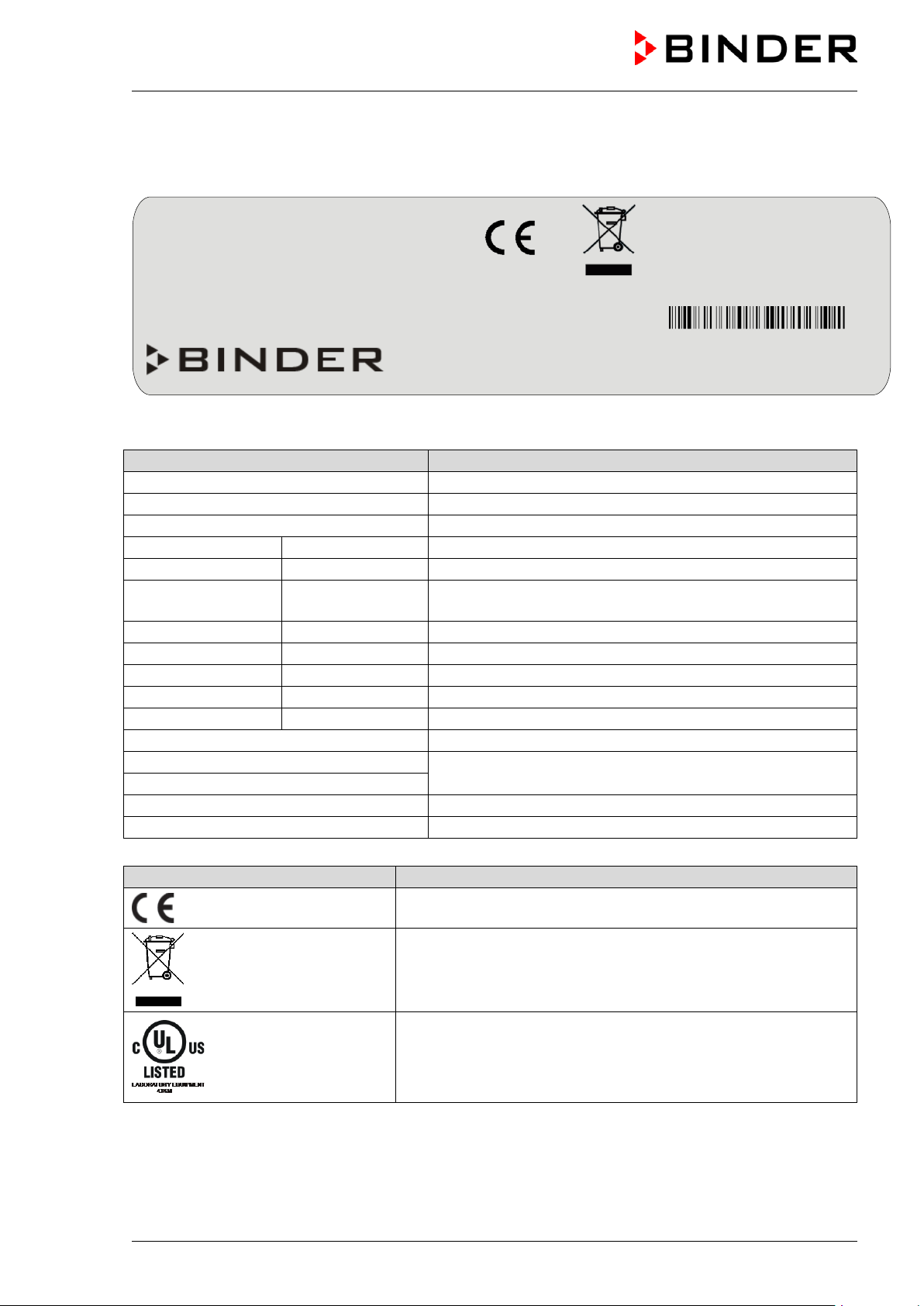

Indications of the type plate (example)

Information

BINDER

Manufacturer: BINDER GmbH

CB 160

Model designation

CO2 incubator

Device name

Serial No.

00000000000000

Serial no. of the chamber

Built

2017

Year of construction

Nominal

187 °C

369 °F

IP protection

20

IP type of protection acc. to standard EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880

Class

3.1

Class of temperature safety device

Art. No.

9040-0092

Art. No. of the chamber

Project No.

---

Optional: Special application acc. to project no.

1,30 kW

Nominal power

230 V / 50 Hz

230 V / 60 Hz

1 N ~

Current type

5,7 A

Nominal current

Symbol on the type plate

Information

Nominal temp.

187 °C

1,30 kW / 5,7 A

369 °F

230 V / 50 Hz

IP protection

20

230 V / 60 Hz

Safety device

DIN 12880

1 N ~

Class

3.1

Art. No.

9040-0092

Built

2017

CO2 incubator

BINDER GmbH

www.binder-world.com

CB 160

Serial No. 00000000000000

1.4 Type plate

Position of type plate: left chamber side (see n from front), at the bottom in the middle

Project No.

temperature

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

E6.1

Made in Germany

Figure 2: Type plate (example of CB 160 regular chamber)

Nominal temperature

Nominal voltage ± 10% at the indicated power fre quency

CE conformity marking

Electrical and electronic equipment manufactured / placed on

the market in the EC after 13 August 2005 and to be disposed of

in separate collection according to Directive 2012/19/EU on

waste electrical and electronic equipment (WEEE).

®

The chamber is certified by Underwriters Laboratories Inc.

according to the following standards:

(CB-UL only)

CAN/CSA-C22.2 No. 61010-1, 2

UL 61010-1, 2

nd

Edition, 2005-07-22

nd

Edition, 2004-07

CB (E6.1) 07/2017 Page 10/145

Page 11

1.5 General safety instructions on installing and operating the CO2 incubator

With regard to operating the chamber and to the installation location, please observe the guideline

BGI/GUV-I 850-0 on safe working in laboratories (formerly BGR/GUV-R 120 or ZH 1/119 laboratory

guidelines issued by the employers’ liabilit y insurance association) (for Germany).

BINDER GmbH is only responsible for the safety features of the chamber provided skilled electricians or

qualified personnel authorized by BINDER perform all maintenance and repair, and if components

relating to chamber safety are replaced in the event of failure with original spare parts.

To operate the chamber, use only original BINDER accessories or accessories from third-party suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized acces sories.

CAUTION

Danger of overheating.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Do not operate the chamber in hazardous locati ons.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the chamber in potentially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the chamber.

The chamber does not dispose of any measures of explosion protection.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT introduce any sub st ance into the chamber which is combustible or explosiv e at

working temperature.

∅ NO explosive dust or air-sol vent mixture in the inner chamber.

Any solvent contained in the charging material must not be explosive or inflammable. I.e., irrespective of

the solvent concentration in the steam room, NO explosive mixture with air must form. The temperature

inside the chamber must lie below the flash point or below the sublimation point of the charging material.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy.

Familiarize yourself with any potential health risks caused by the charging material, the contained

moisture constituent or by reaction products which may arise during the temperature process. Take

adequate measures to exclude such risks prior to putting the chamber into operation.

DANGER

Electrical hazard.

Danger of death.

∅ The chamber must NOT become wet during operation or m ai ntenance.

The chambers were produced in accordance with VDE regulations and were routinely tested in

accordance to VDE 0411-1 (IEC 61010-1).

CB (E6.1) 07/2017 Page 11/145

Page 12

During and after a sterilization the temperature of the inner surfaces almost equals the set-point.

CAUTION

The inner doors, the inner door and glass door handles, and the inner cham ber will

become hot during a sterilization.

Danger of burning.

∅ Do NOT touch the inner doors, the inner door and glass door handles, and the inner

surfaces after a sterilization.

WARNING

Stability hazard.

Danger of injury.

Damage to the chamber and the charging material.

Housing cover breakaway.

∅ Do NOT climb on the lower housing cover.

∅ Do NOT load the lower housing cover with heavy objects while the chamber door is

open.

1.6 Precautions when working with gases

Notes on handling carbon dioxide (CO2)

Carbon dioxide (CO

and therefore practically imperceptible. Vent out any CO

or a suitable connection to an exhaust sy st em. We recommend installing a CO

) in high concentrations is hazardous to health. It is colorless and almost odorless

2

gas that may escape via good room ventilation

2

WARNING

High concentration of CO2 (> 4 Vol.-%).

Risk of death by suffocation.

Danger of poisoning.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling CO

.

2

warning system

2

CB (E6.1) 07/2017 Page 12/145

Page 13

t and necessary safety

them for leaks (e.g. with leak

equipment with oil or fat. Use only materials and spare parts which are

Strictest smoking ban and no ignition sources in areas where oxygen enrichment is

areas where oxygen enrichment is possible (location of the

enriched atmosphere must keep away

15

Chamber with O

Oxygen (O

2

control: Notes on handling oxygen (O2)

2

) is colorless and almost odorless and therefore practically imperceptible. It promotes burns,

which can proceed explosively. There is a fire hazard for flammable oxygenated materials, e.g. clothes

and hair. O

is heavier than air and may accumulate in low-lyin g areas.

2

WARNING

High concentration of O2 (> 21 % O2).

Fire and explosion hazard through contact of combustible materials with O

Risk of burns and other injuries.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling O

.

2

Take appropriate measures to prevent oxygen enrichment and fire and explosion hazards in areas where

oxygen enrichment is possible.

General information for safe handling of oxy gen:

• Make sure training of personnel on hazards of oxygen enrichmen

measures.

• Make sure adequate labeling of all oxygen equipment and facilities.

• Make sure gas tightness of all gas connections by checking

spray or diluted soap solution).

.

2

• Close the main valve of the source of oxygen after work when not using the chamber.

• Never lubricate O

2

approved for use with oxygen.

• Regularly inspect fire extinguishers for proper condition.

• Set up emergency showers where oxygen enrichment is possible.

•

possible.

• Make sure good ventilation of

chamber and/or O2 cylinders.

• Persons who may have been in a possibly oxygenfrom ignition sources (flames, cigarettes, etc.) and ventilate their clothes at least

minutes.

• Always keep emergency routes free.

Chamber with O2 control: Notes on handling nitrogen (N2)

Nitrogen (N

) in high concentrations is hazardous to health. It is colorless and almost odorless and

2

therefore practically imperceptible. Any N

gas t hat may escape must be safely led out via good room

2

ventilation or a suitable connection to an exhaust system.

WARNING

High concentration of N2.

Risk of death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling N

.

2

CB (E6.1) 07/2017 Page 13/145

Page 14

on the cap when not in

1.7 Precautions when handling gas cylinders

General information for safe handling of gas cy li nders:

• Store and use gas cylinders only in well-ventilated locations.

• Open the gas cylinder valve slowly to avoid pressure surges.

• Secure gas cylinders during storage and use against falling (chaining).

• Transport gas cylinders with a cylinder cart, do not carry, roll, or throw them.

• Always close the valve even with apparently empty cylinders; screw

use. Return gas cylinders with the valve closed.

• Do not open gas cylinders by force. Mark them when damaged.

• Protect gas cylinders against fire, e.g. do not store together with flammable liquids.

• Observe relevant regulations for dealing with gas cylinders.

Secure the gas cylinders against falling and other mechanical damage.

WARNING

Safety valve tearing off.

Sudden release of the stored pressure energy.

Risk of injury.

Secure gas cylinders against falling (chaining).

Transport gas cylinders with a cylinder cart.

The valve of the gas cylinder always must be clo sed before screwing on or unscrewing the gas hose.

WARNING

Opening the cylinder valve when the cylinder is not connected.

Sudden release of the stored pressure energy.

Risk of injury.

Close the gas cylinder valve before connecting or removing the gas hose.

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or

diluted soap solution).

CB (E6.1) 07/2017 Page 14/145

Page 15

stible or explosive at working temperature into

1.8 Intended use

Series CB incubators are suitable for the cultivation of mammal cells under typical conditions of approx.

37 °C / 98.6°F. The chamber permits setting defined pH conditions by common NaHCO

of commercial cell media by keeping an exact CO

atmosphere inside. The chambers guarantee high

2

humidity inside to avoid osmolarity increasin g caused by the evaporation of the cell media.

buffer systems

3

With the chamber w ith O

control, a variable oxygen atmosphere can additionally influence the growth of

2

the cells.

The chambers are suitable for exact conditioning of harmless materials. Any possible solvent any solvent

must not be explosive and flammable. Components of the charging material must NOT form an explosive

mixture with air. The operating temperature must lie below the flash point or below the sublimation point

of the charging material. Any component of the charging material must NOT be able to release toxic

gases.

DANGER

Explosion or implosion hazard.

Danger of poisoning.

Danger of death.

∅ Do NOT introduce any substance combu

the chamber, in particular no energy sources such as batteries or lithium-ion batteries.

∅ NO explosive dust or air-sol vent mixture in the inner chamber.

∅ Do NOT introduce any sub st ance which could lead to release of toxic gases.

Other applications are not approved.

Following the instructions in this operating manual and conducting regular maintenance work

(chap. 19.1) are part of the intended use.

The chambers are not classified as medical devices as defined by the Medical Device Directive

93/42/EEC.

Due to the special demands of the Medical Device Directive (MDD), these chambers are not

qualified for sterilization of medical devic es as defined by the directive 93/42/EWG.

WARNING: If customer should use a BINDER ch am ber running in non-supervised

continuous operation, we strongly recomm end in case of inclusion of irrecoverable specime n

or samples to split such specimen or samples a nd store them in at least two chambers, if this

is feasible.

The charging material shall not contain any corrosive ingredients that may damage the

machine components made of stainless steel, al um i num, and copper. Such ingredients

include in particular acids and halides. Any cor rosive damage caused by such ingredients is

excluded from liability by BINDER GmbH.

In case of foreseeable use of the chamber there is no risk for the user through the integration of the

chamber into systems or by special environmental or operating conditions in the sense of EN 610101:2010. For this, the intended use of the chamber and all its connections must be observed.

CB (E6.1) 07/2017 Page 15/145

Page 16

2. Chamber description

The CO2 incubators CB are equipped with a multifunctional microprocessor display controller for

temperature, CO

degree resp. 0.1 vol.-%

The inner chamber, the pre-heating chamber and the inside of the doors are all made of stainless steel

V2A (German material no. 1.4301, US equivalent AISI 304). The inner surfaces are smooth and therefore

easy to clean. The inner chamber is deep-drawn from one piece, polished (suitable for pharmaceutical

applications) and has no welds or inaccessible corners. The hinges and the seal of the inner glass door

are glued from the outside to aid cleaning of the inner chamber. When operating the chamber at high

temperatures (sterilization), the impact of the oxygen in the air may cause discoloration of the metallic

surfaces (yellowish-brown or blue) by natural oxidation processes. These colorations are harmless and

will in no way impair the function or quality of the chamber.

The perforated shelves are also made of stainless steel. You can insert a maximum of 3 (CB 60), 6 (CB

160), resp. 8 (CB 220) shelves.

The housing is RAL 7035 powder-coated. All corners and edges are also completely coated.

The chamber’s heating system permits hot-air auto-sterilization at a setpoint of 187.5 °C / 369.5°F. Thus,

a temperature of 180 °C / 356°F is maintained for at least 30 minutes on all internal surfaces, resulting in

sterilization of the entire inner chamber. Therefore, this procedure meets all international guidelines

regarding hot air sterilization, e.g. AA M I ST63, DIN 58947, European Pharmacopoeia.

, and O2 (chamber with O2 control) levels and a digital display accurate to one-tenth of a

2

Thanks to the standard safety device (class 3.1 according to DIN 12880), the set temperature is

maintained in case of failure.

The gas enters the chamber via a fine filter (aseptic filter) with a high filtration efficiency that also filters

the smallest particles.

A highly precise, drift-free CO

gas through a special proprietary gas mixing head developed by BINDER allows precise and

CO

2

constant CO

The CO

concentrations for long periods. This creates optimum growth conditions for cultures.

2

incubator is also available with O2 control in addition to CO2 control. There are two different

2

infrared measuring system in combination with the permanent mixture of

2

control ranges:

• Regular equipment: Hypoxic control range 0.2 to 20 vol. % O

concentration; it is not possible to connect O2 gas bottles to increase O2 concentration. Control in

O

2

the low O

• Alternative control range 10 to 95 vol. % O

range is very precise, in particular in the ra nge below 1 vol. % O2.

2

(option no. 8012-1106). Although the high control range is

2

intended in particular for hyperoxic applications (> 21 vol. % O

applications between 10 and 20 vol. % O

and O2 sensors

CO

2

.

2

Fast reaction times, maximum accuracy and selectivity characterize the CO

the CB incubator series. The accuracy of the CO

measuring system is based on a double-beam

2

. Only N2 can be connected to reduce

2

), it is also suitable for slightly hypoxic

2

measuring procedure of

2

infrared measuring cell with NDIR (non-dispersive infrared) sensor, which continuously regulates to a

reference value. Therefore, disturbance variables and aging phenomena in the measuring system are

almost completely eliminated, so that this measuring system, in contrast to other measuring

procedures, remains practically drift-free between calibrations and is entirely selective for CO

. The

2

sensor is built into the chamber and can be sterili zed.

The O

The accuracy of the indicated values of CO

sensor is a semiconductor gas sensor with Z rO2 ceramic.

2

and O2 (chamber with O2 control) depends on the

2

ambient air pressure (approx. 0.08 vol.-% per 10 mbar / 0.15 psi). To compensate for this effect in the

measurement, the controller measures the ambient air pressure and automatically includes it in

CO

2

the calculation.

The chambers are equipped with an Ethernet interface for computer communication, e.g. with the

communication software APT-COM™ 3 DataControlSystem (option, chap. 15.1). For further options, see

chap. 22.5.

CB (E6.1) 07/2017 Page 16/145

Page 17

Temperature range: 7 °C / 12.6 °F above ambient temperature up to +60 °C / 140 °F

CO

range: 0 vol.-% up to 20 vol.-%)

2

range (chamber with O2 control): 0.2 vol.-% up to 20 vol.-% (hypoxic control range) or 10 Vol.-%

O

2

up to 95 Vol.-% (alternative control range)

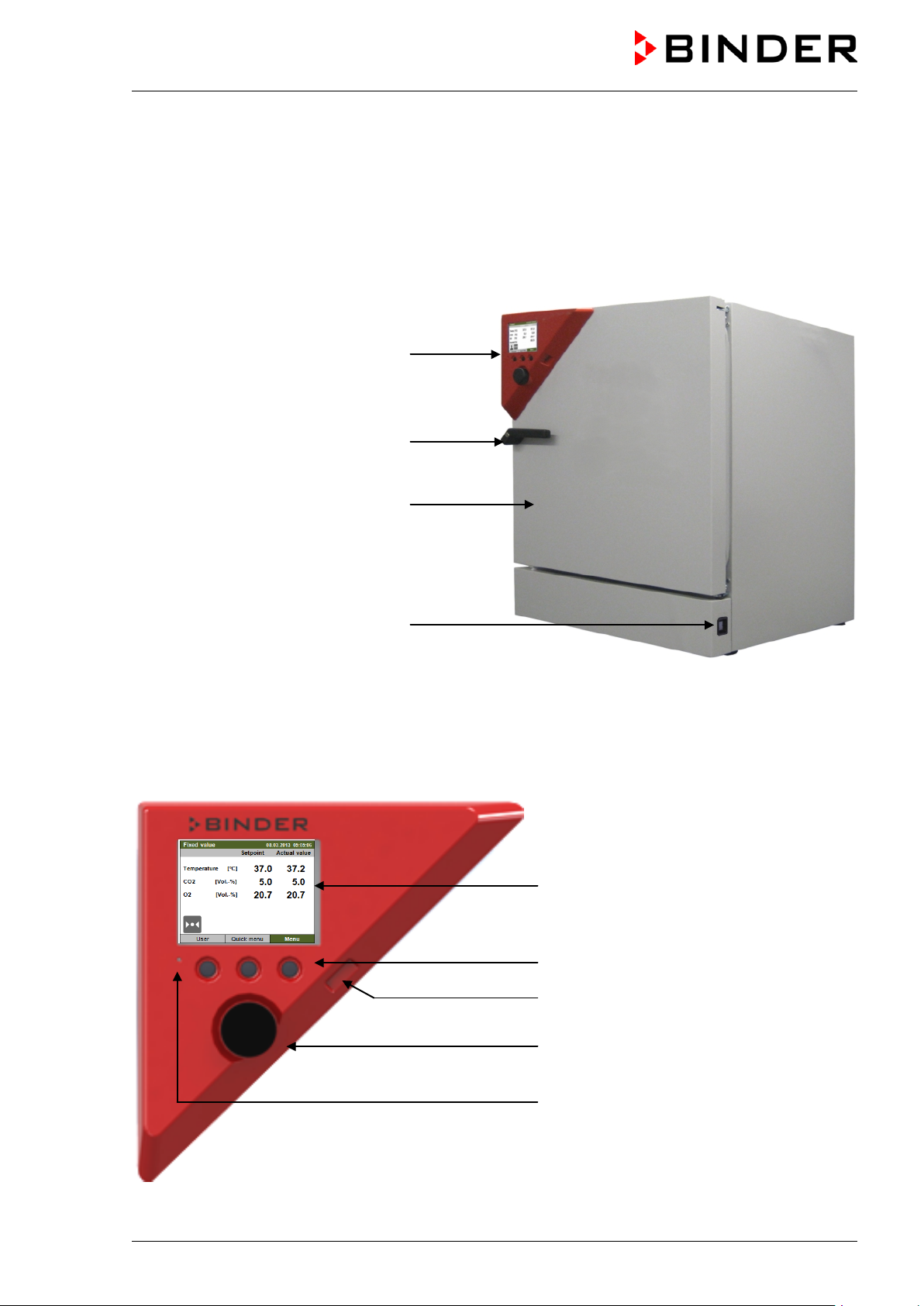

2.1 Chamber overview

Instrument panel with microprocessor

controller T4.12 and USB interface

Door handle

Chamber door

Main power switch

Figure 3: CO2 incubator CB (example: model CB 160)

2.2 Instrument panel

5,7" controller display

Context-sensitive buttons

USB interface

Operating button

Pilot lamp: ready for operation

Figure 4: Instrument panel with microprocess or controller T4.12 and USB interface

CB (E6.1) 07/2017 Page 17/145

Page 18

(A)

(B)

(C)

(D)

(

(G)

(F)

(E)

(

(I)

(

(

(

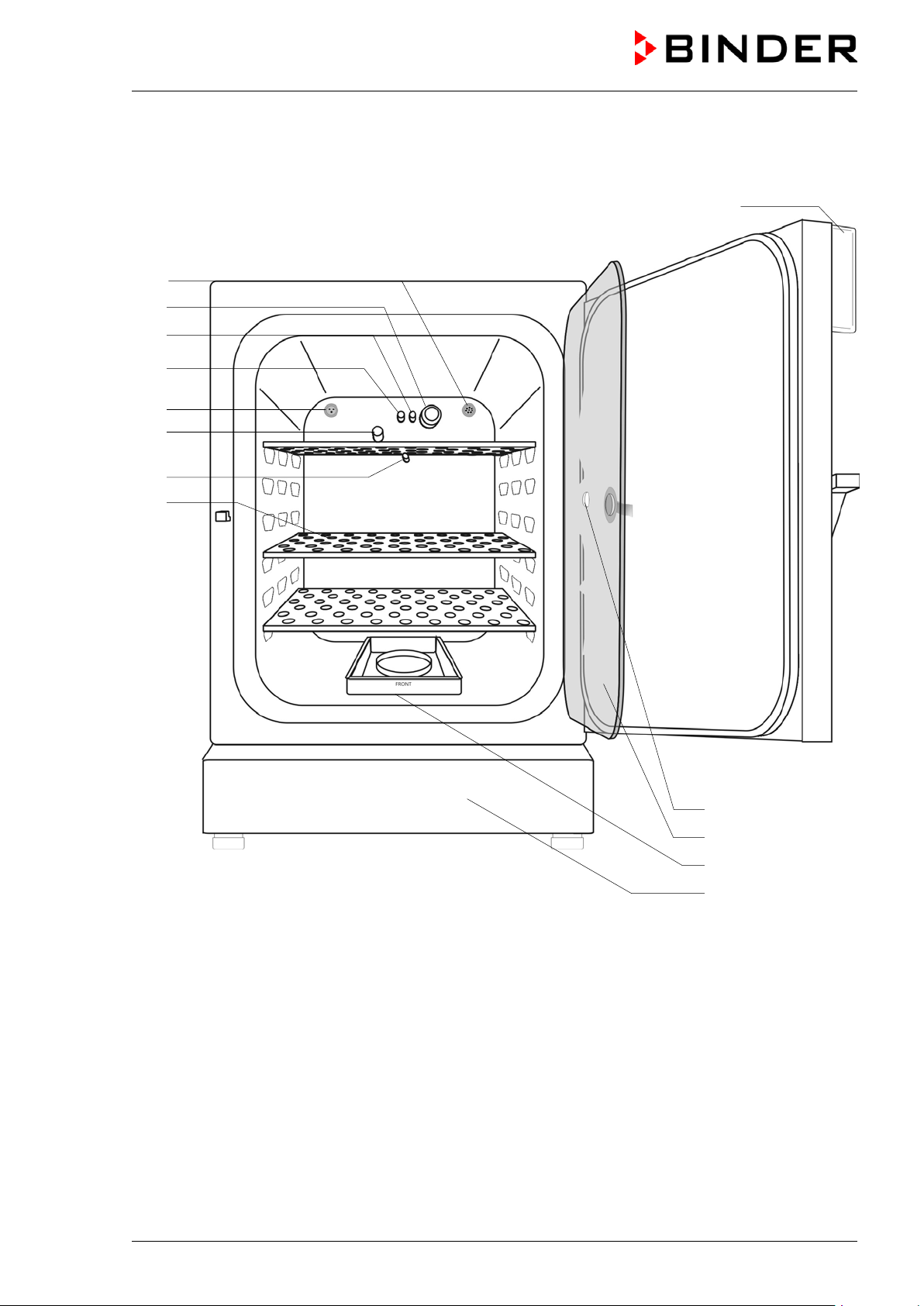

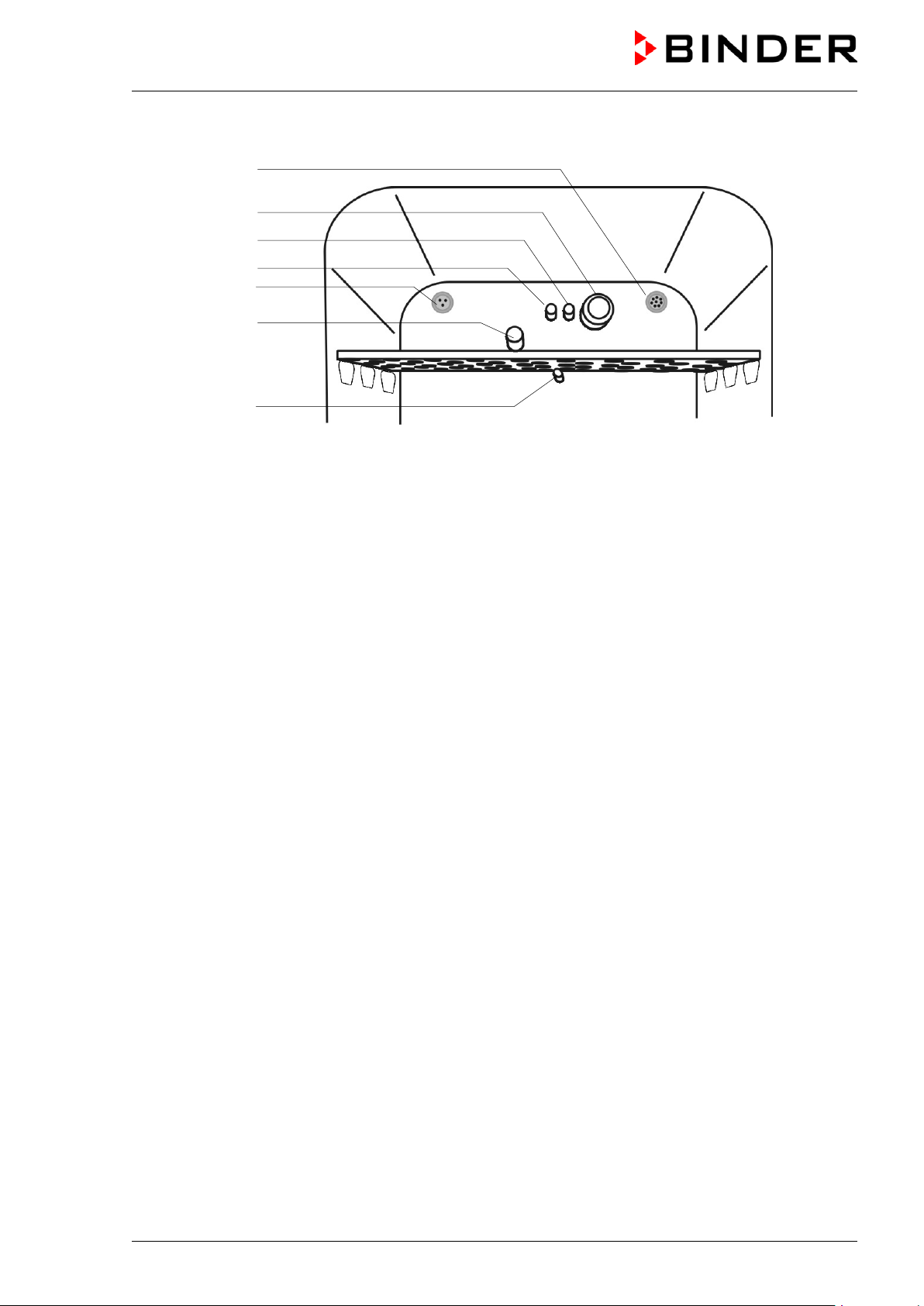

2.3 Inner chamber

D2)

H)

J)

K)

Figure 5: CB 160 with O

control and options

2

L)

CB (E6.1) 07/2017 Page 18/145

Page 19

(B)

(C)

(D)

(D2)

(G)

(F)

(E)

Figure 6: CB 160 / CB 220 with O

control and options

2

(A) Instrument panel with microprocessor controller T4.12, indicating temperature and CO

(chamber with O2 control)”

O

2

(B) Connection socket for extra-low voltage supply (option, chap. 15.6)

(C) CO

(D) Gas mixing head CO

(D2) Additional gas mixing head O

sensor

2

2

/ N2 (chamber with O2 control)

2

(E) Pt 100 temperature probe

(F) O

sensor (chamber with O2 control)

2

(G) Internal socket 230V (max. 3 A) (option, chap. 15.4)

(H) Perforated shelves, made of st ainl ess steel

(I) Measuring access port

(J) Inner glass doors

(K) Permadry™ water pans

(L) Lower housing cover

as well as

2

CB (E6.1) 07/2017 Page 19/145

Page 20

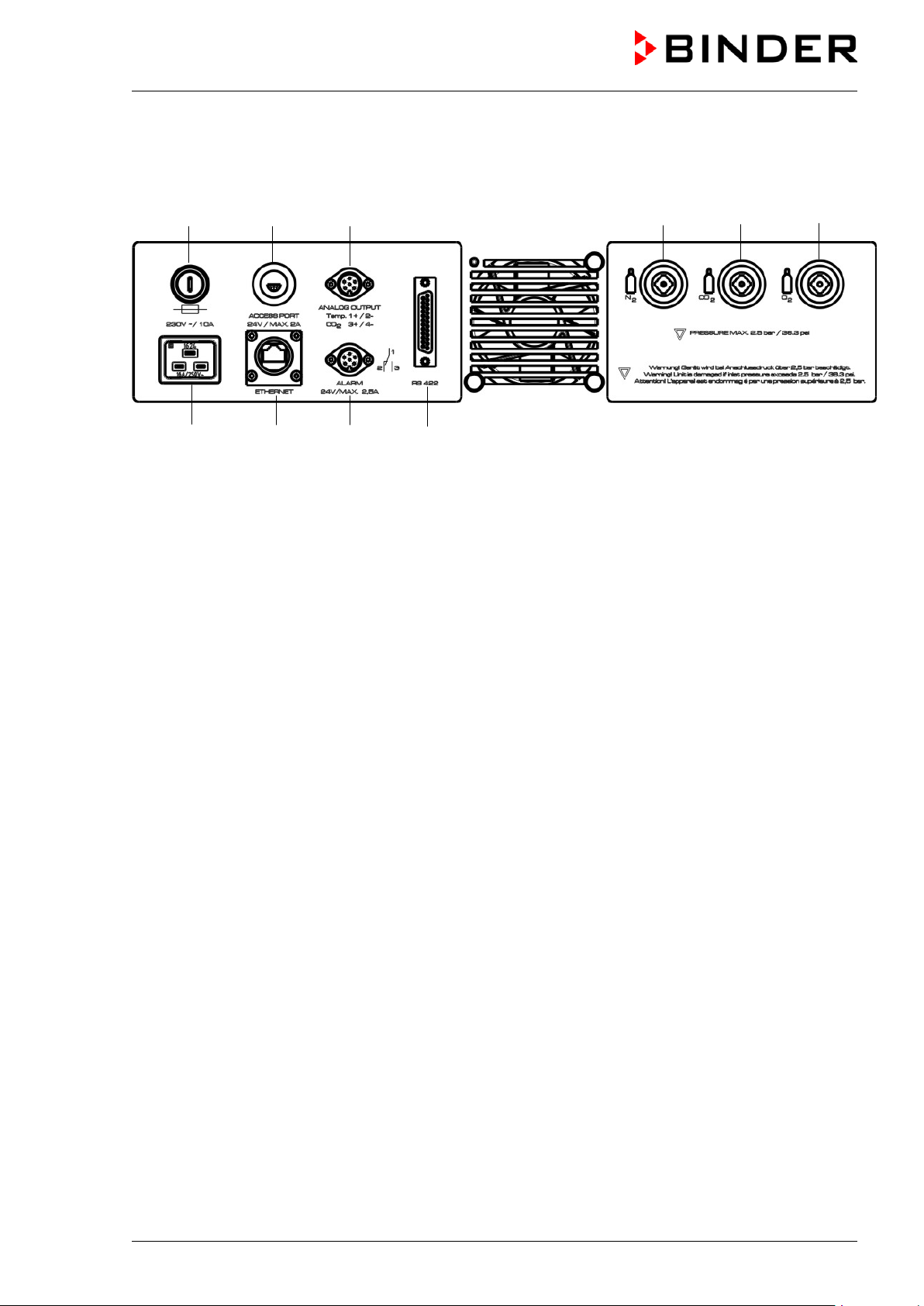

2.4 Control panel on the rear of t he chamber

(1) (2) (3) (6) (4) (5)

(7) (8) (9) (10)

Figure 7: Rear control panel CB with O

control and options

2

(1) Miniature fuse

(2) External socket for extra-low voltage supply (option for CB 160 / CB 220, chap. 15.6)

(3) DIN socket for analog outputs 4-20 mA (option, chap. 15.5)

(4) Quick acting closure socket for CO

(5) Quick acting closure socket for O

10 up to 95 vol.-% O

)

2

(6) Quick acting closure socket for N

2

(chamber with O2 control and optional alternative control range

2

(chamber with O2 control)

2

(7) Socket for IEC connector plug for power cable

(8) Ethernet interface for computer communication

(9) DIN-socket for zero-voltage relay alarm outputs

(10) RS 422 interface for computer communication ( option)

CB (E6.1) 07/2017 Page 20/145

Page 21

3. Completeness of delivery, transportation, storage, and

installation

3.1 Unpacking, and checking equipm ent and completeness of delivery

After unpacking, please check the chamber and its optional accessories, if any, based on the delivery

receipt for completeness and for transportation damage. Inform the carrier immediately if transportation

damage has occurred.

The final tests of the manufacturer may have caused traces of the shelves on the inner surfaces. This has

no impact on the function and performance of the chamber.

Please remove any transportation protection devices and adhesives in/on the chamber and on the doors

and remove the operating manuals and accessory equipment.

Remove any protective lamination sheet on the inner metal surfaces prior to commissioning.

CAUTION

Sliding or tilting of the chamber.

Damage to the chamber.

Risk of injury by lifting heavy loads.

Do NOT lift or transport the chamber using the doo r handle, the door or the lower

housing.

Lift the chamber from the pallet at the four lower corners with the aid of four people.

If you need to return the chamber, please use the original packing and observe the guidelines for safe

lifting and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 20.1.

Note on second-hand chambers (Ex-Demo-Units):

Second-hand chambers are chambers that were used for a short time for tests or exhibitions. They are

thoroughly tested before resale. BINDER ensures that the chamber is technically sound and will work

flawlessly.

Second-hand chambers are marked with a sticker on the chamber door. Please remove the sticker before

commissioning the chamber.

3.2 Guidelines for safe lifting and t ransport ation

After operation, please observe the guidelines for temporary decommissioning (chap. 20.2). Empty the

Permadry™ water pan before moving the chamber. In case of any spilling of the contents, shut down the

chamber and dry it out carefully and completely.

CB (E6.1) 07/2017 Page 21/145

Page 22

CAUTION

Sliding or tilting of the chamber.

Damage to the chamber.

Risk of injury by lifting heavy loads.

Transport the chamber in its original packaging only.

For moving or shipping, secure the chamber with transport straps.

∅ Do NOT lift or transport the chamber using the door handle, the door or the lower

housing.

Lift the chamber at the four lower corners with the aid of 4 peopl e and place it on a

rolling pallet.

Move the chamber to the desired location and lif t it from the rolling pallet with the aid of

four people.

• Permissible ambient temperature range during transport: 10 °C / 14 °F to +60 °C / 140 °F.

You can order transport packing for moving or shipping purposes from BINDER service.

3.3 Storage

Intermediate storage of the chamber is possible in a closed and dry room. Observe the guidelines for

temporary decommissioning (chap. 20.2).

• Permissible ambient temperature range during storage: -10 °C / 14 °F to +60 °C / 140 °F.

• Permissible ambient humidity: max. 70 % r.H., non-condensing

When after storage in a cold location you transfer the chamber to its warmer installation site,

condensation may form. Before start-up, wait at least one hour until the chamber has attained ambient

temperature and is completely dry.

3.4 Location of installation and ambi ent conditions

Notes on the location of installation

Set up the chamber on a flat, even surface, free from vibration and in a well-ventilated, dry location. The

chambers are designed for setting up inside a building (indoor use).

Freestanding chamber are suitable for installation on tables or on the optionally available stand (height

200 mm / 0.5 ft). Note: The site of installation must be capable of supporting the chamber’s weight (see

technical data, chap.22.4).

Align the chamber using a spirit level to ensure even covering of the cell-cultures with the medium. For

this purpose, manually adjust the four chamber feet.

The chambers can be stacked on top of each other (two chambers maximum). For safe stacking that is

easy to maintain, use the original BINDER stacking stand (chap. 15.8.1) or the stacking adapter (chap.

15.8.2).

CAUTION

Sliding of stacked chamber.

Damage to the chambers.

When stacking, use rubber pads (Art. No. 8012-0376) for the feet of the upper

chamber.

To completely separate the chamber from the power supply, you must disconnect the power plug. Install

the chamber in a way that the power plug is ea sily accessible and can be easily pulled in case of danger.

For the user there is no risk of temporary ov ervoltages in the sense of EN 61010-1:2010.

CB (E6.1) 07/2017 Page 22/145

Page 23

CAUTION

In order to avoid contamination, never place the chamber directly on the floor.

Danger of overheating.

Damage to the chamber.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure sufficient ventilation for dispersa l of the heat.

Do not install or operate the chamber in potentially explosive areas.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the chamber in pot entially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the vicinity of the chamber.

Ambient conditions

• Permissible ambient temperature range for operation: +18 °C / 64.4 °F to +30 °C / 86 °F

At elevated ambient temperature values, f l uct uations in temperature can occur.

• Ideal ambient temperature: at least 7 °C / 12.6 °F below the intended working temperature. E.g.,

working temperature 37 °C / 98.6 °F = ambient temperature 30 °C / 86 °F and lower. In the event of

working temperatures of less than 7 °C / 12.6 °F above the ambient temperature, the setpoint can be

exceeded.

The ambient temperature should not be substanti al ly higher than the indicated ambient

temperature of 22 ±3 °C / 71.6 ±5.4 °F to which the specified technical data relates. For other

ambient conditions, deviations from the indicated data are possible.

Avoid direct solar radiation on the chamber.

• Permissible ambient humidity: 70 % r.H. max., non-condensing.

• Installation height : max. 2000 m / 6561.7 ft above sea level.

• Wall distances: rear 100 mm / 3.94 in, sides 50 mm / 1.97 in.

CB (E6.1) 07/2017 Page 23/145

Page 24

Notes on handling carbon dioxide (CO

Carbon dioxide (CO

) in high concentrations is hazardous to health. It is colorless and almost odorless

2

and therefore practically imperceptible. Vent out any CO

or a suitable connection to an exhaust sy st em . We recommend installing a CO

)

2

gas that may escape via good room ventilation

2

warning system.

2

WARNING

High concentration of CO2 (> 4 Vol.-%).

Danger of death by suffocation.

Danger of poisoning.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling CO

Observe the occupational exposure limit OEL for CO2 set by the national authorities (formerly

maximum permitted workplace concentration). Check compliance when operating all chambers located in

the room.

3

• OEL for Germany: 5000 ml/m

• CO

lost with each opening the door: about 16.4 g, i.e. 0.0084 cubic meters / 0.296 cubic feet (under

2

(ppm) = 0,5 Vol.-%

normal pressure)

• CO

lost during 12h at 5 vol.-% without opening the door: approx. < 2 g, i.e. 0.001 cubic meter / 0.035

2

cubic feet (under normal pressure 1013 mbar / 14.7 psi)

.

2

An example of how to evaluate laboratory volume and air change rate:

Question: Is an air change rate of 1/h sufficient for a lab with a volume of 100 cubic meters /

3,531.5 cubic feet with 10 incubators CB, opened 4 times per hour?

Calculation: CO

concentration = CO2 lost by opening the door, multiplied by 10 chambers,

2

multiplied by opening the door 4 times per hour, di vided by lab volume

0.0084 cubic meters x 10 x 4 div. 100 cubic meters = 0.00336, i.e. 0.336 % or 3360 ppm.

0.296 cubic feet x 10 x 4 div. 3,531.5 cubic feet = 0.00336, i.e. 0.336 % or 336 0 ppm.

Result: The maximum permissible value of 5000 ppm is not exceeded under these operation

conditions.

Even when CO

or systems operated with CO2 are handled carefully and appropriately, a residual risk

2

remains, which can lead to life-threatening situations under certain circumstances. Therefore we strongly

recommend continuous monitoring of CO

be ensured permanently that the maximum permissible occupational exposure limit OEL for CO

% CO

for Germany) is not exceeded.

2

concentration in the ambient air of the CO2 incubator. It must

2

(0.5 vol -

2

Chamber with O

Oxygen (O

2

control: Notes on handling oxygen (O2)

2

) is colorless and almost odorless and therefore practically imperceptible. It promotes burns,

which can proceed explosively. There is a fire hazard for flammable oxygenated materials, e.g. clothes

and hair. O

is heavier than air and may accumulate in low-lyin g areas.

2

WARNING

High concentration of O2 (> 21 % O2).

Fire and explosion hazard through contact of combustible materials with O

.

2

Risk of burns and other injuries.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling O

.

2

CB (E6.1) 07/2017 Page 24/145

Page 25

t and necessary safety

all gas connections by checking them for leaks (e.g. with leak

parts which are

Strictest smoking ban and no ignition sources in areas where oxygen enrichment is

Make sure good ventilation of areas where oxygen enrichment is possible (location of the

enriched atmosphere must keep away

ventilate their clothes at least 15

Take appropriate measures to prevent oxygen enrichment and fire and explosion hazards in areas where

oxygen enrichment is possible.

General information for safe handling of oxygen:

• Make sure training of personnel on hazards of oxygen enrichmen

measures.

• Make sure adequate labeling of all oxygen equipment and facilities.

• Make sure gas tightness of

spray or diluted soap solution).

• Close the main valve of the source of oxygen after work when not using the chamber.

• Never lubricate O

equipment with oil or fat. Use only materials and spare

2

approved for use with oxygen.

• Regularly inspect fire extinguishers for proper condition.

• Set up emergency showers where oxygen enrichment is possible.

•

possible.

•

chamber and/or O2 cylinders.

• Persons who may have been in a possibly oxygenfrom ignition sources (flames, cigarettes, etc.) and

minutes.

• Always keep emergency routes free.

Chamber with O

Nitrogen (N

therefore practically imperceptible. Any N

control: Notes on handling nitrogen (N2)

2

) in high concentrations is hazardous to health. It is colorless and almost odorless and

2

gas that may escape must be safely led out via good room

2

ventilation or a suitable connection to an exhaust system.

WARNING

High concentration of N2.

Risk of death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling N

.

2

CB (E6.1) 07/2017 Page 25/145

Page 26

CB 60

CB 160 / CB 220

4. Installation and connections

4.1 Shelves

You can put the shelves in different positions at the line of channel beads in the inner chamber. Hold the

shelf straight and then insert it so it will go smoothl y inside the chamber.

Permitted shelf loads:

Maximum load of one single shelf: 10 kg / 22 lb

Maximum total load of all shelves: 30 kg / 66 lb

4.2 Permadry™ water pan

The Permadry™ system developed by BINDER is an effective and easy to handle system that ensures

high humidity inside the chamber without any condensation forming on the inner surfaces. The

Permadry™ water pan consists of two pans in which the outer one is heated and the inner one cooled.

With the slight difference of temperature caused by that cooling, the central pan is the specific point for

condensation of the surplus humidity. Therefo re, all other inner surfaces remain dry.

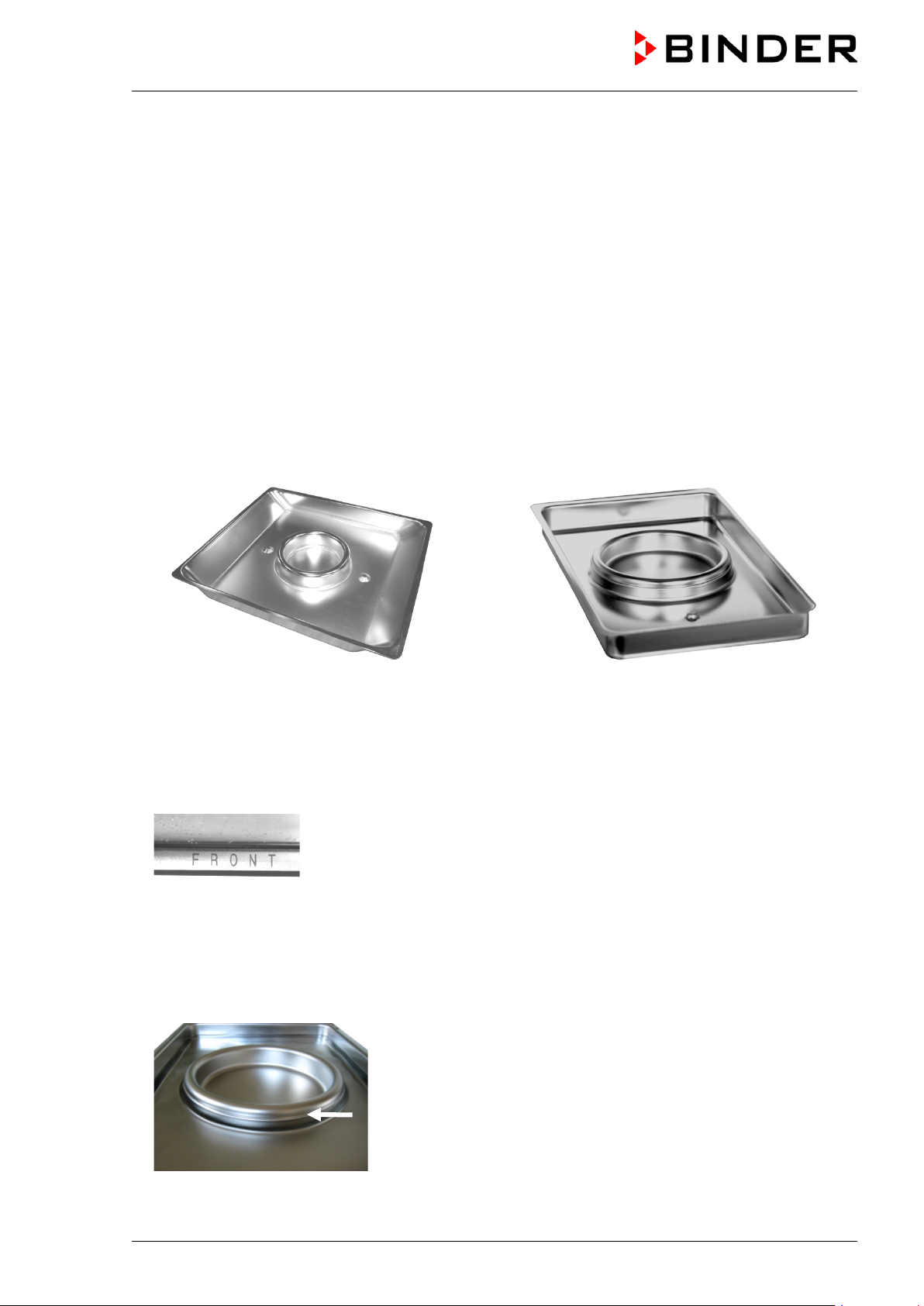

Figure 8: Permadry™ water pan

• Put the Permadry™ water pan on the bottom of the inner chamber in a way that both notches lock into

place.

• The front side of the Permadry™ water pan is marked “FRONT”.

Figure 9: Letters “FRONT” indicating the front of the Permadry™ water pan

• Please make sure that the Permadry™ water pan has firm contact to the inner chamber bottom and

rests tightly on it.

• Fill only the outer pan with distilled, sterilized water up to the filling level marking on the edge of the

inner pan.

Maximum filling quantity of the outer pan: CB 60: approx. 0.7 liters, CB 160 and CB220): approx.

2 liters.

Figure 10: Filling height line of the outer basin CB 160 / CB 220

CB (E6.1) 07/2017 Page 26/145

Page 27

• We recommend cleaning and refilling the pans 2 to 3 times a week. For evacuation, remove the

Permadry™ water pan.

• We recommend using distilled, sterile water to achieve optimum growth results. Any corrosive damage

that may arise following the use of water of different quality or by additives is excluded from the liability

agreement.

• If required, you can add microbiologically inhibiting substances such as copper chips, copper sulfate

or ethylene diamine tetra-vinegar acid (EDTA) in a concentration of 1 to 5 mmol/l.

Empty the Permadry™ water pan before moving the chamber. In case of the contents spilling,

immediately shut down the chamber and dry it careful ly and completely.

4.3 Connecting the O2 sensor (chamber with O2 control)

The O2 sensor is supplied with the chamber in a separate package.

Connect or remove the O2 sensor only when the chamber is turned off.

Open the door of the inner chamber and plug the O2 sensor (F) into the left connection socket located in

the upper part of the rear of the inner chamber. P ay attention to the correct positioning of the pins.

Figure 11: O2 sensor Figure 12: Connecting the O2 sensor

The O2 sensor must be plugged in during a hot-air sterilization.

CB (E6.1) 07/2017 Page 27/145

Page 28

Always close the valve even with apparently empty cylinders; screw on the cap when not in

4.4 Gas connections

General information for safe handling of gas cy l i nders:

• Store and use gas cylinders only in well ventilated areas.

• Open the gas cylinder valve slowly to avoid pressure surges.

• Secure gas cylinders during storage and use against falling (chaining).

• Transport gas cylinders with a cylinder cart, do not carry, roll, or throw them.

•

use. Return gas cylinders with the valve closed.

• Do not open gas cylinders by force. Mark them when damaged.

• Protect gas cylinders against fire, e.g. do not store together with flammable liquids.

• Observe relevant regulations for dealing with gas cylinders.

Secure the gas cylinder against falling and other m echanical damage.

WARNING

Safety valve tearing off.

Sudden release of the stored pressure energy.

Risk of injury.

Secure gas cylinders against falling (chaining).

Transport gas cylinders with a cylinder cart.

The valve of the gas cylinder always must be clo sed before screwing on or unscrewing the gas hose.

WARNING

Opening the cylinder valve when the cylinder is not connected.

Sudden release of the stored pressure energy.

Risk of injury.

Close the gas cylinder valve before connecting or removing the gas hose.

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or

diluted soap solution).

CB (E6.1) 07/2017 Page 28/145

Page 29

4.4.1 Connection of the CO2 gas cylinder

Carbon dioxide (CO2) in high concentrations is hazardous to health. It is colorless and almost odorless

and therefore practically imperceptible. Vent out any CO

or a suitable connection to an exhaust sy st em . We recommend installing a CO

High concentration of CO2 (> 4 Vol.-%).

Risk of death by suffocation.

Danger of poisoning.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling CO

The CO2 gas necessary for operation must have a t echnical grade of 99.5 %.

The gas connections must be established by quali fied personnel who are trained in handling

the respective gases and familiar with the required safety measures.

gas that may escape via good room ventilation

2

WARNING

2

.

warning system.

2

The following steps are required:

Ensuring the correct CO

output pressure

2

A gas supply pressure above 2.5 bar / 36 psi will result in chamber damage.

Use a pressure reducer and make sure to avoid any excessive outlet pressure when connecting the

gas hose to the chamber.

The real outlet pressure of gas cylinders, sets of gas cylinders or central gas supplies am on the

second manometer must not exceed 2.5 bar / 36 psi.

CAUTION

Excessive outlet pressure > 2.5 bar / 36 psi.

Damage to the chamber.

∅ The outlet pressure must NOT exceed the indicated value of 2.5 bar / 36 psi.

Before connecting, check the outlet pressure on the pressure reducer of the

cylinder.

Adjust the outlet pressure to 2.0 bar / 29 psi above the ambient pressure.

Observe the correct outlet pressure also when replacing t he gas cylinders.

Establishing the connection to the chamber

Connect the supplied gas hose (internal diameter 6 mm / 0.24 inches) to the pressure reducer of the

gas cylinders or central gas supply and secure the connection with the supplied hose clamp.

Connect the pre-assembled hose nozzle of the gas hose to the quick acting closure socket (4) DN 6

on the chamber rear, as described in chap. 4.4.4.

Leak test

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or diluted

soap solution).

CB (E6.1) 07/2017 Page 29/145

Page 30

cylinder or disconnect the gas supply (by pulling off the gas hose)

CAUTION

The recovery times of the gas concentrations inside the chamber after opening the door are

indicated in the technical data (chap. 22.4) and refer to a connecti on pressure of 2.0 bar / 29

psi. Decreasing supply pressure will result in l onger recovery times.

Conversion table for gas inlet pressures, bar – psi, see chap. 22.8.

4.4.2 Connection of the O2 gas cylinder (chamber with O2 control and optional

alternative control range 10 up to 95 vol.-% O

Note: Do not connect the O2

when operating at setpoints below 19 vol.-% O2.

Oxygen (O2) is colorless and almost odorless and therefore practically imperceptible. It promotes burns,

which can proceed explosively. There is a fire hazard for flammable oxygenated materials, e.g. clothes

and hair. O

is heavier than air and may accumulate in low-lyin g areas.

2

)

2

WARNUNG

High concentration of O2 (> 21 % O2).

Fire and explosion hazard through contact of combustible materials with O

Risk of burns and other injuries.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling O

.

2

The O2 gas necessary for operation must have a t echnical grade of 99.5 %.

.

2

The gas connections must be established by quali fied personnel who are trained in handling

the respective gases and familiar with the required safety measures.

The following steps are required:

Ensuring the correct O

output pressure

2

A gas supply pressure above 2.5 bar / 36 psi will result in chamber damage.

Use a pressure reducer and make sure to avoid any excessive outlet pressure when connecting the

gas hose to the chamber.

The real outlet pressure of gas cylinders, sets of gas cylinders or central gas supplies am on the

second manometer must not exceed 2.5 bar / 36 psi.

Excessive outlet pressure > 2.5 bar / 36 psi.

Damage to the chamber.

∅ The outlet pressure must NOT exceed the indicated value of 2.5 bar / 36 psi.

Before connecting, check the outlet pressure on the pressure reducer of the

cylinder.

Adjust the outlet pressure to 2.0 bar / 29 psi above the ambient pressure.

Observe the correct outlet pressure also when replacing t he gas cylinders.

CB (E6.1) 07/2017 Page 30/145

Page 31

Establishing the connection to the chamber

Connect the supplied gas hose (internal diameter 6 mm / 0.24 inches) to the pressure reducer of the

gas cylinders or central gas supply and secure the connection with the supplied hose clamp.

Connect the pre-assembled hose nozzle of the gas hose to the quick acting closure socket (5) DN 6

on the chamber rear, as described in chap. 4.4.4.

Leak test

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or diluted

soap solution).

The recovery times of the gas concentrations inside the chamber after opening the door are

indicated in the technical data (chap. 22.4) and refer to a connecti on pressure of 2.0 bar / 29

psi. Decreasing supply pressure will result in longer recovery t i m es.

Conversion table for gas inlet pressures, bar – psi, see chap. 22.8.

4.4.3 Connection of the N2 gas cylinder (chamber with O2 control)

Nitrogen (N2) in high concentrations is hazardous to health. It is colorless and almost odorless and

therefore practically imperceptible. Any N

ventilation or a suitable connection to an exhaust system.

gas that may escape must be safely led out via good room

2

WARNING

High concentration of N2.

Risk of death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure technical ventilation measures.

Observe the relevant regulations for handling N

The N2 gas necessary for operation must have a t echnical grade of 99.5 %.

The gas connections must be established by quali fied personnel who are trained in handling

the respective gases and familiar with the required safety measures.

The following steps are required:

Ensuring the correct N

output pressure

2

A gas supply pressure above 2.5 bar / 36 psi will result in chamber damage.

Use a pressure reducer and make sure to avoid any excessive outlet pressure when connecting the